Page 1

USER'S INFORMATION MANUAL

Commercial Boilers

SERIES 8H / 8HE

Gas - Fired Boiler

WARNING: If the information in this

manual is not followed exactly, a re or

explosion may result causing property

damage, personal injury or loss of life.

-

Do not store or use gasoline or other

ammable vapors and liquids in the

vicinity of this or any other appliance.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do

not use any phone in your building.

• Immediately call your gas supplier

from a neighbor's phone. Follow the

gas supplier's instructions.

• If you cannot reach your gas supplier,

call the re department.

-

Installation and service must be

performed by a qualied installer,

service agency or the gas supplier.

AVERTISSEMENT. Assurez-vous de bien

suivre les instructions données dans cette

notice pour réduire au minimum le risque

d'incendie ou d'explosion ou pour éviter

tout dommage matériel, toute blessure ou

la mort.

Ne pas entreposer ni utiliser d'essence ni

-

d'autres vapeurs ou liquides inam-mables

dans le voisinage de cet appareil ou de tout

autre appareil.

QUE FAIRE SI VOUS SENTEZ UNE ODEUR

DE GAZ:

• Ne pas tenter d'allumer d'appareils.

• Ne touchez à aucun interrupteur. Ne pas

vous servir des téléphones dans le

bâtiment où vous vous trouvez.

• Appelez immédiatement votre

fournisseur de gaz depuis un voisin.

Suivez les instructions du fournisseur.

• Si vous ne pouvez rejoindre le

fournisseur de gaz, appelez le service

des incendies.

L'installation et I'entretien doivent être

-

assuréx par un installateur ou un service

d'entretien qualié ou par le fournisseur de

gaz.

81416892R1 - X/15

BOILER NOT FOR INSTALLATION ON COMBUSTIBLE

FLOORS UNLESS FLOOR SHIELD OR NATIONAL BUILDING

CODE APPROVED MATERIALS ARE INSTALLED BETWEEN

BOILER AND FLOOR.

www.burnhamcommercial.com

Page 2

The following terms are used throughout this manual to bring attention to the presence of hazards of various risk levels.

Refractory Ceramic Fiber Product

Indicates a potentially hazardous situation which,

if not avoided, could result in death, serious injury

or substantial property damage.

Important Product Safety Information

The Repair Parts list designates parts that contain refractory ceramic fibers

(RCF). RCF has been classified as a possible human carcinogen. When

exposed to temperatures above 1805°F, such as during direct flame contact,

RCF changes into crystalline silica, a known carcinogen. When disturbed as a

result of servicing or repair, these substances become airborne and, if inhaled,

may be hazardous to your health.

AVOID Breathing Fiber Particulates and Dust

Precautionary Measures:

Do not remove or replace RCF parts or attempt any service or repair work

involving RCF without wearing the following protective gear:

Indicates a potentially hazardous situation which,

if not avoided, may result in moderate or minor

injury or property damage.

1. A National Institute for Occupational Safety and Health (NIOSH)

approved respirator

2. Long sleeved, loose fitting clothing

3. Gloves

4. Eye Protection

• Take steps to assure adequate ventilation.

• Wash all exposed body areas gently with soap and water after contact.

• Wash work clothes separately from other laundry and rinse washing

machine after use to avoid contaminating other clothes.

• Discard used RCF components by sealing in an airtight plastic bag. RCF

and crystalline silica are not classified as hazardous wastes in the United

States and Canada.

First Aid Procedures:

• If contact with eyes: Flush with water for at least 15 minutes. Seek

immediate medical attention if irritation persists.

• If contact with skin: Wash affected area gently with soap and water.

Seek immediate medical attention if irritation persists.

• If breathing difficulty develops: Leave the area and move to a location

with clean fresh air. Seek immediate medical attention if breathing

difficulties persist.

• Ingestion: Do not induce vomiting. Drink plenty of water. Seek

immediate medical attention.

2

Page 3

Basic Operation

Should overheating occur or the gas supply fail to shut off, do not turn off or disconnect the electrical

supply to the pump. Instead, shut off the gas supply at a location external to the appliance.

En cas de surchauffe ou si I'admission de gaz ne peut étre coupée, ne pas couper ni débrancher

l'alimentation électrique de la pompe. Fermer plutôt le robinet d'admission de gaz à l'extérieur de

I'appareil.

