Part 2

Technical

Information

1. TECHNICAL DESCRIPTION

1.1 AF System

While based on the EOS-3, the EOS-1V’s AF system incorporates major enhancements including a newly designed AF unit and a new AI Servo AF sequence and

algorithm for improved speed, precision, and reliability. Other components are

based on the EOS-3’s such as the large, oval secondary mirror, the optical system’s basic configuration and focusing principle, the focusing point’s automatic

selection algorithm, and the low-contrast countermeasures.

1) Faster Area AF

● High-speed, 33.3 MHz, RISC microcomputer and high-speed software processing

The high-speed RISC microcomputer

with a clock speed of 33.3 MHz is dedicated to AF calculations and shooting

data memory. The processing speed is

faster than the EOS-3’s (clock speed:

24.576 MHz). And with the same highspeed, predictive calculation algorithm

and other software processing, the

focusing point selection speed is faster than the EOS-3’s. Even the manual focusing point selection speed is the world’s fastest.

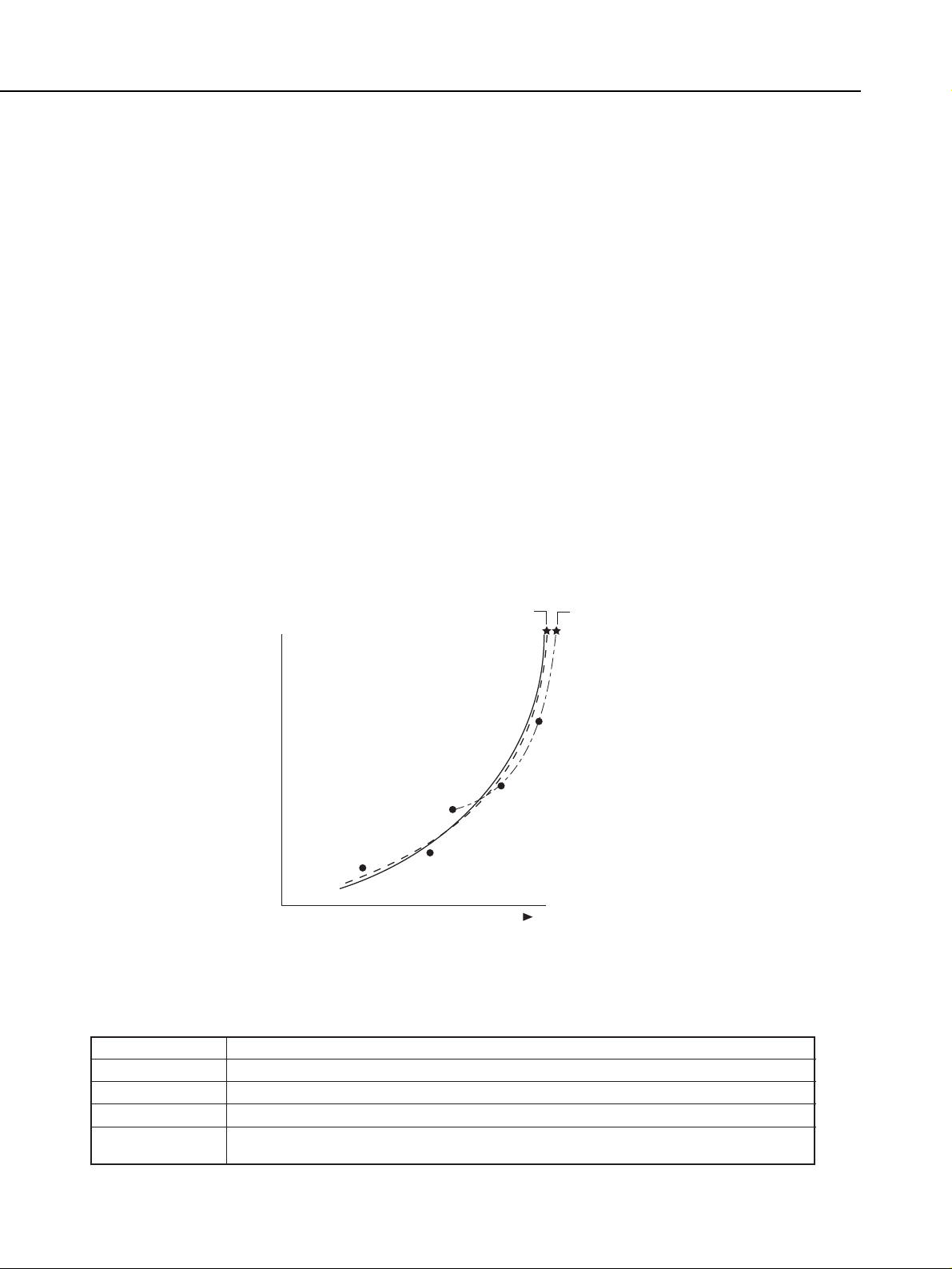

2) Area AF with higher precision

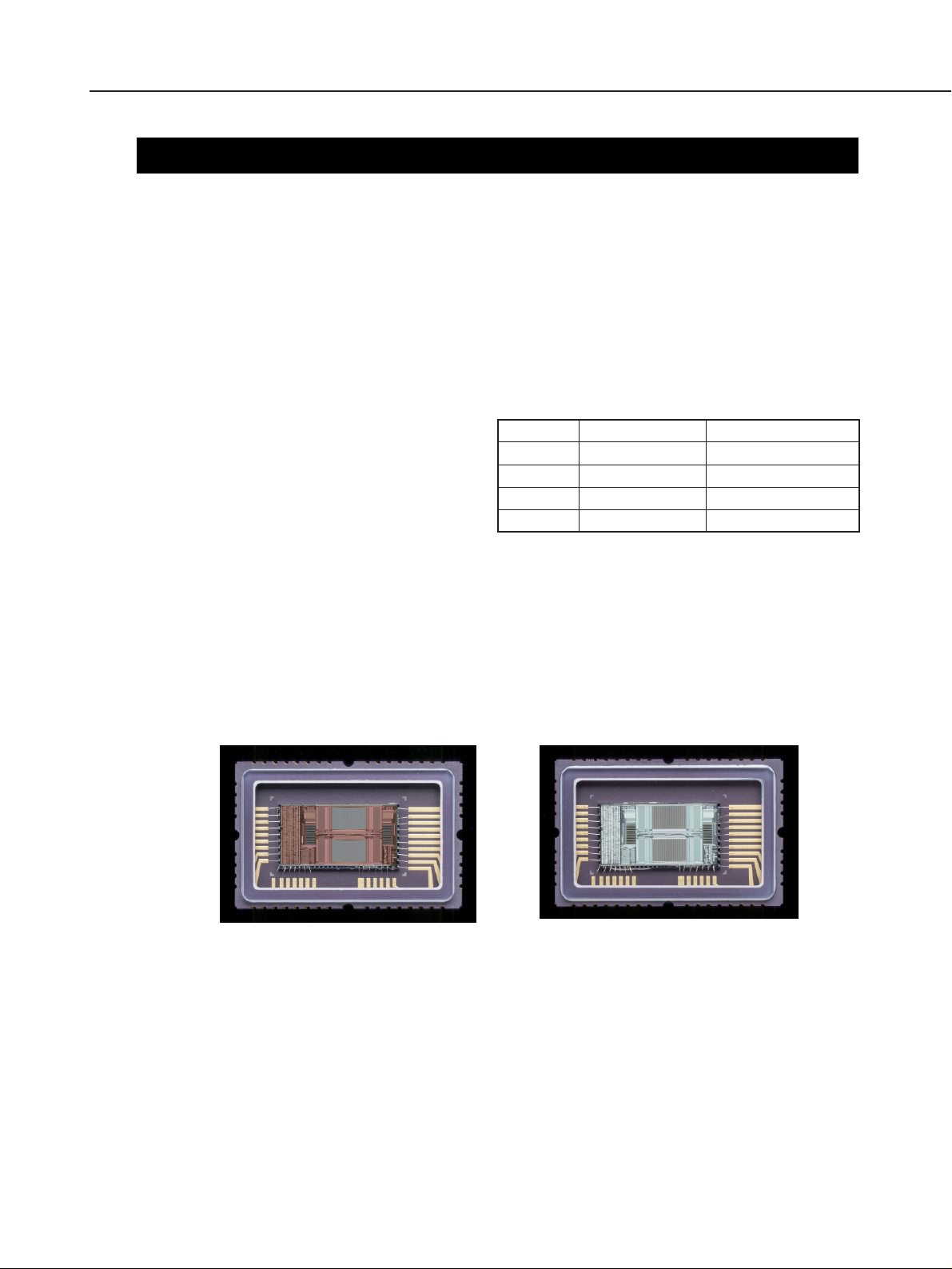

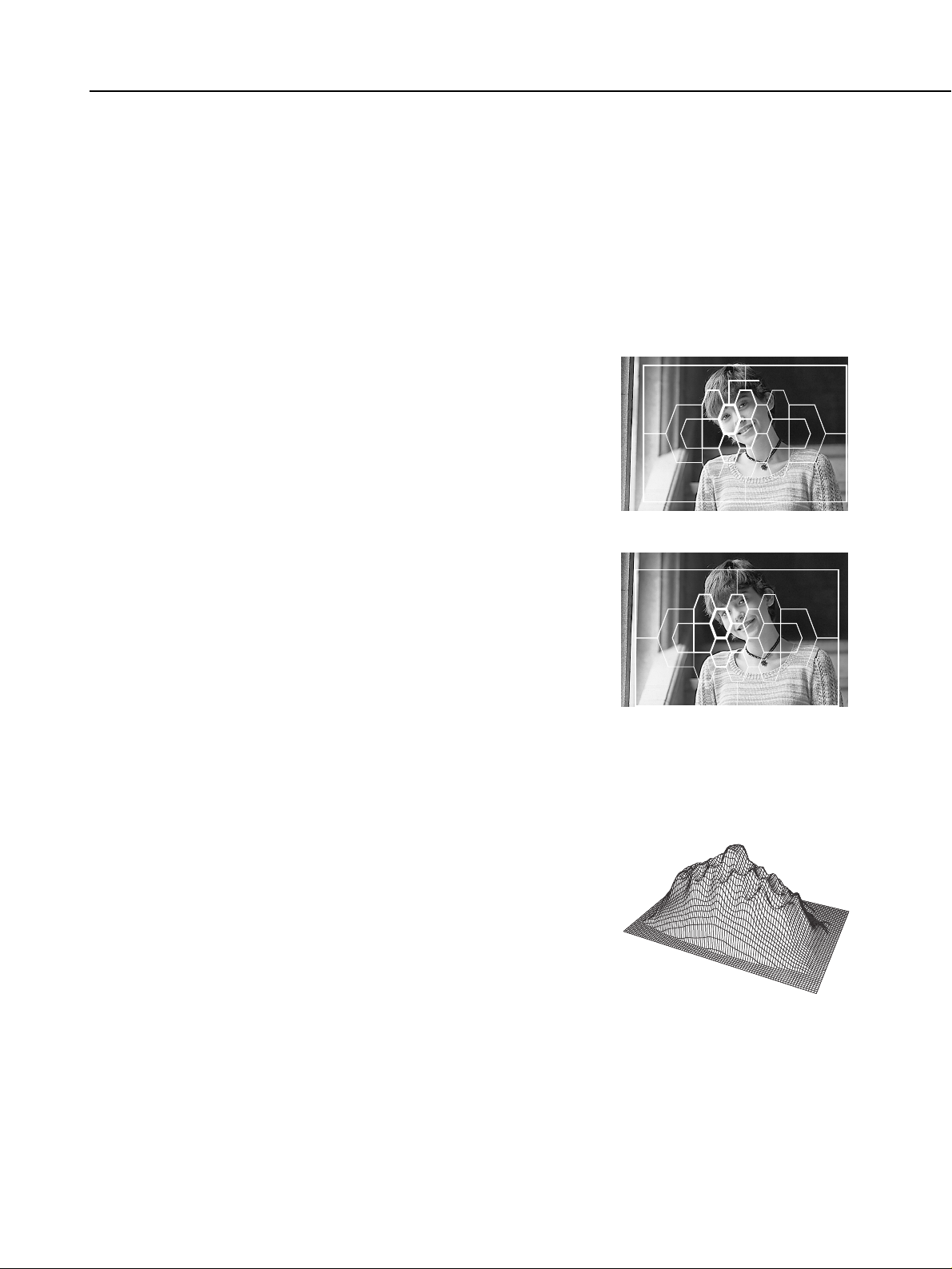

● Improved S/N ratio and in-focus indicator with guaranteed precision

q To further improve the S/N ratio, the sensor’s effective light-sensing area per

pixel has been increased by 12 percent. Also, the AF sensor’s light-sensing surface has an anti-reflection layer to reduce the ghosting that affects the S/N ratio.

(Fig. 2-1)

w In low-light, whether focus has been achieved or not depends on how reliable the

focusing signal is. To obtain the correct result, focusing signal precision has been

given priority. Of course, focusing precision is officially guaranteed in low light

down to EV 0.*

* Although this specification is common to all EOS cameras, it has not been men-

tioned in the manual until now.

2-1

Part 2: Technical Information

Camera

EOS-1

EOS-1N

EOS-3

EOS-1V

Basic Clock Speed

12 MHz

12 MHz

24.576 MHz

33.3 MHz

Fastest Processing Speed

0.33 µs

0.17 µs

0.04 µs

0.03 µs

Table 2-1 AFCPU

Fig. 2-1 EOS-1V’s AF sensor. Fig. 2-2 EOS-3’s AF sensor.

