Page 1

See Warranty on page 10 for important information about commercial use of this product.

Operating Instructions MXS3000

lease read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain the product described.

P

Protect yourself and others by observing all safety information. Failure to comply with instructions could result in personal injury and/or

property damage! Retain instructions for future reference.

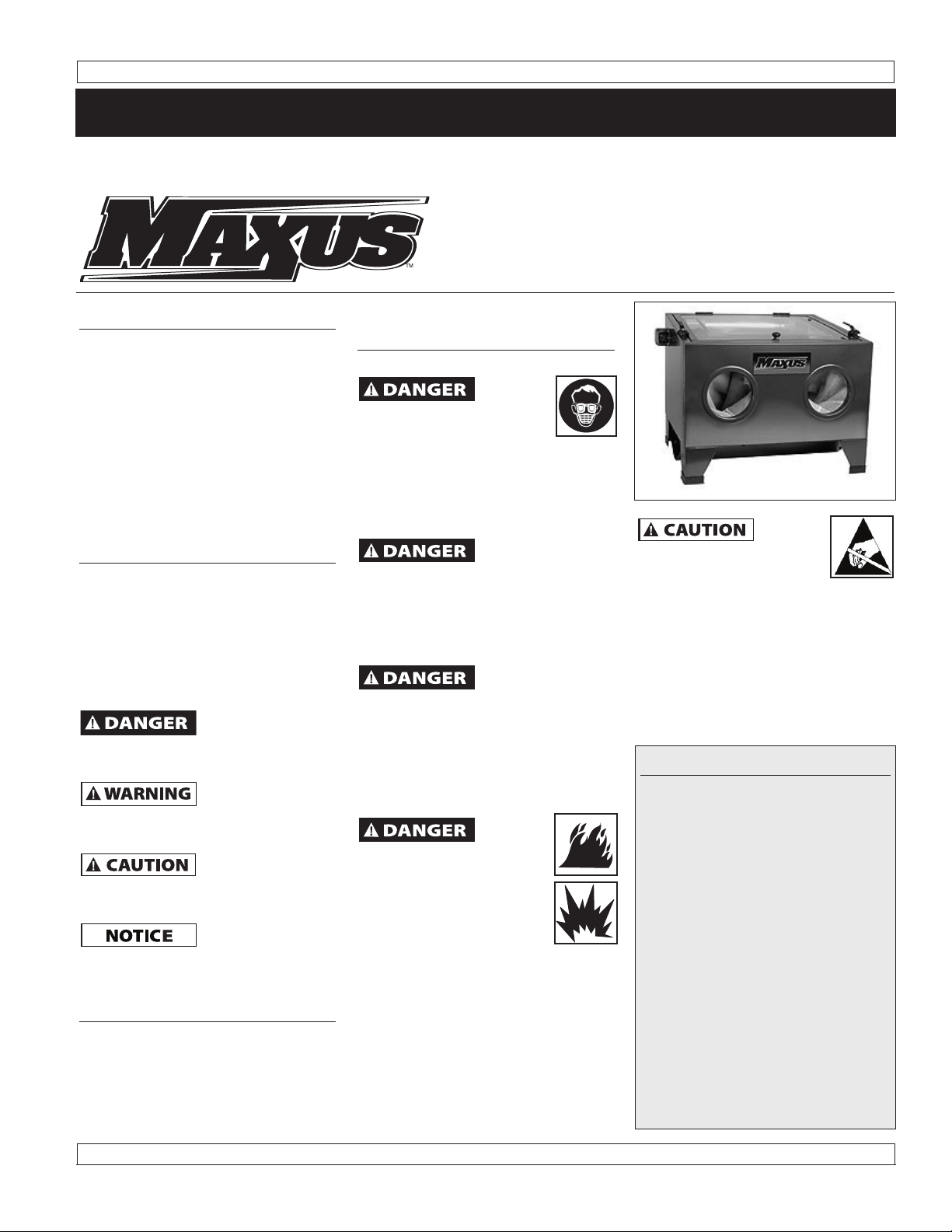

Benchtop Blast Cabinet

Description

Maxus Benchtop Blast Cabinet is

designed for cleaning and removing

rust, scale, and paint. It is the ideal

method for stripping, polishing and

etching projects. A blast cabinet keeps

sandblasting particles in a contained

area and allows them to be recycled.

The cabinet also confines dust particles

and a vacuum hook-up can remove any

dust that occurs during sandblasting.

Safety Guidelines

This manual contains information that is

very important to know and understand.

This information is provided for SAFETY

and to PREVENT EQUIPMENT PROBLEMS.

To help recognize this information,

observe the following symbols.

Danger indicates an

imminently

hazardous situation which, if not avoided,

will result in death or serious injury.

Warning indicates a

potentially

hazardous situation which, if not avoided,

could result in death or serious injury.

Caution indicates a

potentially

hazardous situation which, if not avoided,

may result in minor or moderate injury.

Notice indicates

important

information, that if not followed, may

cause damage to equipment.

Unpacking

After unpacking, carefully inspect for

any damage that may have occurred

during transit. Check for loose, missing

or damaged parts.

General Safety

Information

CALIFORNIA PROPOSITION 65

You can

create

dust when you sweep, blast,

cut, sand, drill or grind

materials such as wood, paint,

metal, concrete, cement, or other

masonry. This dust often contains

chemicals known to cause cancer, birth

defects, or other reproductive harm.

Wear protective gear.

This product or its

power cord contains

chemicals, including lead, known to the

State of California to cause cancer and

birth defects or other reproductive

harm. Wash hands after handling.

SILICA ABRASIVE HAZARD

Breathing

dust from abrasives

containing silica can be dangerous.

Exposure can cause SILICOSIS, lung

disease, or other respiratory problems,

Wear NIOSH/MSHA approved respirator

at all times when performing abrasive

blasting and while cleaning up.

Fire or

Explosion

Hazard!Never use a sand

blaster around combustible or

flammable liquids, gases,

dusts, oily rags, or other

materials that can explode or

burn quickly. Some abrasives

create sparks when they hit

metal. Abrasives similar to aluminum

oxide may generate static electric

sparks. In an unsafe environment, these

sparks will start fires or explosions that

will result in death or serious personal

injury. For your safety and the safety of

people nearby, DO NOT USE this sand

blaster where there are combustible or

flammable liquids, gases, dusts, oily

rags, or other materials that can

explode or burn quickly.

Model MXS3000

Static

electric

shocks can be painful. Some

abrasives similar to aluminum

oxide can create static

electricity while you are sand blasting.

If you are not grounded, the static

electricity can build up on your body

and cause a shock when you touch a

metal object. You can avoid static

electricity by wearing leather soled

shoes and standing on the ground. If

necessary, a grounded wire attached to

the sand blast gun will safely remove

Specifications

Dimensions:

Footprint: 23 in. W x 19 in. D

Overall Hgt: 19.25 in.

Overall Depth: 19.75 in.

Overall Width: 24.75 in.

Work Area Hgt: 11.5 in. to 13.5 in.

Work Area Depth: 18.0 in. to 18.5 in.

Work Area Width: 21.75 in. to 23.50 in.

Top Opening: 19.25 in. W x 15.50 in. D

12V fluorescent work light with 120VAC

60Hz input 12V 800mA output Class 2 UL

listed power supply

Right Side 1-3/8 in. ID shop vac outlet port

with replaceable paper & sponge conical

filter

Max. psi . . . . . . . . . . . . . . . . . . . . . . . . .125

Air Inlet . . . . . . . . . . . . . . . . .1/4 in. NPT (F)

Media Capacity . . . . . . . . . . . . .2.5 Gallons

REMINDER: Keep your dated proof of purchase for warranty purposes! Attach it to this manual or file it for safekeeping.

© 2008 IN709902AV 12/08

For parts, product & service information

visit www.maxustools.com

Page 2

perating Instructions

MANUAL

O

General Safety

Information (cont.)

the static electricity. Remember, you are

not grounded if you are insulated from

the ground. Rubber soled shoes, rubber

boots, or other rubber or plastic

footwear are insulators. Avoid standing

on dry wood (like a wooden pallet) a

dry mat, or dry carpet.

GENERAL SAFETY INFORMATION

Do not misuse this

product. Excessive

exposure to vibration, work in

awkward positions, and repetitive

work motions can cause injury to hands

and arms. Stop using any tool if

discomfort, numbness, tingling or pain

occur, and consult a physician.

1. Read this instruction

manual before

connecting this device to

the compressor.

2. Safety glasses and a

NIOSH/ MSHA approved

respirator must be worn

during operation and

clean up.

3. During operation, do not expose the

hands or skin directly in the line of

the blast nozzle.

4. After assembly, inspect to make

sure all components seal properly.

5. Do not exceed the maximum

operating pressure of the blasting

equipment (125 psi).

Disconnect the

cabinet from the

air supply before changing accessories

or attempting to install, service,

relocate or perform any maintenance.

Check hoses and air lines for weak

6.

or worn condition before each use.

Make sure all connections are

secure before use.

Do not point the

abrasive blaster

gun at anyone or objects other than

the intended work object.

7. Do not depress the trigger when

connecting the air supply hose.

Do not work near

flammable liquids.

Blasting media striking metal can cause

a spark and create a fire or explosion.

Do not spray acids

or caustics.

Figure 1 - Do not spray acids or caustics

Assembly

Note: A small (P2) Phillips-Head

screwdriver and adjustable wrench

are required for assembly.

• Remove cabinet and other pieces

from packaging. Make sure there

are no missing pieces (see parts list).

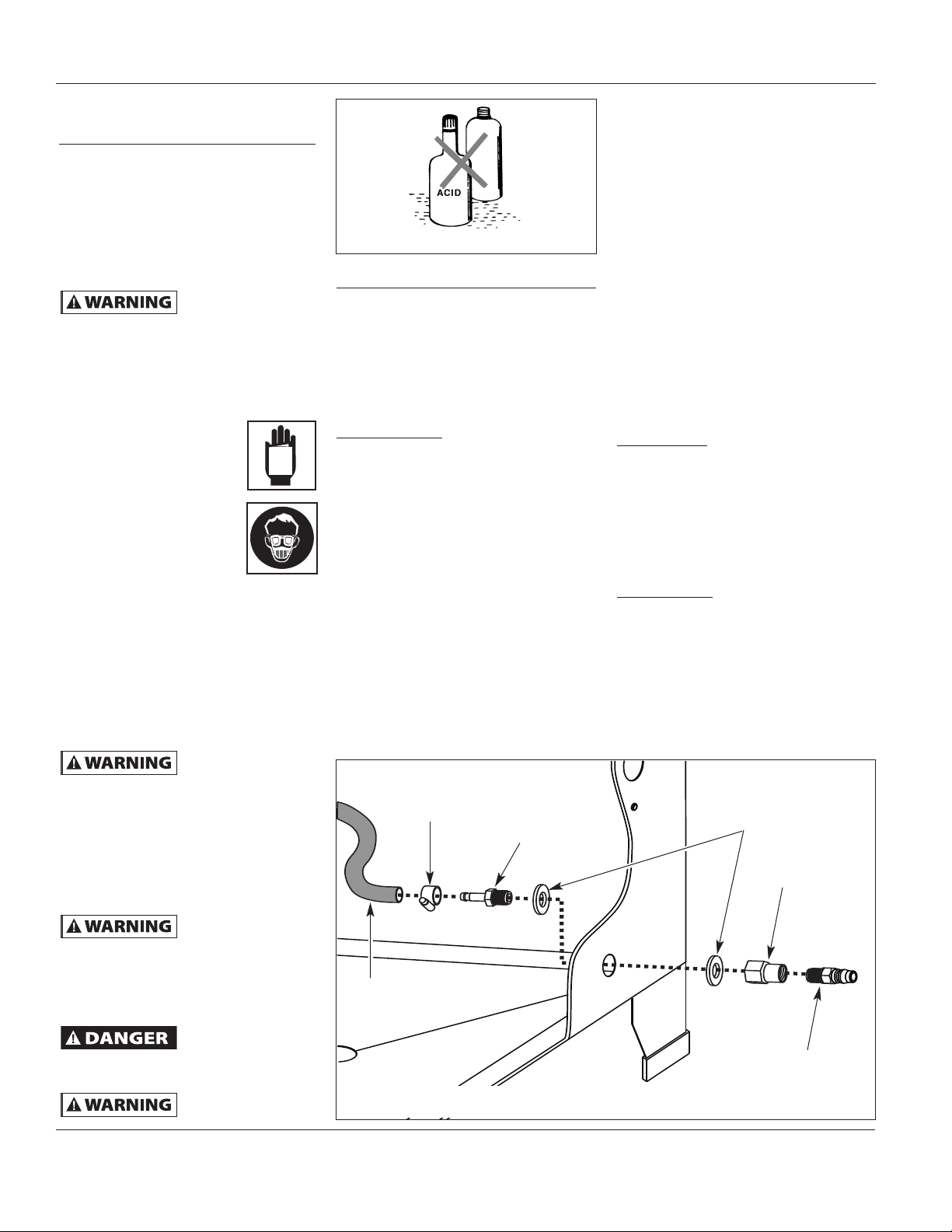

GGuunn aanndd hhoossees

• Press other end of AIR hose fully

onto barbs of cabinet inlet fitting.

