Page 1

Service Bulletin

Issued by Canon Europa N.V.

COPIER

Model :

Location :

Subject :

Reason :

GP405/335

SERVICE MANUAL (FY8-13FV-000)

UPDATING IMAGE BASIC ADJUSTMENT PROCEDURE

No.:

DATE:

GP405-010

(FF-T01-J7-000028-01)

10.09.99

The descriptions for the “Image Basic Adjustment Procedure” found on p. 14-3 of the

Service Manual (FY8-13FV-000) are not adequate, requiring modification.

Reference:

In the case of a digital copier, the following mechanisms are employed to enhance the reproduction of

images:

1. edge emphasis processing

2. density processing

As a result, the overall density of images tends to appear higher (darker) when compared with the

density of images produced by an analog copier.

Details :

For specific changes, see the pages that follow.

-

1 / 7 -

Page 2

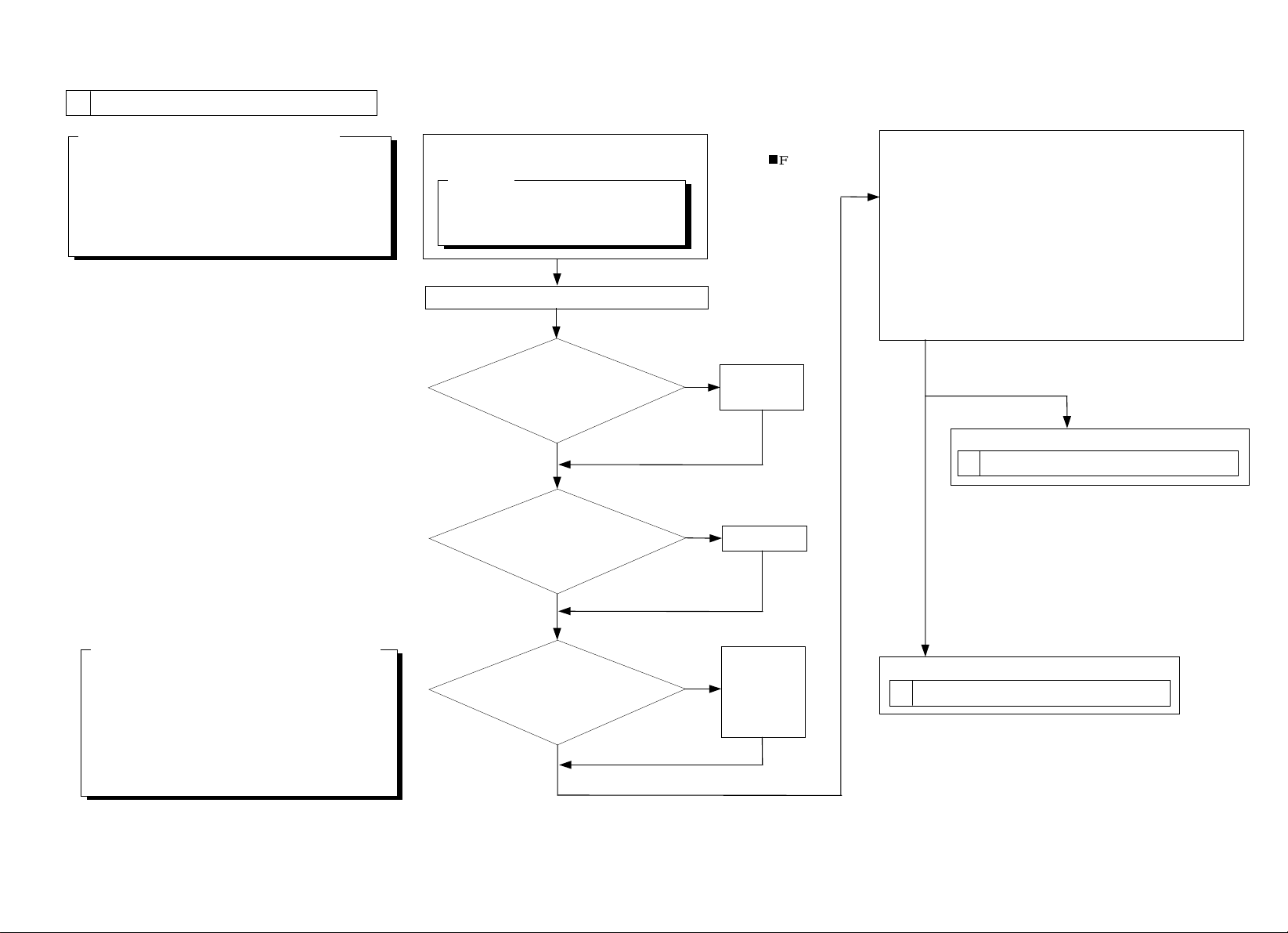

1 Making Initial Checks

GP405-010

Conditions for Mak ing I m age A djus tm e nts

1. Be sure to use copy paper fresh out of package.

(Moist paper will ma ke e valuation of image qu ality

difficult.)

