Canon GP-160, GP-160F, GP-160DF Service Manual

SERVICE

MANUAL

REVISION 0

FY8-13G2-000

FEB. 1999

COPYRIGHT © 1999 CANON INC. CANON GP160 REV.0 FEB. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

GP160F/160DF/160

IMPORTANT

THIS DOCUMENTATION IS PUBLISHED BY CANON INC., JAPAN, TO SERVE AS A SOURCE OF

REFERENCE FOR WORK IN THE FIELD.

SPECIFICATIONS AND OTHER INFORMATION CONTAINED HEREIN MAY VARY SLIGHTLY

FROM ACTUAL MACHINE VALUES OR THOSE FOUND IN ADVERTISING AND OTHER PRINTED

MATTER.

ANY QUESTIONS REGARDING INFORMATION CONTAINED HEREIN SHOULD BE DIRECTED

TO THE COPIER SERVICE DEPARTMENT OF THE SALES COMPANY.

THIS DOCUMENTATION IS INTENDED FOR ALL SALES AREAS, AND MAY CONTAIN INFORMATION NOT APPLICABLE TO CERTAIN AREAS.

COPYRIGHT © 1999 CANON INC.

Printed in Japan

Imprimé au Japon

Use of this manual should

be strictly supervised to

avoid disclosure of confidential information.

Prepared by

OFFICE IMAGING PRODUCTS TECHNICAL SUPPORT DEPARTMENT 3

OFFICE IMAGING PRODUCTS TECHNICAL SUPPORT DIVISION

CANON INC.

5-1, Hakusan 7-chome, Toride-shi, Ibaraki 302-8501 Japan

COPYRIGHT © 1999 CANON INC. CANON GP160 REV.0 FEB. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

COPYRIGHT © 1999 CANON INC. CANON GP160 REV.0 FEB. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

This service manual provides basic information required for perfor ming field service

to maintain the product quality and functions of the this machine. The structure of the

manual is as described below.

Each chapter consists of the following sections.

Chapter 1, “Introduction,” : Features, specifications, operation methods, copying

process.

Chapter 2, “Basic operation,”: Explanation of the machine’s basic operations

Chapter 3, “Exposure system,” : Explanation of the exposure system’s mechanical /

electrical system operating principles, timing, disassembly, assembly and adjustment

methods.

Chapter 4, “Image processing system,” : Explanation of the CCD, analogue / digital

image processing, disassembly, assembly and adjustment methods.

Chapter 5, “Laser exposure system,” : Explanation of the laser exposure system’s

mechanical / electrical system operating principles, timing, disassembly, assembly and

adjustment methods.

Chapter 6, “Image for mation system,” : Explanation of the image formation system’s

mechanical / electrical system operating principles, timing, disassembly, assembly and

adjustment methods.

Chapter 7, “Pick-up / Feed system,” : Explanation of the pick-up / feed system’s

mechanical / electrical system operating principles, timing, disassembly, assembly and

adjustment methods.

Chapter 8, “Fixing system,” : Explanation of the fixing system’s mechanical / electrical system operating principles, timing, disassembly, assembly and adjustment methods.

Chapter 9, “Outer cover / auxiliar y control system,” : Explanation of the outer cover /

auxiliary control system’s mechanical / electrical system operating principles, timing,

disassembly, assembly and adjustment methods.

Chapter 10, “Cassette feeder,” : Explanation of the cassette feeder’s mechanical /

electrical system operating principles, timing, disassembly, assembly and adjustment

methods.

Chapter 11, “Installation,” : Conditions relating to the place of installation, and the

installation procedures.

INTRODUCTION

Material Name

Main unit service manual

G3 FAX manual

ADF

Content

The main unit and cassette feeder’s; functions, mechanism,

disassembly, assembly, adjustment methods, etc.

The main unit’s G3 facsimile functions.

The functions, mechanism, disassembly, assembly, adjust-

ment method, etc. of the main unit’s ADF.

i

COPYRIGHT © 1999 CANON INC. CANON GP160 REV.0 FEB. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

Chapter 12, “Maintenance and Inspection,” : Table of periodic replacement par ts and

consumables replacement targets, periodic service list and parts to be cleaned dur ing a

customer service call.

Chapter 13, “Troubleshooting,” : Standards / adjustments, operation failure countermeasures and delivery failure countermeasures

Appendix : General timing chart, general circuit diagram, etc..

The explanations in this manual are based on the following principles.

1. Each chapter gives an over view of each function’s purpose, role and the connection

between the electrical and mechanical systems as well as the operation timing of

each part.

In the outline diagram, the signal shows the mechanical drive transmission.

When the signal is shown with a signal name, it indicates the electric signal

flow.

In the explanation of this units digital circuit, “1” is indicated when the signal’s voltage level is high, and “0” is indicated when it is low. However, the voltage value will

differ depending on the electrical circuit. Furthermore, the * in the signal v

alue

[DRMD*] shows the DRMD signal is “0”and ON.

In each chapter, [Power supply ON] indicates the power supply SW has been turned

“ON”, the front door, etc., has been shut, and power is being supplied to the copier.

2. This unit utilizes micro processors, however, due to the impossibility of checking the

micro processor’s internal operation, an explanation of the micro processor’s operation has been omitted. Further more, assuming that internal repair of the pr int circuit

board will not take place on the customer’s premises, the explanation of the circuit in

the print circuit board’s circuit is limited to an outline explanation using a block diagram. Consequently, the electrical circuit explanations consist of 2 types, from the

sensors to the main circuit board’s input section, and from the main circuit board’s

output section to the load, and block diagrams by function.

Changes of the contents made for the sake of product improvements will be notified

in Service Information (Technical Information).

Gaining a sound and thorough understanding of the copier through careful reading

of this service manual and the subsequently issued Service Information (Technical

Information) bulletins is the only way to develop the technical skill necessary to prolong

product quality and functionality and the practical ability to be able to determine the

cause of breakdowns.

ii

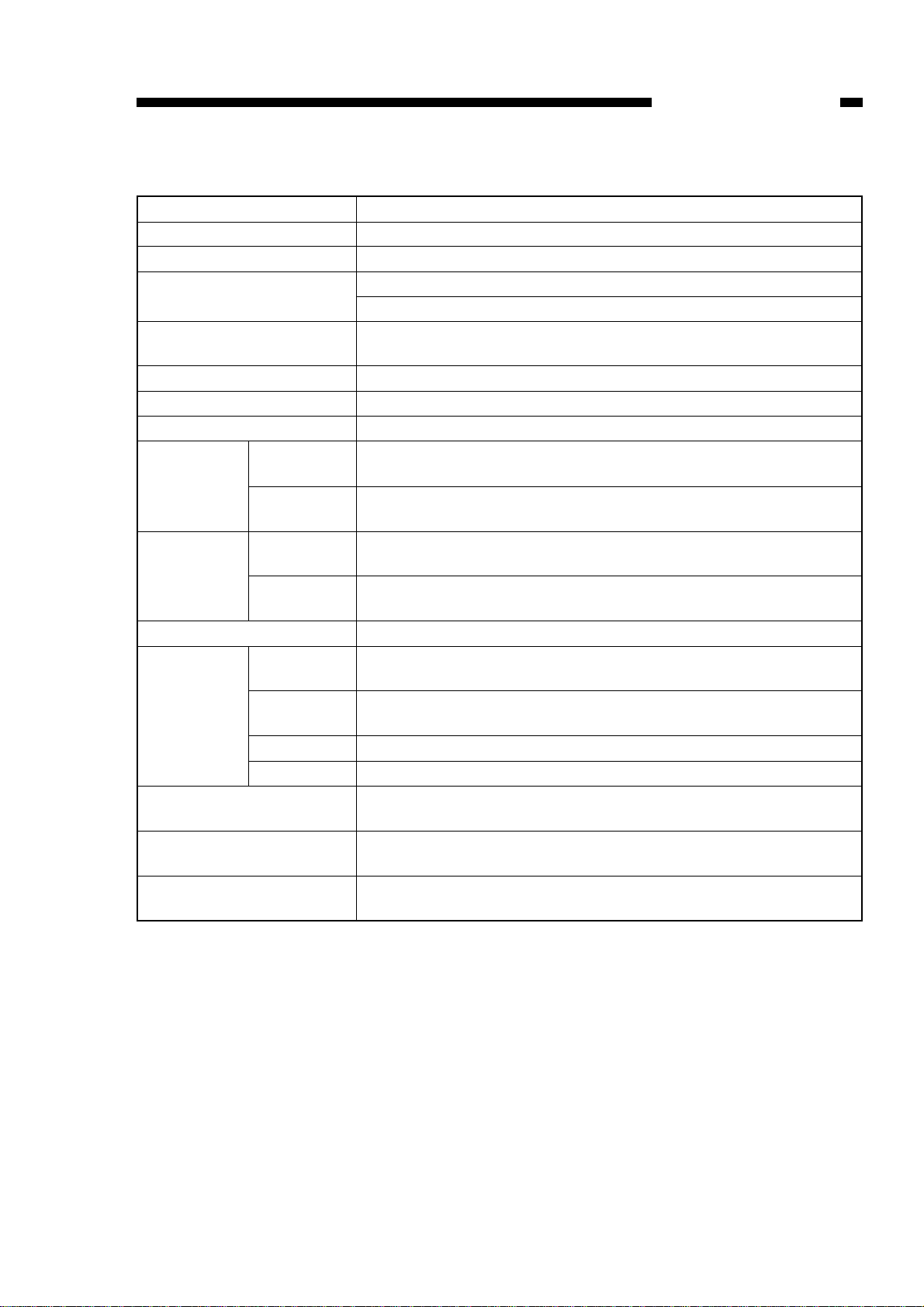

System

configuration

COPYRIGHT © 1999 CANON INC. CANON GP160 REV.0 FEB. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

