Page 1

XL5050us_cover

Operation Manual

English

885-448

XC6752-021

Printed in China

XC6752-021 XL5050 (NA03J061) Bk

Page 2

XL5000us.book Page 1 Tuesday, November 11, 2003 9:25 AM

IMPORTANT SAFETY INSTRUCTIONS

When using this machine, basic safety precautions, including the following, should always be taken:

Read all instructions before use.

DANGER - To reduce the risk of electric shock:

1. The machine should never be left unattended while plugged in. Always unplug the machine

from the electrical outlet immediately after using it and before cleaning it.

2. Always unplug the machine before you change the light bulb.

Replace the bulb with the same type and rated 15 watts.

WARNING - To reduce the risk of burns, fire, electric shock, or injury to persons:

1. Do not allow this machine to be used as a toy. Close attention is necessary when the machine is

used by or near children.

2. Use this machine only for its intended use as described in this manual. Use only accessories

recommended by the manufacturer as contained in this manual.

3. Never operate this machine if it has a damaged cord or plug, if it is not working properly, if it has

been dropped or damaged, or dropped into water. Return the machine to the nearest authorized

dealer or service center for examination, repair, or electrical or mechanical adjustment.

4. Never operate the machine with any air openings blocked. Keep ventilation openings of the

machine and foot controller free from the accumulation of lint, dust, and loose cloth.

5. Never drop or insert any object into any opening.

6. Do not use outdoors.

7. Do not operate where aerosol (spray) products are being used or where oxygen is being

administered.

8. To disconnect the machine, set the main switch to the “{” position (which represents off), and

then remove the plug from the outlet.

9. Do not unplug by pulling on the cord. To unplug, grasp the plug, not the cord.

10. Keep fingers away from all moving parts. Special care is required around the machine needle.

11. Always use the proper needle plate. The wrong plate can cause the needle to break.

12. Do not use bent needles.

13. Do not pull or push fabric while stitching. It may deflect the needle, causing it to break.

14. Switch the machine to the “{” position to turn it off when making any adjustments in the needle

area, such as threading the needle, changing the needle, threading the bobbin, or changing the

presser foot.

15. Always unplug the machine from the electrical outlet when removing covers, lubricating, or

when making any other user servicing adjustments mentioned in the instruction manual.

16. This sewing machine is not intended for use by young children or infirm persons without

supervision.

17. Young children should be supervised to ensure that they do not play with this machine.

SAVE THESE INSTRUCTIONS

This machine is intended for household use.

1

Page 3

—

XL5000us.book Page 2 Tuesday, November 11, 2003 9:25 AM

——————————————————————————————————————————————————————————————

FOR USERS IN THE UK, EIRE, MALTA AND CYPRUS ONLY

If this machine is fitted with a three-pin non-rewireable BS plug then please read the following.

IMPORTANT (in the United Kingdom)

Main supply (AC 230/240V, 50Hz)

DO NOT cut off the main plug from the equipment. If the plug

fitted is not suitable for the power outlet in your home or the

cable is too short to reach a power outlet, then obtain an

appropriate safety-approved extension lead or consult your

dealer.

BE SURE to replace the fuse only with an identical approved

type, as originally fitted, and to replace the fuse cover.

If the main plug is cut off, be sure to remove the fuse and

dispose of the plug immediately, to avoid a possible shock

hazard by inadvertent connection to the main power supply.

IMPORTANT (in the other countries)

If the available socket outlet is not suitable for the plug

supplied with this equipment, it should be cut off and an

appropriate three-pin plug should be fitted. With alternative

plugs, an approved fuse must be fitted in the plug.

NOTE: The plug severed from the main leads must be

destroyed as a plug with bared flexible cords is hazardous if

engaged in a live socket outlet. In the event that the plug

fuse is replaced, use a fuse approved by ASTA to BS 1362,

i.e., carrying the mark, rated as marked on the plug.

Always replace the fuse cover. Never use plugs with the

fuse cover omitted.

WARNING: DO NOT CONNECT EITHER

WIRE TO THE EARTH TERMINAL WHICH IS

MARKED WITH THE LETTER ‘E’ OR BY THE

EARTH SYMBOL , OR COLORED GREEN

OR GREEN AND YELLOW.

The wires in this main lead are colored in accordance with

the following code:

Blue Neutral

Brown Live

As the colors of the wiring in the main lead of this

appliance may not correspond with the colored markings

identifying the terminals in your plug, proceed as follows:

The wire that is colored blue must be connected to the

terminal marked with the letter ‘N’ or colored black or

blue.

The wire that is colored brown must be connected to the

terminal marked with the letter ‘L’ or colored red or brown.

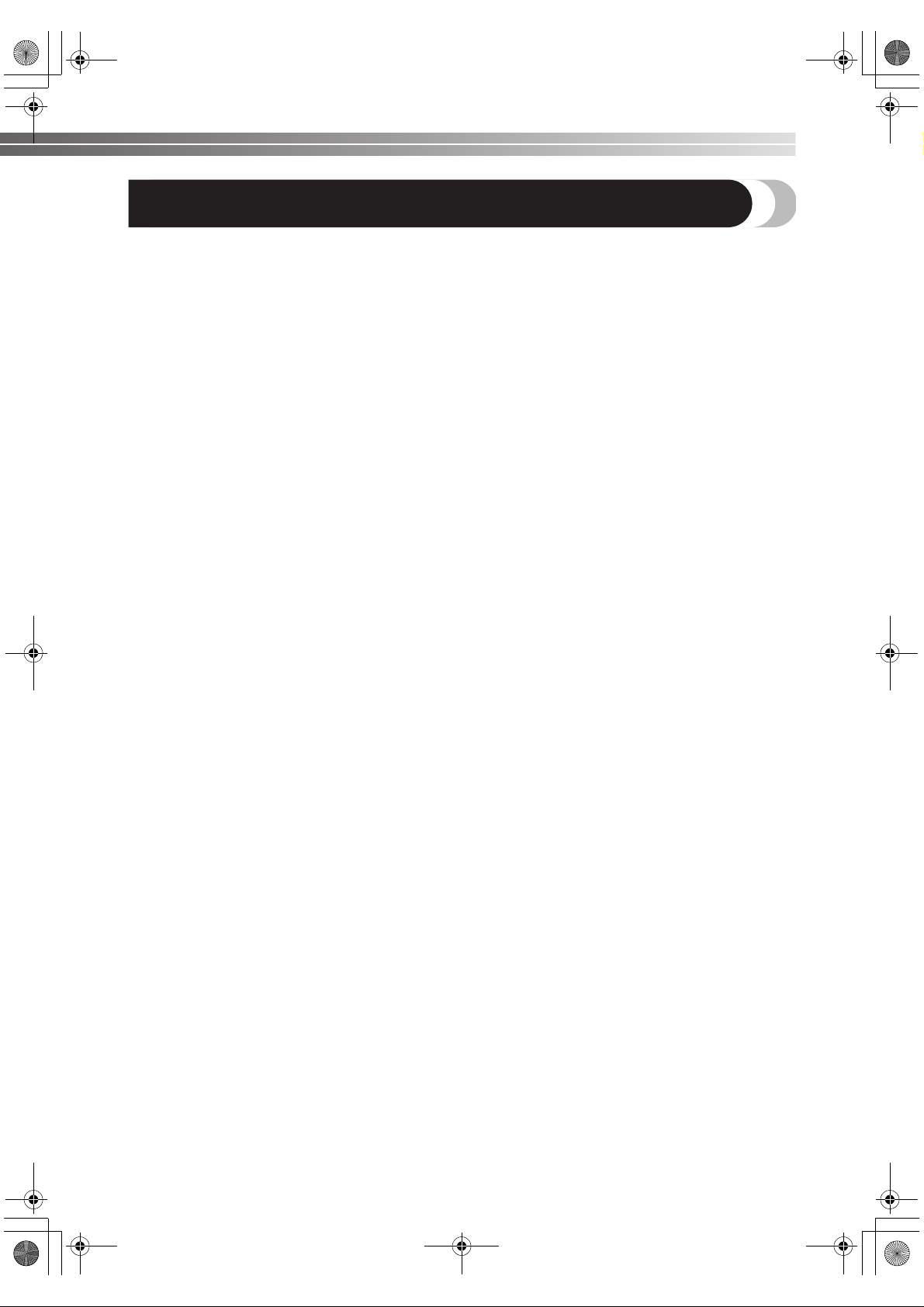

CONNECTING PLUGS AND MAIN POWER/SEWING LIGHT SWITCH

1

2

1. Connect the three-prong plug into the machine.

2. Connect the electrical supply plug into a wall outlet.

• When leaving the machine unattended, the main

power switch of the machine should be switched off

or the plug must be removed from the socket outlet.

The main power/sewing light switch turns the main power

and sewing light on or off.

1 Turn on

2 Turn off

• When servicing the machine, removing covers or

changing bulbs, the machine must be unplugged.