2. Be sure to use copy paper with a high degree of

whiteness.

3. If possible, be sure to use A3 paper.

Execute ‘roller cleaning’, which is unde r

‘ADJUSTMENT/CLEANING’ of user mode.

Reference:

Execute cleaning for the following:

1. Primary charging roller

2. Transfer charging roller

Clean t he se paration static eliminato r.

Is the setting

of ‘density correction’, which

is under ‘A DJ USTMENT/CLEANING’

of use r mode, at the

middle?

Yes

Is the se tting of

ADJUST>DENS>DENS-ADJ

of service mode ‘5’?

No

No

Output Con dition

F value = 5

Set it to the

middl e.

Set it to ‘5 ’.

Using the NA3 Test Chart, make 2 copies in the following

mode:

1. text mode

Refere nce: At the optimum density, the copy sh ould barely

show gray scale No. 10.

Generate 2 each of the following test prints:

COPIER>TEST>PG

1. TYPE 4 (solid w hite )

2. TYPE 5 (halftone)

3. TYPE 6 (solid black)

If only the copy images have a fault,

Go to

2 Checking the Scanner Side (1/2)

Items under COPI ER> ADJUST of se r vice m ode

1. AE>AE-TBL

2. DEVELOP>DE-DC

3. DEVELOP>DE-NO-D

4. DEVELOP>DE-OFST

5. HV-PRI>P-DC

6. HV-PRI>P-NO-DC

7. HV-PRI>OFST1-DC

Yes

Are the seven

items on the left in service

mod e identical to those

indicated on the service

label?

Yes

No

Ente r the

settin gs

indicated on

the service

label.

