Burnham 8B Series, 805B, 806B, 810B, 807B Installation, Operating And Servicing Instructions

...Page 1

SEIRESB8

RELIOBDERIF-SAG

DNAGNITAREPO,NOITALLATSNI

ROFSNOITCURTSNIECIVRES

,reliobnonoitamrofnignikeesnehW.rotcartnocgnitaehruoyllac,reliobotsriaperroecivresroF

.lebaLgnitaRnonwohssarebmuNlaireSdnarebmuNledoMrelioBedivorp

rebmuNledoMrelioBrebmuNlaireSrelioBetaDnoitallatsnI

____-_____8________6

rotcartnoCgnitaeH rebmuNenohP

sserddA

8141602R13-7/03

1

Price - $5.00

Page 2

IMPORTANT INFORMATION - PLEASE READ THIS PAGE CAREFULLY

NOTE: The equipment shall be installed in accordance with those installation regulations enforced in the area where the

installation is to be made. These regulations shall be carefully followed in all cases. Authorities having jurisdiction

shall be consulted before installations are made.

All wiring on boilers installed in the USA shall be made in accordance with the National Electrical Code and/or local

regulations.

All wiring on boilers installed in Canada shall be made in accordance with the Canadian Electrical Code and/or local

regulations.

This Series 8B Boiler has been approved by the Massachusetts Board of Plumbers and Gas Fitters:

Approval No. G1-0202-11A.

The Commonwealth of Massachusetts requires this product to be installed by a licensed Plumber or Gas Fitter.

The following terms are used throughout this manual to bring attention to the presence of hazards of various risk levels,

or to important information concerning product life.

REGNAD

noitautissuodrazahyltnenimminasetacidnI

,htaednitluserlliw,dediovatonfi,hcihw

ytreporplaitnatsbusroyrujnisuoires

.egamad

.egamad

GNINRAW

noitautissuodrazahyllaitnetopasetacidnI

,htaednitluserdluoc,dediovatonfi,hcihw

ytreporplaitnatsbusroyrujnisuoires

.egamad

NOITUAC

noitautissuodrazahyllaitnetopasetacidnI

nitluseryam,dediovatonfi,hcihw

ytreporproyrujnironimroetaredom

ECITON

nosnoitcurtsnilaicepssetacidnI

ecnanetniamro,noitarepo,noitallatsni

otdetalertontubtnatropmierahcihw

.sdrazahyrujnilanosrep

REGNAD

rosihtfoytinicivehtnisdiuqilrosropavelbammalfrehtoroenilosagesuroerotsTONOD

.ecnailpparehtoyna

lacirtceleynahcuotTONOD-ecnailppaynaetarepootyrtTONOD,sropavsagllemsuoyfI

yletomeramorfreilppussagehtllac,yletaidemmI.gnidliubehtnienohpynaesurohctiws

,elbaliavanusireilppusehtfirosnoitcurtsnis'reilppussagehtwolloF.enohpdetacol

.tnemtrapederifehttcatnoc

elbitsubmocrevoetercnoc,teprac,gniroolfelbitsubmocnoreliobsihtllatsniTONOD

rognipipcitsalpsahcuslairetamdetceffataehynarevoetercnocnoron,doowrogniroolf

.dleihsroolfelbitsubmocdellatsniylreporpatuohtiwgniriw

2

Page 3

GNINRAW

ehtwolloF.ylefasetarepootecivresdnaecnanetniamralugerseriuqerreliobsihT

.launamsihtnideniatnocsnoitcurtsni

ytreporpesuacnacecnanetniamroecivres,noitaretla,tnemtsujda,noitallatsnireporpmI

erofeblaunameritneehtdnatsrednudnadaeR.efilfossolroyrujnilanosrep,egamad

ebtsumecivresdnanoitallatsnI.ecivresro,noitarepopu-trats,noitallatsnignitpmetta

.ycnegaecivresrorellatsnidelliksdna,decneirepxe,elbaegdelwonkaybylnodemrofrep

.detnevylreporpebtsumreliobsihT

snoisivorperaerehtosdellatsniebtsumdnanoitarepoefasrofriahserfsdeenreliobsihT

.rianoitalitnevdnanoitsubmocetauqedarof

ehtfotratsehterofebdenaelcdnadetcepsniebtsummetsysgnitnevehtforoiretniehT

rofnosaesgnitaehehttuohguorhtyllacidoirepdetcepsniebdluohsdnanosaesgnitaeh

suoixonwollaotyrassecensimetsystnevdetcurtsbonudnanaelcA.snoitcurtsboyna

drawotetubirtnoclliwdnaylefastnevotefilfossolroyrujniesuacdluoctahtsemuf

.ycneiciffes'reliobehtgniniatniam

gnippatehtotnidellatsnisievlavfeilererusserpasselnuetelpmoctonsinoitallatsnI

roflaunamsihtfonoitceSmirTdnagnipiPretaWehteeS-reliobfopotehtnodetacol

.sliated

dnanwodtuhsotreliobehtesuacyamhcihwsecivedytefashtiwdeilppussireliobsihT

gnitaeheht,ytilibissopasisepipnezorfoteudegamadfI.ecivrestuohtiwtrats-erton

dnasdraugefasetairporpparo;rehtaewdlocnidednettanutfelebtondluohsmetsys

sireliobehtfiegamadtneverpotmetsysgnitaehehtnodellatsniebdluohssmrala

.evitareponi

sgnittifepipynawercsnutonoD.erusserphgihrednuretawtohyrevsniatnocreliobsihT

ehtgnirussaylevitisoptuohtiwreliobsihtfostnenopmocynatcennocsidottpmettaron

nehwtnempiuqednagnihtolcevitcetorpraewsyawlA.erusserponsahdnaloocsiretaw

ehtnoylertonoD.seirujnidlacstneverpotreliobsihtgnicivresropugnitrats,gnillatsni

.reliobehtfoerusserpdnaerutarepmetehtenimretedotseguagerutarepmetdnaerusserp

oD.gnitareposireliobehtnehwtohyrevemocebhcihwstnenopmocsniatnocreliobsihT

.loocerayehtsselnustnenopmocynahcuotton

,animulaniatnocleufehtdnanoitsubmocfostcudorp,noitcurtsnocfoslairetamrelioB

rocixotrehtoro/dnasedyhedla,sedixonegortin,edixonomnobrac,slatemyvaeh,acilis

ehtotnwonkerahcihwdnayrujnisuoiresrohtaedesuacnachcihwsecnatsbuslufmrah

esusyawlA.mrahevitcudorperrehtodnastcefedhtrib,recnacesuacotainrofilaCfoetats

ehtybraengnikrowrognicivresnehwtnempiuqednasrotaripser,gnihtolcytefasreporp

.ecnailppa

.htaedroyrujnilanosrepesuacnacredroreporpehtnisnoitcurtsnillawollofoteruliaF

slaunamsrerutcafunamtnenopmocnideniatnocesohtllagnidulcni,snoitcurtsnilladaeR

rogniniatniam,gnitarepo,pugnitrats,gnillatsnierofebreliobehthtiwdedivorperahcihw

.gnicivres

elbammalfrehtodnaenilosag,slairetamelbitsubmocmorfeerfdnaraelcaerareliobpeeK

.sdiuqilrosropav

.retawottcejbusneebsahhcihwlortnochtiwreliobetarepotonoD

.semitllataecalpniebtsumsdraugdnaserusolcne,setalprevocllA

ECITON

.launamsihtfokcabehtnodetnirpsihcihwfoypoca,ytnarrawdetimilasahreliobsihT

yltcerroceraslortnocllatahteesotrotcartnocgnillatsniehtfoytilibisnopserehtsitI

.etelpmocsinoitallatsniehtnehwylreporpgnitarepoeradnadellatsni

evahlevelaesevobateef000,2nahtretaergsedutitlatanoitallatsniroftliubsreliobASU

replevelaesevobateef000,1reptnecrep4etartupnisagecuderotdecifiroyllaicepsneeb

naidanaC.FxidneppAdna2.1.8noitceS,1.322ZISNA/45APFN,edoCsaGleuFlanoitaNeht

.lebalgnitarehtnodetacidnisignizisecifiro'sreliob

3

Page 4

Table of Contents

I. Pre-Installation ................................................ 6

II. Boiler Assembly ................................................ 8

III. Gas Control System Assembly ....................... 15

(Knockdown Boilers)

IV. Water Trim and Piping .................................... 27

V. Gas Piping ....................................................... 31

VI. Venting ............................................................33

VII. Electrical .......................................................... 36

VIII. System Start-up ............................................... 59

IX. Service ............................................................. 68

X. Repair Parts ..................................................... 75

4

Page 5

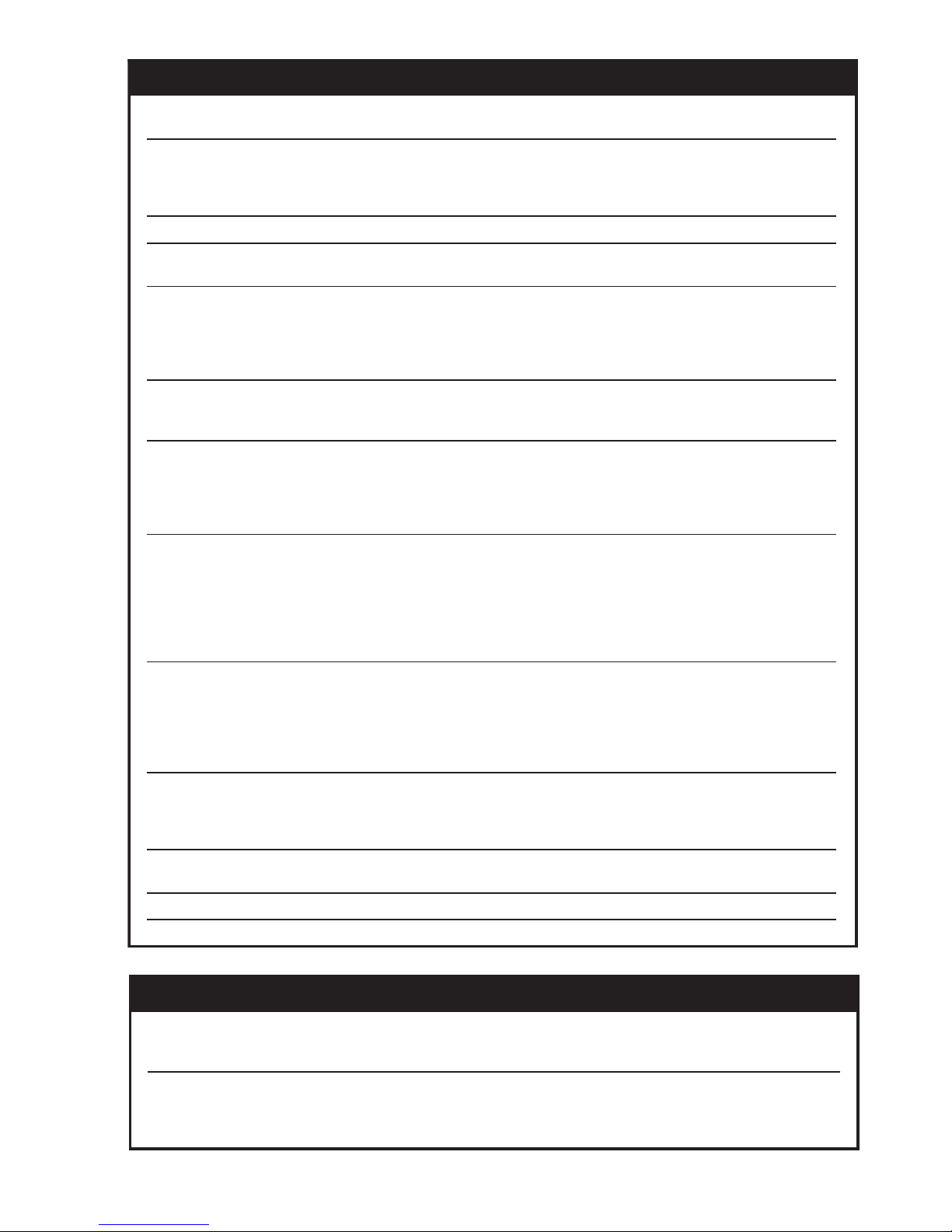

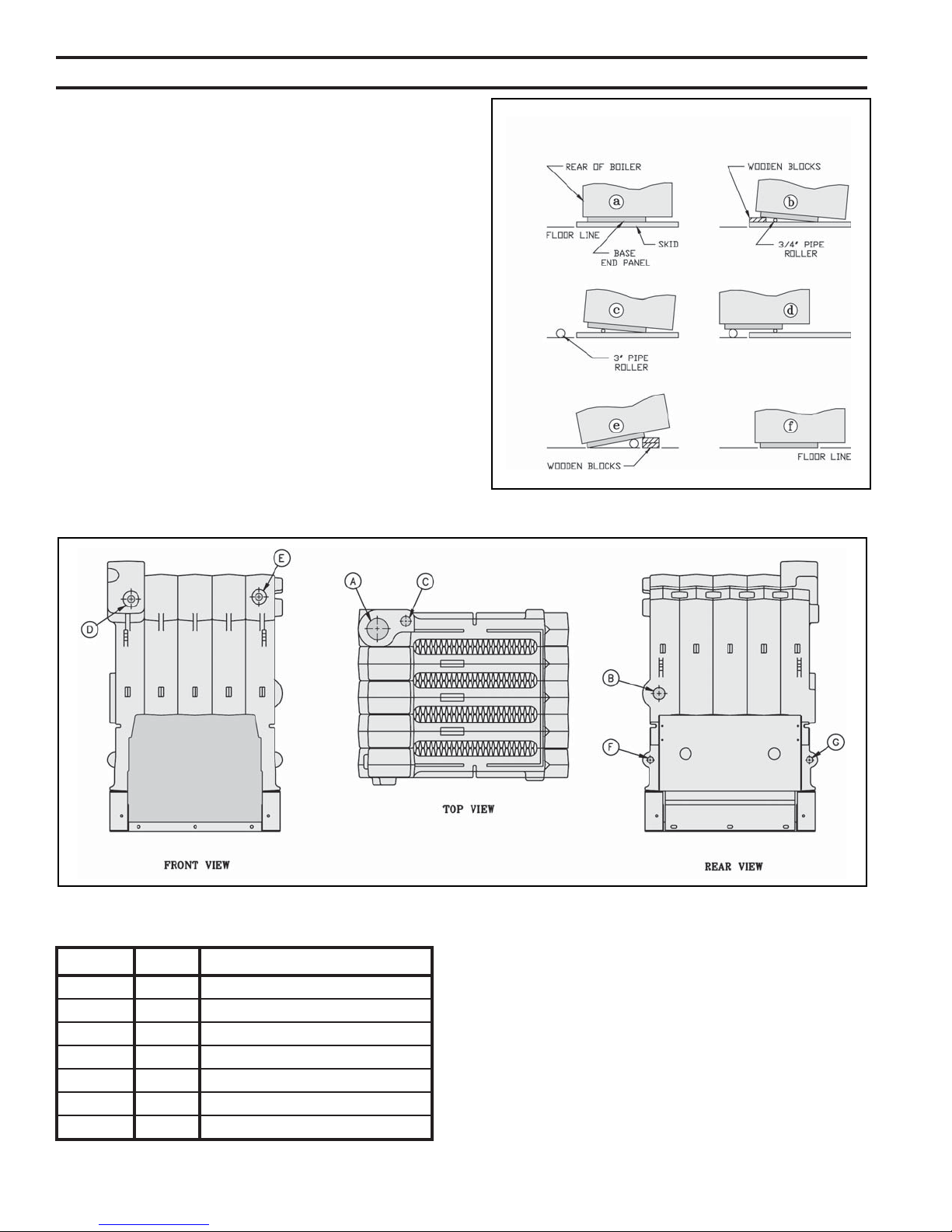

Table 1: Dimensional Data

Figure 1: Dimensional Data

relioB

ledoM

ABC

.oN

B50802017 61/31-4261/31-428/1-618/1-61.tf51x.aid"79.11096

B6084/3-328/7-118 61/31-724/3-528161.tf51x.aid"89.31077

B7082/1-724/3-319 61/31-824/3-528161.tf51x.aid"99.51578

B8084/1-138/5-519 61/31-0361/11-620261.tf51x.aid"99.71089

B908532/1-71012/1-3361/7-622251.tf51x.aid"019.910801

B0184/3-838/3-91012/1-3361/7-622251.tf51x.aid"019.120021

)1(

.)"4/1-73silenap

)2(

)3(

)4(

)sehcnI(snoisnemiD

DE

ASUadanaCASUadanaC

TPN1:ezisnoitcennocsaG

)ylnOretaW(isp05:erusserPgnikroWelbawollAmumixaM

.rellatsniybdeilppussenilneddihninwohssmetI

5

dednemmoceR

eziSyenmihC

)dnuoR(

retaW

tnetnoC

)snollaG(

.xorppA

gnippihS

thgieW

)BL(

pottekcajotroolf(thgiehreliobot"4/3-4sdda;gniroolfelbitsubmocnosnoitallatsnirofderiuqeresablaicepS

Page 6

I. Pre-Installation

GNINRAW

erofebsnoitcurtsnilladaerylluferaC

llawollofoteruliaF.reliobgnillatsni

esuacnacredroreporpnisnoitcurtsni

.htaedroyrujnilanosrep

A. Inspect shipment carefully for any signs of damage.

All equipment is carefully manufactured, inspected and

packed. Our responsibility ceases upon delivery of

boiler to carrier in good condition. Any claim for

damage or shortage in shipment must be filed

immediately against carrier by consignee. No claims

for variances or shortages will be allowed by Boiler

Manufacturer, unless presented within sixty (60) days

after receipt of equipment.

B. Installation must conform to the requirements of the

authority having jurisdiction. In the absence of such

requirements, installation must conform to the

National Fuel Gas Code, NFPA 54/ANSI Z223.1 and/

or CAN/CGA B149 Installation Codes. Where

required by the authority having jurisdiction, the

installation must conform to the Standard for Controls

and Safety Devices for Automatically Fired Boilers,

ANSI/ASME No. CSD-1.

C. Provide clearance between combustible material

and boiler jacket (following clearances are minimums):

1. USA, 805B-807B: listed for Alcove installation

a. Front: 18"

b. Top: 36"

c. Draft hood, rear, sides and flue connector: 6"

2. USA, 808B-810B: for installation in room which is

large in comparison with size of boiler.

a. Front: 18"

b. Top: 51½"

c. Draft hood, rear, sides, and flue connector: 6"

3. Canada, 805B-810B:

a. Top and front: 18" (45.7cm)

b. Flue, rear and sides: 6" (15.2cm)

D. Provide clearance for servicing and proper operation

(following clearances are recommended and may be

reduced to minimum clearances shown above):

1. Single boiler, 805B-807B, Front/Top: 24" (61cm)

2. Single boiler, 808B-810B, Front/Top: 48" (122cm)

3. Multiple/modular boiler, USA/Canada, Sides:

1" (2.5cm)

E. Install boiler on level floor as close to chimney as

possible. For basement installation provide a solid base

such as concrete or masonry construction if floor is not

level or if water may be encountered on floor around

boiler.

F. Protect gas ignition system components from water

(dripping, spraying, rain, etc.) during boiler operation

and service (circulator replacement, control

replacement, etc.).

