Part 3

Repair

Information

Part 3: Repair Information

3-1

1. REPAIR PREPARATIONS

1.1 INITIAL CHECK LIST

(1) Before repairing the camera, measure and record the flange focal distance. After

completing the repair, measure the flange focal distance again. The before and after

flange focal distance measurements should be the same. (The AF precision will

depend on whether the flange focal distance is the same before and after the repair.)

(2) Check that the AF sensors are clean. To clean, use the adjustment software’s “Clean

AF Sensors” menu.

(3) Check the error codes. Execute any necessary corrective measures. Also, clear the

error codes before returning the camera to the customer.

(4) Check the camera’s serial number and classification number. If repair is necessary,

execute the stipulated repair. Refer to any service manual reports to be issued

henceforth.

(5) Record the user’s mode settings (especially the Custom Function settings). After

repairing the camera, set the same mode and Custom Function settings. Executing a

data transfer of all the settings will make this easy.

(6) Save the camera’s data.

(7) Record the shutter release count. Use this as a reference for replacing the shutter

and lubricating mechanical parts.

(8) Be sure to replace all tape holding lead wires, etc. at the same location. Double

check this after replacing a part or removing any tape.

(9) Check the operation of all the camera buttons and controls.

(10) Inspect the lens contacts and camera-back contacts and clean if necessary.

(11) Inspect the inside of the viewfinder and other parts and clean if necessary.

(12) After replacing the main board unit or DX flex unit, make sure the short pads are in

the same state as before the replacement.

(13) Be sure to execute all the necessary procedures to keep the camera water-resistant.

1.2 CAUTIONS FOR REMOVING THE COVERS

1) Camera Operation After Bottom Cover Removal

After the bottom cover is removed, the main switch cannot be turned on. To work

around this, short-circuit the short pad on the main board. This will enable camera

operation.

When reattaching the bottom cover, be sure to completely remove the solder from the

short pad.

2) Camera Operation After Top Cover Removal

After the top cover is removed, the X-sync contact will be open. In this state, releasing the shutter will result in an error. To work around this, short-circuit the X-sync

contact pad on the DX flex. This will enable camera operation.

When reattaching the top cover, be sure to completely remove the solder from the

short pad.

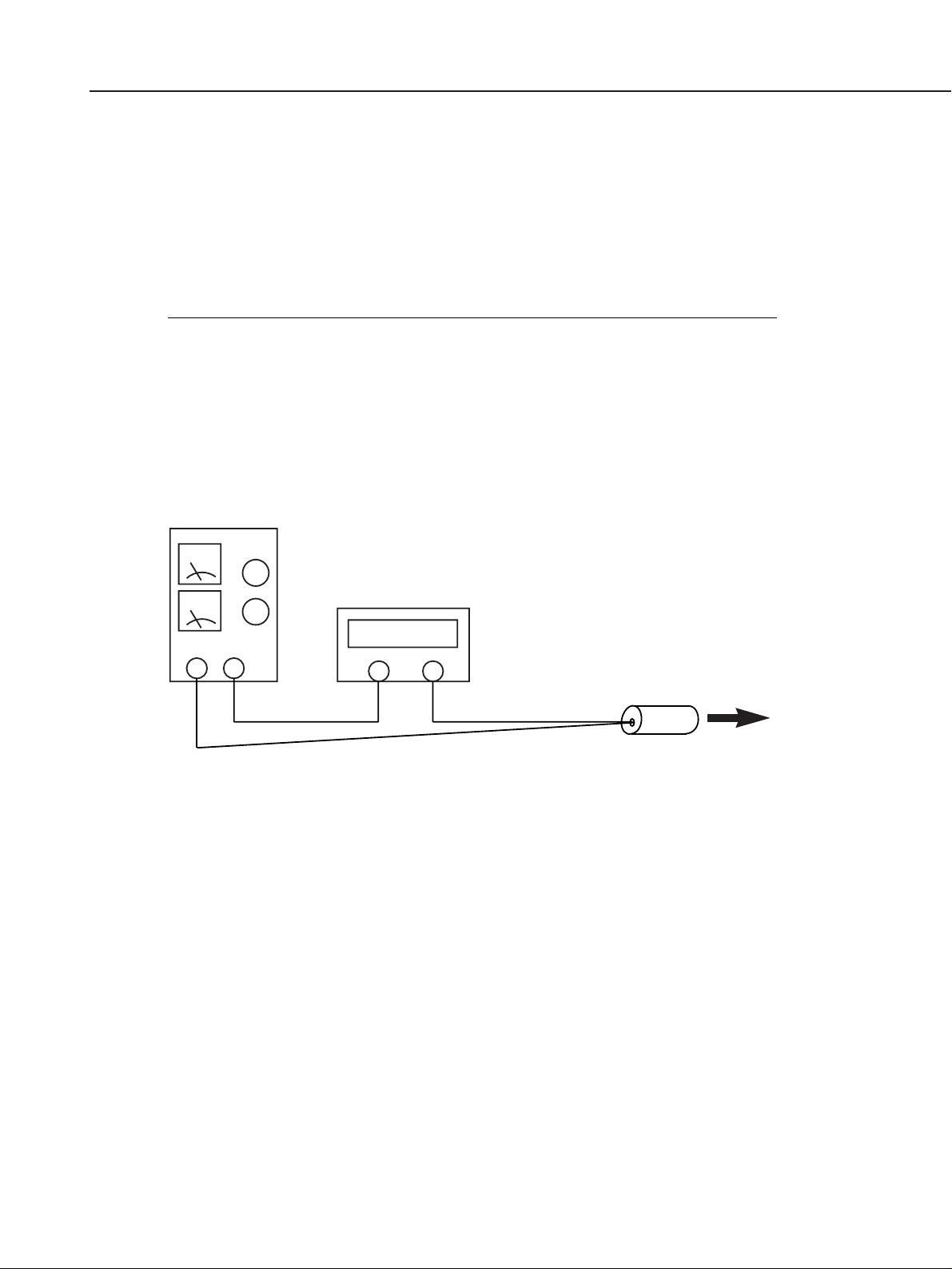

1.3 ABOUT THE DC/DC FLEX UNIT

1) DC/DC Flex Unit (Interim)

Applicable Units: DC/DC unit classification No. C and before

A small flex is attached.

