Page 1

SERVICE

HANDBOOK

REVISION 0

JAN. 1999

COPYRIGHT © 1999 CANON INC. CANON 405/335 REV.0 JAN. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

FY8-23AZ-000

Page 2

IMPORTANT

THE INFORMATION CONTAINED HEREIN IS PUBLISHED BY CANON, INC., JAPAN, AND IS

FOR REFERENCE USE ONLY. SPECIFICATIONS AND OTHER INFORMATION CONTAINED

HEREIN MAY VARY SLIGHTLY FROM ACTUAL MACHINE VALUES OR THOSE FOUND IN

ADVERTISING AND OTHER PRINTED MATTER.

ANY QUESTIONS REGARDING INFORMATION CONTAINED HEREIN SHOULD BE DIRECTED

TO THE COPIER SERVICE DEPARTMENT OF THE SALES COMPANY.

COPYRIGHT © 1999 CANON INC.

Printed in Japan

Imprimé au Japon

Use of this manual should be

strictly supervised to avoid

disclosure of confidential

information.

Prepared by

OFFICE IMAGING PRODUCTS TECHNICAL SUPPORT DEPARTMENT 1

OFFICE IMAGING PRODUCTS TECHNICAL SUPPORT DIVISION

CANON INC.

5-1, Hakusan 7-chome, Toride-shi Ibaraki, 302-8501 Japan

COPYRIGHT © 1999 CANON INC. CANON 405/335 REV.0 JAN. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

Page 3

CONTENTS

CHAPTER 1 MAINTENANCE AND INSPECTION

1

2

A. Scheduled Servicing Table........................1-1

1. Copier ..................................................1-1

2. Paper Deck..........................................1-2

B. Periodically Replaced Parts.......................1-3

C. Consumables and Durables ...................... 1-3

1. Copier ..................................................1-3

2. Side Paper Deck..................................1-4

D. Image Basic Adjustment Procedure..........1-5

E. Points of Scheduled Servicing................... 1-6

CHAPTER 2 STANDARDS AND ADJUSTMENTS

A. Image Adjustment...................................... 2-1

B. Exposure System ......................................2-6

C. Image Formation System ..........................2-9

D. Pick-Up/Feeding System.........................2-11

E. Fixing System ..........................................2-16

F. Electrical System .....................................2-18

CHAPTER 3 ARRANGEMENT AND FUNCTIONS OF

ELECTRICAL PARTS

A. Clutches and Solenoids.............................3-2

B. Motors........................................................3-4

C. Fan.............................................................3-6

D. Sensors......................................................3-8

E. Switches and Counters............................3-10

F. PCBs........................................................3-12

G. Side Paper Deck...................................... 3-14

1. Sensors and Switches.......................3-14

2. Motors, Solenoids, and PCBs ...........3-16

H. Variable Resisters, Light-Emitting Diodes,

and Check Pins by PCB ..........................3-18

1. Image Processor PCBs

(main controller).................................3-19

2. DC Controller PCB (DC driver)..........3-21

3. Composite Power Supply CPB .........3-23

4. Deck Driver (side paper deck)...........3-24

I. Upgrading ................................................3-25

1. Removing the DIMM.......................... 3-26

2. Mounting the DIMM ...........................3-27

3. Downloading...................................... 3-28

3

4

5

i

Page 4

CHAPTER 4 SERVICE MODE

A. Outline .......................................................4-1

1. Starting Service Mode and Making

Selections ............................................ 4-1

2. Ending Service Mode .......................... 4-2

3. Backing Up the RAM ...........................4-2

4. Basic Operation ................................... 4-4

B. DISPLAY Control Display Mode................4-7

C. I/O Operation Check Mode ...................... 4-22

1. DC-CON ............................................4-23

2. IP .......................................................4-30

CHAPTER 5 SELF DIAGNOSIS

A. Copier ........................................................ 5-3

B. DADF .......................................................5-10

C. Cassette Feeding Unit-R1/S1 .................. 5-11

D. Multi Output Tray-D1 ...............................5-11

E. Finisher-C1 .............................................. 5-12

3. FEEDER ............................................ 4-31

4. SORTER (Finisher C1, Saddle

Finisher C2, Finisher E1)................... 4-34

D. ADJUST Adjustment Mode...................... 4-45

E. FUNCTION Operation Check Mode........4-53

F. OPTION Settings Mode ........................... 4-65

G. PG test Print ............................................4-73

H. COUNTER Mode ..................................... 4-78

I. FEEDER ..................................................4-81

J. SORTER (finisher, saddle stitcher) .........4-85

F. Saddle Finisher-C2 ..................................5-14

G. Finisher-E1 ..............................................5-18

H. Paper Deck-B1 ........................................5-20

I. SCSI Interface Board-D1.........................5-21

APPENDIX

A. General Timing Chart ............................... A-1

B. Signal name/abbreviation list.................... A-3

C. General Circuit Diagram ........................... A-7

D. General Circuit Diagram Paper Deck ..... A-13

E. Specifications .......................................... A-15

1. Copier ............................................... A-15

2. Paper Deck....................................... A-21

ii

Page 5

CHAPTER 1 MAINTENANCE AND INSPECTION

CHAPTER 1 MAINTENANCE AND INSPECTION

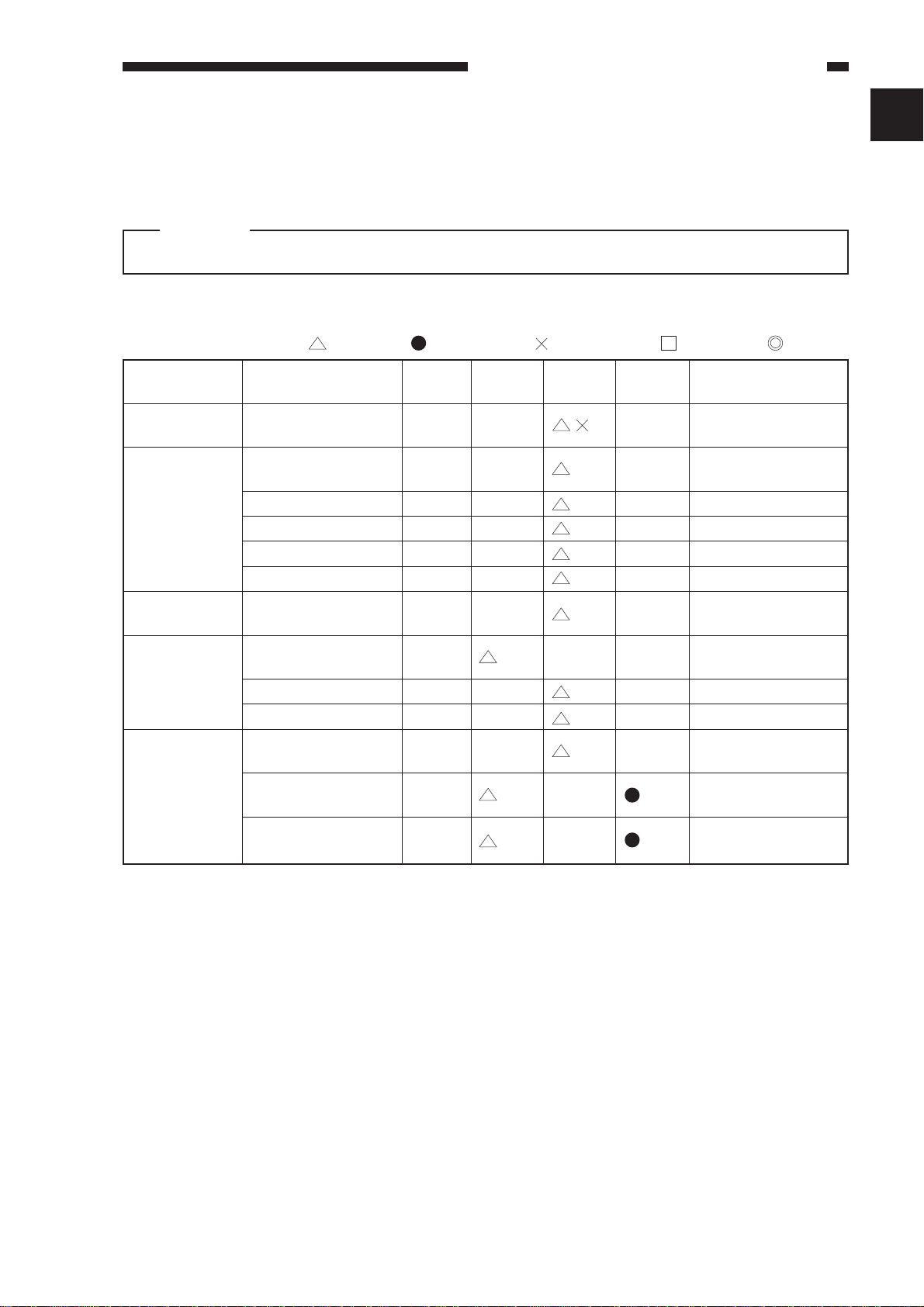

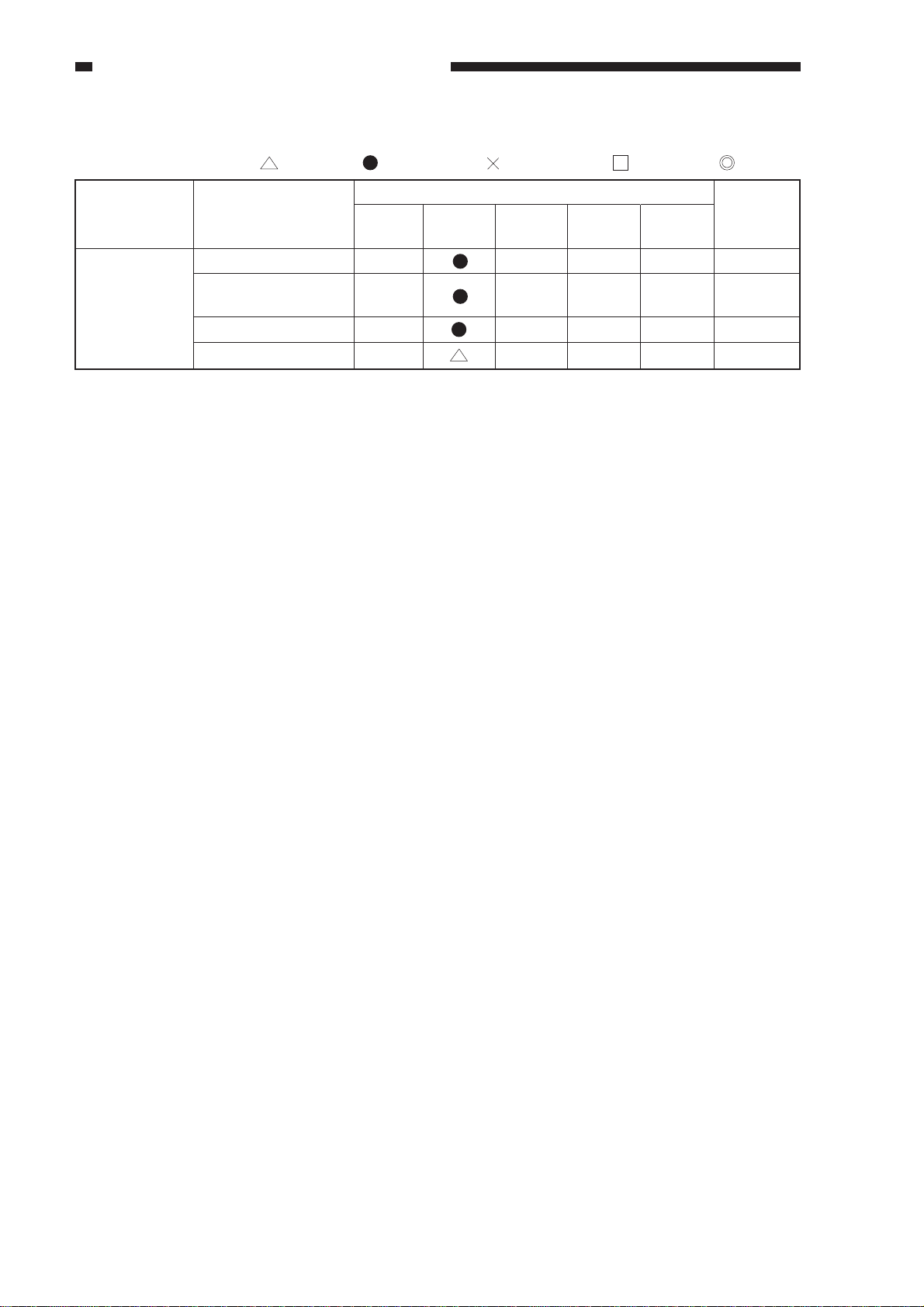

A. Scheduled Servicing Table

Caution:

Do not use solvents/oils not indicated here.

1. Copier

: Clean : Replace : Lubricate : Adjust : Inspect

Unit

Scanner drive

assembly

Optical assembly

Developing

assembly

Feeding assembly

Fixing

assembly

Part

Scanner rail

No. 1 through No. 3

mirrors

Dust-proofing glass

Lens

Reflecting plate

Original size sensor

Developing assembly

roll

Transfer guide

Feeding belt

Feeding assembly base

Fixing assembly

inlet guide

Upper separation claw

Lower separation claw

Installation

every

60,000

every

120,000

every

240,000

Remarks

Use lubricant.

Note

During a visit.

Clean as necessary.

During a visit.

Clean as necessary.

During a visit.

Clean as necessary.

1

Note: For cleaning intervals, use the hardware counter reading as a reference.

1-1

Page 6

CHAPTER 1 MAINTENANCE AND INSPECTION

2. Paper Deck

: Clean : Replace : Lubricate : Adjust : Inspect

Unit

Pick-up

assembly

Pick-up roller

Pick-up/feeding

roller

Separation roller

Feeding roller, roll

Part

Installation

Maintenance intervals

every

250,000

every

500,000

every

750,000

every

1,000,000

Remarks

1-2

Page 7

CHAPTER 1 MAINTENANCE AND INSPECTION

B. Periodically Replaced Parts

The machine does not have parts that need to be replaced on a periodical basis.

C. Consumables and Durables

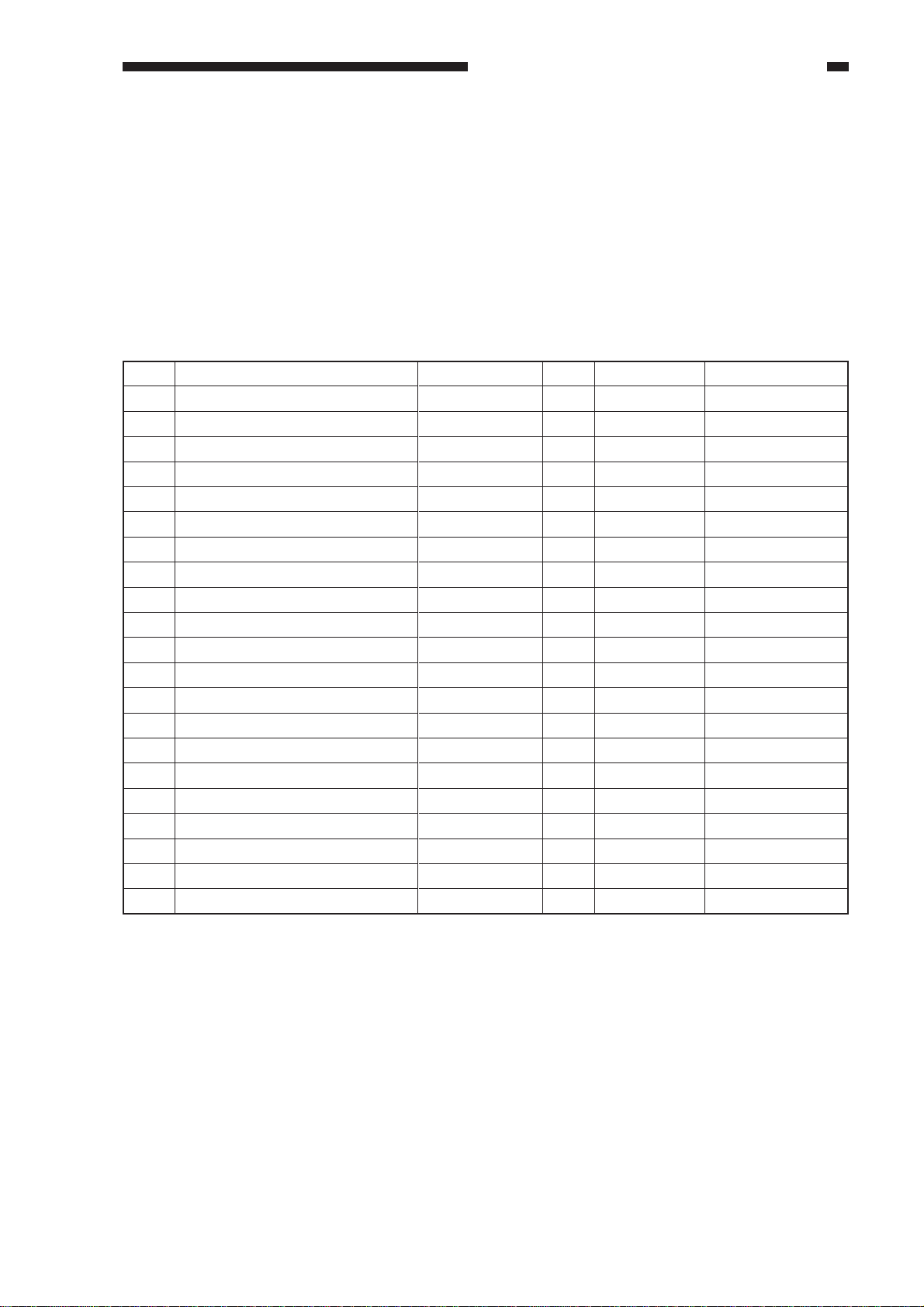

1. Copier

Some parts of the machine may require replacement once or more over the period of warranty

because of wear or damage. Replace them as necessary.

As of Dec. 1998

No.

1

Pick-up roller

2

Feeding roller

3

Separation roller

4

Pick-up roller (multifeeder)

5

Separation pad (multifeeder)

6

Transfer roller

7

Separation static eliminator

8

Scanning lamp

9

Pre-exposure lamp

10

Developing cylinder

11

Upper fixing roller

12

Lower fixing roller

13

Upper fixing separation claw

14

Lower fixing separation claw

15

Fixing cleaning belt

16

Heat insulating bush

17

Fixing heater (main)

18

Fixing heater (sub)

19

Thermistor

20

Internal delivery roller

21

Internal delivery sensor

Parts name

Parts No.

FF5-4552-020

FF5-4552-020

FF5-4634-020

FB1-8581-000

FC1-9022-030

FF5-6980-000

FF5-7246-000

FH7-3314-000

FG5-6297-000

FG6-0626-000

FB5-0289-000

FB4-2867-000

FB1-7075-000

FA2-9037-000

FA3-8908-000

FB1-6823-000

FH7-4570-000

FH7-4573-000

FG6-3881-000

FB4-2901-000

FH7-7394-000

Q'ty

2

2

2

1

1

1

1

1

1

1

1

1

5

2

1

2

1

1

1

1

1

Life (copies)

120,000

120,000

120,000

240,000

240,000

240,000

240,000

240,000

240,000

480,000

240,000

240,000

240,000

240,000

160,000

240,000

360,000

360,000

240,000

240,000

500,000

Remarks

Actual copies made.

Actual copies made.

Actual copies made.

Actual copies made.

Actual copies made.

