Canon CS TWIN BROCHURE

Product

Specications

Version 2

July 2012

For internal use only –

Company confidential

Océ ColorStream 3000 series

you can

Océ ColorStream 3000 series

Product Specications

This catalogue contains a concise overview of the Océ ColorStream 3000 product specification.

Information herein can change without prior notice.

This document is company confidential and for internal use only. Information on energy usage

and heat generation is based on an average print job at 75 meters per minute.

1 General

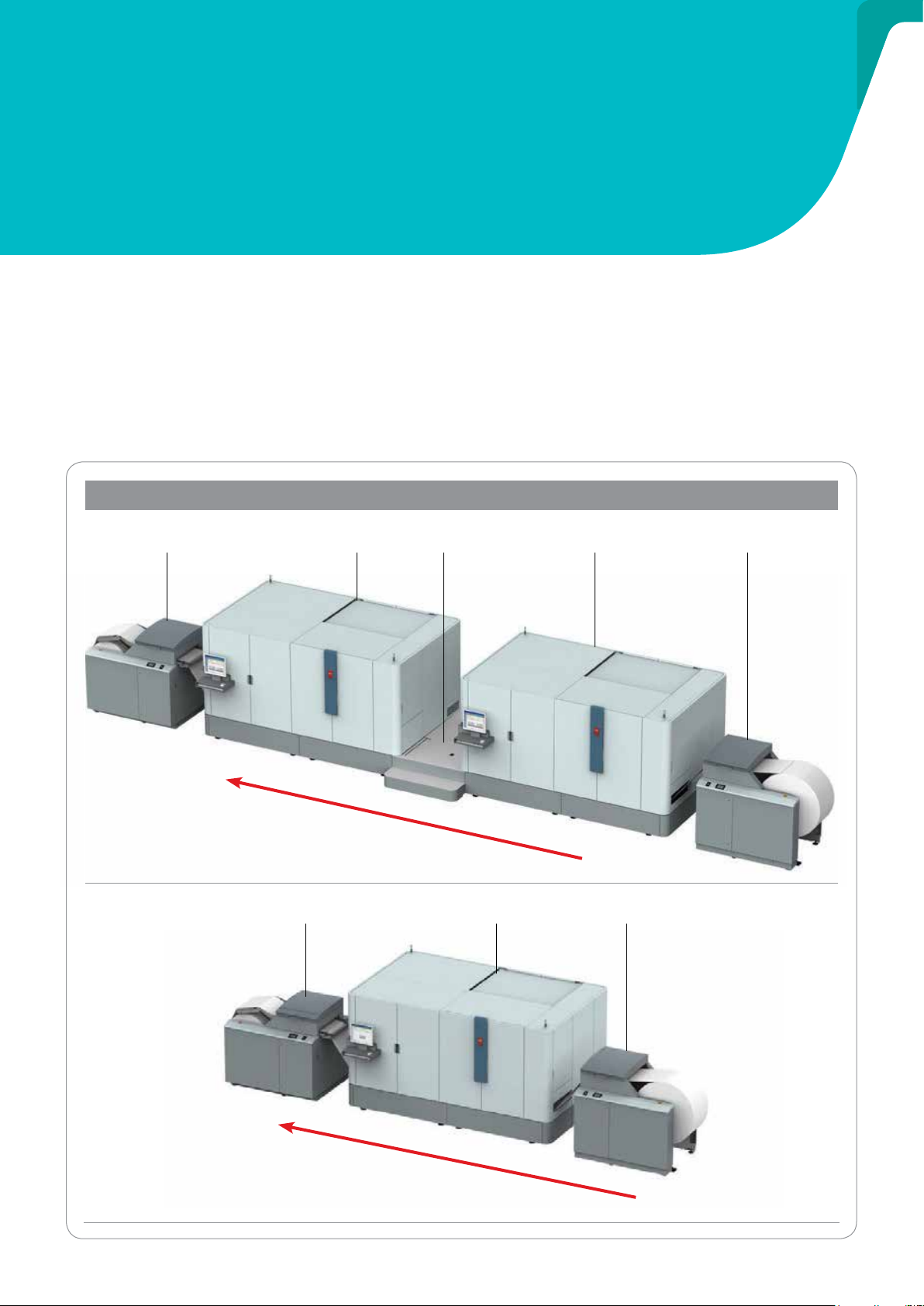