2) DC/DC flex unit (permanent)

Applicable Units: DC/DC unit classification No. D onward

The small flex and lead wire will be eliminated.

Part 3: Repair Information

3-2

Small flex

Small flex

Small flex

Fig. 3-3 Interim DC/DC (top) Fig. 3-4 Interim DC/DC

(bottom)

Fig. 3-5 Installed state.

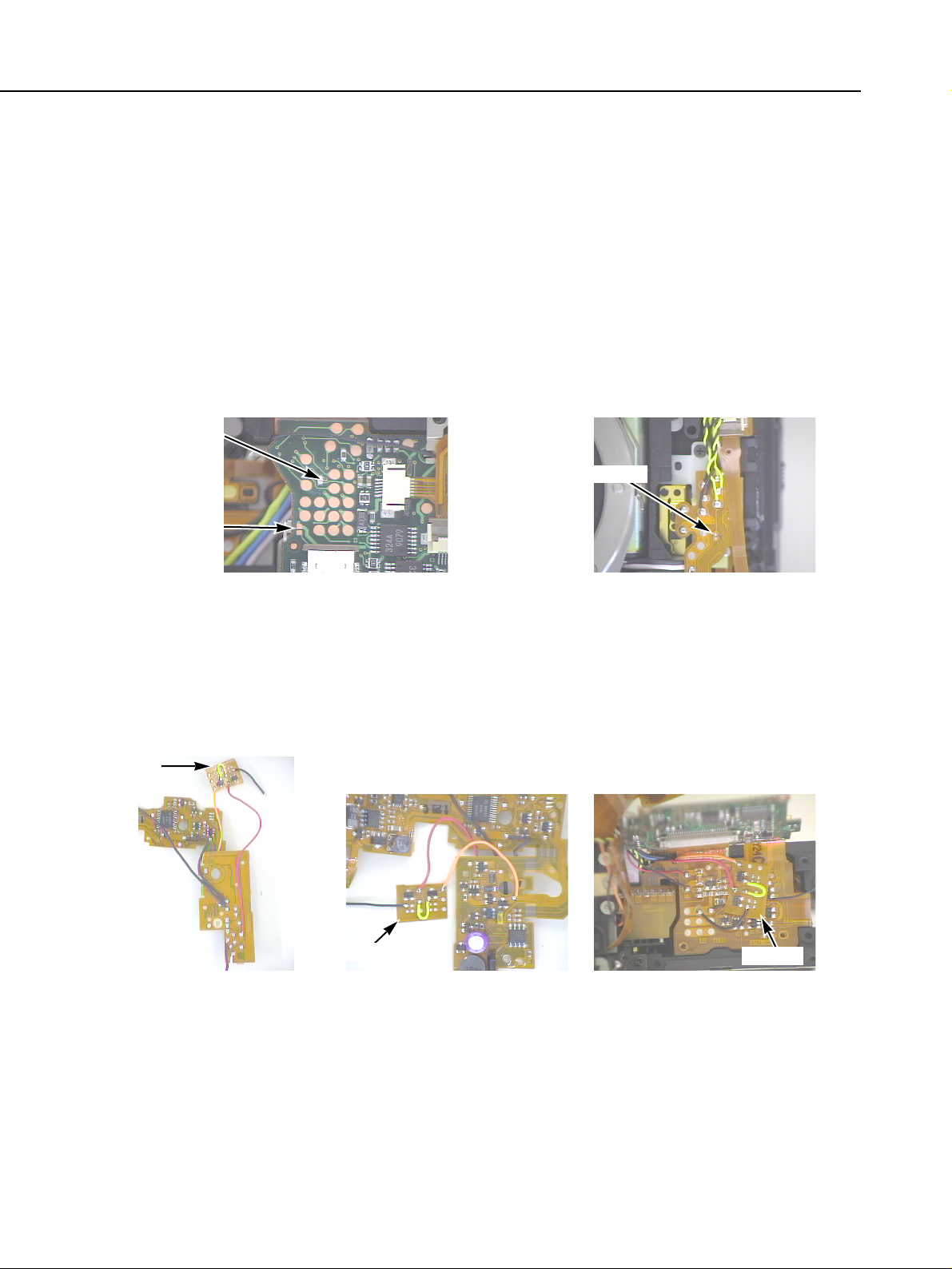

Fig. 3-1 Main SW pad.

X-sync contact pad (DX)

Fig. 3-2 X-sync contact pad.

SPADRTCVDD pad

(Always shorted)

Main SW pad

(Open when bottom

cover is attached.)