1-3

Page 8

CHAPTER 1 MAINTENANCE AND INSPECTION

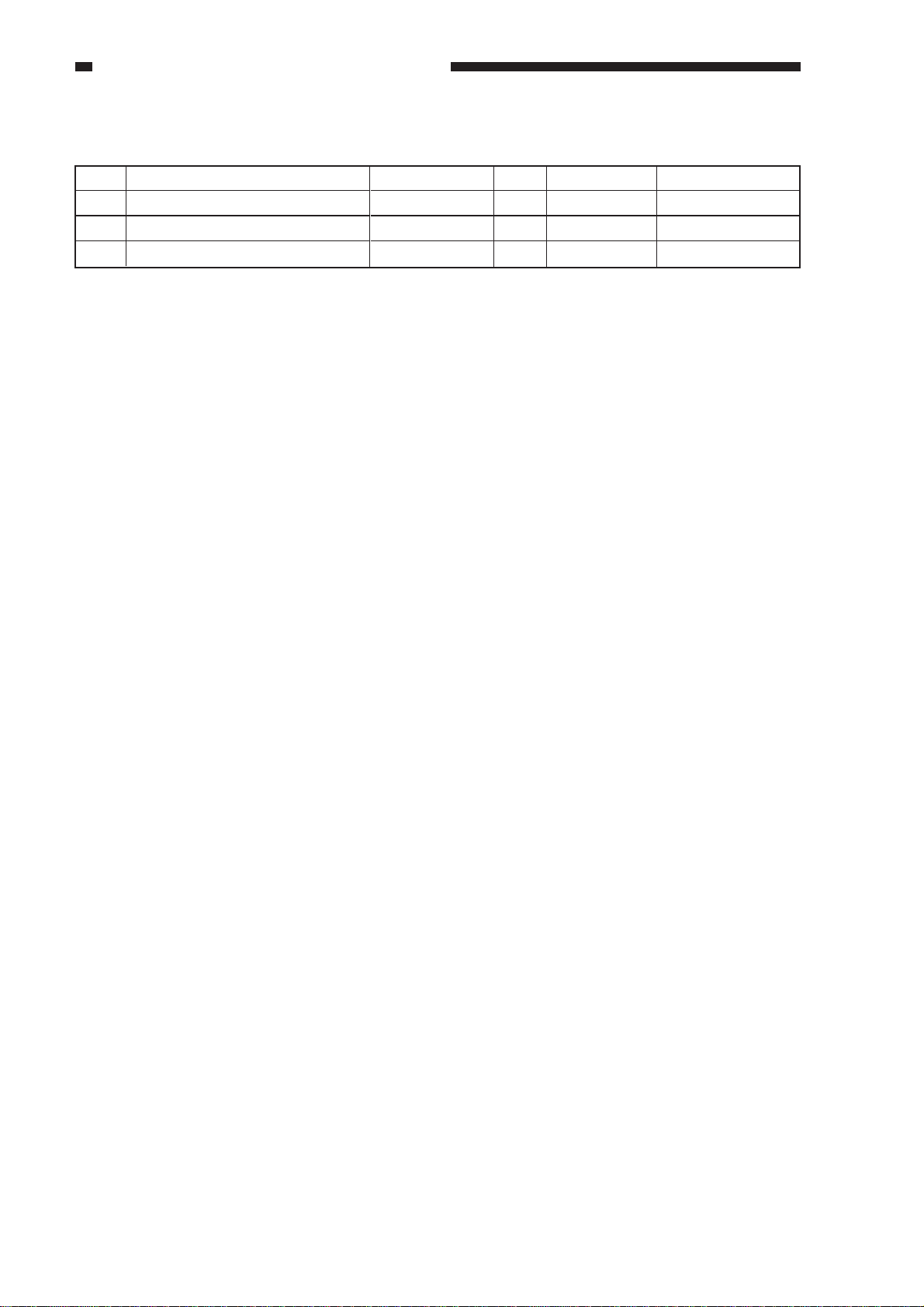

2. Side Paper Deck

As of Dec. 1998

No.

1

2

3

Parts name

Side paper deck pick-up roller

Side paper deck feeding roller

Side paper deck separation roller

Parts No.

FB4-2033-000

FB4-2034-000

FB2-7777-000

Q'ty

2

2

1

Life (copies)

250,000

250,000

250,000

Remarks

Actual copies made.

Actual copies made.

Actual copies made.

1-4

Page 9

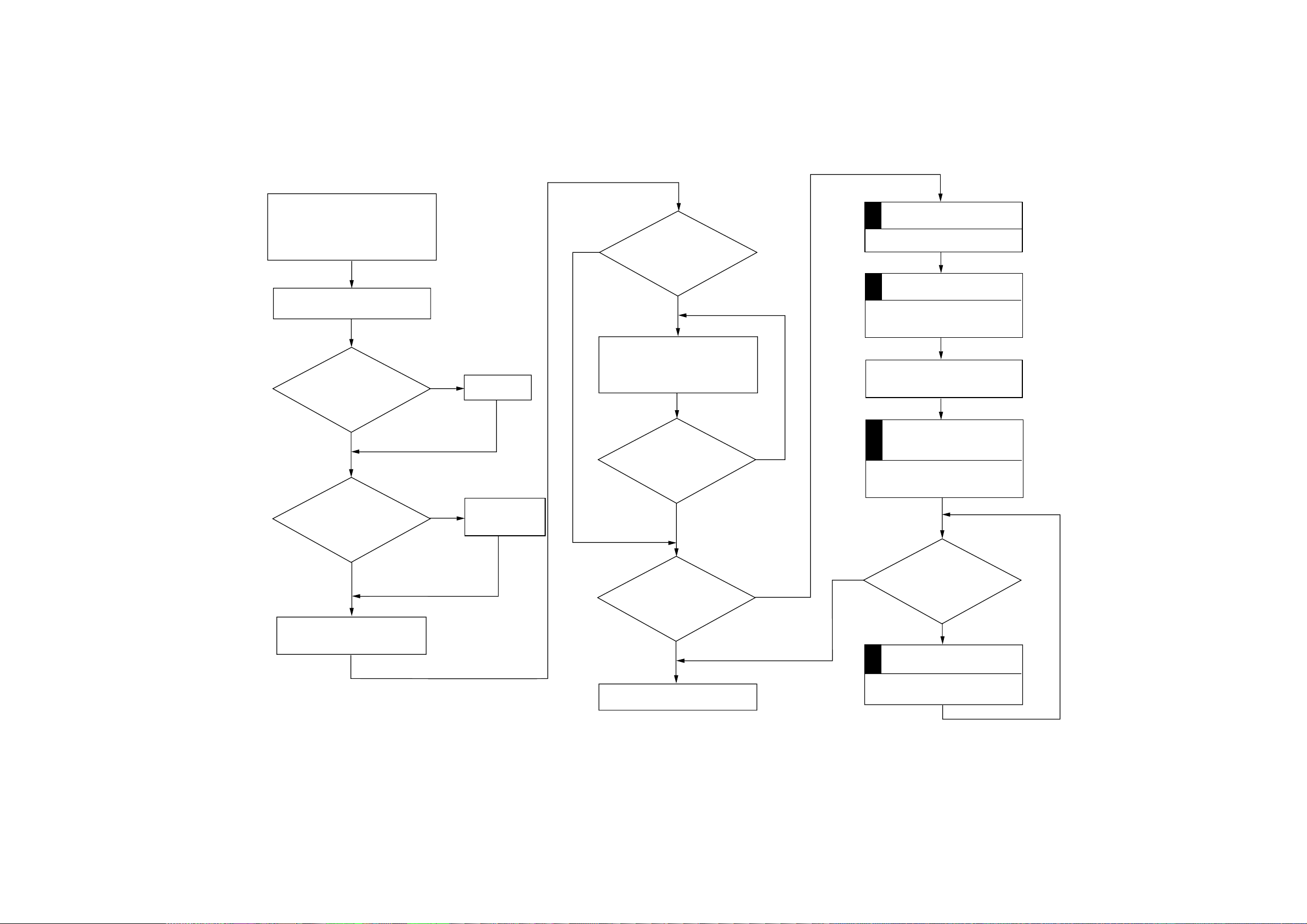

D. Image Basic Adjustment Procedure

Clean the primary charging roller

/transfer charging roller.

¥ To clean the primary/transfer

charging roller, use ’roller clean’

under ’adjustment/clean’ in user mode.

Clean the separation static

eliminator.

Is the

setting of ’density

correction’ under ’adjust/clean’

in user mode the medium

value?

YES

It the

setting of

’ADJUST’ in service

mode the value indicated on the

label attached to the

front door?

NO

Set it to the

medium value.

Enter the value

NO

indicated on the

label.

NO

Are there vertical

lines (white, black)?

YES

Clean the separation static

eliminator, dust-proofing glass,

mirrors (No. 1, No. 2, No. 3),

standard white plate, and lens.

Are the vertical lines gone?

YES

NO

Service Mode

ADJUST>DENS>DENS-ADJ

Set DENS-ADJ to 5.

Service Mode

FUNCTION>CCD>CCD-ADJ

Execute auto correction.

Open the copyboard cover or the

feeder, and make 2 solid black

copies.

Service Mode

Density Auto Adjustment

5 items under FUNCTION>DENS.

WHITE-ME, PD-DENS, PD-ME,

DZ-DENS, DZ-ME

YES

Make 2 to 3 copies in non-AE

at copy density 5.

Is the white

background foggy?

NO

End.

YES

YES

Is the fogging in the white

background gone?

NO

Service Mode

ADJUST/DENS/DENS-ADJ

Set DENS-ADJ lower than 5.

1-5

Page 10

E. Points of Scheduled Servicing

Copyboard/Scanner

Item

Copyboard glass

Original size sensor

Scanning lamp

Reflecting plate

No.1 through No.3 mirrors

Standard white plate

Scanner rail

Tool/solvent

Alcohol

Blower brush

Lint-free paper

Blower brush

Alcohol

Alcohol,

Lubricant

Work/remarks

Clean.

Clean.

Dry-wipe.

As necessary, dry-wipe

with lint-free paper.

Clean

Clean, and lubricate.

Optical Assembly

Item

Lens

Dust-proofing glass

Developing Assembly

Item

Developing roll

Tool/solvent

Blower brush

Blower brush

Tool/solvent

Alcohol Clean.

Work/remarks

Work/remarks

Clean.

Clean.

Fixing/Delivery Assembly

Item

Separation

Inlet guide

Tool/solvent

Solvent

Solvent

Work/remarks

Clean.

Clean.

Transfer/Feeding/Pick-Up Assembly

Item

Transfer guide

Static eliminator

Feeding assembly

base/Feeding belt

Pick-up/feeding/

separator roller

Tool/solvent

Moist cloth*

Special brush

Moist cloth*

Alcohol

*Take care not to leave droplets of water.

Do not turn on the power before it is

completely dry.

Work/remarks

Clean.

Clean.

Clean.

Clean.

1-6

Page 11

CHAPTER 2 STANDARDS AND ADJUSTMENTS

CHAPTER 2 STANDARDS

AND ADJUSTMENTS

A. Image Adjustment

Adjust the image margin, and then the

non-image width.

Adjusting the Image Leading Edge

Margin and the Non-Image Width

a. Change the following settings in service

mode so that they are as indicated on the

service label.

• ADJUST>ADJ-XY>ADJ-X, ADJ-Y

• ADJUST>FEED-ADJ>REGIST

b. Adjusting the Image Margin

1) Put A4 or A3 paper in the cassette, and

select the cassette.

2) Select '6' in service mode (TEST>PG>

TYPE), and generate a solid black copy.

3) Make adjustments so that the margin is

2.5 ±1.5 mm.

<Main Scanning Direction>

Use the horizontal registration mount.

(See A-2.)

<Sub Scanning Direction>

Use service mode (ADJUST>FEEDADJ>REGIST; see A-1).

c. Adjusting the Non-Image Width

1) Select the cassette used for adjusting the

image margin, and make a copy of the

NA-3 Chart.

2) Make adjustments so that the leading edge

and left/right non-image widths are 2.5

mm.

<Main Scanning Direction>

ADJUST>ADJ-XY>ADJ-Y

<Sub Scanning Direction>

ADJUST>ADJ-XY>ADJ-X

2

Caution:

Be sure that the NA-3 is placed on the

copyboard glass correctly.

2-1

Page 12

CHAPTER 2 STANDARDS AND ADJUSTMENTS

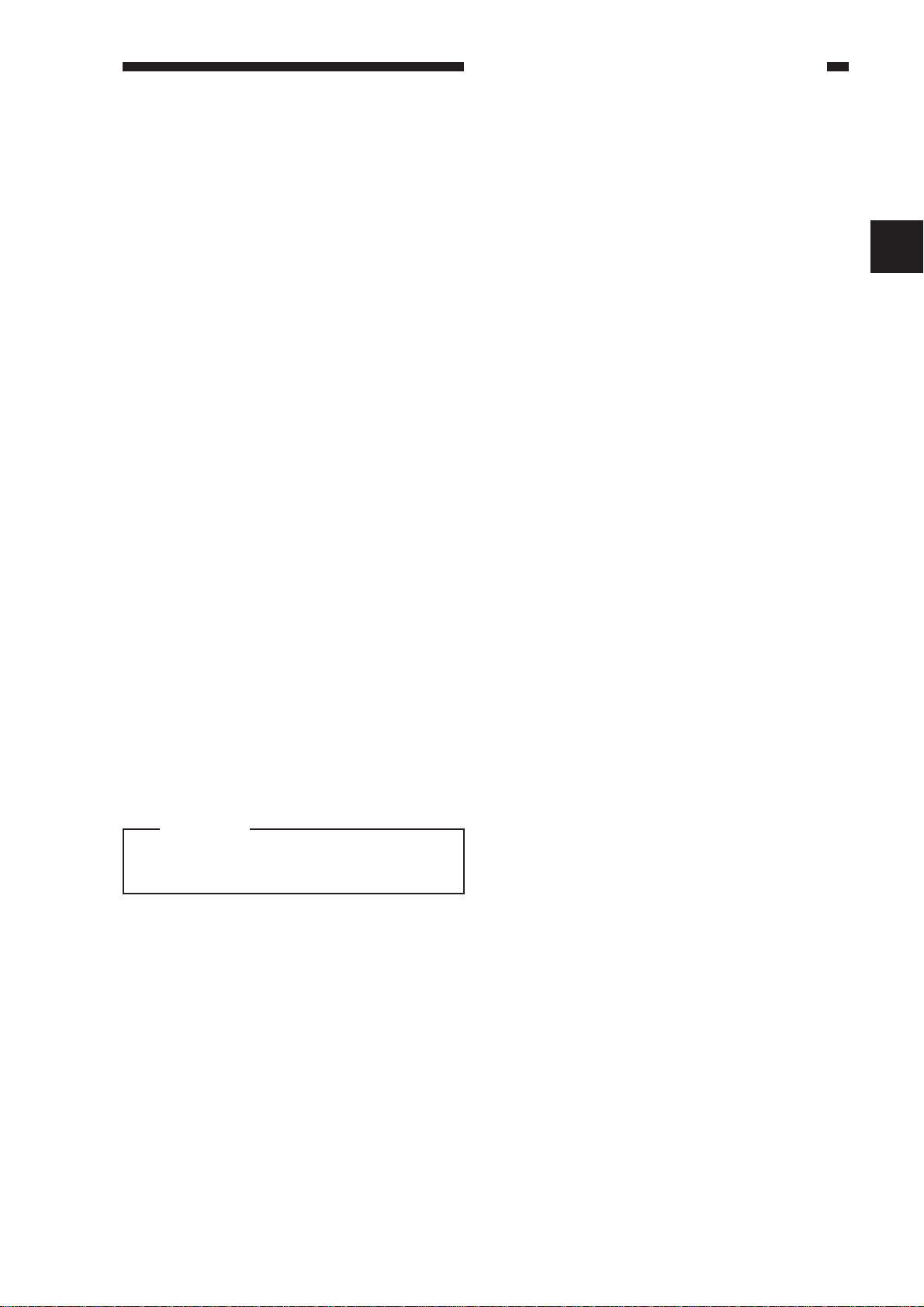

Image Leading Edge Margin

(REGIST; registration roller

1

activation timing)

Standard: 2.5 ±1.5 mm

For steps see the previous page.

n COPIER>ADJUST>FEED-ADJ>

REGIST

2.5 ± 1.5mm

Figure 2-1

<Making Adjustments>

• To increase the leading edge margin,

increase the setting of REGIST (thereby

delaying the activation of the registration

roller).

• To decrease the leading edge margin,

decrease the setting of REGIST.

n After adjusting the image leading edge

margin, be sure to make adjustments

under ADJUST>ADJ-XY>ADJ-X. (See

the descriptions for service mode.)

Adjusting the Left/Right

2

Registration (front)

a. Pick-Up from the Cassette

Check to see if the margin on the image

front is 2.5 ±1.5 mm for each cassette.

( ) ( + )

2.5 1.5mm

0

2

4

6

8

10

Figure 2-2

If it is not as indicated, perform the following:

1) Slide out the cassette in question.

2) Remove the two screws [1], and detach

the horizontal registration mount.

2-2

[1]

Horizontal registration mount

Figure 2-3

Page 13

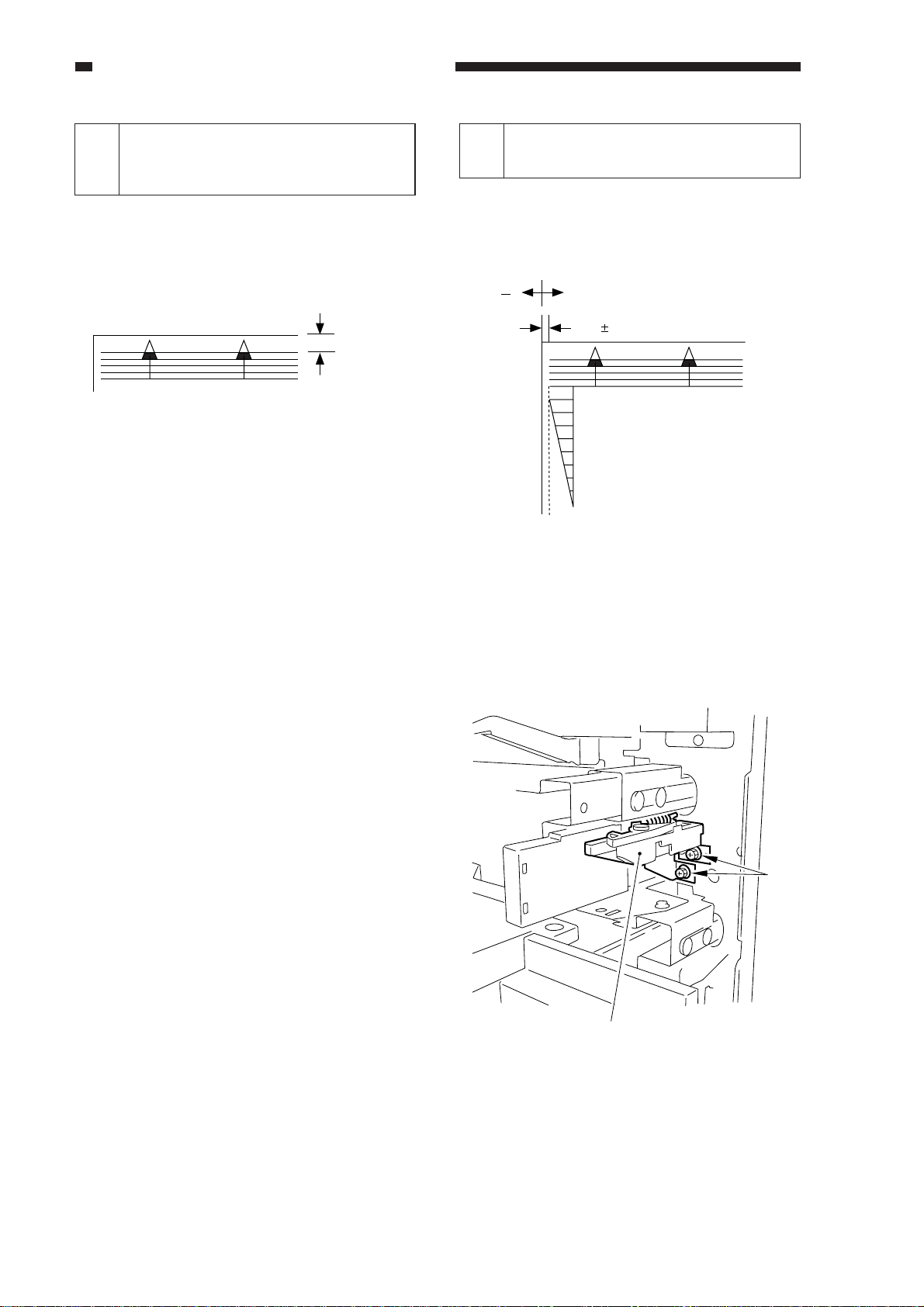

CHAPTER 2 STANDARDS AND ADJUSTMENTS

2.5mm ±2.0

Decrease ADJ-REFE.