3) Area AF with higher reliability

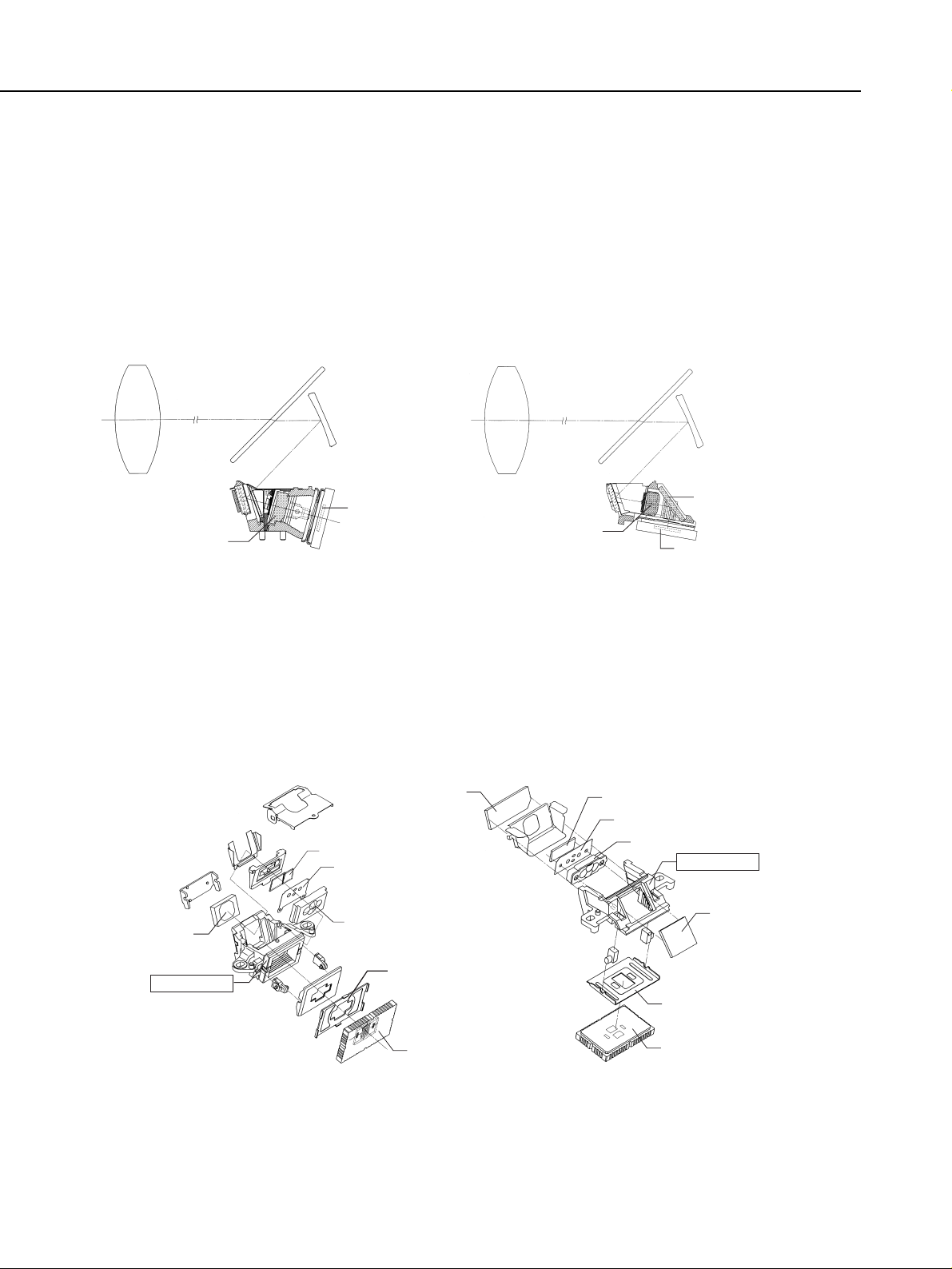

● New AF optical system eliminating unstable precision

The new AF optical system (Fig. 2-3) does not have the fully-reflective mirror 2

which the EOS-3 has near the sensor. The mirror’s reflective surface which

caused unstable precision has thereby been eliminated.

Also, the secondary image-forming lens is now made of molded glass instead of

plastic resin. It enables consistent focusing precision even under high temperatures and humidity.

● AF unit in a strong box

The AF unit’s AF chassis (Fig. 2-4) is now made of a material whose properties

change little when the humidity changes. The rigid box construction is also able

to withstand shock and other environmental influences to improve precision stability.

2-2

Part 2: Technical Information

Prime lens

Main reflex mirror

Secondary mirror

Prime lens

Main reflex mirror

Secondary mirror

Fully-reflective mirror Fully-reflective mirror 1

Fully-reflective

mirror 2

Secondary

image-forming lens

Area AF sensor

Area AF sensor

Secondary

image-forming lens

EOS-1V AF optical system EOS-3 AF optical system

Fig. 2-3 Comparison of the EOS-1V and EOS-3’s AF optical systems.

Fully-reflective

mirror 1

Fully-reflective

mirror 2

Infrared filter

Fixed diaphragm

Secondary image-forming lens

Center holder

Area AF sensor

Fully-reflective

mirror

AF chassis

Infrared filter

Fixed diaphragm

Secondary image-forming lens

Center holder

Area AF sensor

EOS-1V AF unit EOS-3 AF unit

AF chassis

Fig. 2-4 Comparison of EOS-1V and EOS-3’s AF units.

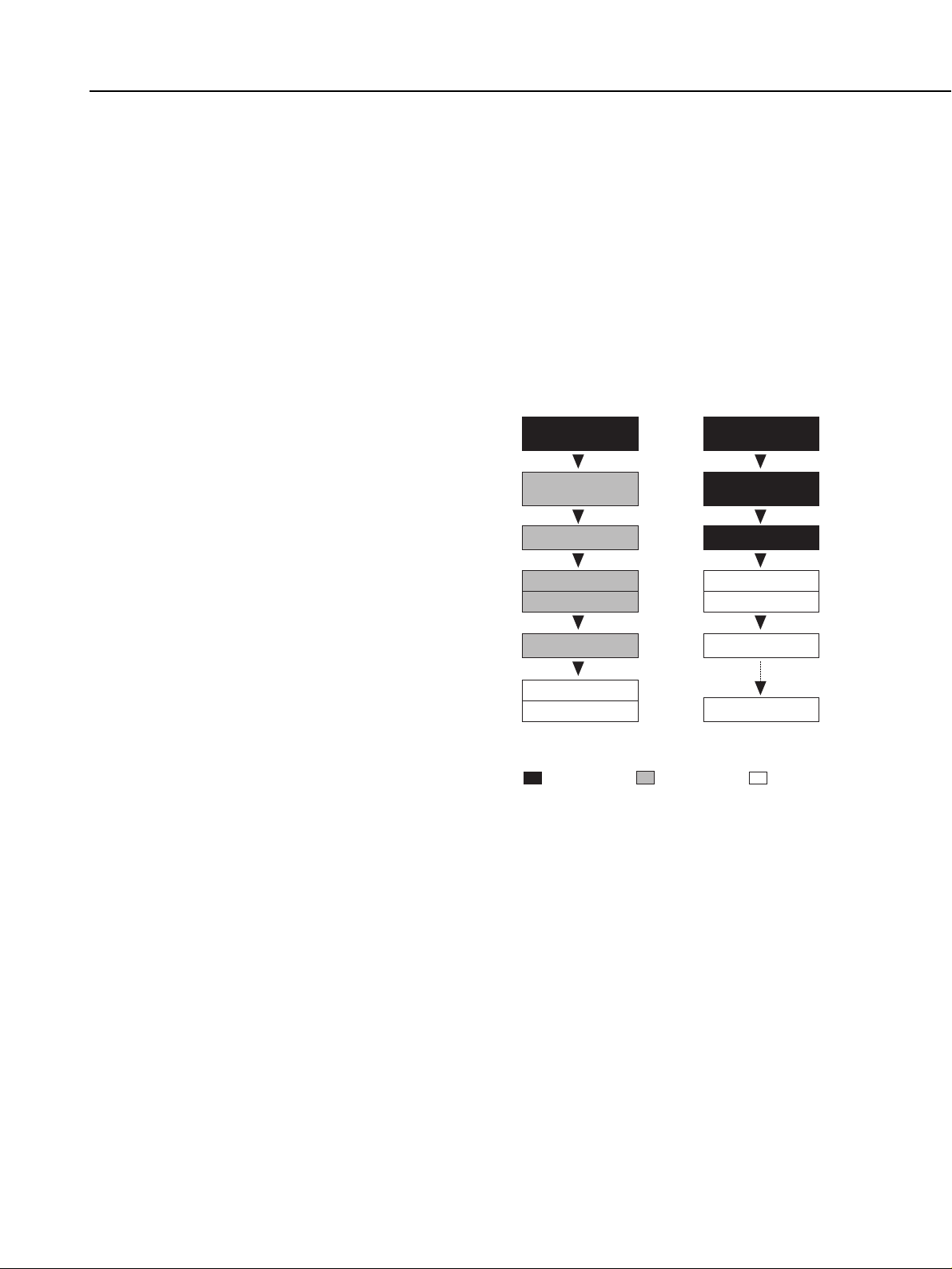

4) Predictive AI Servo AF Control

During continuous shooting, the EOS-3’s AI Servo AF incorporates shutter release

priority for the first shot and focusing priority (lens drive priority) from the second

shot onward. So for a fast-moving subject at a close distance, the first shot might

be out of focus (the point of focus is in front of the subject) or camera shake may

cause focusing error. This causes the continuous film advance speed to become

irregular.

To resolve this problem with the EOS-1V, the priority control for the first shot

during AI Servo AF continuous shooting has been changed and the predictive AF

algorithm and continuous shooting sequence for 9 fps have been newly developed.

The result is better focus tracking of the subject and better focusing precision.

The continuous film advance speed is also more stable.

(1) AI Servo AF control for the first shot

The EOS-3’s predictive AF control (Fig. 2-

5) stops driving the lens immediately

when the shutter is released. Therefore,

for a subject moving quickly across the

image plane, the camera must overshoot

the predictive lens drive amount to compensate for the time lag between the lens

drive stoppage and the start of the exposure. Depending on the moment of the

shutter release, the lens drive overshoot

might be excessive, resulting in the point

of focus falling slightly in front of the subject. Since a point of focus in front of the

subject is more favorable (the picture is

still salvageable) than one behind the subject, this control inclination was intentional.

● The lens, aperture, and mirror are driven

simultaneously from the first shot with the

EOS-1V.

When focus must be achieved as quickly

as possible during AF search, the standard power is used after focus is achieved

during AI Servo AF when the lens drive

amount for the maximum power and time is minimal. This enables the predictive

lens drive, aperture, and reflex mirror to be driven simultaneously (with or without PB-E2 attached). It reduces the lens drive overshoot amount before the shutter is released.

* AF search drive: During SW-1 ON when the AF system cannot detect the sub-

ject, the lens is driven to find the subject.

* AI Servo AF drive: After focus is achieved, the moving subject is tracked during

continuous focusing.

* Standard power: This is the amount of power supplied to the lens at the EOS-

1N’s level.

* Maximum power: This is twice the amount of the standard power.

2-3

Part 2: Technical Information

Shutter released

EOS-3

Lens drive stops

Aperture stopped down

Mirror goes up

Exposure

Shutter released

AI Servo AF

Lens driven

AI Servo AF

Lens driven

EOS-1V

Aperture stopped down

Predictive lens drive

Mirror goes up

Lens drive stops

Exposure

AF search

Lens driven

AF search

Lens driven

Maximum

power supplied.

Power cut

by half.

Power stopped.

Power supply to lens drive

Fig. 2-5 Comparison of

AI Servo AFcontrol.

● Lens driving time setting after SW-2 ON

Regardless of when the shutter is released, the lens drive stops at the predicted

point of focus. The lens driving time after SW-2 ON is set (0 - 35 ms). Thus, while

shutter release-priority is maintained, the correct focus drive is obtained for the

predicted point of focus.

(2) AI Servo AF control from the second shot onward

To improve the EOS-1V’s AI Servo AF tracking perfor mance and focusing precision and to maintain the film advance speed at a consistent level, the following

measures were incorporated. Other than the below, the basic AI Servo AF control

system is the same as the EOS-3’s.

