Page 1

See Warranty on page 6 for important information about commercial use of this product.

Operating Instructions Single-Stage Compressor Pumps

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain the product described.

Protect yourself and others by observing all safety information. Failure to comply with instructions could result in personal injury and/or

property damage! Retain instructions for future reference.

Air Compressor

Pumps

Table of Contents

Description . . . . . . . . . . . . . . . . . . . . . .1

Unpacking . . . . . . . . . . . . . . . . . . . . . . .1

Safety Guidelines . . . . . . . . . . . . . . . . .1

General Safety Information . . . . . . . . .2

Assembly . . . . . . . . . . . . . . . . . . . . . . . .2

Maintenance . . . . . . . . . . . . . . . . . . . . .3

Troubleshooting Chart . . . . . . . . . . . . .5

Warranty . . . . . . . . . . . . . . . . . . . . . . . .6

Description

Single stage, oil lubricated air

compressor pumps are intended for

use as replacements on air compressor

units, and for use as components in

specially designed air compressor

systems. For replacement use, the

compressor pump must match the

vibration characteristics of the original

pump. The compressed air from these

pumps is intended to be used with

air tools and spray guns. Atmospheric

moisture and trace oil from compressors

may require additional treatment

for some application. All models are

equipped with solid cast-iron cylinders

and crankcase, an aluminum head and

stainless steel valves.

This compressor/pump is NOT equipped and should NOT be used “as is” to supply

breathing quality air. For any application of air for human consumption, you must

fit the air compressor/pump with suitable in-line safety and alarm equipment. This

additional equipment is necessary to properly filter and purify the air to meet minimal

specifications for Grade D breathing as described in Compressed Gas Association

Commodity Specification G 7.1 - 1966, OSHA 29 CFR 1910. 134, and/or Canadian

Standards Associations (CSA).

DISCLAIMER OF WARRANTIES

In the event the compressor is used for the purpose of breathing air application

and proper in-line safety and alarm equipment is not simultaneously used, existing

warranties are void, and Campbell Hausfeld disclaims any liability whatsoever for any

loss, personal injury or damage.

Unpacking

After unpacking the unit, inspect carefully for any damage that may have occurred

during transit. Make sure to tighten fittings, bolts, etc., before putting unit into

service.

Do not operate unit if damaged during shipping, handling or

use. Damage may result in bursting and cause injury or

property damage.

Safety Guidelines

This manual contains information that is very important to know and understand.

This information is provided for SAFETY and to PREVENT EQUIPMENT PROBLEMS.

To help recognize this information, observe the following symbols.

Danger indicates an imminently hazardous situation which, if

not avoided, WILL result in death or serious injury.

Warning indicates a potentially hazardous situation which, if

not avoided, COULD result in death or serious injury.

Caution indicates a potentially hazardous situation which, if

not avoided, MAY result in minor or moderate injury.

Notice indicates important information, that if not followed,

may cause damage to equipment.

NOTE: Information that requires special attention.

Breathable Air Warning

READ & FOLLOW ALL INSTRUCTIONS

SAVE THESE INSTRUCTIONS

DO NOT DISCARD

REMINDER: Keep your dated proof of purchase for warranty purposes!

© 2010 Campbell Hausfeld/Scott Fetzer

Attach it to this manual or file it for safekeeping.

For parts, product & service information

visit www.chpower.com

IN228704AV 7/10

Page 2

Operating Instructions

General Safety Information

CALIFORNIA PROPOSITION 65

This product or

its power cord may

contain chemicals known to the State

of California to cause cancer and birth

defects or other reproductive harm.

Wash hands after handling.

GENERAL SAFETY

Since the air compressor and other

components (pump, spray guns, filters,

lubricators, hoses, etc.) used make up

a high pressure pumping system, the

following safety precautions must be

observed at all times:

1. Read all manuals included

with this product carefully.

Be thoroughly familiar

with the controls and the

proper use of the equipment.

2. Follow all local safety codes and, in

the United States, the Occupational

Safety and Health Act (OSHA).

3. Only persons well acquainted with

these rules of safe operation should

be allowed to use the compressor.

4. Keep visitors away and NEVER allow

children in the work area.

5. Wear safety glasses and use hearing

protection when operating the

pump or unit.

6. Do not stand on or use the pump or

unit as a handhold.

7. Before each use, inspect compressed

air system, fuel system and electrical

components for signs of damage,

deterioration, weakness or leakage.

Repair or replace defective items

before using.

8. Check all fasteners at frequent

intervals for proper tightness.

Motors, electrical equipment

and controls can cause

electrical arcs that will

ignite a flammable gas or vapor. Never

operate or repair in or near a flammable

gas or vapor. Never store flammable

liquids or gases in the vicinity of the

compressor.

Never operate compressor

without a beltguard.

Compressors can start

automatically without warning.

Personal injury or property damage

could occur from contact with moving

parts.

9. Do not wear loose clothing or

jewelry that will get caught in the

moving parts of the unit.

Compressor parts may be hot

even if the unit is stopped.

10. Keep fingers away from

a running compressor; fast moving

and hot parts will cause injury and/

or burns.

Vibrations may

cause cracks in

tanks and result in bursting. Do not

install pump on a tank not designed for

use with that pump.

11. If the equipment should start to

vibrate abnormally, STOP the engine/

motor and check immediately for

the cause. Vibration is generally a

warning of trouble.

12. To reduce fire hazard, keep engine/

motor exterior free of oil, solvent, or

excessive grease.

Never remove or

attempt to adjust

safety valve. Keep safety valve free

from paint and other accumulations.

Never attempt to repair or

modify a tank! Welding,

drilling or any other

modification will weaken the tank

resulting in damage from rupture or

explosion. Always replace worn or

damaged tanks.

13. Tanks rust from moisture build-up,

which weakens the tank. Make sure

to drain tank regularly and inspect

periodically for unsafe conditions

such as rust formation and corrosion.

14. Fast moving air will stir up dust

and debris which may be harmful.

Release air slowly when draining

moisture or depressurizing the

compressor system.

15. Keep hoses away from sharp

objects, chemical spills, oil solvents

and wet floors which can damage

hose. Do not operate compressor

with damaged hose(s) or after the

compressor or attachments have

been dropped or damaged. Notify

the nearest authorized service

facility for examination, repair, or

other adjustment.

Never use plastic

(PVC) pipe for

compressed air. Serious injury or death

could result.

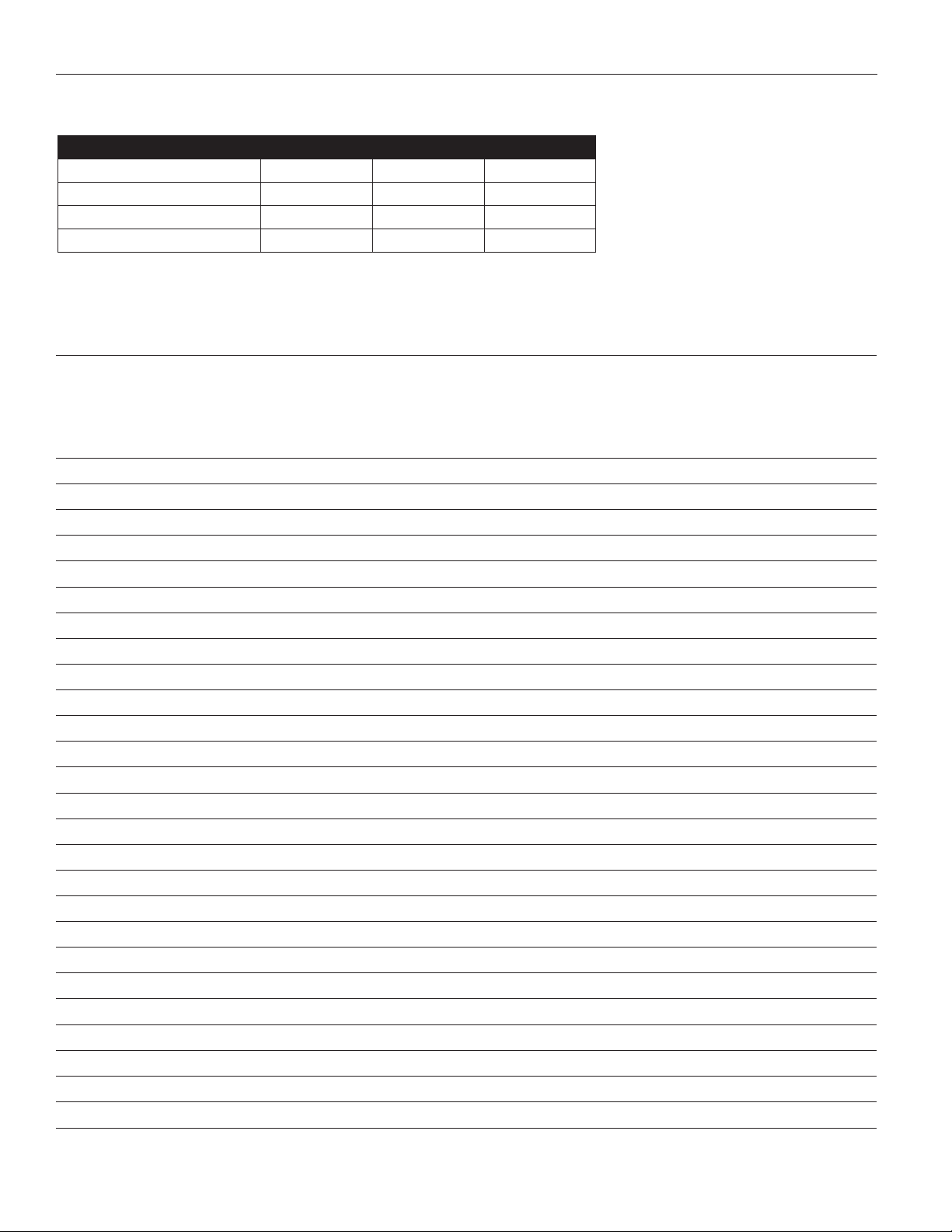

FOR VT2030 & VT2731 ONLY

Free Air CFM @

40 psig 90 psig

Motor Running

HP*

Recommended

Campbell Hausfeld

Motor Part No. Pump RPM**

Outside Dia. of

A-Section Motor

Pulley*

2.0 MC015502IP 700 2.00 8.0 6.4

3.0 MC015403IP 1050 3.00 11.4 9.0

* Note: Motor should be a 3450 RPM compressor duty motor.

