Page 1

properly. Do not use a compressed

air source capable of more than 200

PSI. The nailer could explode and

cause death or serious personal

injury.

● Never use gasoline or

other flammable liquids to clean the nailer. Never use the nailer in the presence of

flammable liquids or

gases. Vapors could ignite by a spark

and cause an explosion which will

result in death or serious personal

injury.

● Always place

yourself in a

firmly balanced

position when

using or handling the

nailer.

● Do not modify

or disable the

Work Contact

Element (WCE)

in a depressed

position or tape

or modify the

trigger in a pulled position. Death or

serious personal injury will occur.

● Never keep the

trigger pulled

when carrying

or holding the

nailer. Make

sure not to pull

the trigger or

depress the

work contact element (WCE) trip

mechanism when connecting the

nailer to an air compressor. Death or

serious puncture wounds will occur

if the work contact element (WCE)

bumps something.

Finishing Nailer

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain the product described.

Protect yourself and others by observing all safety information. Failure to comply with instructions could result in personal injury, death

and/or property damage! Retain instructions for future reference.

General Safety Information

This manual contains safety, operational

and maintenance information.

Read this manual and

understand all safety

warnings and instructions before operating

the nailer. Contact your

Campbell Hausfeld representative if you have any questions.

The operator of this nailer must take

the necessary precautions to prevent

unsafe conditions outlined in this manual from occurring. The operator is also

required to read and understand this

instruction manual and all safety warnings, labels, etc.

Any employer allowing the use of this

nailer in their field of work must distribute this instruction manual to all

users. The employer must also ensure

all users read, understand and follow

the instructions as described in the

manual, safety warnings, labels, etc.

Danger indicates

an imminently

hazardous situation which, if not

avoided, WILL result in death or serious

injury.

● Do not use any type

of flammable gases

or oxygen as a power

source for the nailer.

Use filtered, lubricated, regulated compressed air only. Use

of a compressed gas instead of

compressed air may cause the nailer

to explode and cause death or

serious personal injury.

● Do not exceed maxi-

mum operating pressure of the nailer

(110 PSI). The nailer

will not function

Operating Instructions Model NB0050

IN247201AV 1/97

Description

This nailer is designed for trimwork, interior molding, baseboards, paneling and

cabinet assembly and installation. Features include: convenient side loading magazine which holds up to 100 nails, no-mar tip, adjustable exhaust, single cycle trigger and quick clear nose.

Warning indicates

a potentially hazardous situation which, if not avoided,

COULD result in death or serious

injury.

● Disconnect the

nailer from air

supply before

adjusting, clearing jams, servicing, relocating

and during nonoperation. Remember it is possible

for the nailer to eject a fastener

after servicing the tool. ALWAYS

reconnect the air lines before loading any fasteners. Death or serious

personal injury could result.

● Protect your eyes and

ears. Wear Z87 safety

glasses, with side

shields. Wear hearing

protection. Employers

and users are responsible for ensuring the

user or anyone near

the nailer wears this

safety protection.

Serious eye injury or

permanent hearing

loss could result.

● Do not use a

check valve or

any other fitting which

allows air to

remain in the

nailer. Serious

personal injury

could occur.

MANUAL

CAMPBELL

HAUSFELD

Model NB0050

CAMPBELL

PROFESSIONAL

HAUSFELD

110 PSI

O

CO

2

Campbell Hausfeld Nailers meet or exceed Industries’ Standards as set forth by the American

National Standard/International Staple, Nail and Tool Association in ANSI/ISANTA SNT-101-1993.

© 1996 Campbell Hausfeld

Page 2

Model NB0050

2

Operating Instructions

Warning Continued

● Never place

your hand or

any part of

your body in

the nail discharge area of

the nailer. It is

possible for the

nailer to eject a fastener and could

result in death or serious personal

injury.

● Never carry the

nailer by the air

hose or pull the

hose to move

the nailer or a

compressor.

Keep hoses

away from heat, oil and sharp

edges. Replace any hose that is damaged, weak or worn. Personal injury

or tool damage could occur.

● Always assume the nailer contains

nails. Never use the nailer as a toy.

Do not engage in horseplay. Always

keep others at a safe distance from

the work area in case of accidental

discharge of nails. Never point the

nailer at anyone. Accidental triggering of the nailer could result in

death or serious personal injury.