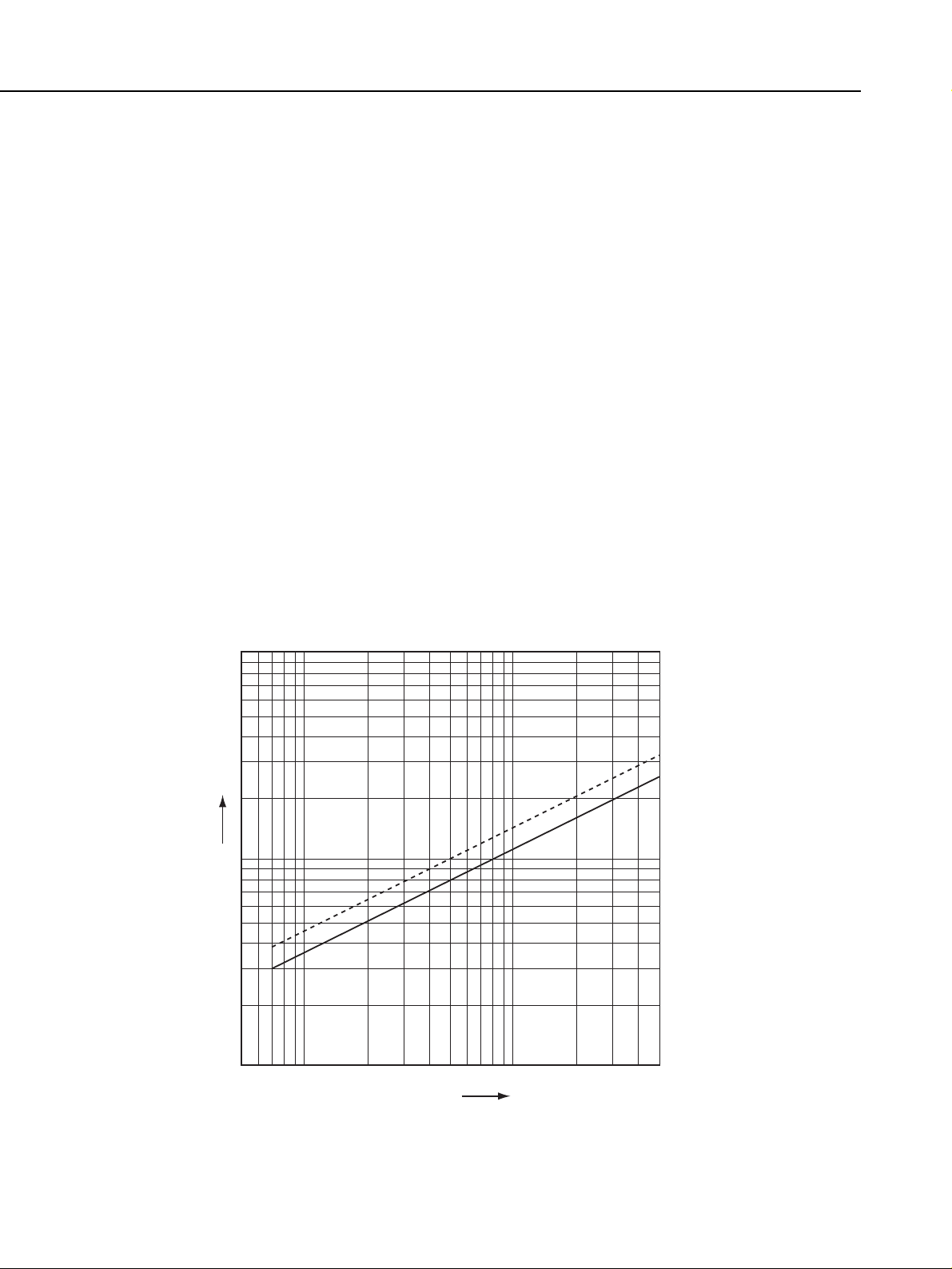

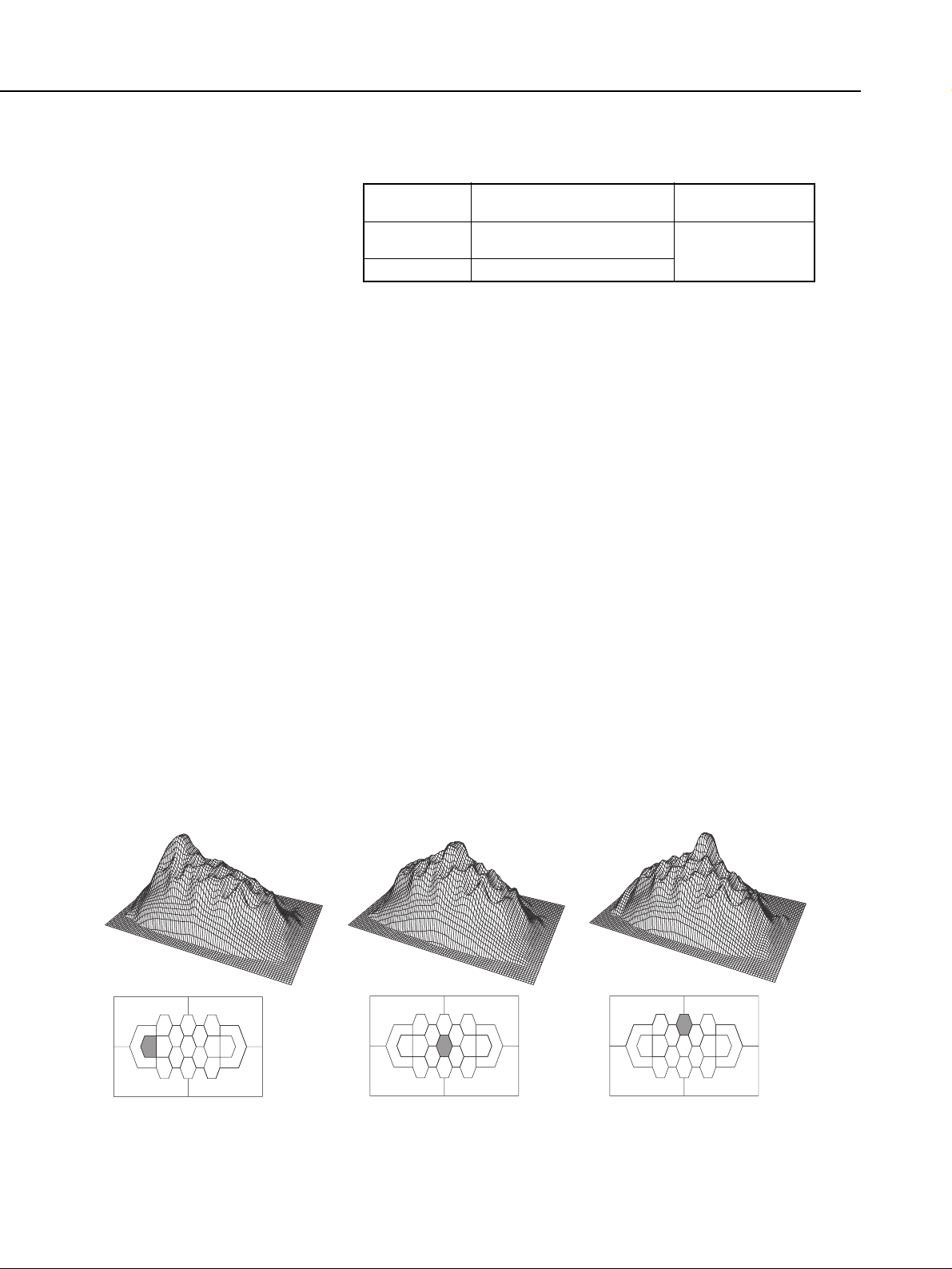

q New predictive AF algorithm suited for 9 fps

● High-precision, predictive AF with statistical operation and analysis

The EOS-3 refers to the last three focusing data readings to predict the next point

of focus. However, the EOS-1V uses more focusing data for statistical operation

and analysis (Fig. 2-6) and compensates for focusing error while predicting the

point of focus. This increases the probability of obtaining the correct focus in the

AI Servo AF mode. And since this enables a stable lens drive and a correct predictive point of focus, it is more likely for the lens drive to end within the time alloted

during the maximum-speed sequence of 9 fps. This also helps to stabilize the

continuous shooting speed. Table 2-2 shows the process of predicting the point of

focus from the first to fourth focusing attempts and beyond.

2-4

Part 2: Technical Information

, Focusing error

Far

Movement speed on image plane

Low speed

High speed

Near

Subject distance

Predictive point of focus

with other cameras

Statistical operation and

predictive point of focus

Subject movement condition/

Fig. 2-6 Comparison of statistical operation and conventional predictive operation.

Focusing Attempts

First time

Second time

Third time

Fourth time onward

Predictive Focusing Method

The lens drive amount from the point of defocus to the point of focus is detected.

With the first focusing data reading, the next point of focus is predicted.

With the first and second focusing data readings, the next point of focus is predicted.

The focusing data obtained so far is used for statistical operation and the focusing error is

corrected to obtain a more precise predicted point of focus.

Table 2-2 Point of Focus Prediction Process

w New continuous shooting sequence

With the EOS-3, the shutter releases immediately when the lens driving ends.

This causes an irregular lens driving time which in turn makes the film

advance speed irregular as well. Since the focusing time for each shot is also

irregular, predictive focusing control also becomes more difficult.

● Exposure standby until the set time after the lens drive ends

During the 9 fps continuous shooting sequence, the exposure is delayed until the

set standby time elapses (since the lens is being driven forward during this standby time, the focus is not affected) even if the lens drive ends earlier (Fig. 2-7). The

standby time cushions the irregular lens driving time, and it thereby stabilizes

the continuous shooting speed increases the probability for achieving correct

focus.

● Securing the exposure standby time

The shooting speed is set to 9 fps even when AI Servo AF can exceed 9 fps. The

extra time is used to stabilize the continuous shooting speed. The ultra-high

speed shooting sequence at 10 fps in the One-Shot AF mode and the new predictive AF algorithm and high-speed EF lenses make it possible to set a standby

time. In the high-speed continuous shooting mode at 7 fps, the sequence provides

even more extra time. Continuous shooting in the AI Servo AF mode is therefore

more stable than with the EOS-3.

● Continuous shooting speed adjusted to suit the lens driving time

If the lens driving cannot be completed within the set time due to difficult subject

tracking conditions, the film advance speed is decreased (in 0.5 fps increments) to

a stable level that is maintainable. This is to prevent the film advance speed from

becoming irregular. When the subject tracking becomes easier, the film advance

speed is increased again.

2-5

Part 2: Technical Information

Standby

AF AF

Lens driven

Exposure starts

Standby

AF

Lens driven

Standby

AF

Lens driven

Exposure starts Exposure starts

AF AF

Lens driven

Exposure starts

AF

Lens driven

AF

Lens driven

Exposure starts Exposure starts

The standby time absorbs the irregular lens driving time, and the AF interval

and exposure interval become uniform.

With no standby time, the irregular lens driving time directly affects the AF interval

and exposure interval.

Standby time provided

No standby time

Fig. 2-7 Comparison of continuous shooting sequences.

(3) Preconditions for attaining 9 fps

When the PB-E2 + NP-E2 and an EF lens having the EF 300mm f/2.8L IS USM’s

lens drive speed are attached to the camera and the lens EMD stopdown time is

35 ms or shorter (equivalent to 2 stops worth with the EF 300mm f/2.8L IS

USM), 9 fps is attained when the lens drive ends within the time in the maximum-speed sequence described above.

The EMD stopdown time decreases the continuous shooting speed accordingly.

Also, when the focusing point selection is automatic during predictive AF and the

subject moves to another focusing point, the continuous shooting speed and the

predictive AF perfor mance deteriorate slightly (by how much depends on how

often the subject moves to another focusing point) due to the extra focusing and

processing time required. The deterioration occurs even while the PB-E2 is

attached to the camera.

e Predictive AF control perfor mance

● 50 kph at 8 meters

The camera can focus track a subject approaching the camera at 50 kph up to 8

meters away (with the EF 300mm f/2.8L IS USM). Each of the 45 focusing points

is capable of the same predictive AF perfor mance. As mentioned before, AI Servo

AF control for the first shot is the same with or without the PB-E2 attached.

Therefore, the predictive AF perfor mance with the EOS-1V is the same with or

without the PB-E2 attached.

When the battery becomes exhausted, the lens, aperture, and reflex mirror are

driven sequentially instead of simultaneously, resulting in lower perfor mance of

the predictive AF control.

2-6

Part 2: Technical Information

100

[m]

Subject Distance

10

1

5 10 50 100 500

Subject Movement Speed (kmh)

EOS-1N

+ PDB-E1: 5 fps

EOS-1V: 9 fps

EOS-3: 7 fps

Fig. 2-8 Comparison of predictive AF control performance.

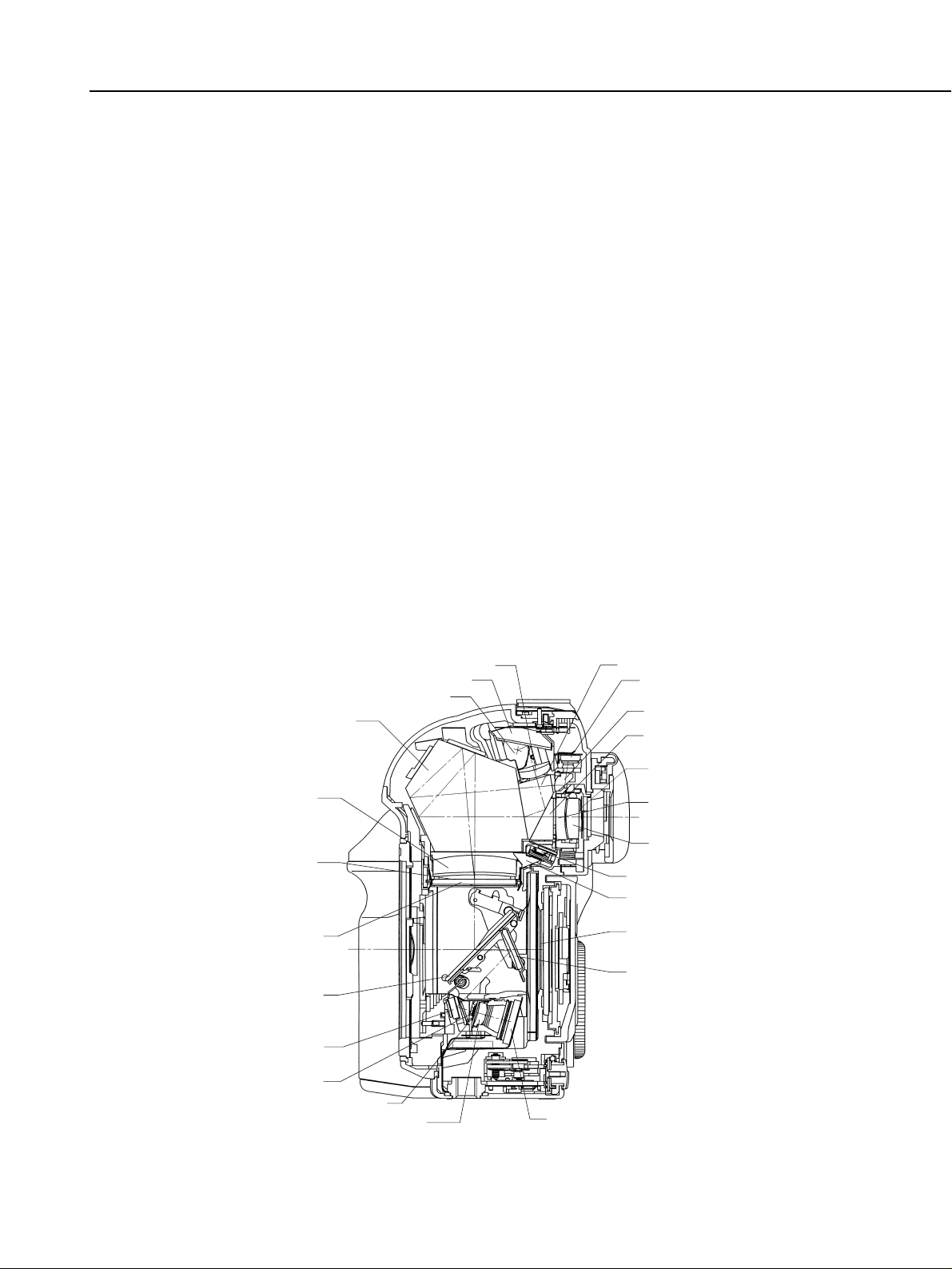

1.2 Viewfinder

1) Configuration

The viewfinder’s basic optical system is the same as the EOS-3’s. The coverage is

100%, the viewfinder magnification is 0.72 ×, dioptric correction is provided, an

eyepiece shutter is provided, and superimposition (SI) display optics is provided.

Even without the Eye Control unit, there was a problem with too little space. The

basic configuration was revamped to minimize space requirements, and the SI

display brightness was increased.

The major changes in the configuration are as follows:

● Pentaprism with a high refractive index

To shorten the viewfinder’s optical path and secure a viewfinder magnification of

0.72 ×, glass with a high refractive index was incorporated in the pentaprism.

● New SI display optics

The EOS-3’s SI display optics have a dichroic mirror between the pentaprism and

eyepiece lens. With this configuration, if the viewfinder coverage is increased or if

dioptric correction is incorporated, the optical path will become longer, resulting

in a lower viewfinder magnification. In the case of the EOS-1V, the dichroic mirror

has been replaced by a prism (Fig. 2-9) to shorten the viewfinder optical path.

And with the pentaprism having a high refractive index, the same viewfinder magnification as the EOS-1N’s could be secured.

● Retractable dioptric correction lens

When the eyepiece shutter is closed, the dioptric correction lens retracts toward

the pentaprism automatically. The eyepiece shutter and dioptric correction lens

share the same operation space. The dioptric correction mechanism is the same

as the EOS-1N’s.

