FINISHER-C1/

SADDLE FINISHER-C2

SERVICE

MANUAL

REVISION 0

DEC. 1998

COPYRIGHT © 1998 CANON INC. FINISHER-C1/SADDLE FINISHER-C2 REV. 0 DEC. 1998 PRINTED IN JAPAN (IMPRIME AU JAPON)

FY8-13F6-000

IMPORTANT

THE INFORMATION CONTAINED HEREIN PUBLISHED BY CANON, INC., JAPAN.

SPECIFICATIONS AND OTHER INFORMATION CONTAINED WHEREIN MAY SLIGHTLY FROM

ACTUAL MACHINE VALUES OR THOSE FOUND IN ADVERTISING AND OTHER PRINTED

MATTER.

ANY QUESTIONS REGARDING INFORMATION CONTAINED HEREIN SHOULD BE DIRECTED

TO THE COPIER SERVICE DEPARTMENT OF THE COMPANY.

COPYRIGHT © 1998 CANON INC.

Printed in Japan

Imprimé au Japon

Use of this manual should be strictly super-

vised to avoid disclosure of confidential in-

formation.

Prepared by

OFFICE IMAGING PRODUCTS TECHNICAL SUPPORT DEPARTMENT 1

OFFICE IMAGING PRODUCTS TECHNICAL SUPPORT DIVISION

CANON INC.

5-1, Hakusan 7-chome, Toride-shi Ibaraki, 302-8501 Japan

COPYRIGHT © 1998 CANON INC. FINISHER-C1/SADDLE FINISHER-C2 REV. 0 DEC. 1998 PRINTED IN JAPAN (IMPRIME AU JAPON)

Prepared by

Office Imaging Products Technical Support Dept. 1

Office Imaging Produce Quality Assurance Center.

CANON INC

Printed in Japan

REVISION 0 (DEC. 1998)(18756)

5-1, Hakusan 7-chome, Toride-shi Ibaraki, 302-8501 Japan

INTRODUCTION

This Service Manual contains basic data and figures for the Finisher-C1/Saddle Fin-

isher-C2 needed to service the machine in the field.

Chapter 1 General Description introduces the finishers features, specifications, and

names of parts, and shows how to operate the sorter.

Chapter 2 Finisher Unit Basic Operation discusses the principles of operation used for

the finisher mechanical and electrical systems. It also explains the timing at

which these systems are operated.

Chapter 3 Saddle Stitcher Unit Basic Operation discusses the principles of operation

used for the saddle stitcher units mechanical and electrical systems. It also

explains the timing at which these systems are operated.

Chapter 4 Mechanical System discusses how the finisher is constructed mechanically,

and shows how it may be disassembled/assembled and adjusted.

Chapter 5 Maintenance and Inspection provides tables of periodically replaced parts

and consumables and durables, together with a scheduled servicing chart.

Chapter 6 Troubleshooting provides tables of maintenance/inspection, standards/ad-

justments, and problem identification (image fault/malfunction).

Appendix contains diagrams showing tables of signals, tables of solvents/

oils, and a general timing chart.

The descriptions in this Service Manual are subject to change without notice for product improvement or other purposes, and major changes will be communicated in the form

of Service Information bulletins.

All service persons are expected to have a good understanding of the contents of this

Service Manual and all relevant Service Information bulletins and be able to identify and

isolate faults in the machine.

COPYRIGHT © 1998 CANON INC. FINISHER-C1/SADDLE FINISHER-C2 REV. 0 DEC. 1998 PRINTED IN JAPAN (IMPRIME AU JAPON)

i

ii

COPYRIGHT © 1998 CANON INC. FINISHER-C1/SADDLE FINISHER-C2 REV. 0 DEC. 1998 PRINTED IN JAPAN (IMPRIME AU JAPON)

CONTENTS

CHAPTER 1 GENERAL DESCRIPTION

I. FEATURES ..................................1-1

II. SPECIFICATIONS .......................1-2

A. Specifications ...........................1-2

B. Cross Section ...........................1-7

III. USING THE MACHINE................1-9

A. Removing Paper Jams from

the Finisher Unit .......................1-9

B. Supplying the Finisher Unit

with Staples ............................ 1-10

C. Removing Staple Jams from

the Finisher Unit .....................1-11

D. Removing Paper Jams from

the Saddle Sticher Unit .......... 1-13

E. Supplying the Saddle Stitcher

Unit with Staples .................... 1-14

F. Removing Staple Jams from

the Saddle Stitcher Unit ......... 1-15

G. Removing Paper Jams from the

Interrupt Tray .......................... 1-17

IV. MAINTENANCE BY THE USER 1-18

A. Maintenance by the User .......1-18

CHAPTER 2 FINISHER UNIT BASIC OPERATION

I. BASIC OPERATION .................... 2-1

A. Outline ......................................2-1

B. Outline of Electrical

Circuitry ....................................2-2

C. Inputs to and Outputs

from the Finisher

Controller PCB .........................2-3

II. FEED/DRIVE SYSTEM ...............2-9

A. Outline ......................................2-9

B. Types of Delivery Paths .......... 2-13

C. Feeding and Delivering .......... 2-16

D. Job Offset ............................... 2-19

E. Stapling Operation .................2-22

F. Stapler Unit ............................ 2-28

G. Tray Operation ........................2-35

H. Detecting the Height of the Stack

on the Tray..............................2-37

I. Shutter Operation ................... 2-39

J. Buffer Path Operation.............2-43

K. Interrupt Tray Delivery .............2-47

L. Detecting Jams ...................... 2-49

III. POWER SUPPLY SYSTEM.......2-55

COPYRIGHT © 1998 CANON INC. FINISHER-C1/SADDLE FINISHER-C2 REV. 0 DEC. 1998 PRINTED IN JAPAN (IMPRIME AU JAPON)

iii

CHAPTER 3 SADDLE STITCHER UNIT

BASIC OPERATION

I. BASIC OPERATION .................... 3-1

A. Outline ......................................3-1

B. Electrical Circuitry .................... 3-2

C. Inputs to and Outputs

from the Saddle Stitcher

Controller PCB .........................3-3

II. FEEDING/DRIVE SYSTEM ......... 3-8

A. Outline ......................................3-8

III. PAPER DEPOSITING

MECHANISM.............................3-14

A. Outline ....................................3-14

B. Controlling the Inlet

Flappers .................................3-17

CHAPTER 4 MECHANICAL CONSTRUCTION

(A) FINISHER UNIT .......................... 4-1

I. EXTERNALS AND

CONTROLS................................. 4-1

A. External Covers ........................4-1

C. Controlling the Movement

of Sheets ................................3-21

D. Aligning the Sheets ................3-22

E. Controlling the Phase of

the Crescent Roller ................ 3-25

IV. STITCHING SYSTEM ............... 3-27

V. FOLDING/DELIVERY

SYSTEM .................................... 3-30

VI. CHECKING FOR A JAM ........... 3-35

VII. POWER SUPPLY ......................3-39

II. FEEDING SYSTEM ..................... 4-8

III. PCBs ......................................... 4-15

(B) SADDLE STITCHER UNIT ........4-16

CHAPTER 5 MAINTENANCE AND INSPECTION

I. PERIODICALLY REPLACED PARTS

....................................................5-1

A. Finisher Unit .............................5-1

B. Saddle Stitcher Unit ................. 5-1

iv

COPYRIGHT © 1998 CANON INC. FINISHER-C1/SADDLE FINISHER-C2 REV. 0 DEC. 1998 PRINTED IN JAPAN (IMPRIME AU JAPON)

II. CONSUMABLES AND

DURABLES .................................5-1

A. Finisher Unit .............................5-1

B. Saddle Stitcher Unit ................. 5-1

III. PERIODICAL SERVICING ..........5-1

CHAPTER 6 TROUBLESHOOTING

I. ADJUSTMENTS ..........................6-1

A. Electrical System

(finisher unit) ............................ 6-1

B. Electrical System

(saddle stitcher unit) ................. 6-3

II. ALIGNMENT OF ELECTRICAL

PARTS .........................................6-8

A. Finisher Unit .............................6-8

B. Saddle Stitcher Unit ............... 6-14

C. Variable Resistors (VR),

Light-Emitting Diodes (LED),

and Check Pins by PCB .........6-20

APPENDIX

A. Finisher Unit General Timing

Chart........................................... A-1

B. Finisher Unit General Timing

Chart........................................... A-2

C. Saddle Stitcher Unit General

Timing Chart............................... A-3

III. TROUBLESHOOTING ............... 6-22

A. Finisher Unit ...........................6-22

B. Saddle Stitcher Unit ............... 6-30

VI. SELF DIAGNOSIS.....................6-37

A. Finisher Unit ...........................6-37

B. Saddle Stitcher Unit ............... 6-39

C. Alarm ...................................... 6-41

D. Copier I/O Notations...............6-43

D. Signal and Abbreviations ............ A-4

E. Finisher Unit General Circuit

Diagram ...................................... A-5

F. Saddle Stitcher Unit General

Circuit Diagram ........................... A-6

G. Solvents and Oils ........................ A-7

COPYRIGHT © 1998 CANON INC. FINISHER-C1/SADDLE FINISHER-C2 REV. 0 DEC. 1998 PRINTED IN JAPAN (IMPRIME AU JAPON)

v

CHAPTER 1

GENERAL DESCRIPTION

I. FEATURES ..................................1-1

II. SPECIFICATIONS .......................1-2

A. Specifications.............................1-2

B. Cross Section ............................ 1-7

III. USING THE MACHINE................1-9

A. Removing Paper Jams from

the Finisher Unit.........................1-9

B. Supplying the Finisher Unit

with Staples ............................. 1-10

C. Removing Staple Jams from

the Finisher Unit.......................1-11

COPYRIGHT © 1998 CANON INC. FINISHER-C1/SADDLE FINISHER-C2 REV. 0 DEC. 1998 PRINTED IN JAPA N (IMPRIME AU JAPON)

D. Removing Paper Jams from

the Saddle Sticher Unit ............1-13

E. Supplying the Saddle Stitcher

Unit with Staples ...................... 1-14

F. Removing Staple Jams from

the Saddle Stitcher Unit ...........1-15

G. Removing Paper Jams from the

Interrupt Tray ............................1-17

IV. MAINTENANCE BY THE USER 1-18

A. Maintenance by the User .........1-18

CHAPTER 1 GENERAL DESCRIPTION

I. FEATURES

1. Accommodates large quantities of sheets

l

Normally, the finisher holds a stack of sheets 220.6 mm in height in its three bins (smallsized paper of 80 g/m

2. Has high paper transportation performance.

l

The finisher is capable of handling papers between 50 and 157 g/m2.

3. Offers a job offset function.

l

The finishers job offset function delivers the first or the last sheet of each job by displacing

it to the front, enabling sorting of copies on the tray.

4. Offers four types of auto stapling.

l

The finisher offers a choice of four stapling modes (1-point stapling at rear, diagonal stapling at front, diagonal stapling at rear, 2-point stapling).

5. Uses a buffer roller.

l

The use of a buffer roller enables the finisher to accept copies without interruption from the

copier even during stapling or offset operation (small-size paper only).

2

; no stapling).

6. Offers an interrupt delivery function.

l

Installation of the interrupt delivery tray will enable an interruption of an ongoing operation (up to 50 copies of small-size paper or up to 30 copies of large-size paper; both

2

of 80 g/m

).

7. Has a saddle stitch function (Saddle Finisher-C2).

l

The finisher can staple along the center of paper and fold it in two (up to 15 sheets).

8. Offers an incoming fax indicator (option).

l

When installed, the incoming fax indicator lamp (LED) will turn on to indicate the arrival of

a fax on tray 2/3.

