Canon CXDI-31 Service manual

Confidential

t

t

y

y

C

C

C

C

S

S

X

X

X

X

err

e

DII--

D

DII--

D

vii

c

v

c

3

3

e

e

1

1

1

1

M

M

S

S

a

a

VVeerr..0066

y

y

n

n

u

u

stt

s

all

a

e

e

m

m

JJuunn.. 22000099

MMeeddiiccaall PPrroodduuccttss

TTeecchhnniiccaall SSeerrvviiccee DDeep

p

CCooppyyrriigghhtt b

CCaannoonn

b

Manual Control No. : BY8-2251-0E6

Name of Product : CXDI-31

Distribution Control No. :

Issued on :

Service Manual

Introduction

This service manual belongs to a series of after-sales guides Canon Inc. publishes as part of its

comprehensive product quality guarantee program, and will make a useful tool in promoting the sales of

the product, let alone repairing it.

This service manual consists of nine chapters; General, Installation Manual, Imaging Unit, E/O Box,

Parts Catalog, and Service Manual Report.

Please fully understand the procedure for installing the product indicated in “Installation Manual”, the

features and specifications of the product indicated in “GENERAL” and principle of system and

operation in “TECHNICAL INFORMATION”

Refer to “REPAIR GUIDE” in order to perform repairs properly, and “PARTS CATALOG” and

“TOOLS” for ordering parts and tools.

If you are using nonstandard connections or settings, refer to the related items in the “Option Setup”

chapter and then correct the connections or settings accordingly.

If the product undergoes a large modification, a new service manual of revised edition will be sent to

you.

In other cases, service manual report will be sent to you to update the manual.

If needed, utilize the related information indicated in the last chapter of Appendix.

Note 1:

This service manual is published by Canon Inc. in accordance with Article 6 (Furnishing the

Referring Materials) of the Service Assignment Contract concluded with your company.

The contract prohibits the exposure of the contents of this service manual in any form to the

third party without a written consent of Canon Inc.

Note 2:

This service manual is property of Canon Inc. and the company may seek to have it returned,

depending on circumstances. You are expected to keep it until then.

Note 3:

Your inquiries, suggestions etc. about the contents of this service manual should be

addressed to:

Medical Equipment Quality Administration Division,

Technical Service Department

Canon Inc.

30-2, Shimomaruko 3-chome, Ohta-ku, Tokyo

146-8501, Japan

1

1. General

This chapter is devoted to the description of the product’s features and specifications.

2. Installation Manual

This chapter indicates the procedure for installing the product.

3. Imagining Unit

This chapter describes unit composition, technical information and repair guide of Imaging Unit.

4. E/O Box

This chapter describes unit composition, technical information and repair guide of E/O Box.

5. Parts Catalog

This chapter consists of sections devoted to the product composition, disassembly diagrams, circuit

diagrams and part number index.

5.1 Product Composition

The main unit and accessories of the product are described.

A. The accessories whose order numbers are listed in the section are available from the Sales

Section as merchandise.

5.2 Disassembly Diagram

The parts specified as repair part are described, classified into groups from the function standpoint.

