Canon FINISHER-E1 Service Manual

FINISHER-E1

REVSION 0

JAN. 1999

COPYRIGHT © 1999 CANON INC. CANON FINISHER-E1 REV.0 JAN. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

FY8-13FU-000

IMPORTANT

THIS DOCUMENTATION IS PUBLISHED BY CANON INC., JAPAN, TO SERVE AS A SOURCE

OF REFERENCE FOR WORK IN THE FIELD.

SPECIFICATIONS AND OTHER INFORMATION CONTAINED HEREIN MAY VARY SLIGHTLY

FROM ACTUAL MACHINE VALUES OR THOSE FOUND IN ADVERTISING AND OTHER

PRINTED MATTER.

ANY QUESTIONS REGARDING INFORMATION CONTAINED HEREIN SHOULD BE DIRECTED

TO THE COPIER SERVICE DEPARTMENT OF THE SALES COMPANY.

THIS DOCUMENTATION IS INTENDED FOR ALL SALES AREAS, AND MAY CONTAIN IN-

FORMATION NOT APPLICABLE TO CERTAIN AREAS.

COPYRIGHT © 1999 CANON INC.

Printed in Japan

Imprimé au Japon

Use of this manual should be strictly su-

pervised to avoid disclosure of confiden-

tial information.

Prepared by

OFFICE IMAGING PRODUCTS TECHNICAL SUPPORT DIVISION

OFFICE IMAGING PRODUCTS QUALITY ASSURANCE CENTER

CANON INC.

5-1, Hakusan 7-chome, Toride-shi, Ibaraki, 302-8501 Japan

COPYRIGHT © 1999 CANON INC. CANON FINISHER-E1 REV.0 JAN. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

Prepared by

Office Imaging Products Technical Support Division

Office Imaging Products Quality Assurance Center

CANON INC.

Printed in Japan

REVISION 0 (JAN. 1999) (34931)

5-1, Hakusan 7-chome, Toride-shi, Ibaraki, 302-8501 Japan

INTRODUCTION

This Service Manual contains basic data and figures for the Finisher-E1 needed to

service the machine in the field.

Chapter 1 General Description introduces the finisher's features, specifications, and

names of parts, and shows how to operate the finisher.

Chapter 2 Basic Operation discusses the principles of operation used for the finisher's

mechanical and electrical systems. It also explains the timing at which these

systems are operated.

Chapter 3 Mechanical System discusses how the finisher is constructed mechanically,

and shows how it may be disassembled/assembled and adjusted.

Chapter 4 Maintenance and Inspection provides tables of periodically replaced parts and

consumables and durables, together with a scheduled servicing chart.

Chapter 5 Troubleshooting provides tables of maintenance/inspection, standards/

adjustments, and problem identification (image fault/malfunction).

Appendix contains diagrams showing electrical parts arrangement, tables of

signals, tables of special tools, tables of solvents/oils, and a general timing

chart.

For installation, see the Installation Procedure that comes with the finisher.

The descriptions in this Service Manual are subject to change without notice for

product improvement or other purposes, and major changes will be communicated in the

form of Service Information bulletins.

All service persons are expected to have a good understanding of the contents of this

Service Manual and all relevant Service Information bulletins and be able to identify and

isolate faults in the machine.

COPYRIGHT © 1999 CANON INC. CANON FINISHER-E1 REV.0 JAN. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

i

CONTENTS

CHAPTER 1 GENERAL DESCRIPTION

I. FEATURES ..................................1-1

II. SPECIFICATIONS .......................1-2

CHAPTER 2 BASIC OPERATION

I. BASIC CONSTRUCTION ............2-1

II. BASIC OPERATIONS .................. 2-6

III. FEEDING DRIVE SYSTEM .........2-9

IV. INTERMEDIARY PROCESSING

TRAY ASSEMBLY ..................... 2-11

CHAPTER 3 MECHANICAL SYSTEM

I. EXTERNALS AND CONTROLS .. 3-1

II. FEEDING SYSTEM .....................3-6

III. PROCESSING TRAY ................... 3-7

IV. RETURNING ROLLER ..............3-16

III. OPERATING THE MACHINE ...... 1-6

IV.

MAINTENANCE BY THE USER .

V. STAPLING ................................. 2-42

VI. OPERATIONS OF THE STACK

TRAY ......................................... 2-45

VII. DETECTING JAMS ................... 2-53

VIII.POWER SUPPLY ...................... 2-58

V. STACK TRAY .............................3-24

VI. STACK TRAY LIFTER UNIT ...... 3-25

VII. STAPLER...................................3-35

VIII.PCBs ......................................... 3-36

1-11

CHAPTER 4 MAINTENANCE AND INSPECTION

I. PERIODICALLY REPLACED

PARTS.........................................4-1

II. CONSUMABLES AND

DURABLES .................................4-1

COPYRIGHT © 1999 CANON INC. CANON FINISHER-E1 REV.0 JAN. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

III. SCHEDULED MAINTENANCE ... 4-1

iii

CHAPTER 5 TROUBLESHOOTING

I. ADJUSTMENTS .......................... 5-1

II. ARRANGEMENT OF ELECTRICAL

PARTS.......................................5-12

APPENDIX

A. SIGNALS AND

ABBREVIATIONS ....................... A-1

B. GENERAL TIMING CHART ........ A-3

C. GENERAL CIRCUIT DIAGRAM . A-5

III. TROUBLESHOOTING ............... 5-15

IV. SELF DIAGNOSIS ..................... 5-19

D. FINISHER CONTROLLER

CIRCUIT DIAGRAM ................... A-6

E. SOLVENTS AND OILS ............. A-15

iv

COPYRIGHT © 1999 CANON INC. CANON FINISHER-E1 REV.0 JAN. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

CHAPTER 1

GENERAL DESCRIPTION

I. FEATURES .................................. 1-1

II. SPECIFICATIONS ....................... 1-2

COPYRIGHT © 1999 CANON INC. CANON FINISHER-E1 REV.0 JAN. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

III. OPERATING THE MACHINE ...... 1-6

IV. MAINTENANCE BY THE

USER ........................................ 1-11

CHAPTER 1 GENERAL DESCRIPTION

I. FEATURES

1. Small in Size, Light in Weight

The finisher is designed as a small, light delivery device.

2. Mono-Frame

The finisher is cased in a mono-frame, which has enabled reduction of the number of covers.

3. Sorting and Stapling by Stack Offset

The finisher puts together stacks of sheets on its intermediary processing tray for offset

sorting and stapling.

4. Stack Tray

The finishers stack tray is capable of holding as many as 1,000 sheets of small-size paper or

15 sheets of large-size paper.

Further, it can hold as many as 30 sets of stapled stacks (each consisting of up to 30 sheets).

COPYRIGHT © 1999 CANON INC. CANON FINISHER-E1 REV.0 JAN. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

1-1

CHAPTER 1 GENERAL DESCRIPTION

II. SPECIFICATIONS

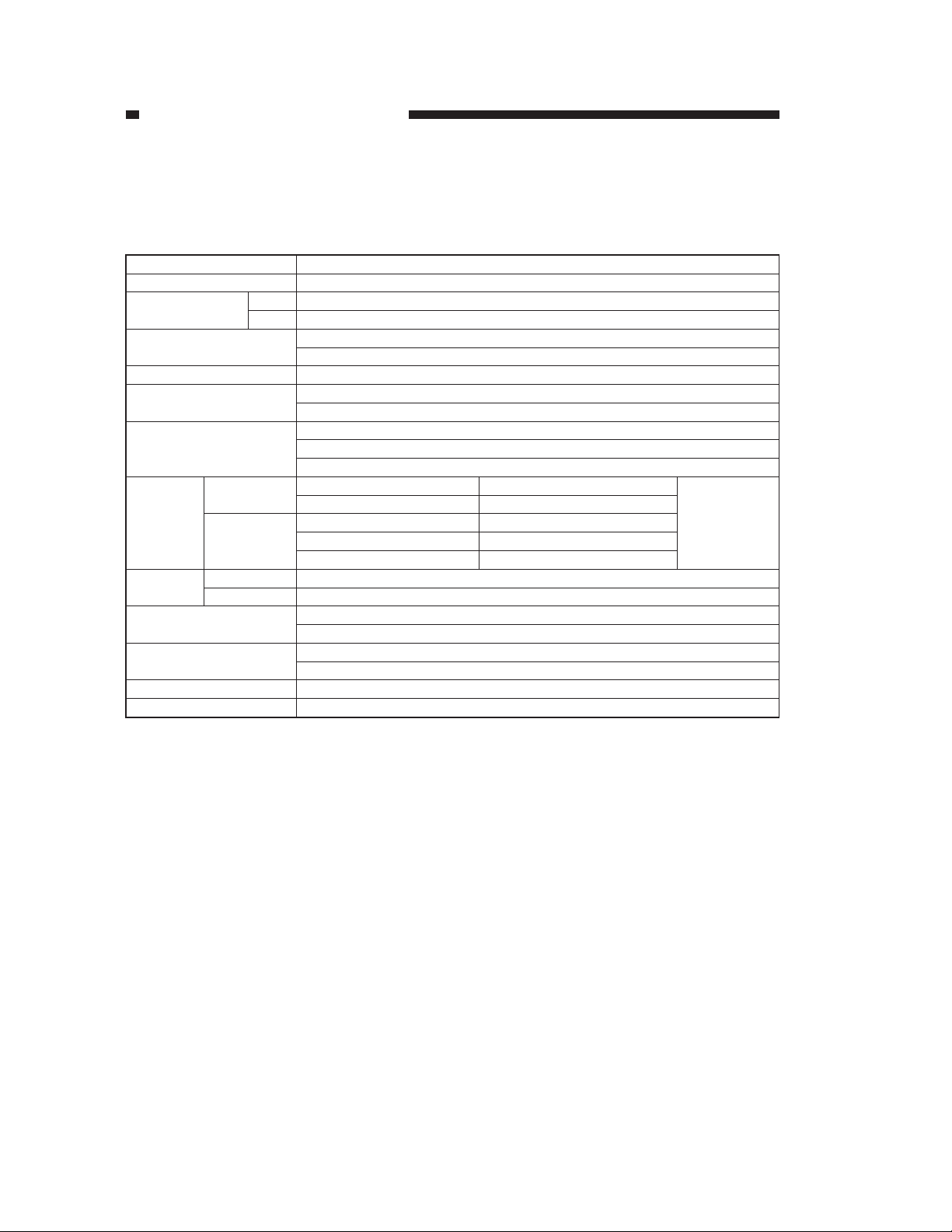

A. Specifications

Item

Stacking

Stacking mode

Stack paper size

Paper weight

Bins

Modes

Stack tray

No stapling

capacity

Staple

sorting

Stacking

width*4

Not stapled

Stapled

Stacking size

Stapling size

Stack offset width*6

Offset width*5

A/B

Inch

Description

Stack tray (tray lift mechanisms, with intermediary tray fixed in position)

Face-down stacking

Face-up stacking (1-to-n mode)

A3, A4, A4R, A5, A5R, B4, B5, B5R, postcard

279x432 mm (11"x17"), LGL, LTR, LTRR, STMT, STMTR

64 to 128 g/m

2

Stack tray 1

Intermediary processing tray 1

Staple stacking

Non-staple stacking

Non-staple offset stacking

Small-size

Medium-/large-size

Small-size*1

Medium-size*2

Large-size*3

1,000 sheets

500 sheets

30-sheet stack (30 sets max.)