Do not use this boiler if any part has been under water. Immediately call a qualied service technician

to inspect the boiler and to replace any part of the control system and any gas control which has been

under water.

A. General This boiler is equipped with controls for

proper operation. All controls must be in proper

working order. Contact a qualied service agency

to provide annual maintenance as specied in the

Installation, Operating and Service Instructions.

Service on this boiler should be undertaken only

by trained and skilled personnel from a qualied

service agency.

1. Limit See Figure 1. A device which automatically

interrupts boiler operation when the water

temperature exceeds the set point. Maximum

allowable boiler water temperature is 250°F. Switch

differential is 30°F.

2. Blocked Vent Switch See Figure 1. A device

which automatically interrupts boiler operation

when excessive vent system blockage occurs. If the

control was activated to interrupt boiler operation,

do not attempt to place boiler in operation. Contact

a qualied service agency.

Do not reset Block Vent Switch unless a qualied

service agency has determined and corrected

the cause of any blockage in the vent system or

chimney.

3. Flame Rollout Switch See Figure 1. A device

which automatically interrupts boiler operation

when ames or excessive heat are present in the

vestibule. The control is a single use device. If the

control was activated to interrupt boiler operation,

do not attempt to place boiler in operation. Contact

a qualied service agency.

4. 24-Volt Continuous Ignition System (Standing

Pilot). See Figure 1. The Continuous Ignition

System consists of:

a. a combination gas valve to regulate gas ow to

burners.

b. a constant burning pilot burner to provide the

ignition source for main burners.

c. a thermocouple to sense pilot burner ame and

cause gas control valve to turn off main burner

and pilot burner gas ow should pilot burner

ame extinguish.

5. 24-Volt Intermittent Ignition System (EI). See

Figure 1. The Electronic Ignition System consists of:

a. an ignition module to initiate, monitor and stop

burner operation.

b. a combination gas valve to regulate gas ow to

burners.

c. a pilot burner to provide the ignition source for

main burners.

6. 120-Volt Intermittent Ignition (EP). See Figure 2.

The Intermittent Ignition System consists of:

a. an automatic main gas valve to regulate gas ow

to burners.

b. an automatic pilot gas valve to regulate gas ow

to the pilot burner.

c. a pilot burner to provide the ignition source for

main burners.

d. an ignition transformer to provide the ignition

source for the pilot burner.

e. a ame sensor to electronically monitor pilot

ame and cause gas control valve to turn off

main burner and pilot burner gas ow should

pilot burner ame extinguish.

B. Instructions to place boiler in operation and to turn

off boiler are shown on the Lighting or Operating

Instruction label posted on the inside of the front

removable door. See Figure 3 for front door removal

instructions. Lighting and Operating Instructions are

also shown in Figures 4 thru 6. Lighting and Operating

Instructions vary with the type of control system

furnished. Refer to Table 1 for the appropriate Figure.