COPYRIGHT © 1998 CANON INC. FINISHER-C1/SADDLE FINISHER-C2 REV. 0 DEC. 1998 PRINTED IN JAPAN (IMPRIME AU JAPON)

1-1

CHAPTER 1 GENERAL DESCRIPTION

II. SPECIFICATIONS

A. Specifications

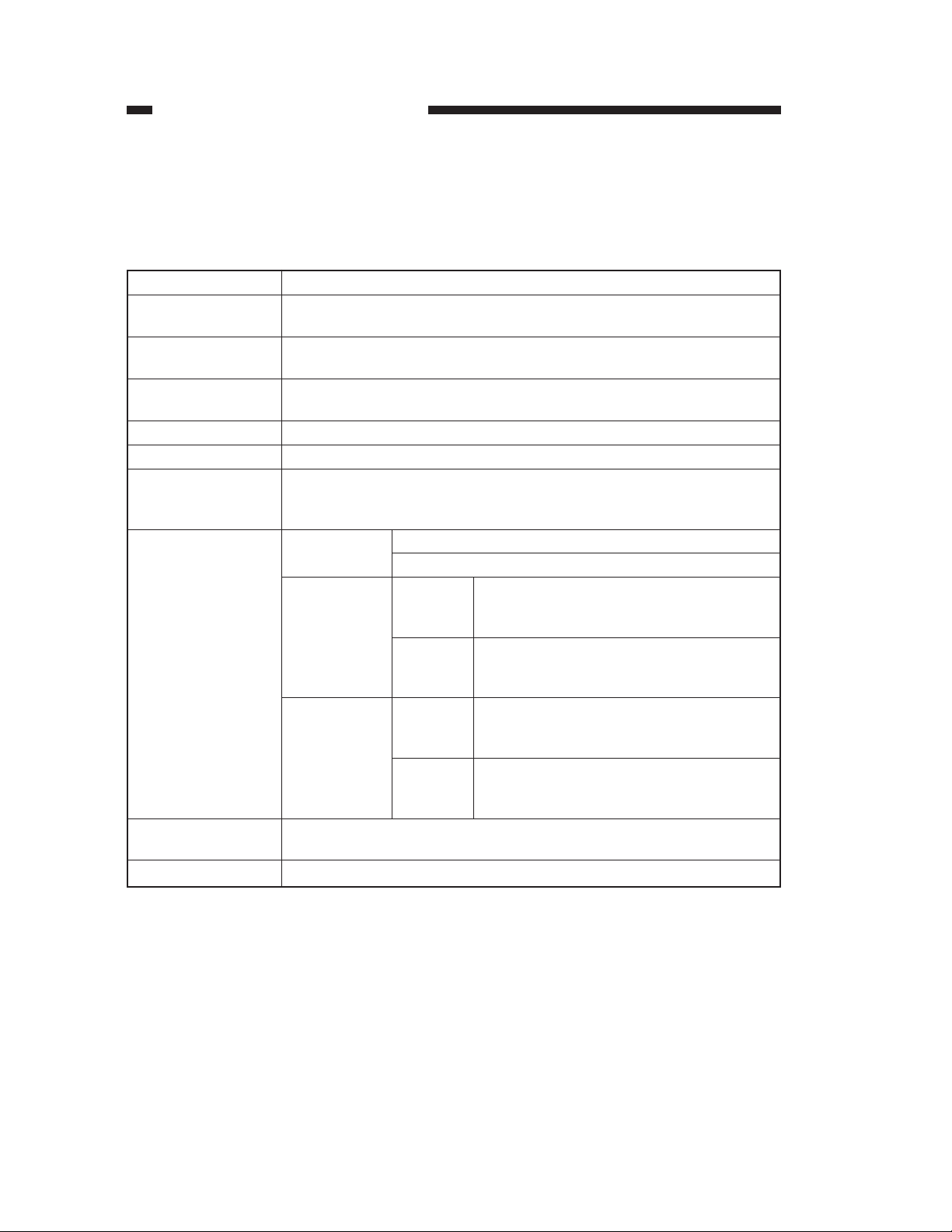

1. Finisher Unit

Item

Stacking method

Trays 1 through 3: by lifting tray

Description

Interrupt tray: by fixed tray

Stacking orientation

Face-down

Face-up (1 to n copies only)

Stacking size

AB: A3, A4, A4R, A5, A5R, B4, B5, B5R, postcard

Inch: 279 × 432 mm (11 × 17), LGL, LTR, LTRR, STMT, STMTR

Paper weight

Bins

Modes

50 to 128 g/m

Interrupt tray, trays 1 through 3

Non-sort: trays 1 through 3 and interrupt tray

2

Sort: trays 1 through 3

Staple: trays 1 through 2

Stacking capacity

Interrupt tray Small size: 50 sheets

Large size: 30 sheets

Non staple sort Small-size Tray 1: 44 mm high (300 sheets)

(Note 1)

Tray 2: 146.6 mm high (1000 sheets)

Tray 3: 30 mm high (200 sheets)

Large-size Tray 1: 22 mm high (100 sheets)

(Note 1)

Tray 2: 74 mm high (500 sheets)

Tray 3: 15 mm high (100 sheets)

Staple sort Small-size Tray 1: 47 mm high/50 sets (300 sheets)

(Note 1)

Tray 2: 146.6 mm high/50 sets (1000 sheets)

Tray 3: Not possible

Large-size Tray 1: 22 mm high/30 sets (150 sheets)

(Note 1)

Tray 2: 74 mm high/30 sets (500 sheets)

Tray 3: Not possible

Size mixing

Size mixing: 44 mm or less (300 sheets)

Stapling: 22 mm or less (150 sheets)

Stacking mixing

Notes:

1. Approximate when computed with reference to 80 g/m

2. Alignment may not be correct if 750 or more small-size sheets are stacked on tray 2.

3. The accuracy of the stack height is ±7 mm.

Face-up/face-down

2

paper.

(Note 2)

1-2

Table 1-201

COPYRIGHT © 1998 CANON INC. FINISHER-C1/SADDLE FINISHER-C2 REV. 0 DEC. 1998 PRINTED IN JAPAN (IMPRIME AU JAPON)

CHAPTER 1 GENERAL DESCRIPTION

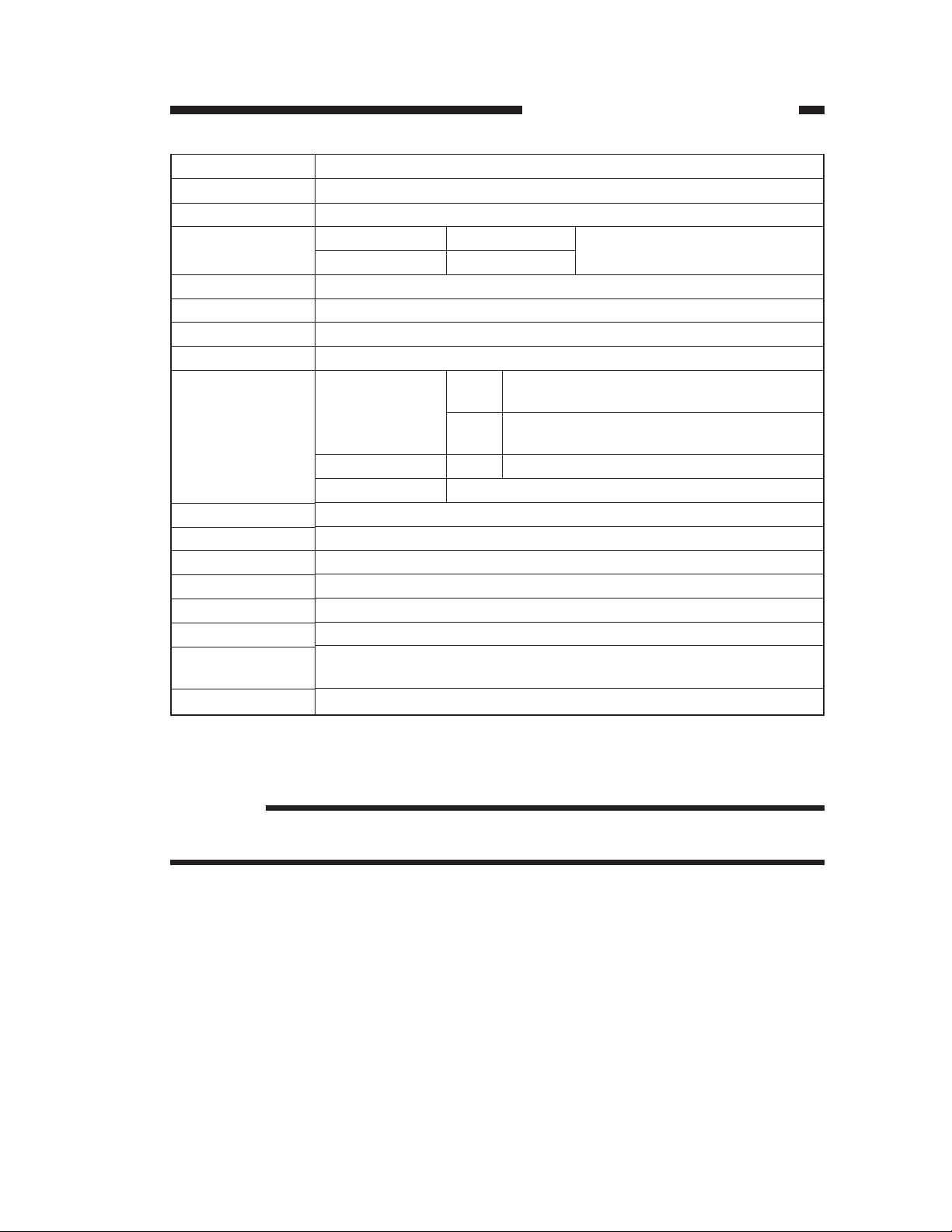

Item

Stapling

Stapling position

Stapling capacity

Staple supply

Staples

Staple detection

Manual stapling

Stapling size

Paper detection

Control panel

Display

Dimensions

Weight

Powr supply

Maximum power

consumption

Serial number

Description

By rotating cam

See Figure 1-201.

Small-size 50 sheets

Large-size 25 sheets

Special staple cartridge (5000 staples)

Special (staple-E1)

Provided

Not provided

1-point (diagonal) Front A3, B4, A4m, A4R, B5, 279 × 432 mm

(11 × 17), LGL, LTR, LTRR

Rear A3, B4, A4, A4R, B5, 279 × 432 mm (11 × 17),

LT R

1-point Rear A4R, LTRR, LGL

2-point A3, B4, A4, B5, 279 × 432 mm (11 × 17), LTR

Trays 1 through 3: provided Interrupt tray: not provided

Not provided

Incoming fax indicator lamp (option)

669 × 582 × 1047 mm (W × D × H; including saddle stitcher unit)

45 kg (including saddle stitcher unit)

From copier (24 VDC)

170 W or less

ZLJXXXXX (Finisher-C1)

Equivalent of 80 g/m2 paper

Table 2-202

Reference:

Small-size represents A4, A5, A5, B5, postcard, LTR, STMT, STMTR, while large-size

represents A3, B4, A4R, B5R, LTRR, 279 × 432 mm (11 × 17), LGL.