2-7

Part 2: Technical Information

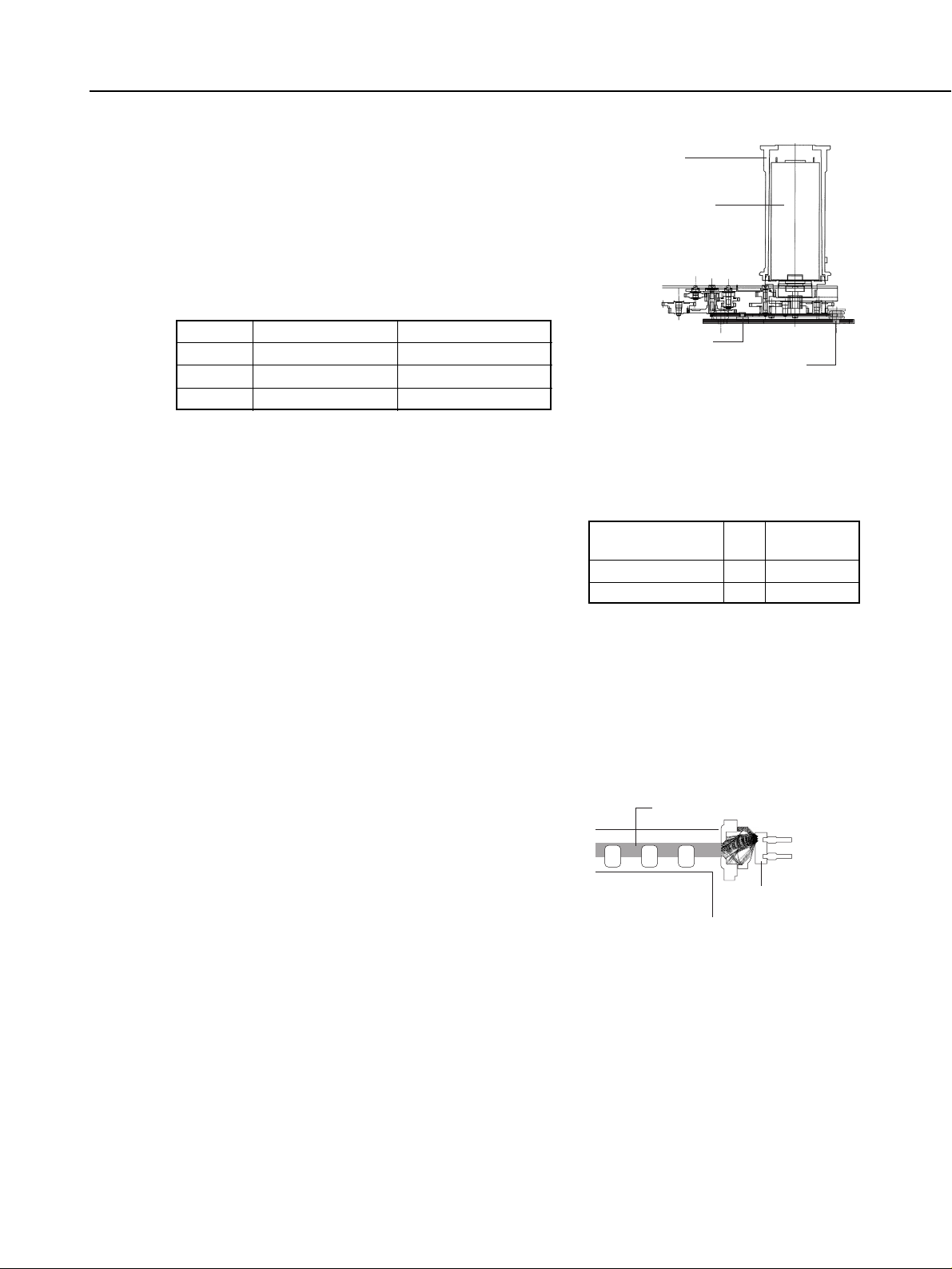

Fig. 2-9 Center cross section.

Metering sensor,

21-zone SPC

Metering lens

SI mirror

SI-LCD

SI lens

Eyepiece lens 1

Eyepiece shutter

SI prism 1

SI prism 2

Eyepiece lens 2

(Dioptric correction lens)

H-LCD

H-LCD prism

Film plane

Secondary mirror

CMOS Area AF sensor

Secondary image-forming lens

Fixed diaphragm

Infrared filter

Fully-reflective mirror

45-deg. main mirror

Focusing screen

Laser Matte surface

Condensor lens

Pentaprism

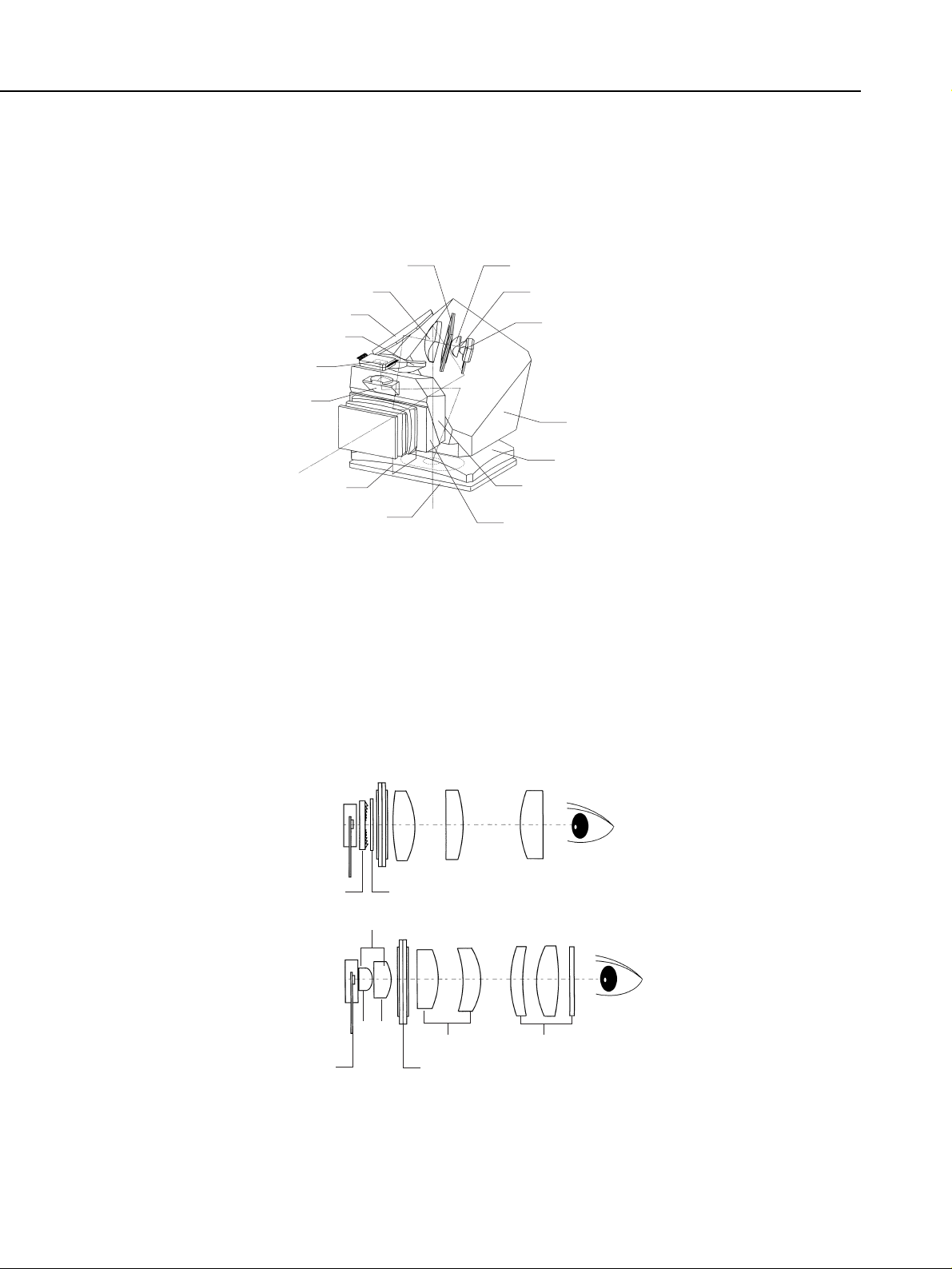

2) Superimposition display optics

Except for not having a dichroic mirror between the pentaprism and eyepiece

lens, the SI display optics (Fig. 2-10) for the focusing points are basically the

same as the EOS-3’s. The improvements are a brighter SI display and an SI display that is easier to see (Fig. 2-11).

● Display brighter by over 2 stops

The backlight optics uses a direct system (lens × 2) instead of a diffusion system

(fresnel lens + diffusion panel). It eliminates the light loss inherent with the fresnel lens and diffusion panel and increases the display brightness by over 2 stops.

● Clear SI display

By incorporating an aspherical surface for backlight lens 2 and the two SI lenses

(focusing point image-forming lens), a clear SI display with minimal aberrations is

obtained.

2-8

Part 2: Technical Information

Focusing screen

Eyepiece lens

SI lens 1

SI lens 2

SI-LED

Pentaprism

Condensor lens

SI prism 1

SI prism 2

Backlight lens 1

Backlight lens 2

SI mirror

Metering sensor

Metering lens

SI-LCD

Fig. 2-10 SI display optics.

SI-LED

12

SI-LCD

SI lens Eyepiece lens

Fresnel lens

Diffusion panel

Backlight lens

EOS-3

EOS-1V

Fig. 2-11 Comparison with the EOS-3’s SI display optics.

1.3 Exposure Control

1) Metering

(1) Metering optics and the AE sensor

The EOS-1V’s metering optics (see Fig. 2-10 on the preceding page) are positioned

above the eyepiece lens to avoid obstructing the SI display optics.

Evaluative metering and E-TTL autoflash use a new algorithm. Otherwise, the

other sensors and metering methods have the same specifications as the EOS-3’s.

(2) Evaluative metering

The EOS-3’s 21-zone evaluative metering system has

won high praise. However, a few users have pointed

out that the exposure can become inconsistent when

the picture is recomposed slightly. The EOS-1V uses a

new algorithm so that a more consistent exposure is

obtained with 21-zone evaluative metering while automatic exposure compensation (a strong point of the

EOS evaluative metering system) remains intact.

● EOS-3’s evaluative metering system

The EOS evaluative metering system hitherto centered

the main metering area around the active focusing

point and executed automatic exposure compensation

for the different brightness (mainly the differ ence with

the backlight areas) of the adjacent and peripheral

areas. However, since the EOS-3’s main metering area

is almost as narrow as the spot metering area, shifting

the main metering area even slightly can cause the

automatic exposure compensation amount to change

(Fig. 2-12). Thus, the exposure setting can change

even with a slight change in the subject framing. Also,

during continuous shooting of a moving subject with

AI SERVO AF and automatic focusing point selection,

the resulting exposures tended to be irregular in the

same series of continuous shots as the focusing point

shifted to next one. The shifting focusing point also

shifted the main metering area, causing the meter

reading to change.

● EOS-1V’s evaluative metering system

The EOS-1V’s evaluative metering system is linked to

and weighted on the active focusing point and the

meter reading is averaged (Fig. 2-14). Automatic exposure compensation is set for bright subjects. In effect,

the manual exposure compensation set for a bright

background during centerweighted averaging metering

has been replaced by focusing point-linked automatic

exposure compensation.

In other words, evaluative metering is now weighted

less on the active focusing point’s metering area. This

makes the exposure more consistent even when the

framing is changed slightly.

When focus is achieved at the desired location with a manually-selected focusing

point in the One-Shot AF mode, it is highly likely that the main metering area will

cover the main subject completely. Therefore, if the main metering area’s brightness level is still low after the automatic exposure compensation for a bright

2-9

Part 2: Technical Information

The main metering

The main metering area covers

the subject completely.

The main metering area is shifted to

cover the subject partially.

Fig. 2-12 EOS-3’s evaluative

metering system.

Fig. 2-13 Metering pattern for

centerweighted metering.

background, conventional

evaluative metering is

applied for backlight exposure compensation to suit

the main metering area’s

brightness level (see Table

2-3). Backlight exposure

compensation is applied

mainly under cloudy conditions, daylight shadows, and other backlit conditions when exposure compensation for a bright subject is not likely to be applied.

Evaluative metering is executed in the following steps:

q The metering is averaged while weighted on the focusing point and correspond-

ing metering area. If the active focusing point is on the border of the metering

area, the metering area with a less bright meter reading is selected as the

focusing point’s corresponding metering area.

w If the metered value is higher than the stipulated brightness level, several adja-

cent bright areas are sampled starting with the brightest area. If the metered

value is lower than the stipulated brightness level, conventional evaluative

metering is applied. The value obtained in q is used as the final reading.

e The sampled bright areas are averaged and a positive amount of exposure com-

pensation is added.

r With manual focusing point selection + One-Shot AF, backlit exposure compen-

sation obtained with conventional evaluative metering is also applied if the

subject’s brightness level at the main metering area is still low even after exposure compensation for a bright subject is applied.

● Evaluative metering for consistent exposures and easy detection of required exposure

compensation

This evaluative metering uses a relatively simple algorithm which weights the

metering relatively lightly on the active focusing point and corresponding metering

area and mainly compensates for high-level brightness instead. Thus, a proper

exposure is obtained consistently even if the framing is slightly altered. For users

who mainly use centerweighted averaging metering, it makes it easier to see how

exposure compensation is applied.

Fig. 2-14 Sample metering patterns of focusing point-weighted averaging metering.

2-10

Part 2: Technical Information

Table 2-3 Conditions for evaluative

metering and exposure compensation.

Manual Focusing Automatic Focusing

Point Selection Point Selection

ONE SHOT AF

Brightness compensation

Brightness

+ Backlit compensation

compensation only

AI SERVO AF Brightness compensation only

Partial and spot metering coverage

Since the EOS-3’s viewfinder coverage is 100% instead of 97%, the partial and

spot metering coverage has become slightly smaller. However, if you round off the

figure to the second decimal place, it becomes the same as the EOS-3. Thus, the

EOS-1V’s partial and spot metering coverage is the same as the EOS-3’s at

approx. 8.5% for partial and 2.4% for spot metering. (These are official specifications.)

