Page 1

As an ENERGY STAR® Partner, Burnham Hydronics has determined that the LEDV1, red at the 0.60 GPH rate,

nonoitamrofnignikeesnehW.rotcartnocgnitaehruoyllac,reliobotsriaperroecivresroF

.lebaLgnitaRnonwohssarebmuNlaireSdnarebmuNledoMrelioBedivorp,reliob

rebmuNledoMrelioB

VDEL

rebmuNlaireSrelioB etaDnoitallatsnI

rotcartnoCgnitaeH rebmuNenohP

sserddA

DNAGNITAREPO,NOITALLATSNI

ROFSNOITCURTSNIECIVRES

EL

®

SEIRESVD

TNEVTCERID

RELIOBDERIF-LIO

meets the ENERGY STAR guidelines for Energy efciency established by the United States Environmental Protection Agency (EPA).

81433101R16-1/10

Price - $3.00

Page 2

IMPORTANT INFORMATION - READ CAREFULLY

All boilers must be installed in accordance with National, State and Local Plumbing, Heating

and Electrical Codes and the regulations of the serving utilities. These Codes and Regulations

may differ from this instruction manual. Authorities having jurisdiction should be consulted

before installations are made.

In all cases, reference should be made to the following Standards:

USA BOILERS

A. Current Edition of American National Standard ANSI/NFPA 31, “Installation of Oil

Burning Equipment”, for recommended installation practices.

B. Current Edition of American National Standard ANSI/NFPA 211, “Chimneys, Fireplaces,

Vents, and Solid Fuel Burning Appliances”, For Venting requirements.

C. Current Edition of American Society of Mechanical Engineers ASME CSD-1, “Controls and

Safety Devices for Automatically Fired Boilers”, for assembly and operations of controls

and safety devices.

D. All wiring on boilers installed in the USA shall be made in accordance with the National

Electrical Code and/or Local Regulations.

CANADIAN BOILERS

A. Current Edition of Canadian Standards Association CSA B139, “Installation Code for Oil

Burning Equipment", for recommended Installation Practices.

B. All wiring on boilers installed in Canada shall be made in accordance with the Canadian

Electrical Code and/or Local Regulations.

The following terms are used throughout this manual to bring attention to the presence of hazards of various risk levels, or to

important information concerning product life.

DANGER

Indicates an imminently hazardous situation

which, if not avoided, will result in death, serious

injury or substantial property damage.

WARNING

Indicates a potentially hazardous situation which,

if not avoided, could result in death, serious injury

or substantial property damage.

Indicates a potentially hazardous situation which,

if not avoided, may result in moderate or minor

injury or property damage.

Indicates special instructions on installation,

operation, or maintenance which are important

but not related to personal injury hazards.

CAUTION

NOTICE

NOTICE

This boiler has a limited warranty, a copy of which is printed on the back of this manual.

It is the responsibility of the installing contractor to see that all controls are correctly installed and are operating

properly when the installation is complete. The warranty for this boiler is valid only if the boiler has been

installed, maintained and operated in accordance with these instructions.

2

Page 3

DANGER

DO NOT store or use gasoline or other ammable vapors or liquids in the vicinity of this or any other

appliance.

If you smell gas vapors, DO NOT try to operate any appliance - DO NOT touch any electrical switch or use

any phone in the building. Immediately, call the gas supplier from a remotely located phone. Follow the gas

supplier's instructions or if the supplier is unavailable, contact the re department.

WARNING

Boiler materials of construction, products of combustion and the fuel contain alumina, silica, heavy metals,

carbon monoxide, nitrogen oxides, aldehydes and/or other toxic or harmful substances which can cause

death or serious injury and which are known to the state of California to cause cancer, birth defects and

other reproductive harm. Always use proper safety clothing, respirators and equipment when servicing

or working nearby the boiler.

This boiler contains very hot water under high pressures. Do not unscrew any pipe ttings nor attempt

to disconnect any components of this boiler without positively assuring the water is cool and has no

pressure. Always wear protective clothing and equipment when installing, starting up or servicing this

boiler to prevent scald injuries. Do not rely on the pressure and temperature gauges to determine the

temperature and pressure of the boiler. This boiler contains components which become very hot when

the boiler is operating. Do not touch any components unless they are cool.

This boiler must be properly vented and connected to an approved vent system in good condition. Do

not operate boiler with the absence of an approved vent system.

This boiler needs fresh air for safe operation and must be installed so there are provisions for adequate

combustion and ventilation air.

The interior of the venting and air intake systems must be inspected and cleaned before the start of the

heating season and should be inspected periodically throughout the heating season for any obstructions.

Clean and unobstructed venting and air intake systems are necessary to allow noxious fumes that could

cause injury or loss of life to vent safely and will contribute toward maintaining the boiler's efciency.

This boiler is supplied with controls which may cause the boiler to shut down and not re-start without

service. If damage due to frozen pipes is a possibility, the heating system should not be left unattended in

cold weather; or appropriate safeguards and alarms should be installed on the heating system to prevent

damage if the boiler is inoperative.

This boiler is designed to burn No. 2 fuel oil only. Do not use gasoline, crankcase drainings, or any oil

containing gasoline. Never burn garbage or paper in this boiler. Do not convert to any solid fuel (i.e.

wood, coal). Do not convert to any gaseous fuel (i.e. natural gas, LP/propane). All ammable debris,

rags, paper, wood scraps, etc., should be kept clear of the boiler at all times. Keep the boiler area clean

and free of re hazards.

All boilers equipped with burner swing door have a potential hazard which if ignored can cause severe

property damage, personal injury or loss of life. Before opening swing door, turn off service switch to

boiler and disconnect two halves of Burner Swing Door Interlock wiring harness to prevent accidental

ring of burner outside the combustion chamber. Be sure to tighten swing door fastener completely and

reconnect two halves of Burner Swing Door Interlock when service is completed.

3

Page 4

WARNING

Improper installation, adjustment, alteration, service or maintenance can cause property damage, personal

injury or loss of life. Failure to follow all instructions in the proper order can cause personal injury or

death. Read and understand all instructions, including all those contained in component manufacturers

manuals which are provided with the appliance before installing, starting-up, operating, maintaining or

servicing this appliance. Keep this manual and literature in legible condition and posted near appliance

for reference by owner and service technician.

This boiler requires regular maintenance and service to operate safely. Follow the instructions contained

in this manual.

Installation, maintenance, and service must be performed only by an experienced, skilled and knowledgeable

installer or service agency.

All heating systems should be designed by competent contractors and only persons knowledgeable in

the layout and installation of hydronic heating systems should attempt installation of any boiler.

Installation is not complete unless a pressure relief valve is installed into the tapping located on top of

appliance - See Water Piping and Trim Section of this manual for details.

It is the responsibility of the installing contractor to see that all controls are correctly installed and are

operating properly when the installation is completed.

This boiler is suitable for installation on combustible ooring. Do not install boiler on carpeting.

Do not tamper with or alter the boiler or controls.

Inspect ueways at least once a year - preferably at the start of the heating season. The inside of

the combustion chamber, the vent system and boiler ueways should be cleaned if soot or scale has

accumulated.

Oil Burner and Controls must be checked at least once a year or as may be necessitated.

Do not operate unit with jumpered or absent controls or safety devices.

Do not operate unit if any control, switch, component, or device has been subject to water.

Table of Contents

I. Pre-Installation ............................................................6

II. Unpack Boiler ..............................................................7

III. Water Piping and Trim .................................................

IV. Venting/Air Intake Piping ..........................................12

V. Electrical and Sequence of Operations .......................

VI. Oil Piping ..................................................................21

VII. System Start-up ..........................................................23

VIII. Service and Cleaning ..................................................

IX. Repair Parts ...............................................................

9

18

29

32

X. Appendix

Low Water Cut Off .....................................................39

4

Page 5

Water Content: 6.1 gallons

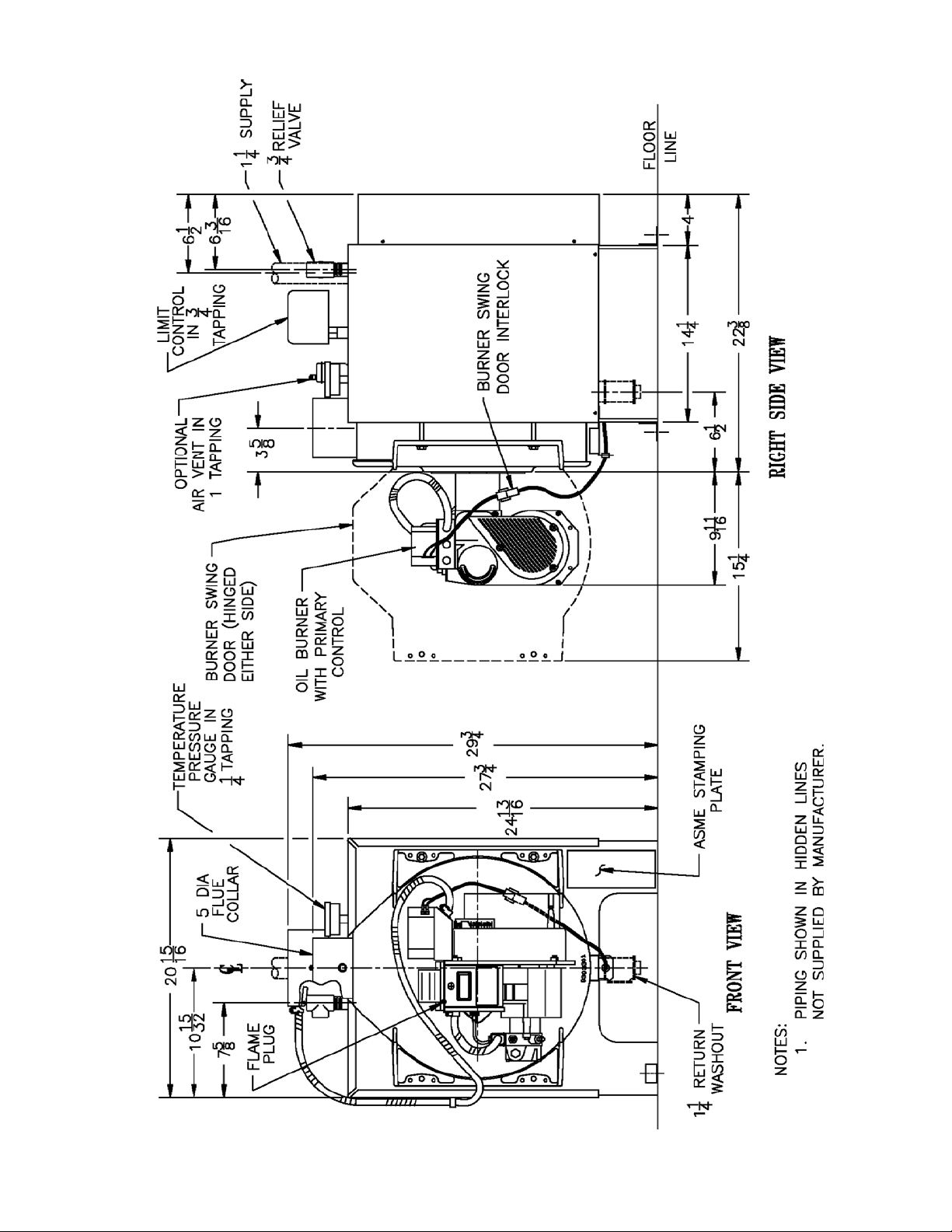

Figure 1: LEDV Packaged Boiler

5

Page 6

I. Pre-Installation

A. INSPECT SHIPMENT carefully for any signs of

damage.