If the test print images have faults,

Go to

4 Checking the Printer Si de ( 1 / 3)

-

2 / 7 -

Page 3

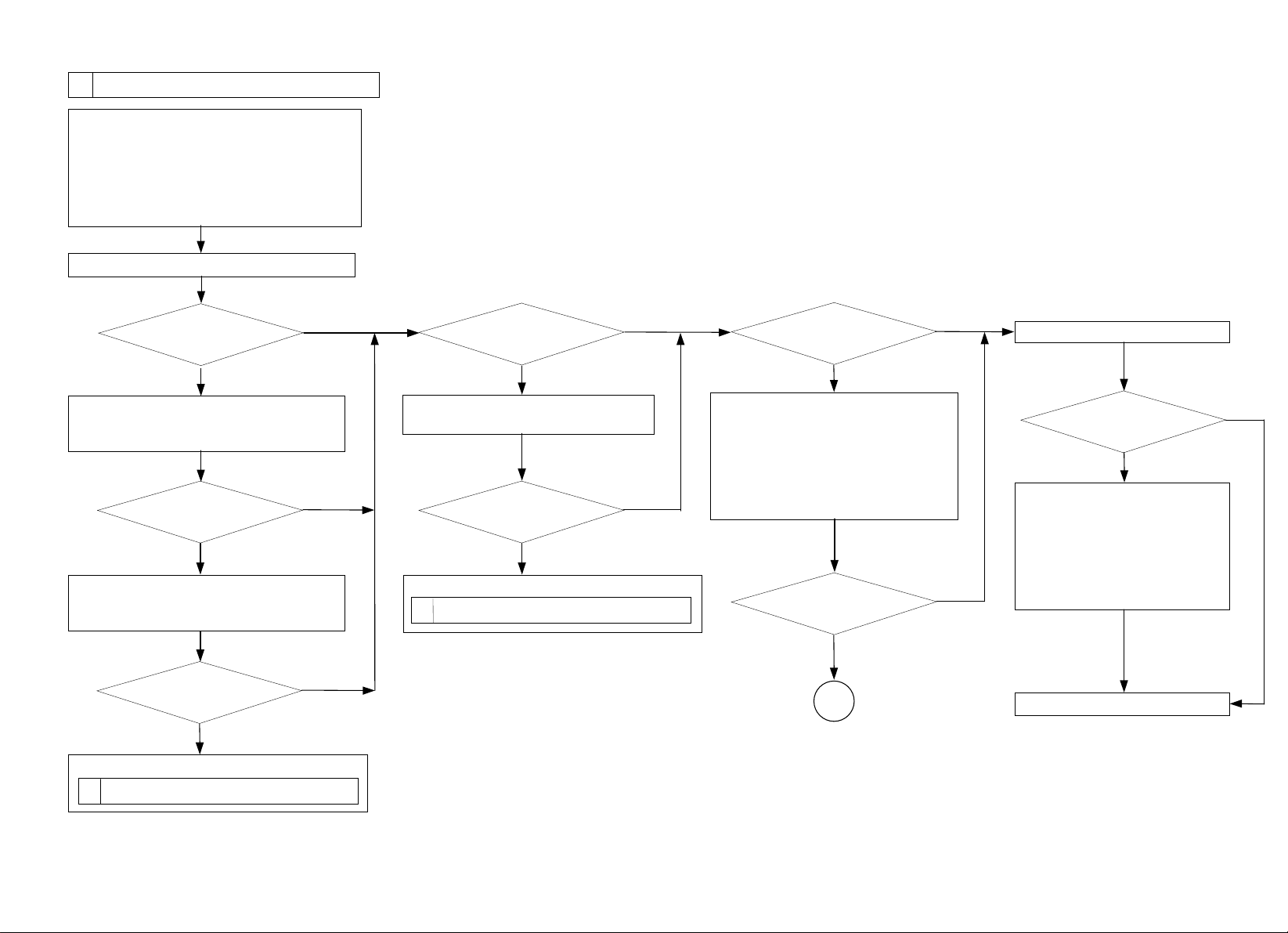

2 Checking the Scanner Side (1/2)

Check/clean the following; if the scanning lamp

has reached the end of its life, replace it:

1. mirrors 2. lens

3. standard white plate 4. copyboard glass

5. dust-proo fing glass 6. scanning lamp

7. reflecting plate

Make a copy in text mode.

GP405-010

Are there

vertical lines in the

image?

Yes

Execute the following in service mode:

COPIER>FUNCTION>CCD>CCD-ADJ.

For detailed instructions, see the Service Manual.

Are there

vertical lines in the

image?

Yes

Execute the following in service mode:

COPIER>FUNCTION>CCD>MAN-ADJ.

For detailed instructions, see the Service Manual.

Are there

vertical lines in the

image?

Yes

No

No

No

Go to

4 Checking the Printer Si de ( 1 / 3)

Is the wh ite

background of the copy

foggy?

Yes

Execute the following in service mode:

COPIER>FUNCTION>CCD>CCD-ADJ.

Is the image foggy?

Yes

No

No

Go to

6 Checking the Printer Si de ( 3 / 3)

Is the

density of the copy image

normal?

No

Change the setting of the following in

service mode:

COPIER>ADJUST>DENS>DENS-ADJ.

If the density is too high (dark), decrease

the setting.

If the dens ity is to o low (light), increase

the setting.

Is the

density of the copy image

normal?

No

A

Yes

Yes

Make a copy in AE mode.

Is the

density of the copy image

normal?

No

Change the setting of the following

in se rvice mode:

COPIER>ADJUST>AE>AE-TBL.

If the density is too high (dark),

decrease the setting.

If the dens ity is to o low (light),

increase the setting.

End.

Yes

-

3 / 7 -

Page 4

3 Checking the Scanner Side (2/2)

A

GP405-010

Reference:

Changing the setting of D EN S -ADJ wil l

change the density in al l the fol l ow ing modes:

auto

•

text

•

text/photo

•

photo

•

Set the foll owing to ‘5’ in serv ice m ode:

COPIER>ADJUST>DENS>DENS-ADJ.

Execute the foll owing in serv ice m ode:

COPIER>FUNCTION>CCD>MAN-ADJ.

Execute the foll owing in serv ice m ode:

COPIER>FUNCTION>DPC>D-GAMMA.

Yes

Is the result ‘0’ or ‘1’?

No

Replace the drum cartridg e; then, execute the

follow ing in serv ice m ode:

COPIER>FUNCTION>DPC>D-GAMM.

Execute the foll ow ing under

COPIER>FUNCTION>DENS

in service mode:

1. WHITE- M E

2. PD-DEN S

3. PD-ME

4. DZ-DENS

5. DZ-ME

Yes

Is the result ‘0’ or ‘1’?