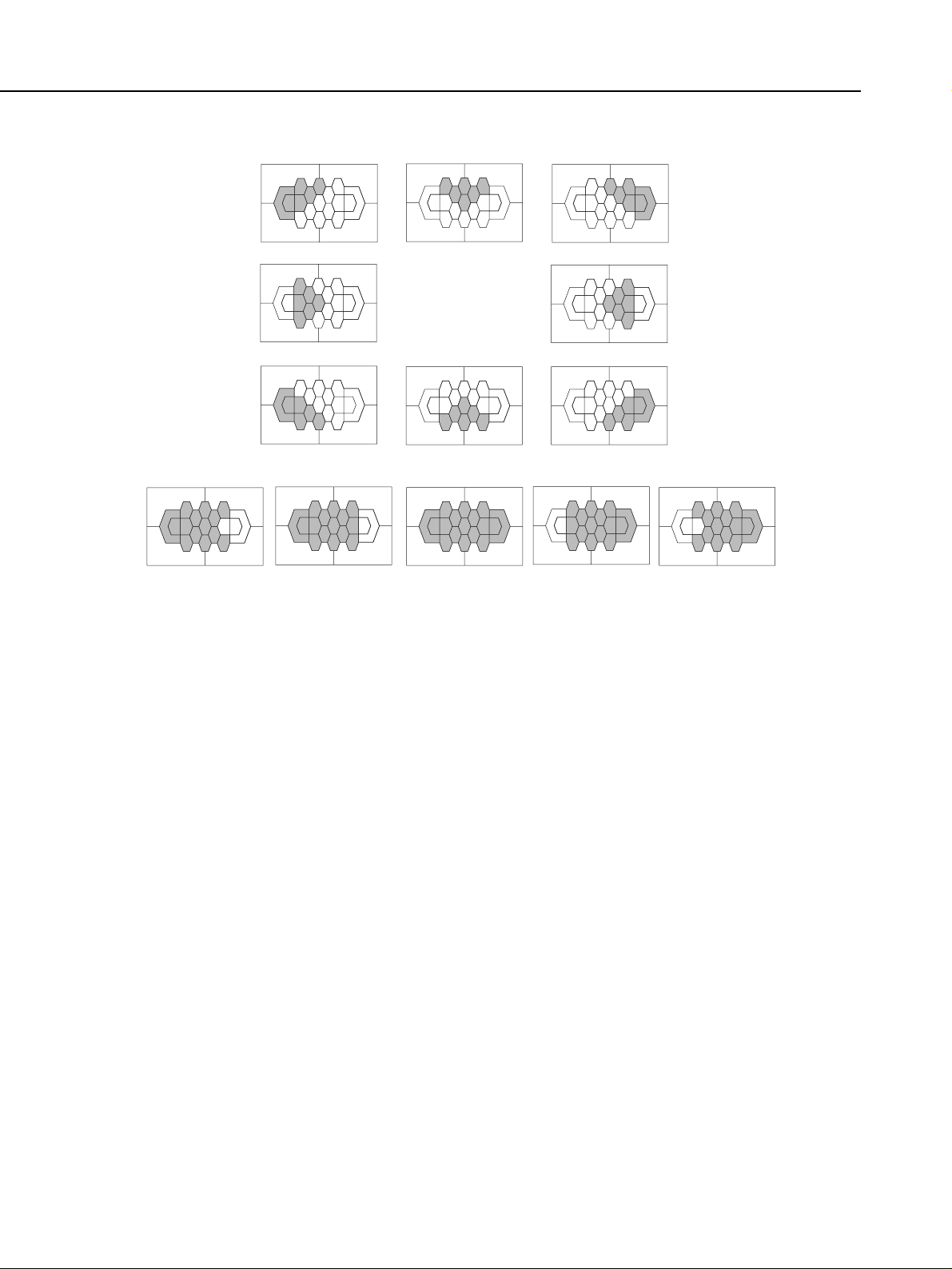

3) E-TTL autoflash

To obtain a more consistent flash exposure, the main flash output calculation

algorithm has been changed.

With the EOS-3, the main flash output is determined by the preflash reflected off

only the areas covered by the main flash metering area (covering the main subject) and adjacent flash metering areas. Thus, if the picture is even slightly

recomposed, a different flash exposure (Fig. 2-15) may result as in the case of

evaluative metering.

With the EOS-1V, preflash meter readings are taken from the main flash metering

area covering the main subject and from a peripheral group of flash metering

areas (Fig. 2-15 - q ) which received the brightest r eflectance. The metering weight

of the main flash metering area and the weight of the brightest peripheral group

are averaged to determine the main flash output. Since the peripheral group covers a larger area than with the EOS-3, the algorithm selects a more consistent

flash exposure level even if the framing changes slightly.

During automatic focusing point selection, the metering is weighted more on the

peripheral flash metering area than on the main flash metering area. This results

in a more consistent flash exposure level even if the subject framing is changed

slightly. In the case of manual focusing point selection, it is more likely that the

entire main flash metering area will cover the subject. Therefore, the metering is

weighted more on the main flash metering area than on the peripheral flash

metering area.

If a peripheral flash metering area receives an abnormally high preflash

reflectance, the peripheral flash metering area expands (Fig. 2-15 - w ) and the

metering weight is averaged with the weight of the main flash metering area. The

main flash output is thereby determined.

2-11

Part 2: Technical Information

q E-TTL autoflash metering areas

w E-TTL autoflash metering areas for abnormally high preflash reflectance.

Fig. 2-15 Grouping of peripheral flash metering areas

2) Exposure control system

The EOS-1V’s exposure control is the same as the EOS-3’s.

2-12

Part 2: Technical Information

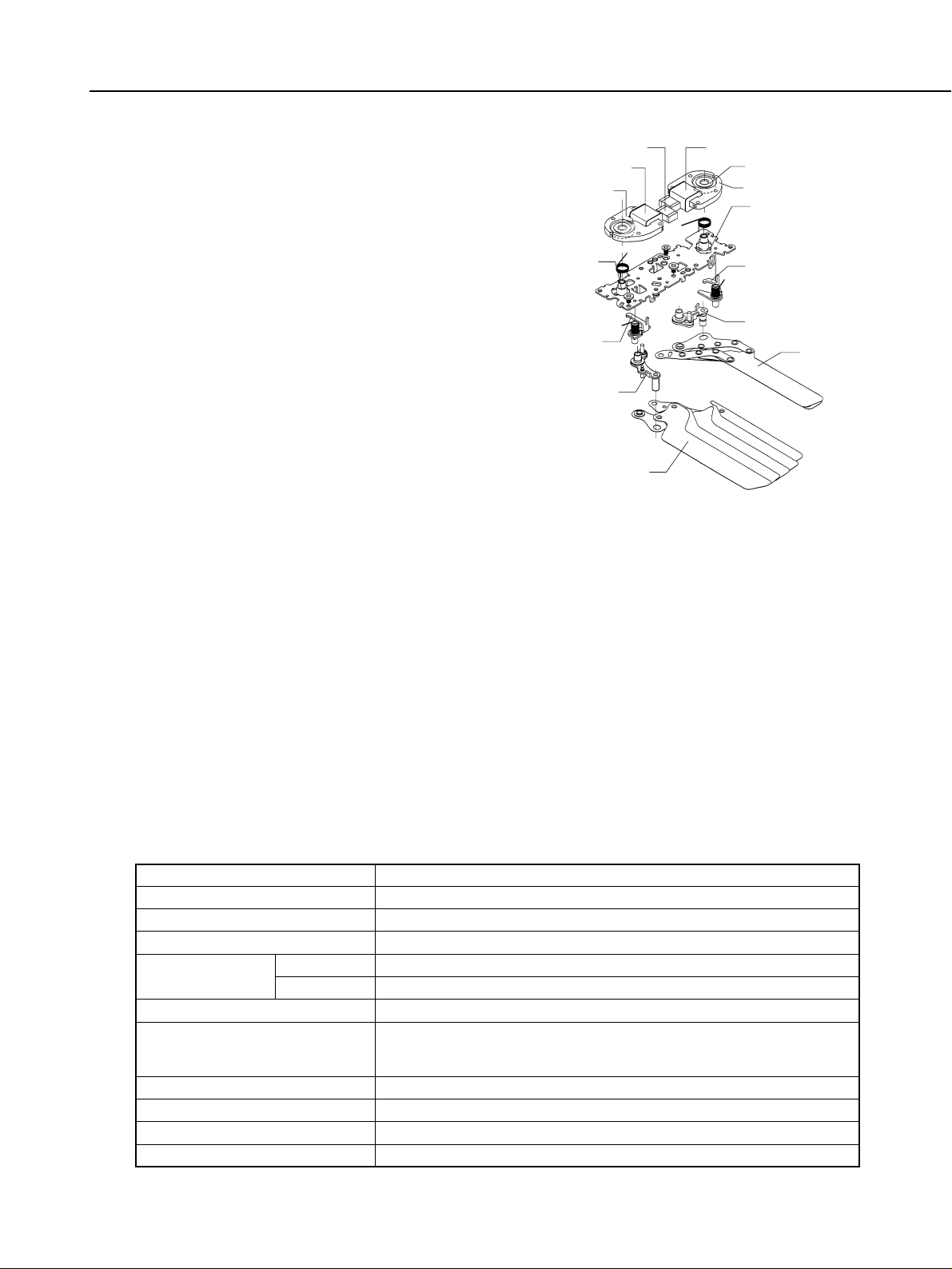

3) Exposure control mechanism

(1) Shutter

While based on the EOS-3’s shutter, the

EOS-1V’s shutter (made by Canon) features improved basic perfor mance, reliability, and durability. The official shutter durability specification is 150,000

cycles. In actual tests, the shutter lasted up to 200,000 cycles. The operation

principle, unit appearance, and the

maximum bulb exposure time (1,000

hr) are all the same as the EOS-3’s

shutter.

q Improved shutter curtain-driving

spring and coil for faster operation

A more powerful shutter curtain-driving spring and coil (Fig. 2-16)

enables the maximum shutter speed

of 1/8000 sec. and maximum X-sync

speed of 1/250 sec. (curtain speed of

2.2 ms/24 mm).

w Higher precision

To enhance precision, the motor shaft now has a different shape, material, and

surface finish to lower friction and the shape of the release lever has been

changed.

e Carbon fiber shutter curtains for better strength and durability

The slit-producing shutter curtains are made of carbon fiber to make the curtain unit lighter, stronger, and more durable.

r Anti-friction material and surface finish for better durability

To improve durability, the rotating shafts and bearings of all drive levers are

now made of a material and surface finish having excellent anti-friction properties.

t Stronger shutter curtain braking for added durability

To cope with the faster shutter curtain drive speed, the curtain brake mechanism is now stronger for better durability.

Table 2-4 Shutter Design Specifications

2-13

Part 2: Technical Information

Fig. 2-16 Exploded view of shutter unit.

Item

1. Type

2. Shutter curtain system

3. Shutter curtains

4. Shutter curtain

material

5. Curtain driver

6. Shutter speed control

7. Curtain speed

8. Shutter speed range

9. Max. flash sync speed

10. Signal

Design Specifications

Vertical-travel, focal-plane shutter

Rectangular, parallel-linked type

1st curtain: 5, 2nd curtain: 5, total 10

2 curtains made of carbon fiber, 3 curtains made of ultra-duralumin

2 curtains made of carbon fiber, 3 curtains made of ultra-duralumin

1st and 2nd curtains each have two dedicated torsion springs

All speeds electronically controlled by controlling the conduction of power

to the dedicated magnets for the 1st and 2nd curtains,

(Magnet type: Newly-developed, rotary magnet)

Approx. 2.2 ms/24 mm

30 - 1/8000 sec., bulb

1/250 sec.

Two types: q X-sync and w 2nd-curtain synchronization

1st curtain

2nd curtain

Coil (for 2nd curtain)

Yoke (for 2nd curtain)

Magnet × 2

Cam (for 2nd curtain)

2nd curtain fixed lever

2nd curtain drive lever

2nd curtain

1st curtain

1st curtain drive lever

1st curtain fixed lever

Cam (for 1st curtain)

Yoke (for 1st curtain)

Coil (for 1st curtain)

Chip condensor × 2

1.4 Film Transport

● High-power film advance motor M1, ● film advance with floating support, and

● a film transport detection system compatible with infrared film. Other features

are the same as with the EOS-3 (see the EOS-3’s Technical Information Part 2).

1) High-power, film advance motor

The EOS-3 uses a motor having a rated voltage of 6 V. The EOS-1V uses the

same high-power, 12 V motor as the EOS-1N. And with the 12 V power supplied

directly by the PB-E2, the EOS-1V can attain a continuous shooting speed of 10

fps.

The difference between the motors used in the EOS-3 and EOS-1V lies in the

design concept. The EOS-3 provides adequate performance even

without the PB-E2. It uses a 6 V

motor to match the 2CR5 6 V battery used when the EOS-3 is powered internally. Whereas the EOS1V was primarily designed to attain

maximum performance with the

PB-E2 attached. It therefore uses a

12 V motor. See Table 15 for the

speed difference with and without

the PB-E2 for both cameras.

● Preconditions to attain 10 fps

The PB-E2 and NP-E2 are attached

and the lens EMD stopdown time is

35 ms or shorter (equivalent to 2

stops worth with the EF 300mm

f/2.8L IS USM). If the aperture is

stopped down, farther the continuous shooting speed decreases due

to the increased EMD stopdown

time. The continuous shooting

speed does not differ with different

lenses.

2-14

Part 2: Technical Information

Table 2-5 Maximum Continuous

Shooting Speed (fps)

M-1: Dedicated motor

for film advance

M-1: Dedicated motor

for film advance

Guide roller 1

M-2: Cocks the shutter and quick-return reflex mirror

and rewinds the film

Guide roller 2

Guide roller 2

Guide roller 1

M-2: Dedicated motor for film rewind

M-3: Cocks the shutter and quick-return reflex mirror

Lo planetary gear

Hi planetary gear

(2) Three-motor system with PB-E2 attached

(1) Two-motor system (without PB-E2)

Fig. 2-17 Film transport system.

Camera only

PB-E2 + NP-E2

EOS-1V

3.5 fps

10 fps

EOS-3

4.3 fps

7 fps

2) Silent film advance

The floating supports at four places (Fig. 2-18) in

the film advance unit have reduced the film

advance noise and vibration (Table 2-6). The shutter cocking system’s floating supports also help to

reduce the continuous film advance noise.

● Discernable noise cut by half with low-speed cocking

With the Personal Function PF-21 “Silent (lowspeed) film advance after film is exposed and

shutter button turns off,” silent film advance is

possible with the EOS-1V (without PB-E2) set to

single-frame advance.

The noise level is 5 dB lower than the standard

cocking noise which is about half the discernable

noise level (Table 2-7). Also, since low-speed film

advance suppresses the high-frequency range (4 - 8 KHz), it actually sounds

much quieter. With mirror lockup, the noise comes from only the shutter, making

it even more quiet. It is suited for when noise is unwanted.

By employing a slow speed (the film advance speed is unchanged) for cocking the

shutter and mirror which usually makes a large noise, the operation is quieter.

The M2 motor’s PWM control and silent rewind have been applied to the cocking

of the shutter and mirror.

3) Film transport detection system

● Compatible with infrared film

The film perforation is detected optically with a

photo reflector (Fig. 2-19). The upper half of the

perforation is detected by condensor optics.

Masking material is used to shield the picture area

against the infrared light. This enables infrared film

to be used. Also, the light reception efficiency has

been improved with the condensor optics, and the

infrared light intensity has been reduced to further

decrease the chances of fogging the film.

2-15

Part 2: Technical Information

Fig. 2-18 Film advance unit’s

floating supports.

EOS-1V

EOS-3

EOS-1N

Continuous Shooting

79.2 (7)

87.1 (7)

78.9 (6)

Single-Frame Shooting

76.2

77.8

79.7

Table 2-6 Comparison of shutter release and film

advance noise in dB (fps)

Standard Cocking

Low-speed Cocking

Noise

67

62

Film Advance

time

0.46

0.73

Table 2-7 Comparison of cocking noise

(dB) and time (sec.)

Fig. 2-19 Film transport

detection system.

Rubber bushing × 1

Rubber bushing × 3

Spool

M1:

Film advance motor

Infrared film fogging area

Photo reflector for film

transport detection

1.5 Overall Operation

1) About high-speed continuous shooting

With high-speed sequence control and quick mirror bound suppression, the EOS1V attains 10 fps in the One-Shot AF mode with real-time AE metering for each

shot. (The EOS-1N RS attains 10 fps only with AE lock and a stopped-down aperture.) In the AI Servo AF mode, the AF-dedicated, high-speed microcomputer

enables a speed of 9 fps, the world’s fastest.