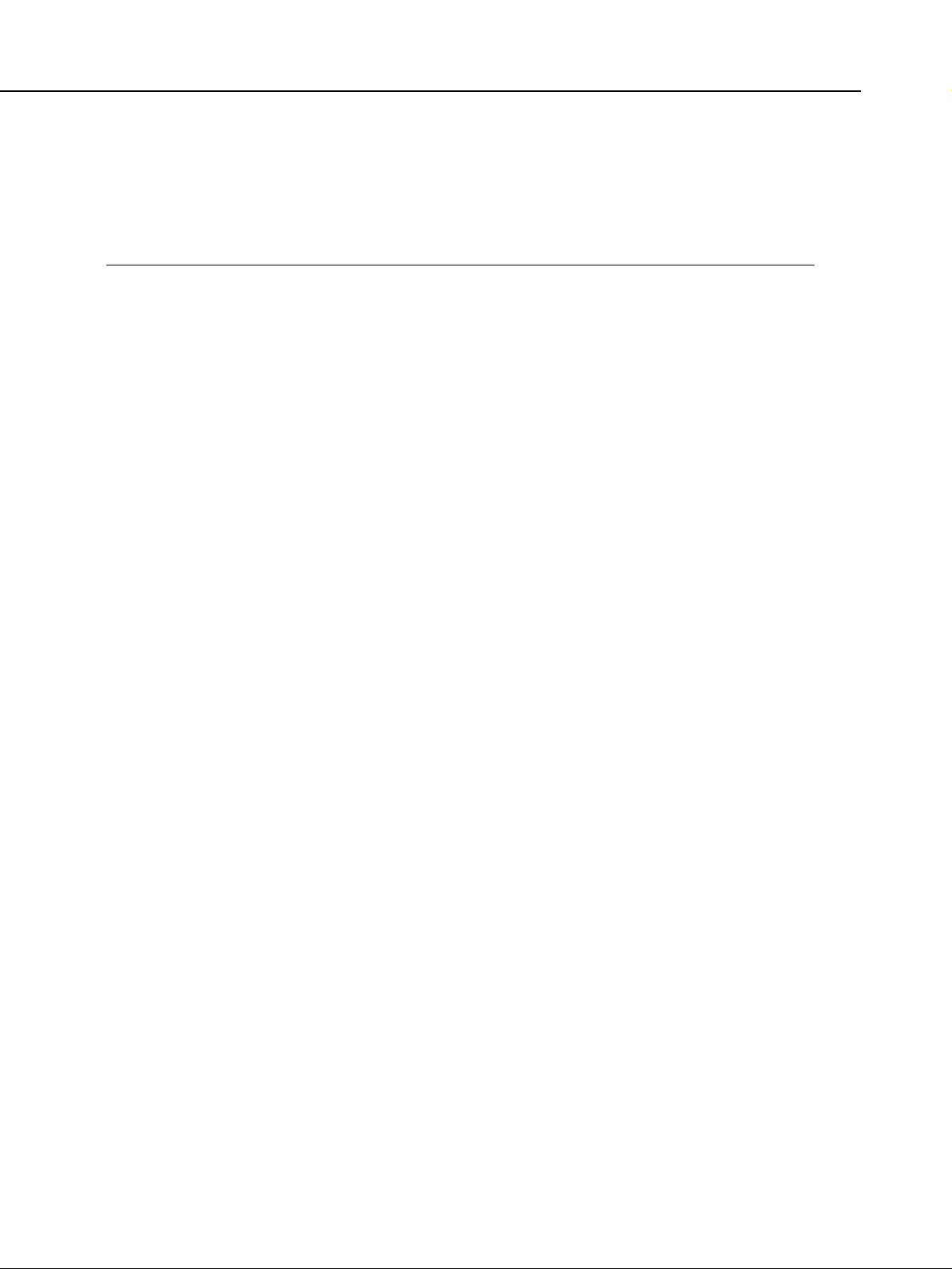

1.4 POWER CURRENT CONSUMPTION

1) Current Consumption Standards

Lens : EF 50mm f/1.8

Power source : Constant voltage 5.4 V, 0.7 ohm

Ambient conditions: Room temperature, normal humidity (below 60%)

Camera Status Standard Actual Measurement

Standby 100 µA or lower Approx. 40 µA

Lock 100 µA or lower Approx. 30 µA

SW1-ON 400 mA or lower Approx. 300 mA

Battery check 1500 mA or lower -Self-timer operation 420 mA or lower Approx. 300 mA

*Note: The Actual Measurement is taken from the initial lot of the camera’s mass pro-

duction. It may differ slightly with subsequent lots.

Fig. 3-6 Power current consumption measuring method.

Part 3: Repair Information

3-3

+

-+-

Constant-Voltage Power Source

Digital tester or other ammeter

Tool battery

To camera

1.5 TOOLS AND EXPENDABLES LIST

The following tools and materials are required for camera reassembly and adjustment.

