Canon imageRUNNER iR2270, imageRUNNER iR2870, imageRUNNER iR3570, imageRUNNER iR4570, Finisher-S1 Service Manual

SERVICE

MANUAL

imageRUNNER

COPYRIGHT 2004 CANON INC. CANON imageRUNNER Finisher-S1 REV. 0 PRINTED IN U.S.A.

DU7-1130-000

SEPT. 2004

REV. 0

iR2270/2870/

3570/4570

Finisher-S1

Application

This manual has been issued by Canon Inc. for qualified persons to learn technical theory, installation,

maintenance, and repair of products. This manual covers all localities where the products are sold. For

this reason, there may be information in this manual that does not apply to your locality.

Corrections

This manual may contain technical inaccuracies or typographical errors due to improvements or changes

in products. When changes occur in applicable products or in the contents of this manual, Canon will

release technical information as the need arises. In the event of major changes in the contents of this

manual over a long or short period, Canon will issue a new edition of this manual.

The following paragraph does not apply to any countries where such provisions are inconsistent with

local law.

Trademarks

The product names and company names used in this manual are the registered trademarks of the

individual companies.

Copyright

This manual is copyrighted with all rights reserved. Under the copyright laws, this manual may not be

copied, reproduced or translated into another language, in whole or in part, without the written consent

of Canon Inc.

COPYRIGHT © 2001 CANON INC.

Printed in Japan

Caution

Use of this manual should be strictly supervised to avoid disclosure of confidential information.

Introduction

Symbols Used

This documentation uses the following symbols to indicate special information:

Symbol Description

Indicates an item of a non-specific nature, possibly classified as Note,

Caution, or Warning.

Indicates an item requiring care to avoid electric shocks.

Indicates an item requiring care to avoid combustion (fire).

Indicates an item prohibiting disassembly to avoid electric shocks or

problems.

Indicates an item requiring disconnection of the power plug from the electric

outlet.

Memo

REF.

Indicates an item intended to provide notes assisting the understanding of the

topic in question.

Indicates an item of reference assisting the understanding of the topic in

question.

Provides a description of a service mode.

Provides a description of the nature of an error indication.

Introduction

The following rules apply throughout this Service Manual:

1. Each chapter contains sections explaining the purpose of specific functions and the

relationship between electrical and mechanical systems with reference to the timing of

operation.

In the diagrams, represents the path of mechanical drive; where a signal name

accompanies the symbol, the arrow indicates the direction of the electric

signal.

The expression "turn on the power" means flipping on the power switch, closing the front

door, and closing the delivery unit door, which results in supplying the machine with

power.

2. In the digital circuits, '1'is used to indicate that the voltage level of a given signal is

"High", while '0' is used to indicate "Low".(The voltage value, however, differs from

circuit to circuit.) In addition, the asterisk (*) as in "DRMD*" indicates that the DRMD

signal goes on when '0'.

In practically all cases, the internal mechanisms of a microprocessor cannot be checked

in the field. Therefore, the operations of the microprocessors used in the machines are

not discussed: they are explained in terms of from sensors to the input of the DC

controller PCB and from the output of the DC controller PCB to the loads.

The descriptions in this Service Manual are subject to change without notice for product

improvement or other purposes, and major changes will be communicated in the form of

Service Information bulletins.

All service persons are expected to have a good understanding of the contents of this

Service Manual and all relevant Service Information bulletins and be able to identify and

isolate faults in the machine."

Contents

Contents

Chapter 1 Specifications

1.1 Product Specifications ............................................................................................... 1-1

1.1.1 Specifications ...................................................................................................... 1-1

1.2 Names of Parts ........................................................................................................... 1-6

1.2.1 External View ..................................................................................................... 1-6

1.2.2 Cross-sectional View .......................................................................................... 1-7

Chapter 2 Functions

2.1 Basic Construction ..................................................................................................... 2-1

2.1.1 Overview ............................................................................................................. 2-1

2.1.2 Outline of Electric Circuits ................................................................................. 2-2

2.2 Basic Operation.......................................................................................................... 2-3

2.2.1 Basic Operation................................................................................................... 2-3

2.3 Feed Drive System..................................................................................................... 2-8

2.3.1 Overview ............................................................................................................. 2-8

2.3.2 Feed Roller Control............................................................................................. 2-9

2.3.3 Offset Roller Control ........................................................................................ 2-10

2.3.4 Feed Motor Control........................................................................................... 2-14

2.3.5 Offset Motor Control ........................................................................................ 2-15

2.4 Staple Operation ...................................................................................................... 2-16

2.4.1 Functional Configuration .................................................................................. 2-16

2.4.2 Staple Motor Control ........................................................................................ 2-18

2.5 Stack Tray Operation ............................................................................................... 2-19

2.5.1 Overview ........................................................................................................... 2-19

2.5.2 Stack Ejection ................................................................................................... 2-20

2.5.3 Stack Slide Motor Control ................................................................................ 2-22

2.5.4 Stack Tray Shift Motor Control ........................................................................ 2-23

2.6 Detecting Jams ......................................................................................................... 2-24

2.6.1 Overview ........................................................................................................... 2-24

2.7 Power Supply........................................................................................................... 2-26

2.7.1 Overview ........................................................................................................... 2-26

2.7.2 Protection Function ........................................................................................... 2-26

Contents

Chapter 3 Parts Replacement Procedure

3.1 External Covers.......................................................................................................... 3-1

3.1.1 Upper Cover ........................................................................................................3-1

3.1.1.1 Removing the PCB Cover ............................................................................ 3-1

3.1.1.2 Removing the Top Harness Cover ............................................................... 3-1

3.1.1.3 Removing the Upper Cover.......................................................................... 3-2

3.1.2 Left Cover ........................................................................................................... 3-2

3.1.2.1 Removing the Left Cover ............................................................................. 3-2

3.1.3 PCB Cover .......................................................................................................... 3-3

3.1.3.1 Removing the PCB Cover ............................................................................ 3-3

3.1.4 Top Harness Cover ..............................................................................................3-3

3.1.4.1 Removing the PCB Cover ............................................................................ 3-3

3.1.4.2 Removing the Top Harness Cover ............................................................... 3-4

3.1.5 Bottom Cover ......................................................................................................3-4

3.1.5.1 Removing the Bottom Cover........................................................................ 3-4

3.1.6 Tray Guide Top Cover ........................................................................................ 3-5

3.1.6.1 Removing the Bottom Cover........................................................................ 3-5

3.1.6.2 Removing the Tray Guide Top Cover .......................................................... 3-6

3.2 Drive System.............................................................................................................. 3-7

3.2.1 Feed Motor ..........................................................................................................3-7

3.2.1.1 Removing the PCB Cover ............................................................................ 3-7

3.2.1.2 Removing the Top Harness Cover ............................................................... 3-7

3.2.1.3 Removing the Upper Cover.......................................................................... 3-8

3.2.1.4 Removing the Stapler Cover ........................................................................ 3-8

3.2.1.5 Removing the Drive Unit ............................................................................. 3-9

3.2.1.6 Removing the Process Tray Unit.................................................................. 3-9

3.2.1.7 Removing the Feed Motor.......................................................................... 3-10

3.2.2 Stack Tray Shift Motor ......................................................................................3-10

3.2.2.1 Removing the PCB Cover .......................................................................... 3-10

3.2.2.2 Removing the Top Harness Cover ............................................................. 3-11

3.2.2.3 Removing the Upper Cover........................................................................ 3-11

3.2.2.4 Removing the Bottom Cover...................................................................... 3-12

3.2.2.5 Removing the Left Cover ........................................................................... 3-12

3.2.3 Stapler ...............................................................................................................3-13

3.2.3.1 Removing the PCB Cover .......................................................................... 3-13

3.2.3.2 Removing the Top Harness Cover ............................................................. 3-13

3.2.3.3 Removing the Upper Cover........................................................................ 3-14

3.2.3.4 Removing the Stapler Cover ...................................................................... 3-15

3.2.3.5 Removing the Stapler ................................................................................. 3-15

Contents

3.2.4 Drive Unit ......................................................................................................... 3-15

3.2.4.1 Removing the PCB Cover .......................................................................... 3-15

3.2.4.2 Removing the Top Harness Cover ............................................................. 3-16

3.2.4.3 Removing the Upper Cover........................................................................ 3-16

3.2.4.4 Removing the Stapler Cover ...................................................................... 3-17

3.2.4.5 Removing the Drive Unit ........................................................................... 3-17

3.2.5 Offset Motor ...................................................................................................... 3-18

3.2.5.1 Removing the PCB Cover .......................................................................... 3-18

3.2.5.2 Removing the Top Harness Cover ............................................................. 3-19

3.2.5.3 Removing the Upper Cover........................................................................ 3-19

3.2.5.4 Removing the Offset Motor ....................................................................... 3-20

3.2.6 Stack Slide Motor .............................................................................................. 3-20

3.2.6.1 Removing the PCB Cover .......................................................................... 3-20

3.2.6.2 Removing the Top Harness Cover ............................................................. 3-21

3.2.6.3 Removing the Upper Cover........................................................................ 3-21

3.2.6.4 Removing the Stapler Cover ...................................................................... 3-22

3.2.6.5 Removing the Drive Unit ........................................................................... 3-22

3.2.6.6 Removing the Process Tray Unit ............................................................... 3-23

3.2.6.7 Removing the Stack Slide Motor ............................................................... 3-24

3.3 Document Feeding System ...................................................................................... 3-25

3.3.1 Stack Tray Assembly ........................................................................................ 3-25

3.3.1.1 Removing the PCB Cover .......................................................................... 3-25

3.3.1.2 Removing the Top Harness Cover ............................................................. 3-25

3.3.1.3 Removing the Upper Cover........................................................................ 3-26

3.3.1.4 Removing the Bottom Cover...................................................................... 3-26

3.3.1.5 Removing the Left Cover ........................................................................... 3-27

3.3.1.6 Removing the Tray Guide Top Cover ........................................................ 3-27

3.3.1.7 Removing the Stapler Cover ...................................................................... 3-28

3.3.1.8 Removing the Stack Tray Assembly .......................................................... 3-28

3.3.2 Process Tray Assembly ..................................................................................... 3-28

3.3.2.1 Removing the PCB Cover .......................................................................... 3-28

3.3.2.2 Removing the Top Harness Cover ............................................................. 3-29

3.3.2.3 Removing the Upper Cover........................................................................ 3-29

3.3.2.4 Removing the Stapler Cover ...................................................................... 3-30

3.3.2.5 Removing the Drive Unit ........................................................................... 3-30

3.3.2.6 Removing the Process Tray Unit ............................................................... 3-31

3.3.3 Feed Rollor ........................................................................................................ 3-32