** For pump speeds lower than 700 RPM use a 1750 RPM motor with the appropriate pulley.

Do not exceed 1140 RPM at 125 psig or damage may occur to the pump and the warranty will be void.

www.chpower.com

2

Page 3

Single-Stage Compressor Pumps

Assembly

ASSEMBLY INSTRUCTIONS

Disconnect, tag and lock out

power source, then release

all pressure from the system

before attempting to install, service,

relocate or perform any maintenance.

FLYWHEEL (VT2030 & VT2731 ONLY)

Place flywheel on the crankshaft with

setscrew threads on the outside. Tighten

setscrew to 19ft. lbs. on the key. Keep

the setscrew tight. A loose flywheel

causes a knocking noise.

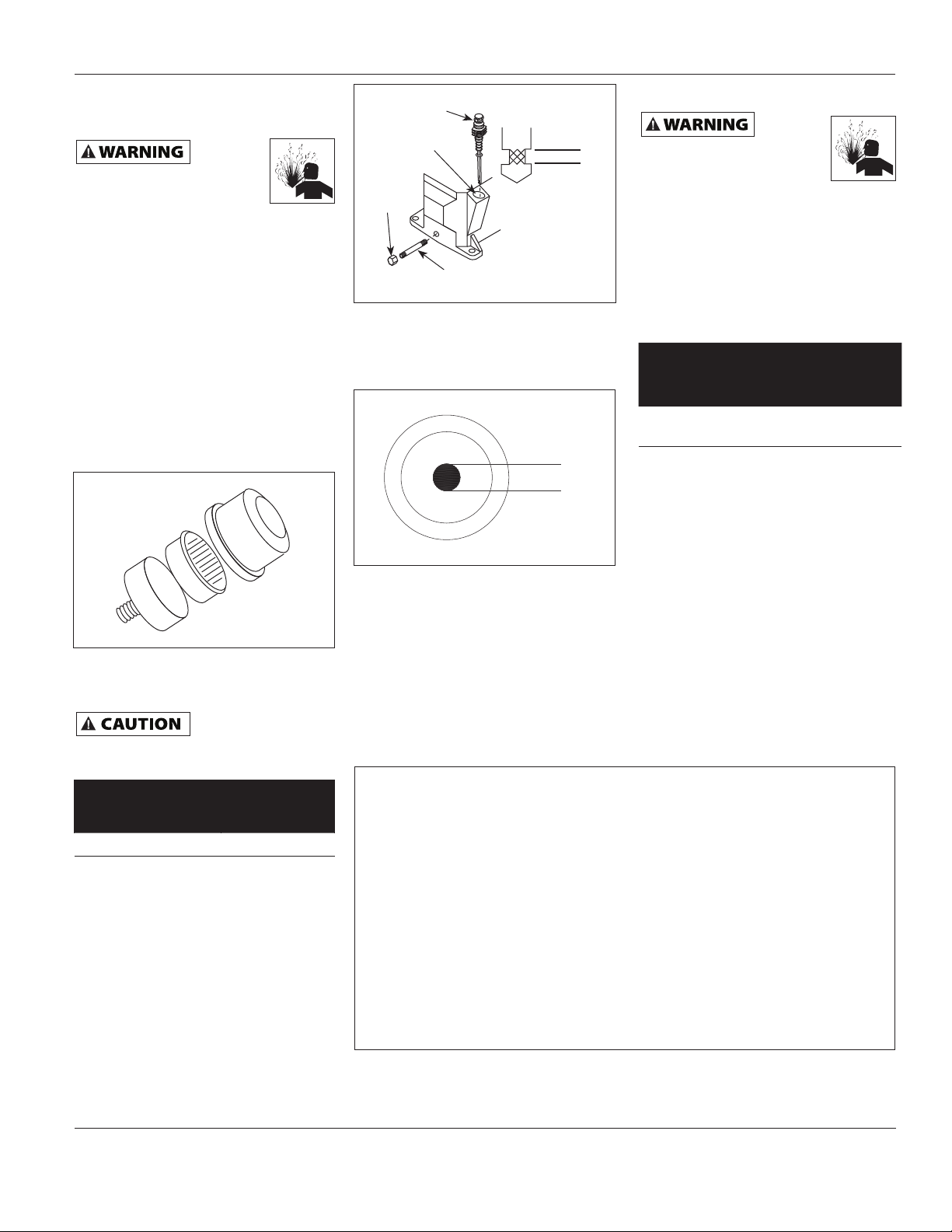

AIR FILTER INSTALLATION

1. Screw inlet filter into 1/2” NPT

threaded inlet port on compressor

head.

Dipstick

Breather

Full

Add Oil

Cap

Oil Drain Extension

(Not included with all models)

Figure 2 - Oil Fill

Max

Low

Add

For pumps with an oil sight glass, oil

level can be monitored and maintained

as shown in Figure 3.

Full

Add Oil

Maintenance

Release all pressure from the

system before attempting to

install, service, relocate or

perform any maintenance.

FOR EFFICIENT OPERATION BEFORE

EACH USE:

1. Check air filter.

2. Check oil level. Low oil level will

result in rapid wear and short pump

life.

TORQUE REQUIREMENTS (IN/LBS.)

Compressor

Model

All VT

Head Bolts

175-225 50-120

models

TECHNICAL SERVICE

For information regarding the

operation or repair of this product,

please call 1-800-543-6400.

Bearing

Cap Bolts

Figure 1 - Air Filter

LUBRICATION

This unit contains

no oil! Follow

lubrication instructions before

operating compressor.

Approximate

Oil Capacity

Model

(oz.)

VT4700 and VT4800 8.5

ALL MODELS

Ensure oil drain extension has been

installed (if included), then remove

the dipstick/breather and fill pump

with oil. Use SAE 30 Industrial Grade

compressor oil or full synthetic motor

oil like Mobil 1® 10W-30. Do not use

regular automotive oil such as 10W-30.

Additives in regular oil can cause valve

deposits and reduce pump life.

Proper oil fill is illustrated in Figure 2.

Figure 3

BREAK-IN

After installing compressor, start the

new pump and run without a load (0

PSI) for 30 minutes. With a pressure

regulator set to 40 PSI and no tool or

hose connected to the outlet, run the

compressor for another 30 minutes.

MOISTURE IN COMPRESSED AIR

Moisture in compressed air will form into droplets as it comes from an

air compressor pump. When humidity is high or when a compressor is in

continuous use for an extended period of time, this moisture will collect in the

tank. When using a paint spray or sandblast gun, this water will be carried from

the tank through the hose, and out of the gun as droplets mixed with the spray

material.

IMPORTANT: This condensation will cause water spots in a paint job, especially

when spraying other than water based paints. If sandblasting, it will cause the

sand to cake and clog the gun, rendering it ineffective.

A filter in the air line, located as near to the gun as possible, will help eliminate

this moisture.

www.chpower.com

3

Page 4

Operating Instructions

Maintenance (Continued)

MAINTENANCE SCHEDULE

Operation Daily Weekly 3 Months

Check Oil Level

Drain Any Tank Used

Check Air Filter

Change Oil

Insufficient oil change intervals will shorten pump life

l

l

l

l

Notes

www.chpower.com

4

Page 5

Single-Stage Compressor Pumps

Troubleshooting Chart

Symptom Possible Cause(s) Corrective Action

Low discharge pressure 1. Air leaks 1. Listen for escaping air. Apply soap solution to all fittings

and connections. Bubbles will appear at points of leakage.

Tighten or replace leaking fittings or connections

2. Slipping belts 2. Loosen motor clamping bolts and move the motor in

a direction away from the compressor, being sure that

the motor pulley is perfectly aligned with the flywheel.

Tighten motor clamping bolts. The belt should deflect

about 1/2 inch under 5-lbs of pressure. Do not “roll” belts

over pulleys

Pump overheating causes

air filter to melt

Excessive noise

(knocking)

Large quantity of oil in

the discharge air

NOTE: Oil lubricated

compressors will always

have a small amount of

oil in the air stream.

Water in discharge air/

tank

3. Air demand exceeds pump

capacity

4. Blown gaskets 4. Replace any gaskets proven faulty on inspection

5. Leaking valves 5. Remove head and inspect for valve breakage, misaligned

6. Restricted air intake 6. Clean the air filter element

7. Low compression 7. Low pressure can be due to worn rings and cylinder walls.

1. Broken valves/blown gasket 1. Replace valve or install new gasket

1. Loose motor or compressor

pulley

2. Lack of oil in crankcase 2. Check for proper oil level; if low, check for possible

3. Worn connecting rod 3. Replace connecting rod; maintain oil level and change oil

4. Worn piston pin bores 4. Remove piston assemblies from the compressor and

5. Worn bearings 5. Replace worn bearings and change oil

6. Piston hitting the valve plate 6. Remove the compressor head and valve plate and inspect

7. Noisy check valve in compressor

system

1. Worn piston rings 1. Replace with new rings. Maintain oil level and change oil

2. Compressor air intake restricted 2. Clean filter. Check for other restrictions in the intake

3. Excessive oil in compressor 3. Drain down to full level.

4. Wrong oil viscosity 4. Use Mobil 1

1. Normal operation. The amount

of water increases with humid

weather

3. Reduce air demand or use a compressor with more

capacity

valves, damaged valve seats, etc. Replace defective parts

and reassemble

Install a new head gasket each time the

head is removed

Correction is made by replacing the rings, cylinders, and

pistons as required

1. Loose motor or compressor pulleys are a very common

cause of compressors knocking. Tighten pulley clamp bolts

and set-screws

damage to bearings. Dirty oil can cause excessive wear

more frequently

inspect for excess wear. Replace excessively worn piston

pin or pistons, as required; maintain oil level and change

oil more frequently

for carbon deposits or other foreign matter on top of

piston. Replace head and valve plate using new gasket

7. Replace

more frequently.

system.