1. ALL EQUIPMENT is carefully manufactured,

inspected and packed. Our responsibility ceases

upon delivery of crated boiler to the carrier in good

condition.

2. ANY CLAIMS for damage or shortage in shipment

must be led immediately against the carrier by the

consignee. No claims for variances from, or shortage

in orders, will be allowed by the manufacturer

unless presented within sixty (60) days after receipt

of goods.

B. LOCATE BOILER in front of nal position before

removing crate. See Figure 1. Boiler's approximate

shipping weight is 325 pounds.

1. LOCATE so that vent pipe will be short and direct.

Refer to Section V. A., General Venting Guidelines.

2. BOILER IS SUITABLE FOR INSTALLATION

ON COMBUSTIBLE FLOOR. Boiler cannot be

installed on carpeting.

3. FOR BASEMENT INSTALLATION, provide a

solid base, such as concrete, if oor is not level, or if

water may be encountered on oor around boiler.

1. In unconned spaces (basement) in buildings of

conventional frame, brick, or stone construction,

inltration normally is adequate to provide air for

combustion. An unconned space is a space whose

volume is greater than or equal to 50 cubic feet

per 1000 BTUH of the combined input of all air

consuming appliances in the space.

2. In a conned space, combustion air may be ducted

directly from the outdoors to the burner. Refer to

Section IV for installation of air intake duct to the

burner.

D. VENTILATION AIR must be provided to maintain the

ambient temperature at safe limits. Local and national

codes may apply and should be referenced.

1. In unconned spaces (basement) in buildings of

conventional frame, brick, or stone construction,

inltration normally is adequate to provide air for

ventilation.

2. In conned spaces (closet, etc.) two permanent

openings, one near the top of the enclosure and one

near the bottom, shall be provided. Each opening

shall have a free area of not less than 1 sq. inch per

1000 BTUH of the total input of all appliances in the

space.

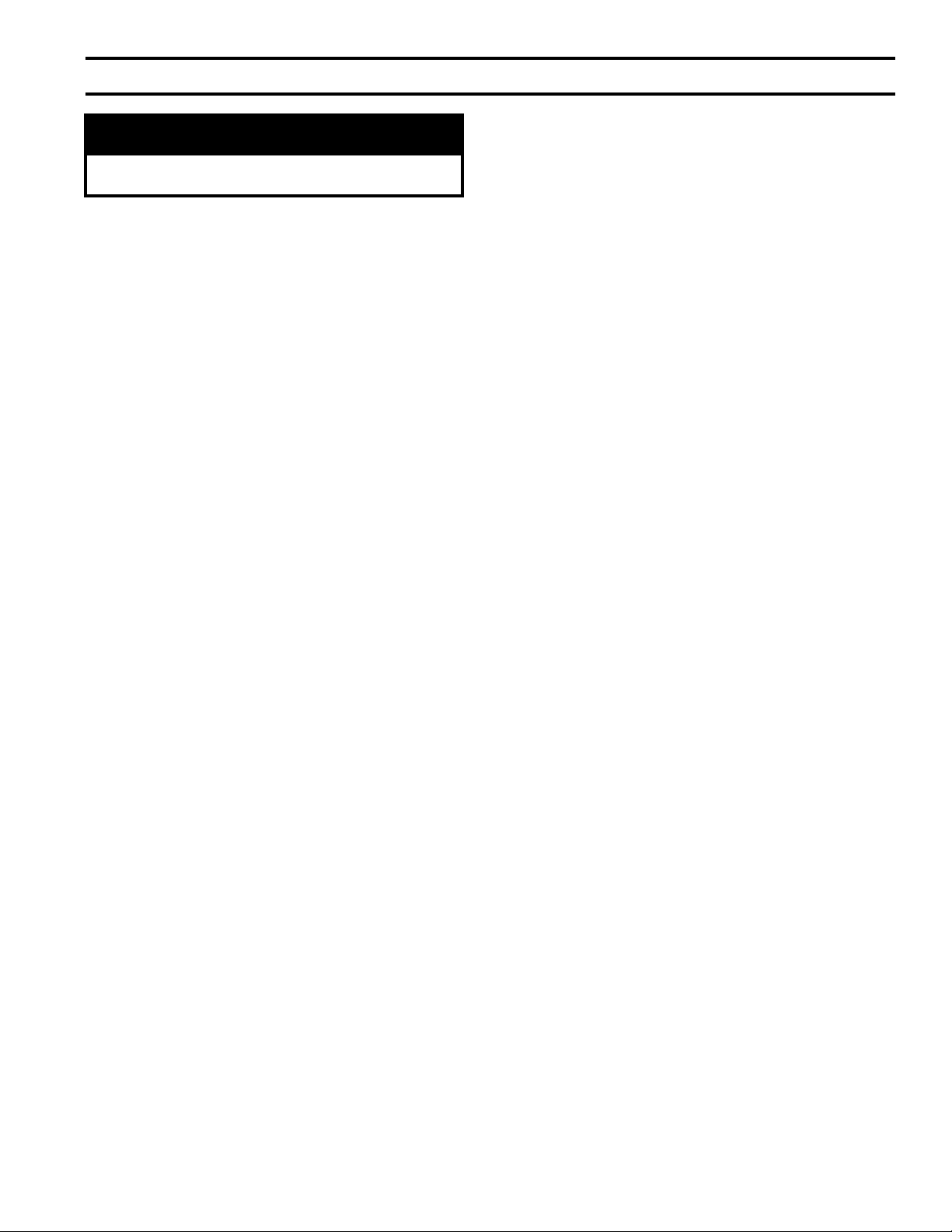

4. PROVIDE SERVICE CLEARANCE of at least 24”

at front of boiler for servicing.

5. For minimum clearances to combustible materials,

see Figure 2.

C. PROVIDE COMBUSTION AIR SUPPLY to

accommodate proper combustion of oil. Local and

national codes may apply and should be referenced.

E. Do not install boiler where gasoline or other ammable

vapors or liquids, or sources of hydrocarbons (i.e.

bleaches, cleaners, chemicals, sprays, paint removers,

fabric softeners, etc.) are used or stored.

6

Page 7

II. Unpack Boiler

CAUTION

Do not drop boiler. Do not bump boiler jacket

against oor.

A. REMOVE CRATE

1. Remove all fasteners at crate skid.

2. Lift outside container and remove all other inside

protective spacers and bracing. Remove vacuum

relief valve and miscellaneous trim bag containing

safety/relief valve, and pipe ttings.

B. REMOVAL OF BOILER FROM SKID

1. Boiler is secured to base with 2 bolts, 1 at left front

and 1 at right rear. Remove both bolts.

2. Tilt boiler, "walk" boiler backward, and set rear

legs down on oor. Tilt boiler backward, pull skid

forward and set front legs down on edge of skid.

Install close nipple, tee, and plug in return coupling.

See Section III and Figure 5. Point tee toward

permanent return location.

3. Tilt boiler backward and remove skid. Be careful not

to damage Burner or Jacket.

C. DETERMINE PROPER HINGE LOCATION FOR

BURNER SWING DOOR. Boiler is shipped with

hinges on left side. Approximately 12 inches are

required on the hinge side for burner clearance. If there

will be less than 12 inches from left side of boiler to

wall, move hinges to right side (refer to Paragraph D).

D. HINGE LOCATION CHANGE (if required) (refer to

Figure 3).

1. Pull 2 halves of Burner Swing Door Interlock apart.

Swing Door Interlock is connected to T-T terminals

on R7184P Control. Lift Honeywell R7184P Control

off of Burner Junction Box and disconnect wiring

harness from burner.

2. Remove 8 sheet metal screws from jacket. Remove

rear jacket box and bend both sides of Jacket

Wrapper up, see Figure 22.

3. Remove 2 (two) 5/16" - 18 x 3" long hex head cap

screws and at washers from right side of door.

Remove 2 hairpin cotter pins and 2 hinge pins

from hinges on left side of door and remove Door

Assembly from boiler. Inspect Front and Rear Door

Insulation Pieces and Combustion Chamber Liner,

see Paragraph G.

4. Remove 4 hex nuts from bolts that attach hinges and

hinge spacers to left side of Tubesheet. Remove 4

hex head cap screws that attach hinges to door.

5. Attach 2 hinge brackets & spacers to Tubesheet and

2 hinge brackets to Door on right side of boiler. 3

Holes in each Hinge Bracket must line up with 3

matching holes in Spacer, Tubesheet or Door. See

Figure 3. Tighten hex nuts, bolts and screws by

hand only.

6. Replace door assembly. Hinge brackets attached to

door must rest on top of hinge brackets attached to

tubesheet. See Figure 3. Slide hinge pins through

hinges from top and install cotter pins. Close door

and install 5/16" - 18 x 3" long hex head cap screws

through at washers and left side of door and into

tapped holes in tubesheet. Tighten all hex nuts,

bolts and screws. When door is installed properly, it

is parallel to Tubesheet when viewed from top and

sides.

7. Bend sides of Jacket Wrapper down and attach 2

Jacket Straps to 4 slots at bottom of Jacket Wrapper

sides with sheet metal screws. Install Rear Jacket

Box with 4 sheet metal screws. See Figure 22.

8. Connect wiring harness to burner Junction Box

and install Honeywell R7184P Control, see Wiring

Diagram, Figure 15 or 15A.

Reconnect Swing Door Interlock.

E. INSTALL BOILER CONTROL.

1. Pull bulb and capillary tube out of hole in back of

control. Insert bulb in immersion well on top of

boiler and secure control with set screw in control.

2. Secure exible conduit to Jacket Wrapper side with

conduit clamp and sheet metal screw. Conduit must

be on same side of boiler as Swing Door hinges.

