COPYRIGHT © 1999 CANON INC. CANON GP160 REV.0 FEB. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

ADF-H1

COPYRIGHT © 1999 CANON INC. CANON GP160 REV.0 FEB. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

This service manual provides basic information required in performing field service to

maintain the product quality and functions of the ADF.

Each chapter consists of the following sections:

Chapter 1, “Introduction,” : Features, Specifications, Operation procedure features,

Specifications , Operation procedures.

Chapter 2, “Operation overview,” : Description of the mechanical and electrical operating principles and timing by function, Description and overview of electric circuit configuration.

Chapter 3, “Mechanical system,” : Description of mechanical structure, and disassembly, assembly and adjustment methods.

Chapter 4, “Maintenance and Inspection,” : Table of periodic replacement parts and

consumables replacement targets, periodic service list.

Chapter 5, “Troubleshooting,” : Standards/adjustments, operation failure countermeasures.

Appendix : General circuit diagram, printed circuit board diagrams.

For information regarding installation, refer to the instruction manual packed with the

ADF.

Changes of the contents made for the sake of product improvements will be notified

in Service Information (Technical Information) whenever such changes are made.

Gaining a sound and thorough understanding of the unit through careful reading of

this service manual and the subsequently issued Service Information (Technical

Information) bulletins is the only way to develop the technical skill necessary to prolong

product quality and functionality and the practical ability to be able to determine the

cause of breakdowns.

i

INTRODUCTION

ii

COPYRIGHT © 1999 CANON INC. CANON GP160 REV.0 FEB. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

iii

CONTENTS

CHAPTER 1 INTRODUCTION

CHAPTER 2 OPERATION OVERVIEW

CHAPTER 3 MECHANICAL SYSTEM

CHAPTER 4 MAINTENANCE AND INSPECTIONS

I. FEATURES ..............................................1-1

II. SPECIFICATIONS....................................1-2

III. NAMES OF PARTS..................................1-3

A. External view......................................1-3

IV. OPERATION DESCRIPTION...................1-4

A. Basic procedures...............................1-4

B. Warning indications and remedies.......1-4

C. User routine inspections....................1-5

I. BASIC CONFIGURATION ........................2-1

A. Overview of electric circuits...............2-1

B. ADF relay controller PCB I/O.............2-2

II. BASIC OPERATION .................................2-3

A. Overview............................................2-3

B. Document detection...........................2-4

C. Pick-up and feed operations..............2-8

D. Stamp function.................................2-13

E. ADF motor (M801) control...............2-14

F. Document jam detection..................2-15

I. EXTERNAL CONTROL ITEMS ...............3-1

A. External covers..................................3-1

B. Removing ADF...................................3-1

C. Removing the document contact

plate ...................................................3-2

D. Removing the hinge unit....................3-3

II. DOCUMENT FEED SYSTEM ..................3-3

A. Removing the ADF motor..................3-3

III. ROLLERS ................................................3-6

A. Removing the separation roller unit......3-6

B. Removing the separation bar.............3-7

C. Removing the document feed

roller...................................................3-9

D. Removing the document delivery

roller.................................................3-10

IV. ELECTRICAL COMPONENTS..............3-13

A. Removing the ADF relay PCB.........3-13

B. Removing the paper detection sensor

PCB..................................................3-13

I. PERIODIC REPLACEMENT PARTS .......4-1 II. CONSUMABLES REPLACEMENT

TARGETS.................................................4-1

COPYRIGHT © 1999 CANON INC. CANON GP160 REV.0 FEB. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

iv

COPYRIGHT © 1999 CANON INC. CANON GP160 REV.0 FEB. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

CHAPTER 5 TROUBLESHOOTING

APPENDIX

I. STANDARDS AND ADJUSTMENTS .......5-1

A. ADF height adjustment ......................5-1

B. Skew feed adjustment ........................5-3

C. Adjusting image position....................5-5

II. OPERATION FAILURE COUNTERMEA-

SURES ...................................................5-11

A. Operation failure countermeasure

procedures.......................................5-11

III. DIAGRAM SHOWING LOCATION OF

ELECTRIC PARTS.................................5-13

IV. LIST OF VARIABLE RESISTORS (VR),

LEDS AND CHECK PINS BY PRINTED

CIRCUIT BOARD...................................5-14

A. GENERAL TIMING CHART.....................A-1

B. LIST OF SIGNAL NAMES.......................A-3

C. GENERAL CIRCUIT DIAGRAM..............A-5

D. LIST OF SPECIAL TOOLS......................A-7

E. SOLVENTS AND OILS............................A-8

COPYRIGHT © 1999 CANON INC. CANON GP160 REV.0 FEB. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

CHAPTER 1

INTRODUCTION

I. FEATURES ..............................................1-1

II. SPECIFICATIONS....................................1-2

III. NAMES OF PARTS..................................1-3

A. External view......................................1-3

IV. OPERATION DESCRIPTION...................1-4

A. Basic procedures...............................1-4

B. Warning indications and remedies.......1-4

C. User routine inspections....................1-5

COPYRIGHT © 1999 CANON INC. CANON GP160 REV.0 FEB. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

CHAPTER 1 INTRODUCTION

1-1

I. FEATURES

1. Document size recognition

When a document is set, the ADF automatically senses a regular document size and

sends information on the document size to the unit.

2. Stamp function

A completion stamp can be stamped on the surface of the document when the

stamp function is selected on the unit.

3. Single document pick-up and separation mechanism

Document pick-up roller, separation roller and drive mechanism have been integrated into one unit to simplify replacement work.

4. Hinge unit for thick documents

Hinge unit modifications have made it possible to lower the pressure applied to the

copyboard glass by the lifting mechanism of the hinge unit when thick documents are

copied in pressure plate mode.

COPYRIGHT © 1999 CANON INC. CANON GP160 REV.0 FEB. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

