Page 1

INSTRUCTION

For

MANUAL

BROTHER

MA4-B972C

High Speed

BROTHER

Safety

NAGOYA

Stitch Over

INDUSTRIES,

JAPAN

loc k

Machine

LTD.

Page 2

CONTENTS

1.

Specification ··· ··· ···· ·· ···· ···· ··· ·· ·· ······ ······ ······· ·· ····

2.

}.'eatures · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·. · ... · · · · · · · · · · · · · · · · · · · · · ·. · ... ·. · · · · · · · · · · · · · · · · · ·

:~.

Operation······························································································································

A)

Sc\\·ing Speed·

B)

:\Iotor, motor

C)

Setting

D)

Oiling, draining and maintenance ..... .... .. .. .. .. .. .. ... ...... ...... ...... .... .. ..

I~)

1\eedle cooler device

I•')

l\Iachine operating

up

(;) Installing needles

'J'hreading

II)

I )

Stitches······························································································································

.l

)

'I'hrL~ad

1.

Adjustlnent of thread take-up ...... · ..... ·

2.

Adjusting double chain stitch needle thread guide

:~.

Adjusting looper thread take-up and thread guide for over lock

4.

Adjusting looper thread take-up and thread guides for double chain stitch ..... .. .. ......

5.

Adjusting thread tension screws

K)

Adjustment on pressure of presser foot: installing and removing feed dogs: and height of feed dogs 8

L)

Adjusting stitch \\·idth ·

l\,1)

Adjusting stitch length

1\)

Adjusting differential feed

..

··· .. ·· ..

pu1Jey

·············

and belt

.... ·· .. · ..... ··· ... ··· ... ·

.........

· ....... · · ·· ... ··· ·

· ........ · .... · ... · .. · · · ·· · · ..... · .... · · .... · · ........ ···

...........................

direction·······

..........

·· ..... · ... ··· ··· ... .... .. ...

.. ···

..............................................................................

............

........................................................................................................................

tension · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·

..............

.......................... · ......................................

..................... · ..

............

······

· ..... · ·· .... ··

................................

.................

··· .. ·· .. · .... ··

.. · ....................... · .............................

..............

····

...............................

............

...... ...... ... ... ...

· ...... · .... · ... · ... .. .. .. .. .... ..

......................................

.............................................

· .... ·

............ · ........ · ..............

..................

..................... · ··

··· ......... ··· .. · ... ·

· ........ ·

·.. .........

............

...............

............

..

· · · · · · · · ·. · · 2

·····............

............

..........

· ...

.........

· .. ·

.... .. ...... ...... ...... ... 4

·................................

............

..............

......... ...... ... 6

..

· · · · · · · · · · · · 7

· ..... · ........ · ..... 7

·........ .... .. 7

stitch.................................

· .... · ·

........

· .. ·

·..

............

.................

...........

...

..................

··· ...

·· · · .. ·· · · ..... ···· ·· ...

· ...... ·· 3

... 3

.........

......

· .. · 8

··········

1

3

3

5

6

6

7

H

H

9

10

10

4.

Adjustn1ent · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·

1\)

I Ieight of needles ........ ·· .... ·

B)

I~L'lation

C)

Installing needle guard · ·· ··· ·· ·· ·· ···· ·· ·· · ··· ·· · ··· · ····· ···· ····· ··· ··· · ·· ··· ·· ·· ·· · ·· ·· · ··· ··· · · · · ·· ·· · · ·· ··· ··· · ·· ·· · · ··

D)

i\Iatching needle guard and needJe..... .... .... ..

E)

I~L·Iation

F)

I~L'lation

between needle and under looper

of needle with under looper and over looper

between needle and double chain stitch looper ·.. .........

(;) Installing double chain stitch needle

II) Installing and maintenance of

5.

'I' rouble shooting

i\)

·rhread

I~)

Skip

C)

1\eedle

IJ)

hnperfect chaining-off ... ···· .... · .. ·· .... ·· .... ·· .. ··· .. ··

E)

Improper thread tension .. ·

F)

Poor trin1n1ing perforrnance .. · · .... · ... · ..... · .... · ·

breaks

stitching···················································

breaks

(;) Irregular stitches

............

··· ··· ······ · ·· ··· ·· ·· ·· ······ · ·· ··· · ·· ···· ·· ···· ··· ·· ······ ···· ·· ··· ······ · ·· ······ ······ ··· ······ ······· ·· ···· ··

······ ·· ···· · ·· ··· ·· · · ·· ·· · · ·· ·· · ··· ·· · ··· ······ ········· ··· ··· · ·· ··· ···· ·· ··· ···· ·· ··· ·· ·· ·· ·· ·· ·· ·· ···· ······ ···

........................................................................

II) Excessi\·e wrink1es along stitches ...... ··· ....... ··

I ) 1\eedlcs produce too large holes··· ...... ···

............

· .... · .. ·

............ · .............. · ..

....................................

guard...........................................................................

knives..................................................................................

· ·· ...... · .... · ... · ..... · .... ·

..

· · · · .... · · .. · ..... · .... · ·

............................

· .... ····· .... ·

·.... .... ......... ...... ... .. .... ......

..........

..............

......... ... .. .... ... .. .. .. .. .. ..... ...... .... ..

................................................

.........

.... .. ... ...... ......... ...... ...

....................................

....

······························································

...................

...................

· ... ·

··

..

..

....................... · ..

··· ......... .........

· .... · ... · .... ···· ...

· ..... · .. · · · · ..

· .... · ... · ....... · ·

.......................................

................................................

······

...........

·········........................

..............

·· .... ····· .... ·

............

·.......................

··

· ·

..........

· · ... · · .. · ·.. ...

....................

···· ·· ......... ...... Iti

· .... · ...

...

·.. ...

11

11

II

11

11

12

12

13

13

I-I

1-1

1-1

I-I

l;j

15

15

16

I6

Page 3

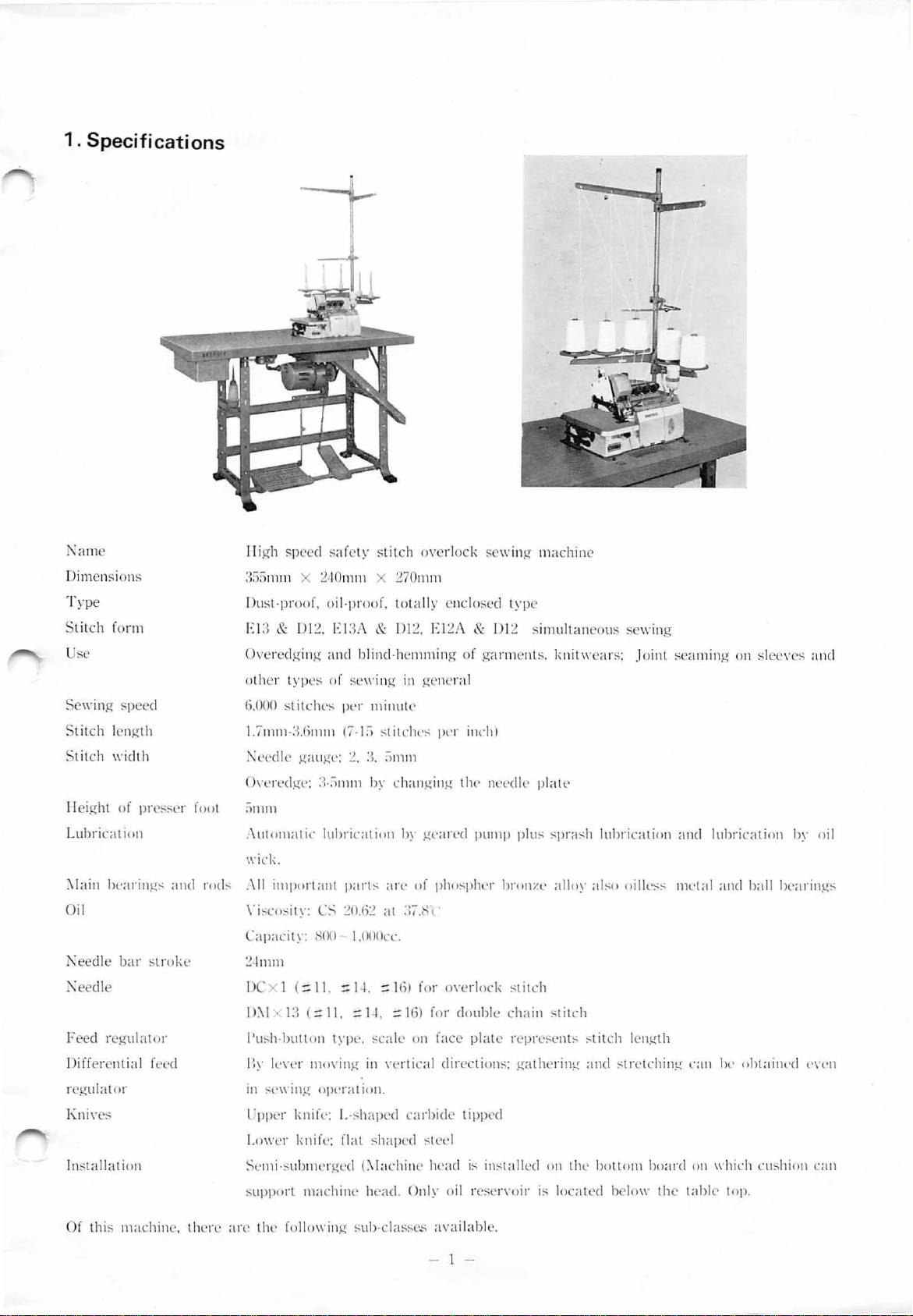

1. Specifications

:\a

me

Dim

ensions

Typ

e

Stitch

form

Usc

Sc"·

i ng

speed

Stitch

length

Stitch

width

!I

eight

of

prcs;;er

foot

Lubrication

\lain

hearing;;

and

Oil \' i;;co,;ity:

.i\

ecd

lc

:\

eed

le

F

eed

Di

fferential

bar ;;trok

regulator

e

feed

regulator

l

~niye

,;

In

stallation

ll

igh

:{S5mnl

Dust-proof.

E13

&.

0\·ercdgi

other

6.000 s

l.rmm-:~.6mm

:\cx•clle g-auge:

(h

·credg-e: :J.:)nun

:lmm

.\utomatic

wick.

rod

;;

.\11

important

Capacity:

~-lmm

DC

' l (

I>\

I ·

l'

ush-buttnn

1:~·

le\'l'r

111

sew in!,!

l '

ppcr knife: I.-shaped

l.m\·

er

Semi-;;ubnwrgcd (\l

;;up

port

speed

D1

types of sc\\·

titches per

13

knifl':

safety stitch

>-.

2·10nlm X

oil-proof.

2. I·:I

:{A

ng ;

111d

blind

(7-1;)

2.

lubrication

part;;

C~

20.62

~00

I.OOOcc.

::1

1.

::I

I. ::16!

(::II. ::1-1.

tn>e.

nln\

·in

.l!

operation.

flat

machine

o\·erlock sc,,

270mm

totally

&.

Dl2. E 12i\

-hem

ming

ing

in

general

minute

sti

tches per inch!

:t :Jmm

by

changing-

by

.l!<'ared

arc

of

at

:ri.~t

for

::

16)

sca

le on

in

,·ertical

carb

sh;qK·cl !'tl

achine

head

. Only oil

·ing

enclosed

&.

IJ

I2 si

type

of garments.

the

needle

pump

pho;;pher

oYerlock

for

face

dire

ide

'l'

l

head

double

plate

ctions:

tipped

i;;

in;;tallcd

l>r<III

,;titch

chain stitch

rcsen·oir i;; located

machine

multaneous

lmitwcars:

plate

plus

;;pra;;h

Zl'

alloy

lubrication

;d;;o oille,;;;

represent,; ,;titc h

gathering

on

and ;;tr

the

bottom

belo,,·

scwmg

Joint

length

etchi

board

the

seaming

and

ml'lal

ng

table

on s

lubrication

and ball

r<lll Ill' "l>tainl'd

on

which

top

.

lcc,

·cs

b~·

hearing-

cushion

and

nil

;;

L'\'l'll

e<tn

or

thi;;

machine.

there

arc the

following

;;ub-cla;;;;c.;;

a\'ailabl

e.