* AEB at 10 fps is also possible (not possible with the EOS-1N RS).

q High-speed sequence control with the PB-E2 and NP-E2

With the PB-E2 and NP-E2 attached to the camera, high-speed drive is

achieved with the M-1 motor (film advance) operating at 12 V, the M1 system

set to Hi gear, and the M-3 system (cocking) set to Hi gear. In the AI Servo AF

mode, the lens is driven simultaneously during all sequences except when the

shutter is opening or closing (as with the EOS-3). This enables faster speed as

well as better predictive AF and subject tracking.

w Mirror bound suppression with the mirror

down/lockup mechanism

The mirror lockup mechanism consists of a

mirror hook and a locking pin on the camera (Fig. 2-20). When the main mirror is

down, it is locked. In the mechanical

sequence, the most unstable element is the

mirror bound that occurs when the main

and secondary mirrors go down. The mirror bound has been suppressed to 45 ms

or less (Table 2-8) in all camera orientations. The continuous shooting speed has

been improved with a quick AF and AE

transition, the viewfinder blackout time

has been shortened, and the viewfinder

image does not shake after the main mirror goes back down.

e 32-bit RISC microcomputer for high-speed

processing

The high-speed, 32-bit RISC microcomputer is dedicated to AF processing and data

memory. It operates at a clock speed of

33.3 MHz (EOS’s fastest) for high-speed

processing.

2-16

Part 2: Technical Information

Locks

DOWN

UP

Released

Mirror hook

Locking pin

Locking arm

Fig. 2-20 Mirror down/lockup mechanism.

EOS-1V

EOS-3

EOS-1N

Mirror-down

Stabilization Time (ms)

45 or less

65 or less

80 or less

Viewfinder

Blackout Time

87

105

140

Table 2-8 Mirror-down stabilization time and

viewfinder blackout time (ms)

2) Stabilizing the continuous shooting interval

q Stable and secure focusing operation with the mirror -stabilizing timer

The main and secondary mirrors give an inconsistent down stabilization time

depending on the camera’s orientation. To resolve this problem, the sequence

has been extended slightly and the timer control has been set so that it goes to

the next focusing sequence after the longest mirror stabilization time elapses.

In other words, even if the mirror bound ends sooner, the focusing operation

remains on standby until the set time elapses. With a regular and proper transition to the next focusing sequence, the continuous shooting interval becomes

consistent and stable. Since this also stabilizes the focusing interval during the

continuous sequence, it enables a more precise statistical operation than when

the preceding focusing data is used.

w Even after the lens drive ends, exposure does not start until the set time elaps-

es

In the 9 fps continuous shooting sequence, even if the lens drive has ended,

the exposure will not start until the set time elapses. By absorbing any inconsistent lens drive time in this way, the continuous shooting interval and focusing interval become consistent. This in turn enables accurate statistical operation.

When (1) and (2) above are applied together, a stable operation sequence with

minimal adverse effect on picture-taking is obtained. In previous cameras, the

sequence control was for maximum speed. With the EOS-1V, all the unstable elements affecting the AI Servo AF continuous shooting speed such as the mirror

operation, focusing, and lens drive are eliminated with a time out and timer control.

3) Data communication

Communication between the EOS-1V and EOS Link Software ES-E1 via the

remote control/communications terminal use the same bi-directional communication system used between the EOS camera and EF lens. The EOS Link Software

ES-E1 communication cable’s signal converter converts the signal into one compatible with USB/EOS. Communication between the EOS-1V and PB-E2 are the

same as with the EOS-3.

4) Shutter release mechanism

The EOS-1V’s shutter release mechanism

uses a two-step switch. At SW-1 ON,

metering and focusing are executed. At

SW-2 ON, the shutter releases and the picture is taken. Table 2-9 shows the shutter

button stroke and pressure. Besides the

button’s standby height and SW-1 ON

stroke, service personnel can also adjust

the stroke between SW-1 and SW-2.

2-17

Part 2: Technical Information

Position

Standby to SW-1 ON

SW-1 ON to SW-2 ON

Beyond SW-2 ON

Stroke

0.6 mm

0.3 mm

0.2 mm

Pressure

85 g

350 g

—

Table 2-9 Shutter Button Stroke and Pressure

Figure 2-21 shows a flowchart for the overall operation sequence, and Fig. 2-22

shows the overall operation’s timing chart.

Precondition: EOS-1V + PB-E2 + USM lens, AI Servo AF mode, new batteries

Fig. 2-21 Operation sequence flowchart.

2-18

Part 2: Technical Information

Initialization

Battery loaded

Ready

Shutter capacitor

charging ON

SW-1 and SW-2

ON?

N

Y

AE metering calculation

SW-1

ON?

N

Y

N

Y

AF calculation

Lens driven

Meter timer

ON?

Normally

approx. 6 sec.

After exposure,

approx. 2 sec.

SW-2

ON?

Self-timer?

N

Y

Y

N

Self-timer operates

BC

EMD stops down

Mg-2 ON/OFF

Mirror goes up

Shutter capacitor

charging OFF

Shutter capacitor

charging ON

Mg-3-1 ON

Exposure starts

Exposure time control

Mg-3-2 ON Exposure ends

M-1 powered

EMD at maximum

aperture

Film advance

AE metering calculation

AF calculation

Mg-2 ON

Lens driven

SW-2

ON?

N

Y

Wait until film advance ends

BC

EMD stopped down

Mg-2 ON/OFF

Mirror

goes up

: Indicates simultaneous control

: Indicates transition to the

next step after all preconditions

are met.

Control sequence for the 1st shot

Continuous shooting sequence for the 2nd and subsequent shots

2-19

Part 2: Technical Information

SW-2

Mg-2

Mirror operation

Mg-3-1

Mg-3-2

Mirror stabilization timer

EMD

CLOSE CLOSE

OPEN

M-1

M-2

M-3

Lens driven

Metering and focusing

10mS

0

50

100

150

200

mS

Writing of shooting data

Lens driven

For one frame during approx. 9 fps continuous shooting

AF and AE

Lens driven

Film advance, mechanical cocking

Mirror goes down

Actual exposure

Stop down

Mirror goes up

←At 10 fps: Reduced according to the stabilization timer for secondary mirror

←At 10 fps: Reduced according to the AF processing time

Precondition: EOS-1V + PB-E2 + NP-E2 (fully charged), USM lens, AI Servo AF mode, ultra-high speed continuous shooting, AF

achieved, SW-2 ON after SW-1 ON

Fig. 2-22 Overall operation timing chart.

UNAPPROVED REPRODUCTION RESTRICTED

1.6 Electronic Circuitry

1) Overview

The electronic circuitry centers on three CPUs. Other components include twelve

LSIs and ICs, a quartz oscillator, and display elements. AF calculation is based on

a high-speed reference clock running at 33.3MHz. Overall camera operation is

based on an 11.059 MHz clock pulse. Fig. 2-24 shows the circuit block diagram.

2) Three CPUs

The CPU dedicated to the AF and data memory is a high-speed, 32-bit RISC

microcomputer. The CPU for AE calculation, display, and sequence control is a

16-bit CISC microcomputer. There is also a CPU for the film ID imprinting module. Each CPU is independent and each operates in parallel simultaneously. Table

2-10 shows the specifications of the three CPUs.

Table 2-10 Specifications of CPUs

2-20

Part 2: Technical Information

Item

1. Main clock

2. Fastest calculation speed

3. Commands

4. Computing power

5. Internal registers

6. ROM

7. RAM

8. EEPROM

9. Timers

AF, Data Memory

CPU V853

33.3 MHz

0.03 µs

74

Add./sub./div.: 32 bit

Mult: 16 × 16 → 32 bit

32 bit × 32

256 KB (flash)

8 KB

—

16 bit × 16

Main CPU

MC68HC912E56

11.059 MHz

0.18 µs

211

Add./sub./div.: 16 bit

Mult: 16 × 16 → 32 bit

16 bit × 5

56 KB

2 KB

2 KB

16 bit × 8

Imprinting Module

CPU µ PD753104

4.19 MHz

0.95 µs

48

Add./sub.: 8 bit

16 bit × 5

4 KB

2 KB

—

8 bit × 5

2-21

Part 2: Technical Information

Fig. 2-23 Block diagram of circuit.

OSC

Display panel illumination EL

Focusing point LED

Viewfinder LED × 3

Film transport detection sensor

Display panel LCD

Focusing point LCD

Viewfinder V-LCD

Viewfinder H-LCD

Self-timer LED

M1

M2

Motor driver 1

Motor driver 2

Input of information

Mg3-1, Mg3-2

Shutter

Shutter DC/DC

Main DC/DC

Imprinting

module

Main CPU

LCD driver

Clock

OSC

Backup super

capacitor

Mg2

AF-CPU

BP-CPU

Electronic beeper

OSC

AF sensor

OSC

EEPROM

Camera

orientation

sensor

DX code

To camera

components

Flash metering

sensor

Metering sensor

SW-2

SW-1

Standard camera

back

To camera components

Direct contacts

Remote switch

ES-E1

Remote control /

Communication terminal

Direct contacts

Dedicated Speedlite

EOS-1V

Electronic mount

USM/AFD EMD

Pulse board

LENS µ-COM

Focal point detection information

Macro information

Focus mode

Control IC

EF lens

BP-E1

Power source

2CR5

Power source

LR6 × 4

Grip

Power source

2CR5

PB-E2

DC/DC

converter

Power source

LR6 × 6

Ni-MH

PB-MPU Motor driver 3

SW electronic lock

SW-1 / SW-2

M3

Bi-directional transmission

Direct contacts

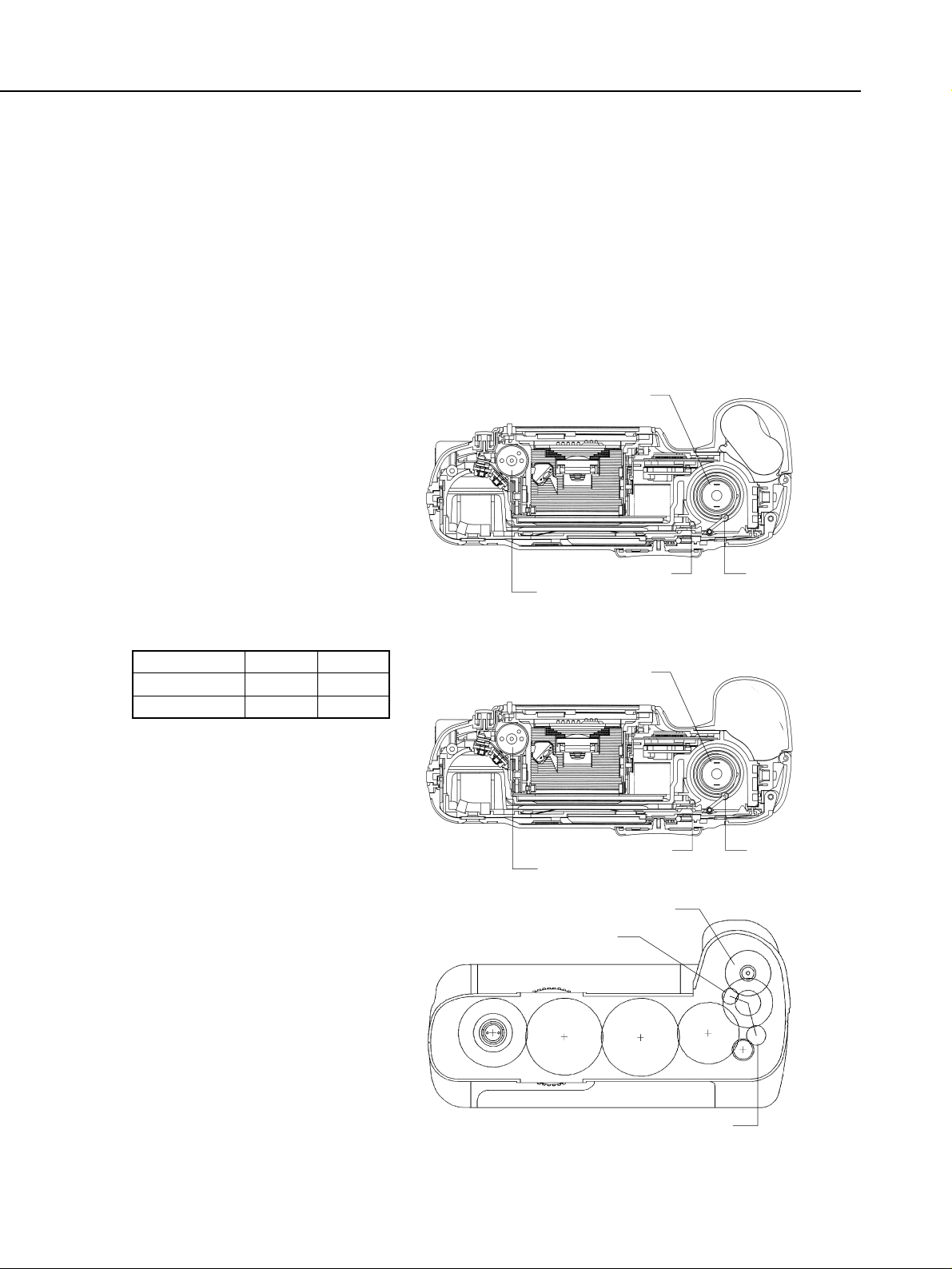

1.7 Internal Construction

1) Covers

● Magnesium alloy covers

The top and front covers (Fig. 2-24) are

made of magnesium alloy which is

lightweight and very strong. Besides the

high-strength exterior, the camera’s

overall rigidity has been improved and it

also shields against electromagnetic

fields at the same time.

Thixotropic mold technology* is used to

manufacture the EOS-1V’s magnesium

alloy covers. With this method, the

three-dimensional curves of EOS-1series cameras are reproduced on the

metal exterior.

Also, the magnesium alloy cover is

painted in black with electrodeposition.

This coat is further covered by three more coats of black baked on the surface.

This tough surface finish make it less prone to paint wear or exposure of the

magnesium alloy.

The other exterior covers are made of engineering plastic while the proper

strength and precision are still attained. The camera’s bottom cover is made of

engineering plastic instead of metal since a metal bottom would add little to its

strength due to the shallow structure.

* Thixotropic mold technology

This is a hybrid method that combines

metal diecast molding technology and

plastic injection molding technology. It

enables magnesium alloy to be molded

into complex, curving, three-dimensional surfaces with high precision and high

density (prevents air bubbles from mixing in) as with plastic.

The molding procedure is as follows

(refer to Fig. 2-25): q . Similar to plastic

injection molding, magnesium pellets

are supplied by a hopper. w . The shearing force of the screw and cylinder

makes it thixotropic, a solid-liquid

state. (Thixotropy is a state when the mold material becomes a mixture of solid

and liquid due to a large shearing force that increases the fluidity.) e . The mold

material is injected into the mold to shape the part.