GNINRAW

noitallatsnirofdeifitrecngisedsiecnailppA

roF.ylnogniroolfelbitsubmocnonno

ylnogniroolfelbitsubmocnonoitallatsni

elbaTnidetsilesablaicepsnodellatsninehw

.gnitepracnodellatsniebtontsumrelioB.2

sihcihwetercnocnodellatsnisireliobnehW

gnitlemottcejbussitahtlairetamarevo

laicepseht,).cte,gnibuttnaidarXEP,CVP(

tonsidapetercnocA.desuebtsumesab

.gniroolfelbitsubmoctcetorpottneiciffus

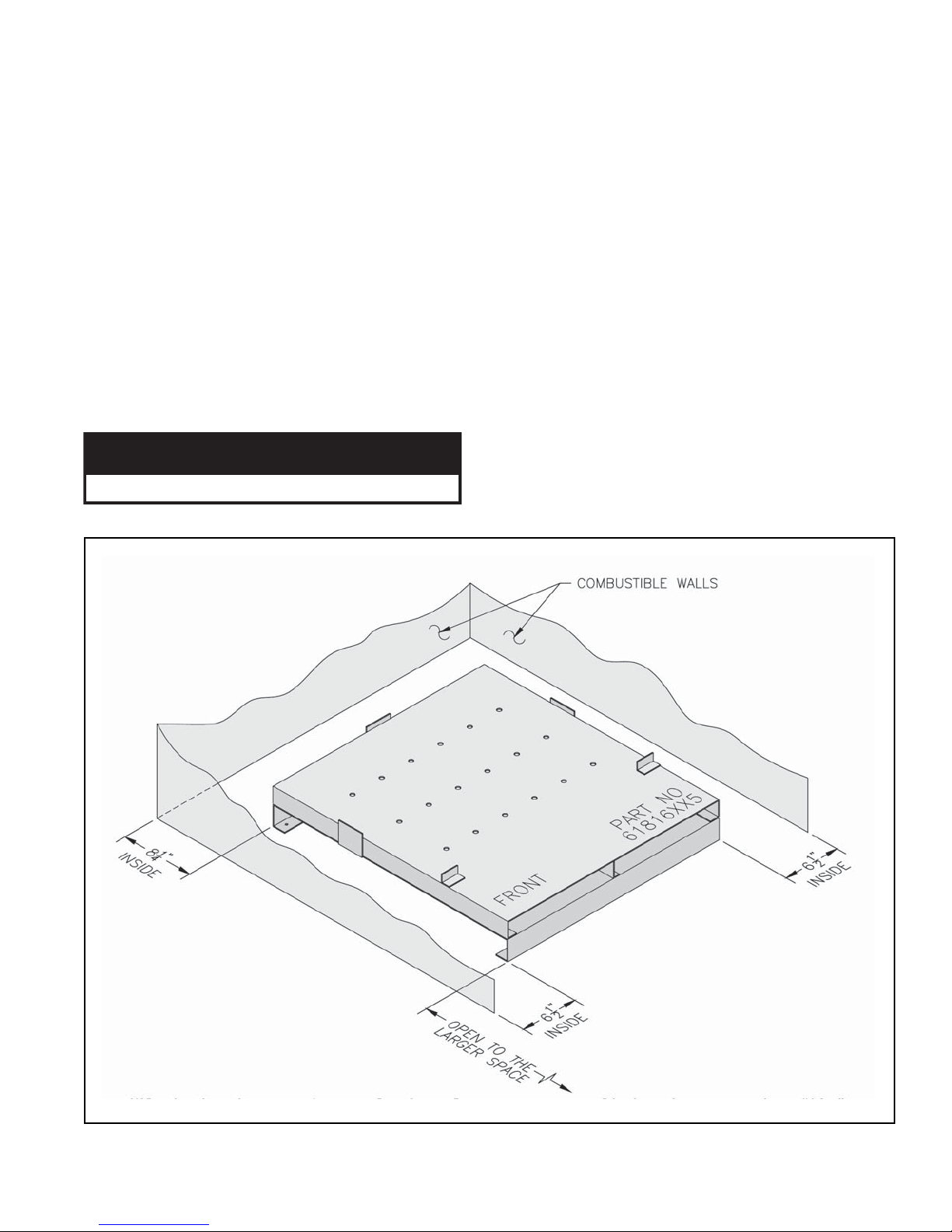

Table 2: Special Base Required for Installation on

Combustible Flooring

.oNledoMrelioBrebmuNtraPesaBlaicepS

B50855061816

B60856061816

B70857061816

B80858061816

B90859061816

B01850161816

G. Provide combustion and ventilation air in

accordance with applicable provisions of local building

codes, or the National Fuel Gas Code, NFPA 54/ANSI

Z223.1, Section 5.3, Air for Combustion and

Ventilation; or CAN/CGA B149 Installation Codes,

Part 5, Venting Systems and Air Supply for

Appliances.

GNINRAW

rianoitalitnevdnanoitsubmocetauqedA

reporperussaotdedivorpebtsum

.noitsubmoc

The following guideline is based on the National Fuel

Gas Code, NFPA 54/ANSI Z223.1.

1. Determine volume of space (boiler room). Rooms

communicating directly with space (through

permanent openings not furnished with doors) are

considered part of space.

Volume [ft³] = Length [ft] x Width [ft] x Height [ft]

2. Determine Total Input of all appliances in space.

Round result to nearest 1,000 Btu per hour (Btuh).

3. Determine type of space. Divide Volume by Total

Input.

6

Page 7

a. If result is greater than or equal to 50 ft³ per 1,000

Btuh, space is considered an unconfined space.

b. If result is less than 50 ft³ per 1,000 Btuh, space is

considered a confined space.

4. Determine building type. A building of unusually

tight construction has the following characteristics:

a. Walls and ceiling exposed to outside atmosphere

have a continuous water vapor retarder with a

rating of 1 perm or less with openings gasketed

and sealed, and

b. Weather-stripping has been added on openable

windows and doors, and

c. Caulking or sealants applied in joints around

window and door frames, between sole plates

and floors, between wall-ceiling joints, between

wall panels, at plumbing and electrical

penetrations, and at other openings.

5. For boiler located in an unconfined space in a

building of other than unusually tight construction,

adequate combustion and ventilation air is normally

provided by fresh air infiltration through cracks

around windows and doors.

6. For boiler located in an unconfined space in a

building of unusually tight construction or in a

confined space, provide outdoor air through

permanent opening(s) which communicate directly

or by duct with the outdoors or spaces (crawl or

attic) freely communicating with the outdoors.

Minimum dimension of air opening(s) is 3" (7.6cm).

a. Two permanent openings: Locate one opening

within 12 " (30.5cm) of top of space. Locate

remaining opening within 12" (30.5cm) of bottom

of space. Size each opening per following:

i. Minimum free area of 1 square inch per 3,000

Btu per hour input of all equipment in space.

ii. Free area shall not be less than the sum of

the areas of all vent connectors in the

confined space.

Alternate method for boiler located within confined

space. Use indoor air if two permanent openings

communicate directly with additional space(s) of

sufficient volume such that combined volume of all

spaces meet criteria for unconfined space. Size each

opening for minimum free area of 1 square inch per

1,000 Btu per hour input of all equipment in

spaces, but not less than 100 square inches.

7. Ventilation Duct Louvers and Grilles. Equip

outside openings with louvers to prevent entrance

of rain and snow, and screens to prevent entrance of

insects and rodents. Louvers and grilles must be

fixed in open position or interlocked with

equipment to open automatically before burner

operation. Screens must not be smaller than ¼ inch

mesh.

Consider the blocking effect of louvers, grilles and

screens when calculating the opening size to

provide the required free area. If free area of louver

or grille is not known, assume wood louvers have

20-25 percent free area and metal louvers and

grilles have 60-75 percent free area.

8. For Specially Engineered Installations. The above

requirements shall be permitted to be waived where

special engineering, consistent with good

engineering practice and approved by the authority

having jurisdiction, provides an adequate supply of

air for combustion, ventilation, and dilution of flue

gases.

i. Direct communication with outdoors.

Minimum free area of each opening must be

1 square inch per 4,000 Btu per hour input

of all equipment in space.

ii. Vertical ducts. Minimum free area of each

opening must be 1 square inch per 4,000

Btu per hour input of all equipment in

space. Duct cross-sectional area shall be

same as opening free area.

iii. Horizontal ducts. Minimum free area of

each opening must be 1 square inch per

2,000 Btu per hour input of all equipment

in space. Duct cross-sectional area shall be

same as opening free area.

b. One permanent opening shall be permitted where

the boiler has clearances of at least 1" (2.5cm)

from the sides and rear and 6" (15.2cm) from the

front. Locate the opening within 12 " (30.5cm) of

top of space. Size opening per following:

GNINRAW

rehtoroenilosagerehwreliobllatsnitonoD

fosecruosro,sdiuqilrosropavelbammalf

,srenaelc,sehcaelb.e.i(snobracordyh

cirbaf,srevomertniap,syarps,slacimehc

.derotsrodesuera).cte,srenetfos

ECITON

ehtotdragerhtiwreliobehtfognizis-siM

evissecxenitluserlliwdaolmetsysgnitaeh

tnenopmocdetareleccadnagnilcycreliob

tnarrawTONSEODmahnruB.eruliaf

reliobdezis-simybdesuacseruliaf

otreliobehtezisrevoTONOD.snoitacilppa

yltaergsreliobelpitlum/raludoM.metsyseht

.gnizisrevoreliobfodoohilekilehtecuder

7

Page 8

II. Boiler Assembly

A. Remove Crate (Semi-Pak and Packaged Only)

1. Remove all fasteners at crate skid.

2. Lift outside container and remove with all other

inside protective spacers and bracing.

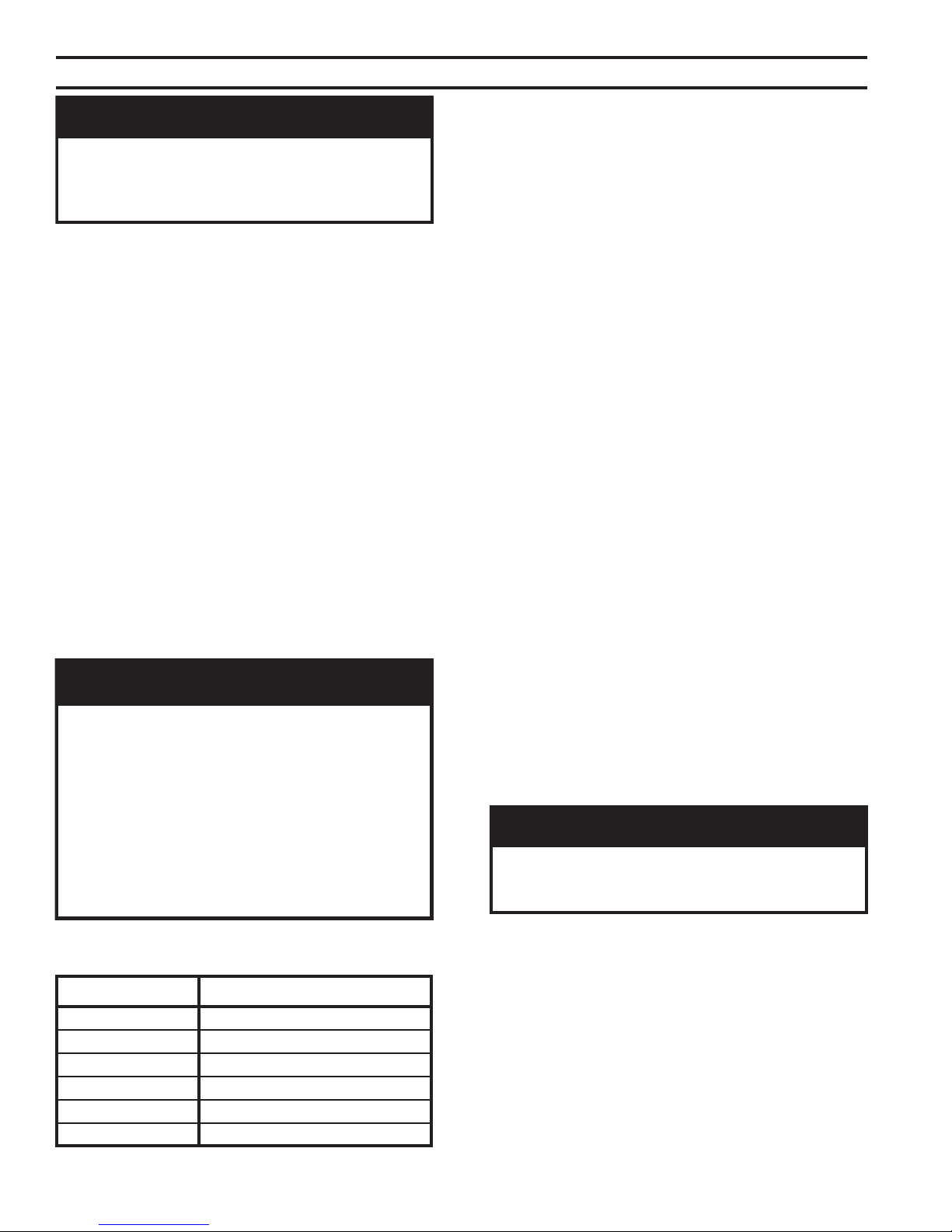

B. Remove boiler from skid. See Figure 2. Exercise care

to avoid dropping boiler.

1. Place boiler in approximate location. Refer to

Section I: Pre-Installation. Remove base hold down

bolts.

2. Using pry bar under rear corner of Base End Panel,

raise boiler and install 1½" wood blocks under rear

corners. Install ¾" pipe roller between Base and

skid.

3. Remove 1½" wood blocks. Place 3" pipe roller on

floor behind skid.

4. Roll boiler off skid. Move skid out of way.

Figure 2: Skid Removal

Table 3: Purpose of Tappings

gnippaTeziSesopruP

A"2ylppuS

B"2nruteR

C"¾evlaVfeileR

D"¾timiL

E"¾timiLyrailixuA

F"¾tuohsaW

G"¾niarD

Figure 3: Tapping Locations

8

Page 9

5. Roll boiler until 3" roller is located as shown. Use

pry bar to install wood blocks under front corners of

base. Remove 3" roller.

6. Lift boiler with pry bar. Remove wood blocks.

Lower boiler.

C. For Packaged Boiler only, proceed to Paragraph E.

D. Test Section Assembly for leaks before connecting to

system and installing controls, trim and jacket. Refer

to Figure 3 and Table 3.

1. Plug Tappings C & E (¾ NPT) and Return Tapping

B (2 NPT).

2. Insert ¾" NPT x ¼" NPT bushing in Tapping D.

Install pressure gauge capable of indicating 50 psi.

3. Insert 2" NPT x ¾" NPT bushing in Supply

Tapping A. Install purge valve with a hose that

runs to a drain.

4. Connect fill valve and piping to Drain Tapping G.

GNINRAW

.reliobtsetkaelotriaesutonoD

5. Fill boiler completely with water by venting air

through purge valve. Close purge valve and apply

water pressure of at least 10 psi but less than 50 psi

gauge pressure.

6. Examine boiler for leaks or damage due to

shipment or handling.

7. Remove plugs from Return Tapping B, Tapping C,

and Tapping E (if second limit or operating control

is used). Also remove fill valve and piping, purge

valve and piping, and pressure gauge.

E. Install special base if installation is on combustible

flooring. See Figure 4. Floor shield adds 4¾" to boiler

height.

1. Place special base on combustible floor with surface

marked "FRONT" in upward position.

2. Locate special base with spacing to combustible

materials as shown in Figure 4.

3. Place boiler on special base. Boiler must rest inside

locating brackets. Boiler jacket panels will

overhang special base.

4. Do not enclose boiler (including special base) on all

four sides. Models 805B - 807B may be enclosed

Figure 4: Installation of Special Base for Combustible Flooring

9

Page 10

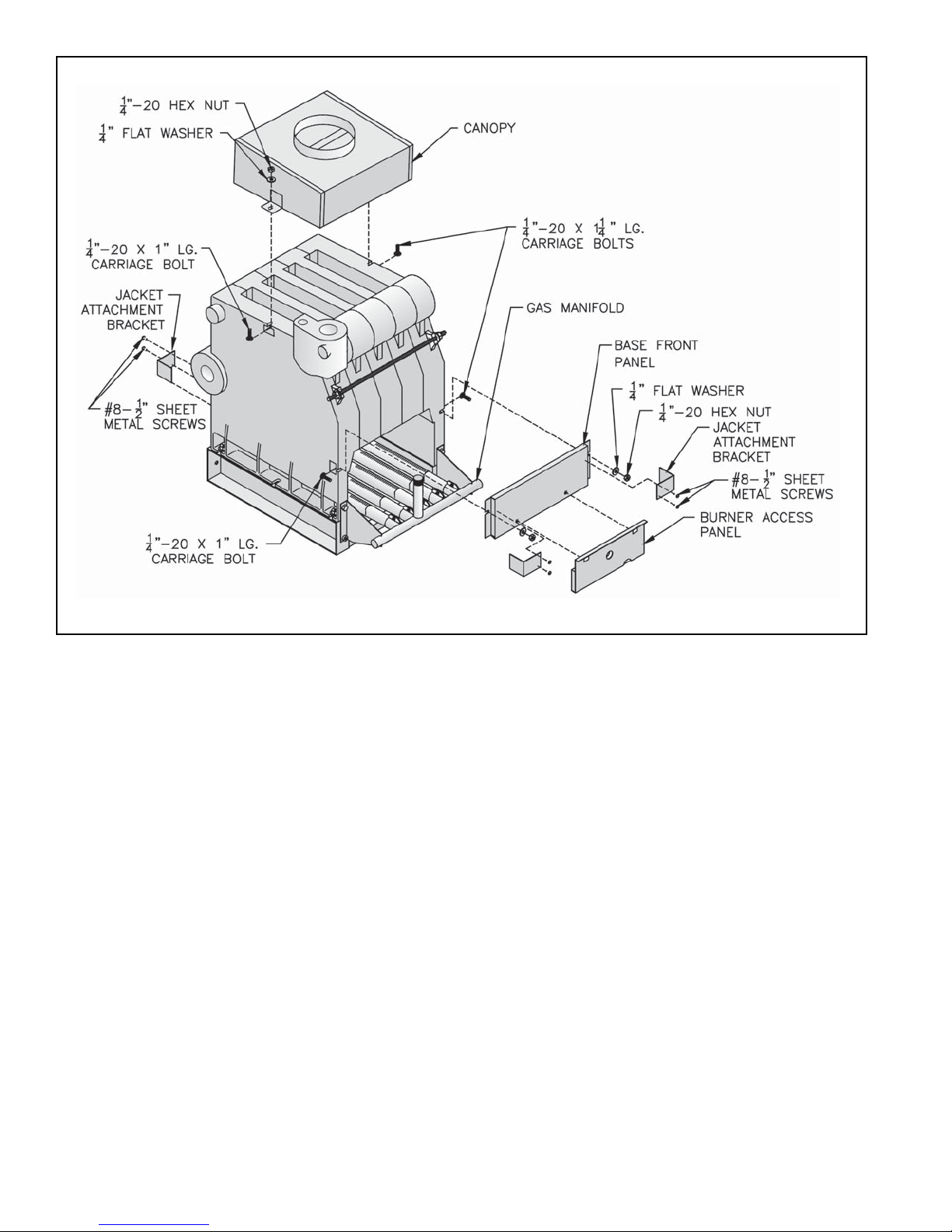

Figure 5: General Assembly (Knockdown Boilers)

on three sides (alcove) while maintaining

clearances shown in Figure 4.

F. Move boiler to permanent location by sliding or

walking. DO NOT DROP.

For Packaged Boiler proceed to Section IV: Trim and

Piping.

G. Install Canopy on section assembly. See Figure 5.

Canopy and hardware are located in Combination

Boiler Parts and Control Carton.

1. Position Canopy on top of Section Assembly.

Locate between end sections and sealing ledge on

front and back of each section.

2. Fasten each end with ¼" - 20 x 1" carriage bolts,

washers and nuts.

3. Seal between Canopy and Section Assembly with

furnace cement.

H. Inspect joints between sections. They were factory

sealed. If any openings resulted during shipment or

handling, reseal with furnace cement. Confirm tie rods

are only hand tight to allow for thermal expansion.

I. Install Base Front Panel. See Figure 5. Panel and

hardware located in Combination Boiler Parts and

Control Carton.

1. Attach Base Front Panel to Section Assembly using

¼" - 20 x 1¼" carriage bolts, washers and nuts.

2. Seal between top of Base Front Panel and Section

Assembly with furnace cement (shipped in

Combination Boiler Parts and Control Carton).

3. Seal between top of Base Rear Panel and Section

Assembly with furnace cement.

J. Install Pilot/Main Burner Assembly. See Figure 7.

Assembly is located in Combination Boiler Parts and

Control Carton. Verify assembly is properly located on

support bracket in Base Rear Panel, seated on Main

Burner Orifice, and secured with hitch pin clip.

