Page 1

Type BBS-11

Safety ingold socket with Asepto sampling system

Sicherheits-Ingoldstutzen mit Asepto Probeentnahme

Raccord Ingold de sécurité avec prélèvement d'échantillons Asepto

Bedienungsanleitung

Manuel d‘utilisation

Operating Instructions

www.burkert.com

International address

www.burkert.com → Bürkert → Company → Locations

Manuals and data sheets on the Internet : www.burkert.com

Bedienungsanleitungen und Datenblätter im Internet: www.buerkert.de

Instructions de service et fiches techniques sur Internet: www.buerkert.fr

© 2013 Bürkert Werke GmbH

Operating Instr uctions 1401/01_EU-ML_00810326 / Original DE

Bürkert Fluid Control Systems

Sales Center

Christian-Bürkert-Str. 13-17

D-74653 Ingelfingen

Tel. + 49 (0) 7940 - 10 91 111

Fax + 49 (0) 7940 - 10 91 448

E-mail: info@de.buerkert.com

Page 2

2

1. THE OPERATING INSTRUCTIONS

The operating instructions contain important information.

• Read the instructions carefully and follow the safety instructions in

particular.

• Keep the instructions in a location where they are available to every

user.

• The liability and warranty for the product do not apply if the procedures in the instructions are not observed.

1.1. Symbols

→ designates a procedure which you must carry out.

Warning of injuries:

DANGER!

Immediate danger! Serious or fatal injuries.

WARNING!

Possible danger! Serious or fatal injuries.

CAUTION!

Danger! Moderate or minor injuries.

Warning of damage:

NOTE!

2. INTENDED USE

Non-authorized use of the Type BBS-11 may be dangerous to

people, nearby equipment and the environment.

• Type BBS-11 has been designed as a safety ingold socket for

sampling of equipment in the sterile area.

• Use according to the authorized data, operating conditions, and

conditions of use specified in the contract documents and operating instructions.

• Correct transportation, storage and installation, as well as careful use and maintenance are essential for reliable and faultless

operation.

• Use the product only as intended.

2.1. Restrictions

If exporting the products, observe any existing restrictions.

2.2. Definitions of terms

The term "product" used in these instructions always refers to Type

BBS-11.

english

3

4. GENERAL INFORMATION

4.1. Contact address

Germany

Bürkert Fluid Control Systems

Sales Center

Christian-Bürkert-Str. 13-17

D-74653 Ingelfingen

Tel. + 49 (0) 7940 - 10 91 111

Fax + 49 (0) 7940 - 10 91 448

E-mail: info@de.buerkert.com

International

Contact addresses can be found on the final pages of the printed

operating instructions. And also on the Internet at: www.burkert.com

4.2. Warranty

The warranty is only valid if the product is used as intended in

accordance with the specified application conditions.

4.3. Information on the Internet

The operating instructions and data sheets for Type BBS-11 can be

found on the Internet at: www.burkert.com

3. BASIC SAFETY INSTRUCTIONS

These safety instructions do not take into account any contingencies and

events which may arise during the installation, operation and maintenance

of the product.

Danger – high pressure and discharge of medium!

• Before loosening the nuts or screws, always turn off the pressure

and relieve the lines/containers.

• Wear protective equipment if media is hazardous.

General hazardous situations

• Do not make any internal or external changes to the product.

• Ensure that the system cannot be activated unintentionally.

• Installation and maintenance work may be carried out only by

authorized technicians with the appropriate tools.

• The product may be operated only when in perfect condition and in

consideration of the operating instructions.

• As far as inspection, maintenance and repairs are concerned,

observe national provisions of the country in which the connection

elements are installed.

• The general rules of technology apply to application planning and

operation of the product.

english

4

5. TECHNICAL DATA

5.1. Conformity

Type BBS-11 conforms to the EC directives according to the EC

Declaration of Conformity.

5.2. Standards (if applicable)

The applied standards which are used to demonstrate compliance with

the EC Directives are listed in the EC type test certificate and/or the

EC Declaration of Conformity.