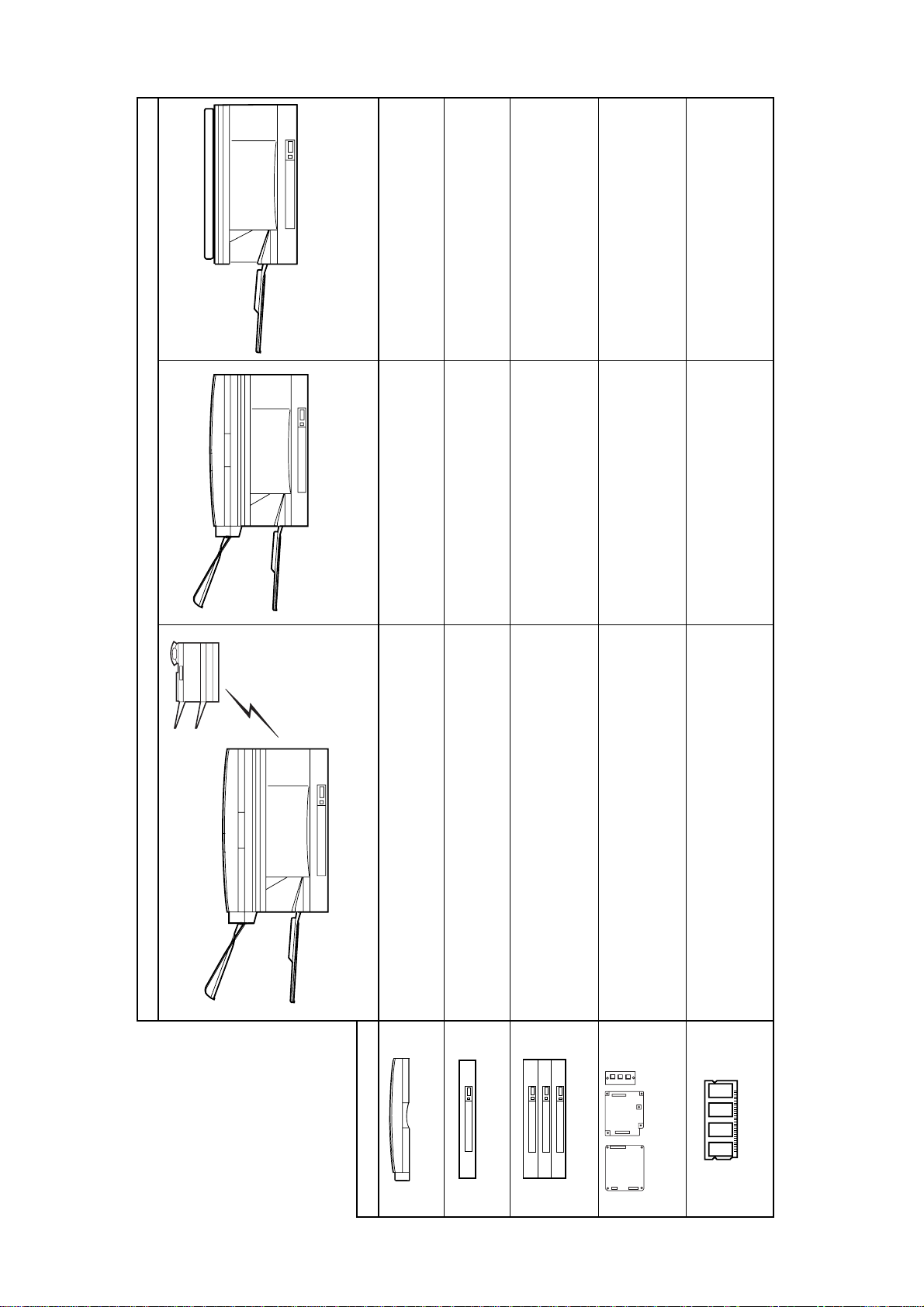

Main unit configuration

ADF-H1

Cassette Unit D1

Cassette unit E1

Modem board

NCU board

Modular

board

Super G3 FAX board

8MB expanded memory

Digital black and white copier and facsimile

Digital black and white copier (with ADF)

Digital black and white copier

(Copy board cover model)

Installation options

Standard equipment Standard equipment Option

Option Option

Option Option

Option Option

Option Option

Option

Option

Standard equipment

Option

iii

GP160F GP160DF GP160

COPYRIGHT © 1999 CANON INC. CANON GP160 REV.0 FEB. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

iv

CONTENTS

CHAPTER 1 INTRODUCTION

CHAPTER 2 BASIC OPERATION

I. FEATURES..............................................1-1

II. SPECIFICATIONS...................................1-2

III. NAMES OF PARTS .................................1-6

A. External view......................................1-6

B. Cross sectional diagram ....................1-8

IV. OPERATION EXPLANATION................1-10

A. Control panel....................................1-10

B. Basic operation ................................1-13

C. Advanced features...........................1-13

D. User mode .......................................1-14

V. ROUTINE MAINTENANCE TO BE

CARRIED OUT BY THE USER .............1-32

VI. SAFETY .................................................1-33

A. Laser beam safety.......................1-33

B. Toner safety.....................................1-36

VII. COPYING PROCESS............................1-37

A. Outline..............................................1-37

I. BASIC OPERATION................................2-1

A. Function configuration........................2-1

B. Copy operation overview ...................2-2

II. ELECTRICAL CIRCUIT OVERVIEW.......2-3

III. BASIC SEQUENCES...............................2-4

IV. MAIN MOTOR..........................................2-5

V. PRINCIPAL CIRCUIT PCB

INPUT/OUTPUT.......................................2-6

CHAPTER 3 EXPOSURE SYSTEM

CHAPTER 4 IMAGE PROCESSING SYSTEM

I. OPERATION OVERVIEW........................3-1

A. Overview............................................3-1

B. Exposure system sequence...............3-2

II. SCANNER DRIVE SYSTEM....................3-3

A. Document scanner motor...................3-3

B. Charging the magnification ratio ........3-4

C. Scanning lamp control .......................3-4

III. DISASSEMBLY, ASSEMBLY ..................3-5

A. Scanning lamp ...................................3-6

B. Document scanning motor.................3-8

I. OVERVIEW..............................................4-1

II. ANALOG IMAGE PROCESSING.............4-2

A. Overview............................................4-2

B. CCD/CCD drive circuit .......................4-2

C. A-D conversion circuit /

ABC circuit .........................................4-3

III. DIGITAL IMAGE PROCESSING..............4-4

A. Overview............................................4-4

B. Shading correction.............................4-5

C. Magnification ratio process ................4-7

D. Edge emphasis / smoothing

process ..............................................4-7

E. Logarithmic correction........................4-8

F. Half tone density processing..............4-9

G. Binarisation........................................4-9

IV. DISASSEMBLY, ASSEMBLY ................4-10

A. CCD unit ..........................................4-11

COPYRIGHT © 1999 CANON INC. CANON GP160 REV.0 FEB. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

v

COPYRIGHT © 1999 CANON INC. CANON GP160 REV.0 FEB. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

CHAPTER 5 LASER EXPOSURE SYSTEM

I. OVERVIEW..............................................5-1

II. BD SIGNAL GENERATION.....................5-3

A. Overview............................................5-3

B. BD generation / detection ..................5-3

III. LASER DRIVER CIRCUIT.......................5-4

A. Operation ...........................................5-4

B. Laser light intensity control ................5-4

IV. LASER SCANNER MOTOR

CONTROL................................................5-6

A. Operation outline................................5-6

V. DISASSEMBLY, ASSEMBLY ..................5-7

A. Laser scanner unit .............................5-8

CHAPTER 6 IMAGE FORMATION SYSTEM

CHAPTER 7 PICK-UP / FEEDING SYSTEM

CHAPTER 8 FIXING SYSTEM

I. OVERVIEW..............................................6-1

A. Construction.......................................6-1

II. PRIMARY CHARGING ROLLER BIAS

CONTROL................................................6-3

A. Outline ...............................................6-3

B. Control operation ...............................6-3

III. TRANSFER CHARGING ROLLER BIAS

CONTROL................................................6-4

A. Overview............................................6-4

B. Bias control ........................................6-5

IV. SEPARATION STATIC CHARGE

ELIMINATOR BIAS CONTROL ...............6-6

A. Operation ...........................................6-6

V. DEVELOPING BIAS CONTROL..............6-7

A. Outline ...............................................6-7

B. Operation ...........................................6-7

VI. RE-CHARGE BIAS CONTROL................6-8

A. Operation ...........................................6-8

VII. CARTRIDGE DETECTION ......................6-9

A. Operation ...........................................6-9

I. OVERVIEW..............................................7-1

A. Construction Overveiw.......................7-1

II. PICK-UP FEEDING OPERATION ...........7-2

A. Overveiw............................................7-2

III. CASSETTE PICK-UP MECHANISM........7-3

A. Pick-up oparation...............................7-3

B. Retry pick-up......................................7-5

C. Paper size detection ..........................7-6

IV. MULTI-FEEDER PICK-UP.......................7-7

A. Overview............................................7-7

B. Multi-feeder pick-up mechanism........7-8

C. Multi-feeder retry pick-up ...................7-9

D. Multi-feeder paper size setting.........7-10

V. PAPER FEEDING OPERATION............7-12

A. Paper leading edge detection ..........7-12

B. Paper width detection ......................7-12

VI. JAM DETECTION ..................................7-13

A. Overview..........................................7-13

B. Types of Jam ...................................7-14

C. Jam sequence..................................7-14

VII. DISASSEMBLY, ASSEMBLY ................7-23

A. Cassette feeding assembly..............7-24

B. Multi-feeder assembly......................7-30

C. Registration roller assembly.............7-33

D. Feeder assembly .............................7-35

I. OPERATIONAL OVERVIEW...................8-1

A. Overview............................................8-1

B. Fixing pressure roller cleaning...........8-1

II. FIXING CONTROL...................................8-3

A. Fixing temperature control .................8-3

B. Fixing heater safety mechanism ........8-5

C. Fixing assembly malfunction

detector..............................................8-5

III. DISASSEMBLY, ASSEMBLY ..................8-6

A. Removing the fixing assembly ...........8-7

vi

COPYRIGHT © 1999 CANON INC. CANON GP160 REV.0 FEB. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

