Page 1

See Warranty on page 8 for important information about commercial use of this product.

Operating Instructions VT6315, VT6358, VT6361

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain the product described.

Protect yourself and others by observing all safety information. Failure to comply with instructions could result in personal injury and/or

property damage! Retain instructions for future reference.

Portable Air Compressor

Table of Contents

Description . . . . . . . . . . . . . . . . . . . . . 1

Unpacking . . . . . . . . . . . . . . . . . . . . . . 1

Safety Guidelines . . . . . . . . . . . . . . . . 1

General Safety Information . . . . . . . . 1

Introduction . . . . . . . . . . . . . . . . . . . . 3

Assembly . . . . . . . . . . . . . . . . . . . . . . . 3

Operation . . . . . . . . . . . . . . . . . . . . . . 5

Maintenance . . . . . . . . . . . . . . . . . . . . 5

Troubleshooting Chart . . . . . . . . . . . . 6

Warranty . . . . . . . . . . . . . . . . . . . . . . . 8

Description

Air compressor units are intended

to provide compressed air to power

pneumatic tools and operate spray

guns. The pumps supplied are oil

lubricated. A small amount of oil

carryover is present in the compressed

air stream. Applications requiring air

free of oil or water should have the

appropriate filter installed. The air

compressor unit must be mounted

as described in the instructions on

a solid floor. Any other use of these

units will void the warranty and the

manufacturer will not be responsible

for problems or damages resulting from

such misuse.

Unpacking

After unpacking the unit, inspect

carefully for any damage that may

have occurred during transit. Make sure

to tighten fittings, bolts, etc., before

putting unit into service.

Do not operate unit

if damaged during

shipping, handling or use. Damage may

result in bursting and cause injury or

property damage.

READ & FOLLOW ALL INSTRUCTIONS

SAVE THESE INSTRUCTIONS

DO NOT DISCARD

Safety Guidelines

This manual contains information

that is very important to know and

understand. This information is

provided for SAFETY and to PREVENT

EQUIPMENT PROBLEMS. To help

recognize this information, observe the

following symbols.

Danger indicates

an imminently

hazardous situation which, if not

avoided, WILL result in death or

serious injury.

Warning indicates

a potentially

hazardous situation which, if not

avoided, COULD result in death

or serious injury.

Caution indicates

a potentially

hazardous situation which, if not

avoided, MAY result in minor or

moderate injury.

Notice indicates

important

information, that if not followed,

may cause damage to equipment.

NOTE: Information that requires special

attention.

General Safety Information

CALIFORNIA PROPOSITION 65

This product or

its power cord may

contain chemicals known to the State

of California to cause cancer and birth

defects or other reproductive harm.

Wash hands after handling.

Breathable Air Warning

This compressor/pump is NOT

equipped and should NOT be

used “as is” to supply breathing

quality air. For any application of

air for human consumption, you

must fit the air compressor/pump

with suitable in-line safety and

alarm equipment. This additional

equipment is necessary to

properly filter and purify the air

to meet minimal specifications

for Grade D breathing as

described in Compressed

Gas Association Commodity

Specification G 7.1, OSHA 29

CFR 1910. 134, and/or Canadian

Standards Associations (CSA).

DISCLAIMER OF WARRANTIES

In the event the compressor is

used for the purpose of breathing

air application and proper in-line

safety and alarm equipment

is not simultaneously used,

existing warranties are void, and

the manufacturer disclaims any

liability whatsoever for any loss,

personal injury or damage.

You can

create

dust when you cut, sand, drill

or grind materials such as

wood, paint, metal, concrete,

cement, or other masonry. This dust

often contains chemicals known to

cause cancer, birth defects, or other

reproductive harm. Wear protective

gear.

© 2010

REMINDER: Keep your dated proof of purchase for warranty purposes!

Attach it to this manual or file it for safekeeping.

IN625502AV 11/10

Page 2

Operating Instructions

General Safety Information

(Continued)

GENERAL SAFETY

Since the air compressor and other

components (material pump, spray

guns, filters, lubricators, hoses, etc.)

used, make up a high pressure pumping

system, the following safety precautions

must be observed at all times:

1. Read all manuals included

with this product carefully.

Be thoroughly familiar

with the controls and the

proper use of the equipment.

2. Follow all local electrical and safety

codes as well as in the United States,

the National Electrical Codes (NEC)

and Occupational Safety and Health

Act (OSHA).

3. Only persons well acquainted with

these rules of safe operation should

be allowed to use the compressor.

4. Keep visitors away and NEVER allow

children in the work area.

5. Wear safety glasses and

use hearing protection

when operating the unit.

6. Do not stand on or use the unit as a

handhold.

7. Before each use, inspect compressed

air system and electrical components

for signs of damage, deterioration,

weakness or leakage. Repair or

replace defective items before using.

8. Check all fasteners at frequent

intervals for proper tightness.

Motors,

electrical

equipment and controls can

cause electrical arcs that

will ignite a flammable gas

or vapor. Never operate or repair in or

near a flammable gas or vapor. Never

store flammable liquids or gases in the

vicinity of the compressor.

MANUAL

Never

operate

compressor without a

beltguard. This unit can

start automatically without

warning. Personal injury or property

damage could occur from contact with

moving parts.

9. Do not wear loose clothing or

jewelry that will get caught in the

moving parts of the unit.

Compressor parts may be hot

even if the unit is stopped.

10. Keep fingers away from a

running compressor; fast moving

and hot parts will cause injury and/

or burns.

11. If the equipment should start to

vibrate abnormally, STOP the engine/

motor and check immediately for

the cause. Vibration is generally a

warning of trouble.

12. To reduce fire hazard, keep engine/

motor exterior free of oil, solvent, or

excessive grease.

An ASME code

safety relief valve

with a setting no higher than 175 psi

MUST be installed in the tank for this

compressor. The ASME safety valve

must have sufficient flow and pressure

ratings to protect the pressurized

components from bursting.

See compressor

specification decal

for maximum operating pressure.

Do not operate with pressure switch

or pilot valves set higher than the

maximum operating pressure.

13. Never attempt to adjust ASME safety

valve. Keep safety valve free from

paint and other accumulations.

Never use plastic

(PVC) pipe for

compressed air. Serious injury or death

could result.

Never

attempt

to repair or modify a tank!

Welding, drilling or any other

modification will weaken the

tank resulting in damage from rupture

or explosion. Always replace worn,

cracked or damaged tanks.

Drain liquid from

tank daily.

14. Tanks rust from moisture build-up,

which weakens the tank. Make sure

to drain tank regularly and inspect

periodically for unsafe conditions

such as rust formation and corrosion.

15. Fast moving air will stir up dust

and debris which may be harmful.

Release air slowly when draining

moisture or depressurizing the

compressor system.

SPRAYING PRECAUTIONS

Do not

spray

flammable materials in

vicinity of open flame or near

ignition sources including the

compressor unit.

16. Do not smoke when spraying paint,

insecticides, or other flammable

substances.

17. Use a face mask /

respirator when spraying

and spray in a well

ventilated area to prevent

health and fire hazards.

18. Do not direct paint or other sprayed

material at the compressor. Locate

compressor as far away from the

spraying area as possible to minimize

overspray accumulation on the

compressor.

19. When spraying or cleaning with

solvents or toxic chemicals, follow

the instructions provided by the

chemical manufacturer.

www.chpower.com

2

Page 3

Operating Instructions

VT6315, VT6358, VT6361

Introduction

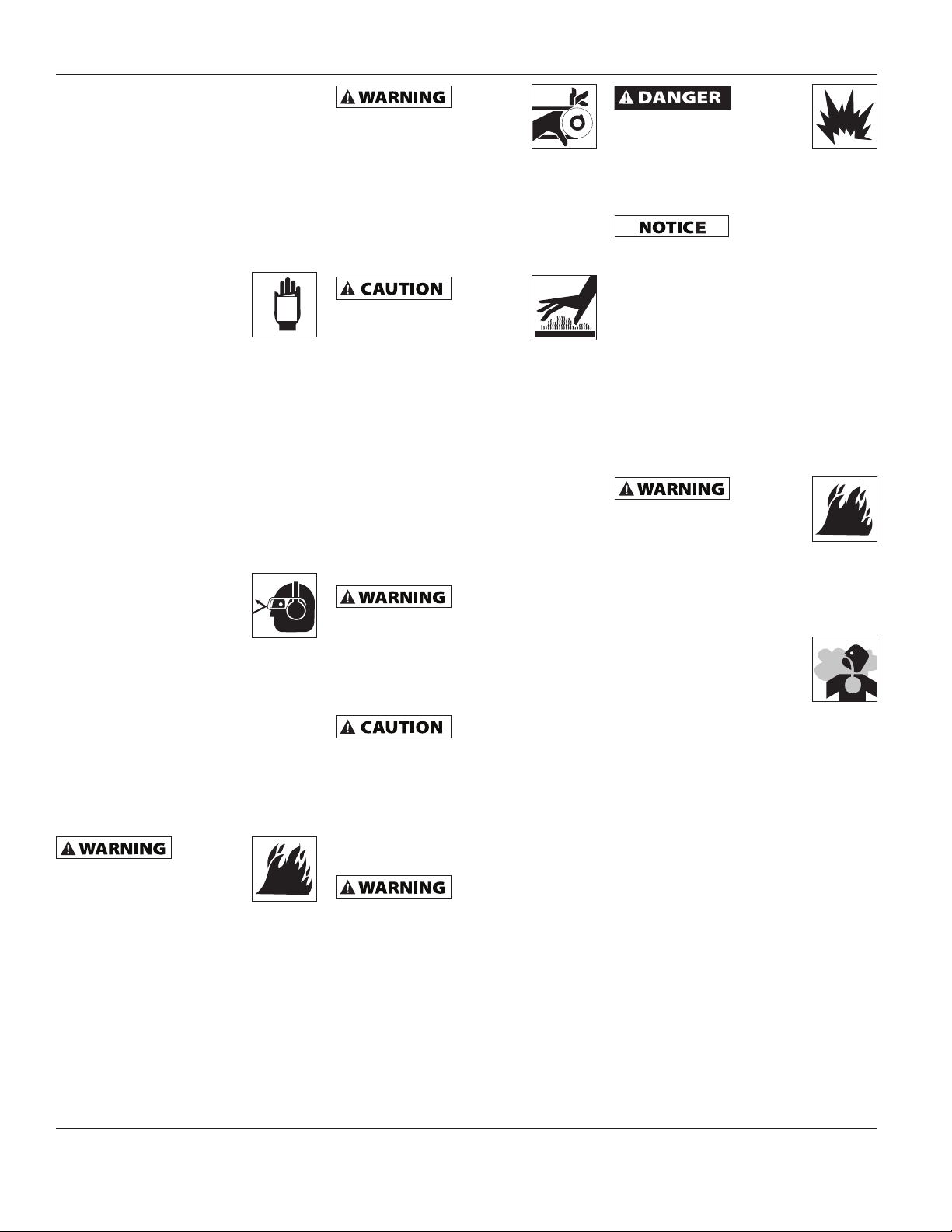

Refer to Figure 1 to locate the following

items.

