Canon GP405, GP605, GP160, Gp-335, Gp-605v Service Bulletin GP605-06

...

Service Bulletin

Issued by Canon Europa N.V.

COPIER

Model :

Location :

Subject :

Reason :

Details :

GP605

DEVELOPER

DEVELOPER CAUSING LIGHT OR COMPLETELY BLANK IMAGE

To communicate procedures for countermeasures regarding the possibility of light or completely blank

image occurring due to scraping of the developer washer which causes electrical leaks.

<Symptom>

Light or com pletely blank image sometimes o ccur depending on the workload in terms of the copy

volume achieved to date.

<Cause>

A washer which has been added (to the space between the electrode positioning plate and the

developer sleeve) as a countermeasure for preventing noise may scrape off over a period of time, and

then the broken fragments falling into the die-cast section of the main unit could result in electrical

leaks.

No.:

DATE:

GP605-006

(FF-T01-K1-000014-01)

07.05.99

Servicing :

<Factory measure>

Temporary countermeasure: Remove the washer which has been used to prevent noise.

* If there is a space of 0.2mm between the electrode positioning plate and the developer sleeve,

noise will not occur even upon removing the washer.

< Procedure >

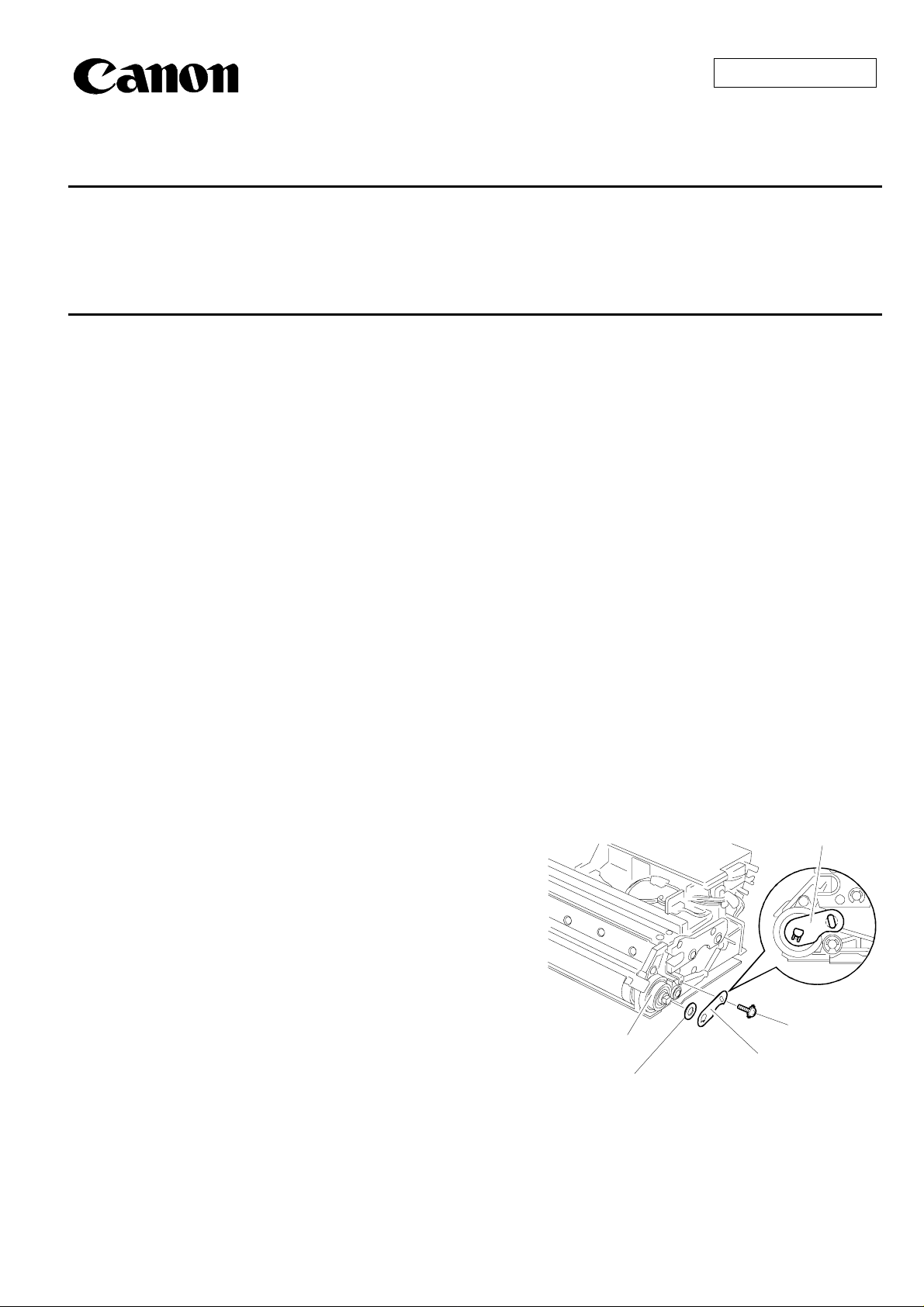

1) Remove the screw.

2) Remove the electrode positioning plate.

3) Remove the washer.