● Do not drive a

nail on top of

other nails. The

nail could

glance and

cause death or

a serious puncture wound.

● Do not operate

or allow anyone

else to operate

the nailer if any

warnings or

warning labels

are not legible.

Warnings or

warning labels are located on the

nailer magazine and body.

● Never leave the nailer unattended or

connected to an air compressor when

not in use. Serious personal injury

can occur if someone picks up and

uses the nailer without knowing the

correct way to operate the nailer.

● Do not drop or throw the tool.

Dropping or throwing the tool can

result in damage that will make the

tool unusable or unsafe. If the tool

has been dropped or thrown, examine the tool closely for bent, cracked

or broken parts and air leaks. STOP

and repair before using or serious

injury could occur.

Caution indicates a

potentially hazardous situation which, if not avoided,

MAY result in minor or moderate injury.

● Do not modify or alter the nailer or

any nailer parts. Do not use the nailer

if any shields or guards are removed

or altered. Do not use the nailer as a

hammer. Serious personal injury may

occur.

● Avoid long extended periods of

work with the nailer. The nailer can

harm the user’s hands or arm. Stop

using the nailer if pain occurs.

● Always check

the work contact element

(WCE) trip

mechanism of

the nailer. A

nail could accidentally be driven if the triggering mechanism is not working

properly. Serious personal injury

may occur.

● Disconnect air supply and release

tension from the pusher before

attempting to clear jams because

fasteners can be ejected from the

front of the nailer. Personal injury

may occur.

Notice indicates

important information, that if not followed, may cause

damage to equipment.

● Avoid using the nailer when there

are no nails in the magazine.

Accelerated wear on the nailer may

occur.

● Clean and check all air supply hoses

and fittings before connecting the

nailer to compressor. Replace any

damaged or worn hoses or fittings.

Tool performance or durability may

be reduced.

● Air compressors providing air to the

nailer should follow the requirements established by the American

National Standards Institute

Standard B19.3-1991; Safety

Standard for Compressors for

Process Industries. Contact your air

compressor manufacturer for information.

!