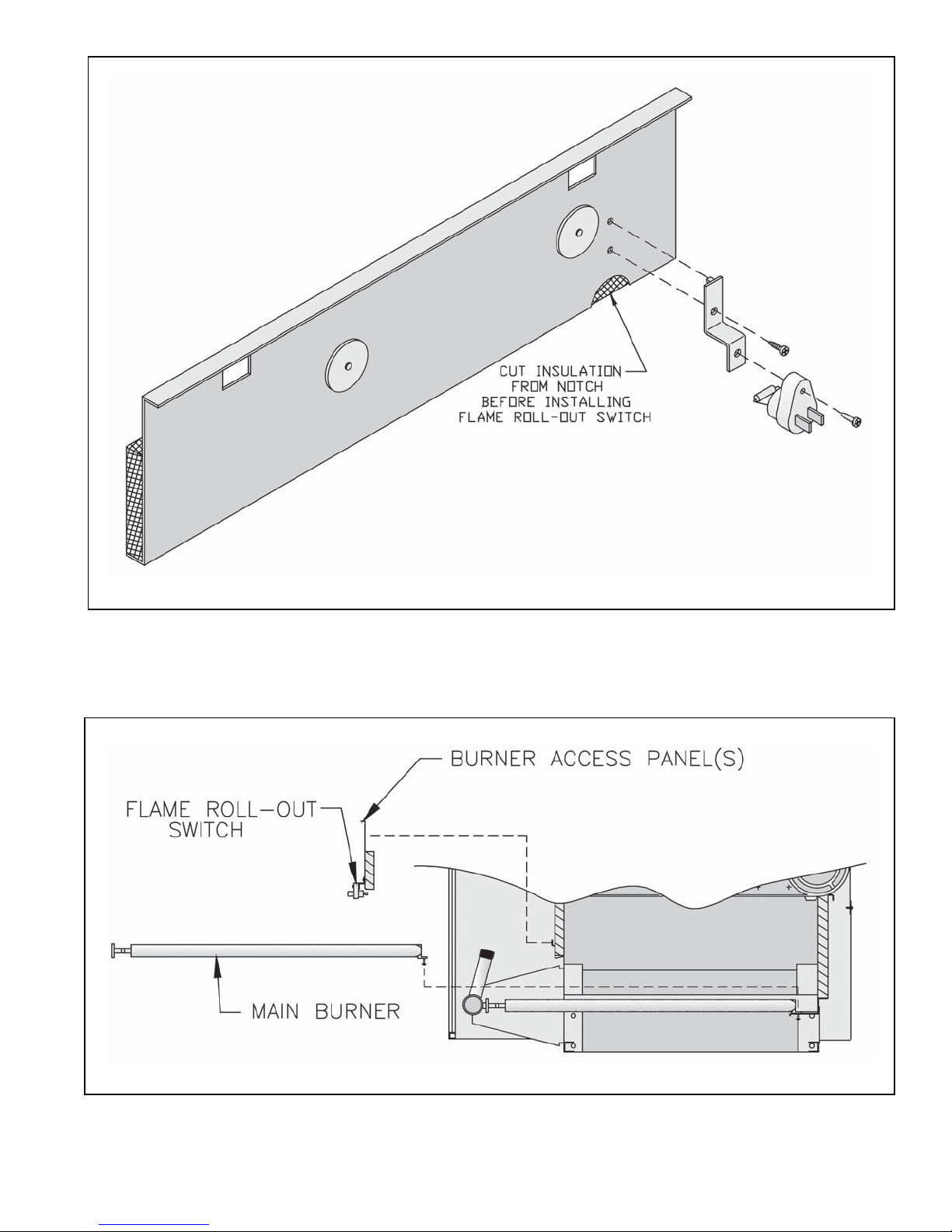

K. Attach Flame Roll-out Switch to Burner Access

Panel. See Figure 6. Flame Roll-out Switch and

hardware are located in Combination Boiler Parts and

Control Carton. Flame Roll-out Switch is a single use

device - do not test with heat - switch cannot be reset.

10

Page 11

Figure 6: Flame Roll-out Switch Installation

Figure 7: Burner/Burner Access Panel Installation

11

Page 12

1. Cut insulation from semicircular notch at right end of

the burner access panel. Models 808B - 810B have

two (2) burner access panels. Remove insulation

from notch of right side burner access panel only.

2. Attach Flame Roll-out Switch Mounting Bracket to

burner access panel with (1) #8 x ½" lg. sheet metal

screw.

3. Attach Flame Roll-out Switch to mounting bracket

with (1) #8 x ¾" lg. sheet metal screw.

L. Install Burner Access Panel(s). Locate Burner

Access Panel(s) in Combination Boiler Parts and

Control Carton. Engage Burner Access Panel holes

with projections on Base Front Panel. See Figure 6.

M. Install Immersion Well(s).

1. Remove Immersion Well(s) from Combination

Boiler Parts and Control Carton..

2. Insert Immersion Well in Tapping D. See Figure 3.

3. If second limit or operating control is used, insert

immersion well in Tapping E. If vertical gas

piping is to be installed inside of boiler jacket, it is

recommended that second limit be installed in

system piping.

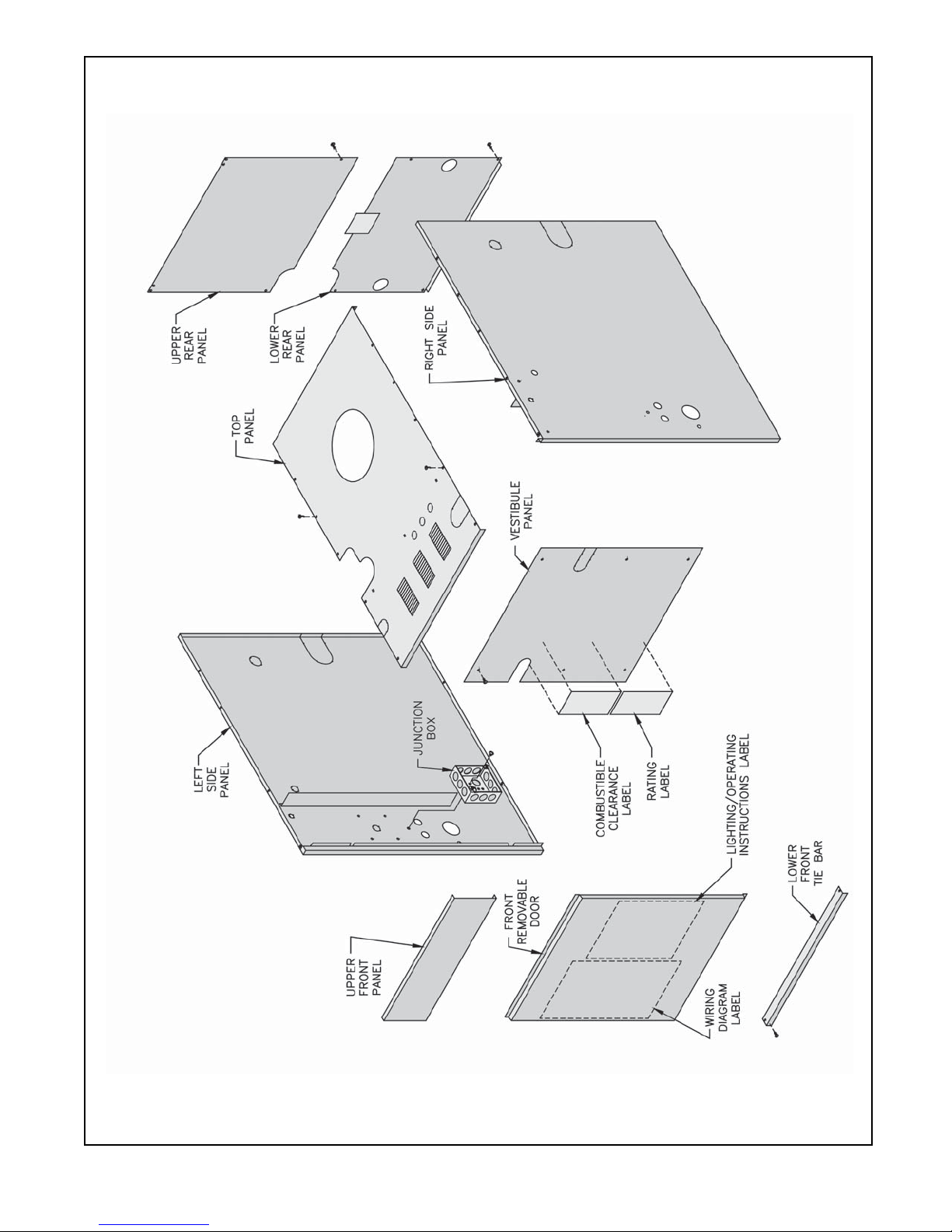

7. Attach Lower Front Tie Bar to Left Side and Right

Side Panels.

8. Engage Upper Front Panel in slots on Left Side and

Right Side Panels. Place Top Panel in position.

Attach Top Panel to Left Side, Right Side and

Upper Rear Panels.

9. Tighten all jacket screws.

10. Affix Lighting/Operating Instructions Label and

Wiring Diagram Label to inside of Front

Removable Door. Labels are located in

Combination Boiler Parts and Control Carton.

O. Install Junction Box. See Figure 8. Attach junction

box to inside of Left Side Panel with ¼" - 20 x ¼" lg.

machine screw (located in Combination Boiler Parts

and Control Carton).

P. Install Limit Control. Locate limit in Combination

Boiler Parts and Control Carton. Insert limit probe into

left immersion well as far as possible. Tighten set

screw.

Q. Install Auxiliary Limit or operating control (if used).

Insert control probe into right immersion well as far as

possible. Tighten set screw.

N. Install Jacket. See Figure 8.

1. Locate four (4) Jacket Attachment Brackets in

Combination Boiler Parts and Control Carton.

Attach to Front Base Panel and Rear Base Panels

with #8 sheet metal screws. See Figure 5.

2. Hang Left Side Panel and Right Side Panel onto

Jacket Attachment Brackets.

3. Attach Lower Rear Panel to Left and Right Side

Panels. Do not tighten sheet metal screws.

4. Attach Upper Rear Panel to Lower Rear Panel. Do

not install three (3) upper screws.

5. Remove Rating Label and Combustible Clearance

Label from Combination Boiler Parts and Control

Carton. Attach to Vestibule Panel in locations

shown.

6. Attach Vestibule Panel to Left Side and Right Side

Panels.

R. Install Gas Control Assembly. Refer to Section III,

Gas Control System Assembly (Knockdown Boilers).

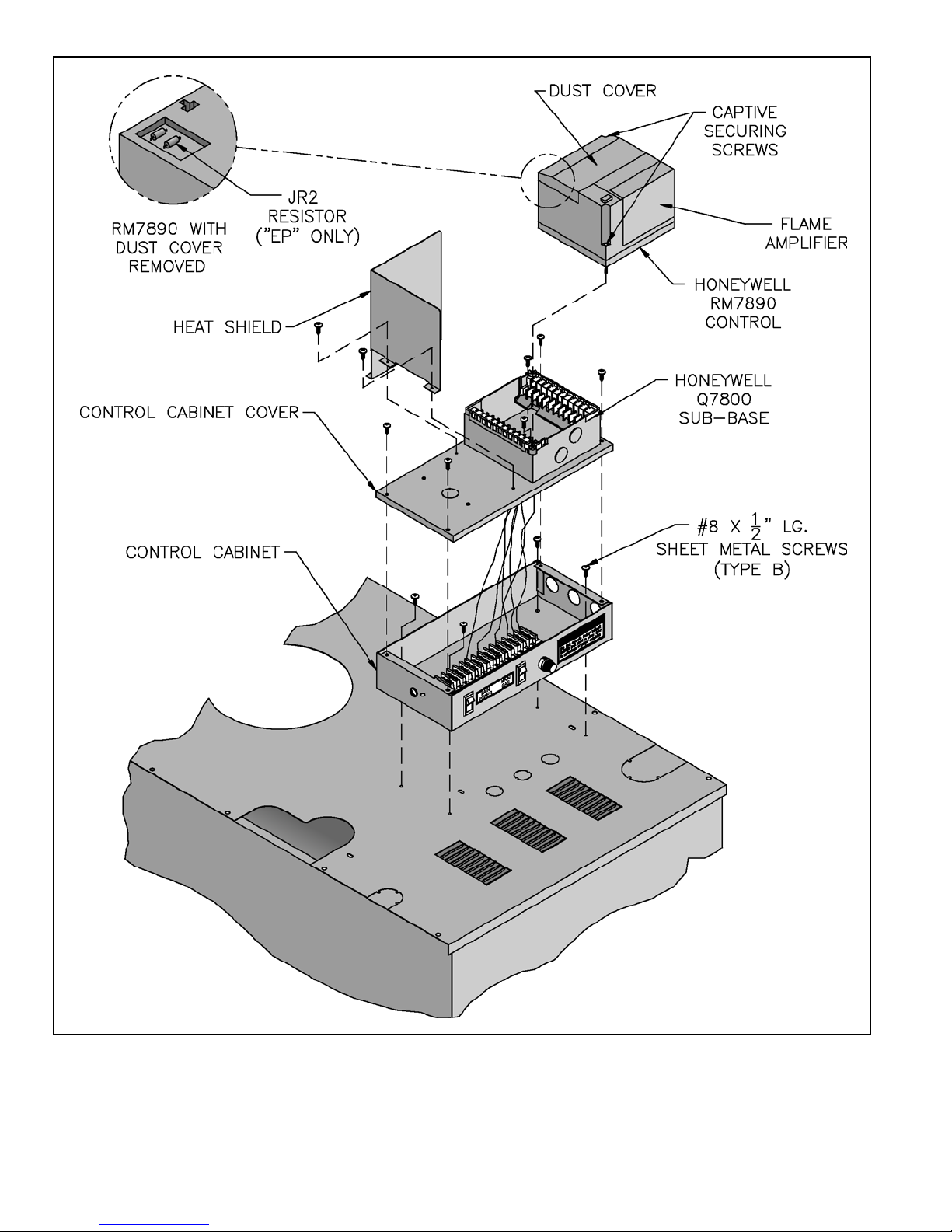

S. EP and OP System: See Figure 9.

1. Install pre-wired EP/OP Control Cabinet Assembly

to right front corner of jacket top panel.

2. Install Honeywell RM7890 Control (located in

RM7890 Control Carton).

3. EP Only: Remove RM7890's Dust Cover. With a

pair of side cutters, carefully snip both wire leads to

the brown resistor labelled "JR2" and discard it.

Replace Dust Cover.

4. Install Honeywell R7847 Flame Amplifier.

5. Install heat shield.

12

Page 13

Figure 8: Jacket Assembly

13

Page 14

Figure 9: EP/OP Control Installation

14

Page 15

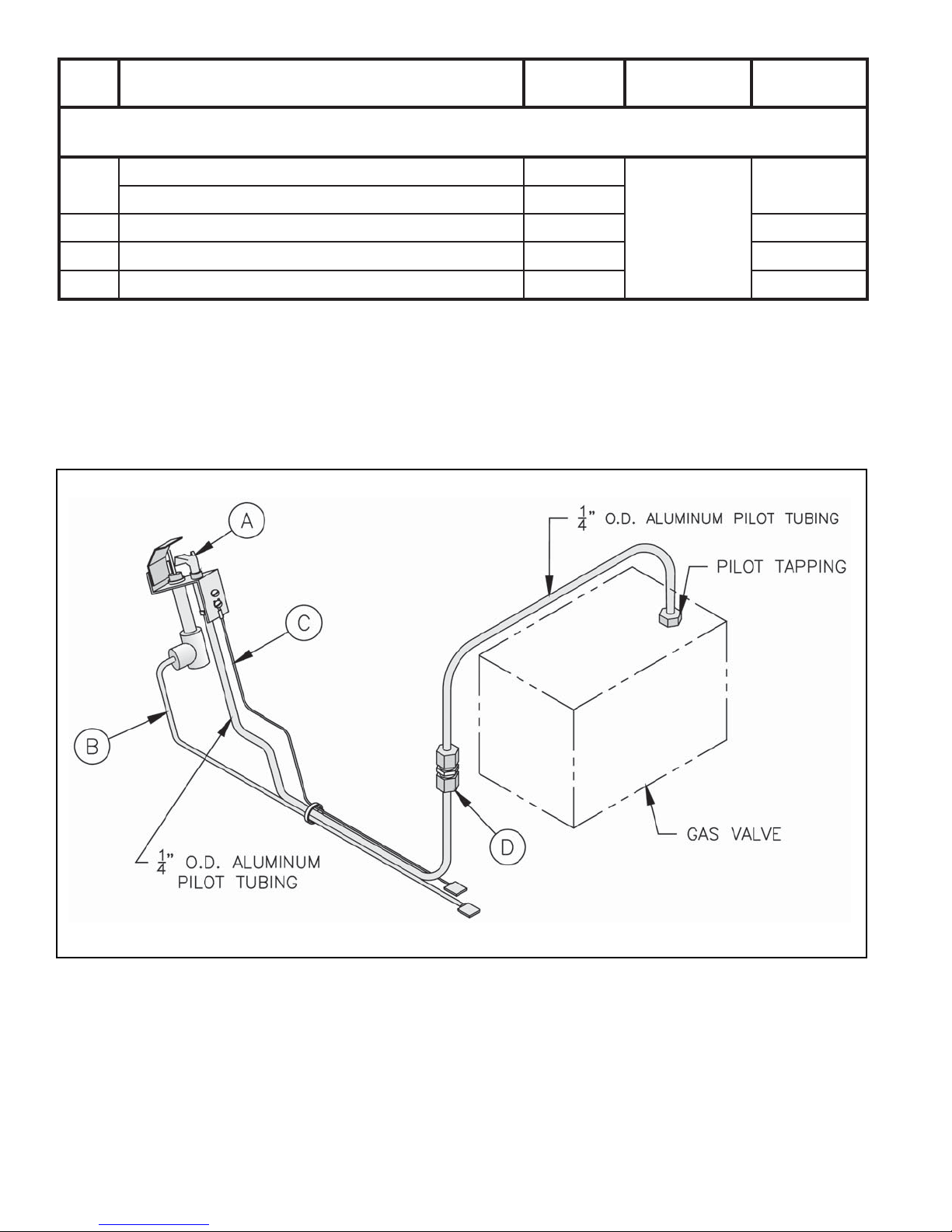

III. Gas Control System Assembly (Knockdown Boilers)

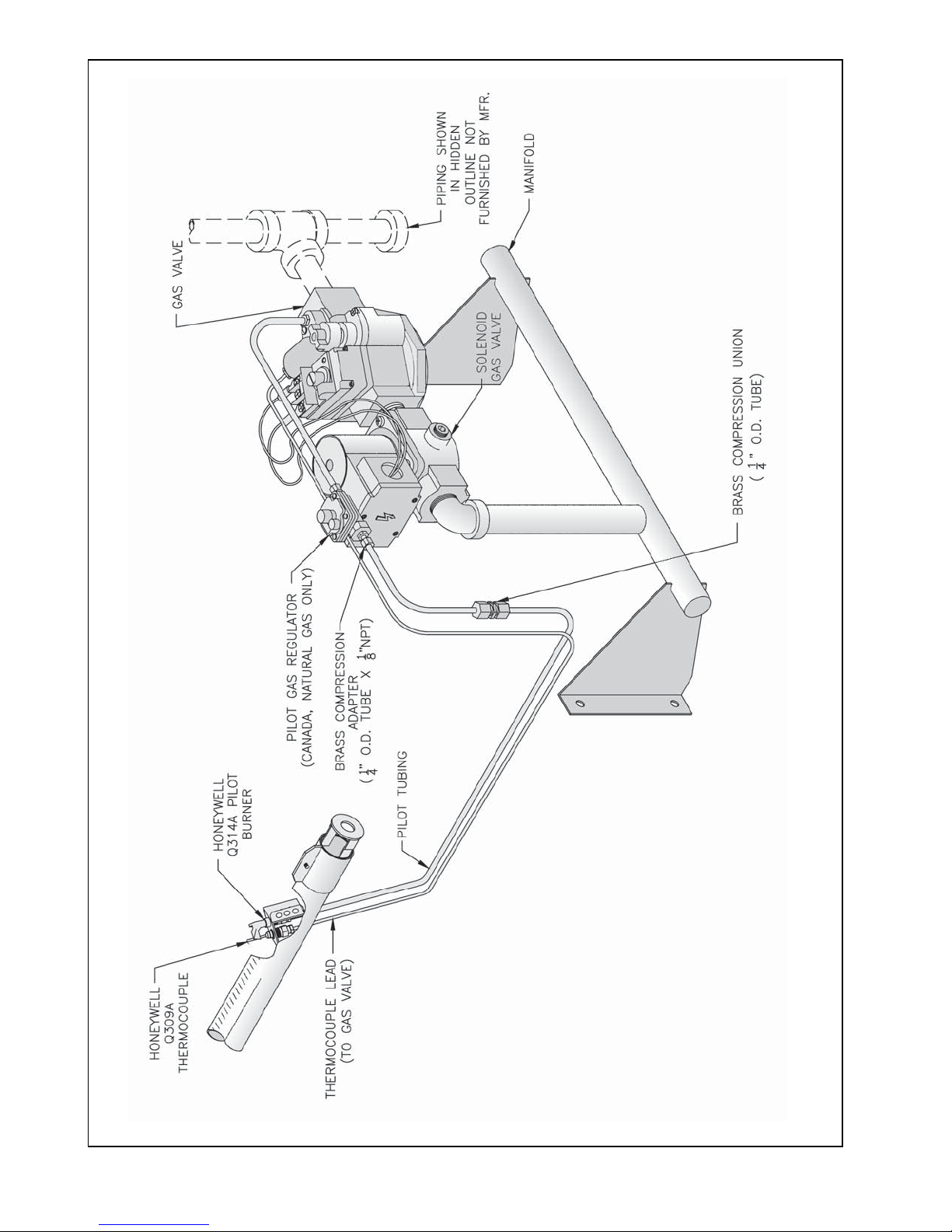

A. 24V Standing Pilot Control System

Install Gas Control System. All components are

located in Combination Boiler Parts and Control Carton.