Place and securely tighten a small

hose clamp around section of hose

covering barb.

• Press end of MATERIAL hose fully

onto tool material inlet flange. Place

and securely tighten a medium hose

clamp around section of hose

covering flange.

• Press other end of MATERIAL hose

about 1 in. - 2 in. onto the small

diameter end of the metal diptube.

Place and securely tighten a medium

hose clamp around section of hose

covering diptube.

Air Hose

Figure 2 - Air Inlet assembly

s

Clamp

Air Inlet

• Place gun and hose assemblies into

abinet, feeding diptube under the

c

wire mesh parts tray. Place a

washer on threaded end of cabinet

nlet fitting, then push fitting

i

through the hole on the lower right

side of cabinet. Place other washer

n the protruding end of the fitting

o

(see Figure 2).

Apply teflon tape to the threads of

•

the inlet fitting to reduce the

possibility of air leaks. Thread the

female fitting onto the protruding

threads of the cabinet inlet fitting

and tighten securely. Make sure the

wrench flats of the female fitting

abut the cabinet (see Figure 2).

DDoooorr llaattcchhees

s

• Place black plastic door latches over

the holes on the edges of the cabinet

top. Secure each to cabinet top using

a 1 in. long bolt and a lock nut.

Tighten firmly, but do not

overtighten.

CCaabbiinneett ffiilltteer

r

• Place round filter sponge in cabinet

filter housing. Place filter housing over

large hole in rear of cabinet, lining up

the holes on the edge of the housing

with the posts above and below the

cabinet hole. Twist and lock.

Washers

Female fitting

Male plug

www.maxustools.com

2

Page 3

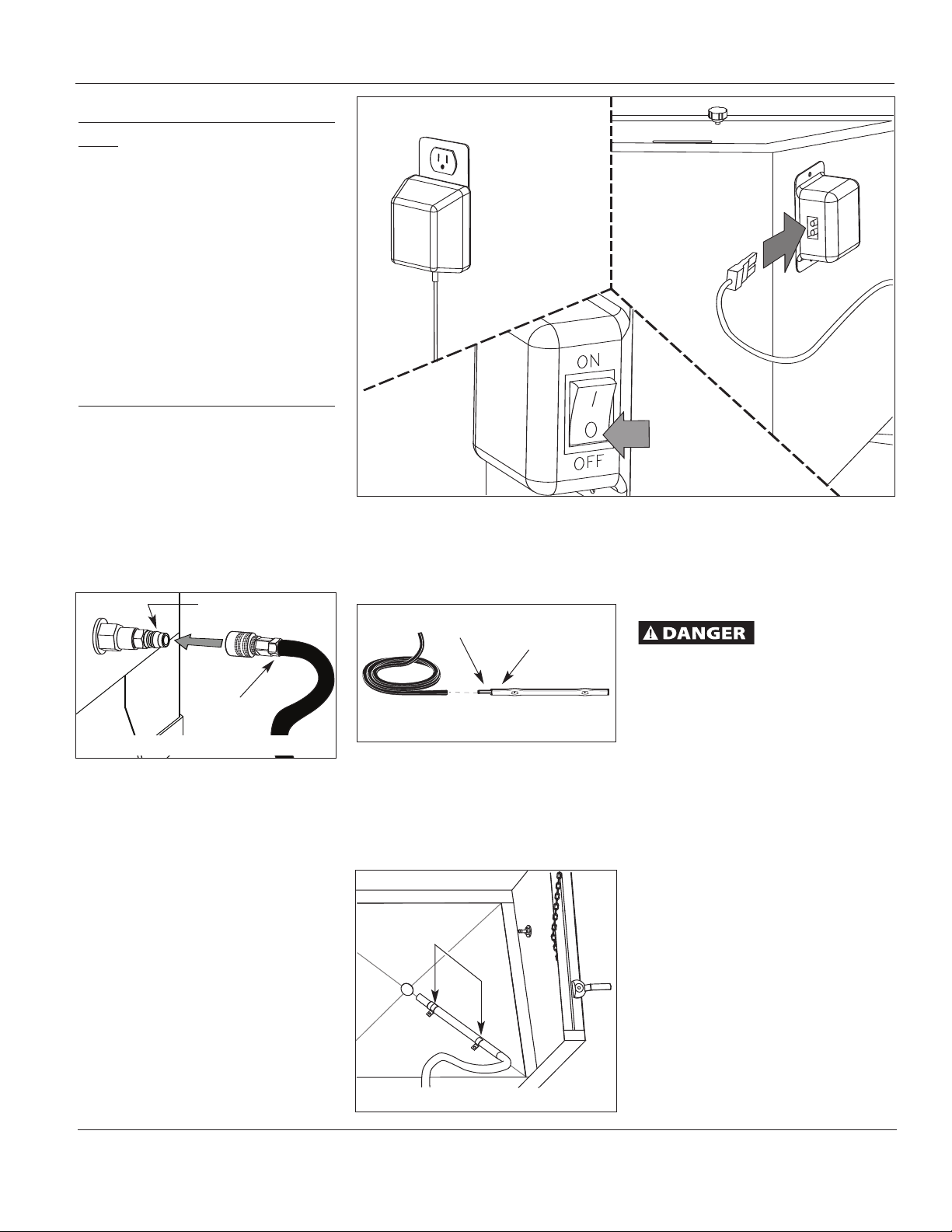

Assembly (cont.)

LLaammp

p

• Make sure the power supply is not

plugged into lamp switch outlet.

Place lamp switch box up to free end

of lamp cord. Connect flag terminals

from the lamp cord to the lamp

switch terminals labeled “2”

together. The brown wire goes on

the top (near the “2”), the blue wire

goes directly beneath. Secure lamp

switch box to the cabinet using two

(2) 5/16 in. long bolts, nuts, and lock

washers. Tighten securely.

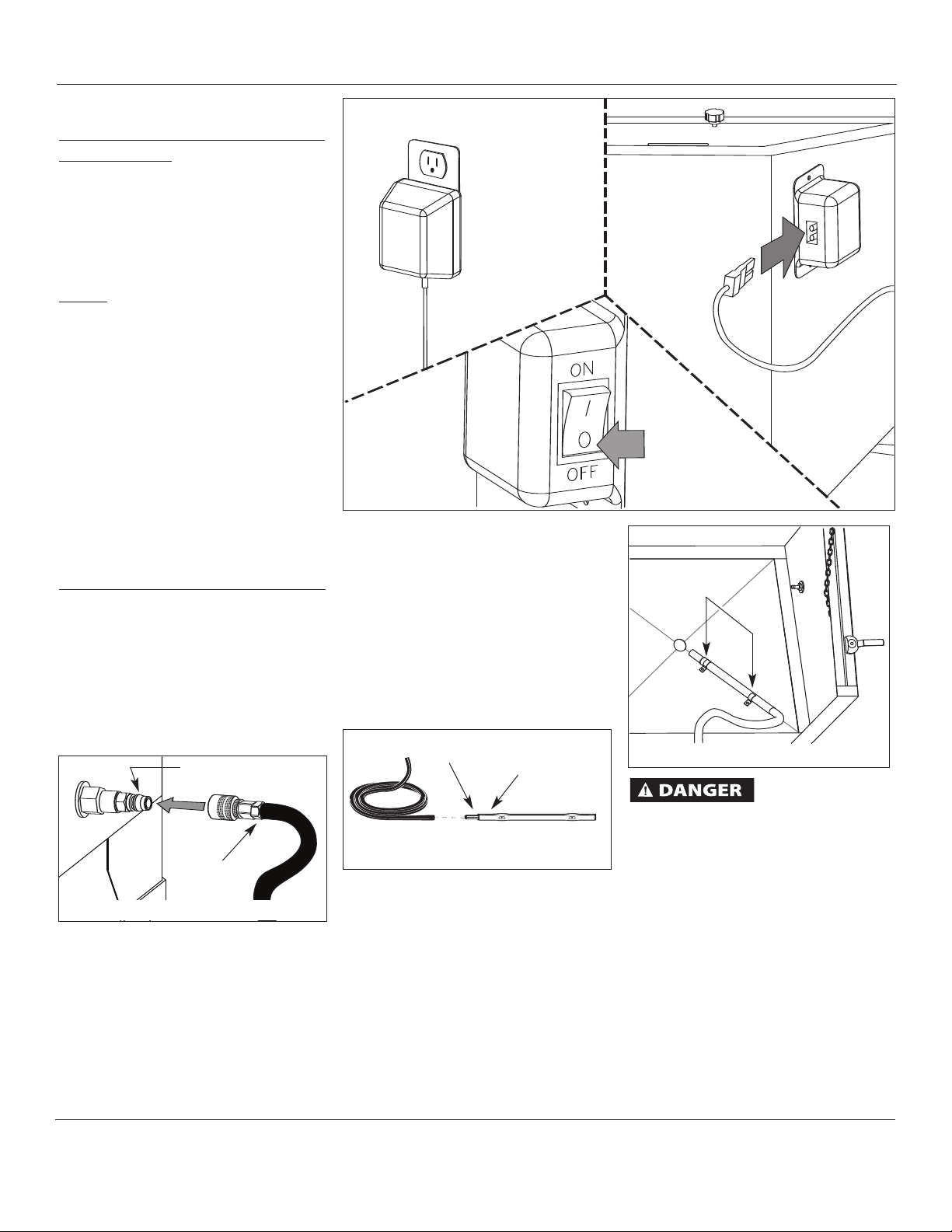

1.Plug power

supply cord

into wall

outlet

3.Plug other

end of power

supply cord

into back of

switch

box

XS3000

M

Operation

After the blast cabinet is completely

assembled, follow these instructions

before supplying air to the cabinet.

1. Position cabinet on a table or

workbench where you will be

performing the work.

2. Connect air supply (max. 125 psi) to

the fitting on the side of the

cabinet (see Figure 3).

Air supply fitting

Air hose

and

connection

Figure 3 – Connect air supply

3. Check for air leaks. If any are found,

repair or add teflon tape if needed.

4.

Plug the 12V power supply into a

110V wall outlet (see Figure 4)

5. Making sure the switch is in the (

position, plug the other end of

OFF

the 12V power supply cord into the

light switch on the cabinet (see

Figure 4).

Check that the light works. It can

6.

be rotated to prevent the light

from shining directly into your

eyes.

7. Add a plastic window protector

(supplied) to the inside surface of

the glass door.

.