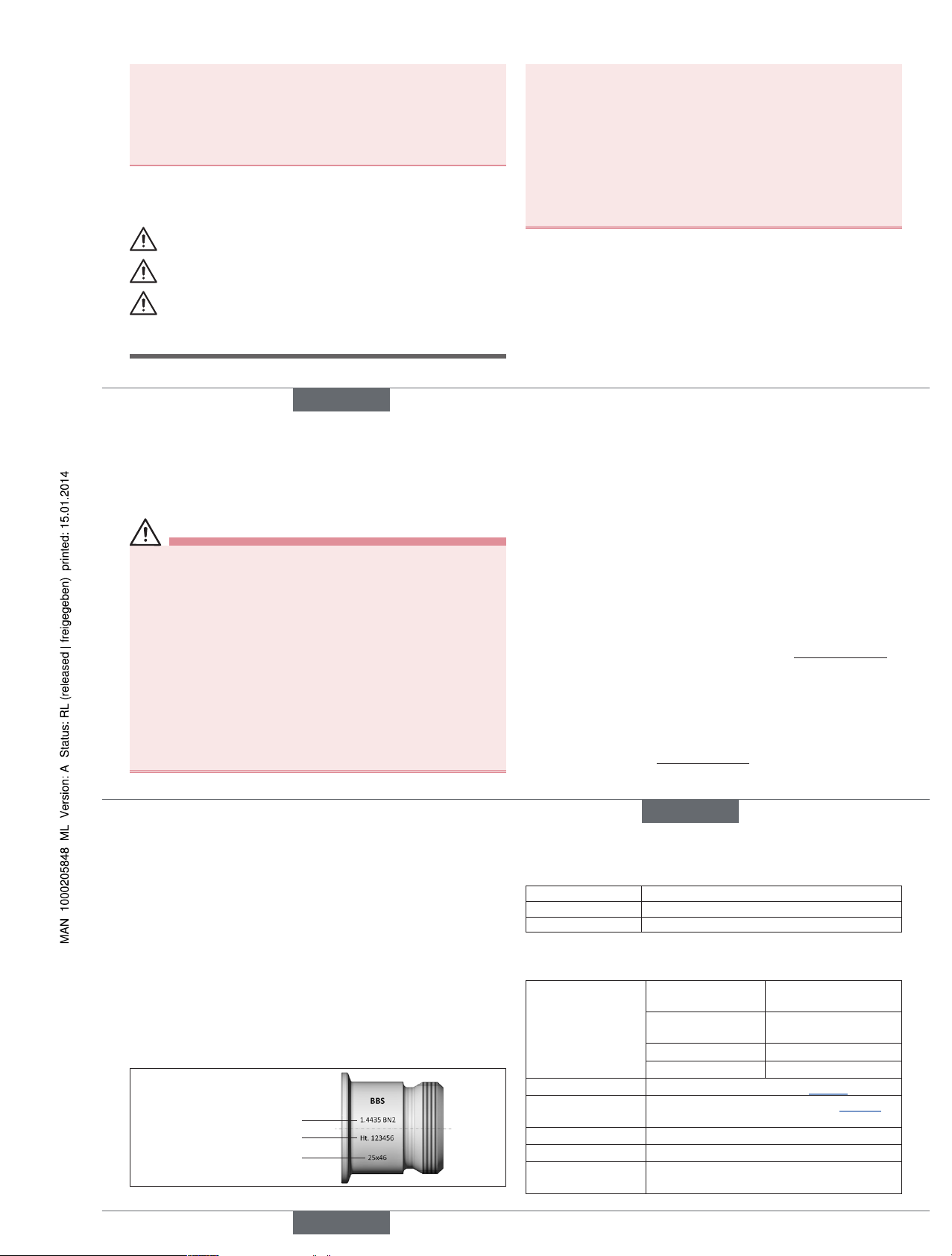

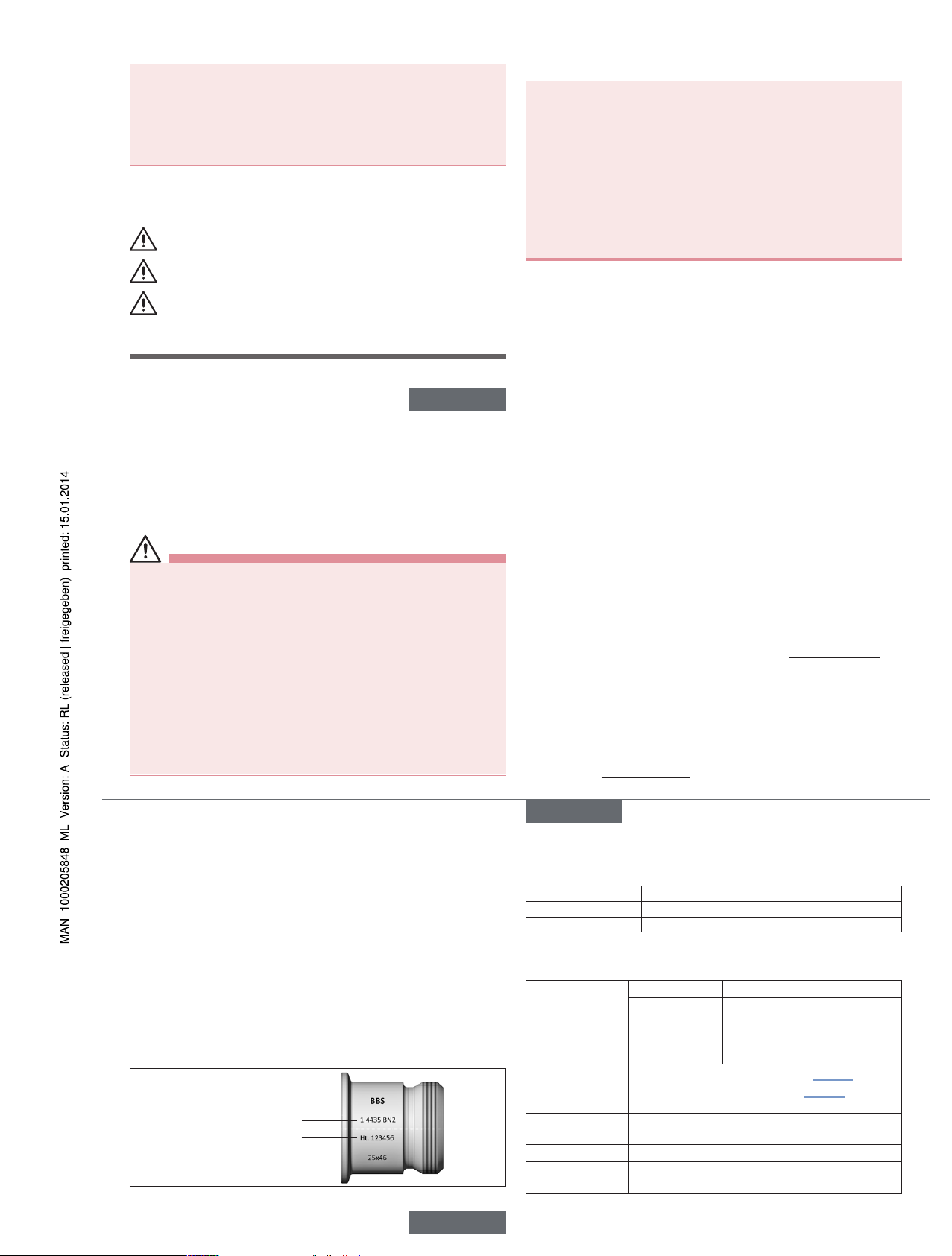

5.3. Identification

Information on material, pipe and connection dimensions can be found

on the stamping on the product. The identification number of the

product can be found on the supplied 3.1 certificate.

Material

Material batch number

Insert dimension

Fig. 1: Example of identification of the product

5.4. Sealing materials

Seal material Operating temperature

EPDM –40 °C to 90 °C, briefly up to 140 °C

FEP -60 °C to 160 °C, briefly up to 205 °C

Tab. 1: Sealing materials BBS-11

5.5. General technical data

Material

comes into contact

with medium

Stainless steel 1.4435

BN2 (316L)

does not comes into

contact with medium

Stainless steel 1.4401

or equivalent

Diaphragm silicone

O-ring EPDM/FEP

Pipe dimensions

see identification on product (“Fig. 1”)

Permitted application temperature

Depending on sealing material, see “Tab. 1”

Ambient temperature –20 °C to +80 °C

Media Fluids

Operating pressure -1 to +16 bar (depending on temperature and

size, see data sheet)

english

Type BBS-11

Page 3

5

6. ASSEMBLY

WARNING!

Danger – high pressure and discharge of medium!

• When working on the product or the system, always switch off the

pressure and relieve the lines/containers.

• Wear protective equipment if media is hazardous.

Risk of injury from improper assembly!

• Installation must only be carried out by authorized technicians and

with the appropriate tools!

• Secure system from unintentional activation.

6.1. Welding in the safety ingold socket

NOTE!

Leak due to damaged sealing elements!

• Do not weld in the assembled product. It is essential to remove

the plug before welding and protect it from dust, flying sparks and

other influences!

Leak due to damaged sealing contour!

• To ensure the sealing function, protect the sealing contour during

installation, welding and cleaning procedures.

• When reworking the welded-in ingold socket, the sealing contour

must not be damaged.

• The inner diameter Di of ingold socket has to be machined

to 25H7 respectively 40H7 after welding.

• Welding in and reworking of the safety ingold socket may be

carried out only by adequately trained professionals!

→ Connect the parts positively in a protective gas shield.

When cleaning the weld seam by grinding or acid cleaning, observe

the following before assembling the connection:

• Carefully remove all grinding dust and acid-cleaning residue.

• Do not damage the label.

• There must be no material abrasion on the sealing edges. Material

abrasion will result in sharp-edged sealing contours and a damaged

seal.

• Check sealing contour for damage.

We recommend preparing a welding report.