CHAPTER 1 INTRODUCTION

1-2

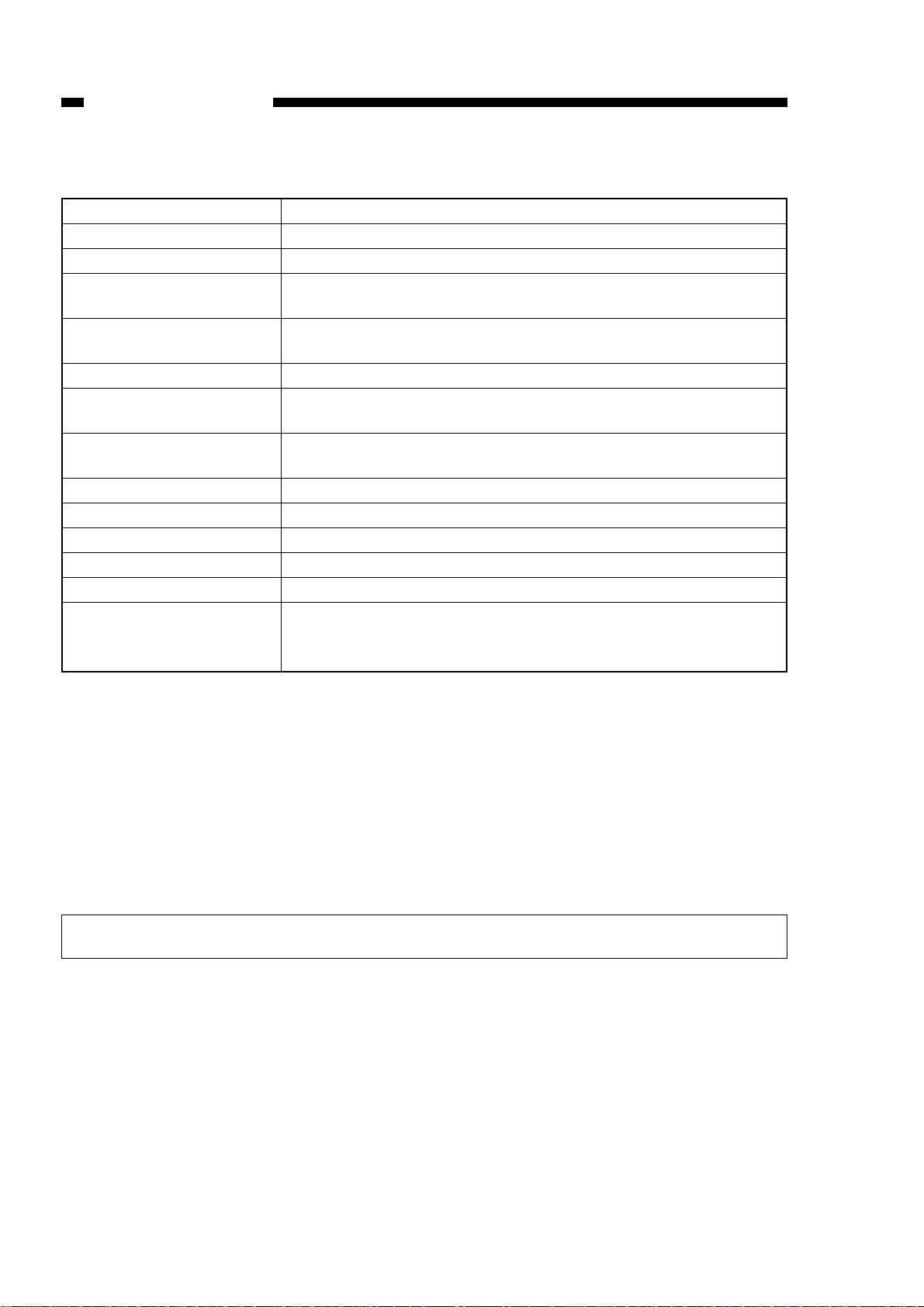

II. SPECIFICATIONS

The following type of documents will not provide guaranteed operation

• OHP film

• Documents with holes for file storage

• Stapled documents, documents containing paper clips or with glue on them

• Documents to which paper clippings have been attached.

• Documents with carbon paper attached on the back

• Excessively curled, folded or wrinkled documents

Tell users that if they have to use curled documents to make them as straight as pos-

sible and to place the most deformed part of the document to the rear.

Item

Document pick-up system

Document types

Document size

Document set orientation

Document set position

Document processing

mode

AutNumber of stackable

documents

Mix originals

Document size recognition

Stamp function

Power supply

Serial number

Operating environment

Ambient temperature

Ambient humidity range

Specifications

Omatic pick-up/delivery system

One-sided sheet documents (50 to 200 g/m2)

A3, B4, A4, A4R, B5, B5R, A5, A5R, 11

×

17, LGL, LTR, LTRR

(paper feed up to 1 m is possible during fax transmission)

• Place documents face down.

• Place the first document page at the bottom.

Center reference.

One-sided original → one-sided scanning.

• A3, B4, 11 ×17, LGL: 20 pages or less.

• A4, A4R, B5, B5R, A5, A5R, LTR, LTRR:50 pages or less.

No

Yes (regular size only)

Yes (yellow)

Supplied by unit (5 or 24 V DC)

Eur: ZSSxxxxx Asia: ZSXxxxxx

As per copier specifications.

Specifications are subject to change for the sake of product improvements.

COPYRIGHT © 1999 CANON INC. CANON GP160 REV.0 FEB. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

