Burkert AirLINE Ex 8650 Quick Start Manual

Quickstart

Electrical and Pneumatic Automation System

Typ 8650

AirLINE Ex

www.burkert.com

We reserve the right to make technical changes without notice.

Technische Änderungen vorbehalten.

Sous resérve de modication techniques.

© Bürkert Werke GmbH & Co. KG, 2007 - 2017

Operating Instructions 1806/02_EU-en_00805635

2

THE QUICKSTART

CAUTION!

The quickstart has to be read and understood.

• Read the quickstart through carefully. Pay attention in

particular to the chapters General Safety Precautions

and Intended Use.

The Quickstart will enable you to install the system.

You will nd more detailed information in the operating instructions on the

Internet under:

www

.buerkert.com

→ Technical Data → manuals →

type 8650

Trademarks

ET 200iSP™ Siemens AG

PROFIBUS® PROFIBUS Nutzerorganisation e. V.

3

SCOPE OF SUPPLY

Immediately upon receipt of delivery, check that the

contents have not been damaged and that the delivery

matches the delivery note or packing list in type and scope.

Please contact us immediately in the event of discrepancies.

Germany

Contact Address:

Bürkert Fluid Control Systems

Sales Center

Chr.-Bürkert-Str. 13-17

D-74653 Ingelngen

Tel. : 07940 - 10 111

Fax: 07940 - 10 448

E-mail: info@de.buerkert.com

International

Contact addresses are found on the nal pages of this

operating manual.

You can also nd information on the Internet under:

www.buerkert.com

Bürkert Company Loca-

tions

4

SYMBOLS

Safety Precautions

DANGER!

High risk!

signies an immediate impending danger. If it is not

avoided, death or serious injury will result.

WARNING!

Medium risk!

signies a potentially dangerous situation. If it is not

avoided, death or serious injury may result

CAUTION!

Low risk!

signies a potentially dangerous situation. If it is not

avoided,

• Minor injury or equipment damage may result.

• The product or its surrounding may be damaged.

Describes important additional information, tips and

recommendations that are important for your safety

and the proper functioning of the device.

Work Steps

→ indicates a work step which you must carry out.

5

INTENDED USE

WARNING!

The device may only be used for the applications

indicated in chapter System Description AirLINE Ex

of the operating manual and only in conjunction with

third-party devices or components recommended or

approved by Bürkert.

Observe the instructions in this operating manual, as

well as the conditions of use and permissible data

specied in the chapter System Description AirLINE Ex

/ Technical data.

The proper and safe function of the product depends

on porper transport, storage and installation, and on

careful operation and maintenance. Use in any other

way does not constitute an intended use.

Limitations

Pay attention to any limitations if the system is to be

exported.

The Ex approval

• Is only valid if the modules and components approved

by Bürkert are used in the manner described in the

operating manual.

• The electronic modules may only be employed in

combination with the pneumatic valves approved by

Bürkert. Use in any other way will invalidate the Ex

approval.

6

• The Ex approval will be invalidated if unauthorised

modications are made to the system, the modules or

components.

Foreseeable misuse

• Do not supply aggressive, inammable or liquid media

to the media connections of the system.

• Do not subject the housing to mechanical loads (e. g.

by placing objects on the housing or using the housing

as a step).

• Do not cover the ventilation slots in the housing.

GENERAL SAFETY PRECAUTIONS

DANGER!

Hazard due to high pressure!

Interference with the system will result in an acute risk

of injury.

• Switch o the pressure and depressurise the system

before loosening pipes and modules!

Hazard due to electrical voltage!

Interference with the system will result in an acute risk

of injury.

• Always switch o the power supply before starting

work! Observe all applicable accident prevention and

safety regulations for electrical equipment.

7

Hazardous situations can arise during installation work.

This work may only be carried out by authorised specialist personnel who have been trained for working in

explosive atmospheres and using suitable tools!

WARNING!

Hazard situations!

Unintentional operation or impermissible damage can

lead to dangerous situations including physical injury.

• Take suitable measures to prevent unintentional opera-

tion or inadmissible damage!

• Ensure that the process is restarted in a dened and

controlled manner after an interruption in the electrical or

pneumatic power supply!

CAUTION!

Electrostatic charges!

The system contains electronic components that react

sensitively to electrostatic discharge (ESD). Touching by

electrostatically charged persons or objects can endanger these components. In the worst case they may be

immediately destroyed or fail after commissioning.