1) Tools List

New Tool Part No. Purpose

HS-I/F CY9-7082-000 Electrical adjustment

Memory expansion CY9-7082-002 Memory expansion for HS-I/F

Multiple Tool 2 CY9-7099-000 Electrical adjustment

Contack adapter (SLR) CY9-7099-002 For Multiple Tool 2

EF-8000 Multi-Camera Tester CY9-7073-000 Shutter AE adjustment

EF-5000 Multi-Camera Tester CY9-7086-000 Shutter AE adjustment

AE sensor (EF-8000) CY9-7102-001 AE adjustment

AE sensor (EF-5000) CY9-7102-002 AE adjustment

Shutter sensor (EF-8000) CY9-7104-001 Shutter adjustment

Shutter sensor (EF-5000) CY9-7104-002 AE adjustment

Direct sensor (EF-8000) CY9-7105-001 Flash metering adjustment

Direct sensor (EF-5000) CY9-7105-002 Flash metering adjustment

Stable DC power source Electrical adjustment

Infrared dark box (NTSC) CY9-6152-000 Jammed film removal

(PAL) CY9-6153-000

Monitor (with video IN terminal) Commercially available

Dial gauge CY9-1001-006 Flange focal distance adjustment

Dial gauge (0.001 mm) CY9-7094-000 Flange focal distance adjustment

Connecting rod (0.001 mm) CY9-7094-002 Flange focal distance adjustment

Point (ruby tip) (0.001 mm) CY9-7094-003 Flange focal distance adjustment

Dial Gauge Holder-2 CY9-1001-004 Flange focal distance adjustment

2 mm adaptor ring CY9-1001-008 Flange focal distance adjustment

Block gauge (44.14 mm) CY9-1001-007 Flange focal distance adjustment

Optical flat CY9-1001-003 Flange focal distance adjustment

Parallel glass CY9-1024-000 Flange focal distance adjustment

AF tool lens CY9-1072-001 AF precision adjustment

Video light Commercially available AF adjustment

Flashmeter Commercially available Flash metering adjustment

Penlight Commercially available SPC positioning

Tripod Commercially available

Dark box Commercially available

Tester Commercially available Voltage measurement

Best Focus tool (PAL) CY9-7110-000 AF check and adjustment

Best Focus tool (NTSC) CY9-7110-001 AF check and adjustment

Focus mirror CY9-7110-002 AF check and adjustment

AF standard charts (set of 3) CY9-1124-000 AF adjustment

Inhibit voltage tool kit CY9-1101-000 Inhibit voltage adjustment

PDB tool battery kit CY9-1104-000 Inhibit voltage adjustment

Part 3: Repair Information

3-4

2) Charts and Locally Fabricated Tools

New Tool Part No. Purpose

18%-reflectance gray card Flash metering adjustment

3D chart *See the EF 300mm f/4.0L IS lens manual

SPC positioning mask Locally fabricated

X-sync shoe Locally fabricated X-sync time lag check

Parallax chart Locally fabricated Viewfinder parallax adjustment

Tool battery See the EOS-1N Service Manual.

* For details, see “About Custom Tools.”

3) Other Products for Testing

New Tool Part No. Purpose

EF 50mm f/1.8 production lens Camera operations, adjustments,

checking

Speedlite (A-TTL with 300EZ, 540EZ, etc.) Flash metering adjustment

Speedlite (E-TTL with 380EX, 550EX, etc.) Flash metering adjustment

Power Drive Booster PDB-E2 Product Inhibit voltage adjustment

Ni-MH battery Product

Ec-D Laser Matte with grid or

Ec-H Laser Matte with scale Product SI adjustment

4) Expendables List

New Tool Part No. Purpose

Light-shield tape CY9-4026-000 M2 motor

Tape (No. 315) CY9-4031-000 DX unit, film transport unit

Double-sided tape CY9-4034-000 Body

Aron Alpha 201 CY9-8007-000 Securing SPD and SI in place

Arontite L CY9-8008-000 For screw heads

Three Bond 1401C CY9-8011-000 Setscrews

UTLM-10 CY9-8031-000 Mirror parts

Silicon KE-347B CY9-8064-000 Water resistance

Grease H-26 CY9-8079-000 Dial unit and other parts

IF10 CY9-8088-000 Mount spring

Lube, Barrierta SJF-102, Grease CY9-8100-000 Release contact

Paint, MM-010A Oil-retardant CY9-8101-001 Prevention of oil oozing under the mount

Longenest Lambda A-74 CY9-8102-000 M2 gear shafts

Diabond 1663B CY9-8110-000 Adhesive for parts

Longenest Lambda NK-74C CY9-8117-000 Shafts and friction parts

*

Cemedine Super X No. 8008 Black CY9-8118-000 Mount ring and other parts

*

Nox Guard ST-420 CY9-8123-000 Parts assembly

*

Longenest Lambda NFH-743C CY9-8125-000 Front cover’s friction surfaces

Part 3: Repair Information

3-5

1.6 LOCALLY FABRICATED PARTS

1) SI Adjustment Chart

As shown in the figure, affix five white

pieces of reflective paper on a black

cardboard. (Sample provided at the

end of the manual.)

2) SPD Positioning Mask

On a low-reflectance, black sheet of

paper, make holes as shown in the figure below.