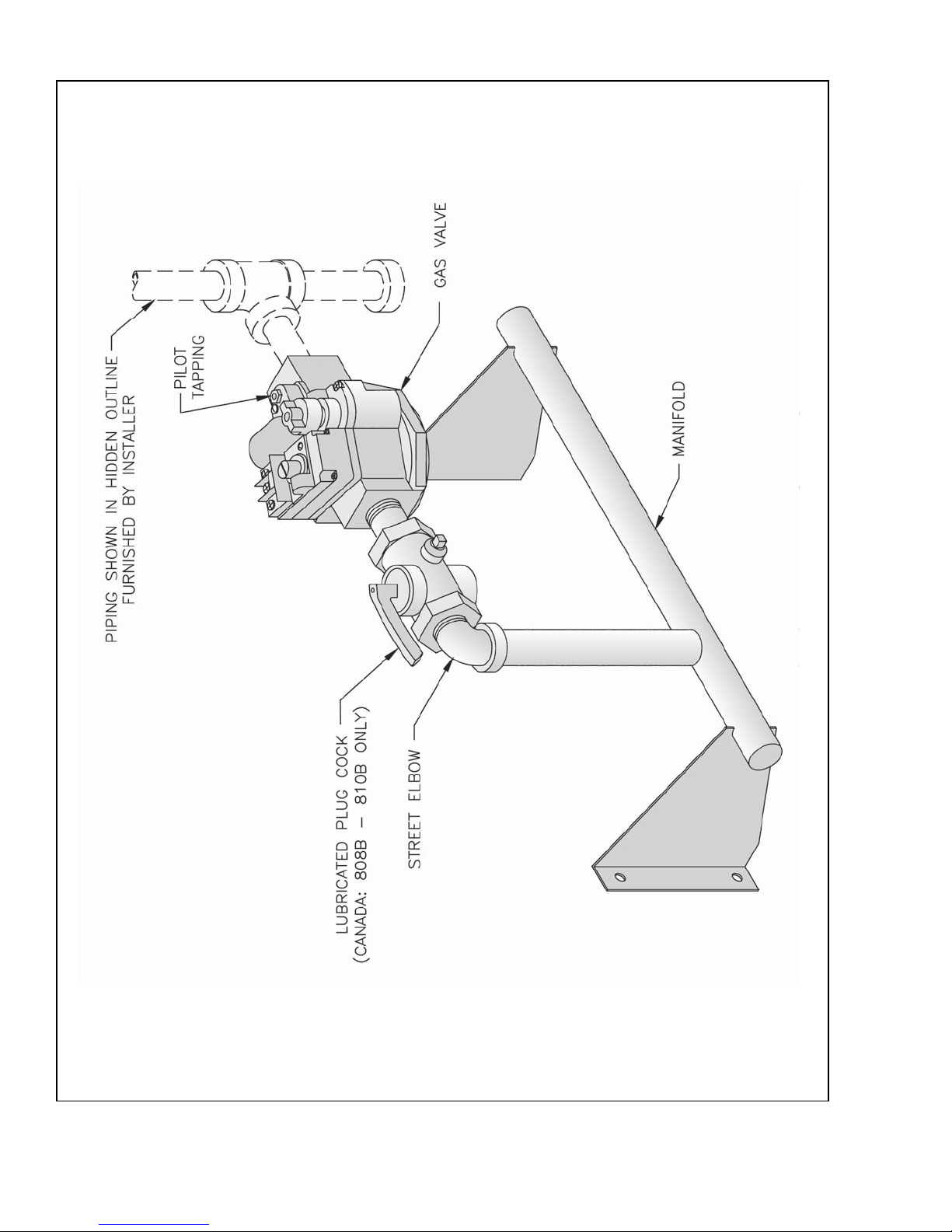

1. Install Gas Control Assembly on Manifold. See

Figure 10. Use thread (joint) compound (pipe dope)

resistant to action of liquefied petroleum gas.

2. Install pilot burner piping and controls. See Figure

10.

3. Connect Thermocouple Lead to Gas Valve.

4. Mount Transformer (continuous circulation) or

Control Center (intermittent circulation) to Junction

Box.

a. Canada only - loop 4" nylon cable tie between

junction box and transformer/control center.

b. Attach transformer/control center to junction

box.

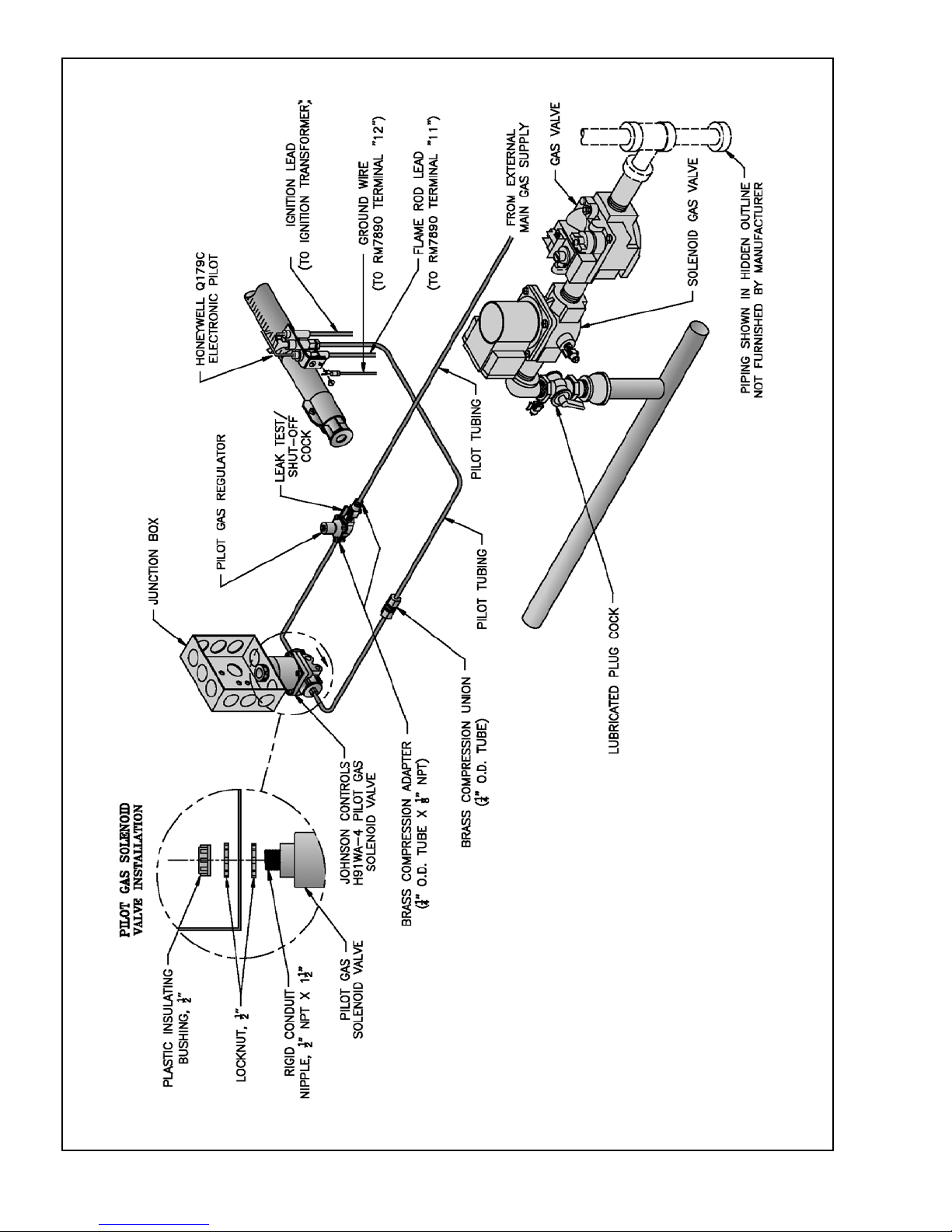

B. EI (Intermittent Ignition)

Install Gas Control System. All components are

located in Combination Boiler Parts and Control Carton.

1. Install Gas Control Assembly on Manifold. See

Figure 11. Use thread (joint) compound (pipe dope)

resistant to action of liquefied petroleum gas.

2. Install pilot burner piping and controls.

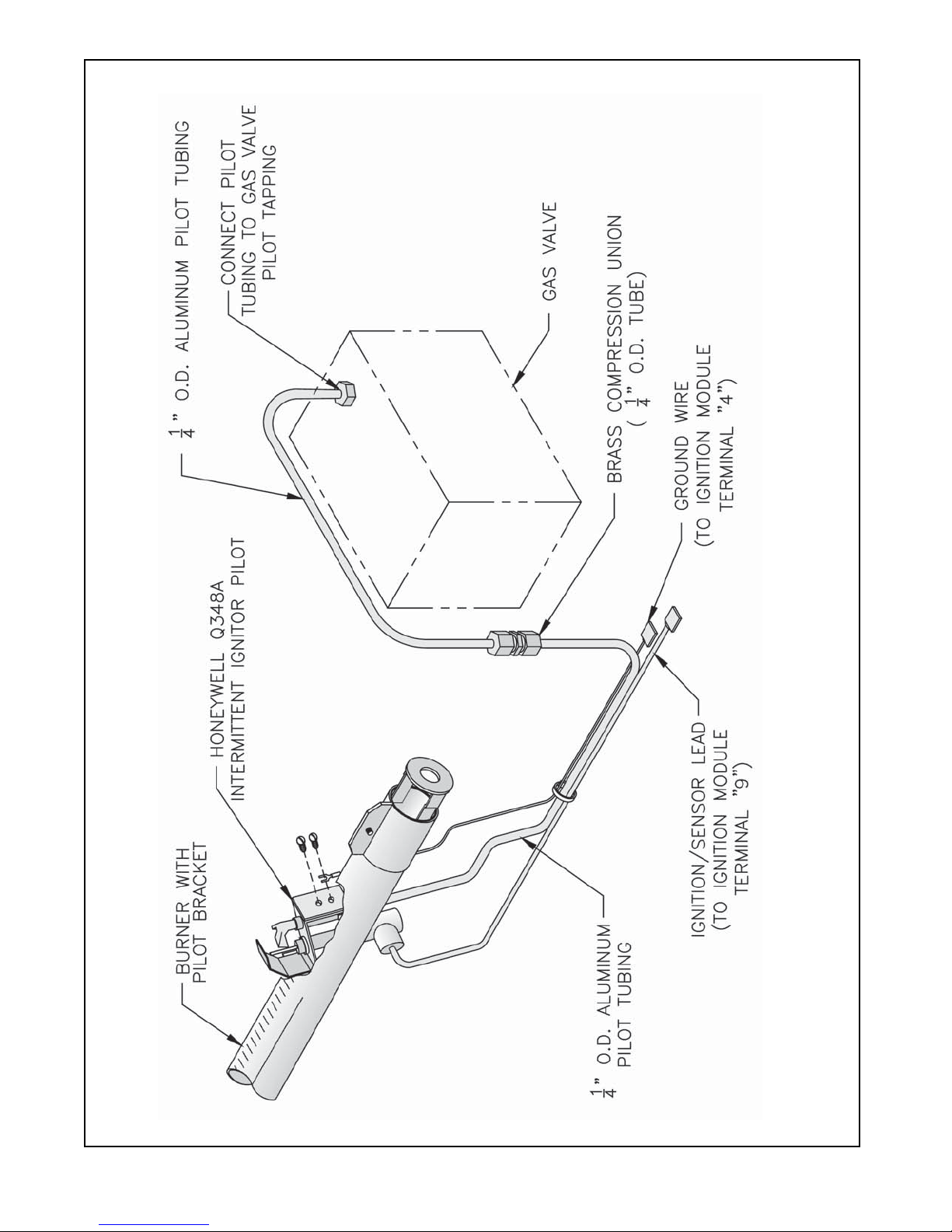

a. Honeywell EI

i. USA - See Figure 12.

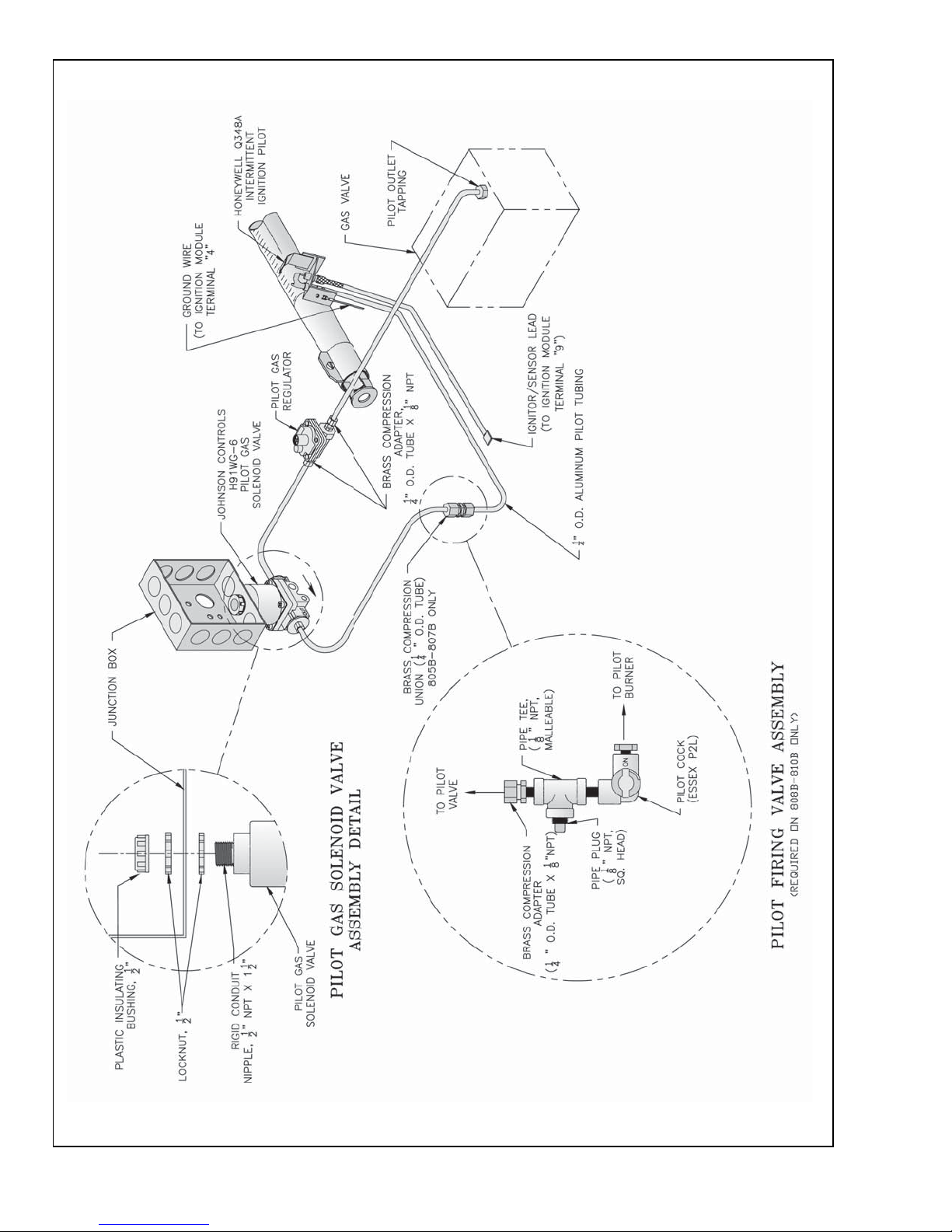

ii. Canada - See Figure 13.