english

6

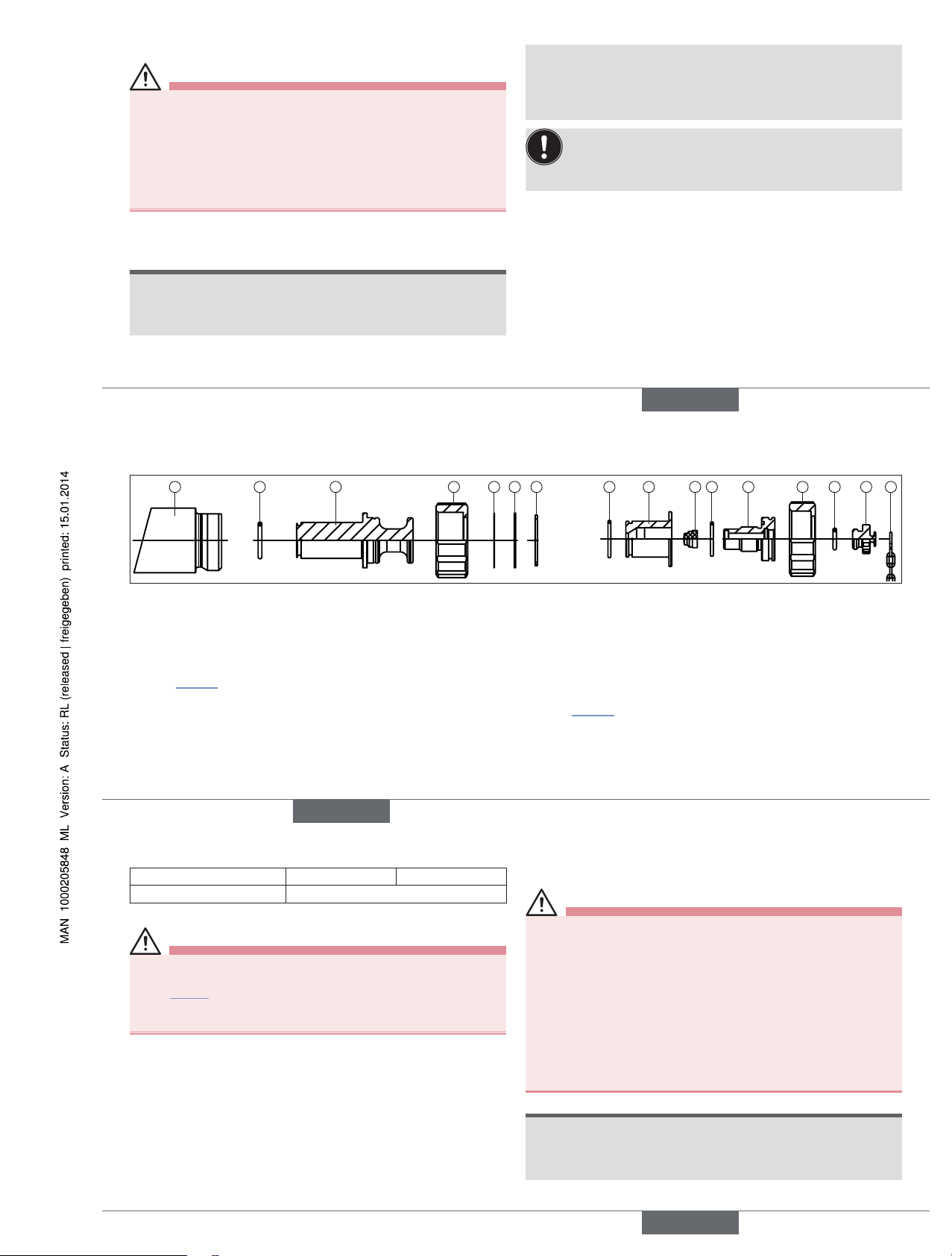

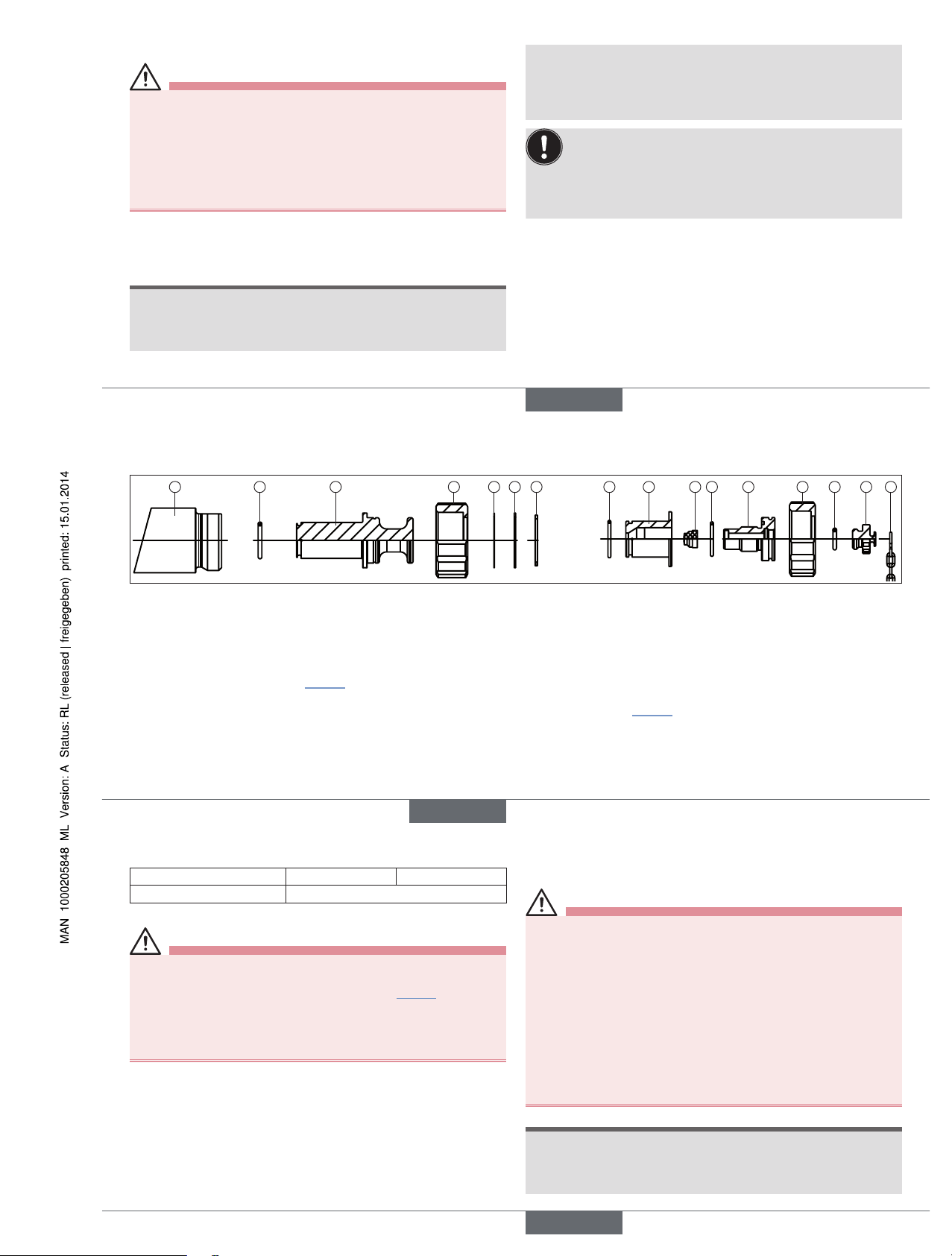

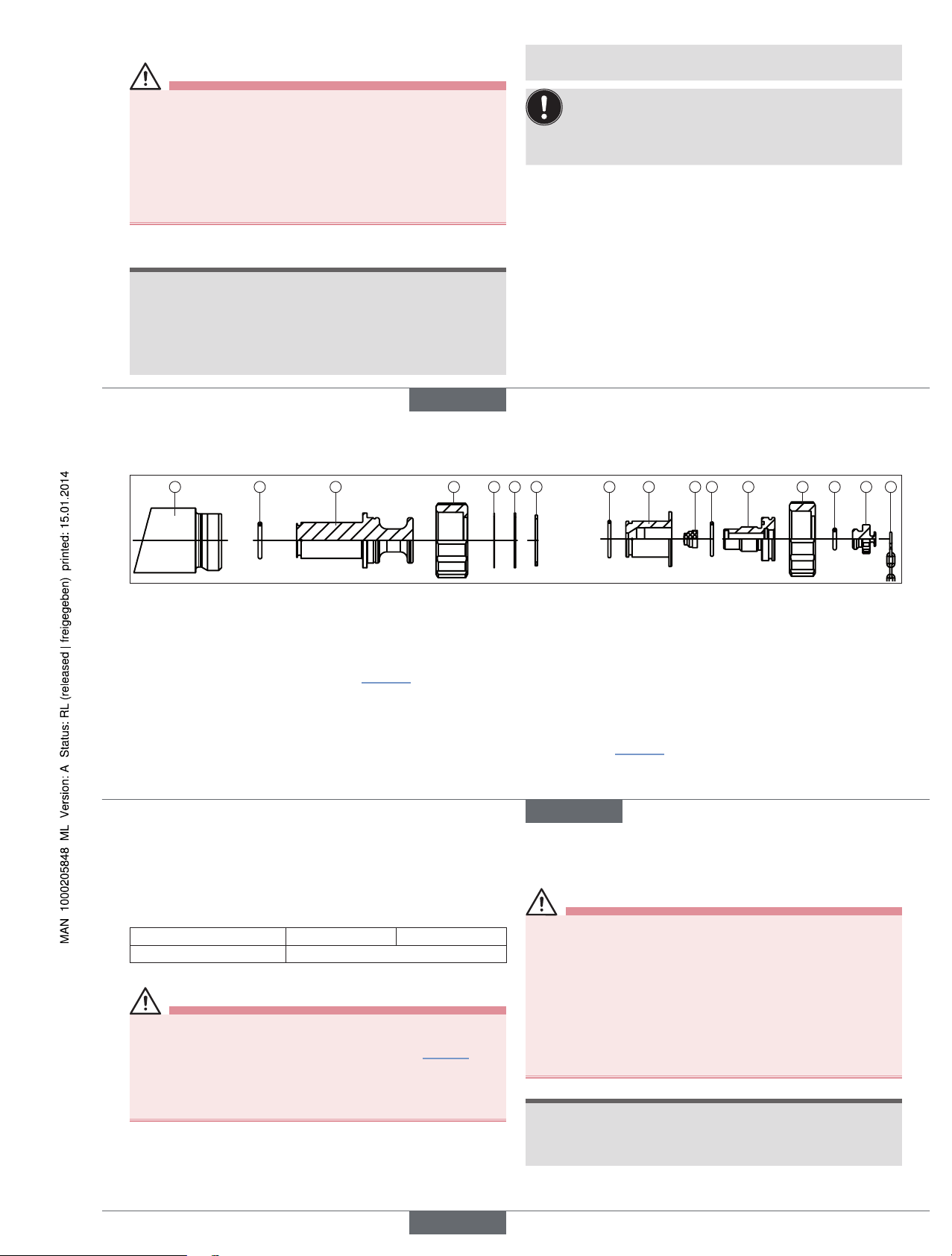

6.2. Assembly of dummy plug and Asepto sampling socket

1 2 3 4 5 6 7 2 8 9

10 11 12 13 14

4

Dummy plug Asepto sampling socket

Fig. 2: Assembly of dummy plug and Asepto sampling socket Type BBS-11

→ Push the diaphragm (9) forward to the limit stop in the sampling

socket (11) and screw the socket tightly to the sampling ingold (8).

Attention: This screw connection may not be loosened during

operation or when under pressure!

→ Push this assembly into the welded-in socket (1) and screw

down securely, using the union nut (4). Observe tightening torque

(see “Tab. 2”). Attention: This screw connection may not be

loosened during operation or when under pressure!

→ Screw the locking element (13) onto the sampling socket. This is

the only screw connection that may be opened during operation

(for the purpose of sampling). The chain (14) prevents that the

locking element gets lost.

Dummy plug

→ Ensure the correct position of the O-ring (2) on the dummy ingold

(3). Screw the dummy ingold into the welded-in ingold socket

(1) to lock it, using the union nut (4). Observe tightening torque

(see “Tab. 2”).

This way, sampling is no longer possible.

Shim ring (5), spacer ring (6) and retaining ring (7) have already been

mounted in the supplied state and should not be removed.

Asepto sampling socket

→ Before screwing the ingold socket in, ensure the presence and

correct position of the O-rings (2, 10, 12).

english

7

Orifice (DN) 25 40

Tightening torque (Nm)

hand-tight

Tab. 2: Tightening torque of union nut Type BBS-11 ingold socket

WARNING!

Danger – high pressure and discharge of medium!

• During operation and/or existing pressure, only the sampling cap

(see “Fig. 2”, sketch on the far right with chain) may be opened. It

can be opened with just a few turns.

• All other screw connections may not be loosened in this state.

6.3. Disassembly

Disassembly is in reverse sequence to assembly.

7. START-UP

WARNING!

Risk of injury from improper operation!

Improper operation may result in injuries as well as damage to the

product and the surrounding area.

• Before start-up, ensure that the operating personnel are familiar

with and completely understand the contents of the operating

instructions.

• Observe the safety instructions and intended use.

• Only adequately trained personnel may start up the equipment/the

product.

• Following assembly, ensure a controlled restart.

• When starting up the equipment, ensure that no unauthorized voltage increases and pressure surges can occur.

NOTE!

Replace wearing parts in time

• It is the responsibility of the plant operator to ensure the durability

of the wearing parts. Observe that the wearing parts are replaced

in time.

english

Type BBS-11

Page 4

8

NOTE!

Dama

ge to the sealing elements when cleaning the system

.

• Clean the system preferably with a cleaning agent which does not

damage the sealing elements.

• Do not clean with wire brushes or machines which cause abrasion

of the surface.

• When using mechanical pipeline monitoring devices, ensure

that they do not damage the sealing elements (also the sealing