2

Page 4

XL5000us.book Page 3 Tuesday, November 11, 2003 9:25 AM

CONTENTS

IMPORTANT SAFETY INSTRUCTIONS ............................................................................... 1

CONNECTING PLUGS AND MAIN POWER/SEWING LIGHT SWITCH ............................. 2

CONTENTS .........................................................................................................................3

PRINCIPAL PARTS ............................................................................................................... 4

ACCESSORIES .....................................................................................................................5

USING YOUR SEWING MACHINE .....................................................................................6

Connecting Plugs .............................................................................................................................................. 6

Main Power/Sewing Light Switch ...................................................................................................................... 7

Foot Controller .................................................................................................................................................. 7

Inserting the Needle .......................................................................................................................................... 7

Checking the Needle ......................................................................................................................................... 8

Changing the Presser Foot ................................................................................................................................. 8

Converting to Free-arm Style ............................................................................................................................. 9

Steadying the Machine ...................................................................................................................................... 9

THE CONTROLS ............................................................................................................... 10

Pattern Selection Dial ...................................................................................................................................... 10

Recommended Widths and Lengths for Stitches .............................................................................................. 11

Stitch Length Dial ............................................................................................................................................ 14

Stretch Stitching .............................................................................................................................................. 14

Reverse Sewing Lever ...................................................................................................................................... 14

Drop Feed Lever (if the machine is equipped with a drop feed lever) .............................................................. 14

THREADING THE MACHINE ............................................................................................15

Winding the Bobbin ........................................................................................................................................ 15

Lower Threading ............................................................................................................................................. 16

Upper Threading ............................................................................................................................................. 18

Using the Needle Threader (models equipped with a needle threader) ............................................................ 19

Quick Thread-Setting System FAST START BOBBIN (models equipped with a quick thread-setting system) .... 20

Drawing up the lower thread .......................................................................................................................... 21

Sewing with a Twin Needle ............................................................................................................................ 21

Tension of the Thread ..................................................................................................................................... 22

CHART OF SEWING FABRICS, NEEDLES AND THREAD COMBINATIONS .....................24

Please Read Before Sewing ............................................................................................................................. 25

Straight Stitching ............................................................................................................................................. 25

Zigzag Stitching .............................................................................................................................................. 26

Blind Hem Stitching ........................................................................................................................................ 27

Shell Tuck Stitching ......................................................................................................................................... 27

Elastic Stitching ............................................................................................................................................... 28

Scallop Stitching ............................................................................................................................................. 28

Overedge Stitching .......................................................................................................................................... 29

Feather Stitching ............................................................................................................................................. 29

Triple Zigzag Stretch Stitching ......................................................................................................................... 30

Decorative Stitching ........................................................................................................................................ 30

Making a Buttonhole (1-Step Automatic Buttonhole) ....................................................................................... 30

Making a Buttonhole (4-Step Buttonhole) ........................................................................................................ 31

Adjusting Buttonholes ..................................................................................................................................... 33

Sewing Buttons ............................................................................................................................................... 33

Zipper Insertion ............................................................................................................................................... 34

Gathering ........................................................................................................................................................ 35

Darning ........................................................................................................................................................... 35

Appliqués ........................................................................................................................................................ 36

Monogramming and Embroidering ................................................................................................................. 36

MAINTENANCE ................................................................................................................38

Changing the Light Bulb .................................................................................................................................. 38

Oiling ............................................................................................................................................................. 38

Cleaning ......................................................................................................................................................... 39

Performance Checklist .................................................................................................................................... 40

Repacking the Machine ................................................................................................................................... 42

INDEX ............................................................................................................................... 43

3

Page 5

—

XL5000us.book Page 4 Tuesday, November 11, 2003 9:25 AM

KNOWING YOUR SEWING MACHINE —————————————————————————————————————————————

PRINCIPAL PARTS

1 Bobbin-winding assembly (page 15)

This winds the thread onto the bobbin, which you use

for the lower thread.

2 Spool pin (page 15 and 18)

Holds the spool of thread.

3 Bobbin-winding tension disc and thread guide

(page 15)

4 Thread take-up lever (page 18)

5 Thread cutter (page 26)

6 Upper tension-control dial (page 22)

This controls the tension of the upper thread.

7 Pattern selection dial (page 10)

You can turn this in either direction to choose the stitch

you want.

8 Stitch length dial (page 14)

This controls the length of the stitches.

9 Reverse-sewing lever (page 14)

You can push this to stitch in the reverse direction.

0 Buttonhole fine adjustment screw (page 33)

A Buttonhole lever (1-Step automatic buttonhole)

(page 30)

B Needle threader (page 19)

This is only available on certain models.

4

C Handle

D Balance wheel

Turn toward you (counterclockwise) to raise and lower

the needle.

E Main power/sewing light switch (page 7)

You can turn the main power and sewing light on and

off.

F Foot controller receptacle (page 6)

Plug in the foot controller plug and connect the

machine to the power supply.

G Presser foot lever (page 8)

This raises and lowers the presser foot.

H Foot controller (page 7)

You can use this to control the sewing speed, and to

start and stop sewing.

I Zigzag presser foot

Page 6

XL5000us.book Page 5 Tuesday, November 11, 2003 9:25 AM

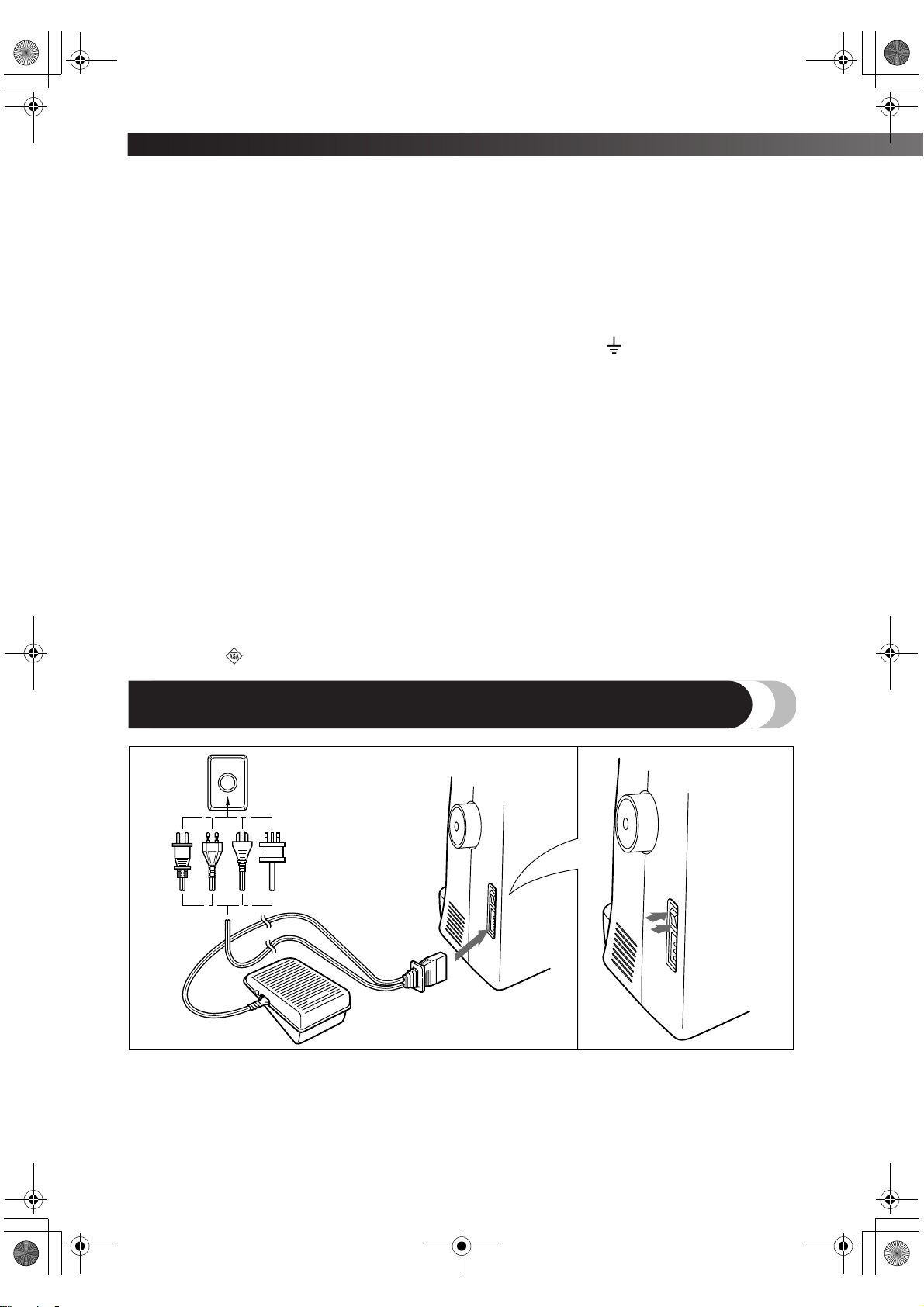

ACCESSORIES

1

XA4911-151 X59369-321

(For 1 Step Automatic Buttonhole)

3 X59375-121

4 129583-001

7 X55467-021

1 Buttonhole foot (1 pc.)

2 Zipper foot (1 pc.)

3 Button sewing foot (1 pc.)

4 Needle pack (regular single needle HAX130) (3 pcs.)

5 Twin needle (1 pc.)

6 Bobbins (3 pcs.)

7 Screwdriver (1 pc.)

8 Extra spool pin (1 pc.)

9 Darning plate (1pc.) (When the machine is not

equipped with a Drop Feed.)

(For 4 Step Buttonhole)

5 X57521-001

8 130920-021

Parts code for zigzag presser foot: 138135-122

Foot controller:

The above accessories are stored in the accessory

bag inside the extension table. These accessories

have been designed to help you carry out most

sewing tasks.

2 X59370-021

6 SA156(For U.S.A.)

SFB(XA5539-151)(For other countries)

9 XA3442-121

XC7359-021 (110/120V areas)

XC7438-021 (220/240V areas)

XC7456-021 (U.K.)

XC7455-021 (Australia, New Zealand)

5

Page 7

—

XL5000us.book Page 6 Tuesday, November 11, 2003 9:25 AM

KNOWING YOUR SEWING MACHINE —————————————————————————————————————————————

USING YOUR SEWING MACHINE

WARNING

●

Use only regular household electricity for the power source. Using other power sources may

result in fire, electric shock, or damage to the machine.