(A decrease of 23

causes a change of

1 mm.)

Increase ADJ-REFE.

(An increase of 23

causes a change of

1 mm.)

3) Loosen the hex screw, and move the

horizontal registration plate to the front/

rear to make adjustments.

(front) (rear)

Hex screw diameter

Horizontal

registration plate

Hex screw

Left/Right Registration for the 2nd

Side of a Double-Sided/Overlay

3

Copy (rear/front direction)

Check to see if the image on the 2nd side

of a double-sided/overlay copy is as indicated.

• Standard: 2.5 mm ±2.0 mm

Figure 2-6

b. Pick-Up from the Multifeeder

4mm

Figure 2-4

Caution:

When making adjustments, match the

inside of the L angle of the horizontal

registration plate with the appropriate

graduation of the scale.

+

-

Figure 2-5

Loosen the screw, and move the tray so

that it is 2.5 ±1.5 mm in Direct mode.

If it is not as indicated, make adjustments

using the following in service mode:

COPIER>ADJUST>FEED-ADJ

>ADJ-REFE

2-3

Page 14

CHAPTER 2 STANDARDS AND ADJUSTMENTS

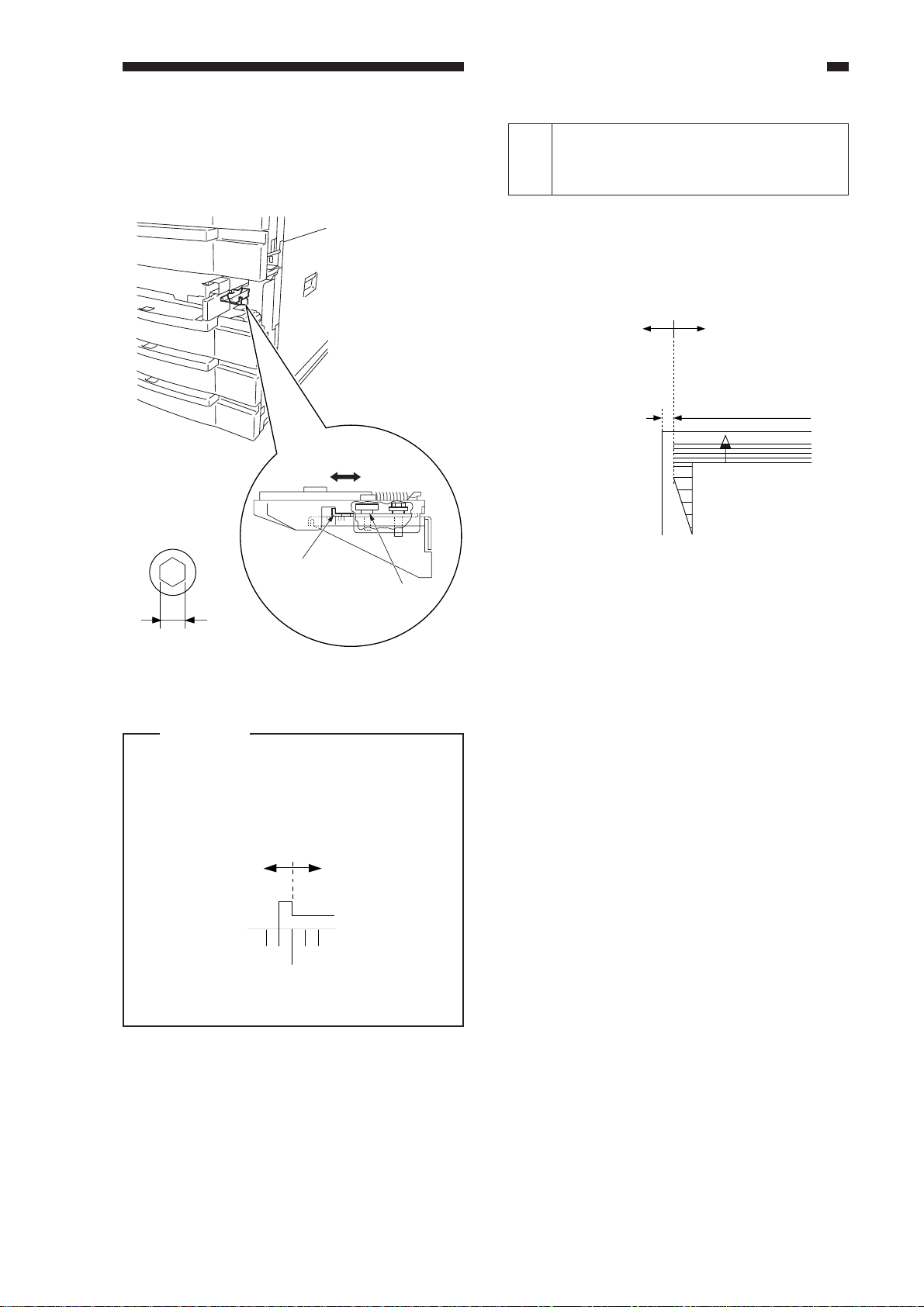

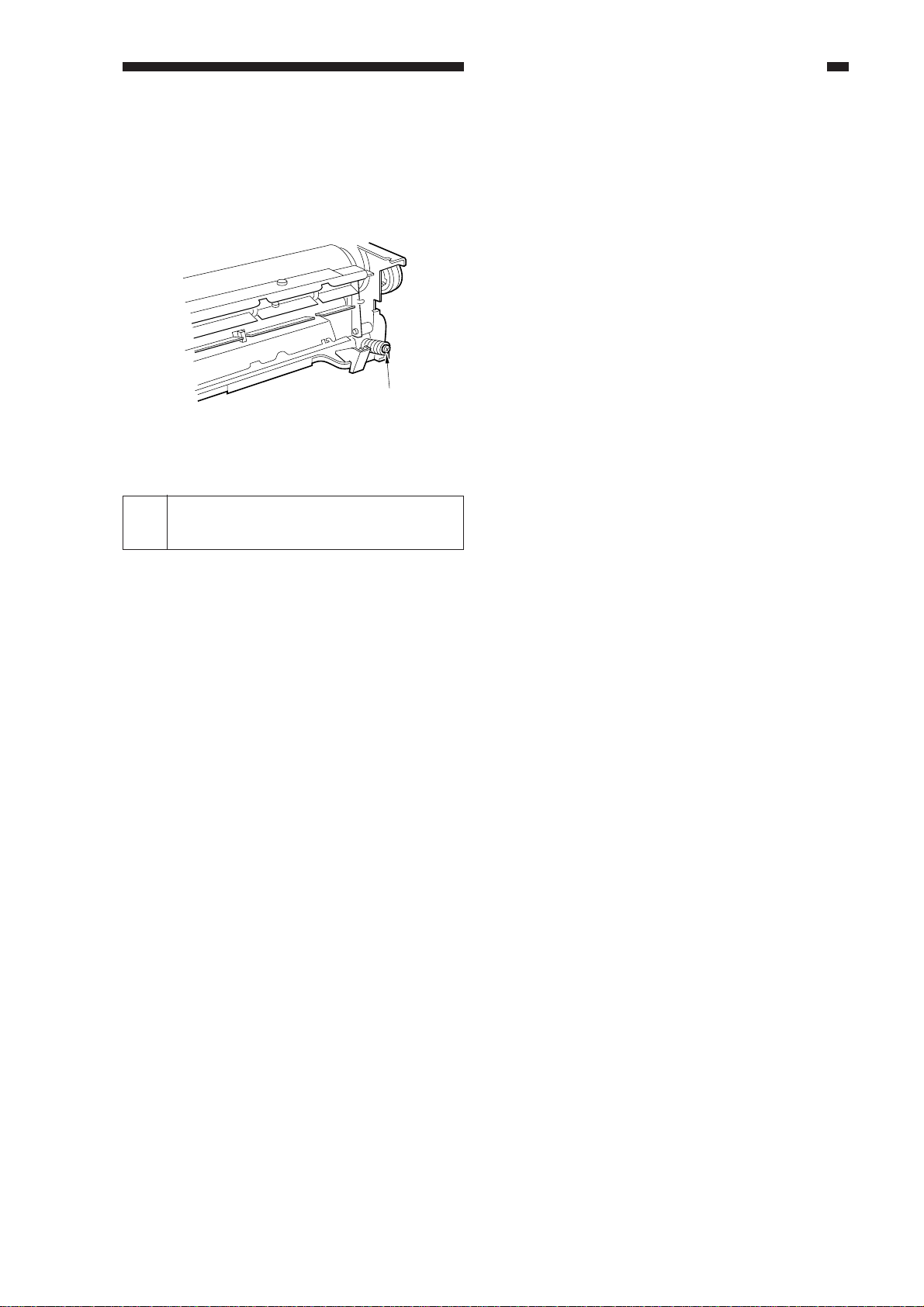

4 Left/Right Registration (side paper deck)

1) Make a copy of the Test Sheet, and check to see if the left/right registration is 0 ±1.5 mm.

2) If it is not as indicated, slide out the compartment, and turn the two screws to adjust the position

of the latch plate of the deck open solenoid. (At this time, refer to the scale on the latch plate.)

Latch plate

Scale

Screws

Figure 2-7 (rear left of the compartment)

2-4

Page 15

CHAPTER 2 STANDARDS AND ADJUSTMENTS

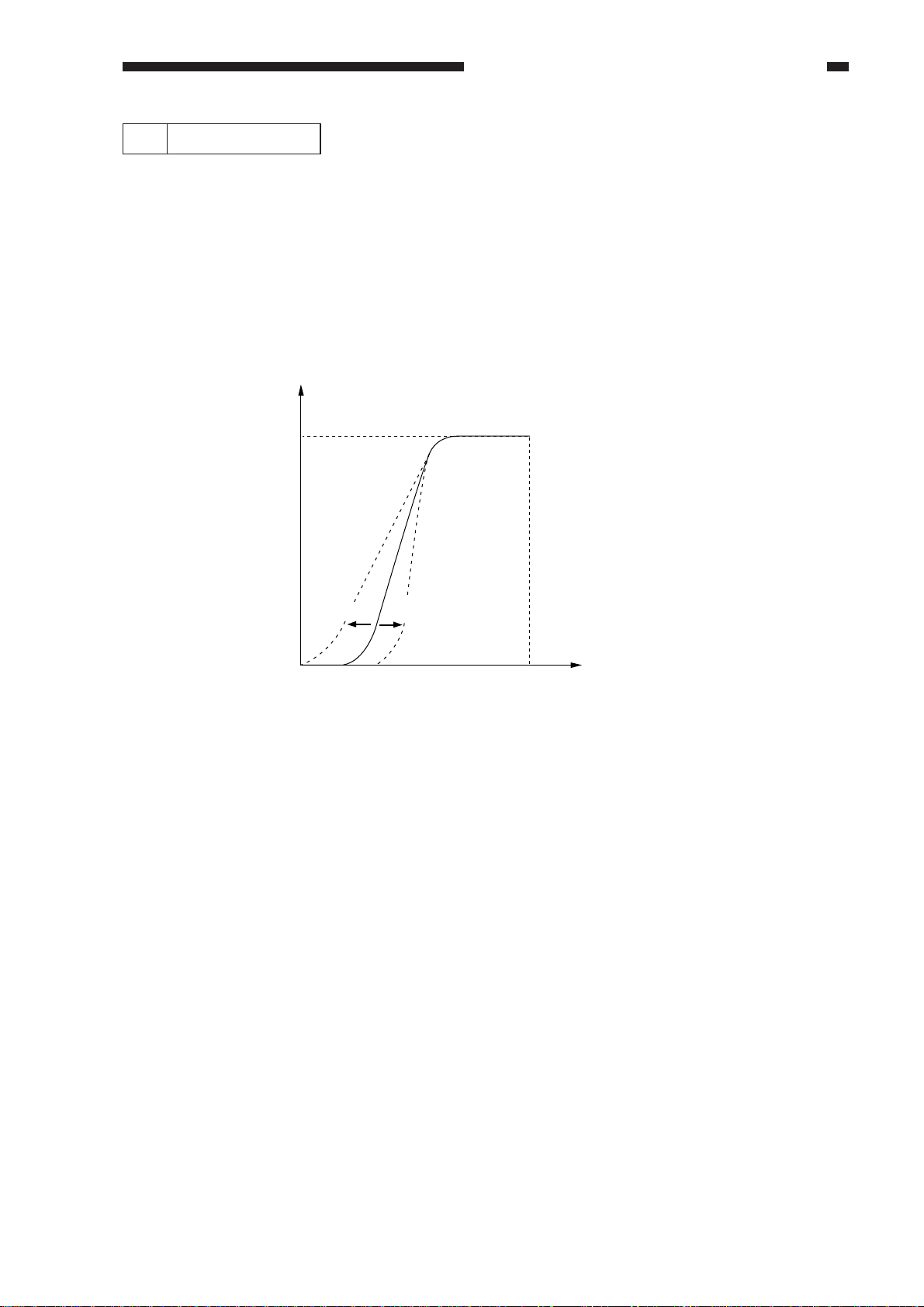

5 AE Adjustment

The machine's AE (auto density adjustment) based on "priority on speed," and its method and

concept are as follows:

1. Adjusting Priority on Speed AE Mode

ADJUST>AE>AE-TBL (1 through 9; 3 at time of shipment)

Adjust the density correction curve (text) for priority on speed AE mode.

• A higher setting makes text lighter.

• A lower setting makes text darker.

Copy density

White

Black

Higher

setting

Black

Lower setting

Original density

White

Figure 2-8

2-5

Page 16

CHAPTER 2 STANDARDS AND ADJUSTMENTS

B. Exposure System

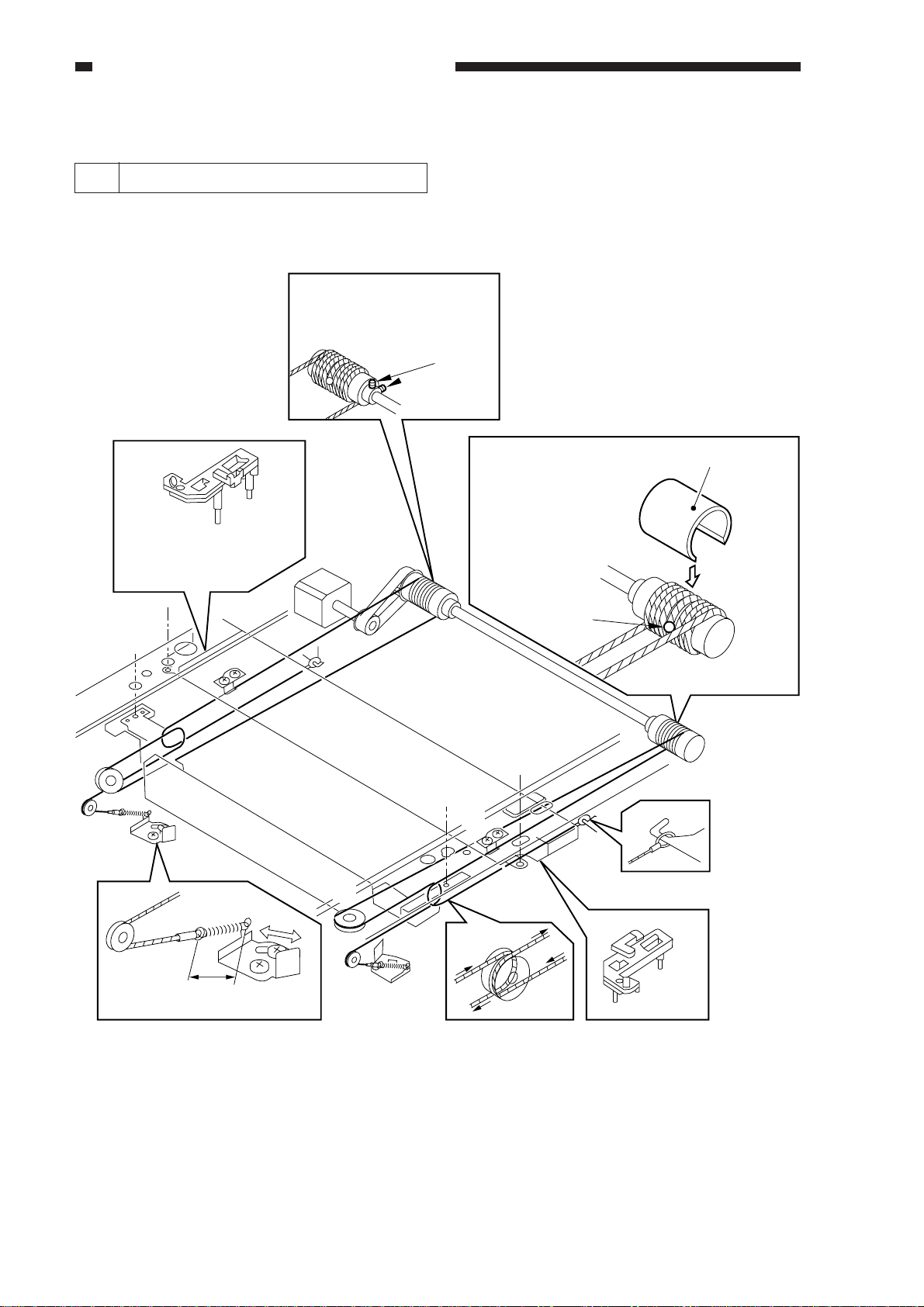

1 Routing the Scanner Drive Cable

Route the cable from [1] through [9]; then, go to the next item, "Adjusting the Mirror Position."

Loosen the set screws

to free the pulley.

Set

screws

[7]

[9]

[2]

Fit the mirror

positioning tool

[5]

Put the steel ball into the

hole in the pulley.

Wind the cable 3.5

times inwardly and

4.5 times outwardly;

then, fit the

pulley clip.