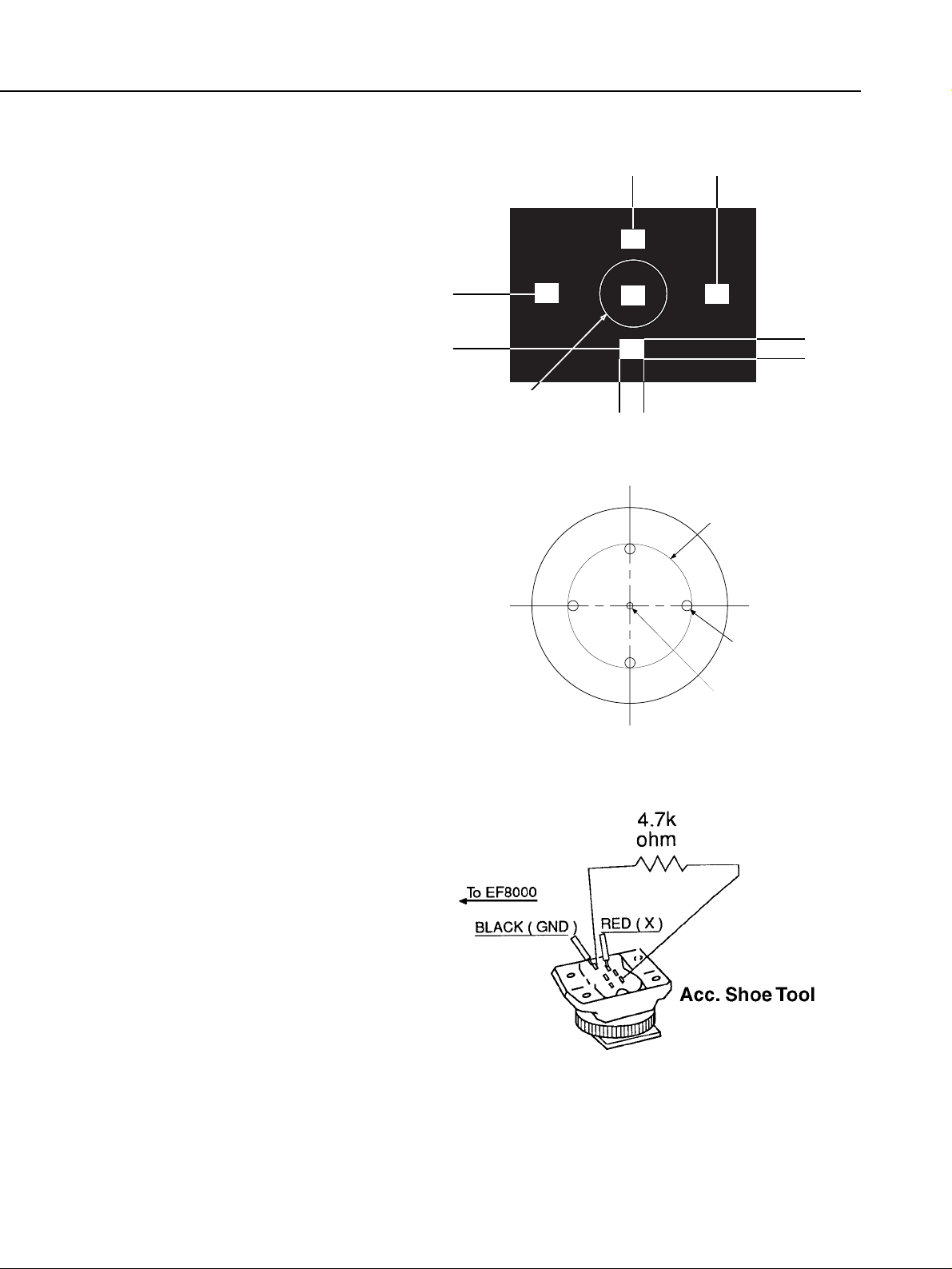

3) X-sync Shoe

This is for measuring the X-sync time

lag.

As shown in the figure, attach a 4.7 k

ohm resistor between the CCC line

and GND on the hot shoe.

Part 3: Repair Information

3-6

Fig. 3-7 SI Adjustment Chart.

145mm

87mm

14.3mm

21.2mm

70.9mm

Fig. 3-8 SPD positioning mask.

ø 57mm

ø 4~6mm

ø 2~3mm

Fig. 3-9 X-sync shoe.

