Page 1

Single Stage Air Compressor

Operating Instructions and Parts Manual

© 2016 Campbell Hausfeld

A Marmon/Berkshire Hathaway Company

Models: CE4104 and TQ3104

EN

IN572800AV 7/16

Page 2

Please read and save these instructions. Read carefully before attempting to

assemble, install, operate or maintain the product described.

Protect yourself and others by observing all safety information. Failure to comply

with instructions could result in personal injury and/or property damage! Retain

instructions for future reference.

REMINDER: Keep your dated proof of purchase for warranty purposes! Attach it to

this manual or file it for safekeeping.

For parts, product & service information

Model #: __________________________

Serial #: ___________________________

Purchase Date: _____________________

REGISTER YOUR PRODUCT ONLINE NOW! www.campbellhausfeld.com

REGISTER YOUR PRODUCT ONLINE NOW! www.campbellhausfeld.com

READ AND FOLLOW ALL INSTRUCTIONS • SAVE THESE INSTRUCTIONS • DO NOT DISCARD

READ AND FOLLOW ALL INSTRUCTIONS • SAVE THESE INSTRUCTIONS • DO NOT DISCARD

visit www.campbellhausfeld.com

Campbell Hausfeld

100 Production Drive

Harrison, Ohio 45030

Page 3

BEFORE YOU BEGIN

Introduction

Air compressor units are intended to provide compressed air to power pneumatic tools, operate spray guns

and supply air for pneumatic valves and actuators. The pumps supplied with these units have oil lubricated

bearings. A small amount of oil carryover is present in the compressed air stream. Applications requiring air

free of oil vapor should have the appropriate filters installed. The air compressor units are to be mounted

per the instructions provided on a solid floor. Any other use of these units will void the warranty and the

manufacturer will not be responsible for problems or damages resulting from such misuse.

UNPACKING

Do not lift or move unit without appropriately rated equipment. Be sure

coolers. Do not use unit to lift other attached equipment.

After unpacking the unit, inspect carefully for any damage that may have occurred during transit. Check for

loose, missing or damaged parts. Check to be sure all supplied accessories are enclosed with the unit. In case

of questions, damaged or missing parts, please visit www.campbellhausfeld.com for customer assistance.

Do not operate unit if damaged during shipping, handling or use. Damage

Required Items - Not Included

• Oil

QUICK REFERENCE

Recommended Oil (2 Options)

Single viscosity SAE 30 ISO100 nondetergent compressor oil. Part number ST126700AV.

10W30 synthetic oil such as Mobil 1® .

Oil Capacity

Approximately 40 oz.

the unit is securely attached to lifting device used. Do not lift unit by holding onto tubes or

may result in bursting and cause injury or property damage.

SPECIFICATIONS

SAFETY /

INSTALLATION

ASSEMBLY /

TROUBLESHOOTINGOPERATION

MAINTENANCE /

REPAIR

1

Page 4

SAFETY /

GENERAL SAFETY INSTRUCTIONS

Safety Guidelines

This manual contains information that is very important to know and understand. This information is

provided for SAFETY and to PREVENT EQUIPMENT PROBLEMS. To help recognize this information, observe

GETTING STARTED

SPECIFICATIONS

the following symbols.

Danger indicates an imminently hazardous situation which, if not avoided, WILL result in death

Warning indicates a potentially hazardous situation which, if not avoided, COULD result in

Caution indicates a potentially hazardous situation which, if not avoided, MAY result in minor or

IMPORTANT: Information that requires special attention.

Safety Symbols

The following Safety Symbols appear throughout this manual to alert you to important safety hazards and

precautions.

or serious injury.

death or serious injury.

moderate injury.

Notice indicates important information, that if not followed, may cause damage to equipment.

MANUAL

ASSEMBLY /

INSTALLATION

TROUBLESHOOTING OPERATION

Wear Eye

and Mask

Protection

Risk of

Fumes

Read

Manual

First

Risk of

Pressure

Risk of

Fire

Risk of

Shock

Risk of

Moving

Parts

Risk of

Hot Parts

Risk of

Explosion

California Proposition 65

This product or its power cord may contain chemicals known to the State of California to cause

You can create dust when you cut, sand, drill or grind materials such as wood,

cause cancer, birth defects, or other reproductive harm. Wear protective gear.

cancer and birth defects or other reproductive harm. Wash hands after handling.

paint, metal, concrete, cement, or other masonry. This dust often contains chemicals known to

Important Safety Information

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain the

product described. Protect yourself and others by observing all safety information. Failure to comply with instructions

could result in personal injury and/or property damage! Retain instructions for future reference.

This manual contains important safety, operational and maintenance information. If you have any

questions, please visit www.campbellhausfeld.com for customer assistance.

Since the air compressor and other components (material pump, spray guns, filters, lubricators, hoses, etc.)

used make up a high pressure pumping system, the following safety precautions must be observed at all

times:

2

Page 5

MANUAL

Important Safety Information (Continued)

BREATHABLE AIR WARNING

This compressor/pump is not equipped and should not be used “as is” to supply breathing quality

air. For any application of air for human consumption, the air compressor/pump will need to be

fitted with suitable in-line safety and alarm equipment. This additional equipment is necessary to

properly filter and purify the air to meet minimal specifications for Grade D breathing as described in

Compressed Gas Association Commodity Specification G 7.1, OSHA 29 CFR 1910. 134, and/or Canadian

Standards Associations (CSA).

DISCLAIMER OF WARRANTIES

In the event the compressor is used for the purpose of breathing air application and proper in-line

safety and alarm equipment is not simultaneously used, existing warranties shall be voided, and

Campbell Hausfeld disclaims any liability whatsoever for any loss, personal injury or damage.

General Safety

• Read all manuals included with this product carefully. Be thoroughly familiar with the controls and the

proper use of the equipment.

• Follow all local electrical and safety codes as well as the United States National Electrical Codes (NEC)

and Occupational Safety and Health Act (OSHA).

• Only persons well acquainted with these rules of safe operation should be allowed to use the

compressor.

• Keep visitors away and NEVER allow children in the work area.

• Wear safety glasses and use hearing protection when operating the unit.

• Do not stand on or use the unit as a handhold.

• Before each use, inspect compressed air system and electrical components for signs of damage,

deterioration, weakness or leakage. Repair or replace defective items before using.

• Check all fasteners at frequent intervals for proper tightness.

Motors, electrical equipment and controls can cause electrical arcs that will ignite a flammable

gas or vapor. Never operate or repair in or near a flammable gas or vapor. Never store

flammable liquids or gases in the vicinity of the compressor.

Never operate compressor without a beltguard. This unit can start automatically without

warning. Personal injury or property damage could occur from contact with moving parts.

SPECIFICATIONS

SAFETY /

INSTALLATION

ASSEMBLY /

• Do not wear loose clothing or jewelry that will get caught in the moving parts of the unit.

Compressor parts may be hot even if the unit is stopped.

• Keep fingers away from a running compressor; fast moving and hot parts will cause injury and/or burns.

• If the equipment should start to vibrate abnormally, STOP the engine/motor and check immediately for

the cause. Vibration is generally an indication of trouble.

• To reduce fire hazard, keep engine/motor exterior free of oil, solvent, or excessive grease.

An ASME code safety relief valve with a setting no higher than the Maximum Allowable

this compressor. The ASME safety valve must have sufficient flow and pressure ratings to protect the pressurized

components from bursting. The flow rating can be found in the parts manual. The safety valve in the intercooler does

not provide system protection.

Maximum operating pressure is 140 psi for single stage compressors. Do not operate with

Working Pressure (MAWP) of the tank MUST be installed in the air lines or in the tank for

pressure switch or pilot valves set higher than 140 psi (single stage).

• Never attempt to adjust ASME safety valve. Keep safety valve free from paint and other accumulations.

3

TROUBLESHOOTINGOPERATION

MAINTENANCE /

REPAIR

Page 6

SAFETY /

ASSEMBLY /

GETTING STARTED

SPECIFICATIONS

INSTALLATION

Important Safety Information (Continued)

Never attempt to repair or modify a tank! Welding, drilling or any other modification will

or damaged tanks.

• Tanks rust from moisture build-up, which weakens the tank. Make sure to drain tank regularly and

inspect periodically for unsafe conditions such as rust formation and corrosion.

• Fast moving air will stir up dust and debris which may be harmful. Release air slowly when draining

moisture or depressurizing the compressor system.

weaken the tank resulting in damage from rupture or explosion. Always replace worn, cracked

Drain liquid from tank daily.

Spraying Precautions

Do not spray flammable materials in vicinity of open flame or near ignition sources including

• Do not smoke when spraying paint, insecticides, or other flammable substances.

• Use a face mask/respirator when spraying and spray in a well ventilated area to prevent health and fire

hazards.

• Do not direct paint or other sprayed material at the compressor. Locate compressor as far away from

the spraying area as possible to minimize overspray accumulation on the compressor.

• When spraying or cleaning with solvents or toxic chemicals, follow the instructions provided by the

chemical manufacturer.

the compressor unit.

Save These Instructions

Do Not Discard

The DANGER, WARNING, CAUTION, and NOTICE notifications and instructions in this manual

cannot cover all possible conditions and situations that may occur. It must be understood by the

operator that caution is a factor which cannot be built into this product, but must be supplied by

the operator.

4

Page 7

Getting To Know Your Compressor

Compressor Pump

Air Filter

Pressure Switch

Tank Pressure

Gauge

Discharge Tube

Beltguard

Unloader Tube

Safety Relief

Motor

SPECIFICATIONS

SAFETY /

INSTALLATION

ASSEMBLY /

Figure 1 - Vertical Unit Identification

Manual Tank Drain

5

TROUBLESHOOTINGOPERATION

MAINTENANCE /

REPAIR

Page 8

SAFETY /

SPECIFICATIONS

Motor HP 5

Power 208-230V

GETTING STARTED

SPECIFICATIONS

Phase 1

Displacement CFM 26.24

Air Delivery CFM @ 90 PSI 17.3

Air Delivery CFM @ 140 PSI 14.2

Max PSI 140

Pump RPM 950

Tank Capacity 80 gallons

Unit Weight 410 lbs

Amp Draw 21.0

Max Duty Cycle 80/20

Tank Outlet 3/4 inch (F) NPT

DIMENSIONS

CE4104 and TQ3104

ASSEMBLY /

INSTALLATION

CE4104 and TQ3104

Length 23 inches

Width 31 inches

Height 71 inches

6

Page 9

INSTALLATION INSTRUCTIONS

inches

Disconnect, tag and lock out power source then release all pressure from the system before

Do not lift or move unit without appropriately rated equipment. Be sure the unit is securely

to lift other attached equipment.

attempting to install, service, relocate or perform any maintenance.

attached to lifting device used. Do not lift unit by holding onto tubes or coolers. Do not use unit

Never use the wood shipping skids for mounting the compressor.

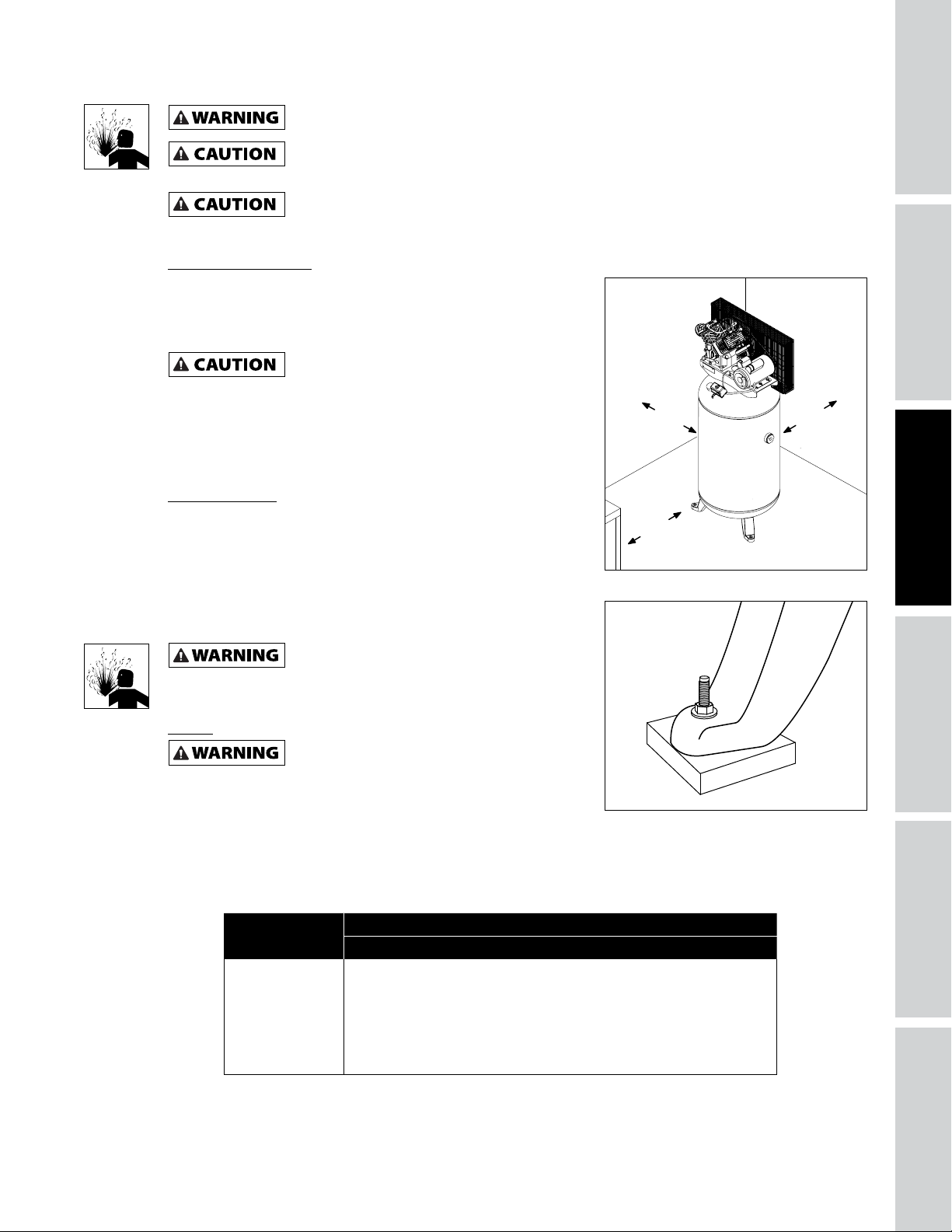

Picking the Location

Install and operate unit at least 18 inches from any obstructions

in a clean, well ventilated area. The surrounding air temperature

should not exceed 100° F. This will ensure an unobstructed flow of

air to cool compressor and allow adequate space for maintenance.

