Page 1

Brother Inkjet DCP/MFC

SERVICE MANUAL

MODELS: DCP-J4110DW

MFC-J2310/J2510/J4310DW

MFC-J4410DW/J4510DW

MFC-J4610DW/J4710DW

July 2012

SM-FAX137

8CAR(4)

Read this manual thoroughly before maintenance work.

Keep this manual in a convenient place for quick and easy reference at all times.

Confidential

Page 2

Trademarks

Windows Vista is either a registered trademark or trademark of Microsoft Corporation in the United

States and/or other countries.

Microsoft, Windows, Windows Server, Outlook and Internet Explorer are either registered trademarks

or trademarks of Microsoft Corporation in the United States and/or other countries.

Apple, Macintosh, Mac OS and Safari are trademarks of Apple Inc., registered in the U.S. and other

countries.

Adobe, Illustrator and Photoshop are either registered trademarks or trademarks of Adobe Systems

Incorporated in the United States and/or other countries.

Nuance, the Nuance logo, PaperPort and ScanSoft are trademarks or registered trademarks of Nuance

Communications, Inc. or its affiliates in the United States and/or other countries.

PowerPC is a registered trademark of IBM in the United States and/or other countries.

Memory Stick PRO Duo, Memory Stick Duo, MagicGate, Memory Stick Micro and M2 are trademarks of

Sony Corporation.

AOSS is a trademark of Buffalo Inc.

WPA, WPA2, Wi-Fi Protected Access, Wi-Fi Protected Setup and Wi-Fi Direct are marks of the Wi-Fi

Alliance.

Wi-Fi and Wi-Fi Alliance are registered marks of the Wi-Fi Alliance.

AMD is a trademark of Advanced Micro Devices, Inc.

FaceFilter Studio is a trademark of Reallusion, Inc.

UNIX is a registered trademark of The Open Group in the United States and other countries.

Linux is the registered trademark of Linus Torvalds in the U.S. and other countries.

Corel and CorelDraw are trademarks or registered trademarks of Corel Corporation and/or its

subsidiaries in Canada, the United States and/or other countries.

Each company whose software title is mentioned in this manual has a Software License Agreement

specific to its proprietary programs.

Any trade names and product names of companies appearing on Brother products, related

documents and any other materials are all trademarks or registered trademarks of those

respective companies.

Open Source Licensing Remarks

This product includes open-source software.

To see the open source licensing remarks, please go to the manual download selection on your

model's home page of Brother Solutions Center at http://solutions.brother.com/.