Steel ball

[8]

Pulley clip

[1]

[4]

2-6

38Å`39mm

[6]

[2][3]

Figure 2-9

Page 17

CHAPTER 2 STANDARDS AND ADJUSTMENTS

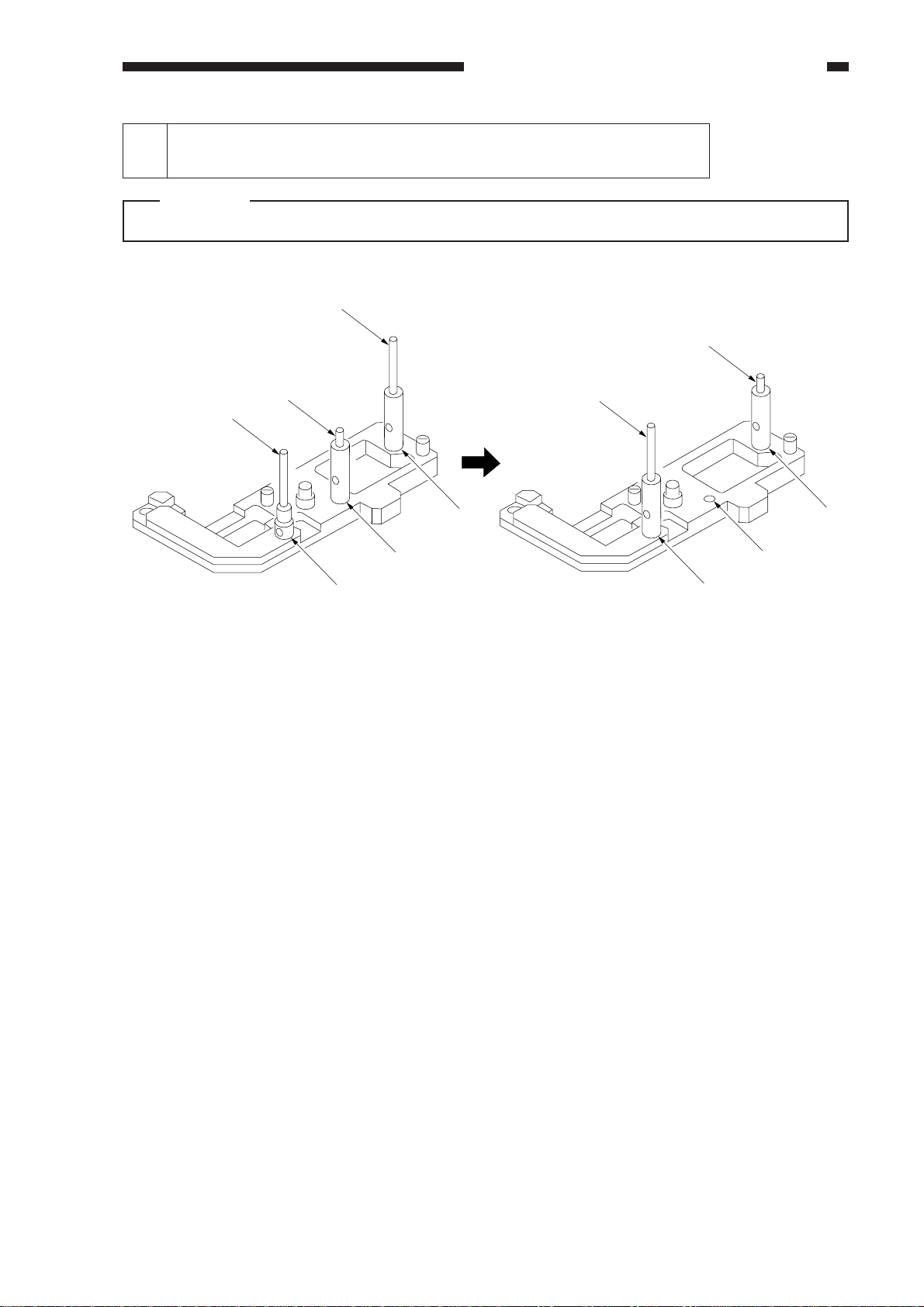

2 Adjusting the Mirror Position

(optical length between No. 1 mirror and No. 2/No. 3 mirror)

Caution:

Use the mirror position tool FY9-3009-040. Be sure to relocate the pins before use.

[C]

[B]

[C][B]

[A]

[2]

[1]

FY9-3009-040 Before Repositioning the Pins

[3]

Figure 2-10

[3]

[2]

[1]

After repositioning the Pins

2-7

Page 18

CHAPTER 2 STANDARDS AND ADJUSTMENTS

1) Loosen the screws on the metal fixings used to secure the cable.

2) Fit the mirror positioning tools (after repositioning its pins) to the No. 1 mirror mount and the

No. 2 mirror mount.

Rear tab

Front tab

Figure 2-11

3) Tighten the screws on the metal fixings.

4) Detach the mirror positioning tools.

2-8

Metal fixing

Figure 2-12

Page 19

CHAPTER 2 STANDARDS AND ADJUSTMENTS

3 Mounting the Scanning Lamp

Keep the following in mind when

mounting the scanning lamp:

1. Orient it so that the side (terminal) with

the manufacturer's name is toward the

rear.

2. Orient it so that its transparent side is

toward the reflecting plate.

3. Do not touch the transparent side.

Transparent side

Reflecting plate

Figure 2-13

C. Image Formation System

1 When Replacing the Drum Unit

• Record the date and the counter reading

on the label, and attach it to the front cover

of the new drum unit.

date

date Datum

counter

compteur Zähler

• Clean the fixing separation claw (upper,

lower).

notes

note Notiz

Make the following adjustments when

replacing the scanning lamp:

1) Shading correction 2

FUNCTION>CCD>MAN-ADJ

2) Auto density correction

FUNCTION>DENS>WHITE-ME

PD-DENS

PD-ME

DZ-DENS

DZ-ME

For details, see the description for

FUCNTION in service mode (VIII. of Chapter

14).

2-9

Page 20

CHAPTER 2 STANDARDS AND ADJUSTMENTS

Positioning the Developing

2

Assembly Magnetic Seal

Mount the magnetic seal by butting it

against the opening as shown.

Check to make sure that the magnetic seal

is in firm contact with the housing.

Magnetic seal

Opening (butted)

Figure 2-14

Mounting the Developing

3

Assembly Blade

The blade is adjusted to a high accuracy

when it is mounted to the blade mount. Avoid

detaching it from its mount.

• If you must replace the blade on its own,

be sure to adjust the position of the blade

so that the gap between the blade and the

developing cylinder is 0.21 ±0.03 mm

when measured with a gap gauge (CK-

0057-000).

Blade

0.21± 0.03mm

Magnetic seal

(rear) (front)

Figure 2-15

Developing cylinder

Figure 2-16

The surface of the developing cylinder

can easily be damaged. Be sure to slide the gap

gauge along its both ends.

2-10

Page 21

CHAPTER 2 STANDARDS AND ADJUSTMENTS

Adjusting the Positioning the

Primary Charging Roller Cleaning

4

Solenoid

Make adjustments so that the length of the

primary charging roller solenoid (SL1)

indicated in the figure is 4.0 ±0.2 mm.

4.0 ± 0.2mm

Figure 2-17

D. Pick-Up/Feeding System

Adjusting the Positioning the

1

Multifeeder paper Guide Cam

Make adjustments so that the paper guide

plate cam is as shown when the solenoid plate

is in contact with the claw of the control ring.

Control ring

Screw w/ hex hole

Claw

Solenoid plate

Paper guide plate

Paper guide plate

Gear 1

Gear 2

Figure 2-18

2-11

Page 22

CHAPTER 2 STANDARDS AND ADJUSTMENTS

Attaching the Timing Belt in

2

the Multifeeder

1) Butt the side guide plate of the multifeeder

against the end (A; open condition).

2) Move the slide volume to the center

(direction B), and fit the timing belt on the

pulley.

Timing belt

Pulley

Rack plate

Slide volume

Pulley

A

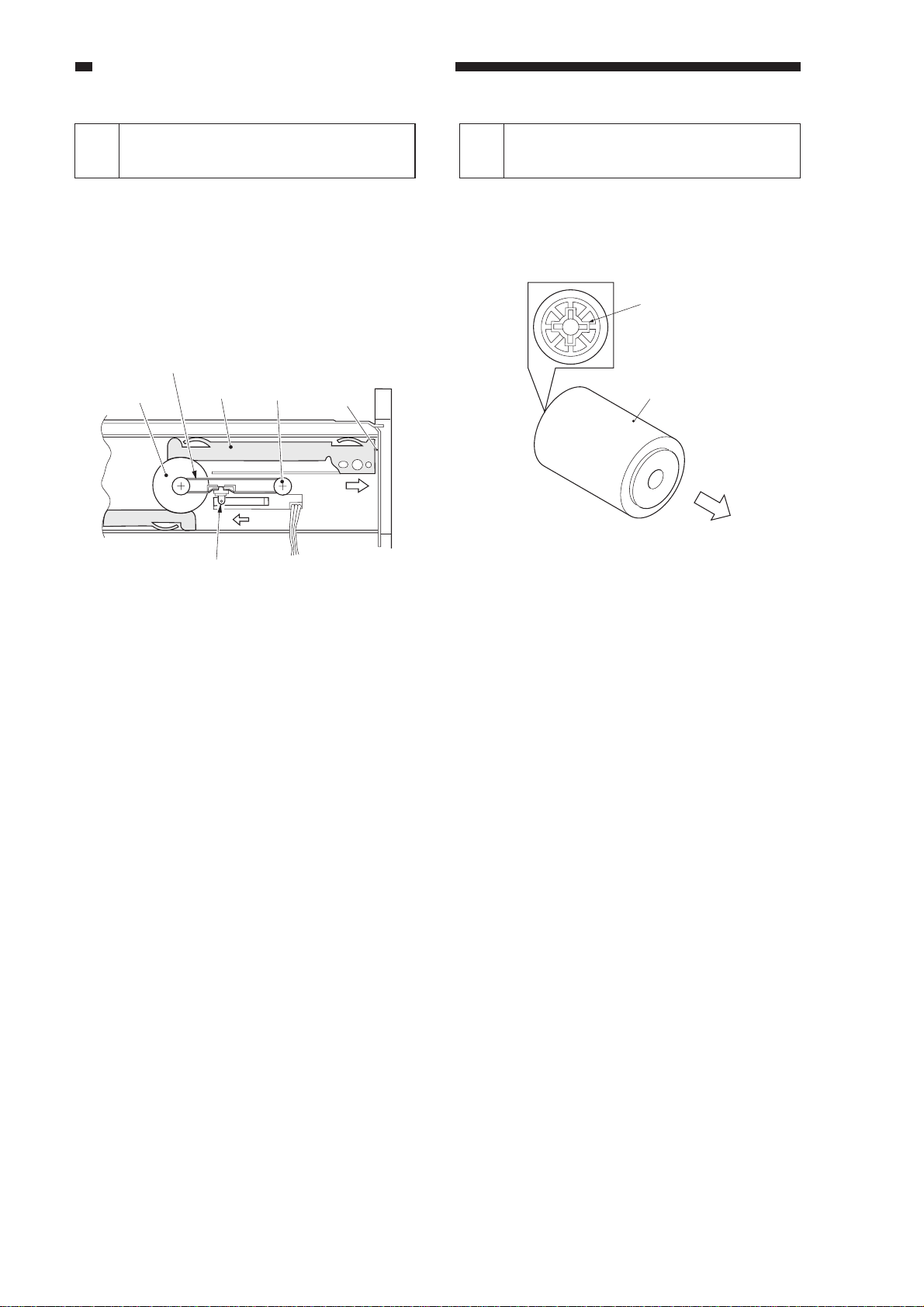

Mounting the Multifeeder Pick-

3

Up Roller

Mount the multifeeder pick-up roller [1]

so that the side with a cross [2] on its collar is

toward the rear.

[2]

[1]

Figure 2-20

Figure 2-19

2-12

Page 23

Mounting the Delivery

Assembly Paper Deflecting

4

Plate Solenoid (SL2)

1) Remove the delivery assembly.

2) Place the delivery assembly upright on a

flat desk.

3) Push in the steel core of the paper

deflecting plate 1 solenoid (SL2) until it

stops.

4) Loosen the adjusting screw, and make

adjustments so that the gap between the

steel core E-ring of the solenoid and the

solenoid frame is about 0.2 mm.

5) Mount the delivery assembly.

CHAPTER 2 STANDARDS AND ADJUSTMENTS

Paper deflecting plate

1 solenoid (SL2)

Figure 2-21

0.2mm

2-13

Page 24

CHAPTER 2 STANDARDS AND ADJUSTMENTS

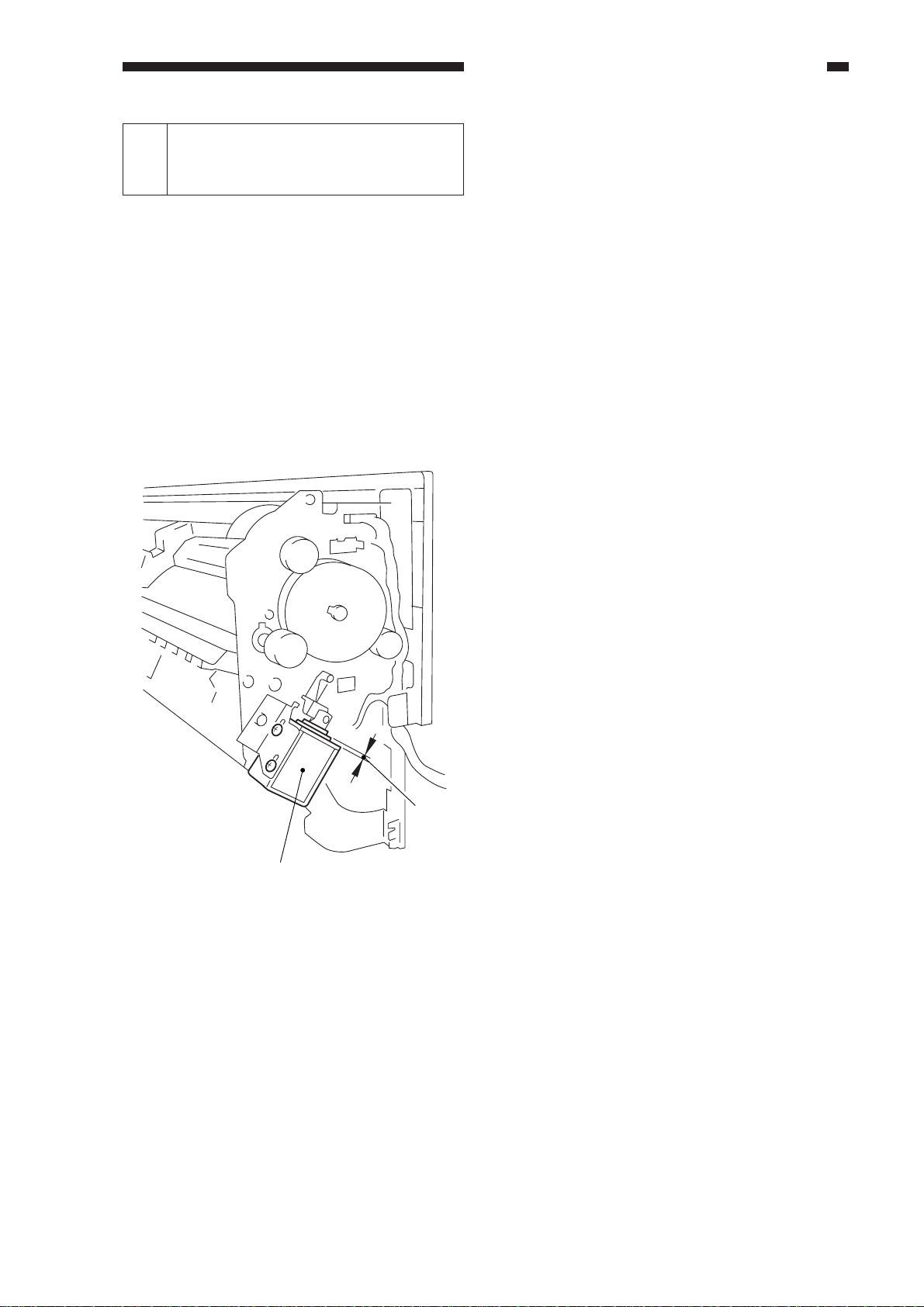

Orienting the Multifeeder Pick-Up Roller

5

(side paper deck)

Mount the multifeeder pick-up roller by reversing the steps used to remove it with the

following in mind:

• The pick-up roller used at the front and the one used at the rear are not interchangeable.

• The collar of the pick-up roller used at the front is silver in color.

When mounting the deck pick-up roller [1] for the front, orient it so that the marking [2] on the

collar (silver) is toward the front, and the marking [3] on the side of the roller is toward the rear.

[3]

(direction

of rotation)

[1]

Collar (silver)

[2]

(front)

Figure 2-22 Pick-Up Roller for the Front

• The collar of the pick-up roller used at the rear is gold in color.

When mounting the deck-pick-up roller [4] for the rear, orient it so that the marking [5] on the

side and the marking [6] on the collar (gold) are toward the rear.

[5]

(direction

of rotation)

[6]

2-14

[4]

Collar (gold)

(rear)

Figure 2-23 Pick-Up Roller for the Rear

Page 25

CHAPTER 2 STANDARDS AND ADJUSTMENTS

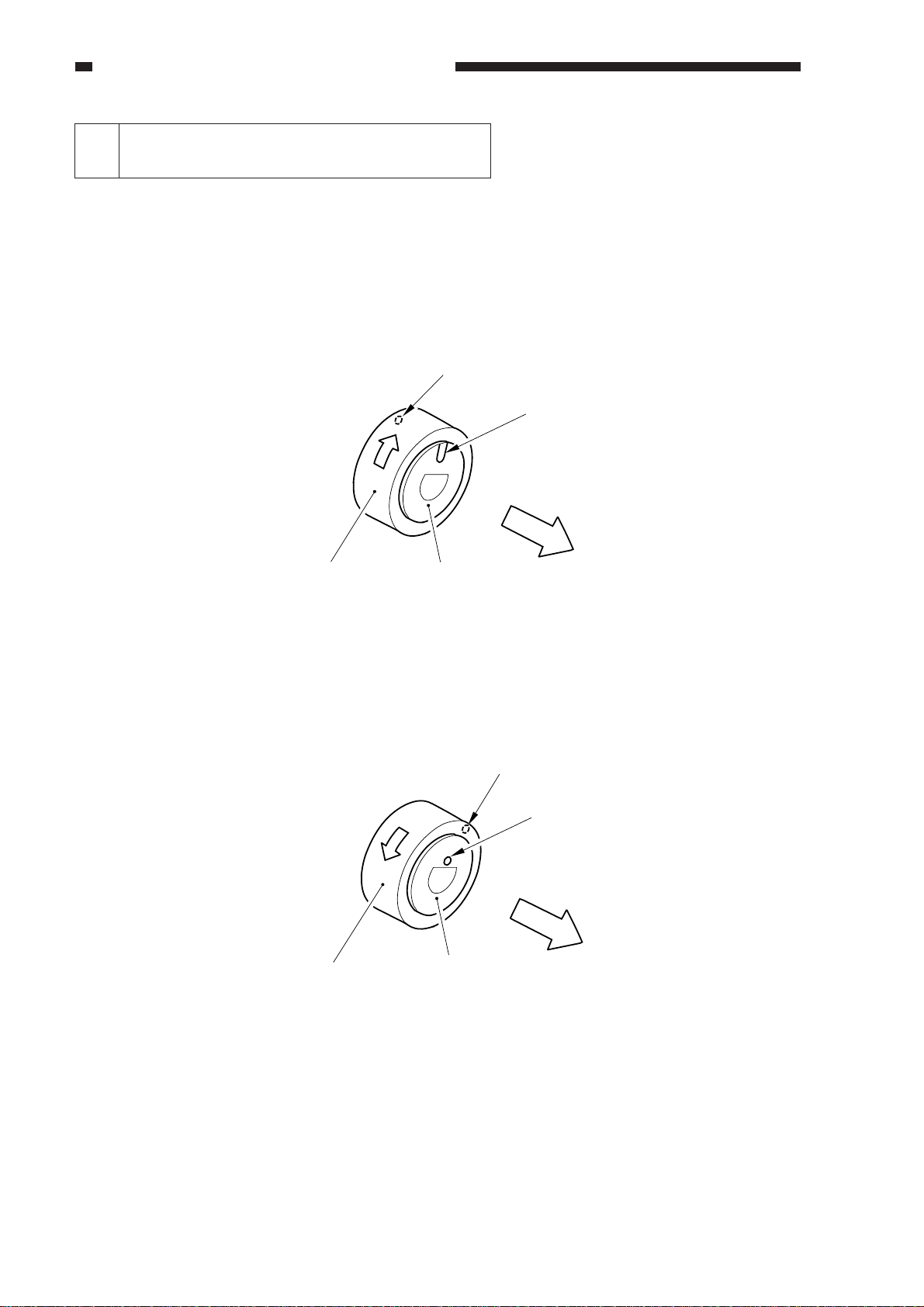

Orienting the Side Paper Deck

6

Feeding Roller

Mount the feeding roller [1] to the side

paper deck pick-up assembly so that the belt

pulley [2] is toward the front.

When attaching the pick-up/feeding roller

rubber to the pick-up/feeding roller shaft, be

sure that the marking [3] is toward the rear.