F. MOVE BOILER TO PERMANENT POSITION by

sliding or walking.

G. INSPECT FRONT AND REAR DOOR INSULATION

AND COMBUSTION CHAMBER LINER

1. OPEN BURNER SWING DOOR on front of boiler.

Use ashlight to inspect insulation secured to

front and rear doors. Inspect ceramic ber blanket

secured to bottom of combustion chamber. Inspect

inner and outer door gaskets. Replace any damaged

pieces.

7

Page 8

Figure 2: Minimum Clearances to Combustible Materials

Figure 3: Proper Hinge Bracket Installation and Assembly

8

Page 9

III. Water Piping and Trim

WARNING

Failure to properly pipe boiler may result in improper operation and damage to boiler or building.

Oxygen contamination of boiler water will cause corrosion of iron and steel boiler components, and

can lead to boiler failure. U.S. Boiler’s Standard Warranty does not cover problems caused by oxygen

contamination of boiler water.

A. Design and install boiler and system piping to

prevent oxygen contamination of boiler water.

There are many possible causes of oxygen

contamination such as:

1. Addition of excessive make-up water as a result of

system leaks.

2. Absorption through open tanks and ttings.

3. Oxygen permeable materials in the distribution

system.

In order to insure long product life, oxygen sources

should be eliminated. This can be accomplished by

taking the following measures:

1. Repairing system leaks to eliminate the need for

addition of make-up water.

2. Eliminating open tanks from the system.

3. Eliminating and/or repairing ttings which allow

oxygen absorption.

4. Use of non-permeable materials in the distribution

system.

5. Isolating the boiler from the system water by

installing a heat exchanger.

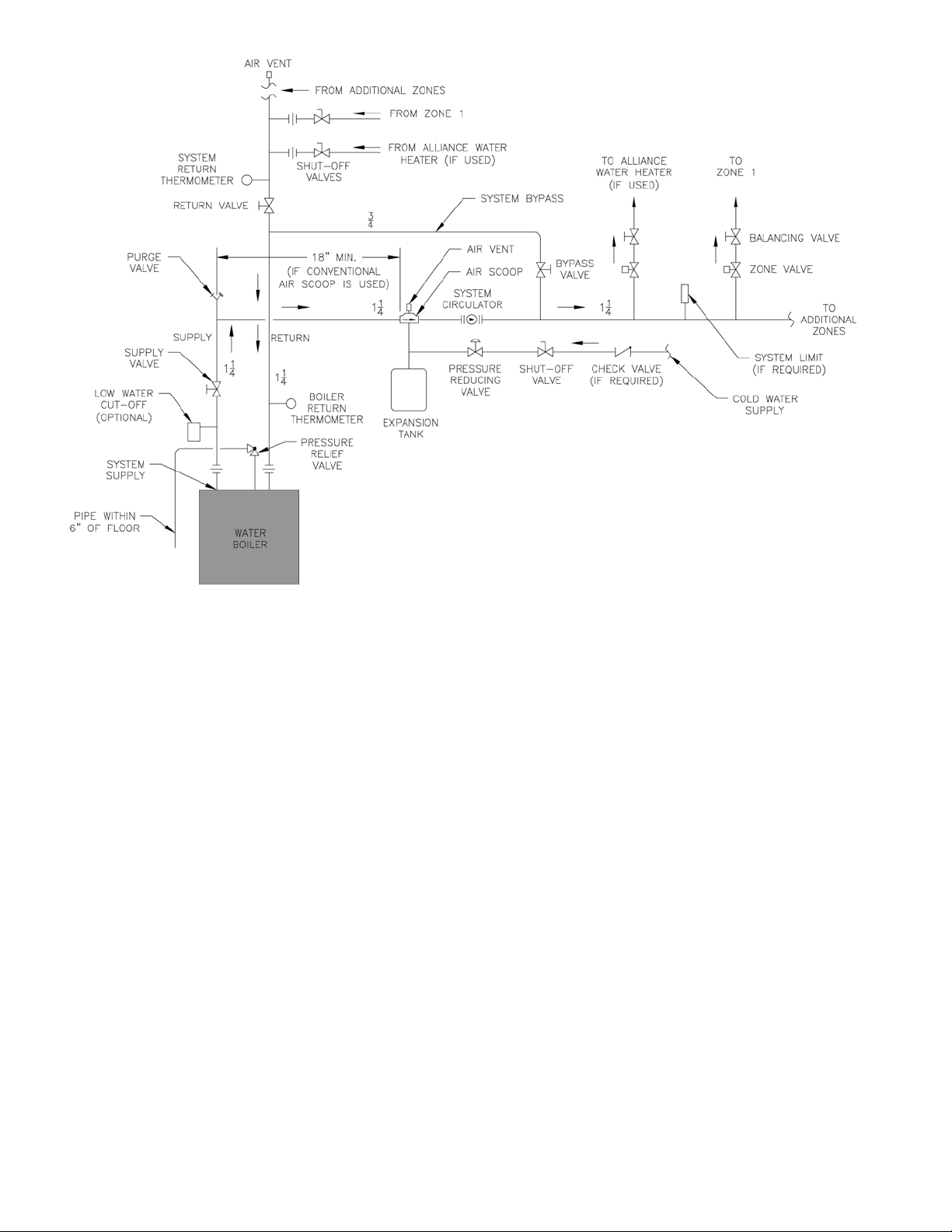

B. Connect System supply and return piping to boiler. See

Figures 5 and 7. Also consult I=B=R Installation and

Piping Guides. Maintain minimum ½ inch clearance

from hot water piping to combustible materials.

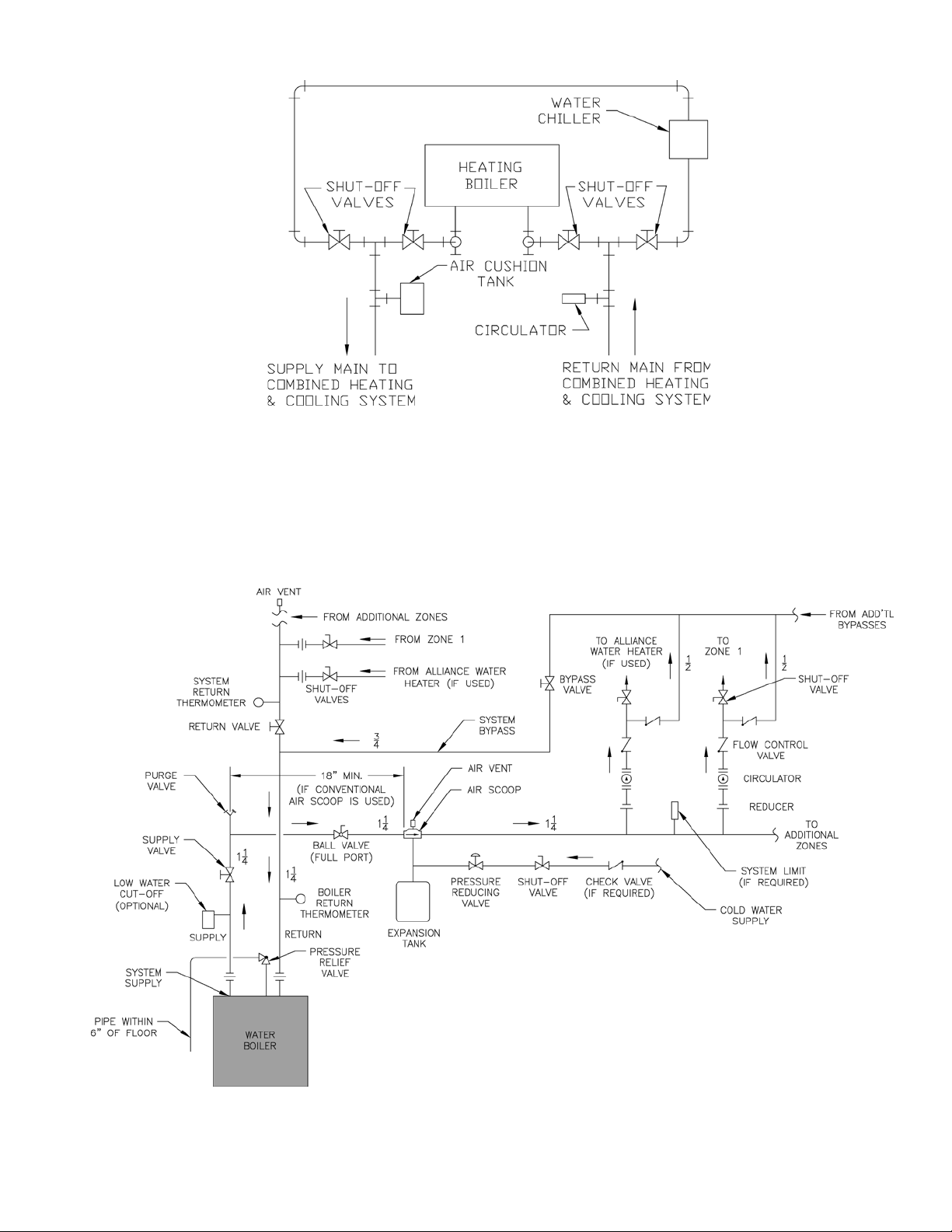

1. If this boiler is used in connection with refrigeration

systems, the boiler must be installed so that the

chilled medium is piped in parallel with the heating

boiler using appropriate valves to prevent the chilled

medium from entering the boiler, see Figure 6. Also

consult I=B=R Installation and Piping Guides.

2. If this boiler is connected to heating coils located

in air handling units where they may be exposed

to refrigerated air, the boiler piping must be

equipped with ow control valves to prevent gravity

circulation of boiler water during the operation of

the cooling system.

3. If boiler is used with an Alliance™ SL IndirectFired Domestic Water Heater, install the Alliance™

SL as a separate heating zone. Refer to the

Alliance™ SL Installation, Operating, and Service

Instructions for additional information.

4. Use a system bypass if the boiler is to be operated

in a system which has a large volume or excessive

radiation where low boiler water temperatures may

be encountered (i.e. converted gravity circulation

system, etc.).

CAUTION

Do not operate boiler with return water

temperatures below 120°F.

The bypass should be the same size as the supply

and return lines with valves located in the bypass

and return line as illustrated in Figures 5 and 7 in

order to regulate water ow for maintenance of

higher boiler water temperature.

Set the by-pass and return valves to a half throttle

position to start. Operate boiler until the system

water temperature reaches its normal operating

range.

Adjust the valves to maintain 180°F to 200°F boiler

water temperature and greater than 120°F return

temperature. Adjust both valves simultaneously.