● Turn off the main power and remove the plug in the following circumstances:

• When you are away from the machine

• After using the machine

• When the power fails during use

• When the machine does not operate correctly due to a bad connection or a disconnection

• During electrical storms

CAUTION

● Do not use extension cords or multi-plug adapters with many other appliances plugged in to

them. Fire or electric shock may result.

● Do not touch the plug with wet hands. Electric shock may result.

● When unplugging the machine, always turn off the main power first. Always grasp the plug to

remove it from the outlet. Pulling on the cord may damage the cord, or lead to fire or electric

shock.

● Do not allow the power cord to be cut, damaged, modified, forcefully bent, pulled, twisted,

or bundled. Do not place heavy objects on the cord. Do not subject the cord to heat. These

things may damage the cord and cause fire or electric shock. If the cord or plug is damaged,

take the machine to your authorized dealer for repairs before continuing use.

● Unplug the power cord if the machine is not to be used for a long period of time, otherwise a

fire may result.

Connecting Plugs

Connect the power cord plug to the machine.

1

Connect the power supply plug to a wall

2

outlet.

6

Page 8

XL5000us.book Page 7 Tuesday, November 11, 2003 9:25 AM

Note

● When leaving the machine unattended, the

main switch of the machine should be

switched off or the plug must be removed

from the socket outlet.

● When servicing the machine, removing

covers or changing bulbs, the machine must

be unplugged.

(For U.S.A. only)

● This appliance has a polarized plug (one

blade wider than the other). To reduce the

risk of electric shock, this plug is intended

to fit in a polarized outlet only one way. If

the plug does not fit fully in the outlet,

reverse the plug.

If it still does not fit, contact a qualified

electrician to install the proper outlet. Do

not modify the plug in any way.

Main Power/Sewing

Light Switch

This switch turns the main power and sewing light

on or off.

1 Turn on (toward the “I” mark)

2 Turn off (toward the “O” mark)

Foot Controller

When you press the foot controller down lightly, the

machine will run at a low speed. When you press

harder, the machine’s speed will increase. When you

take your foot off the foot controller, the machine

will stop. You should make sure that nothing is

placed on the foot controller when the machine is

not in use.

CAUTION

● Do not allow pieces of cloth and dust to

build up on the foot controller, otherwise

a fire or an electric shock could occur.

Note

(For U.S.A. only)

● Foot Controller: Model KD-1902

This foot controller can be used with

Models XL-5050/XL-5060/XL-5070/

1

2

.

XL-5051/XL-5061/XL-5071.

Inserting the Needle

CAUTION

● Turn the main power switch off before

you change the needle. If you leave the

main power on and step on the foot

controller, the machine will start and you

may be injured.

● Only use sewing-machine needles for

home use. Other needles may bend or

break and cause injury.

● Never sew with a bent needle. A bent

needle will easily break and cause injury.

Remove the power supply plug from the

1

electrical outlet.

7

Page 9

—

XL5000us.book Page 8 Tuesday, November 11, 2003 9:25 AM

KNOWING YOUR SEWING MACHINE —————————————————————————————————————————————

Raise the needle bar to its highest position.

2

Checking the Needle

Lower the presser foot.

3

If a needle is already installed, remove it by

4

loosening the needle clamp with a

screwdriver and pulling the needle down.

1

1 Screwdriver

• Do not use extreme force when

loosening or tightening the needle

clamp screw, otherwise certain parts of

the sewing machine may be damaged.

With the flat side of the needle toward the

5

back of the machine, insert the needle until it

touches the needle stopper.

Tighten the needle clamp.

1

The sewing needle must always be straight

1

and sharp for smooth sewing.

To check if the needle is bent, place the flat

2

side of the needle on a flat surface as shown.

Replace the needle if it is bent or dull.

3

Changing the Presser Foot

CAUTION

●

Always turn off the power before you

change the presser foot. If you leave the

power on and step on the controller, the

machine will start and you may be injured.

● Always use the correct presser foot for

the stitch pattern you have chosen. If you

use the wrong presser foot, the needle

may strike the presser foot and bend or

break, and may cause injury.

● Only use presser feet that have been

designed to be used with this machine.

Using other any presser feet may cause

an accident or injury.

3

2

1 Screwdriver

2 Needle stopper

3 Needle

CAUTION

Make sure to push in the needle until it

●

touches the stopper, and securely tighten

the needle clamp screw with a

screwdriver. If the needle is not in fully,

or if the needle clamp screw is loose, the

needle may break or the machine may be

damaged.

8

You will have to change the presser foot depending

on what you want to sew and how.

■ Snap-On Type

Raise the needle to its highest position by turning

1

the balance wheel toward you (counterclockwise)

and raise the presser foot lever.

Release the foot by raising the lever at the

2

back of the holder assembly.

Page 10

XL5000us.book Page 9 Tuesday, November 11, 2003 9:25 AM

Put a different presser foot on the needle plate

3

so that the bar on the presser foot is in line

with the slot on the shank.

Lower the presser foot lever and fix the

4

presser foot onto the shank. If the presser foot

is in the correct place, the bar should snap in.

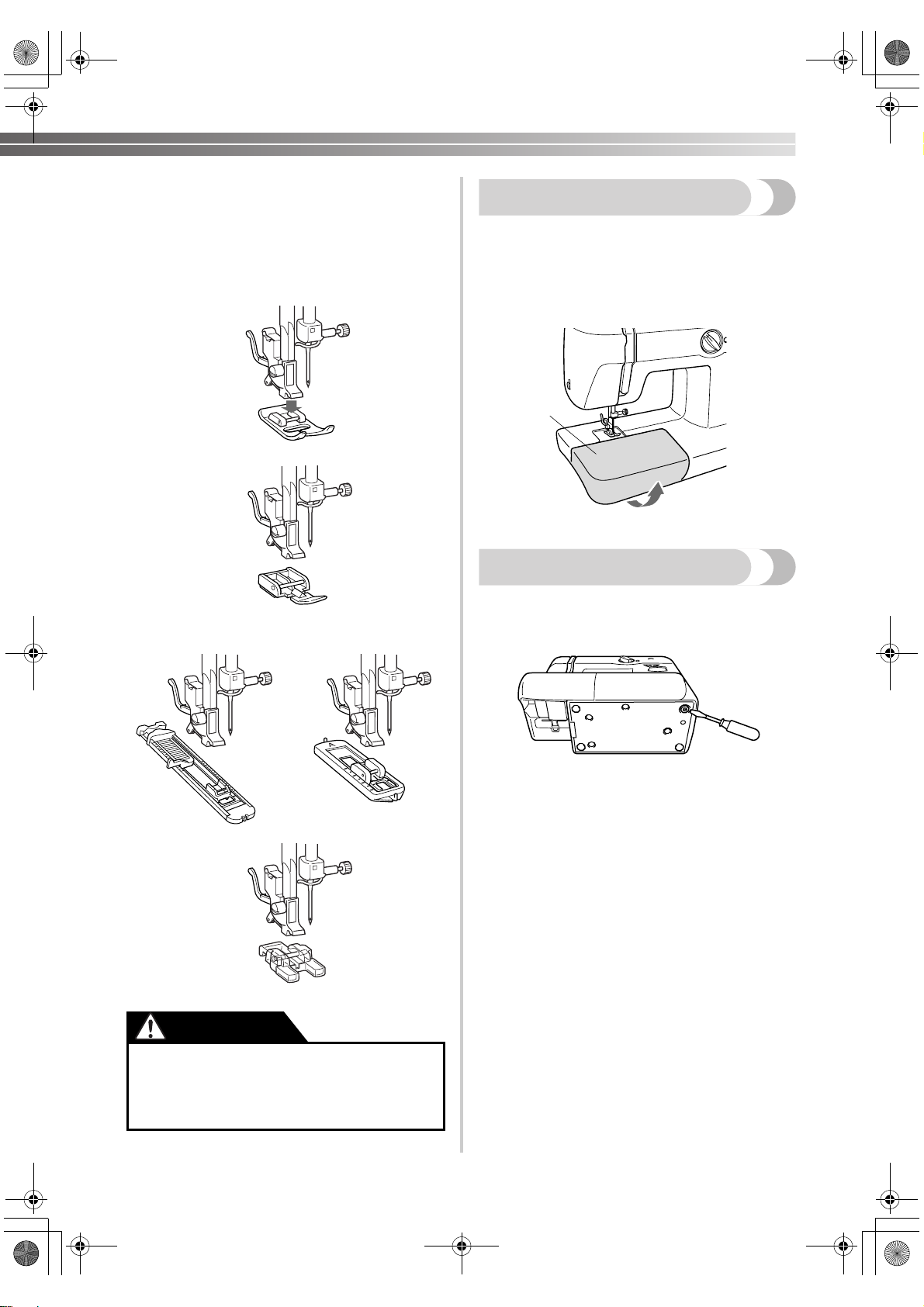

Converting to Free-arm Style

Free-arm sewing is convenient for sewing tubular and

hard-to-reach areas. To change your machine to the

free-arm style, lift out the extension table attachment.

1 Lift the bottom of the extension table up

toward you.

2 Pull the extension table out to remove it.

1

1 Extension table

Steadying the Machine

When the machine is placed on an uneven surface,

turn the rubber cushion on the front right-hand side of

the base plate to adjust it until the machine is stable.

CAUTION

● If the presser foot is not installed with the

correct orientation, the needle may strike

the presser foot, which may bend or

break the needle and cause injury.

9

Page 11

—

XL5000us.book Page 10 Tuesday, November 11, 2003 9:25 AM

KNOWING YOUR SEWING MACHINE —————————————————————————————————————————————

THE CONTROLS

Pattern Selection Dial

To choose a stitch, simply turn the pattern selection

dial in either direction. Stitch widths and lengths are

shown on the following page.