Pay attention also not to touch electronic components

when the supply voltage is switched on.

8

Power supply!

The device may only be operated with direct current. Otherwise damage may be caused to the system.

Ensure that the device is connected only to a DC

power supply!

CAUTION!

Pressure drop!

The pressure in the system may drop during switching.

• Prevent pressure drops. Design the pressure supply

system with as large a volume as possible.

Note!

Operate the AirLINE

Ex System only when it is in perfect condition and

in according with the operating manual.

Failure to observe this information and unauthorised

intervention in the AirLINE Ex System will void any

liability for us and annuls the guarantees applicable

to the devices and accessories!

The Ex approval is only valid if you the modules and

components of the AirLINE Ex System are operated

in the manner described. Unauthorised modications

will invalidate the Ex approval!

9

SYSTEM DESCRIPTION

General technical data

Media clean, dry air (oiled / unoiled)

neutral gases (particle size max. 5 μm)

Ambient temperature 0 ... +55 °C (in operation)

Storage temperature -20 ... +60 °C

Relative humidity 5 ... 95 %, non-condensing

Acceleration 5 m/s2 (in operation)

Rated operating mode 100 % CDF

(continuous operation)

Operating voltage 24 V DC in EEx-e

Degree of protection IP30

Protection class 3 (VDE0580)

Approvals

Elektronic module ATEX II 2 G Ex ib IIC T4 (Zone 1/21),

Installation in an approved

Ex-e cabinet required.

Terminal module ATEX II 2 G Ex e [ia/ib] IIC T4

(Zone 1/21),

Installation in an approved

Ex-e cabinet required.

10

DANGER!

Hazard due to electrical voltage!

The terminal modules (with upright system wiring) are

designed in the explosion-proof class Ex-e (increased

safety).

• When working on the terminal modules, the operating

voltage of the system must be switched o.

• Further information on this can be found in the manual

of the Siemens ET200iSP.

Interference immunity EN 50082-2

Emitted interference EN 50081-2

Power consumption of the active modules, including

the mounted valves

Modul type Power

1)

ID-no.

4 channels 11 mm

max. 2.9 W 171 941

8 channels 11 mm

max. 3.6 W 171 942

4 channels 16,5 mm

max. 2.9 W 171 943

8 channels 16,5 mm

max. 3.6 W 171 944

1)

These values must be taken into consideration when calcu-

lating the max. total power consumption of the station.

(See also table 3-4 in the Siemens manual ET 200 iSP)