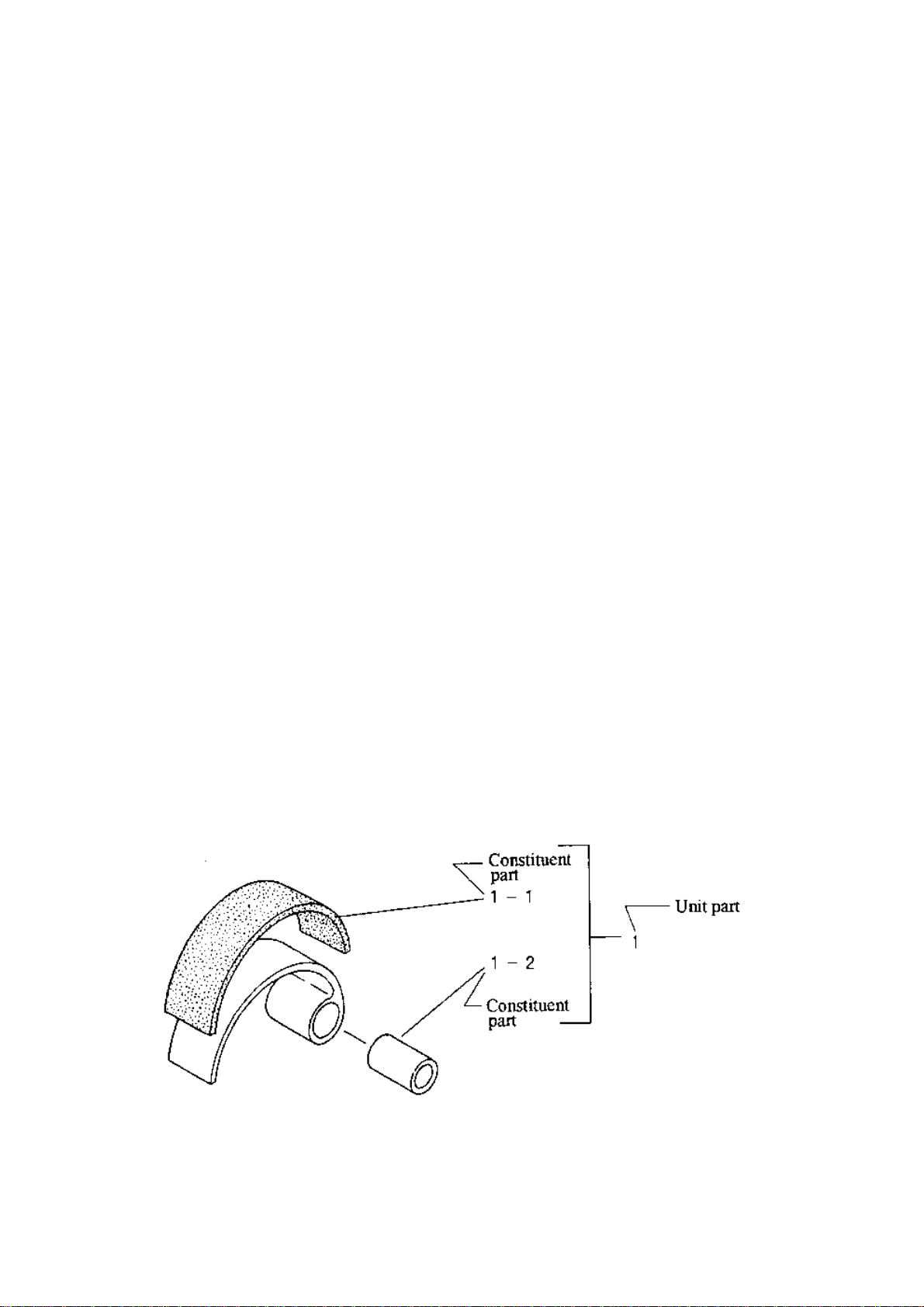

A. Unit Part and Its Constituent Parts

2

r

r

r

r

r

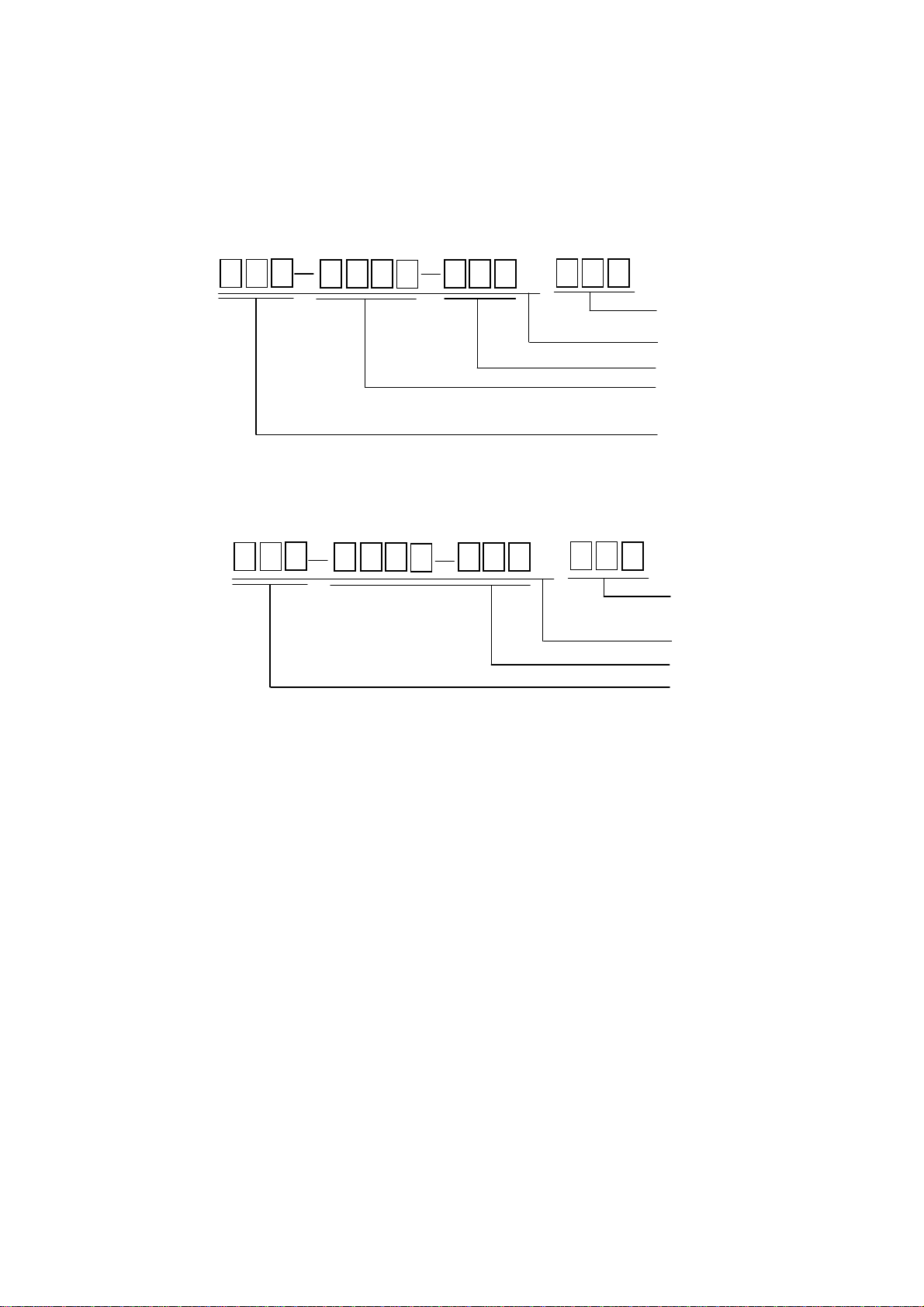

B. Part No. Column

A part number marking is as follows :

General Parts

Standard Parts (Screws, washers, resistors, capacitors, etc.) of Standard Specification

00

Size number

Part number

Revision numbe

Characteristic number

Sorting numbe

0

Supplementary number

Part numbe

Revision numbe

Sorting numbe

Size number: This number is used to classify adjustment parts by size.

The marking is 000 for parts which need not be classified by size.

Revision Number: This number is used to distinguish new parts from old ones.

The number advances when they cease to be interchangeable due to

modification.

Supplementary number: This is simply used to ensure the general and standard part number of

the same length. The marking is always 000.

Standard number: This is used to indicate screw diameters, resistance values, etc.

3

The size and supplementary number 000 marking is omitted.

The size number is given into ( ) below the part number for only adjustment parts.

Example … BA03415-000 …

020 : t= 0.2mm

050 : t= 0.5mm

100 : t =1.0mm

The parts whose part numbers are listed together and enclosed in ( ) are adjustment parts,

Example … XD1-1108-221

XD1-1108-222

XD1-1108-225

C. Q’ty Column

The number of units of parts used in the mechanism are indicated.

The marking is N for those adjustment parts which are not used in uniform quantities.

The marking is 1 for those parts whose length is not specified in the part number. Their length by

standard specified is given in ( ) below the part number in the PARTS NO. column.

Example … BH-2184-000

( l = 20mm)

5.3 Circuit Diagram

Electrical repair parts which are difficult to be showed in disassembly diagrams are illustrated.

5.4 Part Number Index

Except for the standard parts all the repair parts showed in disassembly and circuit diagrams are

listed in the order of the part number.

The page where the part is listed is found by referring its part number.

REVISION NO. – REPORT NO. Column

Informed of an advanced revision number by the Service Manual Report, the customer enters the

new revision number and the report number in this column.

… 1 …

A. REVISION NO.-REPORT NO Column

Informed of an advanced revision number by the Service Manual Report, the customer enters

the new revision and the report number in this column.

4

6. Service Manual Report

This report informs you of changes in the product design, etc., complete with information on the

reason of the changes, their contents and repair instructions.

When you receive the Service Manual Report, you are advised to enter the necessary information in

the service manual and keep the report in the report file according to the filing number.

5

CAUTION

Follow the safety instructions indicated below. Ignoring them may result in injury or accident.

1. Disassembly, Assembly, Adjustment and Maintenance

Disassembly, assembly, adjustment and maintenance must be done only by a service person

who has attended a service training designated by Canon.

2. Removal of Covers

Be sure to turn OFF the power of the instrument before removing the covers for maintenance

and repair. Also, do not touch the instrument with wet hands. Otherwise, you may get an

electric shock that may result in death or serious injury.

3. Fuse

When the fuse is going to be replaced, be sure to turn OFF the power of the instrument and

solve the problem which caused the fuse to blow. Be sure to replace the fuse with the

specified type only. Otherwise, fire or electric shock may result.

4. Ground Wire

Be sure to ground the instrument to an indoor grounded connector. Otherwise, fire or electric

shock may result due to leakage.

5. Modification

Never modify the product as it may result in fire or electric shock.

6. Waste control

The service provider is responsible for the disposal of used service parts, packing material, etc.

resulting from the setup, repair or maintenance of the medical device However, the customer

is responsible for the disposal of the medical device. Disposal activities must follow the

regulations (=specially controlled industrial waste) of the country where the device is used.

VORSICHT

Befolgen Sie die unten angegebenen Sicherheitsanweisungen.

Mißachtung kann zu erletzungenoder Unfällen führen.

1.Zerlegung, Zusammenbau, Einstellung und Wartung

Zerlegung, Zusammenbau, Einstellung und Wartung dürfen nur von einem

Wartungstechniker durchgeführt werden, der an einem von Canon vorgeschriebenen

Wartungslehrgang teilgenommen hat.

2.Entfernen von Abdeckungen

Schalten Sie unbedingt die Stromversorgung des Instruments aus, bevor Sie die

Abdeckungen zwecks Wartung und Reparatur entfernen.

Vermeiden Sie auch eine Berührung des Instruments mit nassen Händen.

Anderenfalls können Sie einen elektrischen Schlag erleiden, der zum Tod oder schwerer

Verletzung führen kann.

3.Sicherung

Wenn die Sicherung ausgewechselt werden muß, schalten Sie unbedingt die

Stromversorgung des Instruments aus, und beheben Sie die Ursache für das

Durchbrennen der Sicherung.

Ersetzen Sie die Sicherung nur durch den vorgeschriebenen Typ.

Anderenfalls kann es zu einem Brand oder elektrischen Schlag kommen.

4.Erdleiter

Erden Sie das Instrument unbedingt an einer Schukosteckdose.

Anderenfalls kann es zu einem Brand oder elektrischen Schlag durch Leckstrom

kommen.

5.Umbau

Jeder Umbau des Produktes ist strengstens untersagt, da dies zu einem Brand oder

elektrischen Schlag führen kann.

Labels and Markings

Labels and Markings

Safety Information(CXDI-31)

For U. S. A.

Do not make any changes or modifications to the equipment unless otherwise

specified in the manual.

If such changes or modifications should be made, you could be required to stop

operation of the equipment.

NOTE:

This equipment has been tested and found to comply with the limits for a Class A

digital device, pursuant to Part 15 of the FCC rules.

These limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial environment.

This equipment generates, uses, and can radiate radio frequency energy and, if not

installed and used in accordance with the instruction manual, may cause harmful

interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful

interference in which case the user will be required to correct the interference at his

own expense.