3.3.3.1 Removing the PCB Cover .......................................................................... 3-32

3.3.3.2 Removing the Top Harness Cover ............................................................. 3-32

3.3.3.3 Removing the Upper Cover........................................................................ 3-33

Contents

3.3.3.4 Removing the Feed Roller.......................................................................... 3-33

3.4 Electrical System ..................................................................................................... 3-35

3.4.1 Stack Tray Paper Surface Sensor ......................................................................3-35

3.4.1.1 Removing the PCB Cover .......................................................................... 3-35

3.4.1.2 Removing the Top Harness Cover ............................................................. 3-35

3.4.1.3 Removing the Upper Cover........................................................................ 3-36

3.4.1.4 Removing the Stapler Cover ...................................................................... 3-36

3.4.1.5 Removing the Stapler ................................................................................. 3-37

3.4.1.6 Removing the Drive Unit ........................................................................... 3-37

3.4.1.7 Removing the Process Tray Unit................................................................ 3-38

3.4.1.8 Removing the Stack Tray Paper Surface Sensor ........................................ 3-38

3.4.2 Stack Tray Lower Limit Sensor ........................................................................ 3-39

3.4.2.1 Removing the Stack Tray Lower Limit Sensor .......................................... 3-39

3.4.3 Process Tray Paper Sensor ................................................................................ 3-39

3.4.3.1 Removing the PCB Cover .......................................................................... 3-39

3.4.3.2 Removing the Top Harness Cover ............................................................. 3-40

3.4.3.3 Removing the Upper Cover........................................................................ 3-40

3.4.3.4 Removing the Stapler Cover ...................................................................... 3-41

3.4.3.5 Removing the Drive Unit ........................................................................... 3-41

3.4.3.6 Removing the Process Tray Unit................................................................ 3-42

3.4.3.7 Removing the Process Tray Paper Sensor .................................................. 3-43

3.4.4 Finisher Controller PCB ....................................................................................3-43

3.4.4.1 Finisher Controller PCB ............................................................................. 3-43

3.4.5 Front Cover Safety Switch ................................................................................ 3-45

3.4.5.1 Removing the PCB Cover .......................................................................... 3-45

3.4.5.2 Removing the Front Door Safety Switch ................................................... 3-45

3.4.6 Inlet Sensor ........................................................................................................3-45

3.4.6.1 Removing the PCB Cover .......................................................................... 3-45

3.4.6.2 Removing the Top Harness Cover ............................................................. 3-46

3.4.6.3 Removing the Upper Cover........................................................................ 3-46

3.4.6.4 Removing the Inlet Sensor ......................................................................... 3-47

3.4.7 Stack Slide HP Sensor ....................................................................................... 3-48

3.4.7.1 Removing the PCB Cover .......................................................................... 3-48

3.4.7.2 Removing the Top Harness Cover ............................................................. 3-48

3.4.7.3 Removing the Upper Cover........................................................................ 3-48

3.4.7.4 Removing the Stapler Cover ...................................................................... 3-49

3.4.7.5 Removing the Drive Unit ........................................................................... 3-49

3.4.7.6 Removing the Process Tray Unit................................................................ 3-50

3.4.7.7 Stack Slide HP Sensor ................................................................................ 3-51

3.4.8 Offset HP Sensor ............................................................................................... 3-51

Contents

3.4.8.1 Removing the PCB Cover .......................................................................... 3-51

3.4.8.2 Removing the Top Harness Cover ............................................................. 3-51

3.4.8.3 Removing the Upper Cover........................................................................ 3-52

3.4.8.4 Removing the Offset HP Sensor ................................................................ 3-53

3.4.9 Tray Clock Sensor ............................................................................................. 3-53

3.4.9.1 Removing the PCB Cover .......................................................................... 3-53

3.4.9.2 Removing the Top Harness Cover ............................................................. 3-54

3.4.9.3 Removing the Upper Cover........................................................................ 3-54

3.4.9.4 Removing the Bottom Cover...................................................................... 3-55

3.4.9.5 Removing the left cover ............................................................................. 3-56

3.4.9.6 Removing the Tray Guide Top Cover ........................................................ 3-56

3.4.9.7 Removing the Stack Tray Assembly .......................................................... 3-57

3.4.9.8 Removing the Tray Clock Sensor .............................................................. 3-57

3.4.10 Offset Solenoid ............................................................................................... 3-58

3.4.10.1 Removing the PCB Cover ........................................................................ 3-58

3.4.10.2 Removing the Top Harness Cover ........................................................... 3-58

3.4.10.3 Removing the Upper Cover...................................................................... 3-58

3.4.10.4 Removing the Offset Solenoid ................................................................. 3-59

3.4.11 Paper Holder Solenoid .................................................................................... 3-60

3.4.11.1 Removing the PCB Cover ........................................................................ 3-60

3.4.11.2 Removing the Top Harness Cover ........................................................... 3-60

3.4.11.3 Removing the Upper Cover...................................................................... 3-60

3.4.11.4 Removing the Stapler Cover .................................................................... 3-61

3.4.11.5 Removing the Stapler ............................................................................... 3-61

3.4.11.6 Removing the Drive Unit ......................................................................... 3-62

3.4.11.7 Removing the Process Tray Unit ............................................................. 3-62

3.4.11.8 Removing the Paper Holder Solenoid ...................................................... 3-63

Chapter 4 Maintenance

4.1 Maintenance and Inspection ...................................................................................... 4-1

4.1.1 Periodically Replaced Parts ................................................................................ 4-1

4.1.1.1 Periodically Replaced Parts.......................................................................... 4-1

4.1.2 Durables .............................................................................................................. 4-1

4.1.2.1 Durables ....................................................................................................... 4-1

4.1.3 Periodical Servicing ............................................................................................ 4-2

4.1.3.1 Periodical Servicing ..................................................................................... 4-2

4.2 Adjustment................................................................................................................. 4-3

4.2.1 Adjustment at Time of Parts Replacement ......................................................... 4-3

Contents

4.2.1.1 Making Adjustments When Replacing the Finisher Controller PCB........... 4-3

4.3 Outline of Electrical Components.............................................................................. 4-4

4.3.1 Outline of Electrical Components....................................................................... 4-4

4.4 Variable Resistors (VR), Light-Emitting Diodes (LED), and Check Pins by PCB... 4-7

4.4.1 Light-Emitting Diodes and Check Pins by PCB ................................................. 4-7

4.4.2 Finisher Controller PCB...................................................................................... 4-8

4.4.3 DIP Switch Functions ......................................................................................... 4-9

Chapter 5 Error Code

5.1 Service Error Code..................................................................................................... 5-1

5.1.1 Service Error Code .............................................................................................. 5-1

Chapter 1

Specifications

Contents

Contents

1.1 Product Specifications................................................................................1-1

1.1.1 Specifications ...................................................................................... 1-1

1.2 Names of Parts ...........................................................................................1-6

1.2.1 External View......................................................................................1-6

1.2.2 Cross-sectional View ..........................................................................1-7

1.1 Product Specifications

Chapter 1

1.1.1 Specifications

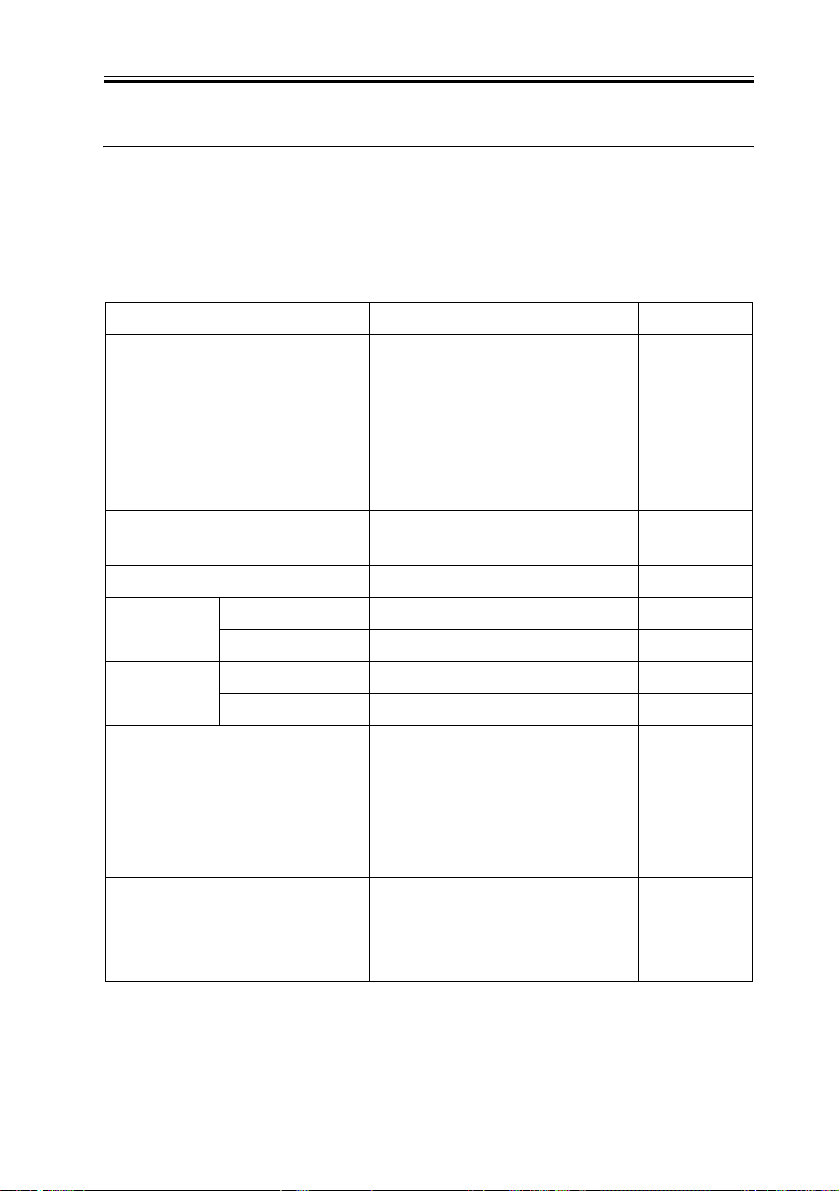

T-1-1

Item Description Remarks

Stack tray 1-stage tray and extension tray for large size

paper

Stacking method Lowering stack tray

(1-bin self-running)