COPYRIGHT © 1998 CANON INC. FINISHER-C1/SADDLE FINISHER-C2 REV. 0 DEC. 1998 PRINTED IN JAPAN (IMPRIME AU JAPON)

1-3

CHAPTER 1 GENERAL DESCRIPTION

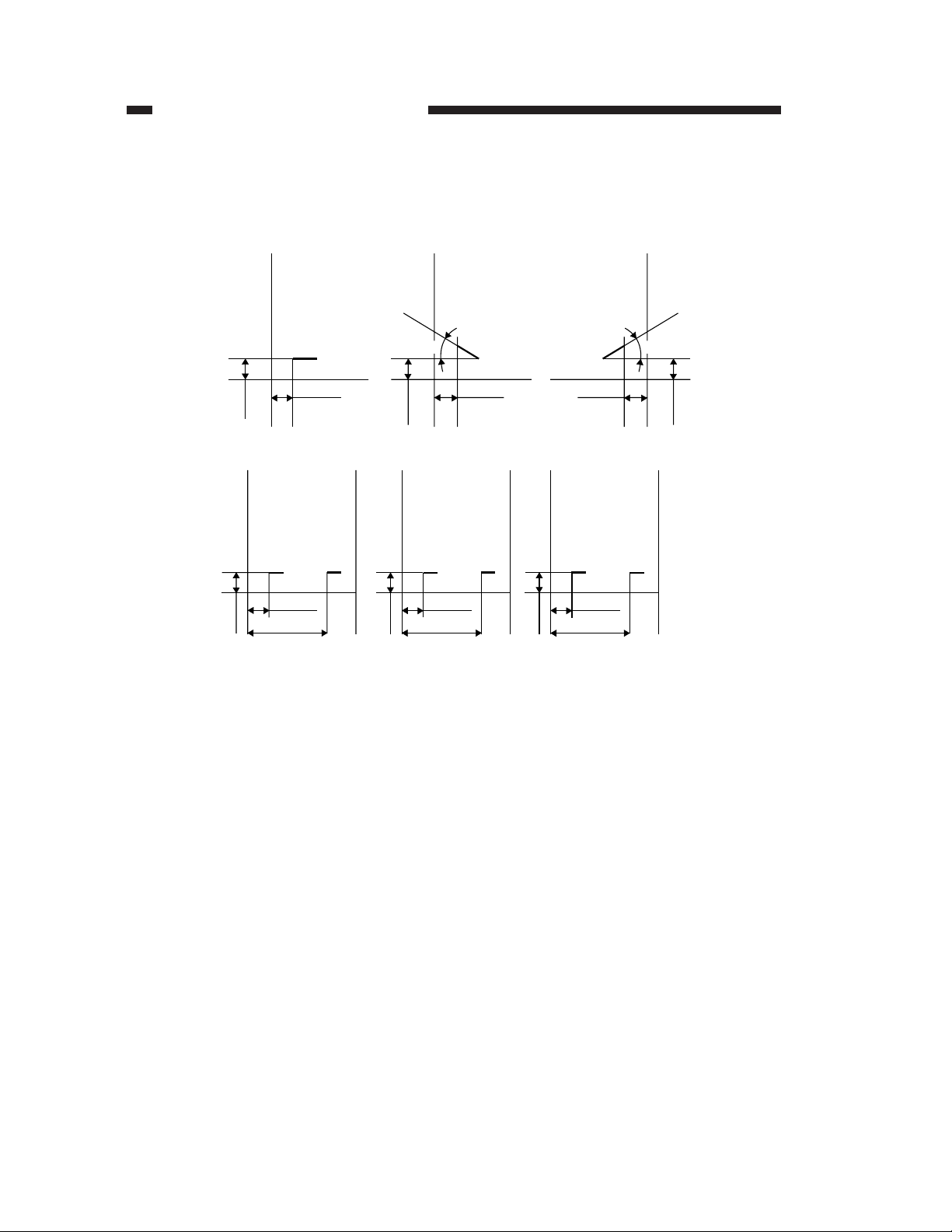

Stapling Positions (finisher unit)

1-point stapling (rear)

6±2mm

5±2mm

2-point stapling

A3 and A4 B4 and B5 279 × 432 mm

82.7±4mm

202.7±4mm

5±2mm

1-point stapling

(diagonal; front)

30

4.5±2mm

4.4±2mm

62.7±4mm

182.7±4mm

5±2mm

(11 × 17), LTR

73.7±4mm

193.7±4mm

5±2mm

1-point stapling

(diagonal; rear)

30

6±2mm

4±2mm

Figure 1-201

1-4

COPYRIGHT © 1998 CANON INC. FINISHER-C1/SADDLE FINISHER-C2 REV. 0 DEC. 1998 PRINTED IN JAPAN (IMPRIME AU JAPON)

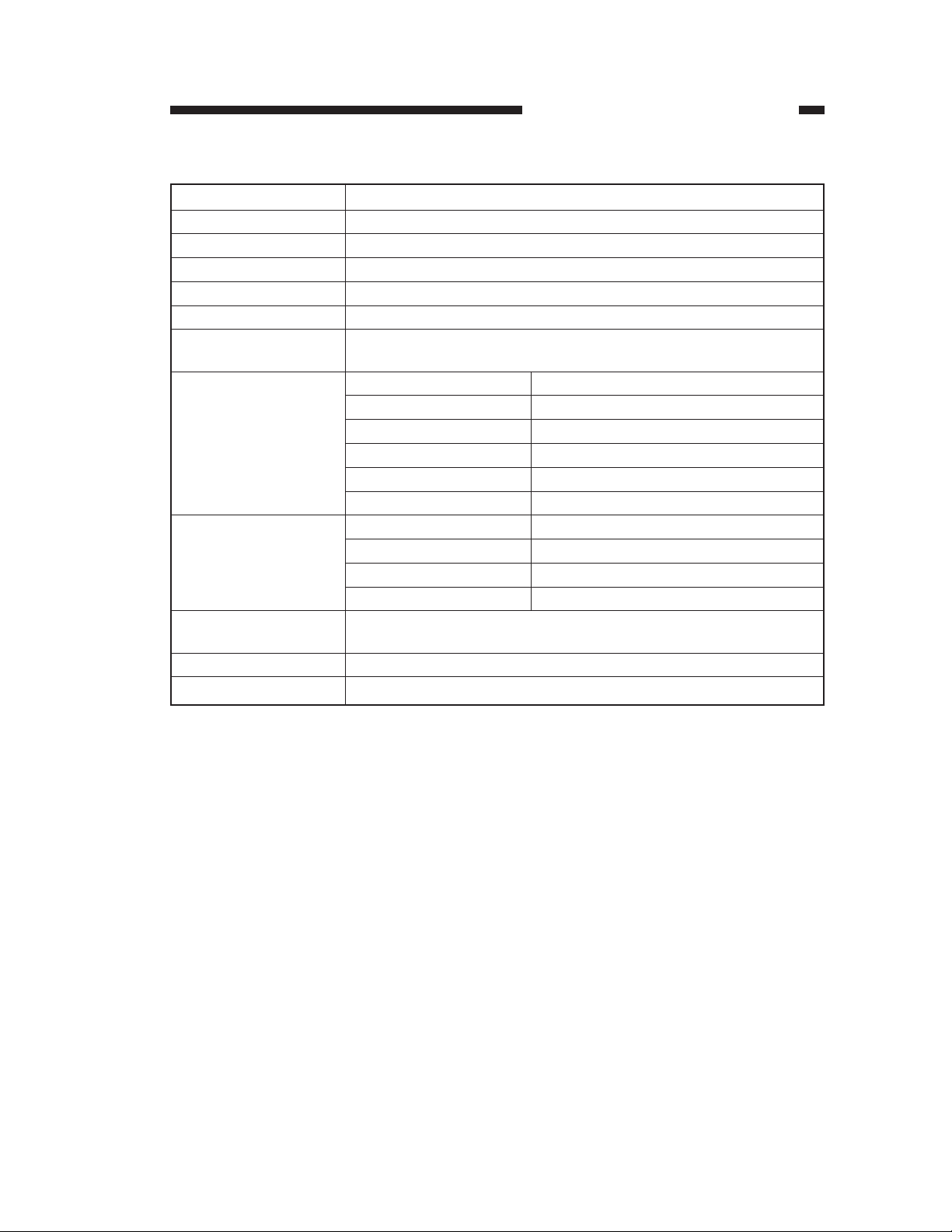

2. Saddle Stitcher Unit

CHAPTER 1 GENERAL DESCRIPTION

Item

Stapling method

Folding position

Paper size

Capacity

Paper weight

Stackihng capacity

Stapling

Folding

Power supply

Power consumption

Serial number

Description

Center binding (double folding)

See Figure 1-202.

A3, B4, AR4, 297mm × 432mm (11 × 17), LTRR

15 sheets (including single cover page)

64 to 80 g (cover page up to 128 g)

10 sets (stack of 11 to 15 sheets), 20 sets (stack of 6 to 10 sheets),

25 sets (stack of 5 sheets or less)

Stapling position 2 points (center distribution; fixed interval)

Staple accommodation 2000 staples

Staple supply Special cartridge

Staples Special staples (Staple-D1)

Staple detection Provided

Manual stapling Not provided

Folding method Roller contact

Folding mode Double folding

Folding position Paper center

Position adjustment Provided

From finisher unit

(24 V channel × 2)

160 W or less

ZLKxxxxx (Saddle Finisher-C2)

Table 2-203

COPYRIGHT © 1998 CANON INC. FINISHER-C1/SADDLE FINISHER-C2 REV. 0 DEC. 1998 PRINTED IN JAPAN (IMPRIME AU JAPON)

1-5

CHAPTER 1 GENERAL DESCRIPTION

Staple and Folding Positions (saddle stitcher unit)

A3

Staple position

L

210±1.5mm

83.5±1.5mm

203.5±1.5mm

Stack front edge

L (difference between folding

and staple positions) =

±0.5mm

297mm × 432mm

(11 × 17)

L

216±1.5mm

74.7±1.5mm

194.7±1.5mm

L (difference between folding

and staple positions) =

±0.5mm

Folding position

B4

L

182±1.5mm

63.5±1.5mm

183.5±1.5mm

L (difference between folding

and staple positions) =

±0.5mm

LTR

L

139.7±1.5mm

43±1.5mm

163±1.5mm

L (difference between folding

and staple positions) =

±0.5mm

A4R

L

148.5±1.5mm

40±1.5mm

160±1.5mm

L (difference between folding

and staple positions) =

±0.5mm

1-6

Figure 1-202

Specifications are subject to change without notice.

COPYRIGHT © 1998 CANON INC. FINISHER-C1/SADDLE FINISHER-C2 REV. 0 DEC. 1998 PRINTED IN JAPAN (IMPRIME AU JAPON)