Do not locate the compressor air inlet near steam,

paint spray, sandblast areas or any other source

of contamination.

NOTE: If compressor operates in a hot, moist environment, supply

compressor pump with clean, dry outside air. Supply air should be

piped in from external sources.

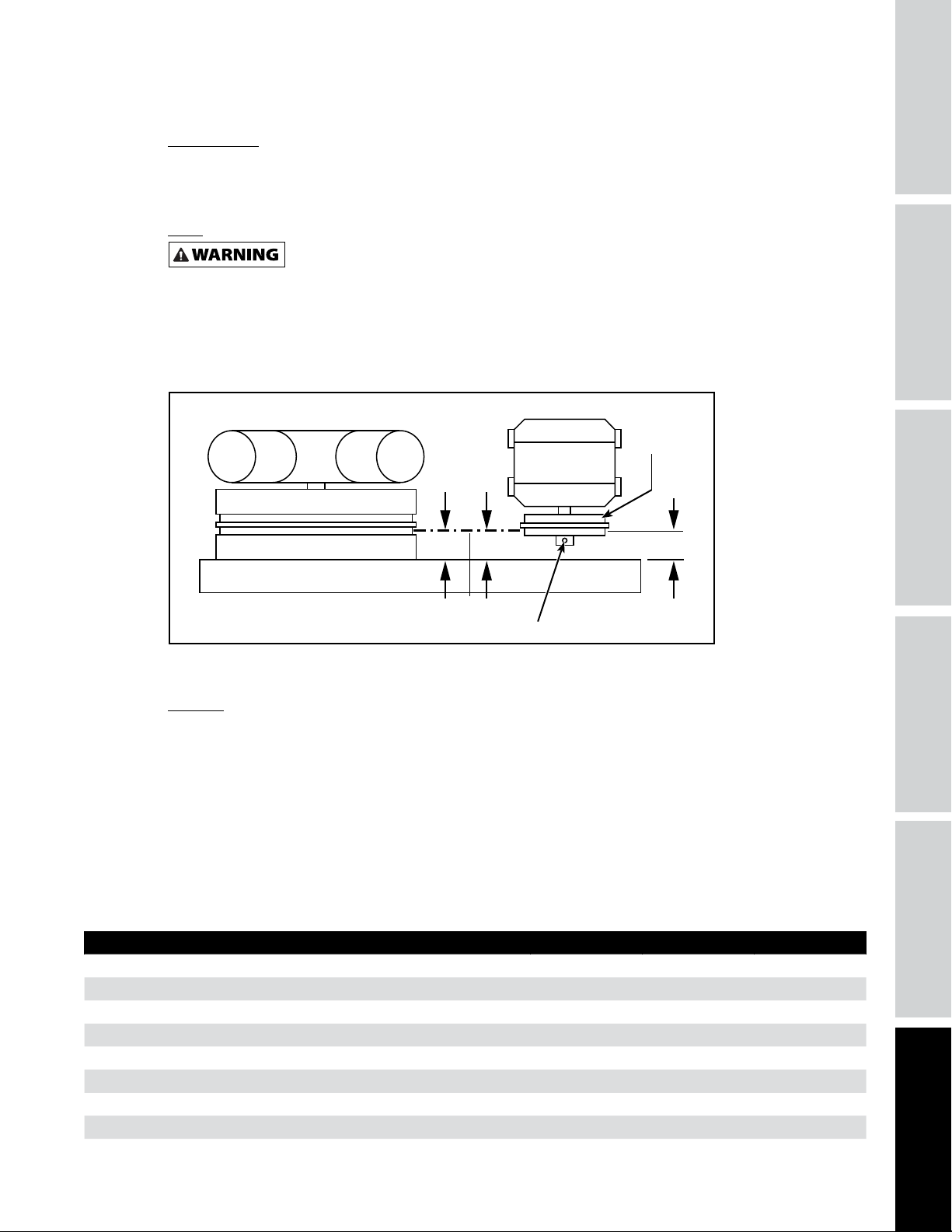

Tank Mounting

The tank should be bolted into a flat, even, concrete floor or on a

separate concrete foundation. Vibration isolators should be used

between the tank leg and the floor. Part number MP345700AJ

isolator pads are recommended for units.

When using isolator pads, do not draw bolts tight. Allow the pads

to absorb vibrations. When isolators are used, a flexible hose or

coupling should be installed between the tank and service piping.

Failure to properly install the tank can lead

to cracks at the welded joints and possible

bursting.

≥ 18

inches

≥ 18

Figure 2 - Location

≥ 18

inches

SPECIFICATIONS

SAFETY /

INSTALLATION

ASSEMBLY /

Piping

Never use plastic (PVC) pipe for compressed air.

Any tube, pipe or hose connected to the unit must be able to

withstand the temperature generated and retain the pressure. All

pressurized components of the air system must have a pressure

rating of 200 psi or higher. Incorrect selection and installation of

any tube, pipe or hose could result in bursting and injury. Connect

piping system to tank using the same size fitting as the discharge port.

Serious injury or death could result.

Figure 3 - Isolator Pad

Minimum Pipe Size For Compressed Air Line

LENGTH OF PIPING SYSTEM

CFM

10 1/2 inch 1/2 inch 3/4 inch 3/4 inch

20 3/4 inch 3/4 inch 3/4 inch 1 inch

40 3/4 inch 1 inch 1 inch 1 inch

60 3/4 inch 1 inch 1 inch 1 inch

100 1 inch 1 inch 1 inch 1-1/4 inch

25 FEET 50 FEET 100 FEET 250 FEET

TROUBLESHOOTINGOPERATION

MAINTENANCE /

REPAIR

7

Page 10

SAFETY /

ASSEMBLY /

INSTALLATION INSTRUCTIONS (CONTINUED)

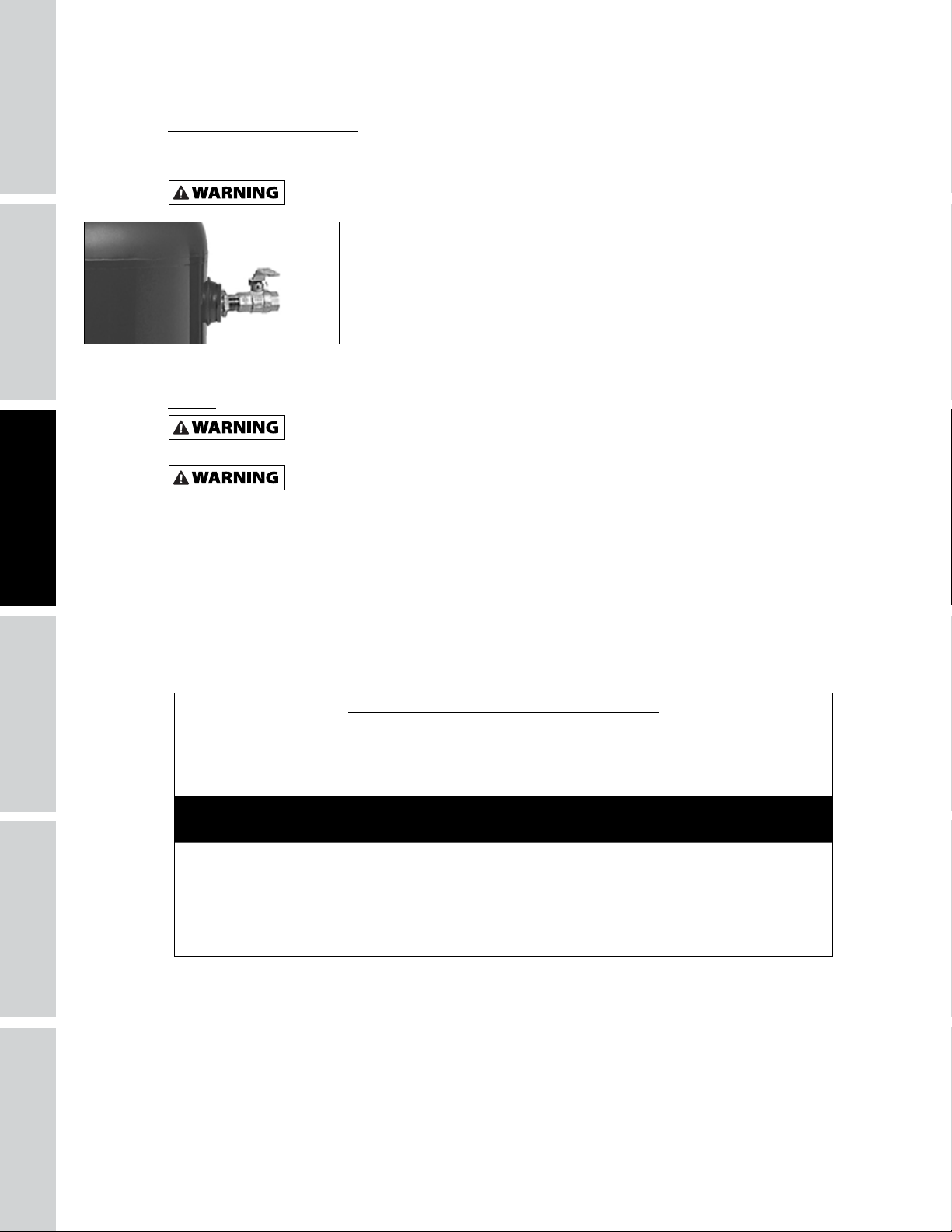

Installing A Shut-Off Valve

A shut-off valve should be installed on the discharge port of the tank to control the air flow out of the tank.

The valve should be located between the tank and the piping system.

GETTING STARTED

SPECIFICATIONS

Figure 4 - Shut-off Valve

INSTALLATION

Never install a shut-off valve between the compressor pump and the tank. Personal injury and/

or equipment damage may occur. Never use reducers in discharge piping.

When creating a permanently installed system to distribute compressed air,

find the total length of the system and select pipe size from the chart on

page 7. Bury underground lines below the frost line and avoid pockets where

condensation can gather and freeze.

Apply air pressure to the piping installation and make sure all joints are

free from leaks BEFORE underground lines are covered. Before putting the

compressor into service, find and repair all leaks in the piping, fittings and

connections.

Wiring

All wiring and electrical connections must be performed by a qualified electrician

national codes.

Wiring must be installed in accordance with National Electrical Code and local codes and standards that

have been set up covering electrical apparatus and wiring. These should be consulted and local ordinances

observed. Be certain that adequate wire sizes are used, and that:

1. Service is of adequate ampere rating.

2. The supply line has the same electrical characteristics (voltage, cycles and phase) as the motor. Refer to

motor name plate for electrical ratings and specifications.

3. The line wire is the proper size and that no other equipment is operated from the same line. The chart

gives minimum recommended wire sizes for compressor installations.

familiar with induction motor controls. Installations must be in accordance with local and

Overheating, short circuiting and fire damage will result from inadequate wiring.

TROUBLESHOOTING OPERATION

Minimum Wire Size (Use 75°C Copper Wire)

Make sure voltage is correct with the motor wiring.

NOTE: If using 208 volts single phase, make sure the motor name plate states it is rated for 208 volts

single phase. 230 volt single phase motors do not work on 208 volts unless they have the 208 volt

rating.

SINGLE PHASE

HP AMPS 230V

1-4 HP UP TO 22.0 10 AWG

5.0 8 AWG

Recommended wire sizes may be larger than the minimum set up by local ordinances. If so, the larger size

wire should be used to prevent excessive line voltage drop. The additional wire cost is very small compared

with the cost of repairing or replacing a motor electrically “starved” by the use of supply wires which are too

small.

8

Page 11

INSTALLATION INSTRUCTIONS (CONTINUED)

Grounding

Improperly grounded electrical components are shock hazards. Make sure all the

components are properly grounded to prevent death or serious injury.

This product must be grounded. Grounding reduces the risk of electrical shock by providing an escape wire

for the electric current if short circuit occurs. This product must be installed and operated with a power cord

or cable that has a grounding wire.

