Campbell Hausfeld IN728900AV, CHN70899 User Manual

3-1/2 inch 34˚

MAKES IT EASY TO DO IT LIKE A PRO chpower.com

Framing Nailer

Operating Instructions and Parts Manual

CHN70899

FRANÇAISE: Page 21

ESPAÑOL: Página 41

© 2010 Campbell Hausfeld/Scott Fetzer

IN728900AV 7/10

Table of Contents

Description . . . . . . . . . . . . . . . . . . . . . . . . . 3

Specifications. . . . . . . . . . . . . . . . . . . . . . . 3

Safety Guidelines. . . . . . . . . . . . . . . . . . . . 4

Safety Symbols. . . . . . . . . . . . . . . . . . . . . . 4

Important Safety Information . . . . . . . . 4

Instructions Pertaining to a Risk

of Fire, Electric Shock, or Injury

to Persons. . . . . . . . . . . . . . . . . . . . . . . . . 4

California Proposition 65 . . . . . . . . . . . 4

General . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Work Area. . . . . . . . . . . . . . . . . . . . . . . . . 4

Personal Safety . . . . . . . . . . . . .. . . . . . . 5

Electrical Safety. . . . . . . . . . . . . . . . . . . . 5

Tool Use and Care . . . . . . . . . . . . . . . . . 5

Service. . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Air Source. . . . . . . . . . . . . . . . . . . . . . . . . 6

Unpacking. . . . . . . . . . . . . . . . . . . . . . . . . . 7

Contents. . . . . . . . . . . . . . . . . . . . . . . . . . 7

Additional Items Not Included . . . . . . 7

Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Getting To Know Your

Framing Nailer Like A Pro . . . . . .. . . . . . 9

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Anti-Dry Fire . . . . . . . . . . . . . . . . . . . . . . 9

Tethered No-Mar Decking Tip . . . . . . 9

Low Nail Indicator Lights. . . . . . . . . . . 9

Bubble Level . . . . . . . . . . . . . . . . . . . . . . 9

Set-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Lubrication . . . . . . . . . . . . . . . . . . . . . . 10

Minimum Components Required

for Hook-up. . . . . . . . . . . . . . . . . . . . . . 10

Hook-up Instructions For Nailer

to Air Supply . . . . . . . . . . . . . . . . . . . . . 10

Air Hose Requirements. . . . . . . . . . . . 10

Loading / Unloading The Nailer . . . . 11

Loading the Nailer . . . . . . . . . . . . . . 11

Unloading the Nailer . . . . . . . . . . . . 11

Adjusting The Nail Penetration. . . . . 11

Adjusting the Direction

of the Exhaust . . . . . .. . . . . . . . . . . . . . 12

Installing No-Mar Tip . . . . . . . . . . . . . 12

Removing No-Mar Tip . . . . . . . . . . . . 12

Pre-Operation. . . . . . . . . . . . . . . . . . . . . . 12

Operational Modes . . . . . . . . . . . . . . . 12

Sequential Mode. . . . . . . . . . . . . . . . 12

Bump Mode . . . . . . . . . . . . . . . . . . . . 13

Safety Lockout Mode . . . . . . . . . . . . 13

Work Contact Element (WCE). . . . . . 13

Electronics ON / OFF Switch . . . . . . . 13

Operation . . . . . . . . . . . . . . . . . . . . . . . . . 14

Firing the Nailer . . . . . . . . . . . . . . . . . . 14

Low Nail Indicator Lights. . . . . . . . . . 14

Bubble Level . . . . . . . . . . . . . . . . . . . . . 14

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Maintenance. . . . . . . . . . . . . . . . . . . . . . . 15

Clearing a Jam from the Nailer . . . . . 15

Nailer Repair . . . . . . . . . . . . . .. . . . . . . 15

Replacement Parts. . . . . . . . . . . . . . . . 15

Battery Replacement. . . . . . . . . . . . . . 15

Assembly Procedure for Seals . . . . . . 15

Technical Service . . . . . . . . . . . . . . . . . 16

Fastener Interchange Information. . 16

Troubleshooting Guide . . . . . . . . . . . . . 17

Replacement Parts List

for Framing Nailer. . . . . . . . . . . . . . 18 - 19

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . 20

For parts, product and service information

Visit: www.chpower.com

Call : Customer Service at 1-800-543-6400

Address any correspondence to: Campbell Hausfeld

Attn: Customer Service

100 Production Drive

Harrison, OH 45030 U.S.A.

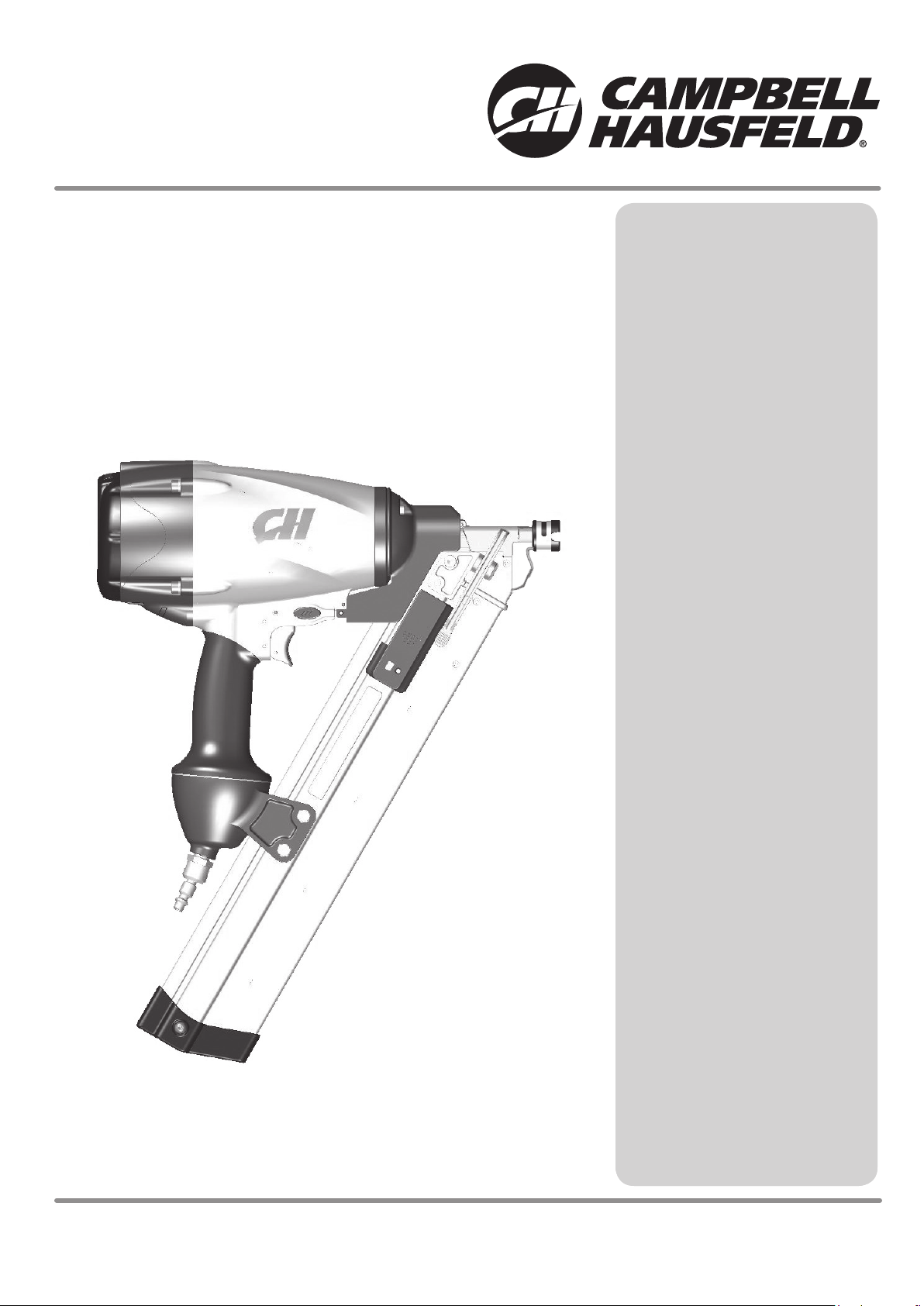

Operating Instructions and Parts Manual

Framing Nailer

Description

This nailer is designed for framing, trusses, sub-floors, sheathing, exterior decks, and

pallet/create assembly. Features include: convenient rear loading magazine which

holds up to 100 nails, tethered no-mar decking tip, quick clear nose, an adjustable

depth of drive mechanism, oil free, electronic low nail indicator, in-line magazine,

bubble level, anti-dry fire, conversion trigger with safety lockout, rubber comfort grip,

swivel plug, and adjustable exhaust.

Specifications

Model CHN70899

Requires: 2.5 Avg SCFM using 16

fasteners per minute at 90 psi

Air Inlet: 1/4 inch NPT

Fastener Size Range:

u 2 inches to 3-1/2 inches long

u 0.113 inch to 0.131 inch

shank diameter

u 31° to 34°

Magazine Capacity:

85 to 100 fasteners per load

Weight: 9 lbs. 4 oz.