contour).

Damaged sealing elements must be replaced!

8. MAINTENANCE

WARNING!

Danger – high pressure and discharge of medium!

• Before loosening the nuts or screws, always turn off the pressure

and relieve the lines/containers.

• Wear protective equipment if media is hazardous.

• Nuts or screws may be retightened on pressurized lines/containers

only by technicians in consideration of special precautions.

• When shutting down the equipment, ensure that no unauthorized

voltage increases and pressure surges can occur.

• Following maintenance, ensure a controlled restart.

Have the product serviced regularly by technicians!

Inspection and maintenance work includes in particular monitoring and

ensuring the

• leak-tightness,

• identification,

• proper mode of operation of the safety and warning devices.

english

9

9. SPARE PARTS

CAUTION!

Risk of injury and/or damage by the use of incorrect parts!

Incorrect accessories and unsuitable spare parts may cause injuries

and damage the product and the surrounding area.

• Use only original accessories and original spare parts from Bürkert.

Spare parts are: O-rings, silicone diaphragm.

The spare parts can be ordered from your Bürkert sales office. The

order numbers for the spare part sets can be found on the corresponding data sheet on the Internet.

NOTE!

Replace wearing parts in time

• It is the responsibility of the plant operator to ensure the durability

of the wearing parts. Observe that the wearing parts are replaced

in time.

10. TRANSPORTATION, STORAGE,

DISPOSAL

NOTE!

Transport damage!

Inadequately protected sealing elements may be damaged during

transportation.

• Transport the product in a firmly assembled state, protected against

moisture and dirt, in shock-resistant packaging.

Incorrect storage may damage the product.

• Prevent the temperature from exceeding or dropping below the

permitted storage temperature.

• Store the product in a dry and dust-free location!

• Store O-rings and diaphragm dry and protected from UV radiation

and for not longer than 3 years.

• Storage temperature -40 to +80°C.

Damage to the environment caused by products contaminated

with media.

• Dispose of the product and packaging in an environmentally friendly

manner!

• Observe applicable disposal and environmental regulations.

english

Type BBS-11

Page 5

Type BBS-11

Safety ingold socket with Asepto sampling system

Sicherheits-Ingoldstutzen mit Asepto Probeentnahme

Raccord Ingold de sécurité avec prélèvement d'échantillons Asepto

Bedienungsanleitung

Manuel d‘utilisation

Operating Instructions

www.burkert.com

International address

www.burkert.com → Bürkert → Company → Locations

Manuals and data sheets on the Internet : www.burkert.com

Bedienungsanleitungen und Datenblätter im Internet: www.buerkert.de

Instructions de service et fiches techniques sur Internet: www.buerkert.fr

© 2013 Bürkert Werke GmbH

Operating Instr uctions 1401/01_EU-ML_00810326 / Original DE

Bürkert Fluid Control Systems

Sales Center

Christian-Bürkert-Str. 13-17

D-74653 Ingelfingen

Tel. + 49 (0) 7940 - 10 91 111

Fax + 49 (0) 7940 - 10 91 448

E-mail: info@de.buerkert.com

Page 6

10

1. DIE BEDIENUNGSANLEITUNG

Die Bedienungsanleitung enthält wichtige Informationen.