CHAPTER 1 INTRODUCTION

1-3

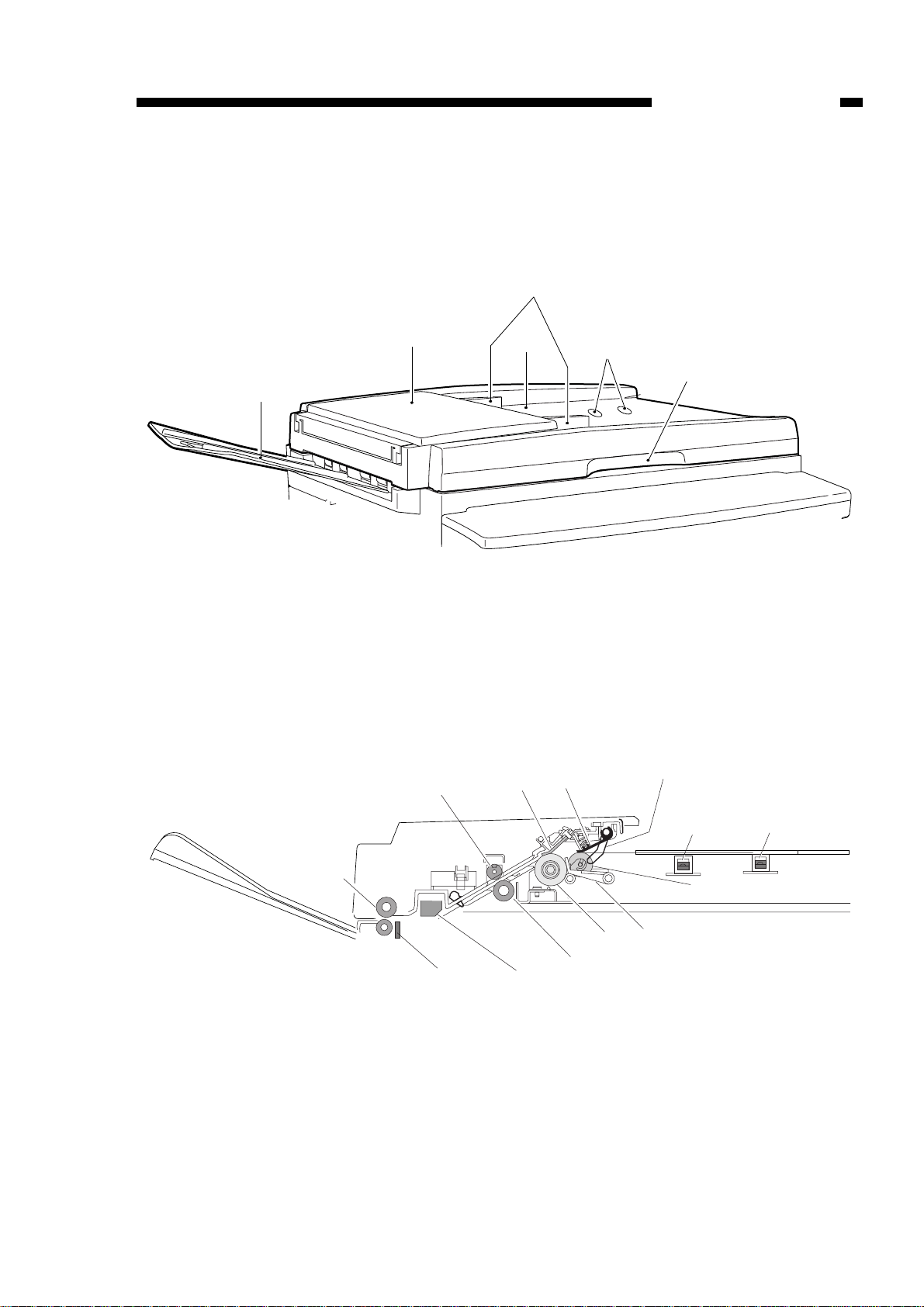

III.NAMES OF PARTS

A. External view

[1] ADF upper cover

[2] Document tray

[3] Slide guide

[4] Document length sensor

[5] Opening grip

[6] Document delivery tray

Figure 1-301

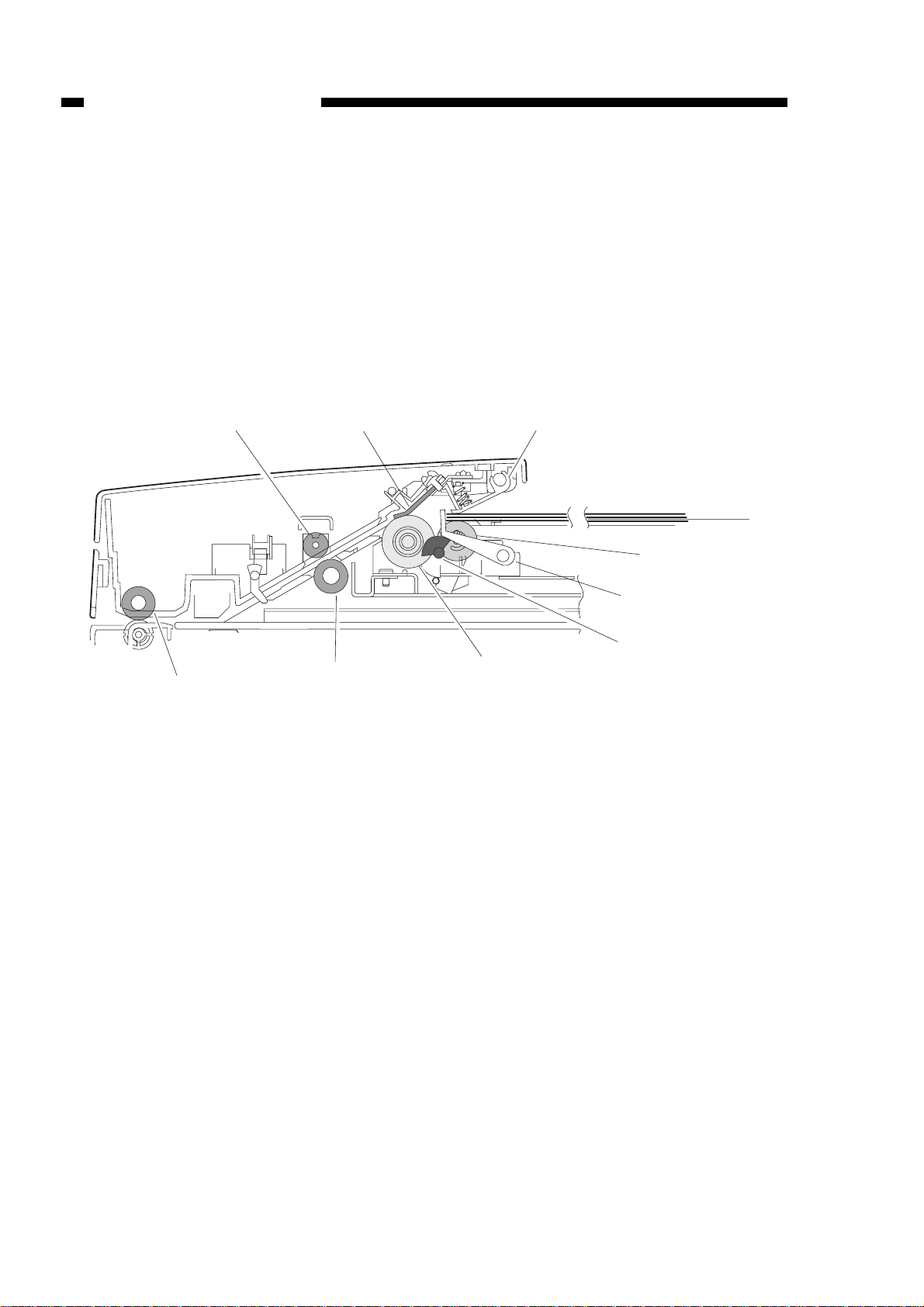

[1] Upper delivery roller

[2] Feed roller

[3] Friction bar

[4] Paper pressing plate

[5] Paper detection sensor lever

[6] Document length sensor 1

[7] Document length sensor 2

[8] Document stopper

[9] Separation roller

[10] Delivery roller

[11] Document contact plate

[12] Stamp

Figure 1-302

[3]

[6]

[1]

[2]

[2]

[4]

[5]

[3]

[4]

[5]

[7]

[1]

[12]

[6]

[9]

[10]

[11]

[8]

COPYRIGHT © 1999 CANON INC. CANON GP160 REV.0 FEB. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

CHAPTER 1 INTRODUCTION

1-4

IV. OPERATION DESCRIPTION

A. Basic procedures

1) Align the leading edges of the document and insert the document with the first page

facing down as far as it will go.

2) Adjust the slide guide to suit the width of the document.

3) Make the required copy or fax settings on the operation panel of the unit.

4) Press the unit Start key.

B. Warning indications and remedies

When a document becomes jammed, the message “Document jam” appears on the

display of the unit operation panel and a red alarm lamp starts to flash. Use the following procedure to clear the paper jam.

1) Press the Stop key on the unit operation panel.This deletes the partly scanned doc-

ument image from memory.

2) Gently open the upper ADF cover and remove the document.

3) Close the feeder cover.

4) Return the documents to their original order.

Advice the user not to touch the upper ADF cover during document feeding.Touching

the upper ADF cover could cause the document to shake during feeding, resulting in

poor images.

Caution:

This unit is not provided with a mix original function. Thus loading documents of different sizes will result in a paper jam.

Caution:

COPYRIGHT © 1999 CANON INC. CANON GP160 REV.0 FEB. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

CHAPTER 1 INTRODUCTION

1-5

C. User routine inspections

Advise the user to perform the maintenance operations described below.