O)

Figure 4 –

Light switch

power supply

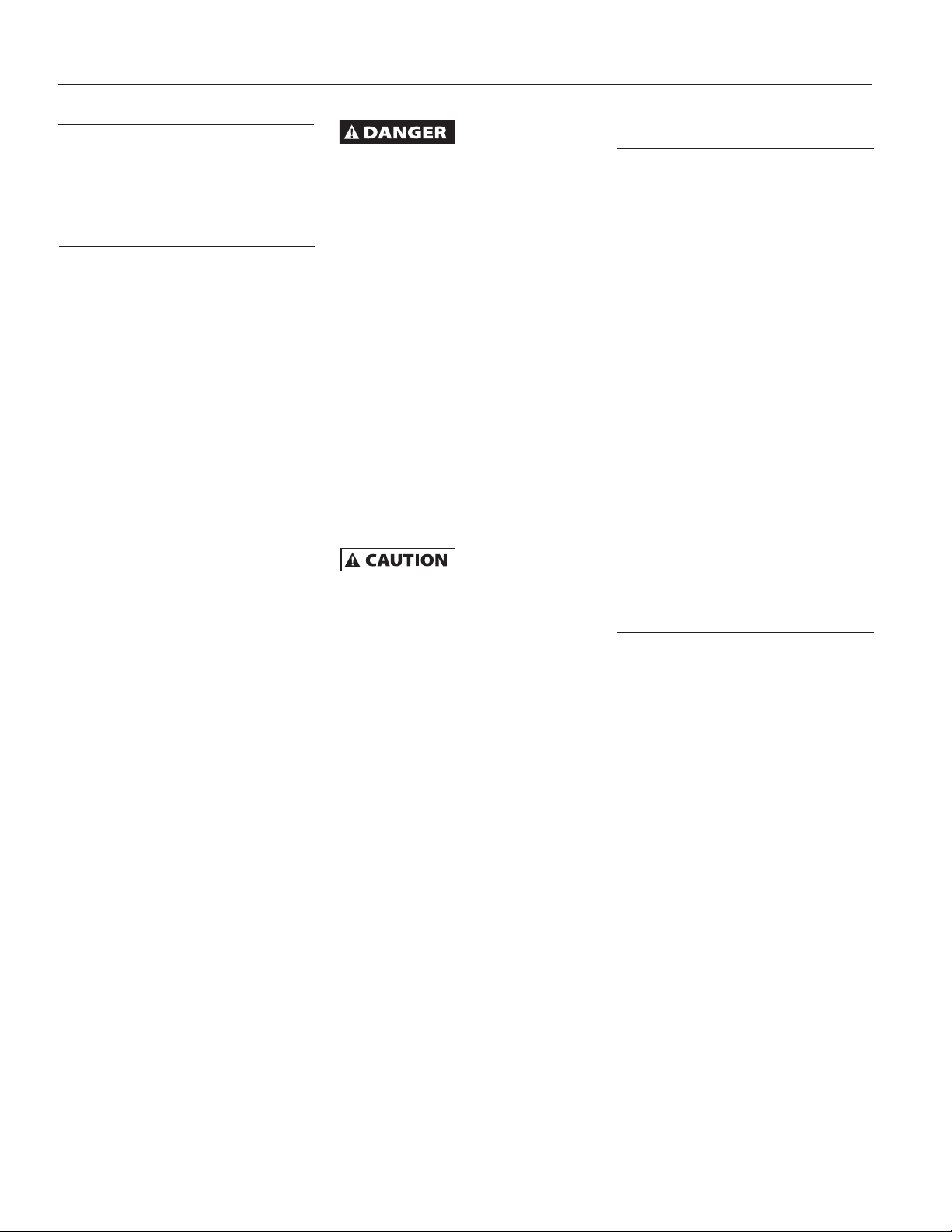

8. Make sure the material hose is

securely attached to the smaller tube

(and does not touch the larger tube)

of the metal pick up (see Figure 5).

Small tube

Larger tube

Figure 5 – Material hose and metal

pick-up tube

9. Position the end of the pick up tube

in the middle of the cabinet where

the blast media will be deepest. There

are metal guides to help stabilize the

pick-up tube (see Figure 6).

Guides

Figure 6 – Pick-up tube and guides

2.Make

sure switch

is in the

O) OFF position

(

10. Put on a NIOSH/MSHA approved

respirator and eye protection.

11. Pour blast media into cabinet basin.

Make sure the end material hose is

completely covered.

You can create dust

when abrasive media

is poured into or drained from the blast

cabinet. Wear a mask and eye protection

when draining the blasting media.

12. Place item to be cleaned inside

cabinet.

13. Close and latch door.

14. If a vacuum is to be used to remove

blast media dust:

A.Remove air filter from back of

cabinet (this filter is for use when

a vacuum is

B. Install a proper sized adapter on

end of vacuum hose and insert

into port on right hand side of

cabinet. If the right size adapter

is not available, any sort of

attachment method that

provides decent seal will work.

15. Place hands in gloves, aim blast gun

at surface to be cleaned and pull

trigger.

NOT used)

www.maxustools.com

3

Page 4

perating Instructions

O

Operation (cont.)

16. A common wire screen placed on

abinet grating can help to prevent

c

small items from getting lost in

hopper.

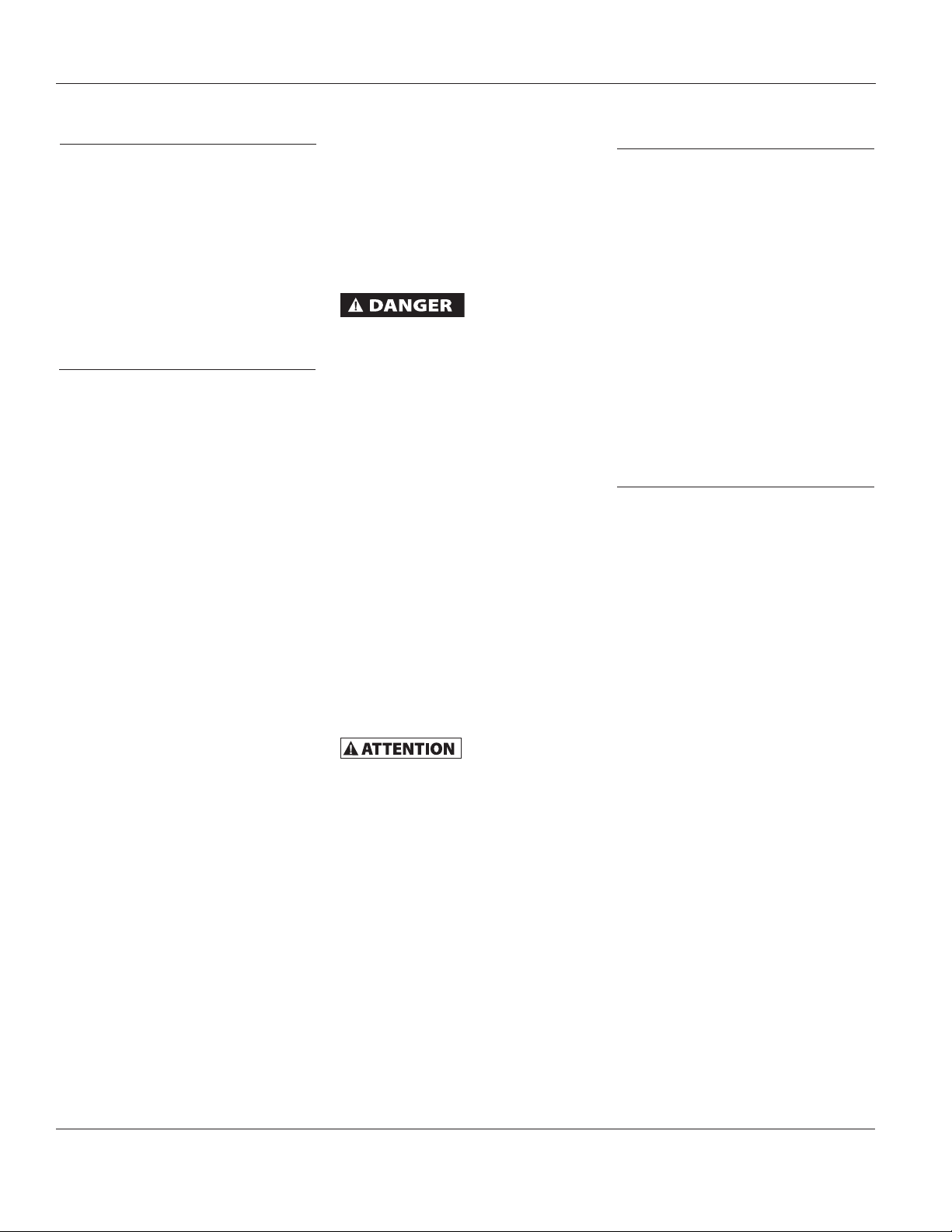

Maintenance

Cleaning

The plastic door cover should be

cleaned with a soft damp cloth. NEVER

use solvents to clean plastic parts. They

could dissolve or otherwise damage

the material.

Changing the Ceramic Gun Nozzle

The blast cabinet is equipped with a

ceramic nozzle that controls the flow

of abrasive media as it exits the spray

gun. The nozzle creates a smaller

opening for the media to exit which

gives a finer spray that easier to

control. Replacements for the ceramic

nozzle are included. To replace a

nozzle, unscrew the outer metal

covering of the nozzle and remove the

old ceramic nozzle. Insert the new

nozzle and reattach the metal cover.

Draining Abrasive Material

The blast cabinet is equipped with a

drain for easy clean up of abrasive

materials. The floor of the blast

cabinet tapers toward the center,

where the drain is located.

In order to remove blast media:

1. Make sure the air supply is

disconnected before doing any

draining.

2. Secure the cabinet in an elevated

position that allows room for a

container below the plug.

3. Place a container within 4 inches of

the drain opening.

4. Pull the plug from the drain and

allow media to drain from cabinet.

DO NOT shake cabinet. Shaking the

cabinet could cause the media to

spill and create dust that could be

hazardous if breathed.

You can create dust

when abrasive media

is poured into or drained from the blast

cabinet. Wear a mask and eye protection

when draining the blasting media.

5. Any excess media can be moved

toward the drain with a brush.

DO NOT use the blasting gun to

blow air to drain the abrasive media.

Doing so can create dust that could

be hazardous if breathed.

Storage

1. Turn ON / OFF switch to the OFF

position.

2. Unplug power cord from outlet.

3. Disconnect the air supply from the

blasting cabinet

4. Remove the abrasive media from

the cabinet using the drain.

5. Store in a cool, dry place.

Service

Tool service must

be performed only

by qualified repair personnel and by an

AUTHORIZED SERVICE CENTER. Service or

maintenance performed by unqualified

personnel could result in a risk of injury.

For information regarding the

operation or repair of this product,

please call 1-800-424-8936.

Abrasive Blasting

Media

Blasting media comes in many different

grit sizes and sometimes is also rated as

extra fine, fine, medium, coarse, and

extra coarse. The larger the grit

number, the smaller the particle size;

the smaller the grit number, the larger

the particle size. Glass media can come

in beads, crushed, or ground.

Aluminum oxide and silicon carbide can

come in several colors. It is common

today to find mixtures of glass and

aluminum oxide.

Abrasive Media - Not

Recommended

Although available, some media are

not recommended for use because of

echanical and/or personal hazards.

m

Silica sand, a common blast media, has

health risk concerns due to the silica

ontent. Restriction on its usage is

c

common in many states.

each sand (play sand) is a common

B

and inexpensive blast media. This

highly aggressive media can have

debris mixed in which will cause

clogging of equipment.

Steel grit produces ideal surface

preparation on new coating. This

media should only be used in a special

blast cabinet designed for this media.

Steel shot, a round, solid particle,

leaves a dimples in a surface after

blasting. It is a very dense media and

should only be used in a special blast

cabinet designed for this media.

Common Abrasive

Media

The more commonly available media

and their uses are listed below.

Walnut shell is one of the most

versatile organic media due to its

angular, durable shape. It is still

considered a soft media, but it is good

to use on delicate parts. Use as an

economical, bio-degradable alternative

for sensitive blasting that will not

scratch or damage surfaces.

Glass beads are the most popular allpurpose media used today. Used for

honing, polishing, peening, blending,

finishing, removing light burrs, frosting

glass, and cleaning most light materials.

Common uses in the removal of paint,

rust, and surface residues. Glass bead

blasting generally will not change the

dimensions of the item being blasted.

Glass beads produce brighter finish than

angular abrasives. Beads can be recycled

and used many times.

www.maxustools.com

4

Page 5

MXS3000

Common Abrasive

Media

Crushed glass is very aggressive. Used

for economical, general clean-up.