Use of shielded cable is required to comply with class A limits in Subpart B of Part

15 of FCC rules.

i

Labels and Markings

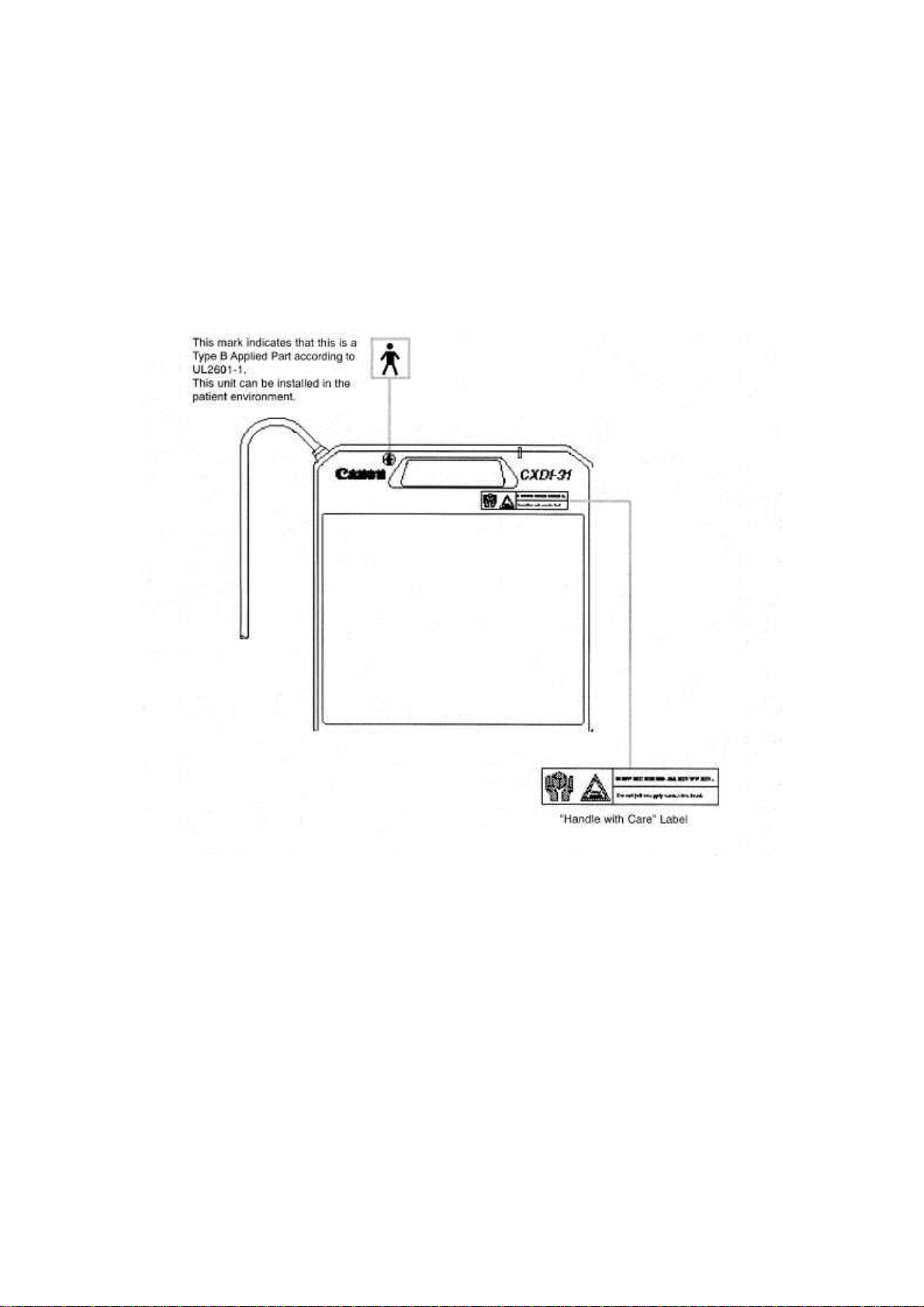

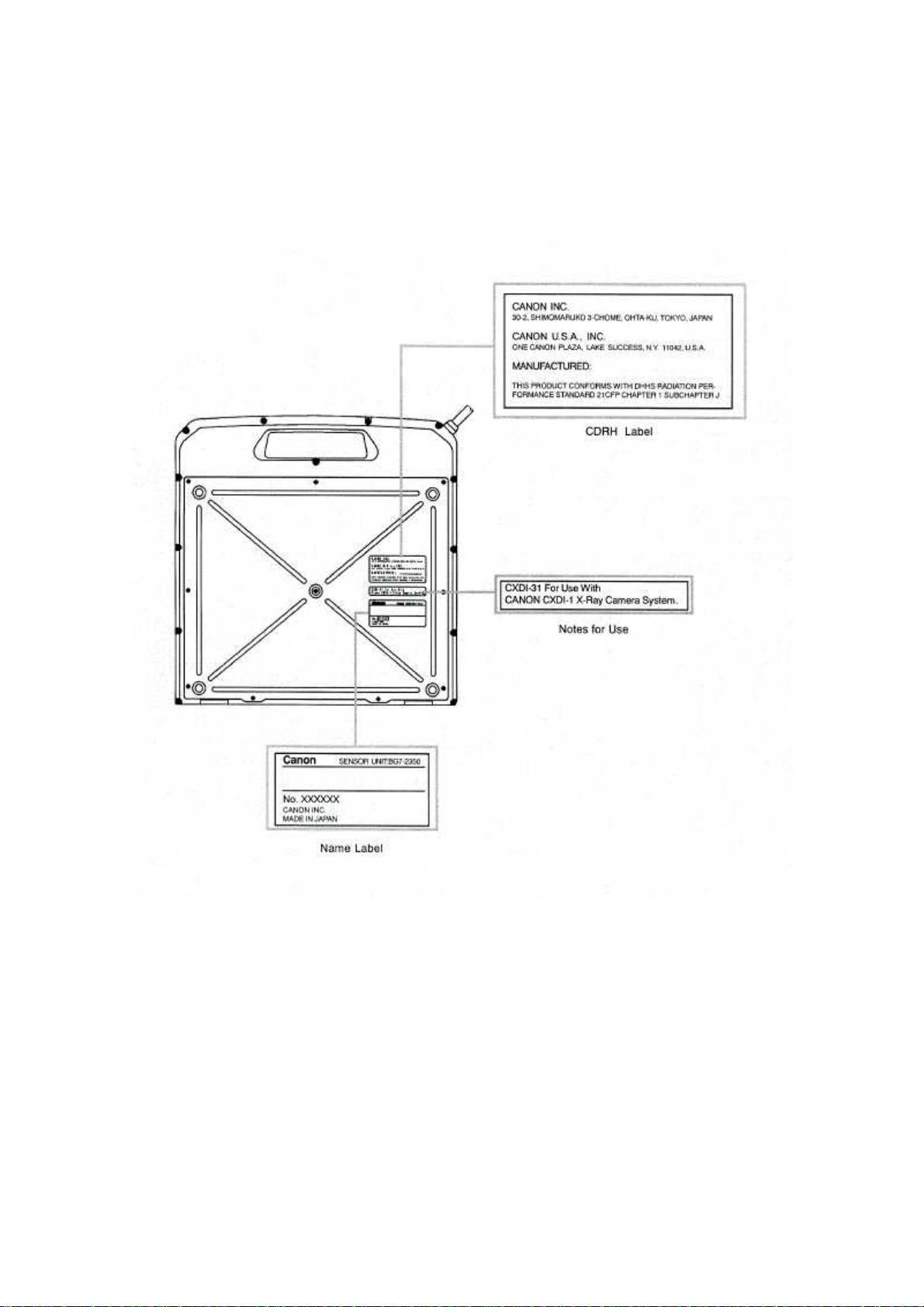

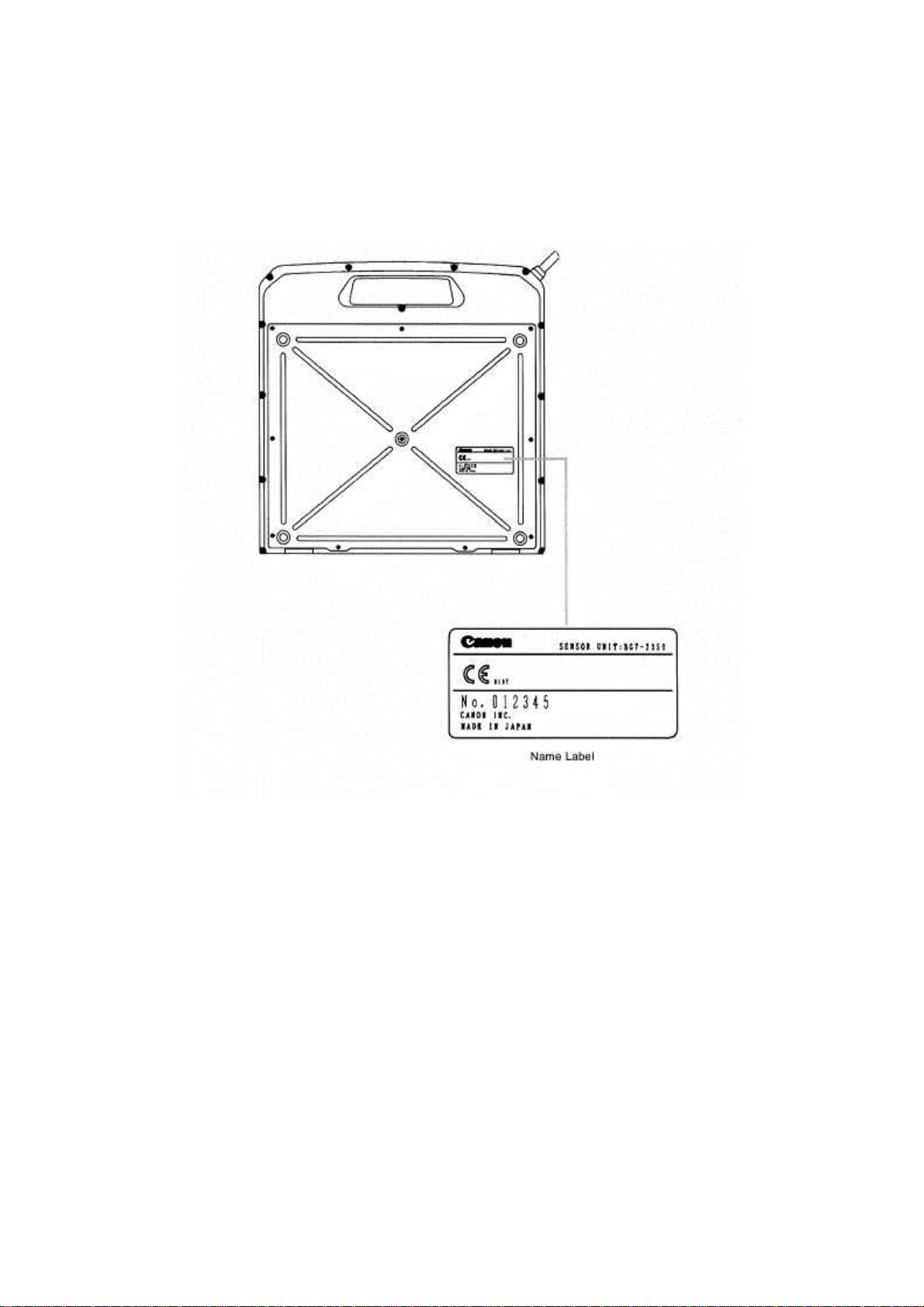

Labels and Markings on the Instrument

The CXDI-31 has a few labels and markings on it.

Contents of them and positions where they are attached are indicated below.

Front

ii

Rear

Labels and Markings

iii

Labels and Markings

For EU Countries

The following mark shows compliance of the instrument with Directive 93/42/EEC.

This instrument has been classified into EN55011 Group 1/Class A.

This instrument is a CLASS I EQUIPMENT according to EN 60601-1.

This instrument has been classified under EN60825-1:1994 and conforms to the

following classes:

CLASS 1 LASER PRODUCT

LASER KLASSE 1

APPAREIL A RAYONNEMENT LASER DE CLASSE 1

APPARECCHIO LASER DI CLASSE 1

PRODUCTO LASER DE CLASE 1

APARELHO A LASER DE CLASSE 1

iv

Labels and Markings

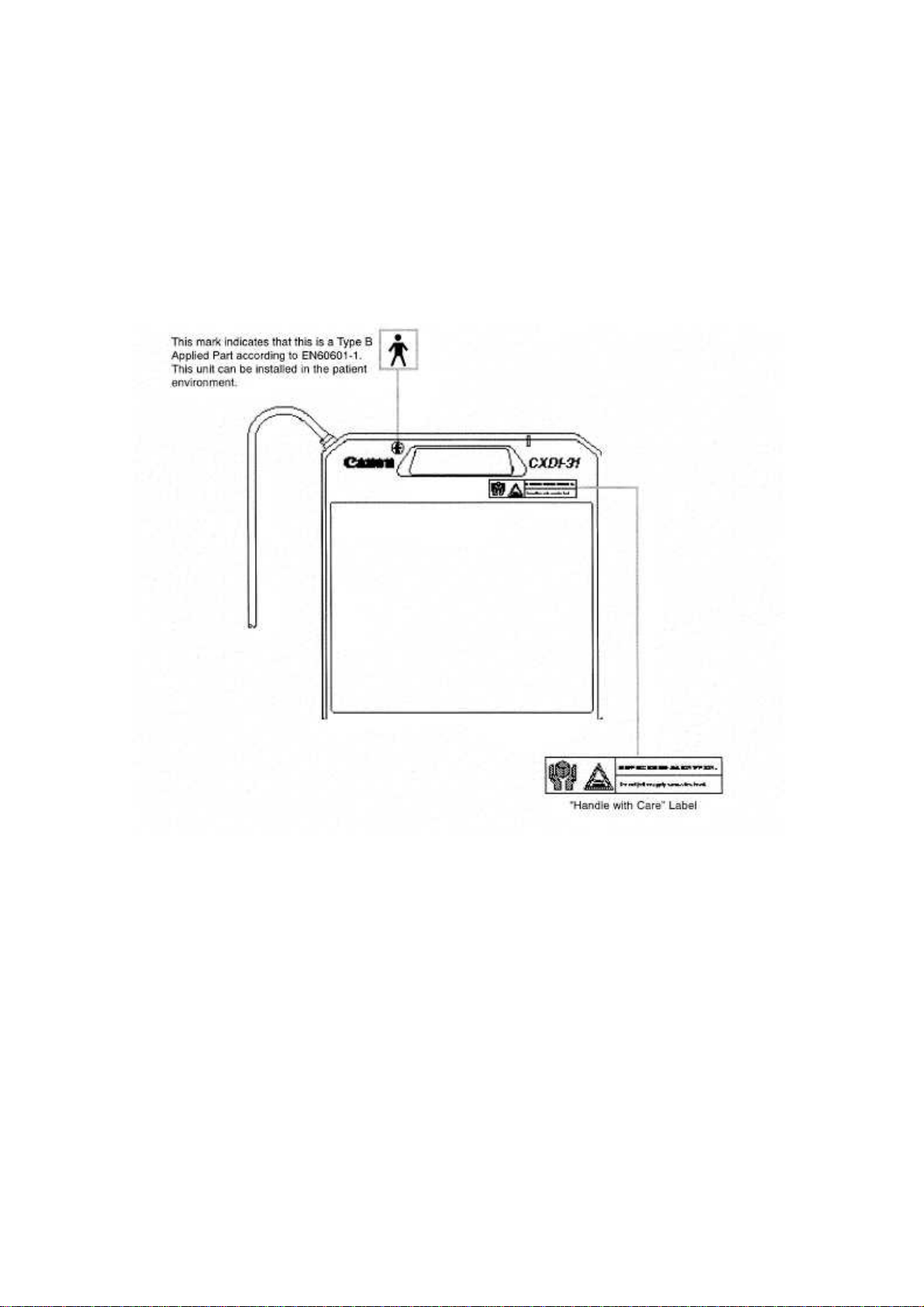

Labels and Markings on the Instrument

The CXDI-31 has a few labels and markings on it.

Contents of them and positions where they are attached are indicated below.

Front

v

Rear

Labels and Markings

vi

Labels and Markings

Safety Information(E/O Box)

For EU Countries

The E/O box has been classified under EN60825-1:1994 and conforms to the

following classes:

CLASS 1 LASER PRODUCT

LASER KLASSE 1

APPAREIL A RAYONNEMENT LASER DE CLASSE 1

APPARECCHIO LASER DI CLASSE 1

PRODUCTO LASER DE CLASE 1

APARELHO A LASER DE CLASSE 1

The E/O box has been classified into EN55011 Group 1/Class A.

For U. S. A.

Do not make any changes or modifications to the equipment unless otherwise

specified in the manual.

If such changes or modifications should be made, you could be required to stop

operation of the equipment.

NOTE:

This equipment has been tested and found to comply with the limits for a Class A

digital device, pursuant to Part 15 of the FCC rules.

These limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial environment.

This equipment generates, uses, and can radiate radio frequency energy and, if not

installed and used in accordance with the instruction manual, may cause harmful

interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful

interference in which case the user will be required to correct the interference at his

own expense.