CHAPTER 9 EXTERNAL / AUXILIARY MECHANISM

CHAPTER 10 CASSETTE FEEDER

CHAPTER 11 INSTALLATION

CHAPTER 12 MAINTENANCE AND INSPECTION

I. CONTROL PANEL...................................9-1

A. Overview............................................9-1

II. POWER SUPPLY ....................................9-2

A. Low-voltage power supply circuit.......9-2

B. High voltage power supply circuit ......9-4

C. Energy save function control..............9-5

III. FAN..........................................................9-7

A. Rotation control mechanism ..............9-7

IV. BACK-UP BATTERY................................9-8

A. Back-up function ................................9-8

B. Back-up Data ...................................9-12

V. DISASSEMBLY, ASSEMBLY ................9-16

A. Control panel....................................9-17

B. Main Motor.......................................9-19

C. DC controller PCB............................9-25

D. Image processor PCB......................9-26

E. DC power supply PCB .....................9-27

I. OVERVIEW............................................10-1

II. OVERVIEW OF THE ELECTRICAL

CIRCUITS..............................................10-3

A. Overview..........................................10-3

III. FEEDER CONTROLLER PCB

INPUT AND OUTPUT.............................10-4

IV. OPERATION OVERVIEW......................10-5

A. Overview..........................................10-5

B. Basic Sequence ..............................10-6

V. FEEDER MOTOR CONTROL................10-7

A. Operation .........................................10-7

VI. JAM DETECTION ..................................10-8

A. Overview..........................................10-8

B. Jam Sensing ....................................10-9

VII. DISASSEMBLY, ASSEMBLY ..............10-11

A. Removing the feeder motor ...........10-12

B. Removing the pick-up/feeder/

separation motor............................10-12

C. Removing the pick-up unit .............10-14

I. CHOOSING AN SUITABLE INSTALLATION

LOCATION.............................................11-1

II. UNPACKING AND INSTALLATION.......11-3

A. Opening the package and removing

the packing materials.......................11-4

B. Installing the cartridge......................11-5

C. Loading paper into the cassette.......11-8

D. Loading paper into the

multi-feeder....................................11-11

E. Attaching the tray/Power cord........11-12

F. Checking the Copy image..............11-13

G. Setting the Fax machine function....11-13

I. PERIODIC REPLACEMENT PARTS.....12-1

II. ESTIMATED LIFESPAN OF CONSUMABLE

PARTS ...................................................12-1

III. BASIC SERVICING PROCEDURES.....12-2

IV. CARTRIDGE STORAGE AND

HANDLING.............................................12-3

A. Storage when the packing seal is

intact ................................................12-3

B. Storage and handling when the

packing seal has been opened ........12-4

vii

COPYRIGHT © 1999 CANON INC. CANON GP160 REV.0 FEB. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

APPENDIX

CHAPTER 13 TROUBLESHOOTING

I. STANDARDS AND ADJUSTMENTS.....13-2

A. Machanical system ..........................13-2

B. Electrical System .............................13-9

II. IMAGE AND MACHINE MALFUNCTION

COUNTERMEASURES.......................13-15

A. Initial check ....................................13-15

B. Treatment procedures by faulty

image type .....................................13-17

C. Operation malfunction

countermeasures ...........................13-26

III. FAULTY FEEDING

COUNTERMEASURES.......................13-34

A. Overview........................................13-34

B. Copy paper jam..............................13-35

C. Faulty feeding ................................13-38

IV. ELECTRICAL PARTS POSITIONS/

FUNCTIONS........................................13-39

A. Clutches, solenoids........................13-40

B. Motor, fan.......................................13-42

C. Sensors..........................................13-44

D. Switches, lamps, miscellaneous ....13-46

E. PCBs..............................................13-48

F. Variable resistor(VR)/LED/check

pin listed by PCB plate...................13-50

V. SERVICE MODE..................................13-55

A. Overview........................................13-55

B. Operating Procedures....................13-56

C. Service mode menu list..................13-57

D. SSSW Default Setting....................13-63

E. Parameter settings.........................13-78

F. Test Mode (TEST MODE)............13-111

VI. REPORTS..........................................13-142

A. User reports .................................13-142

B. Service report...............................13-145

VII. USER ERRORS.................................13-163

VIII. SERVICE ERRORS...........................13-170

A. GENERAL TIMING CHART.....................A-1

B. SIGNALS AND ABBREVIATIONS...........A-3

C. GENERAL CIRCUIT DIAGRAM..............A-5

D. LIST OF SPECIAL TOOLS....................A-11

E. SOLVENTS AND OILS..........................A-12

viii

COPYRIGHT © 1999 CANON INC. CANON GP160 REV.0 FEB. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

CHAPTER 1

INTRODUCTION

I. FEATURES..............................................1-1

II. SPECIFICATIONS...................................1-2

III. NAMES OF PARTS .................................1-6

A. External view......................................1-6

B. Cross sectional diagram ....................1-8

IV. OPERATION EXPLANATION................1-10

A. Control panel....................................1-10

B. Basic operation ................................1-13

C. Advanced features...........................1-13

D. User mode .......................................1-14

V. ROUTINE MAINTENANCE TO BE

CARRIED OUT BY THE USER .............1-32

VI. SAFETY .................................................1-33

A. Laser beam safety.......................1-33

B. Toner safety.....................................1-36

VII. COPYING PROCESS............................1-37

A. Outline..............................................1-37

This chapter provides an overview of the unit’s specifications, operating method and

copying process.

COPYRIGHT © 1999 CANON INC. CANON GP160 REV.0 FEB. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

CHAPTER 1 INTRODUCTION

1-1

I. FEATURES

< Copy function >

• 1200 equivalent × 600dpi high resolution copy

• Due to a new engine, high image quality printing with minute particle super fine

toner (diameter 5 microns) has been made possible.

• Due to the integrated drum, toner cassette, the print inner assembly is refreshed

when the cartridge is replace.

• 256 gradation readings, and realistic half tone rendering.

• Max. 5 way / max. 1100 sheets large volume multi-level pick-up.

• Dual operation - allows copying during fax transmission.

< Fax function >

• High speed Super G3 Fax 2 second transmission (33.6kbps) provided as standard

for ordinary telephone lines.

• Able to send and receive A3 size direct copy.

• 400dpi scanning resolution ultra high image quality (ultra fine mode).

• 600dpi recording resolution ultra high image quality, standard mode 600dpi printing.

• Standard 1megabyte memory (roughly 64 sheets), possibility to expand to maximum 9 megabytes (roughly 576 sheets).

COPYRIGHT © 1999 CANON INC. CANON GP160 REV.0 FEB. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

CHAPTER 1 INTRODUCTION

1-2

II. SPECIFICATIONS

1. Type

2. Method

Item

Main unit

Copyboard

Light source

Lens

Photosensitive medium

Specifications

Desk top

Fixed

Xenon lamp

Fixed focal lens

OPC (φ 30)

Item

Copying

Charging

Exposure

Copy density adjustment

Developing

Pick-up Automatic

Manual

Transfer

Separation

Cleaning

Fixing

Specifications

Indirect electrostatic copying method

AC roller charging method

Semiconductor laser

Automatic or manual

Dry single component jumping method (single unit drum cartridge)

Cassette

Multi-feeder

Roller charging method

Electrostatic separation (static charge elimination) + curvature

separation

Rubber blade

SURF Fixing

COPYRIGHT © 1999 CANON INC. CANON GP160 REV.0 FEB. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

CHAPTER 1 INTRODUCTION

1-3

3. Functions

*1: 50 or less sheets of tracing paper (GNT-80) by cassette.

*2: 50 or less sheets of OHP sheets by cassette (designated paper).

*3: 1 or less sheets of tracing paper (GNT-80) by multi-feeder.

*4: Differs depending on the main unit configuration.

Item

Types of document

Max. document size

Wait time

First copy time

Continuous copying

Pick-up capacity

Delivery tray capacity

Copy size Cassette

pick-up

Multi-feeder

pick-up

Types of Cassette

copy paper pick-up

Multi-feeder

pick-up

Cassette specifications

Non image Leading

width edge

Trailing

edge

Front

Rear

Auto clear

Energy saver

Option *4

Specifications

Sheet, book, three dimensional objects (up to max. 2kg)

A3 / 11 × 17

15 seconds or less from power ON (20°C)

7 seconds or less from the energy saver mode being cancelled

12 seconds or less (main unit cassette pick-up, 1-to-1 copy, A4,

no AE)

1 to 99 sheets

Each cassette 250 sheets *1, multi-feeder 100 sheets (80g/m

2

)

100 sheets *2

Max. : A3 / 11 × 17

Min. : A5

Max. : A3

Min. : A5

Plain paper 64 to 90g/m

2

, recycled paper 64 to 90g/m2, tracing

paper (GNT-80) *1

Plain paper 64 to 128g/m

2

, tracing paper (SM-1) labels, recycled

paper 64 to 128g/m

2

, OHP *2, tracing paper (GNT-80)*3

With tab, universal

4.0 ± 2.0mm

2.5 ± 2.0mm

2.5 ± 2.0mm

2.5 ± 2.0mm

Yes (Standard 2 min., possible to change in units of 1 min.

between 0 to 9 min)

Yes (Standard 3 min., possible to change in units of 1 min.

between 3 to 30 min)

Cassette feeder (1 step type / 3 step type), 8MB expanded

memory, ADF, FAX board

COPYRIGHT © 1999 CANON INC. CANON GP160 REV.0 FEB. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

CHAPTER 1 INTRODUCTION

1-4

4. Other

Item

Operating Temperature range

environment Humidity range

Atmospheric pressure

range

Power

supply

Cassette Feeding Module-D1

Cassette Feeding Module-E1

Power Maximum

consumption Standby

Energy saving mode

Operating When in operation

noise Standby

Dimensions Width

Depth

Height

Mass

Storage of Copy paper

consumable

items Cartridge

Specifications

5 to 35°C

10 to 90% RH

709 to 1013hpa

Supplied by main unit :ZCRxxxxx

Supplied by main unit :ZHRxxxxx

Approx.800W

Approx.20W

Approx.14W

66dB or less

40dB or less

616 (mm) / 24.25”

640 (mm) / 25.20”

427 (mm) / 16.81” (Including ADF)

48.8kg 107.59 Ò

Store with the package closed and avoid

humidity

Refer to page 12-3

Main unit

GP160 GP160DF

• 230V(ITA): PNSxxxxx • 230V(ITA): PHLxxxxx

• 230V(UK): QCTxxxxx • 230V(UK): QCLxxxxx

• 230V(FRN): SBTxxxxx • 230V(FRN): SBRxxxxx

• 230V(GER): TBTxxxxx • 230V(GER): TBQxxxxx

• 230V(AMS): UEHxxxxx • 230V(AMS): UEFxxxxx

• 230V(CA): RCXxxxxx

• 230V(Others):PHXxxxxx

GP160F

• 230V(ITA): PHTxxxxx

• 230V(UK): QCMxxxxx

• 230V(FRN): SBSxxxxx

• 230V(GER): TBRxxxxx

• 230V(AMS): UEGxxxxx

• 230V(CA): RCWxxxxx

• 230V(Others):PHMxxxxx

COPYRIGHT © 1999 CANON INC. CANON GP160 REV.0 FEB. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