<Memo>

Part 3: Repair Information

3-7

This page intentionally left blank

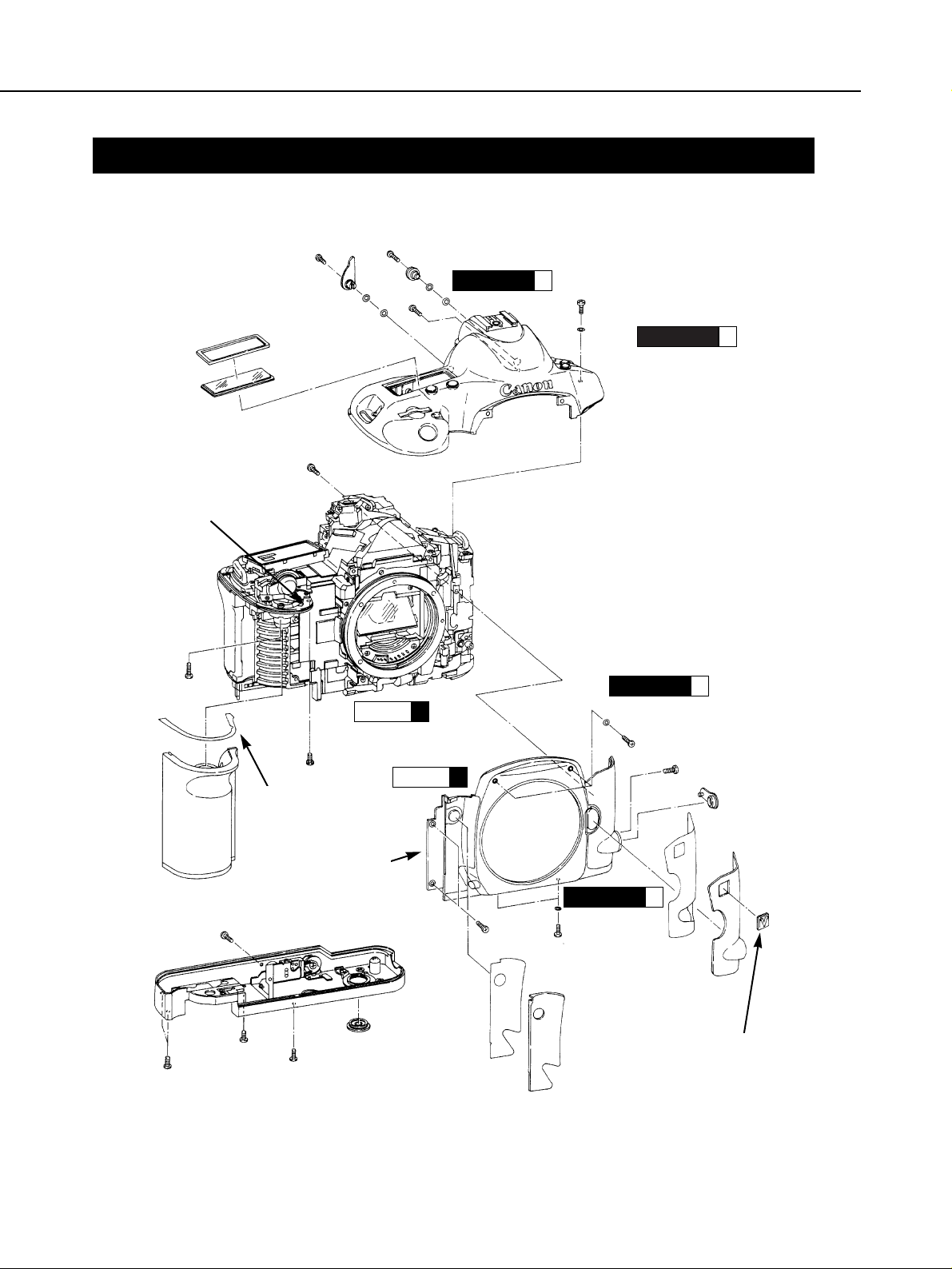

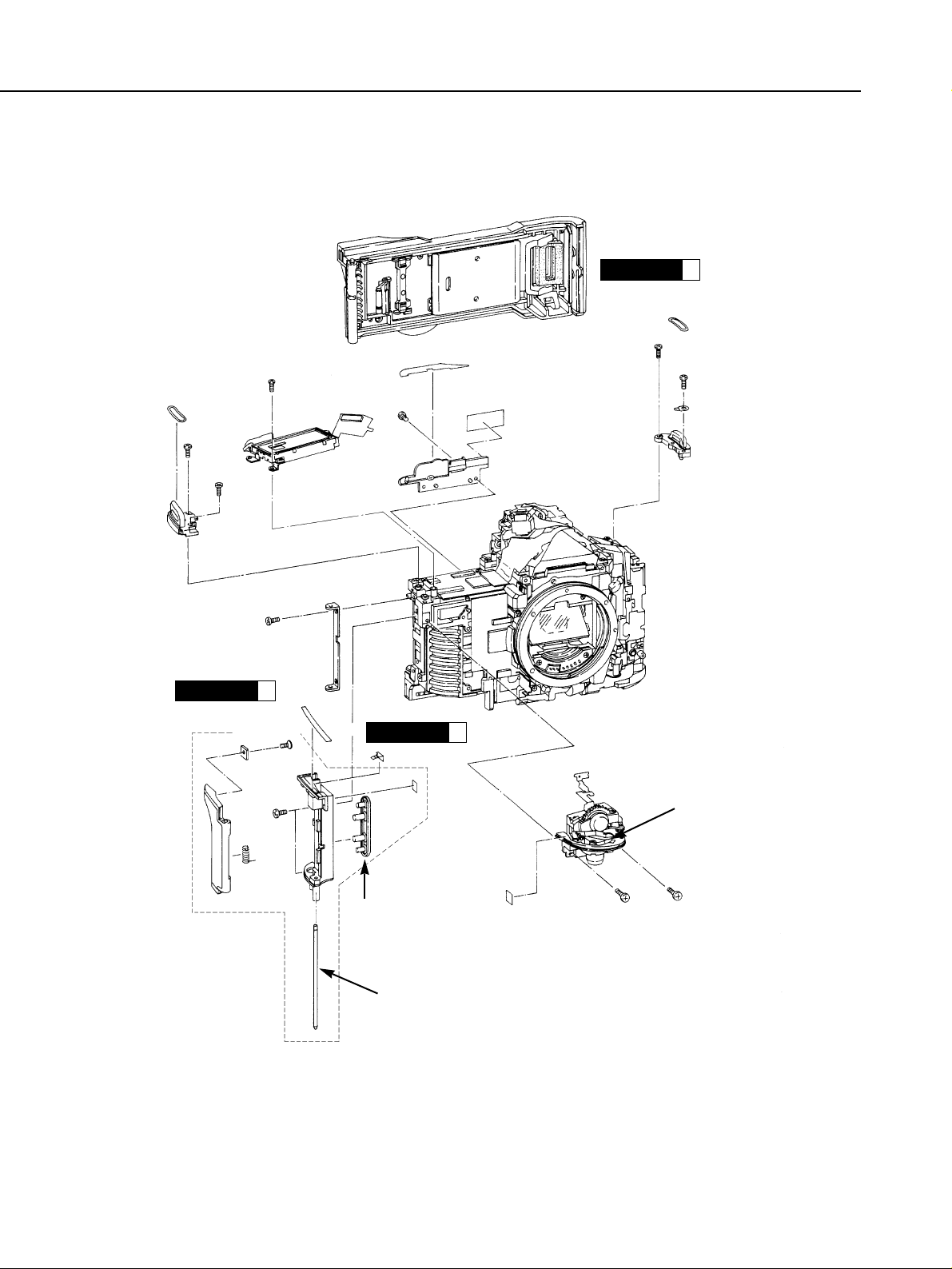

2. DISASSEMBLY AND REASSEMBLY

2.1 EXTERNAL COVERS

Fig. 3-10 External covers.

Part 3: Repair Information

3-8

CAUTION

1

(3)

(2)

NOTE 2

(1)

(4)

★Diabond 1663B

Affix the nameplate.

x2

R= 3.5mm

x2

R= 3mm

x2

x2

R= 4mm

x4

R= 4mm

CAUTION

1

x2

R= 4mm

R= 3.5mm

R= 7mm

R= 3mm

x2

R= 7mm

R= 6mm

NOTE 1

R= 10mm

x2

R= 10mm

★Barrierta SJF-102

Apply a thin film on

the release pin’s

friction surface.

Do not scratch.

★Nox Guard ST-420

Apply along the inside

corner.

CAUTION

1

CAUTION

1

R= 3.5mm

<REMOVAL PROCEDURE>

Assembly location of water-resistant

parts (Do not lose)

• Front cover screws (Front x 2, bottom x 2)

• Top cover left and right screws at bottom

• Eyepiece shutter lever

• Eyepiece adjusting dial

(1) Remove the grip unit.

(2) Remove the front cover assembly.

• Remove the eight screws (front x 2, right x 2,

bottom x 2, remote control side x 1, film chamber x 1).

• Peel off the left front panel cover on the latch

cover.

• Disconnect the remote control flex from the connector.

(3) Removal of bottom cover assembly

• Remove the eight screws (D) securing the bottom

cover.

• Disconnect the main flex from the connector.

(4) Removal of top cover assembly

• Remove the following screws:

Under left and right strap rings (2)

Back screws (2)

Eyepiece shutter lever

Eyepiece adjusting dial

Underside of shutter button grip overhang

screws (2)

• Remove the solder on the two lead wires connected to the DX flex.

• Remove the TOP flex from the connector.

• With the top cover removed, the shutter’s X-sync

contact will be open. Releasing the shutter will

therefore result in error. To prevent this error,

short the X-sync pad (Fig. 3-13).