• Anleitung sorgfältig lesen und besonders die Hinweise zur Sicherheit

beachten.

• Anleitung so aufbewahren, dass sie jedem Benutzer zur Verfügung

steht.

• Haftung und Gewährleistung für das Produkt entfällt, wenn die

Anweisungen der Anleitung nicht beachtet werden.

1.1. Darstellungsmittel

→ markiert einen Arbeitsschritt, den Sie ausführen müssen.

Warnung vor Verletzungen:

GEFAHR!

Unmittelbare Gefahr! Schwere oder tödliche Verletzungen.

WARNUNG!

Mögliche Gefahr! Schwere oder tödliche Verletzungen.

VORSICHT!

Gefahr! Mittelschwere oder leichte Verletzungen.

Warnung vor Sachschäden:

HINWEIS!

2. BESTIMMUNGSGEMÄSSER

GEBRAUCH

Bei nicht bestimmungsgemäßem Gebrauch des Typs BBS-11

können Gefahren für Personen, Anlagen in der Umgebung und

die Umwelt entstehen.

• Typ BBS-11 ist als Sicherheits-Ingoldstutzen zur Probeentnahme für

Anlagen im sterilen Bereich konzipiert.

• Für den Einsatz die in den Vertragsdokumenten und der Bedienungsanleitung spezifizierten zulässigen Daten, Betriebs- und Einsatzbedingungen beachten.

• Voraussetzungen für den sicheren und einwandfreien Betrieb sind

sachgemäßer Transport, sachgemäße Lagerung und Installation

sowie sorgfältige Bedienung und Instandhaltung.

• Setzen Sie das Produkt nur bestimmungsgemäß ein.

2.1. Beschränkungen

Bei der Ausfuhr der Produkte gegebenenfalls bestehende Beschränkungen beachten.

2.2. Begriffsdefinition

Der in dieser Anleitung verwendete Begriff „Produkt“ steht immer für Typ

BBS-11.

deutsch

11

4. ALLGEMEINE HINWEISE

4.1. Kontaktadresse

Deutschland

Bürkert Fluid Control Systems

Sales Center

Christian-Bürkert-Str. 13-17

D-74653 Ingelfingen

Tel. + 49 (0) 7940 - 10 91 111

Fax + 49 (0) 7940 - 10 91 448

E-mail: info@de.buerkert.com

International

Die Kontaktadressen finden Sie auf den letzten Seiten der gedruckten

Bedienungsanleitung. Außerdem im Internet unter: www.burkert.com

4.2. Gewährleistung

Voraussetzung für die Gewährleistung ist der bestimmungsgemäße

Gebrauch des Produkts unter Beachtung der spezifizierten

Einsatzbedingungen.

4.3. Informationen im Internet

Bedienungsanleitungen und Datenblätter zum Typ BBS-11 finden Sie im

Internet unter: www.buerkert.de

3. GRUNDLEGENDE

SICHERHEITSHINWEISE

Diese Sicherheitshinweise berücksichtigen keine Zufälligkeiten und

Ereignisse, die bei Montage, Betrieb und Wartung des Produkts auftreten

können.

Gefahr durch hohen Druck und Mediumsaustritt!

• Vor dem Lösen von Muttern oder Schrauben unbedingt den Druck

abschalten und Leitungen/Behälter entleeren.

• Bei gefährlichen Medien Schutzausrüstung tragen.

Allgemeine Gefahrensituationen

• Am Produkt keine inneren oder äußeren Veränderungen vornehmen.

• Beachten, dass die Anlage nicht unbeabsichtigt betätigt werden kann.

• Installations- und Instandhaltungsarbeiten dürfen nur von autorisiertem Fachpersonal mit geeignetem Werkzeug ausgeführt werden.

• Das Produkt nur in einwandfreiem Zustand und unter Beachtung der

Bedienungsanleitung betreiben.

• Bei Inspektion, Wartung und Instandsetzung nationale Bestimmungen

des Aufstellungslands beachten.

• Für die Einsatzplanung und den Betrieb des Produkts die allgemeinen Regeln der Technik einhalten.

deutsch

12

5. TECHNISCHE DATEN

5.1. Konformität

Typ BBS-11 ist konform zu den EG-Richtlinien entsprechend der

EG-Konformitätserklärung.

5.2. Normen (soweit anwendbar)

Die angewandten Normen, mit denen die Konformität mit den EG-Richtlinien nachgewiesen wird, sind in der EG-Baumusterprüfbescheinigung

und/oder der EG-Konformitätserklärung nachzulesen.

5.3. Kennzeichnung

Angaben zu Material, Rohr- und Anschlussmaß sind auf das Produkt

geprägt. Die Identnummer des Produkts entnehmen Sie bitte dem mitgelieferten 3.1-Zeugnis.

Werkstoff

Materialchargennummer

Einschubmaß

Bild 1: Beispiel für die Kennzeichnung des Produkts

5.4. Dichtungsmaterialien

Dichtwerkstoff Betriebstemperatur

EPDM

–40 °C bis 90 °C, kurzzeitig bis 140 °C

FEP –60 °C bis 160 °C, kurzzeitig bis 205 °C

Tab. 1: Dichtungsmaterialien BBS-11

5.5. Allgemeine technische Daten

Material

mediumberührt Edelstahl 1.4435 BN2 (316L)

nicht

mediumberührt

Edelstahl 1.4401 oder Ähnliches

Membran Silikon

O-Ring EPDM/FEP

Rohrmaße

siehe Kennzeichnung auf Produkt („Bild 1“)

zulässige

Einsatztemperatur

je nach Dichtungsmaterial, siehe „Tab. 1“

Umgebungstemperatur

–20 °C bis +80 °C

Medien Fluide

Betriebsdruck –1 bis +16 bar (in Abhängigkeit von Temperatur

und Größe, siehe Datenblatt)

deutsch

Typ BBS-11

Page 7

13

6. MONTAGE

WARNUNG!

Gefahr durch hohen Druck und Mediumsaustritt!

• Bei Arbeiten am Produkt oder der Anlage unbedingt den Druck

abschalten und Leitungen/Behälter entleeren.

• Bei gefährlichen Medien Schutzausrüstung tragen.

Verletzungsgefahr bei unsachgemäßer Montage!

• Die Montage darf nur autorisiertes Fachpersonal mit geeignetem

Werkzeug durchführen!

• Anlage vor unbeabsichtigtem Betätigen sichern.

6.1. Einschweißen des

Sicherheits-Ingoldstutzens

HINWEIS!

Undichtheit durch beschädigte Dichtelemente!

• Das Produkt nicht in zusammengebautem Zustand einschweißen.

Vor dem Schweißen unbedingt Stopfen entfernen und vor Staub,

Funkenflug und anderen Einflüssen schützen!

Undichtheit durch beschädigte Dichtkontur!

• Zur Sicherstellung der Dichtfunktion die Dichtkontur während

Montage, Schweißen und Reinigungsverfahren schützen.

• Beim Nachbearbeiten des eingeschweißten Ingoldstutzens darf die

Dichtkontur nicht beschädigt werden.

• Den Innendurchmesser Di des Ingoldstutzens nach

dem Einschweißen auf das Fertigmaß 25H7 bzw. 40H7

nachbearbeiten.

• Das Einschweißen und Nachbearbeiten des SicherheitsIngoldstutzens darf nur durch ausreichend geschultes

Fachpersonal erfolgen.

→ Verbindung formschlüssig unter Schutzgas heften.