Confidential

Page 3

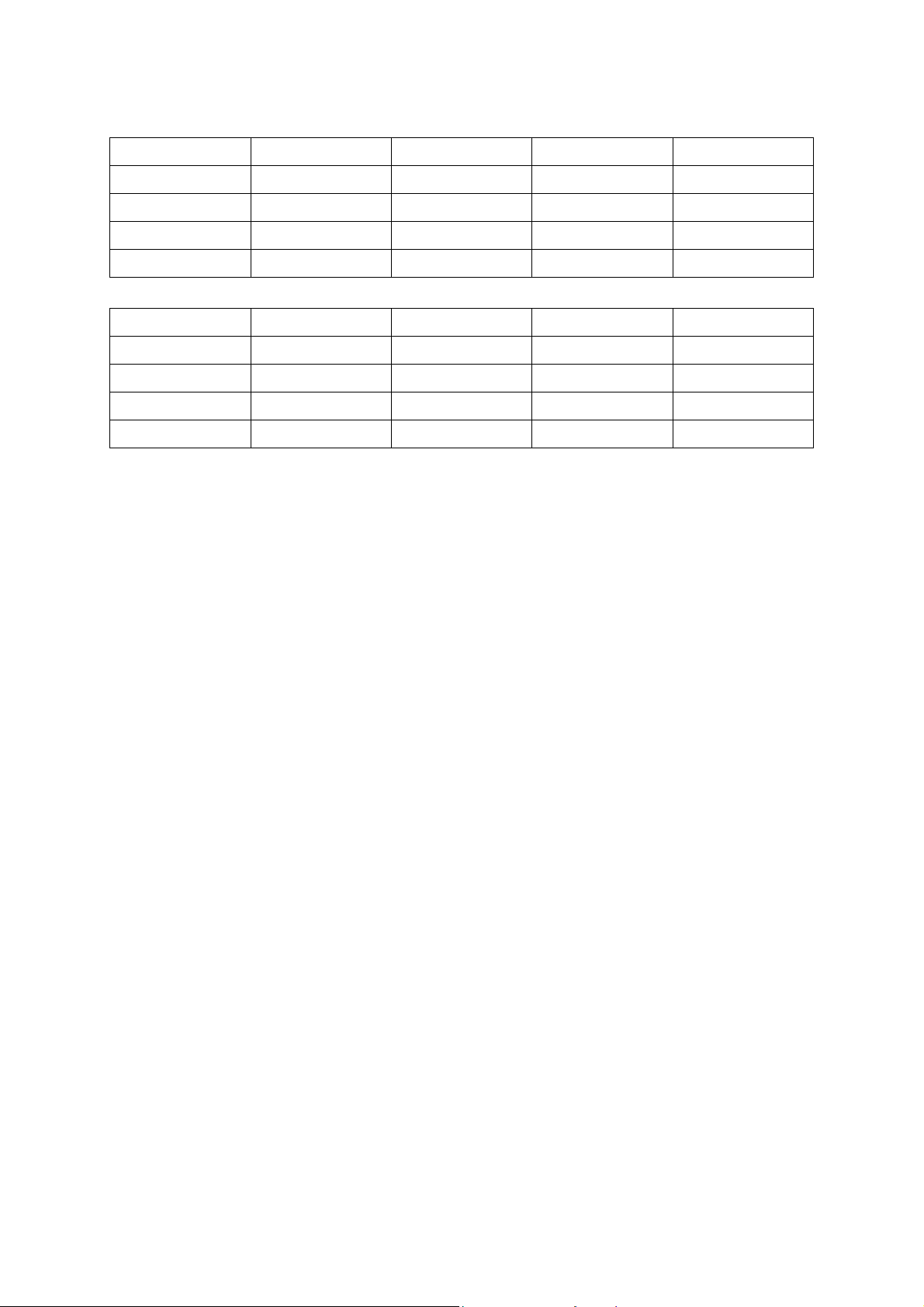

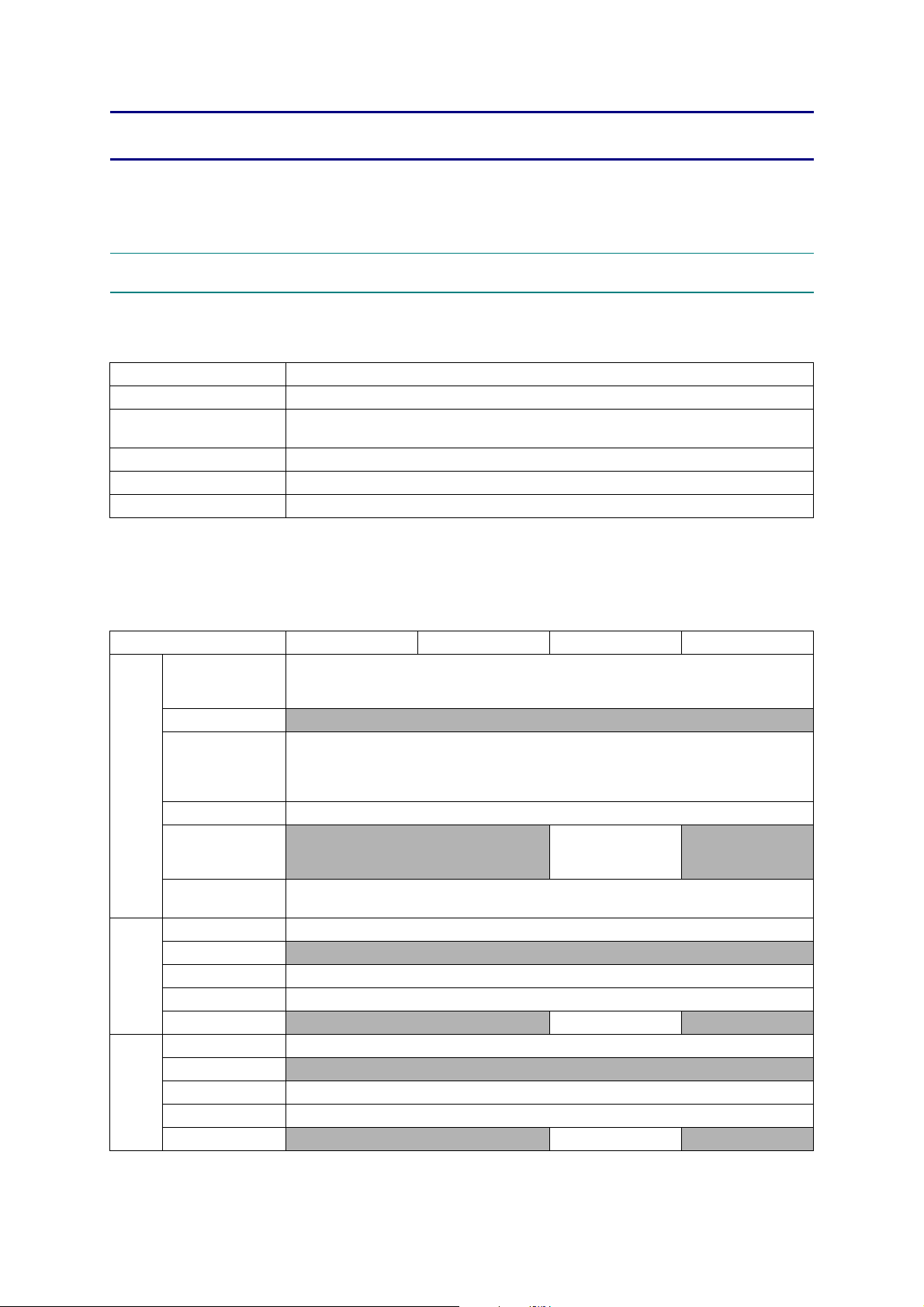

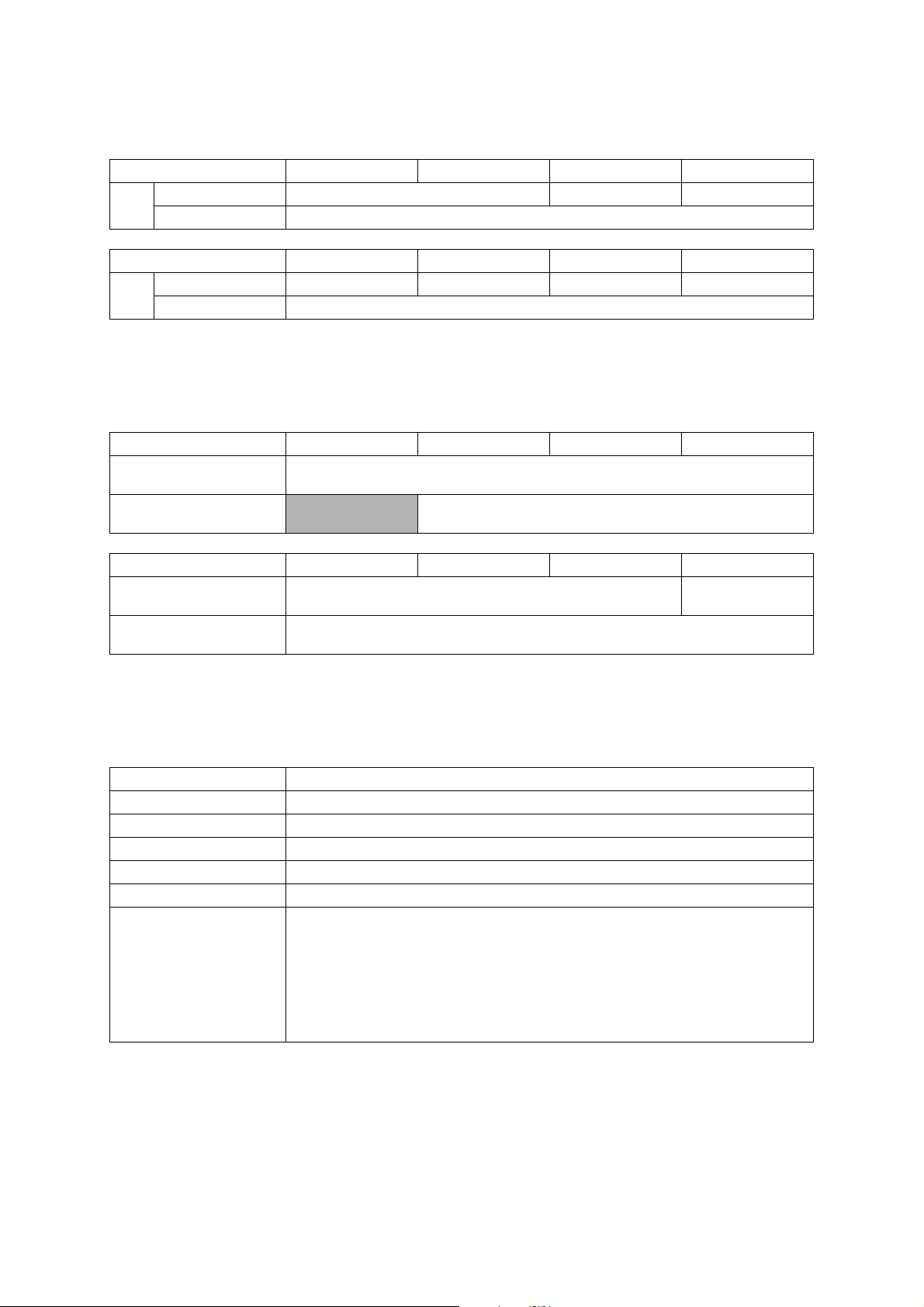

The table below shows the functional comparison between the models covered by this manual.

DCP-J4110DW MFC-J2310 MFC-J2510 MFC-J4310DW

LCD 1.8 inch 1.8 inch 3.7 inch 1.8 inch

Lower Tray --- --- --- --ADF --- --- ---

Duplex scan --- --- --- ---

MFC-J4410DW MFC-J4510DW MFC-J4610DW MFC-J4710DW

LCD 1.8 inch 3.7 inch 1.8 inch 3.7 inch

Lower Tray --- --- A4 and Letter A3 and LGR

ADF

Duplex scan --- --- ---

Confidential

Page 4

TABLE OF CONTENTS

REGULATION ........................................................................................................................ ix

SAFETY INFORMATION ..................................................................................................... xiv

CHAPTER 1 SPECIFICATIONS ........................................................................................ 1-1

1 GENERAL ..................................................................................................................... 1-1

1.1 General .................................................................................................................1-1

1.2 Media Specification ..............................................................................................1-1

1.3 Paper Handling .....................................................................................................1-2

1.4 LCD Panel ............................................................................................................ 1-3

1.5 Memory .................................................................................................................1-3

1.6 Interface ................................................................................................................1-3

1.7 Others ...................................................................................................................1-4

2 FAX ................................................................................................................................1-5

3 PRINTER .......................................................................................................................1-5

4 COPY ............................................................................................................................. 1-6

5 SCANNER .....................................................................................................................1-7

6 SOFTWARE ..................................................................................................................1-7

7 NETWORK .................................................................................................................... 1-8

7.1 Network ................................................................................................................1-8

7.2 Wired ....................................................................................................................1-8

7.3 Wireless ................................................................................................................1-8

8 SUPPLIES/OPTIONS ....................................................................................................1-9

9 SERVICE INFORMATION ............................................................................................. 1-9

10 PAPER ........................................................................................................................1-10

10.1 Paper ..................................................................................................................1-10

10.2 Printable Area .....................................................................................................1-13

CHAPTER 2 TROUBLESHOOTING ..................................................................................2-1

1 INTRODUCTION ...........................................................................................................2-1

1.1 Precautions ...........................................................................................................2-1

1.2 Initial Check ..........................................................................................................2-2

2 OVERVIEW ................................................................................................................... 2-4

2.1 Cross-section Drawings ........................................................................................2-4

i

Confidential

Page 5

2.1.1 Document scanning ..................................................................................... 2-4

2.1.2 Printer part ................................................................................................... 2-5

2.2 Document Feeding Path/Recording Paper Feeding Path .................................... 2-6

2.2.1 Document Feeding Path .............................................................................. 2-6