Use of shielded cable is required to comply with class A limits in Subpart B of Part

15 of FCC rules.

vii

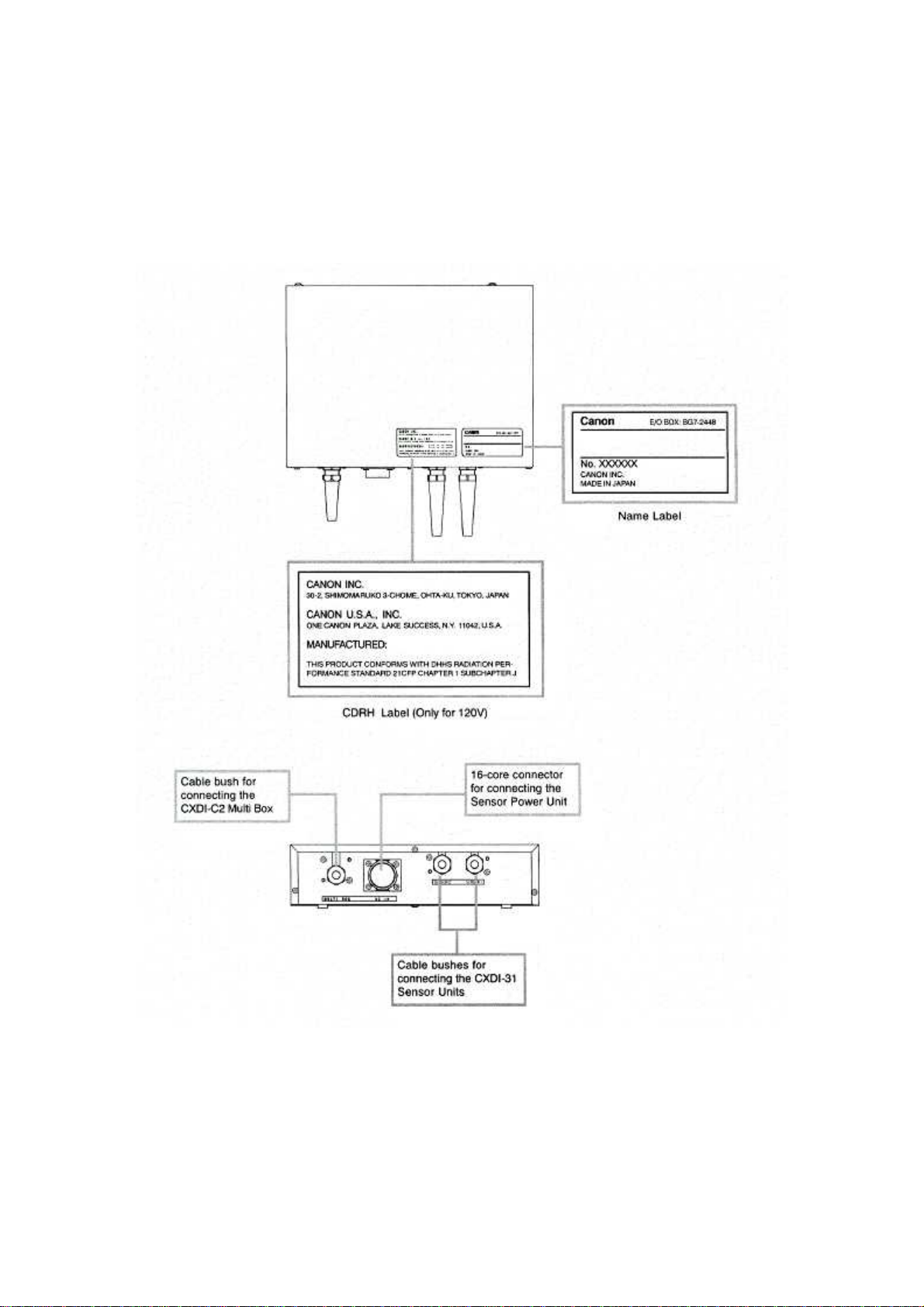

Labels and Markings

Labels and Markings on the Instrument

The E/O box has a few labels and markings on it.

Contents of them and positions where they are attached are indicated below.

viii

X

-

3

C

1..

1

G

G

D

e

e

n

n

I

err

e

1

all

a

VVeerr..0011

AAuugguusstt,, 22000011

MMeeddiiccaall PPrroodduuccttss

TTeecchhnniiccaall SSeerrvviiccee DDeeppt

t

CCooppyyrriigghhtt bbyy

CCaannoonn

1 General

CONTENTS

1.CXDI-1 System Block Diagram........................................................................1

2.CXDI Image Processing ..................................................................................2

2.1 Processing Flow........................................................................................2

2.2 Image Types .............................................................................................3

1.GENERAL

(Op

)