Pressure switch - Auto/Off Switch - In

the AUTO position, the compressor

shuts off automatically when tank

pressure reaches the maximum preset

pressure. After air is used from the tank

and drops to a preset low level, the

pressure switch automatically turns the

motor back on. In the OFF position, the

compressor will not operate. This switch

should be in the OFF position when

connecting or disconnecting the power

cord from the electrical outlet.

When the pressure switch turns the

motor off you will hear air leaking out

of the pressure switch unloader valve

for a short time. This releases the air

pressure from the discharge tube and

allows the compressor to restart easier.

Regulator - The regulator controls the

amount of air pressure released at the

hose outlet.

Discharge Tube

Handle

Tank

Pressure

Gauge

Tank

Belt Guard

Intake Filter

Pressure

Switch

Breather/

Dipstick

& Oil Fill

Hole

ASME Safety Valve - This valve

automatically releases air if the tank

pressure exceeds the preset maximum.

Discharge tube - This tube carries

compressed air from the pump to the

check valve. This tube becomes very hot

during use. To avoid the risk of severe

burns, never touch the discharge tube.

To avoid the risk of

severe burns, never

touch the discharge tube.

Check valve - One-way valve that

allows air to enter the tank, but

prevents air in the tank from flowing

back into the compressor pump.

Handle - Designed to move the

compressor.

Never use the

handle to lift the

unit completely off the ground. Handle

is intended only for pushing or pulling

product.

Belt Guard - Covers the belt, motor

pulley and flywheel.

Never

operate

compressor without a

beltguard. This unit can

start automatically without

warning. Personal injury or property

damage could occur from contact with

moving parts.

Tank Drain Valve - This valve is located

on the bottom of the tank. Use this

valve to drain moisture from the tank

daily to reduce the risk of corrosion.

Reduce tank pressure below 10 psi,

before opening drain valve.

Tank Pressure Gauge - Indicates

amount of air pressure stored in tank.

Hose Pressure Gauge - Indicates

amount of air pressure in hose used to

operate tools. This pressure is increased

or decreased by the regulator.

Assembly

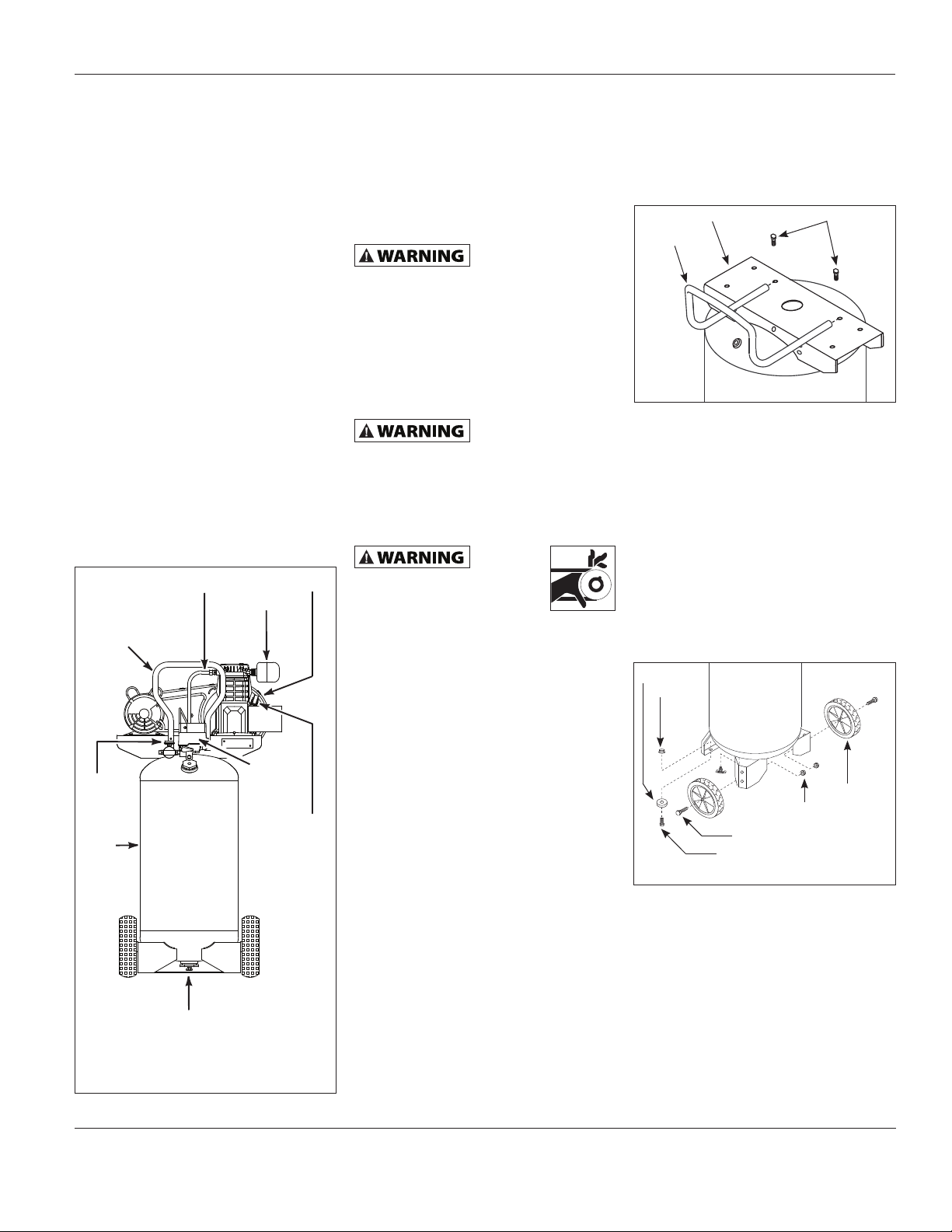

HANDLE ASSEMBLY - Handle may be

pre-assembled on some units.

Insert four handle screws through holes

in handle and tighten to tank baseplate

(See Figure 2).

Tank Baseplate Handle Screw

Handle

Figure 2

FOOT ASSEMBLY

The items marked with an asterisk (*)

were shipped loose with the unit (See

Figure 3).

1. Tilt unit to allow access to front foot

and secure properly to ensure unit

does not tip over.

2. Insert bolt through foot and bracket.

The foot should be on the lower side

of bracket.

3. Tightly secure with the lock nut.

Repeat on opposite side.

Foot*

Nut*

Wheel*

Lock Nut*

Shoulder Bolt*

Bolt*

Figure 3

Figure 1

Drain

Petcock

www.chpower.com

3

Page 4

Operating Instructions

Assembly (Continued)

BREATHER INSTALLATION

Remove cap from oil fill opening. Install

breather (found in parts bag with this

manual). See Figure 4.

Remove

Cap

Install

Breather

Figure 4

LUBRICATION

CHECK OIL LEVEL.

SOME UNITS

INCLUDE OIL. Follow lubrication

instructions before operating

compressor.

Ensure oil drain extension and cap has

been installed (if included) then remove

the breather (See Figure 5) and fill

pump oil according to the chart.

Pump Approx. Oil Capacity

VS260000KB 6.0 oz

VT470000KB 8.5 oz

VT480000KB 8.5 oz

See specification label on air tank for

pump model number and refer to the

chart for the proper oil capacity.

OIL DRAIN EXTENSION

Some models include an oil drain

extension and cap (found with the

owner’s manual). Install the oil drain

extension and cap before adding oil to

the pump. To avoid oil leaks, it is highly

recommended to apply thread seal

tape or plumber’s putty to the threads

on each end of the oil drain extension.

Screw the cap onto one end of the

extension. Remove the oil drain plug

from the base of the pump and install

the oil drain extension (See Figure 5).

Oil Fill Cap

(Dispose of

Dipstick

Breather

Cap*

Max

Low

Dipstick Oil Read

Figure 5

Full

Add

OR

Oil Drain Extension*

* Not included with all models.

properly)

Breather

Add Oil

Full

Add

Sight Glass

OIL

Use SAE 30 industrial grade air

compressor oil or full synthetic motor

oil like Mobil 1 10W30. Do not use

regular automotive oil such as 10W-30.

Additives in motor oil can cause valve

deposits and reduce pump life. For

maximum pump life, drain and replace

oil after the first hour of run time.

Proper oil fill level is illustrated in

Figure 5.

For pumps with an oil sight glass, oil

level can be monitored and maintained

as shown in Figure 5.