CHAPTER 1 INTRODUCTION

1-5

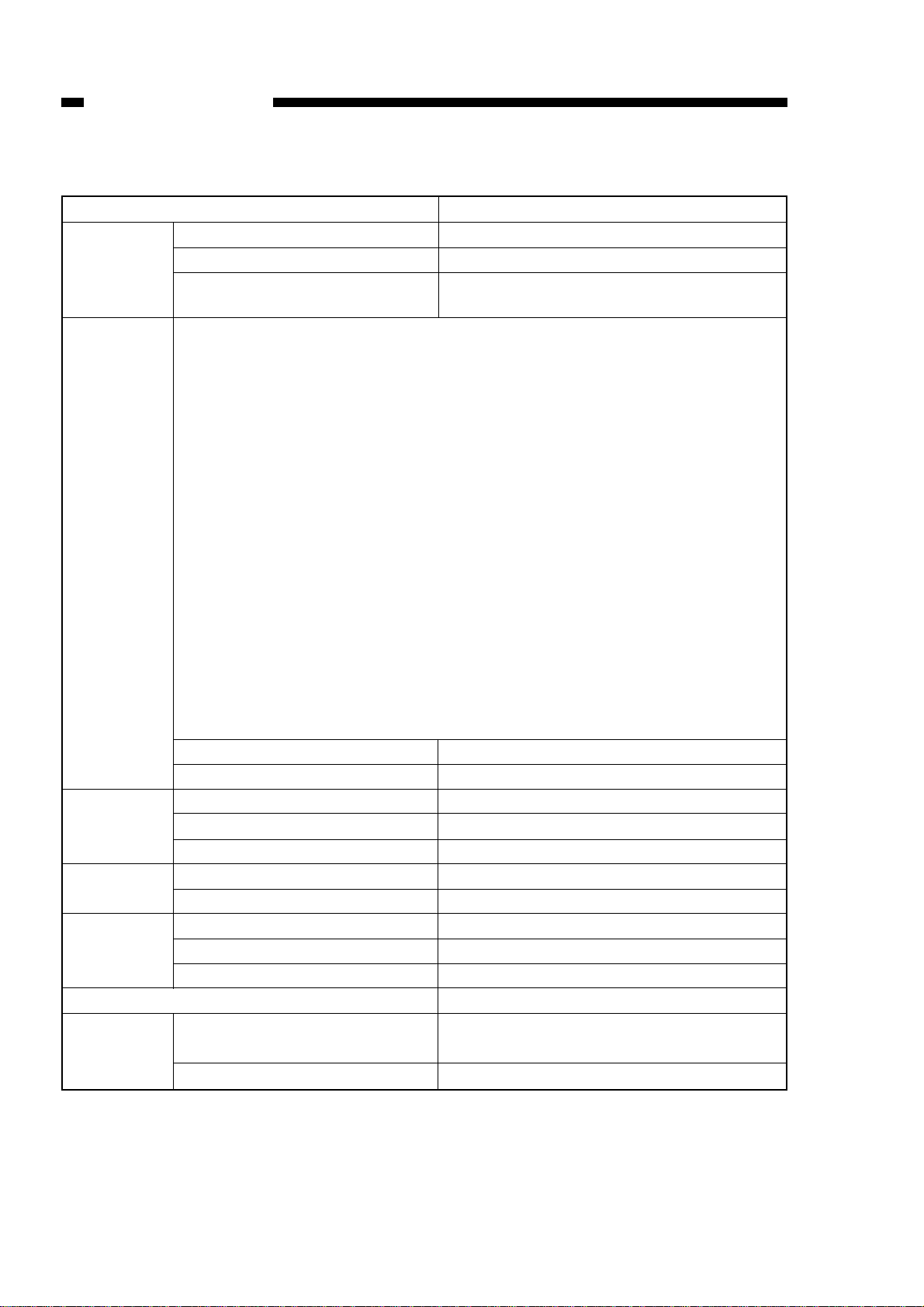

5. Copy speed

Reproduction mode

Direct copy

Size

A4 (210 × 297mm)

A3 (297 × 420mm)

B4 (257 × 364mm)

A4R (297 × 210mm)

B5 (182 × 257mm)

B5R (257 × 182mm)

A4 (148.5 × 210mm)

LTR (216 × 279mm)

LTRR (279 × 216mm)

LGL (216 × 356mm)

11 × 17 (279 × 432mm)

Copy paper size

A4

A3

B4

A4R

B5

B5R

A5

LTR

LTRR

LGL

11 × 17

No.of copies / minute

16

9

10

9

16

12

12

16

9

9

9

Specifications are subject to change for the sake of product improvements.

COPYRIGHT © 1999 CANON INC. CANON GP160 REV.0 FEB. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

CHAPTER 1 INTRODUCTION

1-6

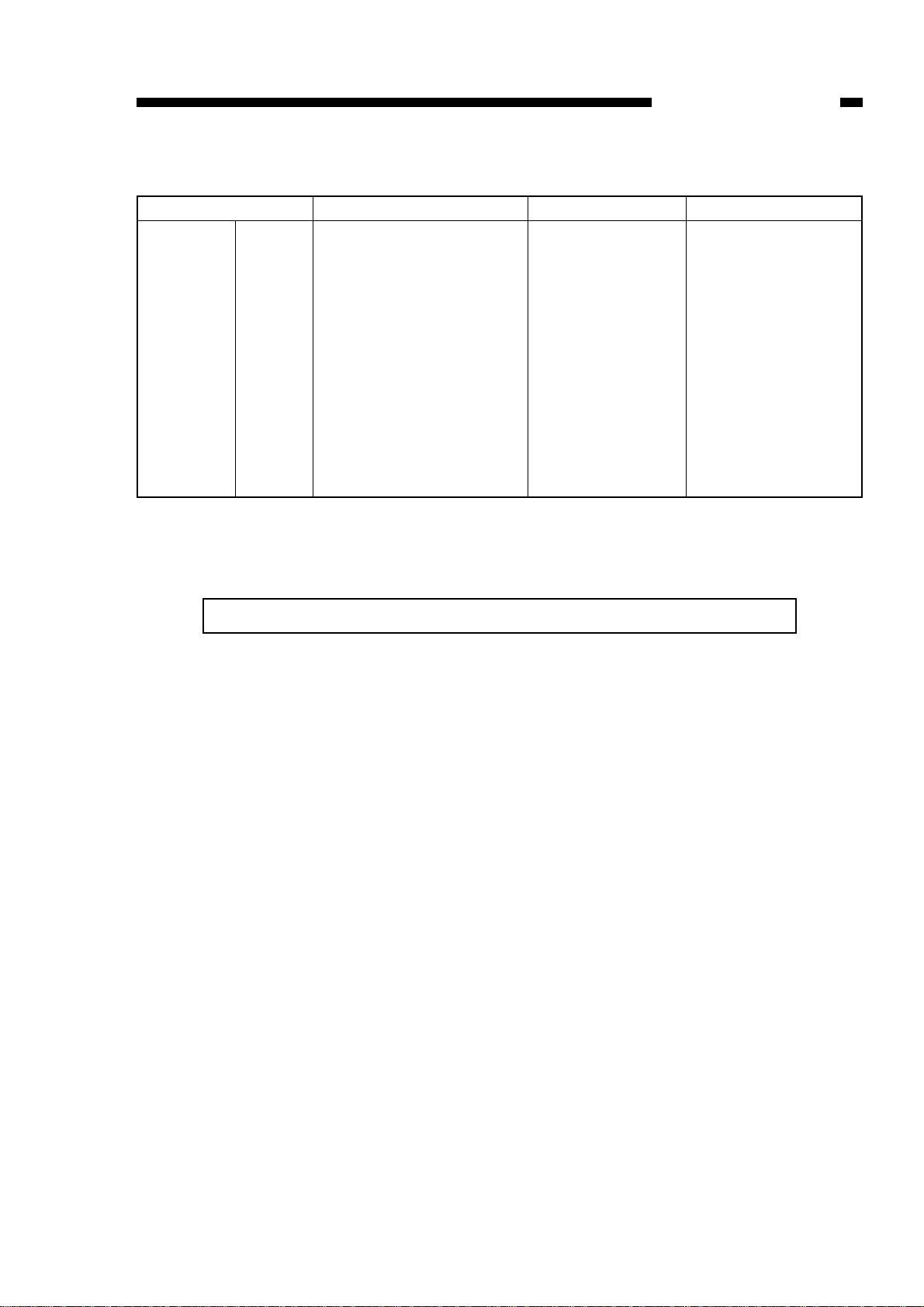

III.NAMES OF PARTS

A. External view

Main unit

ADF standard equipment model

Figure 1-301 Figure 1-302

Copyboard cover model

Figure 1-303 Figure 1-304

Cassette feeder (accessory)

Figure 1-305

[2]

[3]

[4]

[1]

[5]

[2]

[4]

[1]

[5]

[7]

[7]

[8]

[8]

[9]

[9]

[10]

[6]

[10]

[6]

[4]

[3]

[1]

[2]

COPYRIGHT © 1999 CANON INC. CANON GP160 REV.0 FEB. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

CHAPTER 1 INTRODUCTION

1-7

Main unit

Cassette feeder (accessory)

[1] Cassette feeder

[2] Cassette

[3] Right door

[4] Feeder lifting handle

[1] Control panel

[2] ADF

[3] Document delivery tray

[4] Delivery tray

[5] Cassette

[6] Right lower cover

[7] Front cover

[8] Printer unit release handle

[9] Printer unit

[10] Multi feeder tray

COPYRIGHT © 1999 CANON INC. CANON GP160 REV.0 FEB. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

CHAPTER 1 INTRODUCTION

1-8

B. Cross sectional diagram

Figure 1-306

[1]

[2]

[3]

[4]

[5]

[6]

[7]

[8]

[9]

[11]

[10]

[12]

[13]

[14]

[15]

[16]

[17]

[18]

[19]

[20]

[21]

[22]

[38]

[37]

[36]

[35]

[31]

[33]

[34]

[32]

[30]

[29]

[28]

[27]

[26]

[25]

[23]

[24]

COPYRIGHT © 1999 CANON INC. CANON GP160 REV.0 FEB. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

CHAPTER 1 INTRODUCTION

1-9

[1] Mirror 3

[2] Mirror 2

[3] White reference assembly

[4] Mirror 1

[5] Document scanning lamp

[6] Copyboard glass

[7] Fixing delivery roller

[8] Cleaning roller

[9] Fixing film

[10] CCD

[11] Lens

[12] Charge eliminator

[13] Laser scanner unit

[14] Photosensitive drum

[15] Primary charging roller

[16] Mirror 4

[17] Developing cylinder

[18] Cartridge

[19] Registration pressure roller

[20] Registration roller

[21] Multi-feeder pick-up roller

[22] Multi-feeder tray

[23] Vertical path roller (Main unit pick-up

assembly)

[24] Vertical path roller (Cassette feeder)

[25] Separation roller (Main unit pick-up

assembly)

[26] Separation roller (Cassette feeder)

[27] Feed roller (Cassette feeder)

[28] Feed roller (Main unit pick-up

assembly)

[29] Pick-up roller (Cassette feeder)

[30] Pick-up roller (Main unit pick-up

assembly)

[31] Transfer charging roller

[32] Separation static charge elimination

[33] Paper sensor lever (Cassette feeder)

[34] Paper sensor lever (Main unit pick-

up assembly)