®

10W-30

1. Drain tank more often. At least daily.

2. Add a filter to reduce the amount of water in the air line.

www.chpower.com

5

Page 6

Operating Instructions

LIMITED WARRANTY

1. DURATION: From the date of purchase by the original purchaser as follows: One year.

2. WHO GIVES THIS WARRANTY (WARRANTOR): Campbell Hausfeld / Scott Fetzer Company, 100 Production Drive, Harrison,

Ohio, 45030, Telephone: (800) 543-6400.

3. WHO RECEIVES THIS WARRANTY (PURCHASER): The original purchaser (other than for purposes of resale) of the Campbell

Hausfeld compressor.

4. WHAT PRODUCTS ARE COVERED BY THIS WARRANTY: This Campbell Hausfeld single stage, air compressor pump.

5. WHAT IS COVERED UNDER THIS WARRANTY: Parts and Labor to remedy substantial defects due to material and

workmanship during the specific warranty period with the exceptions noted below. Parts only to remedy substantial defects

due to material and workmanship during remaining term of coverage with exceptions noted below.

6. WHAT IS NOT COVERED UNDER THIS WARRANTY:

A. Implied warranties, including those of merchantability and FITNESS FOR A PARTICULAR PURPOSE ARE LIMITED FROM

THE DATE OF ORIGINAL PURCHASE AS STATED IN THE DURATION. If the compressor is used for commercial, industrial

or rental purposes, the warranty will apply for ninety (90) days from the date of purchase. Some States do not allow

limitations on how long an implied warranty lasts, so the above limitations may not apply to you

B. ANY INCIDENTAL, INDIRECT, OR CONSEQUENTIAL LOSS, DAMAGE, OR EXPENSE THAT MAY RESULT FROM ANY DEFECT,

FAILURE, OR MALFUNCTION OF THE CAMPBELL HAUSFELD PRODUCT. Some States do not allow the exclusion or

limitations of incidental or consequential damages, so the above limitation or exclusion may not apply to you.

C. Any failure that results from an accident, purchaser’s abuse, neglect or failure to operate products in accordance with

instructions provided in the owner’s manual(s) supplied with compressor.

D. Pre-delivery service, e.g. assembly, oil or lubricants, and adjustment.

E. Items or service that is normally required to maintain the product, e.g. lubricants, filters and gaskets, etc.

F. Gasoline engines and components are expressly excluded from coverage under this limited warranty. The Purchaser

must comply with the warranty given by the engine manufacturer which is supplied with the product

G. Additional items not covered under this warranty:

1. Excluded items pertaining to All Compressors

a. Any component damaged in shipment or any failure caused by installing or operating unit under conditions not

in accordance with installation and operation guidelines or damaged by contact with tools or surroundings.

b. Pump or valve failure caused by rain, excessive humidity, corrosive environments or other contaminants.

c. Cosmetic defects that do not interfere with compressor functionality.

d. Damage due to incorrect voltage, improper wiring, rotation, or rotation speed.

e. Other items not listed but considered general wear parts.

f. Damage from inadequate filter maintenance.

2. Excluded items specific to Lubricated Compressors:

a. Pump wear or valve damage caused by using oil not specified.

b. Pump wear or damage caused by any oil contamination.

c. Pump wear or damage caused by failure to follow proper oil maintenance guidelines, operation below proper oil

level or operation without oil.

H. Labor, service call, or transportation charges after the first year of ownership of stationary compressors. Stationary

compressors are defined as not including a handle or wheels.

7. RESPONSIBILITIES OF WARRANTOR UNDER THIS WARRANTY: Repair or replace, at Warrantor’s option, compressor or

component which is defective, has malfunctioned and/or failed to conform within the duration of the specific warranty

period.

8. RESPONSIBILITIES OF PURCHASER UNDER THIS WARRANTY:

A. Provide dated proof of purchase and maintenance records.

B. Portable compressors or components must be delivered or shipped to the nearest Campbell Hausfeld Authorized Service

Center. Freight costs, if any, must be borne by the purchaser.

C. Use reasonable care in the operation and maintenance of the products as described in the owner’s manual(s).

D. Repairs requiring overtime, weekend rates, or anything beyond the standard manufacturer warranty repair labor

reimbursement rate.

E. Time required for any security checks, safety training, or similar for service personnel to gain access to facility.

F. Location of unit must have adequate clearance for service personnel to perform repairs and easily accessible.

9. WHEN WARRANTOR WILL PERFORM REPAIR OR REPLACEMENT UNDER THIS WARRANTY: Repair or replacement will be

scheduled and serviced according to the normal work flow at the servicing location, and depending on the availability of

replacement parts.

This Limited Warranty applies in the U.S., Canada and Mexico only and gives you specific legal rights. You may also have other

rights which vary from State to State or country to country.

www.chpower.com

6

Page 7

Voir la Garantie à la page 12 pour de l’information importante sur l’utilisation commercial de ce produit.

Instructions d’Utilisation Pompes Pour Compresseurs À Une Étage

Veuillez lire et conserver ces instructions. Lire attentivement avant de commencer à assembler, installer, faire fonctionner ou entretenir

l'appareil décrit. Protégez-vous et les autres en observant toutes les informations sur la sécurité. Négliger d'appliquer ces instructions peut

résulter en des blessures corporelles et/ou en des dommages matériels ! Conserver ces instructions pour références ultérieures.

Pompes Pour

Compresseurs

D’Air

Table des matières

Description . . . . . . . . . . . . . . . . . . . 7-Fr

Déballage . . . . . . . . . . . . . . . . . . . . 7-Fr

Directives De Sécurité . . . . . . . . . . . .7 Fr

Généralités Sur La Sécurité. . . . . . . .8 Fr

Montage . . . . . . . . . . . . . . . . . . . . . 9-Fr

Entretien . . . . . . . . . . . . . . . . . . . . . .9 Fr

Guide De Dépannage . . . . . . . . . . .11 Fr

Garantie limitée . . . . . . . . . . . . . . .12 Fr

Description

Les pompes de compresseurs d'air

lubrifiées à l'huile, monophases sont

à utiliser comme remplacements

des unités de compresseurs d'air

et aussi comme composants dans les

systèmes de compresseurs d'air de

conception spéciale. Pour l’utilisation

comme remplacement, la pompe

de compresseur doit correspondre

aux caractéristiques de vibration

de la pompe originelle. L’air

comprimé provenant de ces pompes

et prévue pour l’utilisation avec

les outils pneumatiques et les

pistolets vaporisateurs. L’humidité

atmosphérique et l’huile résiduelle des

compresseurs peuvent nécessiter des

traitements addtionnels pour certaines

applications. Tous les modèles sont

équipés de cylindres et carter en fonte,

culasse en aluminium et soupapes en

acier inoxydable.

Ce compresseur/pompe N’EST PAS équipé pour et NE DEVRAIT PAS être utilisé “comme

soi” pour fournir de l’air respirable. En cas d’applications d’air pour la consommation

humaine, le compresseur d’air/pompe doit être équipé avec de l’équipement de

sécurité en canalisation et d’alarme. Cet équipement additionnel est nécessaire pour

filtrer et purifier l’air afin d’atteindre les spécifications minimales pour la respiration

Grade D décrite dans le Compressed Gas Association Commodity Specification G 7.1 1966, OSHA 29 CFR 1910. 134, and/or Canadian Standards Associations (CSA).

DÉNÉGATION DES GARANTIES:

Si le compresseur est utilisé pour les applications d’air respirable et l’équipement de

sécurité en canalisation et d’alarme n’est pas utilisé simultanément, les garanties

en existance seront annulées, et Campbell Hausfeld nie toute responsabilité pour

n’importe quelle perte, blessure ou dommage.

Déballage

Dès que l’appareil est déballé, l’inspecter attentivement pour tout signe de

dommages en transit. S’assurer de resserrer tous les raccords, boulons, etc. avant de

le mettre en service.

Ne pas utiliser un modèle qui a été endommagé pendant le

résulter en explosion et peut causer des blessures ou dégâts matériels.

CONSERVER CES INSTRUCTIONS - NE LES JETEZ PAS

Directives de Sécurité

Ce manuel contient de l’information très importante qui est fournie pour la

SÉCURITÉ et pour ÉVITER LES PROBLÈMES D’ÉQUIPEMENT. Rechercher les symboles

suivants pour cette information.

Danger indique une situation hasardeuse imminente qui

Avertissement indique une situation hasardeuse potentielle

Attention indique une situation hasardeuse potentielle qui

Avis indique de l’information importante pour éviter le

REMARQUE: L’information qui exige une attention spéciale.

Avertissement D’Air Respirable

transport, la manipulation ou l’utilisation. Le dommage peut

LIRE ET SUIVRE TOUTES LES INSTRUCTIONS.

RÉSULTERA en perte de vie ou blessures graves.

qui PEUT résulter en perte de vie ou blessures graves.

PEUT résulter en blessures.

dommage de l’équipement.

MÉMENTO: Gardez votre preuve datée d'achat à fin de la garantie!

Joignez-la à ce manuel ou classez-la dans un dossier pour plus de sécurité.

© 2010 Campbell Hausfeld/Scott Fetzer IN228704AV 7/10

7-Fr

Page 8

Instructions d’utilisation

Généralités sur la Sécurité

PROPOSITION 65 DE CALIFORNIE

Ce produit ou son

cordon peuvent

contenir des produits chimiques qui, de

l’avis de l’État de Californie, causent le

cancer et des anomalies congénitales

ou autres problèmes de reproduction.

Lavez-vous les mains après la

manipulation.

GÉNÉRALITÉS SUR LA SÉCURITÉ

Puisque le compresseur d’air et les

autres pièces détachées (pompe,

pistolets, filtres, graisseurs, tuyaux,

etc.) font partie d’un système de haute

pression, il est nécessaire de suivre les

précautions suivantes:

1. Lire attentivement tous

manuels compris avec ce

produit. Se familiariser

avec ce produit, ses

commandes et son

utilisation.

2. Suivre tous les codes de sécurité

locaux ainsi que l’Occupational

Safety and Health Act (OSHA) des

É-U.

3. Seules les personnes bien

familiarisées avec ces règles

d’utilisation doivent être autorisées

à se servir du compresseur.

4. Garder les visiteurs à l’écart de/et NE

JAMAIS permettre les enfants dans

l’endroit de travail.