- l -

Page 4

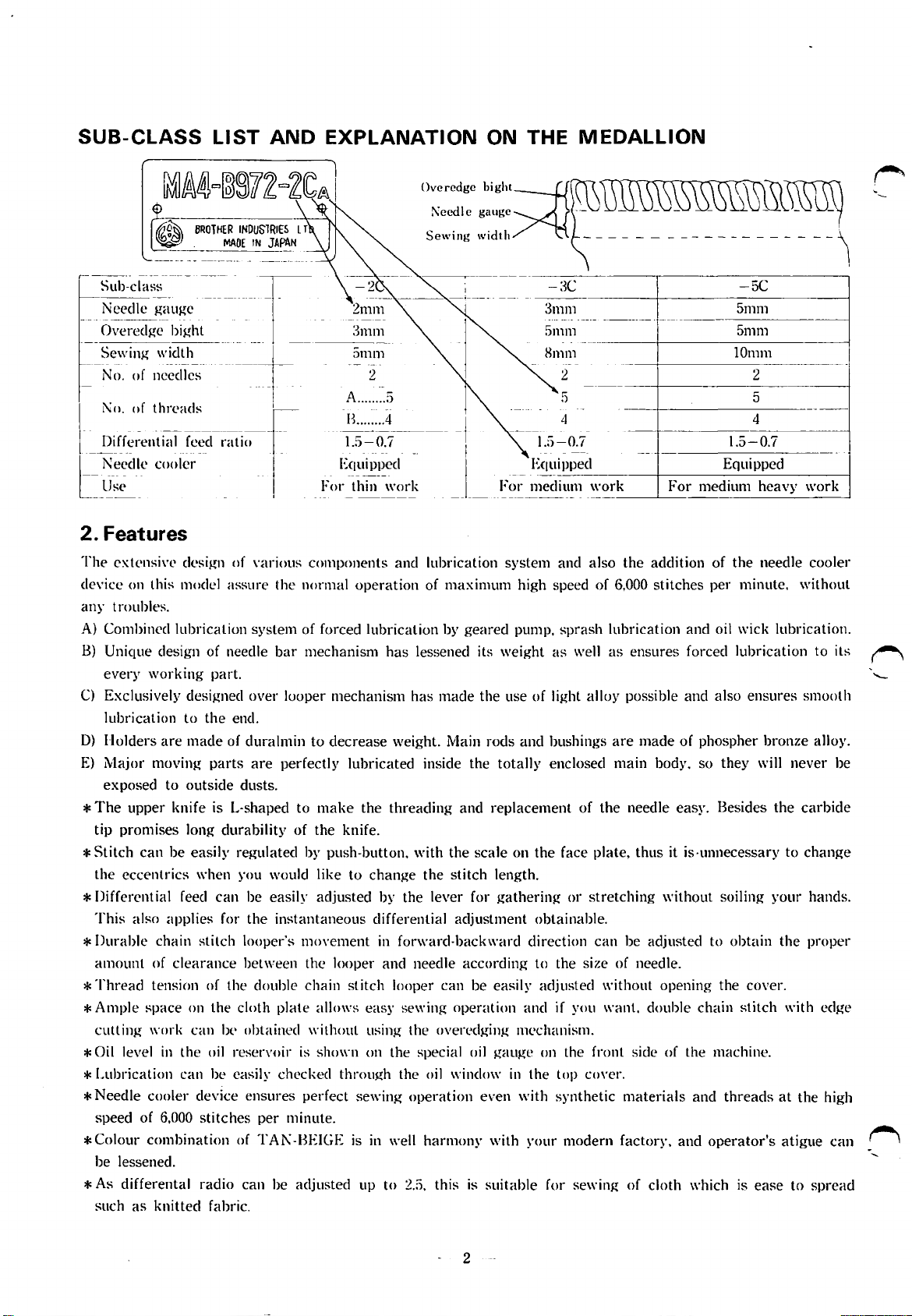

SUB-CLASS

LIST

AND EXPLANATION

ON

THE MEDALLION

Overcdgc

Needle

Sewing

Sub-cia~~

Needle

--

-~-----

Overedge bight

Sewing width t

No._

~

No. of

-------

Differ~~nt~a~~ed

_

~eec~:_coolc~------1-----

U~e

I

-----

2.

Features

The

device on

gauge

---

--·--

-------

-----~11~!11

of

nc<:_dles_ _ ____

. A

thread~

··-----------

_ratio _ _ _

-

cxtcn~ive

design of various components and lubrication system and also

this model assure the normal

_ _ _

1

f

-----

----------

___

--~--

H ........ 4

-----------

_ __

1.5-0.~-

Equipped

For

----

-

3mm

........

:)

-

thin work

----

operation

__

__

of

hight;:{l~nlT\\\\\C\\\1\T\\\\1\\\Im

gauge - !

width

_

maximum

any troubles.

A)

Combined lubrication system of forced lubrication by

B)

Unique design of needle

every

working

C)

Exclusively designed over looper mechanism

lubrication to

D)

E)

Holders

Major

are

moving

part.

the

made

parts

of duralmin

end.

bar

mechanism

to

decrease

are

perfectly lubricated inside the totally enclosed

has

weight. Main rods and bushings

lessened its weight

has

geared

made

the use of light alloy possible and also ensures smooth

exposed to outside dusts.

*The

upper knife is L-shaped

to

make

the

threading

and replacement of the needle easy. Besides the

tip promises long durability of the knife.

*Stitch

*Differential

*Durable

*Thread

*Ample

*Oil

*Lubrication

*Needle

*Colour

can

be easily regulated by push-button. with the scale on the face plate, thus it is-unnecessary to

the eccentrics when you would like

feed

can

be easily adjusted by the lever for

This

also applies for

the

instantaneous differential adjustment obtainable.

chain stitch looper's movement in

amount

of

clearance

between the looper and needle according to the size of needle.

tension of the double chain stitch looper can be easily adjusted without opening the cover.

space on the cloth plate allows easy sewing operation and if you want. double chain stitch with edge

cutting

level

work

can

be obtained without using the overedging mechanism.

in

the oil reservoir is shmn1 on the special oil

can be easily checked through the oil window

speed of

cooler device

6,000

combination of

stitches

ensures

per

minute.

TAN

perfect sewing

-BEIGE is

to

change the stitch length_

forward-backward

in

operation

well

harmony

even with synthetic

gathering

gauge

in

with your modern factory, and

be lessened.

*As

differental radio can be adjusted up

such

as

knitted fabric.

to

2.5.

this is suitable for sewing of cloth which is

\j_\j_lj_\j~

----

-3C

3mm

-··-

--~

.

--·-

5mm 5mm

-

-·

-------

8mm

-·.

.

--

2 2

--

5

--~

--------

4 4

--

---

1.5-0.7

~-------

- - -

---.

\,l\j\,l\jU\._,_'.Ju_'/

--

-------

-5C

5mm

lOmm

1.5-0.7

Equipped Equipped

medium

----

work

high speed of 6,000 stitches

pump,

sprash

as

lubrication and oil wick lubrication.

we11

as

are

main

or

stretching

direction

can

For

medium heavy

the

addition of

the

per

minute. without

ensures forced lubrication to its

made of phospher bronze

body, so they will never be

without soiling your hands.

be adjusted to obtain the proper

on the front side of the machine.

the top cover.

materials

and

threads

operator's

-

--

5

work

needle cooler

a11oy.

carbide

change

at

the high

atigue

ease

to

spread

~

-

~

......_

can

2

Page 5

3.

Operation

A.

Sewing

speed

lVlaxtmum speed of thts machine is 6,000 stitches per minute.

the new

thts runnmg-m

destrable

B.

I) Use a clutch motor,

2)

3)

machme

should be

penod.

~'OU

for machine's long life.

Motor,

motor

pulley and belt.

l/2 H p,

1\;'lD-344

(single phase) and MD-354 (three phase)

Use M-type V -belt.

Machine speed (s.p.m.),

operated

may

operate

2 pole, single

diameter

at

about 5,000 s.p.m. so

the machine

or

three

of

motor

pulley and length of

at

maximum

phase. Our

For

that

the first

all the

100

actual working hours, however.

working

parts

are

speed of 6.000 stitches per minute.

motor

motor

available

is Models

belt ts related

to

well run-in. After

This

is

the fo])owing table.

Stitches

-------~--

per

5,200

minute

5,500

6,000

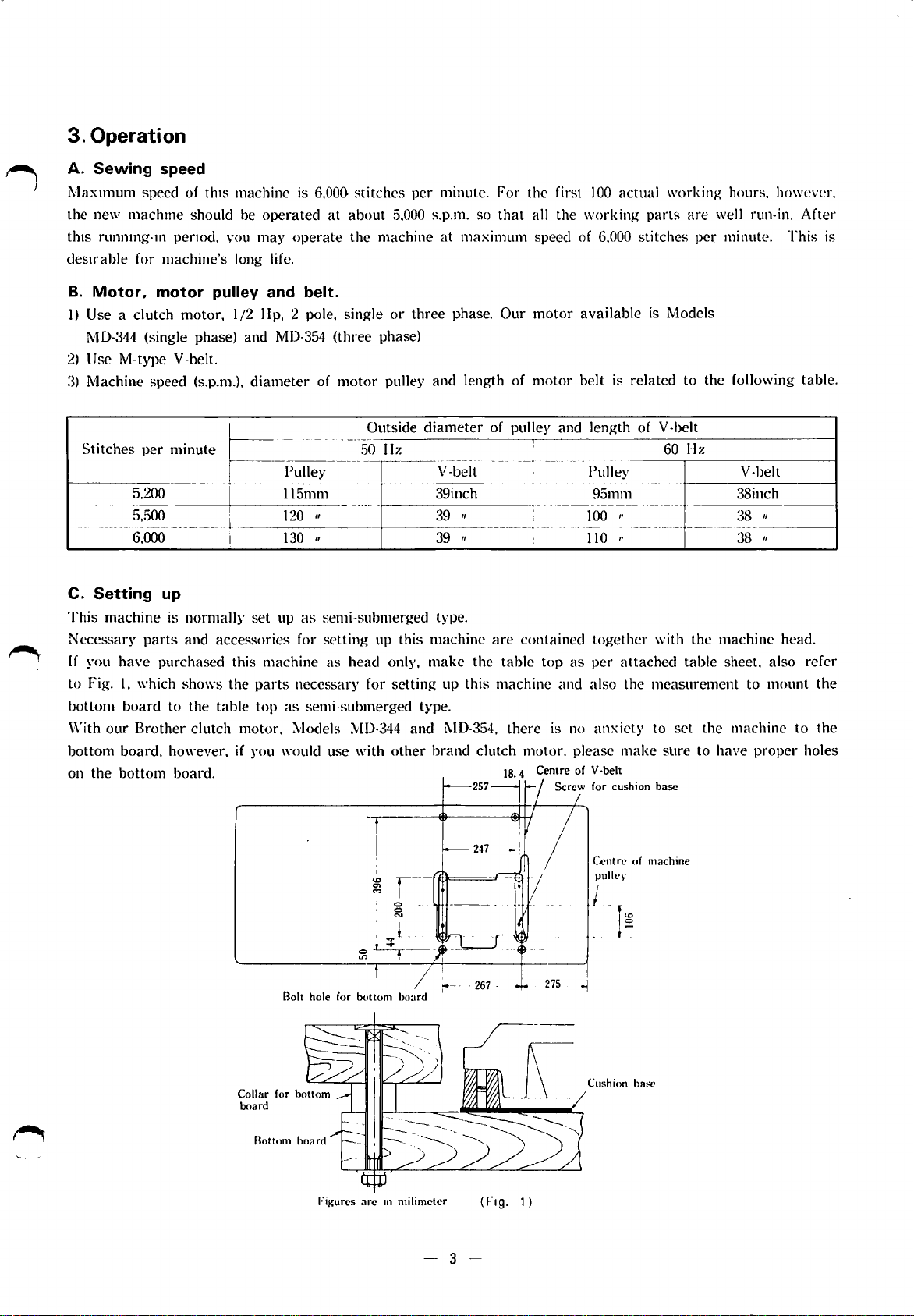

C.