2.2.2 Recording Paper Feeding Path .................................................................... 2-6

2.3 Parts Names and Functions ................................................................................. 2-7

2.4 Block Diagram ...................................................................................................... 2-8

2.5 Components .........................................................................................................2-9

3 ERROR INDICATION .................................................................................................. 2-10

3.1 Error Code ..........................................................................................................2-10

3.2 Error Messages ................................................................................................. 2-15

3.3 Communications Error .......................................................................................2-17

4 TROUBLESHOOTING ................................................................................................2-21

4.1 Error Cause and Solutions ................................................................................. 2-21

4.2 Recording Paper Feeding Problems .................................................................. 2-58

4.2.1 Paper is not fed from paper tray .................................................................2-58

4.2.2 Paper is not fed from manual feed slot ...................................................... 2-60

4.2.3 Two or more sheets of paper fed at a time ................................................ 2-60

4.2.4 Paper feeding at an angle .......................................................................... 2-60

4.2.5 Recording paper jam ..................................................................................2-61

4.2.6 Prints only single side of the paper when duplex-printing .......................... 2-64

4.3 Print-image Problems .........................................................................................2-65

4.3.1 Defective images ........................................................................................2-65

4.3.2 Print-image problems .................................................................................2-66

4.4 Software-related Problems ................................................................................. 2-76

4.4.1 Cannot print data ........................................................................................2-76

4.5 Network Problems ..............................................................................................2-77

4.5.1 Cannot make a print through network connection ...................................... 2-77

4.6 Control Panel Problems ......................................................................................2-78

4.6.1 No display on LCD ..................................................................................... 2-78

4.6.2 No display on LED ..................................................................................... 2-78

4.6.3 The control panel does not work ................................................................ 2-78

4.6.4 Touch panel inoperative ............................................................................. 2-78

4.7 Document Feeding Problems .............................................................................2-79

4.7.1 Document can not be fed ........................................................................... 2-79

4.7.2 Document double feeding .......................................................................... 2-79

4.7.3 Document jam ............................................................................................2-80

ii

Confidential

Page 6

4.7.4 Wrinkles on documents ..............................................................................2-82

4.7.5 Document size not correctly detected ........................................................ 2-82

4.8 Scanned-image Problems .................................................................................. 2-83

4.8.1 Defective images .......................................................................................2-83

4.8.2 Troubleshooting from image defect ............................................................2-83

4.9 Fax Problems .....................................................................................................2-88

4.9.1 No faxes can be sent ................................................................................. 2-88

4.9.2 No faxes can be received ...........................................................................2-88

4.9.3 A communications error occurs ..................................................................2-88

4.10 Other Problems .................................................................................................. 2-89

