Canon GP405, GP605, GP160, Gp-335, Gp-605v Service Bulletin acc-147

...

Service Bulletin

Issued by Canon Europa N.V.

COPIER

Model :

Location :

Subject :

Reason :

Details :

Finisher D1

BUFFER ROLLER ASSEMBLY

ALIGNMENT FAULTS (DURING WRAPPING ON BUFFER ROLLER)

An alignment fault can occur during staple sorting if the degree of wrapping of paper on the buffer

roller is not appropriate, and the problem can be corrected by providing the measures shown herein

during servcing wor k.

<Symptom>

An alignment fault can occur in sheets delivered after stapling by the sorter.

<Cause>

If the degree of wrapping of paper on the buffer roller is not appropriate, the resulting displacement of

sheets will lead to misalignment during stapling operation.

No.:

DATE:

Acc-147 Rev. 1

(FF-T01-W-000049-02)

10.08.99

Servicing :

<Factory measure>

The work rules imposed on the factory ar e now being imposed strictly, and additional work (i.e.,

checking adjustment values) has been added.

< Making Checks and Maki ng Adjustments >

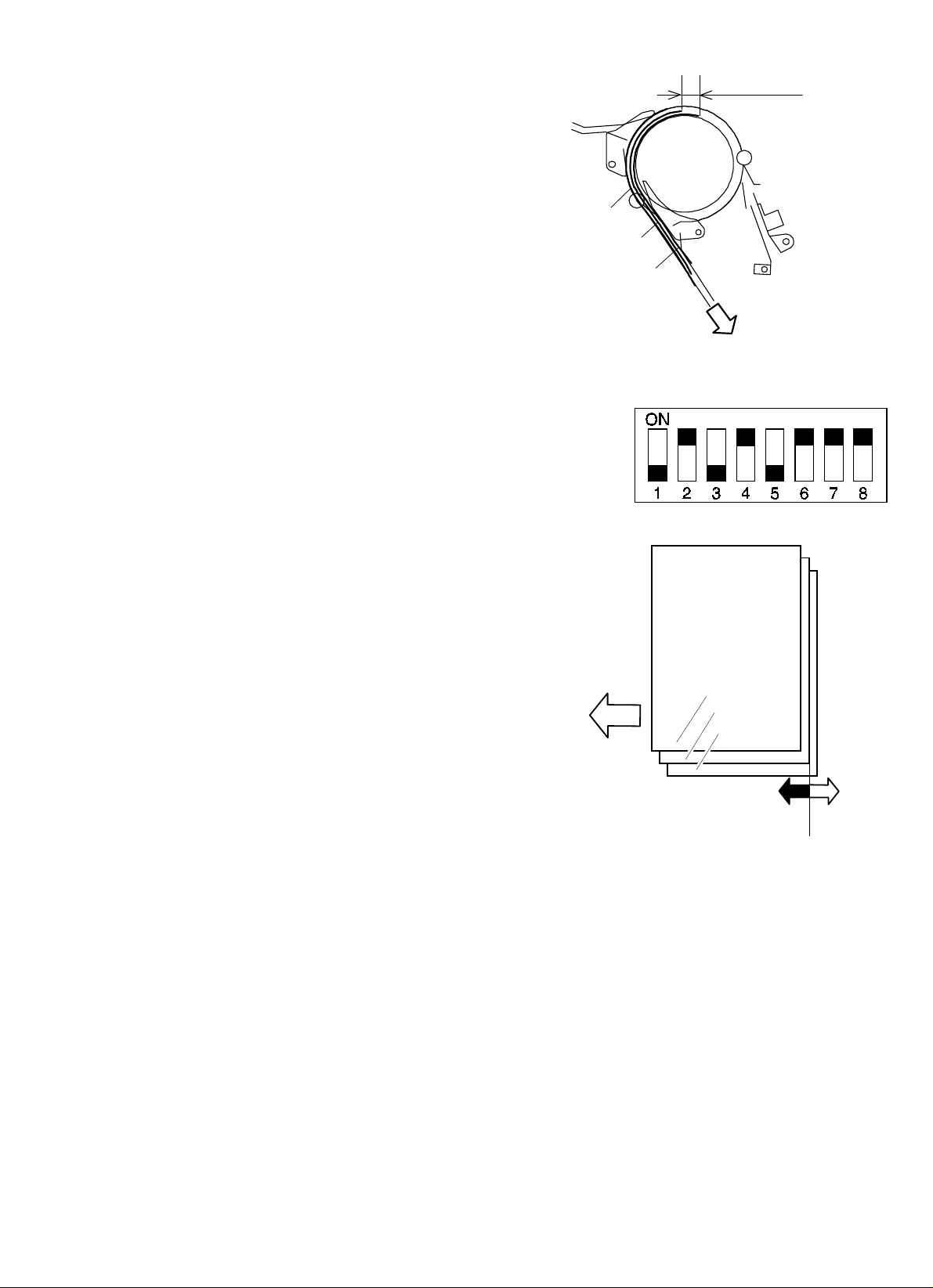

1. Turn off the power, and set the DIP switch

(SW103) on the finisher controller PCB as

shown in Figure 1.

2. Set the copier so that the copy count is '2' and

sort mode is selected; then, place three originals.

3. Press the Copy Start key.

•

The copier starts to operate and stops as soon as

sheet wrap a ro und the buff e r r o lle r.

4. Open the front cover and the upper cover, and

measure the displacement of sheets wrapping

around the buffer ro ller.

•

After taking measurements, remove the sheets.

Fig. 1

-

1 / 2 -

5. Compare the degree (displacement) of wrapping

against the standard (2 ±1 mm; see Figure 2).

3rd sheet

6. Turn off the power, and set the DI P switch (SW103)

on the finisher controller PCB as shown in Figure 3.

7. Turn on the po wer, and press t he push switch

(SW104) on he finisher controller.

•

LED101 will indic ate the present setting.

8. As necessar y, press the push switch (SW105 or

SW106) on the finisher controller PCB. ( See Figure

4.)

•

Each press o n S W105 increa ses the degree of

wrapping by 1.74 m m.

•

Each press o n S W106 decrea s e s t he degree o f

wrapping by 1.74 m m.

9. Press the push switch ( S W104) on the finisher

controller PCB.

10. See that the new setting has been stored in memory

and LED101 indicates '0'.

11. Turn off the power , and shift all bits of SW103 to

OFF.

2nd sheet

1st sheet

(direction

of deliv ery)

Acc-147 Rev. 1

Degree of wrapping

(displacement)

2 ±1 mm

Fig. 2

Fig. 3

3rd sheet

2nd sheet

1st sheet

Shift of 2nd

and 3rd sheets

by SW105

Fig. 4

Affected machines:

NLF00229 and later ULF00316 and later

Shift of 2nd

and 3rd sheets

by SW106

←←←←

-

2 / 2 -

Loading...

Loading...