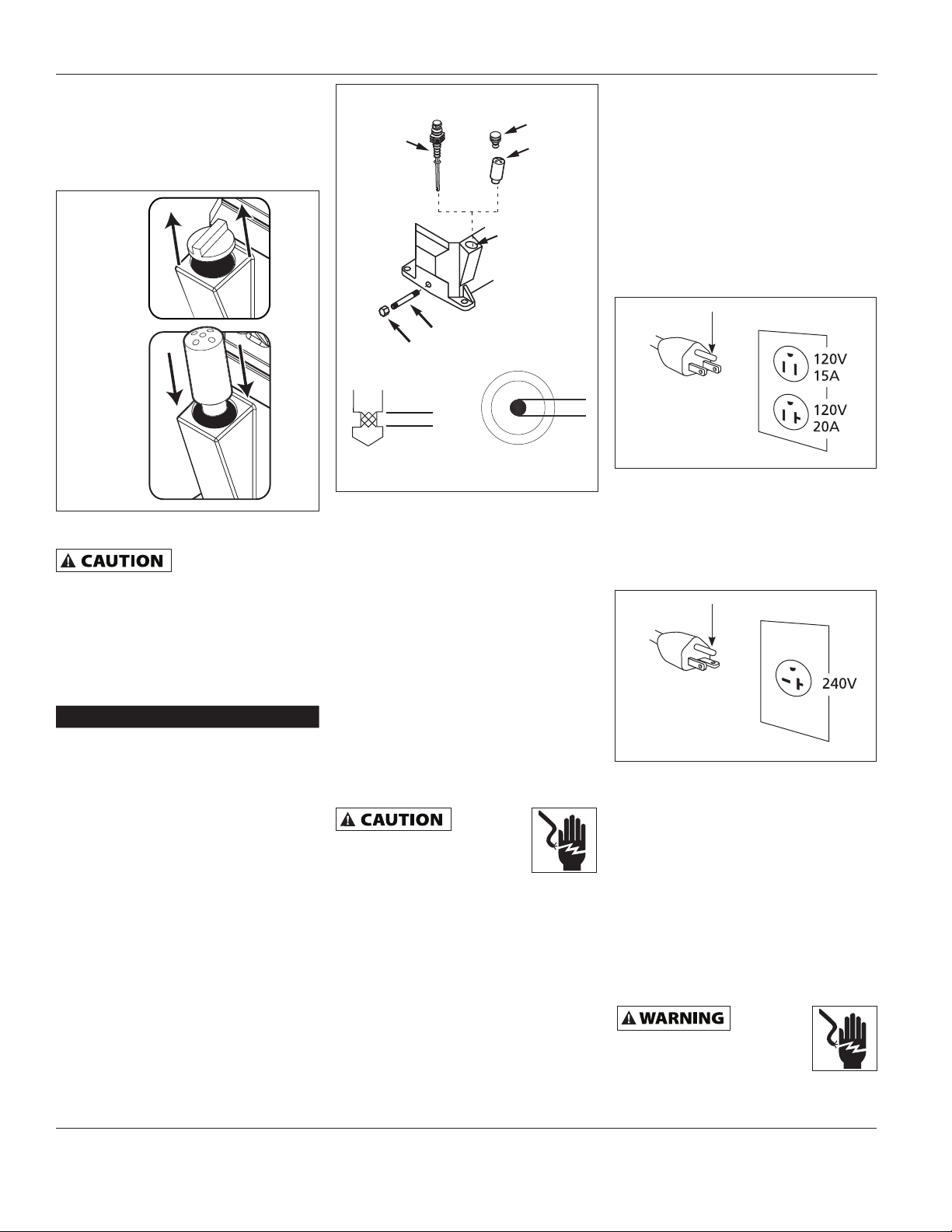

ELECTRICAL DATA

Overheating, short-circuiting

and fire damage will result

from inadequate wiring.

Do not use an extension cord, use a

longer air hose.

The 120 volt, 15 amp units can be

operated on a 120 volt 15 amp circuit

under the following conditions:

1. No other electrical appliances or

lights are connected to the same

branch circuit.

2. Voltage is 120 Volts.

3. Circuit is equipped with a 15 amp

circuit breaker or a 15 amp slow

blow fuse type T (For Canada use

Type D).

4. The length of copper wire between

the outlet and circuit breaker is not

longer than 40 feet of 14 AWG or 70

feet of 12 AWG.

If the above conditions cannot be met

or if nuisance tripping of the current

protection device occurs, it may be

possible to operate the compressor from

a 120 volt 20 amp circuit. See Figure 6.

Grounded OutletGround Pin

Figure 6

Check motor data plate for 240 volt

compatability. A 240 volt unit must be

operated on a 240 volt circuit. The cord

must only plug into a 240 volt grounded

outlet and may require a new cord and

plug. See Figure 7.

Grounded OutletGround Pin

Figure 7

GROUNDING INSTRUCTIONS

This product must be grounded. In

the event of an electrical short circuit,

grounding reduces the risk of electric

shock by providing an escape wire

for the electric current. This product

is equipped with a cord having a

grounding wire with an appropriate

grounding plug. The plug must be

plugged into an outlet that is properly

installed and grounded in accordance

with all local codes and ordinances.

Improper

installation of the grounding

plug is able to result in a risk

of electric shock. When repair

or replacement of the cord or plug is

required, do not connect the grounding

www.chpower.com

4

Page 5

Operating Instructions

VT6315, VT6358, VT6361

wire to either flat blade terminal. The

wire with insulation having an outer

surface that is green with or without

yellow stripes is the grounding wire.

Do not use grounding adapter.

Check with a qualified electrician

or serviceman when the grounding

instructions are not completely

understood, or when in doubt as

to whether the product is properly

grounded. Do not modify the plug

provided; if it does not fit the outlet,

have the proper outlet installed by a

qualified electrician.

This product is for use on a nominal

120-V circuit and has a grounding plug

similar to the plug illustrated in Figure

6. Only connect the product to an outlet

having the same configuration as the

plug. Do not use an adapter with this

product.

When converting

to an alternate

voltage, be sure the green ground wire

of the cord connects to the ground pin

of the plug and to the metal body of

the pressure switch.

Operation

START-UP

This compressor

pump must be filled

with oil before startup. See lubrication

section.

Do not attach air

tools to open end of

the hose until start-up is completed and

the unit checks OK.

Never disconnect

threaded joints with

pressure in tank!

1. Check for proper oil level. See

Lubrication Section.

2. Open tank drain valve.

3. Turn pressure switch lever or knob

to OFF position and plug in power

cord.

4. Turn pressure switch lever or knob to

AUTO position and run unit for 30

minutes to break in the pump parts

(See Figure 8).

5. Turn regulator knob fully

counterclockwise. Compressor will

build to maximum preset pressure

and shut off.

Lever - Off

A

U

T

F

O

F

/

O

Knob

Auto/Off

Figure 8

Lever - Auto

6. Turn regulator knob clockwise to

cause air to bleed off. Compressor

will restart at preset pressure.

7. Turn pressure switch lever or knob to

OFF position and unplug powercord.

Slowly turn regulator knob clockwise

to allow all air pressure to be

released. Do not proceed to the next

step until the tank pressure reaches

zero (0).

8. Attach hose, then add chuck or

other tool to open end of hose. Plug

in powercord. Turn pressure switch

lever to AUTO position. When full

pressure is reached turn regulator

knob clockwise until desired outlet

pressure is achieved.

9. After use, turn pressure switch lever

or knob to the OFF position.

MOISTURE IN COMPRESSED AIR

Moisture in compressed air will form

into droplets as it comes from an air

compressor pump. When humidity

is high or when a compressor is in

continuous use for an extended

period of time, this moisture will

collect in the tank. When using a

paint spray or sandblast gun, this

water will be carried from the tank

through the hose, and out of the

gun as droplets mixed with the spray

material.

IMPORTANT: This condensation will

cause water spots in a paint job,

especially when spraying other than

water based paints. If sandblasting, it

will cause the sand to cake and clog

the gun, rendering it ineffective.

A filter in the air line, located as

near to the gun as possible, will help

eliminate this moisture.

10. If compressor is not used for a long

time period, bleed air from line

and use drain valve to drain water

from the tank. Then, follow the

maintenance schedule.

NOTE: Electric models are equipped

with a pressure switch that

automatically turns the motor OFF when

the tank pressure reaches a preset level.

After air is used from the tank and

drops to a preset low level, the pressure

switch automatically turns the motor

back on.

Maintenance

Disconnect, tag and lock out

power source, then release

all pressure from the system

before attempting to install, service,

relocate or perform any maintenance.

All repairs should be performed by an

authorized service representative.

FOR EFFICIENT OPERATION:

Perform the following test to verify free

operation of the safety valve weekly

and follow maintenance schedule.

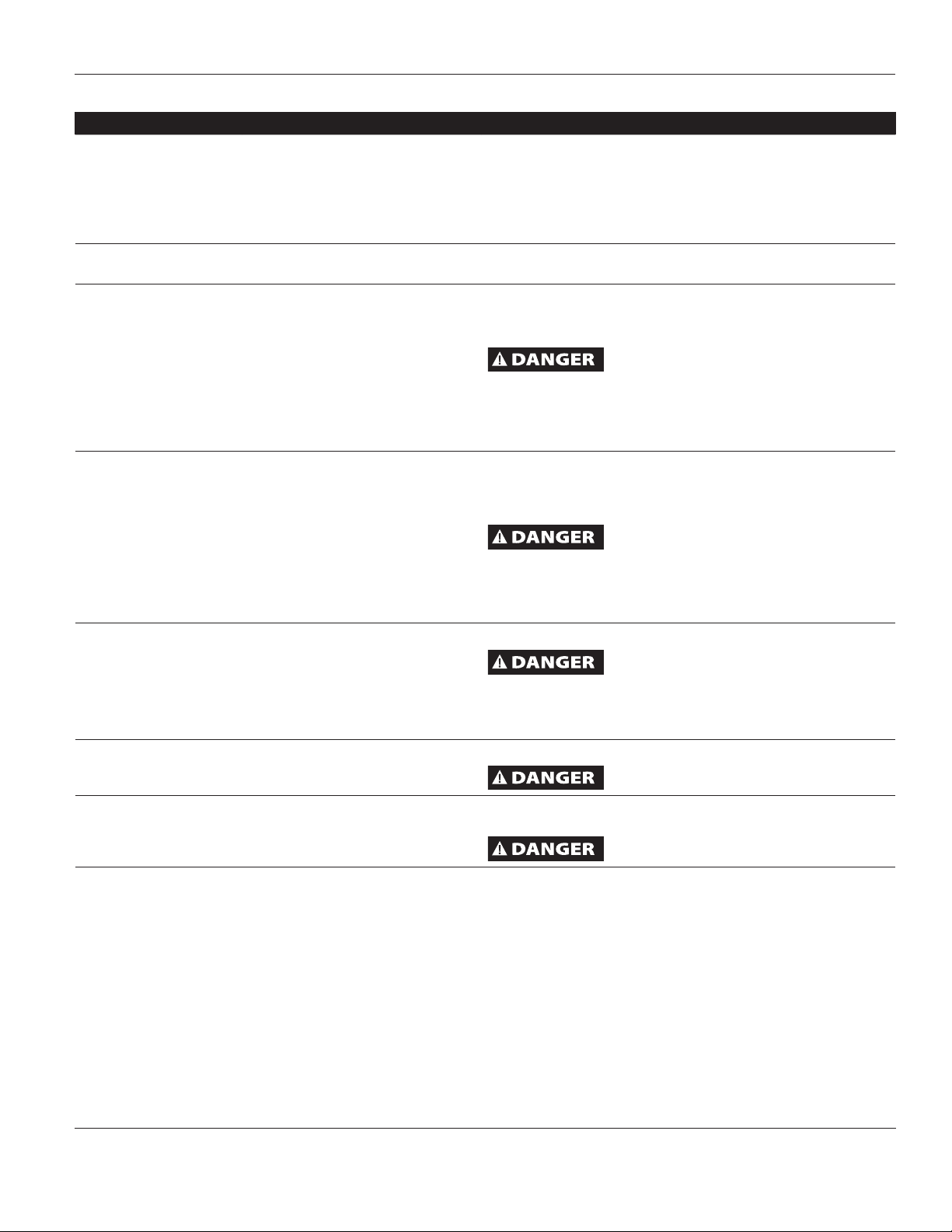

1. Pull ring on safety valve and allow

the ring to snap back to normal

position (see Figure 9). This valve

automatically releases air if the

tank pressure exceeds the preset

maximum.