Loading method Face-down

Loading paper

size

Paper weight

Paper size A3, B4, A4, A4R, B5, B5R, A5R, postcard,

Media type Plain paper, recycled paper, colored paper,

Longitudinal 139.7 mm to 457 mm

Lateral 98.4 mm to 320 mm

Staple loading 64g/m2 to 80g/m2

Non-staple loading 64g/m2 to 128g/m2

double postal card, 4-leaf postcard, irregular

sizes (182 x 140 mm to 297 x 432 mm),

envelope (105 mm x 235 mm, COM10,

Monarch, DL, ISO-B5, ISO-C5)

64g/m2 to 128g/m2

punched paper, thick paper, secondary

original drawing, transparency, label sheet,

postcard, double postal card, 4-leaf postcard

0006-1918

Two-bin

configuration can

be used by

attaching

additional

finisher tray

(B1).

1-1

Chapter 1

Item Description Remarks

Staple loading A3,A4,A4R,B4,B5,LDR,LGL,LTR,LTRR

Non-staple loading A3,A4,A4R,A5,A5R,B4,B5,B5R,LDR,LGL,

LTR,LTRR, postcard, envelope

Modes

Stack offset loading A3,A4,A4R,B4,B5,LDR,LGL,LTR,LTRR - Shift amount:

43.5 to 87 mm

- Shiftable width:

210 mm to 297

mm

1-2

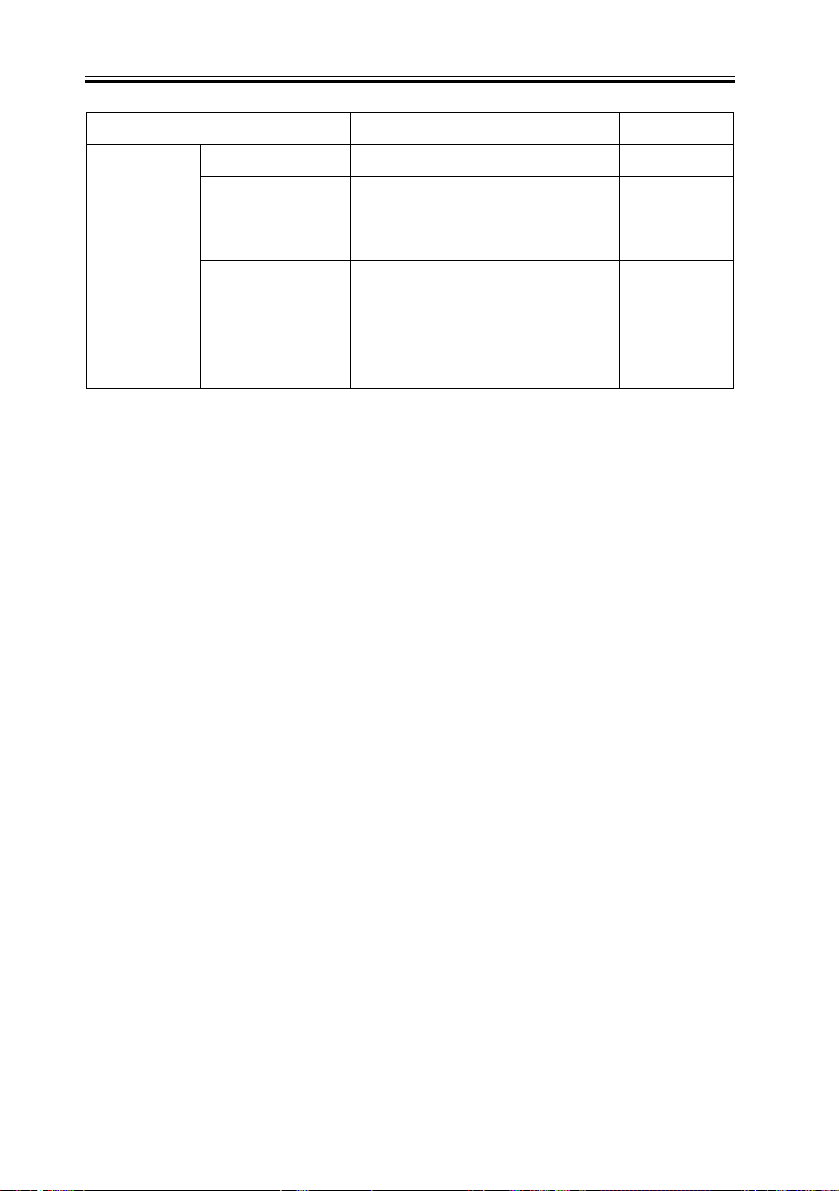

Number of

loadable sheets

Alignment range

Chapter 1

Item Description Remarks

Standard tray Non-sort, sort, group

A4, B5, A5R: 1000 sheets (height = 130 mm)

A3, B4, A4R, B5R: 500 sheets (height = 65

mm)

Staple sort

A4, B5: 1000 sheets/30 copies (height = 130

mm)

Non-sort, sort, group (Mixed size): 500

sheets (height = 65 mm)

Staple sort (Mixed size): 500 sheets/30 copies

(height = 65 mm)

Optional tray Non-sort, soft, group

A4, B5, A5R: 300 sheets (height = 40 mm)

A3, B4, A4R, B5R: 150 sheets (height = 20

mm)

Staple sort

A4, B5: 300 sheets/30 copies (height = 40

mm)

A3, B4, A4R: 150 sheets/30 copies (height =

20 mm)

Non-sort, sort, group (Mixed size):,150

sheets (height = 20 mm)

Staple sort (Mixed size): 150 sheets/30 copies

(height = 20 mm)

When optional tray is

installed

Staple stack A4, B4: 50 sheets (64 to 80 g/m2)

Staple loading Paper width: 210.0 mm to 297.0 mm

Non-staple loading Paper width: 210.0 mm to 297.0 mm

Stack offset loading Paper width: 210.0 mm to 297.0 mm

Upper tray

Small size: Height = 40 mm; Large size:

Height = 20 mm

Lower tray

Small size: Height = 40 mm; Large size:

Height = 20 mm

A3, B4, A4R: 30 sheets (64 to 80 g/m2)

80 g/m2 paper

1-3

Chapter 1

Paper detection Intermediate process

Number of mixed

sheets

Operation panel None

Display screen None

Installation type Built-in

Dimensions 480mm(W) x 520mm(D) x 300mm(H)

Weight 12kg

Power supply Powered from main body (24 V/13 V)

Max. power

consumption

Operating noise Main body + DF +

Options Additional finisher tray-B1

Item Description Remarks

Detected

tray

Stack tray Detected

Mixed size 65 mm or lower in height 20 mm when

Mixed staple 65 mm or lower in height or 30 or fewer

copies

Mixed mode 65 mm or lower in height or 30 or fewer

copies

Powered from main

body

Finisher

Approx. 45 W or less

Noise specification for main body + 3 dB (full

system)

Puncher unit-R1/S1/T1

additional

finisher tray (B1)

is installed

(loadability is not

quaranteed)