[35] Feed assembly

[36] Fixed pressure roller

[37] Paper cassette (Main unit)

[38] Paper cassette (Cassette feeder)

COPYRIGHT © 1999 CANON INC. CANON GP160 REV.0 FEB. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

CHAPTER 1 INTRODUCTION

1-10

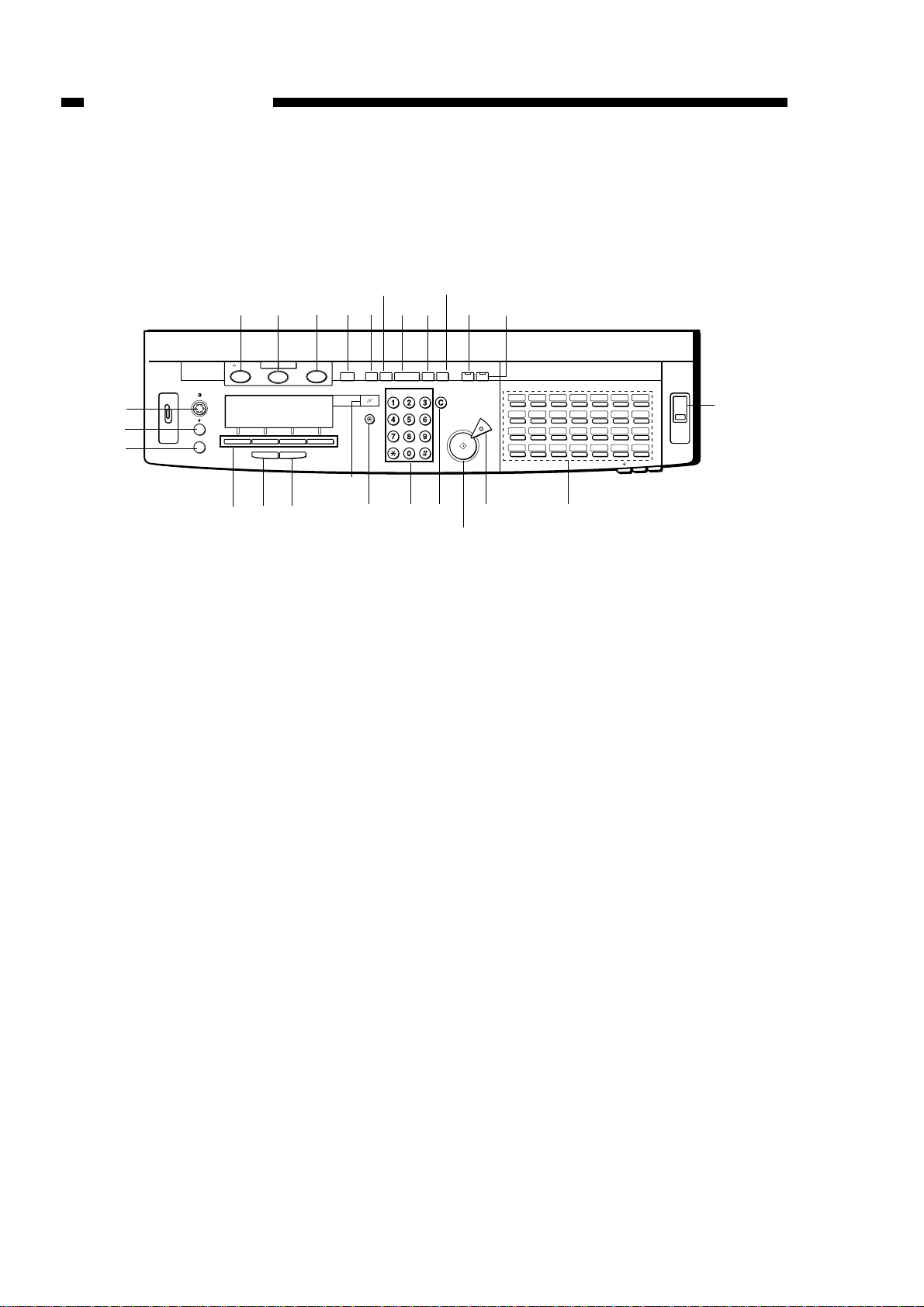

IV.OPERATION EXPLANATION

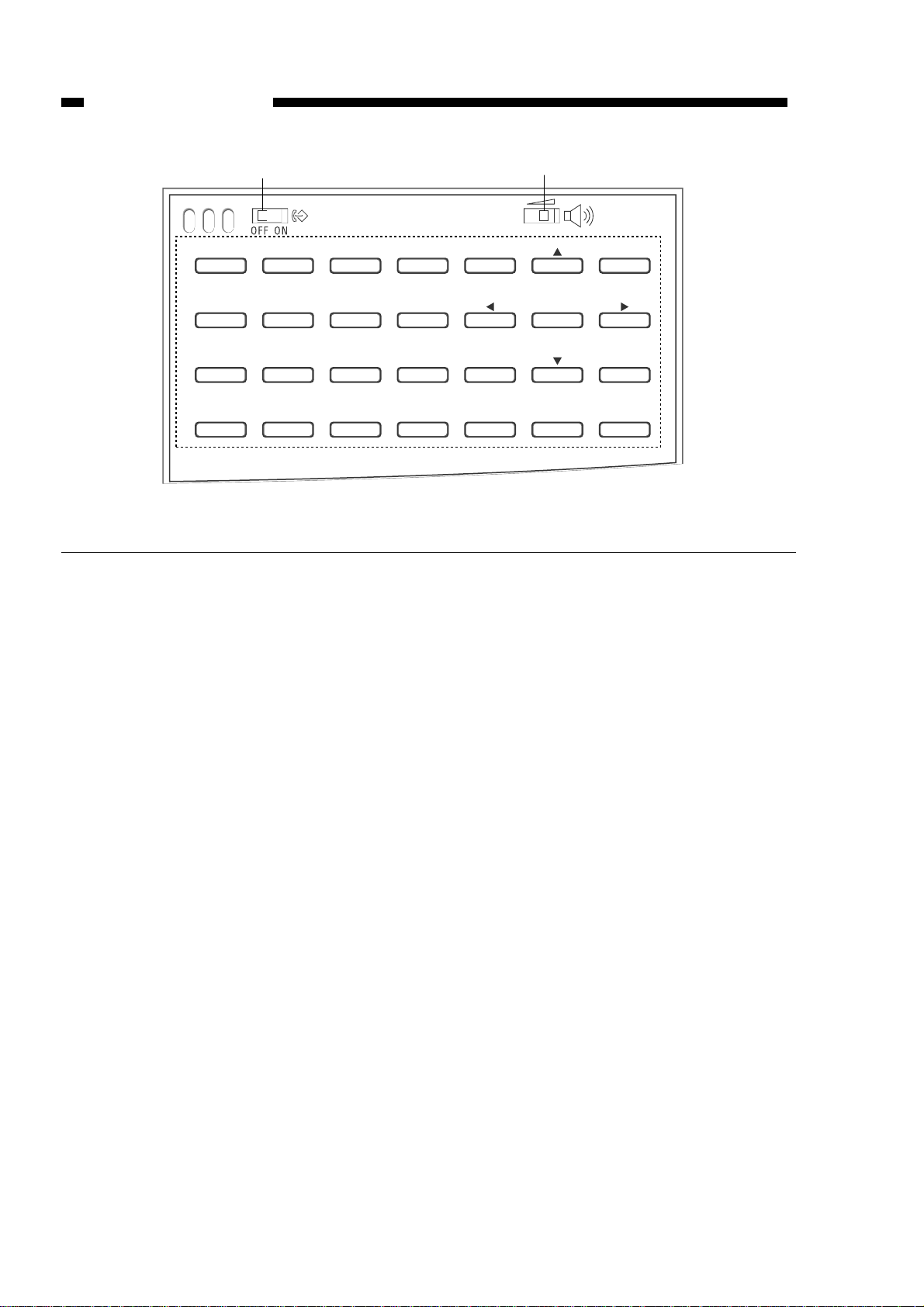

A. Control panel

Figure 1-401

[1]

[2]

[3]

Copy Special Features

[7]

[4]

In Use/Memory

[5]

Return Set

[8]

[6][10][11]

Error

[9]

[12]

[13][14]

Coded

Fax Monitor

Program

Dial

Reset

GHI

Data Registration

PRS

Tone

[18]

[20]

[19]

Hook

ABC

JKL MNO

TUV WXY

OPER SYMBOLS

DEF

[21]

[15]

RedialR Stamp

Clear

[16]

Start

[22]

Direct

Stop

[23]

TX

[17]

1

8

16

15

23

22

2 3 4 5 6 7

9

10

11

13

12

17

18

20

19

24

25

27

26

[25]

Energy Saver

14

21

28

29 ~ 56

57 ~ 84

[24]

COPYRIGHT © 1999 CANON INC. CANON GP160 REV.0 FEB. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

CHAPTER 1 INTRODUCTION

1-11

No. Key name Function outline

[1] Display contrast VR Adjusts the control panel contrast.

[2] Collate key Performs sort copying when copying with the ADF.

[3] Copy special features Performs frame erasing, margin, transferring and 2 in 1

copying.

[4] COPY Changes over to the copy mode.

[5] FAX* Changes over to the fax mode.

[6] PRINT/SCAN* Changes over to the printer mode.

[7] Display selection Selects functions shown in the display.

[8] Return Returns to the previous display.

[9] Set Confirms the registration/setting.

[10] Fax Monitor* Confirms the transmission conditions, clears transmission

reservations.

[11] Program* Registers a single operation that can be selected by simply

pushing this key.

[12] Coded Dial* Uses speed dial.

[13] Hook* Ability to listen to the other party’s response through the

speaker.

[14] R* Press to dial an outside telephone number, or an extension

number, when the fax is connected through a swichboard

(PBX).

[15] Redial* Redials the last number dialed.

[16] Stamp* Stamps a completed transmission.

[17] Direct TX* Executes direct transmission.

[18] Reset Resets the copy mode.

[19] Data registration Calls up the user mode setting display.

[20] Numeric key Dials the telephone number, sets the number of copies, etc..

[21] Clear Clears the registration/setting.

[22] Start Starts transmission / copying.

[23] Stop Stops transmission / copying.

[24] Energy saver Clears the energy saver mode.

[25] One touch panel* One touch dial key.