1

1 Pattern selection dial

Note

● Since the pattern selection dial is not

continuous, it cannot be turned directly

from the last stitch to the first one or from

the first stitch to the last one. To select the

first stitch when the last one is displayed or

to select the last stitch when the first one is

displayed, turn the pattern selection dial in

the opposite direction until the desired

stitch is displayed.

■ 21 Stitches (1-Step Automatic Buttonhole)

1

2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21

■ 17 Stitches (1-Step Automatic Buttonhole)

1

2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17

■ 17 Stitches (4-Step Buttonhole)

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17

10

Page 12

XL5000us.book Page 11 Tuesday, November 11, 2003 9:25 AM

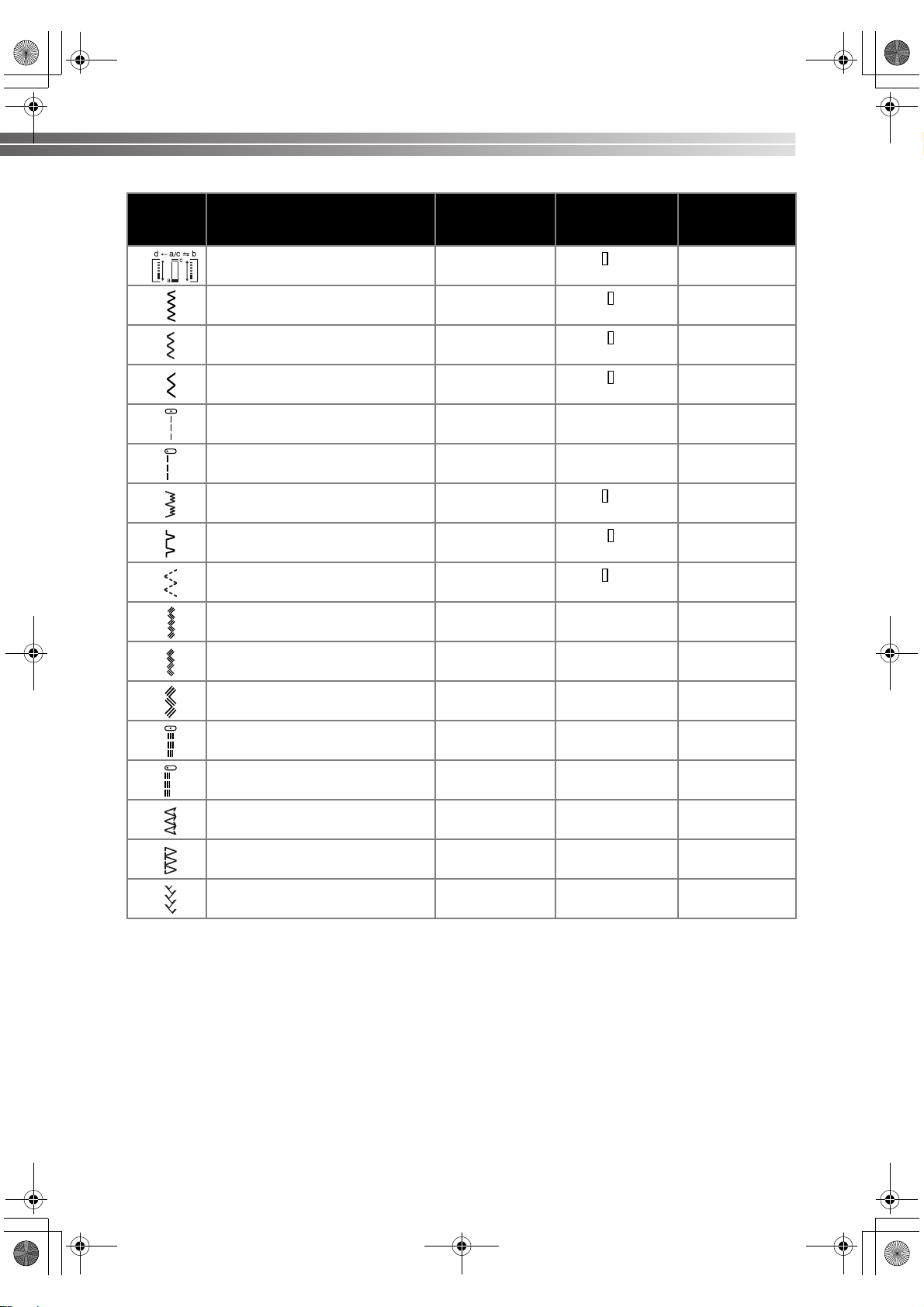

Recommended Widths and Lengths for Stitches

■ 21 Stitches (1-Step Automatic Buttonhole)

Recommended

Pattern Stitch Name

[mm (inch)]

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

1-STEP AUTOMATIC

BUTTONHOLE

STRAIGHT STITCH

(CENTER)

STRAIGHT STITCH

(LEFT)

ZIGZAG STITCH

ZIGZAG STITCH

ZIGZAG STITCH

BLIND HEM STITCH

SHELL TUCK STITCH

ELASTIC STITCH

STRETCH BLIND HEM STITCH

SCALLOP STITCH

TRIPLE STRETCH STITCH

(CENTER)

TRIPLE STRETCH STITCH

(LEFT)

TRIPLE ZIGZAG STRETCH STITCH

TRIPLE ZIGZAG STRETCH STITCH

TRIPLE ZIGZAG STRETCH STITCH

STRETCH OVERLOCK STITCH

ELASTIC OVERLOCK STITCH

FEATHER STITCH

ARROWHEAD STITCH

DECORATIVE STITCH

Width

5

(3/16)

-

-

1.7

(1/16)

3.5

(1/8)

5

(3/16)

3.5

(1/8)

5

(3/16)

5

(3/16)

5

(3/16)

5

(3/16)

-

-

1.7

(1/16)

3.5

(1/8)

5

(3/16)

3.5

(1/8)

5

(3/16)

5

(3/16)

5

(3/16)

5

(3/16)

Recommended

Length

[mm (inch)]

-1.5

(1/64-1/16)

1-4

(1/16-3/16)

1-4

(1/16-3/16)

-4

(1/64-3/16)

-4

(1/64-3/16)

-4

(1/64-3/16)

-2

(1/64-1/16)

-3

(1/64-1/8)

-2.5

(1/64-3/32)

-1.5

(1/64-1/16)

-1.5

(1/64-1/16)

Fixed

2.5 (3/32)

Fixed

2.5 (3/32)

Fixed

2.5 (3/32)

Fixed

2.5 (3/32)

Fixed

2.5 (3/32)

Fixed

2.5 (3/32)

Fixed

2.5 (3/32)

Fixed

2.5 (3/32)

Fixed

2.5 (3/32)

Fixed

2.5 (3/32)

Page in

Instructions

30

25, 34, 35

25, 34, 35

26, 33, 36

26, 33, 36

26, 33, 36

27

27

28

27

28

25

25

30

30

30

29

29

29

29

30

11

Page 13

—

XL5000us.book Page 12 Tuesday, November 11, 2003 9:25 AM

KNOWING YOUR SEWING MACHINE —————————————————————————————————————————————

■ 17 Stitches (1-Step Automatic Buttonhole)

Pattern Stitch Name

1

1-STEP AUTOMATIC

BUTTONHOLE

2

STRAIGHT STITCH

(CENTER)

3

STRAIGHT STITCH

(LEFT)

4

5

6

7

8

9

10

ZIGZAG STITCH

ZIGZAG STITCH

ZIGZAG STITCH

BLIND HEM STITCH

SHELL TUCK STITCH

ELASTIC STITCH

TRIPLE STRETCH STITCH

(CENTER)

11

TRIPLE STRETCH STITCH

(LEFT)

12

13

14

15

16

17

TRIPLE ZIGZAG STRETCH STITCH

TRIPLE ZIGZAG STRETCH STITCH

TRIPLE ZIGZAG STRETCH STITCH

STRETCH OVERLOCK STITCH

ELASTIC OVERLOCK STITCH

FEATHER STITCH

Recommended

Width

[mm (inch)]

5

(3/16)

-

-

1.7

(1/16)

3.5

(1/8)

5

(3/16)

3.5

(1/8)

5

(3/16)

5

(3/16)

-

-

1.7

(1/16)

3.5

(1/8)

5

(3/16)

3.5

(1/8)

5

(3/16)

5

(3/16)

Recommended

Length

[mm (inch)]

-1.5

(1/64-1/16)

1-4

(1/16-3/16)

1-4

(1/16-3/16)

-4

(1/64-3/16)

-4

(1/64-3/16)

-4

(1/64-3/16)

-2

(1/64-1/16)

-3

(1/64-1/8)

-2.5

(1/64-3/32)

Fixed

2.5 (3/32)

Fixed

2.5 (3/32)

Fixed

2.5 (3/32)

Fixed

2.5 (3/32)

Fixed

2.5 (3/32)

Fixed

2.5 (3/32)

Fixed

2.5 (3/32)

Fixed

2.5 (3/32)

Page in

Instructions

30

25, 34, 35

25, 34, 35

26, 33, 36

26, 33, 36

26, 33, 36

27

27

28

25

25

30

30

30

29

29

29

12

Page 14

XL5000us.book Page 13 Tuesday, November 11, 2003 9:25 AM

■ 17 Stitches (4-Step Buttonhole)

Pattern Stitch Name

1

2

3

4

5

4-STEP BUTTONHOLE

ZIGZAG STITCH

ZIGZAG STITCH

ZIGZAG STITCH

STRAIGHT STITCH

(CENTER)