20 stacks (30 sets max.)

15 stacks (30 sets max.)

Equivalent of

2

80 g/m

paper

139.7 to 297 mm

210 to 297 mm (stapling not available for A5)

A3, A4, A4R, A5, A5R, B4, B5, B5R

279 x 432 mm (11" x 17"), LGL, LTR, LTRR, STMT, STMTR

A3, A4, A4R, B4, B5

279 x 432 mm (11" x 17"), LGL, LTR, LTRR

210 to 297 mm

20 mm

1-2

COPYRIGHT © 1999 CANON INC. CANON FINISHER-E1 REV.0 JAN. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

CHAPTER 1 GENERAL DESCRIPTION

Item

Stapling method

Stapling position

Stack thickness

Staple source

Staple

Staple detection

Manual stapling

Paper detection

Control panel

Display

Dimensions (WxDxH)

Weight

Power supply

Maximum power

consumption

Serial number

Punching by rotating cam

1-point rear, slant (Figure 1-101)

Small-size 30 sheets max.

Medium-size 20 sheets max.

Large-size 15 sheets max.

Special cartridge (3,000 staples)

Special staple (Staple L1)

Yes

No

Yes

No (operated from copier)

None (display on copier)

553 x 574 x 362 mm

12 kg for body; 3 kg for installation kit

24V (from copier)

40W or less

ZRZ

Description

*1 Small-size, i.e., A4, A4R, A5, A5R, B5, B5R, postcard, LTR, LTRR, STMT, and STMTR.

*2 Medium-size, i.e., B4 and LGL.

*3 Large-size, i.e., A3 and 279 x 432 mm (11" x 17").

*4 The width of paper that may be put into order in front/rear direction.

*5 The distance a stack is displaced during sorting.

*6 The width of paper that may be put into order during sorting.

45˚

5±2mm

5±2mm

Figure 1-201 Stapling Positions

COPYRIGHT © 1999 CANON INC. CANON FINISHER-E1 REV.0 JAN. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

1-3

CHAPTER 1 GENERAL DESCRIPTION

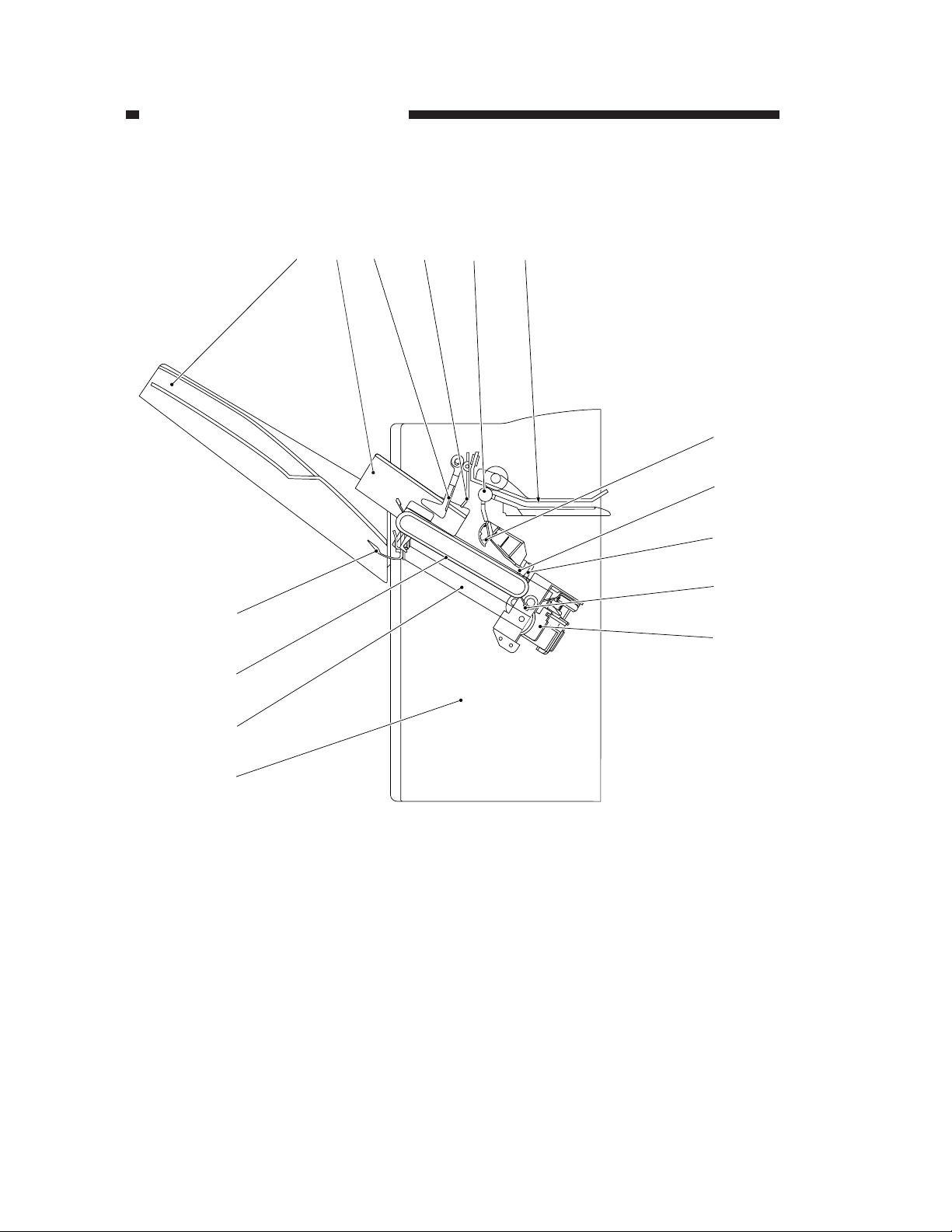

n Cross Section

[1] [2] [3] [4] [5] [6]

[7]

[8]

[11A]

[10]

[11]

[12]

[13]

[1] Stack tray

[2] Jogging plate (front, rear)

[3] Paper feeding guide A

[4] Paper feeding guide B

[5] Delivery roller

[6] Paper path

[7] Returning roller

[8] Stopper plate

[11B]

[9]

[9] Stapler unit

[10] Paper holding lever

[11] Stack delivery belt

[11A] Stack delivery lever

[11B] Intermediary processing tray

auxiliary plate

[12] Intermediary processing tray

[13] Frame

Figure 1-202

1-4

COPYRIGHT © 1999 CANON INC. CANON FINISHER-E1 REV.0 JAN. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

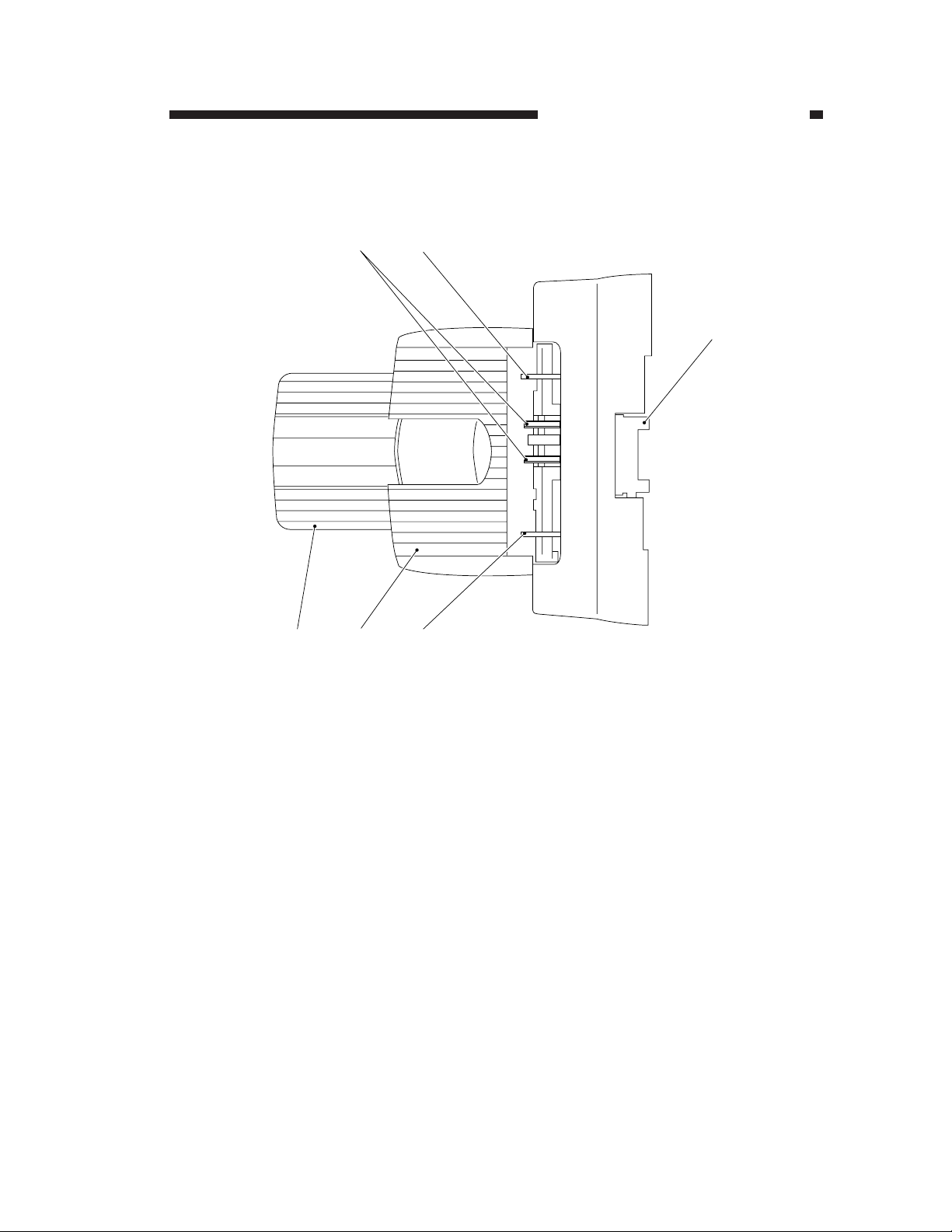

n Top View

CHAPTER 1 GENERAL DESCRIPTION

[1] [2]