5. Utiliser des lunettes de sécurité

et la protection auditive pendant

l’utilisation du modèle.

6. Ne pas se tenir debout sur/ou utiliser

le modèle comme une prise à main.

7. Inspecter le système d’air comprimé,

le système d’essence et les pièces

détachées électriques pour

toute indication de dommage,

détérioration, faiblesse ou fuites

avant chaque utilisation. Réparer

ou remplacer toutes pièces

défectueuses avant l’utilisation.

8. Inspecter le degré de serrage de

toutes attaches par intervalles

régulières.

Les moteurs, l’équipement et

les commandes électriques

peuvent causer des arcs

électriques qui peuvent allumer un gaz

ou une vapeur inflammable. Ne jamais

utiliser ou réparer le modèle près d’un

gaz ou d’une vapeur inflammable. Ne

jamais entreposer les liquides ou gaz

inflammables près du compresseur.

Ne jamais faire fonctionner

un compresseur sans carter

de courroie. Les compresseurs

peuvent se démarrer sans avis. Le

contact avec les pièces mobiles peut

causer des blessures personnelles ou

dégâts matériels.

9. Ne pas porter des vêtements

flottants ou des bijoux qui peuvent

se prendre dans les pièces mobiles

du modèle.

Les pièces du compresseur

peuvent être chaudes, même

si le modèle est hors circuit.

10. Garder les doigts à l’écart du

compresseur; les pièces mobiles

et chaudes peuvent causer des

blessures et/ou des brûlures.

Les vibrations

peuvent causer le

craquement des réservoirs résultant en

éclatement. Ne pas installer une pompe

sur un réservoir qui n’est pas conçue

pour l’utilisation avec cette pompe.

11. Si l’équipement vibre anormalement,

ARRÊTER le moteur et l’inspecter

immédiatement. La vibration est

généralement une indication d’un

problème.

12. Pour réduire le risque d’incendie,

garder l’extérieur du moteur libre

d’huile, de solvant ou de graisse

excessive.

Ne jamais

enlever

ou

essayer d’ajuster la soupape de sûreté.

Garder la soupape de sûreté libre de

peinture et autres accumulations.

Ne jamais essayer de réparer ou de

modifier un réservoir! Le soudage,

perçage ou autre modifications peuvent

affaiblir le réservoir et peut résulter en

dommage de rupture ou d’explosion.

Toujours remplacer un réservoir usé,

fendu ou endommagé.

13. L’accumulation d’humidité cause la

rouille qui peut affaiblir le réservoir.

Purger le réservoir quotidiennement

et l’inspecter périodiquement pour

la rouille et la corrosion ou autre

dommage.

14. L’air mouvante peut agiter la

poussière et le débris qui peut être

dangereux. Lâcher l’air lentement

en purgeant l’humidité ou pendant

la dépressurisation du système de

compresseur.

15. Garder les tuyaux à l’écart des objets

pointus, déversements chimiques,

solvants d’huile et planchers

trempes car ceux-ci peuvent

endommager les tuyaux. Ne pas

faire fonctionner le compresseur

avec un(des) tuyau(x) endommagé(s)

ni suivant l’échappement ou le

dommage du/au compresseur ou aux

accessoires. Avertir votre centre de

service autorisé pour l’inspection,

la réparation ou n’importe quel

ajustement nécessaire.

POUR VT2030 ET VT2731 SEULEMENT

Air Libre pi∆/min à

40 psig 90 psig

Moteur En

Marche HP*

Moteur Campbell

Hausfeld

Recommandé No

De Pièce Pompe tr/min**

Dia. extérieur de

poulie de moteur

type Section-A*

2.0 MC015502IP 700 2,00 8,0 6,4

3.0 MC015403IP 1050 3,00 11,4 9,0

* Remarque: Le moteur devrait être un moteur de type compresseur, 3450 tr/min.

** Pour les vitesses de pompe plus basses que 700 tr/min, utiliser un moteur de 1750 tr/min avec la poulie appropriée.

Ne pas dépasser 1140 tr/min à 125 psig. Ceci peut caser du dommage à la pompe et annulera la garantie.

8-Fr

Page 9

Ne jamais utiliser

les tuyaux en

plastique (CPV) pour l’air comprimé.

Ceci peut résulter en blessures grâves

ou en perte de vie.

Montage

INSTRUCTIONS DE MONTAGE

Débrancher, étiquetter

et vérouiller la source de

puissance électrique et

dissiper toute la pression du système

avant d’essayer d’installer, réparer,

déplacer ou de procéder à l’entretien du

modèle.

VOLANT (VT2030 ET VT2731

SEULEMENT)

Placer le volant sur le vilebrequin

avec les filets de la vis de pression à

l’extérieur. Serrer la vis de pression à

19 lb-pi sur la clavette et la garder bien

serrée. Un volant dégagé peut causer

Pompes Pour Compresseurs À Une Étage

TOUS LES MODÈLES

S'assurer que la rallonge de vidange

d'huile a été installée (s'il y a lieu), puis

retirer la jauge/reniflard et remplir la

pompe d'huile. Utiliser de l'huile pour

compresseur de qualité industrielle SAE

30 ou une huile à moteur entièrement

synthétique telle que Mobil 1® 10W-

30. Ne pas utiliser d'huile à moteur

courante telle que la 10 W-30. Les

additifs de l'huile régulière peuvent

provoquer des dépôts dans la soupape

et réduire la durée de vie utile de la

pompe.

Le niveau d’huile correct est illustré sur

la Figure 2.

Reniflard de

la reglette-

jauge

Ajoutez

l’huile

Capuchon

Rallonge de vidange

(non inclus avec tous

d’huile

les modèles)

Figure 2 - Remplissage d’huile

Max

Low

Plein

Ajoutez

L’HUMIDITÉ DANS

L’AIR COMPRIMÉ

L’humidité dans l’air comprimé

forme des goutelettes en arrivant

de la pompe du compresseur.

Si l’humidité est élevée ou

si le compresseur est utilisé

continuellement, cette humidité

s’accumulera dans le réservoir. En

utilisant un pistolet à peinture

ou un pistolet pour décapage au

sable, cette eau sera transportée du

réservoir par moyen du tuyau, et

en forme de goutelettes mélangées

avec le matériel utilisé.

IMPORTANT: Cette condensation

peut avoir comme résultat des

tâches d’eau sur votre travail de

peinture, surtout en pulvérisant

la peinture à l’huile. Pendant la

décapage au sable, cette eau servira

à tenir le sable ensemble et à causer

une obstruction dans le pistolet.

Un filtre dans la ligne d’air situé

aussi proche du pistolet que

possible, peut aider à éliminer cette

humidité.

Entretien

Figure 1 - Filtre À Air

un cognement.

INSTALLATION DU FILTRE D'AIR

1. Visser le filtre d'aspiration dans

l'orifice d'entrée filetée de 1/2 po (13

mm) NPT sur la tête du compresseur.

GRAISSAGE

Ce modèle ne

contient pas

d’huile! Il est nécessaire de suivre

les instructions de graissage avant

d’utiliser le compresseur.

Capacité

D’Huile

Modèle

Approx. (litres)

VT4700 et VT4800 0,25 L

Pour les pompes dotées d’un regard

d’huile, on peut vérifier et maintenir le

niveau d’huile comme indiqué dans la

Figure 3.

Plein

Ajouter l’huile

Figure 3

RODAGE

Suivant le montage du compresseur,

démarrer la pompe et la faire

fonctionner sans charge (0 PSI) pendant

30 minutes. Avec le manomètre réglé à

40 PSI, et aucun outil ou tuyau branché

à l’orifice de sortie, faire fonctionner le

compresseur pour 30 minutes de plus.

Dissiper toute la pression

du système avant d’essayer

d’installer, réparer, déplacer

ou de procéder à l’entretien.

POUR UN FONCTIONNEMENT SÛR

AVANT CHAQUE UTILISATION:

1. Vérifier le filtre à air.

2. Vérifier le niveau d’huile. Un niveau

bas résultera en usure rapide et

une espérance de vie de la pompe

raccourcie.

EXIGENCES DE COUPLE (LB-PO.)

Modèle

VT

Boulons

À Tête De

Compresseur

175-225 50-120

Boulons À

Chapeau

De Palier

Modèles

SERVICE TECHNIQUE

Pour des informations concernant le

fonctionnement ou la réparation de ce

produit, composer le 1-800-543-6400.

9-Fr

Page 10

Instructions d’utilisation

Entretien (Suite)

HORAIRE D’ENTRETIEN

Fonctionnement Quotidiennement Hebdomadaire 3 Mois

Vérifier le niveau d’huile

Vidanger tout réservoir utilisé

Vérifier le filtre à air

Changer l’huile

Manque de changer l’huile par intervalles régulières raccourciera l’espérance de vie de la pompe

l

l

l

l

Notes

10-Fr

Page 11

Pompes Pour Compresseurs À Une Étage

Guide De Dépannage

Symptôme Cause(s) Possible(s) Mesures Correctives

Pression de débit basse 1. Fuites d’air 1. Écouter pour une fuite d’air. Appliquer une solution

2. Patinage de courroies 2. Desserrer les boulons de serrage du moteur et déplacer le

3. Demande d’air dépasse la

capacité de la pompe

4. Joints d’étanchéité en panne 4. Remplacer tous joints défectueux

5. Fuites de soupapes 5. Enlever la tête et rechercher tout dommage ou faiblesse de

6. Restriction dans la prise d’air 6. Nettoyer la cartouche filtrante

7. Compression basse 7. Les bagues et parois du cylindre usées peuvent causer la

Surchauffage de la

pompe fait fondre le

1. Soupapes cassées ou joint

d’étanchéité en panne

filtre

Bruit excessif

(cognement)

1. Moteur ou poulie du

compresseur lâche

2. Manque d’huile dans le carter 2. Inspecter le niveau d’huile; si bas, inspecter les paliers pour

3. Bielle usée 3. Remplacer la bielle; maintenir le niveau d’huile et changer

4. Alésages de l’axe de piston

usés

5. Paliers usés 5. Remplacer les paliers usés et changer l’huile

6. Piston qui frappe la plaque de

soupape

7. Clapet bruyant dans le système

de compresseur

Large quantité d’huile

1. Segments de piston usés 1. Remplacer les segments de piston. Entretenir le niveau

dans l’air de décharge

REMARQUE: Il y aura

toujours un peu d’huile

dans le jet d’air avec un

compresseur graissé par

l’huile.