Plastic is available in a variety of sizes

and materials (urea, acrylic, polyester,

nd melamine). These materials are

a

ideal for application such as auto

restoration to deliver a high stripping

ate without damaging or warping the

r

substrate material.

Brown aluminum oxide is a widely used

abrasive media. This media produces a

extured surface, good for repairing

t

surfaces for recoating. It is excellent for

removing heavy foreign materials,

eburring, and etching glass and stone.

d

It is a fast-cutting media that can be

reused many times.

White aluminum oxide can be used in

the same applications as the brown

luminum oxide, but white aluminum

a

oxide is considered to be a clean media,

used in high performance processes

where contamination of metal oxide

must be kept to a minimum.

Common abrasive media guide

Grit Abrasive Abrasive Dust Relative

Range Type Life Level Cost

35-60 Walnut shell Good High Low

25-325 Glass beads Better Low Low

25-70 Crushed glass Better Low Low

30-40 Plastics Better Low High

24-400 Brown alum. oxide Best Low Med -High

150-240 White alum. oxide Best Low High

50-100 Alum./glass mixture Best Low Med

24-240 Silicon carbide Best Low High

Aluminum / glass mixtures provides a

combination of glass bead finishing

nd aluminum oxide cleaning. It

a

provides a brighter finish than single

abrasives, and it is good for removing

ust and machine marks on metal.

r

Silicon carbide is the hardest abrasive

aterial available. It is fast cutting and

m

can be reused many times. It is high in

initial cost, but removes material

uickly to reduce blasting time.

q

Available commercial abrasive blasting media

Acrylic

Aluminum oxide

Ceramic beads

Corn cob

Garnet

Glass Beads

Glass, crushed

Melamine

Pecan shell

Polyester

MATERIAL SAFETY DATA SHEET (MSDS) CAN BE

OBTAINED FROM YOUR ABRASIVE SUPPLIER

Pumice

Sand

Silicon carbide

Sodium Bicarbonate (soda)

Starch

Steel grit

Steel shot

Urea

Walnut shell

Consult your abrasive supplier for

recommendations.

MMOOIISSTTUURREE IINN CCOOMMPPRREESSSSEEDD AAIIR

R

Moisture in the air when compressed will create water in the compressor tank. When humidity is high or when a compressor is in

continuous use for an extended period of time, moisture will collect in the tank. When blasting, this water will be carried from

the tank through the hose and will be mixed with the abrasive media.

IMPORTANT: THIS MIXING

OF WATER AND ABRASIVE MATERIAL WILL CLOG THE SYSTEM. THE BLASTER WILL NOT OPERATE.

A compressed air dryer and/or water separator will help eliminate this problem.

www.maxustools.com

5

Page 6

perating Instructions

O

Troubleshooting Chart

Symptom Possible Cause(s) Corrective Action

Low or no air pressure at tool

Material not blasting from gun

Gun will not shut off - trigger

stuck

Sputtering - low vacuum

1. Regulator set incorrectly

2. Pinched hose

3. Dirty compressor filter

1. Clogged material hose

2. Buildup around jet

3. Damp or heavy material

4. Water in air supply

Damaged o-rings in air valve

1. Worn jet and/or nozzle

2. Abrasive buildup around jet/nozzle

1. Reset regulator

2. Straighten hose

3. Clean or replace filter

1. Lower the pressure below 40 psi.

irmly hold the gun tip flat against

F

the ground and pull the trigger to

force the material back out of the

material hose

2. Remove nozzle and clean around jet

3. Replace with dry abrasive. (Damp

material can be dried and reused)

4. Drain compressor tank and install

water separator, See “Moisture in

Compressed Air” box

Remove and replace o-rings

1. Replace jet and/or nozzle

2. Remove nozzle and jet and clean.

Make sure the threads are clean

before re-assembling

Sputtering - air/abrasive leaks at

nozzle/jet area

Sputtering - vacuum leak

Sputtering - particle clogging

www.maxustools.com

1. Loose nozzle or jet

Damaged o-ring

2.

1. Loose material hose

2. Damaged o-ring

Hose connector hole is covered

6

1. Tighten nozzle or jet

2. Replace o-ring

1. Tighten material hose

Replace o-ring

2.

Uncover hose connector hole

Page 7

XS3000

M

o

angle.

o

t with low

angle.

o

angle. For fine polishing,

o

angle.

o

angle.

o

carefully. Soft wood will wear faster than hardwood.

Smaller grit sizes give a smoother finish. Start with low

Use brushing strokes and watch the abrasion rate

use glass beads for the abrasive.

Move gun back and forth over the template in a

brushing manner. Blast at a 90

40 - 90

1 - 4 in.

Etching glass

40 - 90

2 - 6 in.

Antiquing or

pressure and gradually build up pressure. Blast at a 45

angle.

weathering wood

carefully. Use walnut shells for coarse finishing and glass

beads for final finishing. Blast at a 45

Use brushing strokes and watch the abrasion rate

40 - 70

1 - 6 in.

Wood sanding and

refinishing

furniture

an 80 – 90

material is being damaged, use a smaller grit. Blast at

Use larger grit media on a hidden area. If the base

40 - 80

1 - 4 in.

Cleaning

automotive parts

carefully. Soft wood will wear faster than hard wood.

Smaller grit sizes give a smoother finish. Star

Use brushing strokes and watch the abrasion rate

pressure and gradually build up pressure. Blast at a

40 - 125

1 - 6 in.

Cleaning or

paint

preparing for

Remove flaking paint first with wire brush, then blast

45 - 60

50 - 125

1 - 3 in.

Cleaning or

blasting to prevent corrosion. Blast at a 45 - 60

with a heavy grit abrasive. Multiple layer of old paint

should be scraped first. Prime immediately following

stripping outdoor

equipment

Abrasive media that has not been cleaned and screened could contain material that will clog the gun nozzle and should be avoided.

Use low air pressure (60 psi or less) for soft metals, glass , and wood.

Use higher pressures for hard steels; do not exceed 125 psi.

:

:

E

E

T

ound pecan

Type of Distance

Abrasive Application from psi Suggestions

(Sieve/Size) Work

Suggested Uses

Glass beads

shells

Ground walnut

shells

Glass beads,

ground walnut

7

Aluminum

oxide

shells and corn

or walnut

Gr

cob meal

oxide (50-80)

Aluminum

www.maxustools.com

T

O

O

N

N

Page 8

perating Instructions

O

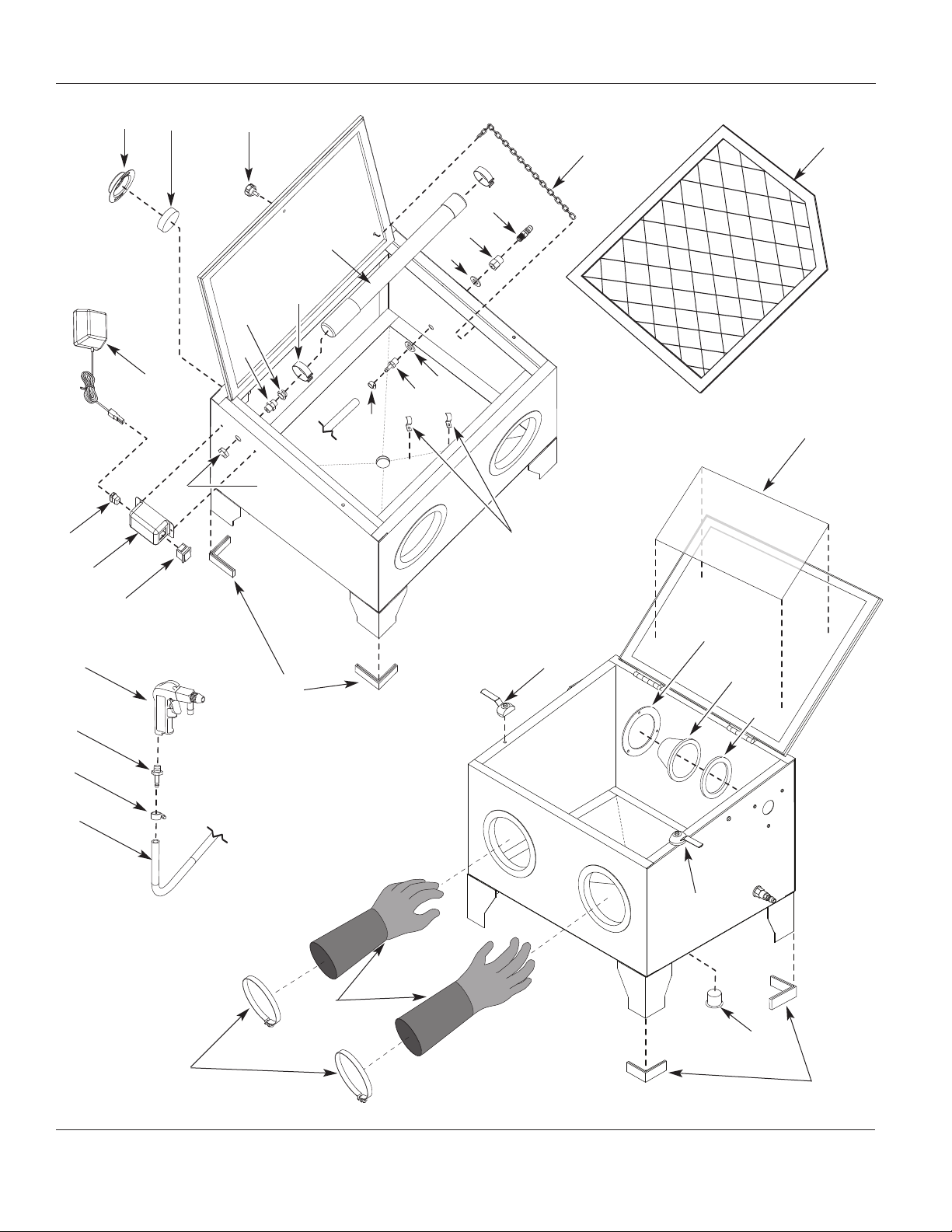

2425

27

3

2

17

16

22

1

2

8

15

4

1

26

5

12

13

28

29

31

6

12

7

4

1

13

14

30

10

20

9

19

18

2

www.maxustools.com

9

3

11

1

8

Page 9

XS3000

M

For Replacement Parts or Technical Assistance,

Call 1-888-Maxus4U (1-888-629-8748)

Please provide following information: Address parts correspondence to:

-Model number Attn: Customer Service

-Date code (if any) 100 Production Drive

-Part descriptions and number as shown in parts list Harrison, OH 45030

Replacement Parts List

Ref.

No. Description Part No. Qty.

1 Foot cover ; SV611000AV 4

2 Large hose clamps SV611100AV 2

3 Glove SV611200AV 2

4 Lamp switch ; SV611300AV, s 1

5 Switch outlet

6 Power supply SV611800AV 1

7 Plastic hex nut

8 Plastic feed through ; SV612100AV, l 1

9 Door latch

10 Pipe clamp

11 Plastic plug SV612500AV 1

12 Small hose clamp G 2

13 1/4 in. hose end connector (cabinet inlet fitting)

14 Washers (shown for placement only)

15 Female fitting SV613100AV 1

16 1/4 in. I/M (M) NPT plug HF001300AV 1

17 Chain

18 Large rubber seal

19 Vacuum sponge and paper filter

20 Retaining ring SV613700AV 1

21 Lamp clip

22 Lamp

23 Knob

24 Cabinet filter SV614300AV 1

25 Filter housing SV614400AV 1

26 Parts tray

27 Plastic open acorn nut

28

29

30 Plastic door cover

31 Lamp switch box

Other cabinet hardware not listed are standard hardware items which are available at local hardware stores

; Required 6 - 8 week lead time necessary for order

g Standard Hardware Item

— Not Available

REPLACEMENT PARTS KITS (Kits include necessary hardware)

l Lamp kit SKS30001AV

s Lamp switch kit SKS30002AV

n Chain kit SKS30003AV

u Vacuum filter kit SKS30004AV

r Parts tray kit SKS30005AV

t Plastic door cover (5) kit SKS30006AV

m 1/4 in. hose end (2) kit SKS30007AV

G Small hose clamp (5) kit SKS30008AV

; SV614100AV 1

1/4 in. air hose SV615400AV 1

Gun AT212000AV

Warning decal

Carbon nozzle kit (not shown) MXS40003AV

Ceramic nozzle kit (not shown) MXS40002AV

; SV611600AV, s 1

; SV612000AV, l 1

; SV612200AV 2

; SV612300AV 2

m 2

g —

n —

u 1

u 1

; SV613800AV 2

l 1

r 1

; SV615500AV, l 1

—

t 3

s 1

DK765000AV

www.maxustools.com

9

Page 10

perating Instructions

O

MXS3000

Limited Warranty – Abrasive Blasters

. DURATION: From the date of purchase by the original purchaser as follows: for five (5) years, with exceptions noted below.