Bei Schweißnahtreinigung mittels Schleifen oder Beizen vor dem

Zusammenbau der Verbindung beachten:

• Alle Schleifstaub- und Beizereste sorgfältig entfernen.

• Beschriftung nicht beschädigen.

• An den Dichtkanten darf kein Materialabtrag vorgenommen werden.

Materialabtrag führt zu scharfkantigen Dichtkonturen und damit zur

Verletzung der Dichtung.

• Dichtkontur auf Beschädigung kontrollieren.

Wir empfehlen die Erstellung eines Schweißprotokolls.

deutsch

14

6.2. Montage Blindstopfen und Asepto Probeentnahmestutzen

1 2 3 4 5 6 7 2 8 9

10 11 12 13 14

4

Blindstopfen Asepto Probeentnahmestutzen

Bild 2: Montage Blindstopfen und Asepto Probeentnahmestutzen Typ BBS-11

→ Die Membran (9) vorne bis zum Anschlag in den Probeentnahme-

stutzen (11) schieben und diesen fest mit dem Probeentnahmeingold (8) verschrauben. Achtung: diese Verschraubung darf im

Betrieb oder unter Druck nicht gelöst werden.

→ Diese Baugruppe in den eingeschweißten Stutzen (1) schieben und

mit der Überwurfmutter (4) gut verschrauben. Anziehdrehmoment

beachten (siehe „Tab. 2“). Achtung: diese Verschraubung darf im

Betrieb oder unter Druck nicht gelöst werden.

→ Verschluss (13) auf den Probeentnahmestutzen aufschrauben.

Dies ist die einzige Verschraubung, die während des Betriebs (zum

Zwecke der Probeentnahme) geöffnet werden darf. Die Kette (14)

verhindert, dass der Verschluss verloren geht.

Blindstopfen

→ Die korrekte Lage des O-Rings (2) am Blindingold (3) sicherstellen.

Blindingold in eingeschweißten Ingoldstutzen (1) mit Hilfe der Überwurfmutter (4) einschrauben, um diesen zu verschließen. Anziehdrehmoment beachten (siehe „Tab. 2“).

Eine Probeentnahme ist nun nicht mehr möglich.

Passscheibe (5), Distanzscheibe (6) und Sicherungsring (7) sind im

Lieferzustand bereits montiert und sollten nicht entfernt werden.

Asepto Probeentnahmestutzen

→ Vor dem Einschrauben in den Ingoldstutzen das Vorhandensein und

die korrekte Lage der O-Ringe (2, 10, 12) sicherstellen.

deutsch

15

Nennweite (DN) 25 40

Anziehdrehmoment (Nm)

handfest

Tab. 2: Anziehdrehmoment Überwurfmutter Typ BBS-11 Ingoldstutzen

WARNUNG!

Gefahr durch hohen Druck und Mediumsaustritt!

• Während des Betriebs und/oder anstehendem Druck darf ausschließlich die Kappe zur Probeentnahme (siehe „Bild 2“, Skizze

ganz rechts mit Kette) geöffnet werden. Diese lässt sich mit wenigen

Umdrehungen öffnen.

• Alle anderen Verschraubungen dürfen in diesem Zustand nicht

gelöst werden.

6.3. Demontage

Die Demontage erfolgt in umgekehrter Reihenfolge wie die Montage.

7. INBETRIEBNAHME

WARNUNG!

Verletzungsgefahr bei unsachgemäßem Betrieb!

Nicht sachgemäßer Betrieb kann zu Verletzungen sowie Schäden am

Produkt und seiner Umgebung führen.

• Vor der Inbetriebnahme muss gewährleistet sein, dass der Inhalt

der Bedienungsanleitung dem Bedienungspersonal bekannt ist und

vollständig verstanden wurde.

• Die Sicherheitshinweise und der bestimmungsgemäße Gebrauch

müssen beachtet werden.

• Nur ausreichend geschultes Personal darf die Anlage/das Produkt

in Betrieb nehmen.

• Nach der Montage einen kontrollierten Wiederanlauf gewährleisten.

• Anlage so in Betrieb nehmen, dass sich keine unzulässigen Spannungserhöhungen und Druckschläge ergeben können.

HINWEIS!

Verschleißteile rechtzeitig tauschen

• Die Haltbarkeit der Verschleißteile liegt in der Verantwortung des

Anlagebetreibers. Auf rechtzeitigen Austausch der Verschleißteile

muss geachtet werden.

deutsch

Typ BBS-11

Page 8

16

HINWEIS!

Beschä

digung der Dichtelemente beim Reinigen der Anlage

.

• Zur Reinigung der Anlage möglichst Reinigungsmittel verwenden,

welche die Dichtelemente nicht beschädigen.

• Zur Reinigung keine Drahtbürsten oder Maschinen benützen, die

einen Oberflächenabtrag zur Folge haben.

• Bei Verwendung mechanischer Rohrleitungs-Kontrollgeräte beachten, dass diese keine Beschädigung der Dichtelemente (auch der

Dichtkontur) verursachen.

Beschädigte Dichtelemente müssen ausgetauscht werden!

8. WARTUNG

WARNUNG!

Gefahr durch hohen Druck und Mediumsaustritt!

• Vor dem Lösen von Muttern oder Schrauben unbedingt den Druck

abschalten und Leitungen/Behälter entleeren.

• Bei gefährlichen Medien Schutzausrüstung tragen.

• An unter Druck stehenden Leitungen/Behältern dürfen Muttern oder

Schrauben nur von Fachpersonal unter Beachtung besonderer

Vorsichtsmaßnahmen nachgezogen werden.

• Anlage so abfahren, dass sich keine unzulässigen Spannungserhöhungen und Druckschläge ergeben können.

• Nach der Wartung einen kontrollierten Wiederanlauf gewährleisten.

Produkt regelmäßig durch fachkundiges Personal warten!

Zu den Inspektions- und Wartungsarbeiten gehören insbesondere die

Überwachung und Sicherstellung der

• Dichtheit,

• Kennzeichnung,

• ordnungsgemäßen Funktionsweise der Sicherheits- und

Warneinrichtungen.

deutsch

17

9. ERSATZTEILE

VORSICHT!

Verletzungsgefahr, Sachschäden durch falsche Teile!

Falsches Zubehör und ungeeignete Ersatzteile können Verletzungen

und Schäden am Produkt und dessen Umgebung verursachen.

• Nur Originalzubehör sowie Original-Ersatzteile der Firma Bürkert

verwenden.

Ersatzteile sind: O-Ringe, Silikon-Membran.

Die Ersatzeile können Sie über Ihre Bürkert-Vertriebsniederlassung

bestellen. Die Bestell-Nummern zu den Ersatzteil-Sets entnehmen Sie

bitte dem entsprechenden Datenblatt im Internet.

HINWEIS!

Verschleißteile rechtzeitig tauschen

• Die Haltbarkeit der Verschleißteile liegt in der Verantwortung des

Anlagebetreibers. Auf rechtzeitigen Austausch der Verschleißteile

muss geachtet werden.

10. TRANSPORT, LAGERUNG,

ENTSORGUNG

HINWEIS!

Transportschäden!

Unzureichend geschützte Dichtelemente können durch den Transport

beschädigt werden.

• Produkt in fest zusammengesetztem Zustand vor Nässe und

Schmutz geschützt in einer stoßfesten Verpackung transportieren.

Falsche Lagerung kann Schäden am Produkt verursachen.

• Eine Über- bzw. Unterschreitung der zulässigen Lagertemperatur

vermeiden.

• Produkt trocken und staubfrei lagern!

• O-Ringe und Membran trocken und vor UV-Strahlung geschützt und

nicht länger als 3 Jahre lagern.

• Lagertemperatur –40 … +80 °C.

Umweltschäden durch von Medien kontaminierte Produkte.

• Produkt und Verpackung umweltgerecht entsorgen!