[3]

[4] [5] [6]

[1] Stack delivery belt

[2] Rear jogging plate

[3] Grip

[4] Stack extension tray

[5] Stack tray

[6] Front jogging plate

Figure 1-203

COPYRIGHT © 1999 CANON INC. CANON FINISHER-E1 REV.0 JAN. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

1-5

CHAPTER 1 GENERAL DESCRIPTION

III. OPERATING THE MACHINE

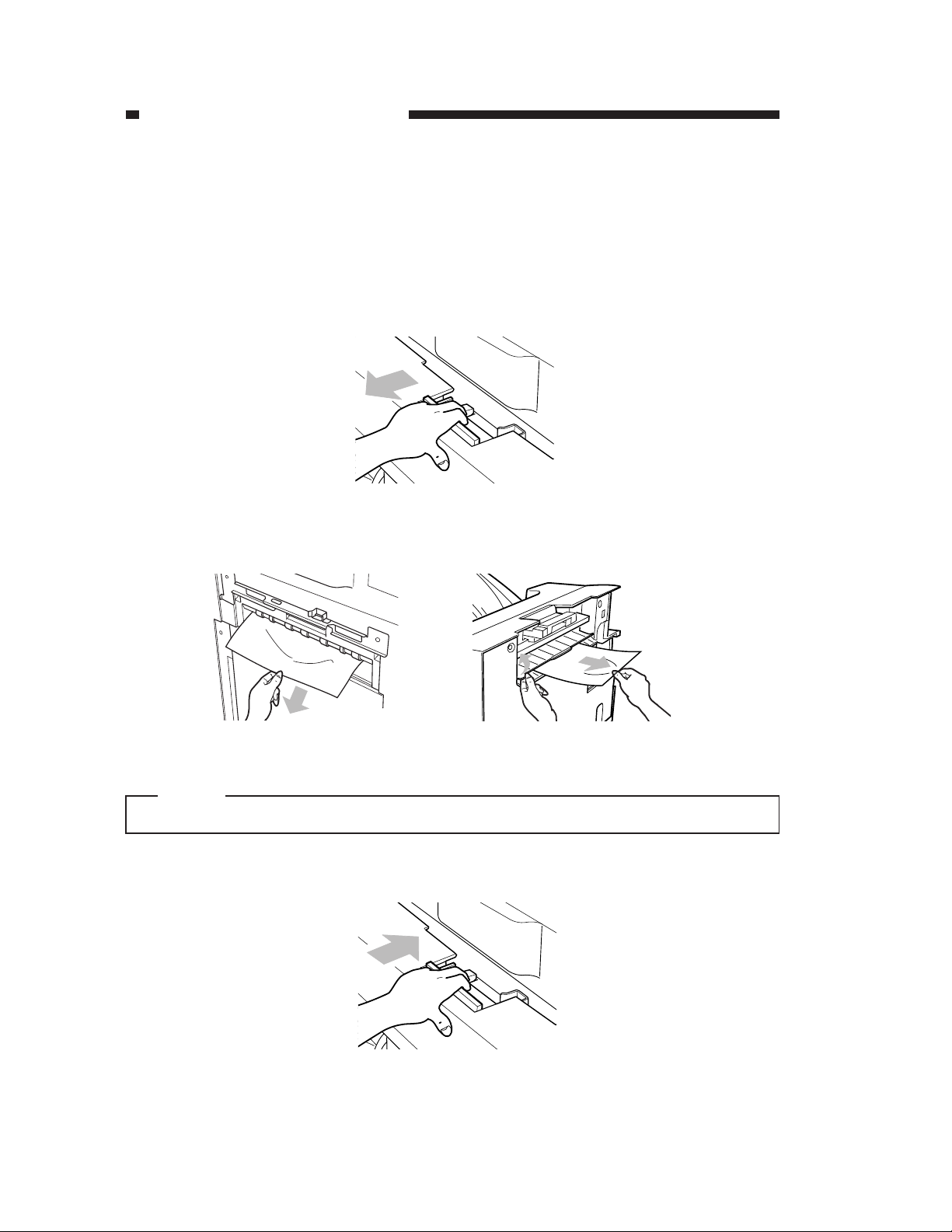

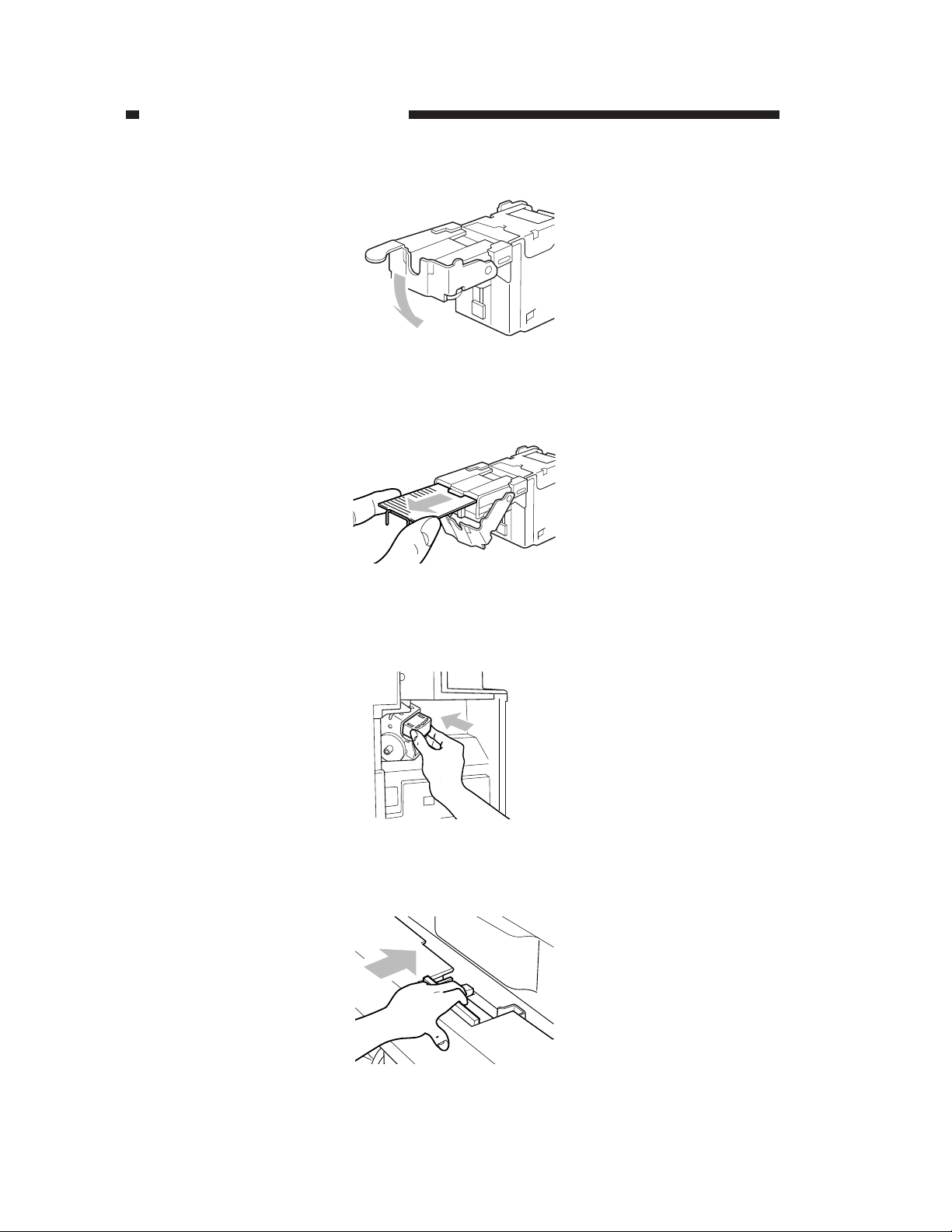

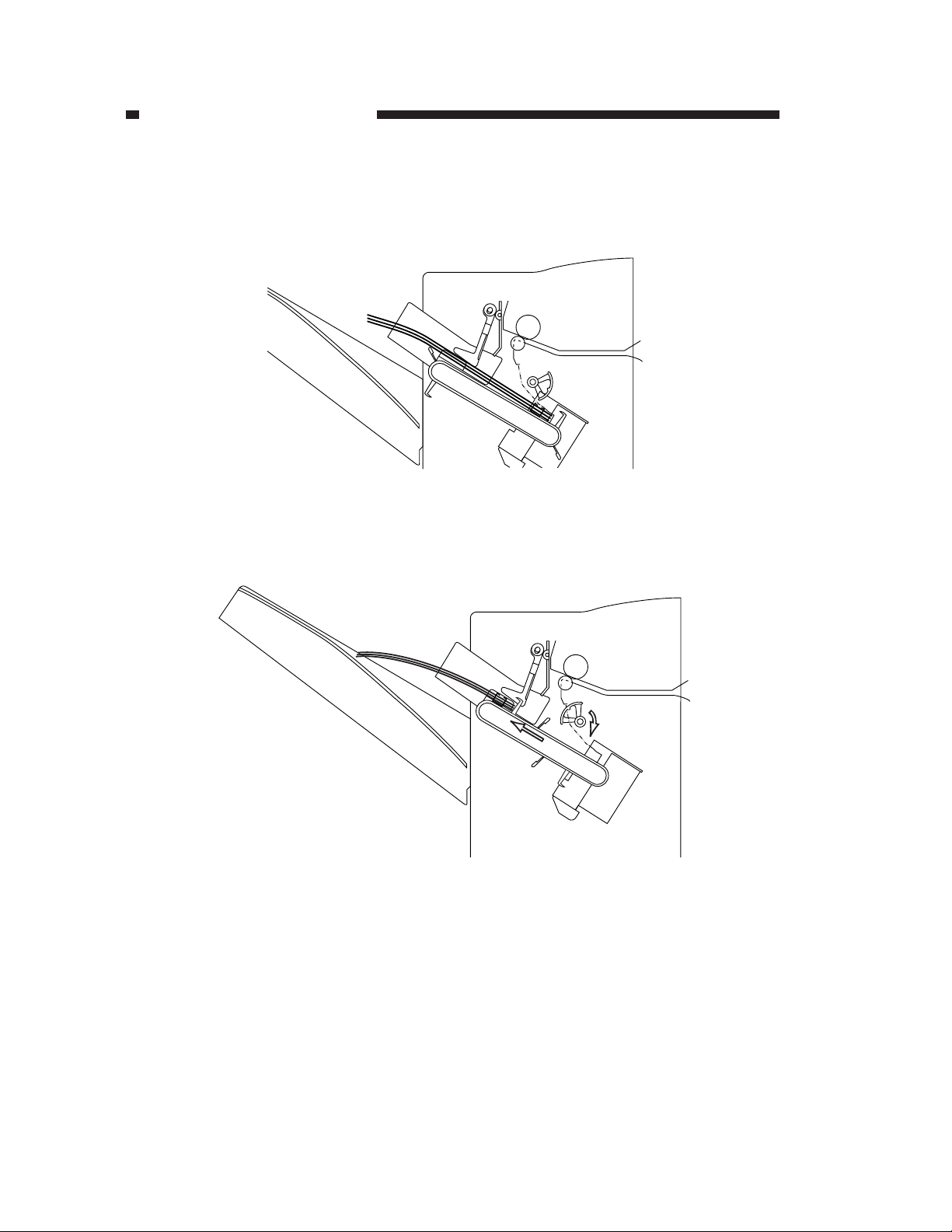

A. Removing Paper Jams

If the Jam indicator turns on to indicate the presence of a jam in the finisher, perform the

following:

1) Grasping the grip, disconnect the finisher from the copier.

Figure 1-301

2) Remove the paper visible from the outside.

Figure 1-302

Caution:

Do not remove the paper from the intermediary processing tray before removing the jam.

3) Connect the finisher to the copier.

Figure 1-303

1-6

COPYRIGHT © 1999 CANON INC. CANON FINISHER-E1 REV.0 JAN. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