Closing the boiler return valve while opening

the by-pass valve will raise the boiler return

temperature. Opening the boiler return valve while

closing the by-pass valve will lower the boiler return

temperature.

5. A hot water boiler installed above radiation level

must be provided with a low water cutoff device as

part of the installation.

If a low water cut-off is required, it must be

mounted in the system piping above the boiler.

The minimum safe water level of a hot water boiler

is just above the highest water containing cavity of

the boiler; that is, a hot water boiler must be full of

water to operate safely.

WARNING

Safety (relief) valve discharge piping must be

piped near oor to eliminate potential of severe

burns. Do not pipe in any area where freezing

could occur. Do not install any shut-off valves,

plugs or caps.

C. Install Safety Relief Valve. See Figures 5 and 7.

Safety Relief Valve must be installed with spindle in

vertical position. Installation of the relief valve must

be consistent with the ANSI/ASME Boiler and Pressure

Vessel Code, Section IV.

9

Page 10

Figure 5: Recommended Water Piping for Zone Valve Zoned Heating Systems

D. Install Drain Valve in return piping. See Figure 5.

E. Oil, grease, and other foreign materials which

accumulate in new hot water boilers and a new or

reworked system should be boiled out, and then

thoroughly ushed. A qualied water treatment

chemical specialist should be consulted for

recommendations regarding appropriate chemical

compounds and concentrations which are compatible

with local environmental regulations.

F. After the boiler and system have been cleaned and

ushed, and before relling the entire system add

appropriate water treatment chemicals, if necessary, to

bring the pH between 7 and 11.

G. Fill entire heating system with water and vent air

from system. Use the following procedure on a Series

Loop System equipped with zone valves. (See Figure

5).

1. Close isolation valve in boiler supply piping.

2. Isolate all circuits by closing zone valves or

balancing valves.

3. Attach a hose to hose bib located just below

isolation valve in boiler supply piping. (Note

- Terminate hose in ve gallon bucket at a suitable

oor drain or outdoor area).

4. Starting with one circuit, open zone valve.

5. Open hose bib.

6. Open ll valve (Make-up water line should be

located directly above isolation valve in boiler

supply piping).

7. Allow water to overow from bucket until discharge

from hose is bubble free for 30 seconds.

8. Open zone valve to the second zone to be purged,

then close the rst. Repeat this step until all zones

have been purged, but always have one zone open.

At completion, open all zone valves.

9. Close hose bib, continue lling the system until

the pressure gauge reads 12 psi. Close ll valve.

(Note - If make-up water line is equipped with

pressure reducing valve, system will automatically

ll to 12 psi.

10. Open isolation valve in boiler supply piping.

11. Remove hose from hose bib.

10

Page 11

Figure 6: Recommended Piping for Combination Heating &

Cooling (Refrigeration) Systems

Figure 7: Recommended Water Piping for Circulator Zoned Heating Systems

11

Page 12

IV. Venting / Air Intake Piping

A. General Guidelines

1. Vent system installation must be in accordance

with these instructions and applicable provisions of

local building codes. Contact local building or re

ofcials about restrictions and installation inspection

in your area.

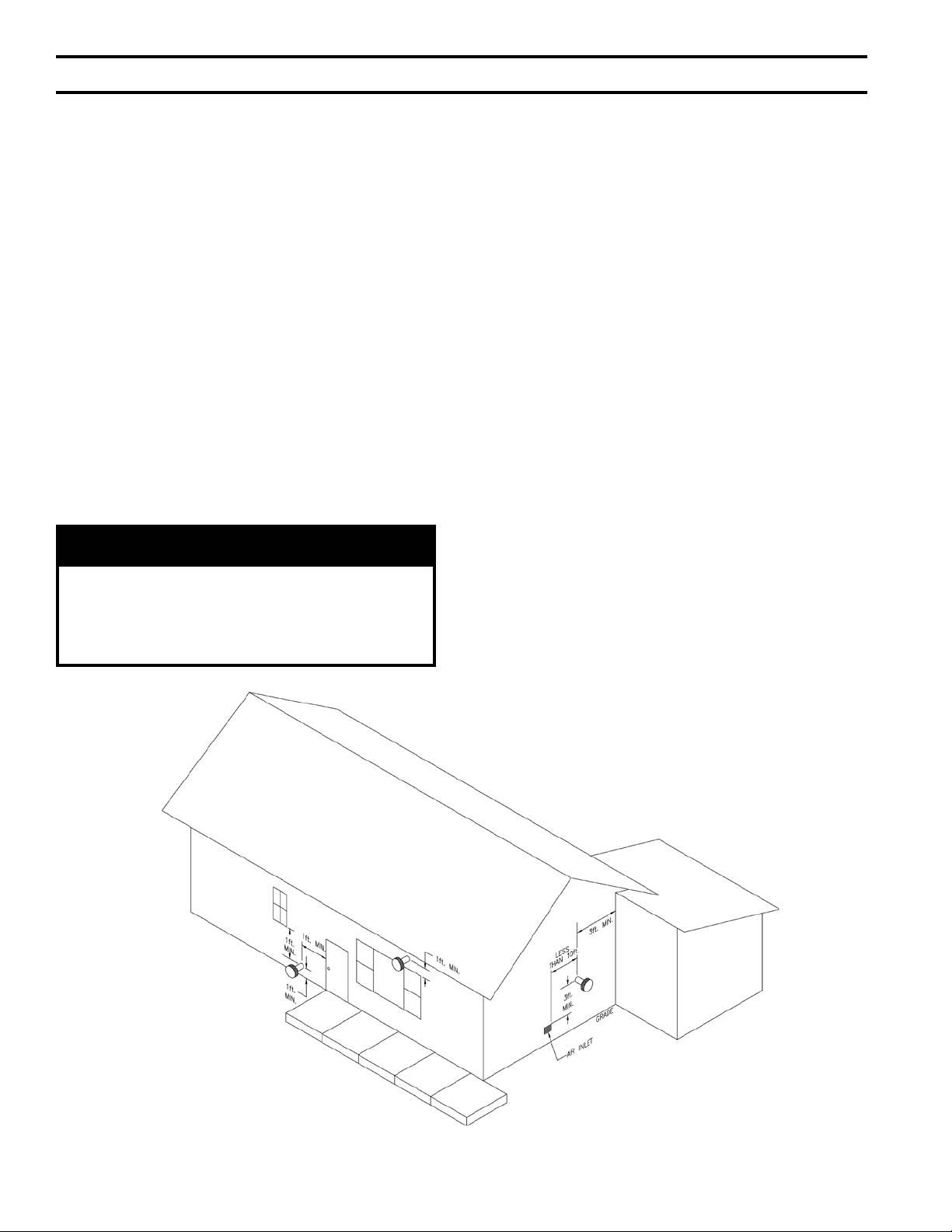

2. The LE®DV Series is designed as a Direct Vent

boiler. In this conguration, all air for combustion

is supplied directly to the burner from outdoors and

ue gases are vented directly outdoors (through

wall). See Figures 10 and 11. The LEDV may

be side-wall vented with combustion air supplied

from indoors. This conguration may be used in

installations where inltration provides adequate air

for combustion and ventilation. Flue gases are still

vented directly outdoors (through wall).

3. For minimum clearances to combustible materials

refer to Figure 2.

4. Maximum wall thickness that vent terminal may be

installed through is 10 inches.

WARNING

DO NOT locate vent terminal where exposed to

prevailing wind. Moisture and ice may form on

surfaces around vent termination. To prevent

deterioration, surfaces should be in good repair

(sealed, painted, etc.).

5. Locate the vent terminal so vent pipe is short and

direct, and at a place on the exterior wall that

complies with the minimum distances as specied in

Figure 8 and listed below. The vent terminal must

be located:

a. Not less than 12 inches above grade plus snow

accumulation (as measured to the nearest edge of

terminal).

b. Not less than 3 feet to center of terminal above

any forced air inlet located within 10 feet.

c. Not less than 1 foot to center of terminal

horizontally from any door, window or gravity

air inlet.

d. Not less than 7 feet to center of terminal above a

public walkway.

e. Not less than 3 feet to center of terminal from an

inside corner of an L-shaped structure.

f. Not less than 1 foot from nearest surface of

terminal to a roof soft.

g. Not directly above, or not less than 6 feet

horizontally from an oil tank vent or gas meter.

h. Not less than 2 feet from nearest surface of

terminal to an adjacent building.

12

Figure 8: Vent Terminal Location

Page 13

CAUTION

Operation of boiler with improperly adjusted

burner may result in soot damage to side of

house.

6. Intake Terminal Location (Direct Vent only) Locate Air Intake Terminal not less than 12 inches

to the left, right, or bottom of the vent terminal. Do

not locate air intake terminal above vent terminal.

Intake terminal must be at least 12 inches above

grade plus snow accumulation; at least 1 foot from a

roof soft; at least 3 feet from an inside corner of an

L-shaped structure. See Figure 9.

7. The LEDV must be vented with 4" Z-Flex Direct

Oil™ Vent. 20 feet is the maximum vent length

allowed. The vent pipe is available in 5, 10, 15, and

20 foot lengths. Table 1 lists vent part numbers.

Table 1: Vent Pipe Part Numbers

4" Direct Oil™ Vent Pipe

Pipe Length Part No.

5 Ft. 8113302

10 Ft. 8113303

15 Ft. 8113304

20 Ft. 8113305

8. The vent system must be completed with the Direct

Oil™ Vent Kit, which is shipped with the boiler.

Components of this kit are listed in the Repair Parts

Section of this manual.

DANGER

Vent pipe may not be spliced. Do not drill through

vent pipe. Do not operate boiler if vent pipe has

been crushed. Vent pipe must be completely

sealed. Do not operate boiler if vent pipe insulation

sleeve is damaged, frayed or missing.

B. Vent Installation (Direct Vent and Side-Wall Vent)

1. Install Vent Terminal. See Figure 10.

a. After determining the location from previous

Section, cut an opening in the wall for the vent

terminal.

• Combustible wall: 8 inches diameter hole

is required to maintain a 1 inch clearance to

combustible materials.

• Non-combustible wall: 6½ inches diameter

hole is required.

b. Secure 10" square trim plate to outside wall.

c. Insert the vent terminal through the opening until

the stop bead rest against the trim plate.

d. Slide the 10" square inside trim plate assembly

(tted with gear clamp) onto the terminal pipe.