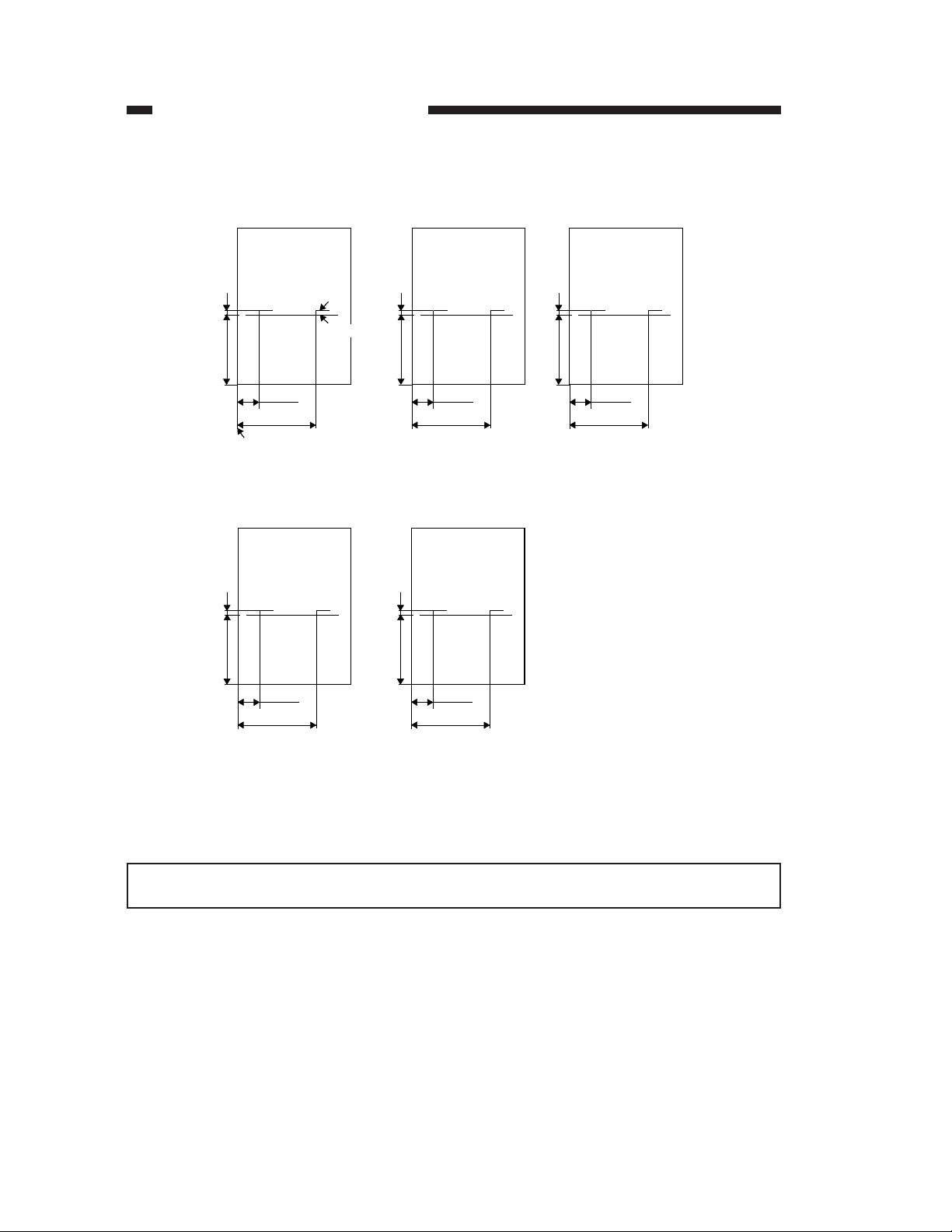

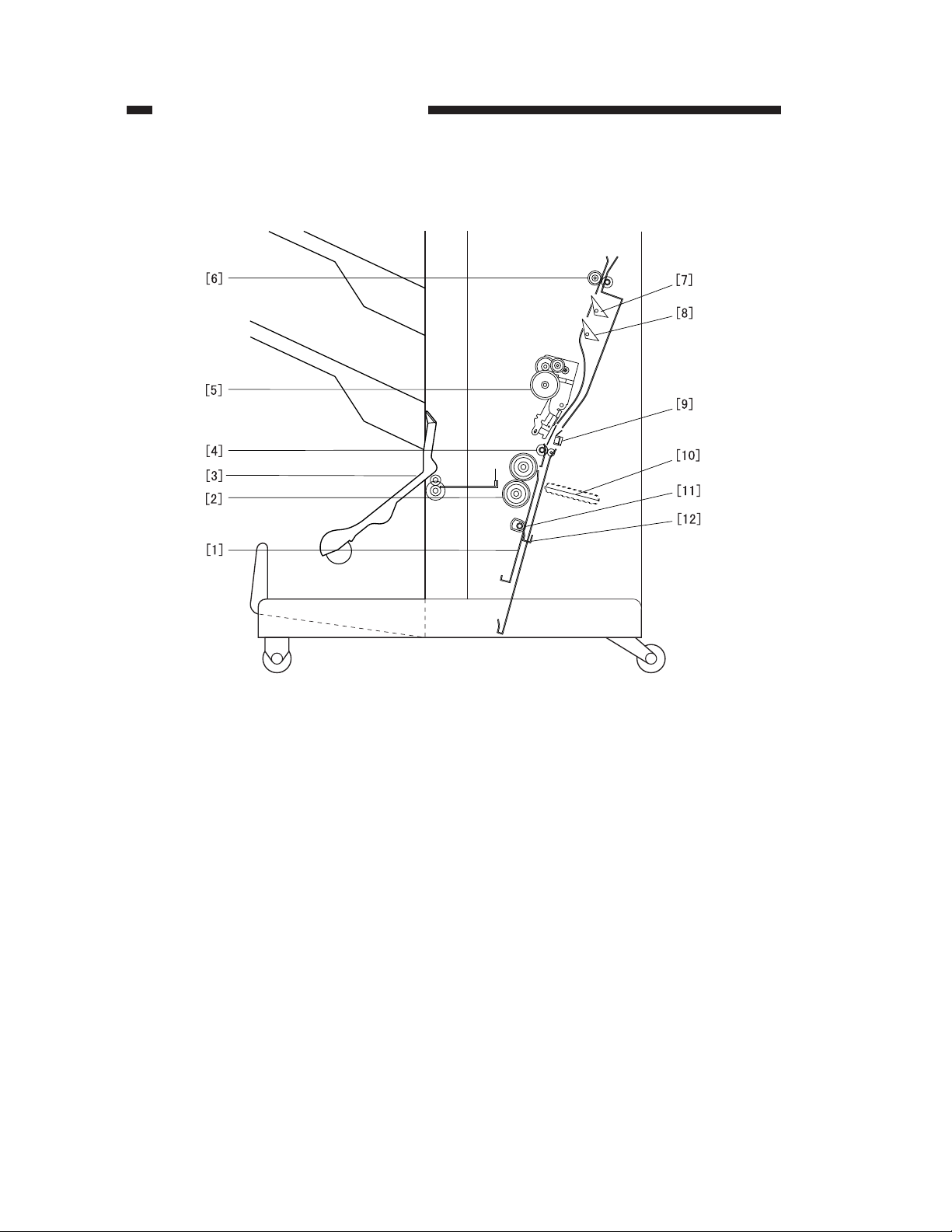

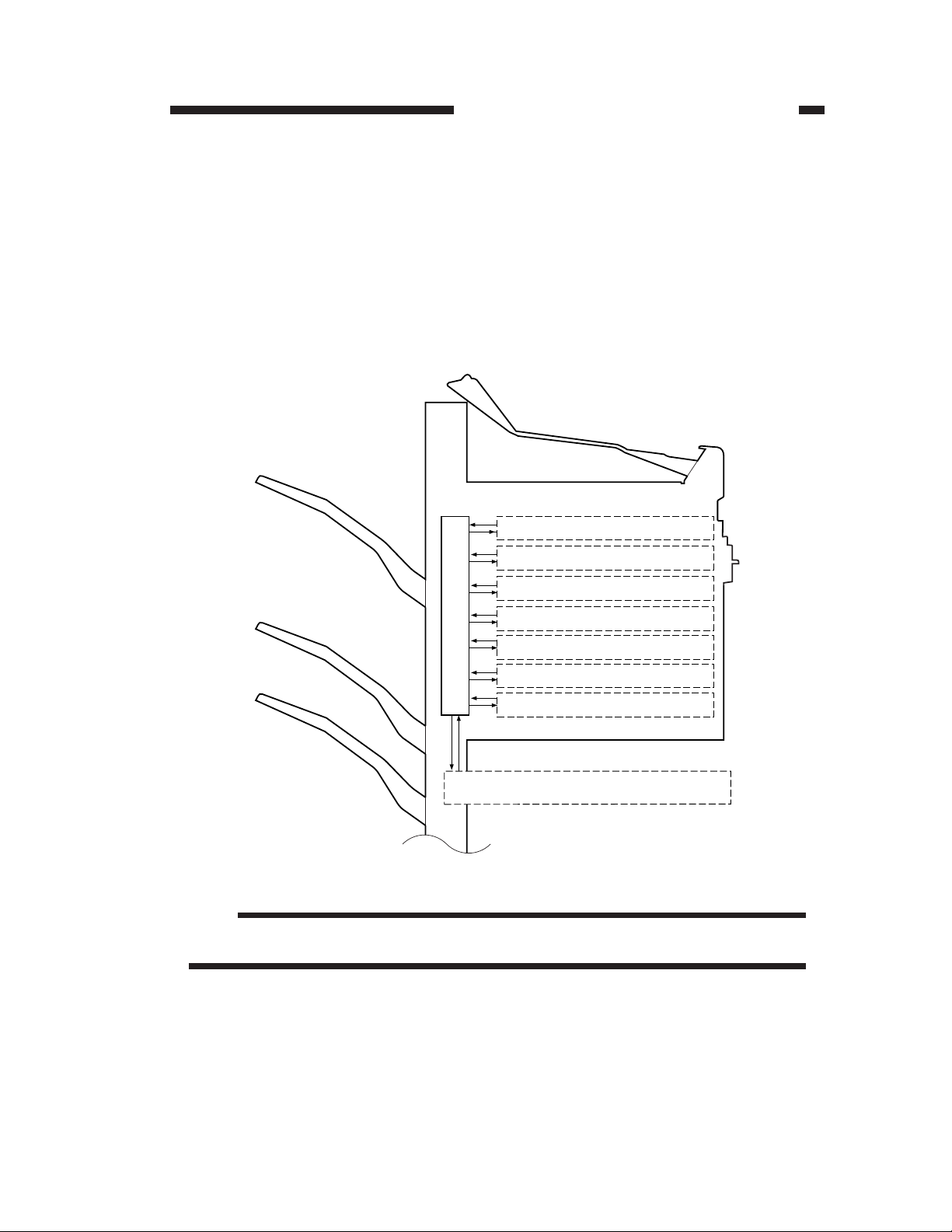

B. Cross Section

1. Finisher Unit

CHAPTER 1 GENERAL DESCRIPTION

[1] Tray 1/2/3

[2] Shutter

[3] Delivery roller

[4] Jog guide

[5] Feed roller 2

[6] Height sensor

[7] Interrupt tray

[8] Incoming fax indicator lamp

(option; 115V)

[9] Wrap flapper

[11] Interrupt flapper

[12] Buffer inlet flapper

[13] Saddle stitcher flapper

[14] Feed roller 1

[15] Vertical path

[16] Stapler

[17] Feed belt

[18] Tray lift motor

[19] Saddle stitcher unit

(Saddle Finisher-C2)

[10] Buffer roller

Figure 1-203

COPYRIGHT © 1998 CANON INC. FINISHER-C1/SADDLE FINISHER-C2 REV. 0 DEC. 1998 PRINTED IN JAPAN (IMPRIME AU JAPON)

1-7

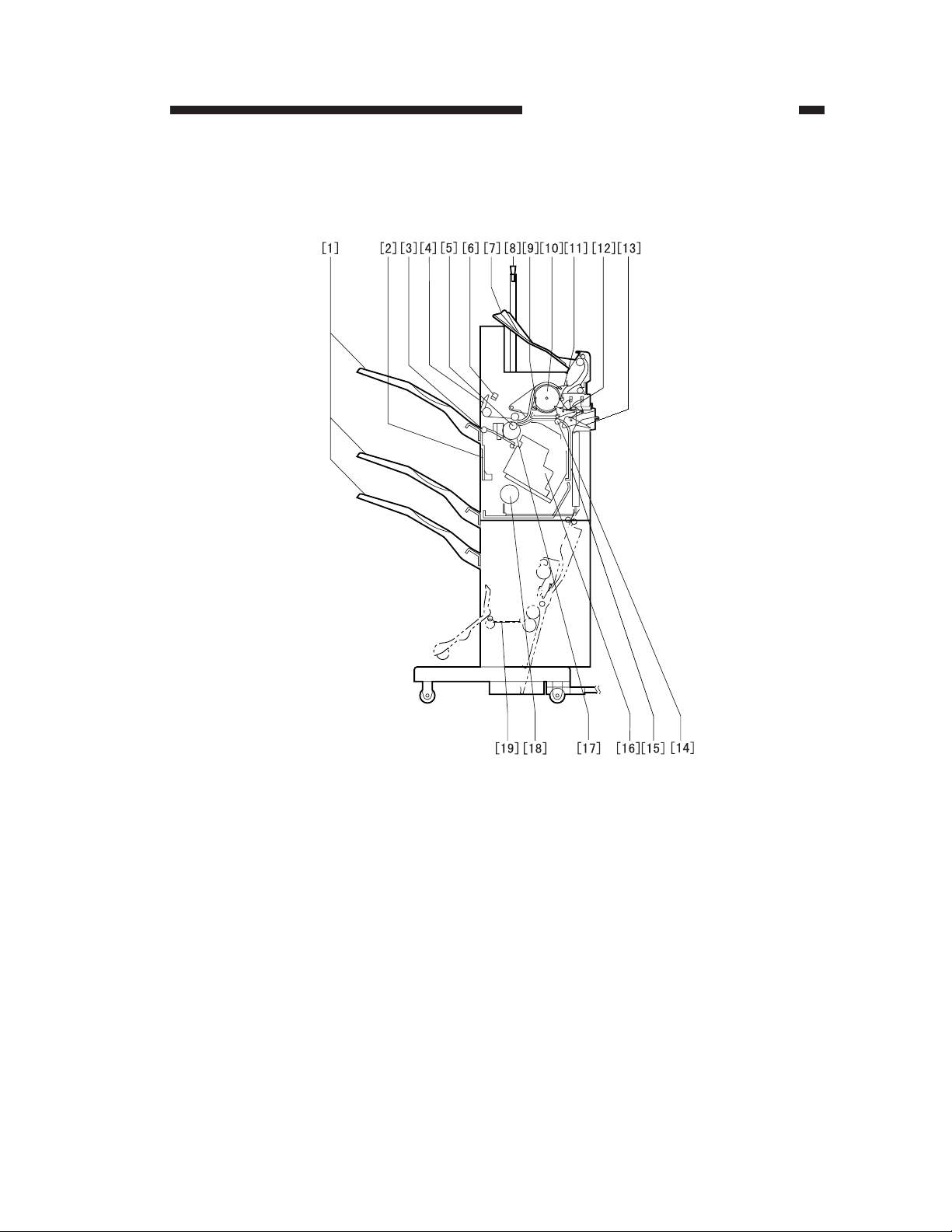

CHAPTER 1 GENERAL DESCRIPTION

2. Saddle Stitcher Unit

1-8

[1] Guide plate

[2] Folding roller

[3] Delivery guide plate

[4] Holding roller

[5] Stitcher (front, rear)