4.10.1 The machine cannot be powered on .......................................................... 2-89

4.10.2 Memory card/PictBridge does not function (no response) ......................... 2-89

4.10.3 Data of memory card/PictBridge does not read ......................................... 2-89

4.10.4 Internal memory errors ............................................................................... 2-90

4.10.5 Security Function Lock related problems ................................................... 2-90

CHAPTER 3 DISASSEMBLY AND ASSEMBLY .............................................................. 3-1

1 PRECAUTIONS BEFORE PROCEEDING ...................................................................3-1

2 PACKING ......................................................................................................................3-3

3 SCREW CATALOGUE .................................................................................................. 3-4

4 SCREW TORQUE LIST ................................................................................................3-5

5 LUBRICATION ..............................................................................................................3-6

6 OVERVIEW OF GEARS .............................................................................................. 3-11

7 ROUTING OF HARNESSES AND INK SUPPLY TUBES .......................................... 3-12

8 DISASSEMBLY FLOW ............................................................................................... 3-20

9 DISASSEMBLY PROCEDURE ................................................................................... 3-22

9.1 Preparation .........................................................................................................3-22

9.2 Scanner Cover Damper and Scanner Cover Support ........................................ 3-27

9.3 ADF Unit .............................................................................................................3-29

9.3.1 ADF Hinge R ..............................................................................................3-34

9.3.2 ADF Document Support .............................................................................3-35

9.3.3 ADF Cover ASSY ....................................................................................... 3-36

9.3.4 ADF Back Cover, ADF Side Covers R and L, and ADF Front Cover ......... 3-37

9.3.5 ADF Separation Pad Holder ASSY ............................................................ 3-39

9.3.6 Eject Films ..................................................................................................3-41

iii

Confidential

Page 7

9.3.7 Document Separation Roller ASSY ........................................................... 3-42

9.3.8 Document Detection Sensor PCB and Document Scanning Position

Sensor PCB ...............................................................................................3-44

9.3.9 ADF Hinge L ...............................................................................................3-45

9.3.10 ADF Motor ..................................................................................................3-47

9.3.11 Second Side CIS Unit (Duplex scanning models only) .............................. 3-51

9.3.12 Second Side CIS Flat Cable (Duplex scanning models only) .................... 3-54

9.4 Manual Feed Slot Cover ASSY .......................................................................... 3-56

9.5 Document Scanner Top Cover ........................................................................... 3-57

9.5.1 First Side CIS Unit ......................................................................................3-58

9.5.2 First Side CIS Flat Cable ............................................................................3-60

9.6 Upper Cover ....................................................................................................... 3-62

9.7 Ink Cartridge Cover ............................................................................................ 3-64

9.8 Front Cover .........................................................................................................3-64

9.9 Lower Side Covers R and L ................................................................................3-65

9.10 Jam Clear Cover .................................................................................................3-66

9.11 Bank ASSY .........................................................................................................3-67

9.12 Media Module Cover .......................................................................................... 3-68

9.13 Inner Media Module Cover ................................................................................. 3-68

9.14 Ink Absorber Box ................................................................................................3-69

9.15 Control Panel ASSY ........................................................................................... 3-71

9.16 Wireless LAN PCB ASSY ...................................................................................3-73

9.17 Main PCB ASSY .................................................................................................3-74

9.18 Sensor Relay PCB ASSY ................................................................................... 3-76

9.19 MJ PCB ASSY ....................................................................................................3-77

9.20 Head/Carriage Unit and CR Timing Belt ............................................................. 3-78

9.21 Lower Tray Unit (LT models only) ...................................................................... 3-88

9.22 Power Supply PCB ASSY .................................................................................. 3-93

9.23 Speaker ..............................................................................................................3-96

9.24 Ink Refill ASSY ................................................................................................... 3-97

9.25 CR Encoder Strip ..............................................................................................3-100

9.26 Encoder Strip Guard Film ................................................................................. 3-101

9.27 Ink Cartridge Cover Sensor ASSY ................................................................... 3-102

9.28 Flushing Base ...................................................................................................3-103

9.29 Carriage Motor ASSY ....................................................................................... 3-106

9.30 Switchback Roller .............................................................................................3-107

9.31 Flushing Box .....................................................................................................3-109

9.32 PF Encoder Disk and PF Encoder Sensor PCB ASSY .................................... 3-110

iv

Confidential

Page 8

9.33 Paper Feed Motor .............................................................................................3-112

9.34 Paper Feed Roller ............................................................................................ 3-115

9.35 Paper Ejection Roller ........................................................................................3-116

9.36 Platen ...............................................................................................................3-118

9.37 Maintenance Unit ..............................................................................................3-119

9.38 Registration Sensor PCB ASSY .......................................................................3-120

9.39 Base Pad on Paper Tray ASSY ........................................................................ 3-124

9.40 T1 Paper Pull-in Roller ..................................................................................... 3-125

CHAPTER 4 ADJUSTMENTS AND UPDATING OF SETTINGS, REQUIRED AFTER

PARTS REPLACEMENT ..............................................................................4-1

1 IF YOU REPLACE THE MAIN PCB .............................................................................. 4-1

1.1 Customize destinations (Maintenance mode 74) ................................................. 4-3

1.2 Set the CIS type (Maintenance mode 59) ............................................................ 4-3

1.3 Install the firmware (Maintenance mode 28) ........................................................ 4-3

1.4 Initialize the EEPROM parameters (Maintenance mode 01) ................................4-5

1.5 Restore the head property data (Maintenance mode 68) ..................................... 4-5

1.6 Set the serial number (Maintenance mode 80) .................................................... 4-5

1.7 Restore machine information (Maintenance mode 46) .........................................4-8

1.8 Adjust the touch panel (Maintenance mode 78) ................................................... 4-8

1.9 Update the head property data (Maintenance mode 68) ...................................... 4-8

1.10 Acquire white level data (Maintenance mode 55) .................................................4-8

1.11 Adjustment of vertical print lines/software correction for inclination/corrugation/

ruled lines (Maintenance mode 65) ...................................................................... 4-8