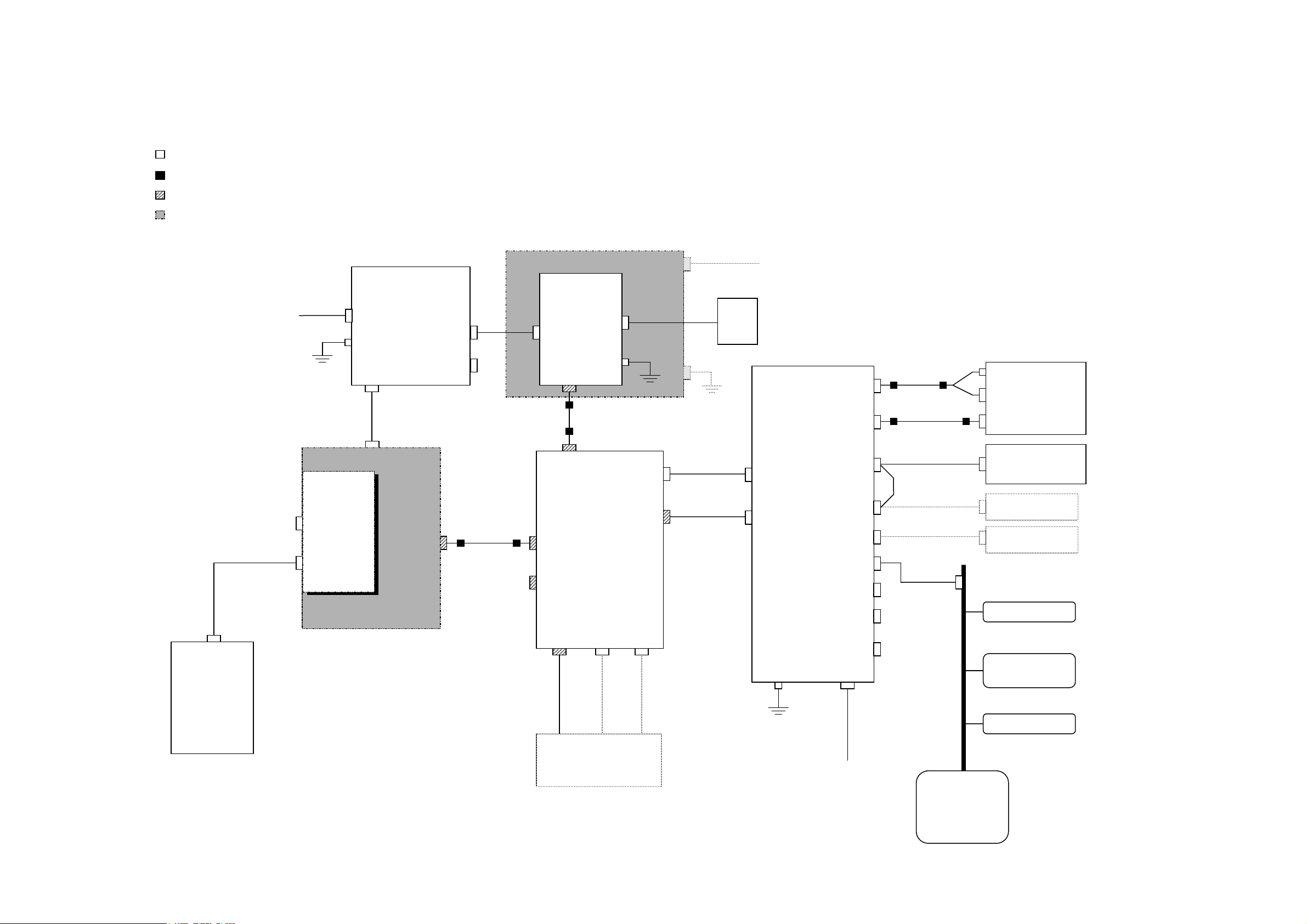

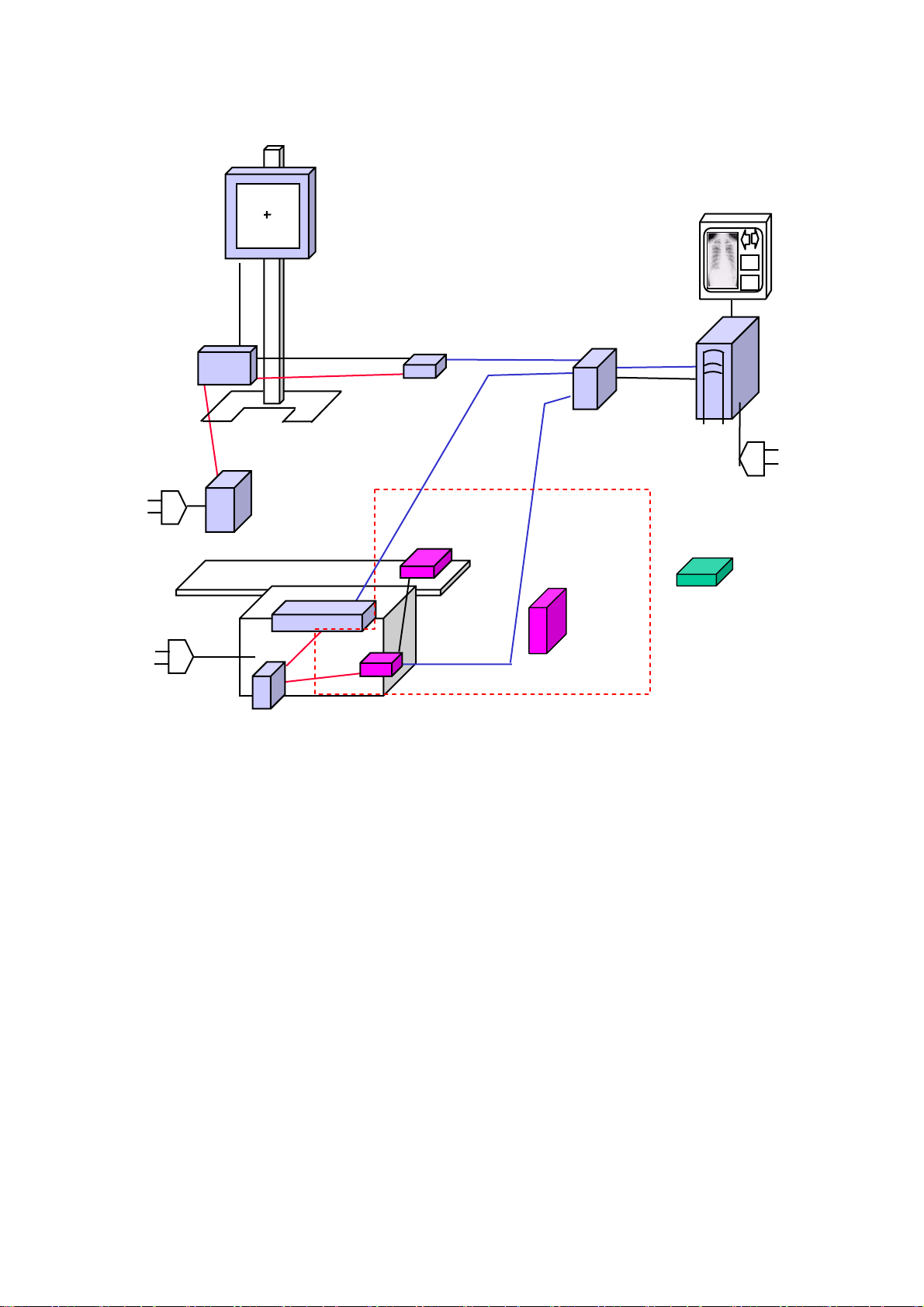

1. CXDI-1 SYSTEM BLOCK DIAGRAM (CXDI-31)

* 1. : Connector

* 2. : Ferrite Core

* 3. : Cord Bush

* 4. : Option

AC100V/120V/220/240V

(AC85-264V)

CA4

CA3

Sensor Power

Supply Unit

AC Power IN

FG

OUT PUT 2

(DC Power)

SPW

OUT PUT 1

(DC Power)

OUT PUT 3

(DC Power)

CA2

Table

Imaging Unit

(CXDI-22)

DC Power

METALOPTICAL

CA1

Ready

Lamp

FG

CA3

CA17

Ready

Lamp

AC120V

AC230V

Control PC

(CXDI-C2)

OPERATION

VGA

CA9

CA8

DC12V

RS232C

VGA

Operation

Unit

I/F Board

SENSOR 2

(CXDI-31)

SENSOR 1

(CXDI-31)

Imaging Unit

(CXDI-31)

DC Power

31E/O Box

METALOPTICAL

METALOPTICAL 1

(CXDI-22)

Multi Box

METALOPTICAL 2

(CXDI-31,E/O Box)

METALOPTICAL 3

(E/O Box)

X-Ray

I/F

CA5

Tube

Sync 1

X-Ray Generator

MULTIMETAL

MULTIOPTICAL

Tube

Sync 2

CA11

CA12

MULTIMETAL

MULTIOPTICAL

FG AC Power IN

CA7

AC120V±10% 60Hz 2A

AC230V±10% 50/60Hz 1.5A

SERIAL1

MOUSE

KEY BOARD

LAN

SCSI

SERIAL2(COM3)

SERIAL2(COM4)

CA6

CA10

Network

RS232C

ID Unit

tion

Mouse

Key Board

Printer

Image diagnosis

W/S

Image file device

Ethernet

(100/10bese-T)

1

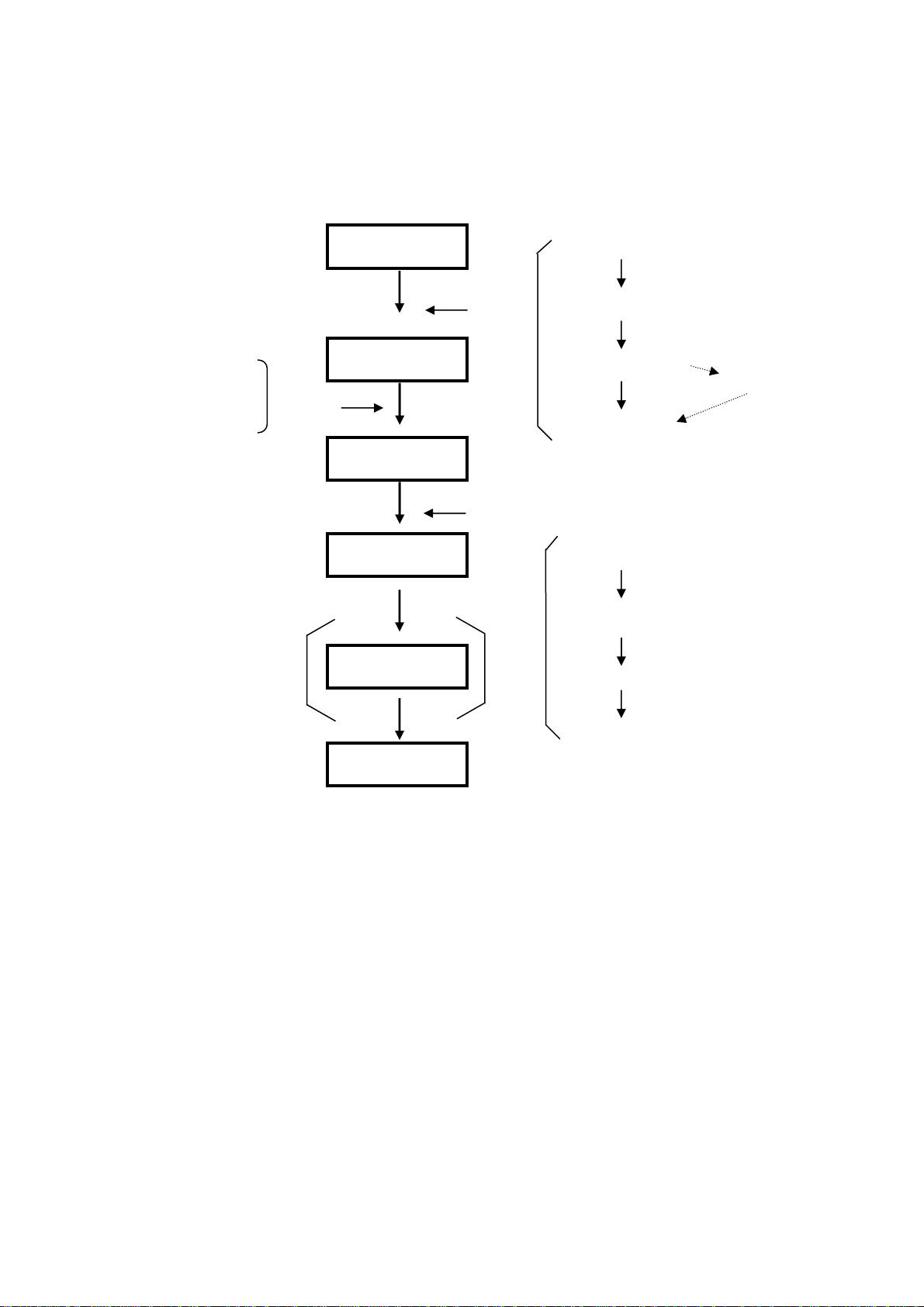

2. CXDI Image Processing

2.1 Processing flow

Born image

1. GENERAL

Offset correction

MTF improvement

(Frequency

improvement

processing)

Preprocessing

Raw image

Original image

QA image

DICOM output

Diag. image

Processed image

Correction

processing

QA processing

Gain correction

Defect correction

Seamless

correction

Characteristic

extraction

Sharpening

DEP

Gradation

processing

dtstore

2

2.2 Image types

(1) Born image

The image obtained with LANMIT before any correction is made.

Outside distribution of these images is prohibited, including dtstore images.

(2) Raw image

Born image after offset processing, gain correction, and splice processing.

