Canon ELPH 100 HS User manual

Adafruit Guide To Excellent Soldering

Created by Bill Earl

Last updated on 2014-06-28 08:30:54 PM EDT

Guide Contents |

|

Guide Contents |

2 |

Tools |

4 |

Building a Soldering Toolkit |

4 |

Choosing a Soldering Iron |

4 |

Basic Irons |

5 |

Better Irons |

5 |

Best Irons |

5 |

Irons to avoid |

6 |

For emergencies only: |

6 |

Not for circuit board use: |

6 |

Essential Tools and Supplies: |

6 |

Stand |

7 |

Solder |

7 |

Diagonal Cutters |

7 |

Other Handy Tools and Supplies |

7 |

Vise |

8 |

Third Hand |

8 |

Solder Sucker |

9 |

Solder Wick |

9 |

Preparation |

10 |

Heat the Iron |

10 |

Clean the Iron |

10 |

Tin the Tip |

11 |

Make sure that the joint is clean |

11 |

Immobilize the Joint |

11 |

Steady the Board |

12 |

Making a good solder joint |

13 |

Heat the joint |

13 |

Apply the solder |

14 |

Let It Flow |

14 |

© Adafruit Industries |

https://learn.adafruit.com/adafruit-guide-excellent-soldering |

Page 2 of 35 |

Let It Cool |

14 |

Trim the Lead |

14 |

Congratulations! |

15 |

Problems? |

16 |

Surface Mount Components |

17 |

Immobilize the Joint |

17 |

Heat the Joint |

17 |

Apply the Solder |

18 |

Let it Flow |

18 |

Let it Cool |

18 |

Problems? |

18 |

Common Soldering Problems |

20 |

The Ideal Solder Joint |

20 |

Disturbed Joint |

21 |

Cold Joint |

22 |

Overheated Joint |

24 |

Insufficient Wetting (Pad) |

25 |

Insufficient Wetting (Pin) |

27 |

Insufficient Wetting |

28 |

(Surface Mount) |

28 |

Solder Starved |

29 |

Too Much Solder |

30 |

Untrimmed Leads |

31 |

Solder Bridge |

32 |

Lifted Pad |

33 |

Repairing a Lifted Pad |

34 |

Stray Solder Spatters |

34 |

All of the Above! |

35 |

© Adafruit Industries |

https://learn.adafruit.com/adafruit-guide-excellent-soldering |

Page 3 of 35 |

Tools

Building a Soldering Toolkit

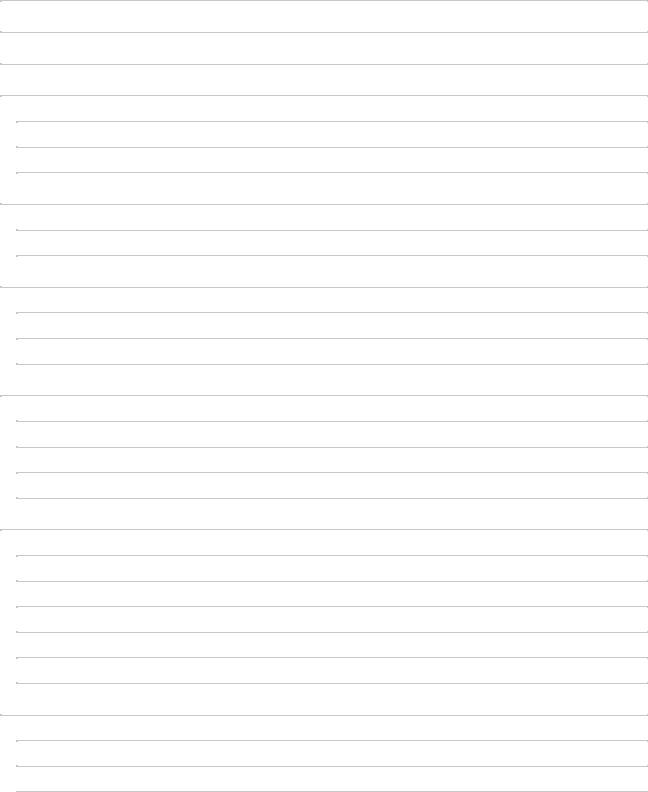

If you are just getting started in Electronics, Ladyada's Electronics

Toolkit (http://adafru.it/136) (pictured above) is a great kit full of quality tools - including everything you need to make great solder joints. If you would rather build your toolkit piece- by-piece, read on:

Choosing a Soldering Iron

There are many types of soldering irons. For most Adafruit kits and projects, you will want a pencil-style soldering iron with 25 watts or more.