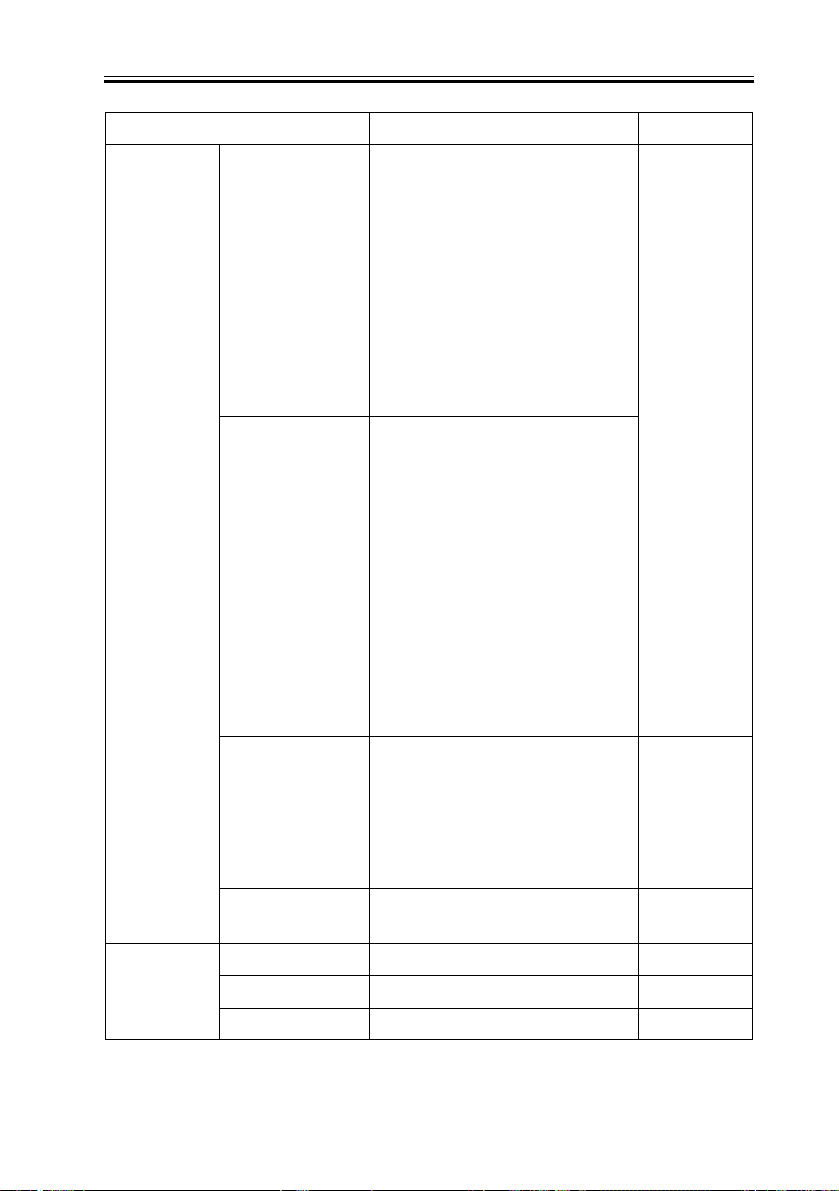

T-1-2

Item Description

Stapling method Stapling by rotary cam

Stapling position - Oblique stapling at one position

Number of sheets that can

be stapled

Staple loading method Replacement of dedicated staple sheet cartridge

Small size: 50 sheets; Large size: 30 sheets

Maximum: Two 128 g/m2 sheets + Forty-eight 80

g/m2 sheets (small size)

(5000 staples)

1-4

Remarks

A3,A4,A4R,B4,B5,LD

R,LGL,LTR,LTRR

Paper thickness: 5.5 mm

max.

No staple detection Detected

Manual stapling Disabled

Standby function Provided

- Stapling position (one position, rear)