This is the image with LANMIT specific characteristics corrected.

(3) Original image

Raw image after preprocessing.

(4) QA image

Original image after gradation processing, sharpening, and other processing.

The CXDI performs image processing up to this point.

(5) Diagnosis image

QA image after further image processing necessary for diagnosis.

Image processed by the user for diagnostic purposes.

1. GENERAL

(6) Processing image

Diagnosis image after post-processing.

Image modified by the user or the default processed image.

3

t

t

y

y

5

5

C

22.. IInnssttaallllaattiioonn M

X

D

I-3

1

Maannuuaall

VVeerr..003

3

MMeeddiiccaall PPrroodduuccttss

AAuugg,, 22000

0

TTeecchhnniiccaall SSeerrvviiccee DDeep

p

CCooppyyrriigghhtt b

CCaannoonn

b

2 Installation Manual

CONTENTS

System Overview ............................................................................................................ 1

1. Caution during operating ....................................................................................... 2

2. Installation................................................................................................................ 3

2.1. List of Tools Needed for Installation ............................................................................. 3

2.2. CXDI-31 system installation procedure......................................................................... 4

3. Unpacking ................................................................................................................ 6

3.1. Product configuration..................................................................................................... 6

3.1.1. Digital X-ray camera CXDI-31.............................................................................. 6

3.1.2. Grid (Optional) ....................................................................................................... 6

3.1.3. Product configuration guide ................................................................................... 7

3.2. Packing diagram............................................................................................................. 9

3.2.1. Digital X-ray camera............................................................................................. 9

3.2.2. Imaging unit ........................................................................................................... 9

3.2.3. E/O box ................................................................................................................ 10

3.2.4. Accessories (storage box)..................................................................................... 10

4. Installation.............................................................................................................. 11

4.1. Connecting the units .................................................................................................... 11

4.1.1. Connecting block diagram.................................................................................... 11

4.1.2. Imaging unit and E/O box .................................................................................... 12

4.1.3. Imaging Unit and Multi box................................................................................. 14

4.1.4. Control PC Rear Panel Connectors ...................................................................... 15

4.1.5. Attaching photocoupler cable to the control PC unit ........................................... 16

4.2. Methods for Securing the E/O Box.............................................................................. 18

4.2.1. Simple set-up for a general-purpose table for over including Pausch’s table ...... 18

4.2.2. Set up for the storage box..................................................................................... 19

4.3.

Settings........................................................................................................................21

4.3.1. Checking and Setting the Date and Time ............................................................ 21

4.3.2. LANMIT Image Correction ................................................................................ 22

4.3.3. Checking the Firmware Version.......................................................................... 25

4.3.4. Installing A/D Board Exposure Code.................................................................. 29

4.3.5. Checking the Sensor Serial No............................................................................ 31

4.3.6. Set Up Startup Menu ........................................................................................... 35

4.3.7. Identifying the sensor units and setting the number of units to be connected..... 38

4.3.8. Entering Control PC Serial Number.................................................................... 42

4.3.9. TABLE SETUP Settings ..................................................................................... 44

4.3.10. Performing the annotation settings...................................................................... 45

4.3.11. Network connections........................................................................................... 46

4.3.12. Linearity Check of Transfer Image Density........................................................ 78

4.3.13. Operation Unit Gamma Correction ..................................................................... 87

4.3.14. Changing the Total Image Count ........................................................................ 91

4.3.15. Backing Up When Installing............................................................................... 93

4.3.16. Backing up Important Setting Data..................................................................... 97

4.3.17. Tool Modes ......................................................................................................... 99

2 Installation Manual

5. X-ray Controller Interface.................................................................................. 104

5.1. Interface Signal Description ....................................................................................... 104

5.2. Signal Names and Functions in X-ray Generator Connections .................................. 105

5.3. Ratings and Performance for Relays and Photocouplers ............................................ 106

5.4. Adjusting the Timing with the X-ray Generator......................................................... 110

6. Image Quality Check........................................................................................... 117

7. Post-installation checks ....................................................................................... 122

7.1. Check sheet ................................................................................................................. 122

8. External Dimensional Diagram .......................................................................... 124

8.1. CXDI-31 ..................................................................................................................... 124

8.1.1. Imaging unit ........................................................................................................ 124

8.1.2. E/O Box............................................................................................................... 124

8.1.3. Storage Box ......................................................................................................... 125

8.2. Option ......................................................................................................................... 126

8.2.1. Grid...................................................................................................................... 126

9. Specifications & Standards................................................................................. 127

9.1. Specifications.............................................................................................................. 127

9.1.1. 9.1.1 Imaging unit................................................................................................ 127

9.1.2. E/O box................................................................................................................ 127

9.1.3. Grid (optional)..................................................................................................... 128

9.1.4. Shooting environment ......................................................................................... 128

9.1.5. Environment-related operating parameters ......................................................... 128

9.2. Standards .................................................................................................................... 128

9.2.1. Limit of Load....................................................................................................... 128

System Overview

I

11 Sensor Power Supply

CXDI-22

22 Sensor Power Supply

Upright Stand

CXD

Power Transformer

2. Installation Manual

-11

11 E/O Box

CXDI-31

31 E/O Box

[Fig.1]

Imaging Unit

Storage Box

OPU

Control PC

Multi Box

Density: 60/cm

4:1, 8:1, 10:1

110cm

- -

1

2. Installation Manual

1. Caution during operating

Please pay attention to the following points when installing the machine.

(1) If the equipment is hoisted, lowered or transported, it must be supported at

both sides by a minimum of two people so there is no danger of it falling.

(2) If a forklift, etc. is used to transport the equipment, make sure there is nothing that could

impede the forklift on its route to the final destination.

(3) When installing the equipment, be sure the site meets the following criteria:

1) There must be no dripping water in the area.

2) The environment must be free of harmful elements, such as humid or acidic air, air

with a saline or sulfur content, where there is poor ventilation, or where air pressure

or temperature is abnormal.

3) The equipment must not be placed at an angle or subjected to vibration or shock (this

includes during transportation).

4) The equipment must not be kept where chemical products are stored or where gasses

are generated

5) The site’s power supply must be of the correct voltage and frequency for the

equipment.

6) The site must be connected to a fully earthed cable with sufficient ground resistance

to meet standard values.

(4) After installation, be sure to dispose of waste product packaging with care and with full

respect for the environment.

(5) As the imaging unit is easily portable, take special care that it is not knocked, dropped or

subjected to strong shocks.

(6) Use clamps to secure any excess cable for the imaging unit.