11

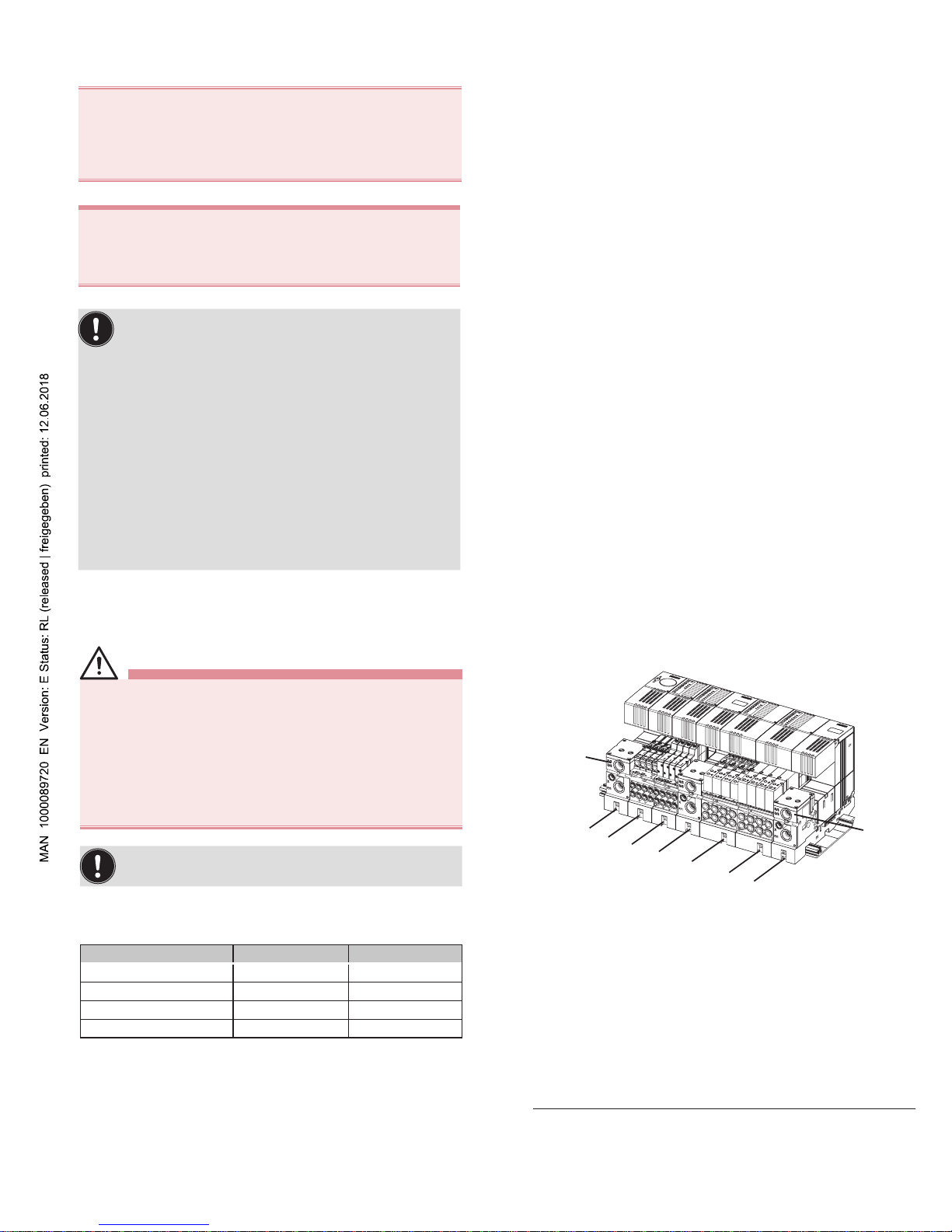

Installation example

1

2

3

8

7

6

5

4

8

Illustration: Installation example

1 Supply slice, left

2 Valve slice 44 mm, 4 Valve functions

3 Valve slice 44 mm, 8 Valve functions

1)

4 Supply slice, middle, Intermediate power supply

5 Valve slice 66 mm, 4 Valve functions

6 Valve slice 66 mm, 8 Valve functions

1)

7 Supply slice, right

8 Starting points for removal on the preassembled sys-

tem

1)