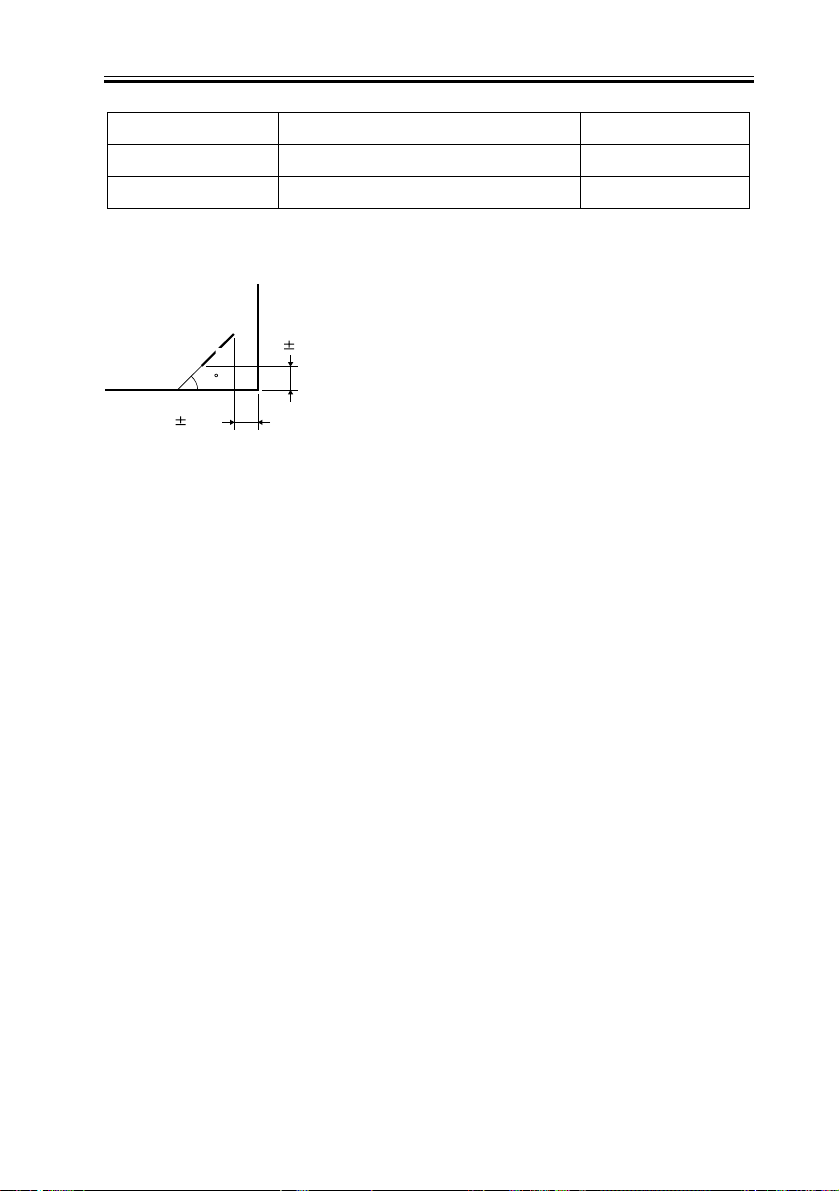

5.0 2mm

45

5.0 2mm

A3 , B4 , A4 , A4R , B5 , LDR , LGL , LTR , LTR-R

F-1-1

Chapter 1

1-5

Chapter 1

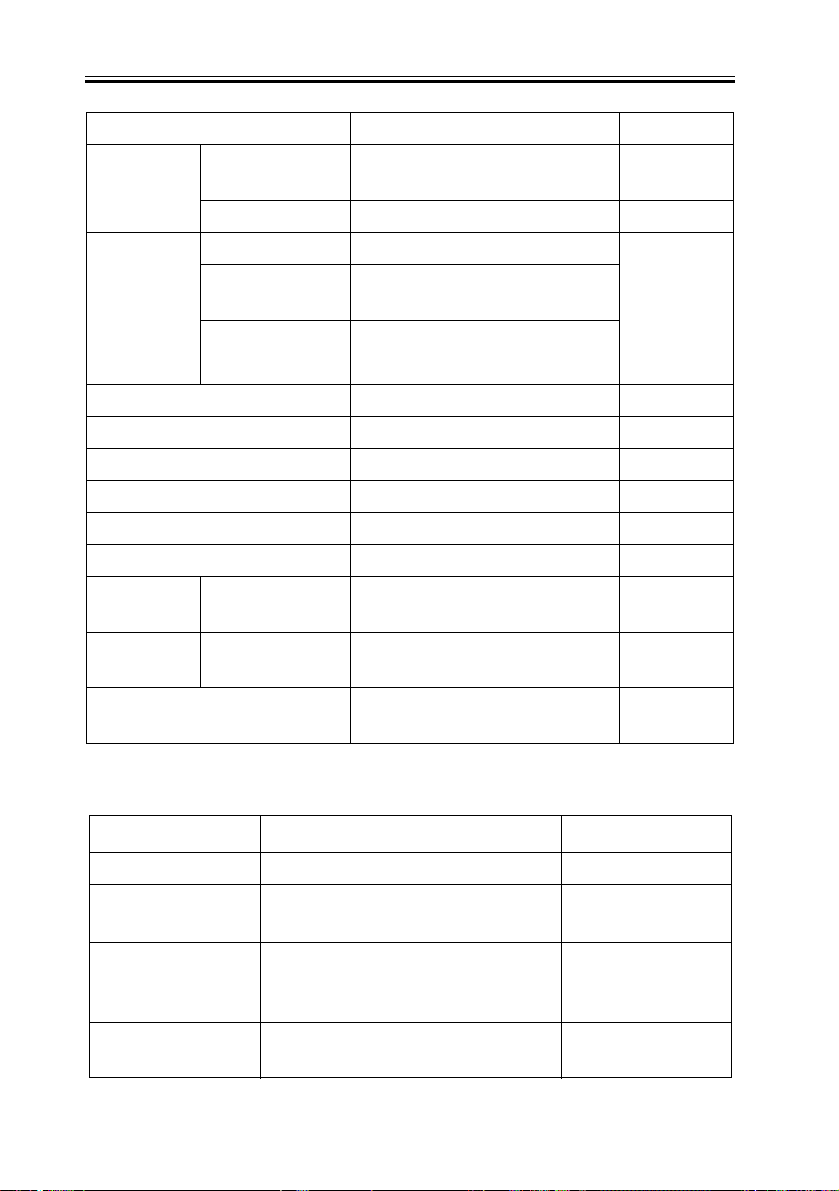

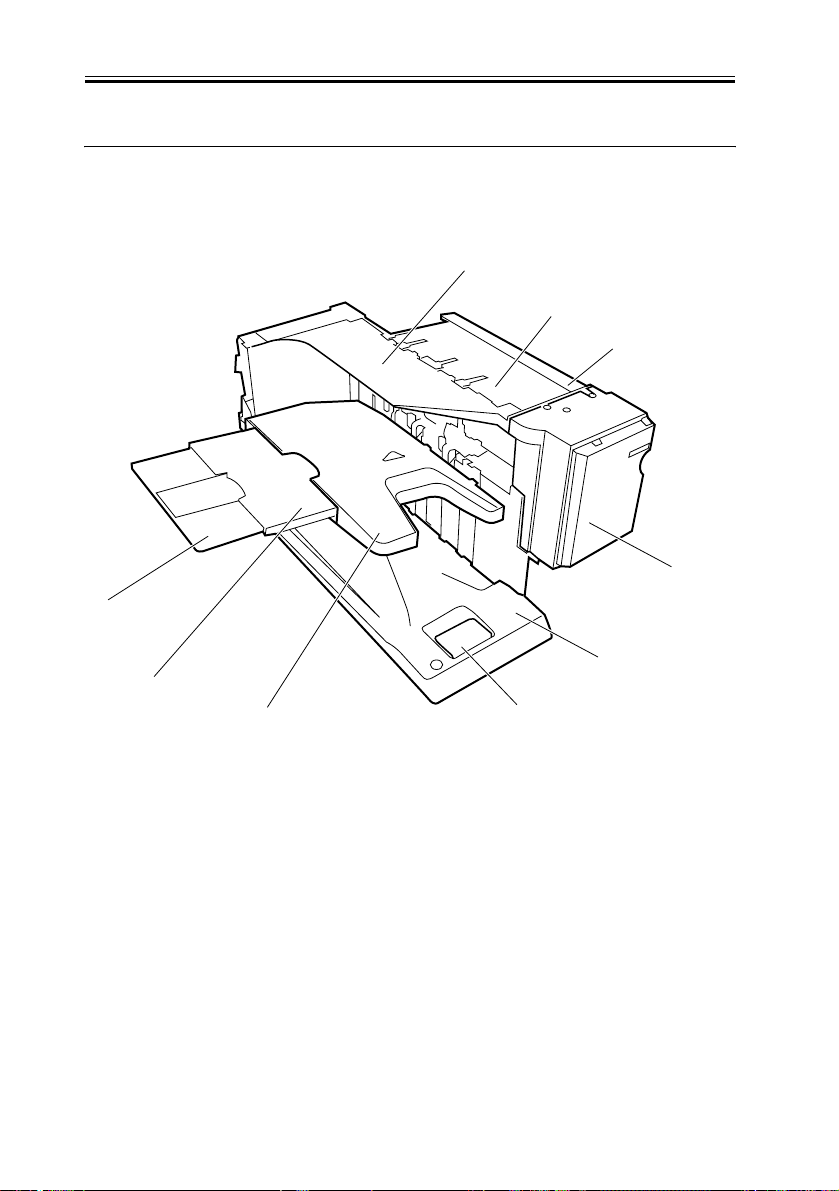

1.2 Names of Parts

1.2.1 External View

[9]

[8]

[7]

F-1-2

0006-1920

[1]

[2]

[3]

[4]

[5]

[6]

[1] Top harness cover

[2] Top cover

[3] Reversal guide

[4] PCB cover

[5] Bottom cover

[6] Pulling handle

[7] Stack tray

[8] Stack extension tray 1

[9] Stack extension tray 2

1-6

Chapter 1

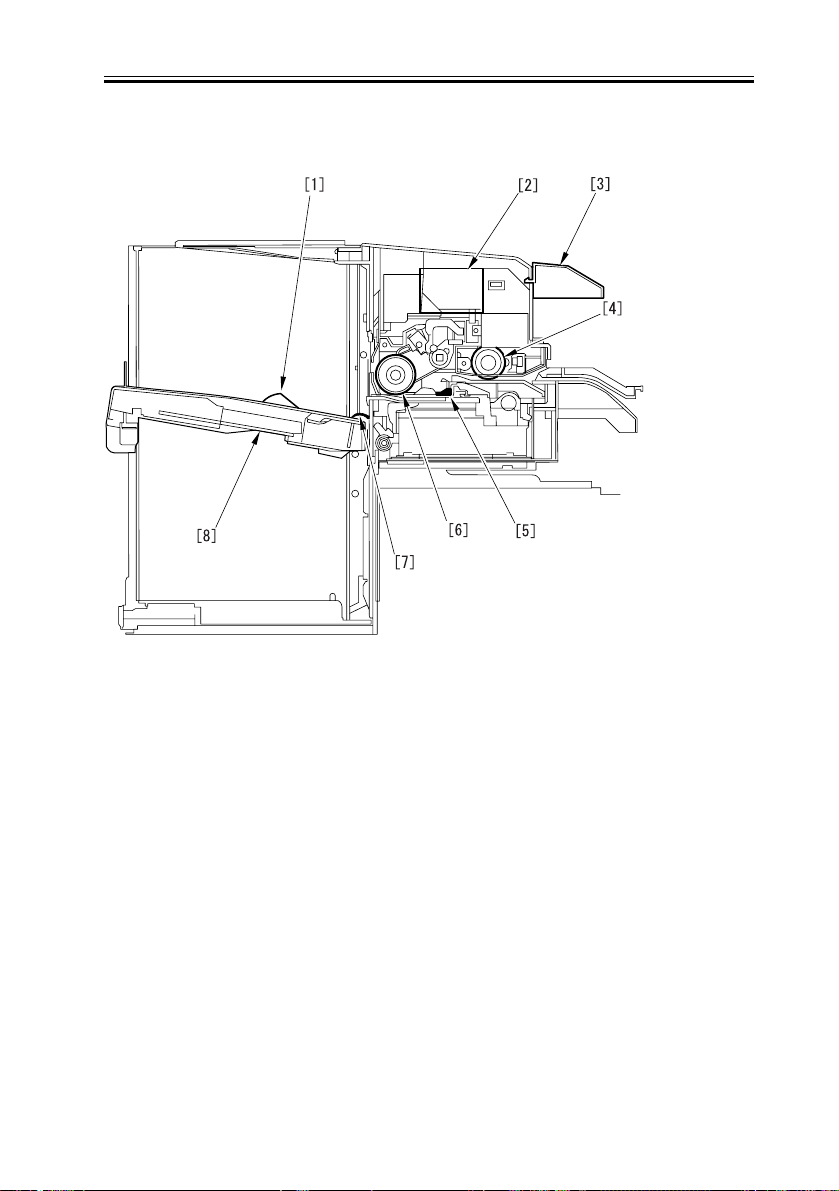

1.2.2 Cross-sectional View

F-1-3

0006-1922

[1] Stack tray paper presence sensor

[2] Stapler

[3] Reversal guide

[4] Feed roller

[5] Stack slider

[6] Offset roller

[7] Paper holder

[8] Stack tray

1-7

Chapter 2

Functions

Contents

Contents

2.1 Basic Construction .....................................................................................2-1

2.1.1 Overview .............................................................................................2-1

2.1.2 Outline of Electric Circuits ................................................................. 2-2

2.2 Basic Operation..........................................................................................2-3

2.2.1 Basic Operation...................................................................................2-3

2.3 Feed Drive System .....................................................................................2-8

2.3.1 Overview .............................................................................................2-8

2.3.2 Feed Roller Control.............................................................................2-9

2.3.3 Offset Roller Control.........................................................................2-10

2.3.4 Feed Motor Control...........................................................................2-14

2.3.5 Offset Motor Control.........................................................................2-15

2.4 Staple Operation.......................................................................................2-16

2.4.1 Functional Configuration ..................................................................2-16

2.4.2 Staple Motor Control.........................................................................2-18

2.5 Stack Tray Operation ...............................................................................2-19

2.5.1 Overview ...........................................................................................2-19

2.5.2 Stack Ejection....................................................................................2-20

2.5.3 Stack Slide Motor Control ................................................................2-22

2.5.4 Stack Tray Shift Motor Control ........................................................2-23

2.6 Detecting Jams ......................................................................................... 2-24

2.6.1 Overview ...........................................................................................2-24

2.7 Power Supply ........................................................................................... 2-26

2.7.1 Overview ...........................................................................................2-26

2.7.2 Protection Function ...........................................................................2-26

2.1 Basic Construction

Chapter 2

2.1.1 Overview

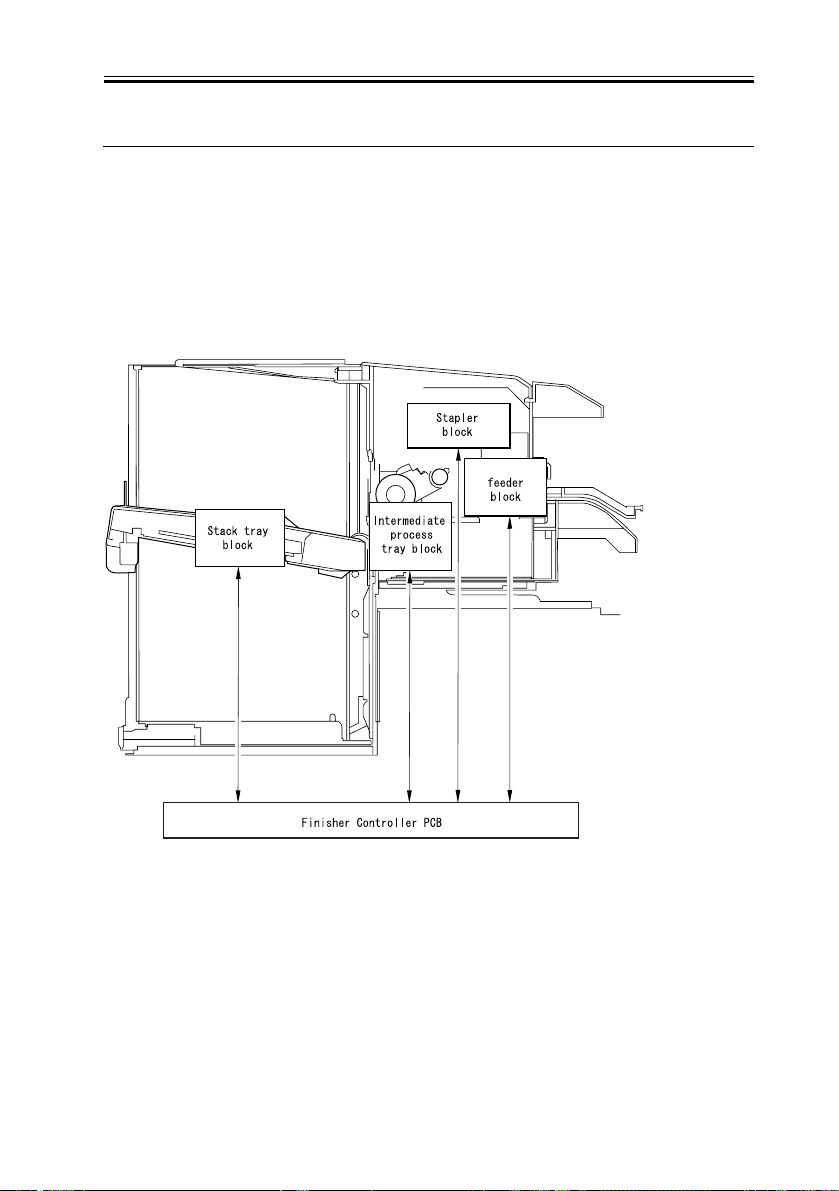

The finisher consists of four blocks: a stack tray, stapler, intermediate process tray, and

feeder blocks.