[6] Inlet roller

[7] No. 1 flapper

[8] No. 2 flapper

[9] Stitcher mount (front, rear)

[10] Butting plate

[11] Crescent roller

[12] Paper positioning plate

Figure 1-204

COPYRIGHT © 1998 CANON INC. FINISHER-C1/SADDLE FINISHER-C2 REV. 0 DEC. 1998 PRINTED IN JAPAN (IMPRIME AU JAPON)

CHAPTER 1 GENERAL DESCRIPTION

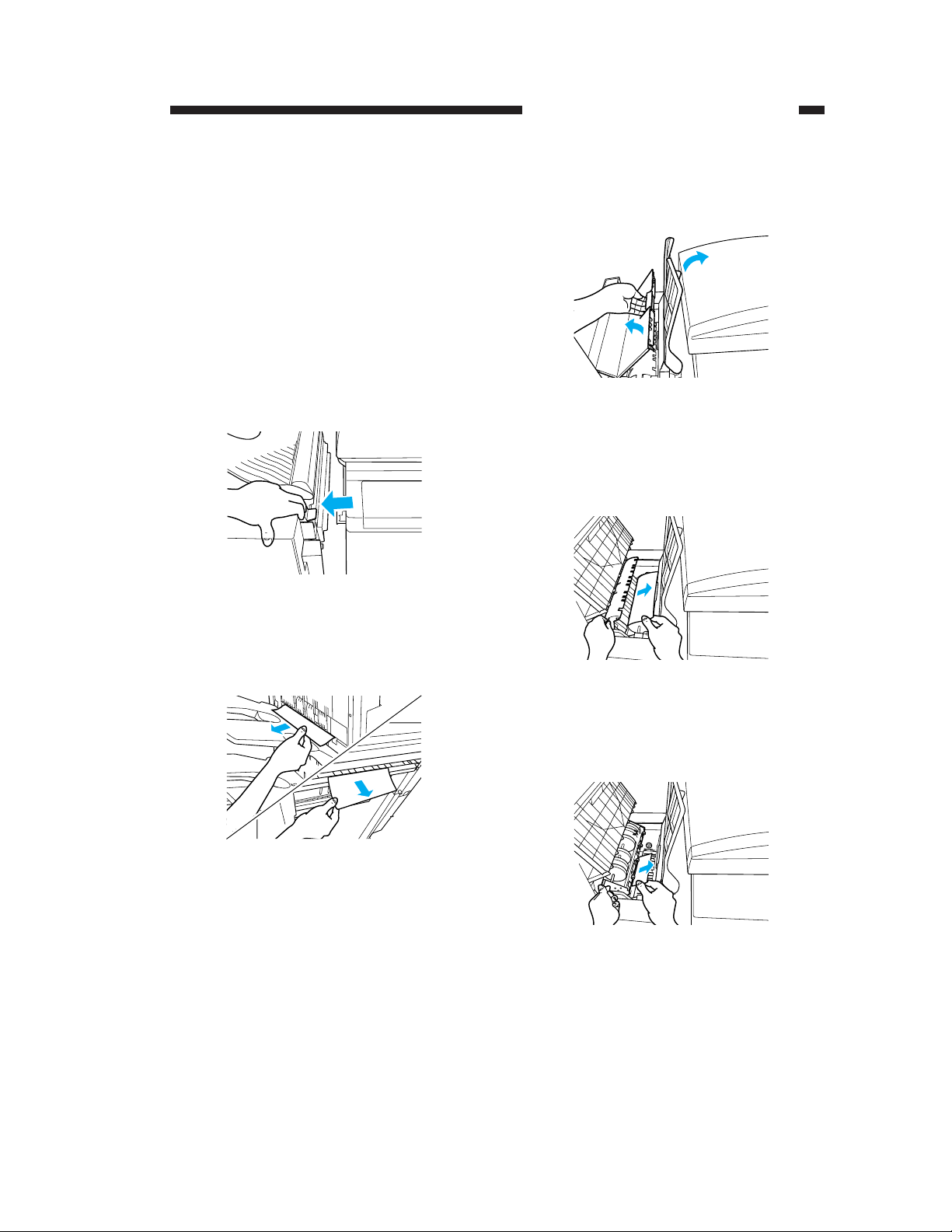

III. Using the Machine

A. Removing Paper Jams

from the Finisher Unit

If the copier indicates the finisher paper jam

message, perform the following to remove the

jam.

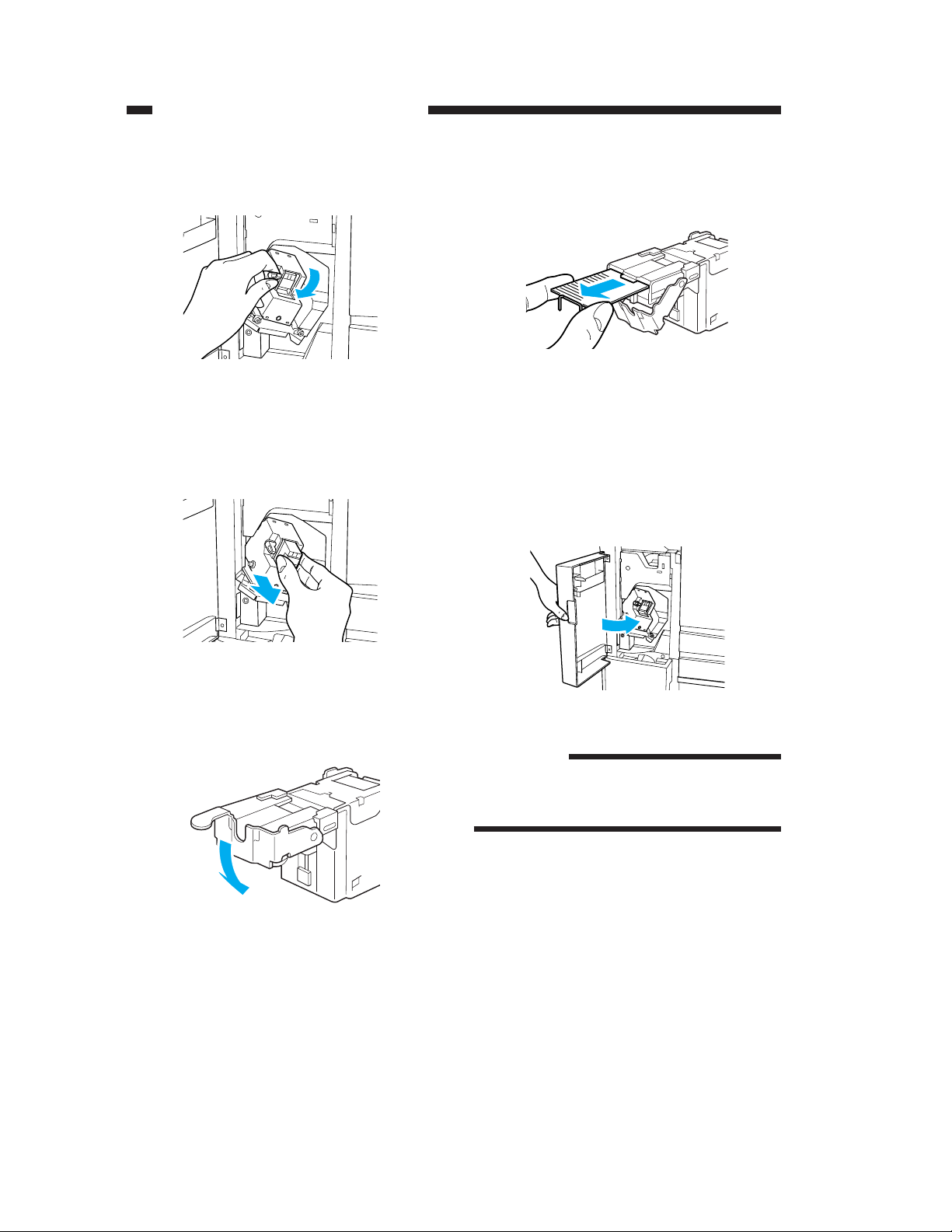

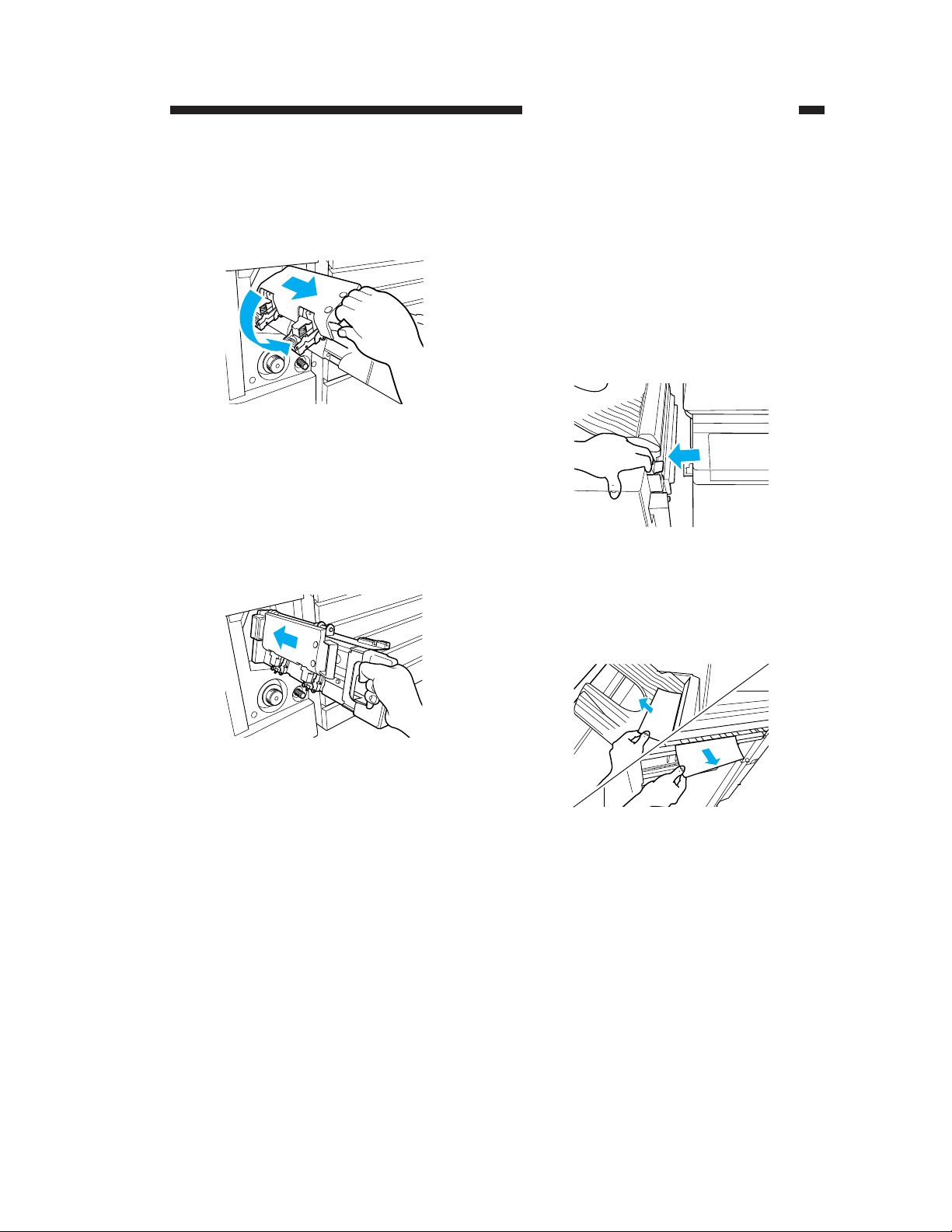

1) Holding the finisher unit as shown, move

it to detach it from the copier.

Figure 1-301

3) Shift up the interrupt tray, open the upper

cover, and check the inside of the finisher.

Figure 1-303

4) Lift the buffer roller cover, and remove the

jam.

2) Remove any jam visible from the outside.

Figure 1-302

Figure 1-304

5) Lift the buffer roller, and remove the jam.