An under-powered iron is a poor investment. It will end up costing you more in ruined kits and damaged components.

It will take longer to heat the joint, allowing heat to spread to the component being soldered - potentially overheating and damaging the component.

Longer heating times will also give more time for oxides to form on the surfaces being soldered. This will prevent the solder from flowing and result in a poor joint.

Longer recovery times between joints can result in frustration, 'cold joints' or both.

You don't need to spend a fortune to get a good iron. Advanced features such as temperature control and interchangeable tips are nice to have, but not essential for hobbiest-level work.

© Adafruit Industries |

https://learn.adafruit.com/adafruit-guide-excellent-soldering |

Page 4 of 35 |

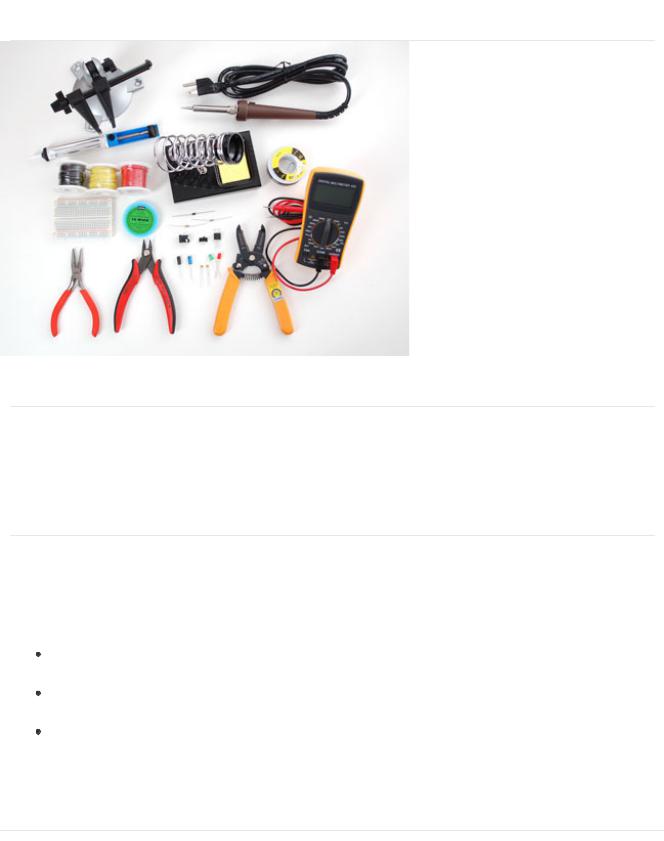

Basic Irons

There are many basic pencil style irons that are suitable for hobbiest use. But you will need one that is capable of heating the joints quickly enough. Choose an iron with 25 watts at a minimum.

Better Irons

An adjustable temperature iron with a little more power will give you a bit more control and allow you to work faster. The Adjustable 30W 110v Soldering Iron (http://adafru.it/180) in the store is an excellent choice.

This iron is also available as part of Ladyada's Electronics Toolkit (http://adafru.it/136), which contains many other essential soldering tools.