Length: 21 inches

Height: 14-1/2 inches

Maximum Pressure:

120 psi

Pressure Range: 70 psi to 120 psi

Batteries: Two (2) AAA

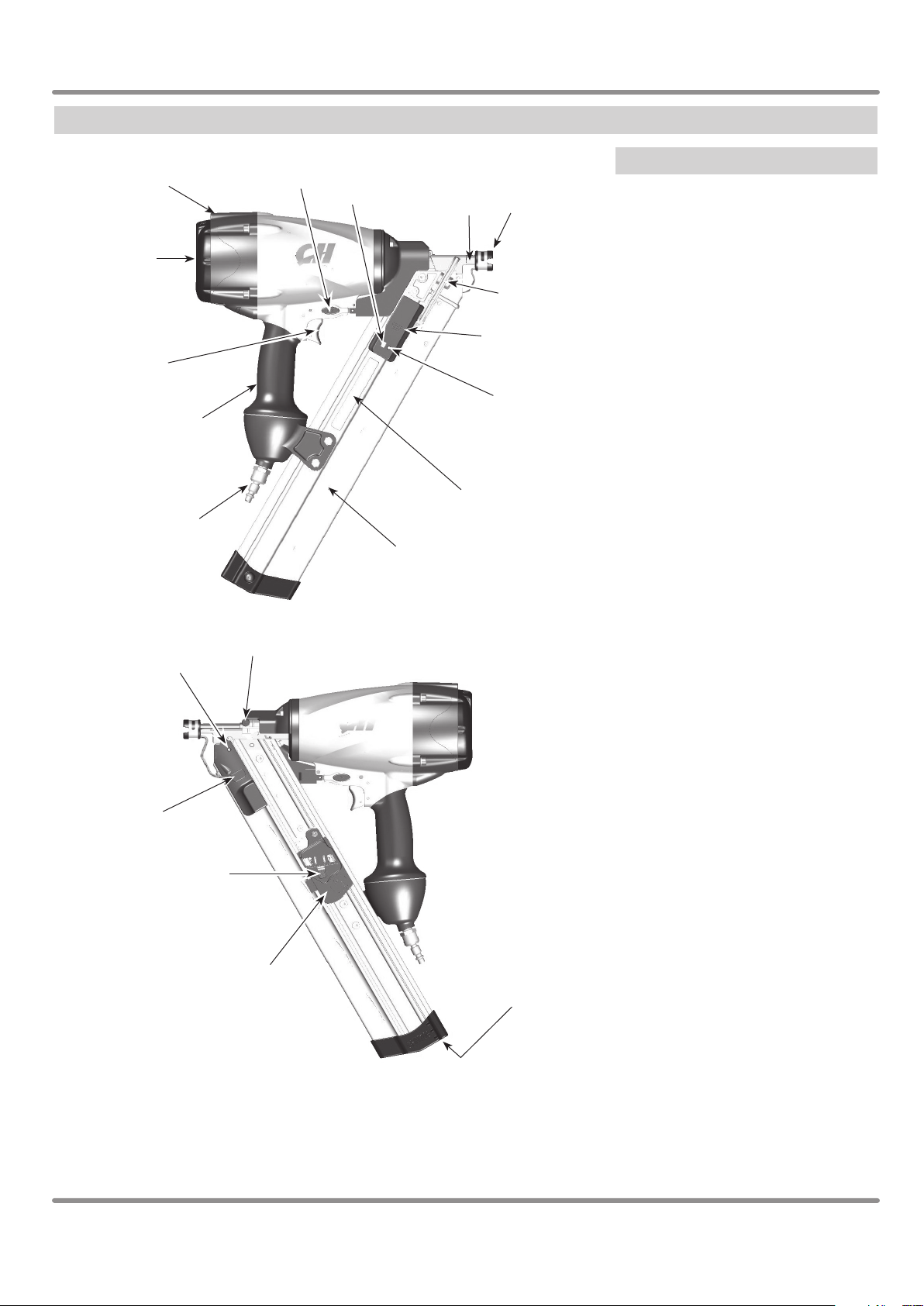

Figure 1 - CHN70899 Framing Nailer

Locate model number and date code on

magazine and / or tool body. Record below:

Model #: _____________________________

Date Code: ___________________________

Retain these numbers for future reference.

www.chpower.com

3

Operating Instructions and Parts Manual

Safety Guidelines

This manual contains

information that is very

important to know and

understand. This information

is provided for SAFETY and

to PREVENT EQUIPMENT

PROBLEMS. To help recognize

this information, observe the

following symbols.

Danger

indicates an

imminently hazardous situation

which, if not avoided, WILL result

in death or serious injury.

Warning

indicates a

potentially hazardous situation

which, if not avoided, COULD

result in death or serious injury.

Caution

indicates a

potentially hazardous situation

which, if not avoided, MAY result in

minor or moderate injury.

Notice

indicates

important information, that if not

followed, may cause damage to

equipment.

IMPORTANT: Information that

requires special attention.

Safety Symbols

The following Safety Symbols

appear throughout this manual

to alert you to important safety

hazards and precautions.

Wear Eye

and Mask

Protection

Risk of Falling Wear Eye

Read Manual

First

Protection

Risk of

Personal

Injury

Wear Hearing

Protection

CHN70899

Important Safety Information

INSTRUCTIONS PERTAINING TO A RISK OF FIRE, ELECTRIC SHOCK, OR

INJURY TO PERSONS

This manual contains important safety, operational and maintenance information. If

you have any questions, please call 1-800-543-6400 for customer assistance.

When using tools, basic precautions should always be followed,

including the following:

CALIFORNIA PROPOSITION 65

This product or its power cord may contain chemicals known to the State

of California to cause cancer and birth defects or other reproductive

harm. Wash hands after handling.

You can create dust when you cut, sand, drill or grind

materials such as wood, paint, metal, concrete, cement, or

other masonry. This dust often contains chemicals known to cause cancer, birth

defects, or other reproductive harm. Wear protective gear.

GENERAL

a. To reduce the risks of electric shock, fire, and injury to persons, read

all the instructions before using the tool. Failure to follow warnings,

dangers, and cautions could result in DEATH or SERIOUS INJURY.

b. Be thoroughly familiar with the controls and the proper use of the

equipment. Follow all instructions. Contact your Campbell Hausfeld representative

if you have any questions.

c. Only persons well acquainted with these rules of safe operation should be allowed

to use the unit.

Do not operate or allow anyone else to operate the nailer if any warnings

or warning labels are not legible. Warnings or warning labels are located

on the nailer magazine and body.

Always assume the nailer contains nails. Respect the tool as a working

implement; no horseplay. Always keep others at a safe distance from

the work area in case of accidental discharge of nails. Do not point the tool toward yourself or

anyone whether it contains fasteners or not. Accidental triggering of the nailer could result in

death or serious personal injury.

Do not make any modifications to the tool without first obtaining

written approval from Campbell Hausfeld. Do not use the nailer if any

shields or guards are removed or altered. Do not use the nailer as a hammer. Personal injury or

tool damage may occur.

Clean and check all air supply hoses and fittings before connecting the

nailer to an air supply. Replace any damaged or worn hoses or fittings.

Tool performance or durability may be reduced.

WORK AREA

a. Keep the work area clean and well lighted. Cluttered benches and dark areas

increase the risks of electric shock, fire, and injury to persons.

b. Do not operate the tool in explosive atmospheres, such as in the

presence of flammable liquids, gases, or dust. The tool is able to create

sparks resulting in the ignition of the dust or fumes.

c. Keep bystanders, children, and visitors away while operating the tool.

Distractions are able to result in the loss of control of the tool.

Risk of Fire

4

www.chpower.com

Risk of

Explosion

Risk of Shock

Operating Instructions and Parts Manual

Important Safety Information (Continued)

PERSONAL SAFETY

a. Stay alert. Watch what you are doing and use common

sense when operating the tool. Do not use the tool

while tired or under the influence of drugs, alcohol, or

medication. A moment of inattention while operating the

tool increases the risk of injury to persons.

b. Dress properly. Do not wear loose clothing or jewelry.

Contain long hair. Keep hair, clothing, and gloves away

from moving parts. Loose clothes, jewelry, or long hair

increases the risk of injury to persons as a result of being

caught in moving parts.

c. Do not overreach. Keep proper footing and

balance at all times. Proper footing and balance

enables better control of the tool in unexpected

situations.

d. Use safety equipment. A dust mask, non-skid safety shoes

and a hard hat must be used for the applicable conditions.

Ensuring that the tool is used

only when the operator and all

other personnel in the work area are wearing ANSI Z87

eye protection equipment, and when required, other

appropriate protection equipment such as head, hearing

and foot protection equipment. Serious eye or permanent hearing

loss could result.

e. Always wear hearing protection when using the

tool. Prolonged exposure to high intensity noise

is able to cause hearing loss.

f. Do not attach the hose or tool to your body.

Attach the hose to the structure to reduce the risk of loss of

balance if the hose shifts.

g. Always assume that the tool contains fasteners.

Do not point the tool toward yourself or anyone

whether it contains fasteners or not.

Do not drop or throw the tool. Dropping

or throwing the tool can result in damage that

will make the tool unusable or unsafe. If the tool has been dropped

or thrown, examine the tool closely for bent, cracked or broken parts

and air leaks. STOP and repair before using or serious injury could

occur.

Avoid long extended periods of work with the

nailer. Stop using the nailer if you feel pain in

hands or arms.

Hold tool by insulated gripping surface when

performing an operation where the tool or

fastener may contact hidden wiring. Contacting a “live” wire will

make exposed metal parts of the tool “live” and shock the operator.

Never place hands or any other

body parts in the nail discharge

area of the nailer. The nailer might eject a fastener and

could result in death or serious personal injury.

CHN70899

ELECTRICAL SAFETY

Replace batteries only with same

size batteries. Do not mix old and

new batteries. Using wrong size batteries can create a risk

of fire or injury.

The front end of the tool may be

made “live” if the tool comes

into contact with live wiring in the wall. TO PREVENT

ACCIDENTAL ELECTRICAL SHOCK, HOLD TOOL ONLY BY

THE SOFT GRIP HANDLE.

TOOL USE AND CARE

a. Do not force the tool. Use the correct tool for the application.

The correct tool will do the job better and safer at the rate for

which the tool is designed.

Disconnect the tool from the air source before

making adjustments, doing tool maintenance,

clearing jams, touching the safety yoke, leaving work area, loading,

or unloading the tool. Such precautionary measures reduce the risk of

injury to persons.

b. Store the tool when it is idle out of reach of children and

other untrained persons. A tool is dangerous in the hands of

untrained users.

c. Maintain the tool with care. A properly maintained tool

reduces the risk of problems and is easier to control.

d. Use only those fasteners listed in the “Fastener Interchange

Information” section on page 12 of this manual. Fasteners

not identified for use with this tool by the tool manufacturer

are able to result in a risk of injury to persons or tool damage

when used in this tool.

e. Always work in a well-ventilated area. Wear OSHA-

approved dust mask.