1

2. WHO GIVES THIS WARRANTY (WARRANTOR): Maxus, 100 Production Drive, Harrison, Ohio, 45030

Telephone: 1-888-Maxus4U (1-888-629-8748) – www.maxustools.com

. WHO RECEIVES THIS WARRANTY (PURCHASER): The original purchaser (other than for purposes of resale) of the Maxus

3

product.

4. WHAT PRODUCTS ARE COVERED BY THIS WARRANTY: Any Maxus abrasive blaster supplied or manufactured by Warrantor.

. WHAT IS COVERED UNDER THIS WARRANTY: Defects due to material and workmanship with the exceptions noted below.

5

6. WHAT IS NOT COVERED UNDER THIS WARRANTY:

A.Implied warranties, including those of merchantability and FITNESS FOR A PARTICULAR PURPOSE ARE LIMITED FROM THE

ATE OF ORIGINAL PURCHASE AS STATED IN THE DURATION. If this product is used for rental purposes, the warranty will

D

apply for ninety (90) days from the date of purchase. Some States do not allow limitations on how long an implied warranty

lasts, so the above limitations may not apply to you.

B. ANY INCIDENTAL, INDIRECT, OR CONSEQUENTIAL LOSS, DAMAGE, OR EXPENSE THAT MAY RESULT FROM ANY DEFECT,

FAILURE, OR MALFUNCTION OF THE PRODUCT. Some States do not allow the exclusion or limitations of incidental or

consequential damages, so the above limitation or exclusion may not apply to you.

C. Any failure that results from an accident, purchaser’s abuse, neglect or failure to operate products in accordance with

instructions provided in the owner’s manual(s) supplied with product.

D.Pre-delivery service, i.e. assembly, filtration, and adjustment.

E. Normal adjustments or expendable items which are explained in the owner’s manual(s) provided with the product including

but not limited to parts subject to normal wear such as nozzles, air jets, seal blocks, valves, o-rings, hose connections, hoses

and blast gun.

F. Items or service that require periodic replacement to maintain the product, i.e. filters, gaskets, valves, etc.

G.Additional items not covered under this warranty:

a. Any component damaged in shipment or any failure caused by installing or operating unit under conditions not in

accordance with installation and operation guidelines.

b. Failure caused by rain, excessive humidity or corrosive environments.

c. Cosmetic defects that do not interfere with blaster functionality.

d. Rusted tanks, including but not limited to rust due to improper cleaning/storage.

e. Other items not listed but considered general wear parts.

7. RESPONSIBILITIES OF WARRANTOR UNDER THIS WARRANTY: Repair or replace, at Warrantor’s option, products or components

which are defective, have malfunctioned and/or failed to conform within duration of the warranty period.

8. RESPONSIBILITIES OF PURCHASER UNDER THIS WARRANTY:

A.Provide maintenance records to make warranty claim.

Portable products or components must be delivered or shipped to the nearest Maxus Authorized Service Center. Freight

B.

costs, if any, must be borne by the purchaser.

C. Use reasonable care in the operation and maintenance of the products as described in the owner’s manual(s).

9. WHEN WARRANTOR WILL PERFORM REPAIR OR REPLACEMENT UNDER THIS WARRANTY:

A.Repair or replacement will be scheduled and serviced according to the normal work flow at the servicing location, and

depending on the availability of replacement parts.

B. If the purchaser does not receive satisfactory results from the Authorized Service Center, the purchaser should contact the

Maxus Product Service Department (see paragraph 2).

Limited Warranty applies in the U.S. and Canada only and gives you specific legal rights. You may also have other rights which

vary from State to State or country to country.

www.maxustools.com

10

Page 11

Voir la Garantie à la page 20 pour de l’information importante sur l’utilisation commercial de ce produit.

nstructions d’Utilisation MXS3000

I

’il vous plaît lire et conserver ces instructions. Lire attentivement avant de monter, installer, utiliser ou de procéder à l’entretien du produit

S

écrit. Se protéger ainsi que les autres en observant toutes les instructions de sécurité, sinon, il y a risque de blessure et/ou dégâts matériels!

d

Conserver ces instructions comme référence.

Cabine de Décapage de Table

Description

La cabine de décapage Maxus est conçue

pour nettoyer et retirer la rouille, le tartre

et la peinture. C’est la méthode idéale pour

les projets de décapage, de polissage et la

gravure. Une cabine de décapage garde les

particules de sablage dans un endroit

refermé et leur permet de recycler. La

cabine enferme aussi les particules de

poussières et un crochet d'aspirateur peut

retirer toute poussière durant le décapage.

Directives de Sécurité

Ce manuel contient de l’information très

importante qui est fournie pour la

SÉCURITÉ et pour ÉVITER LES PROBLÈMES

D’ÉQUIPEMENT. Rechercher les symboles

suivants pour cette information.

Danger indique une

situation hasardeuse

imminente qui RÉSULTERA en perte de vie

ou blessures graves.

Avertissement indique

une situation

hasardeuse potentielle qui PEUT résulter en

perte de vie ou blessures graves.

Attention indique une

situation hasardeuse

potentielle qui PEUT résulter en blessures.

Avis indique de

l’information

importante pour éviter le dommage de

l’équipement.

Déballage

Après avoir déballé, inspecter avec soin

pour tout signe de dommage en transit.

Vérifier s’il y a des pièces desserrées,

manquantes ou endommagées.

Généralités sur la

Sécurité

PROPOSITION 65 CALIFORNIE

Vous

pouvez

créer de la poussière en

coupant, ponçant, perçant ou

meulant les matériaux tels que

le bois, la peinture, le métal, le béton, le

ciment ou autre maçonnerie. Cette

poussière contient souvent des produits

MÉMENTO: Gardez votre preuve datée d’achat à fin de la garantie!

Joignez-la à ce manuel ou classez-la dans un dossier pour plus de sécurité.

© 2008

chimiques reconnus pour causer le

cancer, les déformations congénitales ou

autres problèmes de la reproduction.

Portez de l’équipement de protection.

Ce produit ou son

cordon contient des

produits chimiques, y compris du plomb,

relevés par l'État de Californie comme

cause de cancer, d'anomalies congénitales

ou d'autres problèmes reproductifs. Lavezvous les mains après toute manipulation.

DANGER DES PRODUITS ABRASIFS

DE SILICE

Porter un appareil

respiratoire

homologué NIOSH/MSHA en tout temps

en décapant à l’abrasif et en nettoyant.

Risque

d’explosion

et d’incendie ! Ne jamais utiliser

de sableuse autour de liquides,

gaz, poussières, chiffons huileux

ou autres matériaux

combustibles ou inflammables

qui pourraient exploser ou brûler

rapidement. Certains abrasifs

créent des étincelles en frappant le métal.

Des abrasifs semblables à l’oxyde

d’aluminium peuvent provoquer des

étincelles électriques statiques. Dans un

milieu dangereux, ces étincelles

provoqueront des incendies ou des

explosions menant à de graves blessures ou

à la mort. Pour la sécurité de l’utilisateur et

celle des personnes dans les environs, NE

PAS UTILISER cette sableuse à des endroits

où il y a des liquides, gaz, poussières,

chiffons huileux ou autres matériaux

combustibles ou inflammables qui

pourraient exploser ou brûler rapidement.

Les chocs

d’électricité

statique peuvent être

douloureux. Certains abrasifs

semblables à l’oxyde

d’aluminium peuvent créer de l’électricité

statique en sablant. Si vous n’êtes pas mis

à la terre, l’électricité statique peut

s’accumuler sur votre corps et provoquer

un choc lorsque vous touchez un objet

métallique. Vous pouvez éviter l’électricité

statique en portant des chaussures à

semelles en cuir et en vous tenant sur le

11 Fr

Modéle MXS3000

sol. Si nécessaire, un fil mis à la terre

attaché au pistolet de sablage retirera sans

danger l’électricité statique. N’oubliez pas

que vous n’êtes pas mis à la terre si vous

êtes isolé du sol. Les souliers à semelle de

caoutchouc, les bottes de caoutchouc ou

autres chaussures de caoutchouc ou de

plastique sont des isolants. Évitez de vous

tenir sur un bois sec (comme une palette en

bois), un tapis sec ou une carpette sèche.

Spécifications

Dimensions:

Encombrement : 58,4 de largeur x 48,3 cm

de profondeur (23 po x 19 po)

Hauteur totale : 49 cm (19,25 po)

Profondeur totale : 50 cm (19,75 po)

Largeur totale : 63 cm (24,75 po)

Hauteur de l’aire de travail : 29,2 à 34,3 cm

(11,5 à 13,5 po)

Profondeur de l’aire de travail : 45,7 à 47 cm

(18 à 18,5 po)

Largeur de l’aire de travail : 55,2 à 59,7 cm

(21,75 à 23,5 po)

Ouverture supérieure : 48,9 cm de largeur x

39,4 cm de profondeur (19,25 po x 15,50 po)

Lumière de travail fluorescente de 12 V avec

alimentation de courant à entrée de 120 V c.a.

60 Hz sortie de 12 V 800 mA Classe 2

homologuée UL

Côté droit Port de sortie d’aspirateur

d’atelier de DI de 3,49 cm (1-3/8 po) à filtre

conique remplaçable de papier et d’éponge

kPa Max . . . . . . . . . . . . . . . . . . . . . . . . . 862

Arrivée d’air . . . . . . . . .6,4 cm (1/4 po) NPT

Capacité de média . . . .9,5 litres (2,5 gallons)

IN709902AV 12/08

Page 12

Instructions d’Utilisation

M

ANUAL

Généralités sur la

Sécurité (suite)

IRECTIVES DE SÉCURITÉ

D

Ne pas abuser de ce

produit. Toute

exposition excessive à la vibration, tout

travail dans les positions mal à l’aise et

les motions de travail à répétition

peuvent provoquer des blessures aux

mains et aux bras. Cesser d’utiliser tout

outil si l’on ressent un malaise, un

ngourdissement, un fourmillement ou

e

une douleur et consulter un médecin.

1. Lire ce manuel

d’instructions avant de

connecter cet appareil au

compresseur.

2. Il faut porter des lunettes

de sécurité

et un respirateur approuvé

NIOSH /MSHA en utilisant

l’appareil et en nettoyant.

3. Pendant l’utilisation de l’appareil, ne pas

exposer les mains ou la peau directement

devant la buse de décapage.

4. Après l’assemblage, inspecter

l’étanchéité de tous les composants.

5. Ne pas dépasser la pression maximale

d’exploitation de l’équipement de

décapage (862 kPa).

Débrancher la cabine

de la source

d’alimentation d’air avant de changer les

accessoires ou avant d’essayer d’installer,

de réparer, de déplacer ou de procéder à

tout entretien de l’appareil.

6. Vérifier les tuyaux et les canalisations

d’air pour tout signe de faiblesse ou

d’usure avant chaque utilisation.

S’assurer que tous les raccordements

soient bien en place avant de faire

fonctionner l’appareil.

Ne pas diriger le

pistolet de décapage

vers aucune personne ou objet autre que

le projet prévu.