CHAPTER 1 GENERAL DESCRIPTION

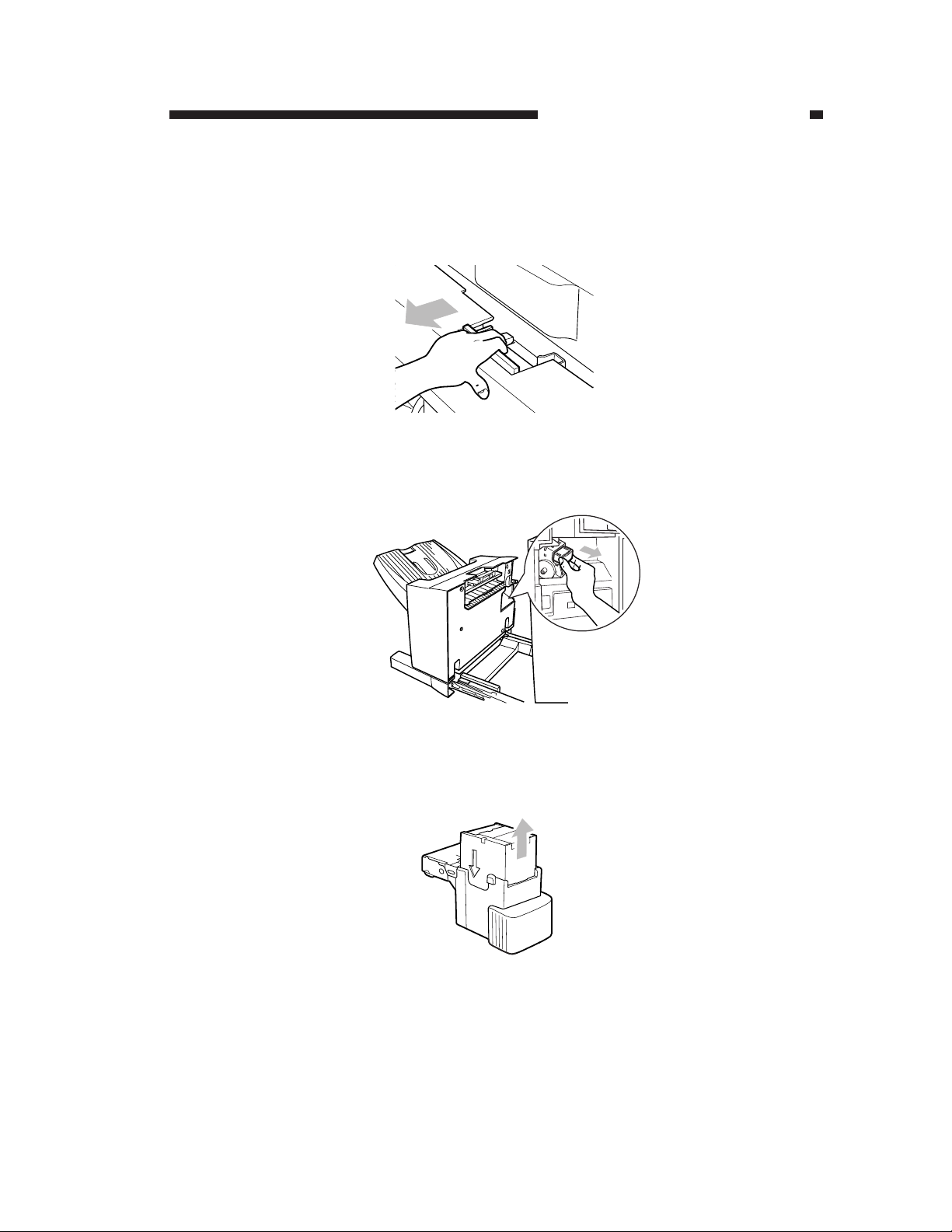

B. Supplying the Stapler Unit with Staples

If the Add Staples indicator turns on, perform the following:

1) Grasping the grip, disconnect the finisher from the copier.

Figure 1-304

2) Pick the staple cartridge on its left and right sides (green), and pull it out.

Figure 1-305

3) Pick the empty staple case on its left and right, and pull it off.

Figure 1-306

COPYRIGHT © 1999 CANON INC. CANON FINISHER-E1 REV.0 JAN. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

1-7

CHAPTER 1 GENERAL DESCRIPTION

4) Set the new staple case.

Figure 1-307

Reference:

No more than one staple case may be set. Be sure to use a staple cartridge specially designed for

the machine.

5) Remove the seal used to hold the staples together by pulling it straight up.

Figure 1-308

6) Fit the staple cartridge into the stapler unit.

Figure 1-309

7) Connect the finisher to the copier.