Breakers and Fuses

The entire electrical system should be checked by a certified electrician. Time delay breakers and fuses are

required for this compressor. A tripped breaker or blown fuses may indicate a direct short to ground, high

current draw, improper wiring, incorrect fuse or breaker size and/or type. This needs to be evaluated by a

certified electrician.

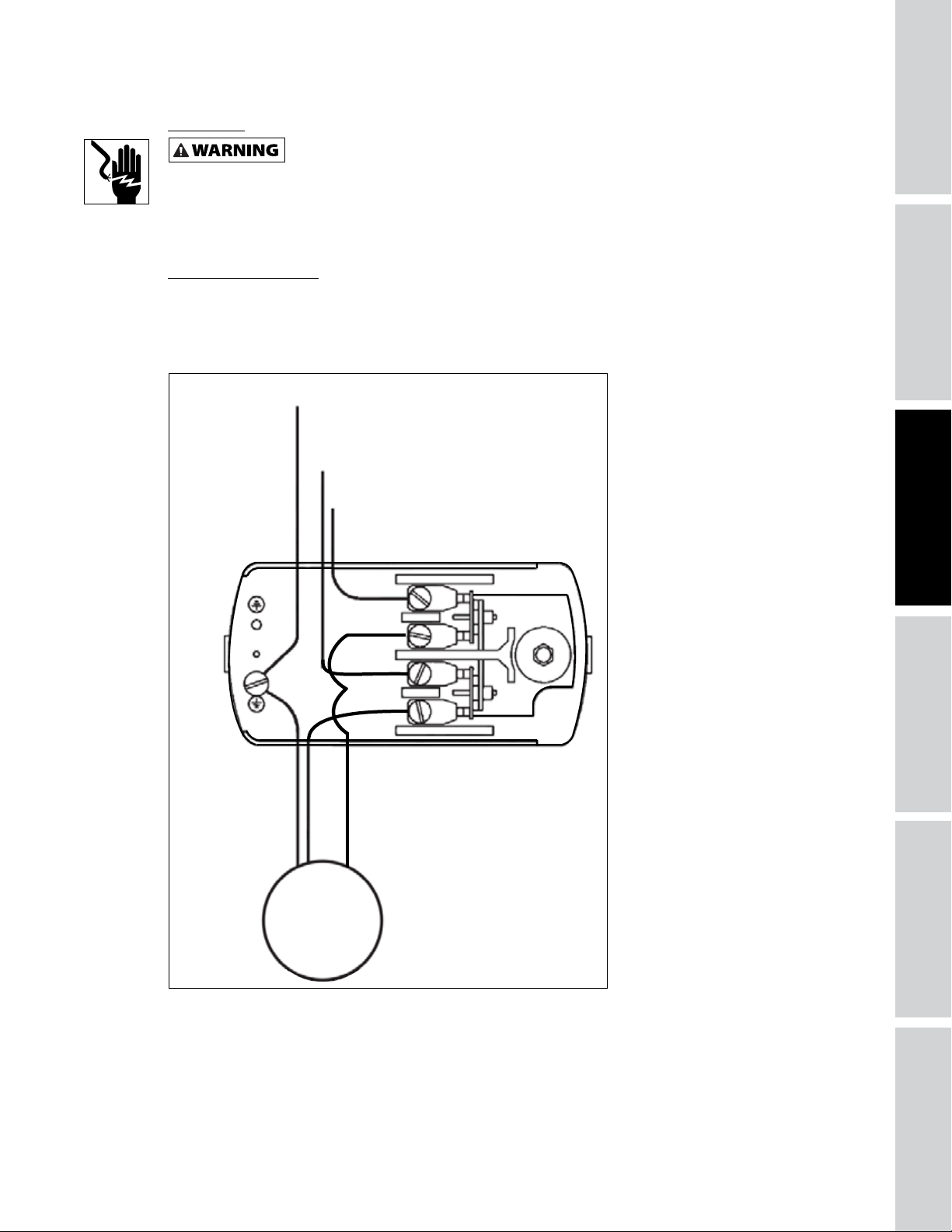

Ground

L1

L2

SPECIFICATIONS

SAFETY /

INSTALLATION

ASSEMBLY /

Motor

Figure 5 - Wiring Diagram

TROUBLESHOOTINGOPERATION

MAINTENANCE /

REPAIR

9

Page 12

SAFETY /

ASSEMBLY /

Installation Instructions (CONTINUED)

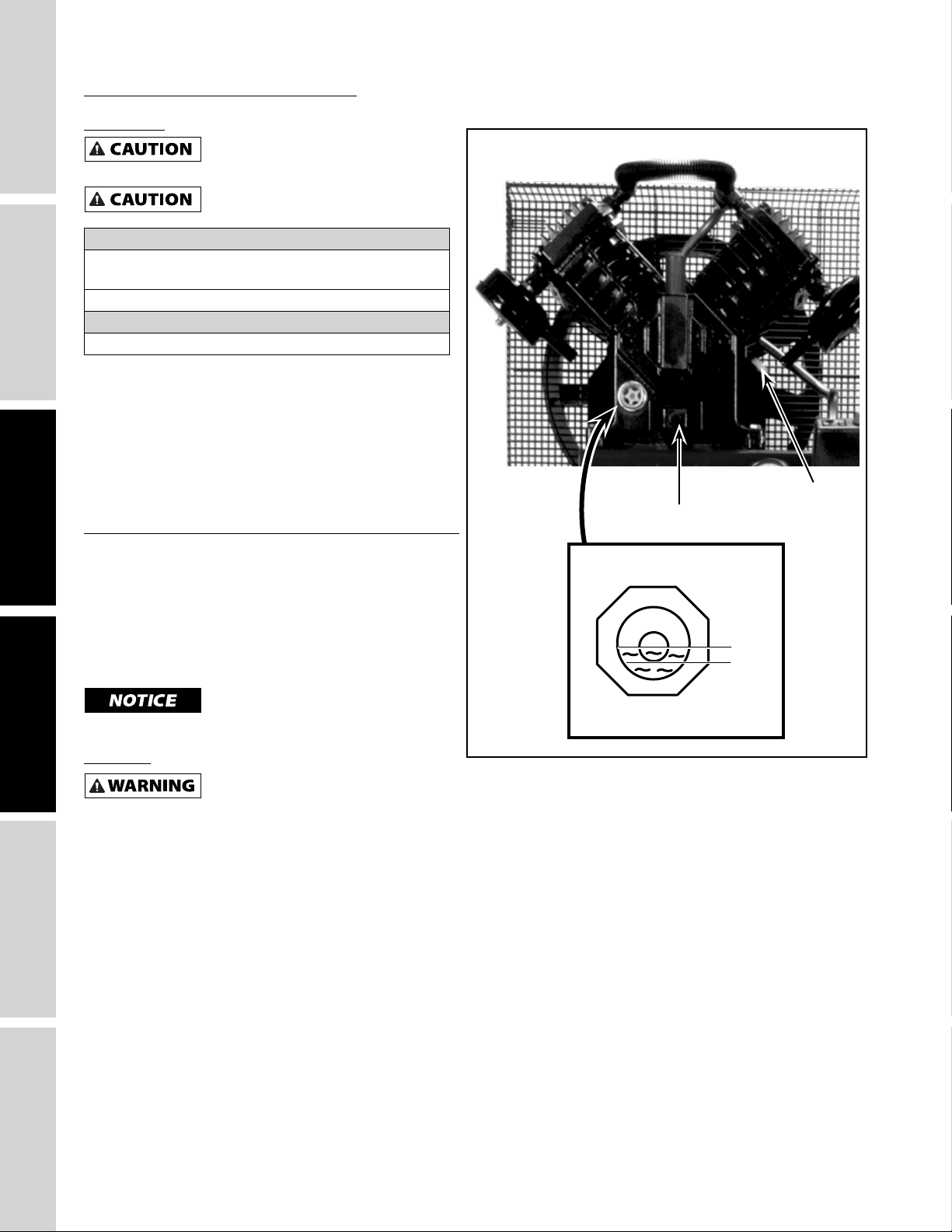

Lubrication

This unit contains no oil. Before

of the sight gauge (see Figure 6).

GETTING STARTED

Using any other type of oil may

Recommended Oil (2 Options)

Single viscosity SAE 30 ISO100 nondetergent

compressor oil. Part number ST126700AV.

10W30 synthetic oil such as Mobil 1® .

Oil Capacity

SPECIFICATIONS

Approximately 40 oz.

Fill the pump with oil to the center of the sight gauge

using oil fill opening (see Figure 6). Do NOT fill the pump

through the breather cap opening as this may cause oil to leak

and spray out during operation.

NOTE: Some residual oil may still be in the pump from

factory testing leaving a thin coat on the sight gauge;

however, there is not enough oil to operate the unit.

INSTALLATION

OPERATING INSTRUCTIONS

IMPORTANT: Check motor rotation before operating the

compressor.

All lubricated compressor pumps discharge some

condensed water and oil with the compressed air. Install

appropriate water/oil removal equipment and controls as

necessary for the intended application.

Failure to install appropriate

in damage to machinery or workpiece.

operating compressor, fill to the center

shorten pump life and damage valves.

water/oil removal equipment may result

Oil Drain Plug

Sight Gauge

Oil Fill Plug

(behind

breather)

Full

Low

Guarding

The belt guard provided must be

installed before operating the unit.

All moving parts must be guarded. All electrical covers must

be installed before turning on the power.

Figure 6 - Lubrication

10

Page 13

OPERATING INSTRUCTIONS (CONTINUED)

Recommended Break-In Period

The compressor should be run continuously at 90 PSI or lower for one hour to allow proper seating of the

piston rings.

1. Open drain cock completely and run the compressor for 60 minutes.

2. Turn off the compressor and close drain cock. The compressor is now ready for use.

If the compressor is run under humid conditions for short periods of time, the humidity will condense in

the crankcase and cause the oil to look creamy. Oil contaminated by condensed water will not provide

adequate lubrication and must be changed immediately. Using contaminated oil will damage bearings,

pistons, cylinders and rings and is not covered under warranty. To avoid water condensation in the oil,

periodically run the compressor with tank pressure near 120 psi for single stage compressors by opening the

drain valve or an air valve connected to the tank or hose. Run the pump for an hour at a time at least once

a week or more often if the condensation reoccurs.

IMPORTANT: Change oil after first 50 hours of operation and every 200 hours afterwards.

Pressure Switch, Start - Stop

NOTE: Single stage compressors have a maximum operating pressure of 140 psi. Do not alter pressure

settings on control components above this limit.

The compressor unit starts and stops based on preset pressure

switch settings of 110 psi cut-in and 140 psi cut-out. The

pressure switch contains an unloader which is a small valve

that vents air to allow the motor to start easily (see Figure 7).

The unloader valve on the pressure switch should hiss for

a short period of time when the compressor shuts off. This

relieves the head and the exhaust tubing of any pressure

and allows the compressor to start under no load. Because

compressors have high starting torque the unloader is

necessary for proper starting of the compressor.

The check valve is a one way valve that keeps the air in the

tank when the unit shuts off. The easiest way to determine

if the check valve is working properly is to make sure that

the pressure switch unloader quits hissing after the compressor shuts off. The hissing should last for several

seconds and then quit.

Unloader

(behind pressure switch)

Safety Relief

Figure 7 - Pressure Switch

SPECIFICATIONS

SAFETY /

INSTALLATION

ASSEMBLY /

Crankcase Breather

During severe operating conditions or initial start-up, some oil may accumulate at the crankcase breather

opening. This is normal and will diminish as the pump accumulates run time and the piston rings become

fully seated.

Draining Tank

Condensate must be drained from the tank daily, use

manual tank drain (see Figure 8).