NOTICE

Table Of Contents

General Safety . . . . . . . . . . . . . . . .1

Specifications . . . . . . . . . . . . . . . .2

Using The Nailer . . . . . . . . . . . . . .3

Operational Modes . . . . . . . . . . . .3

Operating The Nailer . . . . . . . . . .4

Troubleshooting . . . . . . . . . . . . . .6

Warranty . . . . . . . . . . . . . . . . . . . .7

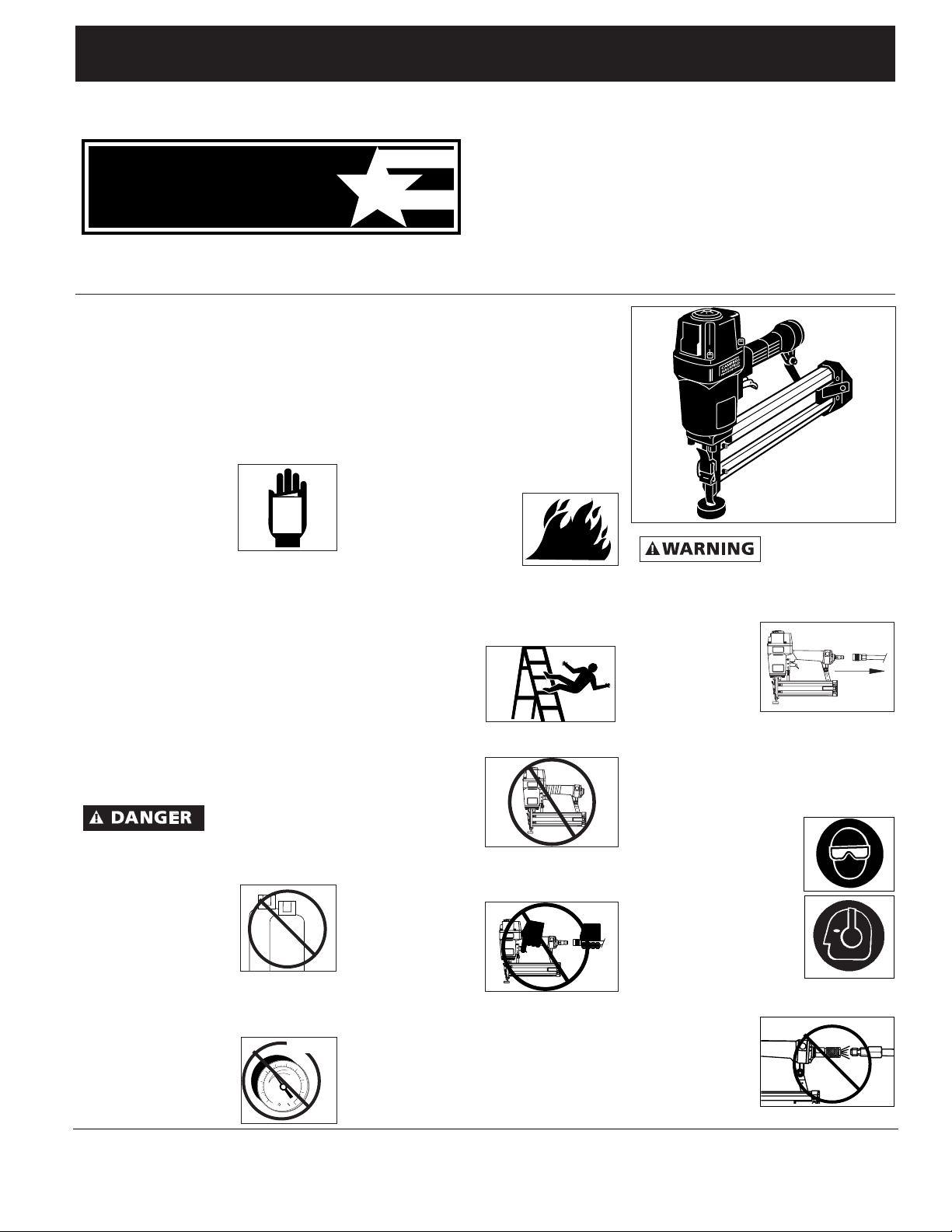

Quick Clear Latch

Rubber

No-Mar Tip

Nail Discharge Area

Pin (Single Cycle)

Trigger

Nail Loading Area

Magazine

Nail Pusher

Release Catch

Adjustable Direction

Exhaust Deflector

• REQUIRES: 1.5 SCFM with 10 nails

per minute @ 90 PSI

• AIR INLET: 1/4” NPT

• NAIL SIZE RANGE: 3/4” to 2”

• MAGAZINE CAPACITY:

100 Nails per load, 16 gauge

• WEIGHT: 4 lbs., 13 oz.

• LENGTH: 11-1/2”

• HEIGHT: 11-1/2”

• MAXIMUM PRESSURE: 110 PSI

• PRESSURE RANGE: 70 - 110 PSI

Nailer Components And Specifications

Work Contact

Element (WCE)

Warning Labels

!

WARNING

Page 3

Model NB0050

SINGLE CYCLE MODE

This method is recommended when

precise nail placement is required.

The single cycle pin

must be installed

in the nailer. This mode requires the

trigger to be pulled each time a nail is

driven. The nailer can be actuated by

depressing the WCE against the work

surface followed by pulling the trigger.

Or the nailer can be actuated by pulling

the trigger and then depressing the

WCE against the work surface.

The trigger must be released to reset

the tool before another nail can be driven.

If the tool is in bottom trip mode

because the single cycle pin has previously been removed, reinstall the single

cycle pin to convert the tool back to single cycle mode.