• Geltende Entsorgungsvorschriften und Umweltbestimmungen

einhalten.

deutsch

Typ BBS-11

Page 9

Type BBS-11

Safety ingold socket with Asepto sampling system

Sicherheits-Ingoldstutzen mit Asepto Probeentnahme

Raccord Ingold de sécurité avec prélèvement d'échantillons Asepto

Bedienungsanleitung

Manuel d‘utilisation

Operating Instructions

www.burkert.com

International address

www.burkert.com → Bürkert → Company → Locations

Manuals and data sheets on the Internet : www.burkert.com

Bedienungsanleitungen und Datenblätter im Internet: www.buerkert.de

Instructions de service et fiches techniques sur Internet: www.buerkert.fr

© 2013 Bürkert Werke GmbH

Operating Instr uctions 1401/01_EU-ML_00810326 / Original DE

Bürkert Fluid Control Systems

Sales Center

Christian-Bürkert-Str. 13-17

D-74653 Ingelfingen

Tel. + 49 (0) 7940 - 10 91 111

Fax + 49 (0) 7940 - 10 91 448

E-mail: info@de.buerkert.com

Page 10

18

1. MANUEL D'UTILISATION

Le manuel d'utilisation contient des informations importantes.

• Lire attentivement le manuel d'utilisation et tenir particulièrement

compte des consignes de sécurité.

• Conserver le manuel d'utilisation afin qu'il soit accessible à tous les

utilisateurs.

• La responsabilité et la garantie légale concernant le produit sont

exclues en cas de non-respect du manuel d'utilisation.

1.1. Symboles

→ identifie une opération que vous devez effectuer.

Mise en garde contre les blessures :

DANGER !

Danger imminent ! Blessures graves ou mortelles.

AVERTISSEMENT !

Danger potentiel ! Blessures graves ou mortelles.

ATTENTION !

Danger ! Blessures légères ou de moyenne gravité.

Mise en garde contre les dommages matériels :

REMARQUE !

2. UTILISATION CONFORME

L'utilisation non conforme du type BBS-11 peut présenter

des dangers pour les personnes, les installations proches et

l'environnement.

• Le Type BBS-11 est conçu comme raccord Ingold de sécurité

pour le prélèvement d'échantillons sur des installations en milieu

stérile.

• Lors de son utilisation, il convient de respecter les données et

conditions d'utilisation et d'exploitation admissibles spécifiées

dans le manuel d'utilisation et dans les documents contractuels.

• Les conditions pour l'utilisation sûre et parfaite sont un transport,

un stockage et une installation dans les règles ainsi qu'une utilisation et une maintenance parfaites.

• Veillez à ce que l'utilisation du produit soit toujours conforme.

2.1. Limitations

Lors de l'exportation des produits, veuillez respecter les limitations éventuelles existantes.

2.2. Définition des termes

Le terme « produit » utilisé dans ce manuel désigne toujours le Type

BBS-11.

français

19

4. INDICATIONS GÉNÉRALES

4.1. Adresse

Allemagne

Bürkert Fluid Control Systems

Sales Center

Christian-Bürkert-Str. 13-17

D-74653 Ingelfingen

Tél. + 49 (0) 7940 - 10 91 111

Fax + 49 (0) 7940 - 10 91 448

E-mail: info@de.buerkert.com

International

Les adresses figurent aux dernières pages de la version imprimée du

manuel d'utilisation. Également sur Internet sous : www.burkert.com

4.2. Garantie légale

La condition pour bénéficier de la garantie légale est l'utilisation

conforme du produit dans le respect des conditions d'utilisation

spécifiées.

4.3. Informations sur Internet

Vous trouverez les manuels et les fiches techniques concernant le

Type BBS-11 sur Internet sous : www.buerkert.fr

3. CONSIGNES DE SÉCURITÉ

FONDAMENTALES

Ces consignes de sécurité ne tiennent pas compte des hasards et des

événements pouvant survenir lors du montage, de l'exploitation et de la

maintenance du produit.

Danger dû à la pression élevée et à la sortie de fluide !

• Avant de desserrer les écrous ou les vis, couper impérativement la

pression et vider les conduites/réservoirs.

• En cas d'utilisation de fluides toxiques, porter l'équipement de

protection.

Situations dangereuses d'ordre général

• N'apportez pas de modifications internes ou externes au produit.

• L'actionnement par inadvertance de l'installation ne doit pas être

possible.

• Les travaux d'installation et de maintenance doivent être effectués

uniquement par des techniciens qualifiés et habilités disposant de

l'outillage approprié.

• Le produit doit être utilisé uniquement en parfait état et en respectant le manuel d'utilisation.

• Respecter les dispositions nationales en vigueur dans le pays d'installation lors de l'inspection, de la maintenance et de la réparation.

• Les règles générales de la technique sont d'application pour

planifier l'utilisation et utiliser le produit.

français

20

5. CARACTÉRISTIQUES TECHNIQUES

5.1. Conformité

Le type BBS-11 est conforme aux directives CE conformément à la

déclaration de conformité CE.

5.2. Normes (si applicables)

Les normes utilisées attestant de la conformité avec les directives CE

figurent dans le certificat d'essai de modèle type CE et/ou la déclaration de conformité CE.

5.3. Identification

Les informations concernant le matériau, la dimension du raccord et

le raccordement sont gravées sur le produit. Vous trouverez le numéro

d'identification du produit dans le certificat 3.1 fourni.

Matériau

Numéro de lot du matériau

Dimension d'introduction

Fig. 1 : Exemple d'identification du produit

5.4. Matériaux d'étanchéité

Matériau du joint Température de service

EPDM

-40 à 90 °C, brièvement jusqu'à 140 °C

FEP -60 à 160 °C, brièvement jusqu'à 205 °C

Tab. 1 : Matériaux d'étanchéité BBS-11

5.5. Caractéristiques techniques générales

Matériau

en contact

avec le fluide

Acier inoxydable 1.4435

BN2 (316L)

non en contact

avec le fluide

Acier inoxydable 1.4401 ou

similaire

Membrane silicone

Joint torique EPDM/FEP

Dimensions du tube

Voir identification sur le produit (« Fig. 1 »)

Température d'utilisation admissible

selon le matériau d'étanchéité, voir « Tab. 1 »

Température ambiante -20 °C à +80 °C

Fluides Fluides

Pression de service -1 à +16 bars (en fonction de la température

et de la taille, voir fiche de données)

français

Type BBS-11

Page 11

21

6. MONTAGE

AVERTISSEMENT !

Danger dû à la pression élevée et à la sortie de fluide !

• En cas de travaux sur le produit ou l'installation, couper impérativement la pression et vider les conduites/réservoirs .

• En cas d'utilisation de fluides toxiques, porter l'équipement de

protection.

Risque de blessures dû à un montage non conforme !

• Le montage doit être effectué uniquement par un personnel qualifié

et habilité disposant de l'outillage approprié !

• Empêcher tout actionnement involontaire de l'installation.

6.1. Soudage du raccord Ingold de sécurité

REMARQUE !

Fuites dues à des éléments d'étanchéité endommagés !

• Ne pas souder le produit lorsqu'il est assemblé. Avant le soudage,

retirer impérativement le bouchon et le protéger de la poussière,

des étincelles et d'autres influences !

Fuites dues à un contour d’étanchéité endommagé !

• Pour garantir la fonction d’étanchéité, protéger le contour

d’étanchéité pendant le montage, le soudage et le nettoyage.

• Le contour d'étanchéité ne doit pas être endommagé lors du réusinage du raccord Ingold soudé.

• Après soudure le diamètre Intérieur Di du raccord Ingold

doit être repris pour obtenir les tolérances 25H7 ou 40H7.

• Le soudage et le réusinage du raccord Ingold de sécurité

doivent être effectués uniquement par un personnel suffisamment formé !