Figure 1-310

1-8

COPYRIGHT © 1999 CANON INC. CANON FINISHER-E1 REV.0 JAN. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

CHAPTER 1 GENERAL DESCRIPTION

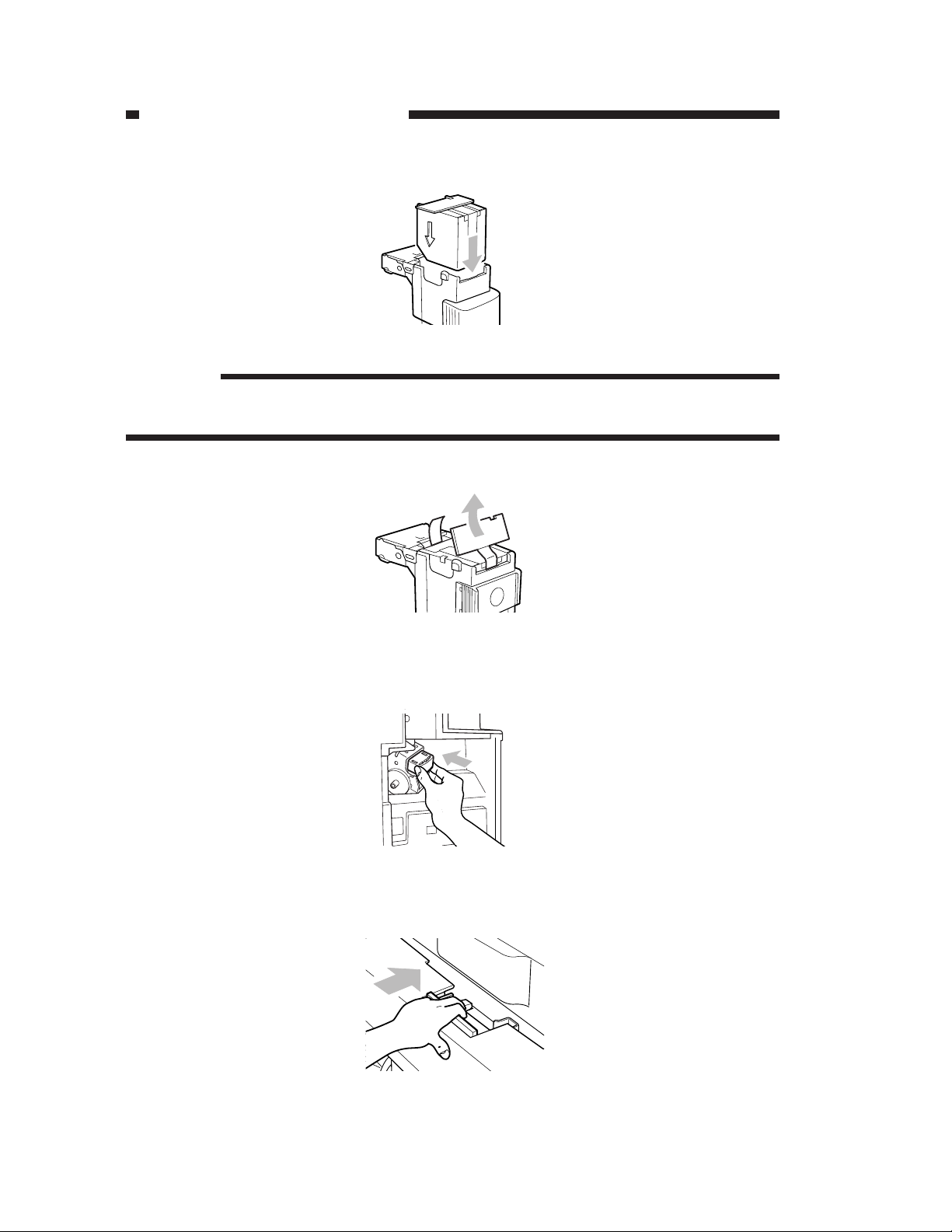

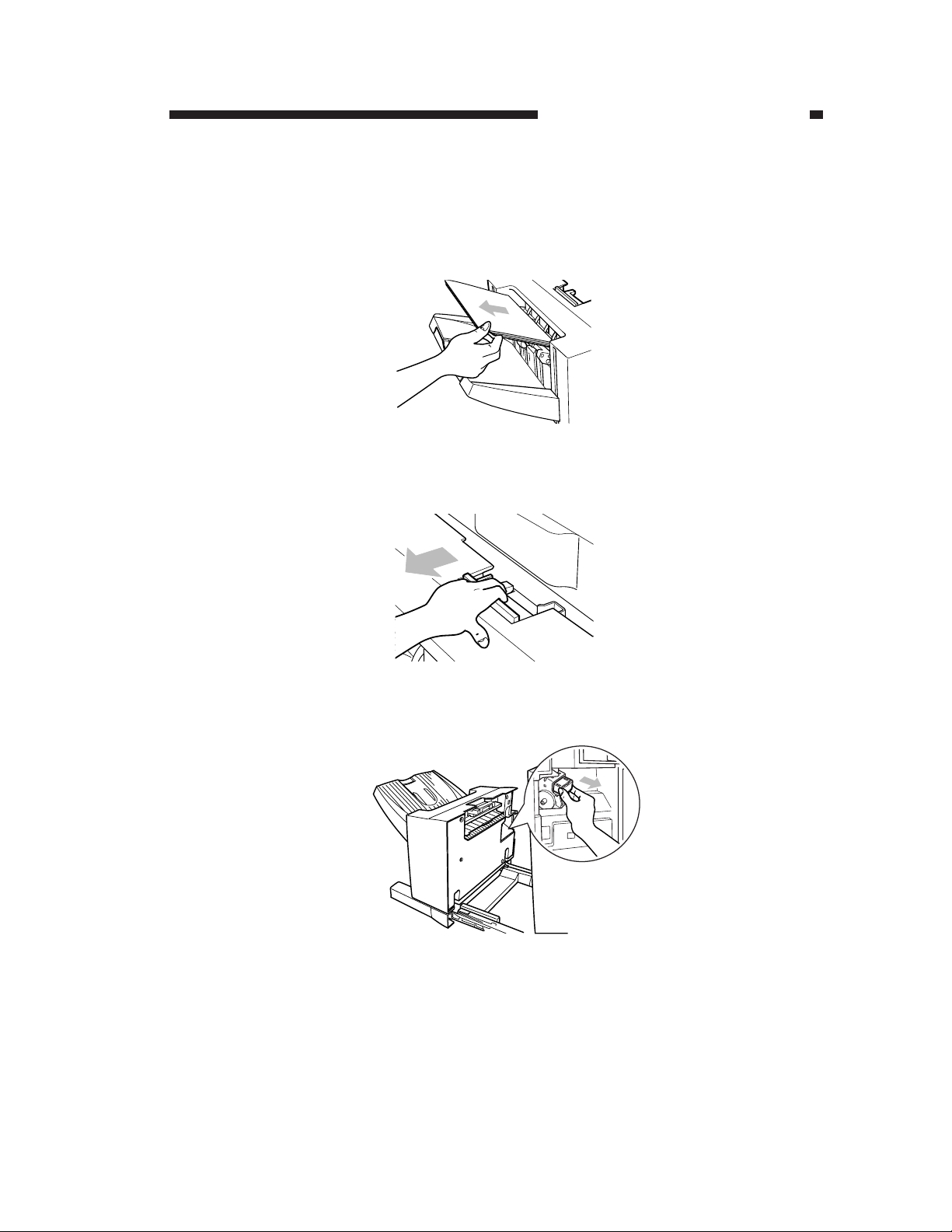

C. Removing a Staple Jam from the Stapler Unit

If the Staple Jam indicator turns on to indicate a staple jam in the stapler unit, perform the

following:

1) Remove the paper waiting to be stapled from the processing tray.

Figure 1-311

2) Grasping the grip, disconnect the finisher from the copier.

Figure 1-312

3) Pick the staple cartridge on its left and right (green), and pull it off.

Figure 1-313

COPYRIGHT © 1999 CANON INC. CANON FINISHER-E1 REV.0 JAN. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

1-9

CHAPTER 1 GENERAL DESCRIPTION

4) Shift down the staple cartridge.

Figure 1-314

5) Remove all staples that slid out of the staple case.

Figure 1-315

6) Shift the tab of the staple cartridge back to its initial position, and fit the staple cartridge into the

stapler unit.

Figure 1-316

7) Connect the finisher to the copier.

1-10

Figure 1-317

COPYRIGHT © 1999 CANON INC. CANON FINISHER-E1 REV.0 JAN. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

CHAPTER 1 GENERAL DESCRIPTION

IV. MAINTENANCE BY THE USER

A. Maintenance by the User

No.