Setting

This

machine is normally set up

Necessary

If

you

to Fig.

bottom

\Vith

our

bottom

on the

up

parts

and accessories for

have

purchased this machine

1.

which shows the

board

to

the table top

Brother

clutch motor. Models MD-344 and MD-354.

board, however. if you would use with

bottom

board.

Pulley

115mm

120

130

parts

necessary for

as

Outside

50

----·· -

II

II

as

semi-submerged type.

setting

as

up this machine

head only,

diameter

Hz

make

setting

semi-submerged type.

other

brand clutch motor, please

of pulley

and

length

of V -belt

60Hz

V-belt Pulley V-belt

39inch

II

39

39

"

_j__

--------------

-----

---

are

contained together with the machine head.

the table top

95mm 38inch

II

100

-----

as

110

per

------------

"

attached

table

II

38

38

"

sheet. also refer

up this machine and also the measurement to mount

there

is no

2571

18.

4 Centre

anxiety

of

V -belt

Centre

pullt•y

to set the machine

make

sure to

of

machine

have

proper

to

holes

the

the

275

Figures

are

m milimcter

-

3-

(Fig.

1)

'-!~

-1

Cushion base

Page 6

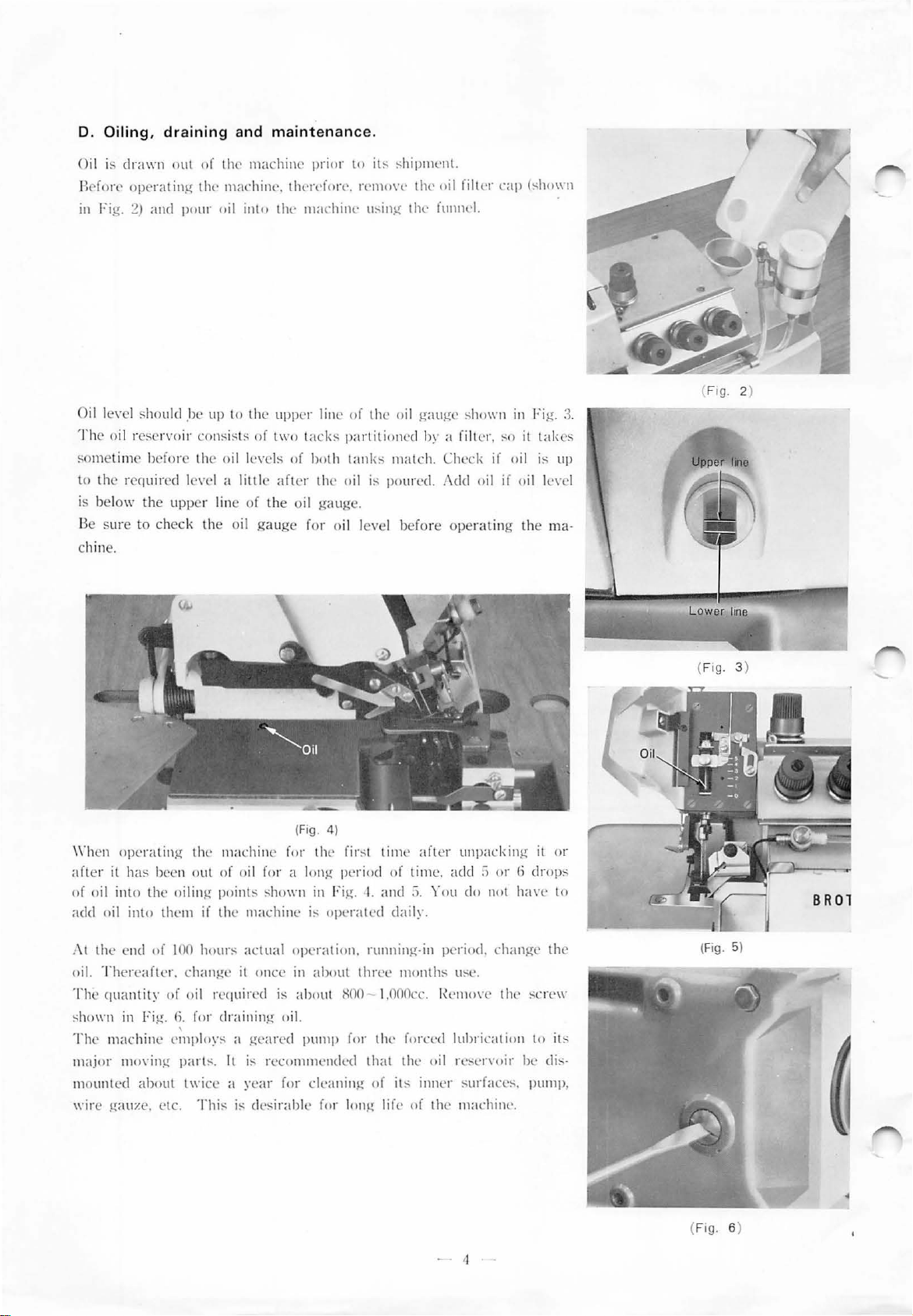

D. Oiling, drai

Oil is

B

efon'

in F ig.

Oil

le,

Th

e o

some

to

the req

is

belo\\'

Be su

chine

dram1

·el s

il

time

re

.

out

operating

~)

and

hould .be

reservoir

befo

re the oil

uired

the

upp

to check

ning and

of the

the

pour

con~ists

lc,·el a lit

machine

machine. therefore.

oil

into

up

to

the

of

le\

·els

tle

er line o f the o

the

oil gau

maintenance

prior

to

n•mm

the mac

upper

t\\'O

after

ge

hine

line

of

lacks partitioned

of

both

tanks

the

oil is

il

gauge.

for o

il

level

.

its

~hipnwnl.

·e

the

using

the

the oil

gauge

by

match.

poured.

before

oil

filtn

cap

funnel.

sho\\'n in Fig. 1.

a filll'l'.

Check

i\dd

so

if oil is up

oil if oil le,·cl

operating

(shmm

it

lakes

the

ma-

(F1g. 2)

\\'hen

ope

rating

after

it

has

of

oil

into

the

add

oil

into

:

\t

the

end

of

nil. There

The

a f

quantity

sho\\'n in Fig.

The

machine

major mo,·

m

ounted

ing

about

\\'ire gauze.

the

been

out

of oil

oiling

points

them

if tlw m

100

hours

ter. changl'

of

oil

required

li

. for

draining

'

('lllploys a

part~.

t \\'icc a

etc.

Thi

s is desi

machine

for a long IK

sho\\'n

achine

actual

it

once

geared

It is

recommended

year

(F

ig.

for

the

in Fig.

is

operation.

in

about

is

about

oil.

pump

for

cleani

rabl

e for

4)

fir

st

time

after unpacking

'riod

of

time.

add

I.

and

;)_ You

operated

daily.

running-in

thr

ee

months

period.

HOO I.OOOcc. l<emm·e

for the forced

that the o

ng

of

long

life

its

inner

of

il

the machine.

it

:)

or 6 drops

do

not

ha,

·e

changl' the

use.

the

~cn'\\'

lubrication

rcscrYoir

to

he

surfaces. pump,

or

to

its

dis-

L

ower

(

F1g.

(Fig. 5)

line

3)

4

(Fig. 6 )

Page 7

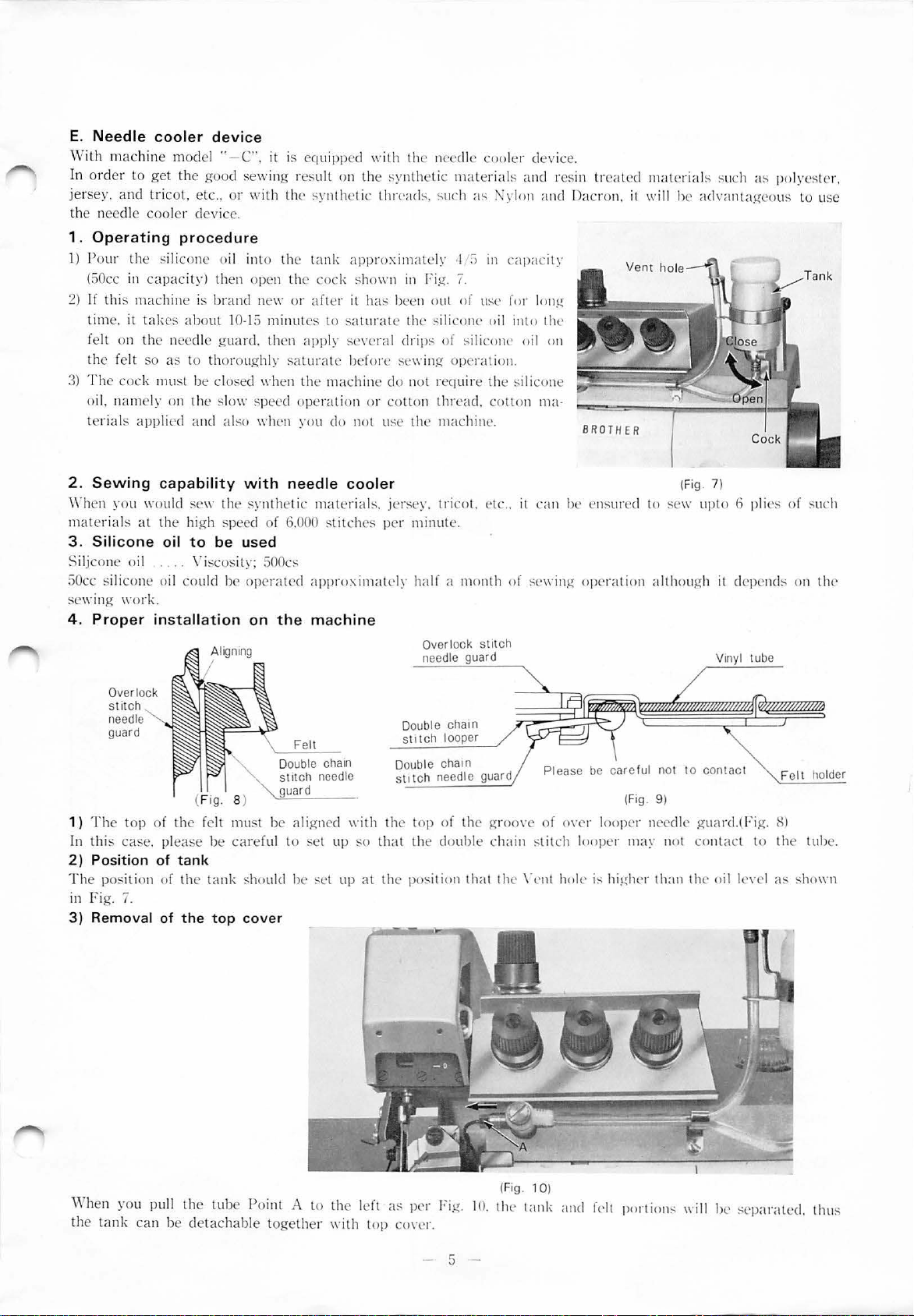

E.

Needle

\Vith machine

In

ord

jer

sey.

the

needle

1.

Operating

1) Pour

(50cc

2) If thi s

tim

felt on

th

e fell

3)

The co

oil.

te

ria

2.