6

STRAIGHT STITCH

(LEFT)

7

8

9

10

11

12

13

STRETCH BLIND HEM STITCH

SHELL TUCK STITCH

ELASTIC STITCH

TRIPLE ZIGZAG STRETCH STITCH

TRIPLE ZIGZAG STRETCH STITCH

TRIPLE ZIGZAG STRETCH STITCH

TRIPLE STRETCH STITCH

(CENTER)

14

TRIPLE STRETCH STITCH

(LEFT)

15

16

17

ARROWHEAD STITCH

ELASTIC OVERLOCK STITCH

FEATHER STITCH

Recommended

Width

[mm (inch)]

5

(3/16)

1.7

(1/16)

3.5

(1/8)

5

(3/16)

-

-

5

(3/16)

5

(3/16)

5

(3/16)

1.7

(1/16)

3.5

(1/8)

5

(3/16)

-

-

5

(3/16)

5

(3/16)

5

(3/16)

Recommended

Length

[mm (inch)]

-1.5

(1/64-1/16)

-4

(1/64-3/16)

-4

(1/64-3/16)

-4

(1/64-3/16)

1-4

(1/16-3/16)

1-4

(1/16-3/16)

-1.5

(1/64-1/16)

-3

(1/64-1/8)

-2.5

(1/64-3/32)

Fixed

2.5 (3/32)

Fixed

2.5 (3/32)

Fixed

2.5 (3/32)

Fixed

2.5 (3/32)

Fixed

2.5 (3/32)

Fixed

2.5 (3/32)

Fixed

2.5 (3/32)

Fixed

2.5 (3/32)

Page in

Instructions

31

26, 33, 36

26, 33, 36

26, 33, 36

25, 34, 35

25, 34, 35

27

27

28

30

30

30

25

25

29

29

29

13

Page 15

—

XL5000us.book Page 14 Tuesday, November 11, 2003 9:25 AM

KNOWING YOUR SEWING MACHINE —————————————————————————————————————————————

1

Stitch Length Dial

Depending on the selected stitch, you may need to

adjust the stitch length for best results. The numbers

marked on the stitch length dial represent the stitch

length in millimeters (mm) (1/25").

THE HIGHER THE NUMBER, THE LONGER THE

STITCH. With the “0” setting material is not fed. This

is used when sewing on a button.

The “ ” range is for making a satin stitch (close zigzag

1 Makes fine stitches

2 Standard position

3 Makes rough stitches

–

SS

2

3

+

•

•

•

•

4

3

stitch), which is used for making buttonholes and

decorative stitches. The position needed for making the

satin stitch varies according to the material and thread

being used. To determine the exact dial position, first

test the stitch and length settings on a scrap piece of

fabric to observe the feeding of the material.

.

Note

●

The dial cannot be turned past “· · · · + -”.

Do not forcefully turn the stitch length dial

out of the allowable range.

SS

1

23

1 Stitch length dial

2 Longer

3 Shorter

0

1

1

CAUTION

● If the stitches are bunched together,

lengthen the stitch length and continue

sewing. Do not continue sewing without

lengthening the stitch length, otherwise

the needle may break and cause injury.

Stretch Stitching

■ Selecting a stretch stitch

Setting the stitch length dial to “ ” changes the

selected pattern to a stretch stitch.

SS

Reverse Sewing Lever

You can use reverse sewing for backtacking and

reinforcing seams.

To sew in reverse, push the reverse sewing lever in

as far as possible and hold it in that position while

you lightly push the foot controller. To sew forward,

release the reverse sewing lever. The machine will

then sew forward.

Drop Feed Lever (if the machine is

equipped with a drop feed lever)

Use the drop feed lever to raise or lower the feed

dogs according to the job that is being done. When

monogramming, embroidering, darning or sewing on

buttons, the feed dogs should be lowered so that the

garment will not be fed.

SS

■ Adjusting the stretch stitching

The machine is adjusted at the factory so that the

stretch stitching can be sewn with the stitch

length dial set to “ ” (standard position).

SS

If different types of fabric or thread are used or the

pattern does not have the correct shape, turn the

dial toward either “+” or “-” to adjust the stitch.

14

1

2

3

1 Drop feed lever

2 Up position: Feed dogs are down.

3 Down position: Feed dogs are up.

Page 16

XL5000us.book Page 15 Tuesday, November 11, 2003 9:25 AM

THREADING THE MACHINE

Winding the Bobbin

CAUTION

right. Turn the bobbin clockwise, by hand,

until the spring slides into the slit.

● Only use the bobbin (part code: SA156,

SFB (XA5539-151)) that has been

designed for this sewing machine. Using

of any other bobbin may cause damage

to the machine.

● The bobbin was designed specifically for

this sewing machine. If bobbins from older

models are used, the machine will not

operate correctly. Use only the enclosed

bobbin or bobbins of the same type (part

code: SA156, SFB (XA5539-151)).

Actual size

11.5 mm

(7/16")

Put the spool of thread on the spool pin and

1

pass the thread around the bobbin-winding

tension disc.

2

1

1 Spring

2 Slit

While holding the end of the thread, gently

4

press the foot controller to wind the thread

around the bobbin a few times. Then, stop the

machine.

Trim the excess thread above the bobbin and

5

continue winding the thread onto the bobbin

by pressing the foot controller.

1

1 Bobbin-winding tension disc

2 Bobbin-winding shaft

CAUTION

● If the spool of thread is not in the right

place, the thread may tangle on the spool

pin.

Pass the end of the thread through the hole on

2

the bobbin from the inside of the bobbin.

Put the bobbin onto the bobbin-winding shaft

3

and slide the bobbin-winding shaft to the

2

Note

● The machine stops automatically when the

bobbin is full.

After the machine stops, cut the thread, slide

6

the shaft to the left, and then remove the

bobbin.

Note

● The needle bar does not move after the

bobbin-winding shaft is slid to the right.

● Immediately after winding the bobbin, it is

normal to hear the sound of the clutch

engaging when beginning to sew or turning

the balance wheel.

15

Page 17

—

XL5000us.book Page 16 Tuesday, November 11, 2003 9:25 AM

KNOWING YOUR SEWING MACHINE —————————————————————————————————————————————

CAUTION

● Make sure you follow the instructions

carefully. If you do not cut the thread

completely, and the bobbin is wound,

when the thread runs low it may tangle

around the bobbin and cause the needle

to break.

CAUTION

● Setting the bobbin improperly may cause

the thread tension to loosen, and may

break the needle.

1

1 Wound evenly

2 Wound poorly

2

Lower Threading

CAUTION

● Setting the bobbin improperly may cause

the thread tension to loosen, breaking the

needle and resulting in injury.

1

1 Wound evenly

2 Wound poorly

● The bobbin was designed specifically for

this sewing machine. If bobbins from older

models are used, the machine will not

operate correctly. Use only the enclosed

bobbin or bobbins of the same type

(part code: SA156, SFB (XA5539-151)).

Actual size

11.5 mm

(7/16")

2

CAUTION

● Make sure you turn the power off while

threading the machine. If you

accidentally step on the foot controller

and the machine starts to work, you

could be injured.

Raise the needle to its highest position by turning

1

the balance wheel toward you (counterclockwise)

and raise the presser foot lever.

Open the shuttle cover behind the extension

2

table on the front of the machine and pull the

bobbin case out of the shuttle race by pulling

the latch toward you.

1

1 Bobbin case latch

2 Bobbin case finger

2

16

Page 18

XL5000us.book Page 17 Tuesday, November 11, 2003 9:25 AM

Unwind about 10 cm (4") of thread from a full

3

bobbin and insert the bobbin into the bobbin

case. (See fig. A-1.) Pull the trailing thread

into the slot, then down and to the left, as

shown in fig. A-2, until it enters the delivery

eye under the tension spring (fig. A-3).

A-1

A-2 A-3

1

CAUTION

● To reduce the risk of injury from moving

parts, be sure to turn off the machine

before servicing it. In addition, be sure to

close the shuttle cover.

1 Tension spring

CAUTION

● Make sure you set the bobbin so the

thread unrolls in the correct direction. If

the thread unrolls in the wrong direction,

it may cause the thread tension to be

incorrect or break the needle.

Holding the bobbin case by the latch, fully

4

insert the bobbin case into the shuttle race

and release the latch. Make sure the bobbin

case finger fits into the notch at the top of the

race.

12

1 Bobbin case finger

2 Notch

Note

● If the bobbin case is not properly placed

back into the machine, it will fall out from

the shuttle immediately after you start

sewing.

17

Page 19

—

XL5000us.book Page 18 Tuesday, November 11, 2003 9:25 AM

KNOWING YOUR SEWING MACHINE —————————————————————————————————————————————

Upper Threading

1

2

4

3

1 Spool pin

2 Thread guide

CAUTION

● Make sure you thread the machine

properly, otherwise the thread could

tangle and break the needle.

Set the main power switch to “O”.

Raise the presser foot lever and turn the balance

1

wheel toward you (counterclockwise) to raise

the thread take-up lever to its highest position.

Pull up the spool pin and put a spool of thread

2

on this pin.

CAUTION

●

If the spool of thread is in the wrong place, or

is set incorrectly, the thread may tangle on

the spool pin and cause the needle to break.

Pass the thread through guides.

3

4

2

3

1

3 Tension discs

4 Thread take-up lever

While holding the thread, pull it between the

4

tension discs.

Guide the thread to the back of the thread

5

take-up lever and around to the left. Bring the

thread through the slit by pulling it toward

you and into the eyelet.

1

1

1 Thread take-up lever

1 Spool pin

2 Thread guide

3 Tension discs

4 Thread take-up lever

18

Page 20

XL5000us.book Page 19 Tuesday, November 11, 2003 9:25 AM

Bring the thread down and pass it behind the

6

thread guide.