If the mold material is melted and then injected into the diecast mold, the material inside the mold becomes an irregular mixture while filling up the mold. When

there are complex, three-dimensional curves or minute shapes, air bubbles are

prone to form in the part being molded. Achieving production consistency for the

part then becomes a problem. Whereas with thixotropic molding, the mold material enters the mold uniformly with few air bubbles. Production then becomes consistent.

2-22

Part 2: Technical Information

Fig. 2-24 Magnesium alloy covers.

Hopper

Feeder

High-speed jet stem

Screw

Rotary drive

Cylinder

Nozzle

Mold

Heating zone

Fig. 2-25 Thixotropic mold technology.

2) Internal construction and parts

location

The main chassis is molded from polycarbonate resin with glass fiber. The

critical film aperture is made of die-cast

aluminum and insert molded into the

chassis. The front panel that, together

with the aperture section, determines

the critical flange to focal plane distance (FFD) is also made of die-cast

aluminum (Fig. 2-27).

Table 2-11 gives the parts count, and

Fig. 2-28 locates the major components.

● Even with multiple quantities of the

same part, each is counted individually.

● Lead wires are also counted as elec-

trical parts.

● The shutter unit is counted as one

part.

● The official parts count excludes screws and washers.

Fig. 2-28 Location of major components.

2-23

Part 2: Technical Information

Fig. 2-26

Fig. 2-27

Mechanical Parts

Screws and washers

Electrical parts

Total

Official total

678

185

461

1324

1139

Table 2-11 Parts Count

Pentaprism

Metering sensor

Viewfinder H-LCD

Viewfinder V-LCD

Film advance mechanism

Main reflex mirror

Secondary mirror

DX code detector

M2 motor

Shutter cocking mechanism

TTL metering sensor

Electronic mount and data transmission

signal contacts

AF unit

Film rewind gear train

Shutter speed control mechanism

System connector

Lithium battery 2CR5

M1 motor

Main Dial

External LCD panel

Quick-return mirror mechanism

Focusing screen

Condensor lens

SI unit

3) Water- and dust-resistant construction

To make the EOS-1V the most water - and dust-resistant SLR camera of all (other

than underwater cameras), a total of 72 locations on the exterior covers and camera controls have been made to resist water and dust.

Also, the camera back and battery compartment cover are lined with packing, and

the top cover and buttons are sealed with silicone* rubber to prevent water and

dust from entering. These countermeasures are visible to the user to give him/her

a sense of security. Water- and dust-resistant measures are featured in the following major locations:

q Push buttons and switches ...... 16

For buttons like those on the left shoulder having a gap

between the exterior cover and the button, a silicone rubber cover is used to seal the perimeter around the buttons (Fig. 2-29). For switches like the shutter button and

FE lock button which have no such gap, a silicone rubber boot is fitted under the button.

w Rotating parts ...... 6

O-rings have been fitted around the Main Dial, Quick

Control Dial, dioptric adjustment knob, and eyepiece

shutter lever (Fig. 2-30) where it is relatively easy for

moisture to seep inside. A high-friction sheet is sealed

around the shafts of the main switch and Quick Control

Dial switch.

e Closing/opening parts ...... 3

The camera back and battery compartment cover are

lined with a silicone rubber packing (Fig. 2-31).

r Exterior cover seams ...... 36

A silicone rubber sheet is used to seal the major seams (20). Silicone, waterproof material, and an adhesive coat are used at 10 seams. And washers are

used for six exterior screws.

t Grip attachment surface and other exter nal inter faces ...... 10

To maintain the EOS-1V’s water - and dust-resistance even while the PB-E2 or

BP-E1 is attached, the grip attachment surface and system connectors are

sealed with silicone rubber.

y Mount surface ...... 1

To match EF lenses having a water -resistant rubber ring on the mount, the

camera’s lens mount also has a matching, water -resistant ring.

* The difference between silicon and silicone: Silicon is the element (Si) and mate-

rial made of silicon crystals. It is used in silicon wafers, silicon solar cells, etc.

Silicone is made of a silicon compound and used in grease, rubber, and resins.

2-24

Part 2: Technical Information

Fig. 2-29 Rubber cover.

Fig. 2-31 Camera back packing.

Silicone rubber

O-ring

Fig. 2-30 Electronic dial.

Fig. 2-32 Major water-resistant locations

2-25

Part 2: Technical Information

4) Electrical components

To enable continuous shooting at 10 fps, the EOS-1V’s electrical circuitry is larger than the EOS-3’s. The DC/DC converter (reduces the shutter cocking time) and

M1 driver (high-power 12 V motor) circuitry is large, and there are also the clock,

data memory, and transmission circuit for EOS LINK Software ES-E1.

This large-scale electronic circuitry has been made to fit within the same body

size as the EOS-3’s thanks to the following technologies:

● High-density, 6-layer main flexible board

The 6-layer flexible board has three double-sided flexible boards stacked together.

This high-density, double-sided configuration with meticulous circuit wiring

resulted in a compact, main flexible board.

● BGA package for the main CPU

The compact, multi-pin BGA package used in the EOS 300/Rebel 2000/EOS Kiss

III is also incorporated in the EOS-1V. Even though the EOS-1V’s CPU has 169

pins, the package is smaller than the EOS-3’s main CPU equipped with 128 pins.

Centering on the main flexible circuit board, the electronic circuitry consists of 21

flexible boards, 15 0.5mm-pitch connectors, and 2 board connectors. This compact configuration makes assembly easy. Figure 2-33 shows the electrical system.

Fig. 2-33 Electrical system.

2-26

Part 2: Technical Information

Hot shoe

21-zone metering sensor

Metering flexible board

Super capacitor

SI-LCD flexible board

Sound element

LCD driver

V-LCD flexible board

Eye Control detection switch

Camera back flexible board

Film ID imprinting CPU

Film ID imprinting module

Quick Control Dial base

H-LED

M2 motor driver

V-LCD

V-LED

DX flexible board

Remote control flexible board

CGE board

H-LCD

Remote control /

Communications terminal

PC terminal

Main switch board

M2 motor

Main switch flexible board

External LCD panel

EL illumination element

Top flexible board

Display panel flexible board

SI-LED

SI-LCD

ADSW flexible board

Main Dial

Main Dial base

H-LCD flexible board

M1 motor driver

Main CPU

DC/DC flexible board

Grip flexible board

Main flexible board

Shutter speed control

mechanism

AF-CPU

M1 motor

Area CMOS focusing sensor

TTL 3-zone flash exposure sensor

Mount contacts

Mount flexible board

AF flexible board

Flash exposure flexible board

System connector

2. SWITCHES

(1) Operation Switches

2-27

Part 2: Technical Information

No. Code Name

1 SW1 Focusing/metering

2 SW2 Release

3 MAIN SW Main

4 AEL SW AE lock

5 FPSEL SW Focusing point selector

6 MODE SW Picture-taking mode

selector

7 AF SW AF mode selector

8 MES SW Metering mode selector

9 COMP SW Exposure compensation

10 LAMP SW LCD panel illumination

11 REW SW Manual rewind

12 SPDN SW Depth-of-field preview

13 DIAL1, 2 SW Electronic dial

14 C Fn SW Custom Function setting

15 Mn SW Extended function

16 ME SW Multiple exposure

setting

17 CLR SW Clear

18 FEL SW FE lock

19 ADD SW Assist button

Function

Starts autofocusing and metering.

Shutter release.

Camera on (Beeper ON selected).

AE lock applied. (AE lock also applied while meter-

ing is active.)

Enables manual focusing point selection with the

electronic dial (same as with EOS-3).

Shooting mode selection in combination with elec-

tronic dial operation.

AF mode selection in combination with electronic

dial operation.

Metering mode selection in combination with elec-

tronic dial operation enables. Also enables flash

exposure compensatin with Quick Control Dial

operation.

Enables exposure compensation to be set with the

electronic dial.

External LCD panel is illuminated. Illumination

continues while metering is active.

Film rewind begins even in midroll.

Metering starts and the aperture stops down in

accordance with the meter reading.

Operates in combination with other switches.

Shooting mode, AF mode, metering mode, etc.

Sets or cancels Custom Function settings.

Each time the button is pressed, it enables data

recording, clock setting, Personal Function settings, data transfer mode setting, etc. (Clock function works only after camera is connected to the

ES-El for the first time.)

Sets multiple exposures.

Clears all settings, which revert to the default settings.

FE lock/muiti-spot metering is applied.

Used in combination with Custom Functions and

extended functions.

(2) Status Switches

(3) Mechanical Switches

2-28

Part 2: Technical Information

No. Code Name

1 BP SW Camera back

open/close switch

2 PTIN SW Film cartridge-loaded

switch

3 BAT SW Reset switch

4 MIF SW Lens switch

5 SWBIRI SW Shock prevention switch

6 DX1-5 SW DX code switch

7 DX6, 7 SW DX code switch

Function

LOW when the camera back is open.

Detects whether or not film is in the camera.

OPEN when film is loaded.

Detects battery. OPENS when the battery is

installed, executing reset.

Detects if a lens is attached. CLOSED when lens

is attached.

Prevents shock from hot shoe when flash is connected to PC.

Detects ISO film speed.

Detects the number of exposures of the loaded film.

No. Code Name

1 MRUP SW Mirror up switch

2 CHG1, 2 SW Shutter-charge phase

switch

3 SWX SW X switch

4 CN2 SW 2nd-curtain switch

5 FILM1, 2 SW Film phase switch

Function

Detects when the mirror is in the up position.

Detects shutter charge, etc.

Triggers flash firing.

Detects completion of second shutter curtain's

travel.

Detects the film's frame count during film advance

and rewind.

3. MAJOR ELECTRICAL COMPONENTS

2-29

Part 2: Technical Information

No. Code Location (Unit)

1 MODULE BP

2 BPPU BP

3 TRBP2 BP

4 CBPU1 BP

5 RREG2 BP

6 RREG3 BP

7 RREG0 BP

8 PRESBP BP

9 RBP1 BP

10 RBP2 BP

11 CBPU2 BP

12 CREGBP BP

13 CRESBP BP

14 CRESBPIC BP

15 CREG1 BP

16 CREG2 BP

17 ZDBP BP

18 ZDBP2 BP

19 TRBP1 BP

20 TRBP3 BP

21 RESBPIC BP

22 VREGBP BP

23 BPFAR BP

24 RPRE BP

25 CBPU3 BP

26 ZDBP3 BP

27 RBPFAR BP

Function

LCD panel and lamp module for film ID imprinting.

Drives the MODULE and executes film ID imprinting in accor-

dance with instructions transmitted from the MPU.

Module imprinting lamp drive transistor.

BPPU power source VDD filter capacitor 1.

Module LCD panel bias resistor 2.

Module LCD panel bias resistor 3.

Module LCD panel bias resistor 0.

BPPU reset control pull-up resistor.

Module lamp drive voltage resistor 1.

Module lamp drive voltage resistor 2.

BPPU power source VDD filter capacitor 2.

Module LCD regulator bias filter.

BPPU reset terminal noise capacitor.

BPPU reset control IC power source filter capacitor.

Module LCD panel bias filter capacitor 1.

Module LCD panel bias filter capacitor 2.

Camera back contacts static charge protection Zener diode 1.

Camera back contacts static charge protection Zener diode 2.

Module LCD panel bias power source switch transistor.

Module lamp drive transistor 3.

BPPU reset control IC.

Module LCD panel bias regulator.

BPPU oscillator.

TRBP1 base resistor.

Camera back contacts static charge protection capacitor.

Camera back contacts static charge protection Zener diode 3.

BPFAR stability resistor (ensure oscillation under high temper-

ature and humidity).

2-30

Part 2: Technical Information

No. Code Location (Unit)

28 TRMG3-1 DC/DC

29 TRMG3-2 DC/DC

30 CDC1 DC/DC

31 CDC4 DC/DC

32 CSHDC1 DC/DC

33 CDC5 DC/DC

34 CDC6 DC/DC

35 CSHDC4 DC/DC

36 FUSE2 DC/DC

37 FUSE DC/DC

38 LSHDC DC/DC

39 LDC DC/DC

40 RDC5 DC/DC

41 RSEN2 DC/DC

42 RVCHK1 DC/DC

43 RSEN1 DC/DC

44 RVCHK2 DC/DC

45 RDC4 DC/DC

46 RSHDC5 DC/DC

47 RSHDC4 DC/DC

48 RPR1 DC/DC

49 RDC3 DC/DC

50 RCOMP3 DC/DC

51 RVB1 DC/DC

52 RSHV1 DC/DC

53 RSHV2 DC/DC

54 RDC2 DC/DC

55 RCOMP2 DC/DC

56 RPR2 DC/DC

57 RCN2 DC/DC

58 RDC6 DC/DC

59 RSHD1 DC/DC

60 RSHD3 DC/DC

61 RSHDC1 DC/DC

62 RSHDC2 DC/DC

63 RSHDC3 DC/DC

64 RSHD2 DC/DC

Function

Shutter drive transistor 1.

Shutter drive transistor 2.

DC/DC1 input filter capacitor.

DC/DC1 charge voltage storage capacitor.

Shutter DC/DC input filter capacitor.

REGVDD output filter capacitor.

REGE1 output filter capacitor.

Shutter DC/DC charge voltage storage capacitor.

Safety measure for VBAT.

Safety measure for VCHK line.

Shutter DC/DC step-up coil.

DCDC1 step-up coil.

DC/DC IC error voltage detection resistor (paired with RDC4).

Shutter DCDC output voltage MPU-monitoring resistor (paired

with RSEN1).

VCHK voltage MPU-monitoring resistor (paired with RVCHK2).

Shutter DCDC output voltage MPU-monitoring resistor (paired

with RESEN2).

VCHK voltage MPU-monitoring resistor (paired with RVCHKl).

DC/DC IC error voltage detection resistor (paired with RDC5).

SH-DC/DC IC error voltage detection resistor (paired with RSHDC4).

SH-DC/DC IC error voltage detection resistor (paired with RSHDC5).

PRFLMV input current limiting resistor. The current is (5-1.5-

0.1)/430 = Approx. 8 mA.

DC/DC IC error amp frequency characteristics improvement.

Creates the PRAD signal hysterisis (together with RCOMP1

and RCOMP2).

VBAT3 line leak-detection resistor.

Shutter drive capacitor load resistor. Paired with TRSHVI.

TRSHV2 base current-limiting resistor.

DC/DC IC oscillation frequency resistor. Paired with CDC2.

Creates the PRAD signal hysteresis (together with RCOMP1

and RCOMP3).

PRFLMV output current voltage transformer resistor.

CN2 signal pull-up resistor (terminals in the MPU do not have pull-up).

TRDC3 base resistor.

Shutter-driving circuit TRMG3-1 base current-limiting resistor.

Shutter-driving circuit TRMG3-2 base current-limiting resistor.

TRSHDC1 base current-limiting resistor.

SH-DC/DC IC oscillation frequency resistor. Paired with CSHDC2.

SH-DC/DC IC error amp frequency characteristics improvement.