Sewing

\\"hen you

er

to

and

cooler

get

tri

coo

model

the good

cot.

etc

ler

devic

device

··

- C". it is equi

sewing res

..

or

\\·i

e.

procedure

the silicone oil into the

in

ma

e. it

ck

namely

ls

appli

capacity

tak

the nee

so

\\"

chin e is

must

ould se\\" the s

) the n open the

brand

es

about 10·

dle gu

as to

be

15

ard. then

thorough!~

closed

on the s low speed ope

ed

and

also \\"h

capability

with

th

ne\\" or

minut

·

\\"

hen the machine do not re

en you do not u

ynthetic

materials at the high speed of 6.

3.

Silicone

Siljconc

5

0cc

silicon e o

se\\·ing

4.

Proper

oil

oil . .

il could be o

\\"Ork.

installation

to

..

\"iscos

be

used

it~·:

500cs

perat

on

the

pp

ed \\"ilh the needle cooler device.

ult

on the synthetic mate

the syntheti

tank

coc

aft

es

c threa

approxim

k sho

\\"11

er it has been out o f u

to saturate the sil

apply se\·eral

s

aturat

e before se\\·ing operation.

rati

on or c

needle

cooler

materials. jersey.

00

0 s

titches pe

ed appr

oxima

te ly half a mo

machine

ds. such ;ts

ate ly I

in

Fi.

~.

dri

ps

otton

thread. coll

se

the machine.

tricot. etc

r minute.

Ov

erloc

needle guard

:>

7.

icune o

of

silicone o

quir

e the silicone

nth

k stitch

rial

s and resin treat

f\y

lon

and Dacron

in capa

se

f

or

il into

on

..

it can

of

Sl'\\"

cit y

long

il

ma

th e

on

·

lll

g

ed materia ls such as pol

. it wi

ll

he a

clv

ant;tgeo

(Fig. 7)

be ensured

to

SC

\\"

up

lo 6 plies

operation although it depends

V1nyl tube

yeste

us to usc

of such

on

th e

r.

Overlock

stitch

needle

guard

Fig.

8 )

(

1)

T he lop of the felt must be a ligned \\"

In this case. please

2)

Position

Th

e p

111

Fig

3)

Removal

os

of

ition or

. 7.

of

tank

th

e tank

the

be caref

~houl

top

cover

Felt

Double

stitch need

uard

ul to set up so

d

be

set

cha

c

ha1

n

looper

needle gua

of the groo\·e

1n

le

ith the l

Double

st1tch

D

ouble cha1n

st 1tch

op

that the double chain stitch

up

at

the

po~ition

that the \ "l'nt h

rd

of

m·er loop

ole

loop

is h

(Fi

g.

er

need

er

may

igher than

9)

le guard

not c

the oil k \·el

ontact

Fe

.(Fig.

Hl

to the lube.

as

sho\\"n

lt

holder

(Fig. 10)

\\"hen you pull the tube Point A to the

the tank can be detachable t

ogether \\·ith top cm·cr.

lef

t as per Fig. 10. t

he tank and felt

5

portions \\"i

ll

be

separate

d.

thu

s

Page 8

F.

Machine

The prop

operating

er

opera! ing direction of thi s machine is clock wise as vi

direction

ewe

d fr

om

the pulley side.

Install

G.

Tu

rn the pulley until the needle

to

its highe

® shown in Fig.

finger and m

dir

the

::.Jo

\\', lo

tlw needl

to\l'ard yo

lamp

c

in the

a

ll

the

sc

rews.

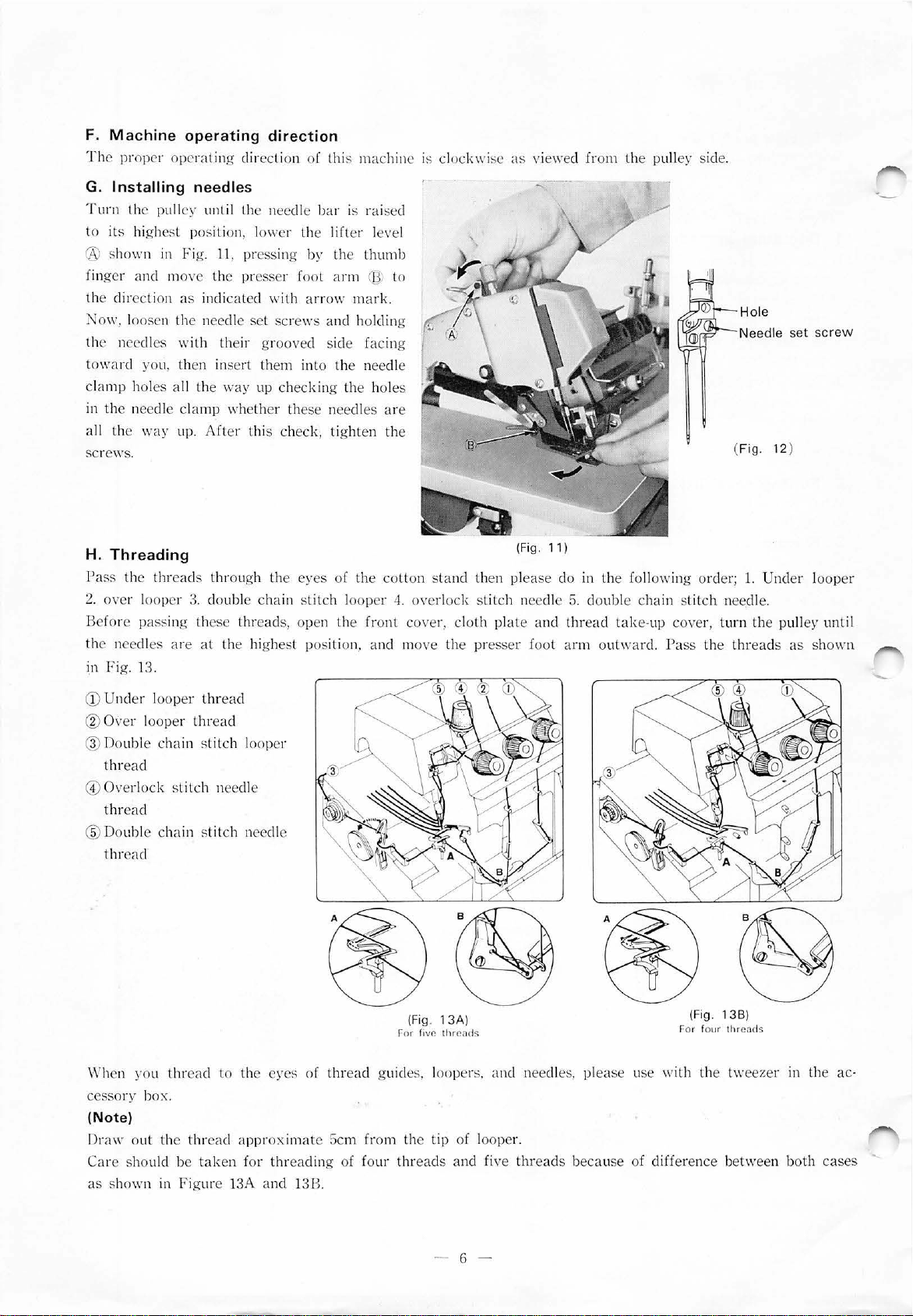

Threading

H.

Pa

ss

over

2.

Before pa ssing these thre

the n

in Fig. 1

CD

Und

® Over looper

® Double cha in stitch loo per

th re

0 Overl

threa

® Double c

thr

ing needles

st

position, l

ove

lhe presse

ection

hol

ne

the threa

eedles are a t

er

ad

ead

as

indicated with arr

osen the needle set sc rew s and holding

es

with their

u.

then insert

es

all the

edle

clamp

way up.

looper

3.

looper

ock

d

Aft

ds

thr

3.

doub le c

thre

thread

stitch needle

ha

in stitch needle

ower

11

, pr

ess

ing by the th

grooved

them

way

up checking the holes

whether th

er this check, tighten the

ough the eyes

hain stitch loo

ad

the highest position, and m

ad

bar

is raised

the lifter leve l

r fool

s, open

arm

ow marl

side facing

into

the nee

ese needles

of

the

umb

<13

lo

<.

dle

are

(Fig. 11)

the

cott

on stand

per

4. overlock stitch needle 5. doubl

fro nt

cover, cloth

ove

then please

plat

e and

the presse r foot arm

do

tn

the foll

thread

outward. Pass

Hole

Needle set screw

(Fig. 12)

owing order;

e chain stitch needle.

tak

e-up cover, turn t

the

threads

1.

he

Under

loop

er

pulley until

as

sho

wn

-

(Fig.

13A

]

thr

eads

r.

s and five thr

es, please

eads

Wh

en

you thread

cesso

ry box.

(Note)

Draw out

C

are shou

as shown in Figure 13A a

the thre

ld

be

taken

to the eyes

ad

approximate 5cm from the tip of loope

fo r threading of four

of thread

nd 138.

r

or fivo

guides, loopers. and needl

thread

- 6 -

becau

(Fig. 1

For

four

use with the twee

se

of

differ

ence between both ca

38)

threads

zer

111

the

ac·

ses

Page 9

I .

Stitches

J)

12

])

I:!

E

13

:\

])

I:!

(Fig. 141

For

five

thread

s specification.

parallel stitching

co

mbinati

on 1s

of

adjusted (Figure I-I).

ment

parallel

El

:~J

\

combination(Figur

a lso be

me

nt

,,-ith

stitch

accompli

turnin

shed upon

g the adjustin g

screw

For

four

thread

s specification.

parallel stitching

co

mbination (Figure

upon

appropnat

J.

Thread

Thread ten

positions of

follow ing

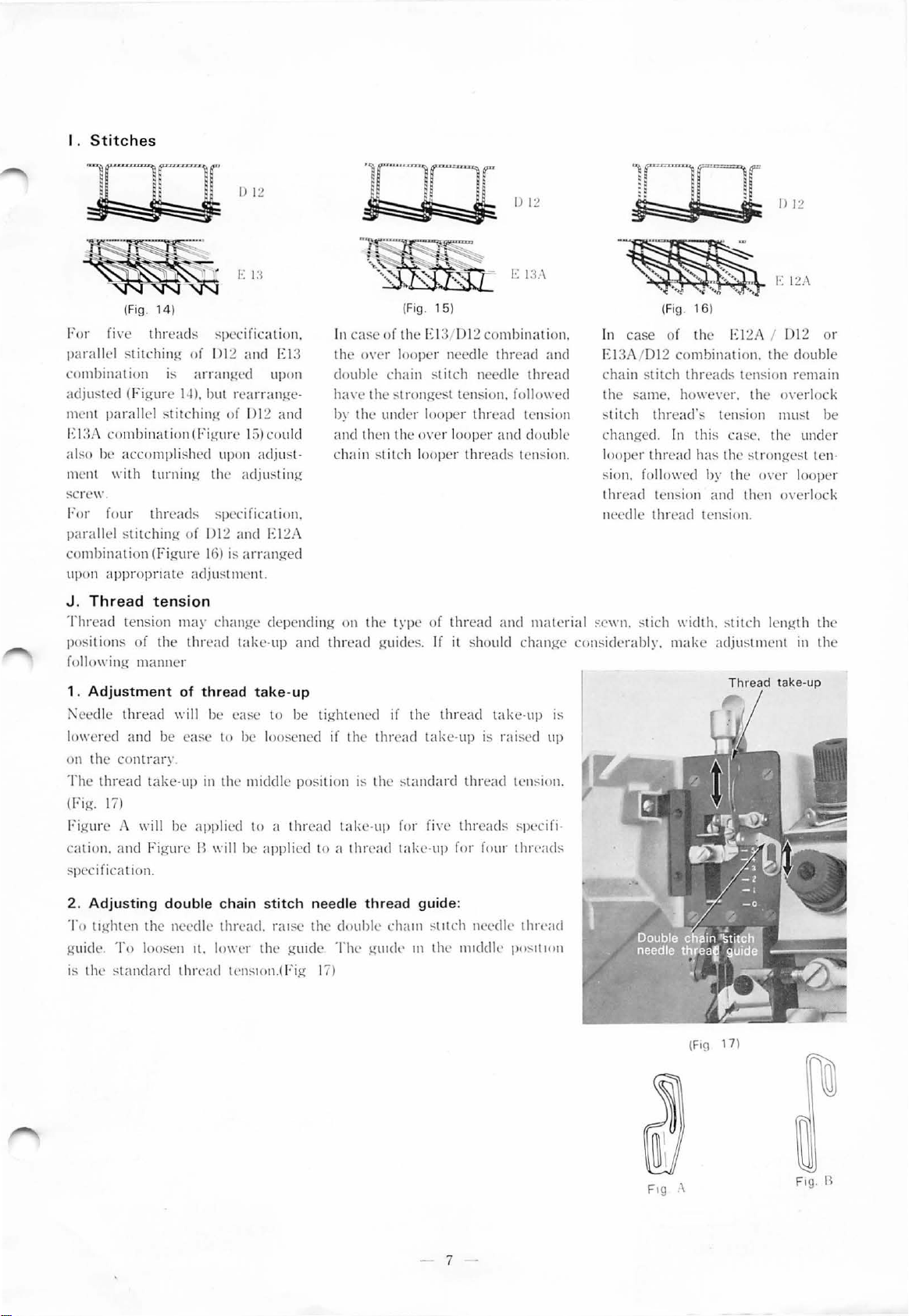

1 .