Figure 1-305

COPYRIGHT © 1998 CANON INC. FINISHER-C1/SADDLE FINISHER-C2 REV. 0 DEC. 1998 PRINTED IN JAPAN (IMPRIME AU JAPON)

1-9

CHAPTER 1 GENERAL DESCRIPTION

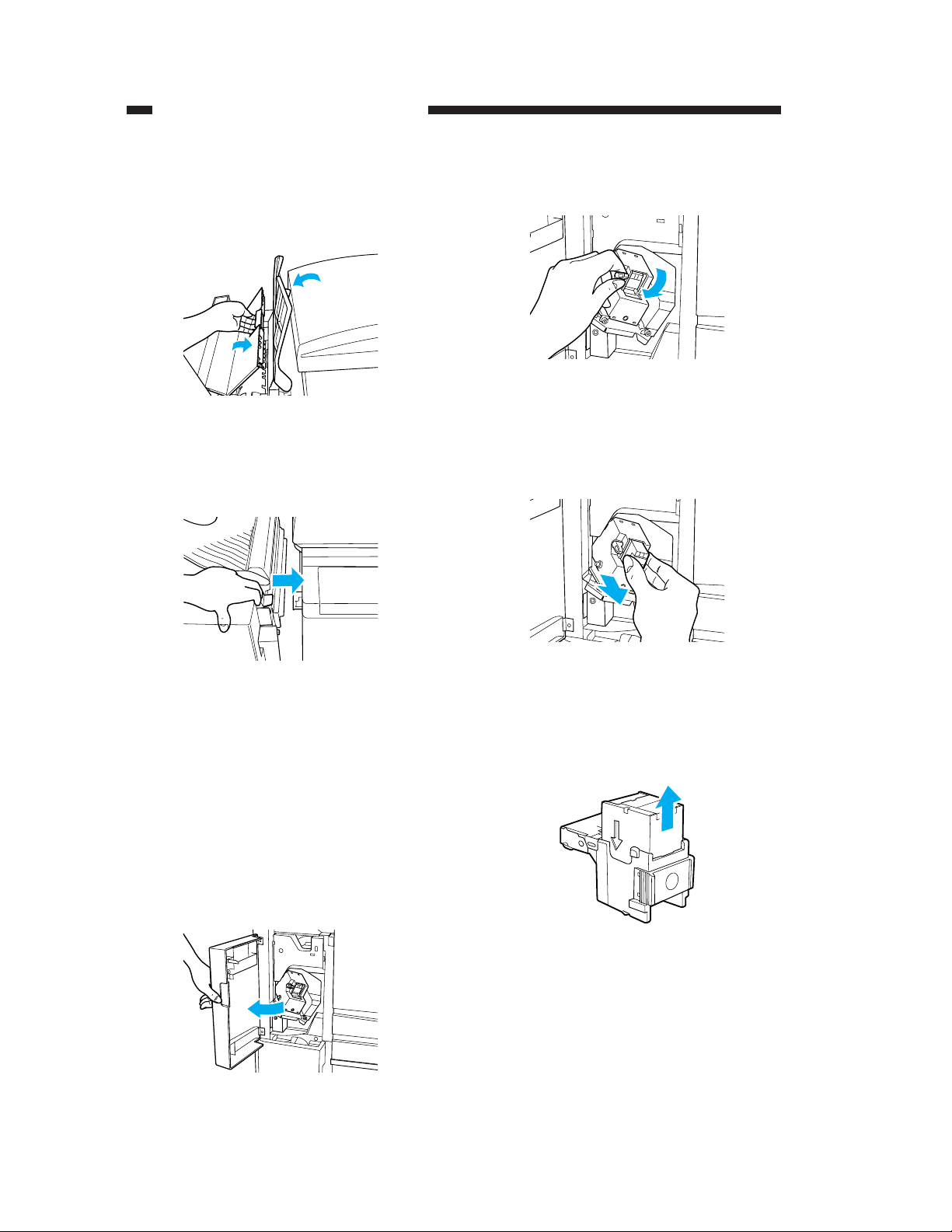

6) Return the buffer roller and the gray cover

to their original position, and close the upper cover and the interrupt tray.

Figure 1-306

7) Connect the finisher to the copier.

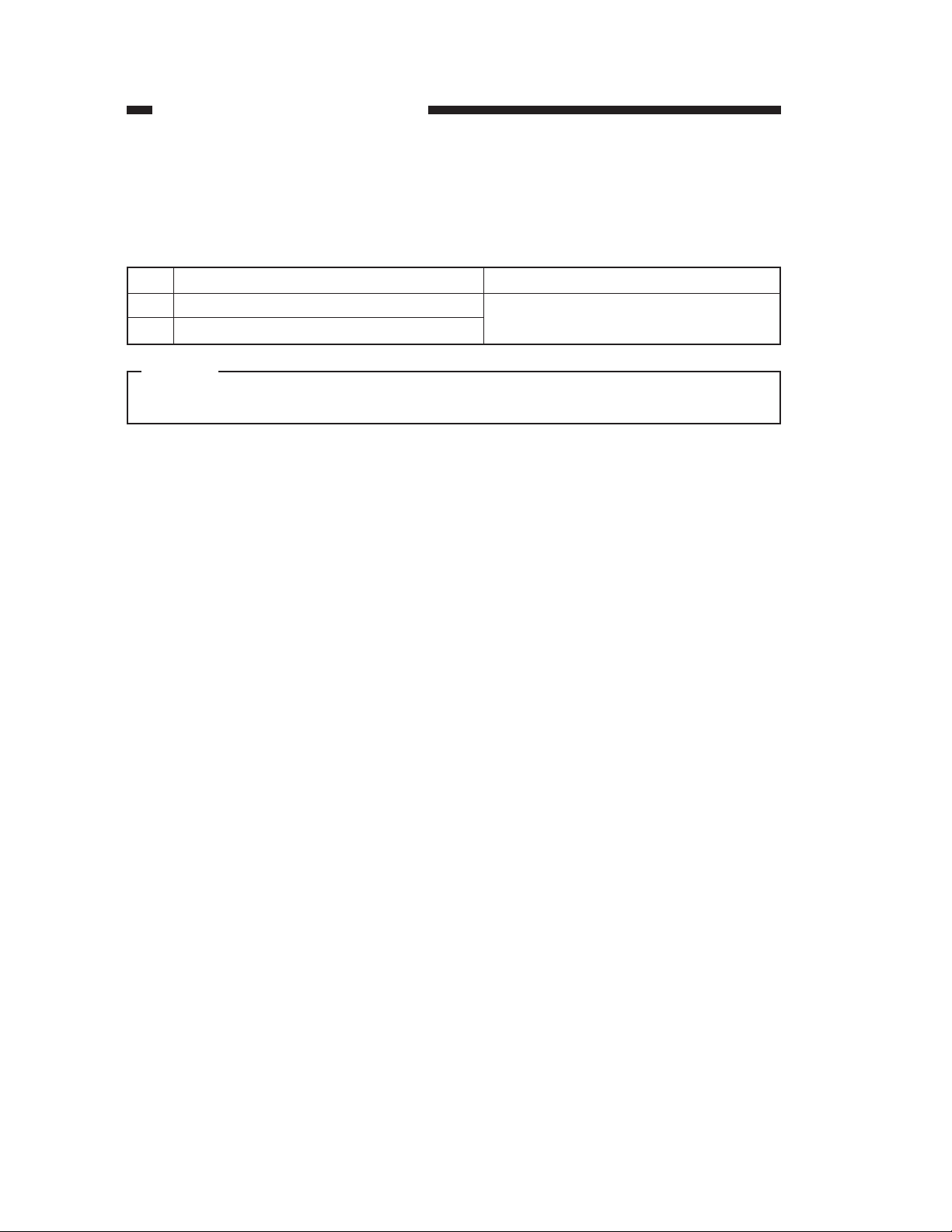

2) Shift down the green lever.

Figure 1-309

3) When the staple cartridge has slightly slid

out, hold and pull it out.

Figure 1-307

8) Operate as instructed on the display.

B. Supplying the Finisher

Unit with Staples

If the copier indicates the finisher unit

staple supply message, perform the following

to supply it with staples.

Figure 1-308

Figure 1-310

4) Hold the empty staple case on its sides, and

slide it out.

Figure 1-311

1-10

COPYRIGHT © 1998 CANON INC. FINISHER-C1/SADDLE FINISHER-C2 REV. 0 DEC. 1998 PRINTED IN JAPAN (IMPRIME AU JAPON)

CHAPTER 1 GENERAL DESCRIPTION

5) Set a new staple case.

Figure 1-312

Reference:

You may set no more than one staple

cartridge at a time.

Make sure that the new cartridge is one

specifically designed for the finisher unit.

6) Pull the length of tape (used to hold the

staples in place) straight out.

8) Check to make sure that the stapler has

been locked in place, and close the front

cover.

Figure 1-315

C. Removing Staple Jams

from the Finisher Unit

If the copier indicates the finisher unit

staple jam message, perform the following to

remove the jam.

1) Remove the stack waiting to be stapled

from the delivery tray.

Figure 1-313

7) Push in the stapler unit until the green lever returns to its original position.

Figure 1-316

2) Open the front cover.

Figure 1-314

Figure 1-317

COPYRIGHT © 1998 CANON INC. FINISHER-C1/SADDLE FINISHER-C2 REV. 0 DEC. 1998 PRINTED IN JAPAN (IMPRIME AU JAPON)

1-11

CHAPTER 1 GENERAL DESCRIPTION

3) Shift down the green lever.

Figure 1-318

4) When the staple cartridge has slightly slid

out, hold and pull it out.

6) Remove all staples that have slid out of the

staple case.

Figure 1-321

7) Return the tab on the staple cartridge to its

original position.

8) Return the staple cartridge to its original

position, and close the front cover.

Figure 1-319

5) Shift down the tab on the staple cartridge.

Figure 1-320

Figure 1-322

Reference

When the cover has been closed, the stapler

unit will automatically execute idle punching

several times to advance the staples.

1-12

COPYRIGHT © 1998 CANON INC. FINISHER-C1/SADDLE FINISHER-C2 REV. 0 DEC. 1998 PRINTED IN JAPAN (IMPRIME AU JAPON)

CHAPTER 1 GENERAL DESCRIPTION

D. Removing Paper Jams

from the Saddle Sticher

Unit

(Saddle Finisher-C2)

If the copier indicates the saddle stitcher

unit paper jam message, perform the following to remove the jam.

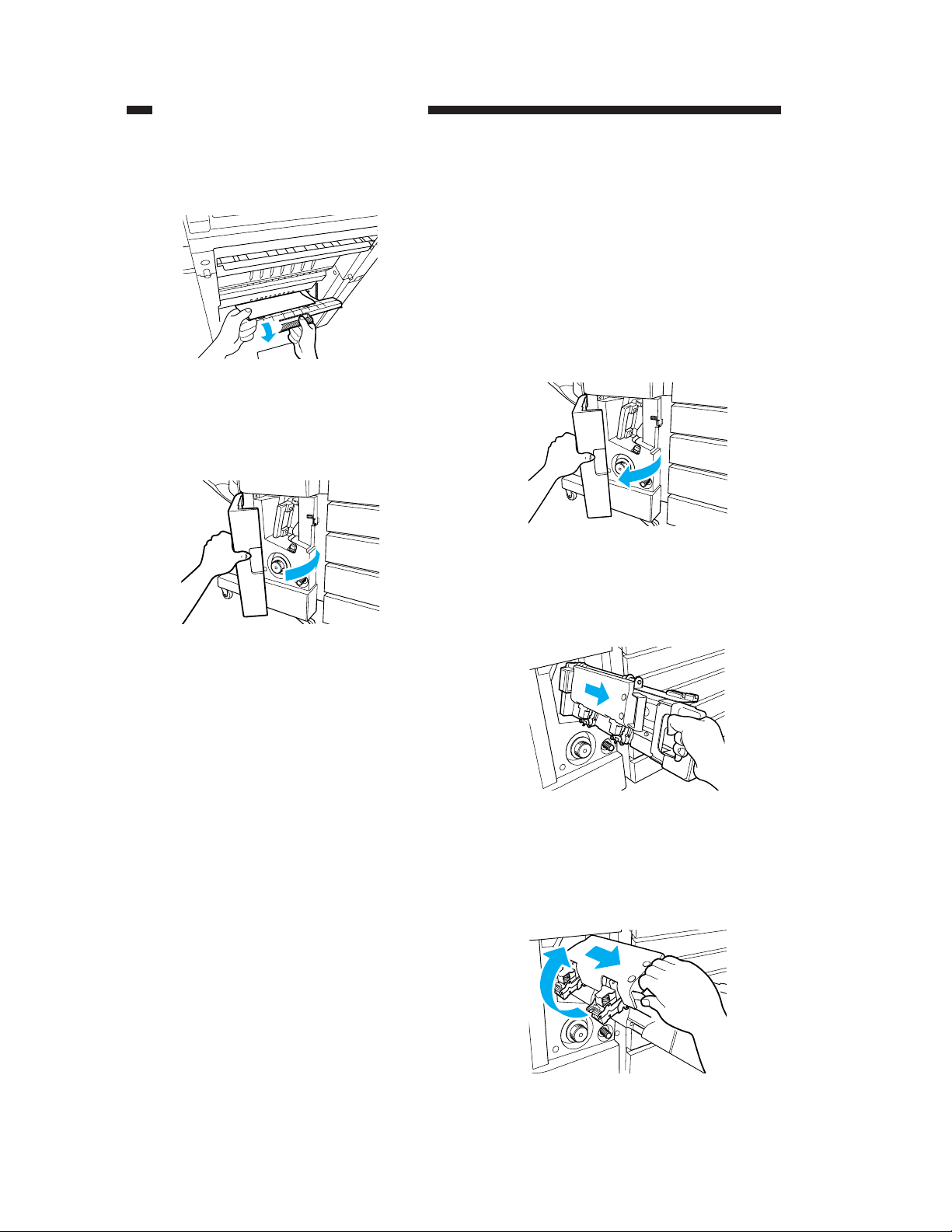

1) Holding the saddle stitcher unit as shown,

move it to detach it from the copier.