3

Page 4

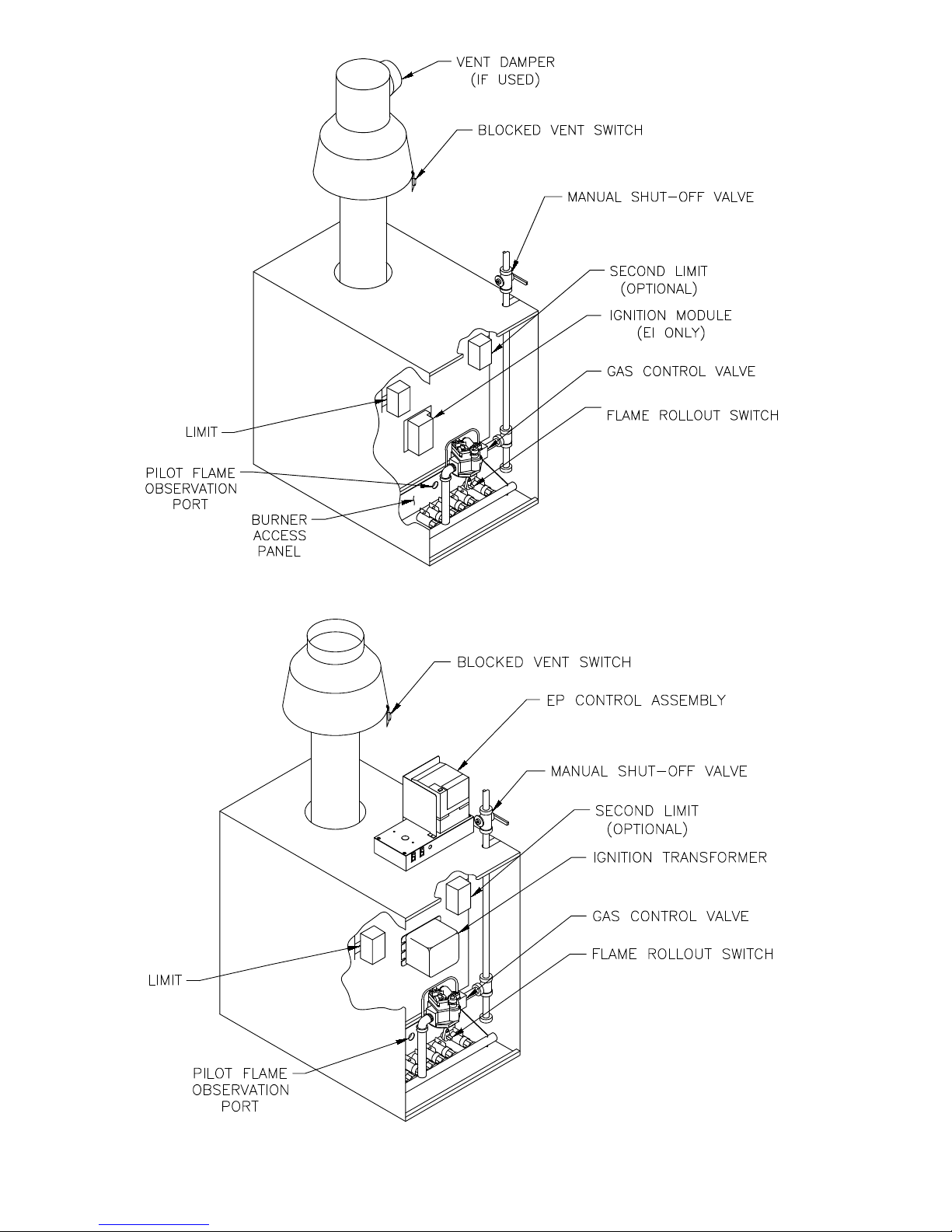

Figure 1: Control Locations (24V Control Systems)

Figure 2: Control Locations (120V Control Systems)

4

Page 5

Table 1: Lighting and Operating Instructions

IGNITION SYSTEM FIGURE

24V Continuous Ignition Figure 4

EI Intermittent Ignition Figure 5

EP Intermittent Ignition Figure 6

Figure 3: Jacket Front Door Removal

5

Page 6

Figure 4: Lighting Instructions, 24-Volt Continuous Ignition System

6

Page 7

FOR YOUR SAFETY READ BEFORE OPERATING

WARNING:

If you do not follow these instructions exactly, a fire or explosion may result

causing property damage, personal injury, or loss of life.

A. This appliance is equipped with an ignition device

which automatically lights the pilot. Do not try to light

the pilot by hand.

BEFORE OPERATING

B. smell all around the appliance area

for gas. Be sure to smell next to the floor because some

gas is heavier than air and will settle on the floor.

WHAT TO DO IF YOU SMELL GAS:

Do not try to light any appliance.

Do not touch any electric switch; do not use any

phone in your building.

Immediately call your gas supplier from a neighbor's

phone. Follow the gas supplier's instructions.

OPERATING INSTRUCTIONS

1. STOP! Read the safety information above on this label.

2. Set the thermostat to lowest setting.

3. Turn off all electric power to the appliance.

4. This appliance is equipped with an ignition device

which automatically lights the pilot. Do not try to

light the pilot by hand.

5. Remove front door.

6. Locate the gas control

valve at the end of the gas

supply pipe going into the

boiler. The gas control

knob is the gray or brown

plastic knob located on top

of the gas control valve.

GAS

INLET

GAS CONTROL KNOB

SHOWN IN "OFF" POSITION

POSITION

INDICATOR

ON OFF

If you cannot reach your gas supplier, call the

fire department.

C. Use only your hand to turn the gas control knob.

Never use tools. If the knob will not turn by hand,

don't try to repair it, call a qualified service technician.