2. Arrivée d’air du compresseur

limité

3. Huile excessive dans le

compresseur

4. Viscosité d’huile incorrecte 4. Utiliser l’huile Mobil 1

Eau dans l’air de débit/

réservoir

1. Fonctionnement normal. La

quantité d’eau augmentera si

le temps est humide

savonneuse sur tous raccords. Inspecter pour des bulles aux

endroits des fuites. Serrer ou remplacer les raccords qui ont

des fuites

moteur à l’écart du compresseur. S’assurer que la poulie du

moteur soit alignée parfaitement avec le volant. Serrer les

boulons de serrage du moteur. La courroie devrait dévier

approx. 1/2 po sous 5 livres de pression. Ne pas “rouler” les

courroies sur les poulies

3. Réduire la demande d’air ou utiliser un compresseur de

capacité plus élevée

soupapes, sièges de soupapes encochés, etc. Remplacer les

pièces défectueuses et rassembler

Assurer que le vieux joint de culasse soit

que la culasse est enlevée

remplacé avec un nouveau chaque fois

pression basse. Remplacer les bagues, cylindres, et pistons si

nécessaire

1. Remplacer la soupape ou installer un nouveau joint

d’étanchéité

1. Les poulies lâches du moteur ou du compresseur sont

souvant la source du cognement. Serrer les boulons et les vis

de serrage de la poulie

la possibilité de dommage. L’huile sale peut causer l’usure

excessive

l’huile plus souvant

4. Enlever les montages de piston du compresseur et inspecter

pour l’usure excessive. Remplacer l’axe de piston usé ou

le piston usés au besoin; maintenir le niveau d’huile et

changer l’huile plus souvant

6. Enlever la tête du compresseur et la plaque de soupape et

inspecter le haut du piston pour l’encrassement ou autres

matières. Remplacer la tête et la plaque en utilisant un joint

nouveau

7. Remplacer

d’huile correct et changer l’huile plus souvent.

2. Nettoyer le filtre. Vérifier le système d’arrivée pour autres

restrictions.

3. Vidanger jusqu’au niveau plein.

®

10W-30

1. Purger le réservoir plus souvent, au moins quotidiennement.

2. Ajouter un filtre pour diminuer la quantité d’eau dans la

canalisation d’air.

11-Fr

Page 12

Instructions d’utilisation

GARANTIE LIMITÉE

1. DURÉE: À partir de la date d’achat par l’acheteur original comme suit : Un an.

2. GARANTIE ACCORDÉE PAR (GARANT) :

Campbell Hausfeld/Scott Fetzer Company, 100 Production Drive, Harrison, Ohio, 45030, Téléphone: (800) 543-6400.

3. BÉNÉFICIAIRE DE CETTE GARANTIE (ACHETEUR) : L’acheteur original (sauf en cas de revente) du produit Campbell Hausfeld.

4. PRODUITS COUVERTS PAR CETTE GARANTIE : Cette pompe de compresseur d'air, monophase Campbell Hausfeld.

5. COUVERTURE DE LA PRÉSENTE GARANTIE : Les pièces et la main d'œuvre pour corriger les défauts importants à cause

de problèmes de matériaux et de main d'œuvre durant la période de garantie précise avec les exceptions indiquées

ci-dessous. Pièces seulement pour remédier à de défauts importants causés par matériau et main d’œuvre pendant le temps

restant de la couverture avec les exceptions indiquées ci-dessous.

6. LA PRÉSENTE GARANTIE NE COUVRE PAS :

A. Les garanties implicites, y compris celles de commercialisation et D’ADAPTATION À UNE FONCTION PARTICULIÈRE SONT

LIMITÉES À PARTIR DE LA DATE D’ACHAT INITIALE TELLE QU’INDIQUÉE DANS LA SECTION DURÉE. Si le compresseur d’air

est utilisé pour une fonction commerciale, industrielle ou pour la location, la durée de la garantie sera quatre-vingtdix (90) jours de la date d’achat. Certaines Provinces (États) n’autorisent pas de limitations de durée pour les garanties

implicites, donc les limitations précédentes peuvent donc ne pas s’appliquer.

B. TOUT DOMMAGE, PERTE OU DÉPENSE FORTUIT OU INDIRECT POUVANT RÉSULTER DE TOUT DÉFAUT, PANNE OU

MAUVAIS FONCTIONNEMENT DU PRODUIT CAMPBELL HAUSFELD. Quelques Provinces (États) n’autorisent pas

l’exclusion ni la limitation des dommages fortuits ou indirects. La limitation ou l’exclusion précédente peut donc ne pas

s’appliquer.

C. Toute panne résultant d’un accident, d’une utilisation abusive, de la négligence ou d’une utilisation ne respectant pas

les instructions données dans le(s) manuel(s) accompagnant le produit.

D. Service avant livraison; le montage, l’huile ou les lubrifiants et les réglages par exemple.

E. Articles ou services qui sont exigés normalement pour l’entretien du produit; par ex. lubrifiants, filtres et joints

d’étanchéité, etc.

F. Les moteurs à essence et les pièces détachées sont expressément exclus de cette garantie limitée. L’acheteur doit

observer la garantie du fabricant de moteur qui est fournie avec le produit.

G. Articles supplémentaires qui ne sont pas couverts sous cette garantie :

1. Articles exclus relatifs à Tous les Compresseurs

a. Toutes pièces détachées endommagées pendant l’expédition, n’importe quelle panne causée par un montage

ou fonctionnement du modèle sous des conditions qui ne se conforment pas aux directives de montage et de

fonctionnement ou dommage causé par le contact avec les outils ou les alentours.

b. La défaillance de la pompe ou de la soupape causée par la pluie, l’humidité excessive, un environnement corrosif

ou autres polluants.

c. Les défauts de forme qui n’ont pas d’effet sur le fonctionnement du compresseur.

d. Dommage dû à la mauvaise tension, l'installation de fils incorrecte, la rotation ou la vitesse de rotation.

e. Autres articles non indiqués mais considérés pièces d’usure générale.

f. Dommage causé par l’entretien insuffisant du filtre.

2. Compresseurs Graissés

a. Usure de la pompe ou dommage aux soupapes causé par l’utilisation d’huile non-spécifiée.

b. Usure de la pompe ou dommage aux soupapes causé par toute contamination d’huile ou par le manque de

suivre les directives d’entretien d’huile.

c. Usure ou dommage de la pompe causé par le manque de suivre les directives d’entretien d’huile, fonctionnement

avec le niveau d’huile au dessous du bon niveau ou fonctionnement sans huile.

H. Main d’œuvre, appel de service, ou frais de transport après le premier an de possession de compresseurs stationnaires.

Les compresseurs stationnaires sont identifiés par l’absence de manchon ou de roues.

7. RESPONSABILITÉS DU GARANT AUX TERMES DE CETTE GARANTIE : Réparation ou remplacement, au choix du Garant,

d’un compresseur ou d’un composant qui s'est révélé défectueux, qui a mal fonctionné et/ou qui s'est avéré non conforme

pendant la durée de garantie précise.

8. RESPONSABILITÉS DE L’ACHETEUR AUX TERMES DE CETTE GARANTIE :

A. Fournir une preuve d’achat datée et un état d’entretien.

B. La livraison ou expédition des compresseurs portatifs ou des pièces détachées au Centre De Service Autorisé Campbell

Hausfeld le plus près. Frais de transport, si applicables, sont la responsabilité de l’acheteur.

C. Utilisation et entretien du produit avec un soin raisonnable, ainsi que le décri(vent)t le(s) manuel(s) d’utilisation.

D. Réparations qui exigent de temps additionnel, taux de charge de fin de semaine, ou tout problème au-delà du taux

normal de remboursement par main d’œuvre de réparations sous garantie du fabriquant.

E. Temps nécessaire pour tout contrôle de sécurité, entraînement de sécurité, ou situation semblable parce que le

personnel de service puisse obtenir l’accès à l’installation.

F. L’emplacement de l’unité doit être facilement accessible et avoir l’espace suffisant parce que le personnel de service

puisse effectuer les réparations.

9. ÉPARATION OU REMPLACEMENT EFFECTUÉ PAR LE GARANT AUX TERMES DE LA PRÉSENTE GARANTIE : La réparation

ou le remplacement sera prévu et exécuté en fonction de la charge de travail dans le centre de service et dépendra de la

disponibilité des pièces de rechange.

Cette Garantie Limitée s’applique aux É.-U., au Canada et au Mexique seulement et vous donne des droits juridiques précis.

L’acheteur peut également jouir d’autres droits qui varient d’une Province, d’un État ou d’un Pays à l’autre.

12-Fr

Page 13

Consulte a Garantia na pagina 18 para informação importante sobre o uso comercial deste produto.

Instruções de Uso Bombas de Compressor de uma Fase

Por favor, leia e guarde essas instruções. Leia com atenção antes de tentar montar, instalar, usar ou fazer manutenção no produto descrito.

Siga todas as informações de segurança para proteger a si mesmo e a outras pessoas; caso contrário, podem ocorrer lesões pessoais e/ou danos

materiais! Guarde essas instruções para futuras consultas.

Cabeçotes do

Compressor de

Ar

Índice

Descrição . . . . . . . . . . . . . . . . . . . . 13-Pg

Remoção da Embalagem . . . . . . . 13-Pg

Normas de Segurança. . . . . . . . . . 13-Pg

Informações Gerais de Segurança 14-Pg

Montagem. . . . . . . . . . . . . . . . . . . 15-Pg

Manutenção . . . . . . . . . . . . . . . . . 15-Pg

Gráfico de Resolução

de Problemas. . . . . . . . . . . . . . . . 17-Pg

Garantia. . . . . . . . . . . . . . . . . . . . . 18-Pg

Descrição

Bombas compressoras de ar de

estágio único, lubrificadas a óleo,

cuja finalidade é a reposição em

unidades de compressor, e uso

como componentes em sistemas

de compressor de ar especialmente

projetados. O cabeçote de compressão

de reposição deve corresponder às

características de vibração da bomba

original. O ar comprimido dessas

cabeçotes é destinado ao uso com

ferramentas de ar comprimido e pistolas

de pulverização. A umidade atmosférica

e os resíduos de óleo dos compressores

podem requerer tratamento adicional

para certas aplicações. Todos os

modelos são equipados com cilindros

e cárter de ferro fundido sólido,

cabeçote de alumínio e válvulas de aço

inoxidável.