1.12 Update the paper feeding correction values (Maintenance mode 58) .................. 4-8

1.13 Adjust margins in borderless printing (Maintenance mode 66) ............................ 4-8

1.14 Reset purge and flushing counts .......................................................................... 4-8

1.15 Write head calibration data (Maintenance mode 02) ............................................ 4-9

1.16 Check scanning and printing ................................................................................ 4-9

2 IF YOU REPLACE THE HEAD/CARRIAGE UNIT ...................................................... 4-12

2.1 Update the head property data (Maintenance mode 68) .................................... 4-13

2.2 Perform ink supply purge (Maintenance mode 76) .............................................4-16

2.3 Check head nozzles (Maintenance mode 09) .................................................... 4-16

2.4 Adjust head inclination ........................................................................................4-16

2.5 Adjustment of vertical print lines/software correction for inclination/corrugation/

ruled lines (Maintenance mode 65) .................................................................... 4-18

2.6 Update paper feeding correction values (Maintenance mode 58) ...................... 4-18

2.7 Adjust margins in borderless printing (Maintenance mode 66) .......................... 4-18

2.8 Write head calibration data (Maintenance mode 02) .......................................... 4-18

v

Confidential

Page 9

2.9 Check scanning and printing .............................................................................. 4-18

2.10 Obtain machine information at the user site (Instruction to the end user) .......... 4-19

3 IF YOU REPLACE THE DOCUMENT SCANNER UNIT, ADF UNIT OR CIS UNIT ... 4-20

3.1 Set the CIS type (Maintenance mode 59) (Not required after replacement of

the ADF unit on simplex scanning models) ........................................................ 4-21

3.2 Acquire white level data (Maintenance mode 55) (Not required after

replacement of the ADF unit on simplex scanning models) ............................... 4-21

3.3 Check scanning .................................................................................................. 4-21

4 IF YOU REPLACE THE CONTROL PANEL ASSY .................................................... 4-22

4.1 Adjust the touch panel (Maintenance mode 78) ................................................. 4-22

4.2 Check LCD operation (Maintenance mode 12) .................................................. 4-22

4.3 Check the operation of the control panel keys (Maintenance mode 13) ............ 4-22

5 IF YOU REPLACE THE INK ABSORBER BOX OR FLUSHING BOX ...................... 4-23

5.1 Reset purge and flushing counts ........................................................................ 4-23

6 IF YOU REPLACE THE PAPER FEEDING RELATED PARTS and

MAINTENANCE UNIT ................................................................................................. 4-24

6.1 Check head nozzles (Maintenance mode 09) .................................................... 4-25

6.2 Adjustment of vertical print lines/software correction for inclination/corrugation/

ruled lines (Maintenance mode 65) .................................................................... 4-25

6.3 Update paper feeding correction values (Maintenance mode 58) ...................... 4-25

6.4 Adjust margins in borderless printing (Maintenance mode 66) .......................... 4-25

6.5 Check printing .....................................................................................................4-25

CHAPTER 5 SERVICE FUNCTIONS ................................................................................ 5-1

1 MAINTENANCE MODE ................................................................................................5-1

1.1 Entry to the Maintenance Mode ............................................................................5-1

1.1.1 How to Enter the Maintenance Mode for Service Personnel ....................... 5-1

1.1.2 How to Enter the End User-accessible Maintenance Mode ......................... 5-3

1.2 List of Maintenance-mode Functions ....................................................................5-4

1.3 Detailed Description of Maintenance-mode Functions ......................................... 5-5

1.3.1 EEPROM Parameter Initialization (Maintenance mode 01, 91) ................... 5-5

1.3.2 Creating of Head Calibration Data and Writing it into Flash ROM

(Maintenance mode 02) ...............................................................................5-6

1.3.3 Printout of Scanning Compensation White/Black Level Data

(Maintenance mode 05) .............................................................................5-11

1.3.4 ADF Performance Test (Maintenance mode 08) ....................................... 5-14

1.3.5 Printout of Test Pattern (Maintenance mode 09) ....................................... 5-14

1.3.6 Worker Switch Setting and Printout (Maintenance modes 10 and 11) ....... 5-16

vi

Confidential

Page 10

1.3.7 Operational Check of LCD (Maintenance mode 12) .................................. 5-19

1.3.8 Operational Check of Keys on Control Panel (Maintenance mode 13) ...... 5-20

1.3.9 EEPROM Dump and Log Information Saving (Maintenance mode 17) ..... 5-21

1.3.10 Updating of Firmware Using an External Memory

(Maintenance mode 28) .............................................................................5-22

1.3.11 Sensor Operational Check (Maintenance mode 32) .................................. 5-23

1.3.12 Printout of Dial Log (Maintenance mode 37) .............................................. 5-25

1.3.13 Backup of Machine Information (Maintenance mode 46) ........................... 5-26

1.3.14 Setting of Country/Language (Maintenance mode 52) ..............................5-28

1.3.15 Transfer of Received FAX Data and/or Equipment's Log

(Maintenance mode 53) .............................................................................. 5-29

1.3.16 Fine Adjustment of Scanning Position (Maintenance mode 54) ................5-31

1.3.17 Acquisition of White/Black Level Data and CIS Scanner Area Setting

(Maintenance mode 55) .............................................................................5-32

1.3.18 Cartridge IC Communication Check (Maintenance mode 57) .................... 5-33

1.3.19 Updating of Paper Feeding Correction Values (Maintenance mode 58) .... 5-34

1.3.20 Checking of CIS Travel and Specifying of CIS Type

(Maintenance mode 59) .............................................................................5-40

1.3.21 Printout of PRN/JPEG Files in Memory Card (Maintenance mode 61) ...... 5-41

1.3.22 Move of the Head/Carriage Unit to the Adjustment Position

(Maintenance mode 63) .............................................................................5-42

1.3.23 Adjustment of Vertical Print Lines/Software Correction for Inclination/

Corrugation/Ruled Lines (Maintenance mode 65) ..................................... 5-43

1.3.24 Margin Adjustment in Borderless Printing (Maintenance mode 66) ........... 5-47

1.3.25 Updating of Head Property Data and Backup/Restoration of Head

Calibration Data (Maintenance mode 68) .................................................. 5-49

1.3.26 Traveling Speed Check of Head/Carriage Unit (Maintenance mode 69) ... 5-51

1.3.27 Customizing Destinations (Maintenance mode 74) .................................... 5-52

1.3.28 Move of the Head/Carriage Unit to the Center (Maintenance mode 75) .... 5-55

1.3.29 Purge Operation (Maintenance mode 76) .................................................. 5-56

1.3.30 Print of the Maintenance Information (Maintenance mode 77) .................. 5-58

1.3.31 Adjustment of Touch Panel (Maintenance mode 78) ................................. 5-60

1.3.32 Display of the Equipment's Log (Maintenance mode 80) ........................... 5-61

1.3.33 Equipment Error Code Indication (Maintenance mode 82) ........................ 5-64

1.3.34 Output of Transmission Log to the Telephone Line

(Maintenance mode 87) .............................................................................5-64