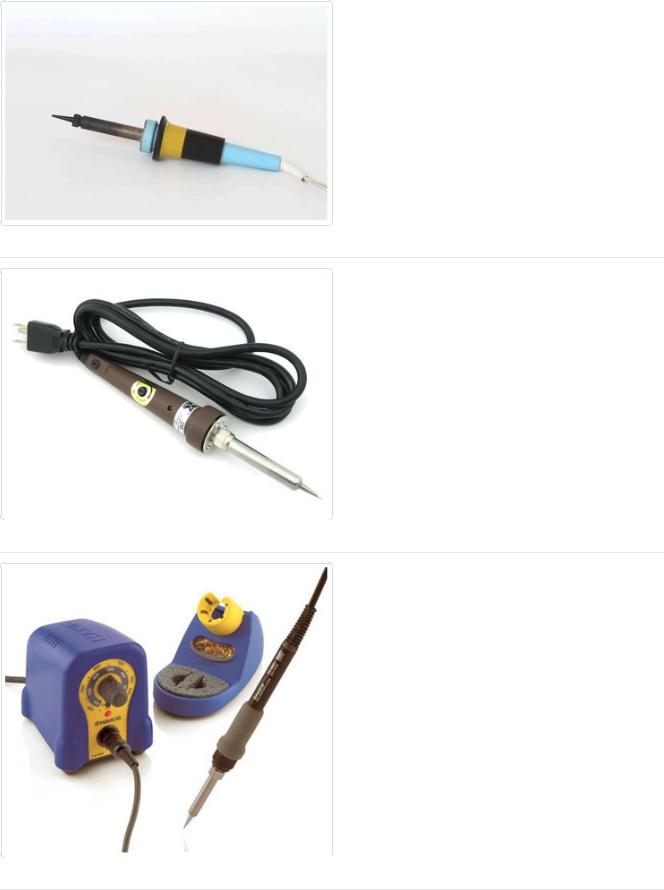

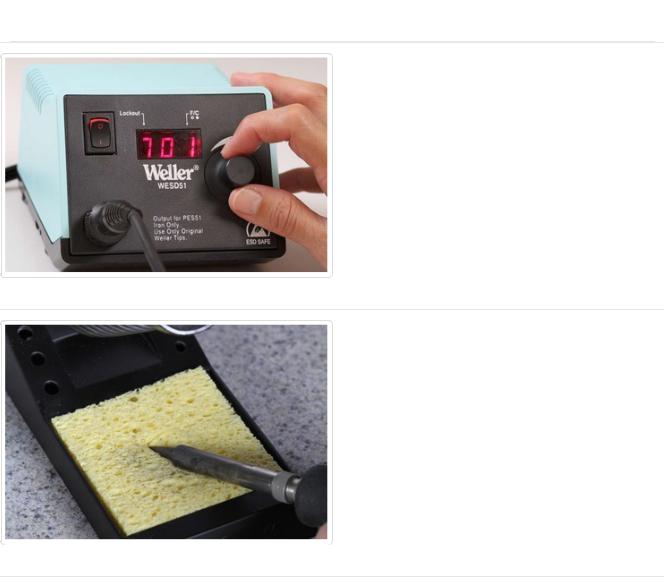

Best Irons

A professional-style temperature-controlled iron with interchangeable tips and 50 watts or more of power is a joy to work with. Feedback control keeps the tip temperature at precisely the level you set. The extra watts speed recovery time so that you can work faster. Interchangeable tips let you select the ideal tip shape for specialized work.

The 65 watt Hakko FX-

888 (http://adafru.it/303) is an

excellent professional quality soldering iron. The Weller WES51 or WESD51 are also  excellent choices for serious electronics work.

excellent choices for serious electronics work.

© Adafruit Industries |

https://learn.adafruit.com/adafruit-guide-excellent-soldering |

Page 5 of 35 |

Irons to avoid

In addition to underpowered irons, there are several types of irons to avoid for general circuit-board work.

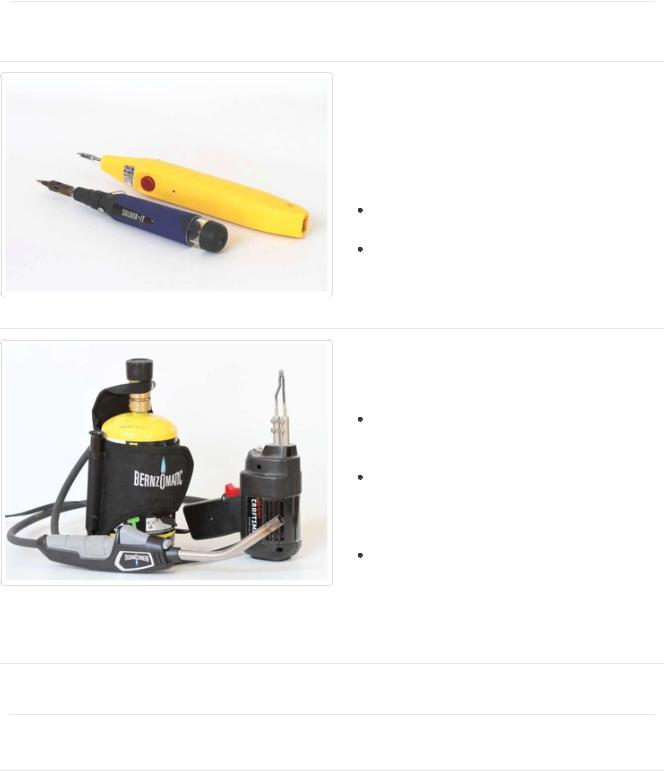

For emergencies only:

These irons are handy for occasions when you have no place to plug in a regular soldering iron. But they are not the best choice for a primary soldering tool:

Butane Powered Irons have plenty of power but are difficult to control.

Battery Powered Irons are generally underpowered for most work.

Not for circuit board use:

These tools are not suitable for circuit board work:

Torches of any kind are not suitable for electronics work and will damage your circuit boards.

Soldering Guns are OK for working with heavy gauge wires, but don't have the precision necessary for soldering delicate electronics components. Cold-Heat™ Irons inject current into the joint to heat the tip. This current can be damaging to sensitive electonic components. Avoid these irons for electronics work.

Essential Tools and Supplies:

These tools are the bare-minimum essentials required for soldering:

© Adafruit Industries |

https://learn.adafruit.com/adafruit-guide-excellent-soldering |

Page 6 of 35 |

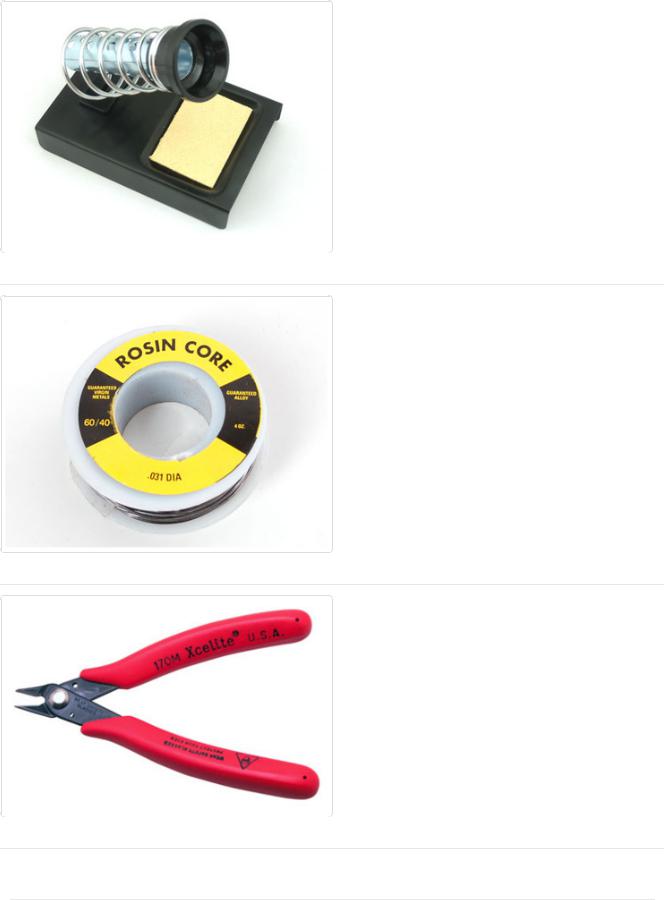

Stand

If your soldering iron does not have a built-in stand, you will need a safe place to rest the hot iron between uses. A Soldering Iron

Stand (http://adafru.it/150) will keep your iron from rolling around and protect both you

and your work surface from burns.

Most stand holders come with a sponge and tray for cleaning your soldering iron.

Solder

Standard 60/40 lead/tin Rosin

Core Solder (http://adafru.it/145) is the easiest type to work with.

Diagonal Cutters

You will also need a pair of Diagonal Cutters (http://adafru.it/152) for

trimming component leads after soldering.

Other Handy Tools and Supplies

© Adafruit Industries |

https://learn.adafruit.com/adafruit-guide-excellent-soldering |

Page 7 of 35 |

These are some other tools and supplies you might find useful when working on soldering projects.

Vise

A vise holds your work steady as you solder. This is important for both safety and sound joints. The Panavise Jr (http://adafru.it/151) is an ideal size for most Adafruit kits and projects.