1

1 Thread guide

Thread the needle from front to back and pull

7

out about 5 cm (2") of thread.

1

Turn the balance wheel toward you

2

(counterclockwise) until the bottom of the

needle holder aligns with the bottom of the

needle-threading-hook holder.

1

2

3

1 Needle holder

2 Needle threader lever

3 Hook holder

4 Align

4

Note

● When you use the needle threader, make

sure to align the bottom of the needle

holder with the bottom of the holder for the

needle-threading hook before lowering the

needle threader lever, otherwise the hook

may be damaged.

While lowering the needle threader lever,

3

hook the thread onto the guide.

1 5cm (2inch)

Note

● If the thread take-up lever is lowered, the

upper thread cannot be wrapped around the

thread take-up lever. Make sure you raise

the presser foot lever and the thread take-up

before you feed the upper thread.

● If you incorrectly feed the thread you may

cause sewing problems.

Using the Needle Threader (models

equipped with a needle threader)

Set the main power switch to “O”.

Lower the presser foot lever.

1

1

2

3

1 Needle holder

2 Needle threader lever

3 Guide

Pull down the needle threader lever as much

4

as possible, and then turn the lever toward the

back of the machine (away from you). Make

sure that the hook passes through the eye of

the needle and grabs the thread.

• Hold the thread in front of the needle to

make sure that the hook grabs it.

19

Page 21

—

XL5000us.book Page 20 Tuesday, November 11, 2003 9:25 AM

KNOWING YOUR SEWING MACHINE —————————————————————————————————————————————

While lightly holding the thread, turn the

5

needle threader lever toward the front of the

machine (toward you). The hook will pull the

thread through the needle.

Quick Thread-Setting System FAST START BOBBIN

(models equipped with a quick thread-setting system)

This new system allows you to start sewing

immediately after inserting the bobbin without pulling

up the lower thread. You can, however, draw up the

lower thread as explained in “Drawing up the lower

thread” if you wish.

1

1 Hook

2 Thread

1

2

Set the main power switch to “O”.

Hold the end of the bobbin thread and insert

1

the bobbin case into the shuttle.

1

Raise the needle threader lever and pull out

6

about 5 cm (2") of thread through the needle

toward the back of the sewing machine.

CAUTION

● The needle threader can only be used

with home sewing machine needles size

75/11-100/16. Check the table on

page 24 for the appropriate needle and

thread combinations. If you are using

transparent nylon mono-filament thread,

you can only use needles in the range of

90/14-100/16.

● You cannot use the needle threader if

you are using decorative threads or

speciality needles, such as the twin

needle and wing needle.

If you are using these types of threads or

needles, thread the needle by hand. Make

sure the main power switch is off when

threading the needle by hand.

2

1 Bobbin case

2 Shuttle

Close the shuttle cover while pulling the

2

thread through the slit in the cover.

2

1

1 Shuttle cover

2 Slit

Slide the thread down to the bottom of the

3

slit, pull it up, and then cut it on the cutter to

complete the lower threading.

Pull out about 15 cm (6") of the upper thread

4

as usual, and then pull it between the toes of

the presser foot and straight toward the back

of the machine.

Start sewing as usual. (It is not necessary to

5

draw up the bobbin thread.) (Refer to page 21.)

20

Page 22

XL5000us.book Page 21 Tuesday, November 11, 2003 9:25 AM

Drawing up the lower thread

Raise the presser foot and the needle to their

1

highest positions.

While lightly holding the end of the upper

2

thread, slowly turn the balance wheel to the

front (counterclockwise) once by hand to

lower, then raise the needle.

The upper thread should have caught the

3

lower thread in a loop. Pull on the upper

thread to draw up the lower thread.

1

2

1 Upper thread

2 Lower thread loop

Sewing with a Twin Needle

We have designed your machine so you can sew

with this needle and two top threads. You can use

the same color or two different colors of thread for

making decorative stitches.

CAUTION

● Use only twin needles that have been

made for this machine (part code:

X57521-001). Other needles could break,

and damage the machine.

● When using the twin needle, make sure

the stitch width dial is not set above “3”

since this may cause the needle to hit the

needle plate and break.

● Do not sew with bent needles. The

needle could break and cause injuries.

● When using the twin needle, make sure

you use the zigzag presser foot only.

■ Attaching the Twin Needle

Attach the twin needle in the same way as a

single needle (see page 7). The flat side of the

needle should face toward the back and the

rounded side should face toward you.

■ Attaching the Extra Spool Pin

Put the extra vertical spool pin in the hole on the

top right-hand side of the machine. Put the

second spool of thread onto the extra spool pin.

1

Pull out about 15 cm (6") of both threads and

4

put them toward the back of the machine

under the presser foot. The upper thread

should pass between the toes of the presser

foot.

1

2

1 Upper thread

2 Lower thread

1 Extra spool pin

21

Page 23

—

XL5000us.book Page 22 Tuesday, November 11, 2003 9:25 AM

KNOWING YOUR SEWING MACHINE —————————————————————————————————————————————

■ Twin Needle Threading

You should thread each needle separately.

Threading the Right Needle

1

Follow the same instructions for threading a

single needle. See page 18 for more details.

Threading the Left Needle

2

Thread the left needle in the same way that

you threaded the right needle using the

thread from the spool on the extra spool pin,

but do not pass the thread through the thread

guide above the needle before you pass it

through the eye of the left needle.

2

1 Right needle thread passes through thread guide

2 Left needle thread passes in front of thread guide

3 Thread guide

1

3

■ Possible Problems If the Tension Is Wrong

Upper tension is too tight.

Locks will appear on the surface of the fabric.

Upper tension control dial

Decrease the tension by turning the dial to a

lower number.

2

2

1 Reverse

2 Surface

1

1

5

4

6

Upper tension is too loose.

Locks appear on the reverse side of the fabric.

Upper tension control dial

Increase the tension by turning the dial to a higher

number.

2

1

5

4

6

Note

Models that are equipped with a Needle

Threader

● You cannot use the needle threader to

thread the twin needle. Instead, thread the

twin needle by hand, from front to back.

Using the needle threader may damage the

machine.

Tension of the Thread

The tension of the thread will affect the quality of

your stitches. You may need to adjust it when you

change fabric or thread.

Memo

● We recommend that you sew a scrap piece

of fabric to check the thread tension before

sewing on your project.

● The basic thread tension setting is “5”.

2

1 Reverse

2 Surface

1

Note

● The lower thread tension has been adjusted

at the factory for general use. For most

sewing applications, no adjustment is

needed. When sewing with thin thread on

thin fabrics, the thread tension cannot be

adjusted adequately with the upper tension

control dial. Instead, the thread tension

must be adjusted according to the

procedure described below.

Lower tension is too loose.

Locks appear on the surface of the fabric.

Decrease the thread tension by turning the dial to

a lower number. If the result is still not

satisfactory, then adjust the bobbin thread tension

as explained below.

Bobbin

Increase the tension in the bobbin by turning the

screw with a small screwdriver in a clockwise

direction. However, do not turn the screw more

than one full turn.

Remember to return the screw to its original

position before starting your next project.

22

Page 24

XL5000us.book Page 23 Tuesday, November 11, 2003 9:25 AM

Correct tension

Correct tension is important as too much or too

little tension will weaken your seams or cause

puckers on your fabric.

1 Reverse

2 Surface

2

2

1

1

23

Page 25

—

XL5000us.book Page 24 Tuesday, November 11, 2003 9:25 AM

KNOWING YOUR SEWING MACHINE —————————————————————————————————————————————

CHART OF SEWING FABRICS, NEEDLES AND THREAD COMBINATIONS

Silk

Thread

60

–80

50

–80

60

–80

50–80

30–50

50

50

–60

30

Medium-

weight

fabrics

Lightweight

fabrics

Heavyweight

fabrics

Stretch

fabrics

For top-stitching

Fabric Type

Broadcloth Cotton

Taffeta

Flannel,

Gabardine

Lawn, Batiste Cotton

Georgette

Challis, Satin Silk

Denim Cotton

Corduroy

Tweed Silk

Jersey

Tricot

Type Size

Synthetic

mercerized

Silk or

silk finished

Synthetic

mercerized

Synthetic

mercerized

Thread for knits

Synthetic

mercerized

Note

● Select the correct needle and thread size from the above chart.

● Use the same size thread for the upper (spool) and lower (bobbin) threads.

● For clear nylon thread, always use needle 90/14 - 100/16.

Size of Needle

75/11–90/14

75/11

90/14

–100/16

Ball-point needle

(golden colored)

75/11–90/14

90/14–100/16

CAUTION

Make sure you follow the needle, thread, and fabric combinations listed in the table. Using

●

the wrong combination, for example, using heavyweight fabric such as denim with a small

needle (for example, 75/11) may bend or break the needle. Also, the seam may be uneven,

the fabric may pucker, or the machine may skip stitches.

24

Page 26

XL5000us.book Page 25 Tuesday, November 11, 2003 9:25 AM

Please Read Before Sewing

CAUTION

● To avoid being injured, watch the needle carefully while you are using the machine. Keep

your hands away from moving parts.

● Do not stretch or pull the fabric during sewing, otherwise the needle may be damaged and

you may be injured.

● Do not use bent or broken needles, otherwise you may be injured.

● Take care that the needle does not hit basting pins or other objects during sewing, otherwise

the needle may break and you may be injured.

● Always use the correct presser foot. If you use the wrong presser, the needle may hit the

presser foot and bend or break and you may also be injured.