1.3.35 Assurance Mode Switch Setting (Maintenance mode 88) .........................5-65

2 OTHER SERVICE FUNCTIONS .................................................................................5-74

2.1 Cancellation of the Secure function lock ............................................................ 5-74

vii

Confidential

Page 11

2.2 Displaying the Firmware Version ........................................................................5-75

2.3 Moving the Head/Carriage Unit .......................................................................... 5-75

2.4 Retrieving the Equipment Log Information ......................................................... 5-76

CHAPTER 6 CIRCUIT DIAGRAMS AND WIRING DIAGRAMS ....................................... 6-1

CHAPTER 7 PERIODICAL MAINTENANCE .................................................................... 7-1

1 PERIODICAL REPLACEMENT PARTS ....................................................................... 7-1

APPENDIX 1 SERIAL NUMBERING SYSTEM .........................................................App. 1-1

APPENDIX 2 DELETION OF USER SETTING INFORMATION ............................... App. 2-1

A2.1 Deleting User Setting Info from the machine ......................................... App. 2-1

APPENDIX 3 INSTALLING THE MAINTENANCE PRINTER DRIVER .................... App. 3-1

viii

Confidential

Page 12

REGULATION

Standard telephone and FCC notices (MFC models only)

These notices are in effect on models sold and used in the United States only.

When

programming emergency numbers or making test calls to emergency numbers:

• Remain on the line and briefly explain to the dispatcher the reason for the call before hanging

up.

• Perform these activities in the off-peak hours, such as early morning or late evening.

This equipment complies with Part 68 of the FCC rules and the requirements adopted by the

ACTA. On the backside of this equipment is a label that contains, among other information, a

product identifier in the format US: AAAEQ##TXXXX. If requested, this number must be

provided to the telephone company.

You may safely connect this equipment to the telephone line by means of a standard modular

jack, USOC RJ11C.

A plug and jack used to connect this equipment to the premises wiring and telephone network

must comply with the applicable FCC Part 68 rules and requirements adopted by the ACTA. A

compliant telephone cord and modular plug is provided with this product. It is designed to be

connected to a compatible modular jack that is also compliant. See installation instructions for

details.

The REN is used to determine the number of devices that may be connected to a telephone line.

Excessive RENs on a telephone line may result in the devices not ringing in response to an

incoming call. In most but not all areas, the sum of RENs should not exceed five (5.0). To be

certain of the number of devices that may be connected to a line, as determined by the total

RENs, contact the local telephone company. For products approved after July 23, 2001, the

REN for this product is part of the product identifier that has the format

US:AAAEQ##TXXXX. The digits represented by ## are the REN without a decimal point

(e.g.,06 is a REN of 0.6). For earlier products, the REN is separately shown on the label.

If this equipment causes harm to the telephone network, the telephone company will notify you

in advance that temporary discontinuance of service may be required. But if advance notice isn't

practical , the telephone company will notify the customer as soon as possible. Also, you will be

advised of your right to file a complaint with the FCC if you believe it is necessary.

ix

Confidential

Page 13

Federal Communications Commission (FCC) Declaration of Conformity (USA

only)

Product Name: MFC-J4310DW/J4410DW/J4510DW/J4610DW/J4710DW

x

Confidential

Page 14

Industry Canada Compliance Statement (Canada only)

This Class B digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe B est conforme à la norme NMB-003 du Canada.

Operation is subject to the following two conditions:

(1) this device may not cause interference, and (2) this device must accept any interference,

including interference that may cause undesired operation of this device.

L'utilisation de ce dispositif est autorisée seulement aux conditions suivantes:

(1) il ne doit pas produire de brouillage et (2) l'utilisateur du dispositif doit être prêt à accepter

tout brouillage radioélectrique reçu, même si ce brouillage est susceptible de compromettre le

fonctionnement du dispositif.

EQUIPMENT ATTACHMENT LIMITATIONS (Canada only) (MFC models only)

NOTICE

This product meets the applicable Industry Canada technical specifications.

Le présent materiel est conforme aux specifications techniques applicables d'Industrie Canada.

NOTICE

The Ringer Equivalence Number is an indication of the maximum number of devices allowed to

be connected to a telephone interface. The termination on an interface may consist of any

combination of devices subject only to the requirement that the sum of the RENs of all the

devices does not exceed five.

L'indice d'équivalence de la sonnerie (IES) sert à indiquer le nombre maximal de terminaux qui

peuvent être raccordés à une interface téléphonique. La terminaison d'une interface peut

consister en une combinaison quelconque de dispositifs, à la seule condition que la somme

d'indices d'équivalence de la sonnerie de tous les dispositifs n'exc

For use in the USA or Canada only

These machines are made for use in the USA and Canada only. We cannot recommend using

them overseas because it may violate the Telecommunications Regulations (MFC models only)

of that country and the power requirements of your machine may not be compatible with the

power available in foreign countries. Using USA or Canada models overseas is at your own risk

and may void your warranty.

LAN connection

ède pas 5.

xi

Confidential

Page 15

Declaration of Conformity (Europe only)

AT BE CY CZ DK EE

FI FR DE HU IE IT

LV LT LU

MT

NL PL

P T SK S I E S SE

GB

NO CH BG RO GR LI

IS TR

We, Brother Industries Ltd, of 15-1 Naeshiro-cho, Mizuho-ku, Nagoya 467-8561 Japan,

Declare that this product is in compliance with the essential requirements of Directives 1999/5/

EC and 2009/125/EC.

The Declaration of Conformity (DoC) is on our Website.

Please go to http://solutions.brother.com/

-> choose your region (eg. Europe)

-> choose your country

-> choose your model

-> choose "Manuals"

-> choose Declaration of Conformity (Select Language when required.)

CE marking for devices with Wireless LAN

This product supports Wireless LAN.

xii

Confidential

Page 16

Radio interference

This product complies with EN55022 (CISPR Publication 22)/Class B. When connecting the

machine to a computer, ensure that you use a USB cable which does not exceed 2 metres in

length.

Recycling information in accordance with the WEEE (2002/96/EC) Directive.