7. Ne pas appuyer sur la gâchette

branchant le tuyau d’air.

en

Ne pas travailler près

ou de liquides inflammables. Le médium

de décapage frappant le métal peut

produire une étincelle qui à son tour peut

mener à un incendie ou à une explosion.

produits acides ou caustiques.

de torchons huileux

Ne pas pulvériser les

Figure 1 - Ne pas pulvériser les

produits acides ou caustiques.

Instructions de

Montage

Remarque : Pour l’assemblage, il faut un

petit tournevis Phillips (P2) et une clé

ajustable.

• Retirer l’armoire et autres pièces

de l’emballage. S’assurer qu’il ne

manque aucune pièce (voir la liste de

pièces).

PPiissttoolleett eett bbooyyaauux

• Presser l’autre extrémité du boyau d’air

entièrement dans les barbelures du

raccord d’entrée de l’armoire. Placer et

bien resserrer un petit collier de

serrage autour de la section du boyau

recouvrant la barbelure.

• Presser l’extrémité du boyau de

matériel entièrement sur la bride

d’entrée du matériel de l’outil. Placer

et bien resserrer un collier de serrage

de boyau moyen autour de la section

de la bride couvrant le boyau.

Tuyau à air

Figure 2 - Assemblage d'entrée d'air

x

Pince

Arrivée d'air

• Presser l’autre extrémité du boyau de

matériel à environ 2,54 cm à 5,08 cm

(1 po à 2 po) sur l’extrémité de petit

iamètre du tube plongeur de métal.

d

lacer et bien resserrer un collier de

P

serrage de boyau moyen autour de

la section de la bride couvrant le

tube plongeur.

• Placer les assemblages de pistolet et de

boyau dans l’armoire, acheminant le

tube plongeur sous le plateau de

ièces grillagé. Placer une rondelle à

p

l’extrémité filetée du raccord d’entrée

de l’armoire, puis pousser le raccord à

travers le trou du côté inférieur droit

de l’armoire. Placer l’autre rondelle sur

l’extrémité proéminente du raccord

(vior Figure 2).

• Appliquer du ruban de téflon aux

filets du raccord d'entrée pour

réduire la possibilité de fuites d'air.

Enfiler le raccord femelle sur les filets

proéminents du raccord d’entrée de

l’armoire et bien resserrer. S’assurer

que les méplats de clé du raccord

femelle aboutent l’armoire (voir

Figure 2).

LLooqquueettss ddee ppoorrtte

e

• Placer les loquets de porte de plastique

noir sur les trous des bords du dessus

de l’armoire. Fixer chacun sur le dessus

de l’armoire en utilisant un boulon de

2,54 cm (1 po) de longueur et un écrou

à filetage autofreinant (nylock). Bien

resserrer, sans trop resserrer.

Rondelles

Raccord femelle

Fiche mâle

12 Fr

Page 13

Instructions de

Montage (suite)

FFiillttrree dd’’aarrmmooiirre

• Placer une éponge à filtre rond dans

le boîtier du filtre d’armoire. Placer le

boîtier du filtre sur le large trou

l’arrière de l’armoire, en alignant les

à

trous du bord du boîtier avec les

poteaux au-dessus et sous le trou de

l’armoire. Tourner et verrouiller.

LLaammppe

e

• S’assurer que la source de courant ne

soit pas branchée dans la prise de

l’interrupteur de la lampe. Placer la

boîte de l’interrupteur de la lampe

vers le haut pour libérer l’extrémité du

cordon de la lampe. Connecter

ensemble les bornes du cordon de la

lampe aux bornes de l’interrupteur de

la lampe portant la mention “2”. Le fil

brun va sur le dessus (près du “2”), le

fil bleu directement en dessous. Fixer

la boîte de l’interrupteur de la lame

à l’armoire à l’aide de deux (2) boulons

longs de 7,9 mm (5/16 po), écrous et

rondelles de blocage. Bien resserrer.

e

Fonctionnement

Après avoir terminé l’assemblage

complet de la cabine de décapage, suivre

les instructions suivantes avant de

brancher l’air à la cabine.

1. Placer la cabine sur la table ou banc

où le travail sera effectué.

2. Brancher la source d’air (862 kPa max.)

au raccord sur le côté de la cabine (voir

Figure 3).

Raccord

d'alimentation d'air

Boyau

d'air et

connexion

Figure 3 –Raccorder l'alimentation d'air.

Inspecter pour des fuites. S'il y en a,

3.

réparer ou ajouter au besoin du

ruban de téflon.

4. Brancher la source d’énergie de 12 volts

dans la prise de courant de 110 volts.

5. S'assurer que l'interrupteur est à la

position d'arrêt (O), brancher l'autre

extrémité du cordon d'alimentation

de courant 12 V dans l'interrupteur

de la cabine (voir Figure 4).

1.Brancher

le cordon

d'alimentation

dans une prise

de courant

Figure 4 –

Alimentation

de courant de

l'interrupteur

6.

S’assurer du bon fonctionnement de

la lumière. La lumière peut être

tournée pour éviter l’éclairage dans

les yeux de l’opérateur.

7. Ajouter un protecteur de plastique

pour la fenêtre (inclus) à la surface

intérieure de la porte de verre.

8. S’assurer que le tuyau du matériel est

bien branché au tube plus petit (sans

toucher le tube plus grand) du

plongeur de métal (voir Figure 5).

Le tube

plus petit

Figure 5 – Tuyau du matériel et plongeur

de métal

Placer l’extrémité du tube plongeur

9.

dans le milieu de la cabine où le

médium de décapage est plus

profond. Il y a des guides métalliques

pour aider à stabiliser le tube plongeur

(voir Figure 6).

10. Porter un appareil respiratoire

homologué NIOSH/MSHA.

11. Mettre un respirateur approuvé

NIOSH/MSHA et une protection

oculaire.

Le tube

plus grand

MXS3000

.Brancher l'autre

3

extrémité du

cordon

d'alimentation de

courant à

l'arrière de

l'interrupteur

2.S'assurer que

l'interrupteur

soit en position

d’arrêt (

Figure 6 – Tube plongeur et guides

média abrasif est versé ou drainé de la

cabine de décapage. Porter un masque et

une protection oculaire en drainant le média

de décapage.

12.Placer la pièce de travail à décaper

dans la cabine.

13. Fermer et verrouiller la porte.

14. Si l'on utilise un aspirateur pour retirer

la poussière de média de décapage :

Retirer le filtre d'air de l'arrière de

A.

l'enceinte (ce filtre doit être utilisé

lorsqu'on N'utilise

B. Installer un adaptateur de la taille

appropriée à l'extrémité du boyau de

l'aspirateur et insérer dans le port du

côté droit de l'enceinte. Si

l'adaptateur du côté droit n'est pas

O)

Guides

On peut créer de la

poussière lorsque le

PAS d'aspirateur).

13 Fr

Page 14

Instructions d’Utilisation

Fonctionnement

(suite)

disponible, toute méthode à

ccessoire qui fournit une

a

étanchéité appropriée fonctionnera.

5. En portant les gants, pointer le

1

pistolet de décapage à la surface à

décaper et tirer la gâchette.

16. Un écran métallique courant placé sur

la grille de l'enceinte peut aider à

empêcher que de petits articles se

perdent dans la trémie.

Entretien

Nettoyage

Le couvercle de la porte de plastique

devrait être nettoyé avec un chiffon

humide doux. NE JAMAIS utiliser de

solvants sur les pièces de plastique

propres. Ils pourraient dissoudre ou

endommager le matériau.

Changer la buse du pistolet

de céramique

La cabine de décapage est dotée d'une

buse de céramique qui contrôle le débit

de média abrasif en sortant du pistolet

de pulvérisation. La buse crée une

ouverture plus petite pour la sortie du

média ce qui donne une pulvérisation

plus fine plus facile à contrôler. Des

remplacements de buse de céramique

sont inclus. Des remplacements de buse

de céramique sont inclus. Pour

remplacer une buse, dévisser la

couverture métallique extérieure de la

buse et retirer la vieille buse de

céramique. Insérer la nouvelle buse et

replacer la couverture métallique.

Drainer le matériel abrasif

La cabine de décapage est dotée d'un

drain pour faciliter le nettoyage de

matériaux abrasifs. Le plancher de la

cabine de décapage s'effile vers le

centre où se trouve le drain.

Pour retirer les médias de décapage :

. Placer un contenant à 10,16 cm

3

4 po) de l'ouverture du drain.

(

4. Retirer le bouchon du drain

et laisser le média drainer de la

abine. NE PAS secouer la cabine.

c

Secouer pourrait mener au

déversement des médias et créer

de la poussière qui pourrait être

angereuse si respirée.

d

On peut créer de la

poussière lorsque le

média abrasif est versé ou drainé de la

cabine de décapage. Porter un masque et

une protection oculaire en drainant le

média de décapage.

5. Tout média supplémentaire peut

être déplacé vers le drain avec

une brosse.

Rangement

1. Mettre l'interrupteur

MARCHE/ARRÊT à la position ARRÊT.

2. Débrancher le cordon d'alimentation

de la prise.

3. Débranchez l'alimentation d'air de la

cabine de décapage.

4. Retirer le média abrasif de la cabine

par le drain.

5. Entreposer dans un endroit sec et

frais.

Service

Tout le travail

d'entretien et de

réparation de l'outil doit être effectué

seulement par un CENTRE DE SERVICE

AUTORISÉ. L'entretien ou les réparations

non effectué(e)s par un personnel

qualifié pourraient mener à des

blessures.

Pour obtenir de l'information sur le

fonctionnement ou la réparation de ce

produit, appeler le 1-800-424-8936.

Médias de décapage

abrasif

Les médias de décapage sont fournis en

différentes tailles de particules et sont

parfois d’une valeur extra fine, fine,

oyenne, rugueux et extra rugueux.

m

Plus le numéro des particules est

élevée, plus les particules sont petites;

plus le numéro des particules est petit,

plus les particules sont larges. Les

édias de verre sont fournis en perles,

m

écrasés ou moulus. L’oxyde

d’aluminium et le carbure de silicium

peuvent être fournis en plusieurs

couleurs. Il est courant aujourd’hui de

trouver des mélanges de verre et

d’oxyde d’aluminium.

Médias abrasifs - non

recommandés

Bien que certains médias soient

disponibles, ils ne sont pas

recommandés à cause des dangers

personnels et/ou mécaniques.

Le sable siliceux, un médium de

décapage courant, a des risques de

santé à cause du contenu de silicium. La

restriction sur son usage est courante

dans de nombreux États.

Le sable de plage (sable de jeu) est un

médium de décapage courant et peu

dispendieux. Ce médium très agressif

peut avoir des débris mélangés ce qui

pourrait provoquer un blocage de

l’équipement.

Les particules d’acier produisent une

préparation de surface idéale sur le

nouveau revêtement. Ce médium ne

doit être utilisé que dans une armoire

spéciale de décapage conçue pour ce

médium.

Une grenaille d’acier, une particule

ronde, solide, laisse une empreinte sur

une surface après le décapage. C’est un

très dense médium et ne doit être

utilisé que dans une armoire spéciale

de décapage conçue pour ce médium.

1. S'assurer que l'alimentation d'air

est débranchée avant tout

drainage.

2. Fixer la cabine en position élevée

offrant l'espace voulu pour un

contenant sous le bouchon.

14 Fr

Page 15

XS3000

M

Médias abrasifs

courants

Les médias utilisés le plus couramment

et leurs utilisations sont indiquées plus

bas.

L’écaille de noix est l’un des médias

biologiques les plus polyvalents à cause

de sa forme angulaire, durable. Cela

est encore considéré comme un

édium malléable, mais c’est une

m

bonne idée de l’utiliser sur les pièces

délicates. Utiliser comme alternative

économique, bio-dégradable pour le

décapage sensible qui n’égratigne et

n’endommage pas les surfaces.

Les perles de verre sont les médias

polyvalents les plus populaires utilisés

à l’heure actuelle. Utilisées pour

affiner, polir, mater, mélanger, finir,

retirer les ébarbures légères, le verre

givré et nettoyer la plupart des

matériaux légers. Utilisations courantes

pour retirer la peinture, la rouille et les

résidus de surface. Le décapage a perle

de verre ne changera pas normalement

les dimensions de l’article décapé. Les

perles de verre produisent un fini plus

brillant que les abrasifs angulaires. Les

perles se recyclent et sont utilisées

plusieurs fois.