Este compressor/cabeçote NÃO está equipado, e não deve ser usado, do modo como

está, para o fornecimento de ar de qualidade respirável. Para qualquer aplicação do ar

para consumo humano, esta unidade necessitará ser adaptada com equipamento de

alarme e de segurança em linha apropriado. Este equipamento adicional é necessário

para filtrar e purificar o ar apropriadamente para que preencha as especificações

mínimas de grau D como descrito Compressed Gas Association Commodity

Specification G 7.1 - 1966, OSHA 29 CFR 1910. 134 e/ou Canadian Standards

Association (CSA).

EXONERAÇÃO DE RESPONSABILIDADE:

No caso do compressor ser usado em aplicações de ar respirável e o equipamento de

alarme de segurança em linha não forsimultaneamente usado, as garantias existentes

são anuladas e a Campbell Hausfeld se exime de qualquer responsabilidade no que diz

respeito a qualquer perda, danos pessoais ou ao equipamento.

Remoção da Embalagem

Al desempacar este producto, revíselo con cuidado para cerciorarse de que esté en

perfecto estado. Aperte firmemente conexões, parafusos, etc., antes de colocar a

unidade em operação.

Não ponha o equipamento para funcionar se houve danos

causados pelo transporte, manuseio e uso. Danos podem

resultar em explosão e causar acidente pessoais e danos à propriedade.

GUARDE ESTAS INSTRUÇÕES - NÃO DESCARTE

Normas de Segurança

Este manual contém informações muito importantes que devem ser conhecidas e

compreendidas. Essas informações são fornecidas para SEGURANÇA e para EVITAR

PROBLEMAS NO EQUIPAMENTO. Para ajudar a reconhecer essas informações,

observe os seguintes símbolos.

Perigo indica uma situação iminentemente perigosa que, se

não for evitada, RESULTARÁ em morte ou ferimentos graves.

Aviso indica uma situação potencialmente perigosa que, se não

for evitada, PODE resultar em morte ou ferimentos graves.

Cuidado indica uma situação potencialmente perigosa que, se

não for evitada, PODE resultar em ferimentos leves a

moderados.

Nota indica informações importantes que, se não forem

seguidas, podem causar danos ao equipamento.

NOTA: Informação que requer atenção especial.

Alerta Sobre Ar Respirável

LEIA E SIGA TODAS AS INSTRUÇÕES

LEMBRETE: Guarde sua comprovação de compra datada até o fim da garantia!

Junte-a a este manual o arquive-a para mais segurança.

© 2010 Campbell Hausfeld/Scott Fetzer IN228704AV 7/10

13-Pg

Page 14

Instruções de Uso

Informações Gerais de

Segurança

PROPOSIÇÃO 65 DA CALIFÓRNIA

Esse produto, ou o

seu cabo de

alimentação, pode conter substâncias

conhecidas no Estado da Califórnia por

causarem câncer, defeitos congênitos

ou outras lesões ao sistema reprodutor.

Lave as mãos após o manuseio.

SEGURANÇA GERAL

Uma vez que o compressor de ar e

outros componentes usados (cabeçotes,

pistolas, filtros, lubrificadores,

mangueiras, etc.) fazem parte de

um sistema de bombeamento sob

alta pressão, as seguintes precauções

de segurança devem ser sempre

observadas:

1. Ler com atenção todos

manuais que venham

junto com o produto.

Ficar completamente

familiarizado com os

controles e com o uso apropriado do

equipamento.

2. Siga todos os códigos elétricos e

de segurança locais como também

os do NEQ (Códigos Elétricos

Nacionais) e da OSHA (Ato de Saúde

e Segurança Ocupacional) nos E.U.A.

3. Apenas as pessoas que estão bem

cientes das regras de segurança

devem ser autorizadas a usar o

compressor.

4. Manter longe qualquer observador

e NUNCA permitir a presença de

crianças na área do serviço.

5. Use óculos de segurança e proteção

para ouvidos quando operar o

equipamento.

6. Não fique em pé no equipamento e

nem se apoie nele.

7. Antes de cada uso, inspecione o

sistema de ar comprimido e os

componentes elétricos para sinais de

danos, deterioração, vazamento, ou

fraqueza. Conserte ou renove peças

com defeitos antes de usar.

8. Verifique todos os ajustamentos e

pinos com freqüência para assegurar

a tensão correta.

Motores e equipamentos

elétricos podem causar arcos

voltaicos que acenderão gás

ou vapor inflamável. Nunca opere ou

faça reparos dentro ou perto de gás ou

vapor inflamável. Nunca guarde líquido

ou gás inflamável na vizinhança do

compressor.

Nunca opere o compressor

sem o protetor de cinto.

A máquina pode ligarse

automaticamente sem aviso. Acidente

pessoal ou danos na propriedade

podem acontecer pelo contato com

peças em funcionamento.

9. Nunca use roupa largas ou jóias que

podem ser presas no movimento das

peças do equipamento.

As partes do compressor

podem estar quentes mesmo

com a unidade parada.

10. Mantenha os dedos fora do

compressor em funcionamento;

peças em movimento e quentes,

podem causar acidentes e\ou

queimaduras.

As vibrações

podem causar

rachaduras nos tanques e acarretar

explosão. Não instale o cabeçote em

tanque que não seja projetado para uso

com o cabeçote específica.

11. Se o equipamento começar vibrar

de forma anormal, DESLIGUE o

motor e verifique imediatamente a

causa. Geralmente, vibração é uma

advertência de problemas.

12. Para reduzir perigo de fogo,

mantenha o exterior do motor limpo

e livre de óleo, solvente ou graxa em

excesso.

Nunca tente fixar

ou remover a

válvula de segurança. Mantenha a

válvula de segurança livre de tinta e

outras acumulações.

Nunca tente consertar ou

modificar o tanque! Soldar,

furar ou qualquer outra

modificação fará o tanque ficar mais

fraco e pode resultar em danos por

causa de rupturas ou explosão. Sempre

substitua tanques quebrados ou

estragados pelo uso.

13. A ferrugem causada pela umidade

acumulada faz o tanque ficar

fraco. Certifique se que o tanque

seja esvaziado regularmente e

inspecione periodicamente para

evitar condições não seguras como a

corrosão e ferrugem.

14. O movimento rápido de ar

agitará poeira e escombros que

podem causar dano. Solte o ar

devagar quando drenar umidade

ou despressurizar o sistema do

compressor.

15. Manteha as mangueiras distantes

de objetos cortantes, vazamentos

de substâncias químicas, solventes

de óleos e pisos úmidos que possam

danificar a mangueira. Não operar

o compressor se a(s) mangueira(s)

estiver(em) danificada(s), ou depois

que o compressor, ou acessórios,

tenham caído no chão, ou forem

danificados. Notificar o serviço

VT2030 E VT2731 SOMENTE

Codigo Da

Vazão Livre PCM @

Peça Campbell

Diâmetro Ext.

Da Secção-A Da

Polia Do Motor*

40 lbs 90 lbs

Potência Do

Motor HP*

Hausfeld

Do Motor

Recomendada Cabeçote RPM**

2.0 MC015502IP 700 2,00 8,0 6,4

3.0 MC015403IP 1050 3,00 11,4 9,0

* Nota: O motor deve estar a 3450 RPM em regime de trabalho.

** Para cabeçotes com rotações inferior a 700 RPM use um motor de 1750 RPM com polia apropriada.

Não exceda 1140 RPM a 125 lbs ou poderá ocorrer danos no cabeçote e a garantia perderá a validade.

14-Pg

Page 15

Bombas de Compressor de uma Fase

autorizado mais próximo para que

um exame, reparo, ou outro ajuste

seja feito.

Nunca use

tubulação de

plástico (PVC) para ar comprimido. Isto

pode resultar em ferimentos graves ou

morte.

Montagem

INSTRUÇÕES DE MONTAGEM

Desconecte, etiquete e trave

a fonte elétrica e daí solte

toda a pressão do sistema

antes de tentar instalar, consertar,

mudar de lugar ou executar qualquer

manutenção.

POLIA (VT2030 E VT2731 SOMENTE)

Posicione a polia no eixo e aparafuse

mantendo-o suficientemente apertado

para que a mesma não fique frouxa

causando vibrações e ruidos, reduzindo

a vida útil do cabeçote.

INSTALAÇÃO DE FILTRO DE AR

1. Atarraxar o filtro de entrada na

porta de entrada de fibra de 1/2”

NPT sobre a cabeça do compressor.

Figura 1 - Filtro de Ar

LUBRIFICAÇÃO

ESTA UNIDADE É

ENTREGUE SEM

ÓLEO! Siga as instruções de lubrificação

antes de ligar o compressor.

Capacidade

Aproximada de

Modelo

VT4700 e VT4800 0,25 L

Óleo

TODOS OS MODELOS

Certifique-se de que a extensão de

drenagem de óleo tenha sido instalada

(se incluída), então remova a vara de

medição/respiro e encha a bomba

com óleo.Utilize óleo para compressor

Industrial Grade SAE30 ou óleo sintético

para motor, tal como o Mobil 1® 10W-

30. Não use óleo automotivo regular

tal como 10W-30. Os aditivos no óleo

regular podem causar depósitos na

válvula e reduzir a vida útil da bomba.

Veja figura 2 para enchimento correto

do óleo.

Respirador

da vareta de

Tampa

Figura 2 - Abastecer Óleo

óleo

Adicionar

óleo

Cheio

Max

Low

Abastecer

Extensão de drenagem de

(Não incluído com todos os

óleo

modelos)

Para as bombas com um vidro da

vista do óleo, o nível de óleo pode ser

monitorado e mantido como mostrado

em figura 3.