Productmark

EuropeanUniononly

The product is marked with one of the above recycling symbols. It indicates that at the end of

the life of the product, you should dispose of it separately at an appropriate collection point and

not place it in the normal domestic waste stream.

International ENERGY STAR® Qualification Statement

The purpose of the International ENERGY STAR® Program is to promote the development and

popularization of energy-efficient equipment.

As an ENERGY STAR

the ENERGY STAR

®

Partner, Brother Industries, Ltd. has determined that this product meets

®

specifications for energy efficiency.

xiii

Confidential

Page 17

SAFETY INFORMATION

WARNINGWARNING

CAUTIONCAUTION

WARNING indicates a potentially hazardous situation which, if not avoided, could result in

death or serious injuries.

CAUTION

or moderate injuries.

indicates a potentially hazardous situation which, if not avoided, may result in minor

IMPORTANT

IMPORTANT

damage to property or loss of product functionality.

Follow all warnings and instructions marked on the machine.

indicate a potentially hazardous situation which, if not avoided, may result in

Notes tell you how you should respond to a situation that may arise or give tips about

how the operation works with other features.

Electrical Hazard icons alert you to possible electrical shock.

Improper Setup icons alert you to devices and operations that are not compatible with

the machine.

Fire Hazard icons alert you to the possibility of fire.

xiv

Confidential

Page 18

To use the machine safely

! WARNING

ELECTRICAL HAZARDS

Failure to follow the warnings

addition, you could create an electrical short, which may create the risk

There are high-voltage electrodes inside the machine . Before you access the inside

machine, including for routine maintenance such

the power cord from the AC power outlet, as well as any telephone (RJ-11) (MFC models only)

or

Ethernet (RJ-45) (Network models only) cables from the machine.

DO NOT push objects

as they may touch dangerous voltage points

DO NOT handle the plug with wet hands.

of

in

this section may create the risk

as

cleaning, make sure you have unplugged

any kind into this machine through slots

or

short out parts.

of

an electrical shock . In

of

a fire.

or

openings

in

the cabinet,

of

the

Always make sure the plug is fully inserted .

if

DO NOT continue using the machine

Instead, unplug the machine from the power outlet.

it has been dropped

xv

or

the cabinet has been damaged.

Confidential

Page 19

If

water, other liquids, or metal objects get inside the machine, immediately unplug the machine

from the AC power outlet.

to

DO NOT connect the machine

of

power source you have, contact a qualified electrician.

Power Cord Safety:

• DO NOT pull on the middle

to separate from the plug. Doing this might cause

• DO NOT allow anything to rest

• DO NOT place this machine where people can walk on the cord.

• DO NOT place this machine

become worn

• DO NOT use the machine or handle the cord if the cord has become worn or frayed.

unplugging your machine, DO NOT touch the damaged/frayed part.

•Brother

DO NOT use this product during an electrical storm .

or

frayed.

strongly recommends that you DO NOT use any type

a DC power source

of

the

AC

power cord; pulling on the middle may cause the cord

on

the power cord.

in

a position where the cord is stretched

or

inverter.

an

electrical shock.

If

you are not sure what kind

or

strained, as it may

of

extension cord.

If

(MFC models only)

Never touch telephone wires

been unplugged at the wall jack. Never install telephone wiring during a lightning storm. Never

install a telephone wall jack

FIRE HAZARDS

Failure to follow the warnings

DO NOT use flammable substances, any type

alcohol

of fire or electrical shock.

or

ammonia to clean the inside or outside

or

terminals that are

in

a wet location.

in

this section may create the risk

not

of

spray

of

the machine. Doing this may cause a risk

insulated unless the telephone line has

of

a fire.

or

an organic solvent/liquid that contains

&

DO NOT use this machine in the vicinity

For users with pacemakers

This machine generates a weak magnetic field.

your pacemakers when near the machine, move away from the machine and consult a doctor

immediately.

of

combustible dust.

If

you feel anything wrong with the operation

of

xvi

Confidential

Page 20

A CAUTION

DO NOT sit or stand on the machine or use it for any purpose beyond its intended purpose.

If

the machine becomes hot, releases smoke,

unplug the machine from the AC power outlet.

Wait until pages have exited the machine before picking them up. Doing this may cause injury

to your fingers by trapping them in a roller.

(MFC-J4710DW)

If

the lower tray has been expanded to hold large paper such as Ledger size paper, place the

machine on a flat surface that can support both the machine and the lower tray. When the lower

tray is expanded, it will protrude from the machine. Therefore, if someone hits the tray , the

machine could fall and cause injury .