Figure 9: Intake Terminal Location

13

Page 14

Figure 10: Vent Installation

14

Figure 11: Vent Connector, Un-Assembled

Page 15

Figure 12: Vent Connector, Assembled

Figure 13: Air Intake Installation

15

Page 16

e. Secure the inside trim plate to inside wall.

f. Tighten the gear clamp to the terminal pipe.

g. Seal all external joints with a weatherproof

caulk.

b. Avoid any sags or dips in vent pipe.

C. Air Intake Installation (Direct Vent only)

See Figure 13.

2. Cut vent pipe to length with a hack saw.

3. Install Vent Connector/Appliance Adaptor. See

Figures 11 and 12.

a. Apply a continuous bead of high temperature

adhesive/sealant (supplied with boiler) around

outside of corrugated pipe of vent connector.

b. Twist vent connector into end of vent pipe.

Turn the connector counter-clockwise until it is

engaged approximately 4 inches into the inner

vent pipe and the outer collar of the connector

overlaps the outside of the vent pipe.

c. Tighten the gear clamp on the outer collar of the

connector.

d. Repeat steps a. through c. with the appliance

adapter.

4. Connect vent pipe to boiler.

a. Apply a continuous bead of high temperature

adhesive/sealant (supplied with boiler) to inside

of appliance adapter (approximately ½ inch from

end).

b. Slip appliance adapter over boiler ue collar and

tighten gear clamp.

5. Connect vent pipe to terminal.

a. Carefully slide insulation sleeve over vent

connector and vent pipe until gear clamp on

small end of connector can be accessed.

WARNING

Do not operate LEDV with barometric damper in

vent. Do not connect venting to chimney.

b. Apply a continuous bead of high temperature

adhesive/sealant (supplied with boiler) on inside

of cent connector (approximately ½ inch from

end).

c. Clip connector over vent terminal until it is fully

engaged. Then tighten gear clamp.

d. Slide insulation sleeve over terminal connection

so that connector is completely covered.

e. Secure each end of insulation sleeve with the

gear clamps provided.

6. Secure vent pipe in position with pipe straps.

a. All horizontal runs must rise at least ¼ inch per

foot toward vent terminal.

WARNING

Do not reduce size of air intake pipe.

Read, understand and follow combustion air

instruction restrictions contained in the PreInstallation Section of this manual.

1. General

a. Use 4 inch diameter single wall metal pipe and

ttings available at most heating distributors.

Maximum allowable air intake length is 40

equivalent feet. Each elbow is equal to 6

equivalent feet.

b. Start at Burner. Work toward air intake terminal.

c. Maintain minimum of ¼ inch per foot slope in

horizontal run to air intake terminal. Slope down

toward air intake terminal.

d. Seal all joints gas-tight, using silicone caulk or

self-adhesive aluminum tape.

2. After determining location, cut a hole in the wall to

accept 4 inch air intake pipe.

3. Remove the black plastic inlet cover from the right

side of the Beckett AFII burner.

4. Mount the vacuum relief valve tee assembly or 90°

elbow into the burner inlet ring. See Figure 13.

a. Secure with at least three (3) sheet metal screws

evenly spaced around the burner inlet ring.

b. Assemble the vacuum relief valve balance

weight onto the gate. Refer to the vacuum relief

valve manufacturer's instructions.

c. Mount the vacuum relief valve into the tee and

fasten with a screw and nut in collar tabs. To

ensure proper operation, the gate must be level

across the pivot point and plumb. Refer to

vacuum relief valve manufacturer's instructions.

5. Install remainder of air intake, securing each joint

with at least three (3) sheet metal screws evenly

spaced.

WARNING

Do not locate air intake termination where natural

convention or wind conditions may cause the

boiler exhaust gases to be drawn into the air

intake.

16

Page 17

6. Install air intake terminal. See Figure 13.

7. Seal all external joints with weatherproof caulk.

WARNING

Do not locate air intake where petroleum distillates,

CFC's, detergents, volatile vapors or any other

chemicals are present. Severe boiler corrosion

and failure will result.

2. Attach the Air Intake Terminal directly to the burner

intake collar.

3. Discard the Vacuum Relief Valve.

Alternate to 1., 2. and 3.:

Keep the black plastic inlet cover in place and

discard the Air Intake Terminal and the Vacuum

Relief Valve.

WARNING

D. Air Intake Installation (Indoor Air for Combustion)

1. Remove the black plastic inlet cover from the right

side of the Beckett AFII burner.

Do not locate air intake termination into a crawl

space or under a deck that also includes the

vent termination, regardless of distance between

terminations.

17

Page 18

V. Electrical and Sequence of Operations

A. ELECTRICAL

1. Install wiring and ground boiler in accordance with

requirements of authority having jurisdiction, or in

absence of such requirements the National Electrical

Code, ANSI/NFPA 70, and/or the CSA C22.1

Electric Code.

2. A separate electrical circuit must be run from

the main electrical service with an over-current

device/disconnect in the circuit. A service switch is

recommended and may be required by some local

jurisdictions.

3. Wiring should conform to Figures 15 and 15A.

4. Thermostat heat anticipator setting = 0.3 amp.

B. SEQUENCE OF OPERATIONS

1. General

the L7248C limit control which in turn energizes the

R7184P primary control to turn on the burner. The

circulator will operate as long as there is a call for

heat. If the call for heat is not satised and the high

limit setting is reached, the circulator will continue

to operate, and the burner will stop until the high

limit circuit is closed by a drop in boiler water

temperature.

. A call for heat by the thermostat energizes

c. If the burner ignites within 15 seconds from the

time the oil valve opens and the CAD cell senses

a ame, the electronic ignitor is de-energized

and the burner will operate until the call for

heat is satised or the setting of the high limit is

reached.

d. A manual reset button is provided to reset the

safety switch after lockout.

e. When the call for heat ends, or the CAD cell

fails to sense a ame, the oil valve will close.

The combustion blower will continue to operate

for a postpurge period of approximately two (2)

minutes.

4. CAD Cell.

The Beckett AFII burners used on the LEDV Series

are supplied with a C554A Cadmium Sulde (cad

cell) Flame Detector to monitor the burner ame and

shut down the burner on ignition failure or on ame

failure during the run cycle. On either failure, the

manual reset button on the R7184P will be tripped.

2. L7248C Combination Limit control.

The switching action within the L7248C control has

one setting, the high limit. The switching relay is

controlled by the low voltage room thermostat. On

a call for heat, the relay contacts close to complete

the line voltage circulator circuit and also the burner

circuit if the boiler water temperature is below the

high limit setting. The high limit switch shuts off

the burner if boiler water temperature exceeds the

high limit setting. See Figure 14.

3. R7184P Oil Primary Control.

The R7184P operates the oil burner motor, solenoid

oil valve, and the electronic ignitor in response to a

call for heat from the L7248C limit control.

a. A call for heat will energize the burner motor and

electronic ignitor.

b. After a 15 second pre-purge period, in which

time a draft is established in the ueways, the oil

valve is opened.

Figure 14: L7248/L7224 Setpoint and Differential

Switching Action

18

Page 19

Figure 15: Beckett Burner Schematic Wiring Diagram

19

Page 20

Figure 15A: Riello BF Burner Schematic Wiring Diagram

Refer to the information supplied by the burner manufacturer for any additional burner information.

20

Page 21

VI. Oil Piping

A. General

1. Use exible oil line(s) so that Swing Door can be

opened without disconnecting oil supply.

2. A supply line fuel oil lter is recommended as a

minimum for all ring rates but a pleated paper fuel

oil lter is recommended for the lowest (.6 GPH)

ring rate application to prevent nozzle fouling.

3. Use Flared ttings only. Do not use compression

ttings.

4. Use of a high efciency micron oil lter (Garber

or equivalent) in addition to conventional lter is

highly recommended.

B. Single-pipe Oil Lines.

1. Standard burners are provided with single-stage

3450 rpm fuel units with the bypass plug removed

for single-pipe installations.

2. The single-stage fuel unit may be installed singlepipe with gravity feed or lift. Maximum allowable

lift is 8 feet. See Figure 16.

NOTICE

Single-pipe installations must be absolutely airtight

or leaks or loss of prime may result. Bleed line and

fuel unit completely.

Table 2: Single-Stage Units (3450 RPM) -

Two Pipe Systems

Maximum Length of Tubing

"H" + "R"

Lift "H"

3/8" OD

Tubing (3 GPH)

0' 84' 100'

1' 78' 100'

2' 73' 100'

3' 68' 100'

4' 63' 100'

5' 57' 100'

6' 52' 100'

7' 47' 100'

8' 42' 100'

9' 36' 100'

10' 31' 100'

11' 26' 100'

12' 21' 83'

13' --- 62'

1/2" OD

Tubing (3 GPH)

14' --- 41'

Figure 16: Single-Pipe Installation

21

Page 22

Figure 17: Two-Pipe Installation

C. Two-Pipe Oil Lines.

1. For two-pipe systems where more lift is required,

the two-stage fuel unit is recommended. Table

2 (single-stage) and Table 3 (two-stage) show

allowable lift and lengths of 3/8-inch and ½-inch

OD tubing for both suction and return lines. Refer

to Figure 17.

Table 3: Two-Stage Units (3450 RPM) -

Two Pipe Systems

Maximum Length of Tubing

Lift "H"

3/8" OD

Tubing (3 GPH)

0' 93' 100'

2' 85' 100'

4' 77' 100'

6' 69' 100'

8' 60' 100'

10' 52' 100'

12' 44' 100'

14' 36' 100'

16' 27' 100'

18' --- 76'

"H" + "R"

1/2" OD

Tubing (3 GPH)

22

Page 23

VII. System Start-up

WARNING

All boilers equipped with burner swing door have a potential hazard which can cause severe property damage,

personal injury or loss of life if ignored. Before opening swing door, turn off service switch to boiler to

prevent accidental ring of burner outside the combustion chamber. Be sure to tighten swing door fastener

completely when service is completed.

A. ALWAYS INSPECT INSTALLATION BEFORE

STARTING BURNER.

B. FILL HEATING SYSTEM WITH WATER. Refer to

Section III, G.

C. CHECK CONTROLS, WIRING AND BURNER to be

sure that all connections are tight and burner is rigid,

that all electrical connections have been completed and

fuses installed, and that oil tank is lled and oil lines

have been tested.

D. LUBRICATION — Follow instruction on burner and

circulator label to lubricate, if oil lubricated. Most

motors currently used on residential type burners

employ permanently lubricated bearings and thus do

not require any eld lubrication. Water lubricated

circulators do not need eld lubrication.

Do not over-lubricate. This can cause as much trouble

as no lubrication at all.

E. ADJUST CONTROL SETTINGS with burner

service switch turned “ON” and room thermostat set

10° below room temperature.

1.