The following illustration shows locations of these four blocks and the finisher controller

PCB.

0006-1928

F-2-1

2-1

Chapter 2

2.1.2 Outline of Electric Circuits

0006-1929

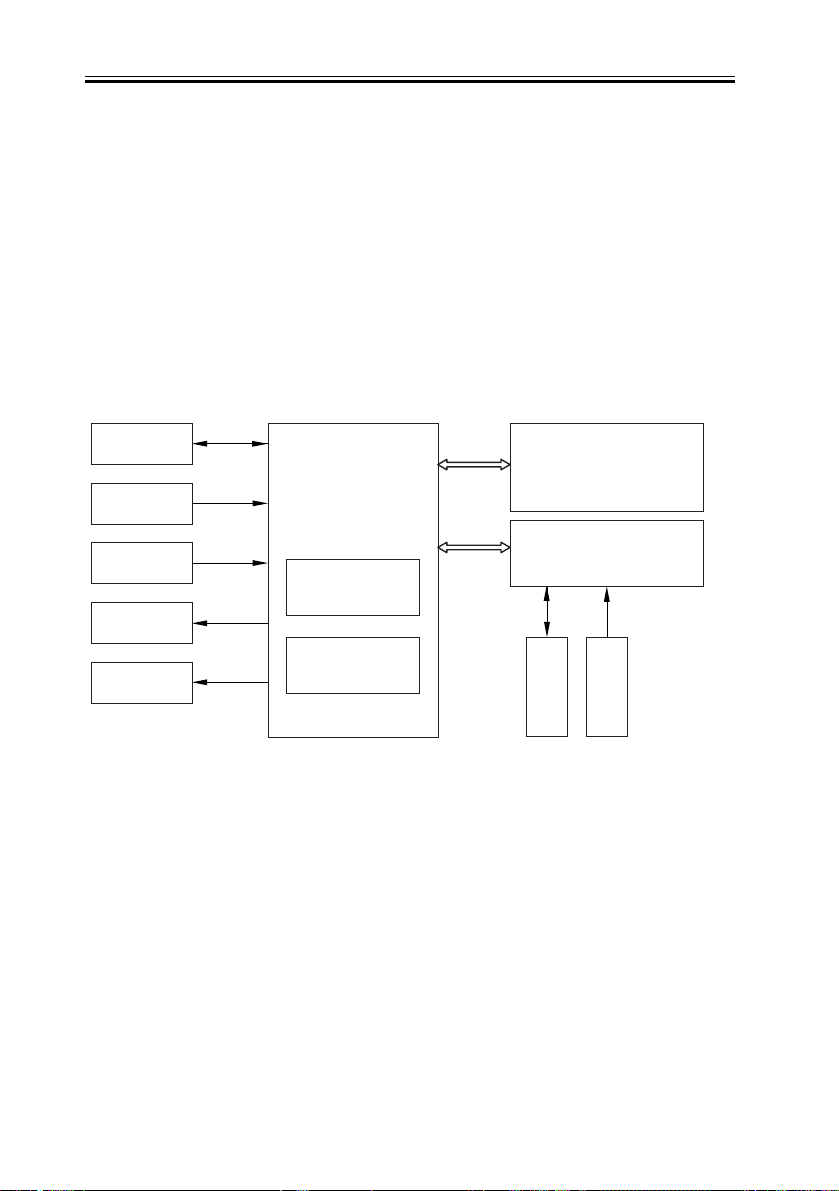

The operation sequence of the finisher is controlled by the finisher controller PCB.

The finisher controller PCB incorporates a 16-bit CPU to perform sequence control (and

serial communication with the host machine).

The CPU on the finisher controller PCB incorporates a ROM that stores an operation

sequence program.

The finisher controller PCB drives motors in response to the commands sent from the host

machine via a serial communication line.

The finisher controller PCB also sends information about various sensors and switches to

the host machine via the serial communication line.

Motor

Sensor

Switch

Solenoid

Clutch*1

Finisher controller

PCB

CPU

Motor driver

Host machine

(DC controller PCB

with CPU)

Option tray PCB*1

Motor*1

Sensor*1

*1: Only when option tray is installed

F-2-2

2-2

2.2 Basic Operation

Chapter 2

2.2.1 Basic Operation

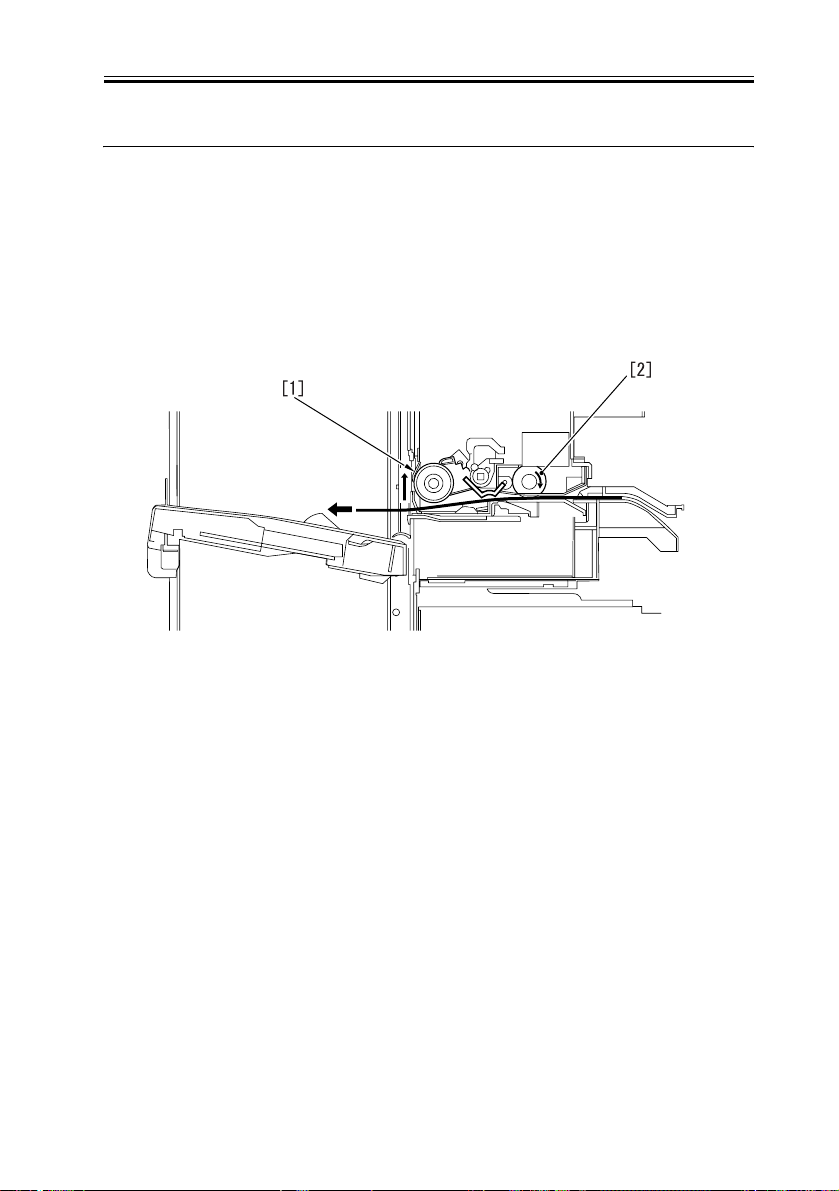

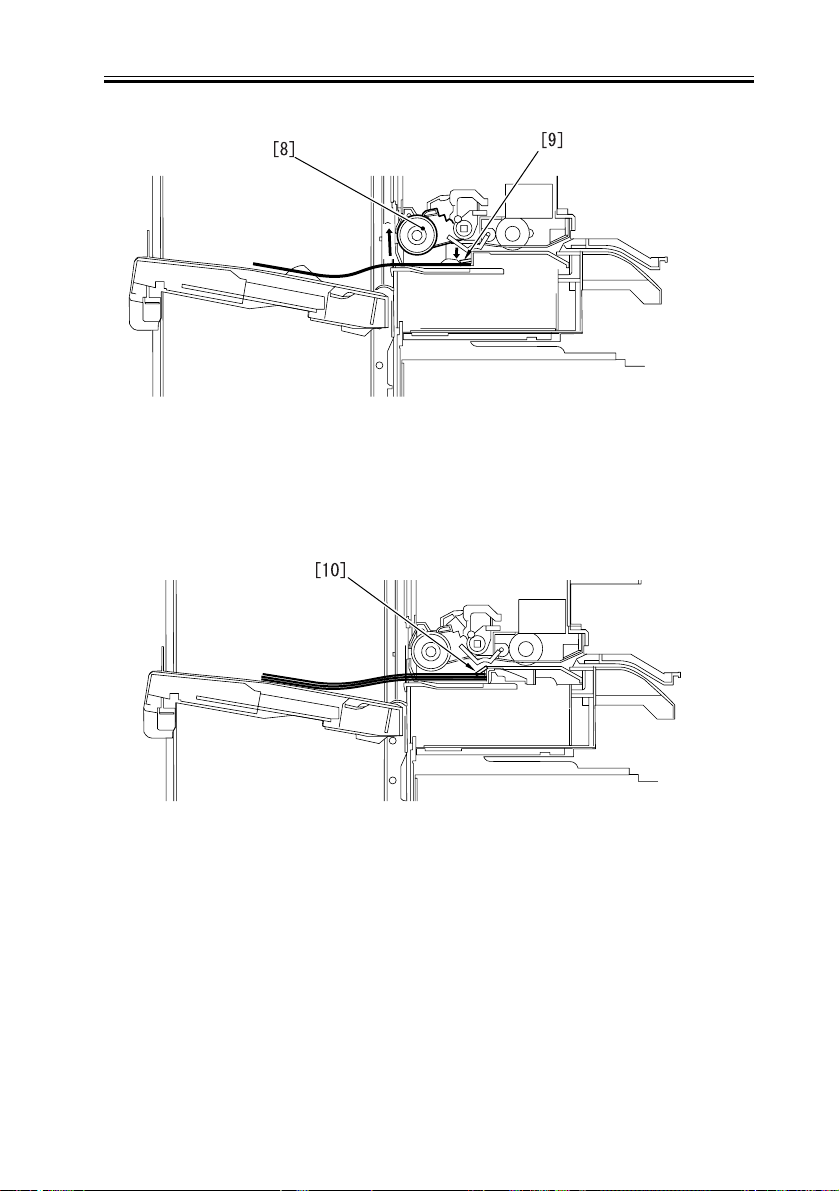

- Ejection of 3-sheet stack (after offsetting and stapling)

1) The offset roller [1] rises.