No

Is the

density of the copy image

made in text mode

normal?

Yes

End.

Replace the composite

power supply PCB.

No

Change the setting of

COPIER>ADJUST>DENS>DENS-ADJ in

service mode.

If the density is too high (dark ), decrease the

setting.

If the density is too l ow (l ig ht), increase the

setting.

Yes

Go to

Is the copy image

density normal?

No

4 Checking the Printer Side (1/3)

-

4 / 7 -

Page 5

4 Checking the Printer Si de ( 1 / 3)

GP405-010

Are there

vertical lines in the

image?

Yes

Clean the following:

1. Dust-proofing glass

2. No. 1 mirror

3. No. 2 mirror

4. No. 3 mirror

Are there

vertical images in the

image?

Yes

Check the surface of the sleeve of

th e de v eloping assembly by t he

naked eye.

Are there

vertical images on the

surface of the

sleeve?

Yes

Generate 10 test prints using the

following: COPIER>TEST>PG

1. T YPE 6 ( so lid black)

Are there

vertical lines on the surface

of the developing

sleeve?

Yes

No

No

No

No

Are there

vertical lines in the

image?

Yes

Replace the drum cartridge.

Execute the following in service mode:

COPIER>FUNCTION>DPC>D-GAMM

(initialization)

Yes

Is the result ‘0’ or ‘1’?

No

Replace the composite power

supply PCB.

No

test p r int) nor mal in term s of

Check the following; if there are faults,

correct them:

1. engagement of the feeding assembly

2. electrode of the transfer roller

No

Cha nge the follo wing in ser v ice mode:

COPIER>ADJUST>DEVELOP>DE-DC

•

COPIER>ADJUST>DEVELOP>DE-NO-DC

•

If the density is too l ow (l ig ht), decrease the setting .

If the density is too high (dark ), increase the

Caution:

setting.

Be sure to change all the settings for the same

degree.

Is the image

density correct?

No

Replace the developing assembly, and start over

with “Making Initial C hecks” to make image

adjustments.

Yes

Is the image

of TYPE 6 (solid black;

density and free of

blurring?

No

Does the image

show blurring?

Yes

Is the image

density correct?

Yes

No

Yes

B

-

5 / 7 -

Page 6

5 Checking the Printer Si de ( 2 / 3)

GP405-010

B

Replace the pre-exposure unit.

Check the imag e density using

test prints (TYPE 5).

Is the density

between right and left of the

ima ge diff e ren t?

Yes

Clean the fol l owi ng:

1. dust-proofing g l ass

2. No. 1 mirror

3. No. 2 mirror

4. No. 3 mirror

Is the density

between right and left of the

ima ge diff e ren t?

Yes

No

pre-exposure lamp on at both

Is the

rear and front ends?

Yes

No

No

C

Is the feeding

assembly (transfer roller)

engaged properly?

No

Yes

Engage it properly. If the pressure

spring is faulty, replace it.

Generate 10 test prints (TYPE 6);

then, if the coating of toner on the

developing sl eev e is unev en,

replace the developing assem bl y.

No

Yes

Is the developin g

assembly en gaged (locked

in place)?

Yes

Is the coating

of toner on the developing

sleeve unev en?

No

Engage the feeding assembly

(transfer roller) properl y.

If the engag em ent is not proper,

replace the transfer unit.

Replace the laser unit.

B

-

6 / 7 -

Page 7

6 Checking the Printer Si de ( 3 / 3)

GP405-010

C

Check the imag e density using test prints

(TYPE 4).

No

Yes

Increase the foll owi ng in serv ice m ode:

COPIER>ADJUST>DEVELOP>DE-DC

•

COPIER>ADJUST>DEVELOP>DE-NO-DC

•

Note:

Be sure to change the settings for the sam e

degree.

If, how ever, the abov e settings hav e been

changed under “Checking the Printer S ide (1/3),”

decrease the follow ing in serv ice m ode:

COPIE R> A D JU S T>H V-PRI >P- D C

•

COPIER>ADJUST>HV-PRI>P-NO-DC

•

Note:

Be sure to change the settings for the sam e

degree.

Is the copy image faulty?Is the image foggy?

Yes

Go to

2 Checking the Scanner Side (1/2)

No

End.

Is the image

density of the test prints

(TYPE 6) normal?

No

Replace the devel oping assembly ; then,

start over with “Mak ing I nitial Check s” to

make im ag e adjustm ents.

Yes

-

7 / 7 -

Loading...

Loading...