*: Not available on copiers not equipped with the fax function

**: Not available on copiers not equipped with the printer function

COPYRIGHT © 1999 CANON INC. CANON GP160 REV.0 FEB. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

CHAPTER 1 INTRODUCTION

1-12

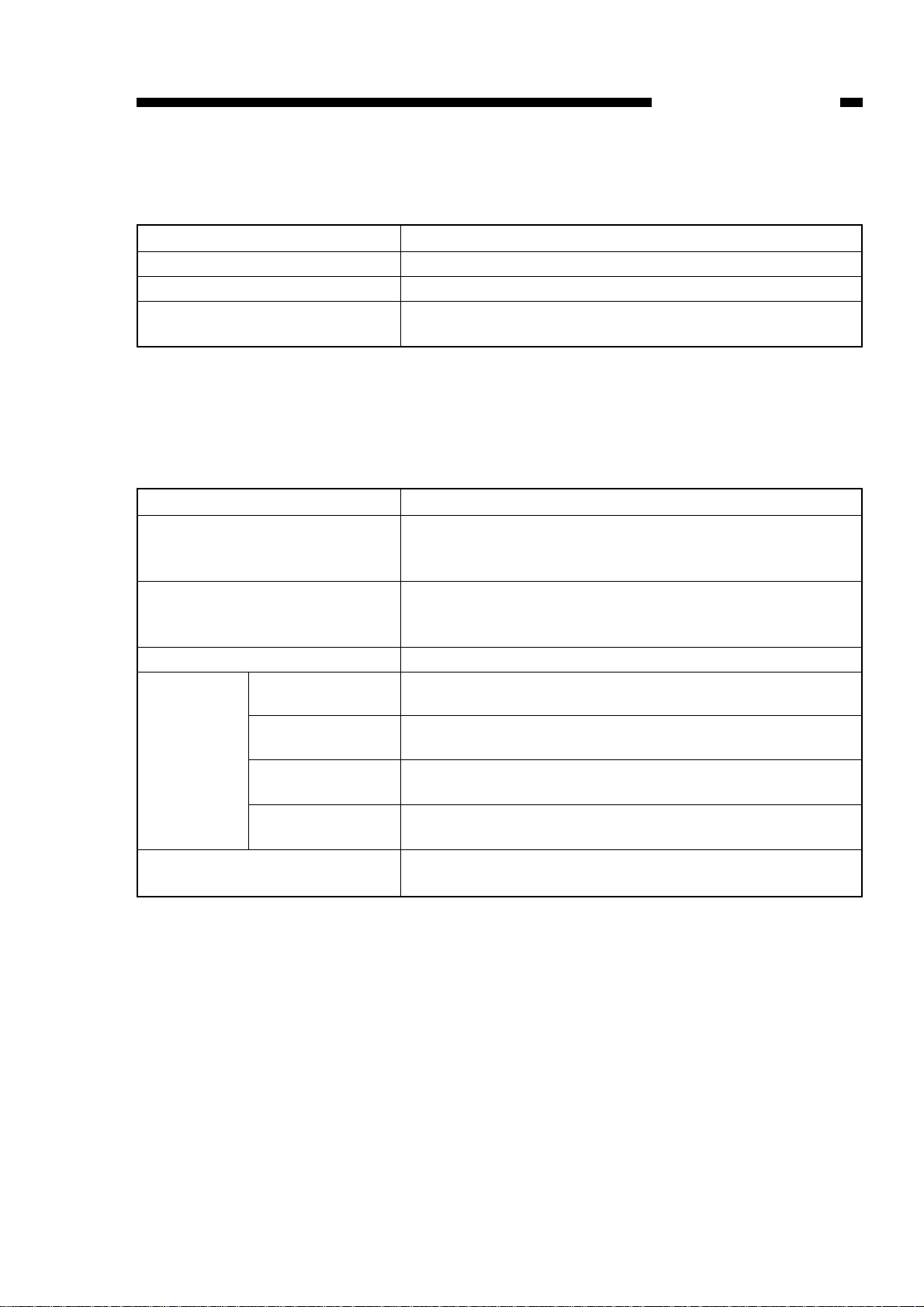

Figure 1-402

Key name Function outline

Delayed Transmission* Designates the sending time of the transmission.

Polling* Designates polling transmission.

Confidential Mailbox* Designates confidential transmission.

Relay Broadcast* Designates relay origination transmission.

Delete* Deletes the input characters.

Pause Inserts a pause in the telephone number.

Memory Box* Prints documents when the y hav e been stored in the Memory box,

or when a document has been reception by the memory box.

Memory Reception* Receives in memory and designates the printing of reception

documents.

Transfer* Designates the transfer of reception documents to other faxes.

Memory Reference* Designates the confirmation or deletion of memory contents.

Report* Designates the output of each kind of report and list.

Clear Designates the deletion of registration/setting.

Set Designates the confirmation of registered/set contents.

TTI Selector* Used when changing the senders name.

Subaddress* Used when performing a subaddress transmission.

Password* Used when transmitting with a fax standard password.

Receive mode* Designates switching to receive mode.

Tone/+ Connects to information services that accept tone dialing only,

even if you are using a rotar y pulse line or enters a plus sign

in a fax number. And enters a plus sign when registering your

fax number.

DT Press to confirm the dial tone when registering a telephone

number.

Space* Creates a space between rows of numbers or characters.

Shift key Use to selecting items on the control panel.

*: Not available on copiers not equipped with the fax function

Slide seitch (Normally off for user speration)

Delayed Transmission

Memory Box

Memory

Reference

TTI Selector

Confidential

Polling

Memory

Reception

Report Clear Set

Subaddress Password

Mailbox

Transfer Space

Relay

Broadcast

Receive

Mode

Spealer volume switch

Pause

Tone/+

D.T.

Delate

COPYRIGHT © 1999 CANON INC. CANON GP160 REV.0 FEB. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

CHAPTER 1 INTRODUCTION

1-13

B. Basic operation

The basic operations of the copy keys on the operation panel are listed below.

Table 1-401

C. Advanced features

The basic operations of the advanced copy feature keys on the operation panel are

listed below.

Table 1-402

Key name

Reproduction ratio key

Paper selection key

Scanning mode key

Details

Selects fixed ratio change (2R2E) or zoom (50 to 200%).

Selects the pick-up cassette.

Selects the scanning density (automatic, F1 to F9) and the

image quality (character, character/photo, photo).

Key name

Page separation

Binding margin

Frame erasing

Document frame

erasing

Sheet frame

erasing

Book frame

erasing

Punch hole

erasing

2 in 1 copy

Details

Performs left/right page separation copy in the book mode.

Sets the left and right margins and designates the 2-page

spread copy size.

Creates a binding margin on the paper.Sets the margin

position (left margin, right margin, top margin, bottom margin) and also the margin width (1 to 10mm).

Sets the frame erasing position.

Copies with document frame erasing.

Creates a margin around the outside of the document and

copies.

When copying books, etc., the surrounding and center

margins are deleted.

Erases punch holes from the left margin of copied documents.

Inputs the document size and paper size and designates 2

in 1 copying.

COPYRIGHT © 1999 CANON INC. CANON GP160 REV.0 FEB. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

CHAPTER 1 INTRODUCTION

1-14

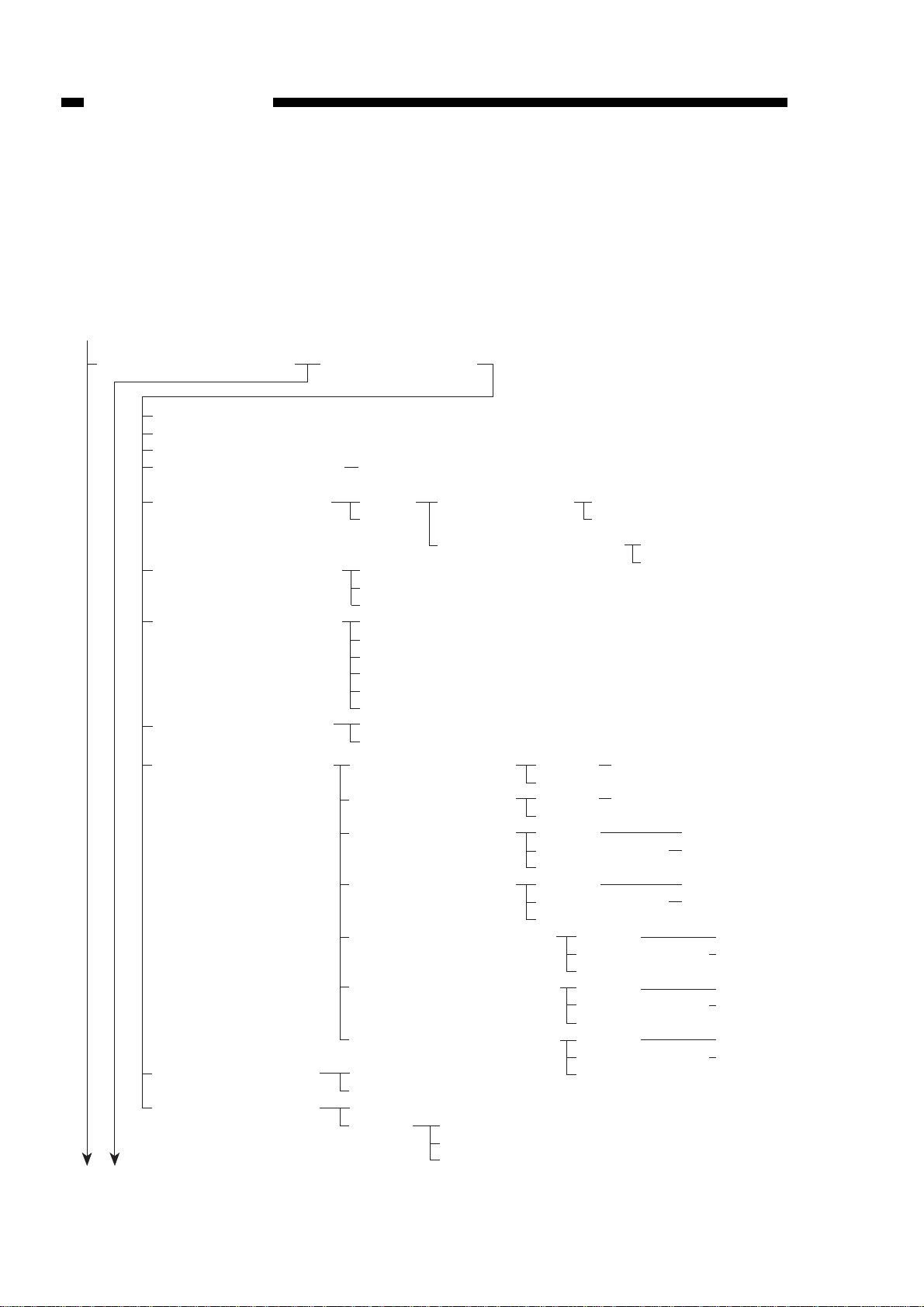

D. User mode

When the registration/setting key is pressed on the control panel, the user mode set-

ting screen is displayed.