Adjustment

i\ee

lower

on

T he

dle

thread

ed

the con

thr

ead

manner

and

of

c adjus

tension

sion may chan

the

thre

of

"·i

ll

be case

trarr

take-up

(Fig. 17)

Figure

ca

spec

tion.

and

ification.

J\

\\·i

Figur

ll

be

e B " ·ill

1>1~

and

El

arranged upon

but

rearrange-

ing

of

Dl 2

and

e 1

5)cou

ld

adjust-

1)12 an

d

E1

2A

16)

is

arranged

tment

.

ge

depe

ad

lake-

up and

thr

ead

take

-up

be

case

to

to

be l

oosened

in

the

middle

applied

to a thread

be

applied to a thre

In

3

th

e m·er lo

double chain

ha\'l' the s

br

and

chain s

ndin

g on

thr

ead

be t

ighte

if

the thread take-up

pos

ition

take-up for fi\-c

(Fig. 15)

case

of the

EU

ope

r n

sti

trongest

the

under

looper thr

then

the

m·er

titch

looper

the

trpe of

gu ides. If it should

ned if the

is

the sta

ad

thread take-up

ndard

take-up

1

DI 2

com

bination.

eed

le

thread

tch n

eed

le

thread

tension. follo\\·ecl

ead

tension

looper

and

doubl

thread

s tensio

thread

and

mat

change

is raised up

thread tens

thread

for

four thre;l(ls

ion.

s spe c if

and

n.

erial

is

i-

In ca

E 13A/

c

hain

the

st

e

ch

oo

l

sion.

thread tension

needle

~-c"·

consid

(Fig. 16)

se

of the E12A I DI2

DI2 combin

stitch

same

. ho\\·e,·cr.

itch

thr

anged.

per

thread has

follo"·ed br

thread

n.

stich \\·idth. s

erabl

r.

ation.

the doub

threads tension rema

the o,·erlock

ead's

In this case.

tension must

the unde

the str

ongest

the

over

and

then

tension.

tit

ch len

mak

e adj ustment in the

Thr

ead take-

loope

o,·er

gth

or

le

in

be

r

ten-

r

lock

the

up

2.

Adjusting

To tighten

guide .

is

To loose

the

stand a rd thre

double chain stitch needle

the

needle

thrl'ad.

n

ll

. lo

ad

reu

se

wer

the guide The gllldl• 1

tens

ion.(Fig 1

the

double

7)

thread

ch;un s

guid e:

titch

11

the

Ill'edle

middle

thread

position

- 7

F1g

F1g

\

. B

Page 10

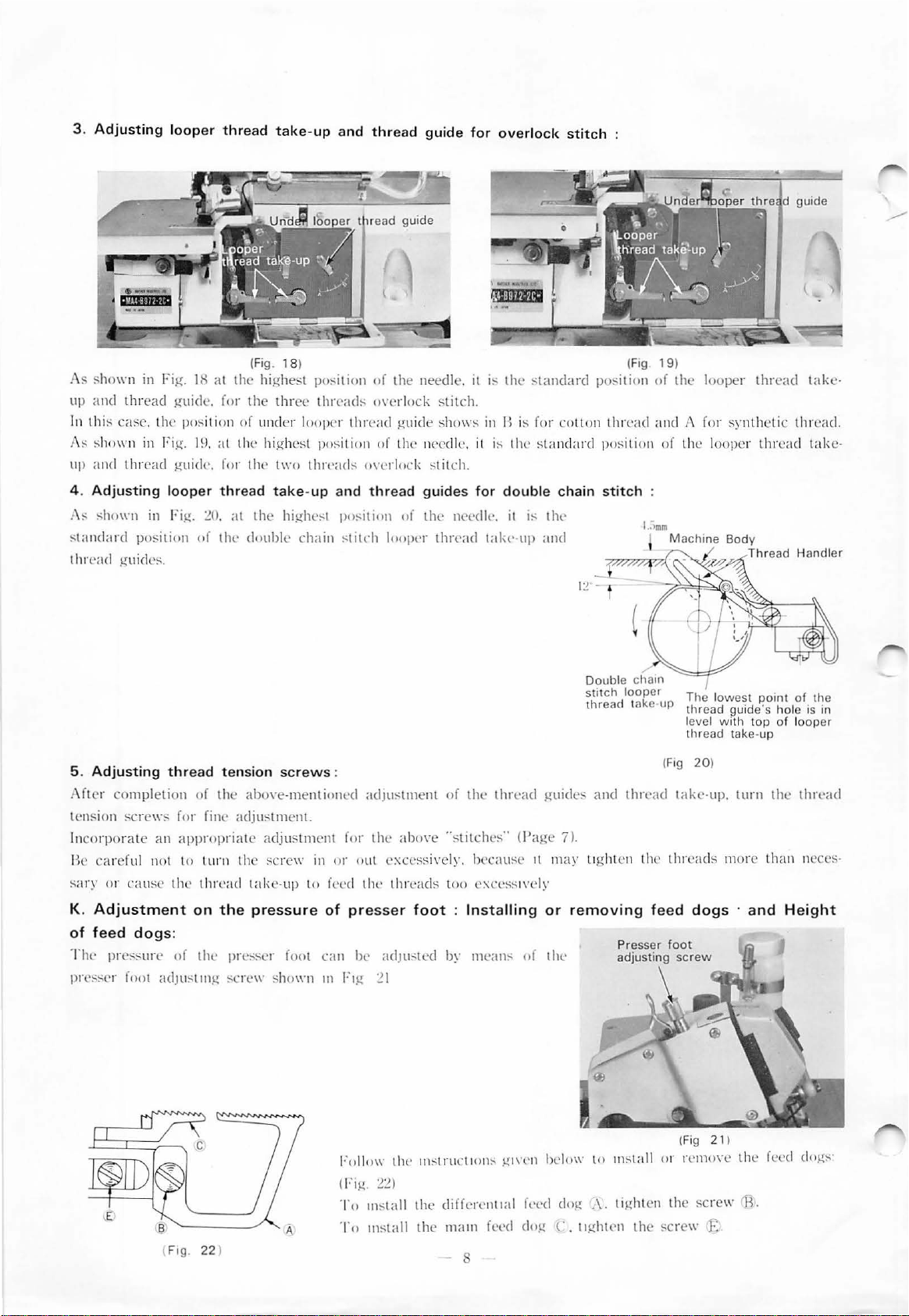

3.

Adjusting looper thread

As shmm

up

and

In this

J\s shmm

in Fig. 1,

thread

guide.

case. the pos

in Fig. 19.

ition of

up ;mel thre ad guide. f

take-up

(Fig.

18)

at

the

highest

for

the

thr

ee

und

er

looper thread

at

the highest positi

or

the t,,.o threads m·cr

and thread guide for overlock stitch

position

threads

of the needle.

m·erlock

guide

on

of

the needle.

lock

sti

tch.

sho\\"s in

stitch.

it

is

the

sta

ll

is for

it

is the standard pos

ndard

cotton

(F1g 19)

position

thrcctel

ition

of

the

and

of the

looper

/\ fo r

looper

thread

synthet

thread

ic thre

tak

ad.

take·

e-

4 . Adjusting looper thread

1\ s

shmm

s

tandard

1

hr

eacl

position

guides

in F ig.

.

~0.

of

the

at

double

take

the

-up and

highest

chain stitch

5. Adjusting thread tension screws :

After

completion

tension sc

I

ncorporate

Be ca r

s

ary

K.

of

The

presse

re\\"s

eful

or

ca u

Adjustment

feed

dogs

pressure

r foot adJUSting scrt'\\"

of thl'

for

an

appropriate adjustment

not

to

se

the th

on

abo,·e-mentioncd

fine

adjustment.

tum the sere,,· in or out c:-;ccssi,·ely.

read

take-up to keel

the

pressure

:

of

the

presser

foot

sho\\·n

of

can

111

thread

posit ion

adJustment

for

the

the threads

presser

be adJUS

Fig

~

guides for double chain stitch :

of

the

needle.

looper

thread

of the

abo,·e

"stitche

too

foot : Installing

ted

by

I

it

is

takl'·UP

thrt•ad

s"

(Page 71.

because

1t

e:-;n·ssl\·ely

means of

the

and

guides

may

or

removing

the

Double

stitch

thr

ead take

and

lighten

l.:imm

cha1n

looper

thn•ad

the threa

feed

Machine

The lowest

up

thread guide's ho

with

level

hr

ead take-

t

(F1g

20)

take-up.

ds

dogs · and

top

turn

more

Handl

point

of

the

le

is in

of looper

up

the

thread

than neces·

Height

er

F

11llo\\"

(

F1g. 22

the mstr

(}."jg

~2)

T o 1ns t

all

To mstall

uctwns gi\Tn

bl'im,· to 1ns

the cliffcrt'llllill feed dog ;\.

the

mam

feed clog C . li

8

ghten

tall

lighten

the sere\\'

(Fig 21 I

or

rcmm

the sere\\"

£

·e

the

keel

clogs·

13.

Page 11

The

standard

that

when

a point 1 mm to

plate

in its

feed

dogs

needle plate. (Fig.

L.

Adjusting stitch

Stitch

width

height of

the

overlock needle

upward

is level with

is

dependent

the

top

surface

travelling,

23)

width

feed dogs is such

pomt

comes

of

the

the

top

the

surface

( overedge bight)

on

cloth

trimming

needle

of

the

of

the

to

width

and

the

tongue

(Fig.

23)

of the needle plate.

Adjust

1)

Remove

2)

Tighten

width

3)

Loosen

the

4)

Tighten

5)

Loosen

spring

Fix

cq

®

(Fig.

the

trimming

the

the

may

the

upper

the

the

pressure.

the

lower

24)

width

as

follows:

upper

knife.

set

screw

Q).':

temporarily

be

obtained.

screw

® and

knife holding block to

screw ® and

set

scrow ® and

knife

by

tightening

adjust

install

please

(Fig.

24)

so

that

the

the

contact

eitJ~·"r

the

upper

make

the

set

of

left

or

knife while pressing it to

sure

screw

(Fig.

lower

knife

may

the

upper and lowt'r knives

right.

that

the

lower

@.

conw

knife

25)

the

may

to

the

as

lower

contact

point

shown

knife.

where

in

with

desired

Fig.

upper

trimming

25

by mm·ing

knife

by

the

-9-

Page 12

M .