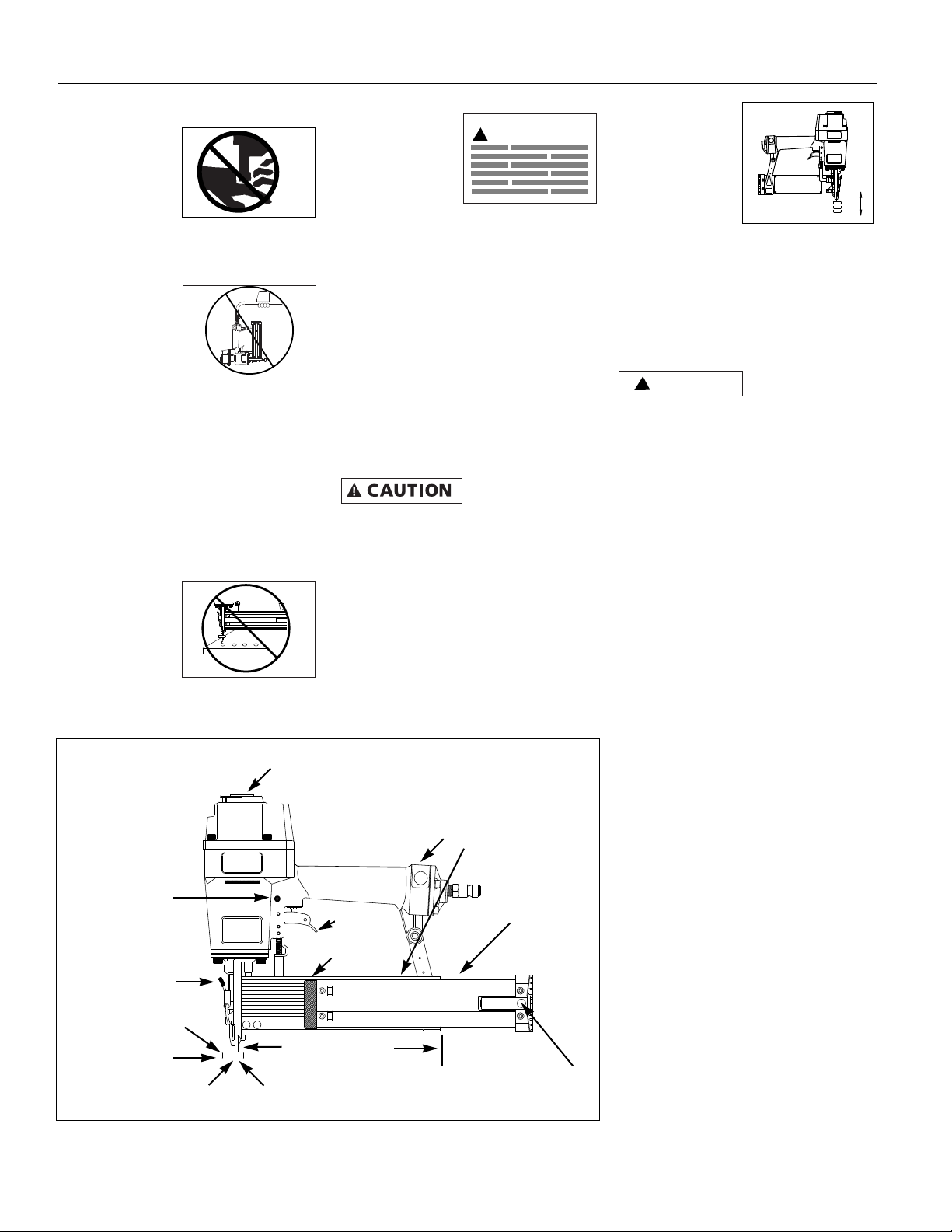

BOTTOM TRIP MODE

This method is recommended when less

precise nail placement is required.

The single cycle pin

must be removed

from the nailer.

Remove the pin by

removing the oring on one end and pushing the pin

out. Replace the o-rings on the pin

after removing the pin from the nailer

and keep the pin assembly for later use.

Bottom trip operation requires the

trigger to be

pulled with the

nailer off the work

surface. Then, the

nose of the nailer is tapped against the

work surface causing a nail to be driven.

3

Operating Instructions

Using The Nailer

Read this manual and understand

all safety warnings and instructions before operating the nailer.

LUBRICATION

This nailer requires lubrication before

using the nailer for the first time and

before each use. If an inline oiler is

used, manual lubrication through the

air inlet is not required on a daily basis.

The work surface

can become damaged by excessive lubrication. Proper

lubrication is the owner’s responsibility. Failure to lubricate the nailer properly will dramatically shorten the life

of the nailer and void your warranty.

1. Disconnect the

air supply from

the nailer to

add lubricant.

2. Turn the nailer

so the air inlet

is facing up and

put 4-to-5

drops of 30 W

non-detergent

oil into air inlet. Do not use detergent oil or oil additives. Run the nailer briefly after adding oil and wipe

off excessive oil at the exhaust.