Océ ColorStream 3000 inline Twin schematic overview

3 2a2b 4 1

1 Unwinder

2a 1st print tower

2b 2nd print tower

3 Rewinder

4 Turnbar

OcéColorStream 3000 Single schematic overview

direction of paper movement

3 2 1

1 Unwinder

2 Simplex print tower

3 Rewinder

2 For internal use only | Company confidential

direction of paper movement

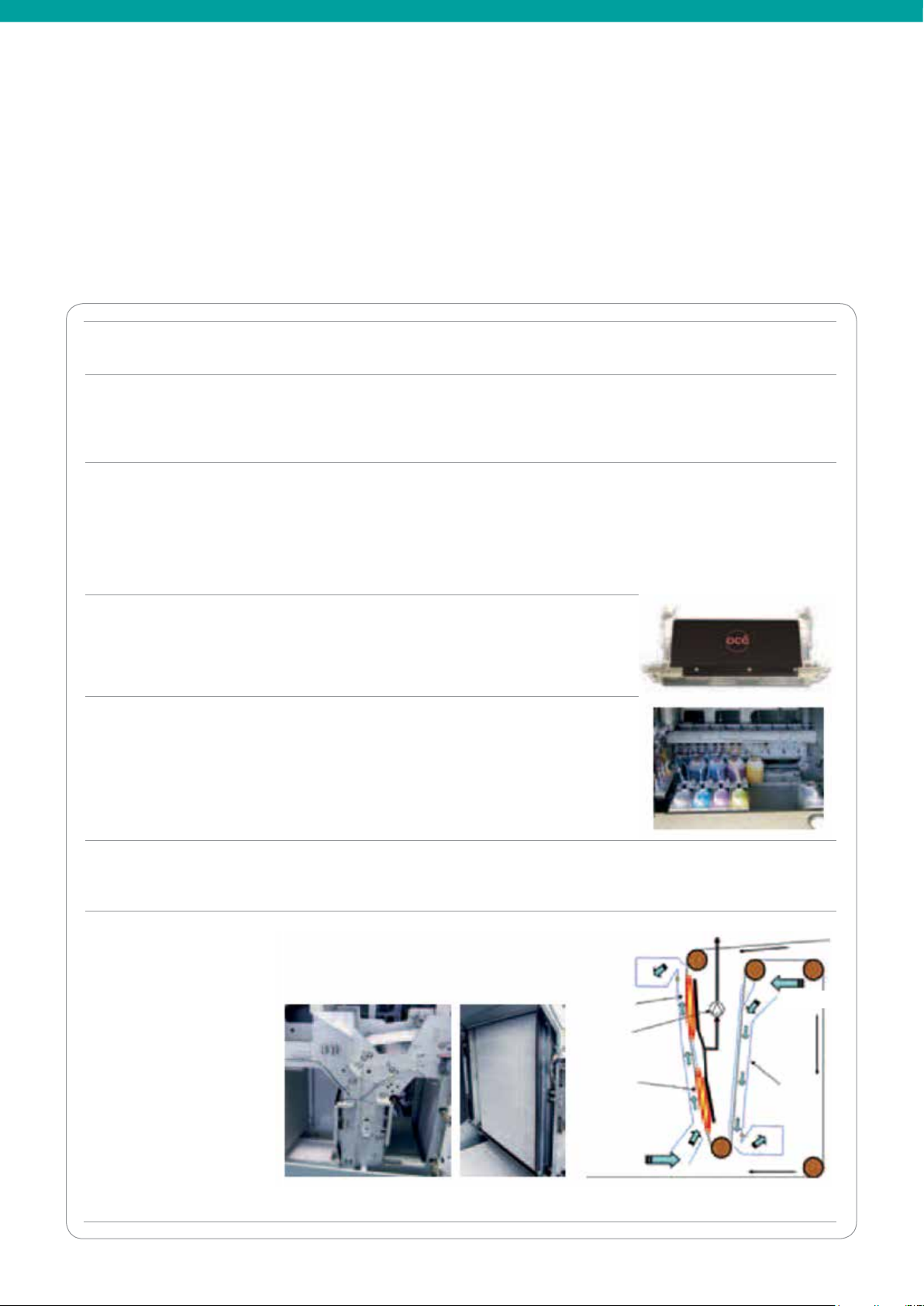

Océ DigiDot™ The Océ DigiDot drop-on-demand inkjet technology embraces the whole inkjet process including

the heads, its ring control, variable droplet size, multilevel droplet modulation and the inks.