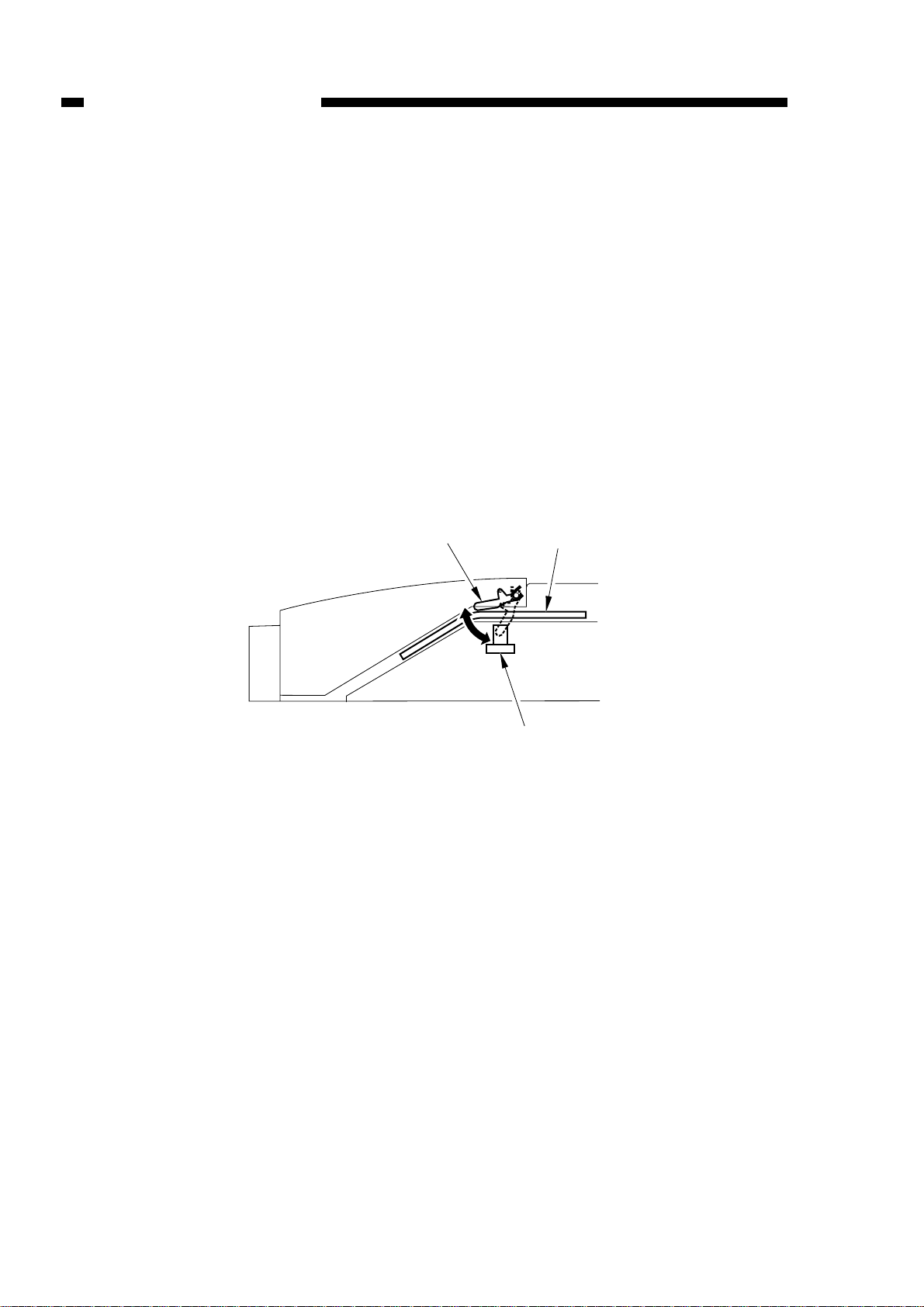

1. Replenishing stamp ink

Replenish stamp ink according to the following procedure.

1) After making sure that the green alarm lamp on the operation panel of the unit is not

on or flashing, power down the unit and open the ADF.

2) Fill one drop of stamp ink at the location shown in the figure.

Figure 1-401

• Since it takes time for the replenished ink to take effect, wait 1 hour to after replenishing the ink before using the stamp function.

• Take care not to add too much ink.

• Turn on the power switch on the main unit as soon as ink has been replenished.

Caution:

Do not touch the stamp surface. Should you by accident get ink on your hands or

other parts of the body, immediately wash it off.

Caution:

Add ink here

COPYRIGHT © 1999 CANON INC. CANON GP160 REV.0 FEB. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

CHAPTER 1 INTRODUCTION

1-6

2. Areas to clean and cleaning methods

• Copyboard glass cleaning

Clean with a cloth moistened in water, alcohol or ??• C-17, and wipe it dry. It is

essential that the copyboard glass is kept clean, as dirt adhering to the glass of the

scanning assembly glass will appear as dark stripes, especially on images scanned

in stream reading mode.

• Cleaning the document pressure sheet

Clean using a cloth with a cloth moistened in water or alcohol.

• Cleaning the document contact plate

Clean using a cloth with a cloth moistened in water or alcohol.

• Cleaning document length sensor cover

Wipe it with a dry cloth.

COPYRIGHT © 1999 CANON INC. CANON GP160 REV.0 FEB. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

CHAPTER 2

OPERATION OVERVIEW

1. This chapter describes the objective and role of each function, the relationship

between the electrical and mechanical systems and also gives an overview of the

operation timing of each part by function.

The symbol in the outline diagram indicates the transmission of mechanical

drive, and the symbol together with a signal name indicates the flow of

electric signals.

2. In the descr iptions of the digital circuits of the cassette feeding unit, “1” indicates a

high electric signal level and “0” indicates a low electric signal level.The voltage differs with the circuit.

Since it is assumed that service engineers will not repair printed circuit boards on the

customer’s premises, descriptions of printed circuit boards are limited to overviews

illustrated with block diagrams. Consequently, circuit descriptions cover from sensors

to the input sections of the ADF connector printed circuit and the image processor

and from the output sections of the image processor and the ADF printed circuit output sections to the loads, as well as block diagrams of each function.

I. BASIC CONFIGURATION ........................2-1

A. Overview of electric circuits...............2-1

B. ADF relay controller PCB I/O.............2-2

II. BASIC OPERATION .................................2-3

A. Overview............................................2-3

B. Document detection...........................2-4

C. Pick-up and feed operations..............2-8

D. Stamp function.................................2-13

E. ADF motor (M801) control...............2-14

F. Document jam detection..................2-15

COPYRIGHT © 1999 CANON INC. CANON GP160 REV.0 FEB. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

CHAPTER 2 OPERATION OVERVIEW

2-1

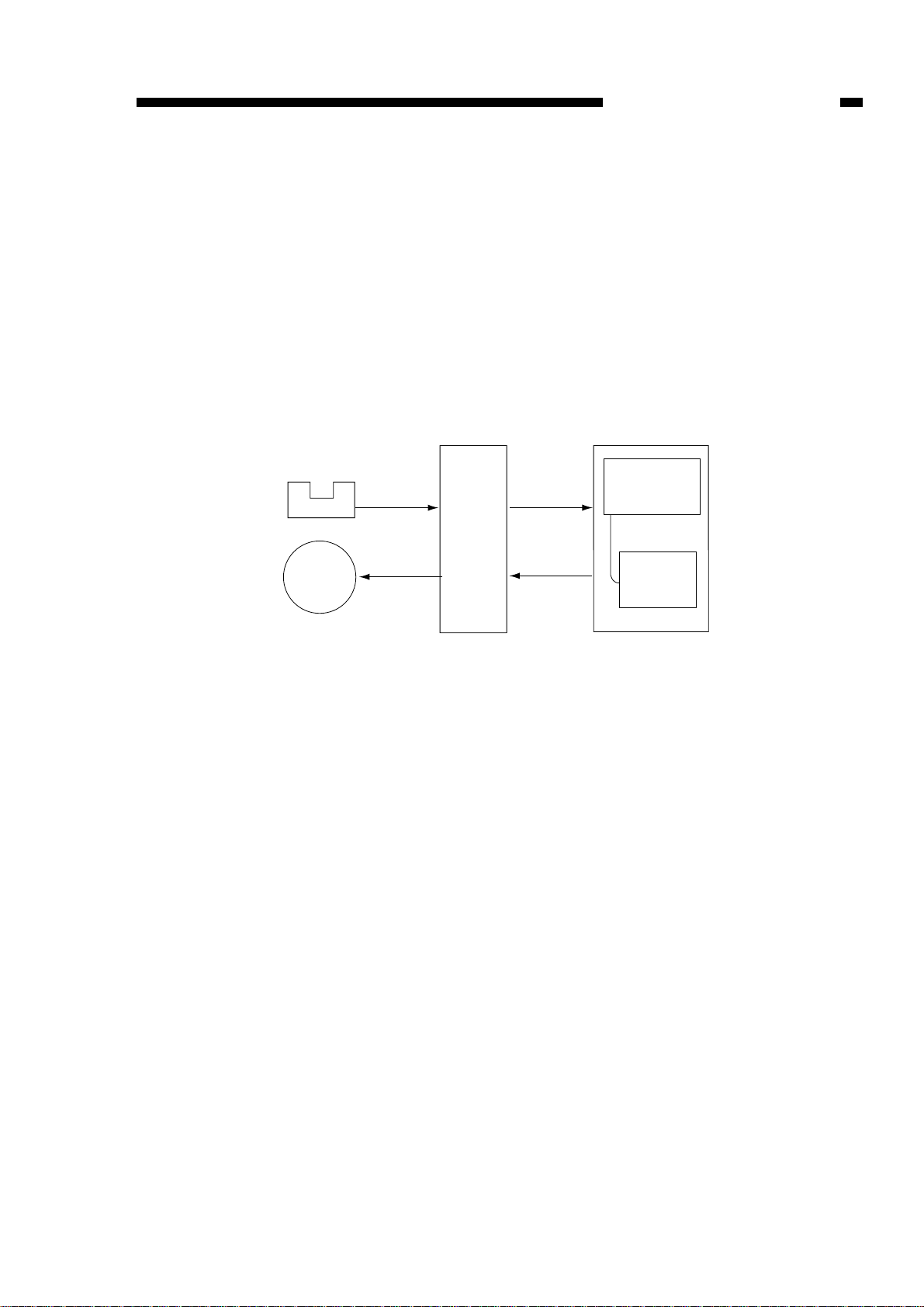

I. BASIC CONFIGURATION

A. Overview of electric circuits

ADF electric control is performed by IC15 on the unit image processor circuit board

running a program stored in the program ROM (IC1, IC2).