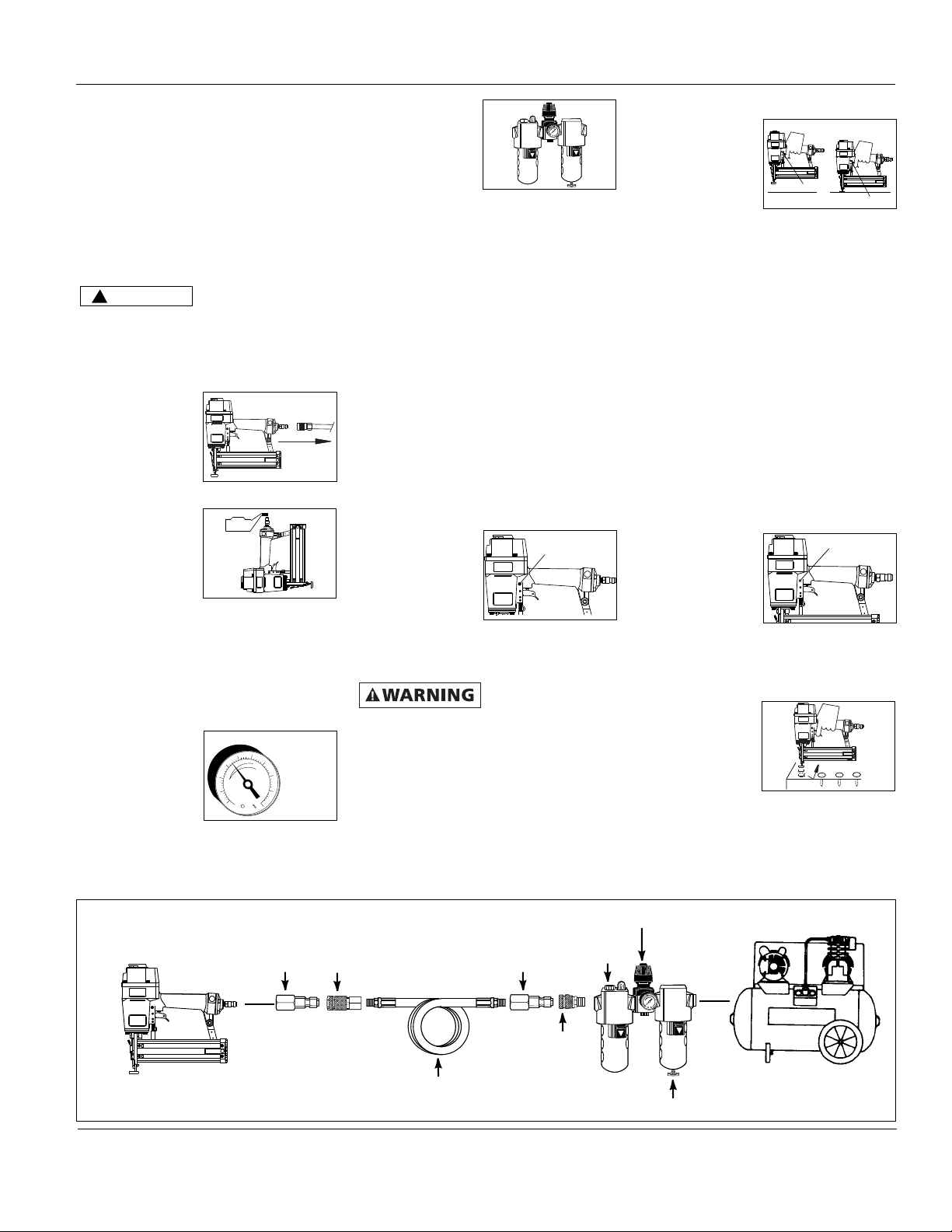

RECOMMENDED HOOKUP

The illustration below shows the

recommended hookup for the nailer.

1. The air com-

pressor must

be able to

maintain a

minimum of 70

PSI when the

nailer is being

used. An inadequate air supply can

cause a loss of power and inconsistent driving.

!

NOTICE

2. An oiler can be

used to provide

oil circulation

through the

nailer. A filter

can be used to

remove liquid

and solid impurities which can rust

or “gum up” internal parts of the

nailer.