The construction of the user mode is shown below.

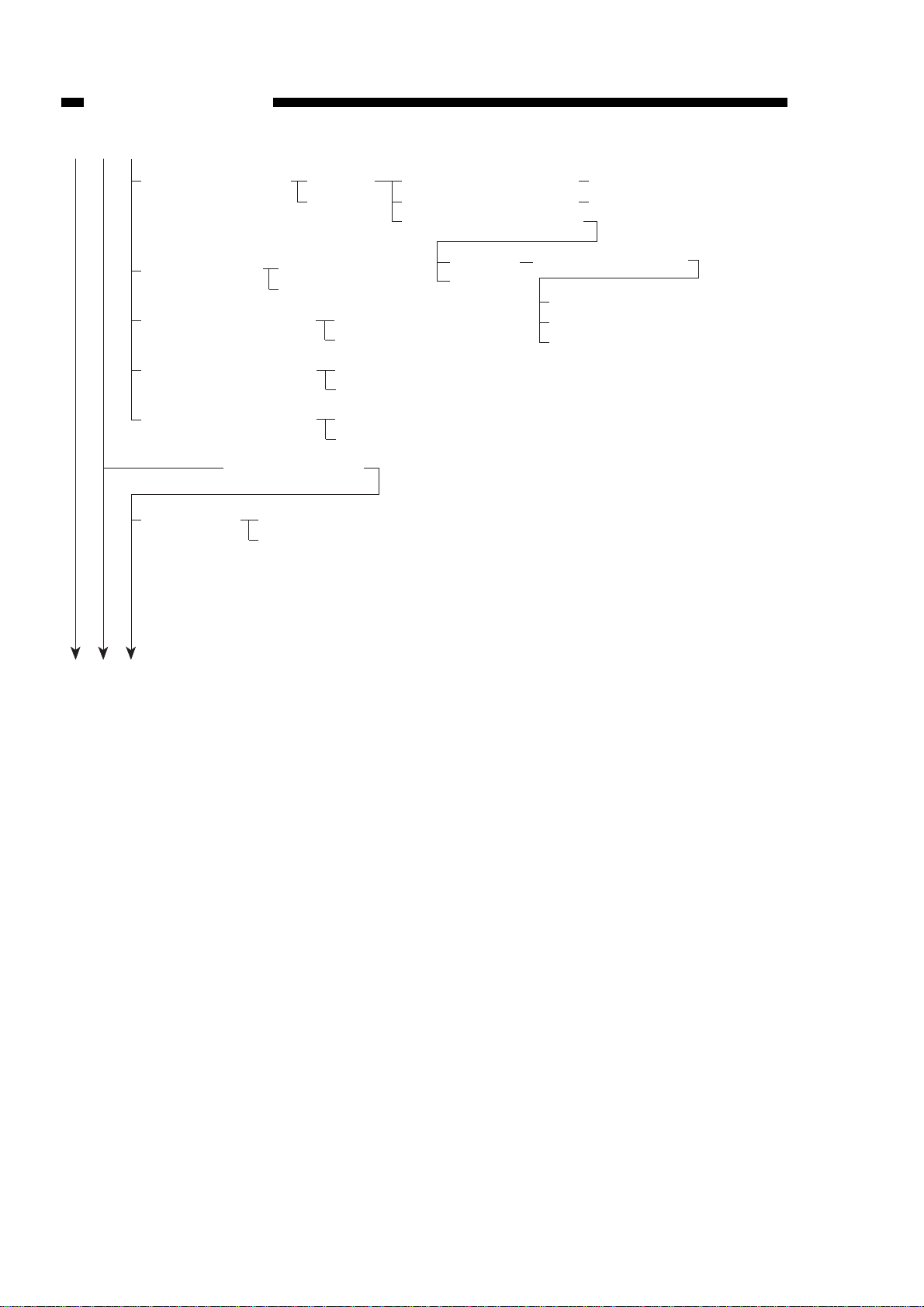

1. User mode for copies equipped with the fax function

Figure 1-403

REGISTRATION/SETTING

01 DATA REGISTRATION

01 DATE/TIME SETTING

02 UNIT TEL NUMBER

03 UNIT NAME

04 SENDER NAME REG.

05 TX TERMINAL ID

06 DENSITY CONTROL

07 PROGRAM KEY REG

08 OFFHOOK ALARM

09 VOLUME CONTROL

10 TEL LINE TYPE

11 R-KEY SETTING

01 USER SETTINGS

(9)

01 ON

02 OFF

01 LIGHT

02 STANDARD

03 DARK

01 PRINT REPORT

02 REPORT

03 TONE

04 SENDER'S NAME

05 SUBADDRESS

06 RX MODE

01 ON

02 OFF

01 KEYPAD VOLUME

02 ALARM VOLUME

03 TX DONE TONE

04 RX DONE TONE

05 PRINTING DONE TONE

06 SCANNING DONE TONE

07 COPYING DONE TONE

01 ROTARY PULSE

02 TOUCH TONE

01 PSTN

02 PBX

01 TTI POSITION

02 TEL NUMBER MARK

3

5

7

01 PREFIX

02 HOOKING

03 EARTH CONNECTION

01 OUTSIDE IMAGE

02 INSIDE IMAGE

01FAX

02 TEL

01 ON

02 OFF

01 ON

02 OFF

01 ON

02 ERROR ONLY

03 OFF

01 ON

02 ERROR ONLY

03 OFF

(1 ~ 3) 1

(1 ~ 3) 1

01 ON

02 ERROR ONLY

03 OFF

01 ON

02 ERROR ONLY

03 OFF

01 ON

02 ERROR ONLY

03 OFF

(1 ~ 3) 1

(1 ~ 3) 1

(1 ~ 3) 1

(1 ~ 3) 1

(1 ~ 3) 1

(1 ~ 3) 1

(1 ~ 3) 1

(1 ~ 3) 1

(1 ~ 3) 1

(1 ~ 3) 1

COPYRIGHT © 1999 CANON INC. CANON GP160 REV.0 FEB. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