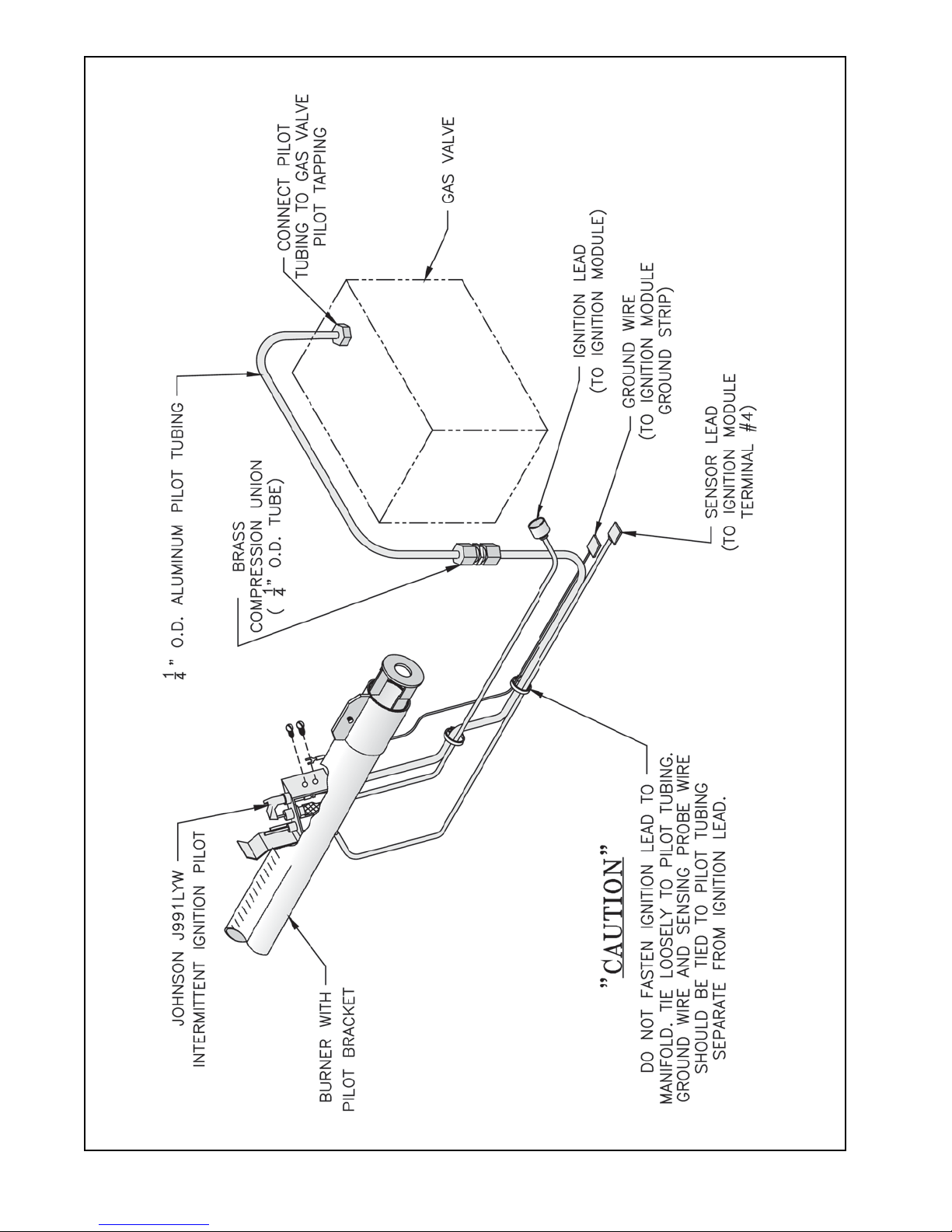

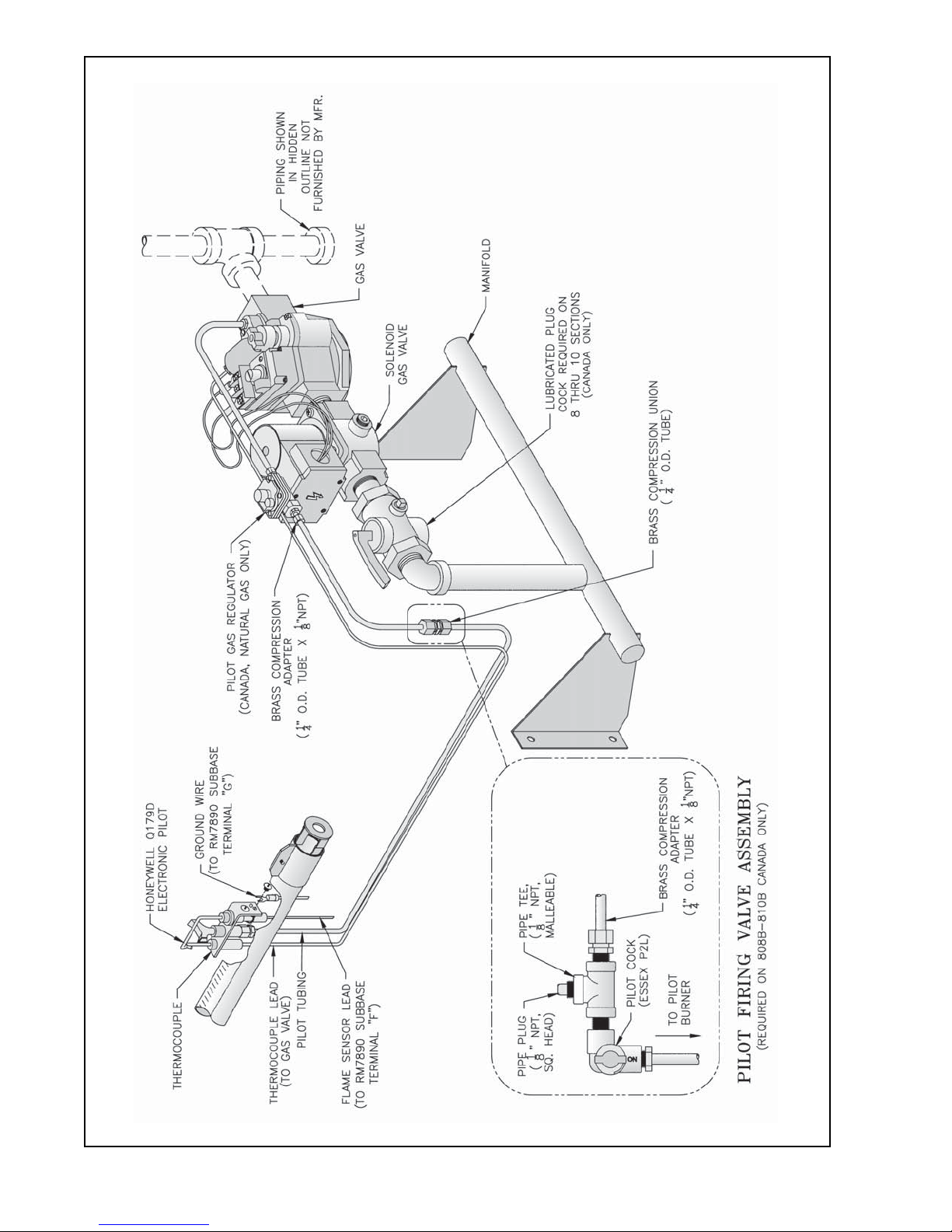

b. Johnson EI

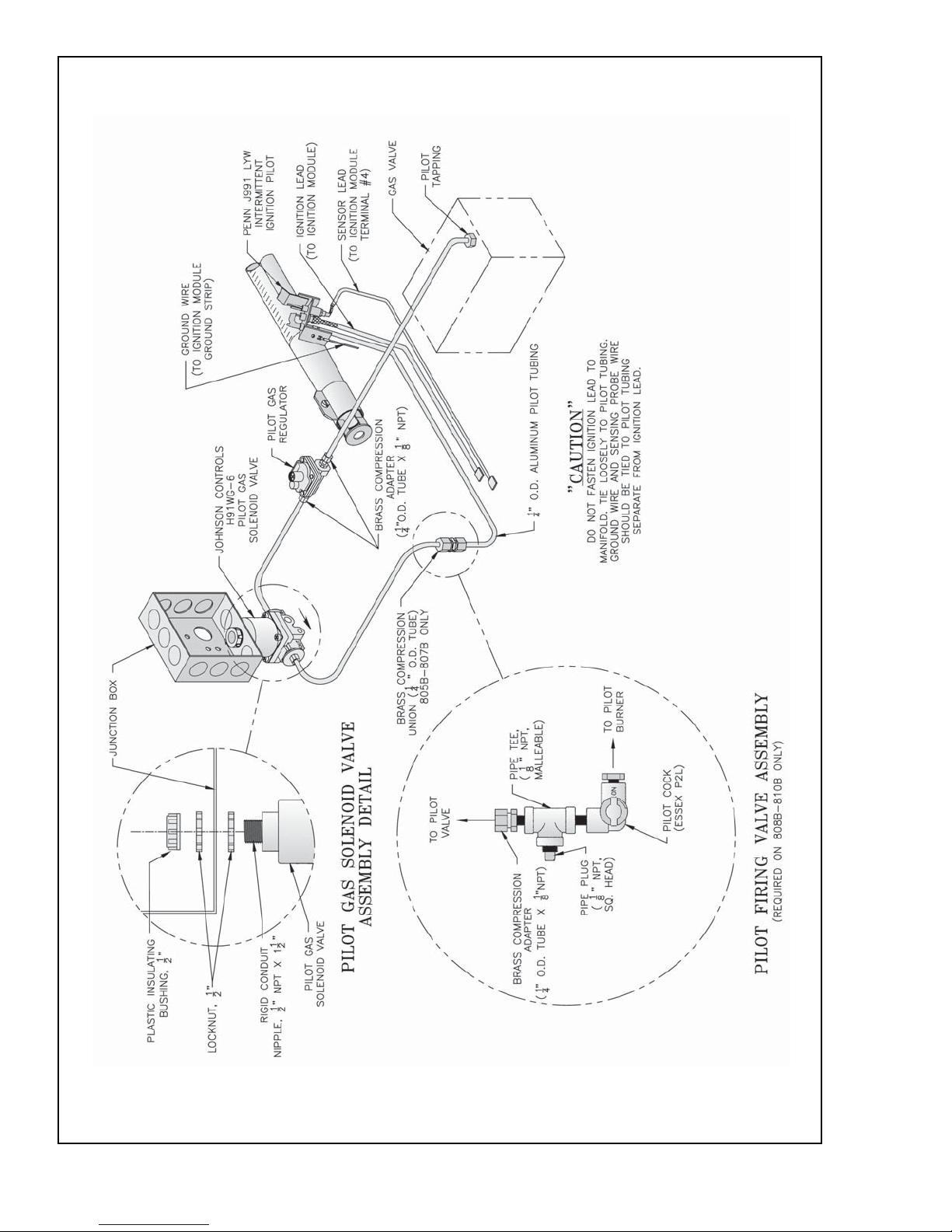

i. USA - See Figure 14.

ii. Canada - See Figure 15.

3. Install Ignition Module.

a. Attach Ignition Control Mounting Bracket to

Jacket Vestibule Panel using two (2) #8 x ½"

sheet metal screws.

b. Attach Johnson Ignition Module to Mounting

Bracket using two (2) #6 x ¾" sheet metal screws

or attach Honeywell Ignition Module to

Mounting Bracket using two (2) #8 x ½" sheet

metal screws.

c. Connect pilot ground wire and ignitor/sensor

lead(s) to ignition module. Refer to "Section VII:

Electrical" for connection details.

4. Mount Transformer (continuous circulation) or

Control Center (intermittent circulation) to Junction

Box. See Figure 8.

a. Canada only - loop 4" nylon cable tie between

junction box and transformer/control center.

b. Attach transformer/control center to junction

box.

C. OP Control System

Install Gas Control System. All components are

located in Combination Boiler Parts and Control Carton.

1. Install Gas Control Assembly on Manifold. See

Figure 16. Use thread (joint) compound (pipe dope)

resistant to action of liquefied petroleum gas.

2. Install pilot burner piping and controls. See Figure

16.

3. Connect Thermocouple Lead to Gas Valve.

4. Mount Transformer (continuous circulation) or

Control Center (intermittent circulation) to Junction

Box.

a. Canada only - loop 4" nylon cable tie between

junction box and transformer/control center.

b. Attach transformer/control center to junction

box.

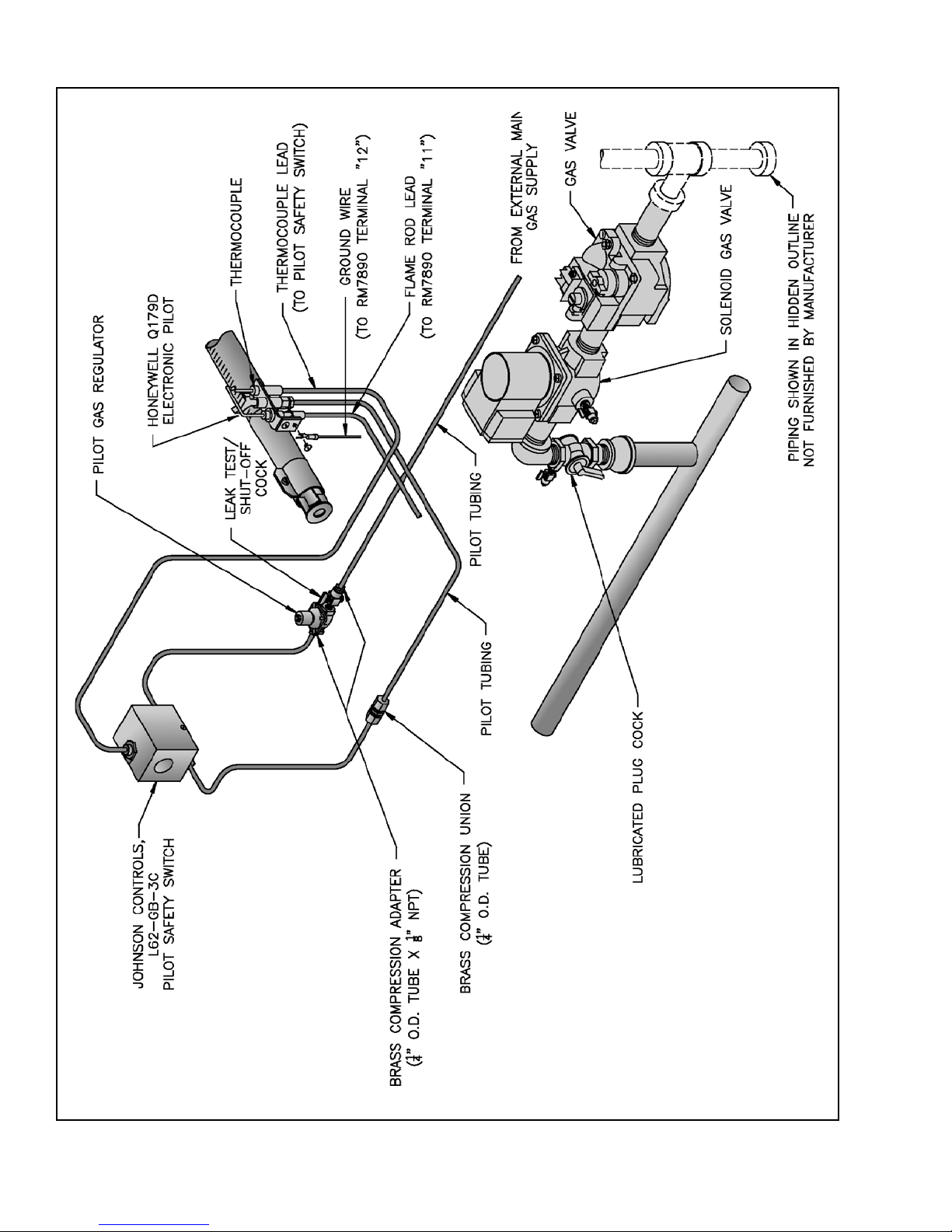

D. OP-CSD-1 Control System

Install Gas Control System. All components are

located in Combination Boiler Parts and Control Carton.

1. Install Gas Control Assembly on Manifold. See

Figure 17. Use thread (joint) compound (pipe dope)

resistant to action of liquefied petroleum gas.

2. Mount pilot switch.

3. Install pilot burner piping and controls. See Figure

17.

4. Connect Thermocouple lead to pilot switch.

5. Mount Transformer (continuous circulation) or

Control Center (intermittent circulation) to Junction

Box.

6. Attach transformer/control center to junction box.

E. EP Control System

Install Gas Control System. All components are

located in Combination Boiler Parts and Control Carton.

1. Install Gas Control Assembly on Manifold. See

Figure 18.

2. Install pilot burner piping and controls. See Figure

18.

3. Install Ignition Transformer.

a. Attach Ignition Transformer to Jacket Vestibule

Panel using four (4) #8 x ½" lg. sheet metal

screws.

b. Connect Ignition Lead from Pilot to Ignition

Transformer.

4. Mount Transformer (continuous circulation) or

Control Center (intermittent circulation) to Junction

Box.

a. Canada only - loop 4" nylon cable tie between

junction box and transformer/control center.

15

Page 16

b. Attach transformer/control center to junction

box.

Panel using four (4) #8 x ½" lg. sheet metal

screws.

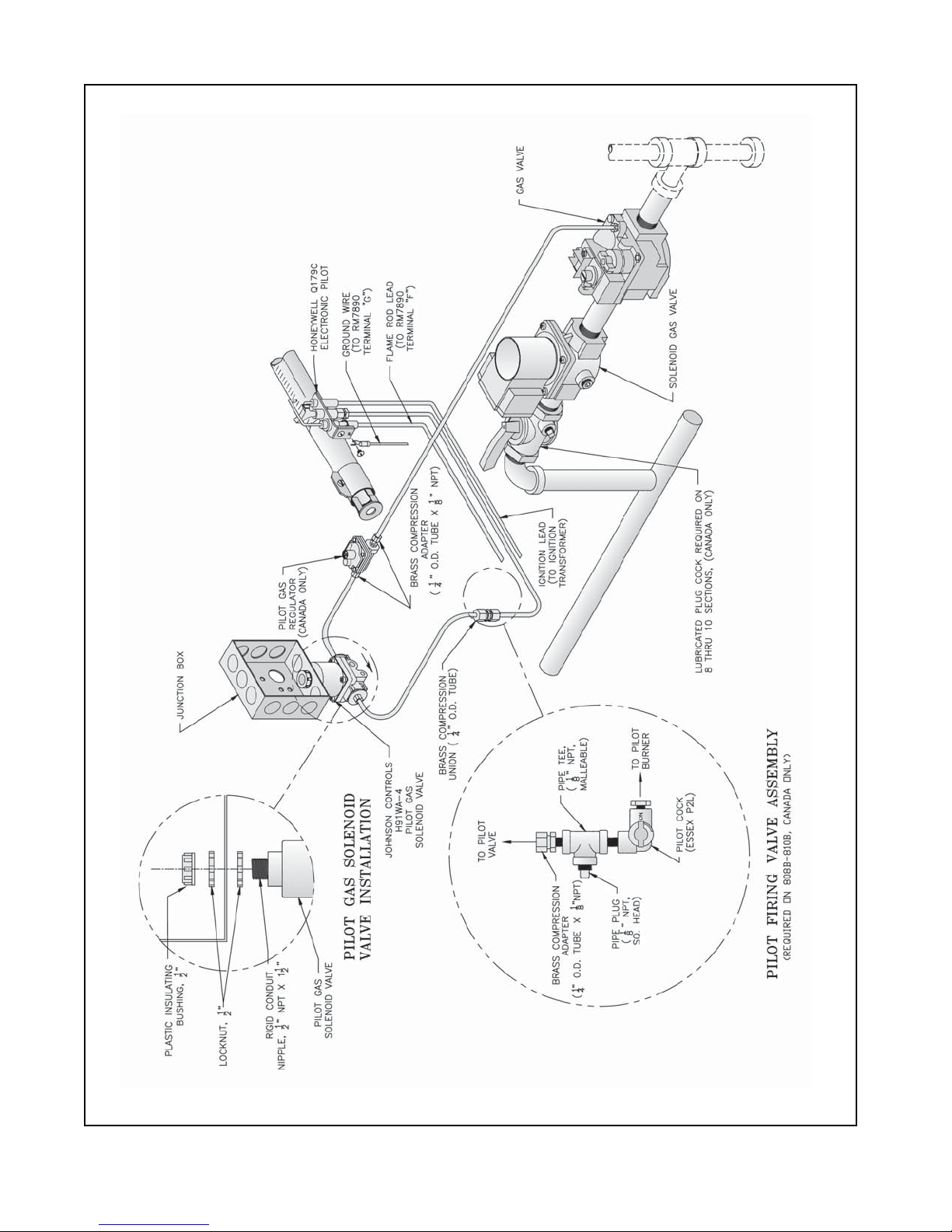

F. EP-CSD-1 Control System

Install Gas Control System. All components are

located in Combination Boiler Parts and Control Carton.

1. Install Gas Control Assembly on Manifold. See

Figure 19.

2. Install pilot burner piping and controls. See Figure

19.

3. Install Ignition Transformer.

a. Attach Ignition Transformer to Jacket Vestibule

b. Connect Ignition Lead from Pilot to Ignition

Transformer.

4. Mount Transformer (continuous circulation) or

Control Center (intermittent circulation) to Junction

Box.

a. Canada only - loop 4" nylon cable tie between

junction box and transformer/control center.

b. Attach transformer/control center to junction

box.

16

Page 17

Figure 10: Schematic Gas Piping, 24V Standing Pilot, 806B & 807B

17

Page 18

Figure 11: Main Gas Piping, Intermittent Ignition (EI)

18

Page 19

Figure 12: Schematic Pilot Piping (Honeywell EI), USA

19

Page 20

Figure 13: Schematic Pilot Piping (Honeywell EI)

Canada: Natural Gas, 805B - 810B; LP Gas, 806B - 807B

20

Page 21

Figure 14: Schematic Pilot Piping (Johnson EI), USA

21

Page 22

Figure 15: Schematic Pilot Piping (Johnson EI)

Canada: Natural Gas, 805B - 810B; LP Gas, 806B - 807B

22

Page 23

Figure 16: Schematic Gas Piping, OP Control System, 806B - 810B

23

Page 24

Figure 17: Schematic Gas Piping, OP-CSD-1 Control System, 808B - 810B

24

Page 25

Figure 18: Schematic Gas Piping, EP Control System (Natural Gas Only), 806B - 810B

25

Page 26

Figure 19: Schematic Gas Piping, EP-CSD-1 Control System, 808B - 810B

26

Page 27

IV. Water Trim and Piping

.erutcurts

.retawfonoitidda

GNINRAW

roreliobotegamaddnanoitareporeporpminitluseryamreliobepipylreporpoteruliaF

reliobleetsdnanorifonoisorrocesuaclliwretawreliobfonoitanimatnocnegyxO

smelborprevoctonseodytnarraWs'mahnruB.eruliafreliobotdaelnacdna,stnenopmoc

tneuqerfybdesuacpu-dliub)emil(elacsroretawreliobfonoitanimatnocnegyxoybdesuac

A. Design and install boiler and system piping to prevent

oxygen contamination of boiler water and frequent water

additions.

1. There are many possible causes of oxygen

contamination such as:

a. Addition of excessive make-up water as a result

of system leaks.

b. Absorption through open tanks and fittings.

c. Oxygen permeable materials in the distribution

system.

2. In order to insure long product life, oxygen sources

must be eliminated. This can be accomplished by

taking the following measures:

a. Repairing system leaks to eliminate the need for

addition of make-up water.

b. Eliminating open tanks from the system.

c. Eliminating and/or repairing fittings which allow

oxygen absorption.

d. Use of non-permeable materials in the

distribution system.

e. Isolating the boiler from the system water by

installing a heat exchanger.

f. Use properly designed and operating air

elimination devices in water piping.

B. Design system to obtain a 20°F temperature rise through

the boiler (see Table 4). If a temperature rise greater

than 40°F is desired, consult Burnham.