Adjusting stitch

Stitch

leng

th

thread

depressed.

is

release

depending

take-up

turned.

the

turn

Stop the

push-hullon. The

on

(Fig.

can

cm·cr

the

the

be

kind

length

26)

;tdjusted

.\.

!Fig.

pulle~·

slo

\\'ly in the

pulley

of

\\·hen

numbers

the

to

any

26J

Then.

the

material

puint

\\'ith

normal

pointer

indicates

s.

their

\\'ithin

the

the

push-button

ran

ge from 1./mm

I~

operating direction. The

reaches

thickness

the stit

the

ch

and

llltlllber

length.

differential

(Fig.

(Fig. 27)

push-button

representing

hm\·e\·er.

feeding.

27)

to

:t6mm.

located

your

the

actual

in

front

goes

desired

:\t

stitch

first.

of

the

in\\'ard

stitch

length

open

machine

as

the

nel•dlc

the

pulley

length.

ma~·

change

kepl

and

N.

Adjusting

l>ifferemial

loosening

dm,·n

as r

is in

line

to ( )

str

the sere\\' :\

In

l~emo

feed link

\\'lwn

l'n

etching

the

case

H'

till'

tial

ratio

sign.

clo

shaft

differenti

ieed

may

the

scrl'\\'

equired.

,,·ith

the

~·ou

\\'ill

..

\ft

er

adjustment

st•curel~·.

to

requtre

th

pla

te

b~

·

an

main

feed link s

\\'

ill bt·cotlll' its follo\\'s.

lliffl'rl'nti<tl <tdjusting

l

lifft•rt'tltial

\\'lwn

feed

link

;trill

.

a n

;tdjusting

wdium

sh<tft

diffl'l'ential

at

an

al

feed.

be

adjusted

.\ sh

m\'11

:\ormal feed

tll<trk

on

get gatherin

in Fig.

is obtaind

the

scale.

to

2H.

g If

is con1pll' t

larger

gathering

and

feeding

nwchanistn

attached \Hl'nch. tlwn

haft

is

lmn·recl

ll'\Tr. upper

ll'n·r.

lmH'r

ratio

t·ncl.

encl. . .

is

required.

itllt•nncdiatt• pos

stretch.

If

clm\'11.

ecl

\

and

b~·

the

to

. pk•;tst•

be

mm·ing

se

lcH'r

difiercntial

co\'l'r. loosen

lo\\'l'r

do\\'n\\'<trd. O:i

until

........

IJiffl'rl'nti;d

...... llifferen

place

ition

in till'

normal

the

or

gather

k•n

tting the il'H·r·s

is lift

ed

up.

( · )

sig

n.

you

mal;e

sure

to

feed.

nut

.\ of

.l!;u

bottoming. the

ratio.

tial

ratio.

and

sellle

tht•

grom·e

of

main

by

•r

up

or

mark

namely

\\'ill

gel

tighten

mam

re

2H

Bl

differ-

~.:i.

1.:1.

main

feed

(Ftg.

28

:\

Li

nk

Shaft

10 --

(Ftg.

28l

ll

M

ain

Feed Arm

Page 13

4.

Adjustment

A. Height of needles (Fig.

For needle replacement.

installation of the

overlock needle should be 11.0 mm

the

plate, and

B.

Relation between needle and under looper (Fig.

\Vhen the under looper

of the under looper and the

The

into the looper holder.

and the needle

\Vhen the point of the under looper is going to pass the back of the

needle.

and point of the under looper is

The

at

under looper is determined its height when it is inserted all the way

which

under looper should be installed

needles. \Vhen the needles

that

time, the double chain stitch needle. about

i~

The

in

its upward travelling

is

in

its downward travelling, the clearance between needle

29)

plt·a~c

its left extremity, the distance between the point

follow the

centre

relation between the point of the under looper

of right needle is 4.0 mm.

about

as

chapter

over

is

shown

less

than

being provided 1.5mm of inclination.

describing the correct

are

at

the highest position,

the surface of the needle

7.8

mm.

30)

in

Fig.

30.

0.1

mm.

(Fig.

29)

C. Installing needle guard

Push the needle with the needle

point of the under looper comes to the

way up, they

needle

guard

are

barely out of

in

that

position.

(for

guard

contact

overlock

to such an

centre

with each

stitch)

D. Matching needle guard and needle. (for

Use the needle

guard

and needle in the following combination.

Needle

guard

1~0.

2 #

(Fig. 31)

extent

axis

other

overlock

that

of the needle on its

and install the

stitch)

Size of needle

when the

(Fig.

11

~~

(Fig. 30)

Pressing needle

needle guard

(Fig.

31)

31)

with

#

14,

#18,

#16

#19

No. 3

No. 4

I

-11-

Page 14

E.

Relation

of

needle

with

\ ~ Overlock needle

under looper and over looper

A clearance

o. 1

mm

but

slight

be permitted.

After

determining

under

and

looper

F.

properly

Relation between needle and double chain stitch looper.

of

about Over looper

is desirable, ·

contact

Under

looper

can

looper

the

relative

mentioned in

as

shown

(Fig.

in Fig.

Needle must pass

bulge on under looper

without

(Clearance: About 0 1 mm)

32)

position

B,

contact

of

position

the

needle

the

below

over

32. & 3:1

Fig.

setting.

:n

shows

for

your

(Fig

(Fig.

the

nwasuremt•nt of

reference.

34 & 35)

33)

the

over

looper

-~=~;;.-

(Fig.

34)

\Vhen

the

the

needle for

with

The

loopt'r

double

There

the

bad~

the

chain

should

double

clearance

of

chain

stitch

double

is

dl'termined

stitch

be

the needle on its

as

chain

of

about

looper

little

its

and

clearance

looper

stitch

L>

mm

height

the

way

is

needle

as

up.

is

at

the left

about

between

when

eye

possiblt'

extremity,

2.0 nun. At

rt'cess

portion

it

is

inserted

on its

between

that

all tlw

upward

needlt•

(F1g.

the

distann•

time.

the

of

the

looper

way

travelling

and

loopt•r

35)

between

doublt•

and

into 1ts

is

as

pomt

its point and

chain

stitch

looper should

nt't'dle

holder

shown

plate

The

relation

m Fig.

when the point IS

holder

35.

the

centre

between

going

to

be

of

set

the

pass

-

12-

Page 15

G. Installing double chain stitch needle guard (Fig. 36)

Install the needle guard

the back of needle

in

such a position

as

the needle rises from its lowest position needle

that

when the looper passes

guard may not contact the needle pressing lightly the needle by finger.

If

the

correct

may be caused when sewing on

adjustment is not made.

materials

skip

pulling

stitch

or

needle

or

in

case of sewing

breakage

folded part.

H. Installing and maintenance of knives (Fig.

l\lount the lower knife to the lower knife holder so

level with the needle plate. Install the upper knife so

edge is

the lowest end

The

ground only with diamond grinding wheel.

0.5-

0.7mm below the edge of the lower knife when it is

of

its

stroke

as

shown

in

Fig.

37.

upper knife is fitted with a tungsten-carbide tip, which

It

lasts its original sharpness

37)

that

its edge is

that

its front

cah

in

at

be

for a long period without re-sharpening. Sharpen the lower knife when

38

necessary. Fig.

shows the shape of lower knife.

Surface

needle plate . ressmg Y

of

(Fig.

(Fig.

............

36)

37)

p . b

fmger

(Fig.

1.4

38)

-

13-

Page 16

5. Trouble shooting

A. Thread breaks

Cause

Poor

thread quality.

Thread

Needle groove

Excessive.

too thick for needle size.

or

needle

eye

pressure of tension disc.

Needle improperly fitted.

1\eedle,

has

looper, needle plate,

flaws.

Relation of needle with looper and

up not right.

'Vrong

Needle

B.

Skip stitching

threading.

gets

hot.

Cause

poorly

or

thread

finished.

passage

thread

take-

Remedy

Use

thread

Change needle

I

I

Change needle for a good one.

of good quality.

or

thread for the right

Adjust to proper pressure.

Refer

to

instructions for "Installing needles."

6)

(Page

Smooth surface with oil stone

Refer to

Refer to

"Thread

tension." (Page

"Threading."

Use with needle cooler

Remedy

··-··-

one.

or

buff.

7)

(Page 6)

or

use smaller size needle.

\Vrong

Point of looper out of shape.

-·~----~

threading.

Needle point blunt or bent.

Needle improperly fitted.

·~--

Relation of needle with looper and

up

or

clearance between them not right.

Needle and needle guard out of proper relation.

---~-----~

thread

-------

·~.

Needle gets hot.

Pressure

of tension disc too small.

C. Needle breaks

Cause

Needle and needle guard out of prnper rl'lat ion.

--~

-

Needle and looper out of

proper

------

relation.

1\eedle bent.

take-

-

---

Refer to

"Threading."

Reshape with oil stone

(Page

or

6)

replace.

Replace.

-

~

Refer to

Refer to

-~--

(Pages

Refer to "Installing needle guard." (Page

Use with needle cooler

"Installing needles." (Page

"Thread

7 &

tension" and "Adjustment."

11)

------

or

use smaller size needle.

6)

11)

Adjust to proper pressure.

------

-·-------------·

Remedy

J<der to "Installing needle guard'',

guard

":\latching needll•

"Installing

(!)age

---

I<efer

II

)

---

"){elation

to

douhll'

and needle" and

chain

stitch needle

-

------

between

guard."

needle and under

looper" and "){elation of needle \\·ith under looper

and

over

looper." (Pages

11

&

12)

Replace.

Needle imporoperly

fitted.

Refer to

"Installing needles." (Page 6)

14

Page 17

D.

Imperfect

chaining-off

(overlock stitch)

--

------

---

\\'rong

-

Stitch

Looper

threading.

tongue on

thread

--

needle

take-up

position.

Chain

Threads

feed

too

clog

improperly

tight.

(Double chain stitch)

------

\Yrong threading.

Needle

too

Differential feed

Needle

Lower

thread

strong

thread

thread

and looper

or

too weal\.

dog

guide out of position.

take-up out of timing.

Cause

plate

has

flaw.

and

thread guide

installed.

Cause

thread

have

not in level with

--

tension

main

out of

·----

feed.

emery

tension"

Remedy

(Page

paper and

(Page

6)

-.

polish

7)

--

with

buff.

-~-

----~

---

Refer

---

---------

---

to

Smooth

Refe·r

to

f---

-------

---~--

----

"Threading."

with

"Thread

- -

l{efer to "Adjustment on the pressure of presser

fool: Installing

of feed dogs."

---

----------

Adjust

Refer to

--

to

or

removing feed dogs: and Height

(Page

proper tension.

Remedy

"Threading."

8)

(Page

6)

-·--

----

. -

-

--

Adjust to proper tension.

---------~

Refer to

foot: Installing

Height of feed

Refer

Refer

--

-------

"Adjustinent on the pressure

and

removing feed dogs: and

to

"Thread

to

"Thread

dogs."

tension."

tension." (Page

(Page

8)

(Page

7)

7)

-------~-

of

presser

-~

-

·-

-·-

---

E.

Improper thread tension

Cause

}{elation of needle with

up

Tension

Thread

not

right.

disc

will not work properly.

------

--

..

too

thick

looper and

for needle.

\Vrong threading.

F.

Poor trimming performance

~----

Lower knife worn

----

Cause

out.

Upper and lower knives installed

Spring

materials

pressure on

to be trimmed.

lower

thread

improperly.

knife not

take-

-----

right for

--

I

i

~--+--

I Refer to

I

---

--

~~---

-

----

l{efcr

(J>age

Clean

smooth

Use needle

-----------------

-

to

"Adjustment"

7

11)

&

tension

operation.

or

"Threading.''

Remedy

---

"Thread

and

---

-------------

disc of foreign particles

thread

of

-

--

the right

(Page

size.

6)

tension.

to allow

Remedy

Re-sharpen.

------

Refer to "Installing and Maintenance of kni\·cs .