3. Use 3/8” air hoses with a minimum

working pressure of 150 PSI. Use

1/2” air hoses for 50’ run or longer.

For better performance, install a

3/8” quick plug with (1/4” NPT

threads) with an inside diameter of

.315 (8mm) on the nailer and a 3/8”

quick coupler on the air hose.

4. Use a pressure regulator on the

compressor, with an operating pressure of 0 - 125 PSI. A pressure regulator is required to control the operating pressure of the nailer.

Operational Modes

The NB0050 finish nailer may be operated in the “Single Cycle” or the

“Bottom Trip” mode. The nailer comes

delivered in the

single cycle mode.

A pin when in

place in the nailer

allows you to

operate in the single cycle mode.

When the pin is removed, the nailer

will operate in the bottom trip mode.

Always know the

operational mode

of the nailer before using. Failure to

know the operational mode could

result in death or serious personal

injury.

70 PSI

Min.

Recommended Hookup

Single Cycle Pin

110 PSI

Max.

OIL

Pin Out

Quick

Plug

Quick

Coupler

Air

Hose

Quick Plug

(Optional)

(Optional)

Regulator

Oiler

Quick

Coupler

Filter

Page 4

Model NB0050

4

Operating Instructions

Each time the

Work Contact

Element (WCE) is

depressed, a nail is

driven into the

work surface. Care

should be taken

when using this method because a nail

will be driven when the WCE is

depressed by any surface.

To convert the tool back to single cycle

operation, reinstall the single cycle pin

and attach an o-ring to each end.

Operating The Nailer

Disconnect the

nailer from the air

compressor before adjusting, clearing

jams, servicing, relocating, and during

non-operation.

WORK CONTACT ELEMENT (WCE)

Check the opera-

tion of the Work

Contact Element (WCE) trip mechanism

before each use. The WCE must move

freely without binding through its

entire travel distance. The WCE spring

must return the WCE to its fully extended position after being depressed. Do

not operate the nailer if the WCE trip

mechanism is not operating properly.

Personal injury may occur.

1. Disconnect the

air supply from

the nailer.

2. Remove all

nails from the

magazine (See

LoadingUnloading)

3. Make sure the

trigger and

work contact

element (WCE)

move freely up

and down

without sticking or binding.

4. Reconnect air

supply to the

nailer.

5. Depress the

work contact

element (WCE)

against the

work surface

without pulling

the trigger. The nailer MUST NOT

cycle. Do not use the nailer if it

cycles. Personal injury could result.

6. Hold the nailer

clear of the

work surface.

The work contact element

(WCE) should

return to its original down position.

Pull the trigger. The nailer MUST

NOT cycle. Do not use the nailer if a

cycle occurs. Personal injury could

result.

7. Pull the trigger

and depress the

work contact

element (WCE)

against the

work surface.

The nailer MUST cycle.

8. Depress the

work contact

element (WCE)

against the

work surface.

Pull the trigger.

The nailer MUST cycle.

LOADING/UNLOADING THE NAILER

1. Always connect the tool to the air

supply before loading fasteners.

2. Press down on

the latch. Pull

back on the

magazine

cover.

3. Insert a stick of

Campbell

Hausfeld nails

or equivalent

(See Fastener

Section)into the

magazine. Make sure the pointed

ends of the nails are resting on the

bottom ledge of the magazine

when loading. Make sure the nails

are not dirty or damaged.

4. Push the magazine cover forward until the

latch

catches.

5. Unloading is the reverse of loading, except always disconnect the

air hose before proceeding.

ADJUSTING THE NAIL PENETRATION

1. Regulate the air pressure to 70 PSI

at the nailer.

2. Connect the air

hoses and test

for penetration

by driving nails

into a sample

piece of wood.

If the nails do

not achieve the desired penetration, adjust the air pressure to a

higher setting until the desired penetration is achieved. Do not exceed

110 PSI at the nailer or durability of

the nailer will be reduced.

ADJUSTING THE DIRECTION OF THE

EXHAUST

The NB0050 is

equipped with an

adjustable direction exhaust

deflector. This is

intended to allow

the user to change

the direction of the exhaust. Simply

twist the deflector to any direction

desired.