ADF operation control signals transmitted from the image processor PCB and sig-

nals relaying ADF load operation states are all transferred via the ADF relay PCB.

The unit supplies 5 V DC and 24 V DC power.

Figure 2-101

Sensor

Motor

ADF relay

PCB

Main unit image

processor PCB

Control IC

(IC15)

Program

ROM

(IC1, IC2)

COPYRIGHT © 1999 CANON INC. CANON GP160 REV.0 FEB. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

CHAPTER 2 OPERATION OVERVIEW

2-2

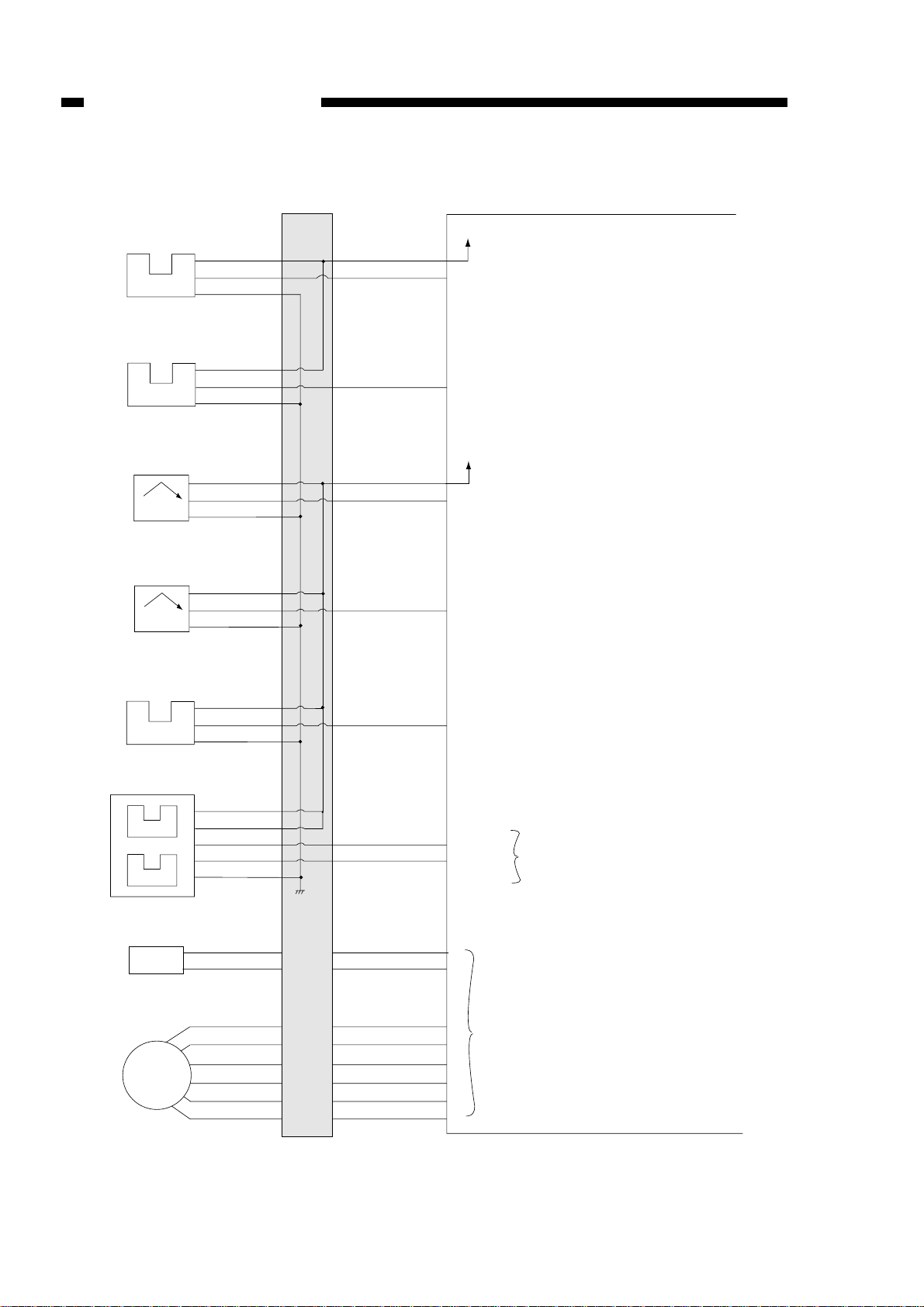

B. ADF relay controller PCB I/O

Figure 2-102

J813-1

PS801

Document sensor

J810-1

PS806

ADF closed sensor

J812-9

PS802

Document length sensor 1

J812-6

PS803

Document length sensor 2

ADF relay PCB

J801-1

-3

-2

-3

-2

-8

-7

-5

-4

J802-7

J802-3

J802-6

-12

J801-4

J205-A16

-A5

J205-B10

J205-A13

-B14

J205-B11

+5V

PS801S*

PS806S

+5V

PS802S

PS803S

Main unit image processor PCB

“0” when document is detected

(when the light shield is not at sensor

position)

“1” when the ADF is closed

(when the light shield obstructs

the sensor)

“1” when the document is detected

“1” when the document is detected

PS805

Document leading

edge sensor

PS851

PS802

Document width sensor

circuit board

TH801

ADF motor thermoswitch

M801

ADF motor

J811-1

J813-4

J814-1

J815-1

-4

-3

-2

-8

-7

-5

-6

-2

-2

-3

-5

-6

J802-4

J801-14

J801-13

J205-B13

J205-A3

-A4

PS805S*

PS851S

PS852S

See page 2-14.

“0” when the document is detected

In combination, these two sensors

detect the paper width

??????

COPYRIGHT © 1999 CANON INC. CANON GP160 REV.0 FEB. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