[5]

[3]

[4]

[2]

[1]

(front)

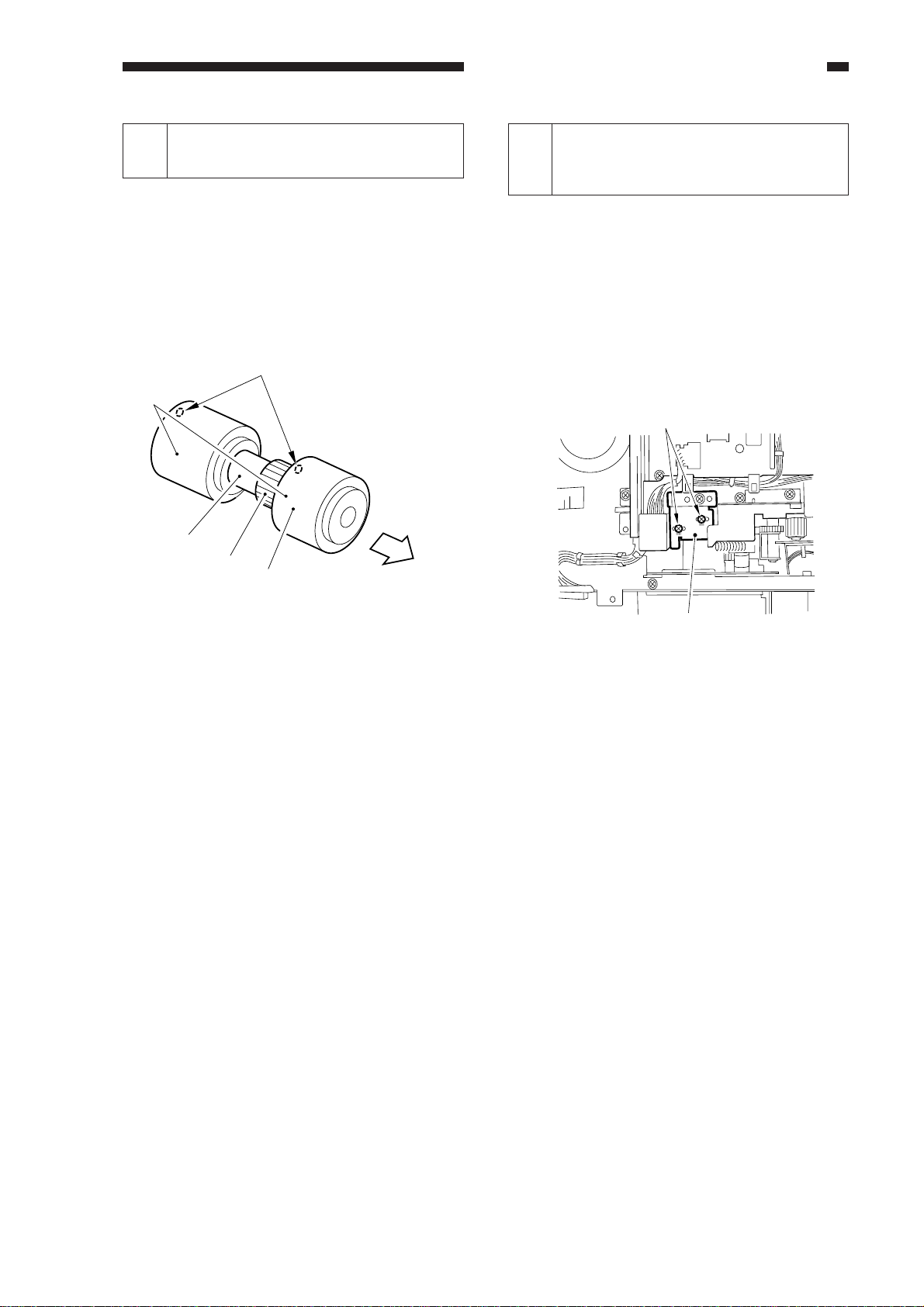

Positioning the Side Paper

Deck Pick-Up Roller Releasing

7

Solenoid

Take note of the position of the two fixing

screws of the deck pick-up roller releasing

solenoid with reference to the scale on the

support plate before removing the solenoid.

Or, mark the position of the solenoid on the

support plate with a scriber.

When mounting the solenoid on its own,

be sure to secure it back to its initial position.

[2]

Figure 2-24

[1]

Figure 2-25

2-15

Page 26

CHAPTER 2 STANDARDS AND ADJUSTMENTS

E. Fixing System

When Mounting the Fixing

1

Heater

1) Do not touch the heater surface.

2) Orient it so that the side with the longer

heater wire is toward the front.

3) Mount the main heater (700 W) to the

right and the sub heater (600 W) to the left

when viewing the fixing assembly from

the front.

4) Connect the right faston of the heater to

the main heater and the upper faston to the

sub heater when viewing it from the rear.

(The fastons are found at the rear.)

Sub heater

(Delivery side)

Main heater

(pick-up side)

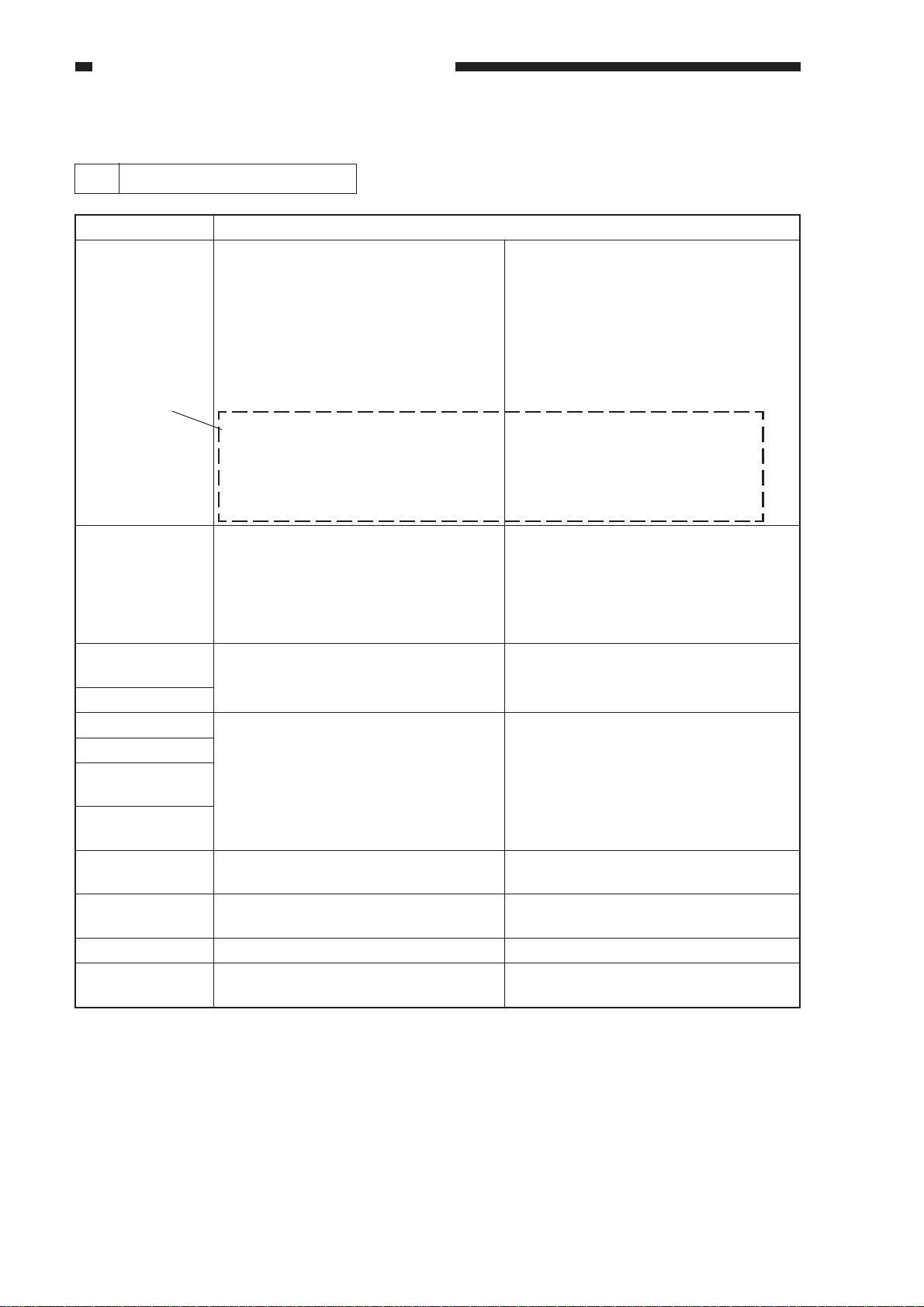

Adjusting the Lower Fixing

3

Roller Pressure (nip)

If you have replaced the upper fixing

roller or the lower fixing roller, or if fixing

faults occur, make the following adjustments:

If you are taking measurements while the

fixing roller is cold, leave the machine alone

for 15 min after it ends its wait period and

make 20 copies before taking measurements:

<Taking Measurements>

1) Make an A4 solid black copy, and make a

copy of it. Set the output in the

multifeeder.

2) Select NIP-CHK in service mode

(FUNCTION>FIXING), and press the

OK key.

3) The paper will be picked up and is stopped

between the fixing rollers temporarily;

then, it will automatically be discharged in

about 20 sec.

4) Measure the width of the area where toner

is shiny (Figure 2-27).

Upper fixing roller

Figure 2-26

Positioning the Fixing

2

Assembly Paper Guide

Caution:

If you removed the inlet guide plate, you

would need to adjust the position of the

inlet guide. To avoid the work, do not

loosen the mounting screw (paintlocked) on the inlet guide mount;

otherwise, be sure to set it to its initial

position by referring to the scale on the

fixing assembly.

c

(Feeding

direction)

A3

b

Center of

the copy

a

Figure 2-27

Caution:

a and c are points 10 mm from both

edges of the copy paper.

Point

b

a-c

* Measured when the upper/lower roller is

adequately heated.

Measurements*

5.5 ±0.3 mm

0.5 mm or less

2-16

Table 2-1

Page 27

5) If not as indicated, turn the pressure

adjusting screw 1 found at the rear and the

front of the fixing assembly to make

adjustments.

[1]

Figure 2-28

When Replacing the Lower

4

Fixing Roller

CHAPTER 2 STANDARDS AND ADJUSTMENTS

When replacing the lower fixing roller or

the bearing of the lower roller shaft, be sure to

apply heat-resisting grease (MO-138S) to the

shaft to prevent adhesion of the shaft and the

bearing.

2-17

Page 28

CHAPTER 2 STANDARDS AND ADJUSTMENTS

F. Electrical System

1 Replacing the Major Part

Parts

Image processor

PCB

[A]

Composite power

supply PCB

Laser scanner

unit

Laser unit

CCD unit

Scanning lamp

DC controller

PCB

Standard white

plate

Control panel LCD

Multifeeder size

detecting volume

Fixing assembly

Fixing cleaning

belt

Description/Service mode

n Before Replacement

Generate stored data of ADJUST,

OPTION, and COUNTER.

n After Replacement

1) Execute RAM clear (image

processor PCB).

2) Enter data under AJDUST and

OPTION.

3) Execute shading auto correction 2.

4) Execute density correction.

4-1) Execute standard white plate

density read.

4-2) Execute density auto correction.

4-3) Execute DZ density auto

correction.

n After Replacement

1) Enter the values indicated on the

label attached to the composite

power supply PCB in service mode.

2) Execute shading auto correction 1.

3) Execute auto density correction.

1) Execute shading auto correction 1.

2) Execute auto density correction.

1) Execute shading auto correction 2.

2) Execute auto density correction.

Adjust the coordinate position of the

analog touch panel.

Store the paper width basic value for

the multifeeder.

Nip (as indicated?)

Execute cleaning belt clear.

FUNCTION>MISC-P>P-PRINT

FUNCTION>CLEAR>IP

YAKUNUKE

FUNCTION>CCD>MAN-ADJ

FUNCTION>DENS>WHITE-ME

FUNCTION>DENS>PD-DENS

FUNCTION>DENS>DZ-DENS

FUNCTION>DENS>DZ-ME

FUNCTION>CCD>CCD-ADJ

Same as [A] above.

FUNCTION>CCD>CCD>ADJ

Same as [A] above.

FUNCTION>CCD>MAN-ADJ

Same as {A] above.

FUNCTION>PANEL>TOUCHKEY

FUNCTION>CST>MF-A4R, A6R, A4

FUNCTION>FIXING>NIP-CHK

COUNTER>MISC>FIX-WEB

2-18

Page 29

CHAPTER 2 STANDARDS AND ADJUSTMENTS

2 Shading Auto Correction

• Shading auto correction may be either of two types (CCD-ADJ, MAN-AJD). Select the

appropriate mode.

• In shading auto correction, various data measurements are taken and stored in the RAM on the

image processor PCB for use as the target value for shading correction performed before

scanning operation.

The following are service mode item related to shading auto correction; see the appropriate

service mode item for details:

ADJUST

FUNCTION

ADJ-XY

CCD

CCD

ADJ-S

PPR

W-PLT

CCD-ADJ

MAN-ADJ

standard white plate read position

standard white paper density data

standard white plate density data

shading auto correction 1 (for normal image adjustment)

shading auto correction 2 (for PCB, lamp replacement)

n Using CCD-ADJ

• Start service mode.

1) Press the asterisk key.

2) Press '2' and '8' on the keypad at the same time.

3) Press the asterisk key.

4) On the screen, select <COPIER>, <FUNCTION>, and <CCD> in sequence.

5) Select <CCD-ADJ>, and press the OK key. (You need not place standard white paper.)

n Using MAN-ADJ

1) Remove the rear cover, and check the position of VR200 on the DC controller PCB.

2) Place the standard white paper on the copyboard glass.

3) Start service mode. (See steps 1) through 4) under "Using CCD-ADJ.")

4) Select <MAN-ADJ>, and press the OK key.

5) When VO is indicated and the beep is sounded, press the OK key. If the beep is not heard, turn

VR200 on the DC controller PCB; when the beep is sounded, press the OK key. Adjustments

are needed if LED201 turns on.

6) Check to see if END is indicated.

DC controller PCB

Figure 2-29

LED201

VR200

2-19

Page 30

CHAPTER 2 STANDARDS AND ADJUSTMENTS

3 Copy Density Auto Correction

n Execute copy density auto correction for the following:

The copy image is not proper (image fault).

The laser unit has been replaced.

The image processor has been replaced.

The composite power supply PCB has been replaced.

n When executing copy density auto correction, be sure to execute the following three types (five

items) as a set. Be sure to execute shading correction before executing density correction.

• Standard white paper density read FUNCTION>DENS>WHITE-ME

• PD density auto correction FUNCTION>DENS>PD-DENS

(text, text/photo mode) FUNCTION>DENS>PD-ME

• DZ density auto correction FUNCTION>DENS>DZ-DENS

(photo mode) FUNCTION>DENS>DZ-ME

n The following blocks are subjected to correction processing:

Laser characteristic correction

Developing bias correction

n Executing the Mode

a. Executing Shading Correction

1) Start service mode.

2) Select COPIER>FUNCTION>CCD in sequence; then, select <CCD-ADJ>.

3) Press the OK key. (You need not place standard white paper.)

4) End service mode; then, make two solid black copies while holding the feeder or the copyboard

glass open. Check to make sure that white lines did not occur.

2-20

Page 31

CHAPTER 2 STANDARDS AND ADJUSTMENTS

b. Executing WHITE-ME

1) Place five sheets of standard white paper, and close the feeder or the copyboard cover.

• Be sure that the paper is A4 or larger and placed vertically.

2) Start service mode, and select COPIER>FUNCTION-DNS>WHITE-ME.

3) Press the Copy Start key.

• The scanner moves forward and reads the white paper.

White paper

Figure 2-30

c. Executing PD-DENS

1) Select COPIER>FUNCTION>DENS>PD-DENS, and press the OK key.

• A 15-graduation patter will be generated. (The patches are black.)

d. Executing PD-ME

1) Remove the white paper from the copyboard, and place the PD-DENS output on the

copyboard.

• Place the printed side down (for reading the pattern).

• Place the white side as the leading edge and the black side toward the center.

• Be sure to place originals against the marking V on the copyboard glass.

In practice, place

it so that the printed

side is down.

PD-DENS output

Figure 2-31

2-21

Page 32

CHAPTER 2 STANDARDS AND ADJUSTMENTS

2) Select <PD-ME> under <PD-DENSE>; then, press the OK key.

• The scanner makes 13 scans.

3) After reading operation, PD auto density correction ends when OK is indicated to the right of

<PD-ME>. If NG, check the following:

• Is the original placed correctly?

• Is the original the PD-DENS output? (The patches are black.)

After checking the above, execute PD-DENS once again. If still NG, go to the next page.

d. Executing DZ-DENS

1) Select COPIER>FUNCTION>DENS>DZ-DENS; then, press the OK key.

• A 15-gradation pattern will be generated. (The patches are white.)

e. Executing DZ-ME

1) Remove the PD-DENS output (black patches), and place the DZ-DENS output (white patches)

on the copyboard glass.

In practice, place the

printed side down.

DZ-DENS output

Figure 2-32

2) Select <DZ-ME> under DZ-DENS, and press the OK key.

• The scanner makes 13 scans.

3) After read operation, PD auto density correction ends when OK is indicated to the right of

<DZ-ME>. If NG, check the following:

• Is the read original placed correctly?

• Is the read original the DZ-DESN output? (The patches are white.)

After checking the above, execute DZ-DENS once again. If still NG, go to the next page.

2-22

Page 33

CHAPTER 2 STANDARDS AND ADJUSTMENTS

n If PD-ME/DZ-ME Is NG

1. Clean the scanner.

2. Isolate the problem.

Execute toner stirring COPIER>FUNCTION>INSTALL>TONER-S

Execute drum resistance measurement COPIER>FUNCTION>DPC>D-GAMMA

A this time, take notes of the measurement of D-GAMMA.

3. Execute copy density correction once again.

If the result is still NG, perform the following according to the measurement of D-GAMMA.

If 2.3 or higher, replace the drum cartridge.

If 0.1 or lower, replace the developing assembly.