1

CAUTION

Part 3: Repair Information

3-9

• To remove the front cover assembly,

start with the grip side.

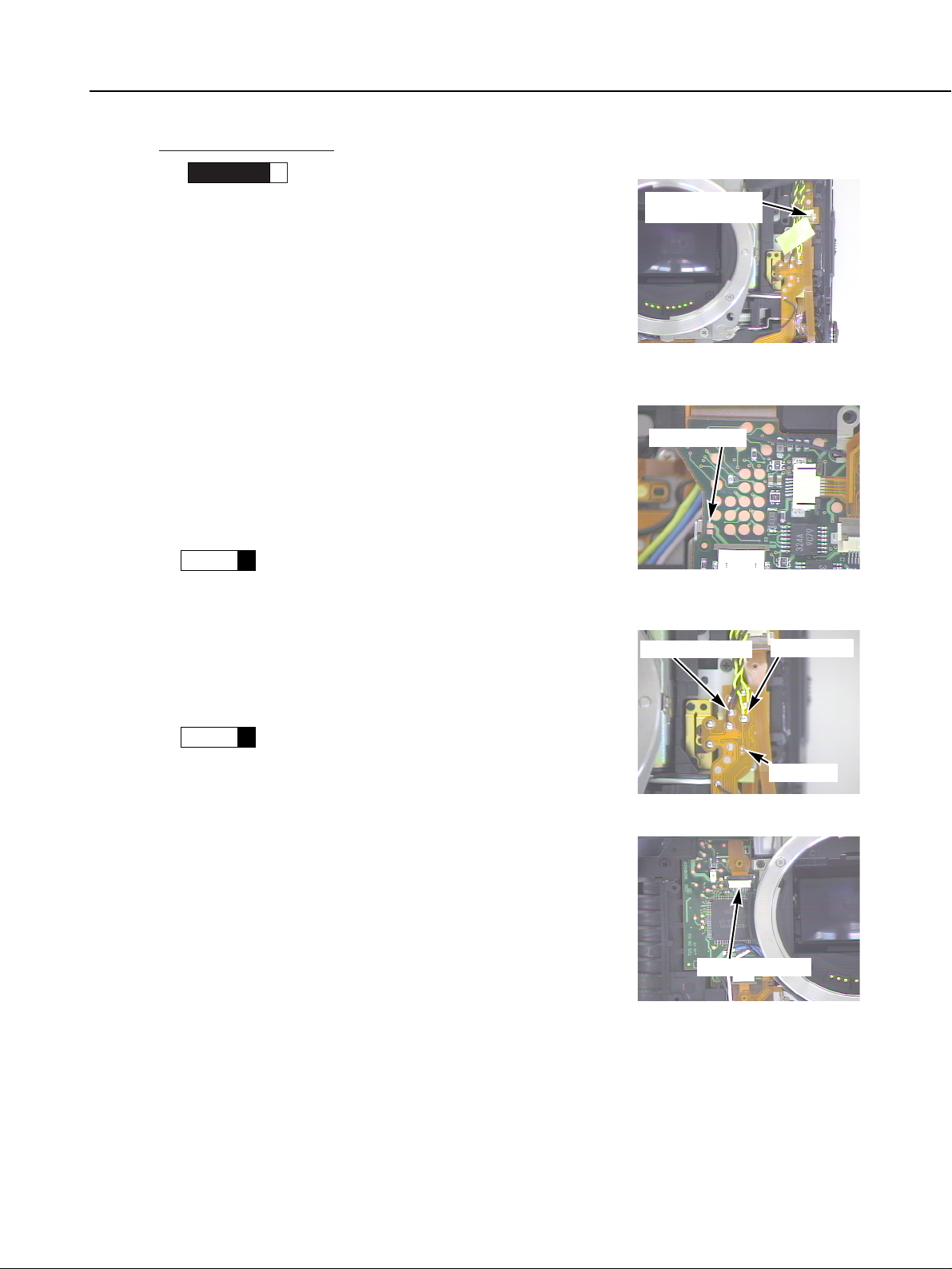

NOTE 1

• Turn on the main switch by short-circuiting the pad (shown on the right) on

the main flex.

NOTE 2

Fig. 3-11 Remote control flex

connector.

Remote control flex

connector

Fig. 3-12 Main SW pad

Main switch pad

Fig. 3-13 Top cover lead wires.

X-sync pad

Yellow (SH-X)

Black (SH-X GND)

TOP flex connector

Fig. 3-14 Top cover connector.