Le verre écrasé est très agressif. Utilisé

pour un nettoyage économique,

énéral.

g

Le plastique est disponible dans une

variété de tailles et de matériaux

urée, acrylique, polyester et

(

élamine). Ces matériaux sont le

m

produit idéal pour l’application telle

que la restauration automobile car elle

fournit un taux élevé de décapage sans

ndommager ou faire gondoler le

e

substrat.

L’oxyde d’aluminium brun est un

médium abrasif utilisé couramment.

Ce médium produit une surface

texturée, bonne pour réparer les

surfaces à revêtir. Il est excellent pour

retirer les matériaux étrangers lourds,

pour ébavurer et graver le verre et la

pierre. C’est un médium à coupe rapide

qu’on peut réutiliser plusieurs fois.

’oxyde d’aluminium blanc peut servir

L

dans les mêmes applications que celles

d’oxyde d’aluminium brun, mais

l’oxyde d’aluminium blanc est

onsidéré un médium propre, utilisé

c

ans les processus haute performance

d

où la contamination de l’oxyde

métallique doit être à un niveau

minimum.

Les mélanges d’aluminium / verre offre

une combinaison de finition de perle

de verre et de nettoyage d’oxyde

’aluminium. Ils fournissent un fini plus

d

brillant que les abrasifs seuls et ils

conviennent pour retirer la rouille et

les marques de machine sur le métal.

Le carbure de silicium est le matériau

le plus dur d’abrasif disponible. Il coupe

rapidement et peut être réutilisé

plusieurs fois. Son coût initial est élevé,

mais retire le matériau rapidement

pour réduire le temps de décapage.

Guide de médias abrasifs courants

Plage de Type Vie Niveau de Coût

particules d’abrasif abrasive poussière relatif

35-60

25-325

25-70

30-40

24-400 Oxyde d’aluminium Le meilleur Bas Moy -

150-240

50-100 Mélange d’aluminium / Le meilleur Bas Moy

24-240 Carbure de silicium

Écailles de noix

Perles de verre

Verre écrasé

Plastiques

brun haut

Oxyde d’aluminium

blanc

verre

Bon Élevé Bas

Meilleur Bas Bas

Meilleur Bas Bas

Meilleur Bas Élevé

Le meilleur

Le meilleur

Bas

Bas

Élevé

Élevé

15 Fr

Médias de décapage abrasif commercial disponibles

Acrylique

Oxyde d’aluminium

Boudins de céramique

Épi de maïs

Grenat

Perles de verre

Verre, écrasé

Mélamine

Écailles de pacanes

Ponce

Sable

Carbure de silicium

Bicarbonate de sodium

Fécule

Particule d’acier

Grenaille d’acier

Urée

Écailles de noix

Polyester

LA FICHE SIGNALÉTIQUE DE SÉCURITÉ DU PRODUIT (FSSP)

EST DISPONIBLE AUPRÈS DU FOURNISSEUR DE L’ABRASIF.

Page 16

Instructions d’Utilisation

HHUUMMIIDDIITTÉÉ DDAANNSS LL’’AAIIRR CCOOMMPPRRIIMMÉ

De l’humidité dans l’air lors de la compression créera de l’eau dans le réservoir du compresseur. Lorsque l’humidité est élevée ou

orsqu’un compresseur est utilisé continuellement pendant de longues périodes, de l’humidité peut s’accumuler dans le réservoir. En

l

décapant, cette eau sera transportée dans le réservoir à travers le boyau et sera mélangée avec le médium abrasif.

IMPORTANT: CE MÉLANGE D’EAU ET DE MATÉRIAU ABRASIF BLOQUERA LE SYSTÈME. LA DÉCAPEUSE NE FONCTIONNERA PAS.

ne sécheuse à air comprimé et/ou un séparateur d’eau aideront à éliminer ce problème.

U

É

Tableau de dépannage

Symptôme Cause(s) possible(s) Mesure(s) corrective(s)

Basse pression ou aucune

pression d’air à l’outil

Matériau ne sort pas du pistolet

1. Mauvais réglage du régulateur

2. Boyau pincé

3. Filtre de compresseur sale

1. Boyau de matériau bloqué

2. Accumulation autour du jet

3. Matériau humide ou lourd

4. Eau dans l’alimentation d’air

1. Régler le régulateur

2. Redresser le boyau

3. Nettoyer ou remplacer le filtre

1. Baisser la pression sous 40 lb/po

kPa). Tenir fermement le bout du

pistolet à plat contre le sol et tirer la

gâchette pour forcer le matériau dans

le boyau de matériau

2. Retirer la buse et nettoyer autour du

jet

3. Remplacer avec de l’abrasif sec.

(Le matériau humide peut être séché

et réutilisé)

4. Vider le réservoir du compresseur et

installer le séparateur d’eau, voir la

case « humidité dans l’air comprimé »

2

(276

Le pistolet ne s’arrête pas gâchette grippée

Èclaboussure - faible vide

Èclaboussure - fuites

d’air/abrasifs à la buse/au jet

Èclaboussure - fuite de vide

Èclaboussure - blocage de

particules

Joints toriques endommagés dans la

soupape d’air

1. Jet et/ou buse usé(e)

Accumulation d’abrasif autour du

2.

jet/buse

1. Buse ou jet dégagé(e)

2. Joint torique endommagé

Boyau de matériau desserré

1.

2. Joint torique endommagé

Le trou du connecteur de boyau est

couvert

Fr

16

Retirer et remplacer les joints toriques

1. Remplacer le jet et/ou la buse

2. Retirer la buse et le jet et nettoyer.

S’assurer que les filets sont propres

avant de réassembler

1. Resserrer la buse ou le jet

2. Remplacer le joint torique

1. Resserrer le boyau de matériau

2. Remplacer le joint torique

Découvrir le trou du connecteur de boyau

Page 17

MXS3000

.

.

o

.

o

.

o

.

o

.

o

o

).

2

Décaper a un angle de 45 à 60

Décaper à un angle de 45

Pour les polis fins, utiliser des perles de verre pour

l’abrasif.

Déplacer le pistolet d’avant en arrière sur le gabarit de la

même manière qu’un pinceau. Décaper à un angle de 90

276 - 621

1 - 4 po

Gravure de verre

Utiliser des mouvements de pinceau et surveiller

attentivement le taux d’abrasion. Le bois mou s’usera plus

276 - 621

2 - 6 po

Bois antique

ou vieilli

basse pression et augmenter graduellement la pression.

particules donnent un fini plus lisse. Commencer avec une

rapidement que le bois dur. Les tailles plus petites de

Utiliser des mouvements de pinceau et surveiller

attentivement le taux d’abrasion. Utiliser des écailles de

noix pour les finis rugueux et les perles de verre pour le

dernier fini. Décaper à un angle de 45

276 - 483

1 - 6 po

finition des

Ponçage du bois et

meubles

retrait. Si le matériau de base est endommagé, utiliser des

Utiliser des particules plus larges sur une surface en

276 - 552

1 - 4 po

Nettoyage des

pièces automobiles

Utiliser des mouvements de pinceau et surveiller

particules plus petites. Décaper à un angle de 80 à 90

attentivement le taux d’abrasion. Le bois mou s’usera plus

276 - 862

1 - 6 po

Nettoyage ou

préparation de

basse pression et augmenter graduellement la pression.

particules donnent un fini plus lisse. Commencer avec une

rapidement que le bois dur. Les tailles plus petites de

de métal, puis décaper avec un abrasif à particules plus

Retirer la peinture qui s’écaille d’abord avec une brosse

345 - 862

1 - 3 po

la peinture

Nettoyage ou

décapage de

pour prévenir la corrosion. Décaper à un angle de 45 à 60

peinture. Apprêter immédiatement après le décapage

lourdes. Il faut gratter d’abord les multiples couches de

) ou moins] pour les métaux mous, le verre et le bois.

2

l’équipement

extérieur

e d’épi

d’abrasifs Application du Suggestions

(taille/crible) travail kPa

Suggestions d’utilisations

Type Distance

Perles de verre

moulues

Écailles de noix

moulues

Perles de verre,

écailles de noix

17 Fr

Oxyde

d’aluminium

poudr

de maïs

ou pacanes et

Écailles de noix

(50-80)

Oxyde

d’aluminium

Les médias abrasifs qui n’ont pas été nettoyés et tamisés pourraient contenir un matériau qui bloquera la buse du pistolet et cela

:

:

E

E

T

T

O

O

N

N

Utiliser des pressions plus élevées pour les aciers durs sans dépasser 862 kPa(125 lb/po

doit être évité.

Utiliser une basse pression d’air [414 kPa (60 lb/po

Page 18

Instructions d’Utilisation

2425

27

3

2

17

16

22

1

2

8

15

4

1

26

5

12

13

28

29

31

6

12

7

4

1

13

14

30

10

20

9

19

18

9

3

11

2

1

18 Fr

Page 19

MXS3000

Pour Pièces De Rechange ou Assistance Technique,

Appeler 1-888-Maxus4U (1-888-629-8748)

S’il vous plaît fournir l’information suivant: Correspondance:

-Numéro du modèle Attn: Customer Service

-Code de date (si présent) 100 Production Drive

-Description de la pièce et son numéro sur la liste Harrison, OH 45030

Liste De Pièces De Rechange

Nº de.

Réf. Description Nº de Pièce Qté.

1

2 Larges colliers de serrage de boyaux SV611100AV 2

3 Gants SV611200AV 2

4 Interrupteur de lampe ; SV611300AV, s 1

5 Prise d’interrupteur ; SV611600AV, s 1

6 Source de courant SV611800AV 1

7 Écrou hexagonal de plastique

8 Orifice d’amenée de plastique ; SV612100AV, l 1

9

10 Collier de serrage de boyau ; SV612300AV 2

11 Bouchon de plastique SV612500AV 1

12 Petit collier de serrage de boyau G 2

13 Raccord d’extrémité de boyau de 6,4 mm (1/4 po) (raccord d'entrée de la cabine) m 2

14 Rondelles (illustrées seulement pour le placement) g —

15 Raccord femelle SV613100AV 1

16 Fiche de 6,4 mm (1/4 po) I/M (M) NPT HF001300AV 1

17 Chaîne n —

18 Large garniture étanche de caoutchouc u 1

19 Filtre de papier et éponge à vide u 1

20 Anneau de retenue SV613700AV 1

21 Pince de lampe

22 Lampe l 1

23 Bouton ; SV614100AV 1

24 Filtre d’armoire SV614300AV 1

25 Boîtier de filtre SV614400AV 1

26 Plateau de pièces

27 Écrou borgne ouvert de plastique ; SV615500AV, l 1

28 Boyau d’air de 6,4 mm (1/4 po) SV615400AV 1

29 Pistolet AT212000AV —

30 Couvercle de porte de plastique t 3

31

D’autre quincaillerie d’armoire non indiquée sont des articles de quincaillerie standard disponibles aux quincailleries locales

; Cette commande exige un préavis de 6 à 8 semaines

g Article normal de quincaillerie

— Pas Disponable

TROUSSES DE PIÈCES DE RECHANGE (les trousses incluent la quincaillerie nécessaire)

l Trousse de lampe

s Trousse d’interrupteur de lampe

n Trousse de chaîne

u Trousse de filtre à vide

r Trousse de plateau de pièces SKS30005AV

t Trousse de couvercle de porte de plastique (5)

m Trousse d’extrémité de boyau de 6,4 mm (1/4 po)

G Trousse de petit collier de serrage de boyau (5)

Couvercle du pied

Verrou de porte

Boîte d’interrupteur de lampe

Décalque d’avertissement

Trousse de buse au carbone (non illustrée)

Trousse de buse de céramique (non illustrée) MXS40002AV

; S

; SV612000AV, l 1

; SV612200AV

; SV613800AV 2

V611000AV 4

2

r 1

s 1

DK765000AV

SKS30001AV

SKS30002AV

SKS30003AV

SKS300004AV

SKS30006AV

SKS30007AV

SKS30008AV

MXS40003AV

19 Fr

Page 20

Instructions d’Utilisation

MXS3000

Garantie Limitée - Souffleurs Abrasifs

1. DURÉE : De la date d’achat de l’acheteur original comme suit : pendant cinq (5) ans avec les exceptions indiquées plus bas.