2) Paper is fed only with the feed roller [2]. (The offset roller and feed roller are driven

together.)

F-2-3

3) The offset roller [3] lowers to feed paper together with the feed roller [4].

4) After passing through the feed roller [4], paper is fed only with the offset roller [3] and

then it stops on the process tray.

0006-1931

2-3

Chapter 2

F-2-4

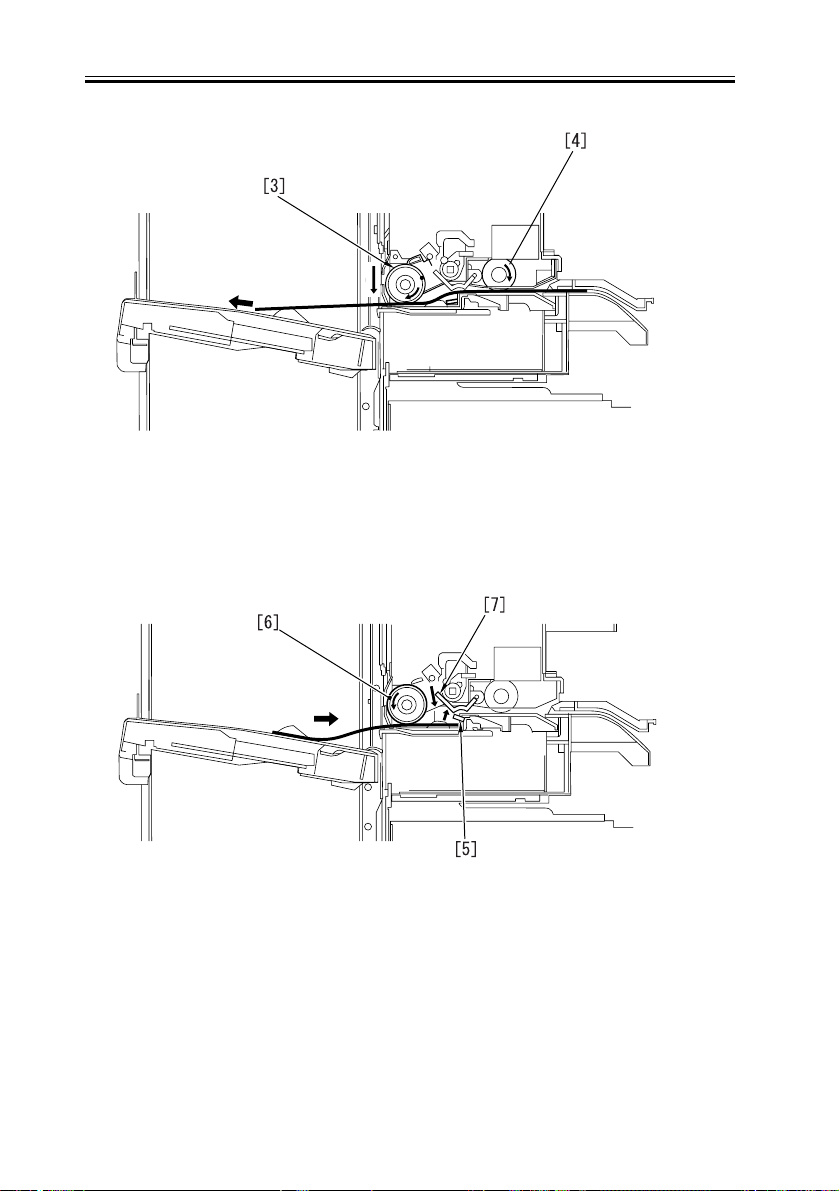

5) The paper holder [5] opens.

6) The offset roller [6] turns reversely to push the paper against the restriction plate.

7) The anti-curl plate [7] blocks the path with the rotation of the feed roller.

F-2-5

8) The offset roller [8] is brought into contact with the upper surface of the paper to offset

the paper. Next, the paper is pushed against the rear restriction plate for alignment.

9) The offset roller [8] is raised to close the paper holder.

2-4

Chapter 2

F-2-6

10) Steps 2 to 10 are repeated to put the succeeding sheet in the process tray.

11) After completion of alignment or stapling, the paper holder [10] catches hold of the

paper stack.

F-2-7

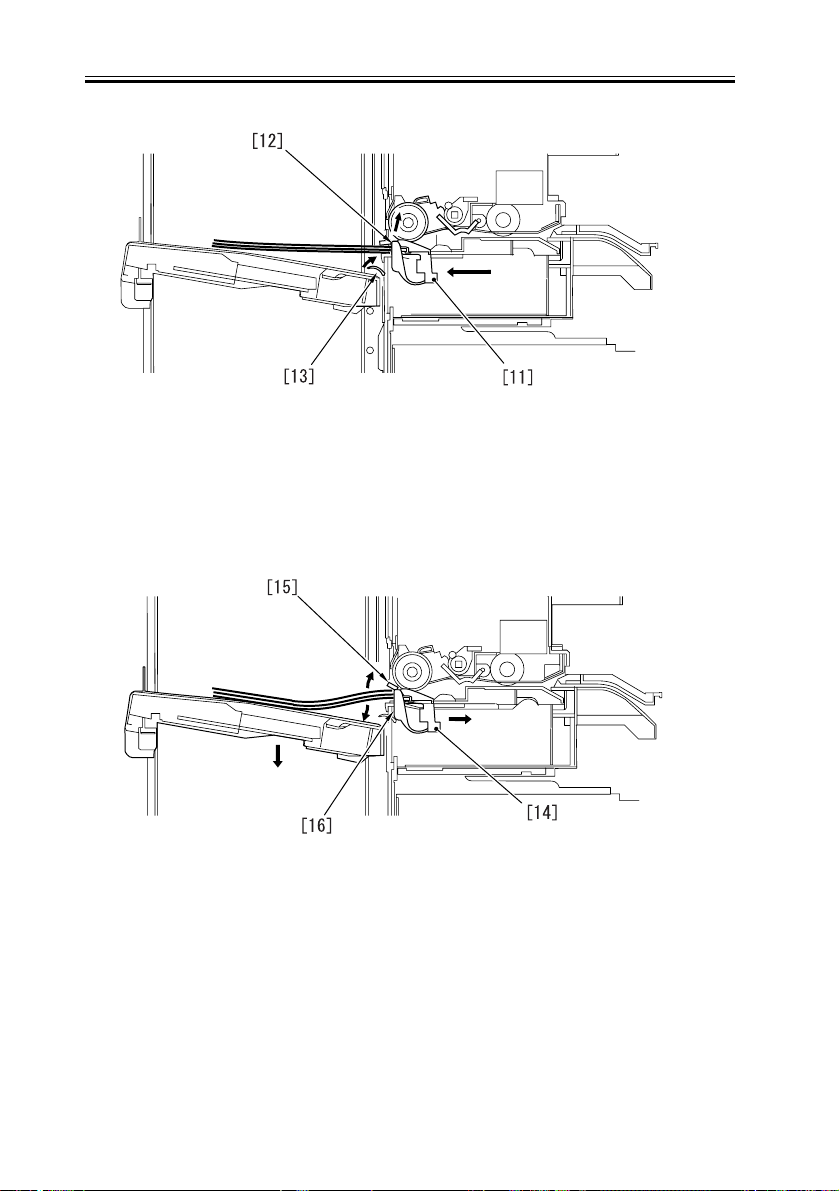

12) With the paper stack held by the paper holder, the stack slider [11] moves toward the

stack tray and stops.

13) The return wall [12] is pressed by the stack slider, being raised on the process tray.

14) The tray paper holder [13] moves away from the stack tray.

2-5

Chapter 2

F-2-8

15) The stack slider [14] moves in the opposite direction from the stack tray.

16) The lever of the paper holder [15] is engaged with the groove in the tray and the paper

holder opens while moving.

17) The stack stops at the return wall [16], falling into the stack stay.