Figure 8 - Manual Tank Drain

11

TROUBLESHOOTINGOPERATION

MAINTENANCE /

REPAIR

Page 14

SAFETY /

ASSEMBLY /

TROUBLESHOOTING GUIDE

SYMPTOM POSSIBLE CAUSE(S) CORRECTIVE ACTION

Excessive noise in operation 1. Loose pulley, flywheel, belt, beltguard,

GETTING STARTED

Milky oil in oil reservoir Water condensing in crankcase due to high

Excessive oil consumption or oil

in air lines

SPECIFICATIONS

Water in discharge air 1. Excessive water in tank 1. Drain tank

Air blowing out of inlet 1. Broken first stage inlet valve (two-

Insufficient pressure 1. Air demand too high 1. Limit air usage

INSTALLATION

Tank does not hold pressure

when compressor is off and

shutoff valve is closed

Excessive belt wear. (Light dust

from start is normal. Worn belts

separate at layers)

Tank pressure builds slowly 1. Dirty air filter 1. Clean or replace filter element

OPERATION

Tank pressure builds up quickly

on compressor

ASME safety valve pops open

while compressor is running

Pressure switch continuously

blows air out the unloader valve

Pressure switch unloader valve

does not release air when the

unit shuts off

etc

2. Lack of oil in crankcase 2. Check for damage to bearings, replenish oil

3. Compressor floor mounting loose 3. Shim to level and tighten or place on islolator pads

4. Malfunctioning check valve 4. Replace check valve

5. Unit not on vibration pads 5. Install vibration pads under compressor feet

humidity

1. Be sure there is a problem 1. Diagnose oil contamination problems by testing the

2. Restricted air intake 2. Clean or replace air filter

3. Wrong oil viscosity 3. Drain oil. Refill with oil of proper viscosity

4. Worn piston rings 4. Replace rings

5. Oil leaks 5. Tighten bolts, replace gaskets or o-rings

6. Scored cylinder 6. Replace cylinder

2. Hot, humid weather 2. Purchase dryer

stage unit)

2. Broken inlet valve (single stage unit) 2. Replace valve assembly

2. Leaks or restrictions in hoses or piping 2. Check for leaks or restriction in hose or piping

3. Slipping belts 3. Tighten belts

1. Worn check valve 1. Replace check valve

2. Check all connections and fittings for

tightness

3. Check tank for cracks or pin holes 3. Replace tank. Never repair a damaged tank

1. Pulley out of alignment 1. Realign motor pulley

2. Belts too tight or too loose 2. Adjust tension

2. Blown cylinder head gasket 2. Install new gasket

3. Worn/broken intake/discharge valves 3. Install new valve plate assembly

4. Air leaks 4. Tighten joints

Excessive water in tank Drain tank, check speed. See Performance table

1. Wrong pressure switch setting 1. Adjust to lower pressure 140 psi for single stage unit

2. Malfunctioning ASME safety valve 2. Replace ASME safety valve

3. Pressure switch contacts welded 3. Replace pressure switch

Malfunctioning check valve Replace the check valve if the unloader valve bleeds off

Malfunctioning unloader valve on pressure

switch

1. Tighten

Pipe air intake to less humid air source. Run pump

continuously for one hour

discharge air or measuring oil consumption from the

crankcase

1. Replace valve assembly

2. Tighten

(See Operation)

constantly

Replace the pressure switch if the unit does not hiss for a

short period of time when the unit shuts off

Do not disassemble check valve with

air in tank

12

Page 15

TROUBLESHOOTING GUIDE (CONTINUED)

SYMPTOM POSSIBLE CAUSE(S) CORRECTIVE ACTION

Motor hums and runs slowly or

not at all

Reset mechanism cuts out

repeatedly or fuses blow

repeatedly

1. Low voltage or no voltage 1. Check with voltmeter, check line voltage to unit. If

2. Shorted or open motor winding 2. Replace motor

3. Malfunctioning check valve or

unloader valve

4. Malfunctioning pressure switch contacts will not close

1. Pressure switch set too high 1. Adjust or replace

2. Malfunctioning check valve 2. Clean or replace faulty valve

3. Incorrect breaker/disconnect size 3. Be sure that breakers/disconnect are rated properly

4. Malfunctioning motor 4. Replace motor

5. Loose Wiring 5. Check all electrical connections

overload or reset switch trips repeatedly, find and

correct the cause. See next item

3. Replace check valve or unloader valve

4. Repair or replace pressure switch

SPECIFICATIONS

SAFETY /

INSTALLATION

ASSEMBLY /

13

TROUBLESHOOTINGOPERATION

MAINTENANCE /

REPAIR

Page 16

SAFETY /

ASSEMBLY /

MAINTENANCE AND INSPECTION INSTRUCTIONS

GETTING STARTED

SPECIFICATIONS

INSTALLATION

Disconnect, tag and lock out power source then release all pressure from the system before

In order to maintain efficient operation of the compressor system, check the air filter and oil level before

each use. The ASME safety valve should also be checked daily (see Figure 9). Pull ring on safety valve and

allow the ring to snap back to normal position. This valve automatically releases air if the tank pressure

exceeds the preset maximum. If air leaks after the ring has been released, or the valve is stuck and cannot

be actuated by the ring, the ASME safety valve must be replaced.

Figure 9 - ASME Safety Valve

Tank

Never attempt to repair or modify a tank! Welding, drilling or any other modification will

or damaged tanks.

The tank should be carefully inspected at a minimum of once a year. Look for cracks forming near the

welds. If a crack is detected, remove pressure from tank immediately and replace.

attempting to install, service, relocate or perform any maintenance.

Do not tamper with the ASME safety valve.

weaken the tank resulting in damage from rupture or explosion. Always replace worn, cracked

Drain liquid from tank daily.

TROUBLESHOOTING OPERATION

Compressor Lubrication

See Installation. Add oil as required. The oil should be changed every three months or after every 200 hours

of operation; whichever comes first.

If the compressor is run under humid conditions for short periods of time, the humidity will condense in

the crankcase and cause the oil to look creamy. Oil contaminated by condensed water will not provide

adequate lubrication and must be changed immediately. Using contaminated oil will damage bearings,

pistons, cylinders and rings and is not covered under warranty. To avoid water condensation in the oil,

periodically run the compressor with tank pressure near 120 psi for single stage compressors by opening the

drain cock or an air valve connected to the tank or hose. Run the pump for an hour at a time at least once a

week or more often if the condensation reoccurs.

IMPORTANT: Change oil after first 50 hours of operation.

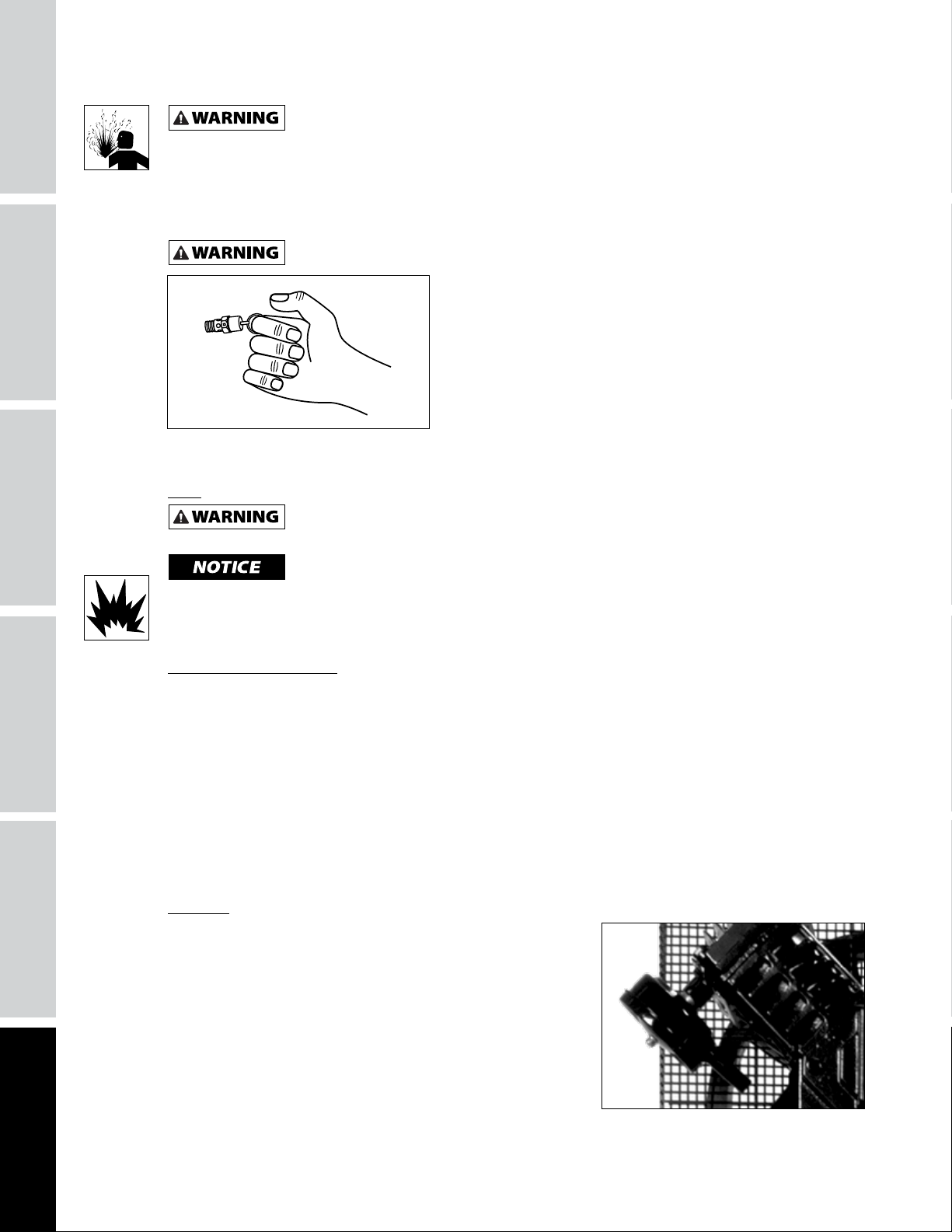

Air Filter

Never run the compressor pump without an intake air filter or

with a clogged intake air filter. The air filter element should be

checked monthly (see Figure 10). Operating compressor with

a dirty filter can cause high oil consumption and increase oil

contamination in the discharge air. If the air filter is dirty it must

be replaced.

14

Figure 10 - Air Filter Element

Page 17

MAINTENANCE AND INSPECTION INSTRUCTIONS (CONTINUED)

Components

Turn off all power and clean the cylinder head, motor, fan blades, air lines, aftercooler and tank on a

monthly basis.

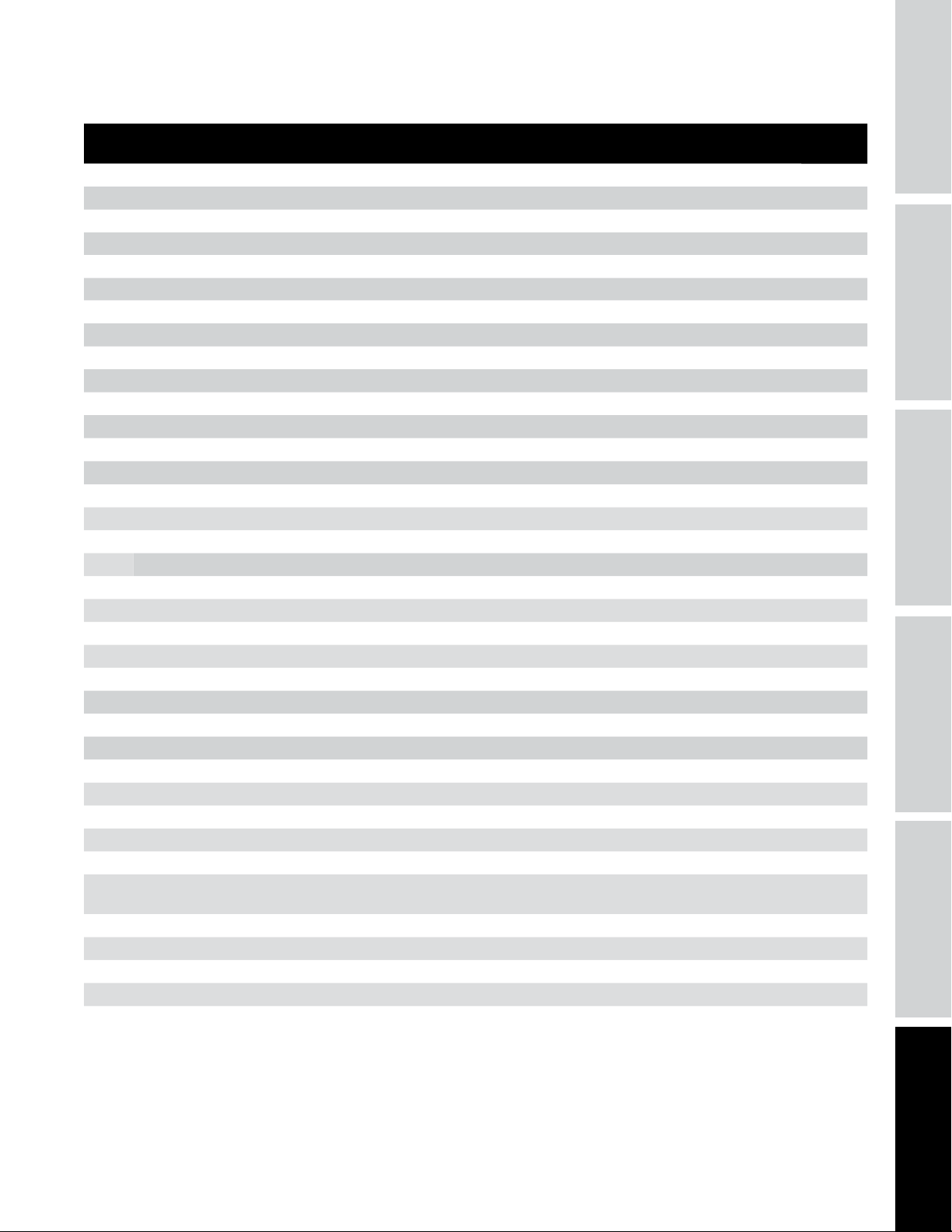

Belts

Lock out and tag the power then release all pressure from the tank to prevent

unexpected movement of the unit.

Check belt tension every 3 months. Adjust belt tension to allow 3/8 inch to 1/2 inch deflection with normal

thumb pressure. Also, align belts using a straight edge against the face of the flywheel and touching the

rim on both sides of the face. The belts should be parallel to this straight edge (see Figure 11). Dimension A

should be the same as B and C to ensure proper alignment of the belts.

Slots in the bed-plate allow for sliding the motor back and forth to adjust belt tension.

Motor

A B

Air Compressor

Motor

Drive

Pulley

SPECIFICATIONS

SAFETY /

INSTALLATION

ASSEMBLY /

Flywheel

Straight Edge

C

Setscrew

Figure 11 - Top View

Storage

If compressor is to be stored for a short period of time, make sure that it is stored in a normal position and

in a cool protected area.