(l>age

13)

----------

to

Refer

(I>agc

"Installing

1:3)

and

:\laintenance of knives .

-----

"

..

..

----

---_

15

-

Page 18

G. Irregular stitches

---

-

\V

rong threading.

f-----·

Thre-ad

Thread

Thread

-

irregular

passage rough.

take-up and thread guide out of position.

Cause

---

---

in

thickness.

-·.

--

-----

-~---

--·----

~-----

---~--

Knives blunt.

----

Lower knife installed improperly.

H. Excessive wrinkles along stitches

Cause Remedy

Differential feed needs adjustment.

Pressure of presser foot not right.

Thread

tension too strong.

Feed dogs installed improperly.

-----

I

-

---r

--

-------

Refer to

Use

"Threading." (Page

thread of good quality.

Remedy

6)

\

Smoothly polish.

Refer to

to

Refer

13)

(Page

-

Refer to

13)

(Page

Refer to

Adjust

Adjust properly.

Refer to

foot: Installing

Height of feed

"Thread

tension." (page

---------~~------------

"Installing and Maintenance of knives."

---

"Installing and Maintenahce of knives."

----------···

"Adjusting differential feed." (Page

to

proper pressure.

----

-----

"Adjustment

and

on pressure of

removing

dogs." (Page

------~~-·-------

feed

8)

7)

-------

dogs: and

-----

.

------

-----

presser

10)

Knives blunt.

Cloth trimming width and stitch tongue of needle

plate out of proportion.

··----·

-----

Needle too thick.

I. Needle produce too large holes

Cause

---- - -

Needle point blunt.

Needle too

Needle

large for materials.

gets

hot.

Refer to

(Page

Adjust trimming width to needle plate

"Installing and Maintenance of knives."

13)

or

replace

needle plate.

Use needle proper for

--

-

-

--

Replace needle.

Use smaller size needle.

-.

-

.

~~--

materials

Remedy

--

and thread.

-

-----

Use needle cooler.

-

16-

Page 19

PARTS LIST for

MA4-B972

Xu.

1

~

INJI.illi

~.f.(iif

- 00367n.i;··l_-l-

-,J0-5660-

·7·~=1

~~i6~1_·3·_1:1

1109670·5·1-1

-!lli!l670·5·l6 I A·lllli

00967l·li-O:I

00961!0·!!-1:!

0096/!J.fi.J.I-

!11196!!1-:!·12

- -oo!IGH:!.II·l·l

!JO!l61!!!--1·12

__

OI_l~li'll-ll·l:l

~ol:m;o.I).J.I

OJ77:>1--1-J:I

-

·---.

------

-lll77!!24J.J

017!!:!:!':2-10 i

-

021770~l_.O:C

02:!710-1-0:I

~080-1-00

0:!50!!0-3-:16

0:!5.1..'>0-:1-32

021!0!!0-2 ..

~>Ti

0-18020-:H:!

041!0S0·3·47

WI!OI!0-:1--16

0-ll!lf.C:l-1·43

..:.0:..:7.:.:.:2600=:.·_:_0·_.:l0:.::__,

08100-1-CI·iO

-l00016-ll-o:l

-~---~---

lll0025-11-0I

)0011:12:().())

IIKIO:I5-IHI2

HMIIIXII-11-11:1

IIKII:I0-11·111

IIKII:Ii·ll-111

111111:17-0-11:!

HMII:Ii-11-o:\

c--IOOI71i-fi-OI

HXJIII5-II-u:!

~-~.

11-------~~·---~----~-·------

__!~!:'i·ll_-()(1

1002-1_:!_-0-02

100251-0-0 I

100260-0-01

100264-0-II:J'~i

100289-1).(11

-IU028!!-o-o:1

100366-0-01 I

~----·--

~:i68-o-o;C1

100469·0·!Y.! I A

100539·0-0:1 i

IOO.'i-41-0-01

1---~---~~~~~~1

100541-0-0:! D

Z-:!~~~

i

i

!'

(;.;,

(;-It!

-

-1

-r;

I!J--

11-til

A-:!11

-ll-111

---

-A~:!---~--·-

11-H:I

C-:!-1

E-ti7

;

C-lti

E--1:>

11-:!:1

11-lti

c.;;

C-:ll

c.;,,

D-111

J).;,:;

E-15

i'

E-:!6

i

F-:!ti

j

B-lill

A~!!x--;

E-1~·-

i

z

-:15

_:~

z~~·-

11-:-.n~~

:

1:1

~i

Z-:11

- Z-:!·1

-T-

F.:;:I~-j

1--::ii--;

F.:~~~--

---~·

___

B

~lll

____

·--

J

::.'Y

--·

~

B

--1!1

J).JIHi

A--111-·

11-5:>

1:-1-1

J-:.:~c

:\-1!!

F-1:!

11--1!1

A-:!X

11-fil

1;

-IH

E--1

:\-:!1

:\-:>:>

11-1

11-11

A-:i1

A-li:!

_A_:Ii9

I

A-7-1

_-

-'cA~~.~

..

;-~·

:\-71!

(~-,.-

~~~·

--

(~1--·

1-:!ll

ll-10~1

:\--1-1~-·

11-!15

Jl .

.j

ll-li4)

i

C-2

-j

C-2K I

B-~l

__

'i

B-1:1 I

E~-1--:

_--=:_

B_

..

1;

.;,r,

J).

51

I .

1·1-::.>o

·I

J-:

..

1·1

~

·

_

--

j

I

-~

.

I

-'

~---

_

-

~-

.

- llllBI:J.0-11_!__)

:\••.

)"arts.

IIK15-II-11-11:!

--Wit}-~T.II-n:l

IIHI:ii!l-11-0:!

~liilti-l·l·lln:l

ll)(l(j.J:i-11-n:l

i(lf:!ir•:ll:ll.l

Jn![.r,:!-o-:-111

IIJI:-,7:!-11-11)

- lll-lillti-11-UI

Jot7!1:-•-0-nl

~-Jii:!:;:JX-11-IMi

lll:!ti:!!I-O-n1

IIJ:!illi-11-n:l

-Jil2H-I:I-O·I~I

Jll~2J;,.II-Ill

-IU~.J-1!1-11-111

IU-15:!1·0·111

)0.!;->fi.l-0·01

111-16:il-ll-lll

-10:1!!:12-0-111

10-t!!:I:I-O-UI

10-100!!-11-0l

IU5U:I-I-O-Il:!

IIJ:-J117X-11-0I

lllfJ1179-IHII

ln:il:!:c.li.lt~l

wr,Jfi:l-ll-111

1~17:1-0-(j:l

1052:!11-11-01

_1()5:!:11~().(11

lll:i:!:l-1-ll-111

_l_ll:'~l'I~IJ.Ill

105:1-1:1-0-11)

-ioil.s-1:111!1

111:->K:!'j':IHII

HMi416!1-CI-O]

!INil:!!l-11-01

IIMiHI:!-0-0I

10711!1:1-0-0:!

_11_1'7~;11_:11-111

llli:!-1-1-0-111

H-17:!i:!-11-0:!

~~~~li:l:il_:ll-111

107-llli-11-0:!

1117-1!11·11-ll:!

IU'iii!I·0-01

10!!7:!1-11-0I

_10~1;!1_1:1·11·01

1119f>7-I-11-0I

10!11\:lli-O-UI

JICIHH

~IlCiltiJ~()":_I__,

IIOHII·0-11_1~-.

IIO.J:IIi-ll-11)~·

_lJII-Hiii_-11~111

l~IJii-11-11-ol

IJ0671-n-m

_J11J1i4il!·CI:Ill

1111671HI·IMI

_IIIJii72-U-IMI

11()()7:1-11-m_.

11116K6-Il-U

t107!1~11-ol

_1107111}-0-11_1_

lJn7:!1l-OOI

~l.oJ

llOii!!·n-111

-iioi93o.ol--:~~·<t!

• l

1108:!1Hl·OI

~d.

~-F-~·---

:\-5

I·"TTJ--;---

J)~il

=-~:E

ll-tl2

z

,,

1>-:.'6

11-:;~

Z-2:!

A~i!l

Z~!~-

(;.-;;;-

:\-111

,\II

E.;,;

:\-:IIi 1

11-27

11:?-;:,-

,_~~·

c

,\

:\·ti:l

11-12

E--111

C-10

C.;jj;--i

E-li

11-:!:!

I~

t;

1>-:.~1

li--:J6_:~

(i-5~,

~

c;

E·_;i_:!_

(;.!!()

z~--~.

z:-;;--·

~-~..;

C-:!:-.

F-:1!1

I

:-til

z

ll·lllll

JI-ll:!

F

11-:-•:!

:\-:!!!

11-:i!l

IJ-116

c;

Z

c;-:!7

c; :G

c:-1i:!

Z ti

z

:\·11!!

11-i.!l

.o:o:c

1>-!i

F.;l!i-~'

I

~-1).:!~--

l _ _::!_fi___,

Z

-A-·1·1-==-A·!IO .

-

B~i!1

11-:l!l

-

l~f

_!

_11~;~1=-

11-5_1

I

1_!-l:i~-

E ·10 I - l-10077

~r~_-;,:~~~

L

c_-:

C.l-1

~:~-3:.!

_ ____:l:!!___,

E·l

_c;-~

___<_!_ffi

~

(j<IO-

I

(j

Xo.

~emark

--

-

--~--

__

---

,

~--

---~--

~=-i~~---

__

!_

-10

..

,,,

~

i -

r-

..

u;

..

ltj

I

·r-~

!=

..

l-1

.;J!!

1

I

I

-:!-~~--·

-

.:_!;,

-~~;

--17

-5

·1!1

__

,

·:!i

_______

·I

___

j

r

)~

__

,

--_

1

_~ ! -~J::~;::i±l

15

=~

,

~---~--~~_Iii_:

__

L...=_ I.JOO!l:WnJ _

__

j .

_I---

-:17

T

-t---

_ ~-_____!

_

~-~-17-il-01

~

~~

__

--~

__

------

__

_--:-=--==~~oo;:;.u-i_!~.=J

-~-

---

~-~;~-01

~

-=-~~()();:;;,ojij_-

____

__

__

.~

-

Parts.

INDEX

l':u. I

~t·f.

!'arts.

:-\o.

~d.

IIM:!fll.l11

llll!!:l:!-i).()J

----

--

(j.(j()--

·-~-:!!!

--~-G-:16

Jf!7'

. -

jj:J;!

11·:!2 I

·-,).:!I;

Xn.

__

--·-

-·

--

~l

,

--11-:.'!1

I -15

IJ.\1

__

l:!:l:il IIIII

II

:!:15!1-11~0

-ll:!:llli-0-0l

___1_!·1~2!1-l-0111

~

~

___!·IIKI:JX.n-11:!

_l.JIMI:i:i-11-111 -:\-S:l

_11~-0-111

___!:_11Xl60-11-lll

I

-___!1-:!7

112-lli7-0-Il1

11:1-1:11-0·0:.!

1171.:!7-11-11:!

117-1:1711-111

117-llili-11-IHI

11/:il:-·

11-111

117:illiUII)

llililili-11-111

1:!1»;:!:1-11-0I

~IJI_NI:I:!-1101

UIH_I:!:l-11-01

I.JINI:Ifi-11-01

I.JIKI:I7·11-0:! A-1:1

1-I_Ofi:I!I-11-0I

1-UHI-11_1:11-0I

~I-11111-11-11-0I

1-IIIOJ:I_II~OI

I·IIMI-I:i-11-0)

1-11~-11-1111

~I-IOO;i-1-11·112

1-IIMI:->6-0-0I

1-IIXI:-.11-0-1!1

l-1006:1-ll-n1

1-ICI(I(j.j.().(IJ

1-IOO(ifi-0-111 I A-52

l-IIXJ67.o-1Jl- :

l-10072-11-111 ' A-115

1400!!:1-0-01

~-~·:1!1

I

__

1 A-:!7 I -

--~A-:!:1

·~~

l

-·A-:-;,_1_

·0·111

I ____A-Il(j__ --- -

r ,,.()] • . K-15 :

-

l-100!!!!-11-01_:

I-11!0!19-00_!_:

1-100!10-11111 • __

1-IOO!li-IIIXI

1·10094-001

___!.!(_IQJ!5:!!:!!l__

1·10096-0-111

~-B-Iil-l_

__!!Ji!l_

~~

_li:!