Figure 9

Do not attempt to

tamper with this

valve. This valve should be checked

occasionally. If air leaks after the ring

has been released, or the valve is stuck

and cannot be actuated by the ring, the

safety valve must be replaced.

A large amount of

fast moving air will

be released if this valve is actuated with

pressure in the tank.

2. With motor OFF and unplugged,

clean debris from motor, flywheel,

tank, air lines and pump cooling fins.

www.chpower.com

5

Page 6

Operating Instructions

TECHNICAL SERVICE

For information regarding the

operation or repair of this product,

please call

1-800-543-6400.

Storage

1. When not in use, hose and

compressor should be stored in a

cool dry place.

2. Tanks should be drained of moisture.

and hose should be disconnected

and hung with open ends down to

allow any moisture to drain.

3. Protect the electrical cord from

possible damage by winding the

cord loosely around the handle of

the unit or coiling the cord up.

Troubleshooting Chart

MAINTENANCE SCHEDULE

OPERATION DAILY WEEKLY MONTHLY 3 MONTHS

CHECK OIL LEVEL

DRAIN TANK

CHECK AIR FILTER

CHECK SAFETY VALVE

CLEAN UNIT

CHECK BELT TIGHTNESS

CHANGE OIL

l

l

l

l

l

l

l

TORQUE REQUIREMENTS (in/lbs)

Model

Compressor

Head Bolts

VS 100-125 50-120

VT 225-300 50-120

Bearing

Cap Bolts

Symptom Possible Cause(s) Corrective Action

Low discharge pressure 1. Air demand exceeds pump capacity 1. Reduce air demand or use a compressor with more capacity.

2. Air leaks 2. Listen for escaping air. Apply soap solution to all fittings and

3. Restricted air intake 3. Clean the air filter element.

4. Blown gaskets 4. Replace any gaskets proven faulty on inspection.

5. Leaking or damaged valves 5. Remove head and inspect for valve breakage, misaligned valves,

Pump overheating causes

air filter to melt

Excessive noise (knocking) 1. Loose motor or compressor pulley 1. Loose motor or compressor pulleys are a very common cause of

1. Insulating gasket between filter and

head is missing

2. Broken valves/blown gasket 2. Replace valves or install new gasket.

2. Lack of oil in crankcase 2. Check for proper oil level; if low, check for possible damage to

3. Worn connecting rod 3. Replace connecting rod. Maintain oil level and change oil more

4. Worn piston pin bores 4. Remove piston assemblies from the compressor and inspect for

5. Piston hitting the valve plate 5. Remove the compressor head and valve plate and inspect for

6. Noisy check valve in compressor

system

connections. Bubbles will appear at points of leakage. Tighten or

replace leaking fittings or connections.

damaged valve seats, etc. Replace defective parts and reassemble.

Install a new head gasket

each time the head is removed

1. Install gasket.

compressors knocking. Tighten pulley clamp bolts and set-screws.

bearings. Dirty oil can cause excessive wear.

frequently.

excess wear. Replace excessively worn piston pin or pistons, as

required. Maintain oil level and change oil more frequently.

carbon deposits or other foreign matter on top of piston. Replace

head and valve plate using new gasket. See Lubrication section for

recommended oil.

6. Replace.

Do not disassemble check

valve with air pressure in tank

www.chpower.com

6

Page 7

Operating Instructions

Troubleshooting Chart (Continued)

Symptom Possible Cause(s) Corrective Action

Large quanity of oil in

the discharge air

NOTE: In an oil lubricated

compressor there will

always be a small amount

of oil in the air stream.

Water in discharge air /

tank

Motor hums and runs

slowly or not at all

Reset mechanism cuts

out repeatedly or fuses

blow repeatedly

Tank does not hold

pressure when

compressors off and the

shut off valve is closed

Pressure switch

continuously blows air

out the unloader valve

Pressure switch does

not release air when

the unit shuts off

Excessive vibration 1. Loose fasteners 1. Tighten.

1. Worn piston rings 1. Replace with new rings. Maintain oil level and change oil more

2. Compressor air intake restricted 2. Clean filter. Check for other restrictions in the intake system.

3. Excessive oil in compressor 3. Drain down to full level.

4. Wrong oil viscosity 4. Use Mobil 1

Normal operation. The amount of

water increases with humid weather

1. Use of extension cord 1. Do not use an extension cord. Use longer air hose with larger

2. Malfunctioning check valve or

unloader valve

3. Low voltage 3. Check with voltmeter, check reset switch on motor. If reset switch

4. Malfunctioning pressure switch contacts will not close

1. Too many devices on same circuit 1. Limit the circuit to the use of only the air compressor.

2. Incorrect fuse size or circuit breaker 2. Be sure that fuses or circuit breakers are rated properly.

3. Malfunctioning check valve

4. Pressure switch set too high 4. Adjust or replace.

5. Loose wiring 5. Check all electrical connections.

6. Malfunctioning motor 6. Replace motor.

1. Worn check valve

2. Check all connections and fittings

for leaks

3. Check tank for cracks or pin holes 3. Replace tank. Never repair a damaged tank.

Malfunctioning check valve Replace the check valve if the unloader valve bleeds off constantly.

Malfunctioning unloader valve on

pressure switch

2. Belt needs replaced 2. Replace with correct size.

3. Belt alignment 3. Align flywhell and pulley.

frequently.

1. Drain tank more often. At least daily.

2. Add a filter to reduce the amount of water in the air line.

diameter.

2. Replace check valve, unloader valve or pressure switch.

Do not disassemble check

trips repeatedly, find and correct the cause. See next item.

4. Repair or replace pressure switch.

3. Replace check valve.

Do not disassemble check

1. Replace check valve.

Do not disassemble check

2. Tighten.

Do not disassemble check

Replace the pressure switch if it does not release the pressure for a

short period of time when the unit shuts off.

Do not disassemble check

VT6315, VT6358, VT6361

®

10W-30.

valve with air pressure in tank

valve with air pressure in tank

valve with air pressure in tank

valve with air pressure in tank

valve with air pressure in tank

www.chpower.com

7

Page 8

Operating Instructions

Limited Warranty

1. DURATION: From the date of purchase by the original purchaser as follows: Three Years or Four Years as indicated on product

specification label.

2. WHO GIVES THIS WARRANTY (WARRANTOR): Campbell Hausfeld / Scott Fetzer Company, 100 Production Drive,

Harrison, Ohio, 45030, Telephone: (800) 543-6400

3. WHO RECEIVES THIS WARRANTY (PURCHASER): The original purchaser (other than for purposes of resale) of the Campbell Hausfeld

compressor.

4. WHAT PRODUCTS ARE COVERED BY THIS WARRANTY: This Campbell Hausfeld air compressor.

5. WHAT IS COVERED UNDER THIS WARRANTY: Parts and Labor to remedy substantial defects due to material and workmanship during

the first year of ownership with the exceptions noted below. Parts only to remedy substantial defects due to material and workmanship

during remaining term of coverage with exceptions noted below.

6. WHAT IS NOT COVERED UNDER THIS WARRANTY:

A. Implied warranties, including those of merchantability and FITNESS FOR A PARTICULAR PURPOSE ARE LIMITED FROM THE DATE

OF ORIGINAL PURCHASE AS STATED IN THE DURATION. If the compressor is used for commercial, industrial or rental purposes, the

warranty will apply for ninety (90) days from the date of purchase. Some States do not allow limitations on how long an implied

warranty lasts, so the above limitations may not apply to you.

B. ANY INCIDENTAL, INDIRECT, OR CONSEQUENTIAL LOSS, DAMAGE, OR EXPENSE THAT MAY RESULT FROM ANY DEFECT, FAILURE,

OR MALFUNCTION OF THE CAMPBELL HAUSFELD PRODUCT. Some States do not allow the exclusion or limitations of incidental or

consequential damages, so the above limitation or exclusion may not apply to you.

C. Any failure that results from an accident, purchaser’s abuse, neglect or failure to operate products in accordance with instructions

provided in the owner’s manual(s) supplied with compressor.

D. Pre-delivery service, e.g. assembly, oil or lubricants, and adjustment.

E. Items or service that is normally required to maintain the product, e.g. lubricants, filters and gaskets, etc.

F. Gasoline engines and components are expressly excluded from coverage under this limited warranty. The Purchaser must comply with

the warranty given by the engine manufacturer which is supplied with the product

G. Additional items not covered under this warranty:

1. Excluded items pertaining to All Compressors

a. Any component damaged in shipment or any failure caused by installing or operating unit under conditions not in accordance

with installation and operation guidelines or damaged by contact with tools or surroundings.

b. Pump or valve failure caused by rain, excessive humidity, corrosive environments or other contaminants.

c. Cosmetic defects that do not interfere with compressor functionality.

d. Rusted tanks, including but not limited to rust due to improper drainage or corrosive environments.

e. The following components are considered normal wear items and are not covered after the first year of ownership. Electric

motor, check valve, pressure switch, regulator, pressure gauges, hose, tubing, pipe, fittings and couplers, screws, nuts,

hardware items, belts, pulleys, flywheel, air filter and housing, gaskets, seals, oil leaks, air leaks, oil consumption or usage,

piston rings.

f. Tank drain valves.

g. Damage due to incorrect voltage or improper wiring.

h. Other items not listed but considered general wear parts.

i. Pressure switches, air governors, load/unload devices, throttle control devices and safety valves modified from factory

settings.

j. Damage from inadequate filter maintenance.

k. Induction motors operated with electricity produced by a generator.

2. Excluded items specific to Lubricated Compressors:

a. Pump wear or valve damage caused by using oil not specified.

b. Pump wear or damage caused by any oil contamination.

c. Pump wear or damage caused by failure to follow proper oil maintenance guidelines, operation below proper oil level or

operation without oil.

H. Labor, service call, or transportation charges after the first year of ownership of stationary compressors. Stationary compressors are

defined as not including a handle or wheels.

7. RESPONSIBILITIES OF WARRANTOR UNDER THIS WARRANTY: Repair or replace, at Warrantor’s option, compressor or component which is

defective, has malfunctioned and/or failed to conform within the duration of the specific warranty period.