● When you turn the balance wheel by hand, always turn it toward the front of the machine

(counterclockwise). Turning it the other way may cause the thread to tangle and damage the

needle or fabric. You may also be injured.

Straight Stitching

Stitch Name Pattern

Straight Stitch

(Center needle

position)

Straight Stitch

(Left needle

position)

Triple Stretch

Stitch

(Center needle

position)

Triple Stretch

Stitch

(Left needle

position)

■ Starting Sewing

Turn the pattern selection dial to choose the

1

Straight Stitch or Triple Stretch Stitch.

Raise the needle to its highest position and lift

2

the presser foot lever.

Pull up the lower thread by turning the

3

balance wheel toward you

(counterclockwise), and place both the upper

and lower threads behind the presser foot.

Put the fabric under the presser foot and

4

position the needle 1 cm (3/8") from the edge

of the fabric.

Lower the presser foot.

5

Stitch Length

[mm (inch)]

1-4

(1/16-3/16)

1-4

(1/16-3/16)

Fixed 2.5

(3/32)

Fixed 2.5

(3/32)

Stitch Width

[mm (inch)]

-

-

-

-

■ Backtacking

Press the reverse sewing lever down as far as

6

possible, and then lightly step on the foot

controller. Sew 5 to 10 stitches in the reverse

direction.

Release the reverse sewing lever and start

7

sewing in the forward direction by pressing

the foot controller.

• You can use reverse sewing for locking the

end of seams and where you need to

strengthen a stitch.

CAUTION

● Make sure the needle does not hit a pin

or any other object during sewing. The

thread could tangle or the needle could

break. You could also be injured.

■ Changing Sewing Direction

With the needle still in the fabric, stop the

1

machine at the point where you want to

change the sewing direction.

25

Page 27

—

XL5000us.book Page 26 Tuesday, November 11, 2003 9:25 AM

KNOWING YOUR SEWING MACHINE —————————————————————————————————————————————

Raise the presser foot and turn the fabric to its

2

new direction using the needle as a turning

point for the fabric.

Lower the presser foot and continue sewing in

3

the new direction.

■ Finishing Sewing

Stitch to the end of the seam and stop.

1

Push the reverse sewing lever and stitch

2

backwards for 1 cm (3/8") from the end of the

fabric.

To prepare the machine for the next seam,

4

pull about 10 cm (4") of thread through the

toes of the presser foot toward the back of the

machine.

■ Top-Stitching and Stretch Materials

You can use the Straight Stitch for top-stitching

and sewing lightweight fabrics.

You can use Triple Stretch Stitch for sewing

stretch fabrics.

Zigzag Stitching

Stitch

Stitch Name Pattern

Zigzag Stitch

Zigzag Stitch

Zigzag Stitch

Length

[mm (inch)]

-4

(1/64-3/16)

-4

(1/64-3/16)

-4

(1/64-3/16)

[mm (inch)]

Fixed 1.7

Fixed 3.5

Fixed 5

Stitch

Width

(1/16)

(1/8)

(3/16)

■ Removing the Material from the Machine

Stop the machine.

1

Raise the needle to its highest position and

make sure that the thread take-up lever is also

at its highest position.

Lift the presser foot and pull the fabric out

2

gently to the left-hand side.

Cut both threads with the thread cutter on the

3

left-hand side of the machine.

1

■ Zigzag Stitch

Turn the pattern selection dial to the Zigzag

Stitch, and then select the stitch length.

We recommend that you sew using the Straight

Stitch at the beginning and end of the zigzag

stitches.

1 Thread cutter

26

Page 28

XL5000us.book Page 27 Tuesday, November 11, 2003 9:25 AM

■ SATIN STITCH

Setting the Zigzag Stitch length in the “ ” range

produces a satin stitch (close zigzag stitch). The

satin stitch can be used for making buttonholes

and decorative stitches. Set the pattern selection

dial to the desired Zigzag Stitch, set the stitch

length in the “ ” range.

Blind Hem Stitching

Stitch

Stitch Name Pattern

Length

[mm (inch)]

Blind Hem

Stitch

Stretch Blind

Hem Stitch

-2

(1/64-1/16)

-1.5

(1/64-1/16)

You can use the Blind Hem Stitch to finish the edge

of a project, like the hem of a pair of trousers,

without the stitch showing. Use the Blind Hem Stitch

when sewing on non-stretch fabrics, and the Stretch

Blind Hem Stitch for stretch fabrics.

Both threads should be the same color as the

1

fabric.

Fold back the hem, as shown in fig. A. Then

2

fold the edge of the fabric as in fig. B. Leave a

6 mm (15/64") overlap at the edge.

Set the pattern selection dial to the Blind Hem

3

Stitch or Stretch Blind Hem Stitch, and then

set the stitch length.

Stitch

Width

[mm (inch)]

3.5

(1/8)

5

(3/16)

When the fabric is unfolded you will have a

5

blind hem stitch as shown in fig. D.

2

A

1

C

1 Right side of fabric

2 Wrong side of fabric

1

2

B

2

2

D

1

1

Note

● The Stretch Blind Hem Stitch is useful for

stretch fabrics.

Shell Tuck Stitching

Stitch

Stitch Name Pattern

Length

[mm (inch)]

Shell Tuck

Stitch

-3

(1/64-1/8)

The Shell Tuck Stitch can be used to sew a picot

(lace-like) edge on lightweight fabric.

Stitch

Width

[mm (inch)]

5

(3/16)

Sew on the fold as in fig. C.

4

Set the pattern selection dial to the Shell Tuck Stitch.

1

Adjust the thread tension so that it is tighter

2

than normal.

Place the fabric under the presser foot so that

3

it will be sewn along the bias with the straight

stitches sewn on the seamline and the zigzag

stitches sewn slightly over the folded edge.

Sew at a slow speed.

4

27

Page 29

—

XL5000us.book Page 28 Tuesday, November 11, 2003 9:25 AM

KNOWING YOUR SEWING MACHINE —————————————————————————————————————————————

■ Joining Fabric

Elastic Stitching

You can use the Elastic Stitch to join two pieces of

fabric together. In addition, it is very effective

when sewing knitted fabrics. If you are using

nylon thread, the stitch will not be visible.

Put the edge of the two pieces of fabric

1

together and center them under the presser

foot.

Stitch Name Pattern

Elastic Stitch

Stitch

Length

[mm (inch)]

-2.5

(1/64-3/32)

Stitch

Width

[mm (inch)]

5

(3/16)

You can use the Elastic Stitch for mending, sewing

elastic or joining fabric. Each is explained below.

Set the pattern selection dial to the Elastic Stitch.

■ Mending

Set the stitch length dial between " " and

1

“2.5”.

Place the reinforcement fabric under the area

2

you want to mend.

Following the line of the tear, sew using the

3

Elastic Stitch as illustrated.

■ Sewing Elastic

Place the elastic on the fabric.

1

As you sew, stretch the elastic in front of and

2

behind the presser foot.

Sew them together using the Elastic Stitch.

2

Make sure you keep the two fabric edges close

together.

Scallop Stitching

Stitch

Stitch Name Pattern

Length

[mm (inch)]

Scallop Stitch

-1.5

(1/64-1/16)

This machine automatically produces a Scallop

Stitch for decorative edging.

Stitch

Width

[mm (inch)]

5

(3/16)

28

Set the pattern selection dial to the Scallop

1

Stitch.

Sew the Scallop Stitch along the edge of the

2

material.

If desired, trim around the scallop with

3

scissors to create a scalloped edge. Be careful

not to cut the thread.

Page 30

XL5000us.book Page 29 Tuesday, November 11, 2003 9:25 AM

Overedge Stitching

Stitch

Stitch Name Pattern

Stretch

Overlock

Stitch

Elastic

Overlock

Stitch

Arrowhead

Stitch

You can use these stitches to join together seams and

finish them in one operation. The Overlock Stitches

are also useful for sewing stretch materials while the

Arrowhead Stitch is ideal for sewing the edge of a

blanket.

Set the pattern selection dial to the Elastic

1

Overlock, Stretch Overlock or Arrowhead.

Put the fabric under the presser foot so that

2

the seamline (or arrowhead point) is

approximately 3 mm (1/8") to the left of the

center of the presser foot. This stitch works

best with a seam allowance of approximately

6 mm (1/4") as this allows the right (zigzag)

side of the stitch to overlock the cut edge of

the fabric.

Length

[mm (inch)]

Fixed 2.5

(3/32)

[mm (inch)]

Stitch

Width

3.5

(1/8)

5

(3/16)

If the seam allowance is wider than the stitch

3

pattern, trim away any excess fabric after

stitching.

A finished Elastic Overlock Stitch is shown in the

diagram below.

Feather Stitching

Stitch

Stitch Name Pattern

Length

[mm (inch)]

Feather Stitch

Fixed 2.5

(3/32)

Use the Feather Stitch as a decorative top-stitch

when hemming blankets, tablecloths or draperies, or

when embroidering.

Set the pattern selection dial to the Feather

1

Stitch.

Place the fabric right side up and sew 1 cm

2

(3/8") from the edge of the fabric.

Stitch

Width

[mm (inch)]

5

(3/16)

Trim close to the stitching.

3

The stitch will prevent the fabric from unravelling.

29

Page 31

—

XL5000us.book Page 30 Tuesday, November 11, 2003 9:25 AM

KNOWING YOUR SEWING MACHINE —————————————————————————————————————————————

Triple Zigzag Stretch Stitching

Stitch

Stitch Name Pattern

Triple Zigzag

Stretch Stitch

Triple Zigzag

Stretch Stitch

Triple Zigzag

Stretch Stitch

This stitch can be used wherever a Zigzag Stitch

would be used to sew heavyweight stretch fabrics.