not yet available

12

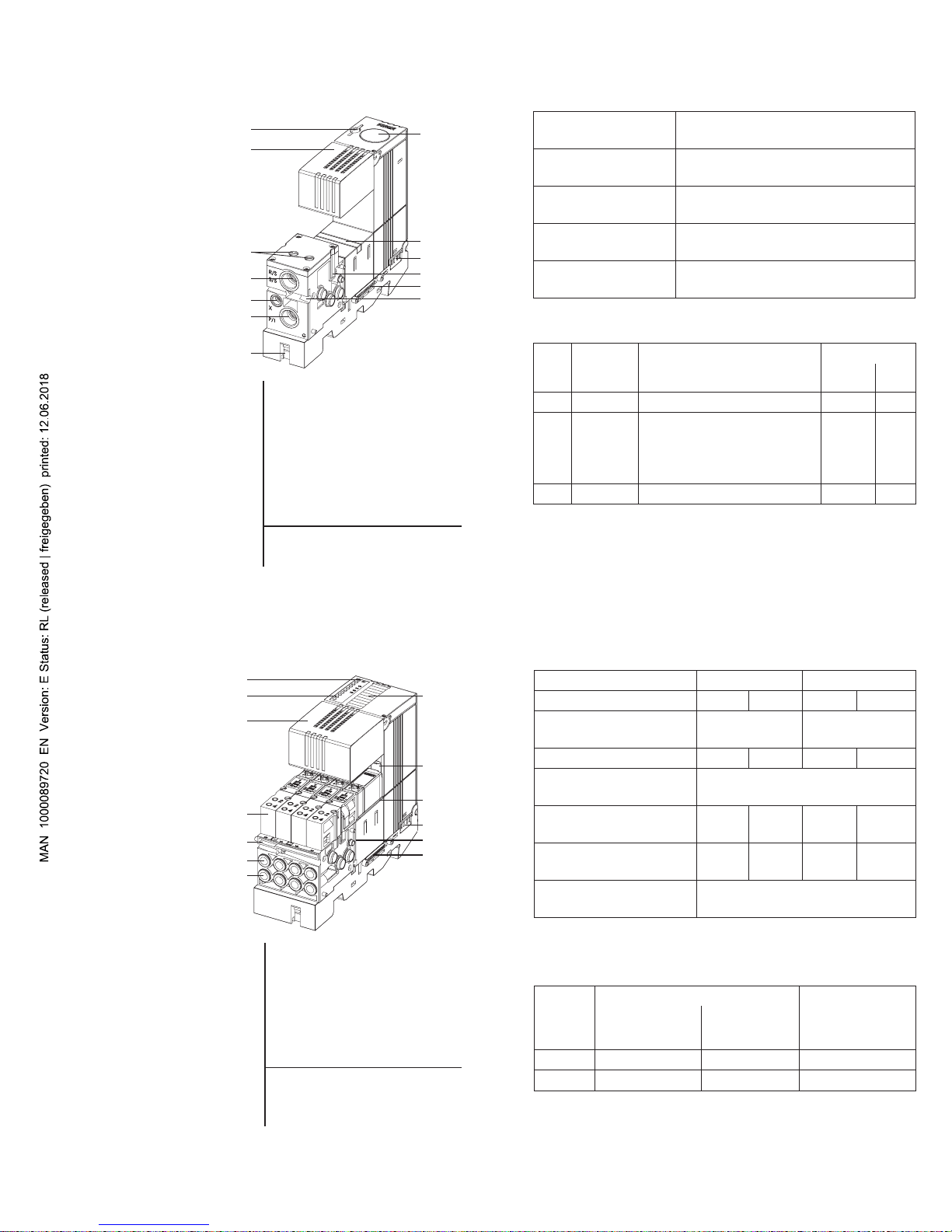

Supply slice

Illustration: Supply

slice

9

10

11

15

14

13

12

16

19

20

19

18

17

9 Storage compartement 15 Unlocking slide

2)

for SD card

16 Pressure gauge

10 Hinged cover ap

(optional)

11 Clamping bolts (2x) 17 Shut-o slide

18 Power-Bus plug

Pneumatic connections:

19 Inclined tie rods

2)

(2x)

12 R/S-3/5

20 Communication bus plug

13 X

2)

Not tted with left-hand

connecting slices

14 P/1

13

Technical data

Power consumption

0 W (Module is electrically passive)

Pneumatic

connections

G 3/8“, G 1/8“

or NPT 3/8“, NPT 1/8“

Dimensions Appr. 50 (per station 44)

x 190 x 120 mm

Material (housing

pneumatic)

PA, PBT, PC

Weight 480 g / 520 g

(without / with manometer)

Pneumatic connections

Pos. Marking Function Version

G NPT

12 R/S-3/5 Exhaust air 3/8“ 3/8“

13 X Control

EXT: Auxiliary control

air

INT: Pilot exhaust air

1/8“

14 P/1 Compressed air supply 3/8“ 3/8“

14

Valve slice

Illustration:

Valve slice

21

27

26

25

19

23

22

10

17

18

19

20

24

21 Module status (red LED) 27 Labelling panel, slot-in

22 Channel status 24 Valve ejector

1)

(green LED)

17 Shut-o slide

2)

10 Hinged cover ap 18 Power-Bus plug

23 Valves 20 Communication bus plug

19 Inclined tie rods (2x)

Pneumatic working ports:

1)

only with stacking size 66 mm

2)

under the valves

25 see table

26 see table

15

Technical data

Valve width 11 mm 16.5 mm

Valve outlets 4 8 4 8

Dimensions 44 x 120 x 135 mm66 x 120 x 135

mm

Weight with valves 580 g 690 g 1080 g n/a

Material PBT, PC (Housing)

PA (Pneumatic module)

Current consumption

[mA]

250 310 250 310

Max. power loss of

the module

2.9 W 3.6 W 2.9 W 3.6 W

Status displays Module status

1)

: LED red

Channel status: LED green

1)

Function as for Siemens modules

Pneumatic connections

Possible conguration of the working ports

Pos. Valves Double valves

3/2-way

6524/6526

5/2-way

6525/6527

2x 3/2-way

6524/6526

25 not used 2 2 (valve 12)

26 2 4 4 (valve 14)

Loading...

Loading...