2-23

Page 34

CHAPTER 2 STANDARDS AND ADJUSTMENTS

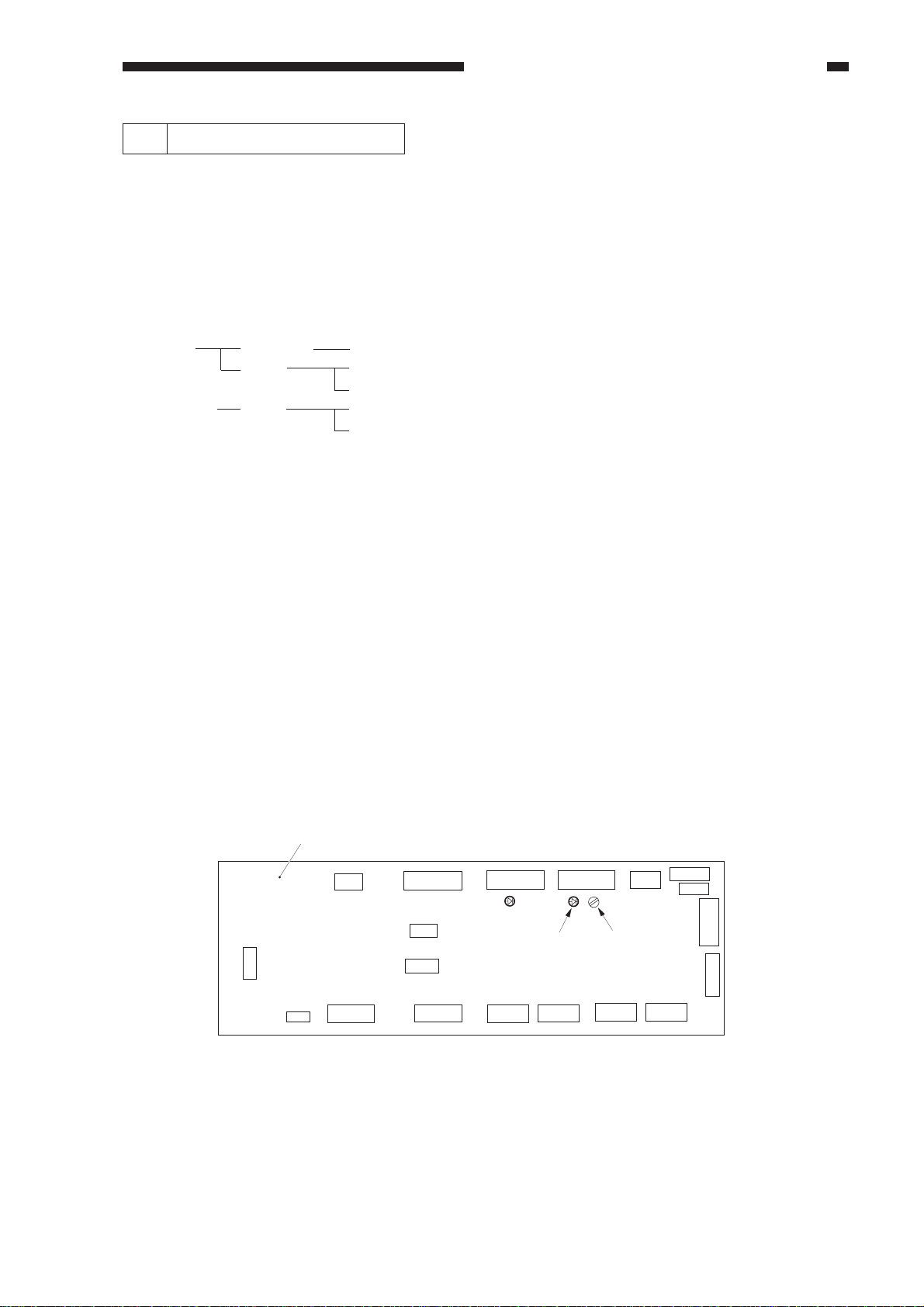

4 Storing the Multifeeder Paper Width Basic Value

Execute this mode if you have replaced the multifeeder paper width detecting volume.

Be sure to try A4R, A6R, and A4 in the order indicated.

n Execution

1) Replace the paper width detecting VR.

2) Start service mode.

asterisk key -> '2' and '8' at the same time -> asterisk key

3) Select COPIER>FUNCTION>CST, and highlight <A4R>.

Display

< CST >

MF-A4R

MF-A6R

MF-A4

I/O

Adjust

Function

< 1/1 > < READY >

Option Test

+/-

OK

Counter

Figure 2-33

4) Place A4R paper in the multifeeder, and adjust the side guide to the paper width.

5) Press the OK key.

6) Repeat steps 3) through 5) for A6R and A4 as in A4R.

7) Press the Reset key to end service mode; then, turn off and then on the main power switch.

2-24

VR output ➞

A4

A4R

A6R

A6R

(105mm)

Paper width ➞

Figure 2-34

A4R

(210mm)A4(297mm)

Page 35

CHAPTER 2 STANDARDS AND ADJUSTMENTS

5 Checking the Photointerrupters

The photointerrupters may be checked in either of the following two methods:

a. Using a meter.

b. Using service mode (I/O mode).

a. Using a Meter

You cannot insert the meter probe directly into the connectors of the machine's PCBs, as they

are designed specially to enable smooth connection. Obtain a probe extension tool (FY9-3038-000/

FY9-3039-000).

1) Set the digital multimeter range to 12 VDC.

2) Connect the meter probe to GND (0 VDC) of the DC controller PCB.

3) Make a check as indicated. (Use the probe extension and the clip as necessary.)

[ Connection 1 ]

Pinch the pin.

FY9-2003-000

Meter

[ Connection 2 ]

Pinch the pin

Probe extension

(FY9-3038)

FY9-2004-000

Probe extension

Clip

7537

04

DIGITAL

MULTIMETER

YOKOGAWA

D•H

Å|

4

2

mV

0

2

Å{

REL/%

POWER

4

MIN/MAX

DATA-H

RANGE

AVG

SELECT

/Å`/Hz

mA

ÉA

10A

Å}

/

Åé

É∂

/Å`/ADP/KÅé

mV

+

Å`

/

LoHz/rpm

V

OPEN

Å`V

Hz

TERMINAL

SHUTTER

20

TRUE RMS

10

kHz

A

0.1% V

mA•ÉA

COM

FUSED

V•

FUSED

É∂

•

1000V

MAX

!

Meter

7537

04

DIGITAL

MULTIMETER

YOKOGAWA

D•H

Å|

4

2

mV

0

2

Å{

REL/%

POWER

4

MIN/MAX

DATA-H

RANGE

AVG

SELECT

/Å`/Hz

mA

ÉA

10A

Å}

/

Åé

É∂

/Å`/ADP/KÅé

mV

+

Å`

/

LoHz/rpm

V

OPEN

Å`V

Hz

TERMINAL

SHUTTER

20

TRUE RMS

10

kHz

A

0.1% V

mA•ÉA

COM

FUSED

V•

FUSED

É∂

•

1000V

MAX

!

Figure 2-35

b. Using Service Mode

1) Start service mode.

2) Press COPIER>I/O, and select DC-CON.

The bit number notations in the tables that follow represent the following:

ex.P001 00000000

bit7 bit0

2-25

Page 36

CHAPTER 2 STANDARDS AND ADJUSTMENTS

Notation

name

Meter probe

Service mode

Check (Normal if

described.)

Display reading

Meter reading (approx.)

Notation

name

Meter probe

Service mode

Check (Normal if

described.)

Display reading

Meter reading (approx.)

PS1

Scanner home position

sensor (PS1S)

J112-B5

While in standby, move

the scanner from the

home position.

When the

scanner is

at the

home

position,

-

5 V

Registration paper

sensor (PS4S)

While in standby, open

the right door, and

insert paper.

When

paper is

not

inserted,

1

5 V

When the

copyboard

cover is

closed,

1

0 V

PS4

J108-B11

P004-bit3

When

paper is

inserted,

0

0 V

PS2

Copyboard cover open/

closed sensor (PS2S)

J108-B2

P003-bit13

While in standby, open

and close the

copyboard cover.

When the

scanner is

not at the

home

position,

-

5 V

Internal delay sensor

(PS6S)

While in standby, open

the delivery assembly,

and move the flag of

PS6.

When the

flag is

blocking

the sensor

(paper

absent),

1

5 V

When the

cupboard

cover is

opened,

0

0 V

PS6

J106-2

P004-bit8

When the

flag is not

blocking

the sensor

(paper

present),

0

0 V

PS3

Multifeeder paper

sensor (PS3S)

J108-B17

P005-bit1

While in standby, place

paper on the

multifeeder tray.

When

paper is

placed,

1

5 V

External delivery

sensor (PS7S)

While in standby, open

the delivery assembly,

and move the flag of

PS7.

When the

flag is not

blocking

the sensor

(paper

present),

1

5 V

When

paper is

not

placed,

0

0 V

PS7

J107-2

P004-bit5

When the

flag is

blocking

the sensor

(paper

absent),

0

0 V

2-26

Page 37

CHAPTER 2 STANDARDS AND ADJUSTMENTS

Notation

name

Meter probe

Service mode

Check (Normal if

described.)

Display reading

Meter reading (approx.)

Notation

name

Meter probe

Service mode

Check (Normal if

described.)

PS8

Duplexing assembly

inlet paper sensor

(PS8S)

J114-B2

P004-bit5

While in standby, open

the delivery assembly,

and move the flag of

PS8.

When the

flag is

blocking

the sensor

(paper

absent),

1

5 V

Vertical path sensor

(PS11)

While in standby, move

up the lever of PS11.

When the

flag is not

blocking

the sensor

(paper

present),

0

0 V

PS11

J108-B8

P004-bit2

PS9

Re-pick up sensor

(PS9S)

J114-B5

P004-bit10

While in standby, open

the duplexing unit, and

move the flag of PS9.

When the

flag is

blocking

the sensor

(paper

absent),

1

5 V

Right cover open/

closed detecting sensor

(PS12S)

While in standby, open

the right door.

When the

flag is not

blocking

the sensor

(paper

present),

0

0 V

PS12

J108-B14

P003-bit13

PS10

Horizontal registration

paper sensor (PS10S)

J102-A8

P004-bit11

While in standby, open

the right door; then,

insert paper into the repick up assembly, and

slide it to the rear.

When the

paper is

slid to the

rear,

1

5 V

Left cover open/closed

sensor (PS13S)

While in standby, open

the left door.

When the

paper is

not slid to

the rear,

0

0 V

PS13

J114-5

P003-bit11

Display reading

Meter reading (approx.)

When the

lever is

moved up

(paper

present),

1

5 V

When the

lever is

moved

back

(paper

absent),

0

0 V

When the

right door

is closed,

1

5 V

When the

right door

is open,

0

0 V

When the

left door

is closed,

1

5 V

When the

left door

is open,

0

0 V

2-27

Page 38

CHAPTER 2 STANDARDS AND ADJUSTMENTS

Notation

name

Meter probe

Service mode

Check (Normal if

described.)

Display reading

Meter reading (approx.)

Notation

name

Meter probe

Service mode

Check (Normal if

described.)

PS14

Front cover open/

closed sensor (PS14S)

J102-A11

P003-bit4

While in standby, open

the front cover.

When the

front

cover is

open,

1

5 V

Fixing assembly outlet

sensor (PS40S)

While in standby, push

the lever on the fixing

assembly outlet

assembly.

When the

lever is

pushed,

When the

front

cover is

closed,

0

0 V

PS40

J114-A2

P004-bit9

When the

lever is

not

pushed,

PS18

Cassette 1 pick-up

sensor (PS18S)

J108-A17

P004-bit0

While in standby, slide

out the cassette, and

insert paper between

the pick-up rollers.

When

paper is

inserted,

1

5 V

When

paper is

not

inserted,

0

0 V

PS19

Cassette 1 pick-up

sensor (PS19S)

J108-A18

P004-bit1

While in standby, slide

out the cassette, and

insert paper between

pick-up rollers.

When

paper is

inserted,

1

5 V

When

paper is

not

inserted,

0

0 V

Display reading

Meter reading (approx.)

2-28

1

5 V

0

0 V

Page 39

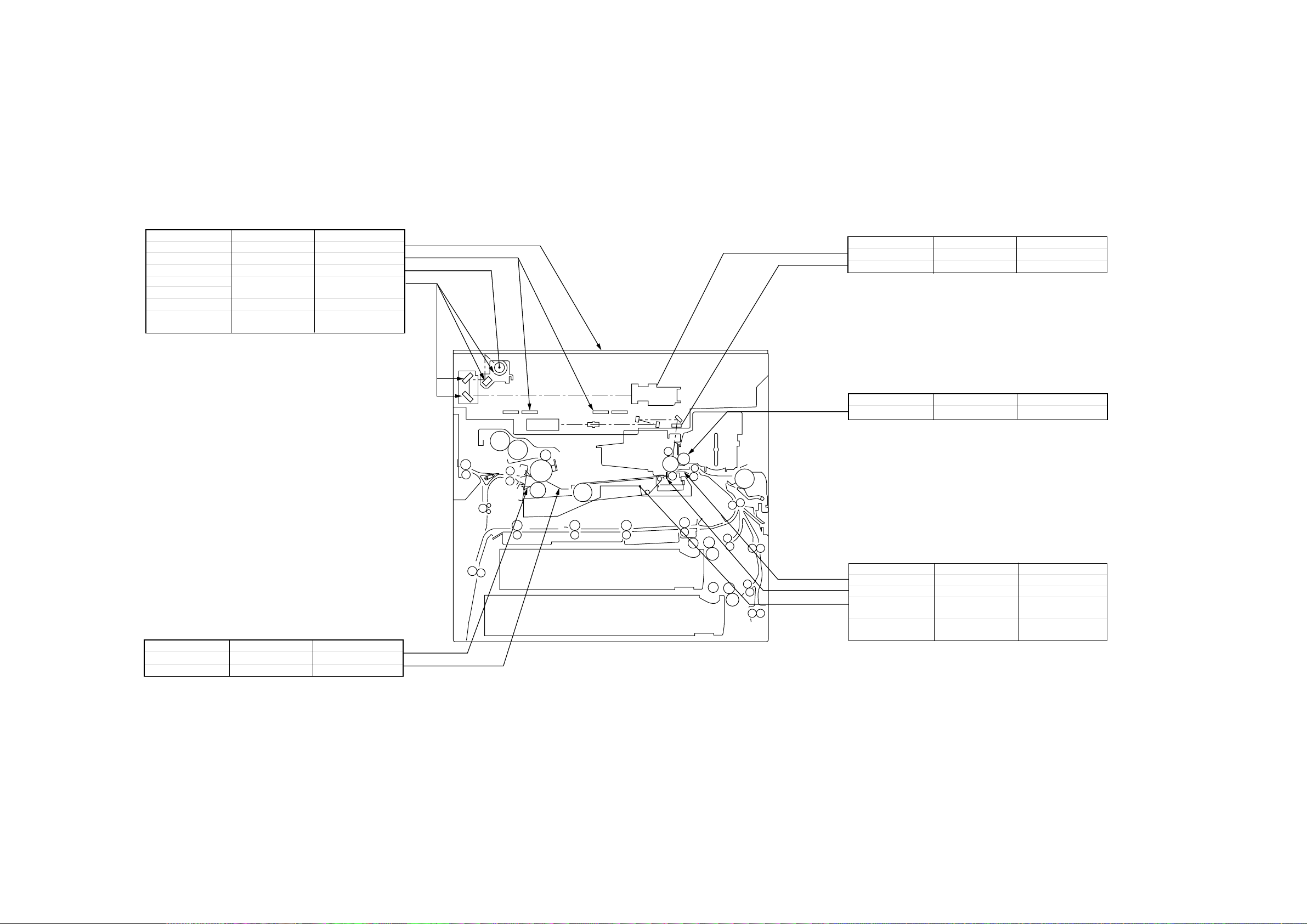

CHAPTER 3 ARRANGEMENT AND FUNCTIONS OF ELECTRICAL PARTS

CHAPTER 3

ARRANGEMENT AND FUNCTIONS OF

ELECTRICAL PARTS

3

3-1

Page 40

CHAPTER 3 ARRANGEMENT AND FUNCTIONS OF ELECTRICAL PARTS

A. Clutches and Solenoids

SL2

SL6

SL4

CL4

SL1

CL2

SL3

CL1

CL3

SL5

3-2

Figure 3-1

Page 41

CHAPTER 3 ARRANGEMENT AND FUNCTIONS OF ELECTRICAL PARTS

Clutches and Solenoids

Symbol Part

Clutch

C L

Solenoid

S L

Notation

CL1

CL2

CL3

CL4

SL1

SL2

SL3

SL4

SL5

SL6

Function

Drives the registration roller.

Drives the multifeeder pick-up

mechanism.

Drives the vertical path roller.

Drives the developing cylinder.

Moves down the pick-up roller.

Drives the delivery flapper.

Releases the multifeeder holding

plate.

Cleans the primary charging roller.

Drives the fixing cleaning belt.

Drives the fixing assembly inlet

guide.

3-3

Page 42

CHAPTER 3 ARRANGEMENT AND FUNCTIONS OF ELECTRICAL PARTS

B. Motors

M3

M1

M8

M10

M6

M5

M9

M4

M2

M7

3-4

Figure 3-2

Page 43

Motor

CHAPTER 3 ARRANGEMENT AND FUNCTIONS OF ELECTRICAL PARTS

Symbol Part

Motor

M

Notation

M1

M2

M3

M4

M5

M6

M7

M8

M9

M10

Function

Main motor

Fixing motor

Scanner motor

Laser scanner motor

Pick-up motor

Lower feeder motor

Reversal delivery motor

Delivery motor

Horizontal registration sensor shift

motor

Duplexing reversal motor

3-5

Page 44

CHAPTER 3 ARRANGEMENT AND FUNCTIONS OF ELECTRICAL PARTS

FM10

FM11

FM8

FM7

FM17

FM18

C. Fan

FM13

FM12

FM3

FM4

FM9

FM2

FM1

FM5

FM16

FM15

FM14

FM6

Figure 3-3

3-6

Page 45

Fans

CHAPTER 3 ARRANGEMENT AND FUNCTIONS OF ELECTRICAL PARTS

Symbol Part

fan

* Rotates at half speed during standby.

Notation

FM1

FM2*

FM3*

FM4*

FM5*

FM6*

FM7*

FM8*

FM9

FM10

FM11

FM12*

FM13*

FM14

FM15

FM16

FM17*

FM18*

Function

Feeding fan

Fixing heat discharging fan 1

Fixing heat discharge fan 2

Laser drive cooling fan

Laser scanner motor cooling fan 1

Laser scanner motor cooling fan 2

Cleaner cooling fan

System cooling fan

Reversal guide cooling fan

Low-voltage power supply cooling

fan 1

Low-voltage power supply cooling

fan 2

Reader cooling fan 1

Leader cooling fan 2

Drum cartridge cooling fan 1

Drum cartridge cooling fan 2

Drum cartridge cooling fan 3

DC controller PCB cooling fan

Scanner motor cooling fan

3-7

Page 46

CHAPTER 3 ARRANGEMENT AND FUNCTIONS OF ELECTRICAL PARTS

D. Sensors

PS2

PS14

PS4

SD4

PS1

SD3

PS11

PS18

PS3

PS12

PS13

PS7

PS8

PS6

PS40

SD1

PS9

SD2

PS19

PS10

TS1

3-8

Figure 3-4

Page 47

Sensors

CHAPTER 3 ARRANGEMENT AND FUNCTIONS OF ELECTRICAL PARTS

Symbol Name

Photointerrupter

Piezoelectric

oscillating

element

Notation

PS1

PS2

PS3

PS4

PS6

PS7

PS8

PS9

PS10

PS11

PS12

PS13

PS14

PS18

PS19

PS40

TS1

Remarks

Scanner home position detection

Copyboard cover open/closed

detection

Multifeeder paper detection

Pre-registration paper detection

Internal delivery assembly paper

detection

External delivery assembly paper

detection

Re-pick up assembly paper detection

Re-pick up assembly paper detection

Horizontal registration paper

detection

Vertical path paper detection

Right door open/closed detection

Left door open/closed detection

Waste toner detection

Cassette 1 retry paper detection

Cassette 2 retry paper detection

Fixing assembly outlet paper

detection

Toner level detection

Reflecting type

sensor

SD1

SD2

SD3

SD4

Original size sensor 1

Original size sensor 2

Original size sensor 3

Original size sensor 4

3-9

Page 48

CHAPTER 3 ARRANGEMENT AND FUNCTIONS OF ELECTRICAL PARTS

E. Switches and Counters

SW1

SW3

SW2

FL1

TH2

TH1

RL1

SSR1

CB1

THSW1

H1

H2

VZ1

LCD1

CNT1

3-10

Figure 3-5

Page 49

CHAPTER 3 ARRANGEMENT AND FUNCTIONS OF ELECTRICAL PARTS

Switches, Counters, Heaters, Varistors, and Fuses

Part

Switch

Counter

Varistor

SSR

Scanning lamp (fluorescent

lamp)

Heater

Thermistor

Thermal switch

Circuit breaker

Notation

SW1

SW2

SW3

CNT1

VZ1

SSR1

FL1

H1

H2

TH1

TH2

THSW

CB1

Name

Main power supply switch

Front door switch

Cassette heater switch

Total copy counter 1

Pre-registration guide varistor

Solid state relay

Scanning lamp

Fixing main heater

Fixing sub heater

Fixing heater main thermistor

Fixing heater sub thermistor (end)