The Triple Zigzag Stretch Stitch can also be used as a

decorative top-stitch. Set the pattern selection dial to

the Triple Zigzag Stretch Stitch.

Length

[mm (inch)]

Fixed 2.5

(3/32)

Stitch

Width

[mm (inch)]

1.7

(1/16)

3.5

(1/8)

5

(3/16)

Making a Buttonhole

(1-Step Automatic Buttonhole)

Stitch

Pattern

(1-Step

Automatic

Buttonhole)

Length

[mm (inch)]

-1.5

(1/64-1/16)

Memo

● We recommend that you practice making a

buttonhole on a scrap piece of fabric before

you try it on the actual garment.

● When making buttonholes on soft fabrics,

place stabilizer material on the underside of

the fabric.

Making a buttonhole is a simple process that

provides reliable results.

■ Making a Buttonhole

Stitch

Width

[mm (inch)]

5

(3/16)

Buttonhole

Foot

Foot

Decorative Stitching

Stitch

Stitch Name Pattern

Decorative

Stitch

This stitch can be used for decorative stitching.

Length

[mm (inch)]

Fixed 2.5

(3/32)

Stitch

Width

[mm (inch)]

(3/16)

Using tailor’s chalk, mark the position and

1

length of the buttonhole on the fabric.

Attach the buttonhole foot and set the pattern

2

selection dial to " ".

You need to sew the front bar tack first. Lower

3

the presser foot to align the marks on the foot

with the mark on the fabric.

Open the button plate and insert the button.

4

5

3

1

–

2

1 Starting mark on the fabric

2 Marks on the foot

3 Button plate

30

Page 32

XL5000us.book Page 31 Tuesday, November 11, 2003 9:25 AM

Lower the buttonhole lever and push it back

5

slightly.

PUSH

While gently holding the upper thread, start

6

the machine.

The bar tacks of the buttonhole are sewn in

7

the order shown.

3

24

Once sewing is completed, gently pull the

4

gimp thread to remove any slack, and then

trim off the excess.

PUSH

Making a Buttonhole

(4-Step Buttonhole)

Stitch

Width

[mm (inch)]

Pattern

Stitch Length

[mm (inch)]

PUSH

Foot

1

Stop the machine when buttonhole stitching is

8

finished.

■ Making a Buttonhole on Stretch Fabrics

When sewing buttonholes on stretch fabric, the

buttonhole stitching is sewn over a gimp thread.

Using tailor’s chalk, mark the position of the

1

buttonhole on the fabric, and then attach the

buttonhole foot and set the pattern selection

dial to “ ”.

Hook the gimp thread onto the back end of

2

the buttonhole foot, bring the two gimp

thread ends to the front of the foot, insert

them into the grooves, and then temporarily

tie them there.

Lower the presser foot and start sewing.

3

(4-Step

Buttonhole)

-1.5

(1/64-1/16)

5

(3/16)

Buttonhole

Memo

● We recommend that you practice making a

buttonhole on a scrap piece of fabric before

you try it on the actual garment.

● When making buttonholes on soft fabrics,

place stabilizer material on the underside of

the fabric.

Making a buttonhole is a simple process that

provides reliable results.

■ Making a Buttonhole

Using tailor’s chalk, mark the position and

1

length of the buttonhole on the fabric.

Attach the buttonhole foot, and then slide the

2

outside frame of the buttonhole foot as far

back as possible.

Foot

31

Page 33

—

XL5000us.book Page 32 Tuesday, November 11, 2003 9:25 AM

KNOWING YOUR SEWING MACHINE —————————————————————————————————————————————

You need to sew the front bar tack first. Line

3

the bar tack mark under the center of the

presser foot and align it with the two lines on

the presser foot.

2

1 Front of chalk mark

2 Red lines

1

CAUTION

● If the presser foot is not installed with the

correct orientation, the needle may strike

the presser foot, bending or breaking the

needle and causing injuries.

■ Making A Buttonhole

Step Sewn section Pattern

Step 1

(Front bar tack)

a

1. Set the pattern selection dial to “a”.

2. Lower the presser foot and sew 5 to 6 stitches.

3. Stop the machine when the needle is at the left

side of the stitches, and then raise the needle

from the material.

Step 2

b

(Left side)

a/c

c

a

b

■ Securing the Stitching and Cutting the

Buttonhole

To secure the stitching, turn the material 90

1

degrees counterclockwise and sew straight

stitches to the end of the front bar tack of the

buttonhole.

Remove the material from the machine. We

2

recommend that you put pins across both

ends of the buttonhole to prevent the stitches

from being cut.

Cut an opening in the middle of the

3

buttonhole with a seam ripper. Be careful not

to cut through any stitches.

CAUTION

● When using the seam ripper to open the

buttonhole, do not put your hand or

fingers in the path of the ripper. The

seam ripper may slip and cause injuries.

1. Turn the pattern selection dial to “b”.

2. Sew the predetermined length of the tailor's

chalk line.

3. Stop the machine when the needle is at the left

side of the stitch, and then raise the needle.

Step 3

(Back bar tack)

c

a/c

c

a

1. Turn the pattern selection dial to “c” (same

position as in step 1).

2. Sew 5 to 6 stitches.

3. Stop the machine when the needle is at the right

side of the stitch, and then raise the needle from

the material.

Step 4

(Right side)

d

d

1. Set the pattern selection dial to “d”.

2. Sew the right side until the needle reaches the

stitches sewn in step 1.

32

Page 34

XL5000us.book Page 33 Tuesday, November 11, 2003 9:25 AM

Adjusting Buttonholes

If the stitching on the two sides of the buttonhole is

not the same, you can make the following

adjustments.

Set the stitch length dial to " " and sew the

1

buttonhole on a scrap piece of fabric to

observe how the material is fed.

If the right side of the buttonhole is too coarse

2

or fine, adjust the feeding of the material with

the Stitch Length Dial.

1

• This adjustment ensures both sides of the

buttonhole are the same.

2

1

3

4

4

0

1

2

3

0

1

1 Right side

2 Shorter

3 Longer

After obtaining a satisfactory feeding on the

3

right side, stitch the buttonhole and observe

23

the feeding.

If the left side is too coarse or fine compared

4

with the right side, adjust the buttonhole fine

adjustment screw as described below.

If the left side is too coarse, turn the buttonhole

fine adjustment screw with a large screwdriver

in the - direction.

If the left side is too fine, turn the buttonhole

fine adjustment screw with a large screwdriver

in the + direction.

0

1

1 Stitch length dial

2 Buttonhole fine adjustment screw

3 Left side

4 In this case

Sewing Buttons

Stitch

Name

Pattern

Stitch

Length

[mm (inch)]

Zigzag

Stitch

(1/64)

Zigzag

Stitch

(1/64)

Zigzag

Stitch

Measure the distance between the holes and

1

select the appropriate pattern with the pattern

(1/64)

selection dial.

Stitch

Width

[mm (inch)]

1.7

(1/16)

3.5

(1/8)

5

(3/16)

Foot

Button

Sewing

Foot

Attach the button sewing foot.

2

33

Page 35

—

XL5000us.book Page 34 Tuesday, November 11, 2003 9:25 AM

KNOWING YOUR SEWING MACHINE —————————————————————————————————————————————

Place the darning plate on the needle plate.

3

(On a machine equipped with a drop feed

Zipper Insertion

lever, lower the feed dogs by setting the drop

feed lever to the up position.)

Stitch

Name

Pattern

Stitch

Length

[mm (inch)]

Stitch

Width

[mm (inch)]

Foot

Straight

Stitch

(Center

needle

2-3

(1/16-1/8)

-

Zipper

Foot

position)

You can use the zipper foot to sew different types of

zippers, and can easily position the zipper to the

right or left side of the needle.

Put a button between the foot and the fabric

4

and make sure that the needle enters the holes

without hitting the button. If it hits, see step

1.

When sewing the right side of the zipper, attach the

presser foot holder to the left pin of the zipper foot.

When sewing the left side of the zipper, attach the

presser foot holder to the right pin of the zipper foot.

At a slow speed, sew about 10 stitches.

5

Remove the material from the machine. Cut

6

the upper and lower threads and tie both

threads at the back of the material.

1

1 Zipper foot

2 Right pin for sewing the left side of the zipper

3 Left pin for sewing the right side of the zipper

2

3

Set the pattern selection dial to the Straight

1

Stitch (center needle position (2.5 mm

(3/32")).

Lower the presser foot lever and fix either the

2

left or right pin of the zipper foot onto the

shank.

Fold the edge of the material 2 cm (3/4") and

3

place the zipper under the folded section.

Lower the needle into the notch on either the

4

left or right side of the zipper foot.

CAUTION

CAUTION

●

Make sure the needle does not hit the

button during sewing, otherwise the

needle may break and you may be

injured.

34

● Turn the balance wheel by hand to make

sure the needle does not hit the presser

foot before you start sewing. If you

choose a different stitch, the needle will

hit the presser foot and break the needle.

You may also be injured.

Page 36

XL5000us.book Page 35 Tuesday, November 11, 2003 9:25 AM

Sew from the bottom of the zipper toward the

5

top on both sides. The needle should be

positioned on the zipper side of the foot for

best results.

Darning

Stitch Name Pattern

Stitch

Length

[mm (inch)]

To sew the opposite side of the zipper, release

6

the foot by raising the lever located at the

back of the presser foot, position the zipper

foot on the other side of the zipper and

continue sewing using the notch on the other

side.

CAUTION

●

Make sure the needle does not hit the zipper

during sewing. If the needle hits the zipper,

the needle may break and you may be injured.

Gathering

Stitch Name Pattern

[mm (inch)]

Straight Stitch

(Center needle position)