Completamente

Adicione o

óleo

Figura 3

PRIMEIRO FUNCIONAMENTO

Depois de instalar o compressor deixe-o

ligado por 30 minutos sem carga. Apos

deixe mais 30 minuto com o regulador

de pressão em 40 LBS. e nenhuma

ferramenta ou mangueira conectada.

UMIDADE NO AR COMPRIMIDO

A umidade no ar comprimido toma

a forma de gotas a medida que o

ar sai da bomba do compressor.

Quando a umidade for alta, ou

quando um compressor estiver em

uso contínuo por um período de

tempo prolongado, esta umidade

será coletada no tanque. Quando

usando um vaporizador de tinta ou

pistola de jato de areia, esta água

será levada do tanque através da

mangueira e para fora da pistola na

forma de gotas misturadas com o

material da vaporização.

Importante: Esta condensação

causará manchas de água em um

trabalho de pintura, especialmente

quando vaporizando com tintas

cuja base não é a água. Se estiver

jateando com areia, elas farão

com que a areia forme um bolo

obstruindo a pistola e tornando-a

inoperante.

Um filtro na linha de ar, localizado

tão próximo quanto possível da

pistola, ajudará a eliminar esta

umidade.

Manutenção

Desconectar da força e liberar toda

a pressão do sistema antes de tentar

instalar, fazer serviços, transportar,

ou realizar qualquer manutenção no

equipamento.

PARA UMA OPERAÇÃO EFICIENTE

ANTES DE CADA USO:

1. Verificar o filtro de ar.

2. Verifique o nível do óleo.

O óleo baixo causará

o desgaste rápido e

encurtará a vida útil da

bomba.

REQUERIMENTOS DE TORQUE

(polegadas/libras)

Modelo

VT

Modelos

Parafusos

da Cabeça do

Compressor

175-225 50-120

Parafusos

Tampa do

mancal

15-Pg

SERVIÇO TÉCNICO

Para informações sobre a operação ou

reparo deste produto, ligue para

1-800-543-6400 (nos EUA).

Page 16

Instruções de Uso

Manutenção (Continuação)

PROGRAMA DE MANUTENÇÃO

Operação Diariamente Semanalmente 3 Meses

Verificar o nível do óleo

Drenar qualquer tanque

utilizado

Verificar o filtro de ar

Trocar o óleo

Intervalos insuficientes de troca de óleo encurtam a vida útil do cabeçote.

l

l

l

l

Notas

16-Pg

Page 17

Bombas de Compressor de uma Fase

Gráfico de Resolução de Problemas

Síntoma Causa Possível Ação Corretiva

Baixa pressão de

descarga

O superaquecimento do

cabeçote faz o filtro de

ar derreter

Ruído excessivo

(batendo)

Grande quantidade de

óleo no ar de descarga

OBSERVAÇÃO:

Os compressores

lubrificados a óleo

sempre terão uma

pequena quantidade de

óleo na corrente de ar.

Água no ar/tanque de

descarga

1. Vazamentos de ar 1. Preste atenção para ouvir vazamento de ar. Aplique uma

solução de sabão em todos os acoplamentos e conexões. O

vazamento produzirá bolhas de ar. Aperte ou substitua o

acoplamento ou conexão com vazamento.

2. Correias patinando 2. Afrouxe os parafusos de fixação e mova o motor na direção

oposta do compressor, certificando-se de que a polia

do motor esteja perfeitamente alinhada com o volante.

Aperte os parafusos de fixação. A correia deve desviar

aproximadamente 13 mm sob a pressão de 5 lbs. Não

“role” as correias sobre a polia.

3. A demanda de ar excede a

capacidade do cabeçote

3. Reduza a demanda de ar ou use um compressor com mais

capacidade.

4. Juntas danificadas 4. Substitua as juntas que estiverem danificadas.

5. Válvulas com vazamento 5. Remova o cabeçote e procure por quebras nas válvulas,

válvulas fora de alinhamento, danos nas sedes das válvulas,

etc. Substitua as peças que estiverem defeituosas e monte

outra vez.

Instale uma nova junta toda vez que o

6. Admissão de ar obstruída 6. Limpe o elemento do filtro de ar.

7. Baixa compressão 7. A baixa pressão pode ocorrer devido ao desgaste dos

anéis e das paredes do cilindro. A correção desse problema

é feita substituindo os anéis, os cilindros e os pistões

conforme necessário.

1. Válvulas quebradas/junta

1. Substitua a válvula ou instale uma nova junta

danificada

1. Motor ou polia do compressor

solta

1. Motor ou polia do compressor solta são causas muito

comuns de batida do compressor. Aperte os parafusos de

fixação da polia e os parafusos de ajuste.

2. Perda de óleo no cárter 2. Cheque o nível do óleo. Se estiver baixo, verifique se há

algum dano nos mancais. Óleo sujo pode causar desgaste

excessivo.

3. Desgaste da biela 3. Substitua a biela, mantenha o nível correto do óleo e

troque de óleo mais frequentemente

4. Desgaste da bucha do pino do

pistão

4. Remova os conjuntos dos pistões do compressor e verifique

se há desgaste excessivo. Substitua os pinos ou os pistões

desgastados conforme necessário, mantenha o nível

correto do óleo e troque o óleo mais frequentemente

5. Mancais gastos 5. Substitua os mancais gastos e troque de óleo

6. O pistão bate na placa da

válvula

6. Remova o cabeçote do compressor e a placa da válvula e

verifique se há depósitos de carbono ou outros materiais

estranhos no topo do pistão. Recoloque o cabeçote e a

válvula usando uma nova junta

7. Válvula de retenção ruidosa no

7. Substitua a válvula

sistema do compressor

1. Anéis de pistão gastos 1. Substituir por novos anéis. Manter o nível de óleo

e trocá-lo com frequência.

2. Absorção de ar do compressor

restrita

2. Limpar o filtro. Procurar por outras restrições no sistema

de entrada.

3. Excesso de óleo no compressor 3. Esvaziar até o nível do combustível.

4. Viscosidade de óleo errada 4. Usar Mobil 1

1. Operação normal. A

quantidade de água aumenta

com clima úmido

1. Esvaziar o tanque com maior frequência. Pelo menos uma

vez ao dia.

2. Adicionar um filtro para reduzir a quantidade de água na

linha de ar.

cabeçote for removido.

®

10W-30

17-Pg

Page 18

Instruções de Uso

GARANTIA LIMITADA

1. DURAÇÃO: A partir da data de compra pelo comprador original como segue: Um ano.

2. QUEM CONCEDE ESTA GARANTIA (GARANTIDOR):

Campbell Hausfeld/Scott Fetzer Company, 100 Production Drive, Harrison, Ohio, 45030, Telefone: (800) 543-6400

3. QUEM RECEBE ESTA GARANTIA (COMPRADOR): O comprador original (não para objetivo de revenda) do compressor da

Campbell Hausfeld.

4. QUAIS SÃO OS PRODUTOS COBERTOS POR ESTA GARANTIA: Esta bomba de compressor de ar de estágio único

Campbell Hausfeld.

5. O QUE ESTÁ COBERTO NESTA GARANTIA: Peças e Mão de obra para consertar defeitos substanciais devido a material

ou mão de obra, durante o período específico da garantia, com as exceções notadas abaixo. Apenas peças para remediar

defeitos substanciais causados por material e mão-de-obra durante o período restante de cobertura exceto os itens

mencionados adiante.

6. O QUE NÃO ESTÁ COBERTO NESTA GARANTIA:

A. Garantias implícitas, incluindo as de comercialidade e ADEQUAÇÃO PARA UM OBJETIVO ESPECÍFICO SÃO LIMITADAS

A PARTIR DA DATA DA COMPRA ORIGINAL CONFORME DECLARADO NO ITEM “DURAÇÃO”. Se o compressor for

usado para fins comerciais, industriais ou para aluguel, a garantia terá a duração de noventa (90) dias a partir da data

de compra. Alguns estados (nos Estados Unidos) não permitem limites referentes ao prazo de duração da garantia

implícita, de forma que os limites acima podem não se aplicar no seu caso.

B. QUALQUER PERDA, DANO OU DESPESA INCIDENTAIS, INDIRETOS OU RESULTANTES QUE POSSAM RESULTAR DE

QUALQUER DEFEITO, FALHA OU MAU FUNCIONAMENTO DOS PRODUTOS DA CAMPBELL HAUSFELD. Alguns estados

(nos Estados Unidos) não permitem a exclusão ou limite de danos incidentais ou resultantes, de forma que o limite e

exclusão acima podem não se aplicar ao seu caso.

C. Qualquer falha resultante de acidente, abuso por parte do comprador, negligência ou da não operação do produto de

acordo com as instruções no(s) manual(ais) do proprietário que acompanha(m) este compressor.

D. Serviço de pré-entrega, ex. montagem, óleo ou lubrificantes e ajustes.

E. Itens ou serviços que sejam normalmente exigidos para manter o produto, ex. lubrificantes, filtros, vedação e etc.

F. Motores e componentes a gasolina são expressamente excluídos da cobertura de acordo com esta garantia limitada.

O comprador deve cumprir com as exigências da garantia fornecida pelo fabricante do motor que acompanha

o produto.

G. Itens adicionais não cobertos de acordo com esta garantia.

1. Itens excluídos referentes a Todos os Compressores

a. Todos os componentes danificados durante a remessa ou qualquer falha causada pela instalação ou operação

da unidade sob condições que não estejam em conformidade com as diretrizes de instalação e operação ou

danificados devido a contatos com ferramentas ou arredores.

b. Falha da bomba ou válvula causada por chuva, umidade excessiva, ambientes corrosivos ou outros

contaminantes.

c. Defeitos cosméticos que não interfiram com a funcionalidade do compressor.

d. Danos devido à voltagem incorreta ou cabeamento, rotação ou velocidade de rotação inadequados.

e. Outros itens não listados mas considerados como peças de desgaste geral.

f. Dano causado por manutenção inadequada do filtro.

2. Compressores lubrificados

a. Desgaste da bomba ou dano das válvulas causados pelo uso de óleo não especificado.

b. Desgaste da bomba ou dano das válvulas causados por qualquer contaminação de óleo ou pela não obediência

das diretrizes apropriadas da manutenção de óleo.

c. Desgaste ou dano à bomba causado por falha em seguir as diretrizes adequadas de lubrificação, operação com

óleo abaixo do nível adequado ou operação sem óleo.