Adjustment and display modes of the L7248/

L7224 Oil Electronic Aquastat Controller.

a. On the L7248/L7224, the overall range of the

High Limit is from 180°F to 240°F (82°C to

116°C).

b. Set the High Limit (designated HL) on the

L7248/L7224 Aquastat Control at 180°F. This

temperature setting may be varied to suit

requirements of installation. Differential is xed

at 15°F.

i. Adjusting Settings:

To discourage unauthorized changing of

Aquastat settings, a procedure to enter the

adjustment mode is required. To enter the

adjustment mode, press the UP, DOWN,

and I buttons (see Figure 18) simultaneously

for three (3) seconds. Press the ‘I’ button

until the feature requiring adjustment is

displayed (press the “I” button again and

will display LL (Low Limit on L7224):

Figure 18: L7248 Circuit Board Layout -

Horizontal Mount

· High Limit

· °F -- °C (Toggle)

Then press the UP and/or DOWN buttons

to move the set point to the desired value.

After 60 seconds without any button inputs,

the control will automatically return to the

READ mode.

ii. Display:

In the RUN mode, the Aquastat will

ash “bt” (boiler temp.) followed by the

temperature (i.e., 220), followed by °F or

°C.

To read boiler settings, press the ‘I’ key to

read the parameter of interest. For example,

press I (HL) High Limit is displayed,

followed by a three-digit number, i.e., 220,

followed by °F or °C.

See Figure 19 for Display Readout

Denitions.

Display

Text Description Shows

bt Boiler Temperature

HL High Limit

err Error Code

f Degrees Fahrenheit

c Degrees Celsius

LL Low Limit

Figure 19: Display Readout Denitions

23

Page 24

After approximately 60 seconds without

noitcA esnopseRmetsyS

tatsomrehT

rofsllac

taeh

.stratsrotalucriC

renruB.dekcehcsierutarepmetrelioB

sierutarepmetretawehtnehwstratser

.gnittestimilhgihwoleb

relioB

ehtsdeecxe

timilhgih

nehwstratserrenruB.ffodenrutsirenruB

ehtwolebsporderutarepmetretaweht

.laitnereffidehtsunimgnittestimilhgih

tatsomrehT

deifsitassi

.ffonrutrenrubdnarotalucriC

rorrE

noitidnoc

stuptuolla,detcetedsinoitidnocrorrenafI

lortnoC.ffosirenruB.nwodtuhsera

nehwstratserdnanoitcnufotseunitnoc

.detcerrocsirorre

eht,ecneuqeskcehcrorreehtgniruD

dnarosnesehtnitfirdrofskcehcmetsys

.snoitcennocehtninoisorroc

any key pressed, the display will enter a

dim display mode. To return to the bright

display mode, simply press any key.

2. Control Operating Characteristics

The L7248/L7224 can be in any three (3)

operational states: Normal, High-Limit and Error.

The controller moves back and forth from HighLimit to Normal state as part of normal operation.

The controller will enter the Error state when there

is an abnormal condition. The operating states are:

a. Normal: Boiler temperature has gone below the

high limit setting (minus the differential) and has

not exceeded the high limit setting.

b. High-Limit: Boiler temperature has gone above

the high limit setting and has not dropped below

the high limit setting (minus the differential).

c. Error: The controller has detected an error

condition (e.g., open sensor) and has shut down

the burner output. The controller continues to

monitor the system and automatically restarts if

the error condition clears. See Table 4.

Table 4: LED Error Codes

Error Code Cause/Action

Err1 Sensor fault; check sensor.

Err2 ECOM fault; check EnviraCom™ wiring.

Err3 Hardware fault’ replace control.

Table 5: L7248/L7224 Controller

Operating Sequence

setting. The high limit switch shuts off the burner

if boiler water temperature exceeds the high limit

setting. The circulator will continue to operate

as long as the thermostat is calling for heat. The

high limit automatically resets after the water

temperature drops past the setpoint and through

the differential.

F. BURNER START-UP

WARNING

d. Low-Limit: Boiler temperature has gone

below the low limit setting (minus the low limit

differential) and has not gone above the low limit

setting.

e. The operating sequence for L7248/L7224 is

described below and shown in Table 5.

The switching action in the L7248/L7224 control

has one setting, the high limit, see Figure 14.

The switching relay is controlled by the low

voltage room thermostat. On a call for heat, the

relay contacts make to complete the line voltage

Table 6: Beckett AFII Burner

Boiler

Model

LEDV1 0.60 AFII 85 HLX50HD 0.50 x 70°B 2.5 #2 140

LEDV2 1.00 AFII 150 HLX50HE 0.85 x 60°B 3.5 #3 140

LEDV3 1.25 AFII 150 HLX50HE 1.00 x 60°B 4.0 #5 140

24

circulator circuit and also the burner circuit if the

boiler water temperature is below the high limit

Firing Rate

(GPH)

Burner

Model

Air Tube

Combination

Do not attempt to start the burner when excess

oil has accumulated in the chamber, when boiler

is full of vapor or when combustion chamber is

very hot.

1. VERIFY burner settings.

a. Refer to Table 6 for Beckett Burner Settings.

Refer to Table 6A for Riello BF Burner Settings.

b. Check electrodes to comply with dimensions

shown in Figure 20A. For adjustment, loosen the

electrode clamp screw and slide/rotate electrodes

as needed. Securely re-tighten the clamp screw

when nished.

Settings

Delavan

Nozzle

Air

Head

(stop screw)

Pump Pressure

(PSIG)

Page 25

Table 6A: Riello BF Burner Settings

Boiler

Model

LEDV1 0.60 BF3 0.50 - 60° A 4.0 145 0

LEDV2 1.00 BF5 0.85 - 60° A 5.0 145 1.0

LEDV3 1.25 BF5 1.00 - 60° A 6.5 145 3.0

c. Upon reinstallation of the nozzle line assembly,

check that head/air plate setting number pointer

lines up with a number on the scale, which

matches a value shown in Table 6 for a particular

boiler/burner model.

2. Open all shut-off valves in the oil supply line to the

burner.

3. Attach a plastic hose to fuel pump vent tting and

provide a container to catch the oil.

4. REMOVE GAUGE PORT PLUG from fuel pump

and install pressure gauge.

5. REMOVE TEST PLUG IN FLUE COLLAR.

6. Close the service switch to start the burner. If the

burner does not start immediately, check the manual

overload switch on the motor, if so equipped, and

the safety switch of the burner primary control.

Firing Rate

(GPH)

Burner

Model

Figure 20A: Electrode Tip Gap & Spacing

Delavan Oil

Nozzle

Air Gate

8. INSTALL PRESSURE GAUGE

a. Either, remove plastic hose and oil pump vent

Pump Pressure

tting, then, install a reliable pressure gauge

into vent tting port, or install the gauge into the

nozzle port. See Figure 20B.

(PSIG)

Settings

Turbulator

WARNING

Very hot ue gases come out of sight hole when

boiler is operated without sight plug installed.

Always wear proper eye protection.

7. Bleed the fuel unit when the burner motor starts

rotating. To bleed, loosen the vent tting (with

plastic hose attached) and catch the oil in an empty

container. Continue to bleed for 15 seconds after oil

is free of air bubbles. Tighten the vent tting when

all the air is purged. NOTE: Bleeding might not be

necessary with a two pipe system. When vent tting

is closed, burner ame should start immediately.

Figure 20B: Checking / Adjusting Fuel

Pump Pressure

9. CHECK / ADJUST OIL PRESSURE

a. Check oil pressure to correspond to a specied

value for a particular LEDV boiler model. Refer

to Table 6.

25

Page 26

b. For adjustment, locate oil pressure adjusting

screw and turn screw to obtain oil pressure

specied.

10. ADJUST AIR SETTING on burner for alight orange

colored ame. Flame should be solid and compact.

Use smoke tester and adjust air for a minimum

smoke (not to exceed #1) with a minimum excess

air. Make nal check using suitable instrumentation

to obtain CO2 of 11.5% to 12%. These settings

will assure a safe and efcient operating condition.

If ame appears stringy instead of solid re, try

another nozzle of the same type.

11. TURN "OFF" BURNER BY OPENING SERVICE

SWITCH. Remove pressure gauge. Install gauge

port plug and tighten. Re-start burner.

12. HINTS ON COMBUSTION

a. NOZZLES — Although the nozzle is a relatively

inexpensive device, its function is critical to

the successful operation of the oil burner. The

selection of the nozzle supplied with the LEDV

boiler is the result of extensive testing to obtain

the best ame shape and efcient combustion.

Other brands of the same spray angle and spray

pattern may be used but may not perform at the

expected level of CO2 and smoke. Nozzles are

delicate and should be protected from dirt and

abuse. Nozzles are mass-produced and can vary

from sample to sample. For all of those reasons a

spare nozzle is a desirable item for a serviceman

to have.

b. FLAME SHAPE — Looking into the

combustion chamber through the ame plug

hole, the ame should appear straight with

no sparklers rolling up toward the top of the

chamber. If the ame drags to the right or left,

sends sparklers upward or makes wet spots on

the rear door insulation piece, the nozzle should

be replaced. If the condition persists look for

fuel leaks, air leaks, water or dirt in the fuel as

described below.

c. FUEL LEAKS — Any fuel leak between the

pump and the nozzle will be detrimental to good

combustion results. Look for wet surfaces in the

air tube, under the transformer, and around the

air inlet. Any such leaks should be repaired as

they may cause erratic burning of the fuel and in

the extreme case may become a re hazard.

d. AIR LEAKS — Any such leaks should be

repaired, as they may cause erratic burning of

the fuel and in extreme cases may become a re

hazard.

There are many possible causes of air leaks in oil

lines such as:

i. Fitting leaks due to mis-ared tubing or

damaged tting.

26

ii. Fuel line leak due to crushed or bent tubing.

iii. Filter connection leaks.

iv. Tank connection leaks.

There are various test kits available to trace

air leaks, such as electronic sight glasses.

Follow the manufacturers' instructions to

nd air leaks.

The following actions can eliminate air leaks:

i. Bleed pump as detailed in System Start-Up

Section of this manual.

ii. Replace are ttings.

iii. Replace oil supply line.

iv. Repair oil lter leaks.

v. Replace or repair tank ttings.

e. GASKET LEAKS — If 11.5 to 12.5% CO2 with

a #1 smoke cannot be obtained in the breeching,

look for air leaks around the ue collar. Such

air leaks will cause a lower CO2 reading in the

breeching. The smaller the ring rate the greater

effect an air leak can have on CO2 readings.

f. DIRT — A fuel lter is a good investment.

Accidental accumulation of dirt in the fuel

system can clog the nozzle or nozzle strainer and

produce a poor spray pattern from the nozzle.