CLEARING A JAM FROM THE NAILER

1. Disconnect the

air supply from

the nailer.

2. Remove all

nails from the

magazine.

Failure to do so

will cause the

nails to eject

from the front

when the quick clear mechanism is

opened and the jam is removed.

3. Undo latch by

pulling out and

down. The wire

latch will disengage from the

hooks on the

nose casting.

Movement

CAMPBELLCAMPBELL

HAUSFELDHAUSFELD

PROFESSIONALPROFESSIONAL

1 2

1 2

Rotate

Page 5

Technical Support

Should you have any questions regarding the operation or repair of this nailer, please call our Nailer Hotline at

1-800-543-6400 for assistance. If you

are calling from Ohio or outside of the

continental United States, please call

collect, 1-513-367-1182.

Record the model number and

serial number below:

Model No___________________________

Serial Number_______________________

Retain these number for future

reference.

Fastener And Replacement

Parts

Use only

genuine Campbell

Hausfeld fasteners (or equivalent) and

replacement parts. Do not use modified parts or parts which will not give

equivalent performance to the original

equipment. Tool performance, safety

and durability could be reduced. When

ordering replacement parts or fasteners, specify by part number.

Model NB0050

5

Operating Instructions

4. The driver

cover plate can

now be rotated, exposing

the jammed

fastener.

5. Remove the

jammed fastener, using

pliers or a

screwdriver if

required.

6 Rotate driver

cover back into

the closed position.

7. Extend the

wire latch and

place over the

hooks on the

nose casting.

8. Close the over

center latch by

pushing the

latch in until

the latch snaps

into place.

Fasteners

The following Campbell Hausfeld finishing nails are available at local retail stores. If you need help locating

any item, call customer service at 1-800-543-6400. Campbell Hausfeld nails meet or exceed Federal

Specifications FF-N-105B.

Shank Nails Per Nails Per

Model # Length

Gauge

Finish Head Collation

Stick Box

FB003060 1-1/4” 16 Gauge Galvanized Brad Adhesive 50 2500

FB004060 1-1/2” 16 Gauge Galvanized Brad Adhesive 50 2500

FB004560 1-3/4” 16 Gauge Galvanized Brad Adhesive 50 2500

FB005060 2” 16 Gauge Galvanized Brad Adhesive 50 2500

Interchange Information

Nails used in the Campbell Hausfeld NB0050 Finishing Nailer will also work in Hitachi NT65A, Paslode 3250-F16, IM250F,

Duo Fast LFN-764, Sears 18314, Porter Cable FN200 and FN250.

COLORMATCH™ System

The Campbell Hausfeld Finishing Nailer

has a unique COLORMATCH™ stripe.

Look for the COLORMATCH™ stripe to

choose the right Campbell Hausfeld

fasteners for your NB0050 2” finish

nailer.

Nailer Repair

Nailer repairs must be performed by

qualified and experienced service people ONLY.

Assembly Procedure For

Seals

When repairing a nailer, the internal

parts must be cleaned and lubricated.

Parker O-lube or equivalent must be

used on all o-rings. Each o-ring must be

coated with O-lube before assembling.

A small amount of oil must be used on

all moving surfaces and pivots. After

reassembling, a few drops of 30W nondetergent oil or equivalent, must be

added through the air line before testing.

Page 6

Model NB0050

Operating Instructions

6

Air leaking at trigger valve

Air leaking between housing and nose

Air leaking between housing and cap

Nailer skips driving nail

Nailer runs slow or has loss

of power

Nails are jammed in nailer

Air leaking at trigger valve

stem

O-Rings in trigger valve housing are

damaged

Loose screws in housing

Damaged O-Rings

Damage to bumper

Loose screws

Damaged gasket

Worn bumper

Dirt in nose piece

Dirt or damage prevent nails or pusher

from moving freely in magazine

Damaged pusher spring

Inadequate air flow to nailer

Worn O-Ring on piston or lack of

lubrication

Damaged O-Ring on trigger valve

Air leaks

Cap gasket leaking

Nailer not lubricated sufficiently

Broken spring in cylinder cap

Exhaust port in cap is blocked

Guide on driver is worn

Nails are not correct size

Nails are bent

Magazine or nose screws are loose

Driver is damaged

O-Rings or seals are damaged

O-Rings must be replaced & operation of work

contact element must be checked

Screws need to be tightened

O-Rings must be replaced

Bumper needs to be replaced

Screws need to be tightened

Gasket needs to be replaced

Bumper needs to be replaced

Drive channel needs to be cleaned

Magazine needs to be cleaned

Spring needs to be replaced

Fitting, hose or compressor needs to be checked

O-Rings need to be replaced. Lubricate.