8. RESPONSIBILITIES OF PURCHASER UNDER THIS WARRANTY:

A. Provide dated proof of purchase and maintenance records.

B. Call Campbell Hausfeld (800-543-6400) to obtain your warranty service options. Freight costs must be borne by the purchaser.

C. Use reasonable care in the operation and maintenance of the products as described in the owner’s manual(s).

D. Repairs requiring overtime, weekend rates, or anything beyond the standard manufacturer warranty repair labor reimbursement rate.

E. Time required for any security checks, safety training, or similar for service personnel to gain access to facility.

F. Location of unit must have adequate clearance for service personnel to perform repairs and easily accessible.

9. WHEN WARRANTOR WILL PERFORM REPAIR OR REPLACEMENT UNDER THIS WARRANTY: Repair or replacement will be scheduled and

serviced according to the normal work flow at the servicing location, and depending on the availability of replacement parts.

This Limited Warranty applies in the U.S., Canada and Mexico only and gives you specific legal rights. You may also have other rights which

vary from State to State or country to country.

www.chpower.com

8

Page 9

Voir la Garantie à la page 16 pour de l’information importante sur l’utilisation commercial de ce produit.

Instructions d’Utilisation et Manual de Pièces VT6315, VT6358, VT6361

Veuillez lire et conserver ces instructions. Lire attentivement avant de commencer à assembler, installer, faire fonctionner ou entretenir

l'appareil décrit. Protégez-vous et les autres en observant toutes les informations sur la sécurité. Négliger d'appliquer ces instructions peut

résulter en des blessures corporelles et/ou en des dommages matériels ! Conserver ces instructions pour références ultérieures.

Compresseurs d’Air Portatifs

Table des matières

Descripion . . . . . . . . . . . . . . . . . . . . . . 9

Déballage . . . . . . . . . . . . . . . . . . . . . . 9

Directives de Sécurité . . . . . . . . . . . . . 9

Généralités sur la Sécurité . . . . . . . . . 9

Introduction . . . . . . . . . . . . . . . . . . . 11

Montage . . . . . . . . . . . . . . . . . . . . . . 11

Fonctionnement . . . . . . . . . . . . . . . . 13

Entretien . . . . . . . . . . . . . . . . . . . . . . 13

Guide de Dépannage . . . . . . . . . . . . 14

Garantie. . . . . . . . . . . . . . . . . . . . . . . 16

Description

Les modèles de compresseurs d’air sont

conçus pour fournir de l’air comprimé

aux outils pneumatiques et pour faire

fonctionner les pistolets vaporistateurs.

Les pompes fournies sont graissées à

l’huile. Un peu d’huile résiduelle est

présent dans le débit d’air comprimé.

Installer les filtres appropriés pour les

applications qui requièrent de l’air libre

d’huile ou d’eau. Le compresseur d’air

doit être monté selon les instructions,

sur un plancher solide. Autres usages

de ces modèles nieront la garantie et le

fabricant ne sera pas responsable pour

les problèmes ou dommages résultant

de l’usage incorrect.

Déballage

Dès que l’appareil est déballé,

l’inspecter attentivement pour tout

signe de dommages en transit. S’assurer

de resserrer tous les raccords, boulons,

etc. avant de le mettre en service.

LIRE ET SUIVRE TOUTES LES

INSTRUCTIONS

CONSERVER CES INSTRUCTIONS

NE PAS JETER

Directives de Sécurité

Ce manuel contient de l’information

très importante qui est fournie pour

la SÉCURITÉ et pour ÉVITER LES

PROBLÈMES D’ÉQUIPEMENT. Rechercher

les symboles suivants pour cette

information.

Danger indique

une situation

dangereuse imminente qui MÈNERA à

la mort ou à des blessures graves si elle

n’est pas évitée.

Avertissement

indique une

situation potentiellement dangereuse

qui, si elle n’est pas évitée, POURRAIT

mener à la mort ou à de graves

blessures.

Attention

indique une

situation potentiellement dangereuse

qui, si elle n’est pas évitée, PEUT mener

à des blessures mineures ou modérées.

Avis indique

de l’information

importante qui pourrait endommager

l’équipement si elle n’est pas respectée.

REMARQUE: L’information qui exige

une attention spéciale.

Généralités sur la Sécurité

PROPOSITION 65 DE CALIFORNIE

Ce produit ou son

cordon peuvent

contenir des produits chimiques qui, de

l’avis de l’État de Californie, causent le

cancer et des anomalies congénitales

ou autres problèmes de reproduction.

Lavez-vous les mains après la

manipulation.

Vous

pouvez

créer de la poussière en

coupant, ponçant, perçant

ou meulant les matériaux

tels que le bois, la peinture, le métal, le

béton, le ciment ou autre maçonnerie.

Cette poussière contient souvent des

Avertissement D’Air

Respirable

Ce compresseur/pompe n’est

pas équipé pour et ne devrait

pas être utilisé “comme soi”

pour fournir de l’air respirable.

En cas d’applications d’air pour

la consommation humaine, le

compresseur d’air/pompe doit

être équipé avec de l’équipement

de sécurité en canalisation

et d’alarme. Cet équipement

additionnel est nécessaire

pour filtrer et purifier l’air afin

d’atteindre les spécifications

minimales pour la respiration

Grade D décrites dans le

Compressed Gas Association

Commodity Specification G

7.1 - 1966, OSHA 29 CFR 1910.

134, et/ou Canadian Standards

Associations (CSA).

DÉNÉGATION DES GARANTIES

Si le compresseur est utilisé pour

les applications d’air respirable

et l’équipement de sécurité en

canalisation et d’alarme n’est

pas utilisé simultanément, les

garanties en existance seront

annulées, et el fabricante nie

toute responsabilité pour

n’importe quelle perte, blessure

ou dommage.

produits chimiques reconnus pour

causer le cancer, les déformations

congénitales ou autres problèmes de la

reproduction. Porter de l’équipement de

protection.

© 2010

MÉMENTO: Gardez votre preuve datée d'achat à fin de la garantie!

Joignez-la à ce manuel ou classez-la dans un dossier pour plus de sécurité.

9 Fr

IN625502AV 11/10

Page 10

Instructions d’utilisation

Généralités sur la Sécurité

(Suite)

GÉNÉRALITÉS SUR LA SÉCURITÉ

Puisque le compresseur d’air et les

autres pièces détachées (pompe,

pistolets, filtres, graisseurs, tuyaux,

etc.) font partie d’un système de haute

pression, il est nécessaire de suivre les

précautions suivantes:

1. Lire attentivement tous

manuels compris avec ce

produit. Se familiariser

avec ce produit, ses

commandes et son

utilisation.

2. Suivre tous les codes de sécurité

et d’électricité locaux ainsi que les

codes des É-U; National Electrical

Codes (NEC) et Occupational Safety

and Health Act (OSHA).

3. Seules les personnes bien

familiarisées avec ces règlements

d’utilisation doivent être autorisées

à se servir du compresseur.

4. Garder les visiteurs à l’écart de/et NE

JAMAIS permettre les enfants dans

l’endroit de travail.

5. Utiliser des lunettes de

sécurité et la protection

auditive pendant

l’utilisation du modèle.

6. Ne pas se tenir debout sur/ni utiliser

le modèle comme une prise à main.

7. Inspecter le système d’air comprimé

et pièces détachées électriques

pour toute indication de dommage,

détérioration, faiblesse ou fuites

avant chaque utilisation. Réparer ou

remplacer toutes pièces défectueuses

avant l’utilisation.

8. Inspecter le degré de serrage de

toutes les attaches par intervalles

régulières.

Les

moteurs, l’équipement et

les commandes électriques

peuvent causer des arcs

électriques qui peuvent allumer un gaz

ou une vapeur inflammable. Ne jamais

utiliser ou réparer le modèle près d’un

gaz ou d’une vapeur inflammable. Ne

jamais entreposer les liquides ou gaz

inflammables près du compresseur.

Ne

jamais

utiliser un compresseur sans

carter de courroie. Ce modèle

peut se démarrer sans avis.

MANUEL

Le contact avec les pièces mobiles peut

causer des blessures personnelles ou

dégâts matériels.

9. Ne pas porter des vêtements

flottants ni des bijoux qui peuvent se

prendre dans les pièces mobiles du

modèle.

Les

pièces

du compresseur peuvent être

chaudes même si le modèle

est hors circuit.

10. Garder les doigts à l’écart du

compresseur; les pièces mobiles

et chaudes peuvent causer des

blessures et/ou des brûlures.

11. Si l’équipement vibre anormalement,

ARRÊTER le moteur et l’inspecter

immédiatement. La vibration est

généralement une indication d’un

problème.

12. Pour réduire le risque d’incendie,

garder l’extérieur du moteur libre

d’huile, de solvants et de graisse

excessive.

Une soupape de

sûreté ASME avec

une classification qui ne dépasse pas

1207 kPa doit être installée dans le

réservoir de ce compresseur. La soupape

de sûreté ASME doit avoir un débit

d’air et une classification de pression

suffisants pour protéger les pièces

pressurisées contre l’éclatement.

Voir la

décalcomanie

de spécifications sur le compresseur

pour retrouver la pression de service

maximum. Ne pas faire fonctionner

avec un manostat ou soupapes pilotes

réglés au delà de la pression de

fonctionnement maximum.

13. Ne jamais essayer de régler la

soupape de sûreté ASME. Garder la

soupape de sûreté libre de peinture

et autres accumulations.

Ne jamais utiliser

les tuyaux

plastiques (CPV) pour l’air comprimé.

Ceci peut causer des blessures graves

ou la mort.

Ne

jamais

essayer de réparer ni de

modifier un réservoir!

Le soudage, perçage ou

autre modifications peuvent affaiblir

le réservoir et peuvent résulter en

dommage de rupture ou d’explosion.

Toujours remplacer un réservoir usé,

fendu ou endommagé.

Purger le liquide

du réservoir

quotidiennement.

14. L’accumulation d’humidité cause la

rouille qui peut affaiblir le réservoir.

Purger le réservoir régulièrement

et l’inspecter périodiquement pour

la rouille et la corrosion ou autres

conditions dangereuses.

15. L’air mouvante peut agiter la

poussière et le débris qui peut être

dangereux. Dissiper l’air lentement

en purgeant l’humidité ou pendant

la dépressurisation du système de

compresseur.

PRÉCAUTIONS DE PULVÉRISATION

Ne

pas

pulvériser des matériaux

inflammables près d’une

flamme ni près d’une source

d’ignition y inclus le compresseur.