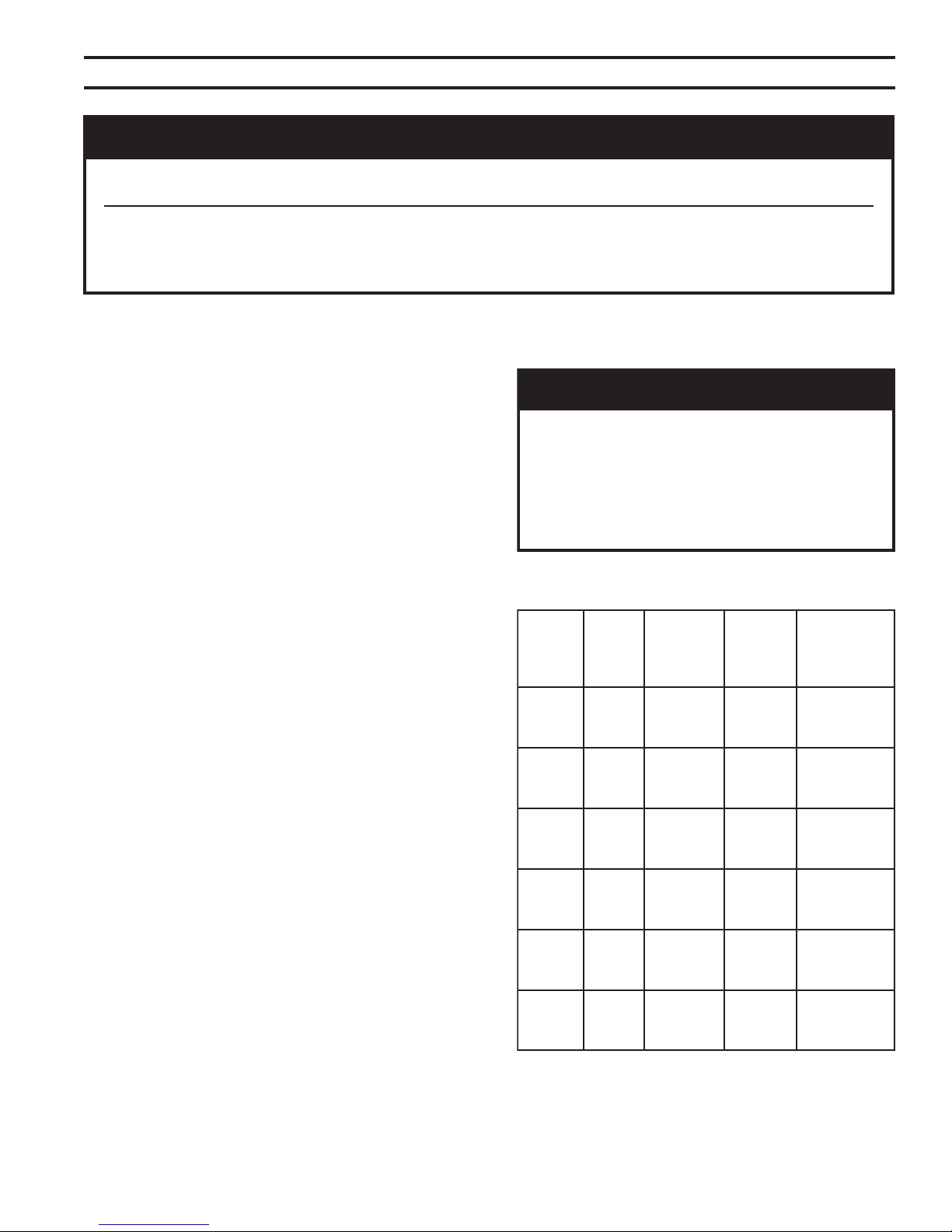

C. Install Safety Relief Valve. See Figure 20. Components

are located in Water Trim Carton. Safety Relief Valve

must be installed with spindle in vertical position.

1. Install ¾" NPT x 3½" lg. nipple in tapping "C". See

Figure 3.

2. Install safety relief valve on ¾" NPT nipple.

GNINRAW

.tnemegnarragnipip

Table 4: Flow Rate, Temperature Rise, and

Pressure Drop

RELIOB

EZIS

B508

B608

B708

B808

B908

B018

WOLF

ETAR

)MPG(

12

41

01

62

71

31

13

12

51

73

42

81

24

82

12

74

13

32

.PMET

ESIR

URHT

RELIOB

F°02

F°03

F°04

F°02

F°03

F°04

F°02

F°03

F°04

F°02

F°03

F°04

F°02

F°03

F°04

F°02

F°03

F°04

.NIM

RELIOB

GNIPIP

)TPN(

"½1

"¼1

"¼1

"½1

"½1

"¼1

"2

"½1

"¼1

"2

"½1

"½1

"2

"2

"½1

"2

"2

"½1

tsumgnipipegrahcsidevlavfeilererusserP

erevesfolaitnetopehttahthcusdepipeb

ynaniepipTONOD.detanimilesisnrub

TONOD.ruccodluocgnizeerferehwaera

.spacrosgulp,sevlavffotuhsynallatsni

egrahcsidreporprofsedoClacoLtlusnoC

RELIOB

ERUSSERP

PORD

'3

'2

'1

'3

'2

'1

'3

'2

'1

'3

'2

'1

'3

'2

'1

'3

'2

'1

27

Page 28

Figure 20: Safety Relief Valve Installation

Figure 21: Drain Piping Installation

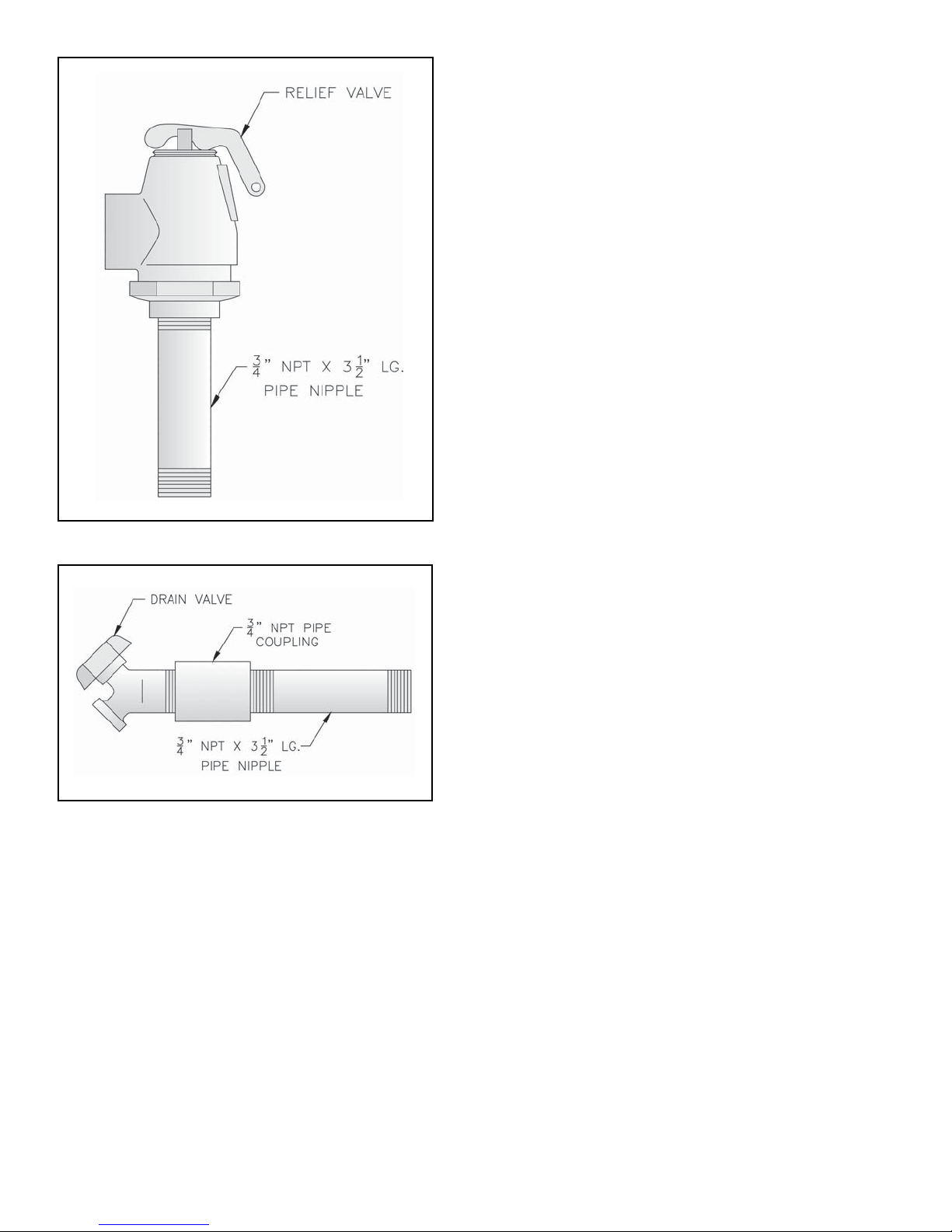

b. Insert Temperature-Pressure Gauge. Tighten by

applying pressure to square shank on back of

gauge. DO NOT APPLY PRESSURE ON GAUGE

CASE since this may ruin gauge calibration.

2. Alternate Temperature-Pressure Gauge Piping. See

Figure 23.

a. Install 2 NPT x 10" Nipple into Supply Tapping

"A". See Figure 3.

b. Install 2 NPT x ¾ NPT x 2 NPT Tee (provided) or

2 NPT x 2 NPT x ¾ NPT Tee (installer furnished).

¾" NPT leg should face forward.

c. Install ¾ NPT x ¼ NPT Bushing.

d. Insert Temperature-Pressure Gauge. Tighten by

applying pressure to square shank on back of

gauge. DO NOT APPLY PRESSURE ON GAUGE

CASE since this may ruin gauge calibration.

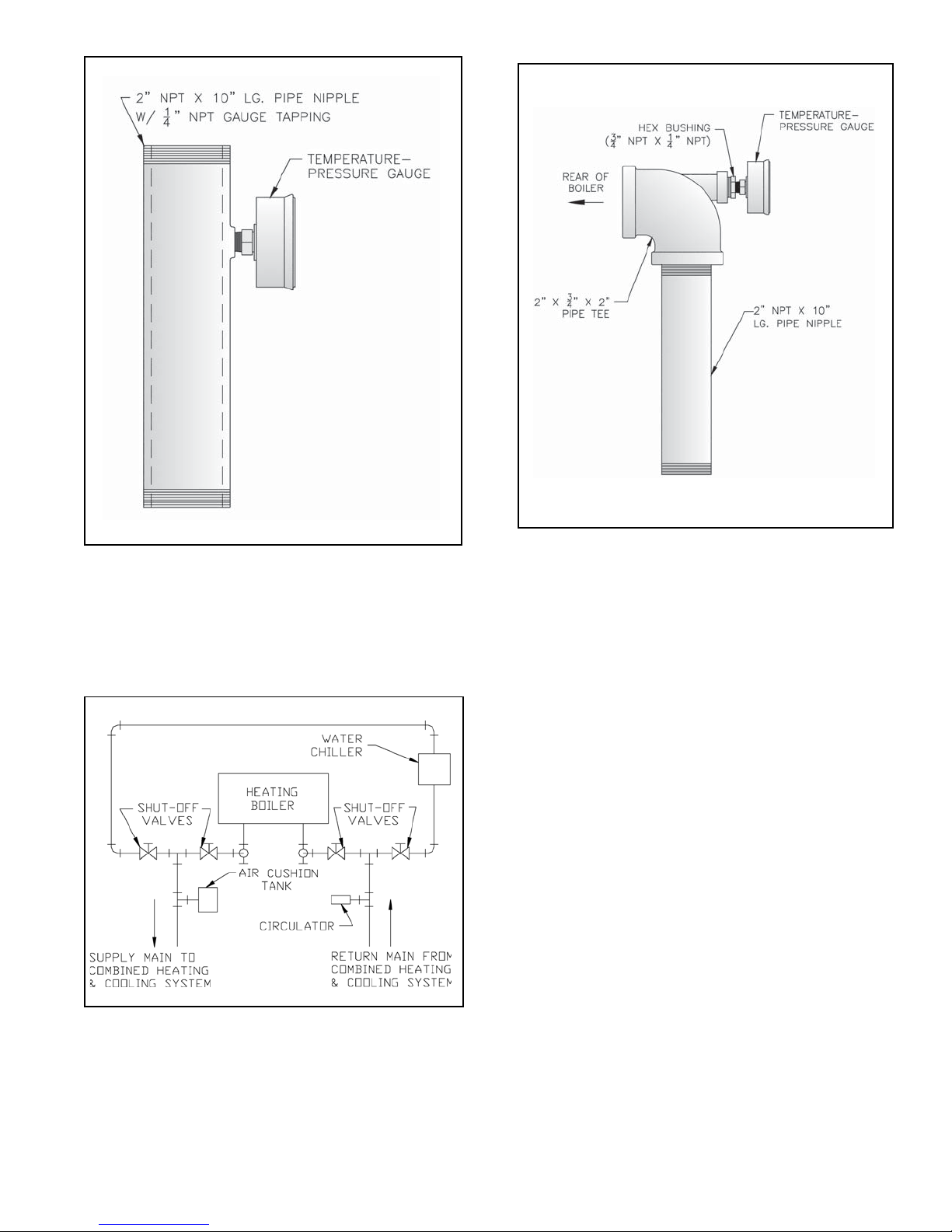

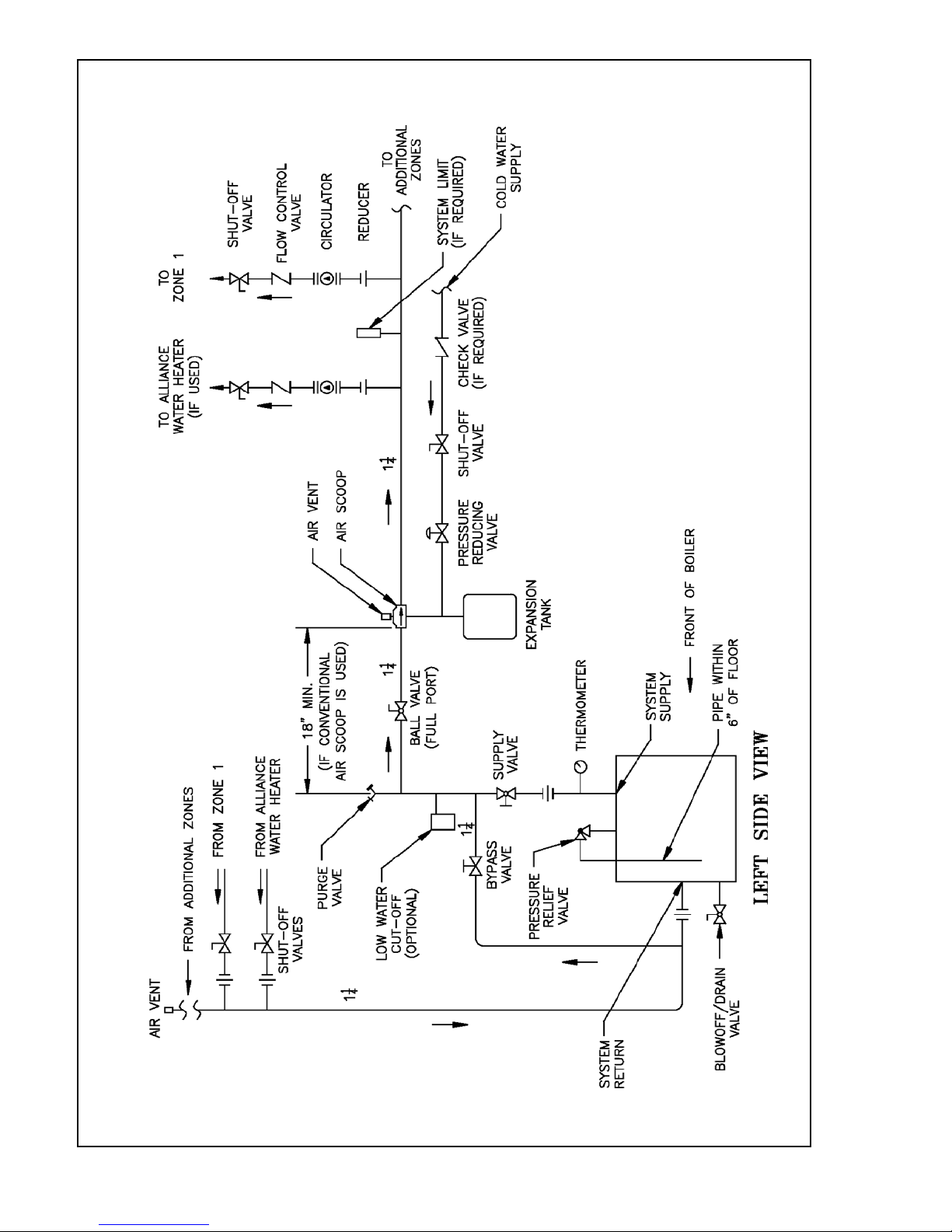

F. Connect system supply and return piping to boiler. See

Figure 25. Also consult I=B=R Installation and Piping

Guides. Maintain minimum ½ inch clearance from hot

water piping to combustible materials.

1. If boiler is used in connection with refrigeration

systems, boiler must be installed with chilled medium

piped in parallel with heating boiler using

appropriate valves to prevent chilled medium from

entering boiler. See Figure 24. Also consult I=B=R

Installation and Piping Guides.

2. If boiler is connected to heating coils located in air

handling units where they may be exposed to

refrigerated air, boiler piping must be equipped with

flow control valves to prevent gravity circulation of

boiler water during cooling system operation.

3. Use boiler bypass if boiler is operated in system

which has a large volume or excessive radiation

where low boiler water temperatures may be

encountered (i.e. converted gravity circulation

system, etc.). See Figure 25.

4. A hot water boiler installed above radiation level

must be provided with a low water cutoff device as

part of installation.

D. Install Drain Valve in rear of Left End Section, Tapping

"G". See Figure 21. Components are located in Water

Trim Carton.

E. Install Temperature-Pressure Gauge. Components are

located in Water Trim Carton.

1. Standard Temperature - Pressure Gauge Piping. See

Figure 22.

a. Install 2" NPT x 10" lg. nipple with gauge tapping

into Supply Tapping "A". See Figure 3. Gauge

tapping should face forward.

5. A start-up strainer is recommended for practically all

modular installations (new and replacement alike) to

prevent system debris and sediment from ending up

in the boilers where it will inhibit heat transfer and

may eventually cause a cast iron section to crack

from overheating.

G. Alliance Water Heater (if used). Refer to Alliance

Installation, Operating and Service Instructions for

additional information. Install in same manner as space

heating zone.

28

Page 29

Figure 22: Temperature-Pressure Gauge

Installation

Figure 23: Alternate Temperature-Pressure

Gauge Installation

Figure 24: Recommended Piping for Combination

Heating & Cooling (Refrigeration) System

29

Page 30

Figure 25: Recommended Boiler Piping for Circulator Zoned Heating Systems

30

Page 31

V. Gas Piping

GNINRAW

.daoldetcennoc

.reilppussagtlusnoC.dedeeneb

Size gas Piping. Design system to provide adequate

A.

gas supply to boiler. Consider these factors:

1. Allowable pressure drop from point of delivery to

boiler. Maximum allowable system pressure is ½

psig. Actual point of delivery pressure may be less;

contact gas supplier for additional information.

Minimum allowable gas valve inlet pressure is

indicated on rating label.

2. Maximum gas demand. Table 5 lists boiler input rate.

Also consider existing and expected future gas

utilization equipment (i.e. water heater, cooking

equipment)

3. Length of piping and number of fittings. Refer to

Table 6 for maximum capacity of Schedule 40 pipe.

Table 7 lists equivalent length for standard fittings.

4. Specific gravity of gas. Gas piping systems for gas

with a specific gravity of 0.70 or less can be sized

otylppussagepipylreporpoteruliaF

dnanoitareporeporpminitluseryamreliob

syawlA.erutcurtsroreliobehtotegamad

eerfkaelyletulosbasignipipsagerussa

ehtrofepytdnaezisreporpehtfodna

yamrotalugererusserpsaglanoitiddanA

directly from Table 6, unless authority having

jurisdiction specifies a gravity factor be applied. For

specific gravity greater than 0.70, apply gravity

factor from Table 8. If exact specific gravity is not

shown choose next higher value.

For materials or conditions other than those listed

above, refer to the National Fuel Gas Code, NFPA

54/ANSI Z223.1 and/or CAN/CGA B149 Installation

Codes, or size system using standard engineering

methods acceptable to authority having jurisdiction.