®

Océ SRA

MP The Océ high-performance SRA MP (Scalable Raster Architecture Massively Parallel) controller

is responsible for native RIPping of IPDS (IS/3 compliant), PCL6 (includes PCL 5c, PCL XL and

bi-directional PJL) and PDF data using the Adobe PDF Print engine 2.5 and also performs color

management fully compliant to the rules of the AFP color consortium.

Inkjet head unit Each print tower or print engine contains one inkjet head unit. One inkjet head unit can

accommodate up to 6 inkjet heads for Monochrome, CMYK and two additional colors for MICR,

custom inks or special inks.

Inkjet head

Each inkjet head is used for printing one color onto the full paper width.

An inkjet head contains up to 5 inkjet modules for a maximum print width of up to 21,25 (540 mm).

Inkjet module The inkjet modules are based on the Kyocera KJ4B.

Width 108 mm (4.25“); 2,656 nozzles; 600 dpi, re

frequency 30 kHz or 40 kHz.

Ink supply system The ink supply system prepares the ink to be supplied to

the heads. It is integrated into the print tower, controls the

temperature (typically 32 °C) and lters out any pollution

particles. A de-gassing unit removes possible air in the inks.

The ink supply system also has an ink buffer to allow printing

while ink loading.

Ink lling system During transport, ink modules are lled with a special preserving uid. Before start of production

the modules are to be lled with the respective inks. This duty is done by Océ during the

installation or in the ColorStream 3000. No special external unit is needed.

Paper drying unit Heated saddles (80–130 °C) with air fans are used to

Paper

extract the water from the paper.

Heating

saddle 1

Fresh air

Steam

extraction

(vacuum)