16. Ne pas fumer pendant la

pulvérisation de peinture,

d’insecticides ou d’autres substances

inflammables.

17. Utiliser un masque /

respirateur pendant la

pulvérisation et pulvériser

dans un endroit bien

ventilé pour éviter les

dangers de santé et d’incendie.

18. Ne pas pulvériser vers le compresseur.

Situer le compresseur aussi loin que

possible de l’endroit de pulvérisation

pour minimiser l’accumulation de

surpulvérisation sur le compresseur.

19. Pour pulvériser ou nettoyer avec

des solvants ou produits chimiques

toxiques, suivre les instructions

fournies par le fabricant du produit

chimique.

Introduction

Se référer à la Figure 1.

Manostat - Interrupteur Auto/OFF -

Dans la position AUTO, le compresseur

se coupe automatiquement quand la

pression du réservoir atteint la pression

maximum réglée d’avance. Une fois

que l’air est usé du réservoir et baisse à

une niveau réglé d’avance, le manostat

remet le moteur en marche (on)

automatiquement. Dans la position OFF,

le compresseur ne fonctionnera pas.

Cet interrupteur devrait être dans la

position OFF pendant le branchement

ou le débranchement du cordon

d’alimentation de la prise de courant.

10 Fr

Page 11

Instructions d’utilisation

VT6315, VT6358, VT6361

Lorsque le manostat coupe le moteur

(off), vous entenderez de l’air qui

s’échwappe de la soupape de décharge

du manostat pendant un peu de

temps. Ceci relâche la pression d’air du

tuyau de décharge et permet que le

compresseur se remet en marche plus

facilement.

Régulateur - Le régulateur contrôle la

quantité de pression d’air échappée à la

sortie de tuyau.

Soupape de Sûreté ASME -

Cette soupape laisse échapper l’air

automatiquement si la pression du

réservoir dépasse la pression maximum

réglée d’avance.

Tuyau de Décharge - Ce tuyau

transporte l’air comprimé de la pompe

au clapet. Ce tuyau devient très chaud

pendant son utilisation. Ne jamais

toucher le tuyau de décharge afin

d’éviter des brûlures sévères.

Pour éviter le

graves, ne jamais toucher le tuyau de

décharge.

Discharge Tube

Tuyau de décharge

Handle

Manche

Manomètre

Tank

Pressure

de Réservoir

Gauge

Tank

Réservoir

risque de brûlures

Belt Guard

Intake Filter

Filtre d’Arrivée

Manostat

Pressure

Switch

Breather/

Réglette-Jauge

Dipstick

et Orifice de

& Oil Fill

Remplissage

Hole

d’Huile

Carter De

Courroie

Clapet - Une soupape à sens unique

qui permet à l’air d’entrer le réservoir

mais qui empêche que l’air du

réservoir retourne dans la pompe du

compresseur.

Manche - Conçue pour le déplacement

du compresseur.

Ne jamais utiliser

la manche pour

soulever le modèle du plancher.

Le manche est conçu seulement pour

pousser ou tirer le produit.

Carter de Courroie - Couvre la

courroie, la poulie de moteur et le

volant.

Ne

jamais

utiliser le compresseur sans

un carter de courroie. Ce

modèle peut se démarrer

sans avis. Le contact avec

les pièces mobiles peut causer des

blessures graves ou le dégât matériel.

Robinet de Purge de Réservoir -

Cette soupape est située au fond

du réservoir. Utiliser cette soupape

pour purger l’humidité du réservoir

quotidiennement afin de réduire le

risque de corrosion.

Réduire la pression du réservoir sous

68,95 kPa avant d'ouvrir le robinet de

vidange.

Manomètre de Réservoir - Indique la

pression d’air présente dans le réservoir.

Manomère de Tuyau d’Air - Indique

la quantité de pression d’air dans le

tuyau utilisé pour actionner les outils.

Cette pression est augmentée ou

diminuée avec le régulateur.

Montage

MONTAGE DE MANCHE - La manche

peut être pré-assemblée sur certains

appareils.

Introduire quatre vis de manche à

travers les trous dans le manche et

serrer à la plaque de base (Voir

Figure 2).

Plaque de base du réservoir Vis de manche

Manche

MONTAGE DE PIED

Les articles indiqués d’un astétrisque (*)

sont livrés dégagés, avec le modèle (Voir

Figure 3).

1. Incliner le modèle afin de permettre

l’accès au pied avant et le stabiliser

avec sûreté afin d’assurer que le

modèle ne bascule pas.

2. Introduire le boulon à travers le pied

et le support. Le pied devrait être

situé sur le côté plus bas du support.

3. Fixer avec sûreté avec l’écrou de

blocage. Répéter au sens opposé.

* Pied

* Écrou

* Roue

* Écrou de serrage

* Boulon à épaulement

* Boulon

Figure 3

INSTALLATION DU RENIFLARD

Retirer le bouchon de l’orifice de

remplissage d’huile. Installer le reniflard

(qui se trouve dans le sachet de pièces

avec ce manuel). Voir la Figure 4.

Retirer le

bouchon

Installer le

reniflard

Figure 4

Figure 1

Robinet de Purge

Drain

Petcock

de Réservoir

GRAISSAGE

VÉRIFIER LE NIVEAU

D'HUILE. CERTAINS

UNITÉS INCLUENT L’HUILE. Suivre les

instructions de graissage avant de faire

fonctionner le compresseur.

Figure 2

11 Fr

Page 12

Instructions d’utilisation

Montage (Suite)

Vérifier que la rallonge pour le

drainage de l’huile et le bouchon ont

étés installés (si inclus) puis quitter le

reniflard (voir la Figure 5) et remplir

avec l’huile de la pompe selon le

tableau.

Pompe Capacité d’huile approx.

VS260000KB 0,18 L

VT470000KB 0,25 L

VT480000KB 0,25 L

Voir l’étiquette des caractéristiques sur

le réservoir pour le numéro de modèle

de la pompe et se reporter au tableau

pour la bonne capacité d’huile.

PROLONGEMENT DE VIDANGE

D’HUILE

Quelques modèles ont un prolongement

de vidange d’huile et un bouchon (situé

avec le manuel d’utilisation). Installer

le prolongement de vidange d’huile

et le bouchon avant d’ajouter l’huile

à la pompe. Pour éviter des fuites,

l’utilisation du ruban d’étanchéité ou

du mastic en pate sur les filets aux

deux extrémités du prolongement de

vidange est recommandé. Visser le

bouchon sur un bout du prolongement.

Enlever le bouchon de vidange d’huile

de la base de la pompe et installer

le prolongement de vidange d’huile

(Voir Figure 5).

HUILE

Utiliser l’huile pour compresseur

d’air industrielle SAE 30 ou l’huile

complètement synthétique pour

moteurs telle que Mobil 1 10W-30.

Ne pas utiliser l’huile pour automobile

ordinaire telle que

10W-30. Les additifs dans l’huile

de moteur peuvent causer de

l’encrassement dans les soupapes et

peuvent diminuer la vie de la pompe.

Pour assurer la durée maximum

de la pompe, purger et remplacer

l’huile après la première heure de

fonctionnement. Le niveau d’huile

correct est illustré dans la Figure 5.

Pour les pompes dotées d’un regard

d’huile, on peut vérifier et maintenir

le-niveau d’huile comme indiqué dans

la Figure 5.

DONNÉES ÉLECTRIQUES

L’installation de fils

insuffisante peut causer le

Oil Fill Cap

Bouchon

(Dispose of

(Éliminer

Reniflard de

Dipstick

Breather

réglette-

jauge

OU

OR

Rallonge de vidange d’huile *

Oil Drain Extension*

Bouchon *

Cap*

Plein

Max

Low

Dipstick Oil Read

Niveau d’huile sur la jauge

Figure 8

surchauffage, court-circuit et dommage

d’incendie.

Full

Add

Ajoutez

* Non inclus avec tous les modèles

* Not included with all models.

properly)

correctement)

Breather

Reniflard

Ajoutez

Add Oil

l’huile

Sight Glass

Regard

Plein

Full

Add

Ajoutez

N'utilisez pas un cordon d'extension,

utilisez un tuyau à air plus long.

Les modèles de 120 volts, 15 A peuvent

fonctionner sur un circuit de 120 volts

15 A sous les conditions suivantes:

1. Aucun autre appareil électrique

ou lumière soit connecté au même

branchement.

2. Le voltage est de 120 volts.

3. Le circuit est équipé d’un disjoncteur

de 15 A ou une fusée à retardement

sauté en T (Pour le Canada utiliser

Type D).

4. La longueur du câble de cuivre entre

la prise et le disjoncteur ne dépasse

pas les 12 m (40 pi) AWG 14, ou 21 m

(70 pi) AWG 12.

S’il n’est pas possible d’atteindre les

conditions ci-dessus ou s’il y a un

déclenchement du protecteur de

courant à maintes reprises, il peut

être nécessaire de faire fonctionner le

compresseur sur un circuit de 120 volts,

20 ampères. Voir la Figure 6.

Vérifier la compatibilité avec 240 volts

sur la plaque de donnés du moteur.

L’unité de 240 volts doit travailler sur

un circuit de 240 volts. La câble doit

être branché seulement dans une prise

de 240 volts mise à la terre et pourrait

exiger un nouveau câble et fiche.

Voir la Figure 7.

Broche De Terre

Figure 6

Broche De Terre

Figure 7

Prise De Courant

Mise à la Terre

Prise De Courant

Mise à la Terre

INSTRUCTIONS DE MISE À LA TERRE

Ce produit doit être mis à la terre. Dans

le cas d’un court-circuit, la mise à la terre

diminue le risque de secousse électrique

en fournissant un fil d’échappement

pour le courant électrique. Ce produit

est équipé d’un cordon qui a un fil de

terre avec une fiche de terre appropriée.

La fiche doit être branchée dans une

prise de courant installée et mise à la

terre correctement, conformément à

tous les codes et ordonnances locaux.

Une

mauvaise installation de la fiche

de terre peut créer des risques

de chocs électriques. En cas de

réparation ou remplacement du cordon ou

de la fiche, ne pas connecter le fil de terre

à ni une ni l’autre borne plate. Le fil avec

l’isolation à surface externe verte, avec ou

sans lignes jaunes, est le fil de terre.

N'utilisez pas d'adaptateur de mise à la

terre.

Si vous ne comprenez pas les instructions

pour la mise à la terre ou si vous n’êtes

pas certains si le produit est mis à la

terre correctement, vérifier avec un

électricien ou une personne qualifiée.