B. Connect boiler gas valve to gas supply system.

GNINRAW

nosdnuopmocdaerhtreporpesuoteruliaF

foskaelnitluseryamsrotcennocsaglla

.sagelbammalf

GNINRAW

ebtsummetsysdnareliobotylppussaG

rognillatsniotroirpffotuhsyletulosba

.gnipipsagreliobgnicivres

Table 5: Rated Input

relioB

ledoM

rebmuN

B5084625.5011

B6080332311

B7086935.8511

B80826457.4811

B90882552.1121

B0184955.7321

larutaNenaporP/PL

1. Use methods and materials in accordance with local

plumbing codes and requirements of gas supplier. In

absence of such requirements, follow the National

yticapaCdetaR

]ruohrepteefcibuc[

saG

noitcennoC

eziS

Fuel Gas Code, NFPA 54/ANSI Z223.1 and/or CAN/

CGA B149 Installation Codes.

2. Use thread (joint) compound (pipe dope) resistant to

action of liquefied petroleum gas.

3. Install sediment trap, ground-joint union and manual

shut-off valve upstream of boiler gas valve and

outside jacket. See Figure 26.

4. All above ground gas piping upstream from manual

gas valve must be electrically continuous and

bonded to a grounding electrode. Do not use gas

piping as a grounding electrode. Refer to the

National Electrical Code, ANSI/NFPA 70 and/or

CSA C22.1 Electrical Code.

ECITON

neebevahlevelaesevobateef000,2nahtretaergsedutitlatanoitallatsniroftliubsreliobASU

ehtreplevelaesevobateef000,1reptnecrep4etartupnisagecuderotdecifiroyllaiceps

'sreliobnaidanaC.FxidneppAdna2.1.8noitceS,1.322ZISNA/45APFN,edoCsaGleuFlanoitaN

ehtybelbaifitnedierasledomreliobedutitlahgiH.lebalgnitarehtnodetacidnisignizisecifiro

)'0005-'0002=5,'0054-'0002=4(.lebalgnitarehtnotigidhtnins'rebmunledom

31

Page 32

Table 6: Maximum Capacity of Schedule 40 Pipe in CFH for Gas Pressures of 0.5 psig or Less

htgneL

]teeF[

01231872025050,1571063086004,1

0229091053037021052564059

033725158209579002573077

043603154200528071023066

056551151204437151582085

060550159100466831062035

07646908107316521042094

08340907105375811022064

09044806102335011502034

001839705150305301591004

Table 7: Equivalent Lengths of Standard Pipe Fittings & Valves

½¾ 1 ¼1½¾1¼1

porDerusserP.c.whcni3.0porDerusserP.c.whcni5.0

)nepOylluF(sevlaVsgnittiFdedaerhT

epiP

eziS

.D.I

sehcnIetaGebolGelgnA

gniwS

kcehC

°09

woblE

°54

woblE

wolF,eeT°09

nuRhguorhT

wolF,eeT°09

hcnarBhguorhT

"½226.053.06.813.93.46.187.00.11.3

"¾428.044.01.325.113.51.279.04.11.4

"1940.165.04.927.418.66.232.18.13.5

"¼1083.147.06.833.919.85.36.13.29.6

Table 8: Specific Gravity Correction Factors

cificepS

ytivarG

05.001.103.170.1

55.040.104.140.1

06.000.105.100.1

56.069.006.179.0

07.039.007.149.0

57.009.0

08.078.0

noitcerroC

rotcaF

cificepS

ytivarG

noitcerroC

rotcaF

.ecruosnoitingirehtoro

C. Pressure Test. The boiler and its gas connection must

be leak tested before placing boiler in operation.

1. Protect boiler gas valve. For all testing over ½ psig,

boiler and its individual shut-off valve must be

disconnected from gas supply piping. For testing at

½ psig or less, isolate boiler from gas supply piping

by closing boiler's individual manual shut-off valve.

2. Locate leaks using approved combustible gas

detector, soap and water, or similar nonflammable

solution.

Figure 26: Recommended Gas Piping

32

GNINRAW

,semalfnepo,seldnac,sehctamesutonoD

Page 33

VI. Venting

A. Install vent system in accordance with local building

codes; or local authority having jurisdiction; or

National Fuel Gas Code, ANSI Z223.1/NFPA 54, Part 7,

Venting of Equipment and/or CAN/CGA B149

Installation Codes, Part 5, Venting Systems and Air

Supply for Appliances. Install any of the following for

this Series 8B Category I, draft hood equipped

appliance:

1. Type B or Type L gas vent. Install in accordance

with listing and manufacturer's instructions.

2. Masonry or metal chimney. Build and install in

accordance with local building codes; or local

authority having jurisdiction; or Standard for

Chimneys, Fireplaces, Vents, and Solid Fuel

Burning Appliances, ANSI/NFPA 211 and/or

National Building Code of Canada.

Masonry chimney must be lined with approved clay

flue lining or listed chimney lining system except as

provided in ANSI Z223.1/NFPA 54, Paragraph

7.5.4(a): Exception: Where permitted by the

authority having jurisdiction, existing chimneys

shall be permitted to have their use continued when

an appliance is replaced by an appliance of similar

type, input rating, and efficiency.

3. Single wall metal vent. Allowed by ANSI Z223.1/

NFPA 54 under very restrictive conditions.

B. Inspect chimney and remove any obstructions or

restrictions. Clean chimney if previously used for solid

or liquid fuel-burning appliances or fireplaces.

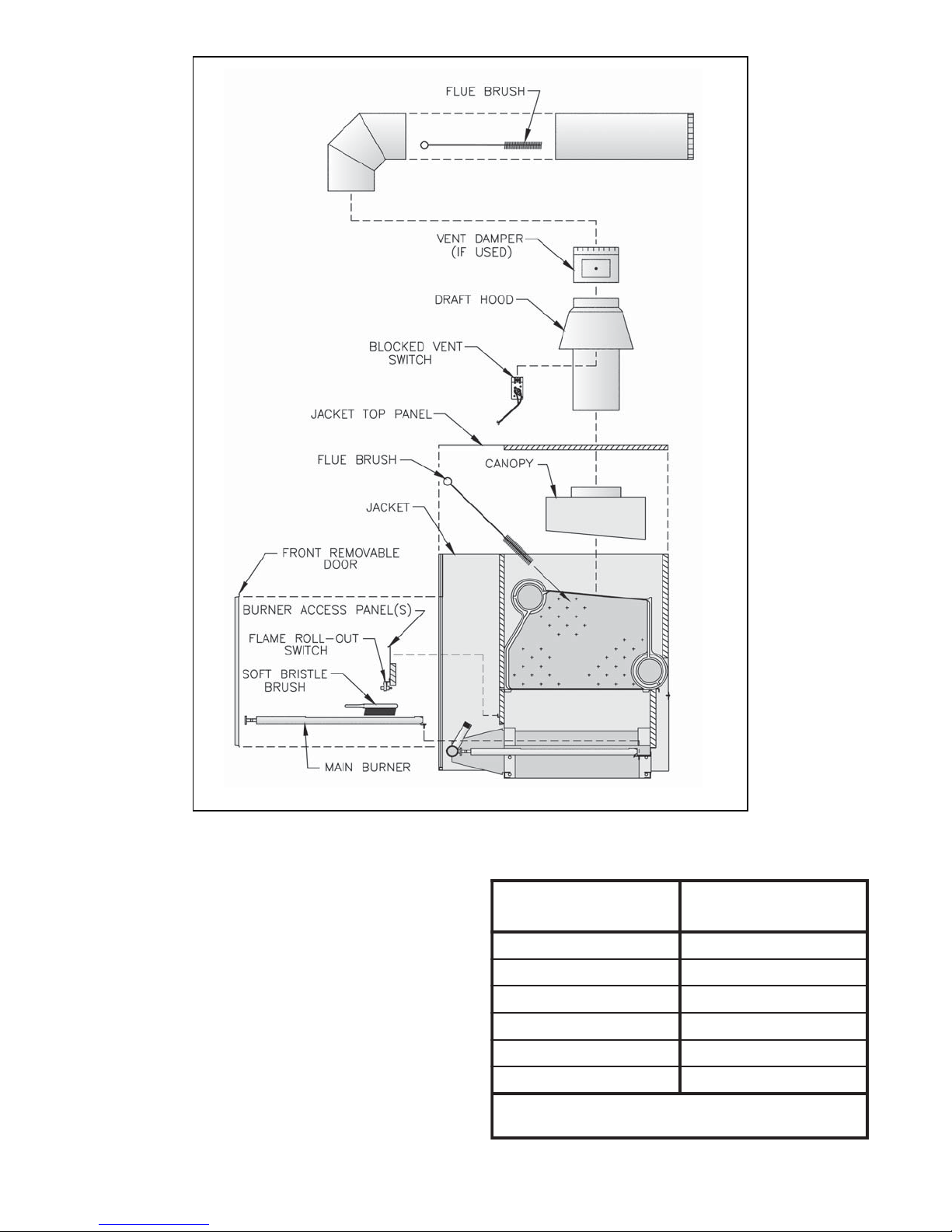

top of boiler. On Knocked Down boilers, the assembly is

located in Combination Boiler Parts and Control Carton.

1. Uncoil power cord.

2. Position mounting bracket onto lower edge of Draft

Hood skirt. Locate center tooth (with #10 sheet metal

screw) on outside and other two teeth inside Draft

Hood skirt. See Figure 27.

3. Slide mounting bracket tight against lower edge of

Draft Hood skirt. Position #10 sheet metal screw

above skirt's stiffening rib.

4. Secure bracket in position by tightening #10 sheet

metal screw against outer surface of Draft Hood

skirt.

5. Insert excess power cord through Jacket Right Side

Panel hole. Remove slack.

6. Position strain relief bushing around power cord.

Pinch bushing's two halves together and snap back

into hole in Jacket Right Side Panel.

7. Verify power cord, mounting bracket, and Blocked

Vent Switch are secure and located as shown in

Figure 27.

GNINRAW

tneVdekcolBtuohtiwreliobetarepotonoD

.dellatsniylreporphctiwS

REGNAD

gnillatsnierofebyenmihcgnitsixetcepsnI

detarofrepecalperronaelcoteruliaF.reliob

.htaed

C. Install Draft Hood on canopy outlet. Maintain height

from Jacket Top Panel to Draft Hood skirt as shown in

Figure 1. DO NOT ALTER, CUT, OR MODIFY

DRAFT HOOD.

GNINRAW

ynaecalprodoohtfardreliobretlatonoD

ehtnirepmaddevorppa-nonronoitcurtsbo

egallipssageulF.metsystnevrognihceerb

lliwnoitareporeliobefasnU.rucconac

.rucco

D. Install Blocked Vent Switch. The Blocked Vent Switch

Assembly consists of a strain relief bushing, power

cord, and switch attached to mounting bracket. On

Packaged boilers, the assembly is shipped attached to

royrujnierevesesuaclliwgninilelitroepip

Figure 27: Blocked Vent Switch Installation

33

Page 34

E. Boiler Equipped With Vent Damper. See Figure 28.

1. Open Vent Damper Carton and remove Installation

Instructions. Read Installation Instructions

thoroughly before proceeding.

NOITUAC

owtlortnocotrepmadtnevenoesutonoD

.secnailppagnitaeheromro

2. Vent damper must be same size as draft hood outlet.

See Figure 1. Unpack vent damper carefully. Forcing

vent damper open or closed may damage gear train

and void warranty. Vent damper assembly includes

pre-wired connection harness with polarized plug.

3. Mount vent damper assembly on draft hood without

modification to either (Refer to instructions packed

with vent damper for specific instructions). Vent

damper position indicator to be visible to users.

NOITUAC

-gnicivresrofecnaraelcetauqedaedivorP

neewtebecnaraelcmuminim"6edivorp

.noitcurtsnocelbitsubmocdnarepmad

F. Install Vent Connector from draft hood or vent damper

to chimney. See Figure 29. For modular or multiple

boiler installations, review "Multiple-Modular Manual

for Series 8B Gas Boilers", P/N 8141615.

1. Do not connect into same leg of chimney serving an

open fireplace.

2. Where two or more appliances vent into a common

vent, the area of the common vent should at least

equal the area of the largest vent plus 50 % of the

area of the additional vents. Do not connect the

vent of this appliance into any portion of mechanical

draft system operating under positive pressure.

3. Vent connector should have the greatest possible

initial rise above the draft hood consistent with the

head room available and the required clearance from

adjacent combustible building structure.

4. Install vent connector above bottom of chimney to

prevent blockage - inspect chimney for obstructions

or restrictions and remove - clean chimney if

necessary.

5. Vent connector should slope upward from draft

hood to chimney not less than one inch in four feet.

No portion of vent connector should run downward

or have dips or sags. Vent connector must be

securely supported.

6. Use thimble where vent connector enters masonry

chimney - keep vent connector flush with inside of

flue liner.

7. Do not install Non-listed (AGA, CGA, CSA, ETL, or

UL) vent damper or other obstruction in vent pipe.

8. Locate Boiler as close to Chimney as possible

consistent with necessary clearances. See Section I:

Pre-Installation.

Figure 28: Vent Damper Installation

34

Page 35

9. Design vent system for sea level input.

10. Provide adequate ventilation of Boiler Room. See

Section I: Pre-Installation.

11. Never pass any portion of vent system through a

circulating air duct or plenum.

G. If an Existing Boiler is Removed:

At the time of removal of an existing boiler, the

following steps shall be followed with each appliance

remaining connected to the common venting system

GNINRAW

nommoceht,metsysgnitnevnommoc

.tiotdetcennoc

placed in operation, while the other appliances

remaining connected to the common venting system are

not in operation:

1. Seal any unused openings in the common venting

system.

2. Visually inspect the venting system for proper size

and horizontal pitch and determine there is no

blockage or restriction, leakage, corrosion, or other

deficiencies which could cause an unsafe condition.

3. Insofar as is practical, close all building doors and

windows and all doors between the space in which

the appliances remaining connected to the common

venting system are located and other spaces of the

building. Turn on clothes dryers and any appliance

not connected to the common venting system. Turn

on any exhaust fans, such as range-hoods and

bathroom exhausts, so they will operate at maximum

speed. Do not operate a summer exhaust fan. Close

fireplace dampers.

4. Place in operation the appliance being inspected.

Follow the Lighting (or Operating) Instructions.

Adjust thermostat so appliance will operate

continuously.

5. Test for spillage at the draft hood relief opening after

amorfdevomersireliobgnitsixenanehW

rofegralootebotylekilsimetsysgnitnev

gniniamersecnailppaehtfognitnevreporp

5 minutes of main burner operation. Use the flame of

a match or candle, or smoke from a cigarette, cigar or

pipe.

6. After it has been determined that each appliance

remaining connected to the common venting system

properly vents when tested as outlined above,

return doors, windows, exhaust fans, fireplace

dampers and any other gas-burning appliance to

their previous condition of use.

7. Any improper operation of the common venting

system should be corrected so the installation

conforms with the National Fuel Gas Code, NFPA

54/ANSI Z223.1. When resizing any portion of the

common venting system, the common venting

system should be resized to approach the minimum

size as determined using the appropriate tables in

Part 7 and Part 11 in the National Fuel Gas Code,

NFPA 54/ANSI Z223.1.

Figure 29: Typical Vent System

35

Page 36

VII. Electrical

.mrah

REGNAD

ecivresronoitallatsnignitpmettaerofebderewopnuerasnoitcennoclacirtcelellaerussaylevitisoP

sexoblacirtcelellatuokcoL.gnidliubroreliobehtfosnoitcennocrostnenopmoclacirtcelefo

.ffodenrutsirewopecnokcoldaphtiw

GNINRAW

lacisyhpsuoiresnitluseryamreliobehtotsnoitcennoclacirtceleeriwylreporpoteruliaF

erofebffosirewopllaerusekaM.ecruosenonahterommorfebyamrewoplacirtcelE

.krowlacirtceleynagnitpmetta

.tcennocsiddesufdezisylreporpahtiwdetcetorpebtsumreliobhcaE

.slortnocgnitareporoytefasynaevitareponiekamrotuopmujreveN

reliobhcaE.ylnosesoprupecnereferroferalaunamsihtnideniatnocsmargaidgniriwehT

ehtdnamargaidsihtotrefeR.roodtnorfehtotdehcattamargaidgniriwahtiwdeppihssi

gniriwllawollofdnadnatsrednu,daeR.reliobehthtiwdesuslortnocynafomargaidgniriw

.slortnocehthtiwdeilppussnoitcurtsni

A. Install Boiler Wiring

1. Knockdown boilers only. Locate wiring harnesses in

Combination Boiler Parts and Control Carton. Refer

to Table 10 and connect wiring as shown on the

appropriate wiring diagram.

2. Connect supply wiring and electrically ground boiler

in accordance with requirements of authority having

jurisdiction, or in absence of such requirements the

National Electrical Code, ANSI/NFPA 70 and/or

CSA C22.1 Electrical Code.

B. Wire Vent Damper (if used; required on 805, optional

on 806-810). See Figure 28.

1. Attach Vent Damper Harness to mounting hole in

Jacket Left Side Panel. Install Cable Clamp around

flexible conduit and attach to Jacket Top Panel.

2. Remove factory installed Jumper Plug from Vent

Damper Receptacle on Vestibule Wiring Harness

and discard.

3. Plug Vent Damper Harness Plug into Vent Damper

Receptacle. See Figure 28.

C. Install thermostat. Locate on inside wall approximately

4 feet above floor. Do not install on outside wall, near

fireplace, or where influenced by drafts or restricted air

flow, hot or cold pipes, lighting fixtures, television, or

sunlight. Allow free air movement by avoiding

placement of furniture near thermostat.

Set heat anticipator to match control system

requirements. Refer to Table 9.

D. Wire thermostat. Provide Class II circuit between

thermostat and boiler. Refer to appropriate wiring

diagram for control system being used.

Figure 30: Vent Damper Schematic Wiring Diagram

36

Page 37

E. Alliance Water Heater (if used). May be used with

Intermittent Circulation only.

Refer to Alliance Installation, Operating and

Service Instructions for wiring, piping and

additional information.

F. Vent Damper Sequence of Operation. See Figure 30 for

schematic wiring diagram.

1. The Vent Damper is continuously powered at

Terminal 1.

2. When there is a call for heat, the damper relay coil

is energized through Terminal 5 if all limits ahead

of the damper are satisfied.

3. The relay coil closes contacts which energize the

damper motor, causing the damper to open.

4. When the damper blade reaches the fully open

position, power is sent back to the ignition circuit

through Terminal 2 and the damper motor is deenergized.

5. When the call for heat is satisfied, the damper relay

coil is de-energized - closing contacts which

energize the damper motor. This causes the damper

to close. When the damper blade reaches the fully

closed position, the damper motor is de-energized.

POWER FAILURE - The damper blade will stop in

the position it was in when power failed.

(Combustion can never take place unless the

damper blade is in the fully open position.)

G. Sequence of Operation and Wiring. Refer to Table 10

for the appropriate control system.

H. Optional Low-Water Cut-Off Wiring. See Figures 45

through 48.