4) Clean the pressure roller.

Caution:

There can be recurrence of the

problem for developers whi ch have

had light or completely blank

image occurring, and for this

reason replace the pressure roller.

Pressure roller

(FS5-6574)

Washer

Fig. 1

Positioning plate

Screw

Positioning plate

-

1 / 2 -

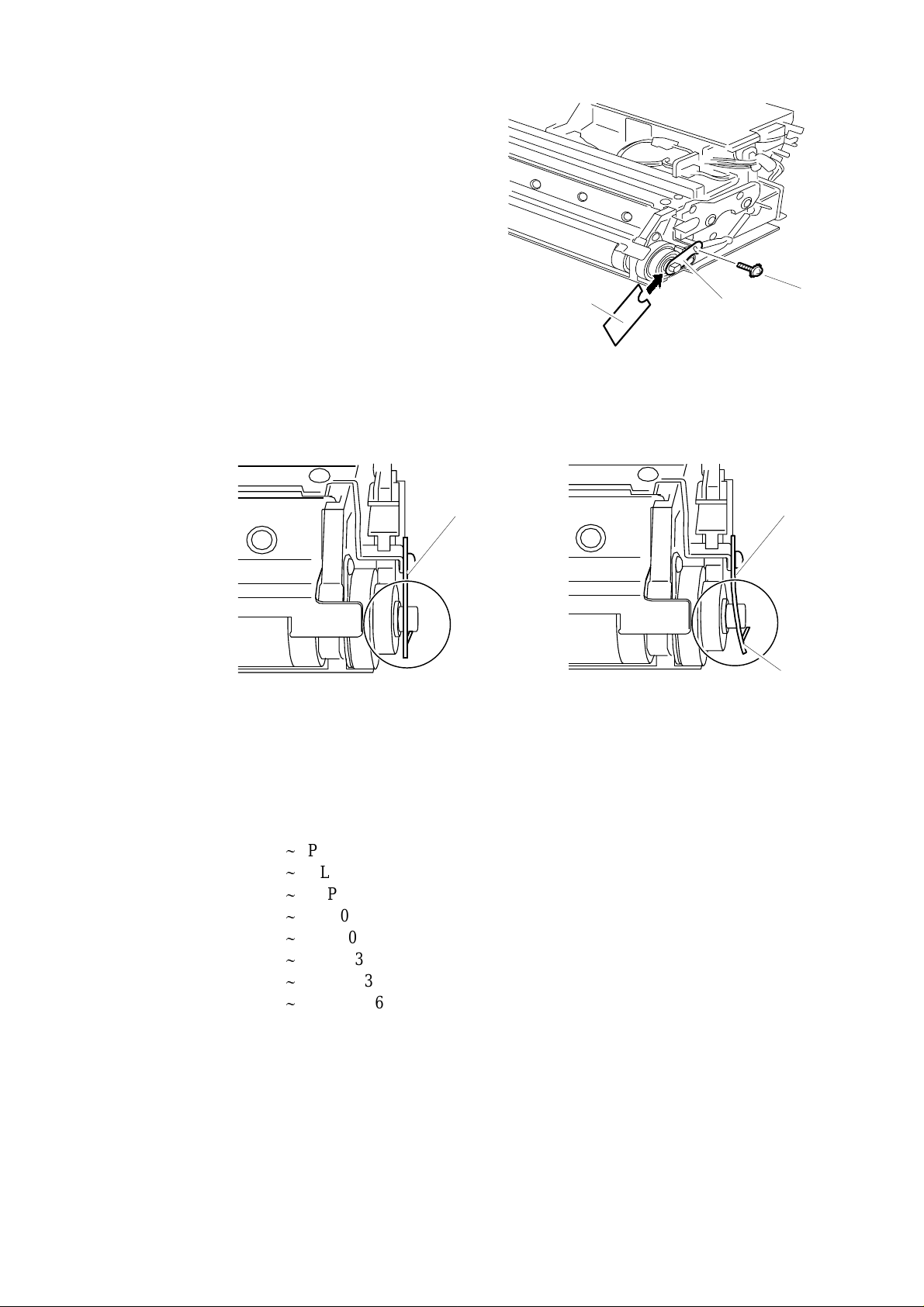

5) Insert the 0.2mm spacer (for

example, OHP sheets of about

0.2mm thickness) and place the

electrode positioning plate.

6) Tighten the screw.

* Since there is a magnet in the

developer sleeve roller, tighten

the screw at the natural position

without going against the effect

of the magnet.

Spacer

(0.2mm)

GP605-006

Screw

Positioning plate

Fig. 2

Affected machines:

Affected machines

A round yellow label has been a ttached to the outside of boxes for modified machines.

Caution:

In attaching the electrode positioning plate, exercise caution not to raise it up or bend it.

OK

PLE00027

PLE00102

NLE00848NLE01858

PLP00007

QLE0052

PLP00048

QLE00245

RLE00017RLE00039

SLE00235

SLE00371

TLE00082TLE00139

ULE00362ULE00536

Positioning plate

Fig. 3

NG

Positioning plate

Be careful not to raise

it up or bend it.

-

2 / 2 -

Loading...

Loading...