CHAPTER 1 INTRODUCTION

1-15

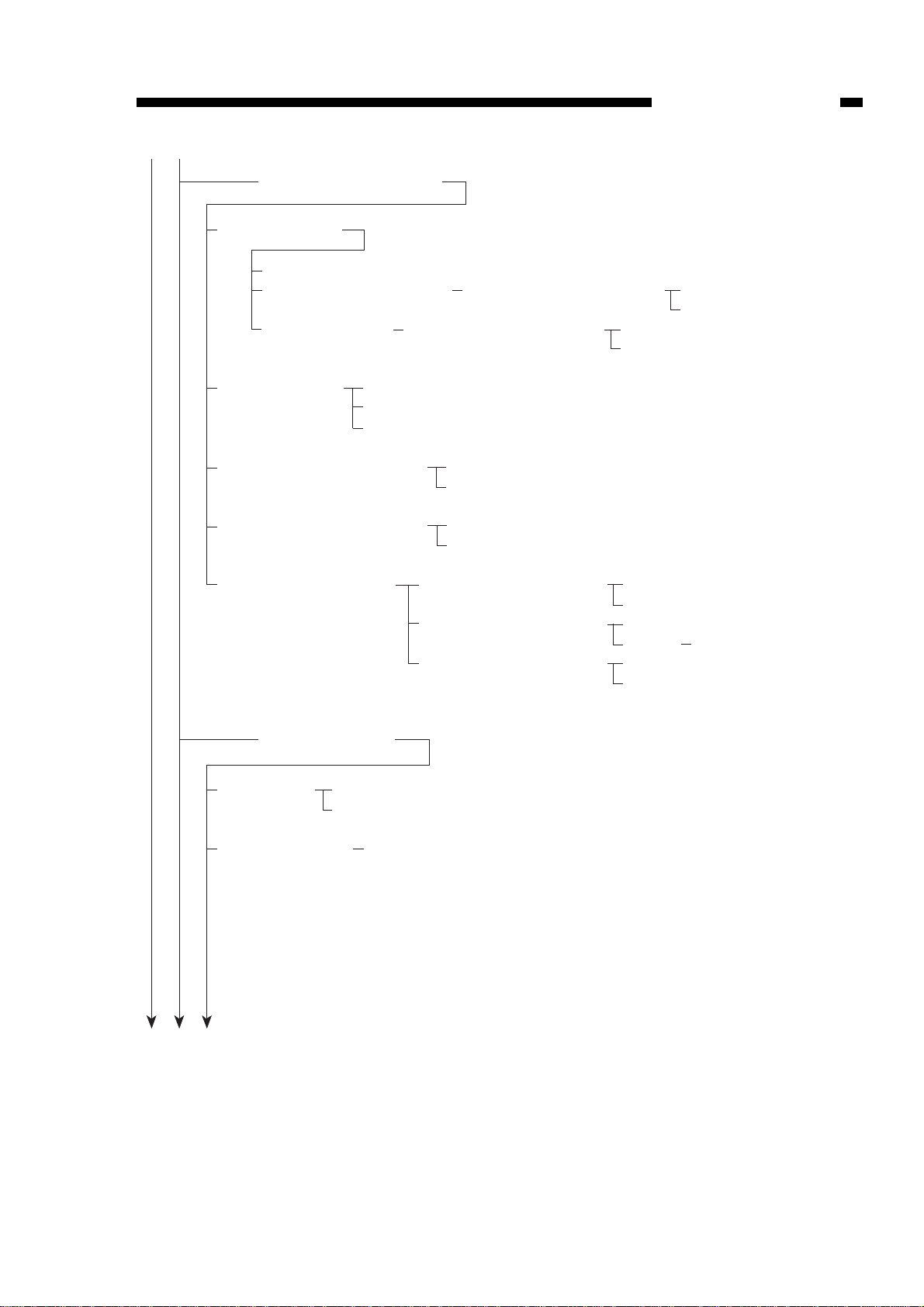

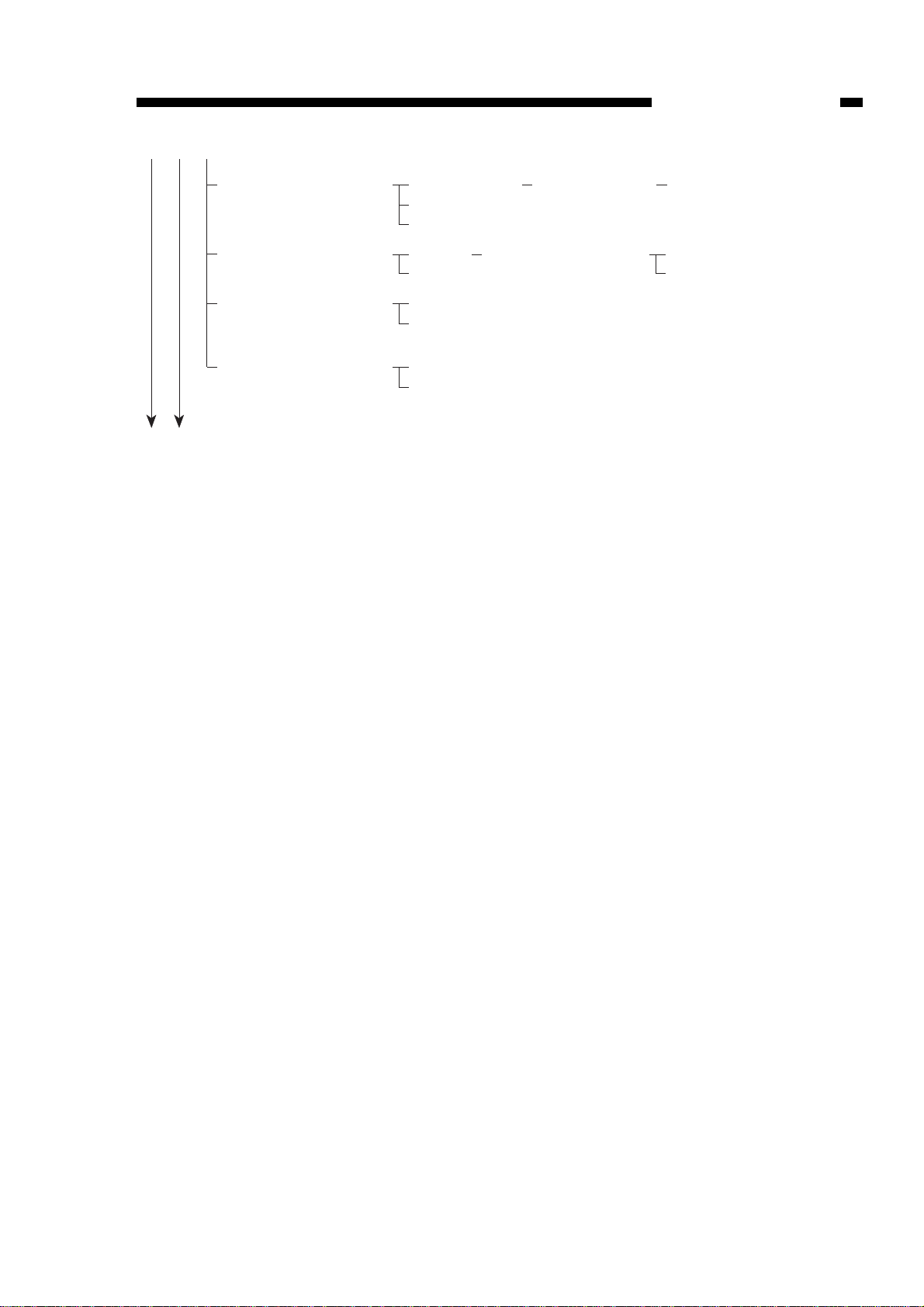

Figure 1-404

02 REPORT SETTINGS

01 TX REPORT

01 OUTPUT NO

02 PRINT ERROR ONLY

03 OUTPUT YES

REPORT WITH TX IMAGE

REPORT WITH TX IMAGE

01 OFF

02 ON

01 OFF

02 ON

02 RX REPORT

01 OUTPUT NO

02 PRINT ERROR ONLY

03 OUTPUT YES

03 CONFID. RX REPORT

04 MEMORY BOX REPORT

05 ACTIVITY REPORT

03 TX SETTINGS

01 ECM TX

01 ON

02 OFF

01 OUTPUT NO

02 OUTPUT YES

01 OUTPUT NO

02 OUTPUT YES

01 AUTO PRINT

02 DAILY REPORT TIME

03 TX/RX SEPARATE

01 ON

02 OFF

01 OFF

02 ON REPORT PRINT TIME

01 OFF

02 ON

02 PAUSE TIME

(01 ~ 15) 02 SEC

COPYRIGHT © 1999 CANON INC. CANON GP160 REV.0 FEB. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

CHAPTER 1 INTRODUCTION

1-16

Figure 1-405

03 AUTO REDIAL 01 ON

02 OFF

04 BATCH TX

01 ON

02 OFF

05 ERASE FAILED TX

01 OFF

02 ON

06 TIME OUT

01 ON

02 OFF

07 STAMP ACTION

01 DIRECT & MEMORY TX

02 DIRECT TX

04 RX SETTINGS

01 ECM RX

01 ON

02 OFF

01 REDAIL TIMES

02 REDIAL INTERVAL

03 TX ERROR RESEND

01 ON

RESEND TX FROM

02 OFF

01 ALL PAGES

02 ERROR & 1ST PG

03 ERROR PAGE

(01 ~ 15) 02 TIMES

(02 ~ 99) 02 MIN.

COPYRIGHT © 1999 CANON INC. CANON GP160 REV.0 FEB. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

CHAPTER 1 INTRODUCTION

1-17

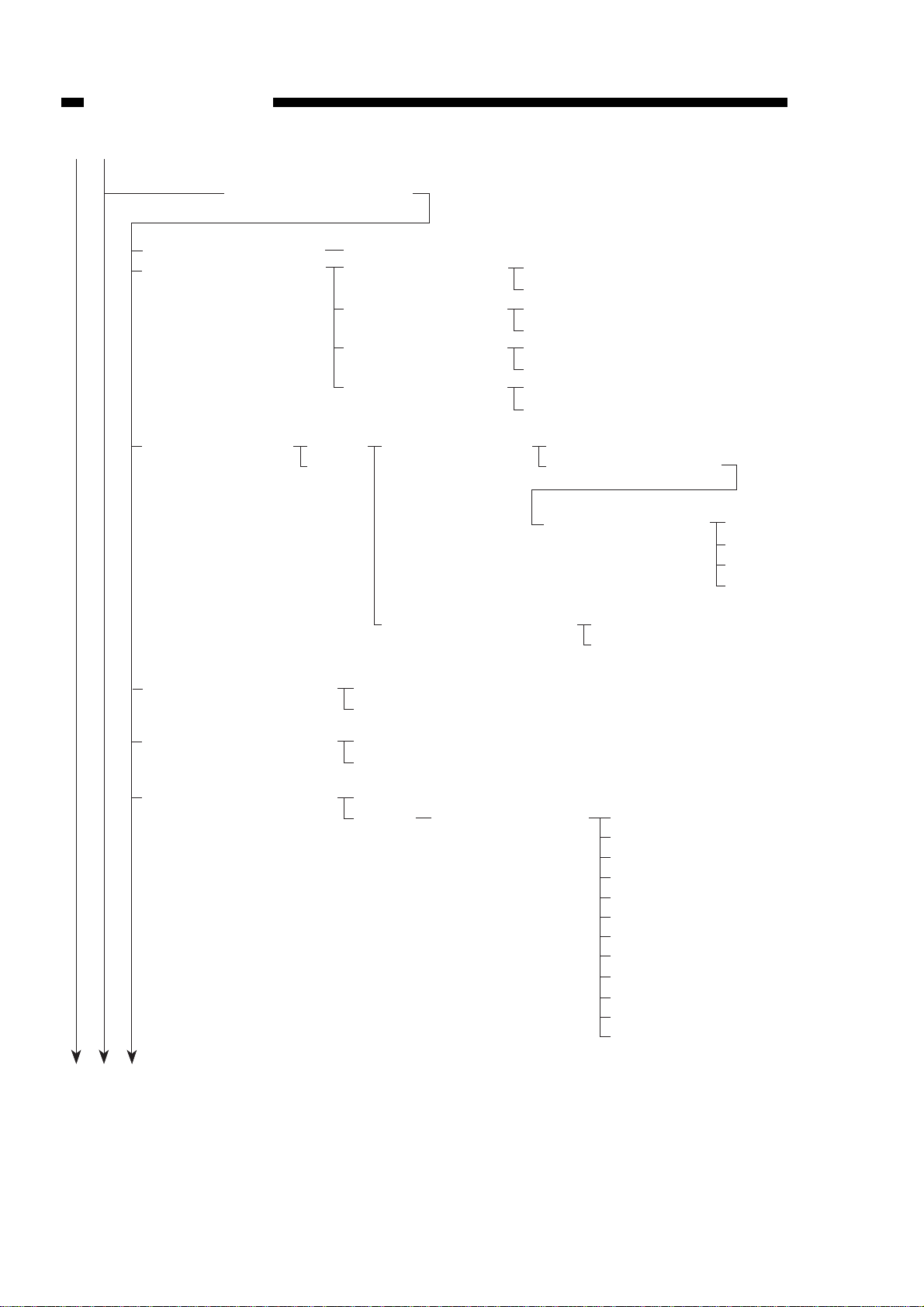

Figure 1-406

02 REMOTE RX

03 MEMORY RX

04 RX PAGE FOOTER

05 N ON ONE PRINT

01 ID CALL #

02 HOOK

03 OFF

01 ON

MEMORY RX ALARM

02 OFF

01 OFF

02 ON

01 OFF

02 ON

REMOTE RX ID

(00 ~ 99, *, #) 25

01 OFF

02 ON

COPYRIGHT © 1999 CANON INC. CANON GP160 REV.0 FEB. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

CHAPTER 1 INTRODUCTION

1-18

Figure 1-407

05 PRINTER SETTINGS

01 # OF RX COPIES

02 SELECT CASSETTE

03 RX REDUCTION

04 PRINT IN ORDER

(01 ~ 99) 01 COPIES

01 CASSETTE SW A

02 CASSETTE SW B

03 CASSETTE SW C

04 CASSETTE SW D

01 ON

01 RX REDUCTION

02 OFF

02 SELECT REDUCE DIR

01 OFF

02 ON

ON

OFF

ON

OFF

ON

OFF

ON

OFF

01 AUTO SELECTION

02 FIXED REDUCTION

SELECT REDUCE %

01 VERTICAL ONLY

02 HORIZ & VERTICAL

97%

95%

90%

75%

05 TONER SUPPLY LOW

01 RX TO MEMORY

02 KEEP PRINTING

*1

06 NAME STACK SIZE

01 OFF

02 ON

BYPASS DOC. SIZE

01 A3

02 A4

03 B4

04 B5

05 A4R

06 A5

07 B5R

08 A5R

09 11 x 17

10 LTR

11 LTRR

12 LGL

*1 Even when the [NAME STACK SIZE] is set to [OFF], if [STACK BYPASS] is selected by [CASSETTE

ELIGIBLTY] or [SET REPORT CASSETTE], [STACK BYPASS] will automatically come [ON]

Loading...

Loading...