Table 9: Heat Anticipator Settings

metsySlortnoC

toliPgnidnatSV421.13.0

)IE(noitingIcinortcelEV42

* ybgnittesrotapicitnataehecuder,gnitteserutarepmettatsomrehtevobadetaehsimoorfI

gnitteSrotapicitnAtaeH *

noitalucriCsuounitnoCnoitalucriCtnettimretnI

9.0:ASU

3.0

2.1:adanaC

esaercni,erutarepmetderisedgnihcaermoortuohtiwseclyctrohsreliobfI.spma2.0ro1.0

.spma2.0ro1.0ybgnittesrotapicitnataeh

37

Page 38

Table 10: Sequence of Operation and Wiring Diagrams

metsySnoitingIyrtnuoCleuFseziSrelioB

)V42(toliPgnidnatS

toliPgnidnatS

)V021--PO(

toliPgnidnatS

)V021--1-DSC-PO(

noitingItnettimretnI

)V42--IEllewyenoH(

noitingItnettimretnI

)V42--IEnosnhoJ(

noitingItnettimretnI

)V021--PE(

&ASU

adanaC

&ASU

adanaC

ASUsaGPL.tceS01-833erugiF43erugiF14egaP

ASU

adanaC

ASU

adanaC

&ASU

adanaC

saGlarutaN

saGPL

saGlarutaN

saGPL

saGlarutaN

saGPL

saGlarutaN.tceS01-5

saGPL.tceS7-5

saGlarutaN

saGPL

saGlarutaN.tceS01-5

saGPL.tceS7-5

saGlarutaN.tceS01-634erugiF44erugiF45egaP

saGPLelbaliavAtoN

erugiFmargaiDgniriW

suounitnoCtnettimretnI

.tceS7&613erugiF23erugiF83egaP

.tceS01-633erugiF43erugiF14egaP

.tceS01-553erugiF63erugiF

73erugiF83erugiF

.tceS01-593erugiF04erugiF

14erugiF24erugiF

foecneuqeS

noitarepO

44egaP

94egaP

noitingItnettimretnI

)V021--1-DSC-PE(

ASUsaGlarutaN.tceS01-834erugiF44erugiF45egaP

1. Standing Pilot (24) Sequence of Operation

a. Normal Operation

i. Thermostat or operating control calls for

heat. Vent Damper (if used) opens.

ii. Gas valves are energized allowing main gas

flow and ignition of main burners.

iii. Call or heat ends. Gas valves are de-

energized, extinguishing main flame. Vent

Damper (if used) closes.

b. Safety Shutdown

i. Limit: Automatically interrupts main burner

operation when water temperature exceeds

set point. Maximum allowable temperature is

250°F. Circulator continues to operate with

call for heat, Vent Damper (if used) closes.

Normal operation resumes when water

temperature falls below set point.

ii. Blocked Vent Switch: Automatically

interrupts main burner operation when

excessive flue gas spillage occurs. Circulator

continues to operate and Vent Damper (if

used) remains open with call for heat. If

blocked vent switch is activated do not

attempt to place boiler in operation. Correct

cause of spillage and reset blocked vent

switch.

iii. Flame Roll-out Switch: Automatically

interrupts main burner operation when

flames or excessive heat are present in

vestibule. Circulator continues to operate

and Vent Damper (if used) remains open with

call for heat. Control is single use device. If

flame roll-out switch is activated, do not

attempt to place boiler in operation. Correct

cause of spillage and replace flame roll-out

switch.

iv. Thermocouple: Senses pilot flame and

causes gas valves to turn off main burner

and pilot burner gas flow should pilot burner

flame extinguish. Circulator continues to

operate and Vent Damper (if used) remains

open with call for heat.

38

Page 39

Figure 31: Wiring Diagram, Standing Pilot (24), USA and Canada, Continuous Circulation

39

Page 40

Figure 32: Wiring Diagram, Standing Pilot (24V), USA and Canada, Intermittent Circulation

40

Page 41

2. Electronically Supervised Standing Pilot (OP)

Sequence of Operation

a. Normal Operation

i. Thermostat or operating control calls for

heat.

ii. Terminal #6 of RM7890C Burner Control is

energized, initiating a microcomputer

monitored circuit test.

iii. Pilot Flame Establishing Period (PFEP)

begins.

iv. After pilot flame is proven, terminal #9 of

RM7890C is energized, allowing main gas

flow and ignition of main burners. "Main"

gas light will be illuminated.

v. Call for heat ends. Terminal #6 of RM7890C

is de-energized, in turn de-energizing gas

valves and extinguishing main flame.

"Main" gas light is de-energized.

3. Electronically Supervised Standing Pilot (OP-CSD-1)

Sequence of Operation

a. Normal Operation

i. Thermostat or operating control calls for

heat.

ii. Terminal #6 of RM7890C Burner Control is

energized, initiating a microcomputer

monitored circuit test.

iii. Pilot Flame Establishing Period (PFEP)

begins.

iv. After pilot flame is proven, terminal #9 of

RM7890C is energized, allowing main gas

flow and ignition of main burners. "Main"

gas light will be illuminated.

v. Call for heat ends. Terminal #6 of RM7890C

is de-energized, in turn de-energizing gas

valves and extinguishing main flame.

"Main" gas light is de-energized.

b. Safety Shutdown

i. Limit: Automatically interrupts main burner

operation when water temperature exceeds

set point. Maximum allowable temperature is

250°F. Circulator continues to operate with

call for heat. Normal operation resumes

when water temperature falls below set point.

ii. Blocked Vent Switch: Automatically

interrupts main burner operation when

excessive flue gas spillage occurs. Circulator

continues to operate with call for heat. If

blocked vent switch is activated do not

attempt to place boiler in operation. Correct

cause of spillage and reset blocked vent

switch.

iii. Flame Roll-out Switch: Automatically

interrupts main burner operation when

flames or excessive heat are present in

vestibule. Circulator continues to operate

with call for heat. Control is single use

device. If flame roll-out switch is activated,

do not attempt to place boiler in operation.

Correct cause of spillage and replace flame

roll-out switch.

iv. RM7890C Burner Control: Automatically

interrupts main burner operation if a pilot

flame is not detected during the four or ten

second pilot flame establishing period. The

RM7890C will lockout or recycle based on

jumper settings. "Alarm" light will be

illuminated. Refer to instructions supplied

with RM7890C for additional control

information.

b. Safety Shutdown

i. Limit: Automatically interrupts main burner

operation when water temperature exceeds

set point. Maximum allowable temperature is

250°F. Circulator continues to operate with

call for heat. Normal operation resumes

when water temperature falls below set point.

ii. Blocked Vent Switch: Automatically

interrupts main burner operation when

excessive flue gas spillage occurs. Circulator

continues to operate with call for heat. If

blocked vent switch is activated do not

attempt to place boiler in operation. Correct

cause of spillage and reset blocked vent

switch.

iii. Flame Roll-out Switch: Automatically

interrupts main burner operation when

flames or excessive heat are present in

vestibule. Circulator continues to operate

with call for heat. Control is single use

device. If flame roll-out switch is activated,

do not attempt to place boiler in operation.

Correct cause of spillage and replace flame

roll-out switch.

iv. RM7890C Burner Control: Automatically

interrupts main burner operation if a pilot

flame is not detected during the four or ten

second pilot flame establishing period. The

RM7890C will lockout or recycle based on

jumper settings. "Alarm" light will be

illuminated. Refer to instructions supplied

with RM7890C for additional control

information.

v. Pilot Safety Switch: Automatically de-

energizes main gas valve and interrupts pilot

gas supply if pilot flame is not detected at

any time.

41

Page 42

Figure 33: Wiring Diagram, OP/OP-CSD-1 Ignition System, Continuous Circulation

42

Page 43

Figure 34: Wiring Diagram, OP/OP-CSD-1 Ignition System, Intermittent Circulation

43

Page 44

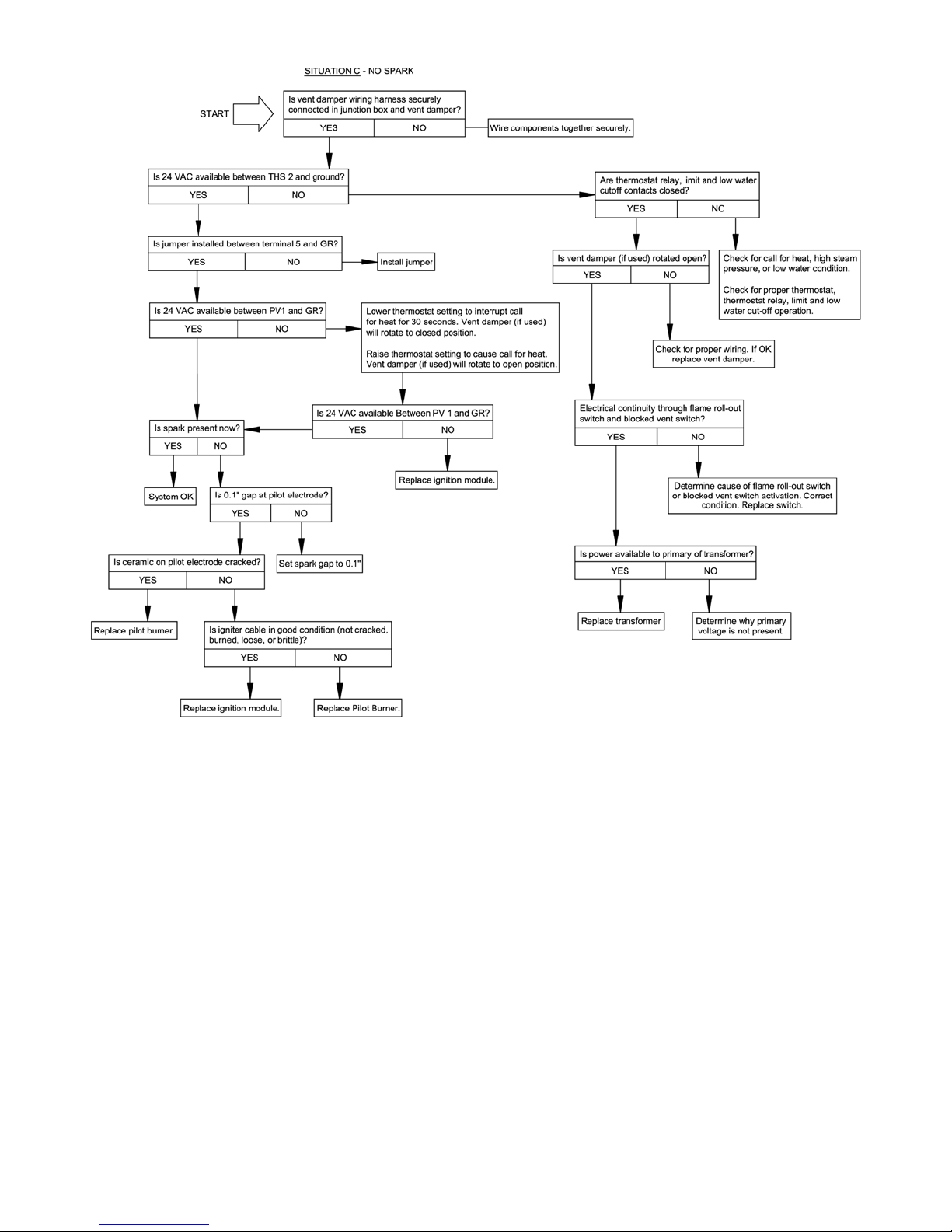

4. Honeywell EI Sequence of Operation

a. Normal Operation

i. Thermostat or operating control calls for

heat. Vent Damper (if used) opens.

ii. Ignition Module Terminals PV, MV/PV

and the Ignition Terminal are energized.

Terminals PV and MV/PV power the Pilot

Valve in the Gas Valve supplying gas to the

Pilot. The Ignition Terminal supplies

voltage to the Ignition Electrode creating an

electric spark to ignite the Pilot.

iii. The sensing Circuit between the Q348 Pilot

Burner and the IGNITION MODULE

proves the presence of the Pilot Flame

Electronically and the Ignition Terminal is

de-energized.

iv. Terminals MV and MV/PV of the

IGNITION MODULE are energized and

supply power to the Main Gas Valve. The

Gas Valve is energized allowing main gas

flow, and ignition of Main Burners.

v. Call for heat ends. Ignition module is de-

energized, de-energizing gas valve, and

extinguishing pilot and main flame. Vent

Damper (if used) closes.

b. Safety Shutdown

i. Limit: Automatically interrupts power to

the Ignition Module and Gas Valve(s),

extinguishing pilot and main flame, when

water temperature exceeds set point.

Maximum allowable temperature is 250°F.

Circulator continues to operate with call for

heat, Vent Damper (if used) closes. Normal

operation resumes when water temperature

falls below set point.

ii. Blocked Vent Switch: Automatically

interrupts main burner operation when

excessive flue gas spillage occurs.

Circulator continues to operate and Vent

Damper (if used) remains open with call for

heat. If blocked vent switch is activated do

not attempt to place boiler in operation.

Correct cause of spillage and reset blocked

vent switch.

iii. Flame Roll-out switch: Automatically

interrupts main burner operation when

flames or excessive heat are present in

vestibule. Circulator continues to operate,

Vent Damper (if used) remains open with

call for heat. Control is single use device.

If flame roll-out switch is activated, do not

attempt to place boiler in operation.

Correct cause of spillage and replace flame

roll-out switch.

iv. Pilot

– Pilot failure can occur during the start-up or

the operating cycle of the boiler. Any pilot

failure of the Q348 Electronic Pilot, after

ignition of pilot flame will close the main

gas valve in 0.8 seconds.

– For approximately 90 seconds after failure

of the Q348 pilot, the module through the

ignition terminal will try to reestablish pilot

flame. If no pilot flame can be sensed by

the flame rod circuit, terminals PV and

MV/PV are de-energized and the module

will lock out on safety. Five to six minutes

after shutdown, the IGNITION MODULE

restarts the ignition sequence. The ignition

trial, shutdown, and wait sequence

continues until either the pilot lights or the

Thermostat is set below room temperature

(to end the call for heat). The ignition

sequence can be reset by setting down the

Thermostat for one minute.

c. Trouble Shooting Guide. See Page 71.

44

Page 45

Figure 35: Wiring Diagram, Honeywell EI, USA, Continuous Circulation

45

Page 46

Figure 36: Wiring Diagram, Honeywell EI, USA, Intermittent Circulation

46

Page 47

Figure 37: Wiring Diagram, Honeywell EI, Canada, Continuous Circulation

47

Page 48

Figure 38: Wiring Diagram, Honeywell EI, Canada, Intermittent Circulation

48

Page 49

5. Johnson EI Sequence of Operation

a. Normal Operation

i. Thermostat or operating control calls for

heat. Vent Damper (if used) opens.

ii. Ignition Module Terminals 1, GND and the

Ignition Terminal are energized. Terminals 1

and GND power the Pilot Valve in the Gas

Valve supplying as to the Pilot. The Ignition

Terminal supplies voltage to the Ignition

Electrode creating an electric spark to ignite

the Pilot.

iii. The sensing Circuit between the J991 Pilot

Burner and the IGNITION MODULE proves

the presence of the Pilot Flame electronically

and the Ignition Terminal is de-energized.

iv. Terminals 3 and GND of the IGNITION

MODULE are energized and supply power to

the Main Gas Valve. The Gas Valve is

energized allowing main gas flow, and

ignition of Main Burners.

v. Call for heat ends. Ignition module is de-

energized, de-energizing gas valve, and

extinguishing pilot and main flame. Vent

Damper (if used) closes.

b. Safety Shutdown

i. Limit: Automatically interrupts power to the

Ignition Module and Gas Valve(s),

extinguishing pilot and main flame, when

water temperature exceeds set point.

Maximum allowable temperature is 250°F.

Circulator continues to operate with call for

heat, Vent Damper (if used) closes. Normal

operation resumes when water temperature

falls below set point.

ii. Blocked Vent Switch: Automatically

interrupts main burner operation when

excessive flue gas spillage occurs. Circulator

continues to operate, Vent Damper (if used)

remains open with call for heat. If blocked

vent switch is activated do not attempt to

place boiler in operation. Correct cause of

spillage and reset blocked vent switch.

iii. Flame Roll-out switch: automatically

interrupts main burner operation when

flames or excessive heat are present in

vestibule. Circulator continues to operate,

Vent Damper (if used) remains open with call

for heat. Control is single use device. If

flame roll-out switch is activated, do not

attempt to place boiler in operation. Correct

cause of spillage and replace flame roll-out

switch.

iv. Pilot:

– Pilot failure can occur during the start-up

or the operating cycle of the boiler. Any

pilot failure of the J991 Electronic Pilot, after

ignition of pilot flame will close the main gas

valve.

– For approximately 90 seconds after failure

of the J991 pilot, the module through the

ignition terminal will try to reestablish pilot

flame. If no pilot flame can be sensed by the

flame rod circuit, terminals 1 and GND are deenergized and the module will lock out on

safety. Five to six minutes after shutdown,

the IGNITION MODULE restarts the ignition

sequence. The ignition trial, shutdown, and

wait sequence continues until either the pilot

lights or the Thermostat is set below room

temperature (to end the call for heat). The

ignition sequence can be reset by setting

down the Thermostat for one minute.

c. Trouble Shooting Guide. See Pages 72 and 73.

49

Page 50

Figure 39: Wiring Diagram, Johnson EI, USA, Continuous Circulation

50

Page 51

Figure 40: Wiring Diagram, Johnson EI, USA, Intermittent Circulation

51

Page 52

Figure 41: Wiring diagram, Johnson EI, Canada, Continuous Circulation

52

Page 53

Figure 42: Wiring Diagram, Johnson EI, Canada, Intermittent Circulation

53

Page 54

6. Electronically Supervised Intermittent Ignition

(EP/EP-CSD-1) Sequence of Operation

a. Normal Operation

i. Thermostat or operating control calls for

heat.

ii. Terminal #6 of RM7890A Burner Control is

energized, initiating a microcomputer

monitored circuit test.

iii. The pilot valve (terminal 8) and ignition

transformer (terminal 10) are energized. The

pilot valve opens and the ignition electrode

sparks, igniting the pilot.

iv. After the pilot flame is proven, the ignition

terminal (10) is de-energized and the main

valve terminal (9) is energized, allowing main

gas flow and ignition of main burners.

"Main" gas light will be illuminated.

v. When the call for heat ends, terminal #6 is

de-energized, extinguishing the pilot and

main flames. "Main" gas light is deenergized.

b. Safety Shutdown

i. Limit: Automatically interrupts main burner

operation when water temperature exceeds

set point. Maximum allowable temperature is

250°F. Circulator continues to operate with

call for heat. Normal operation resumes

when water temperature falls below set point.

ii. Blocked Vent Switch: Automatically

interrupts main burner operation when

excessive flue gas spillage occurs. Circulator

continues to operate with call for heat. If

blocked vent switch is activated, do not

attempt to place boiler in operation. Correct

cause of spillage and reset blocked vent

switch.

iii. Flame Roll-out Switch: Automatically

interrupts main burner operation when flames

or excessive heat are present in vestibule.

Circulator continues to operate with call for

heat. Control is single use device. If flame

roll-out switch is activated, do not attempt to

place boiler in operation. Correct cause of

spillage and replace flame roll-out switch.

iv. RM7890A Burner Control: Automatically

interrupts main burner operation if a pilot

flame is not detected during the four or ten

second pilot flame establishing period. The

RM7890A will lockout or recycle based on

jumper settings. "Alarm" light will be

illuminated. Refer to instructions supplied

with RM7890A for additional control

information.

54

Page 55

Figure 43: Wiring Diagram, EP/EP-CSD-1 Ignition System, USA, Continuous Circulation

55

Page 56

Figure 44: Wiring Diagram, EP/EP-CSD-1 Ignition System, USA, Intermittent Circulation

56

Page 57

Figure 45: McDonnell & Miller PS-851 (120V) L.W.C.O. Wiring for Boilers with 24V Limit Circuits

Figure 46: McDonnell & Miller PS-851 (120V) L.W.C.O. Wiring for Boilers with 120V Limit Circuits (OP & EP)

57

Page 58

Figure 47: Hydrolevel OEM - 170/550/650/750 (120V) L.W.C.O. Wiring for Boilers with 24V Limit Circuits

Figure 48: Hydrolevel OEM - 170/550/650/750 (120V) L.W.C.O. Wiring for Boilers with 120V Limit Circuits

58

Page 59

VIII. System Start-up

GNINRAW

llawollofdnadnatsrednu,daeryletelpmoC

erofeblaunamsihtnisnoitcurtsni

.putratsgnitpmetta

A. Safe operation and other performance criteria were met

with the gas manifold and control assembly provided

on boiler when boiler underwent tests specified in

American National Standard for Gas-Fired LowPressure Steam and Hot Water Boilers, ANSI Z21.13.

B. Check Main Burners. Main burners must be properly

located on support bracket in Base Rear Panel, seated

on Main Burner Orifices, and secured with hitch pin

clips.

C. Verify that the venting, water piping, gas piping and

electrical system are installed properly. Refer to

installation instructions contained in this manual.

D. Confirm all electrical, water and gas supplies are

turned off at the source and that vent is clear of

obstructions.

E. FILL ENTIRE HEATING SYSTEM WITH WATER

and vent air from system. Use following procedure on a

Series Loop or multi-zoned system installed as per

Figure 25 to remove air from system when filling.

GNINRAW

sihtfoerusserpgnitarepomumixamehT

.erusserpsihtdeecxereveN.gisp05sireliob

.evlavfeilererusserpyfidomrogulptonoD

At completion, open all zone valves or shut-off

valves.

9. Close purge valve, continue filling the system until

the pressure gauge reads the desired cold fill

pressure. Close fill valve.

(Note - If make-up water line is equipped with