F-2-9

2-6

Chapter 2

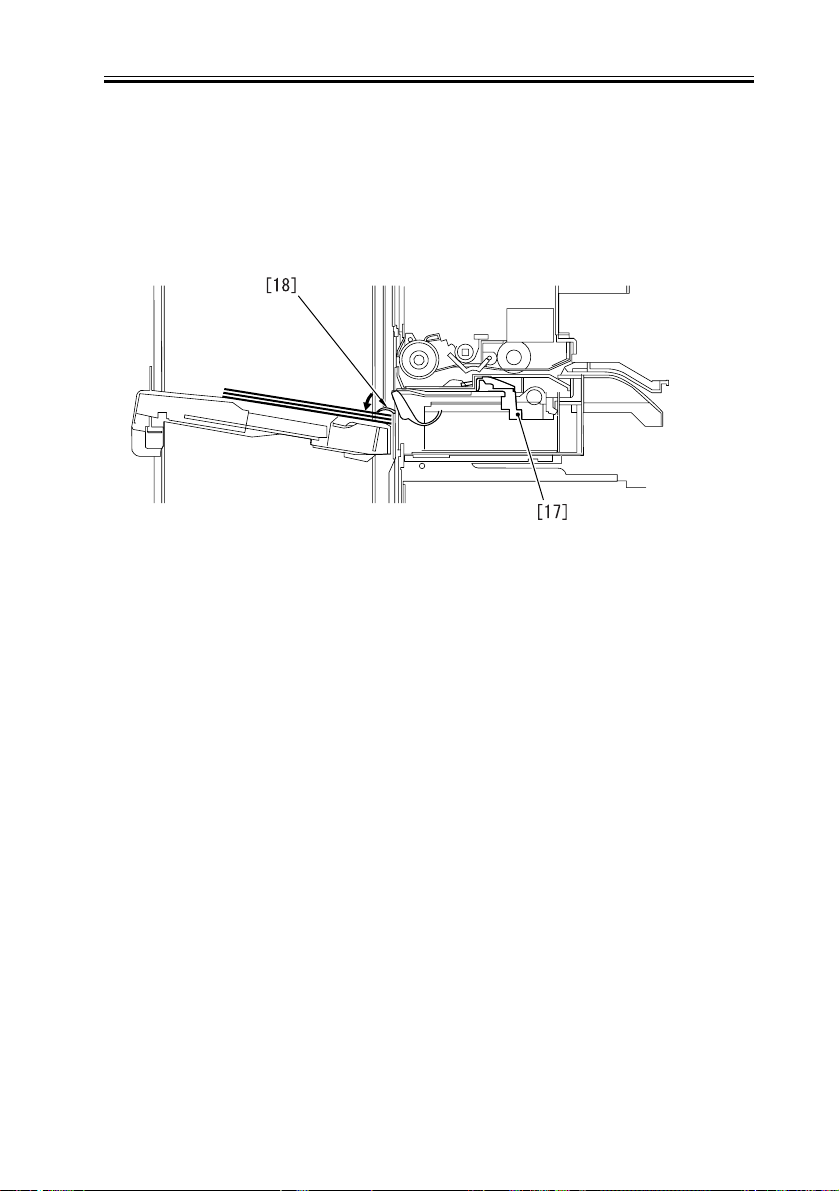

17) The slider [17] moves to the original position.

18) The tray paper holder [18] catches hold of the sheets dropped in the stack tray.

F-2-10

2-7

Chapter 2

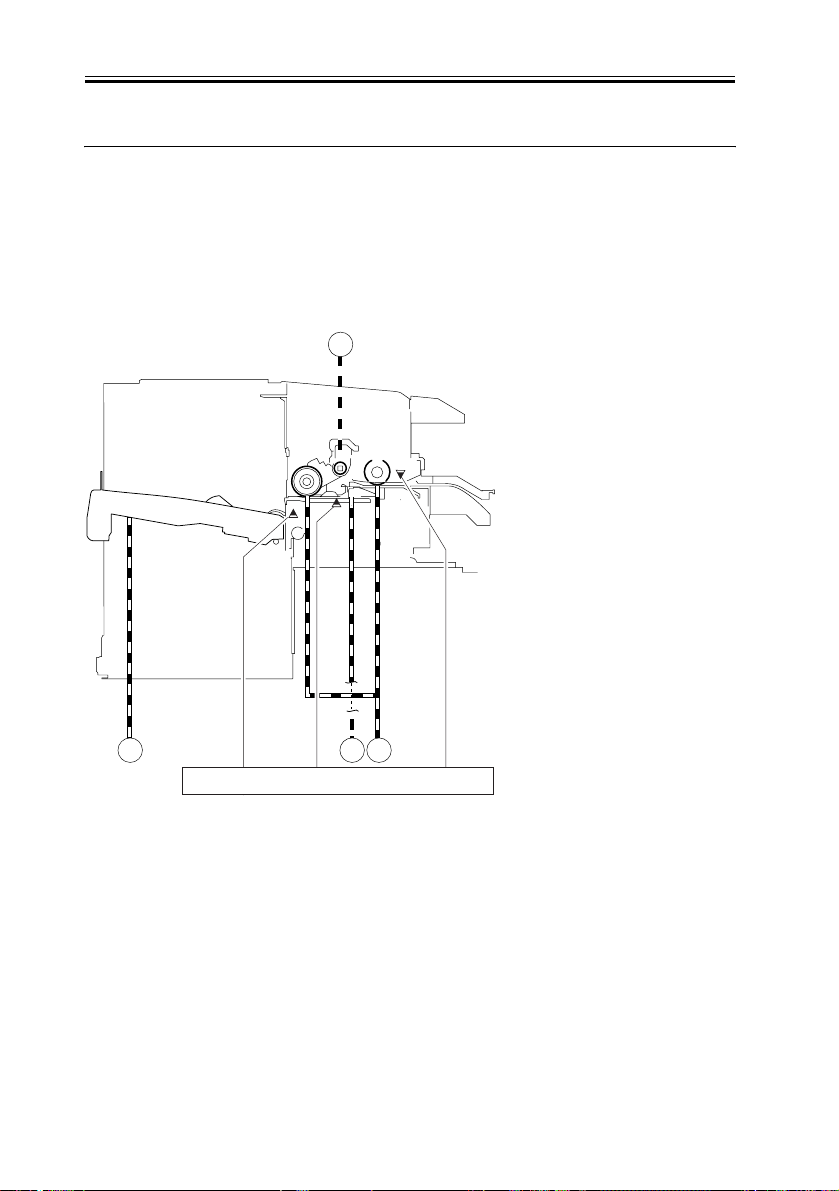

2.3 Feed Drive System

2.3.1 Overview

0006-1934

Sheets of paper fed from the host machine are put in the process tray.

The sheets are aligned and stapled in the process tray and then ejected to the stack tray.

The following illustration shows major components of the feed system.

M4

M1 M3[2]

M2

[4][3]

[1]

F-2-11

M1: Stach tray shift motor

M2: Feed motor

M3: Stack slide motor

M4: Offset motor

[1]: Finisher controller PCB

[2]: Paper surface sensor signal

[3]: Process tray papepr presence sensor signal

[4]: Inlet sensor signal

2-8

Chapter 2

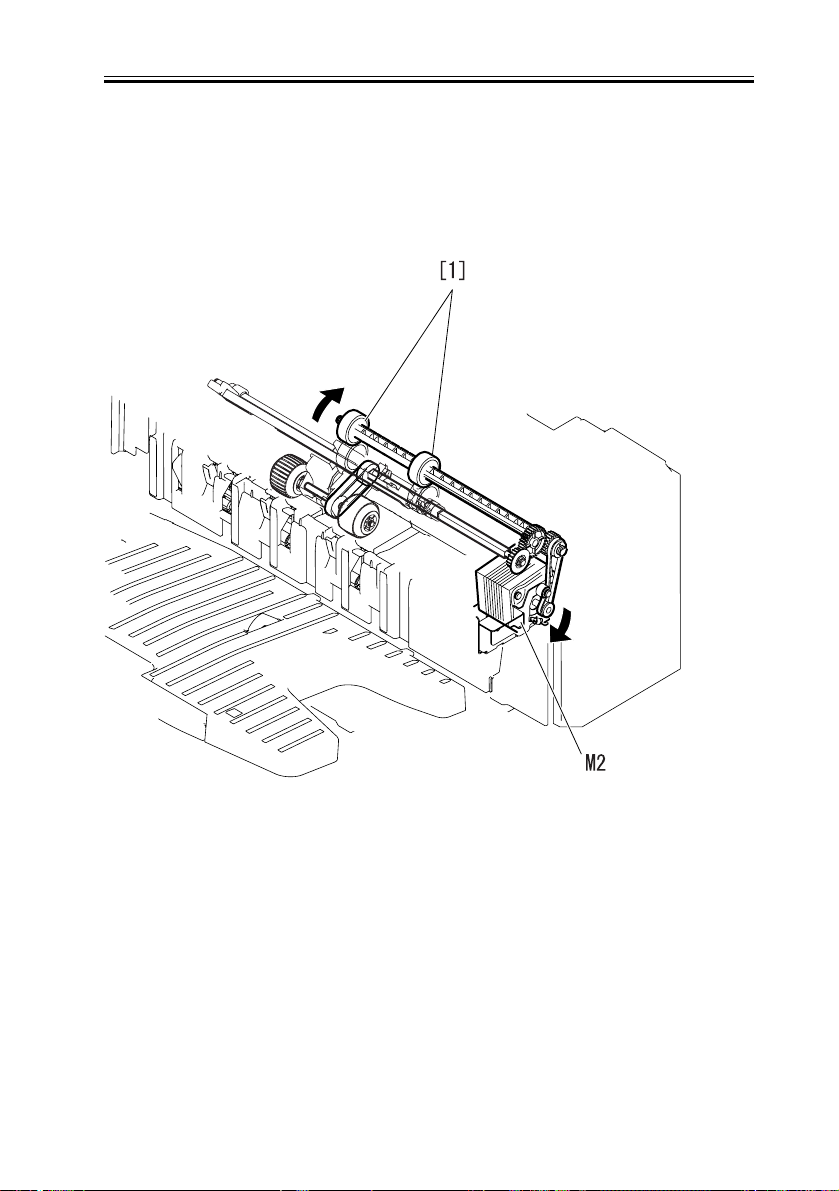

2.3.2 Feed Roller Control

The feed roller is driven by the feed motor (M2).

When the motor turns in the normal direction, the feed roller [1] is driven to eject paper

toward the stack tray.

0007-5484

F-2-12

2-9

Loading...

Loading...