H. Taxas de serviços, solicitação de serviços ou de transporte após o primeiro ano de propriedade dos compressores fixos.

Compressor estacionário definido por não ter alça o rodas.

7. RESPONSABILIDADES DO GARANTIDOR DE ACORDO COM ESTA GARANTIA: Consertar ou repor, à escolha do Garantido,

o compressor ou componente que esteja defeituoso, com mau funcionamento e/ou que não tenha estado em

conformidade dentro da duração do período de garantia específico.

8. RESPONSABILIDADES DO COMPRADOR DE ACORDO COM ESTA GARANTIA:

A. Fornecer comprovante de compra datado e registros de manutenção.

B. Os compressores ou componentes portáteis devem ser entregues ou remetidos ao mais próximo Centro de Serviço

Autorizado da Campbell Hausfeld.Os custos de frete, se houver, devem ser por conta do comprador.

C. Usar cuidado adequado na operação e manutenção dos produtos conforme descrito no(s) manual(ais) do proprietário.

D. Reparos com necessidade de hora extra, taxas de fins de semana ou algo que não esteja incluído na taxa de reembolso

padrão para serviços de reparo pelo fabricante.

E. Tempo necessário para quaisquer verificações de segurança, treinamento de segurança ou procedimento semelhante ao

pessoal de serviços para ter acesso à instalação.

F. O local da unidade deve ter espaço adequado para o pessoal de serviços realizar os reparos e deve ser facilmente

acessível.

9. QUANDO O GARANTIDOR IRÁ CONSERTAR OU SUBSTITUIR DE ACORDO COM ESTA GARANTIA: Consertos ou substituições

serão programados e realizados de acordo com o fluxo de trabalho normal no local de conserto e dependendo da

disponibilidade da peças de substituição.

Esta garantia limitada é valida somente nos E.U.A., no Canadá e no México e oferece direitos legais específicos. Você pode

também ter outros direitos que variam de um estado para outro (nos Estados Unidos), ou de um país para outro.

18-Pg

Page 19

Ver la Garantía en página 24 para información importante sobre el uso comercial de este producto.

Manual de Instrucciones de Operación Para Compresores De 1 Etapa

Por favor lea y guarde estas instrucciones. Léalas cuidadosamente antes de tratar de montar, instalar, operar o dar mantenimiento al producto

aquí descrito. Protéjase usted mismo y a los demás observando toda la información de seguridad. ¡El no cumplir con las instrucciones puede

ocasionar daños, tanto personales como a la propiedad! Guarde estas instrucciones para referencia en el futuro.

Bombas de

compresor

Índice

Descripción . . . . . . . . . . . . . . . . . . 19-Sp

Desempaque . . . . . . . . . . . . . . . . . 19-Sp

Medidas de Seguridad . . . . . . . . . 19-Sp

Informaciones Generales

de Seguridad . . . . . . . . . . . . . . . . 20-Sp

Ensamblaje . . . . . . . . . . . . . . . . . . 21-Sp

Mantenimiento. . . . . . . . . . . . . . . 21-Sp

Guía de Diagnóstico de Averías. . 23-Sp

Garantía Limitada . . . . . . . . . . . . . 24-Sp

Descripción

Las bombas para compresores de aire

lubricadas con aceite de una fase están

diseñadas para utilizarse como repuesto

en unidades compresoras de aire y como

componentes en sistemas compresores

de aire diseñados especialmente.

Al usarlos para reemplazar el cabezal

de un compresor, cerciórese de que el

cabezal esté di-señado para la vibración

del cabezal original. Estos cabezales

están diseñados para suministrale

aire comprimido a herramientas

neumáticas y pistolas pulverizadoras.

En ciertos casos, deberá proveer

tratamientos adicionales para eliminar

la humedad atmosférica y los residuos

de aceite. Todos los modelos tienen

cilindros y caja de cigüeñal de hierro

colado sólido, culatas de aluminio

y válvulas de acero inoxidable.

Este compresor/cabezal NO VIENE listo de fábrica para suministrarle aire respirable

y NO SE DEBE usar con este fin. Antes de utilizarlos con este fin, deberá instalarle

un sistema de seguridad y alarma incorporado a la línea. Este sistema adicional

es necesario para filtrar y purificar el aire adecuadamente, para cumplir con las

especificaciones mínimas sobre aire respirable de Grado D descritas en la Especificación

de Productos G.7.1.1966 de la Asociación de Gases Comprimidos.Igualmente, deberá

cumplir los requisitos establecidos por el Artículo 29 CFR 1910.134 de la Organización

norteamericana OSHA y/o la Canadian Standards Associations (CSA).

RENUNCIA A LAS GARANTIAS:

Si el compresor se utiliza para producir aire respirable SIN haberle instalado el

sistema de seguridad y alarma, todas la garantías se anularán y la compañía Campbell

Hausfeld no asumirá NINGUNA responsabilidad por pérdidas, heridas personales o

daños.

Desempaque

Al desempacar este producto, revíselo con cuidado para cerciorarse de que esté en

perfecto estado. Cericiórese de apretar todas las conexiones, pernos, etc. antes de

comenzar a utilizar la unidad.

No debe utilizar la unidad si se ha dañado durante el envío,

ocasionarle heridas o daños a su propiedad.

GUARDE ESTAS INSTRUCCIONES – NO LAS DESECHE

Medidas de Seguridad

Este manual contiene información que es muy importante que sepa y comprenda.

Esta información se la suministramos como medida de SEGURIDAD y para EVITAR

PROBLEMAS CON EL EQUIPO. Debe reconocer los siguientes símbolos.

Ésto le indica que hay una situación inmediata que LE

Ésto le indica que hay una situación que PODRIA ocasionarle la

Ésto le indica que hay una situación que PODRIA ocasionarle

Ésto le indica una información importante, que de no seguirla,

NOTA: Información que requiere atención especial.

Advertencia sobre el aire respirable

manejo o uso. Los daños podrían ocasionar una explosión y

LEA Y SIGA TODAS LAS INSTRUCCIONES

OCASIONARIA la muerte o heridas de gravedad.

muerte o heridas de gravedad.

heridas no muy graves.

le podría ocasionar daños al equipo.

RECORDATORIO: ¡Guarde su comprobante de compra con fecha para fines de la garantía!

Adjúntela a este manual o archívela en lugar seguro.

© 2010 Campbell Hausfeld/Scott Fetzer IN228704AV 7/10

19-Sp

Page 20

Manual de Instrucciones de Operación

Informaciones Generales de

Seguridad

PROPOSICIÓN 65 DE CALIFORNIA

Este producto, o

su cordón eléctrico,

puede contener productos químicos

conocidos por el estado de California

como causantes de cáncer y defectos de

nacimiento u otros daños reproductivos.

Lave sus manos después de usar.

INFORMACIONES GENERALES DE

SEGURIDAD

Como el compresor de aire y otros

componentes usados (cabezales, pistolas

pulverizadoras, filtros, lubricadores,

mangueras, etc.), forman parte de un

sistema de bombeo de alta presión,

deberá seguir las siguientes medidas de

seguiridad todo el tiempo:

1. Lea con cuidado todos

los manuales incluídos

con este producto.

Familiarícese con los

controles y el uso adecuado del

equipo.

2. Siga todos los códigos de seguridad

laboral establecidos en su país, por

ejemplo, los de la OSHA en EE.UU.

3. Este compresor sólo debe ser usado

por personas que estén bien familiarizadas con las reglas de seguridad

de manejo.

4. Mantenga a los visitantes alejados

y NUNCA permita la presencia de

niños en el área de trabajo.

5. Siempre use anteojos de seguridad

y protéjase los oídos para operar el

cabezal o el compresor.

6. No se encarame sobre el cabezal ni

lo use para sostenerse.

7. Antes de cada uso, inspeccione el

sistema de aire comprimido, sistema

de combustible y los componentes

eléctricos para ver si están dañados,

deteriorados, desgastados o tienen

fugas. Repare o reemplace las piezas

dañadas antes de usar el equipo.

8. Chequée todas las conexiones

frecuentemente para cerciorarse de

que estén bien apretadas.

Los motores, equipos

eléctricos y controles, pueden

ocasionar arcos eléctricos

que se encenderían con gases o vapores

inflama-bles. Nunca utilice o repare el

compresor cerca de gases o vapores

inflama-bles. Nunca almacene líquidos o

gases inflamables cerca del compresor.

Nunca utilice el compresor

sin la tapa de las bandas.

Los compresores se pueden

encender automáticamente sin previo

aviso. Las piezas en movimiento podrían

ocasio-narle heridas o daños a su

propiedad.

9. No se ponga ropa muy holgada

o joyas, ya que éstas se le

podrían enredar en las piezas en

movimiento.

Las piezas del compresor

podrían estar calientes

inclusive cuando la unidad

esté apagada.

10. Mantenga los dedos alejados

del compresor cuando éste

esté funcionando; las piezas

en movimiento o calientes

le ocasionarían heridas y/o

quemaduras.

La vibración podría

ocasionar rupturas

en el tanque. Éstas podrían ocasionar

explosiones. No instale el cabezal en

un tanque que no esté diseñado para

usarse con este tipo de cabezales.

11. Si el equipo comienza a vibrar

excesivamente, APAGUE el motor

y chequéelo inmediatamente para

determinar la razón. Generalmente,

la vibración excesiva se debe a una

falla.

12. Para reducir el peligro de incendio,

mantenga el exterior del motor

libre de aceite, solventes o exceso de

grasa.

Nunca trate de

ajustar la válvula

de seguridad. Evite que se le acumule

pintura u otro residuos.

¡Nunca trate de reparar o

modificar el tanque! Si lo

suelda, taladra o modifica

de cualquier otra manera, el tanque se

debilitará y se podría dañar al romperse

o explotar. Siempre reemplace los

tanques desgastados, rotos o dañados.

13. Los tanques se oxidan debido a la

acumulación de humedad y ésto

debilita el tanque. Cerciórese de

drenar el tanque con regularidad e

inspeccionarlo periódicamente para