Shutter-driving circuit TRMG3-1 base-emitter resistor to pre-

vent misoperation while the battery is removed, etc.

2-31

Part 2: Technical Information

No. Code Location (Unit)

65 RSHD4 DC/DC

66 RSHDC6 DC/DC

67 RCOMP1 DC/DC

68 RDC1 DC/DC

69 CCN2 DC/DC

70 CDC8 DC/DC

71 CDC9 DC/DC

72 CPR1 DC/DC

73 CPR3 DC/DC

74 C1M DC/DC

75 C2M DC/DC

76 CAMP2 DC/DC

77 CM1 DC/DC

78 CMTDR1 DC/DC

79 CPR2 DC/DC

80 CVPP DC/DC

81 CDC3 DC/DC

82 CSHDC3 DC/DC

83 CDC2 DC/DC

84 CSHDC2 DC/DC

85 ZDM1 DC/DC

86 ZDMD1 DC/DC

87 DDC1 DC/DC

88 DDC2 DC/DC

89 DSHDC DC/DC

90 TRDC2 DC/DC

91 TRE1ON3 DC/DC

92 TRVB2 DC/DC

93 TRE1ON1 DC/DC

94 TRE1ON2 DC/DC

95 TRPR1 DC/DC

96 TRSHV2 DC/DC

97 TRVCHK DC/DC

98 TRVB1 DC/DC

Function

Shutter-driving circuit TRMG3-2 base-emitter resistor to prevent misoperation while the battery is removed, etc.

SH-DC/DC IC control resistor. The driving starts when VBAT3

increases.

Creates the PRAD signal hysteresis (together with RCOMP2

and RCOMP3).

TRDC1 base current-limiting resistor.

CN2 line noise-reduction capacitor.

REGVDD output noise-reduction capacitor.

REGE1 E2 output noise-reduction capacitor.

PRFLMV output current voltage-transformed signal noise-

reduction capacitor.

MPU DA output PRDA signal noise reduction capacitor.

MTDR1 charge pump capacitor.

MTDR1 charge pump capacitor.

OPAMP2 power source filter capacitor.

Ml noise-control capacitor.

MTDR1 power source (El) filter capacitor.

PRFLMV power source (El) filter capacitor.

MTDR1 charge pump terminal voltage-retaining capacitor (15 V).

Capacitor for DC/DC IC error amp frequency characteristics.

Capacitor for SH- DC/DC IC error amp frequency characteristics.

DC/DC IC oscillation frequency capacitor. Paired with RDC2.

SH-DC/DC IC oscillation frequency capacitor. Paired with RDC2.

Ml (Hi film rewind) surge voltage-clamping Zener diode.

Zener diode as a motor driver latch-up countermeasure.

Suppresses reverse voltage caused by inductance of the lead

wire between VMl and MTDR1.

Shockley diode to prevent a reverse current from VDD to REG.

DC/DC1 rectification.

SH-DC/DC rectification diode.

Current cut-off transistor for current flowing to RDC4 and

RDC5 when DC/DC1 is off.

SHDC/DC control transistor.

Switch transistor turns on the TRVBL via MTDR1 when VBAT3

has no leakage or other problems.

DC/DC1 control transistor.

DC/DC1 control transistor. Since the standby current is elimi-

nated when the PDB is attached, TRE1ON1 and 2 are used.

Film signal photo reflector (FLMV) drive transistor.

Shutter-drive capacitor charge control transistor.

Switch transistor that turns on the PDB when El ON.

Power MOSFET connecting VBAT3 to VBAT.

2-32

Part 2: Technical Information

No. Code

Location (Unit)

99 TRSHDC1 DC/DC

100 TRDC3 DC/DC

101 TRSHV1 DC/DC

102 TRDC1 DC/DC

103 PWRAIC DC/DC

104 MTDR1 DC/DC

105 DC/DC_IC DC/DC

106

SH-DC/DC-IC

DC/DC

107 PWRDET DC/DC

108 REG DC/DC

109 OPAMP2 DC/DC

110 REGE1E2 DC/DC

111 REGVDD DC/DC

112 REGVDD2 DC/DC

113 DVDD DC/DC

Function

Shutter DC/DC switching-regulation transistor.

Switch transistor to prevent VDD flow to REGVDD input terminal.

Shutter-drive capacitor charging current transistor. Paired with

RSHV1.

DC/DC1 switching-regulation transistor.

Analog switch IC for power selection.

Ml (Hi, Lo film advance) motor driver IC.

PWM switching-regulator control IC (DCDC1 control).

PWM switching-regulator control IC (shutter DCDC control).

Reset IC (Active low, open drain output) for PWR2 detection.

The voltage detected is 4.2 V (only while PDB is attached).

Regulator IC that extracts 5 V from the VCHK output.

Comparator IC with hysterisis for the PRFLMV output current

voltage-transformed signal buffer (PRAD) and PRAD signal

and PRDA signal.

Regulator IC (4.8 V) for supplying El and E2.

Regulator IC (5.0 V) for supplying VDD.

VDD backup regulating IC when El OFF. Countermeasure for

lenses that consume a lot of power from standby.

Shockley diode to prevent reverse current from VDD to

REGVDD2.

2-33

Part 2: Technical Information

No. Code

Location (Unit)

114 RHLED1 DSP

115 RAFLED2 DSP

116 RHLED2 DSP

117 RPULLEL DSP

118 RAFLED1 DSP

119 DEL DSP

120 TREL2 DSP

121 TREL DSP

122 TRAFLED DSP

123 TRHLED DSP

124 LEL DSP

125 EL DSP

126 ZDM2 DX

127 C1M2 DX

128 C2M2 DX

129 CM2 DX

130 CMTDR2 DX

131 CVPP2 DX

132 ZDMD2 DX

133 MTDR2 DX

Function

HLED-drive transistor base resistor.

AFLED-drive, constant-current circuit resistor. (Set to approx.

5mA.)

HLED-driving, constant-current circuit resistor. (Set to approx.

35mA.)

TREL predriver output current-limiting resistor.

AFLED-drive transistor base resistor.

Negative-side protective diode for EL oscillating transistor

TREL collector when EF oscillates.

TREL predriver transistor. (With MPU direct PORT connection,

the TREL base current is insufficient.)

For oscillation. Wavelength: 732 us, 610 us On, 122 us OFF

(equivalent to 5/6 duty). Be aware of withstand pressure.

AFLED-drive transistor. Configured with RAFLED2 in a con-

stant-current circuit.

HLED-drive transistor. Configured with RHLED2 in a con-

stant-current circuit.

Resonates the EF step-up coil and EL equivalent capacity.

+160 V to -100 V (at VBAT=6.4 V).

Outside LCD backlight. Resonate frequency is about 23 KHz.

M2 motor (rewind, shutter cocking 6 V) surge voltage-clamp-

ing Zener diode.

MTDR2 charge pump capacitor.

MTDR2 charge pump capacitor.

M2 noise control filter.

MTDR2 power source (El) filter capacitor.

MTDR1 charge pump terminal voltage-retaining capacitor (15 V).

Zener diode as a countermeasure for motor driver latch-up.

Suppresses reverse voltage caused by inductance of the lead

wire between VM2 and MTDR2.

M2 (rewind, shutter cocking) motor-driving driver IC.

2-34

Part 2: Technical Information

No. Code

Location (Unit)

134 EFIC EF

135 CEF3 EF

136 RIREF1 EF

137 CRES2 EF

138 CE1 EF

139 CEFVC EF

140 CVBAT EF

141 CVRH1 EF

142 AF SENSOR GA

143 CGA2 GA

144 CREGIN GA

145 RG1 GA

146 RG2 GA

147 RGREG2 GA

148 RGREG1 GA

149 ROSC GA

150 RFIN GA

151 RG3 GA

152 RIRSP GA

153 CGDA1 GA

154 CGDA2 GA

155 CREGGA GA

156 CGA1 GA

157 CREG GA

158 CVGR GA

159 CVRS GA

160 GREG GA

161 REGGA GA

162 GFAR GA

Function

Flash metering sensor and flash communication IC.

EFIC power source (E2) filter capacitor.

Resistor that determines the EFIC IREF (for thermometers

constant current and external Speedlite flash-ready detection).

/RES2 signal noise-reduction capacitor.

EFIC power source (El) filter capacitor.

EFIC band gap voltage (VC=1.25 V) filter capacitor.

EFIC monitor voltage (VBAT) filter capacitor.

EFIC flash-metering reference voltage (VRH=3.2 V) filter

capacitor.

AF sensor with built-in I/0 function.

AF SENSOR power source (GVDD) filter capacitor.

REGGA input voltage filter capacitor.

Control signal line (READ, CSAF2, CSAF1 FOUT) pull-down

resistor from the AF SENSOR FPU.

Control signal line (CSAFO, DSEL, AFH, TCLK) ) pull-down

resistor from the AF SENSOR FPU.

GREG output voltage divider that produces VVC (1.20 V).

Paired with RGREG1.

GREG output voltage divider that produces VVC (1.20 V).

Paired with RGREG2.

AF SENSOR oscillation stabilization resistor.

AF SENSOR FPU transmission line (FIN) pull-down resistor.

AF SENSOR FPU transmission line (FCLK) pull-up resistor.

Constant-current circuit load resistor in the AF SENSOR.

DAC1 output filter capacitor.

DAC2 output filter capacitor.

REGGA output noise-reduction capacitor.

AF SENSOR power source (GVDD) filter capacitor.

AF SENSOR reference voltage (VVC) filter capacitor.

AF SENSOR reference voltage (VGR) filter capacitor.

AF SENSOR reference voltage (VRS) filter capacitor.

Regulator IC that produces the AF SENSOR VVC.

Regulator IC that supplies the AF SENSOR power source

(GVDD).

AF SENSOR Oscillator. The EOS-1 V uses a smaller pack-

age than the EOS-3.

2-35

Part 2: Technical Information

No. Code

Location (Unit)

163 RM3F2 GRIP

164 RDC2ON GRIP

165 RM3F1 GRIP

166 RMG21 GRIP

167 RMG22 GRIP

168 RM3HG GRIP

169 DMGM2 GRIP

170 DBAT GRIP

171 ZD1 GRIP

172 ZD2 GRIP

173 ZD3 GRIP

174 ZD4 GRIP

175 TRDATE1 GRIP

176 TRMG2 GRIP

177 CSDIAL1 GRIP

178 CSDIAL2 GRIP

179 HLED HLC

180 PIHV1 HV2

181 PIHV2 HV2

Function

Static discharge protection resistor.

VDD direct external output protection resistor. Also for

DCfDC2 ON-driving current limiting.

/M3F terminal PULL DOWN resistor. Also detects the attach-

ment of the normal grip. It has a high resistance to ensure

detection of the size-AA battery pack.

MG2-drive transistor TRMG2 base resistor.

Resistor between the MG2-drive transistor TRMG2 base-emit-

ter resistor.

PDB detector resistor.

MG2 (mirror up, down) coil reverse voltage prevention diode.

VCHK voltage (12 V) diode to prevent flow to the /RESMPU

line while the PDB is attached.

Static charge prevention Zener diode for camera back con-

tacts (MISOB, MOSIB, /DBUSY, SDIALL).

Static charge prevention Zener diode on SYSCON-2 terminal

(/M3HG, DIAL2, FEL, FPSEL).

Static charge prevention Zener diode on the camera back and

SYSCON terminal (SCLKB, M3F, SDIAL2).

Static charge prevention Zener diode on the SYSCON and

SYSCON-2 terminals (SW2, AEL, SW1, DIALL).

ID (and date) imprinting lamp-drive transistor.

MG2 (mirror up, down) drive transistor. Turns on for 8 ms dur-

ing mirror up, and mirror down operation.

DIAL1 signal static charge protection capacitor.

DIAL2 signal static charge protection capacitor..

Includes backlight LED for viewfinder horizontal LCD, 4-chip

LED (35 mA driving), and for AF in-focus LED1 chip (5 mA

driving).

Camera orientation sensor with integrated optical detection.

Camera orientation sensor with integrated optical detection.

2-36

Part 2: Technical Information

No. Code

Location (Unit)

182 MPU MAIN

183 FPU MAIN

184 CAMP1 MAIN

185 CAMPF1 MAIN

186 CAVREF3 MAIN

187 CFPU3 MAIN

188 CVRH2 MAIN

189 CVRHF MAIN

190 CFVPP MAIN

191 CFP2 MAIN

192 CFP3 MAIN

193 CVREF MAIN

194 CDC7 MAIN

195 CFPU1 MAIN

196 CMPU1 MAIN

197 CRES MAIN

198 RBAT1 MAIN

199 RDX1 MAIN

200 RDX2 MAIN

201 RDA3 MAIN

202 RFDA3 MAIN

203 RDA4 MAIN

204 RDAC MAIN

205 RFDA4 MAIN

206 RFDAC MAIN

207 RCHG MAIN

208 RDA5 MAIN

209 RFDA5 MAIN

210 RBSCMO MAIN

211 RFPU1 MAIN

212 RFP3 MAIN

213 RFP4 MAIN

214 RFPU2 MAIN

215 RBAT2 MAIN

Function

Main Microcomputer, sequence system, AE flash system,

Switch operation power source control, display control, superimpose control, etc.

AF microcomputer, DX reading, data memory writing, HV-SW

detection, etc.

Flash metering DAC OPAMP (OPAMPL) power source (E2) filter capacitor.

AF DAC OPAMP (OPAMPF) power source (E2) filter capacitor.

FPU A/D converter reference voltage filter capacitor.

FPU power source (E3) filter capacitor.

MPU A/D - D/A converter reference voltage (VRH=3.2 V) filter

capacitor.

FPU D/A converter reference voltage (VRH=3.2 V) filter capacitor.

FPU flash-writing voltage (10.3 V) filter capacitor.

REGFP1 input voltage (12 V) filter capacitor.

REGFP1 output voltage (10.3 V) filter capacitor.

VREF input power source filter capacitor.

REGE3 output voltage (E3=4.8 V) filter capacitor.

FPU power source (E3) filter capacitor.

PU power source (VDD) filter capacitor.

RESIC power source (VDD) filter capacitor.

Battery check load resistor. Together with RBAT2, a 4.7 ohm

load resistance is produced.

DX3, 4, 5, 7 terminal PULL-UP resistor. PULL UP to E3 via TRDX.

DX1, 2, 6 terminal PULL-UP resistor. PULL UP to E3 via TRDX.

OPAMP1 low voltage output linearity resistor.

OPAMPF low voltage output linearity resistor.

MPU flash metering DAC gain resistor. (Paired with RDA5.)

OPAMP1 low voltage output linearity resistor.

FPU AF DAC gain resistor. (Paired with RFDA5.)

OPAMPF low voltage output linearity resistor.

CHG1and CHG2 signal pull-up resistor (pull-up terminals in

the MPU are not used).

MPU flash metering DAC gain resistor. (Paired with RDA4.)

FPU AF DAC gain resistor. (Paired with RFDA4.)