2. QUI OFFRE CETTE GARANTIE (GARANT) : Maxus, 100 Production Drive, Harrison, Ohio, 45030

éléphone : 1-888-Maxus4U (1-888-629-8748) – www.maxustools.com

T

3. QUI REÇOIT CETTE GARANTIE (ACHETEUR) : L’acheteur original (sauf en cas de revente) du produit Maxus.

4. QUELS PRODUITS SONT COUVERTS SOUS CETTE GARANTIE : Tout souffleur abrasif Maxus fourni ou fabriqué par le garant.

. CE QUI EST COUVERT PAR LA PRÉSENTE GARANTIE : Défauts de matériau et de fabrication avec les exceptions indiquées

5

ci-dessous.

6. LA PRÉSENTE GARANTIE NE COUVRE PAS :

.Les garanties implicites, y compris celles de commercialité et D’ADAPTATION À UNE FONCTION PARTICULIÈRE SONT LIMITÉES

A

À PARTIR DE LA DATE D’ACHAT INITIALE TELLE QU’INDIQUÉE DANS LA SECTION DURÉE. Si ce produit est utilisé à des fins de

location, la garantie s’applique pendant quatre-vingt-dix (90) jours de la date d’achat. Certaines Provinces (États) n’autorisent

pas de limitations de durée pour les garanties implicites, donc les limitations précédentes peuvent ne pas s’appliquer.

B. TOUT DOMMAGE, PERTE OU DÉPENSE FORTUIT, INDIRECT OU CONSÉCUTIF POUVANT RÉSULTER DE TOUT DÉFAUT, PANNE

OU MAUVAIS FONCTIONNEMENT DU PRODUIT. Quelques Provinces (États) n’autorisent pas l’exclusion ni la limitation des

dommages fortuits ou indirects. La limitation ou l’exclusion précédente peut donc ne pas s’appliquer.

C. Toute panne résultant d’un accident, d’une utilisation abusive, de la négligence ou d’une utilisation de l’acheteur ne respectant

pas les instructions données dans le(s) manuel(s) accompagnant le produit.

D.Service pré-livraison soit l’assemblage, la filtration et l’ajustement.

E. Les ajustements normaux ou les articles non réutilisables expliqués dans le(s) manuel(s) du propriétaire fourni(s) avec le produit y

compris, mais sans s’y limiter, les pièces sujettes à l’usure normale comme les embouts, les jets d’air, les blocs étanches, les

soupapes, les joints toriques, les connexions de tuyau, les tuyaux et les pistolets de sablage.

F. Articles ou services qui sont exigés pour l’entretien normal du produit, soit filtres, joints d’étanchéité, soupapes, etc.

G.Articles supplémentaires qui ne sont pas couverts sous cette garantie :

a. Tout composant endommagé pendant l’expédition ou par n’importe quelle panne causée par un montage ou

fonctionnement de l’appareil sous des conditions qui ne se conforment pas aux directives de montage et de

fonctionnement.

b. La défaillance causée par la pluie, l’humidité excessive ou des environnements corrosifs.

c. Les défauts cosmétiques qui n’ont pas d’effet sur le fonctionnement du souffleur.

d. Les réservoirs rouillés, y compris, mais sans s’y limiter, la rouille causée par le nettoyage/rangement inapproprié.

e. Autres articles non indiqués mais considérés pièces d’usure générale.

7. RESPONSABILITÉS DU GARANT AUX TERMES DE CETTE GARANTIE : Réparation ou remplacement, au choix du Garant, de produits

ou composants défectueux, ont connu une défaillance ou qui ne sont pas conformes pendant la durée de validité de la garantie.

8. RESPONSABILITÉS DE L’ACHETEUR AUX TERMES DE CETTE GARANTIE :

A.Fournir des dossiers d’entretien pour présenter une demande sous garantie.

B. La livraison ou expédition des produits ou composants portatifs au Centre de service autorisé Maxus le plus près. Les frais

de transport, si applicables, sont la responsabilité de l’acheteur.

Utilisation et entretien du produit avec un soin raisonnable, ainsi que le décri(vent)t le(s) manuel(s) d’utilisation.

C.

9. LORSQUE LE GARANT FOURNIT LA RÉPARATION OU LE REMPLACEMENT SOUS LA GARANTIE :

A.La réparation ou le remplacement se fera et sera établi conformément au déroulement du travail normal du centre de service et

selon la disponibilité des pièces de rechange.

B. Si l’acheteur n’est pas satisfait des résultats du travail du Centre de service autorisé, il doit contacter le département du service

des produits Maxus (voir le paragraphe 2).

Cette Garantie limitée s’applique aux É.-U. et au Canada seulement et vous donne des droits juridiques précis. Vous pourriez aussi

avoir d’autres droits qui varient d’une province, d’un état ou d’un pays à l’autre.

20 Fr

Page 21

er la Garantía en página 30 para información importante sobre el uso comercial de este producto.

V

Manuel de Instrucciones MXS3000

írvase leer y guardar estas instrucciones. Lea con cuidado antes de tratar de armar, instalar, manejar o darle servicio al producto descrito en este

S

anual. Protéjase Ud. y a los demás observando todas las reglas de seguridad. El no seguir las instrucciones podría resultar en heridas y/o daños a

m

su propiedad. Guarde este manual como referencia.

Cabina de Chorreado de Mesa

Descripción

La Cabina de chorreado de mesa Maxus

está concebida para limpiar y quitar

óxido, escamas y pintura. Este método es

ideal para trabajos de raspar pinturas,

brillar y grabar. Una cabina de chorreado

mantiene las partículas de arena en

un área cerrada y permite que sean

recicladas. La cabina también retiene

las partículas de polvo y una conexión

de vacío puede quitar todo el polvo que

se produzca durante el pulido con

chorro de arena.

Medidas de Seguridad

Este manual contiene información que

es muy importante que sepa y

comprenda. Esta información se la

suministramos como medida de

SEGURIDAD y para EVITAR PROBLEMAS

CON EL EQUIPO. Debe reconocer los

siguientes símbolos.

Esto le indica que

hay una situación

inmediata que LE OCASIONARIA la

muerte o heridas de gravedad.

Ésto le indica que

hay una situación

que PODRIA ocasionarle la muerte o

heridas de gravedad.

Ésto le indica que

hay una situación que

PODRIA ocasionarle heridas no muy graves.

Ésto le indica una

información

importante, que de no seguirla, le

podría ocasionar daños al equipo.

Desempaque

Después de desempacar, inspecciónelo

cuidadosamente para detectar cualquier

daño que pueda haber ocurrido durante

el envío. Revise si hay partes dañadas,

faltantes o sueltas.

Informaciones

Generales de Seguridad

ROPOSICIÓN DE CALIFORNIA 65

P

uando

C

corta, lija,

taladra o pule materiales

como por ejemplo madera,

pintura, metal, hormigón,

cemento, u otro tipo de mampostería se

puede producir polvo. Con frecuencia este

polvo contiene productos químicos que se

conocen como causantes de cáncer,

defectos congénitos u otros daños

reproductivos. Use equipo de protección.

Este producto o su

cable de corriente

pueden contener químicos, incluido plomo,

que es conocido por el Estado de California

como causante de cáncer y defectos de

nacimiento u otros daños reproductivos.

Lávese las manos después de manipularlo.

PELIGROS DE LA ABRASIÓN CON SILICE

El inhalar polvo de

abrasivos que

contienen sílice puede ser peligroso. La

exposición puede causar SILICOSIS, una

enfermedad pulmonar, u otros problemas

respiratorios.

Cuando use una chorreadora abrasiva

o limpie después del uso, póngase

siempre un respirador homologado

NIOSH/MSHA.

por

¡Peligro de

incendio o

explosión! No use nunca una

chorreadora de arena cerca de

líquidos, gases, polvos, trapos

empapados de aceite u otros

materiales inflamables o

combustibles que puedan

explotar o incendiarse. Algunos abrasivos

producen chispas cuando golpean metal.

Los abrasivos similares al óxido de aluminio

pueden producir chispas de corriente

estática. En un medio no seguro, estas

chispas causarán incendios o explosiones

que pueden resultar en muerte o lesiones

personales graves. Para la seguridad suya y

de las demás personas cerca, NO USE esta

chorreadora de arena donde haya líquidos,

gases, polvos, trapos empapados de aceite

u otros materiales inflamables que puedan

explotar o incendiarse.

Modelo MXS3000

Los choques

de

electricidad estática pueden ser

dolorosos. Algunos abrasivos

similares al óxido de aluminio

pueden crear electricidad estática mientras

usted usa la chorreadora de arena. Si usted

no tiene una conexión a tierra, la

electricidad estática puede acumularse en su

cuerpo y acusar un choque cuando usted

toque un objeto metálico. Usted puede

evitar la electricidad estática usando zapatos

con suela de cuero y manteniendo los pies

en el piso. Si fuese necesario, un cable

conectado a tierra y a la pistola chorreadora

Especificaciones

Dimensiones:

Espacio que ocupa: 58 cm A x 48 cm P

(23 in. x 19 in.)

Altura total: 49 cm (19,25 in.)

Profundidad total: 50 cm (19,75 in.)

Ancho total: 63 cm (24,75 in.)

Altura del área de trabajo: 29 cm a 34 cm

(11,5 in. a 13,5 in.)

Profundidad del área de trabajo: 46 cm a 47 cm

(18 in. a 18,5 in.)

Ancho del área de trabajo: 55 cm a 60 cm

(21,75 in. a 23,5 in.)

Abertura superior: 49 cm x 39 cm

(19,25 in. A x 15,5 in. P)

Luz de trabajo fluorescente de 12V con entrada

para 120VCA 60Hz, salida de 12V 800mA,

fuente de energía clasificada Clase 2 UL.

Puerto de salida de vacío del lado derecho de

DI 3,5 cm (1-3/8 in.) con filtro cónico de

esponja y papel

bar máx. . . . . . . . . . . . . . . . . . . . . . . . . 8,62

Entrada de aire

Capacidad del medio . . .9,5 L (2,5 galones)

. . . . . . . . . . . .

6,4 mm (1/4 in.)

NPT (hembra)

© 2008

RECORDATORIO: ¡Guarde su comprobante de compra con fecha para fines de la garantía!

Adjúntela a este manual o archívela en lugar seguro.

IN709902AV 12/08

21 Sp

Page 22

Manuel de Instrucciones

MANUAL

Informaciones

Generales de

Seguridad (continuación)

de arena eliminará el peligro descargando la

electricidad estática. Recuerde, usted no está

conectado a tierra si está aislado del piso.

Los zapatos con suela de caucho, las botas de

caucho u otros zapatos de caucho o plástico

son aislantes. Evite estar parado sobre

madera seca (como una paleta de madera)

un tapete o alfombra secos.

INFORMACIONES GENERALES DE

SEGURIDAD

No use este producto

en forma inadecuada.

La exposición excesiva a la vibración,

rabajar en posiciones incómodas y los

t

movimientos de trabajo repetitivos

pueden causar lesiones a las manos y

brazos. Deje de usar cualquier

herramienta si aparece incomodidad,

cosquilleo o dolor y consulte a un médico.

1. Lea este manual de

instrucciones antes

de conectar este dispositivo

al compresor.

2. Durante el uso y la

limpieza, es indispensable

ponerse gafas de seguridad

y un espirador homologado

por NIOSH/MSHA.

3. Durante el uso, no exponga las manos

o la piel directamente en la

trayectoria de la boquilla de abrasión.

4. Después del montaje, revise para

asegurarse de que todos las partes

sellen adecuadamente.

5. No exceda la presión de

funcionamiento máxima del equipo de

abrasión (8,62 bar).

Desconecte la cabina

de la fuente de aire