Maintenance Schedule

OPERATION DAILY MONTHLY 3 MONTHS

Check Safety Valve

Drain Tank (see Figure 8)

Check Oil Level

Clean or Change Air Filter

Check Intercooler

Clean Unit Components

Check Belt Tightness

Change Oil (see Figure 6)

l

l

l

l

l

l

l

l

TROUBLESHOOTINGOPERATION

MAINTENANCE /

REPAIR

15

Page 18

11

28

9

10

30

6

7

29

8

15

5

2

1

14

13

12

5

16

27

18

3

4

21

17

19

20

22

23

24

25

23

26

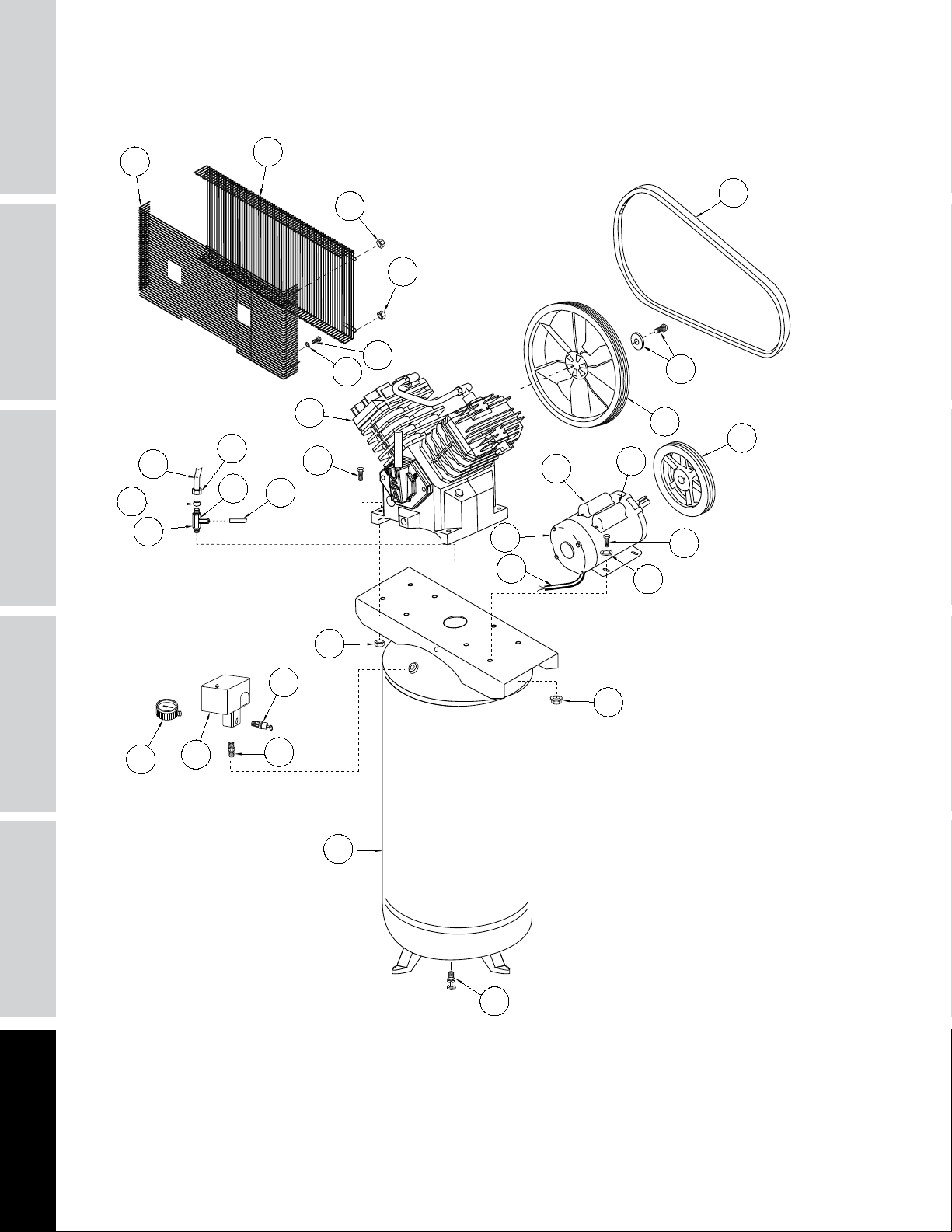

REPAIR PARTS ILLUSTRATION FOR CE4104 AND TQ3104

GETTING STARTED

SAFETY /

SPECIFICATIONS

ASSEMBLY /

INSTALLATION

For Repair Parts, visit www.campbellhausfeld.com

24 hours a day – 365 days a year

Please provide following information:

- Model number

- Serial number (if any)

- Part description and number as shown in parts list

16

Page 19

REPAIR PARTS LIST FOR CE4104 AND TQ3104

Ref

No Description Part Number Qty

1 AIR TANK AG232401CG 1

2 DRAIN VALVE ST127700AV 1

3 AIR COMPRESSOR PUMP WITH FLYWHEEL TQ3010 1

4 5/16 INCH - 18 X 1-1/2 INCH HEX HEAD BOLT

5 5/16 IN - 18 LOCKNUT

6 5/16 INCH - 18 X 3/4 INCH HEX HEAD BOLT

7 5/16 INCH WASHER

8 ELECTRIC MOTOR MC035700AV 1

9 MOTOR PULLEY PU017001AV 1

10 FLYWHEEL PU017100AV 1

11 BELT BT013101AV 1

12 PIPE NIPPLE

13 PRESSURE GAUGE

14 SAFETY VALVE

15 ELECTRIC CORD EC014800AV 1

16 UNLOADER TUBE ST117802AV 1

17 STRAIGHT PUSH CONNECT ST081301AV 1

18 CHECK VALVE CV223300AV 1

19 1/2 INCH COMPRESSION SLEEVE ST032900AV 1

20 1/2 INCH COMPRESSION NUT ST033001AV 1

21 DISCHARGE TUBE TQ901600AP 1

22 FRONT BELTGUARD BG307400AV 1

23 10 - 24 HEX-FLANGE NUT ST116201AV 5

24 5/16 INCH WASHER ST011200AV 2

25 5/16 INCH SELF-TAPPING SCREW ST016500AV 4

26 BACK BELTGUARD BG307500AV 1

27 PRESSURE SWITCH (WITH UNLOADER VALVE)

28 FLYWHEEL FASTNER KIT TQ901400AV 1

29 CAPACITOR - START MC507025AV 1

30 CAPACITOR - RUN MC506912AV 1

WARNING DECAL (NOT SHOWN) DK747600AV 1

PRESSURE SWITCH UNLOADER VALVE

(NOT SHOWN)

PRESSURE SWITCH COVER (NOT SHOWN)

s

MULTI-PORT PRESSURE SWITCH ASSEMBLY

-- NOT AVAILABLE

=

AVAILABLE AT LOCAL HARDWARE STORE

=

=

=

=

HF002401AV s

GA031900AV s

V-215105AV s

CW212201AV s

CW210001AV s

CW217800AV s

4

8

SPECIFICATIONS

SAFETY /

4

1

1

1

INSTALLATION

ASSEMBLY /

1

TROUBLESHOOTINGOPERATION

1

1

17

REPAIR

MAINTENANCE /

Page 20

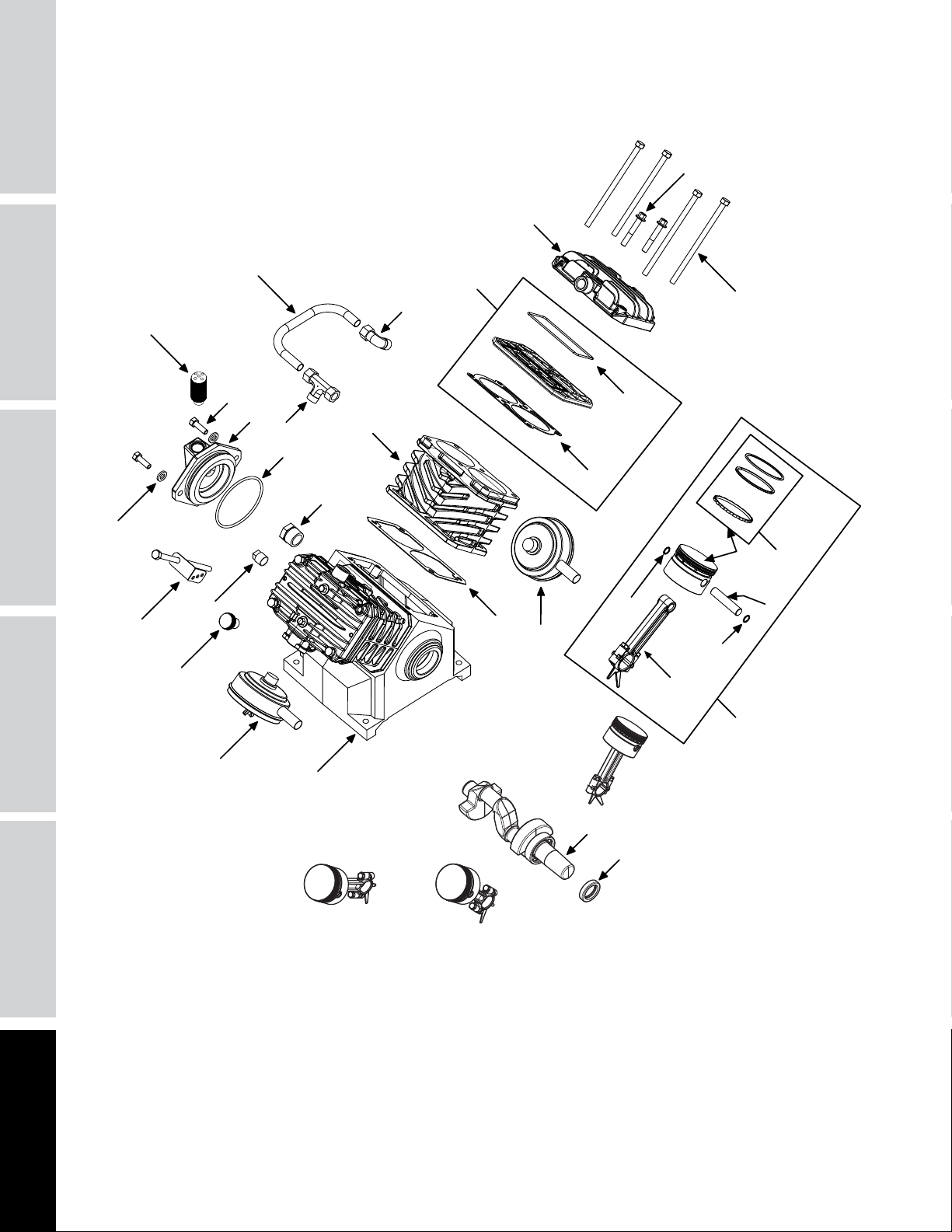

REPAIR PARTS ILLUSTRATION FOR TQ3010

GETTING STARTED

17

15

SAFETY /

ASSEMBLY /

SPECIFICATIONS

INSTALLATION

28

27

21

22

26

20

14

19

5

3

18

11

13

16

4

12

25

30

9

10

31

7

23

10

29

23

1

For Repair Parts, visit www.campbellhausfeld.com

24 hours a day – 365 days a year

Please provide following information:

-Model number

-Serial number (if any)

-Part description and number as shown in parts list

8

6

2

18

Page 21

REPAIR PARTS LIST FOR TQ3010

Ref.

No. Description Part Number: Qty.

1 CRANKCASE TQ010001AV 1

2 OIL SEAL ST120000AV 1

3 BEARING CAP TQ010201AV 1

4 O-RING

5 HEX HEAD CAP SCREW M8 X 1-1/4 INCH X 25 MM † 2

6 CRANKSHAFT AND BEARING ASSEMBLY TQ900201AJ 1

7 CRANKCASE GASKET

8 CONNECTING ROD ASSEMBLY

9 PISTON RING SETS (TWO SETS)

10 INTERNAL RETAINING RING

11 CYLINDER VT040915AV 2

12 CYLINDER GASKET

13 MOLDED O-RING

14 VALVE PLATE KIT VT470800AJ 2

15 CYLINDER HEAD

16 HEX HEAD CAPSCREW M8 X 150 MM

17 FLANGE HEAD SCREW

18 EXHAUST TEE FITTING TQ901100AV 1

19 EXHAUST ELBOW FITTING TQ901200AV 1

20 EXHAUST TUBE TQ901300AV 1

21 BREATHER VH901100AV 1

22 OIL FILL PLUG VH900800AV 1

23 AIR FILTER WITH ELEMENT VH901700AV 2

24 t

25 SIGHT GLASS VH901000AV 1

26 PIPE PLUG 1/4 INCH NPT ST072915AV 1

27 BELT GUARD BRACKET TQ012000AV 1

28 BRASS WASHER ST070925AV 2

29 CONNECTING ROD TQ010901AJ 4

30 PISTON WITH RINGS KIT TQ901700AV 4

31 WRIST PIN KIT (INCLUDES #10(2)) TQ901800AV 4

REPLACEMENT PARTS KITS

s

n

l

t

† STANDARD HARDWARE ITEM

AIR FILTER ELEMENT ONLY VH901800AV 2

CYLINDER HEAD AND FASTENERS KIT TQ900800AJ

CONNECTING ROD / PISTON RING ASSEMBLY KIT TQ901500AV

GASKET KIT TQ901001AJ

NOT SHOWN

l

l

n

VT911200AV n

n

l

l

s

s

s

1

SPECIFICATIONS

SAFETY /

2

4

2

8

2

2

2

8

4

INSTALLATION

ASSEMBLY /

TROUBLESHOOTINGOPERATION

19

REPAIR

MAINTENANCE /

Page 22

Reminder: Keep your dated proof of purchase for warranty purposes! Attach it to this manual or file it for safekeeping.