Always disconnect the tool from the power

source when unattended, performing any

maintenance or repair, clearing a jam, loading, unloading , or moving

the tool to a new location.

Always fit tool with a fitting or hose coupling

on or near the tool in such a manner that all

compressed air in the tool is discharged at the time the fitting or hose

coupling is disconnected. Do not use a check valve or any other fitting

which allows air to remain in the nailer. Death or serious personal

injury could occur.

Never carry the nailer by the air hose or pull

the hose to move the nailer or a compressor.

Keep hoses away from heat, oil and sharp edges. Replace any hose

that is damaged, weak or worn. Personal injury or tool damage could

occur.

Do not drive a nail on top of other nails. The

nail could glance and cause death or a serious

puncture wound.

Do not expose tool to extreme heat.

f. Do not store in locations where the temperature may reach

or exceed 120°F (49°C), such as a metal tool shed, or a car in

the summer. This can lead to deterioration of the battery.

www.chpower.com

5

Operating Instructions and Parts Manual

Important Safety Information (Continued)

CHN70899

g. Do not disassemble tool.

h. Remove batteries when storing tool for an extended time.

NOTE: Battery temperature will increase during and shortly

after use.

Only use new Alkaline replacement batteries [two (2) AAA

required]. Do not mix old and new batteries.

Battery shelf life - the included batteries may be in a slightly

depleted state or dead depending on how long the product has

awaited purchase. Do not return product to store for depleted

batteries; please call Campbell Hausfeld at 1-800-543-6400 for

assistance.

i. Do not modify or alter the nailer or any nailer parts. Do

not use the nailer if any shields or guards are removed or

altered. Do not use the nailer as a hammer. Personal injury

or tool damage may occur.

Do not use any type of flammable gases or

oxygen as a power source for the nailer.

Use filtered, lubricated, regulated compressed air only. Use of a

compressed gas instead of compressed air may cause the nailer to

explode which will cause death or serious personal injury.

Never use gasoline or other flammable liquids

to clean the nailer. Never use the nailer in

the presence of flammable liquids or gases. Vapors could ignite by a

spark and cause an explosion which will result in death or serious

personal injury.

Do not modify or disable the Work Contact

Element (WCE). Do not tie or tape the WCE

or trigger in a depressed position. Death or serious personal injury

could result.

Always check that the Work Contact Element

(WCE) is operating properly. A nail could

accidentally be driven if the WCE is not working properly. Personal

injury may occur.

Do not touch the trigger unless driving nails.

Never attach air line to nailer or carry nailer

while touching the trigger. The tool could eject a fastener which will

result in death or serious personal injury.

SERVICE

a. Tool service must be performed only by qualified repair

personnel.

b. When servicing a tool, use only identical replacement

parts. Use only authorized parts.

c. Use only the lubricants supplied with the tool or specified

by the manufacturer.

Disconnect air supply and release tension

from the pusher before attempting to clear

jams because fasteners can be ejected from the front of the nailer.

Personal injury may occur.

AIR SOURCE

a. Never connect to an air source that is capable of exceeding

200 psi. Over pressurizing the tool is able to result in

bursting, abnormal operation, breakage of the tool or

serious injury to persons. Use only clean, dry, regulated

compressed air at the rated pressure or within the rated

pressure range as marked on the tool. Always verify prior to

using the tool that the air source has been adjusted to the

rated air pressure or within the rated air-pressure range.

b. Never use oxygen, carbon dioxide, combustible gases or

any bottled gas as an air source for the tool. Such gases are

capable of explosion and serious injury to persons.

Air compressors providing air to the nailer

should follow the requirements established

by the American National Standards Institute Standard B19.3-1991;

Safety Standard for Compressors for Process Industries. Contact your

air compressor manufacturer for information.

SAVE THESE INSTRUCTIONS

DO NOT DISCARD

The DANGER, WARNING, CAUTION, and NOTICE

notifications and instructions in this manual cannot

cover all possible conditions and situations that may

occur. It must be understood by the operator that

common sense and caution are factors which cannot

be built into this product, but must be supplied by the

operator.

6

www.chpower.com

Operating Instructions and Parts Manual

CHN70899

Framing Nailer

Operating Instructions

r

e

l

ai

N

g

n

i

am

r

F

Carry Bag

Batteries

Allen Wrenches

3-1/2 inch, 34° nails

Unpacking

After unpacking the unit, inspect carefully

for any damage that may have occurred

during transit. Check for loose, missing

or damaged parts. Make sure to tighten

fittings, bolts, etc., before putting unit

into service. Check to be sure all supplied

accessories are enclosed with the unit. In

case of questions, damaged or missing

parts, please call 1-800-543-6400 for

customer assistance.

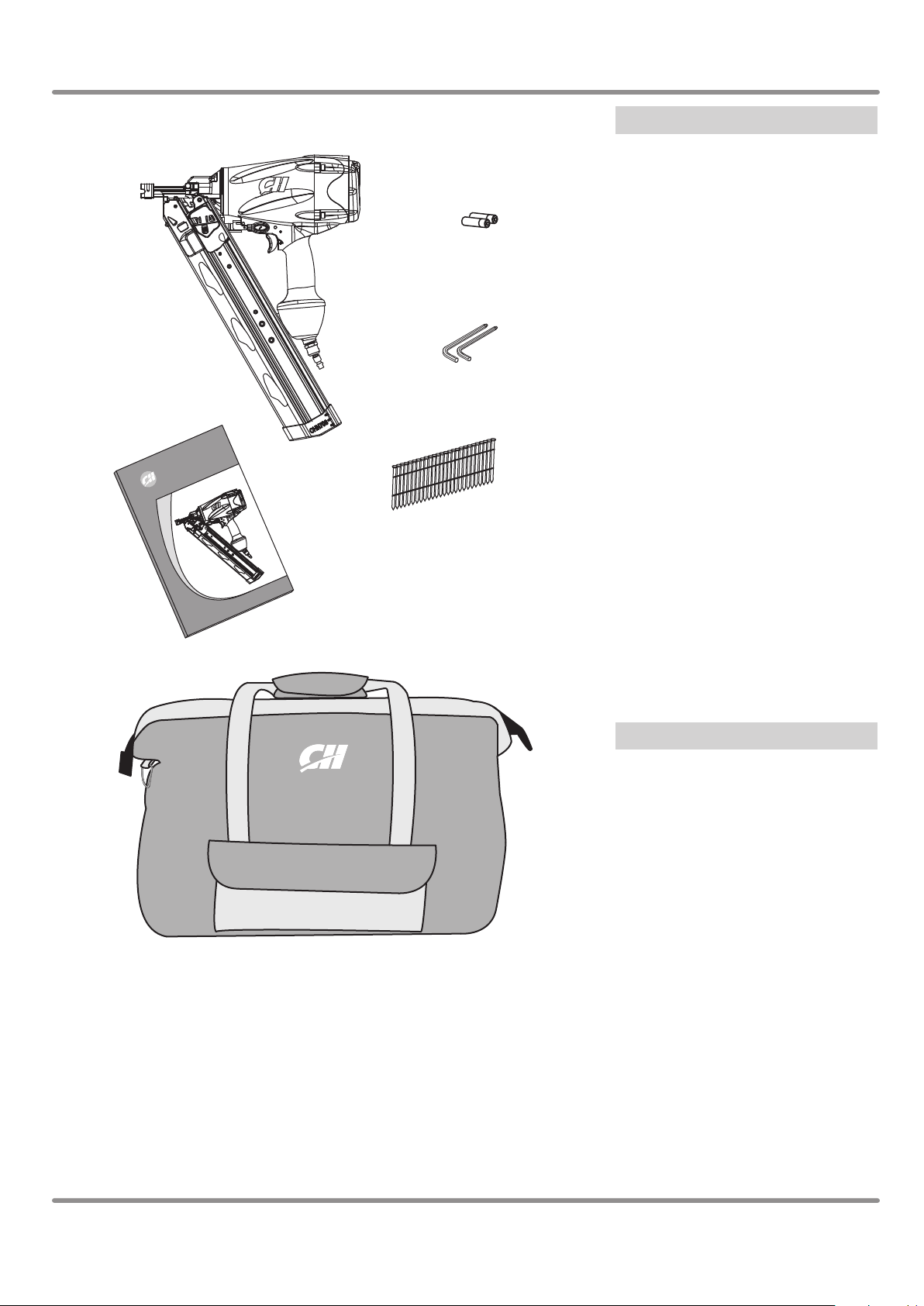

CONTENTS

u Framing Nailer

u 3-1/2 inch, 34° nails

u Batteries

u Allen Wrenches

u Operating Instructions

u Warranty Card

u Carry Bag

ADDITIONAL ITEMS NOT INCLUDED

u Compressor (must be able to maintain

a minimum of 70 psi when the nailer is

being used)

u Air hose

u Small tool for clearing jams

u Threadlock glue

u ANSI Z87 eye protection

u Hearing protection and other personal

protective equipment as required

Figure 2

Assembly

This tool comes fully assembled.

www.chpower.com

7

Operating Instructions and Parts Manual

Glossary

Become familiar with these terms before operating the unit.

ACTUATE (TOOL) — To cause movement to the tool’s component(s) intended to

drive the fastener.

ACTUATION SYSTEM — The use of a trigger, work contact element (WCE) and/

or other operating control, separately or in combination or sequence, to actuate

the tool.

CHN70899

AIR INLET — The opening in which the compressed air supply is connected,

usually by means of a threaded fitting.

FASTENERS — The nailer uses fasteners ranging from 2 inches to 3-1/2 inches

long, from 0.113 inch to 0.131 inch in shank diameter, and from 31° to 34°.

MAGAZINE — The part of the nailer that holds the Fasteners.

MAXIMUM AIR PRESSURE — The maximum allowable pressure of compressed

air, as specified by the manufacture, for operating the tool.

NO-MAR DECKING TIP — The no-mar decking tip is designed to eliminate

marks caused by the serrated Work Contact Element (WCE). The no-mar tip may

be removed and tethered to the tool if not required (See REMOVING NO-MAR

DECKING TIP) or when a slightly deeper countersink is preferred. Simply slide

the no-mar off the WCE and attach to the retainer on the magazine. Use tool in

single cycle mode (SEE OPERATIONAL MODES) when no-mar tip is in place (see

Figure 5).

psi (POUNDS PER SQUARE INCH) —Measurement of the pressure exerted by

the force of the air. The actual psi output is measured by a pressure gauge on the

compressor.