Heating

saddle 2

After drying

line

Fresh air

Low energy capsuled

Drying saddles Drying process illustration

drying saddles

For internal use only | Company confidential 3

Océ ColorStream 3000 series

Product Specications

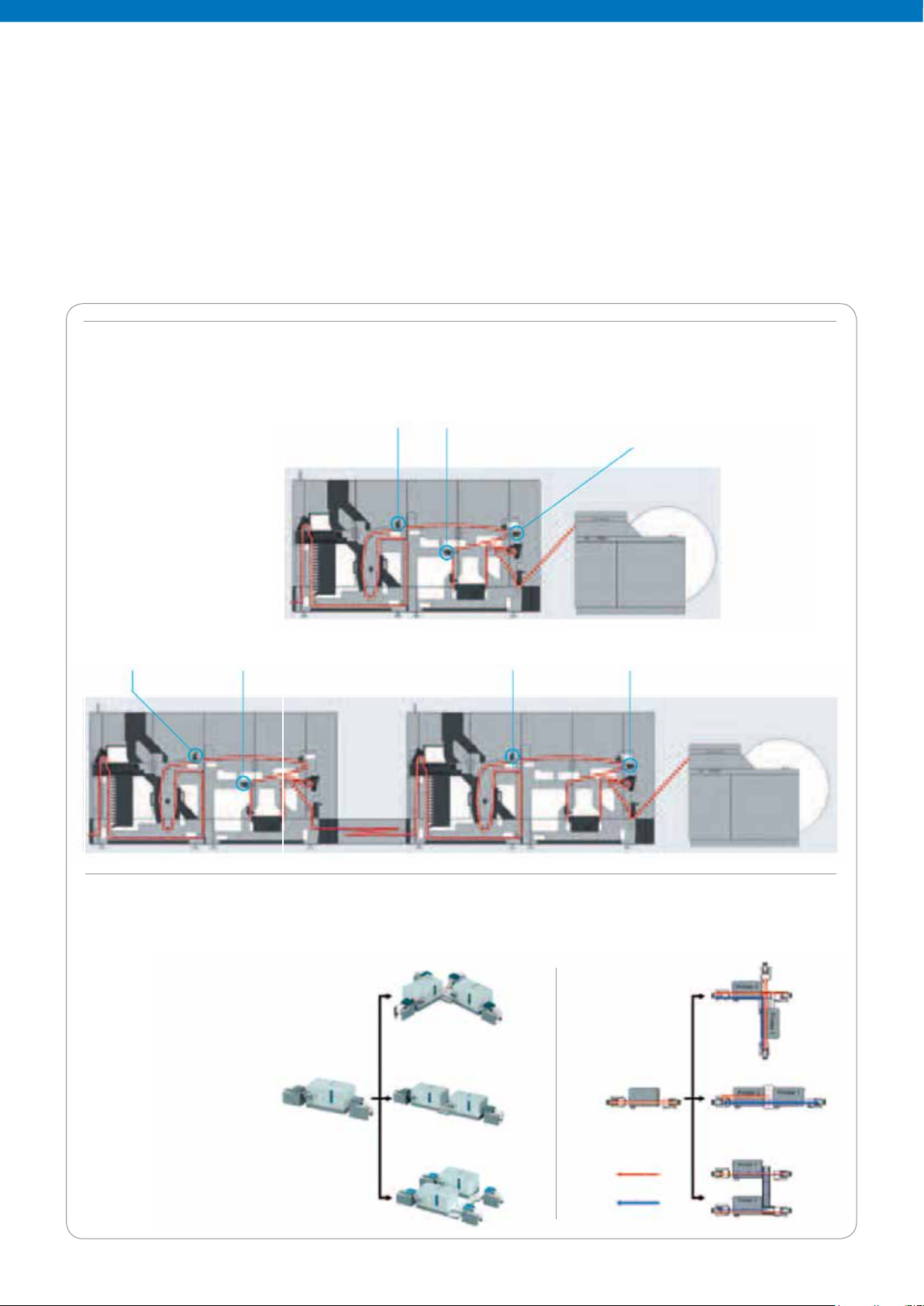

Paper transport Océ ColorStream 3000 Single conguration

Océ ColorStream 3000 Twin conguration

1 Input paper roller including sticky roller

2 Main drive and friction brake for paper tension

X Encoder for printing in speed ramps

3 Steering frame

(web guide for paper transport accuracy)

4 Steering sensor

5 Back preprinted marks sensor

(aka sync sensor) (only tower 2 in a Twin)

6 Front preprinted marks sensor

7 Ionizer and resolver for printing in speed ramps

Cooling roller The purpose of the cooler roller is to reduce the temperature of the paper after it was heated by

the dryer. The cooling also conditions the paper for an improved color consistency. Cooling is only

needed in a Twin conguration and integrated in the paper turning unit between tower 1 and tower 2.

First page printing* The Océ ColorStream 3000 has a unique feature for drop on demand inkjet printing. With the ability

to print in speed ramps, a paper waste free acceleration of the paper with quality print outs in the

speed ramps is possible.

Waste free print pause* By printing in the speed ramps the Océ ColorStream 3000 can be slowed down to a full stop of the

paper movement and back to production speed without paper waste. This enables to perform a

timely limited (1 minute) waste free print pause to visually inspect the printouts or perform other

tasks around the system. After the dened time, the system will continue printing fully automatically.

Long stop white paper

between stop and start

To prevent an impact on print quality, the pause is timely limited. A longer term stop will produce

paper waste as on all inkjet solutions. The amount of paper waste is around 20 (±3) meters for

an inline Twin conguration.

8 Printing heads

(six single print heads in one larger array)

9 Data integrity (DI) sensor

10 Drying saddles

11 Cooler (only tower 1 in a Twin)

12 Output paper drive incl. friction break

13 Cooling roller

A Tight and slack web paper outfeed

B Tight web paper outfeed

* Function is not available using MICR ink to ensure readability of MICR lines

4 For internal use only | Company confidential

Printing on preprinted paper On the Océ ColorStream 3000 imprints on preprinted forms can be done by all towers. For that

purpose all Océ ColorStream towers have dedicated sensors for preprinted marks and Data

Integrity marks.

Océ ColorStream 3000 Single conguration

Data integrity (DI)

sensor

Optional back preprinted

marks sensor (aka sync sensor)

Front preprinted

marks sensor

Océ ColorStream 3000 Twin conguration

Data integrity (DI)

sensor

Back preprinted marks sensor (aka sync sensor)

(only tower 2 in a Twin)

Data integrity (DI)

sensor

Front preprinted

marks sensor

Simplex/Duplex efciency The Océ ColorStream 3000 offers the Océ Simplex/Duplex efciency of the Océ VarioStream

family. As a single unit, purely simplex productivity is available. Through the combination with

a second tower in an inline twin full duplex efciency can be generated. The combination in a

H- or L-Twin offers both, full simplex and duplex productivity in one conguration.

L-Twin

Single

Inline-Twin

Simplex

Duplex

H-Twin

For internal use only | Company confidential 5

Loading...

Loading...