Figure 1-323

3) Turn the knob on the right side.

Figure 1-325

4) Turn the knob on the left side.

2) Open the front lower cover.

Figure 1-324

Figure 1-326

5) Remove the jam.

Figure 1-327

COPYRIGHT © 1998 CANON INC. FINISHER-C1/SADDLE FINISHER-C2 REV. 0 DEC. 1998 PRINTED IN JAPAN (IMPRIME AU JAPON)

1-13

CHAPTER 1 GENERAL DESCRIPTION

6) Open the inlet cover, and remove the jam.

Figure 1-328

7) Close the front lower cover.

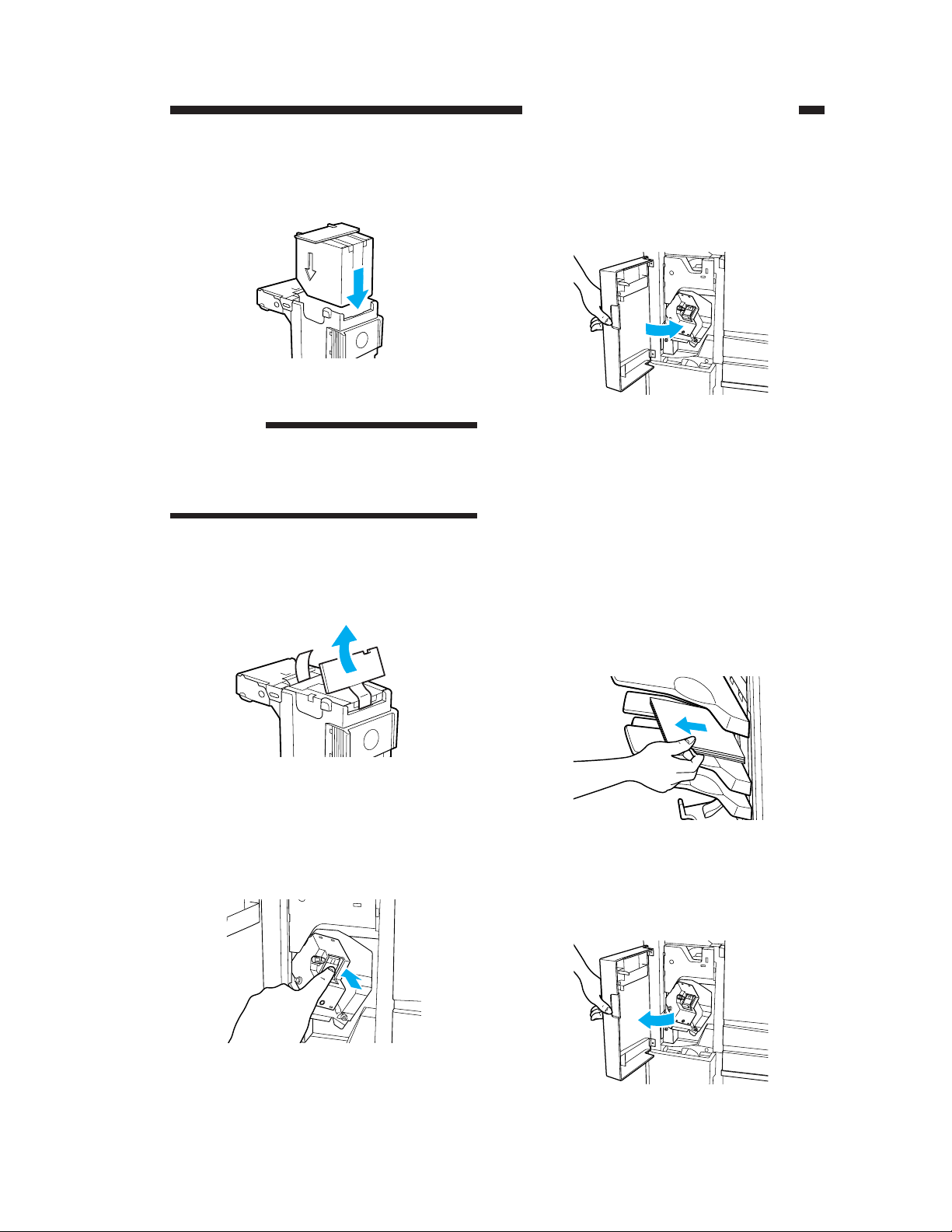

E. Supplying the Saddle

Stitcher Unit with Staples

(Saddle Finisher-C2)

If the copier indicates the saddle stitcher

unit staple supply message, perform the following to supply it with staples.

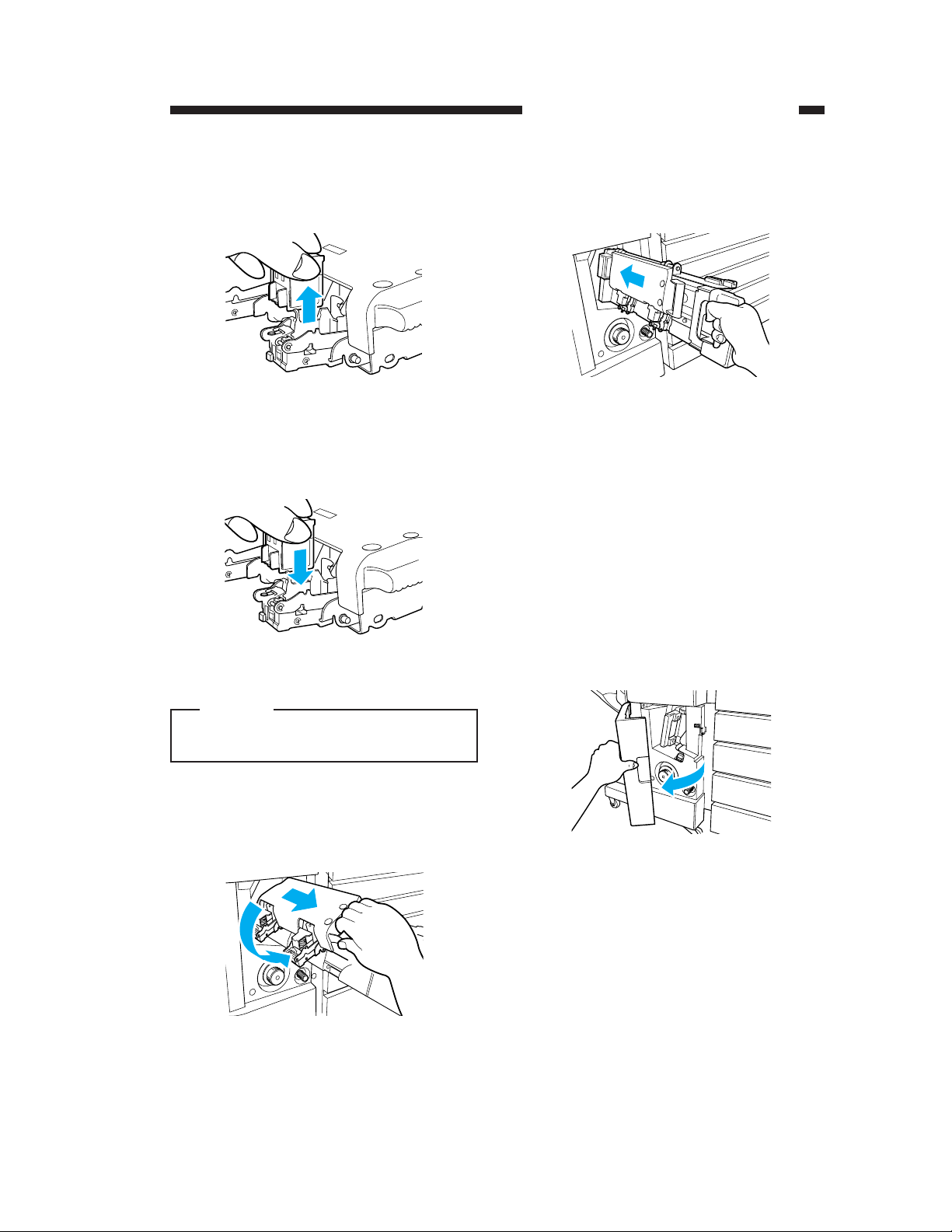

1) Open the front lower cover.

Figure 1-330

2) Slide out the stitcher unit.

Figure 1-329

8) Connect the finisher unit.

9) Operate as instructed on the display.

Figure 1-331

3) Pull the stitcher unit to the front once, and

then shift it up.

Figure 1-332

1-14

COPYRIGHT © 1998 CANON INC. FINISHER-C1/SADDLE FINISHER-C2 REV. 0 DEC. 1998 PRINTED IN JAPAN (IMPRIME AU JAPON)

CHAPTER 1 GENERAL DESCRIPTION

4) Hold the empty cartridge on its sides, and

remove it.

Figure 1-333

5) Fit the new cartridge.

7) Push in the stitcher unit, and close the front

cover.

Figure 1-336

F. Removing Staple Jams

from the Saddle Stitcher

Unit

(Saddle Finisher-C2)

If the copier indicates the saddle stitcher

unit staple jam message, perform the following to remove the jam.

Figure 1-334

Caution:

You must always replace both cartridges at

the same time.

6) Pull the stitcher to the front once, and then

put it back to its original position.