Ne pas modifier la fiche fournie; si elle

n'entre pas correctement dans la prise,

faire installer une prise convenable par

un électricien qualifié.

Ce produit est conçu pour l’utilisation

sur un circuit de 120 volts nominales et

a une fiche de mise à la terre comme

celle indiquée sur la Figure 6. Brancher

ce produit seulement à une prise avec la

même configuration de la fiche. Ne pas

utiliser un adaptateur avec ce produit.

12 Fr

Page 13

Instructions d’utilisation

VT6315, VT6358, VT6361

Montage (Suite)

Pendant la

transformation à une tension

alternative, s’assurer que le fil de mise

à la terre vert du cordon soit branché à

la broche de terre de la fiche et au corps

métallique du manostat.

Functionnement

DÉMARRAGE

Cette pompe pour

être remplie d’huile avant le démarrage.

Se référer à la section de Graissage.

Ne pas brancher

pneumatiques au bout ouvert du tuyau

avant que le démarrage soit complet et

que le modèle fonctionne correctement.

Ne jamais

raccords filetés si le réservoir est

pressurisé!

1. Enlever la réglette-jauge du

reniflard et remplir la pompe au

niveau correct. Voir la section de

Graissage.

2. Ouvrir le robinet de purge du

réservoir.

3. Tournez le levier ou le bouton

du manostat à la position OFF

(ARRÊT) et branchez le cordon

d’alimentation.

4. Tournez le levier ou le bouton du

manostat à la position AUTO et

faites fonctionner l’appareil pendant

30 minutes pour roder les pièces de

la pompe (reportez-vous à la

Figure 8).

5. Tourner le bouton du régulateur

complètement au sens contraire

des aiguilles d’une montre. Le

compresseur fonctionnera jusqu’à la

pression maximale réglée d’avance

et s’arrêtera.

A

U

T

F

O

F

/

O

Bouton

Auto/Off

Figure 8

compresseur doit

les outils

débrancher les

Levier - Off

Levier - Auto

6. Tourner le bouton du régulateur

au sens des aiguilles d’une montre

pour purger l’air. Le compresseur

se remettra en marche à la pression

réglée d’avance.

7. Tourner le levier ou bouton

du manostat à la position

OFF et débrancher le cordon

d’alimentation. Tourner le bouton

du régulateur lentement dans le

sens des aiguilles d’une montre afin

de dissiper toute la pression d’air.

Ne pas procéder à l’étape suivante

jusqu’à ce que la pression du

réservoir est à zéro (0).

8. Brancher le tuyau, et ensuite fixer un

mandrin ou un autre outil au bout

ouvert du tuyau. Brancher le cordon

d’alimentation. Tourner le levier du

manostat à la position AUTO. Une

fois que le modèle soit pressurisé,

tourner le bouton du régulateur

dans le sens des aiguilles d’une

montre afin d’atteindre la pression

de sortie désirée.

Entretien

Débrancher, étiquetter et

verrouiller la source de

puissance et dissiper la

pression du système avant de monter,

réparer, déplacer ou de procéder à

l’entretien du modèle.

Toutes réparations doivent être

performées par un représentant de

service authorisé.

POUR LE FONCTIONNEMENT

EFFICACE:

Faire l’essaie de la soupape de sûreté

chaque semaine pour s’assurer qu’elle

fonctionne librement et respecter

l’horaire d’entretien.

1. Tirer sur l’anneau de la soupape

de sûreté et la laisser revenir à sa

position normale (voir

Figure 9). Cette soupape relâche

l’air automatiquement lorsque la

pression du réservoir dépasse le

maximum réglé d’avance.

9. Après avoir utilisé l’appareil, tournez

le levier ou le bouton du manostat à

la position OFF (arrêt).

10. Si le compresseur sera hors usage

pendant longtemps, purger l’air des

canalisations et purger l’humidité du

réservoir avec le robinet de purge.

Ensuite suivre l’horaire d’entretien.

REMARQUE: Les modèles électriques

sont équipé d’un manostat qui coupe le

moteur (OFF) automatiquement quand

la pression du réservoir atteint un

niveau réglé d’avance. Une fois que l’air

soit utilisé dans le réservoir et que la

pression du réservoir atteint un niveau

bas réglé d’avance, le manostat met le

moteur en marche automatiquement.

Figure 9

Ne pas trifouiller

avec cette soupape.

Vérifier cette soupape de temps en

temps. S’il y a des fuites d’air après que

l’anneau soir relâché, ou si la soupape

est prise et ne peut pas être actionnée

par l’anneau, la soupape de sûreté doit

être remplacée.

Une large quantité

d’air sera relâchée

rapidement si cette soupape est

actionnée lorsque le réservoir est

pressurisé. Une large quantité d’air sera

relâchée rapidement si cette soupape

HUMIDITÉ DANS L’AIR COMPRIMÉ

L’humidité dans l’air comprimé forme des gouttelettes en arrivant de la pompe

du compresseur d’air. Si l’humidité est élevée, ou si le compresseur est utilisé

continuellement, cette humidité s’accumulera dans le réservoir. Pendant

l’utilisation d’un pistolet à peinture ou d’un pistolet pour le décapage au sable,

cette eau sera transportée du réservoir par moyen du tuyau, et en forme de

gouttelettes, mélangée avec le matériel utilisé.

IMPORTANT: Cette condensation peut causer des taches d’eau sur votre travail

de peinture, surtout pendant la pulvérisation de peinture qui n’est pas à base

d’eau. Pendant le décapage au sable, cette eau servira à tenir le sable ensemble

et causera une obstruction dans le pistolet.

Un filtre à air en canalisation situé aussi près du pistolet que possible aidera à

éliminer cette humidité.

13 Fr

Page 14

Instructions d’utilisation

Entretien (Suite)

est actionnée lorsque le réservoir est

pressurisé.

2. Avec le moteur dans la position OFF

et débranché, nettoyer le débris du

moteur, du volant , du réservoir, des

canalisations d’air et des ailettes de

refroidissement de la pompe.

SERVICE TECHNIQUE

Pour des informations concernant le

fonctionnement ou la réparation de ce

produit, composer le 1-800-543-6400.

Entreposage

1. Lorsque hors d’usage, le tuyau

et le compresseur devraient être

entreposés dans un endroit frais et

sec.

2. Purger l’humidité du/des réservoir(s).

Débrancher le tuyau et l’accrocher

avec les bouts ouverts faisant face

en bas pour que l’humidité se purge.

OPÉRATION QUOTIDIEN HEBDOMAD AIRE MENSUEL 3 MOIS

Vérifier le niveau

d’huile

Purger le réservoir

Vérifier le filtre

à air

Vérifier la soupape

de sûreté

Nettoyer le modèle

Vérifier le serrage

des courroies

Changer l’huile

3. Protéger le cordon électrique contre

le dommage en le tortillant sans

serrer autour de la manche du

modèle ou en le roulant.

Guide De Dépannage

Symptom Possible Cause(s) Corrective Action

Pression de décharge

basse

Le filtre à air fond à

cause du surchauffage

de la pompe

Bruit excessif

(cognement)

1. Demande d’air dépasse la

capacité de la pompe

2. Fuites d’air 2. Écouter pour des fuites d’air. Appliquer une solution savonneuse à tous

3. Arrivée d’air limitée 3. Nettoyer la cartouche filtrante.

4. Joints éclatés 4. Remplacer tous joints défectueux.

5. Fuites ou dommage aux

soupapes

1. Joint isolant entre le filtre et la

culasse manquant

2. Soupape cassée/joint éclaté 2. Remplacer les soupapes ou installer un nouveau joint d’étanchéité.

1. Moteur ou poulie de

compresseur dégagé

2. Manque d’huile dans le carter 2. Vérifier le niveau d’huile; si bas, inspecter les paliers pour du dommage.

3. Bielle usée 3. Remplacer la bielle. Entretenir le niveau d’huile et changer l’huile plus

4. Alésages d’axe de piston usés 4. Enlever le piston équipé du compresseur et l’inspecter pour l’usure

5. Piston frappe la plaque de

soupape

1. Diminuer la demande d’air ou utiliser un compresseur de plus haute

capacité.

les raccords et branchements et vérifier pour des bulles qui indiquent

des fuites. Serrer ou remplacer les raccords ou branchements qui ont des

fuites.

5. Enlever la culasse et inspecter pour des soupapes cassées, soupapes mal

dressées, sièges de soupapes endommagés, etc. Remplacer toutes les

pièces défectueuses et remonter.

Installer un nouveau joint d’étanchéité

est enlevée

1. Installer un joint d’étanchéité.

1. Poulies de moteur et de compresseur dégagés sont causes communes de

cognement. Serrer les boulons de serrage et vis de pression de poulie.

L’huile sale peut causer l’usure excessif.

souvent.

excessif. Remplacer les axes de piston ou pistons usés au besoin. Entretenir

le niveau d’huile correct et changer l’huile plus souvent.

5. Enlever la tête du compresseur et la plaque de soupape et inspecter pour

de l’encrassement charbonneux ou autre matières étranges sur la partie

supérieure du piston. Remplacer la culasse et la plaque de soupape et

utiliser un nouveau joint d’étanchéité. Voir la section de Graissage pour

l’huile recommandée.

HORAIRE D’ENTRETIEN

l

l

l

l

EXIGENCE DE COUPLE (kg-cm)

Modéle

VS 115-144 58-138

VT 259-346 58-138

de culasse chaque fois que la culasse

Boulons de

tête de

compresseur

l

l

l

Boulons de

chapeau de

palier

14 Fr

Page 15

Instructions d’utilisation

Guide De Dépannage (Suite)

Symptom Possible Cause(s) Corrective Action

Bruit excessif

(cognement)

(Suite)

Large quantité d’huile

dans l’air de décharge

REMARQUE: Il y aura

toujours un peu d’huile

dans le jet d’air avec

un compresseur graissé

par l’huile

6. Clapet bruyant dans le système

de compresseur

1. Segments de piston usés 1. Remplacer les segments de piston. Entretenir le niveau d’huile correct et

2. Arrivée d’air du compresseur

limité

3. Huile excessive dans le

compresseur

4. Viscosité d’huile incorrecte 4. Utiliser l’huile Mobil 1

6. Remplacer.

Ne pas démonter le clapet si le réservoir

changer l’huile plus souvent.

2. Nettoyer le filtre. Vérifier le système d’arrivée pour autres restrictions.

3. Vidanger jusqu’au niveau plein.

est pressurisé

®

10W-30.