CHAPTER 2 OPERATION OVERVIEW

2-3

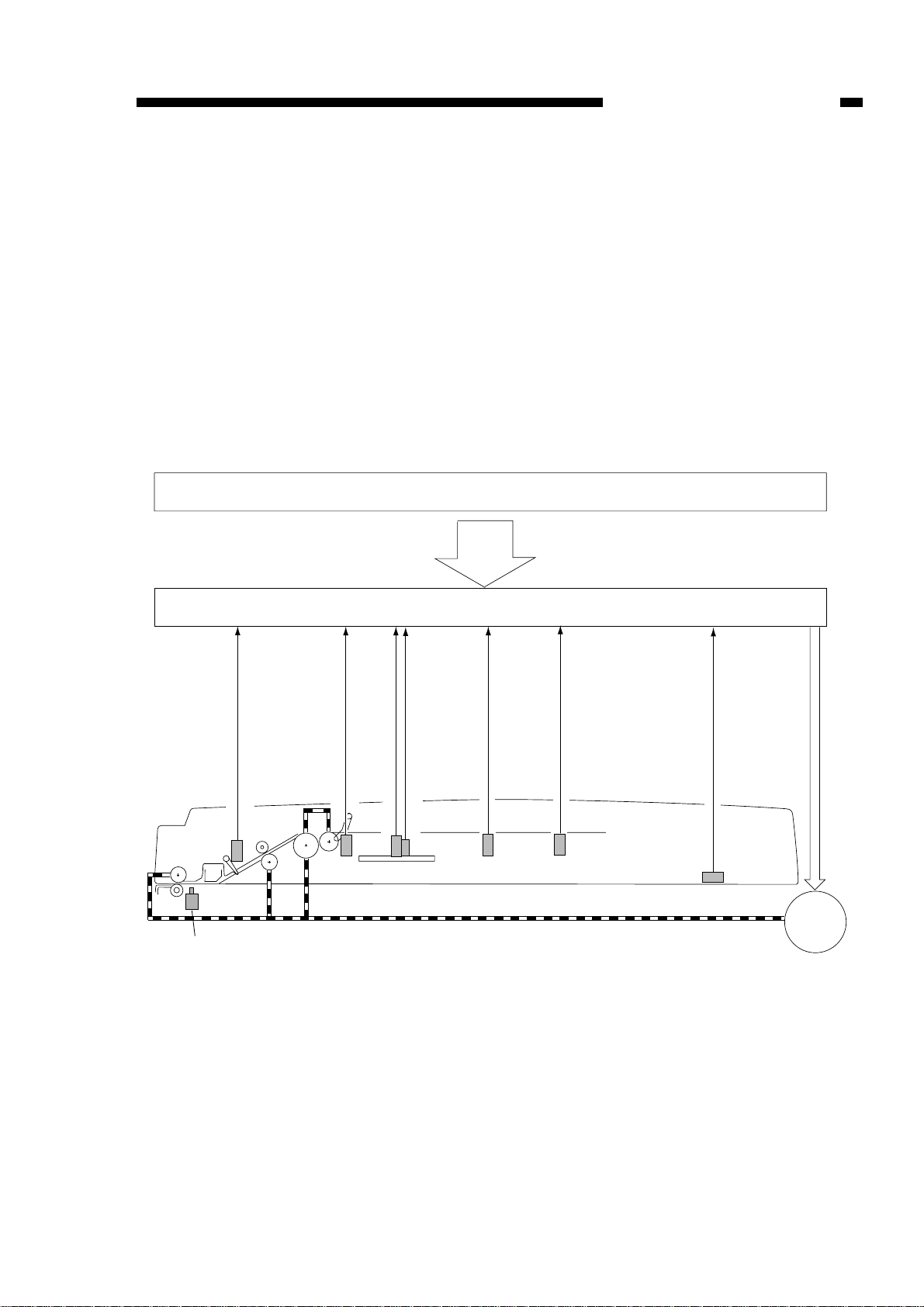

II. BASIC OPERATION

A. Overview

This is a dedicated stream reading document feeder.

The document pick-up, feed and delivery sequence of the unit is performed using

drive provided by the ADF motor (M801).

Documents on the document tray are picked up in order from the bottom of the document sheaf (the first page of the document) in response to commands from the copier

and moved (streamed) across the copyboard glass.

The stamp is located on the upper left cover of the unit in which the ADF has been

installed.When the stamp function is set to ON in the unit, the surface of fax documents

that have been transmitted will be stamped.

Figure 2-201

Main unit image processor PCB

Document leading edge

signal (PS805S)

Stamp solenoid

(controlled by the unit image processor PCB)

Document detection signal

Paper detection signal

(PS801S)

Document width sensor PCB

Paper detection signal

(PS851S)

ADF relay PCB

(PS852S)

Document length detection

signal (PS802S)

Document length detection

signal (PS803S)

ADF closed signal (PS806S)

ADF motor drive signal

M801

ADF motor

COPYRIGHT © 1999 CANON INC. CANON GP160 REV.0 FEB. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

CHAPTER 2 OPERATION OVERVIEW

2-4

B. Document detection

1. Overview

This unit incorporates three types of document sensors.

• Document detection sensor

• Document size sensor

• Document leading edge sensor

2. Document detection

The document sensor (PS801) detects documents in the document tray.When documents are inserted in the document tray, the light shield is separated from the document

sensor (PS801) resulting in the generation of a paper detection signal (PS801S*).

The signal output by the sensor is transmitted to the unit image processor PCB

where paper detection is confirmed.

Figure 2-202

Light shield

OFF

ON

Document

Document sensor (PS801)

COPYRIGHT © 1999 CANON INC. CANON GP160 REV.0 FEB. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

CHAPTER 2 OPERATION OVERVIEW

2-5

3. Document size detection

Regular size document sizes are detected through a combination of ON and OFF

states of the paper detection sensors (PS851, PS852) and document length sensors

(PS802, PS803).

Sensor ON and OFF states are transferred to the unit image processor PCB, which

identifies the document sizes.

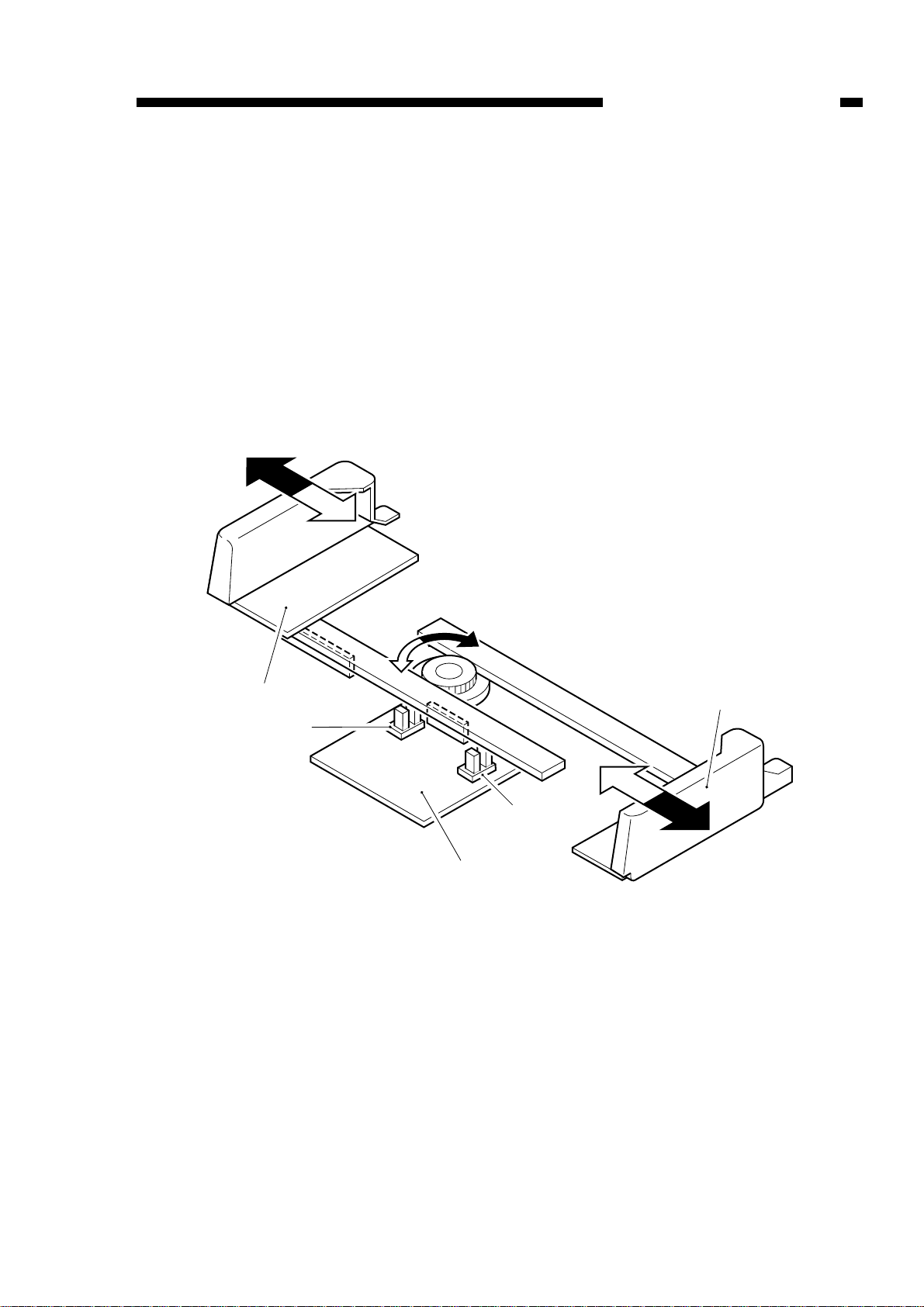

a. Paper detection

The light shields interlocked with the slide guides obstruct (sensor ON) or do not

obstruct (sensor OFF) the two paper detection sensors (PS851, PS852) on the paper

width sensor PCB and it is a combination of these two states that allow the unit to detect

document width.