The smaller the ring rate, the smaller the slots

become in the nozzle and the more prone to

plugging it becomes with the same amount of

dirt.

g. WATER — Water in the fuel in large amounts

will stall the fuel pump. Water in the fuel in

smaller amounts will cause excessive wear on

the pump, but more importantly water doesn’t

burn. It chills the ame and causes smoke and

unburned fuel to pass out of the combustion

chamber and clog the ueways of the boiler.

h. COLD OIL — If the oil temperature approaching

the fuel pump is 40°F or lower poor combustion

or delayed ignition may result. Cold oil is harder

to atomize at the nozzle. Thus, the spray droplets

get larger and the ame shape gets longer. An

outside fuel tank that is above grade or has fuel

lines in a shallow bury is a good candidate for

cold oil. The best solution is to bury the tank and

lines deep enough to keep the oil above 40°F.

i. HIGH ALTITUDE INSTALLATIONS — Air

settings must be increased at higher altitudes.

Use instruments and set for 11.5 to 12.5% CO2.

j. START-UP NOISE — Late ignition is the

cause of start-up noises. If it occurs recheck for

electrode settings, ame shape, air or water in

the fuel lines.

k. SHUT DOWN NOISE — If the ame runs out

of air before it runs out of fuel, an after burn

with noise may occur. That may be the result

Page 27

of a faulty cut-off valve in the fuel pump, or it

may be air trapped in the nozzle line. It may take

several ring cycles for that air to be fully vented

through the nozzle. Water in the fuel or poor

ame shape can also cause shut down noises.

NOTICE

CHECK TEST PROCEDURE. A very good test for

isolating fuel side problems is to disconnect the

fuel system and with a 2 foot length of tubing, re

out of an auxiliary ve gallon pail of clean, fresh,

warm #2 oil from another source. If the burner runs

successfully when drawing out of the auxiliary

pail then the problem is isolated to the fuel or fuel

lines being used on the jobsite.

G. TEST CONTROLS

WARNING

Before installation of the boiler is considered

complete, the operation of all boiler controls must

be checked, particularly the primary control and

high limit control.

1. CHECK THERMOSTAT OPERATION. Raise and

lower thermostat setting as required to start and stop

burner.

2. VERIFY PRIMARY CONTROL SAFETY

FEATURES using procedures outlined in

Instructions furnished with control (See back of

Control Cover) or Instructions as follows:

WARNING

ONLY

a. Simulate ame failure:

• Follow the starting procedure to turn on the

• Close the hand valve in the oil supply line.

• Safety switch should lock out in

• Push red reset button to reset safety switch.

b. Simulate ignition failure:

• Follow the starting procedure to turn on the

• Safety switch should lock out in

• Push red reset button to reset safety switch.

FOR HEATING SERVICEMAN

burner.

approximately 15 seconds. Ignition should

stop and oil valve should close. Blower will

stop after postpurge period.

burner, but do not open the oil supply hand

valve.

approximately 15 seconds. Ignition and

motor should stop and oil valve should

close.

Simulate power failure:

c.

• Follow the starting procedure to turn on the

burner.

• With the burner running, turn off the power

to the system by tripping the circuit breaker

or removing the fuse.

• Burner should stop.

• Restore power. Burner should start.

d. If system does not operate as described, go to the

TROUBLESHOOTING AND MAINTENANCE

section.

3. VERIFY HIGH LIMIT OPERATION.

a. Adjust thermostat to highest setting.

b. Observe temperature gauge. When temperature

is indicated, adjust limit to setting below

observed temperature. Burner should stop.

c. Adjust limit to setting above observed

temperature. Burner should start.

d. Adjust thermostat to lowest setting. Adjust limit

to desired setting.

4. CHECK LOW WATER CUTOFF (if so equipped).

a. Adjust thermostat to highest setting.

b. With boiler operating, open drain valve and

slowly drain boiler.

c. Burner should stop when water level drops

below low water cutoff probe. Verify limit,

thermostat or other controls have not shut off

boiler.

d. Adjust thermostat to lowest setting. Rell boiler.

H. Boiler is now ready to be put into service.

IMPORTANT

IF, DURING NORMAL OPERATION, IT IS

NECESSARY TO ADD WATER MORE FREQUENTLY

THAN ONCE A MONTH, CONSULT A QUALIFIED

SERVICE TECHNICIAN TO CHECK YOUR

SYSTEM FOR LEAKS.

A leaky system will increase the volume of make-up

water supplied to the boiler which can signicantly

shorten the life of the boiler. Entrained in make-up

water are dissolved minerals and oxygen. When the

fresh, cool make-up water is heated in the boiler

the minerals fall out as sediment and the oxygen

escapes as a gas. Both can result in reduced boiler

life. The accumulation of sediment can eventually

isolate the water from contacting the steel. When this

happens the steel in that area gets extremely hot and

eventually cracks. The presence of free oxygen in the

boiler creates a corrosive atmosphere which, if the

concentration becomes high enough, can corrode the

27

Page 28

steel through from the inside. Since neither of these

failure types are the result of a manufacturing defect

the warranty does not apply. Clearly it is in everyone’s

best interest to prevent this type of failure. The

maintenance of system integrity is the best method to

achieve this.

28

Page 29

Section VIII: Service and Cleaning

WARNING

All boiler cleaning must be completed with burner service switch turned off. Boilers equipped with burner

swing door have a potential hazard which can cause severe property damage, personal injury or loss of

life if ignored. Before opening swing door, turn off service switch to boiler to prevent accidental ring of

burner outside the combustion chamber. Be sure to tighten swing door fasteners completely when service

is completed.

NOTICE

BURNER SHUTDOWN: Open Service Switch

to turn off burner.

Manual Oil Supply Valve should be closed

and Electric Service to boiler turned off if

boiler will not be operated for an extended

period of time.

A. General. Inspection, service and cleaning should

be conducted annually. Turn off electric power and

close oil supply valve while conducting service or

maintenance.

B. Firetubes and Combustion Chamber.

1. CLEAN THE FIRETUBES

a. For access to reside of boiler, pull two halves

of Burner Swing Door Interlock wiring harness

apart, remove fasteners holding door closed and

open swing door.

b. Prior to cleaning boiler, lay a protective cloth or

plastic over combustion chamber liner.

c. Using a 1 1/2" diameter wire brush (30" handle),

clean retubes. Measure 15" from end of brush

opposite handle, and mark handle. DO NOT

allow this mark to go past front end of retube

during cleaning, or brush will hit rear door

insulation piece.

2. CLEAN THE COMBUSTION CHAMBER

Using wire or ber bristle brush, clean inside of

combustion chamber. DO NOT let brush hit rear

door insulation piece or combustion chamber liner.

3. AFTER CLEANING

a. Vacuum debris inside bottom of rear door,

remove protective cloth, and vacuum remaining

reside of boiler as necessary. BE CAREFUL

not to damage liner or rear door insulation piece.

Inspect front and rear door insulation pieces,

front door gaskets and combustion chamber liner

for damage. Replace any damaged pieces.

4. CLOSE BOILER

CAUTION: Do not start burner unless burner swing

door is securely closed. Close door, install fasteners,

and tighten securely. Door should be parallel

to tubesheet when viewed from top and sides.

Reconnect two halves of Swing Door Interlock.

C. Vent/Air Intake System. Inspect for obstructions, soot

accumulation, proper support, and deterioration of pipe,

ttings, and joints.

1. Inspect inside of vent pipe.

a. Disconnect appliance adapter from boiler ue

collar.

b. Remove any obstructions and clean with a wire

brush as required.

c. Reconnect appliance adapter to boiler ue collar

as detailed in Section IV: Venting/Air Intake

Piping.

2. Clean terminal screens. Terminals must be free of

obstruction, undamaged, with screens securely in

place.

3. Terminal and wall thimbles (if used) must be

weather-tight.

4. Pipe must be full round shape, and show no damage

from impact or excessive temperature.

5. Pipe must be supported at minimum 5 foot intervals

and must not sag.

6. All vent joints must be secure and watertight.

7. All air intake joints must be secure and airtight.

D. Burner.

1. Replace the oil supply line lter.

2. Remove and clean the pump strainer (if applicable).

3. Replace the nozzle with an equivalent nozzle. Refer

to Table 6 for Beckett Burner Settings. Refer to

Table 6a for Riello BF Burner Settings.

4. Clean and inspect the electrodes for damage,

replacing any that are cracked or chipped.

5. Clean the combustion head of all lint and soot.

29

Page 30

6. Inspect the transformer cables and connectors.

7. Remove and clean the cad cell.

8. Clean the blower wheel and the air control of any

lint.

9. Check all wiring for secure connections or insulation

breaks.

10. Re-adjust the burner as detailed in Section VII:

System Start-up, Paragraph F.

E. Controls. Test Controls for proper operation as

detailed in Section VII: System Start-up, Paragraph G.

F. Low water cutoff (if so equipped).

1. Float Type

a. Monthly Blowoff. During the heating season, if

an external oat type low water cutoff is on the

boiler, the blow off valve should be opened once

a month (use greater frequency where conditions

warrant), to ush out the sediment chamber so

the device will be free to function properly.

b. Annual Service. Float type low water cutoffs

should be dismantled annually by qualied

personnel, to the extent necessary to insure

freedom from obstructions and proper

functioning of the working parts. Inspect

connecting lines to boiler for accumulation of

mud, scale, etc., and clean as required. Examine

all visible wiring for brittle or worn insulation

and make sure electrical contacts are clean

and that they function properly. Give special

attention to solder joints on bellows and oat

when this type of control is used. Check oat

for evidence of collapse and check mercury bulb

(where applicable) for mercury separation or

discoloration.

2. Probe Type (Annual Service). Probe type LWCO

should be removed once a year, examined and

cleaned of any dirt accumulations to assure proper

operations. Do not attempt to repair mechanisms

in the eld. Complete replacement mechanisms,

including necessary gaskets and installation

instructions, are available from the manufacturer.

30

Page 31

Important Product Safety Information

Refractory Ceramic Fiber Product

Warning:

The Repair Parts list designates parts that contain refractory ceramic fibers

(RCF). RCF has been classified as a possible human carcinogen. When

exposed to temperatures about 1805°F, such as during direct flame contact,

RCF changes into crystalline silica, a known carcinogen. When disturbed as a

result of servicing or repair, these substances become airborne and, if inhaled,

may be hazardous to your health.

AVOID Breathing Fiber Particulates and Dust

Precautionary Measures:

Do not remove or replace RCF parts or attempt any service or repair work

involving RCF without wearing the following protective gear:

1. A National Institute for Occupational Safety and Health (NIOSH)

approved respirator

2. Long sleeved, loose fitting clothing

3. Gloves

4. Eye Protection

• Take steps to assure adequate ventilation.