Force or attempted repair may result in a fire or

explosion.

D. Do not use this appliance if any part has been under

water. Immediately call a qualified service technician

to inspect the appliance and to replace any part of the

control system and any gas control which has been

under water.

7. Rotate gas control knob clockwise from "ON"

position to "OFF". Make sure knob rests against stop.

8. Wait five (5) minutes to clear out any gas. Then smell

for gas, including near the floor. If you smell gas,

STOP! Follow "B" in the safety information above on

this label. If you do not smell gas, go to the next step.

9. Rotate gas control knob counterclockwise from

"OFF" to "ON". Make sure knob rests against stop. Do

not force.

10. Replace front door.

11. Turn on all electric power to the appliance.

12. Set thermostat to desired setting.

13. If the appliance will not operate, follow the

instructions "TO TURN OFF GAS TO APPLIANCE"

and call your service technician or gas supplier.

TO TURN OFF GAS TO APPLIANCE

1. Set the thermostat to the lowest setting.

2. Turn off all electric power to the appliance if service is

to be performed.

3. Remove front door.

Figure 5: Operating Instructions, EI Intermittent Ignition System

4. Rotate gas control knob clockwise from "ON"

position to "OFF". Make sure knob rests against stop.

5. Replace front door.

81460160

7

Page 8

FOR YOUR SAFETY READ BEFORE OPERATING

WARNING:

A. This appliance is equipped with an ignition device

which automatically lights the pilot. Do not try to light

the pilot by hand.

B. smell all around the appliance area

BEFORE OPERATING

for gas. Be sure to smell next to the floor because some

gas is heavier than air and will settle on the floor.

WHAT TO DO IF YOU SMELL GAS:

Do not try to light any appliance.

Do not touch any electric switch; do not use any

phone in your building.

Immediately call your gas supplier from a neighbor's

phone. Follow the gas supplier's instructions.

If you do not follow these instructions exactly, a fire or explosion may result

causing property damage, personal injury, or loss of life.

OPERATING INSTRUCTIONS

1. STOP! Read the safety information above on this label.

2. Set the thermostat to lowest setting.

3. Turn off all electric power to the appliance.

RESET SAFETY

SWITCH BUTTON

RM7890A

ELECTRONIC

CONTROL

PANEL

If you cannot reach your gas supplier, call the

fire department.

C. Use only your hand to push in or turn the gas control

knob. Never use tools. If the knob will not push in or

turn by hand, don't try to repair it, call a qualified

service technician. Force or attempted repair may

result in a fire or explosion.

D. Do not use this appliance if any part has been under

water. Immediately call a qualified service technician

to inspect the appliance and to replace any part of the

control system and any gas control which has been

under water.

POSITION

INDICATOR

GAS

INLET

ON OFF

PILOT

GAS CONTROL KNOB

SHOWN IN "OFF" POSITION

MAIN POWER

ROCKER

SWITCH

MAIN GAS ROCKER

SWITCH

CONTROL LOCATION DIAGRAM

4. EP SYSTEM: Flip both rocker switches to "O" position (off).

5. This appliance is equipped with an ignition device

which automatically lights the pilot. Do not try to light

the pilot by hand.

6. Remove front door.

7. Open manual pilot valve (CSD-1 Boilers Only).

8. Locate the gas control valve at the end of the gas

supply pipe going into the boiler. The gas control knob

is the knob located on top of the gas valve (see diagram

to right).

8. Rotate gas control knob clockwise from "ON"

position to "OFF". Make sure knob rests against stop.

9. Wait five (5) minutes to clear out any gas. Then smell

for gas, including near the floor. If you smell gas,

STOP! Follow "B" in the safety information above on

this label. If you do not smell gas, go to the next step.

TO TURN OFF GAS TO APPLIANCE

1. Set the thermostat to the lowest setting.

2. Turn off all electric power to the appliance if service is

to be performed.

3. Remove front door.

11. EP SYSTEM

Turn gas control knob counterclockwise from

"OFF" to "PILOT". When the proper position is reached

the gas control knob will pop up.

Turn on all electric power to the appliance.

Set the thermostat or operating control to desired

setting.

See control location diagram. On the electronic control

panel, flip the main power rocker switch to "l" position

(on). The "POWER" status indicator will light.