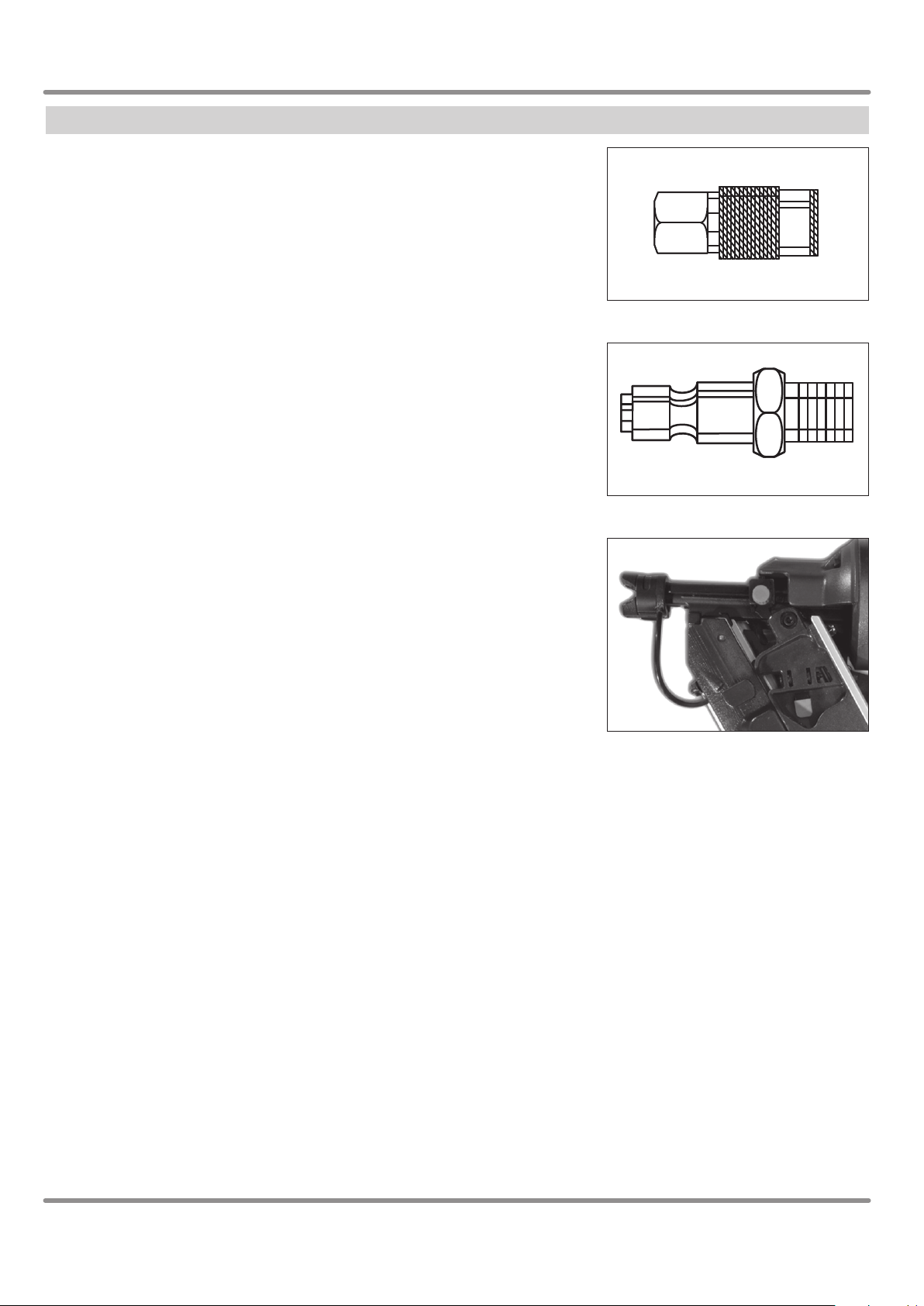

QUICK COUPLER — A quick coupler is designed to work in combination with a

quick plug to quickly and easily join a pneumatic tool to an air hose (see Figure 3).

QUICK PLUG — A quick plug is designed to work in combination with a quick

coupler to quickly and easily join a pneumatic tool to an air hose (see Figure 4).

Figure 3 - Quick Coupler

Figure 4 - Quick Plug

Figure 5 - No-mar Decking Tip

REGULATOR — A device used to control air pressure to an air operated tool

THREAD LOCK GLUE — A locking glue that is applied to the screw threads

before installing. Prevents the screws from working loose during tool operation.

8

www.chpower.com

Operating Instructions and Parts Manual

Getting To Know Your Framing Nailer Like A Pro

CHN70899

Bubble

Level

Adjustable

Exhaust

Deflecter

Trigger

Rubber Comfort

Grip

Swivel Plug

Low Nail

Indicator

Light

Conversion Switch

Adjustable Depth

Control Knob

Electronics

ON / OFF

Switch

Magazine

Work

Contact

Element

(WCE)

Pull-out Warning

Decal

Tethered

No-mar

Decking Tip

Quick Clear

Nose Lever

Battery Cover/

Compartment

Low Nail

Indicator

Light

Features

ANTI-DRY FIRE

This tool is equipped with an Anti-Dry

Fire feature. This prevents the Work

Contact Element (WCE) from being

pushed in when only a few nails remain.

Simply load new nail clip behind

remaining nails to continue shooting.

TETHERED NO-MAR DECKING TIP

The tool is fitted with a no-mar tip which

is tethered to the tool to prevent loss

when not mounted to tool. To utilize the

no-mar tip, simply slide it over the tools

WCE.

LOW NAIL INDICATOR LIGHTS

The tool is equipped with lights on either

side of the tool near the nose. When the

nail count becomes low, the lights will

turn yellow. When the nail count is nearly

out, the Anti-Dry Fire feature will engage

and the lights will turn red. (See Loading

the Nailer section).

BUBBLE LEVEL

The tool is equipped with a bubble level

located on the head cap. This will assist

in alighning the tool for level driving of

the fastener. The bubble level will assist

in vertical and horizontal positioning of

the tool.

No-mar Tip

Storage

Pusher Latch Button

Nail Pusher

Figure 6 - Components of the Framing Nailer

Nail Loading

Area

www.chpower.com

9

Operating Instructions and Parts Manual

Set-Up

CHN70899

LUBRICATION

This nailer requires NO lubrication for normal operation. However, lubrication will

NOT harm the tool.

The work surface can become damaged by excessive lubrication.

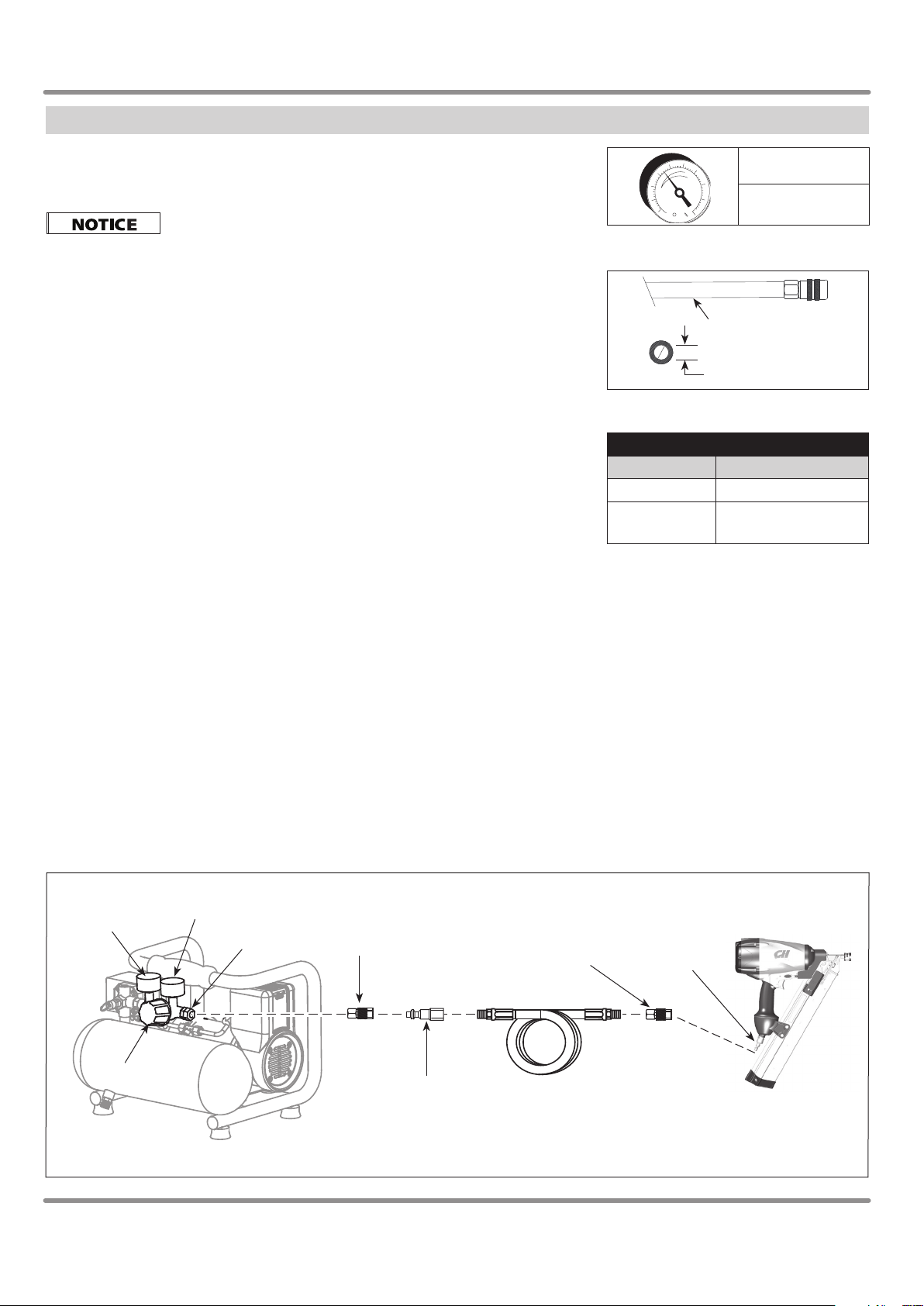

MINIMUM COMPONENTS REQUIRED FOR HOOK-UP

AIR COMPRESSOR: The air compressor must be able to maintain a minimum of 70 psi

when the nailer is being used. An inadequate air supply can cause a loss of power and

inconsistent driving (see Chart 1).