O-Rings need to be replaced

Screws and fittings need to be tightened

Gasket needs to be replaced

Nailer needs to be lubricated

Spring needs to be replaced

Damaged internal parts need to be replaced

Guide needs to be replaced

Nails recommended for nailer must be use

Replace with undamaged nails

Screws need to be tightened

Driver needs to be replaced

O-Rings or seals need to be replaced

Troubleshooting Guide

Stop using nailer immediately if any of the following problems occur. Serious

personal injury could result. Any repairs or replacements must be done by a

Qualified Service Person or Authorized Service Center.

Problem Cause Solution

Page 7

Model NB0050

7

Operating Instructions

Limited Warranty

1. DURATION: One year from the date of purchase by the original purchaser.

2. WHO GIVES THIS WARRANTY (WARRANTOR):

The Campbell Group

A Scott Fetzer Company

100 Production Drive

Harrison, Ohio, 45030

Telephone: 1-800-543-6400.

3. WHO RECEIVES THIS WARRANTY (PURCHASER): The original purchaser (other than for purposes of resale) of the

Campbell Hausfeld product.

4. WHAT PRODUCTS ARE COVERED BY THIS WARRANTY: Any Campbell Hausfeld nailer.

5. WHAT IS COVERED UNDER THIS WARRANTY: Defects on material and workmanship which occur within the duration of

the warranty period.

6. WHAT IS NOT COVERED UNDER THIS WARRANTY:

A. Implied warranties, including those of merchantability and FITNESS FOR A PARTICULAR PURPOSE ARE LIMITED TO ONE

YEAR FROM THE DATE OF ORIGINAL PURCHASE. Some states do not allow limitations on how long an implied warranty

lasts, so the above limitations may not apply to you.

B. ANY INCIDENTAL, INDIRECT, OR CONSEQUENTIAL LOSS, DAMAGE, OR EXPENSE THAT MAY RESULT FROM ANY DEFECT,

FAILURE, OR MALFUNCTION OF THE CAMPBELL HAUSFELD PRODUCT. Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation or exclusion may not apply to you.

C. Any failure that results from an accident, purchaser’s abuse, neglect or failure to operate products in accordance with

instructions provided in the owner’s manual(s) supplied with product. Accident, purchaser’s abuse, neglect or failure to

operate products in accordance with instructions shall also include the removal or alteration of any safety devices. If

such safety devices are removed or altered, this warranty is void.

D. Normal adjustments which are explained in the owner’s manual(s) provided with the product.

E. Items or service that are normally required to maintain the product, i.e. o-rings, springs, bumpers, debris shield, driver,

etc. These said normal wear items will be covered only for ninety days from the date of original purchase.

7. RESPONSIBILITIES OF WARRANTOR UNDER THIS WARRANTY: Repair or replace, at Warrantor’s option, products or components which have failed within duration of the warranty period.

8. RESPONSIBILITIES OF PURCHASER UNDER THIS WARRANTY: A. Deliver or ship the Campbell Hausfeld product or component to the nearest Campbell Hausfeld Authorized Service Center. Freight costs, if any, must be borne by the purchaser.

B. Use reasonable care in the operation and maintenance of the products as described in the owner’s manual(s).

9. WHEN WARRANTOR WILL PERFORM REPAIR OR REPLACEMENT UNDER THIS WARRANTY:

A. Repair or replacement will be scheduled and serviced according to the normal work flow at the servicing location, and

depending on the availability of replacement parts.

B. If the purchaser does not receive satisfactory results from the Authorized Service Center, the purchaser should contact

the Campbell Hausfeld Product Service Department (see paragraph 2).

This Limited Warranty gives you specific legal rights and you may also have other rights which vary from state to state.

Printed In Taiwan

Page 8

Operating Instructions

NB0050

Notes

8

Loading...

Loading...