Figure 2-203

Slide guide Slide guide

PS852

PS851

Document width sensor PCB

COPYRIGHT © 1999 CANON INC. CANON GP160 REV.0 FEB. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

CHAPTER 2 OPERATION OVERVIEW

2-6

b. Document length detection

When a document is placed on the document tray, the combination of ON states of

the reflective document length sensors (PS802, PS803) generated by the document

length makes it possible to detect the length of the document.

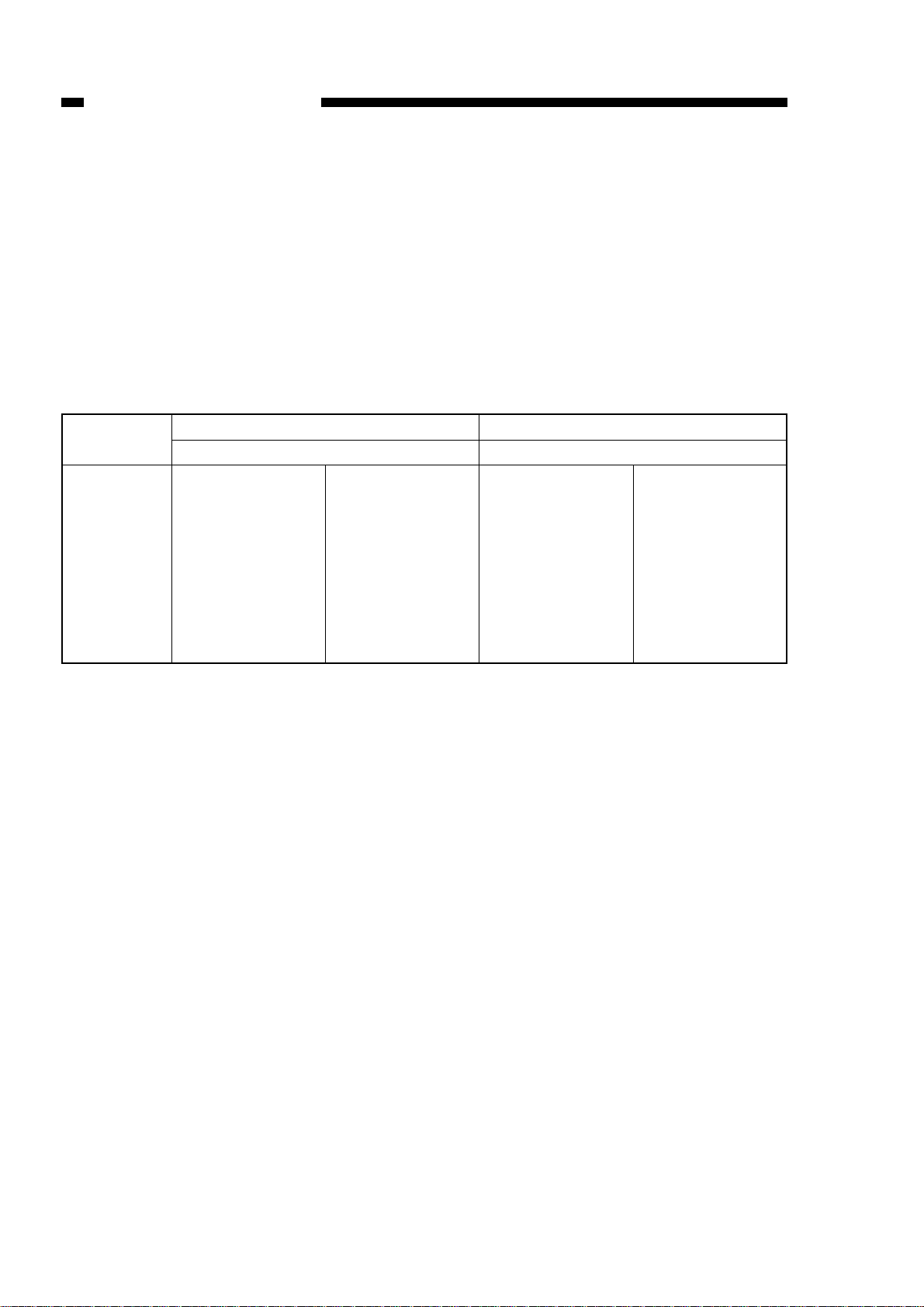

c. List of document size detection

To detect document size, first document width detection is used to determine which

regular size before identifying document length.

Consequently, unless the slide guides of the document tray are correctly set, the

document will be detected as the closest regular document size.

The combination of paper sensor and document length sensor ON and OFF states

for each regular document size are listed below.

*1 The paper detectors (PS851, PS852) are ON when the light shield does not obstruct

the sensor, and are OFF when the light shield obstructs it.

* 2 The document length detectors (PS802, PS803) are ON when a document is above

the sensor and OFF when one is not.

Paper size

A3

A4

B4

B5

A4R

A5

A5R

B5R

Paper width detector *1

PS851 PS852

ON ON

ON ON

ON OFF

ON OFF

OFF OFF

OFF OFF

OFF ON

OFF ON

Paper length detector *2

PS802 PS803

ON ON

ON OFF

ON ON

ON OFF

ON ON

OFF OFF

ON OFF

ON ON

COPYRIGHT © 1999 CANON INC. CANON GP160 REV.0 FEB. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

CHAPTER 2 OPERATION OVERVIEW

2-7

4. Document leading edge detection

The role of the document leading edge sensor (PS805S) is to synchronize the timing

of the document scanning operation and the main unit print operation during stream

reading, and thereby detect the position of the document.

When the Start key is pressed, the document pick-up operation starts. If the document was fed directly to the scanning glass for stream reading, the timing of image

scanning and the print operation would be out of phase.To prevent this from happening,

a document leading edge sensor (PS805S) has been installed in the feeding path.

When this sensor detects the leading edge of the document, it causes the document to

stop for a short while.The document pick-up operation is resumed when a pick-up control signal is received from the unit image processor PCB.(This delay in document feed)

makes it possible to synchronize scanning with the print operation.