LIMITED WARRANTY

1. DURATION: The compressor pump and air receiver is warranted for one year from the date of purchase by the original

purchaser. The balance of the compressor package is warranted for one year from the date of purchase by the original

purchaser.

2. WHO GIVES THIS WARRANTY (WARRANTOR): Campbell Hausfeld a Marmon/Berkshire Hathaway Company, 100 Production

Drive, Harrison, Ohio, 45030. Visit www.campbellhausfeld.com

3. WHO RECEIVES THIS WARRANTY (PURCHASER): The original purchaser (other than for purposes of resale) of the Campbell

Hausfeld air compressor.

4. WHAT PRODUCTS ARE COVERED BY THIS WARRANTY: Campbell Hausfeld CE4104 and TQ3104 air compressors.

5. WHAT IS COVERED UNDER THIS WARRANTY: Parts and Labor to remedy defects in material and/or workmanship with the

exceptions noted below.

6. WHAT IS NOT COVERED UNDER THIS WARRANTY:

A. Implied warranties, including those of merchantability and FITNESS FOR A PARTICULAR PURPOSE ARE LIMITED FROM

THE DATE OF ORIGINAL PURCHASE AS STATED IN THE DURATION. Some States do not allow limitations on how long an

implied warranty lasts, so the above limitations may not apply to you.

B. ANY INCIDENTAL, INDIRECT, OR CONSEQUENTIAL LOSS, DAMAGE, OR EXPENSE THAT MAY RESULT FROM ANY DEFECT,

FAILURE, OR MALFUNCTION OF THE CAMPBELL HAUSFELD PRODUCT. Some States do not allow the exclusion or

limitations of incidental or consequential damages, so the above limitation or exclusion may not apply to you.

C. Any failure due to:

1. Accident or purchaser’s abuse

2. Improper installation

3. Equipment that has not been operated or maintained in accordance with Campbell Hausfeld’s instructions as

detailed in the operating manual provided with the compressor.

4. Equipment that has been repaired or modified without authorization from Campbell Hausfeld.

D. Pre-delivery service, i.e. assembly, oil or lubricants, and adjustment.

E. The effects of normal wear and tear.

F. Gasoline engines and components are expressly excluded from coverage under this limited warranty. The Purchaser must

comply with the warranty given by the engine manufacturer which is supplied with the product.

G. Equipment that has been damaged in transit.

7. RESPONSIBILITIES OF WARRANTOR UNDER THIS WARRANTY: Repair or replace, at Warrantor’s option, compressor or

component which is defective, has malfunctioned and/or failed to conform within duration of the warranty period.

Warranted repairs will be made at the Purchaser’s location.

8. RESPONSIBILITIES OF PURCHASER UNDER THIS WARRANTY:

A. Provide dated proof of purchase and maintenance records.

B. Use reasonable care in the operation and maintenance of the products as described in the owner’s manual(s).

C. Repairs requiring overtime, weekend rates, or anything beyond the standard manufacturer warranty repair labor

reimbursement rate.

D. Time required for any security checks, safety training, or similar for service personnel to gain access to facility.

E. Location of unit must have adequate clearance for service personnel to perform repairs and easily accessible.

9. WHEN WARRANTOR WILL PERFORM REPAIR OR REPLACEMENT UNDER THIS WARRANTY: Repair or replacement will be

scheduled and serviced according to the normal work flow at the servicing location, and depending on the availability of

replacement parts.

This Limited Warranty applies in the U.S., Canada and Mexico only and gives you specific legal rights. You may also have other

rights which vary from State to State or country to country.

20

Page 23

NOTES

SPECIFICATIONS

SAFETY /

INSTALLATION

ASSEMBLY /

21

TROUBLESHOOTINGOPERATION

MAINTENANCE /

REPAIR

Page 24

SAFETY /

ASSEMBLY /

NOTES

GETTING STARTED

SPECIFICATIONS

INSTALLATION

22

Page 25

Compresseur d’air monophasé

Instructions d’Utilisation et Manual de Pièces

© 2016 Campbell Hausfeld

A Marmon/Berkshire Hathaway Company

Modèles: CE4104 et TQ3104

FR

IN572800AV 7/16

Page 26

Lire et conserver ces instructions. Il faut les lire attentivement avant de

commencer à assembler, installer, faire fonctionner ou entretenir l’appareil décrit.

Pour se protéger et protéger autrui, observer toutes les informations sur la

sécurité. Négliger d’appliquer ces instructions peut causer

des blessures et/ou des dommages matériels! Conserver ces instructions pour

consultation ultérieure.

RAPPEL: Conservez votre preuve d’achat datée aux fins de garantie! Attachez-le à

ce manuel ou classez-le pour le garder en sécurité.

Pour de l’information sur les pièces,

produits et services veuillez visiter

N° de modèle : _____________________

N° de série : _______________________

Date d’achat : _____________________

ENREGISTREZ VOTRE PRODUIT EN LIGNE MAINTENANT ! www.campbellhausfeld.com

LIRE ET SUIVRE TOUTES LES INSTRUCTIONS • CONSERVER CES INSTRUCTIONS • NE PAS JETER

www.campbellhausfeld.com

Campbell Hausfeld

100 Production Drive

Harrison, Ohio 45030

Page 27

AVANT DE COMMENCER

Introduction

Les unités de compresseur d’air ont été conçues pour fournir de l’air comprimé aux outils électriques

pneumatiques, faire fonctionner les pistolets de pulvérisation et approvisionner en air les soupapes et

actionneurs pneumatiques. Les pompes alimentées par ces unités comportent des roulements lubrifiés à

l’huile. Un faible contenu en huile est présent dans le flux d’air comprimé. Les applications nécessitant de

l’air sans vapeurs d’huile devraient disposer de filtres adéquats déjà installés. Les unités de compresseur

d’air doivent être installées selon les instructions fournies sur un plancher solide. Toute autre utilisation de

ces unités annulera la garantie et le fabricant ne sera pas tenu responsable des problèmes ou dommages

résultant de cette mauvaise utilisation.

RÉFÉRENCE RAPIDE

Recommended Oil (2 Options)

Huile de compresseur sans détergent à viscosité simple, SAE 30 ISO. N° de pièce

ST126700AV.

Huile synthétique 10W30 telle que Mobil 1® .

Capacité D’Huile

Environ 1,18 L.

DÉBALLAGE

Ne pas soulever ni déplacer le modèle sans équipement convenable et s’assurer

les refroidisseurs. Ne pas utiliser le modèle pour soulever d’autre équipement qui est attaché au compresseur.

Dès que l’appareil est déballé, l’inspecter attentivement pour tout signe de dommages en transit. Vérifier

s’il y a des pièces desserrées, manquantes ou endommagées. Vérifier pour s’assurer que tous les accessoires

fournis sont inclus avec l’appareil. Pour toutes questions, pièces endommagées ou manquantes, please visit

www.campbellhausfeld.com for customer assistance.

Ne pas utiliser l’appareil s’il est endommagé pendant le transport, la manutention

des dommages à la propriété.

que le modèle soit bien fixé à l’appareil de levage. Ne pas soulever le modèle avec les tuyaux ou

ou l’utilisation. Des dommages peuvent entraîner un éclatement et provoquer des blessures ou

SÉCURITÉ / CARACTÉRISTIQUES

ASSEMBLAGE /

INSTALLATION

UTILISATION

Autres articles non inclus

• Huile

DÉPANNAGE

ENTRETIEN /

RÉPARATION

Fr1

Page 28

DÉMARRAGE

INSTRUCTIONS GÉNÉRALES DE SÉCURITÉ

Directives de Sécurité

Ce guide contient de l’information très importante que vous devez savoir et comprendre. Cette information

est fournie à des fins de SÉCURITÉ et dans le but d’ÉVITER DES PROBLÈMES AVEC L’ÉQUIPEMENT. Pour

DE L’APPAREIL

faciliter la reconnaissance de cette information, prenez compte des symboles suivants.

Danger indique une situation hasardeuse imminente qui RÉSULTERA en perte de

vie ou blessures graves.

Avertissement indique une situation hasardeuse potentielle qui PEUT résulter en

perte de vie ou blessures graves.

Attention indique une situation hasardeuse potentielle qui PEUT résulter en

blessures.

Avis indique de l’information importante pour éviter le dommage de

l’équipement.

REMARQUE : Remarque indique : des renseignements additionnels concernant le produit ou son utilisation.

SÉCURITÉ / CARACTÉRISTIQUES

Symboles De Sécurité

Les symboles de sécurité suivants apparaissent dans l’ensemble de ce manuel pour vous aviser des dangers

et précautions importants de sécurité.

Porter une

INSTALLATION

ASSEMBLAGE /

UTILISATION

protection

oculaire et un

masque

Risques de

fumées

Proposition 65 de Californie

Ce produit, utilisé pour la soudure, produit des vapeurs ou gaz qui contiennent des

autre tort aux organes de la reproduction), et en quelques circonstances, le cancer. (le code `California Health & Safety

Code Section 25249.5 et seq’.).

Ce produit et son cordon contient du plomb, un produit chimique qui de l’avis de

pour la reproduction. Se laver les mains après toute manipulation.

MANUAL

Lire le

manuel

d’abord

Risque de

pression

produits chimiques prouvés par I’État de Californie de provoquer des dé fauts de naissance (ou

l’État de Californie peut causer le cancer et des anomalies congénitales ou d’autres problèmes

Risque

d’incendie

Risque de

choc

Risque

de pièces

mobiles

Risque

de pièces

chaudes

Risque

d’explosion

DÉPANNAGE

Consignes importantes de sécurité

Veuillez lire et conserver ces instructions. Lisez attentivement avant d’essayer d’assembler, d’installer, de faire

fonctionner ou de réparer le produit décrit. Protégez-vous et les autres en considérant toutes les informations de

sécurité. Le non-respect des instructions pourrait entraîner des blessures corporelles et/ou des dommages matériels!

Conservez toutes les instructions pour vous y référer ultérieurement.

Ce manuel contiens des informations importantes sur la sécurité opérationnel et entretien. Si vous avez des

questions, veuillez visiter www.campbellhausfeld.com pour l’assistance à la clientèle.

Puisque le compresseur d’air et les autres composants (article pompe, pistolet de pulvérisation, filtres,

lubrifiants, tuyaux, etc.) utilisés font partie d’un système de pompage à haute pression, les précautions de

sécurité suivantes doivent être prises en considération à tout moment :

Fr2

Page 29

Consignes importantes de sécurité (Suite)

AVERTISSEMENT D’AIR RESPIRABLE

Ce compresseur/pompe n’est pas équipé pour et ne devrait pas être utilisé “comme soi” pour fournir

de l’air respirable. Pour les applications d’air pour la consommation humaine, il est nécessaire

d’équiper le compresseur d’air/pompe avec de l’équipement de sécurité en canalisation et d’alarme.

Cet équipement additionnel est nécessaire pour filtrer et purifier l’air afin d’atteindre les spécifications

minimales pour la respiration Grade D décrite dans le Compressed Gas Association Commodity

Specification G 7.1, OSHA 29 CFR 1910. 134, and/or Canadian Standards Associations (CSA).

DÉNÉGATION DES GARANTIES

Si le compresseur est utilisé pour les applications d’air respirable et l’équipement de sécurité en

canalisation et d’alarme n’est pas utilisé simultanément, les garanties en existance seront annulées, et

Campbell Hausfeld dénie toute responsabilité pour n’importe quelle perte, blessure ou dommage.

Généralités sur la Sécurité

• Lire attentivement tous manuels compris avec ce produit. Bien se familiariser avec les commandes et

MANUAL

l’utilisation correcte de l’équipement.

• Suivre tous les codes d’électricité et de sécurité locaux ainsi que: National Electrical Codes (NEC) et

Occupational Safety and Health Act (OSHA) des É.-U.

• Seules les personnes bien familiarisées avec ces règles d’utilisation doivent être autorisées à se servir du

compresseur.

• Garder les visiteurs à l’écart de/et NE JAMAIS permettre les enfants dans l’endroit de travail.

• Utiliser des lunettes de sécurité et la protection auditive pendant l’utilisation du modèle.

• Ne pas se tenir debout sur/ou utiliser le modèle comme une prise.

• Inspecter le système d’air comprimé et pièces détachées électriques pour toute indication de dommage,

détérioration, faiblesse ou fuites avant chaque utilisation. Réparer ou remplacer toutes pièces

défectueuses avant l’utilisation.

• Inspecter le degré de serrage de toutes attaches par intervalles régulières.

Les moteurs, l’équipement et les commandes électriques peuvent causer des arcs électriques qui

peuvent allumer un gaz ou une vapeur inflammable. Ne jamais utiliser ou réparer le modèle près

d’un gaz ou d’une vapeur inflammable. Ne jamais entreposer les liquides ou gaz inflammables près du compresseur.

Ne jamais utiliser un compresseur sans carter de courroie. Ce modèle peut se démarrer sans avis.