→ Pointer le raccord sur toute sa surface sous gaz protecteur.

Lors du nettoyage de la soudure par meulage ou décapage, veiller

avant l'assemblage du raccord à :

• Retirer soigneusement tous les résidus de poussière de meulage et

de décapage.

• Ne pas endommager les inscriptions.

• Ne pas procéder à l'enlèvement de matière au niveau des bords

d'étanchéité. L'enlèvement de matière génère des contours d'étanchéité à arêtes vives endommageant le joint.

• Contrôler la présence de dommages sur le contour d'étanchéité.

Nous recommandons d'établir un rapport de soudage.

français

22

6.2. Montage du faux embout et du raccord pour prélèvement d'échantillons Asepto

1 2 3 4 5 6 7 2 8 9

10 11 12 13 14

4

Faux embout Raccord pour le prélèvement d'échantillons Asepto

Fig. 2 : Montage du faux embout et du raccord pour prélèvement d'échantillons Asepto Type BBS-11

→ Introduire la membrane (9) vers l'avant dans le raccord pour pré-

lèvement d'échantillons (11) jusqu'en butée et serrer à fond ce

dernier avec le raccord Ingold pour le prélèvement d'échantillons

(8). Attention : cette pièce vissée ne doit pas être desserrée

pendant le fonctionnement ou lorsque l'assemblage est sous

pression.

→ Insérer maintenant ce groupe de pièces dans le raccord soudé (1)

et bien le serrer avec l'écrou-raccord (4). Respecter le couple de

serrage (voir « Tab. 2 »). Attention : cette pièce vissée ne doit pas

être desserrée pendant le fonctionnement ou lorsque l'assemblage

est sous pression.

Faux embout

→ S'assurer que le joint torique (2) est correctement placé sur le faux

embout Ingold (3). Visser le faux embout Ingold dans le raccord

Ingold soudé (1) à l'aide de l'écrou-raccord (4) pour fermer celuici. Respecter le couple de serrage (voir « Tab. 2 »).

Il n'est désormais plus possible de prélever des échantillons. À l'état

de livraison, la rondelle d'ajustage (5), la rondelle d'écartement (6) et la

bague de sécurité (7) sont déjà montées et ne doivent pas être retirées.

Raccord pour le prélèvement d'échantillons Asepto

→ Avant insertion dans le raccord Ingold, vérifier la présence et la

position correcte des joints toriques (2, 10, 12).

français

23

→ Visser la fermeture (13) sur le raccord pour prélèvement d'échan-

tillons. C'est la seule pièce vissée qui a le droit d'être ouverte

pendant le fonctionnement (pour prélever les échantillons). La

chaîne (14) empêche que la fermeture ne s'égare.

Diamètre nominal (DN) 25 40

Couple de serrage (Nm)

serré à la main

Tab. 2 : Couples de serrage de l'écrou-raccord type BBS-11 raccord Ingold.

AVERTISSEMENT !

Danger dû à la pression élevée et à la sortie de fluide !

• Pendant le fonctionnement et/ou en présence de pression, seul

le capuchon pour le prélèvement d'échantillons (voir « Fig. 2 »,

croquis de droite avec la chaîne) peut être ouvert. Celui-ci s'ouvre

en quelques tours.

• Toutes les autres pièces vissées ne doivent pas être desserrées

dans cet état.

6.3. Démontage

Le démontage a lieu dans le sens inverse du montage.

7. MISE EN SERVICE

AVERTISSEMENT !

Risque de blessures en cas d'utilisation non conforme !

Une utilisation non conforme peut entraîner des blessures et

endommager le produit et son environnement.

• Avant la mise en service, il faut s'assurer que le contenu du manuel

est connu et parfaitement compris par les opérateurs.

• Respecter les consignes de sécurité et l'utilisation conforme.

• L'installation/le produit doit être mis(e) en service uniquement par

un personnel suffisamment formé.

• Garantir un redémarrage contrôlé après le montage.

• Mettre l'installation en service en veillant à empêcher les

augmentations de tension et les coups de bélier inadmissibles.

REMARQUE !

Remplacer les pièces d'usure dans les délais raisonnables

• La durée des pièces d'usure relève de la responsabilité de

l'exploitant de l'installation. Veiller au remplacement des pièces

d'usure dans les délais raisonnables.

français

Type BBS-11

Page 12

24

REMARQUE !

Endom

magement des éléments d'étanchéité lors du nettoyage

de l'installation

.

• Pour nettoyer l'installation, utiliser dans la mesure du possible

des produits de nettoyage n'endommageant pas les éléments

d'étanchéité.

• Pour le nettoyage, ne pas utiliser de brosses métalliques ou de

machines attaquant la surface.

• Si vous utilisez des appareils de contrôle mécaniques pour tuyauteries, veiller à ce que ceux-ci n'endommagent pas les éléments

d'étanchéité (ni le contour d'étanchéité).

Les éléments d'étanchéité endommagés doivent être

remplacés !

8. MAINTENANCE

AVERTISSEMENT !

Danger dû à la pression élevée et à la sortie de fluide !

• Avant de desserrer les écrous ou les vis, couper impérativement la

pression et vider les conduites/réservoirs.

• En cas d'utilisation de fluides toxiques, porter l'équipement de

protection.

• Seuls les techniciens qualifiés sont autorisés à resserrer écrous

et vis sur les tuyauteries/cuves sous pression en respectant les

mesures de sécurité spécifiques.

• Mettre l'installation hors service en veillant à empêcher les augmentations de tension et les coups de bélier inadmissibles.

• Garantir un redémarrage contrôlé après la maintenance.

Faire effectuer régulièrement l'entretien du produit par un

personnel spécialisé !

Font notamment partie des travaux d'inspection et de maintenance, la

surveillance et la garantie de

• l'étanchéité,

• l'identification,

• et le parfait fonctionnement des dispositifs de sécurité et

d'avertissement.

français

25

9. PIÈCES DE RECHANGE

ATTENTION !

Risque de blessures, de dommages matériels dus à de mauvaises pièces !

De mauvais accessoires ou des pièces de rechange inadaptées

peuvent provoquer des blessures et endommager le produit ou son

environnement.

• Utiliser uniquement des accessoires et des pièces de rechange

d'origine de la société Bürkert.

Les pièce de rechange sont les joints toriques, la membrane en

silicone.

Vous pouvez commander les pièces de rechange auprès de votre filiale de

distribution Bürkert. Les numéros d'article des jeux de pièces de rechange

sont indiqués sur la fiche de données correspondante sur Internet.

REMARQUE !

Remplacer les pièces d'usure dans les délais raisonnables

• La durée des pièces d'usure relève de la responsabilité de l'exploitant de l'installation. Veiller au remplacement des pièces d'usure

dans les délais raisonnables.

10. TRANSPORT, STOCKAGE,

ÉLIMINATION

REMARQUE !

Dommages dus au transport !

Les éléments d'étanchéité insuffisamment protégés peuvent être

endommagés pendant le transport.

• Transporter le produit, bien assemblé, à l'abri de l'humidité et des

impuretés et dans un emballage résistant aux chocs.

Un mauvais stockage peut entraîner des dommages sur le

produit.

• Éviter le dépassement vers le haut ou le bas de la température de

stockage admissible.

• Stocker le produit au sec et à l'abri des poussières !

• Stocker les joints toriques et la membrane au sec et à l'abri des UV,

la durée de stockage ne devant pas dépasser 3 ans.

• Température de stockage -40 à +80 °C.

Dommages sur l'environnement causés par des produits contaminés par des fluides.

• Éliminer le produit et l'emballage dans le respect de l'environnement !

• Respecter les prescriptions en matière d'élimination des déchets et

de protection de l'environnement en vigueur.

français

Type BBS-11

Loading...

Loading...