PRESSURE REGULATOR: A pressure regulator is required to control the operating

pressure of the nailer between 70 psi and 120 psi.

AIR SUPPLY HOSE: ALWAYS use air supply hoses with a minimum working pressure

rating equal to or greater than the pressure from the power source, or 150 psi,

whichever is greater. Use 3/8 inch air hose for runs up to 50 feet. Use 1/2 inch air hoses

for 50 ft. run or longer (see Figure 7 and Chart 2).

HOOK-UP INSTRUCTIONS FOR NAILER TO AIR SUPPLY

Figure 8 shows the recommended hookup for the nailer.

NOTE: For better performance, install a 3/8 inch quick plug (1/4 inch NPT threads) with

an inside diameter of 0.315 inch (8 mm) on the nailer and a 3/8 inch quick coupler on

the air hose.

1. With ON/OFF switch in OFF position, plug compressor into electrical outlet.

2. Close pressure regulator by turning all the way to the left. Turn compressor ON and

let it pump all the way up to automatic shut-off pressure.

3. Attach air hose to regulator outlet. Adjust pressure regulator by turning to the right

so that outlet pressure is between 70 psi to 120 psi.

4. Load fasteners into nailer (See Loading/Unloading the Nailer section on page 11).

5. Point the nailer in a safe direction while attaching to air hose.

6. Nailer is ready for use. You may need to adjust outlet pressure to achieve proper

fastener depth.

70 psi Minimum

120 psi Maximum

Chart 1

Rated 150 psi or greater

Interior Diameter

Figure 7 - Air Hose Requirements

AIR HOSE REQUIREMENTS

DIAMETER LENGTH OF RUN

3/8 inch Less than 50 feet

1/2 inch Greater than or equal

to 50 feet

Chart 2

Outlet

Tank

Pressure

Gauge

Regulator

Figure 8 - Recommended Hookup

10

www.chpower.com

Pressure

Gauge

Regulator

Outlet

Quick

Coupler

Quick

Plug

Quick

Coupler

Air

Hose

Swivel

Plug

Operating Instructions and Parts Manual

Set-Up (Continued)

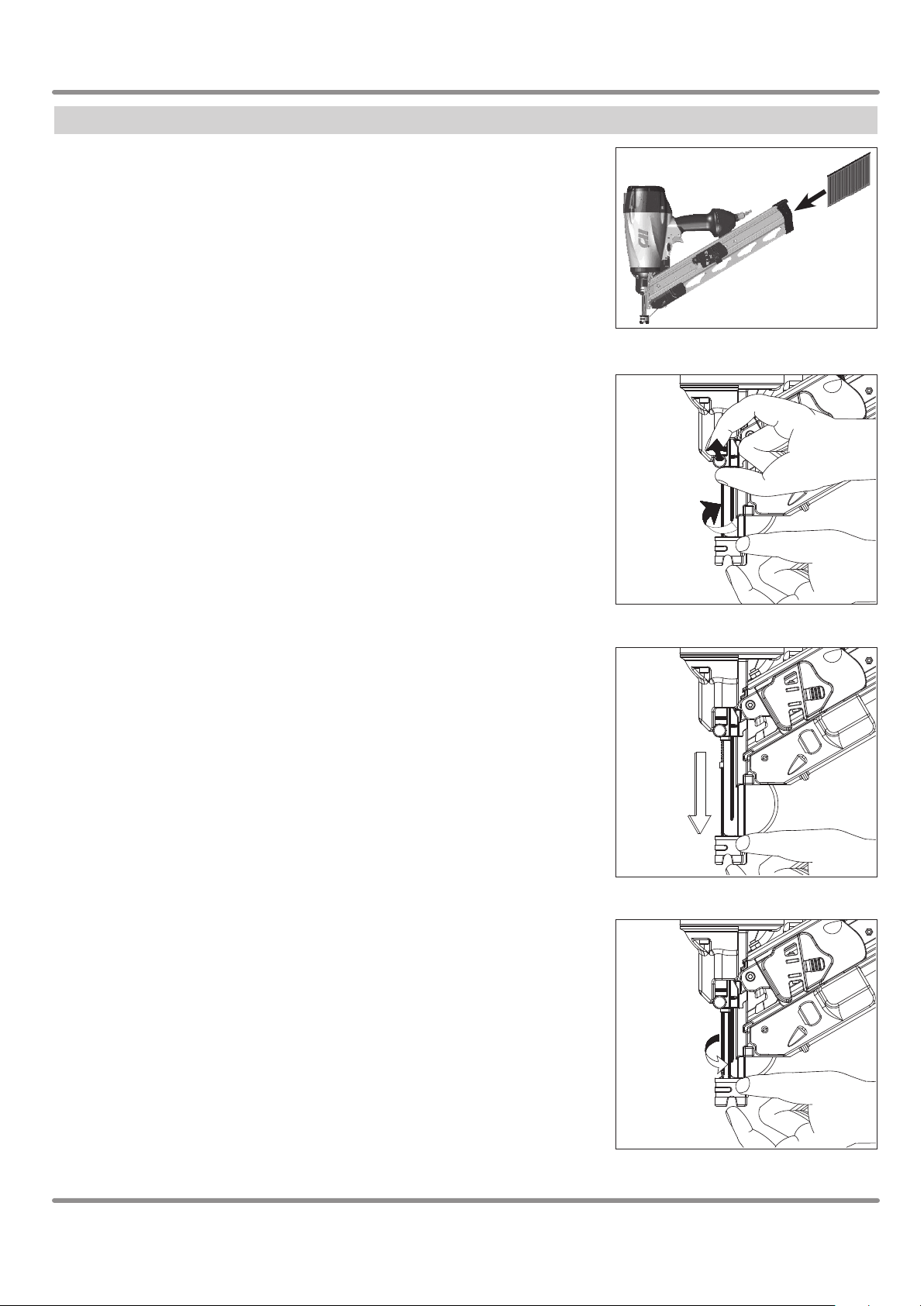

LOADING / UNLOADING THE NAILER

Always disconnect the tool from the air supply before loading / unloading fasteners.

Choose which type of fastener you want to use for you project. Additional fasteners can

be found at major home centers.

Loading the Tool

1. Load strips of fasteners into the slot in the rear of the magazine. Make sure that the

nails are placed into tool at the proper orientation.

2. Press pusher bypass button and drag pusher over nail clip. Release pusher.

3. Reconnect tool to air supply.

Unloading the Tool

1. Always unload all fasteners before removing tool from service.

2. Pull pusher back away from nail clip. Press pusher bypass button and allow pusher

to ride over remaining nails.

3. Hold tool upright so nails will slide backwards toward magazine slot.

4. Remove nails.

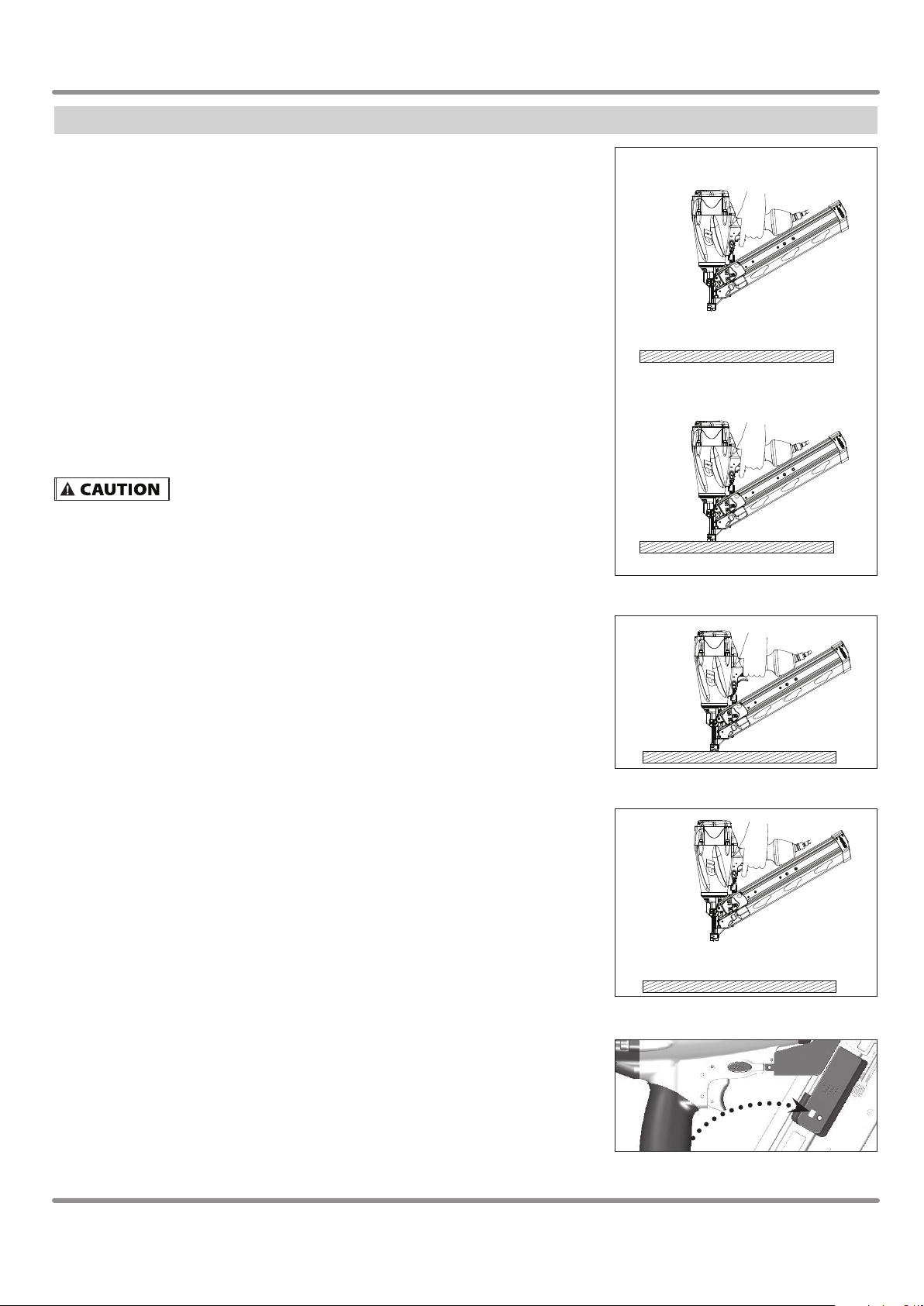

ADJUSTING THE NAIL PENETRATION

The CHN70899 is equipped with an adjustable depth of drive feature. This allows the

user to determine how deep a fastener will be driven into the work surface.