Le contact avec les pièces mobiles peut causer des blessures personnelles ou dégâts matériels.

• Ne pas porter les vêtements flottants ni la bijouterie qui peuvent se prendre dans les pièces mobiles du

modèle.

Les pièces du compresseur peuvent être chaudes même si le modèle n’est pas en

marche.

• Garder les doigts à l’écart d’un compresseur qui est en marche; les pièces mobiles et chaudes peuvent

causer des blessures et/ou brûlures.

• Si le compresseur vibre anormalement, ARRÊTER le moteur et l’inspecter immédiatement. La vibration

est généralement une indication d’un problème.

• Pour réduire le risque d’incendie, garder l’extérieur du moteur libre d’huile, de solvant ou de graisse

excessive.

Pour ce compresseur, c’est indispensable d’installer une soupape de décharge selon les normes

de sûreté ASME avec un réglage non supérieur à la Pression Maximale de Service Permise

(MAWP) sur la tuyauterie ou le réservoir. La soupape de sûreté ASME doit avoir une classificaton de débit et de

pression suffisante afin de protéger les pièces détachées sous pression contre l’éclatement. La soupape de sûreté dans

le refroidisseur ne fournie pas de protection pour le système.

SÉCURITÉ / CARACTÉRISTIQUES

ASSEMBLAGE /

INSTALLATION

UTILISATION

DÉPANNAGE

ENTRETIEN /

RÉPARATION

Fr3

Page 30

DÉMARRAGE

DE L’APPAREIL

Consignes importantes de sécurité (Suite)

La pression de fonctionnement maximale est de 965 kPa pour les compresseurs monophasés.

supérieure à 965 kPa (monophasé).

• Ne jamais essayer d’ajuster la soupape de sûreté ASME. Garder la soupape de sûreté libre de peinture et

autres accumulations.

Ne jamais essayer de réparer ni de modifier un réservoir! Le soudage, le perçage ou autre

d’explosion. Toujours remplacer un réservoir usé, fendu ou endommagé.

• L’accumulation d’humidité cause la rouille qui peut affaiblir le réservoir. Purger le réservoir

quotidiennement et l’inspecter périodiquement pour la rouille et la corrosion ou autre dommage.

• L’air mouvante peut agiter la poussière et le débris qui peut être dangereux. Lâcher l’air lentement en

purgeant l’humidité ou pendant la dépressurisation du système de compresseur.

Ne pas faire fonctionner avec un manostat ou des vannes pilotes configurés sur une valeur

modifications peuvent affaiblir le réservoir et peut résulter en dommage de rupture ou

Purger le liquide du réservoir quotidiennement.

SÉCURITÉ / CARACTÉRISTIQUES

Précautions de Pulvérisation

Ne pas pulvériser les matériaux inflammables dans un endroit de flamme ouverte

• Ne pas fumer pendant la pulvérisation de la peinture, d’insecticides ou autres matières inflammables.

• Utiliser un masque/respirateur pendant la pulvérisation et pulvériser dans un endroit bien aéré pour

éviter le risque de blessures et d’incendie.

• Ne pas diriger la peinture ou autre matériel pulvérisé vers le compresseur. Situer le compresseur aussi

loin que possible de l’endroit de pulvérisation pour réduire l’accumulation de surpulvérisation sur le

INSTALLATION

ASSEMBLAGE /

compresseur.

• Suivre les instructions du fabricant pendant la pulvérisation ou le nettoyage avec des solvants ou

produits chimiques toxiques.

Les symboles DANGER, AVERTISSEMENT, ATTENTION ET AVIS ainsi que les instructions de ce manuel

ne peuvent pas couvrir toutes les conditions et situations qui pourraient se produire. L’opérateur doit

comprendre que les précautions sont des facteurs qui ne peuvent pas être inclus dans ce produit,

maisdoivent être fournis par l’opérateur.

UTILISATION

ni près d’une source d’ignition y compris le compresseur.

Conserver ces instructions

Ne les jetez pas

DÉPANNAGE

Fr4

Page 31

Apprendre à Connaître Votre Compresseur

Tuyau de décharge

Pompe de

compresseur

Filtre à air

Manostat

Manomètre de

réservoir

Carter de courroie

Moteur

Tuyau de déchargement

Soupape

de sécurité

SÉCURITÉ / CARACTÉRISTIQUES

ASSEMBLAGE /

INSTALLATION

Vidange du réservoir

manuel

UTILISATION

DÉPANNAGE

ENTRETIEN /

RÉPARATION

Figure 1 – Identification de l’unité verticale

Fr5

Page 32

CARACTÉRISTIQUES TECHNIQUES

Moteur HP 5

DÉMARRAGE

DE L’APPAREIL

SÉCURITÉ / CARACTÉRISTIQUES

Alimentation 208-230V

Étape 1

Déplacement CFM 658.1 l/min

Débit d’air CFM à 621 kPa 489.9 l/min

Débit d’air CFM à 965 kPa 402.1 l/min

Bars max. 965 kPa

Pompe RPM 950

Capacité du réservoir 302.80 L

Poids de l’unité 185.98 kg

Ampérage 21.0

Cycle d’exploitation max. 80/20

Sortie du réservoir 19.1 mm (3/4 po) (F) NPT

DIMENSIONS

CE4104 et TQ3104

INSTALLATION

ASSEMBLAGE /

Longueur 58.42 cm

Largeur 78.74 cm

Hauteur 180.34 cm

UTILISATION

DÉPANNAGE

CE4104 et TQ3104

Fr6

Page 33

INSTRUCTIONS D’INSTALLATION

Débrancher, étiquetter et vérouiller la source de puissance électrique et dissiper

toute la pression du système avant d’essayer d’installer, réparer, déplacer ou de procéder à

l’entretien du modèle.

Ne pas soulever ni déplacer le modèle sans équipement convenable et s’assurer q

ue le modèle soit bien fixé à l’appareil de levage. Ne pas soulever le modèle avec les tuyaux ou

les refroidisseurs. Ne pas utiliser le modèle pour soulever d’autre équipement qui est attaché au compresseur.

Ne jamais utiliser les palettes d’expédition

pour monter le compresseur.

Choisir l’emplacement

Installer et utiliser le modèle au moins de 46 cm (18 po) d’une

obstruction et dans un endroit propre et bien ventilé. La

température de l’air dans l’endroit ne devrait pas dépasser 38,08°

C. Ceci assure un débit d’air sans obstruction pour refroidir le

compresseur et permet de l’espace pour l’entretien.

Ne pas situer la prise d’air du compresseur

près de vapeurs, pulvérisation de peinture,

endroits de décapage au sable ou n’importe quelle autre source de

contamination.

REMARQUE: Si le compresseur est utilisé dans un endroit chaud

et humide, il est nécessaire de fournir le compresseur avec de l’air

extérieur propre et sec. Cet air devrait être canalisé d’une source

externe.

≥ 46

cm

≥ 46

cm

SÉCURITÉ / CARACTÉRISTIQUES

ASSEMBLAGE /

INSTALLATION

Montage du réservoir

≥ 46

cm

Le résevoir devrait être boulonné dans un plancher en béton

plat et égal ou sur une fondation en béton séparée. Utiliser des

tampons isolateurs entre la jambe du réservoir et le plancher.

Figure 2 - Emplacement

Les blocs d’isolation du numéro de pièce MP345700AJ sont

recommandés pour les unités.

Ne pas trop serrer les boulons en utilisant les tampons isolateurs

afin de permettre que les tampons absorbent les vibrations. Un

tuyau ou raccord flexible doit être installé entre le réservoir et la

tuyauterie de service.

Manque d’installer le réservoir

soudés et la possibilité d’éclatement.

correctement peut causer des fentes aux joints

Tuyauterie

Ne Jamais utiliser les tuyaux en plastique

blessures graves ou perte de vie.

(CPV) pour l’air comprimé. Ceci peut résulter en

N’importe quel tube, tuyau ou tuyau flexible branché au modèle doit pouvoir résister la température qui est

produit et doit conserver la pression. Tous les composants sous pression du système d’air doivent avoir une

valeur nominale de pression de 1 379 kPa ou plus. La sélection ou l’installation incorrecte de n’importe quel

tube, tuyau ou tuyau flexible peut résulter en éclatement et en blessures. Brancher le système de tuyauterie

au réservoir en utilisant un raccord de même taille que celui de l’orifice de décharge.

Taille De Tuyau Minimum Pour Canalisation D’air Comprimé

Longueur Du Système

l/min

7,62 m 15,24 m 30,48 m 76,2 m

283.2 12,7 mm 12,7 mm 19,1 mm 19,1 mm

566.3 19,1 mm 19,1 mm 19,1 mm 2,54 cm

1132.7 19,1 mm 2,54 cm 2,54 cm 2,54 cm

1699.0 19,1 mm 2,54 cm 2,54 cm 2,54 cm

2831.7 2,54 cm 2,54 cm 2,54 cm 3,18 cm

Figure 3 - Coussinet isolant

UTILISATION

DÉPANNAGE

ENTRETIEN /

RÉPARATION

Fr7

Page 34

INSTRUCTIONS D’INSTALLATION (SUITE)

Installation D’une Soupape D’arrét

Une soupape d’arrêt devrait être installée sur l’orifice de décharge du réservoir pour régler le débit d’air du

réservoir. La soupape devrait être située entre le réservoir et le système de tuyauterie.

DÉMARRAGE

DE L’APPAREIL

Figure 4 - Soupape d’arrêt

SÉCURITÉ / CARACTÉRISTIQUES

INSTALLATION

ASSEMBLAGE /

Ne jamais installer une soupape d’arrêt entre la pompe du compresseur et le réservoir. Ceci peut

de réduction dans le tuyau flexible de refoulement.

Câblage

Tout le câblage et les connexions électriques doivent être exécutés par un électricien qualifié au

nationaux.

Un câblage inadéquat mènera à la surchauffe, les court-circuits et les

L’installation de fils doit conformer aux National Electrical Code et aux codes et règlements locaux

concernant les appareils électriques et l’installation de fils. Consulter avec et observer ceux-ci. Utiliser la

taille correcte de fil et assurer que:

1. L’ampérage du service soit suffisant.

2. La ligne d’alimentation corresponde au moteur (tension, cycles et phase).

3. La taille du fil de ligne est correcte et qu’il n’y a pas d’autre équipement qui fonctionne sur la même

résulter en blessures personnelles et/ou dommage à l’équipement. Ne jamais utiliser un appareil

Pour un système d’installation permanent pour la distribution d’air comprimé,

calculer la longueur du système et choisir la taille du tuyau selon le tableau.

Enterrer les lignes souterraines sous le niveau de gélée et éviter les poches où la

condensation pourrait s’accumuler et geler.

Appliquer la pression d’air à la tuyauterie et assurer que toutes les jointures

sont sans fuites AVANT de couvrir les lignes souterraines. Rechercher et réparer

toutes les fuites dans les tuyaux et raccords avant d’utiliser le compresseur.

courant des contrôles à moteurs industriels. L’installation doit conformer aux codes locaux et

dommages d’incendie.

ligne. Le tableau indique la taille minimum de fil pour les installations de compresseurs.

UTILISATION

DÉPANNAGE

Taille de fil minimum utiliser le fil en cuivre 75°C

S’assurer que la tension est correcte avec le câblage du moteur.

REMARQUE: Si l’on utilise une monophase de 208 volts, s’assurer que la plaque

signalétique du moteur indique une valeur nominale de 208 volts en monophase. Les

moteurs monophases de 230 volts ne fonctionnent pas à 208 volts à moins que ce ne soit

une valeur de 208 volts.

MONOPHASÉ

HP AMPS 230V

1-4 HP JUSQU’À 22,0 10 AWG

5.0 8 AWG

Les tailles de fils recommandées peuvent être plus larges que la configuration minimum des ordonnances

locales. Si c’est le cas, utiliser le fil d’une taille plus large pour prévenir toute chute de tension excessive sur la

ligne. Le coût supplémentaire du fil est très petit comparativement au coût de réparation ou de remplacement

d’un moteur « épuisé » électriquement par l’utilisation de fils d’alimentation trop petits.

Fr8

Page 35

INSTRUCTIONS D’INSTALLATION (SUITE)

Mise à la terre

Les composantes électriques qui ne sont pas correctement mise à la terre tiennent le risque

de secousse électrique. S’assurer que toutes les pièces soient mise à la terre correctement pour

éviter les blessures personnelles ou la perte de vie.

Ce produit doit être mise à la terre pour diminuer le risque de secousse électrique en fournissant un fil

d’échappement s’il y arrive un court-circuit. Ce produit doit étre installé avec et utilisé avec un cordon

d’alimentation qui a un fil de terre.

Disjoncteurs et Fusibles

Tout le système électrique doit être vérifié par un électricien agréé. Des fusibles et disjoncteurs à

retardement sont nécessaires pour ce compresseur. Un fusible grillé ou un disjoncteur déclenché peut

indiquer un court-circuit direct à la terre, un tirage élevé de courant, un mauvais câblage, un fusible ou un

disjoncteur de mauvaise taille et/ou type. Ceci doit être évalué par un électricien agréé.

Mise à la terre

L1

L2

SÉCURITÉ / CARACTÉRISTIQUES

ASSEMBLAGE /

INSTALLATION

Moteur

Figure 5 - Schéma de câblage

UTILISATION

DÉPANNAGE

ENTRETIEN /

RÉPARATION

Fr9

Page 36

DÉMARRAGE

INSTRUCTIONS D’INSTALLATION

Graissage

CE MODÈLE NE CONTIENT PAS

Remplir au centre de la jauge visuelle (voir la figure 6).