Replacement of the staple cartridge

1

Item

Timing

When prompted on the copiers display

Table 1-401

COPYRIGHT © 1999 CANON INC. CANON FINISHER-E1 REV.0 JAN. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

1-11

CHAPTER 2

BASIC OPERATION

I. BASIC CONSTRUCTION ............2-1

II. BASIC OPERATIONS .................. 2-6

III. FEEDING DRIVE SYSTEM ......... 2-9

IV. INTERMEDIARY PROCESSING

TRAY ASSEMBLY...................... 2-11

COPYRIGHT © 1999 CANON INC. CANON FINISHER-E1 REV.0 JAN. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

V. STAPLING ................................. 2-42

VI. OPERATIONS OF THE STACK

TRAY ......................................... 2-45

VII. DETECTING JAMS ................... 2-53

VIII.POWER SUPPLY ...................... 2-58

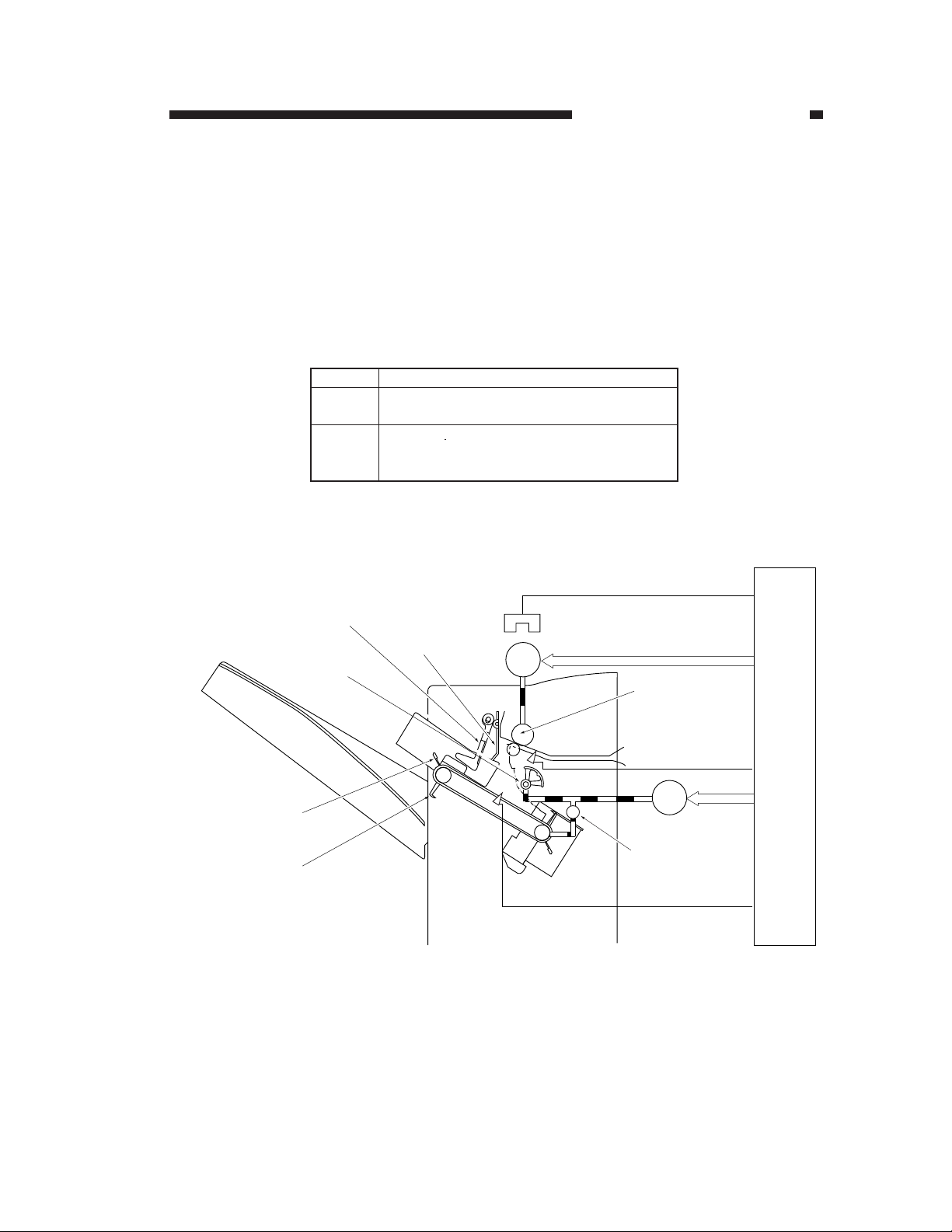

CHAPTER 2 BASIC OPERATION

I. BASIC CONSTRUCTION

A. Outline

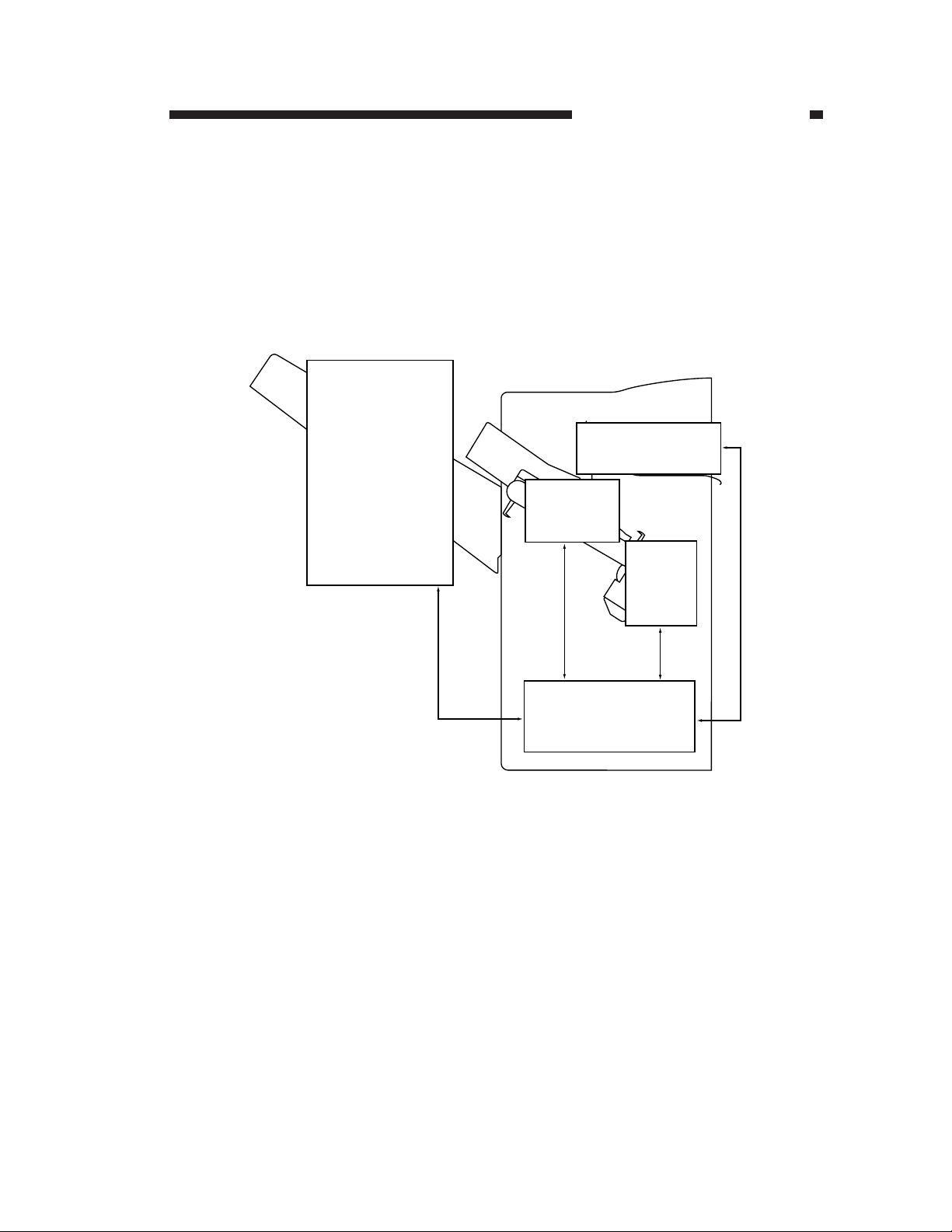

The finisher consists of four blocks: intermediary processing tray assembly, stapler assembly,

and stack tray assembly. Figure 2-101 is a functional diagram of the finisher.

Stack tray

assembly

Delivery assembly

Intermediary

processing

tray assembly

Stapler

assembly

Finisher controller

PCB

Figure 2-101

COPYRIGHT © 1999 CANON INC. CANON FINISHER-E1 REV.0 JAN. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

2-1

CHAPTER 2 BASIC OPERATION

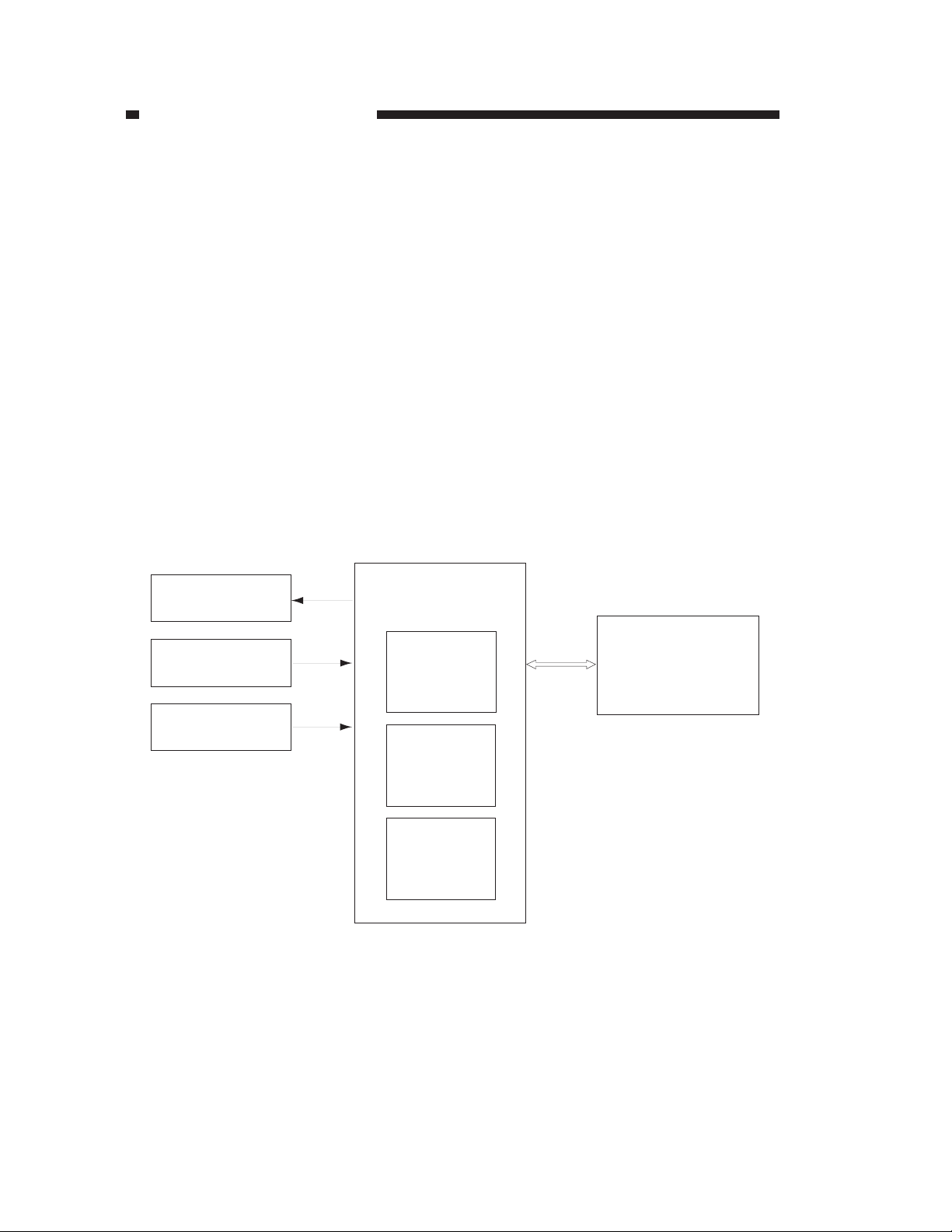

B. Outline of Electrical Circuitry

The finishers operation sequences are controlled by the finisher controller PCB, which is a 32-

bit CPU. The finisher controller PCB is also used to control communication (serial) with the copier.

The CPU on the finisher controller PCB is equipped with a built-in ROM used to store

operation sequence programs.

The finisher controller PCB drives motors in response to various commands coming from the

copier through serial communication lines. On the other hand, it communicates the state of each

sensor and switch to the copier in serial mode of communication.

The ICs on the finisher controller PCB have the following functions:

n Q1 (CPU; w/ built-in flash ROM)

Controls sequence.

Stores sequence programs.

n Q2 (communication IC)

Communicates with the copier (IPC II).

n Q8 (regulator IC)

Generates 5 V used to drive sensors and logic system.

Motor

Sensor

Switch

Finisher controller

PCB

Q1

CPU

Q2

Communication

IC

Q8

Regulator

IC

Figure 2-102

Copier

(CPU on DC

controller PCB)