,

11·26

11-:!1

11-l:l - i

__

]

11<10

!

A-!1·1

1>-:1

11-ti:i

__

•

J .f;

c

·:!7

I~

-ti;

Z-:!ti

Z-11

E.;~;

E-.:-,;

11.:11

J

·:.!

K-:!

J-:.:;;:

Z

-IX

J-:.;,J

:\-:1:!

:\-:11

:\

-li

17

:\-IIi

:\

!=l

:\:_17_

:\-J:-,

:\-!1 __!11-'_llil-IHII

:\-::7

A-lii

:\-11:!

:\-i;

:\-iii

:\-10:!

B·5i'__.

~

--l~

A·1l:!

.

_:_

:~!:~~--

;

~.~-~~=-~~~~it~:~~~·::~~-~--:

~

n_.z_ _,_ _

11-17

ll~X

~-

B_-:1

__

1

f

----~Jl!I·O·OI_.

-r-

B ·26 I

1·11111!1-0-111

ucli:!il-II-01

J.I0121·0-0I

1·1111:!2·0·01

-NOI:!-I·O:III

1-1111:!~·-11-01

__

IIIIJ:!i-0-01

1-IOI:!X-0-01

1-1111:!!1-11-111

1-1111:10-ll-111

1-IIII:C:I-OOI

----.:ifil:ll-11-111

lllll::~.-ll.fll

1-lllt:lli-11-0I

1-IIIJ:I;-O.IHI

lllll:ll<-1101

_ _ lllll:l!I-11-0I

11111-111-11111

11111-11-0-01

1-101-1:!-0-111

1·1111-1:1-11-INI

_1-!111-l;,.o.IUJ

1·101-lfi-0-111

1-1111-IX-Il-111

____!_-11_111!1-0-11)

11111:-~1-0-INI

--1~111151-11-IHI

1-1111:i:!·O·III

1-llll:i:l-0-111 E

i-UWJii-11-111

~

1-1111~•7-11-111

1-IOI~.X-0-IMI

1-IOI:i!I-O-IMI

_l_l_l~lti0-0111

_ _j-llllli:i-11-01

____!_1_(117fi-0-11)

_

_j.JOI711-11-0I

_1-II~I,Z_!I-0-01

__

_____I.JIIJ_X0-0-0I

__1-_111111!.!-nol

110111:1-0-0)

~-

_l.J()_IH-1·0·01

___

1.-1111115-II:I_NI : -1-IO)Hii-fi-(HI ' U-2-1

1-111_1!!7_-11-1111

l-llll!!!!-0-11:1

1-llllii!_HI-111

~

______

---

1-IIIJ!MI-0-11)

l:t_!l_l!l_l_-O·IIl

1-101!13~11-!H

Wll

1-102112-11-nl

=~'();IJI-111

Un:!115-11-111

110:!117-n-111

_

_l:!_ni~JX.0-111

______

~10-0-01

1-1021 I ·0·111

.

l---

:

---~~~~

; -,;-:-i_____

•--A:~i

•

•

~-~~-:!.{_~

!J-1:11:11

I ~ :

I ll-:!1!

!

·-

j

._

l _

__

I

l

l~o·mark

--

--

----&~----

C-:1!1

C--1-1

--~c::G

~ . --~_:___

C--1!1--

·~·

C·:!l-~-·

-c~~:i

C-IS

C--lti

;~1

t.'-li-

C-li

E

IX

~~~

E-:!11

E-:!!1

::1

E·:!!J

E-:ll

E

!I

E-:!11

E-::1

J-:.;,

E-:i

E.£~~

EJ_J

E-ll

E-1::

E·H

E-:11;

E-::7

_1\.:i:_

-:!

E

-:l!l

E-ll

E

-:!X

E

-1:!

JLJ(j_

E--IX

IJTiicl~:

1>-!111

B--1-1

~

11-iH~-

__

I_H;(I

U-7

1>-li_~

A-.Jx_~

11-:16.:17

----.-;::r,

I>·K!l

))

-~--

~11-:1!}=~-~-

.1>:?.!

____

ll-:15

-D-32_.-::::_-:=-----

__l>_:±:i____j

D.:I6

1>-3-1

J>.

Hi

• l!l

_.

i

•.

-j

~

---

·-

~-~

--

--~

__

--

-17-

Page 20

DEX.

N

I

Parts.

l~ef.

Parts.

140212-0-01

140213-0-01

140214-0-01

140215-0-01

140216-0-01

~~~~~+-~~7---~--------4-~~~~~---~~---+----------~-------~-+--~~--~---------4·~~~~~~--~D-111

140217-0-01 D-46

~~~~~+-~~7---~--------4-~~~~-r--~~---+---------4~~~~~~--~~~--+---------4-~~~AT~---"B-68~-~7~2--~--------I

140226-0-01

140228-0-01

~~~~~+-~~----~--------4-~~~~--~---~~--~--------4-~~~~-!--~~---4-----------t-~~~~-t----··3~-:73~--~--------t

140229-0-01

140230-0-01

140231-0-00

140232-0-01

140233-0-01

t-;~=-;:-;~-t---;~:-::---~--------+-:-:=~=--

140235-0-00

140236-0-01

140237-0-01

140238-0-01

140239-0-01

140240-0-01

140241-0-01 E

140242-0-01 E-61

140243-0-01 E

140244-0-01

140246-0-01 E

140247·0·01 E

140260-0-01 F-2R

140261-o-ol

140262-0-00 F -:ll • t K-12

140263-0-01 F-2;>

140264-0-01 F

140266-0-01

1-10267-0-UI I F-1-1

1-10268-0-01

1-10269-o-:oi--K".!l--~------

1-I027o-o.m F-:1

• ' K-!l

140'.!71-0-01

140272·0·111

_ I.J027:Hl-OI

1-1027-1-0-0ll

140275-~:!_11_~--"~2

. " I K

~oiT-K-5

140277-0-01 ~ F.:c;

----uom:o.oJi

.

1-10281-0-01

•

----,-l40286-0-0I

14~ol-

140..?900-01 -,;.:;o

140291·0-01

~01

140293-0-01 <i-48

1-1029-J-0-01

~:1!_:01~

1-1029fj.O.()I

__!:!0298-0-0I_

I-10299-o-nt

1403000111

NO:ws.ont-

1-10:~1:1-o-oi-

1-10.11-l~o.llt.

~-~--r-

1-10.120·0·00

·140325-0-00 I

'140326-:o:ol

t-;;-:-;::='7'::-:-+---:~1_.;·1~0--4------

140327-0-01 B-18

Ref. No. Wemark

No.

D-16

D-19

D-18

D-44

D-43

D-58

D-4

D-5

E-21-25

E-22

E-24

E-25

E-66

E-68

E-63

E-6·1

E-62

E-60

-59

-58

1~

-50

-39

-5-1

i 140888-0-01 F

~~

F-27

-2-1

-~~;

1=-=-~.

K-10

F

K-11

F-1

j K-6

K~--~~-=t=-

G--10

1-~<~1--~-

<i

'---.,.,.,

c;

G-Io

c;.:,_'l

G-51

(i-50

(i·-16 I

A ·50

=-_<i.:!1__j__

<;-r,r,

--I'f=42

--~~~---

E

11-1-1

I-:-27

B-10

11-4

B-6

1 B-23 _!E_:3·I_=!·O·_(ll_[- Z-15

______

.

3~

~

11

r-----_---"i-1099.

___

-_

1

-6

__

-

-7

-19

..

12

-3

~-==

.-----

I 1-1221f;.n.m J

I

-----

------

;------

·---------l-12281-0-111-

_____

1 l-1231Hnou

- 1

------

---

Parts.

No.

140727-.0-01

140736-0-01

140738-0-01

140739-0-01

1-10756-0-01

140758-0-01 A-91

140759-0-00

14076-1-0·01

140768-0-01

1407il-O-OI

140772-0-01

140774-0-00 C-5.1

140774·0-01

140775-0-01

140778-0-01

140779-0-01

140780-0-01

140781-0-01

1407112-0-01

140792-0-01 I z ·23 I

140798-0-01 Z

1409Jo.o.oJ 1

141l912:~~1_j

14091:!-0-01

1409211-0-0fl

:~~~~:~:~:-~~~~\--9

140!J<Jl-O-III_j

:._'_-~_~-~~-.-

14099:1-o-ot

1·1()_997-o-ol

1-IIIR:l-0-111

~--~~1111!11·0-U(

.

1-121:?1'>:.~01C

1-12126-0-UI

142127-0-nl ,

1-121112-0-111

·--

1-12Hlll·ll-:«ll

1-122iii-n-<

___

11

1422:!9·0-lll

1422-11-ll-111

---~:c.o.nt

___

1-12'.!-1-l}).'lll_;

l-122-15-ll-111

-------u-22-li-u•H

-142219-i)(u ' __

t·,:!2:ln-nn• · J.:\c--Jo

--

--

-i'.f2251-ll·lll

142'.!1j(l-ll:01

__

1-12'.!112·1).(11

1-12211-l-0-!ll

1-122!12·1101

1-12:1J I 0-01

14_2:liQ:nOJ

l-12:121·0-lll

Tlz.12:i~Oot

• 1 J -20 i

• i

1-1~_:.'9-0I~l---1---:-1-4___

14ZI:JU-0-01

1·12:!:!-1-001142:!-l·n.l):'ol-i A·7!l . - --j:J.illl-1-0-01-

.....!_:!::!370-0·0I_J

1-12371-0-0I

No.

A-101.102

K-1

Z-31

Z-32

(i-6.'>

z ·17

H-3

11-23

n-:n

D-41

0-30

I

--.,....,,.,....--+--------

I>-56

I-

·---::-::·-=o----~--------~f--:l:-:4-==329=7-"'o--=-o"'1--

H-19

H-28

I

11-6

11-7

11-20

11-11

11·24

11-16

-21

-11

-1_3

J-13

A-19

D-25 i

F-5

_r

F

-7-

i

F-x

___

:,

-~~1-:

..

' ,\-4:1

-i

IJ.12 i - -

'f-_t_2

B-3.1

~_1J\

__

·!.

\H

·~-~-,J···ll.~.

1-

-~~-

,--J~·-i

jy1

J

.;

•

--J---~~------

-5

i

__

Li_-_--r-- -t:l-&fixt.O.III

_!-_1-1

-;

__

L~

• Jl.!JI; :

-(~---

-·-1--1-1

(

:j!J-

-~~i-

.

,\.7~

I-~C___.J1=

l-Ui

I :22 1

~--~~

K-111

1-211

-~~--

J ·15

I J

-16

Remark

----------t--:-14:-:;3""3:."">4:-:-o::-.o·t

I 143326-0-01 F

I 143374·0·01 A-101 I

I 143375-0-01

l__

!

__

-i~__

·r---- 14:!537-0-00 A-29 I

i -

_____

)

1

~------·

1:1

.

==~-:....=_

·-

-~:

= -.

I l-13i7-I·O·Ill .

1 -

-~-~-

1 .

_ _

___

~~-

-

__

.

___

,_

.

~--

)- --_- fi:Ji()f,.().f'll

-

--.

___

.~_-----

Parts.

No. Ref. No.

143179-0-01

143182-0-01 B-41

143280·0·01 J

143282-0-01

143284-0-01

1-13286·0·0

143287-0-01

143292-0·02

--1~~-:!:3

-~-----·-----;A

143"l96-0·01

1-13312-o-oo

14332:3-0-0l F

143325·0·01 F

1434-12-0-01

143524-0-00 t B

---

~~