Figure 2-204

Main unit image processor PCB

Leading edge and trailing

edge detector signals

Document leading

edge sensor

(PS805)

Feed operation start control

and feed operation finish control

ADF relay PCB

Leading edge and trailing edge detector signals (PS805S)

COPYRIGHT © 1999 CANON INC. CANON GP160 REV.0 FEB. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

CHAPTER 2 OPERATION OVERVIEW

2-8

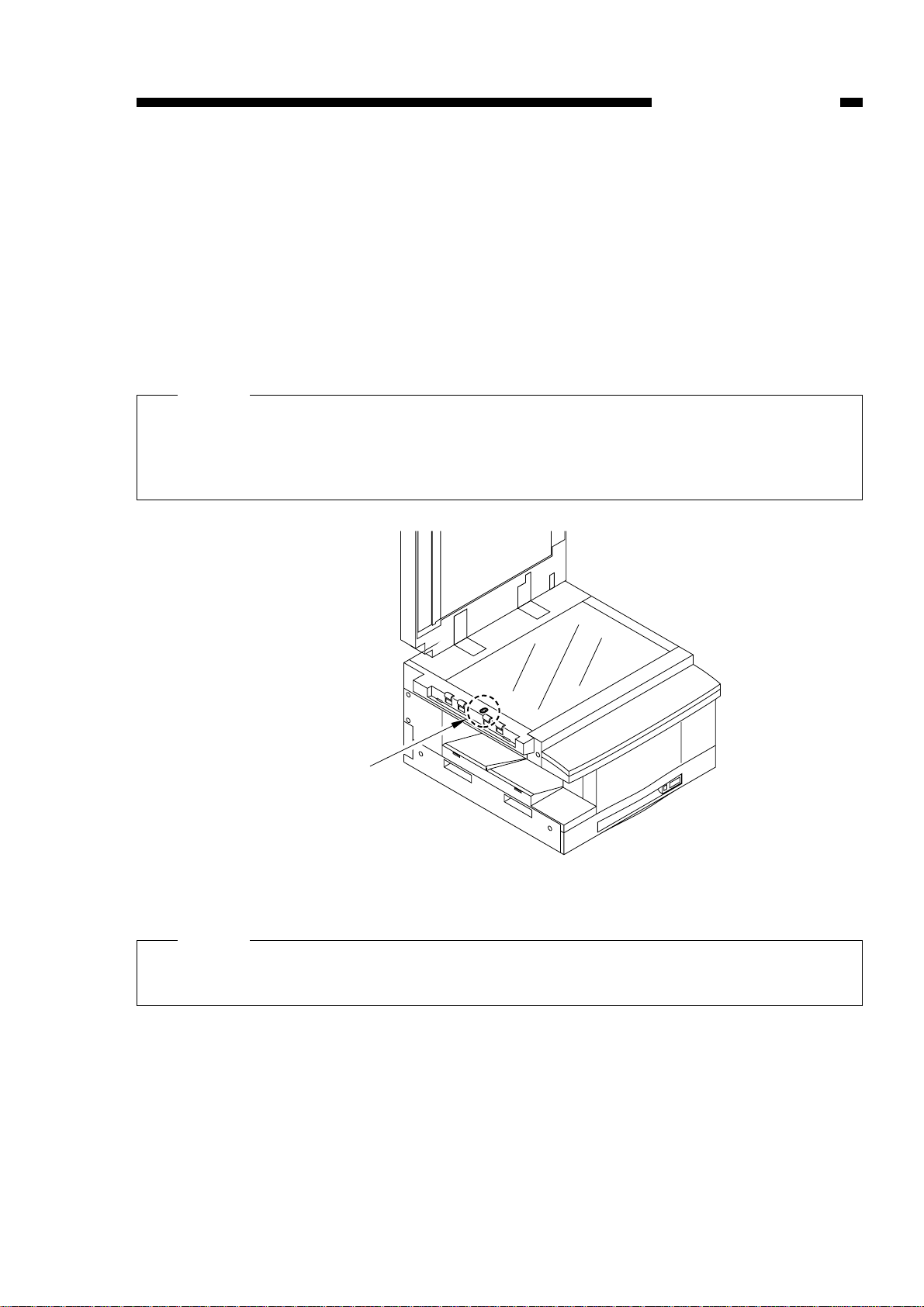

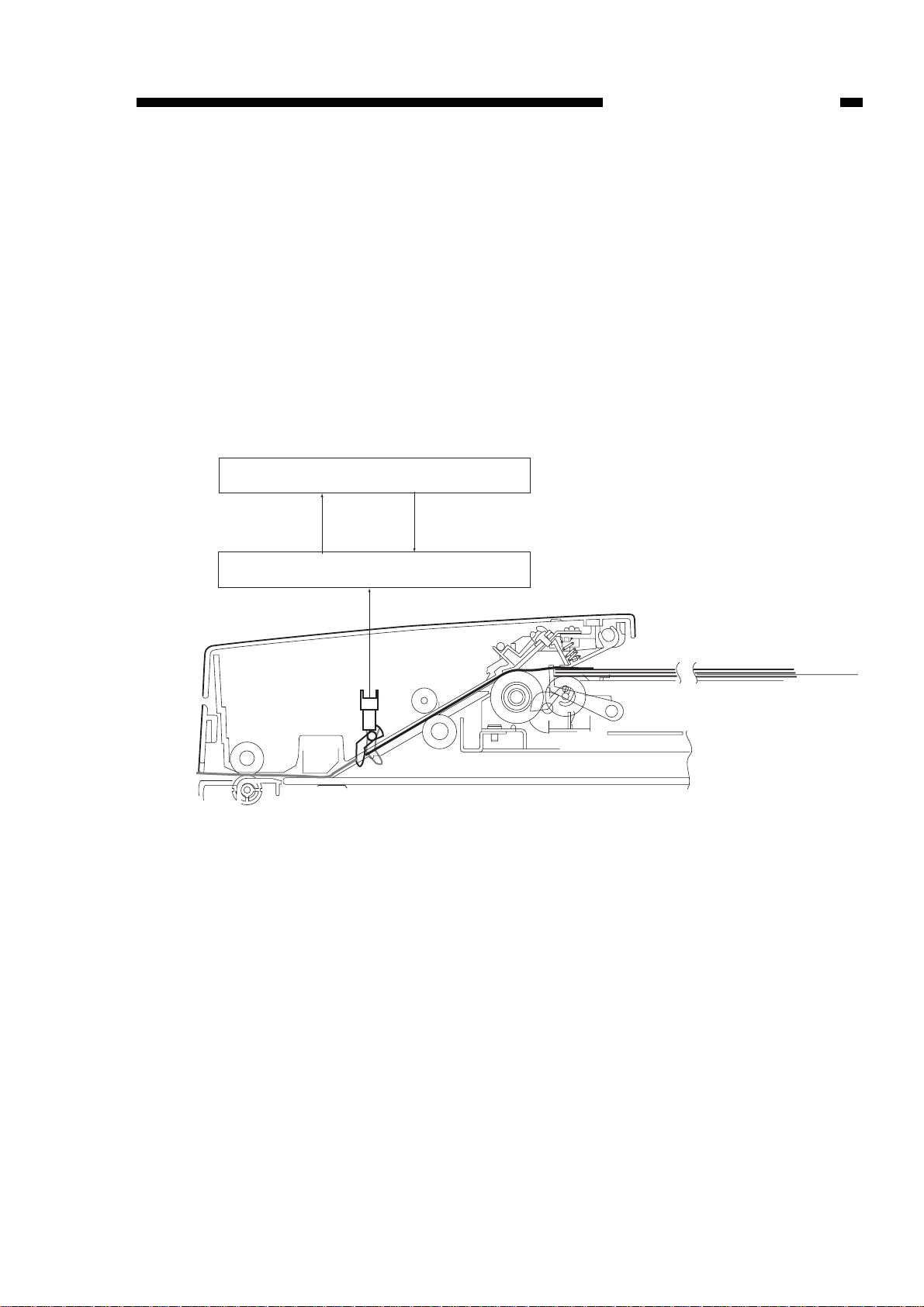

C. Pick-up and feed operations

1. Overview of pick-up operation

When a document is placed in the document tray and the Start key is pressed, the

ADF motor starts turning and document pick-up starts.The picked up document is fed to

the stream reading position on the copyboard glass by (the drive of) the feed rollers.

The stream scanned document is delivered to the document delivery tray by the document delivery rollers.

The document pick-up and separation mechanism is shown below.

Figure 2-205

Document feed roller

Document delivery roller

Friction bar

Feed roller

Copyboard cover

Document

Pick-up roller

Document stopper

Cam

Document separation roller

Loading...

Loading...