2-2

COPYRIGHT © 1999 CANON INC. CANON FINISHER-E1 REV.0 JAN. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

CHAPTER 2 BASIC OPERATION

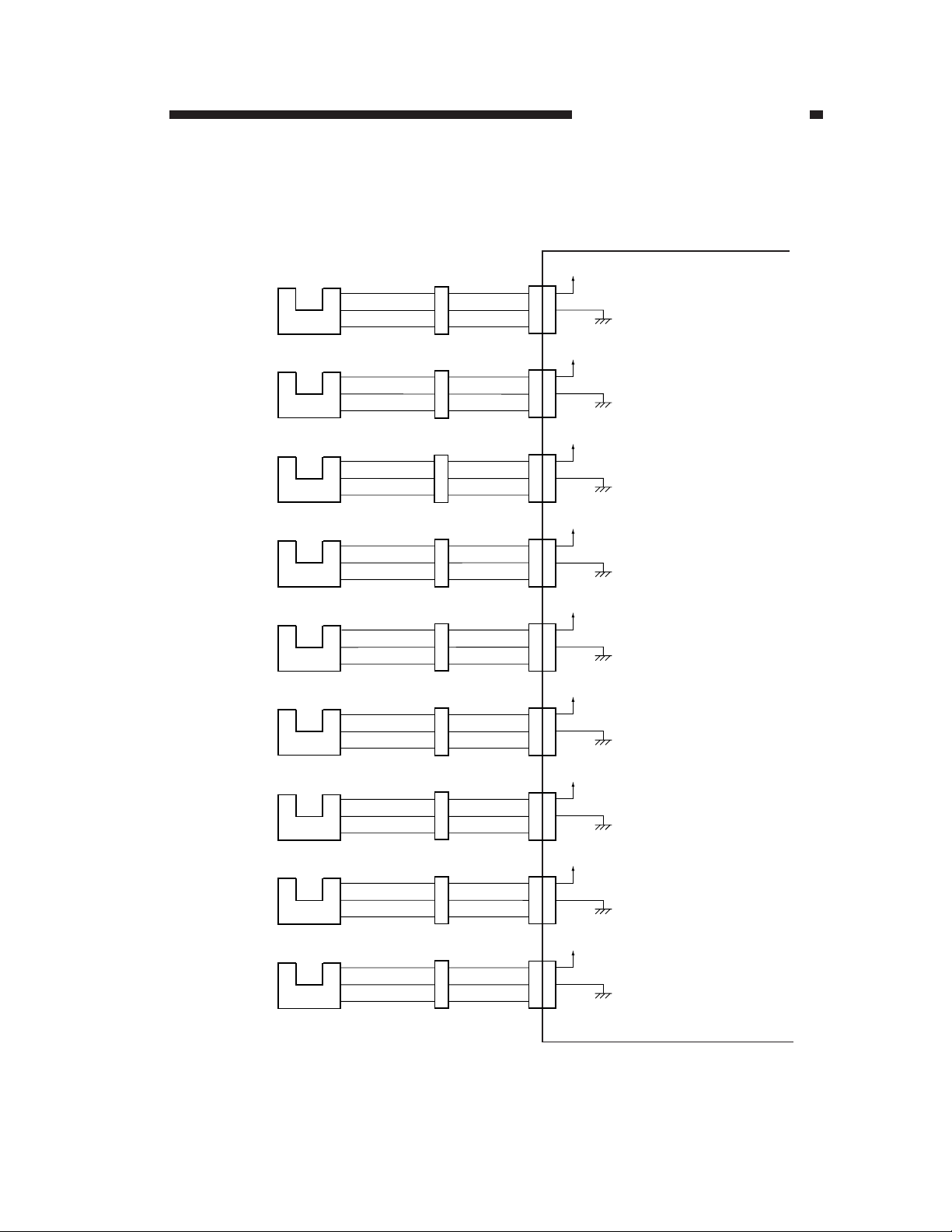

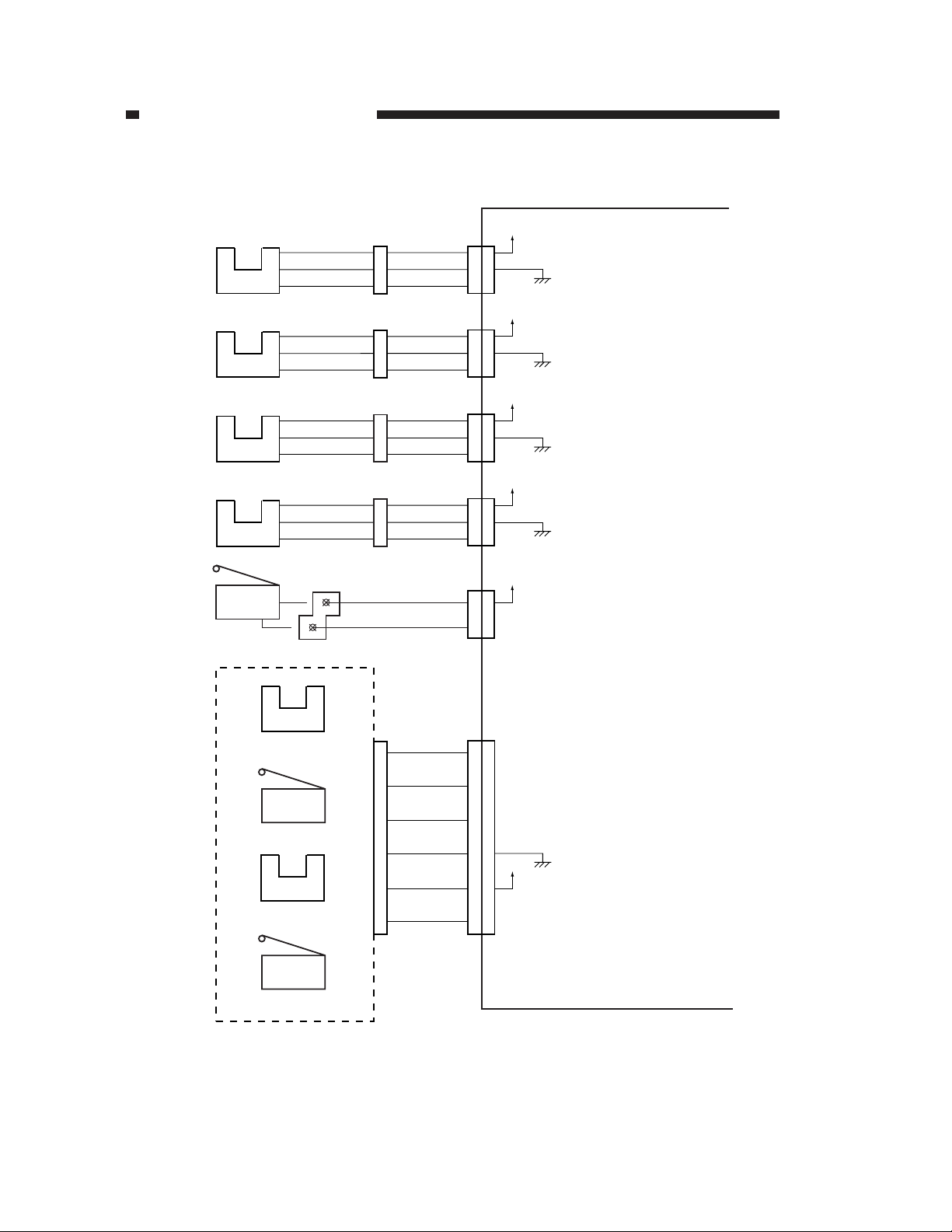

C. Inputs to and Outputs from the Finisher Controller PCB

Inputs to the Finisher Controller PCB (1/2)

Delivery motor

clock sensor

Inlet sensor

Returning roller

home position sensor

Joint sensor

Intermediary

processing tray

paper sensor

Front jogging plate

home position sensor

Rear jogging plate

home position sensor

Stack delivery lever

home position sensor

Stack tray lift

clock sensor

S1

S2

S3

S4

S5

S6

S7

S8

S9

J602

J612

J603

J610

J504

J502

J503

J505

J609

Finisher controller PCB

J601

J10

+5V

1

1

2

2

S1D

3

3

J11

J605

J601

J605

J501

J501

J501

J501

10

11

12

J604

+5V

16

7

17

8

S2D

18

9

J10

+5V

4

4

5

5

S3D

6

6

J11

+5V

10

1

11

2

S4D

12

3

J9

+5V

7

7

8

8

S5D

9

9

J9

+5V

1

1

2

2

S6D

3

3

J9

+5V

4

4

5

5

S7D

6

6

J9

+5V

10

11

S8D

12

J11

+5V

7

7

8

8

S9D

9

9

Pulses according to the rotation

speed of the delivery motor.

When paper is moving over

the sensor, '1'.

(The light-detecting plate is at S2.)

When the returning roller is

at the home position, '1'.

(The light-blocking plate is at S3.)

When the finisher is connected

to the copier, '0'.

(The light-blocking plate is not at S4.)

When paper is over the sensor, '1'.

(The light-blocking plate is at S5.)

When the front jogging plate is

at the home position, '1'.

(The light-blocking plate is at S6.)

When the rear jogging plate is

at the home position, '1'.

(The light-blocking plate is at S7.)

The stack delivery plate is

at the home position, '0'.

(The light-blocking plate is not at S8.)

Pulses according to the rotation speed

of the stack tray lift motor.

Figure 2-103

COPYRIGHT © 1999 CANON INC. CANON FINISHER-E1 REV.0 JAN. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

2-3

CHAPTER 2 BASIC OPERATION

Inputs to the Finisher Controller PCB (2/2)

Stack tray paper

height sensor

Stack tray paper

sensor

Stack tray lower

limit sensor

Stack tray upper

limit sensor

Stapler safety

switch

S10

S11

S12

S13

S14

N.O.

J611

J702

J607

J608

Finisher controller PCB

J605

J11

+5V

4

13

5

14

6

15

S10D

J701

J12

+5V

1

1

2

2

S11D

3

3

J604

J11

+5V

1

1

2

2

S12 D

3

3

J11

J604

J801

4

5

6

121

4

5

6

2

+5V

S13D

J7

+24V

S14D

When the top of paper is

detected, '1'.

(The light-blocking is at S10.)

When paper is over the sensor, '1'.

(The light-blocking plate is at S11.)

When the stack tray is

at the lower limit, '1'.

(The light-blocking plate is at S12.)

When the stack tray is

at the upper limit, '1'.

(The light-blocking plate is not at S13.)

When the switch is open,

'1'.

Stapler staple

absent sensor

Stapler edging

sensor

Stapling home

position sensor

Stapler cartridge

sensor

2-4

S15

J602

7

8

J401

J8

7

7

S15D

S16D

8

8

When the stapler has no staple, '1'.

(The light-blocking plate is not at S15.)

The tip of the staple is not at stapling position, '1'.

S16

S17

9

11

12

13

9

1111

1212

13

S17D

9

+5V

13

S18D

When the stapler is at stapling home position, '0'.

(The light-blocking plate is at S17.)

When the stapler cartridge is not set,

'1'.

S18

Stapler unit

Figure 2-104

COPYRIGHT © 1999 CANON INC. CANON FINISHER-E1 REV.0 JAN. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

Outputs of the Finisher Controller PCB

Delivery motor

Stack processing

motor

Front jogging motor

M1

M2

M3

J202

J304

J302

CHAPTER 2 BASIC OPERATION

Finisher controller PCB

J4

1

M1DA

2

M1DB

3

M1DA*

4

M1DB*

J201

J301

5

6

J5

1

1

2

2

3

3

4

4

5

5

6

6

J6

1

1

2

2

3

3

4

4

5

5

6

6

24V

M2DA

M2DB

M2DA*

M2DB*

M3DA

M3DB

M3DA*

M3DB*

By changing the sequence of drive

pulses (A, A*, B, B*) and the

frequency, the timing of rotation

is controlled.

By changing the sequence of drive

pulses (A, A*, B, B*) and the

frequency, the timing of rotation

is controlled.

(See p. 2-12)

24V

By changing the sequence of drive

pulses (A, A*, B, B*) and the

frequency, the timing of rotation

is controlled.

24V

(See p.2-26.)

Rear jogging motor

Stack tray lift

motor

Stapler motor

M4

M5

M6

Stapler unit

J402

J305

J303

Figure 2-105

J301

J401

J6

7

7

M4DA

8

8

M4DB

9

9

M4DA*

10

10

M4DB*

11

11

12

12

J3

M5D1

1

2

M5D2

By changing the sequence of drive

pulses (A, A*, B, B*) and the

frequency, the timing of rotation

is controlled.

(See p. 2-26)

24V

CW rotation at M5D1

CCW rotation at M5D1 '1', M5D2 '0

Stop at M5D1 '0', M5D2 '0

'0',

M5D2 '1

'.