Fixing heater thermal switch

Circuit breaker

3-11

Page 50

CHAPTER 3 ARRANGEMENT AND FUNCTIONS OF ELECTRICAL PARTS

18

21

20

19

22

17

16

F. PCBs

12

8

9

10

11

15

3

4

5

6

2

7

23

13

14

1

3-12

Figure 3-6

Page 51

CHAPTER 3 ARRANGEMENT AND FUNCTIONS OF ELECTRICAL PARTS

Switches, Counters, Heaters, Varistors, and Fuses

Part

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

Notation

Composite power supply PCB

DC controller PCB

Image processor PCB

Accessories power supply

Pick-up unit PCB

Low-voltage power supply PCB

Noise filter

Control panel key PCB

Control panel CPU PCB

Inverter PCB

Downloading PCB

Function key PCB

Upper cassette size detection PCB

Lower cassette size detection PCB

Multifeeder paper width detection

PCB

Laser driver PCB

Laser scanner driver PCB

Analog processor PCB

BD PCB

Pre-exposure lamp PCB

Environment sensor PCB

Intensity sensor PCB

Battery PCB (accessory)

Name

HVT, lamp regulator, DC power

supply

DC load control (DC driver)

Image processing (main controller)

DADF, side paper deck

Pick-up assembly sensor

DC power supply

AC power supply noise removal

LCD (back light) power supply

Upper cassette size detection

Lower cassette size detection

Multifeeder paper width detection

Laser dive

Laser scanner motor drive

CCD drive, analog image processing

Laser beam detection

Photosensitive drum residual charge

removal

Machine internal humidity detection

Scanning lamp intensity detection

Fax image memory retention

3-13

Page 52

CHAPTER 3 ARRANGEMENT AND FUNCTIONS OF ELECTRICAL PARTS

G. Side Paper Deck

1. Sensors and Switches

PS104

PS102

PS109

SW102

PS107

SW101

PS108

PS106

PS105

SW100

PS103

PS101

3-14

Figure 3-7a (side paper deck)

Page 53

CHAPTER 3 ARRANGEMENT AND FUNCTIONS OF ELECTRICAL PARTS

Symbol Part

Photointerrupter

Switch

Microswitch

Table 3-1a (side paper deck)

Notation

PS102

PS103

PS104

PS105

PS106

PS107

PS108

PS110

SW100

SW102

SW103

Function

Deck lifter upper limit detection

Deck paper supply position detection

Deck set detection

Deck pick-up guide open detection

Deck vertical path paper detection

Deck pick-up paper detection

Deck paper detection

Deck lifter position detection

Deck open switch

Deck open detecting switch

Deck lifter upper limit detecting

switch

3-15

Page 54

CHAPTER 3 ARRANGEMENT AND FUNCTIONS OF ELECTRICAL PARTS

2. Motors, Solenoids, and PCBs

SL101

CL101

CL102

SL102

M102

[1]

M101

[2]

3-16

Figure 3-7b (paper deck)

Page 55

CHAPTER 3 ARRANGEMENT AND FUNCTIONS OF ELECTRICAL PARTS

Symbol Part

Motor

M

Clutch

C L

Solenoid

S L

PCB

Table 3-1b (paper deck)

Notation

M101

M102

CL101

CL102

SL101

SL102

[1]

[2]

Function

Deck main motor

Deck lifter motor

Deck vertical path clutch

Deck pick-up clutch

Deck pick-up roller releasing

solenoid

Deck open solenoid

Side deck driver PCB

Open switch PCB

3-17

Page 56

CHAPTER 3 ARRANGEMENT AND FUNCTIONS OF ELECTRICAL PARTS

H. Variable Resisters, Light-

Emitting Diodes, and

Check Pins by PCB

Of the variable resistors (VR), lightemitting diodes (LED), and check pins used in

the machine, those needed in the field are

discussed.

Caution:

1. Some LEDs emit dim light when they

are off because of leakage current.

This is a normal condition, and must

be kept in mind.

2. VRs that may be used in the field.

:

VRs that must not be used in the field.

:

Caution:

Those VRs and check pins not listed

in the tables are for factory use only,

requiring special tools and high

accuracy. Do not touch them in the

field.

3-18

Page 57

CHAPTER 3 ARRANGEMENT AND FUNCTIONS OF ELECTRICAL PARTS

1. Image Processor PCBs (main controller)

J715 J716

J714

J713

J723

J724

J712

J722 J721

SW702

2

1

OFF

3

ON

J720

J717

J702

J703

J701

J704

J705

J706

SW701

J711

J710

J709

J718

J707

J708

Figure 3-8

J721: Flash ROM slot for the IP-CPU (IP, DIMM); use the bottom slot for a 4-MB DIMM,

and the top slot for a 1-MB DIMM.

J722: Flash ROM slot for the DC-CPU (DCC DIMM); 1-MB, DIMM

K723, J724: Slot for expansion memory (32 MB each); however, be sure to use J723 first (as when

installing only one DIMM).

J720: Not used.

3-19

Page 58

CHAPTER 3 ARRANGEMENT AND FUNCTIONS OF ELECTRICAL PARTS

n SW701 States

SW1

SW2

SW3

SW4

SW5

SW6

AB

OFF

OFF

OFF

OFF

OFF

OFF

Inch

ON

OFF

ON

OFF

ON

OFF

AB/Inch

ON

ON

OFF

ON

OFF

OFF

A

OFF

ON

ON

ON

OFF

ON

n Size Configuration

Use service mode to set the appropriate size (COPIER>OPTION>BODY>MODEL-SZ).

MODEL-SZ setting

AB

Inch

A

AB/Inch

0

1

2

3

The setting will affect the following items:

• Pattern for default enlargement/reduction.

• Size detection by the feeder. (If the setting under FEEDER>OPTION>SIZE-SW in service

mode is '1', AB/Inch detection will be made regardless of the country of installation.

n Arrangement of the Original Sensor

The arrangement of original sensors may be changed. If the feeder is used, these switch settings

need not be changed, since detection will be by the feeder. For sensor arrangement, see

"Identifying the Size of Originals" in Chapter 3.

Use SW5 and SW6.

AB

Inch

A

AB

OFF

ON

OFF

Inch

OFF

OFF

ON

3-20

Page 59

CHAPTER 3 ARRANGEMENT AND FUNCTIONS OF ELECTRICAL PARTS

2. DC Controller PCB (DC driver)

J101

J114

J113 J112

J111

J110

J109

LED201

J116

J118

J115

J117

J119

J102

LED200

J103J104

VR200

J105

J106

J108

J107

Figure 3-9

LED200: Check it to find out the state of the composite power supply PCB is indicated by

flashing at different intervals. For details, see Table 13-601.

VR200: Turn it to adjust the lamp intensity used when shading auto correction

(FUNCTION>CCD>MAN-ADJ) is executed in service mode. The result is good if

LED201 turns on. Its adjustment range is equal to 3 rotations.

If LED201 does not turn on after a single rotation, try rotating it in the opposite

direction.

LED201: Check it to find out whether VR200 is correctly adjusted (it should turn on).

3-21

Page 60

CHAPTER 3 ARRANGEMENT AND FUNCTIONS OF ELECTRICAL PARTS

States and LED Flashing Intervals

Flashing intervals

u Flashes at 0.5-sec intervals

0.5 sec

ON

OFF

0.5 sec

u OFF for 4 sec; then, flashes twice

at 0.5-sec intervals

0.5 sec

ON

OFF

4 sec

Twice

u OFF for 4 sec; then, flashes 5 times

at 0.5-sec intervals.

0.5 sec

ON

OFF

4 sec

3 times

u OFF for 4 sec; then, flashes 3times

at 0.5-sec intervals.

0.5 sec

ON

OFF

4 sec

5 times

u OFF for 4 sec; then, flashes 4 times

at 0.5-sec intervals.

0.5 sec

ON

OFF

4 sec

4 times

u OFF for 4 sec; then, flashes 6 times

at 0.5-sec intervals.

0.5 sec

ON

OFF

4 sec

6 times

State

Normal

Over-current/over-

voltage detected

Error in

communication

with the DC

controller PCB

Low-voltage

control error* in

standby

Low-voltage

control error*

during copying

DC controller PCB

check sum

Error detection

Description

The composite power supply PCB is

operating normally.

An over-current/over-voltage condition

has been detected in the +24-VU or

+24-VR output.

An over-current condition has been

detected because of wire trapping or the

like.

n The control panel indicates 'E803'.

An error has occurred in

communication between the DC

controller PCB and the composite

power supply PCB, not updating the

communication data for 8 sec or more.

Note that this error may not flash/turn

on LED100 on the DC controller PCB.

• The output of the main transformer

stops.

• The control panel indicates 'E191'.

In standby, the difference between the

+24-VR setting and the actual control

value is larger than indicated.

• The output of the main transformer

stops.

• Error data is sent to the DC

controller PCB.

• The control panel indicates 'E803'.

During copying, the difference between

the +24-VR setting and the actual

control value is larger than indicated.

• +24 VR is set to standby voltage

(+18 VR).

• Error data is sent to the DC

controller PCB.

• The control panel indicates 'E803'.

The CPU on the DC controller PCB has

detected a check sum of communication

data twice or more continuously.

• The output of the main transformer

stops.

• The control panel indicates 'E191'.

* The same error can occur owing to activation error in the fluorescent lamp (because of deterioration

over time). If the LED flashes in threes or fours, check to see if the glass around the filament on

both sides of the lamp is not black.

3-22

Page 61

CHAPTER 3 ARRANGEMENT AND FUNCTIONS OF ELECTRICAL PARTS

3. Composite Power Supply CPB

J204

J206

J208

J220

J205

J209

J203

J201

J210

Figure 3-10

Label: Enter the values indicated on the label in service mode when replacing the composite

power supply CPB.

OFST-DC

AGS-GAIN

AGS-OFST

OFST1-AC

FL-OFST

xx

xxx

xxx

xxx

xxx

Table 3-2 Label on the Composite Power Supply PCB

3-23

Page 62

CHAPTER 3 ARRANGEMENT AND FUNCTIONS OF ELECTRICAL PARTS

4. Deck Driver (side paper deck)

13 6

J103

1

J104

12

1

J107

10

11

J105

2

J106

Figure 3-11

1

3

J101

1

7

J102

1

8

J108

1

3

J109

1

3-24

Page 63

CHAPTER 3 ARRANGEMENT AND FUNCTIONS OF ELECTRICAL PARTS

I. Upgrading

The machine may be upgraded in either of the following two ways:

• By replacing the DIMM on the image processor PCB.

• By updating the DIMM contents through downloading from a computer.

1. Replacing the DIMM

The DIMM (flash ROM) used in the machine comes in two types; both types are mounted on

the image processor PCB. Figure 3-12 shows a view in which the IP small cover has been removed:

• DIMM for the IP-CPU

4 MB: bottom of 2-layer slot

1 MB: top of 2-layer slot

• DC-CPU DIMM (1 MB)

DIMMs lot for

Image

processor PCB

DC-CPU

IP cover

Figure 3-12

DIMM slot for

IP-CPU

3-25

Page 64

CHAPTER 3 ARRANGEMENT AND FUNCTIONS OF ELECTRICAL PARTS

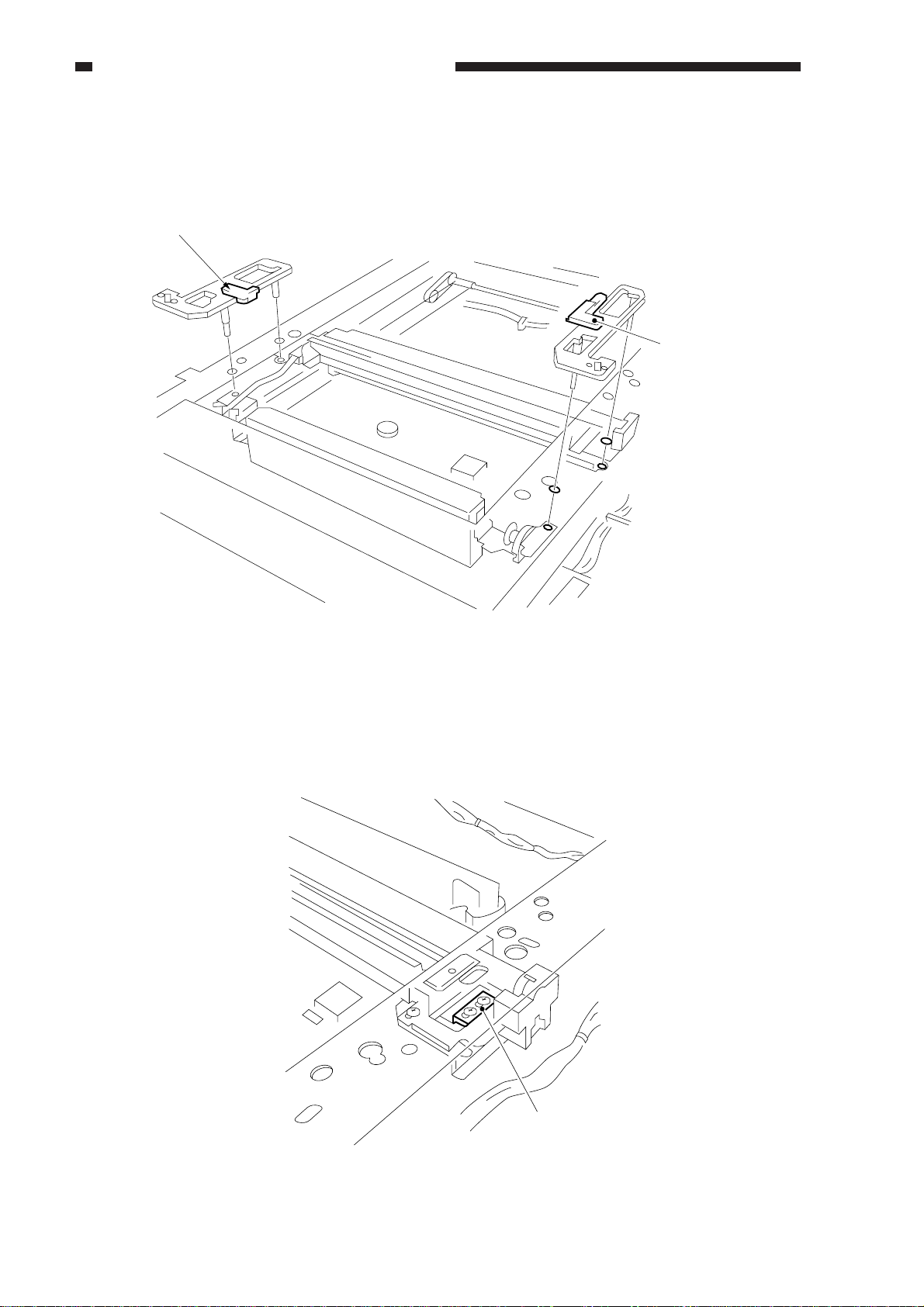

1. Removing the DIMM

1) Turn off the main power switch, and

disconnect the power cord.

2) Remove the copyboard glass; then,

remove the screw, and detach the small

cover from the IP cover.

Small cover

M4 × 4bis

3) Open the slot claw, and pull off the

DIMM as if to lift it.

IP,DIMM(1MByte)

Push

Push

Figure 3-13

Figure 3-14

3-26

Page 65

CHAPTER 3 ARRANGEMENT AND FUNCTIONS OF ELECTRICAL PARTS

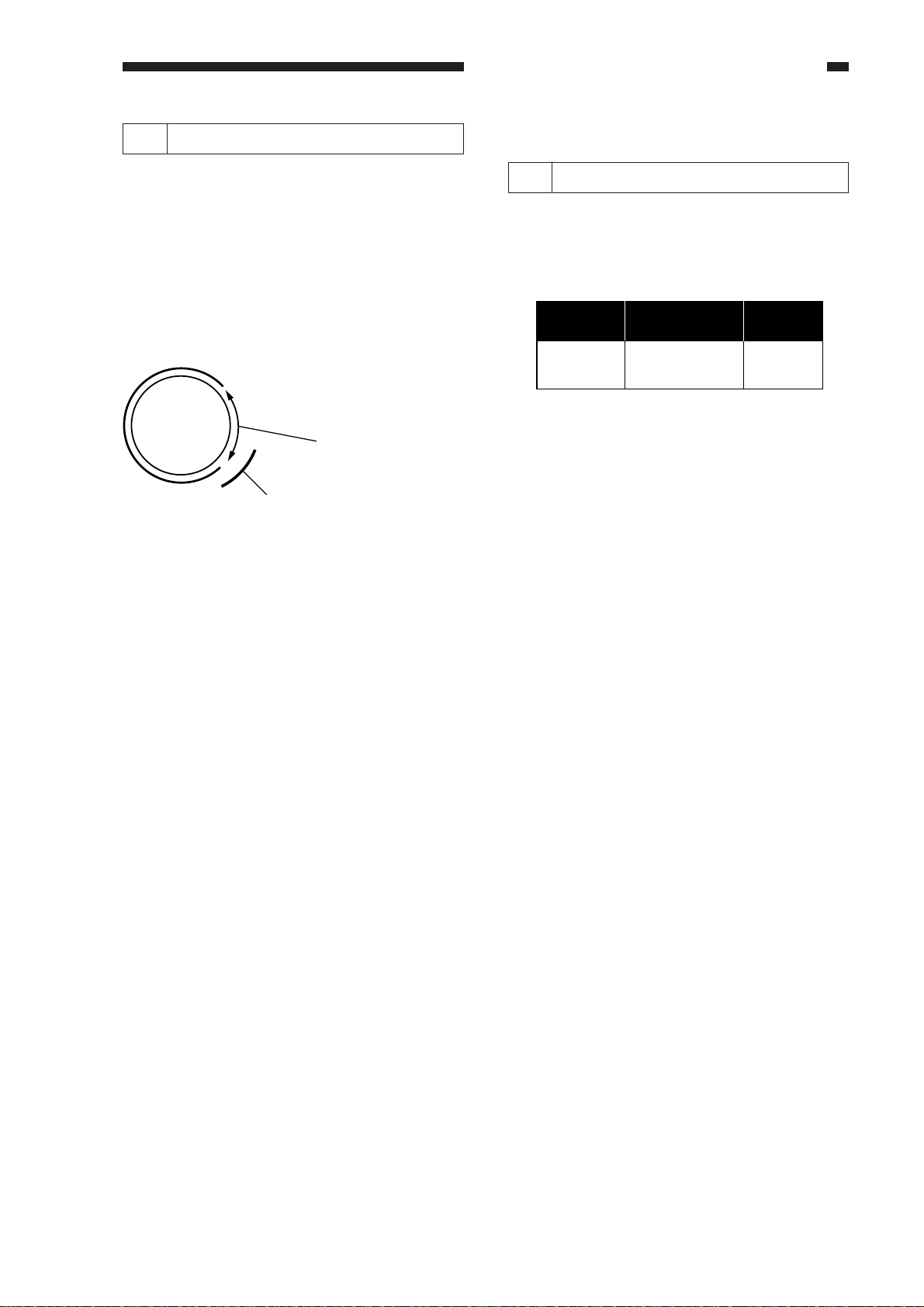

2. Mounting the DIMM

1) Check the DIMM slot on the IP PCB. The

wrong slot can cause malfunction; pay

attention. (Figure 3-12)

2) Insert the DIMM into the slot at an angle.

At this time, check to be sure that the

DIMM is fully inserted into the slot.

3) Shift down the DIMM until the claw of

the slot clicks into position.

At this time, do not force in the DIMM;

such can damage the DIMM.

IP, DIMM (1 MB)

Cut-off

4) Mount the IP small cover (M4x4 screw, 1

pc.); then, mount the copyboard cover.

Connect the power cord, and turn on the

main power supply.