1. Adjust the operating pressure to a pressure which will consistently drive the

fasteners. Do not exceed the maximum operating pressure of 120 psi.

2. Pull red pin out. Twist Work Contact Element (WCE) 1/4 turn as shown.

Release red pin. See Figure 10.

3. Move WCE back and forth to the extent desired. Move the WCE toward the tool to

increase nail depth. Move WCE away from tool to reduce nail depth. See Figure 11.

4. Twist WCE 1/4 turn back to its original position as shown.

See Figure 12.

5. Make sure that the trigger and WCE move freely up and down without binding or

sticking after each adjustment.

CHN70899

Figure 9 - Loading the Nailer

Figure 10 - Nail Depth Adjust

Figure 11 - Nail Depth Adjust

Figure 12 - Nail Depth Adjust

www.chpower.com

11

Operating Instructions and Parts Manual

Set-Up (Continued)

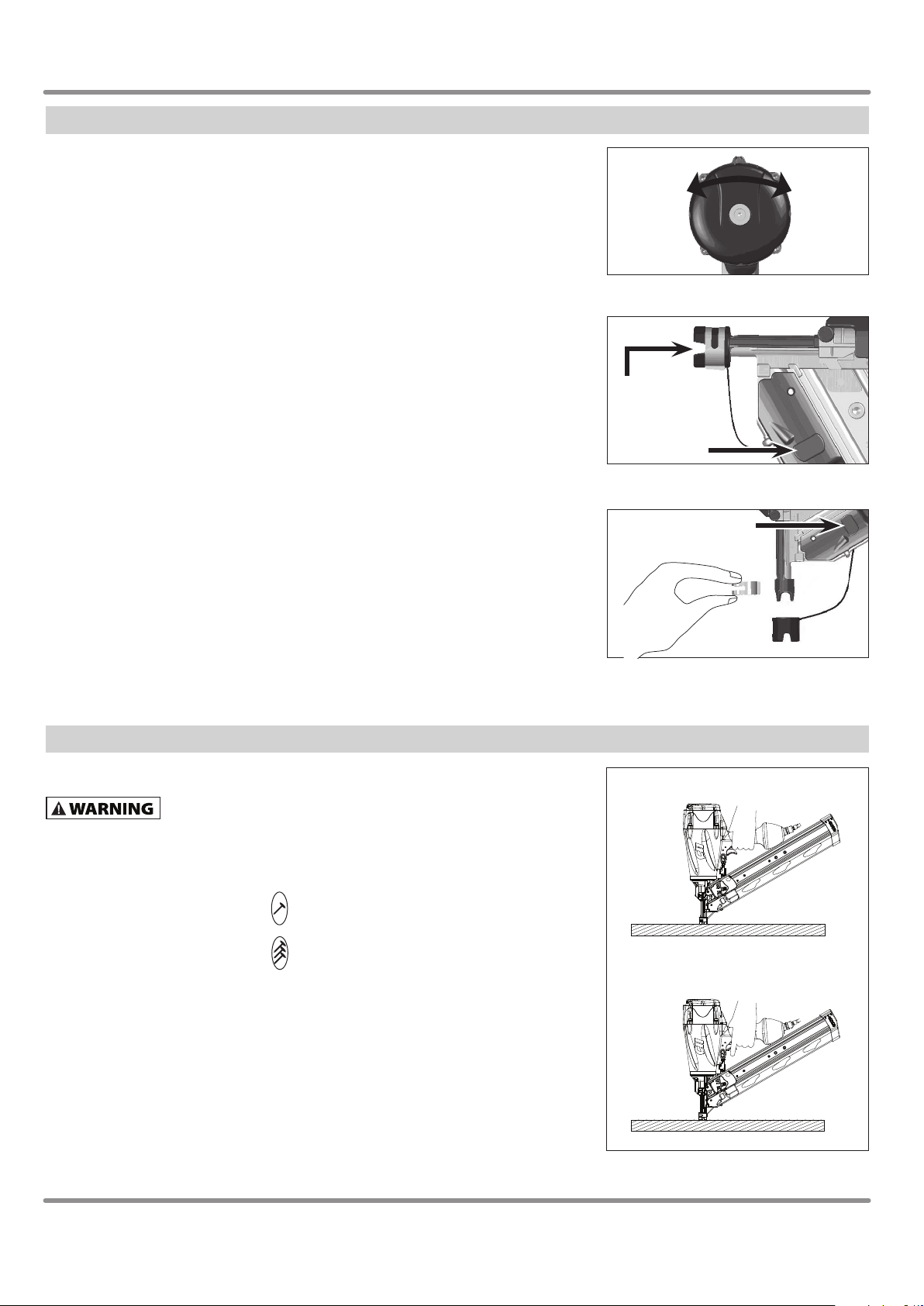

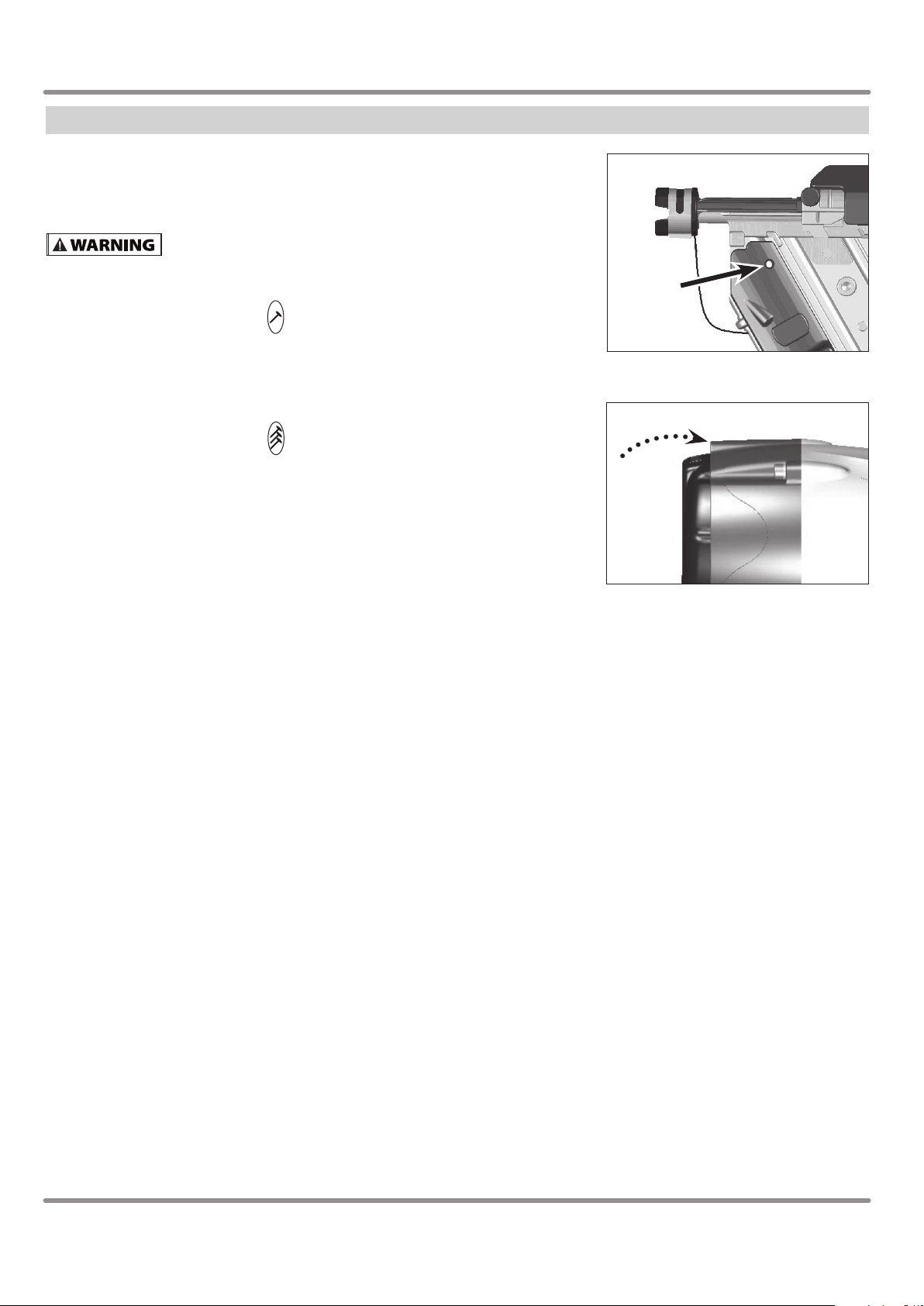

ADJUSTING THE DIRECTION OF THE EXHAUST

The CHN70899 is equipped with an adjustable direction exhaust deflector. This is

intended to allow the user to change the direction of the exhaust. Simply twist the

deflector to any direction desired.