'.

'.

J8

1

1

2

4

5

M6DA

2

M6DB

4

5

CW rotation at M6DA

CCW rotation at M6DA '1', M6DB '0

Stop at M6DA '0', M6DB '0

'0',

M6DB '1

'.

'.

'.

COPYRIGHT © 1999 CANON INC. CANON FINISHER-E1 REV.0 JAN. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

2-5

CHAPTER 2 BASIC OPERATION

II. BASIC OPERATIONS

The finisher is designed to operate as follows:

1. Paper arrives from the copier.

Figure 2-201

2. Paper reaches the intermediary processing tray.

Figure 2-202

2-6

COPYRIGHT © 1999 CANON INC. CANON FINISHER-E1 REV.0 JAN. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

CHAPTER 2 BASIC OPERATION

3. Paper is moved until it butts against the stopper plate by the work of the returning roller.

Figure 2-203

4. The paper is put into order by the work of the front/rear jogging plate.

Figure 2-204

COPYRIGHT © 1999 CANON INC. CANON FINISHER-E1 REV.0 JAN. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

2-7

CHAPTER 2 BASIC OPERATION

5. Operations 1 through 4 are repeated until a specific number of sheets have been stacked on the

intermediary processing tray.

6. The sheets are stapled. (If stapling is selected.)

Figure 2-205

7. The stack on the intermediary processing tray is moved to the stack tray.

2-8

Figure 2-206

COPYRIGHT © 1999 CANON INC. CANON FINISHER-E1 REV.0 JAN. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

CHAPTER 2 BASIC OPERATION

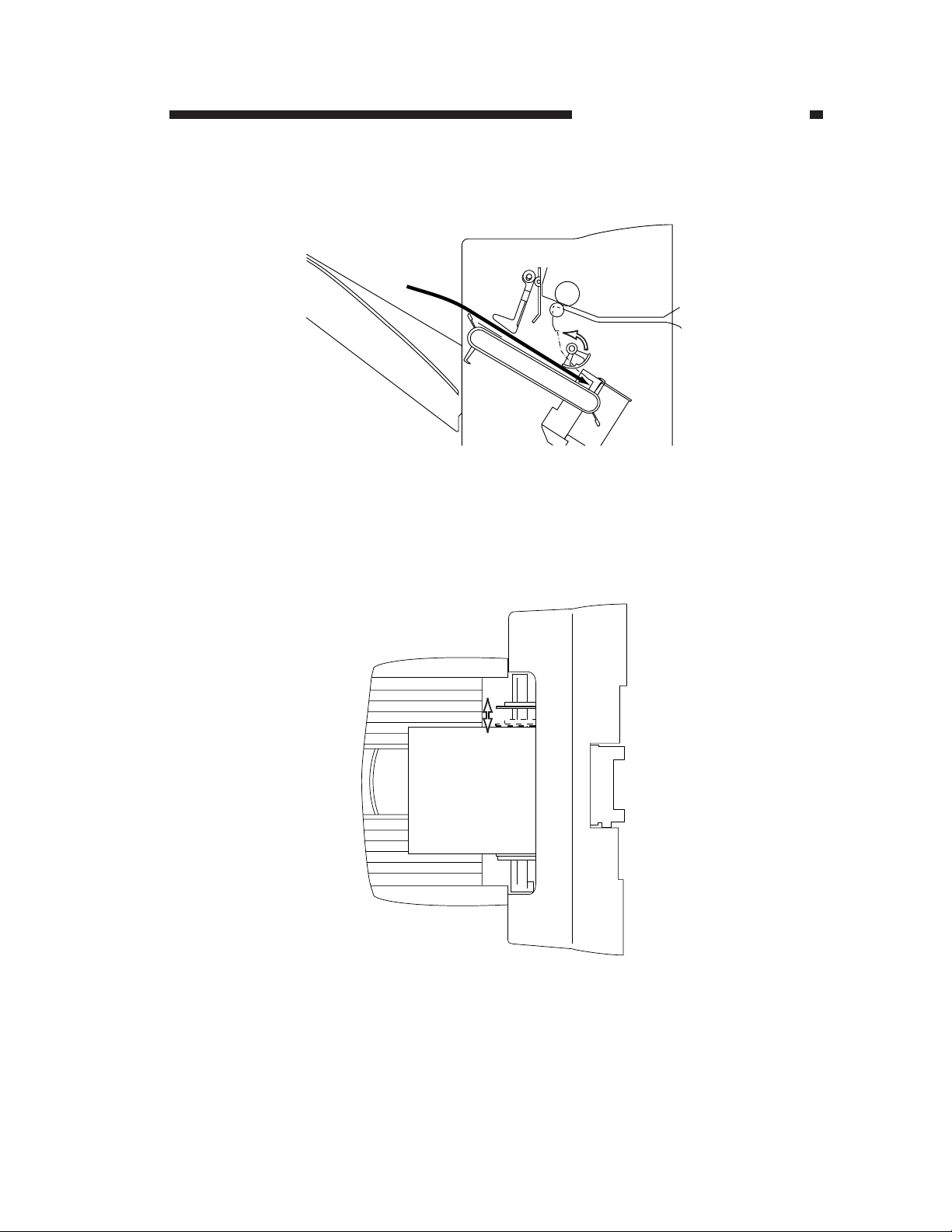

III. FEEDING DRIVE SYSTEM

A. Outline

Paper coming from the copier is sent to the intermediary processing tray, on which it is put into

order and offset/stapled for delivery to the stack tray.

The machine detects jams using the inlet sensor (S2).

Figure 2-301 shows the construction of the feeding drive system.

Notation

M1

M2

S1

S2

S5

Feeding guide A

Returning roller

Intermediary processing

tray auxiliary plate

Stack delivery lever

Name

Delivery motor

Stack processing motor

Delivery motor clock sensor

Inlet sensor

Intermediary processing tray paper sensor

Table 2-301

S1

Feeding guide B

M1

J10-3

S1D

J4

Delivery roller

J11-18

S2D

J5

M2

One-way clutch

J9-9

S5D

Finisher controller PCB

Figure 2-301

COPYRIGHT © 1999 CANON INC. CANON FINISHER-E1 REV.0 JAN. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

2-9

CHAPTER 2 BASIC OPERATION

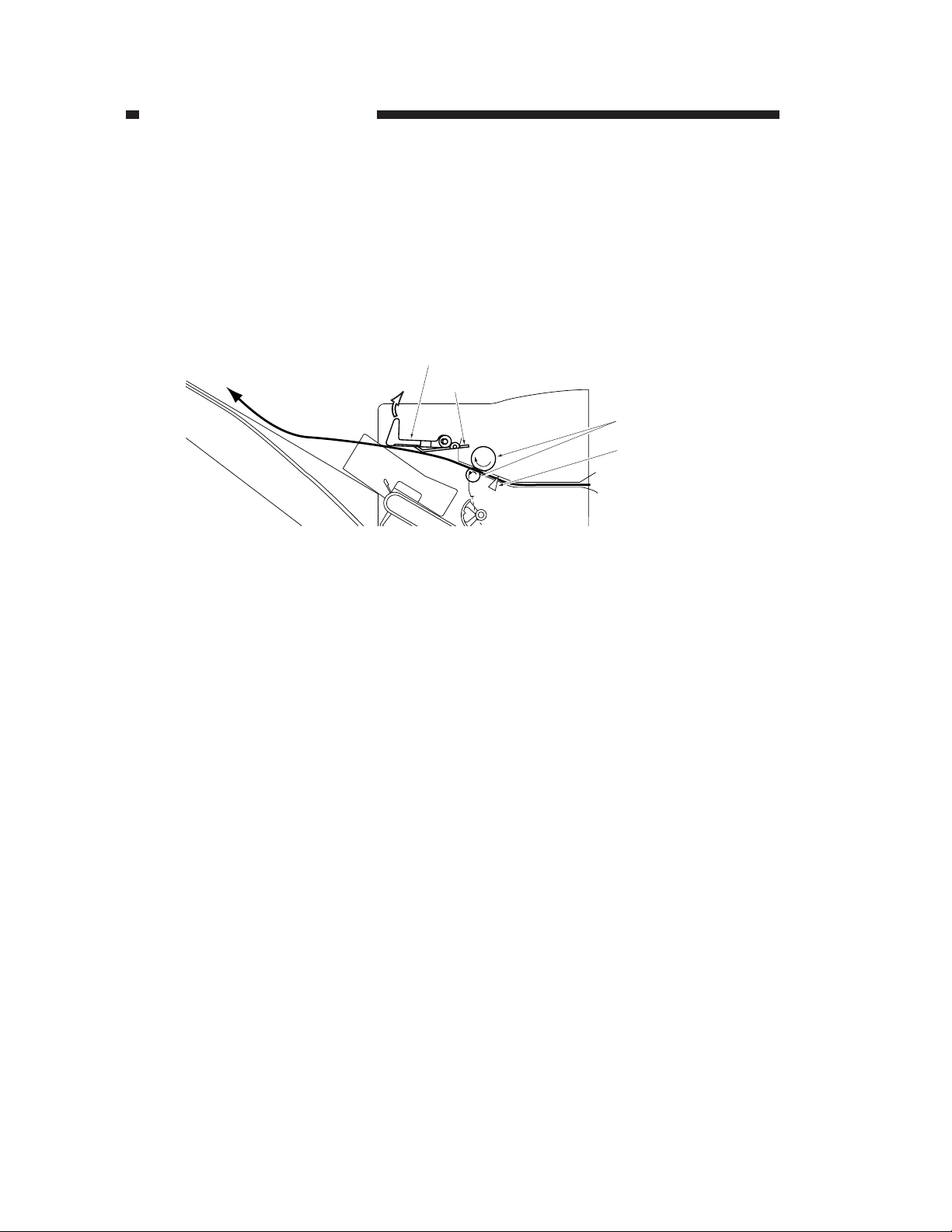

B. Delivery

Paper coming from the copier is sent to the intermediary processing tray by the work of the

delivery motor (M1), and the movement of paper is monitored by the inlet sensor (S2).

The delivery slot of the machine is equipped with a feeding guide (A/B). The feeding guide A/

B holds down the trailing edge of paper using its own weight so as to help move paper as far as the

returning roller.

Feeding guide A

Feeding guide B

Delivery roller

S2

Figure 2-302

2-10

COPYRIGHT © 1999 CANON INC. CANON FINISHER-E1 REV.0 JAN. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

Loading...

Loading...