Figure 3-15

3-27

Page 66

CHAPTER 3 ARRANGEMENT AND FUNCTIONS OF ELECTRICAL PARTS

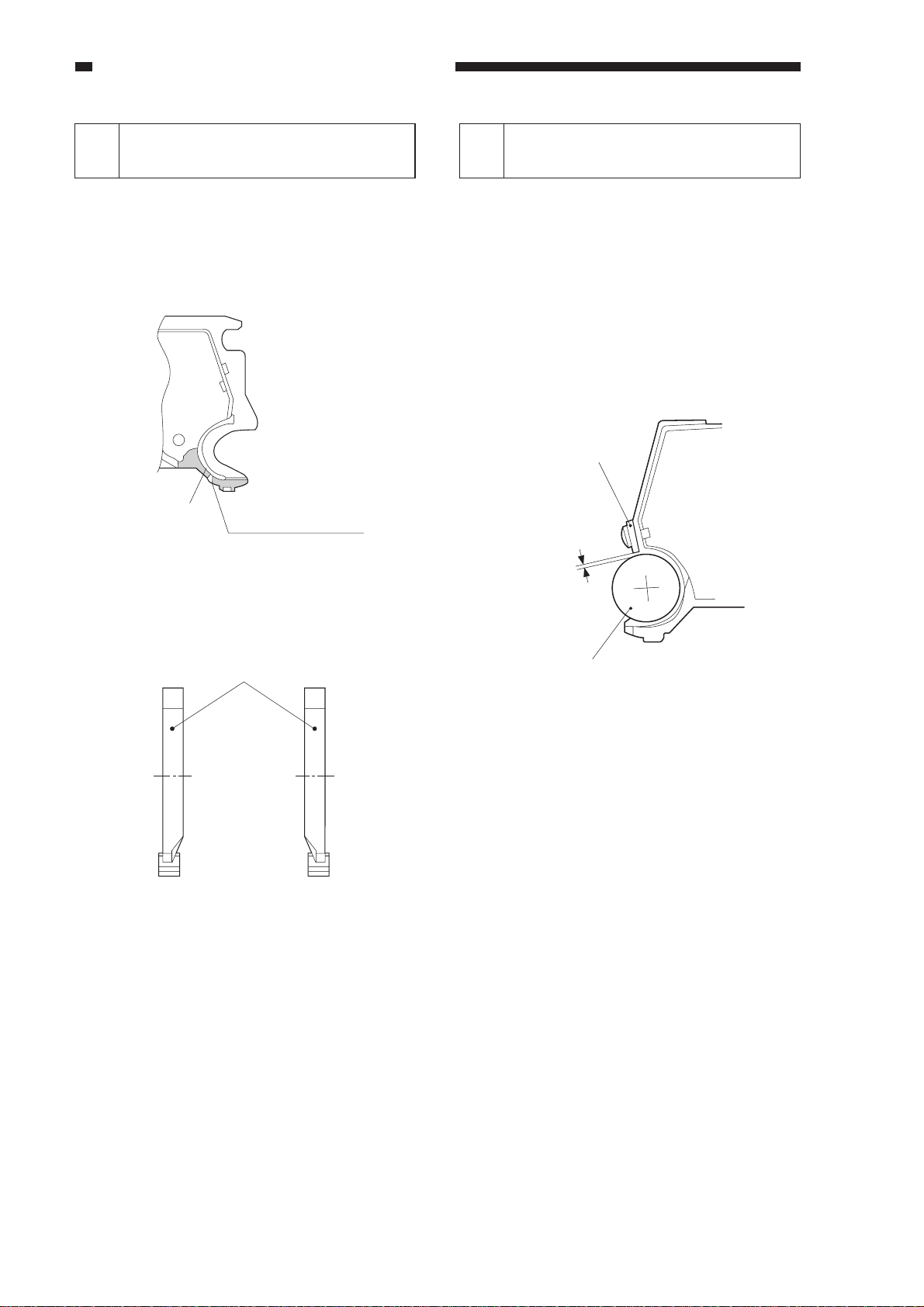

3. Downloading

1. Before Starting the Work

Obtain the following:

• PC to which the downloading tool

(service tool) has been installed.

• Bi-Centronics cable (with an IEEE 1284

Standard-compliant marking)

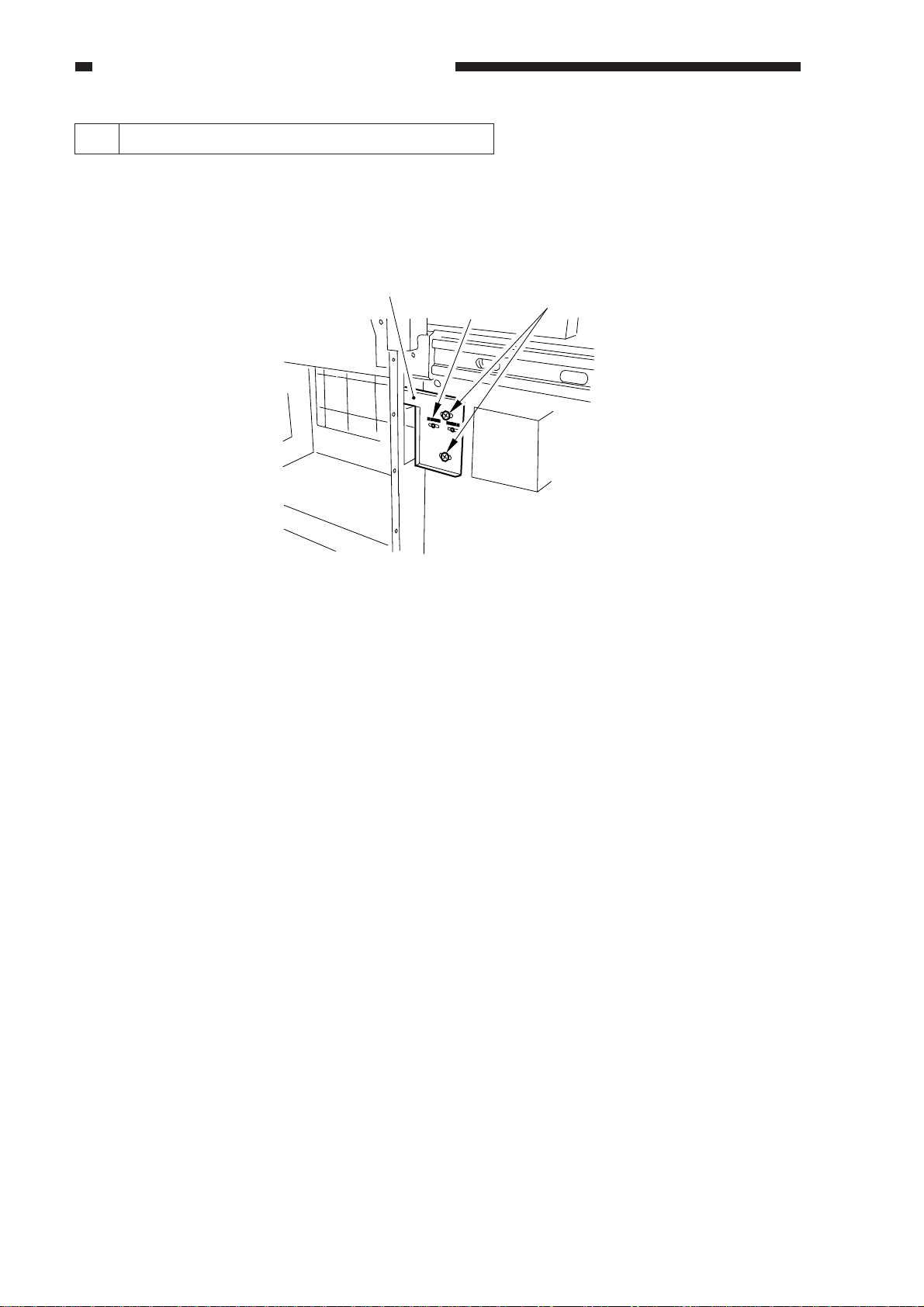

2. Downloading

a. Connection

• Check to make sure that the

communication memory lamp is off.

1) Turn off the machine's main power

switch; then, disconnect the power plug,

and disconnect the modular cable

(telephone).

2) Open the front door, and open the

connector cover for downloading.

3) Connect the machine to the PC with a biCentronics cable.

• Make sure that the PC is off.

• Connect the 25-pin connector of the cable

to the PC, and 36-pin connector to the

machine.

4) Slide the switch to LOAD.

Downloading switch

COPY

LOAD

Bi-Centronics interface

connector

Figure 3-17

5) Turn on the PC, and start the downloading

tool.

Connector cover

for downloading

Figure 3-16

Downloading

switch

COPY LOAD

Connector cover

opened

3-28

Page 67

CHAPTER 3 ARRANGEMENT AND FUNCTIONS OF ELECTRICAL PARTS

6) Connect the machine's power plug to the

power outlet, and turn on the main power

switch.

b. Downloading

1) Select 'To Main Menu' in response to the

start-up message of the downloading tool.

End

To Main Menu

2) Select 'Next' under the Download/Upload.

Manage Data

Next

Download/Upload

Next

3)

Click the model and PCB for downloading.

IP: DIMM for the IP-CPU

DC-CON: DIMM for the DC-CPU

4) Start upgrading the flash ROM following

the instructions on the PC screen.

5) When downloading is done, operate as

follows to turn off the PC:

OK → To Main Menu → End Tool →

End

To Main Menu

End

End Tool

3-29

Page 68

CHAPTER 3 ARRANGEMENT AND FUNCTIONS OF ELECTRICAL PARTS

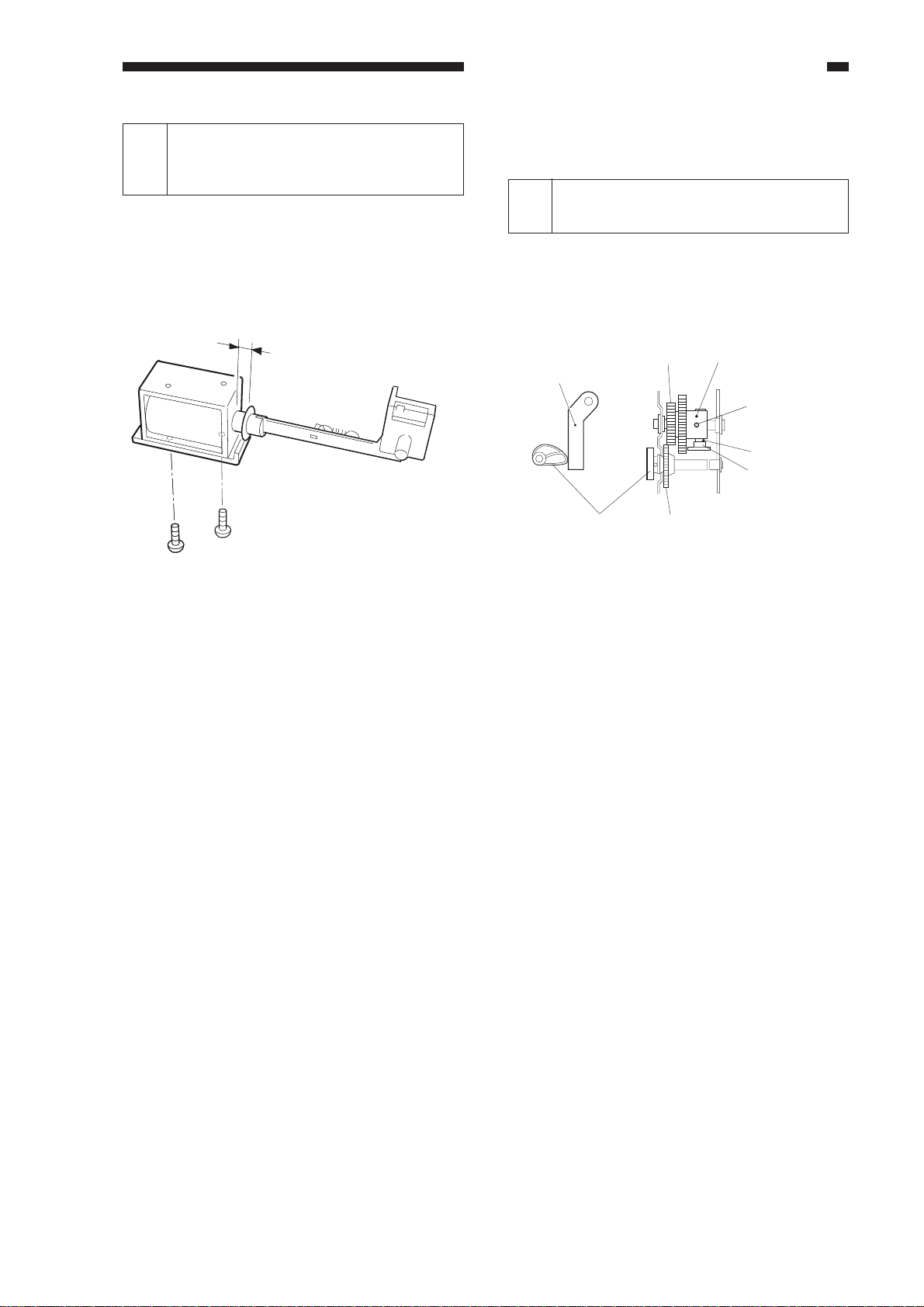

c. After Downloading

1) Turn off the machine's main power

switch, and disconnect the power plug.

2) Disconnect the bi-Centronics cable from

the PC and the machine.

3) Slide the download switch to COPY.

Downloading switch

COPY

LOAD

Figure 3-18

4) Close the connector cover, and close the

front door.

5) If the machine is equipped with fax

functions, connect the modular cable.

6) Turn on the main power switch.

7) Start service mode, and check the ROM

version.

COPIER> DISPLAY>VERSION

3-30

Page 69

CHAPTER 4 SERVICE MODE

A. Outline

The machine's service mode is divided into the following seven:

CHAPTER 4 SERVICE MODE

Cause

1

2

3

4

5

6

7

Step

DISPLAY

I/O DISPLAY

ADJUST

FUNCTION

OPTION

TEST

COUNTER

Display Mode

I/O Display Mode

Adjustment Mode

Function Mode

Setting Mode

PG Test Mode

Counter Mode

Check

Table 4-1

1. Starting Service Mode and Making Selections

1) Press the asterisk key '

Display

Adjust

Function

OptionTest

Counter

I/O

<1/1> <READY>

<LAMP>

<(yyyyy) {aaaaa~ bbbbb}

xxxxx

FL-OFST

A press on

xxxxx: value before change

an item highlights

yyyyy: input value

the notation.

aaaaa-bbbbb: value input range

FL-OFST

' on the control panel.

+/-

OK

2) Press '2' and '8' on the keypad at the same time.

3) Press the asterisk key '

' on the control panel.

• The display changes to the screen shown in Figure 13-801, indicating the connected

accessories (FEEDER, SORTER, FAX).

4

COPIER

FEEDER

SORTER

FAX

COPIER Copier service mode

FEEDER DADF service mode

SORTER Finisher service mode

FAX Fax service mode

Figure 4-1

4-1

Page 70

CHAPTER 4 SERVICE MODE

2. Ending Service Mode

Press the Reset key once to return to the Service Mode Initial screen (Figure 4-1).

Press the Reset key twice to end service mode and return to the User screen (standard).

3. Backing Up the RAM

The RAM data may be backed up in either of the following two ways:

Service Label: The label is found on the left side of the back of the front cover (Figure 4-2).

Each machine is adjusted at the factory, and the adjustment values are recorded

in the label.

List Print: The command generates a back-up output of ADJUST, OPTION, and

COUNTER.

COPIER>FUNCTION>MISC-P>P-PRINT

• When Replacing the Image Processor PCB

Enter the values indicated in the list print obtained before replacement.

• When Replacing the Composite Power Supply PCB

Enter the values indicated on the label attached to the composite power supply.

4-2

Page 71

CHAPTER 4 SERVICE MODE

COPIER/ADJUST

Service Date

LAPM FL-OFST

FL-DUTY

FL-PDUTY

AE AE-TBL

ADJ-XY ADJ-X

ADJ-Y

ADJ-S

CCD PPR

W-PLT

LASER

DEVELOP DE-DC

DENS

HV-PRI P-DC

Boby No.

PVE-OFST

LA-OFF

DE-NO-DC

DE-OFST

DENS-ADJ

P-NO-DC

P-AC

P-NO-AC

Factory

1

Date.

COPIER/ADJUST

2

Service Date

HV-PRI

HV-TR TR-N1

FEED-ADJ REGIST

CST-ADJ MF-A4R

AGS-GAIN

AGS-OFST

OFST1-DC

OFST1-AC

OFST2-AC

P-AC2

P-AC3

TR-N2

TR-OFST

TR-SPP

LOOP-CST

LOOP-MF

ADJ-REFE

RVS-FD1

RVS-FD2

RVS-DUP

MF-A6R

MF-A4

Factory

FB4-3277

1 2

Figure 4-2 Service Label

OFST-DC

AGS-GAIN

AGS-OFST

OFST1-AC

FL-OFST

xx

xxx

xxx

xxx

xxx

Figure 4-3 Label on the Composite Power Supply PCB

4-3

Page 72

CHAPTER 4 SERVICE MODE

4. Basic Operation

The screen design consists of three layers: Level 1, Level 2, and Level 3 screens.

a. Initial Screen

COPIER

FEEDER

SORTER

FAX

Initial items

However, FEEDER, SORTER,

and FAX appear only when they are

installed.

Figure 4-4

• An initial item is selected when the highlighted notation is pressed.

b. Level 1/Level 2 Screen

Display

VERSION

USER

ACC-STS

ANALOG

CST-STS

JAM

ERR ALARM-1

HV-STS

I/O

Adjust

Function

Option Test

Level 1 item

Level 2 item

Counter

Figure 4-5

• To select a Level 1 item, press an item at the top of the screen.

• To select a Level 2 item, press a highlighted item.

4-4

Page 73

c. Level 3 Screen

FL-OFST

FL-OFST

<LAMP>

<1/1> <READY>

xxxxx

< (yyyyy) {aaaaa ~ bbbbb}

A press on

an item highlights

the notation.

xxxxx: value before change

yyyyy: input value

aaaaa-bbbbb: value input range

+/-

OK

Display

Adjust

Function

Option Test

Counter

I/O

Level 1 items

Level 2 item

CHAPTER 4 SERVICE MODE

Number of pages

; e.g., 1/3

Display

DC-CON

IP

PANEL

ANAPRO

POWER

I/O

<VERSION>

To previous page

Adjust

Function

< 1/3 > < READY >

Status

READY

JAM Paper jam

SERVICE Service operation

WAITING Initial rotation, etc.

DOORDoor open

COPYING Copying

ERROR Service error

Reverse + and -

To next page

Figure 4-6

Option Test

Ready for servicing/copying

+/-

Counter

OK

To store

Figure 4-7

• A level 3 item may be selected by pressing it, and the selection is indicated by highlighting

the item.

4-5

Page 74

CHAPTER 4 SERVICE MODE

d. Selecting a Screen

User screen

( )(2,8)( )

Level 1/2 screen

Reset key

Initial screen

Select an item

Select a Level 1 item at the top;

then, select a Level 2 item.

Level 3 screen Level 3 screen

To previous

/next screen

Reset key

From Level

1/2 screen

To previous

/next screen

Level 3 screen

Level 3 screen

To previous

/next screen

e. Guide to Keys

1. Keypad

Use it to enter a numeral (0 through 9).

2. User Mode Key

Use it to start user mode.

3. Reset Key

Use it to end service mode.

4. Stop Key

Use it to stop ongoing operation.

5. Clear Key

Use it to initialize settings in service mode or software counter readings.

6. Copy Start Key

Use it to make copies without ending service mode after making adjustments.

7. Previous Page Key

Use it to return to the previous page.

8. Next Page Key

Use it to move to the next page.

9. +/- Key

USe it to switch between + and -.

10. OK Key

Use it to store an input value.

Figure 4-8

4-6

Page 75

B. DISPLAY Control Display Mode

Figure 4-9 shows the DISPLAY mode Level 2 screen and its items.

CHAPTER 4 SERVICE MODE

Display

VERSION

USER

ACC-STS

ANALOG

CST-STS

JAM

ERR

HV-STS

I/O

Adjust

ALARM-1

Function

Option Test