The pilot will light electronically. If pilot failure occurs,

the "ALARM" indicator will light. In case of pilot

failure, proceed to step 11.

Turn gas control knob counterclockwise to "ON".

On the electronic control panel, flip the main gas valve

rocker switch to "l" position (on). The "MAIN" gas valve

indicator will light. Main burners will operate.

"MAIN" gas valve indicator will cycle on and off at the

same time as the thermostat or operating control and

the main burners.

Replace front door.

12. If the appliance will not operate, follow the instructions

"TO TURN OFF GAS TO APPLIANCE" and call your

service technician or gas supplier.

4. Rotate gas control knob clockwise from "ON"

position to "OFF". Make sure knob rests against stop.

5. Close manual pilot valve (CSD-1 Boilers Only).

6. Replace front door.

81460284R4

Figure 6: Operating Instructions, EP Ignition System

8

Page 9

User Maintenance

Service on this boiler should be undertaken only by trained and skilled personnel from a qualied service

agency. Inspections should be performed at intervals specied in Installation, Operating and Service

Instructions and this manual. Maintain manuals in a legible condition.

Keep boiler area clear and free of combustible materials, gasoline and other ammable vapors and liquids.

Do not place any obstructions in boiler room that will hinder ow of combustion and ventilation air.

A. General Housekeeping (Continuous).

1. Keep boiler area clear and free of combustible

materials and obstructions to the free ow of

combustion and ventilation air to the boiler.

2. Do not store or use gasoline or other ammable

vapors or liquids in the vicinity of the boiler or any

other appliance.

3. Do not store or use sources of hydrocarbons in

the vicinity of the boiler. Sources of hydrocarbons

include bleaches, cleaners, chemicals, sprays, paint

removers, fabric softeners, cat litter and refrigerants.

B. Inspect Vent System (Monthly). See Figure 7. Follow

instructions TO TURN OFF GAS TO APPLIANCE

(see Figures 4 thru 6) and contact a qualied service

agency if any of the following conditions are found:

1. Collapsed vent pipe

2. Disconnected or loose joints

3. Sags in horizontal runs

4. Corrosion or other deterioration

5. Broken or loose supports

6. Blocked vent switch not attached to draft hood.

C. Inspect Pilot and Main Burner Flame (Monthly).

1. Adjust thermostat to lowest setting.

2. Remove front removable panel. See Figure 3.

3. Adjust thermostat to highest setting.

4. Check pilot burner ame through observation port.

See Figures 8 through 11 for appropriate pilot burner

illustration. The center ame should be steady,

medium hard blue enveloping 3/8 to 1/2 inch of

thermocouple. If ames are yellow and lazy, follow

instructions TO TURN OFF GAS TO APPLIANCE

(see appropriate Figure as listed in Table 1) and

contact qualied service agency.

5. Check main burner ames through observation port.

See Figure 11. Flame should have clearly dened

inner cones with no yellow tipping. Orange-yellow

streaks caused by dust should not be confused with

true yellow tipping. If yellow ames are observed,

follow instructions TO TURN OFF GAS TO

APPLIANCE (see appropriate gure as listed in

Table 1) and contact qualied service agency.

6. Adjust thermostat to normal setting.

D. Schedule Inspection by Qualied Service Agency

(Annual or at Beginning of Heating Season). For

continued safe operation a qualied service agency

must provide a more detailed inspection of burners, heat

exchanger and vent system, and provide maintenance

as specied in Installation, Operating and Service

Instructions.

Figure 7: Typical Vent System Installations

Figure 8: 24-Volt Continuous Ignition System,

Honeywell Q314 Pilot Flame

9

Page 10

Figure 9: EI Intermittent Ignition

(Honeywell Q3481B Pilot Flame)

Figure 10: EP Intermittent Ignition

(Honeywell Q179C Pilot Flame)

Figure 11: Main Burner Flame

10

Page 11

Figure 12: EP-CSD-1 Intermittent Ignition Pilot Piping

All Series 8H / 8HE repair parts may be obtained through your local Burnham Wholesale distributor. Should

you require assistance in locating a Burnham distributor in your area, or have questions regarding the

availability of Burnham products or repair parts, please contact Burnham Customer Service at

888-791-3790 or Fax (717) 293-5803.

11

Page 12

12

Loading...

Loading...