VT6315, VT6358, VT6361

Eau dans l’air de débit/

réservoir

Le moteur ronronne et

fonctionne lentement

ou pas du tout

Le mécanisme de

réenclenchement se

déclenche à maintes

reprises ou les fusibles

sautent à maintes

reprises

Le réservoir ne

conserve pas la

pression quand le

compresseur est hors

circuit et la soupape

d’arrêt est fermée

Le manostat laisse

souffler de l’air

continuellement à

travers de la soupape

de déchargement

Le manostat ne

relâche pas l’air

lorsque le modèle se

coupe (OFF)

Vibration excessive 1. Attaches désserrés 1. Serrer.

Fonctionnement normal. La

quantité d’eau augmente avec le

temps humide

1. Cordon prolongateur utilisé 1. N’utilisez pas un cordon prolongateur. Utilisez un tuyau d’air plus long

2. Fonctionnement défectueux

du clapet ou de la soupape de

déchargement

3. Basse tension 3. Vérifier avec un voltmètre, inspecter le disjoncteur de réenclenchement

4. Panne de manostat - contacts ne

ferment pas

1. Trop d’appareils sur le même

circuit

2. Taille de fusible ou de

disjoncteur incorrecte

3. Fonctionnement défectueux du

clapet

4. Manostat réglé trop haut 4. Régler ou remplacer.

5. Fils désserrés 5. Inspecter tous les branchements électriques.

6. Fonctionnement défectueux du

moteur

1. Clapet usé

2. Inspecter tous branchements et

raccordements pour des fuites

3. Inspecter le réservoir pour des

fentes ou des trous d’épingles

Fonctionnement défectueux du

clapet

Fonctionnement défectueux de la

soupape de déchargement sur le

manostat

2. Changement de la courroie

exigé

3. Redressage de la courroie 3. Aligner le volant et la poulie.

1. Purger le réservoir plus souvent, au moins quotidiennement.

2. Ajouter un filtre pour diminuer la quantité d’eau dans la canalisation

d’air.

avec un diamètre plus large.

2. Remplacer le clapet, la soupape de déchargement ou le manostat.

Ne pas démonter le clapet si le réservoir

du moteur. Si le disjoncteur de réenclenchement se déclenche à maintes

reprises, rechercher et corriger la cause. Voir l’article suivant.

4. Réparer ou remplacer le manostat.

1. Limiter l’usage du circuit au compresseur d’air seulement.

2. Vérifier la classification des fusibles et des disjoncteurs.

3. Remplacer le clapet.

Ne pas démonter le clapet si le réservoir

6. Remplacer le moteur.

1. Remplacer le clapet.

Ne pas démonter le clapet si le réservoir

2. Serrer.

3. Remplacer le réservoir. Ne jamais réparer un réservoir endommagé.

Remplacer le clapet si la soupape de déchargement a une fuite d’air

continue.

Ne pas démonter le clapet si le réservoir

Remplacer le manostat si la pression n’est pas dissipé pendant une courte

durée quand le modèle se coupe.

Ne pas démonter le clapet si le réservoir

2. Remplacer avec une courroie de taille correcte.

est pressurisé

est pressurisé

est pressurisé

est pressurisé

est pressurisé

15 Fr

Page 16

Instructions d’utilisation

Garantie Limitée

1. DURÉE: À partir de la date d’achat par l’acheteur original comme suit : Trois Ans ou Quatre Ans comme indiqué sur l’étiquette de

caractéristiques du produit.

2. GARANTIE ACCORDÉE PAR (GARANT) :

Campbell Hausfeld/Scott Fetzer Company, 100 Production Drive, Harrison, Ohio, 45030, Téléphone: (800) 543-6400.

3. BÉNÉFICIAIRE DE CETTE GARANTIE (ACHETEUR) : L’acheteur original (sauf en cas de revente) du produit Campbell Hausfeld.

4. PRODUITS COUVERTS PAR CETTE GARANTIE : Cette compresseur d’air Campbell Hausfeld.

5. COUVERTURE DE LA PRÉSENTE GARANTIE : Pièces et Main d’œuvre pour remédier à de défauts importants causés par matériau et main

d’œuvre pendant la première année de possession avec les exceptions indiquées ci-dessous. Pièces seulement pour remédier à de défauts

importants causés par matériau et main d’œuvre pendant le temps restant de la couverture avec les exceptions indiquées ci-dessous.

6. LA PRÉSENTE GARANTIE NE COUVRE PAS :

A. Les garanties implicites, y compris celles de commercialisation et D’ADAPTATION À UNE FONCTION PARTICULIÈRE SONT LIMITÉES À

PARTIR DE LA DATE D’ACHAT INITIALE TELLE QU’INDIQUÉE DANS LA SECTION DURÉE. Si le compresseur d’air est utilisé pour une fonction

commerciale, industrielle ou pour la location, la durée de la garantie sera quatre-vingt-dix (90) jours de la date d’achat. Certaines Provinces

(États) n’autorisent pas de limitations de durée pour les garanties implicites, donc les limitations précédentes peuvent donc ne pas

s’appliquer.

B. TOUT DOMMAGE, PERTE OU DÉPENSE FORTUIT OU INDIRECT POUVANT RÉSULTER DE TOUT DÉFAUT, PANNE OU MAUVAIS

FONCTIONNEMENT DU PRODUIT CAMPBELL HAUSFELD. Quelques Provinces (États) n’autorisent pas l’exclusion ni la limitation des

dommages fortuits ou indirects. La limitation ou l’exclusion précédente peut donc ne pas s’appliquer.

C. Toute panne résultant d’un accident, d’une utilisation abusive, de la négligence ou d’une utilisation ne respectant pas les instructions

données dans le(s) manuel(s) accompagnant le produit.

D. Service avant livraison; le montage, l’huile ou la graisse et les réglages par exemple.

E. Articles ou services qui sont exigés pour l’entretien normal du produit; graisses, filtres et joints d’étanchéité par exemple.

F. Les moteurs à essence et les pièces détachées sont expressément exclus de cette garantie limitée. L’acheteur doit observer la garantie du

fabricant de moteur qui est fournie avec le produit.

G. Articles supplémentaires qui ne sont pas couverts sous cette garantie :

1. Articles exclus relatifs à Tous les Compresseurs

a. Toutes pièces détachées endommagées pendant l’expédition, n’importe quelle panne causée par un montage ou fonctionnement

du modèle sous des conditions qui ne se conforment pas aux directives de montage et de fonctionnement ou dommage causé

par le contact avec les outils ou les alentours.

b. La défaillance de la pompe ou de la soupape causée par la pluie, l’humidité excessive, un environnement corrosif ou autres polluants.

c. Les défauts de forme qui n’ont pas d’effet sur le fonctionnement du compresseur.

d. Les réservoirs rouillés, y compris mais sans s’y limiter à la rouille causée par la vidange incorrecte ou par un environnement

corrosif.

e. Les composants suivants sont considérés comme des articles sujets à l’usure normale et ne sont pas couverts après le premier an

de possession. Moteur électrique, soupape de retenue, interrupteur de pression, régulateur, manomètres, tuyaux, tubes, raccords,

vis, écrous, articles de quincaillerie, courroies, poulies, volant, filtre d’air et boîtier, joints d’étanchéité, fuites d’air et d’huile,

consommation ou usage d’huile, anneaux de piston.

f. Robinets de vidange.

g. Dommage dû à la tension ou installation de fils incorrecte.

h. Autres articles non indiqués mais considérés pièces d’usure générale.

i. Manostats, régulateurs d’air et soupapes de sûreté qui ont étés modifiés d’après les réglages de l’usine.

j. Dommage causé par l’entretien insuffisant du filtre.

k. Moteurs à induction utilisant l’électricité produite par un générateur.

2. Compresseurs Graissés

a. Usure de la pompe ou dommage aux soupapes causé par l’utilisation d’huile non-spécifiée.

b. Usure de la pompe ou dommage aux soupapes causé par toute contamination d’huile ou par le manque de suivre les directives

d’entretien d’huile.

c. Usure ou dommage de la pompe causé par le manque de suivre les directives d’entretien d’huile, fonctionnement avec le niveau

d’huile au dessous du bon niveau ou fonctionnement sans huile.

H. Main d’œuvre, appel de service, ou frais de transport après le premier an de possession de compresseurs stationnaires. Les compresseurs

stationnaires sont identifiés par l’absence de manchon ou de roues.

7. RESPONSABILITÉS DU GARANT AUX TERMES DE CETTE GARANTIE : Réparation ou remplacement, au choix du Garant, de produits ou

composants défectueux, ont connu une défaillance ou qui ne sont pas conformes pendant la durée précise de validité de la garantie.

8. RESPONSABILITÉS DE L’ACHETEUR AUX TERMES DE CETTE GARANTIE :

A. Fournir une preuve d’achat datée et un état d’entretien.

B. Appelez Campbell Hausfeld (800-543-6400) pour obtenir vos options de service sous garantie. Les frais de transport sont la responsabilité

de l’acheteur.

C. Utilisation et entretien du produit avec un soin raisonnable, ainsi que le décri(vent)t le(s) manuel(s) d’utilisation.

D. Réparations qui exigent de temps additionnel, taux de charge de fin de semaine, ou tout problème au-delà du taux normal de

remboursement par main d’œuvre de réparations sous garantie du fabriquant.

E. Temps nécessaire pour tout contrôle de sécurité, entraînement de sécurité, ou situation semblable parce que le personnel de service puisse

obtenir l’accès à l’installation.

F. L’emplacement de l’unité doit être facilement accessible et avoir l’espace suffisant parce que le personnel de service puisse effectuer les

réparations.

9. RÉPARATION OU REMPLACEMENT EFFECTUÉ PAR LE GARANT AUX TERMES DE LA PRÉSENTE GARANTIE : La réparation ou le remplacement

sera prévu et exécuté en fonction de la charge de travail dans le centre de service et dépendra de la disponibilité des pièces de rechange.

Cette Garantie Limitée s’applique aux É.-U., au Canada et au Mexique seulement et vous donne des droits juridiques précis. L’acheteur peut

également jouir d’autres droits qui varient d’une Province, d’un État ou d’un Pays à l’autre.

16 Fr

Page 17

Ver la Garantía en página 24 para información importante sobre el uso comercial de este producto.

Manual de Instrucciones de Operación y Lista de Partes VT6315, VT6358, VT6361

Por favor lea y guarde estas instrucciones. Léalas cuidadosamente antes de tratar de montar, instalar, operar o dar mantenimiento al producto