Third Hand

A Helping Third Hand (http://adafru.it/291) Tool is a good for smaller boards, or to hold things in place while terminating or splicing wires.

© Adafruit Industries |

https://learn.adafruit.com/adafruit-guide-excellent-soldering |

Page 8 of 35 |

Solder Sucker

A Solder Sucker (http://adafru.it/148) is a very helpful tools for removing excess solder

or when you need to de-solder a joint. As the name implies, this device literally sucks the solder out of the joint.

Solder Wick

Solder Wick (http://adafru.it/149) is another way to clean excess solder from a joint. Unlike the solder sucker, the wick soaks up the molten solder.

© Adafruit Industries |

https://learn.adafruit.com/adafruit-guide-excellent-soldering |

Page 9 of 35 |

Preparation

Heat the Iron

Plug an and/or turn on your soldering iron to warm up. If you are using a temperature controlled iron, set it to 700F/370C for 60/40 or 750F/400C for lead-free solder.

While the iron is heating dampen the sponge with a little bit of water.

Clean the Iron

Wipe the tip of the hot iron on the damp sponge to clean off any oxidation.

Do not use files or abrasives to clean the tip. It will damage the plating and ruin the tip.

© Adafruit Industries |

https://learn.adafruit.com/adafruit-guide-excellent-soldering |

Page 10 of 35 |

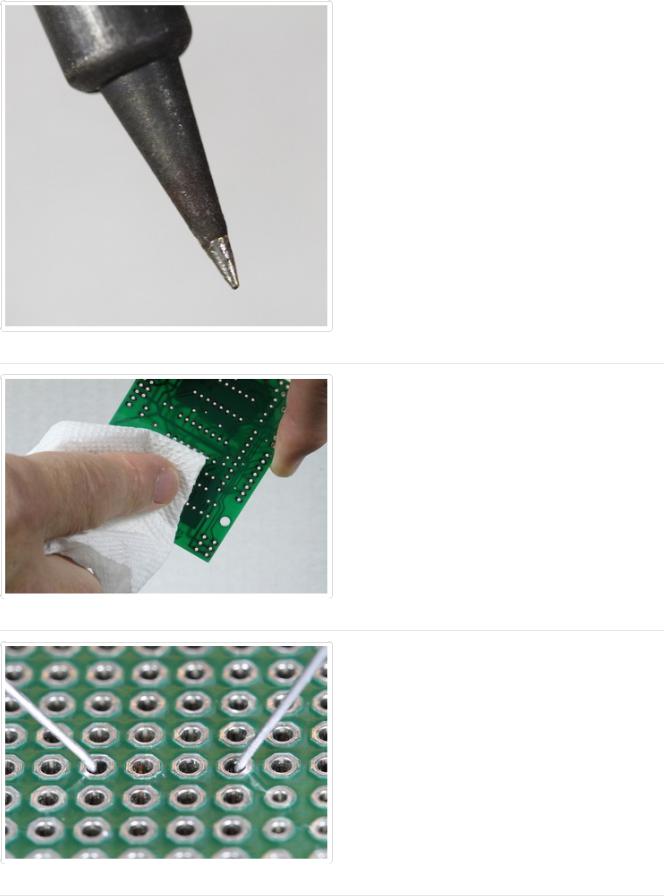

Tin the Tip

Apply a small amount of solder to the tip and wipe again to tin the tip. You should have a thin, shiny layer of molten solder on the tip of your iron.

If the tip is badly oxidized and difficult to tin, it can usually be reconditioned with some tiptinning paste.

Make sure that the joint is clean

Dirt, oxidation and oily fingerprints can prevent the solder from wetting the solder-pad to create a solid joint. All Adafruit boards are plated to prevent oxidation, but if your

board appears dirty from storage or handling, wipe it down with a little isopropyl alcohol.

Immobilize the Joint

This is very important! The parts being joined must not move during the soldering process. If there is any movement as the molten solder is solidifying, you will end up with an unreliable 'cold joint'.

Most through-hole components can be immobilized by simply bending the leads on the solder-side of the hole.

© Adafruit Industries |

https://learn.adafruit.com/adafruit-guide-excellent-soldering |

Page 11 of 35 |

Loading...

Loading...