INSTALLING NO-MAR TIP

1. Disconnect air supply from nailer.

2. Remove no-mar tip from storage post.

3. Remove retaining ring from no-mar tip.

4. Carefully place no-mar tip over the end of work contact element. Position tip

onto WCE making certain serrated gooves on each piece are in line and fit snugly

together.

5. Position retaining ring on no-mar tip and press firmly in place.

6. Check that the WCE and trigger move up and down freely without sticking or

binding.

REMOVING NO-MAR TIP

1. Disconnect air supply from nailer.

2. Remove no-mar tip retaining ring.

3. Pry no-mar tip away from the work contact element.

4. Replace retaining ring onto no-mar tip, then store tip on storage post for future use.

CHN70899

Figure 13 - Exhaust Adjustment

No-mar Tip

Storage Post

Figure 14 - No-mar Tip

Storage Post

Pre-Operation

OPERATIONAL MODES

Always know the operational mode of the nailer before using. Failure to

know the operational mode could result in death or serious injury.

This nailer may be operated in the “Sequential” mode (as supplied by the

manufacturer) or “Bump” mode. The tool may be converted from one mode to the

other by firmly pressing the conversion switch from one position to the other.

Press the conversion switch on the “

Press the conversion switch on the “ ” side to activate Bump Mode.

Press either side to the middle position to activate the Safety Lockout Mode.

Sequential Mode

This method is recommended when precise nail placement is required. Operation in

this mode requires trigger to be pulled each time a nail is driven. Nailer can be actuated

by depressing the Work Contact Element (WCE) against work surface followed by

pulling the trigger.

The trigger must be released after each fastener is driven to allow tool to reset.

Since the tool can only be actuated by first removing the finger from the trigger, this

is considered to be a more restrictive mode of operation, suitable for less experienced

users.

” side to activate Sequential Mode.

Figure 15 - Remove No-mar Tip

Depress WCE first...

Work Surface

Then pull trigger.

Work Surface

Figure 16 - Sequential Mode

12

www.chpower.com

Operating Instructions and Parts Manual

Pre-Operation (Continued)

CHN70899

Bump Mode

This method is recommended when less precise nail placement is required. Operation

in this mode requires the trigger to be depressed with nailer off of the work surface.

Then, the nose of the nailer is tapped against the work surface causing a nail to be

driven.

Each time the Work Contact Element is depressed, a nail is driven into the work

surface. Extreme care should be taken because a nail will be driven when the WCE is

pressed against any surface.

Since the tool can be actuated without removing the finger from the trigger, this is

considered to be a less restrictive mode, suitable for more experienced users.

Safety Lockout Mode

When the conversion switch is pressed into the middle position, the trigger is in Safety

Lockout Mode. In this mode, no combination of WCE and trigger activations will allow

the tool to cycle or fire. If tool does operate while in Safety Lockout Mode, contact

Campbell Hausfeld for technical support, and do not use the nailer until repaired.

WORK CONTACT ELEMENT (WCE)

Check the operation of the Work Contact Element (WCE) trip mechanism

before each use. The WCE must move freely without binding through its

entire travel distance. The WCE spring must return the WCE to its fully extended position after

being depressed. Do not operate the nailer if the WCE trip mechanism is not operating properly.

Personal injury may occur.

1. Disconnect the air supply from the nailer.

2. Make sure the trigger and Work Contact Element (WCE) move freely up and down

without sticking or binding.

NOTE: If the tool is not loaded with nails, the anti-dry fire feature will not allow the

WCE to be depressed.

3. Reconnect air supply to the nailer.

4. Use a scrap piece of wood as a work surface.

5. Depress the WCE against the work surface without pulling the trigger (See

Figure 18). The nailer MUST NOT OPERATE. Do not use the tool if it operates

without pulling the trigger. Personal injury may result.

6. Remove nailer from work surface. The WCE must return to its original down

position. Pull the trigger (See Figure 19). The nailer MUST NOT OPERATE. Do not

use the tool if it operates while lifted from the work surface. Personal injury may

result.

7. Pull the trigger and depress the WCE against the work surface. The nailer MUST

OPERATE when in bump mode. The nailer MUST NOT OPERATE if in sequential

mode.

8. Depress the WCE against work surface. Pull the trigger. The nailer MUST OPERATE.

9. Switch nailer into the other Mode as described in Operational Modes section and

repeat.

Pull trigger first...

Work Surface

Then depress WCE.

Work Surface

Figure 17 - Bump Mode

Work Surface

Figure 18

Work Surface

IMPORTANT: Repeat steps one through nine with tool in Safety Lockout Mode. Tool

SHOULD NOT operate at any step. If tool does operate while in Safety Lockout Mode,

contact Campbell Hausfeld for technical support.

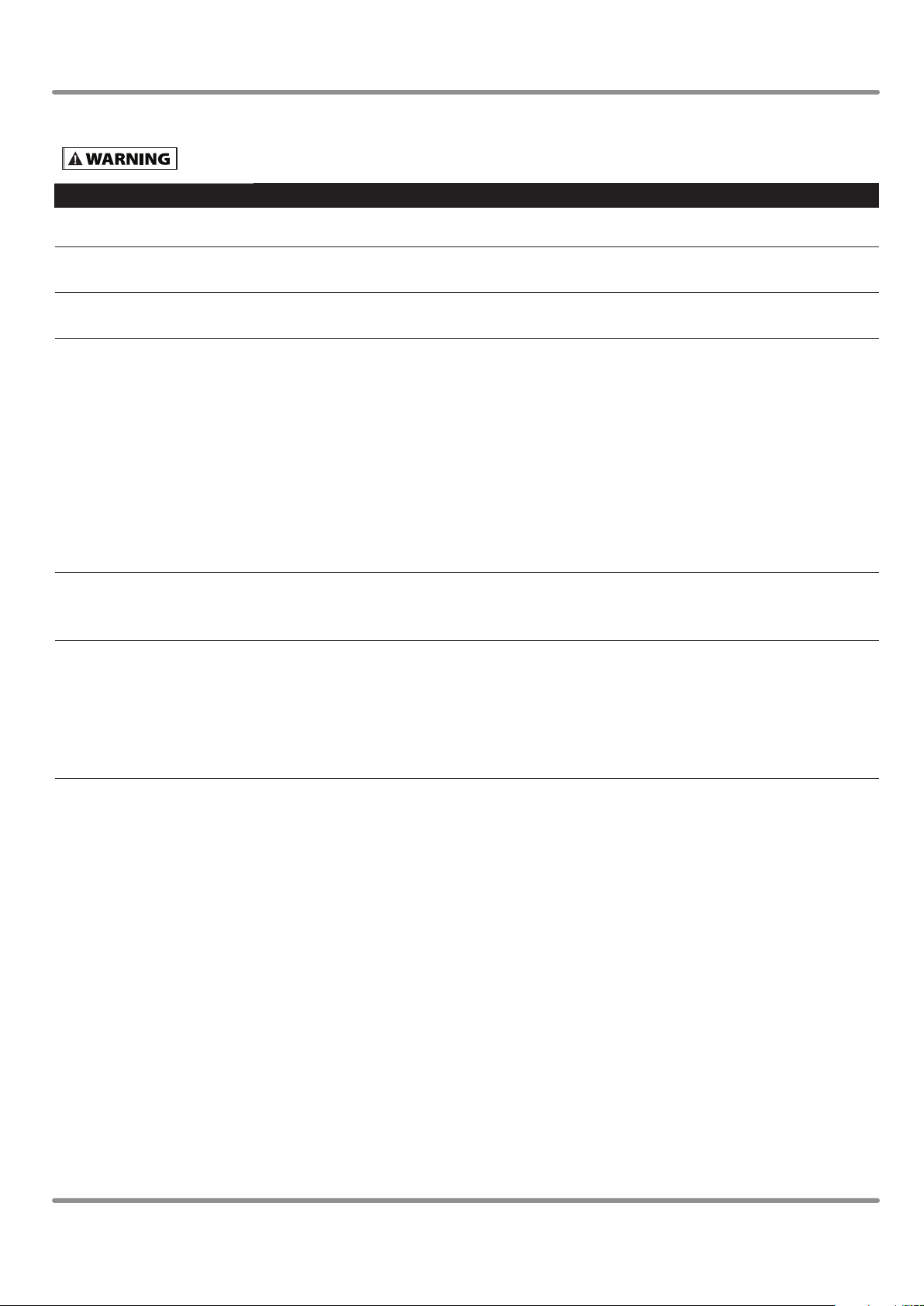

ELECTRONICS ON / OFF SWITCH

Located on the battery compartment is an ON/ OFF for the tool’s electronic functions

and low nail indicator LEDs (See Figure 20).

To utilize the function, turn the battery switch to the “ON” position. To avoid unwanted

battery depletion during storage, turn the switch to the “OFF” position.

Figure 19

Figure 20 - Electronic ON/OFF Switch

www.chpower.com

13

Operating Instructions and Parts Manual

Operation

FIRING THE NAILER

1. Load fasteners (see Loading / Unloading the Nailer section).

2. Connect the air supply to the nailer.

An improperly functioning tool must not be used. Do not actuate

the tool unless the tool is placed firmly against the work piece.

In Sequential Mode

CHN70899

Press the conversion switch to the “

1. Fully depress WCE.

2. Pull trigger. Fastener will be driven into workpiece.

In Bump Mode

Press the conversion switch to the “

1. Remove tool from work surface. DO NOT point tool at yourself or others.

2. Pull trigger.

3. Firmly depress Work Contact element (WCE) against work surface. Tool will cycle.

4. Remove tool from work surface. Move tool to the next area where fastener is to be

driven and repeat.

LOW NAIL INDICATOR LIGHTS

The tool is equipped with lights on either side of the tool near the nose. Turn the

electronics switch to the ON position. When the nail count becomes 10 or so nails

remaining in the magazine, the lights will come on yellow. You may reload at that time

(See Loading the Nailer section). When the nail count becomes 5 or so remaining nails,

the Anti-Dry Fire will engage and the lights will turn red. You MUST reload at that time.

BUBBLE LEVEL

The tool is equipped with a bubble level located on the head cap. When the gun is in a

horizontal driving orientation, a level condition can easily be observed and controlled

by simply aligning the tool in such a manner whereas the bubble is between the center

markings on the length of the level. The same is true when in a vertically downward

driving orientation by aligning the tool such that the bubble is centered in the circular

marking at the top of the level.