DE L’APPAREIL

L’utilisation d’un autre type d’huile

et endommager les soupapes.

Recommended Oil (2 Options)

Huile de compresseur sans détergent à viscosité

simple, SAE 30 ISO. N° de pièce ST126700AV.

Huile synthétique 10W30 telle que Mobil 1® .

Capacité D’Huile

Environ 1,18 L.

D’HUILE. Avant d’utiliser le compresseur.

pourrait raccourcir la durée de la pompe

SÉCURITÉ / CARACTÉRISTIQUES

Remplir la pompe d’huile au centre de la jauge visuelle

en utilisant l’ouverture de remplissage d’huile (voir la

figure 6). NE PAS remplir la pompe jusqu’à l’ouverture du

bouchon de reniflard, car ceci pourrait mener à une fuite d’huile

et une pulvérisation vers l’extérieur durant l’utilisation.

REMARQUE: Il pourrait y avoir des résidus d’huile dans la

pompe des tests en usine laissant une mince couche sur

la jauge visuelle, mais il n’y a pas assez d’huile pour faire

fonctionnerl’unité.

INSTALLATION

ASSEMBLAGE /

FONCTIONNEMENT

IMPORTANT: Vérifier la rotation du moteur avant

d’utiliser le compresseur.

Toutes les pompes de compresseur graissées débitent un

peu d’humidité et d’huile avec l’air comprimé. Installer

l’équipement pour l’enlevage d’eau/huile et commandes

convenables à l’application.

Manque d’installer l’équipement

UTILISATION

endommager les machines ou l’objet de travail.

Carters

Le carter de courroie fournit doit

Toutes les pièces mobiles doivent être protégées. Tous

les couvercles électriques doivent être installés avant de

mettre en circuit.

pour ’élevage d’eau/huile peut

être installé avant l’utilisaton du modèle.

Figure 6 - Graissage

Regard

Capuchon de

vidange d’huile

Bouchon de

remplissage d’huile

(derrière le reniflard)

Plein

Bas

DÉPANNAGE

Fr10

Page 37

FONCTIONNEMENT (SUITE)

Rodage Recommandé

Le compresseur devrait fonctionner en continu pendant une heure à moins de 621 kPa pour permettre aux

bagues de piston d’être dans la bonne position.

1. Ouvrir le robinet de purge et faire fonctionner le compresseur pour 60 minutes.

2. Mettre le compresseur hors circuit et fermer le robinet de purge. Le compresseur est maintenant prêt à

utiliser.

Si le compresseur fonctionne dans des conditions humides pendant de courtes périodes, l’humidité se

condensera dans le carter et donnera à l’huile une apparence crémeuse. L’huile contaminée par de l’eau

condensée n’offrira pas la lubrification nécessaire et devra être changée immédiatement. L’utilisation d’huile

contaminée endommagera les roulements, les pistons, les cylindres et les joints et n’est pas couverte par la

garantie. Pour éviter la condensation de l’eau dans l’huile, faites périodiquement fonctionner le compresseur

avec une pression au réservoir près de 827 kPA pour un compresseur à deux phases ou 120 psi pour un

compresseur à phase unique, en ouvrant le robinet de vidange ou un robinet d’admission d’air branché au

réservoir ou à un tuyau. Faites fonctionner la pompe pendant une heure à la fois, au moins une fois par

semaine ou plus fréquemment si la condensation se produit encore.

IMPORTANT : Changez l’huile après les premières 50 heures d’utilisation ou toutes les 200 heures après.

SÉCURITÉ / CARACTÉRISTIQUES

Manostat Démarrage - Arrêt

REMARQUE: La pression de fonctionnement maximale est de 965 kPa pour les compresseurs monophasés.

Ne pas altérer les réglages de pression sur les pièces de commandes afin qu’ils dépassent cette limite.

Le compresseur démarre et s’arrête selon les configurations

de pressostat préréglées de 758 kPa de fermeture et de 965

kPa de coupure. Le manostat a un appareil de déchargement

qui est une soupape qui sert à ventiler l’air et permet le

démarrage facile du modèle (Voir la Figure 7).

La soupape de décharge du pressostat devrait siffler pendant

un certain temps lorsque le compresseur s’éteint. Ceci

dégage la hauteur de charge et le tube d’échappement

de toute pression et permet au compresseur de démarrer

sans charge. Puisque les compresseurs ont un couple de

démarrage élevé, il faut la décharge pour un démarrage

approprié du compresseur.

Le clapet de non-retour est un clapet d’une direction qui

conserve l’air dans le réservoir lorsque l’appareil est éteint. Le moyen le plus facile pour déterminer si le

clapet de non-retour fonctionne correctement est de s’assurer que la décharge de pressostat cesse de siffler

après que le compresseur s’éteint. Ce sifflement devrait durer quelques secondes, puis s’arrêter.

Figure 7 - Pressostat

Dispositif de délestage

Soupape de sécurité

(derrière le manostat)

Reniflard du Carter

Un peu d’huile peut s’accumuler à l’ouverture du reniflard du carter pendant les conditions de

fonctionnement sévères ou pendant le premier démarrage. Ceci est normal et diminuera après le rodage et

une fois que les segments de piston soient ajustés.

ASSEMBLAGE /

INSTALLATION

UTILISATION

DÉPANNAGE

Vidange du Reservoir

Le condensat doit être vidé du réservoir chaque jour.

Pour les modèles de série d’air d’atelier, utiliser un

drain de réservoir manuel (voir la figure 8).

Fr11

Figure 8 - Drain de réservoir manuel

ENTRETIEN /

RÉPARATION

Page 38

GUIDE DE DÉPANNAGE

SYMPTÔME CAUSE(S) POSSIBLE(S) ACTION CORRECTIVE

Bruit excessif pendant

le fonctionnement

DÉMARRAGE

DE L’APPAREIL

Huile laiteux dans

le réservoir d’huile

Consommation d’huile excessive

ou huile dans les canalisations

d’air

SÉCURITÉ / CARACTÉRISTIQUES

De l’eau dans l’air d’évacuation 1. Eau excessive dans le réservoir 1. Purger le réservoir

Air qui souffle hors de l’orifice

d’admission

INSTALLATION

ASSEMBLAGE /

Pression insuffisante 1. Demande d’air trop haute 1. Limiter l’utilisation d’air

Le réservoir ne tient pas la

pression quand le compresseur

est hors circuit et la soupape

d’arrêt est fermée

UTILISATION

Usure excessive de courroie. (La

poussière légère est normale. Les

courroies usées se séparent aux

couches)

La pression du réservoir

s’accumule lentement

La pression du réservoir

DÉPANNAGE

s’accumule rapidement sur le

compresseur

Soupape de sûreté ASME s’ouvre

pendant que le compresseur

fonctionne

Le manostat souffle l’air

continuellement de la soupape

de déchargement

La soupape de déchargement

du manostat ne lâche pas l’air

lorsque le modèle s’arrête

1. Poulie, volant, courroie, carter de

courroie, etc, dégagés

2. Manque d’huile dans le carter 2. Inspecter les roulements pour le dommage, remplir

3. Montage du compresseur dégagé 3. Caler, niveler et serrer ou placer sur des tampons

4. Fonctionnement défectueux du clapet 4. Remplacer le clapet

5. L’appareil n’est pas placé sur des

coussinets de vibration

Condensation d’eau dans le carter causé

par l’humidité élevée

1. Vérifier s’il y a un problème 1. Diagnostiquer les problèmes de contamination

2. Restriction à la prise d’air 2. Nettoyer ou remplacer le filtre d’air

3. Viscosité d’huile incorrecte 3. Vidanger l’huile et remplir à nouveau avec de l’huile

4. Segments de piston usés 4. Remplacer les segments de piston

5. Fuites d’huile 5. Serrer les boulons, remplacer les joints d’étanchéités

6. Cylindre rayé 6. Remplacer le cylindre

2. Temps chaud et humide 2. Acheter un sécheur

1. Soupape d’admission de première

étage en panne (compresseur à deux

étages)

2. Panne de la soupape d’admission

(compresseur à une étage)

2. Fuites ou restrictions dans tuyaux ou

tubes

3. Patinage de courroies 3. Serrer les courroies

1. Clapet usé 1. Remplacer le clapet

2. Vérifier tous les connexions et les

raccordements pour le serrage

3. Vérifier le réservoir pour des fentes ou

trous d’épingle

1. Poulie hors d’alignement 1. Redresser la poulie du moteur

2. Courroies trop serrées ou dégagées 2. Ajuster la tension

1. Filtre à air sale 1. Nettoyer ou remplacer la cartouche filtrante

2. Joint de culasse de cylindre crevé 2. Installer un nouveau joint

3. Soupapes d’admission/de sortie usées/

cassées

4. Fuites d’air 4. Serrer les joints

Eau excessive dans le réservoir Purger le réservoir. Vérifier la vitesse. Voir le tableau

1. Réglage incorrect du manostat 1. Régler à une pression de fonctionnement plus basse

2. Fonctionnement défectueux de la

soupape de sûreté ASME

3. Contacts du manostat soudés 3. Remplacer le manostat

Fonctionnement défectueux du clapet Remplacer le clapet si le déchargeur purge

Fonctionnement défectueux de la soupape

de déchargement sur le manostat

1. Serrer

l’huile

isolateurs

5. Installez des coussinets de vibration sous les pieds du

compresseur

Canaliser l’air à une source d’air moins humide. Faire

fonctionner la pompe contiuellement pour une heure

d’huile en vérifiant l’air de débit ou la consommation

d’huile du carter

de viscosité correcte

ou les joints toriques

1. Remplacer l’assemblage de soupape

2. Remplacer l’assemblage de soupape

2. Vérifier pour les fuites ou restrictions dans les tuyaux

ou tubes

Ne pas démonter le clapet s’il y

a de l’air dans le réservoir.

2. Serrer

3. Remplacer le réservoir. Ne jamais réparer un réservoir

endommagé

3. Installer un nouveau montage de plaque de soupape

Rendement

de 965 kPa pour une unité monophasée (Voir

Fonctionnement)

2. Remplacer la soupape de sûreté ASME

continuellement

Remplacer le manostat si le modèle ne siffle pas un peu

quand le modèle s’arrête

Fr12

Page 39

GUIDE DE DÉPANNAGE (SUITE)

SYMPTÔME CAUSE(S) POSSIBLE(S) ACTION CORRECTIVE

Le moteur ronron et fonctionne

lentement ou pas du tout

Appareil de réenclenchement

se coupe à maintes reprises ou

les fusibles sautent à maintes

reprises

1. Tension basse ou manque de tension 1. Vérifier avec un voltmètre, vérifiez la tension secteur

2. BobinnEage de moteur raccourci ou

ouvert

3. Fonctionnement défectueux du clapet

ou de la soupape de déchargement

4. Fonctionnement défectueux du

manostat - les contacts ne se ferment

pas

1. Réglage du manostat trop haut 1. Ajuster ou remplacer

2. Fonctionnement défectueux du clapet 2. Nettoyer ou remplacer la soupape défectueuse

3. Taille du disjoncteur/sectionneur

incorrecte

4. Fonctionnement défectueux du

moteur

5. Fils desserrés 5. Vérifier tous les raccordements électriques

à l’unité. Si le disjoncteur à réenclenchement se

déclenche à maintes reprises, le problème n’est pas

avec le moteur.

2. Remplacer le moteur

3. Remplacer le clapet ou la soupape de déchargement

4. Réparer ou remplacer le manostat

3. S’assurer que les disjoncteurs/sectionneurs soient de

classification adéquate

4. Remplacer le moteur

SÉCURITÉ / CARACTÉRISTIQUES

ASSEMBLAGE /

INSTALLATION

UTILISATION

DÉPANNAGE

ENTRETIEN /

RÉPARATION

Fr13

Page 40

INSTRUCTIONS D’ENTRETIEN ET D’INSPECTION

Débrancher, étiquetter, verrouiller la source de puissance et ensuite dissiper toute

Vérifier le filtre à air et le niveau d’huile avant chaque utilisation afin de garder le système de compresseur

DÉMARRAGE

DE L’APPAREIL

SÉCURITÉ / CARACTÉRISTIQUES

INSTALLATION

ASSEMBLAGE /

en bon état de marche. Inspecter la soupape de sûreté ASME quotidiennement (Voir la Figure 9). Tirer sur

la bague de la soupape de sûreté et la laisser revenir à ça position normale. Cette soupape laisse échapper

de l’air automatiquement si la pression dans le réservoir dépasse la pression maximale réglée d’avance.

Remplacer la soupape de sûreté ASME s’il y a une fuite d’air une fois que la soupape soit lâchée ou si la

soupape est grippée.

Figure 9 - Soupape de sûreté ASME

Réservoir

Ne jamais essayer de réparer ou d’altérer un réservoir! Le soudage, perçage

en explosion. Toujours remplacer les réservoirs usés, fendus ou endommagés.

la pression du système avant d’essayer d’installer, réparer, déplacer ou de procéder à l’entretien.

Ne pas toucher la soupape de sûreté ASME.

ou n’importe quelle autre modification peut affaiblir le réservoir et peut résulter en rupture ou

UTILISATION

DÉPANNAGE