- -

2

2. Installation Manual

2. Installation

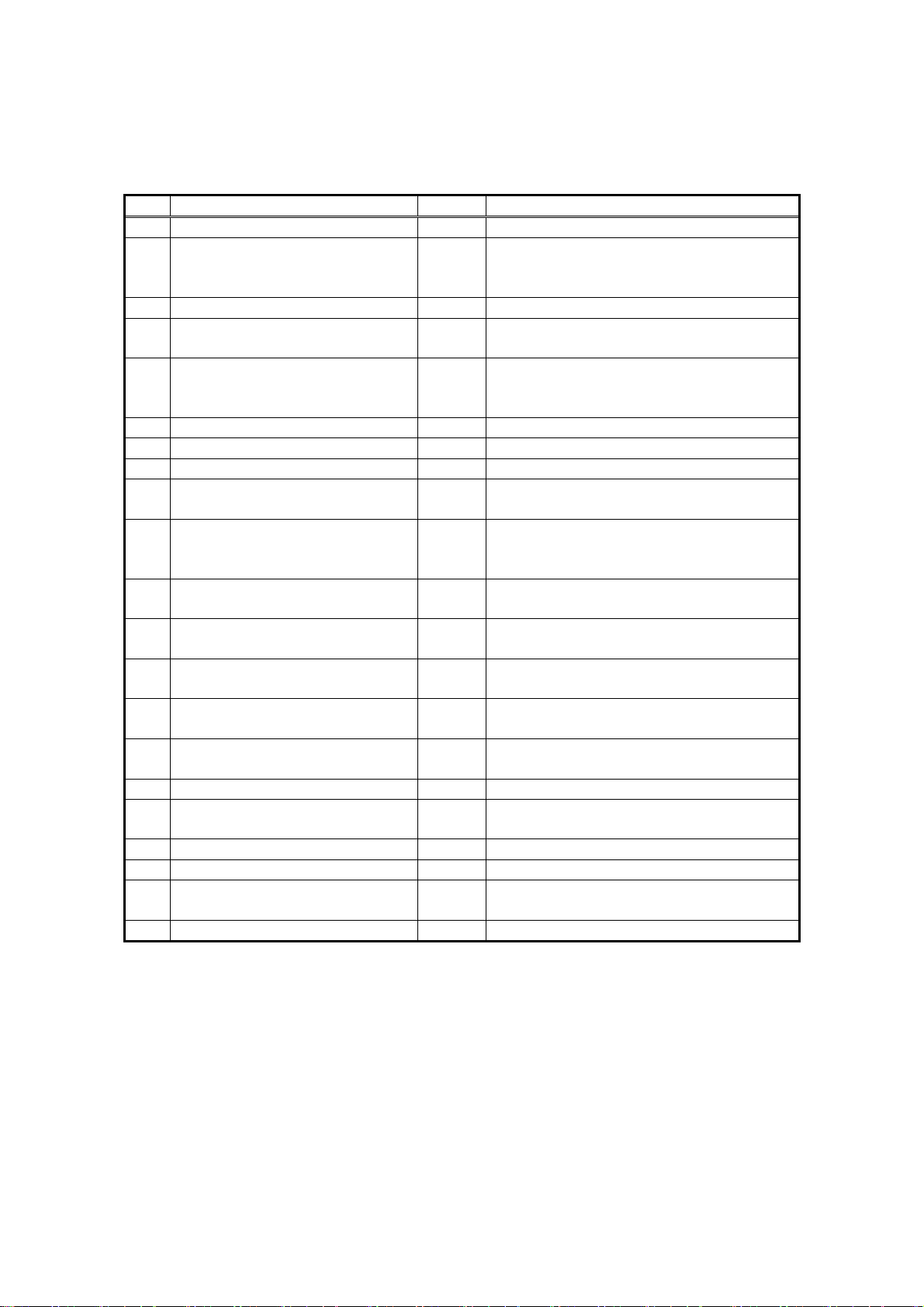

2.1. List of Tools Needed for Installation

Tools needed for new installation

No. Tools name Qty Remarks

1 General tools 1 set

PC/AT compatible

2 Laptop PC 1

3 LAN card 1 For laptop PC [If necessary]

4 Flash1 1

5 RS-232C cable 1

6 Capture board I/F cable 1 BY9-6484-000

7 Mouse 1 PS/2 type

8 Keyboard 1 PS/2 type

9 Hub 1

10 10BASE-T cable 2

Software for service

11

maintenance

Capture board firmware

12

[Imaging codes]

Capture board firmware

13

(Boot loader)

A/D board firmware

14

(Imaging codes)

A/D board firmware

15

(Boot loader)

16 CXDI application 1 Floppy disk, Ver.xxxxxx

CXDI software version

17

compatibility table

18 Resolution chart 1 BY9-7007-000

19 Metal net 1 BY9-6486-000

20 Mirror, oil-based marker, etc. 1

21 Electric drill 1 For opening 11 mm holes

[Table.1]

[OS:Windows 9X/

WindowsNT workstation 4.0 or later]

Flash1 unit, accessory cable,

accessory software

Straight type

[For connection between Laptop PC to

Flash1]

For connection between control PC to

Laptop PC

Straight type

[For connection between Laptop PC to

control PC]

1 BY9-6489-000

1 Floppy disk, Ver.xxxxxx

1 Floppy disk, Ver.xxxxxx

1 Floppy disk, Ver.xxxxxx

1 Floppy disk, Ver.xxxxxx

1

For adjusting the alignment

with the X-ray

- -

3

2. Installation Manual

2.2. CXDI-31 system installation procedure

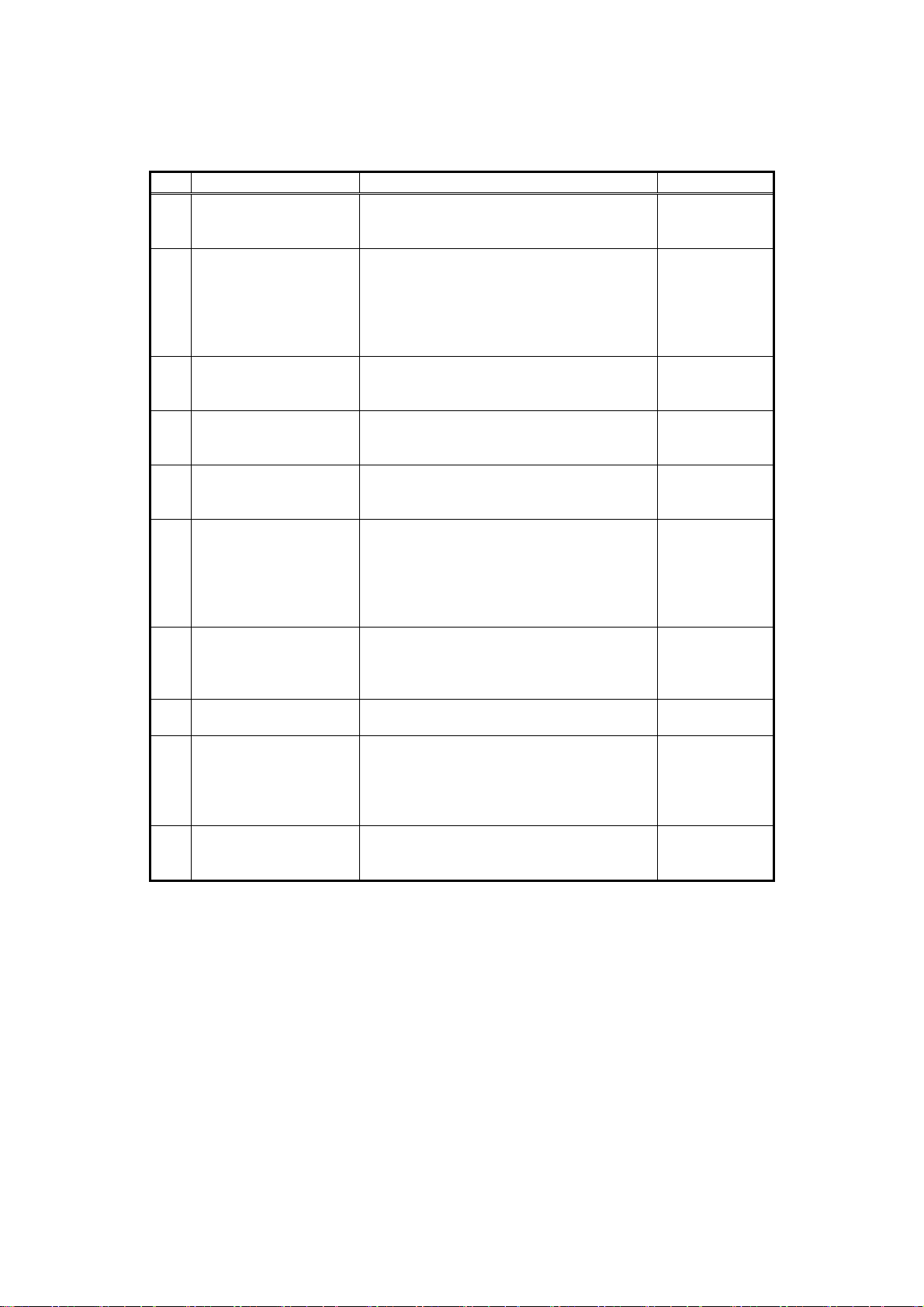

No. Step Conditions and checkpoints Reference

1 Unpacking and

checking the product’s

constituent parts

2 To connect the image

Unit and the E/O box

3 To connect the E/O box

and the sensor unit

4 To connect the E/O box

and the multi box

5 To connect the multi

box and the control PC

6 To connect the multi

box and X-ray

generators

7 Checking the software

program’s version

10 Installing the LANMIT

Image correction data

11 Identifying the imaging

units and setting the

number of units to be

connected (inputting the

sensor serial numbers)

12 Adjusting the timing

with the X-ray

generators

There must be no missing parts, damage,

dents, etc.

- Handle the instrument carefully, as it may

be damaged if something is hit against it,

dropped, or receives a strong jolt.

- The cables must be routed in such a way

that no unreasonable loads are brought to

bear upon them.

- The cables must be routed in such a way

that no unreasonable loads are brought to

bear upon them.

- The cables must be routed in such a way

that no unreasonable loads are brought to

bear upon them.

- The cables must be routed in such a way

that no unreasonable loads are brought to

bear upon them.

- The cables must be routed in such a way

that no unreasonable loads are brought to

bear upon them.

- The manufacturer of the X-ray generators

must be asked to handle the connections with

the generators.

- The compatibility of the sensor unit and the

control PC must be checked on the

compatibility list, and the software program

must be installed or upgraded as required.

Instruction

Instruction

- To support a 2-tube configuration, the

timing must be adjusted with each of the

generators.

Instruction

Manual

Instruction

Manual

The CXDI-C1

Service Manual

Instruction

Manual

The CXDI-C1

Service Manual

Instruction

Manual

Instruction

Manual

Manual

Manual

Instruction

Manual

- -

4

Loading...

Loading...