” side to activate Sequential Mode.

” side to activate Bump Mode.

Figure 21 - Low Nail Indicator Lights

Figure 22 - Bubble Level

14

www.chpower.com

Operating Instructions and Parts Manual

Storage

The nailer should be stored in a cool dry location.

Maintenance

CLEARING A JAM FROM THE NAILER

1. Disconnect nailer from air supply.

2. Remove all nails from the magazine (See Loading/ Unloading).

3. Press down on the Quick-Clear Nose (QCN) lever to disengage portion of nose barrel

(See Figure 23).

4. If necessary, use small hand tools to help free the jammed nail. Sometimes it is

necessary to use a hammer and a long, thin screwdriver to force the driver ram back

all the way into the gun (See Figure 24).

5. Dump jammed nail out.

6. Release QCN lever.

7. Nail pusher must be in the back lock position.

8. Disconnect air supply and reload (See Loading the Tool section).

NAILER REPAIR

Only qualified personnel should repair the tool and they should use genuine Campbell

Hausfeld replacement parts and accessories, or parts and accessories which perform

equivalently.

CHN70899

Figure 23 - Quick Clear Nose Lever

REPLACEMENT PARTS

Use only genuine Campbell Hausfeld service parts. Tool performance,

safety and durability could be reduced if improper parts are used.

When ordering replacement parts, specify by part number.

BATTERY REPLACEMENT

Always disconnect the tool from the power source when unattended,

performing any maintenance or repair, clearing a jam, loading,

unloading, or moving the tool to a new location.

The electronics on the tool (low nail indicator lights) run off of two (2) AAA batteries

located in the compartment on the back of the magazine. When the batteries’ power

is running low and they need to be replaced, the electronic functions may not work

properly or at all. Disconnect the tool from air source. Remove screw and battery

compartment cover. Insert two (2) new batteries in the proper orientation. Do not mix

old and new batteries. Close cover. Replace screw.

ASSEMBLY PROCEDURE FOR SEALS

When repairing a nailer, the internal parts must be cleaned and lubricated. Parker Olube or equivalent must be used on all o-rings. Each o-ring must be coated with O-lube

before assembling. A small amount of oil must be used on all moving surfaces and

pivots. After reassembling, a few drops of 30W non-detergent oil or equivalent, must be

added through the air line one time before normal operational use.

Figure 24

Screw

Figure 25 - Battery Replacement

Figure 26 - Battery Replacement

www.chpower.com

15

Operating Instructions and Parts Manual

Maintenance (Continued)

TECHNICAL SERVICE

For information regarding the operation or repair of this product, please

call 1-800-543-6400.

FASTENER INTERCHANGE INFORMATION

Fasteners used in the Campbell Hausfeld CHN70899 Framing Nailer will also work in

the following brand units:

• DeWalt D51822 and D51823

• Hitachi NR83AA2

• Paslode F-3505

• Porter Cable FC 350A

• Ridgid R350CHA

• Senco FramePro 701XP and 751XP

CHN70899

16

www.chpower.com

Operating Instructions and Parts Manual

Troubleshooting Guide

Stop using nailer immediately if any of the following problems occur. Serious personal injury could result.

Any repairs or replacements must be done by a Qualified Service Person or Authorized Service Center.

SYMPTOM CAUSE SOLUTION

Air leaking at trigger valve O-rings in trigger valve housing are

damaged

Air leaking between housing

and nose

Air leaking between housing

and cap

Nailer skips driving nail 1. Worn bumper 1. Replace bumper

Nailer runs slow or has loss of

power

Nails are jammed in nailer 1. Guide on driver is worn 1. Replace guide

Low nail indicators not

working

1. Damaged O-rings and / or seals 1. Replace O-rings and / or seals

2. Damage to bumper 2. Replace bumper

1. Loose screws 1. Tighten screws

2. Damaged gasket 2. Replace gasket

2. Dirt in nose piece 2. Clean drive channel

3. Dirt or damage prevent nails or

pusher from moving freely in

magazine

4. Damaged pusher spring 4. Replace spring

5. Inadequate air flow to nailer 5. Check fitting, hose, or compressor

6. Worn O-ring on piston or lack of

lubrication

7. Damaged O-ring on trigger valve 7. Replace O-rings

8. Air leaks 8. Tighten screws and fitings

1. Nailer not lubricated sufficiently 1. Lubricate nailer

2. Broken spring in cylinder cap 2. Replace spring

3. Exhaust port in cap is blocked 3. Replace damaged internal parts

2. Nails are not correct type 2. Use only recommended nails

3. Nails are bent 3. Replace with undamaged nails

4. Magazine or nose screws are loose 4. Tighten screws

5. Driver is damaged 5. Replace driver

6. Nails loaded incorrectly 6. Review Loading / Unloading section of manual

1. System power switch not turned on 1. Turn switch on

2. Batteries need to be replaced 2. Replace batteries (see “Changing batteries”

3. Components not properly replaced

during re-assembly after customer

maintenance

Replace O-rings. Check operation of Work Contact

Element (WCE)

3. Clean magazine

6. Replace piston seals

section)

3. Review parts view for assistance in proper reassembly

CHN70899

www.chpower.com

17

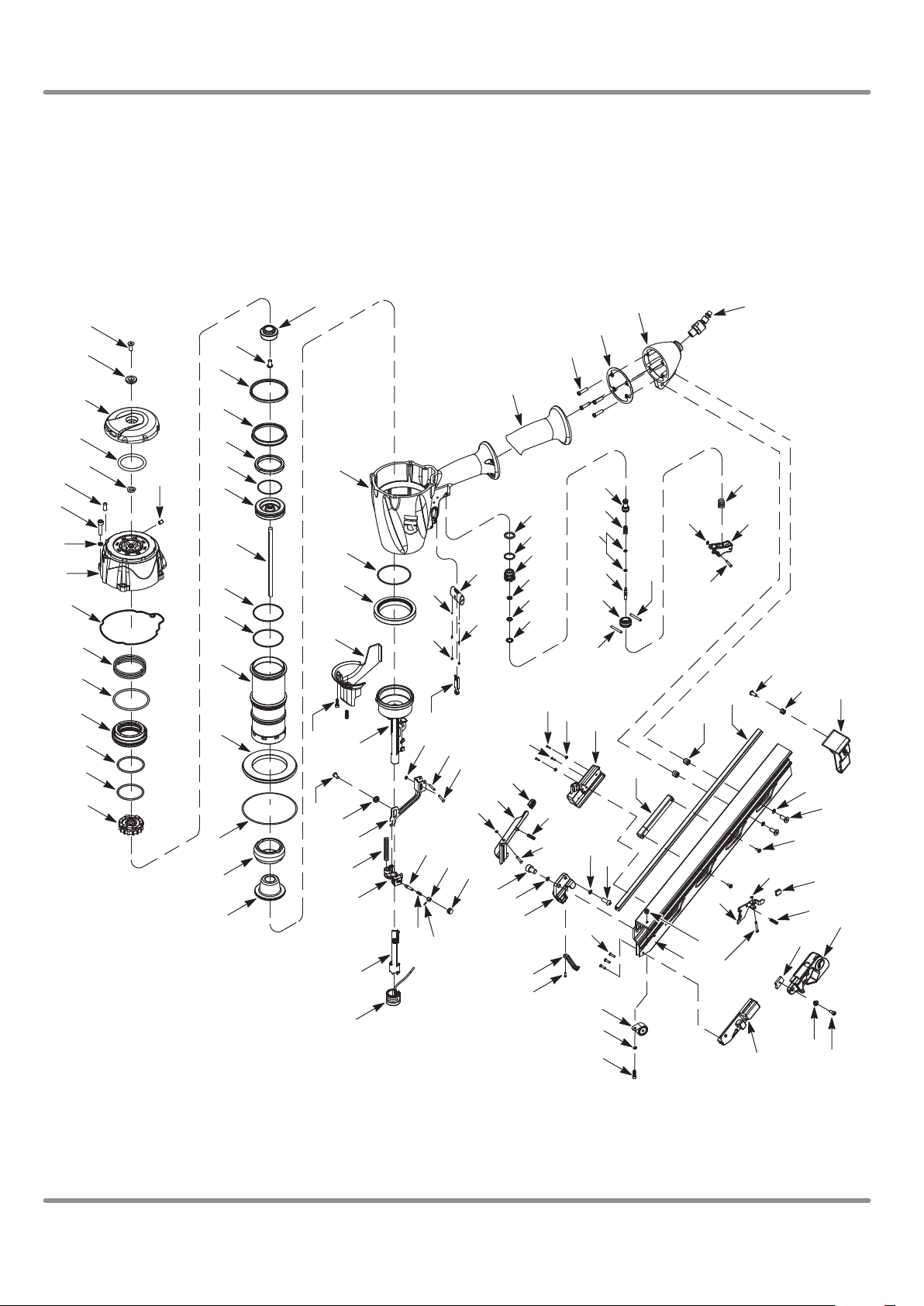

Operating Instructions and Parts Manual

For Replacement Parts or Technical Assistance, Call 1-800-543-6400

Please provide following information: Address any correspondence to:

- Model number Campbell Hausfeld

- Serial number (if any) Attn: Customer Service

- Part description and number as shown in parts list 100 Production Drive

Harrison, OH 45030 U.S.A.

CHN70899

18

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

20

25

27

28

21

23

12

26

29

22

15

30

19

24

35

37

34

31

33

38

32

40

44

41

36

39

43

42

46

48

49

50

110

109

51

53

52

50

54

45

47

72

103

108

85

69

8

73

75

76

58

59

60

55

56

57

82

104

83

86

70

84

74

63

65

66

87

80

81

35

105

61

62

64

106

50

71

52

98

88

77

79

78

89

90

100

107

67

68

101

50

37

96

92

99

74

94

91

102

97

95

93

35

Figure 25 – Repair Parts Illustration for Air Powered Framing Nailer, model CHN70899AV

18

www.chpower.com

Loading...

Loading...