Figure 1-335

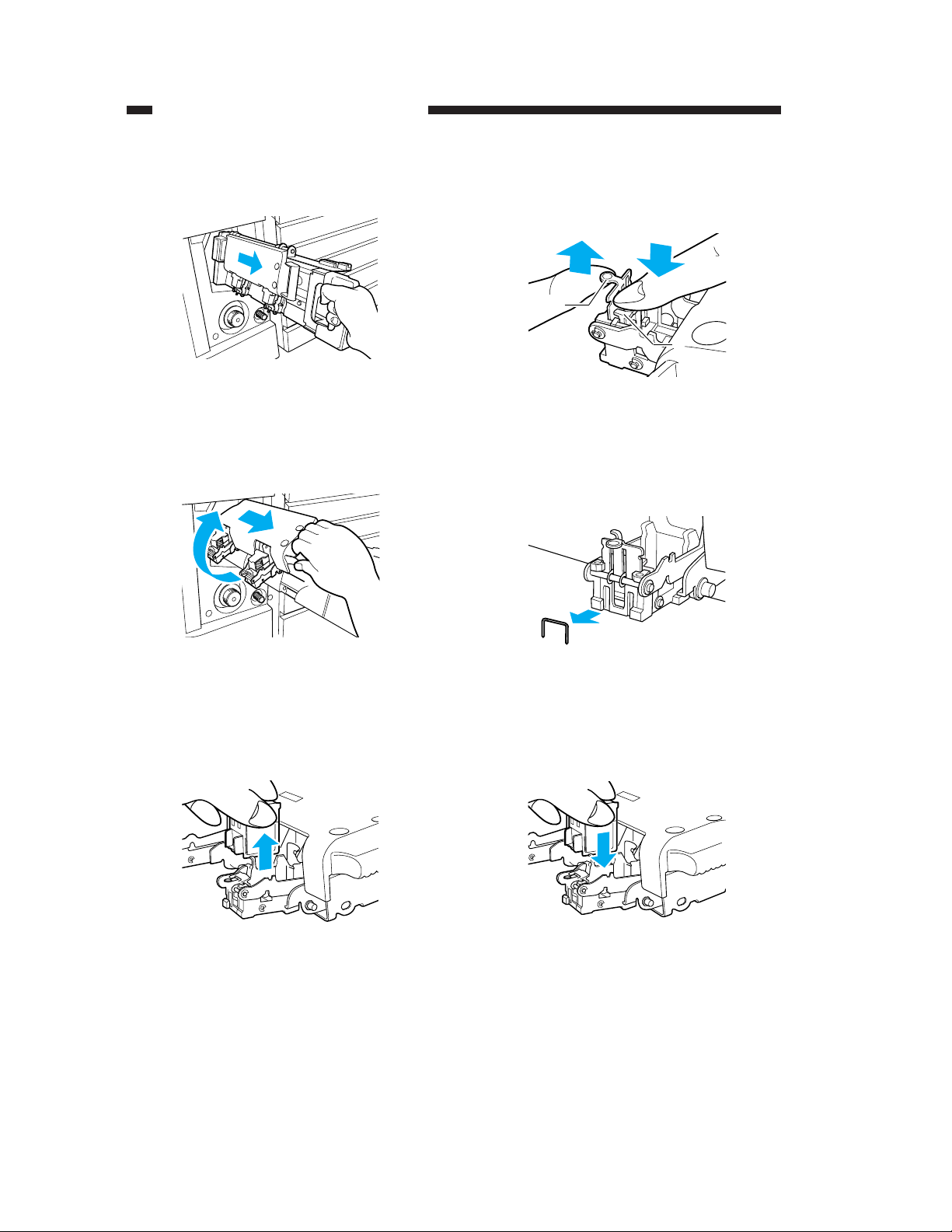

1) Open the front lower cover.

Figure 1-337

COPYRIGHT © 1998 CANON INC. FINISHER-C1/SADDLE FINISHER-C2 REV. 0 DEC. 1998 PRINTED IN JAPAN (IMPRIME AU JAPON)

1-15

CHAPTER 1 GENERAL DESCRIPTION

2) Slide out the stitcher unit.

Figure 1-338

3) Pull the stapler of the stitcher unit to the

front once, and then shift it up.

5) Push down on the area identified as A, and

pull up the tab identified as B.

B

A

Figure 1-341

6) Remove the staple jam, and return the tab

to its original position.

Figure 1-339

4) Hold the cartridge on its sides, and remove

it.

Figure 1-340

Figure 1-342

7) Return the cartridge to its original position.

Figure 1-343

1-16

COPYRIGHT © 1998 CANON INC. FINISHER-C1/SADDLE FINISHER-C2 REV. 0 DEC. 1998 PRINTED IN JAPAN (IMPRIME AU JAPON)

CHAPTER 1 GENERAL DESCRIPTION

8) Pull the stitcher of the stitcher unit to the

front once, and then return it to its original

position.

Figure 1-344

9) Push the stitcher unit back to its original

position, and close the front lower cover.

Whenever you have removed a staple jam,

be sure to execute staple edging.

G. Removing Paper Jams

from the Interrupt Tray

If the display indicates a paper jam on the

interrupt tray, perform the following to remove

the jam:

1) Hold the finisher as shown, and detach it

from the copier.

Figure 1-346

2) Remove the jam.

Figure 1-345

Figure 1-347

3) Connect the finisher to the copier.

4) Operate as instructed on the display.

COPYRIGHT © 1998 CANON INC. FINISHER-C1/SADDLE FINISHER-C2 REV. 0 DEC. 1998 PRINTED IN JAPAN (IMPRIME AU JAPON)

1-17

CHAPTER 1 GENERAL DESCRIPTION

IV. MAINTENANCE BY THE USER

A. Maintenance by the User

As of April 1998

No.

1

Replacing the staple cartridge (finisher unit)

2

Replacing the staple cartridge (saddle stitcher)

Item

When the appropriate indication is made on

the copiers display.

Timing

Caution:

The finisher unit and the saddle unit use different cartridge types. Be sure that the appropriate

type is used for each.

Table 1-401

1-18

COPYRIGHT © 1998 CANON INC. FINISHER-C1/SADDLE FINISHER-C2 REV. 0 DEC. 1998 PRINTED IN JAPAN (IMPRIME AU JAPON)

CHAPTER 2

FINISHER UNIT BASIC OPERATION

I. BASIC OPERATION .................. 2-1

A. Outline ................................. 2-1

B. Outline of Electrical

Circuitry................................2-2

C. Inputs to and Outputs

from the Finisher

Controller PCB .....................2-3

II. FEED/DRIVE SYSTEM .............2-9

A. Outline ................................. 2-9

B. Types of Delivery Paths .....2-13

C. Feeding and Delivering ......2-16

COPYRIGHT © 1998 CANON INC. FINISHER-C1/SADDLE FINISHER-C2 REV. 0 DEC. 1998 PRINTED IN JAPA N (IMPRIME AU JAPON)

D. Job Offset .......................... 2-19

E. Stapling Operation ............. 2-22

F. Stapler Unit ........................ 2-28

G. Tray Operation ...................2-35

H. Detecting the Height of the

Stack on the Tray ............... 2-37

I. Shutter Operation .............. 2-39

J. Buffer Path Operation ........ 2-43

K. Interrupt Tray Delivery .........2-47

L. Detecting Jams .................. 2-49

III. POWER SUPPLY SYSTEM .... 2-55

CHAPTER 2 FINISHER UNIT BASIC OPERATION

I. BASIC OPERATION

A. Outline

The finisher is designed to deliver copies arriving from its host copier, and its modes of delivery

include simple stacking, job offset, staple, and interrupt.

All operations involved in these modes are controlled by the finisher controller PCB, according

to the appropriate commands from the host copier.

In the case of the Saddle Finisher-C2, copies from the host copier may be routed to the saddle

stitcher unit.

Swing guide drive system

Alignment drive system

Stapler drive system

Delivery drive system

Feeder drive system

Control system

Shutter drive system

Tray drive system

Saddle stitcher unit control system

Figure 2-101

Note:

The term job offset refers to shifting of the first sheet of each sorting job, thereby separating a single

stack into several stacks.

COPYRIGHT © 1998 CANON INC. FINISHER-C1/SADDLE FINISHER-C2 REV. 0 DEC. 1998 PRINTED IN JAPA N (IMPRIME AU JAPON)

2-1

CHAPTER 2 FINISHER UNIT BASIC OPERATION

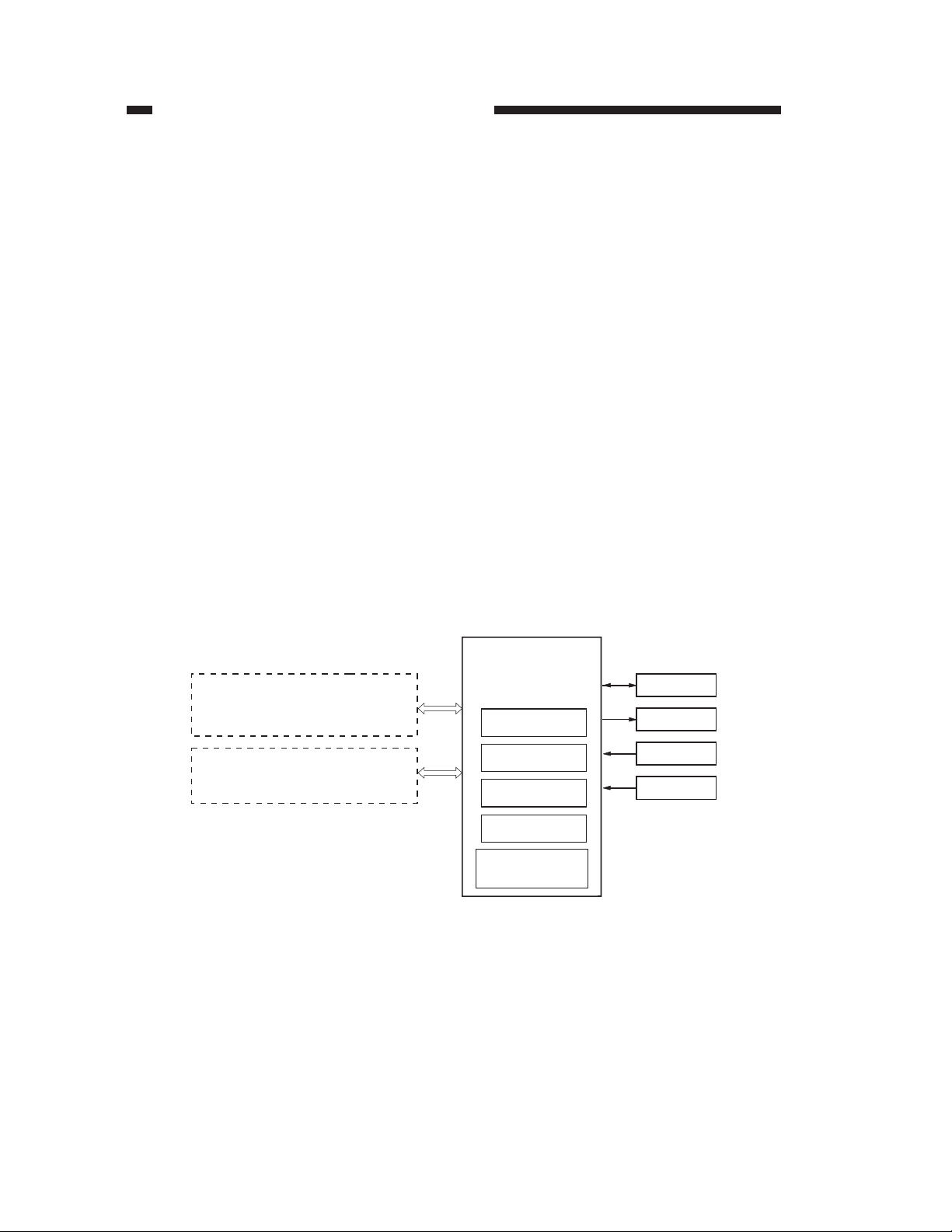

B. Outline of Electrical Circuitry

The finishers sequence of operations is controlled by the finisher controller PCB. The finisher

controller PCB is a 16-bit microprocessor (CPU), and is used for communication with the host

copier (serial) in addition to controlling the finishers sequence of operations.

The finisher controller PCB responds to the various commands coming from the host copier

through a serial communications line to drive solenoids, motors, and other loads. In addition, it

communicates the finishers various states (information on sensors and switches) to the host copier

through a serial communications circuit.

In the case of the Saddle Finisher-C2, the finisher controller PCB not only communicates with

the saddle stitcher controller PCB but also communicates the saddle stitcher units various states

(information on sensors and switches) to the host copier.

The ICs used on the finisher controller PCB are designed for the following:

l

Q1 (CPU)

Controls sequence of operations.

l

Q2 (EP-ROM)

Contains sequence programs.

l

Q3 (RAM)

Backs up initial settings data.

l

Q4 (communications IC)

Communicates with the host copier and the saddle stitcher unit.

l

Q9 (regulator IC)

Generates 5 V.

Figure 2-102 shows the flow of signals between the finisher and the options controller.

Finisher

Saddle stitcher controller

PCB (Saddle Finisher-C2)

Copier

(DC controller PCB CPU)

controller

PCB

Q1

CPU

Q2

EP-ROM

Q3

RAM

Q4

Communications IC

Q9

Regulator IC

Motor

Solenoid

Switch

Sensor

Figure 2-102

2-2

COPYRIGHT © 1998 CANON INC. FINISHER-C1/SADDLE FINISHER-C2 REV. 0 DEC. 1998 PRINTED IN JAPA N (IMPRIME AU JAPON)

Loading...

Loading...