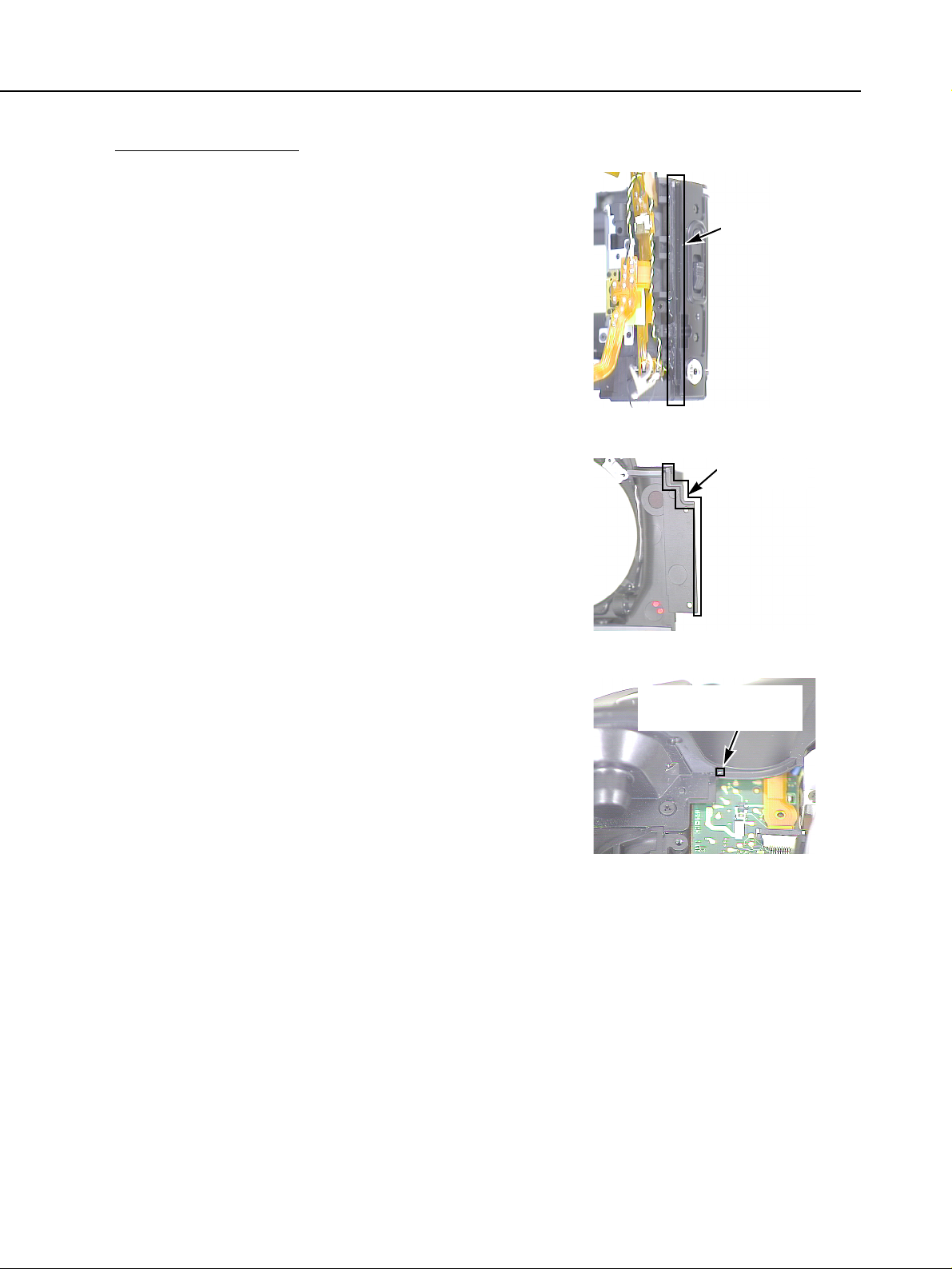

<REASSEMBLY CAUTIONS>

1. Check all the short pads.

2. Make sure none of the lead wires protrude or get

pinched by the covers.

3. If the silicon bond on the latch cover side has

come off, apply Silicon Bond KE-347B.

4. Apply a little Nox Guard ST-420 on the side (grip)

of the front cover. There must be no excess that

oozes outside. After applying it, do not wipe it

with a solvent. Doing so will degrade its waterresistance properties.

5. Use Silicon Bond KE-347B to completely fill in the

gap between the top cover and dial base plate.

Part 3: Repair Information

3-10

Fig. 3-15 Latch cover.

Fig. 3-16 Front cover.

Fig. 3-17 Top cover.

Apply Silicon

Bond KE-347B.

Apply Nox

Guard ST-420

Apply Silicon Bond KE-347B

in the gap between the top

cover and dial base plate.

<Memo>

Part 3: Repair Information

3-11

2.2 PALM SWITCH HOLDER

Fig. 3-18 Palm switch holder.

Part 3: Repair Information

3-12

(3)

(1)

(4)

(2)

x2

R= 3.5mm

R= 6mm

★Longenest Lambda NK-74C

Apply a thin coat on the

entire shaft.

CAUTION

2

★Palm switch

The notched end

must be upward.

★Barrierta SJF-102

Apply a thin coat on

the release pin’s

friction surface.

CAUTION

4

CAUTION

3

R= 5.5mm

(5)

R= 3.5mm

R= 5mm

R= 2.5mm

x2

R= 5mm

(6)

x3

R= 4.5mm

R= 6mm

R= 5.5mm

x2

R= 4mm

(5)

Normally, disassembly

is unnecessary.

<DISASSEMBLY PROCEDURE>

(1) Removal of Camera Back Assembly

• Be careful not to damage the

shutter curtains.

(2) Removal of Back Switch Base

• Detach the two flex from the back switch.

• Remove the two screws.

• Detach the back switch and also remove the

right body seal.

(3) Removal of Outside LCD Unit

• Remove the two lead wires (red, gray) on the

right of the Outside LCD.

• Remove the three screws.

• Disconnect the connector from the main

board unit.

(4) Removal of Dial Unit

• Disconnect the black lead wire from the shutter release arm.

• Peel off the hinge cover seal (top) from the dial

unit.

• Disconnect the AD switch flex from the connector.

• Remove the two screws.

• While peeling off the grip seal on the palm

switch holder, remove the dial unit.

(5) Removal of Left and Right Strap Ring Screws

• Remove the two screws.

• Be careful not to lose or bend the

GND plate under the right ring.

(6) Removal of Palm Switch Holder

• Remove the camera back hinge screws (2).

• Remove the palm switch holder (2 screws).

• The palm switch holder might be

difficult to remove due to the silicon bond applied under the holder on the camera chassis.

See next page about the application area.

4

CAUTION

3

CAUTION

2

CAUTION

Part 3: Repair Information

3-13

Fig. 3-19 Back switch.

Right body seal

Remove flex

Two screws

Fig. 3-20 Dial lead wires.

Red Gray

Black

Grip seal

Hinge cover seal

Fig. 3-21 Removal of OLC unit.

AD switch connector

OLC unit connector

Fig. 3-22 Right ring GND plate.

GND plate

Fig. 3-23 Palm switch holder.

Camera back

hinge screw

Palm switch

holder screws

Loading...

Loading...