• Wash all exposed body areas gently with soap and water after contact.

• Wash work clothes separately from other laundry and rinse washing

machine after use to avoid contaminating other clothes.

• Discard used RCF components by sealing in an airtight plastic bag. RCF

and crystalline silica are not classified as hazardous wastes in the United

States and Canada.

First Aid Procedures

:

• If contact with eyes: Flush with water for at least 15 minutes. Seek

immediate medical attention if irritation persists.

• If contact with skin: Wash affected area gently with soap and water.

Seek immediate medical attention if irritation persists.

• If breathing difficulty develops: Leave the area and move to a location

with clean fresh air. Seek immediate medical attention if breathing

difficulties persist.

• Ingestion: Do not induce vomiting. Drink plenty of water. Seek

immediate medical attention.

31

Page 32

IX. Repair Parts

All LE®DV Series Repair Parts may be obtained through your local U.S. Boiler Wholesale Distributor.

Should you require assistance in locating a U.S. Boiler Distributor in your area, or have questions regarding

the availability of U.S. Boiler products or repair parts, please contact U.S. Boiler Customer Service at (717)

481-8400 or Fax (717) 481-8408.

32

Figure 21: LEDV Boiler Trim & Controls

Item Description Qty. Part Number

1 Honeywell L7248C1014 High Limit & Circulator Relay 1 100059-01

2 Honeywell 123871A, 3/4 NPT x 3 1 80160452

3 Conbraco 10-408-05, 3/4 FPT, 30 PSI Relief Valve 1 81660319

4 Temperature/Pressure Gauge 1-1/2 DIA (Long Shank) 1 100282-02

5 Conbraco 35-302-03, 3/4 FPT Drain Valve 1 806603061

6 Beckett R7184 Oil Primary Control 1 80160847

7 Burner Disconnect Harness 1 8133302

8 Strain Relief Bushing (Not Shown) 1 8136029

Page 33

Figure 22: LEDV Boiler Jacket & Insulation

33

Page 34

34

Figure 23: LEDV Bare Boiler Assembly

Page 35

Figure 24: Vent Kit Repair Parts

35

Page 36

36

Figure 25: Beckett AFII Oil Burner Repair Part

P.O. Box 1289, Elyria, OH 44036 (216) 327-1060 or (800) OIL BURN(645-2876)

For replacement oil burner parts, contact your wholesaler or the burner manufacturer: R.W. Beckett Co.,

Page 37

BECKETT AFII BURNER REPLACEMENT PARTS

LEDV1 LEDV2 LEDV3

Part Description

Beckett Part Number

Complete Burner (without Primary Control) BCB5406 BCB5407 BCB5408

Air Tube Combination HLX50HD HLX50HE

Air Tube Screws 4352

Blower Wheel 21439 21438

Coupling (Motor to Pump) 21437

Electrodes (Replacement Kit) 51484U

Escutcheon Plate 31623

Stop Screw 3166502 3166503 3166505

Fuel Line 5394

Fuel Pump (Single Stage, with Solenoid Valve) 21757

Fuel Pump (Two Stage, with Solenoid Valve) 21941

Gasket, Flange 31658

Head Assembly (AFII) 51671 (6 Slot) 51672 (9 Slot)

Hole Plug 2139

Inlet Air Scoop 51485

Splined Nut 3666

Main Housing Assembly 51584 51476

Motor 21444

Nozzle Adapter 213

Nozzle Line Heater 51621

Rear Access Door 51424GY

Electronic Ignitor 7440

4 x 4 Electrical Box 31613BK

Electrical Box Extension 21821BK

37

Page 38

SERVICE RECORD

DATE SERVICE PERFORMED

38

Page 39

X. Low Water Cut Off (LWCO) on Hot Water Boilers

WARNING

DO NOT ATTEMPT to cut factory wires to install an aftermarket Low Water Cut Off (LWCO). Only use

connections specically identied for Low Water Cut Off.

In all cases, follow the Low Water Cut Off (LWCO) manufacturer's instructions.

When

A low water cutoff is required to protect a hot water

boiler when any connected heat distributor (radiation)

is installed below the top of the hot water boiler (i.e.

baseboard on the same oor level as the boiler). In

addition, some jurisdictions require the use of a LWCO

with a hot water boiler.

Where

The universal location for a LWCO on both gas and oil

hot water boilers is above the boiler, in either the supply

or return piping. The minimum safe water level of a

water boiler is at the uppermost top of the boiler; that is,

it must be full of water to operate safely.

What Kind

Typically, in residential applications, a probe type

LWCO is used instead of a oat type, due to their

relative costs and the simplicity of piping for a probe

LWCO.

How to Pipe

A “tee” is commonly used to connect the probe LWCO

to the supply or return piping, as shown below.

draining the heating system. Many probe LWCO

manufacturers recommend an annual inspection of the

probe.

How to Wire

LWCO’s are available in either 120 VAC or 24 VAC

congurations. The 120 VAC conguration can be

universally applied to both gas and oil boilers by wiring

it in the line voltage service to the boiler (after the

service switch, if so equipped).

The presence of water in a properly installed LWCO

will cause the normally open contact of the LWCO to

close, thus providing continuity of the 120 VAC service

to the boiler.

It is recommended to supply power to the probe LWCO

with the same line voltage boiler service as shown

below.

LWCO Location

Select the appropriate size tee using the LWCO

manufacturer’s instructions. Often, the branch

connection must have a minimum diameter to

prevent bridging between the probe and the tee. Also,

the run of the tee must have a minimum diameter to

prevent the end of the probe from touching or being

located too close to the inside wall of the run of the tee.

Ideally, manual shutoff valves should be located

above the LWCO and the boiler to allow for servicing.

This will allow probe removal for inspection without

Wiring of Typical LWCO

A 24 VAC LWCO is used primarily for gas red

boilers where a 24 volt control circuit exists within the

boiler. However, a 24 VAC LWCO can only be used

if the boiler manufacturer has provided piping and

wiring connections and instructions to allow for this

application.

How to Test

Shut off fuel supply. Lower water level until water

level is BELOW the LWCO. Generate a boiler demand

by turning up thermostat. Boiler should not attempt to

operate. Increase the water level by lling the system.

The boiler should attempt to operate once the water

level is above the LWCO.

39

Page 40

LLiim

miitteedd

W

Waarrrraannttyy

FFoorrRReessiiddeennttiiaallGGrraaddeeWWaatteerraannddSStteeaammBBooiilleerrs

s

Using Cast Iron, Carbon Steel, Cast Aluminum,

or Stainless Steel Heat Exchangers

aannddPPaarrttss//AAcccceessssoorriiees

s

Subject to the terms and conditions set forth below, U.S. Boiler Company, Inc.

Lancaster, Pennsylvania hereby extends the following limited warranties to the original

owner of a residential grade water or steam boiler or U.S. Boiler Company, Inc. supplied

parts and/or accessories manufactured and shipped on or after July 1, 2008:

ONE YEAR LIMITED WARRANTY ON RESIDENTIAL GRADE BOILERS

AND PARTS / ACCESSORIES SUPPLIED BY U.S. BOILER COMPANY, INC.

U.S. Boiler Company, Inc. warrants to the original owner that its residential grade

water and steam boilers and parts/accessories comply at the time of manufacture with

recognized hydronic industry standards and requirements then in effect and will be

free of defects in material and workmanship under normal usage for a period of one

year from the date of original installation. If any part of a residential grade boiler or

any part or accessory provided by U.S. Boiler Company, Inc. is found to be defective

in material or workmanship during this one year period, U.S. Boiler Company, Inc.

will, at its option, repair or replace the defective part.

HEAT EXCHANGER WARRANTIES

U.S. Boiler Company, Inc. warrants to the original owner that the heat exchanger of its

residential grade boilers will remain free from defects in material and workmanship

under normal usage for time period specified in the chart below of the original owner at

the original place of installation. If a claim is made under this warranty during the “No

Charge” period from the date of original installation, U.S. Boiler Company, Inc. will, at its

option, repair or replace the heat exchanger. If a claim is made under this warranty after

the expiration of the “No Charge” period from the date of original installation, U.S. Boiler

Company, Inc. will, at its option and upon payment of the pro-rated service charge set

forth below, repair or replace the heat exchanger. The service charge applicable to a

heat exchanger warranty claim is based upon the number of years the heat exchanger

has been in service and will be determined as a percentage of the retail price of the heat

exchanger model involved at the time the warranty claim is made as follows:

NOTE: If the heat exchanger involved is no longer available due to product obsolescence

or redesign, the value used to establish the retail price will be the published price as

shown in the Burnham

Repair Parts Pricing where the heat exchanger last

appeared or the current retail price of the then nearest equivalent heat exchanger.

*MegaSteam Waterside Corrosion Warranty: U.S. Boiler Company, Inc. warrants the

cast iron sections of the MegaSteam boiler to resist Temperature Induced Chloride

Activated Graphitic Corrosion for a period of five years from the date of original

installation. In the event that any cast iron section of a Mega Steam boiler fails due to

this corrosion mechanism during this period, U.S. Boiler Company, Inc. will repair or

replace, at its option, the cast iron section assembly.

LIFETIME NIPPLE LEAKAGE WARRANTY

U.S. Boiler Company, Inc. warrants the cast iron and steel nipples that join the cast iron

boiler sections to be free of defects in material and workmanship for the lifetime of the

original owner at the original place of installation. In the event that such nipples are

found to be defective in material and workmanship during this period, U.S. Boiler

Company, Inc. will repair or replace at its option, the cast iron section assembly.

ADDITIONAL TERMS AND CONDITIONS

1. Applicability: The limited warranties set forth above are extended only to the

original owner at the original place of installation within the United States and

Canada. These warranties are applicable only to boilers, parts, or accessories

designated as residential grade by U.S. Boiler Company, Inc. and installed in a

single or two-family residence and do not apply to commercial grade products.

2. Components Manufactured by Others: Upon expiration of the one year limited

warranty on residential grade boilers, all boiler components manufactured by

others but furnished by U.S. Boiler Company, Inc. (such as oil burner, circulator

and controls) will be subject only to the manufacturer’s warranty, if any.

3. Proper Installation: The warranties extended by U.S. Boiler Company, Inc.

are conditioned upon the installation of the residential grade boiler, parts, and

accessories in strict compliance with U.S. Boiler Co., Inc. installation

instructions. U.S. Boiler Company, Inc. specifically disclaims liability of any

kind caused by or relating to improper installation.