or

generates any strong smells, immediately

xvii

Confidential

Page 21

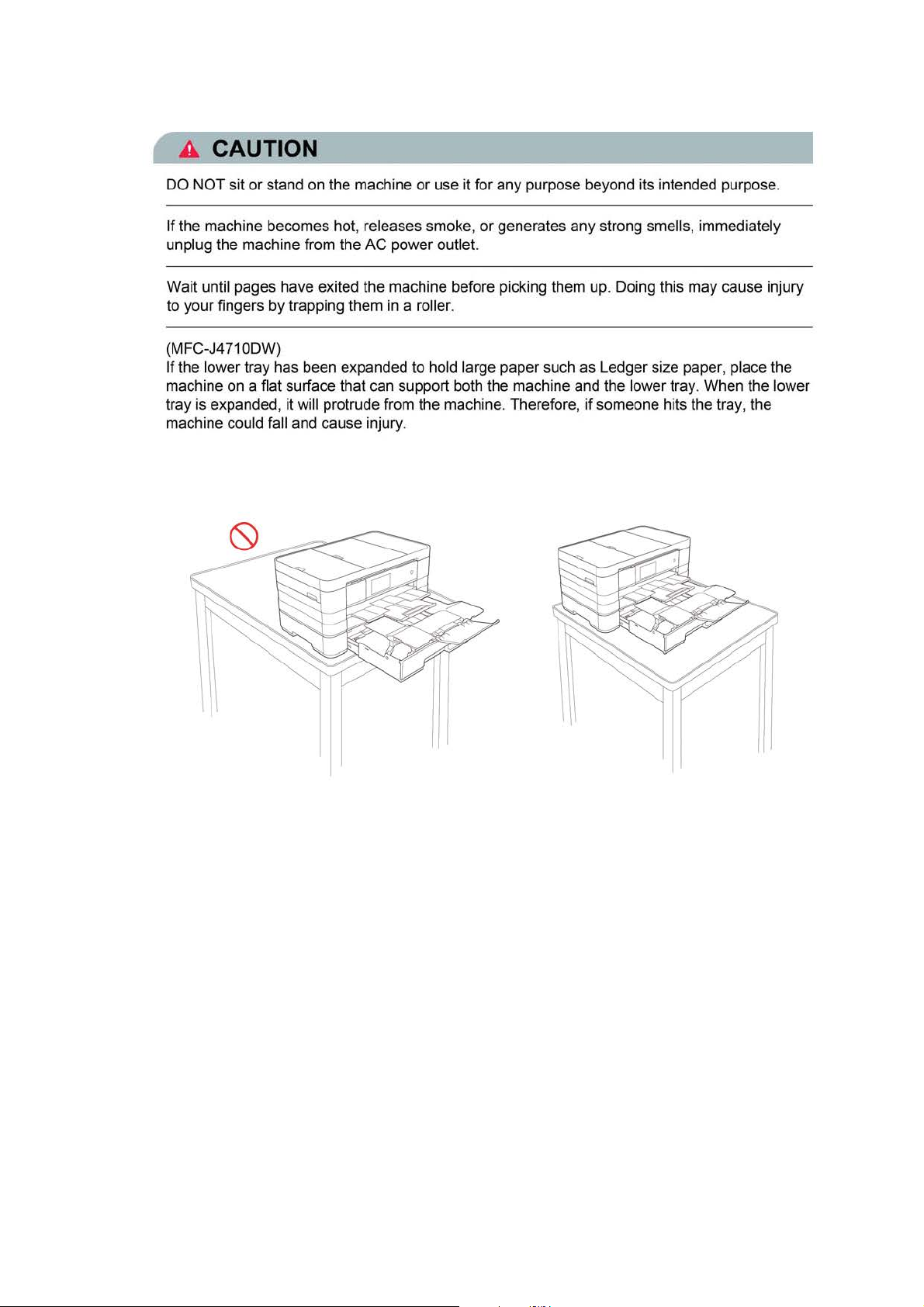

DO NOT put your hands on the edge of the machine. Doing this may cause injury to your

fingers by pinching them.

xviii

Confidential

Page 22

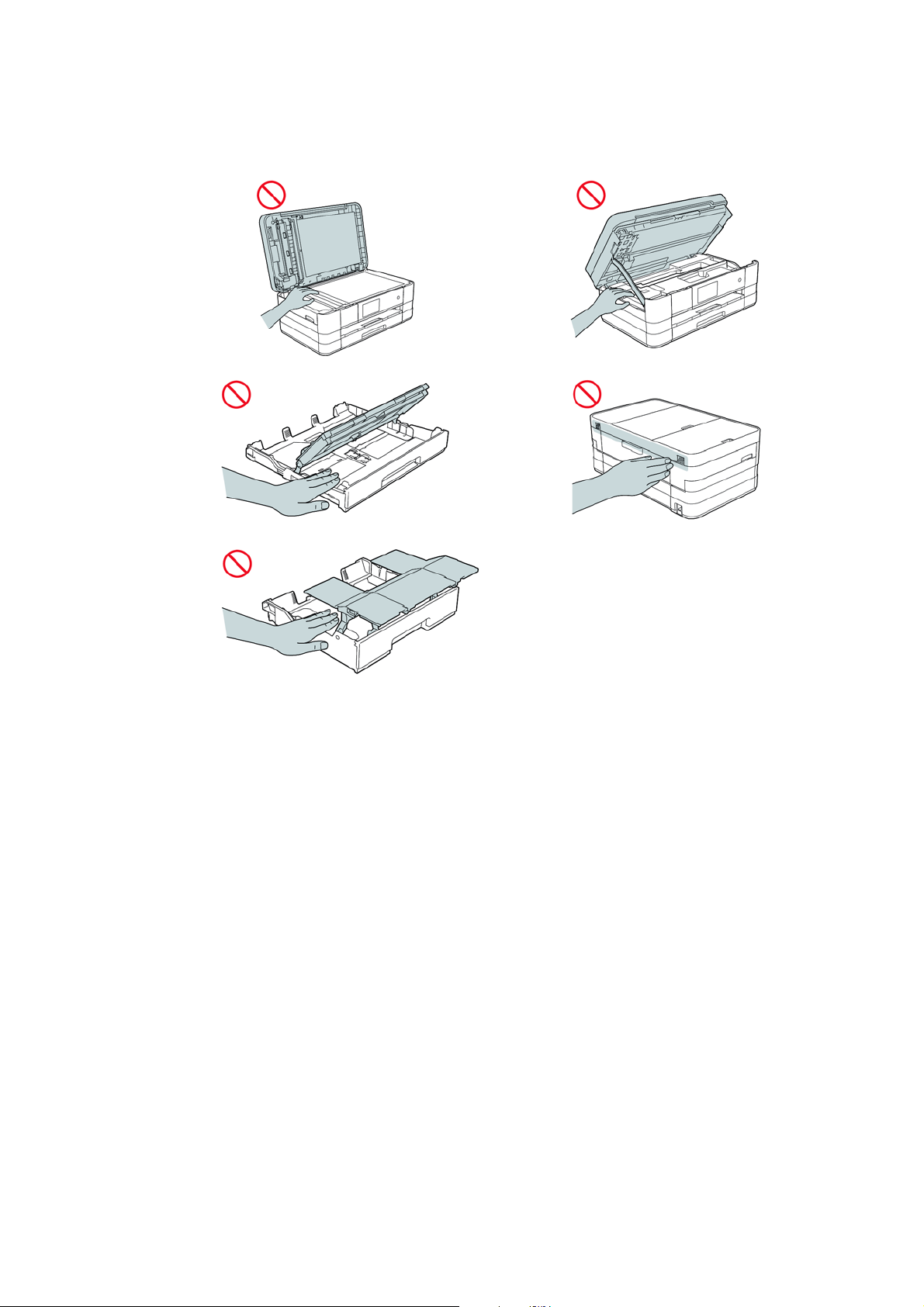

(MFC-J4710DW)

When changing the lower tray size from the Ledger, A3 or legal size to the original size, be

careful not to pinch your fingers

in

the gaps or slots in the bottom

of

the tray. It may cause

injury to you.

DO NOT touch the area shaded in the illustration. Doi

cutting them on the edge

of

the machine.

ng

this may cause injury to your fingers

by

xix

Confidential

Page 23

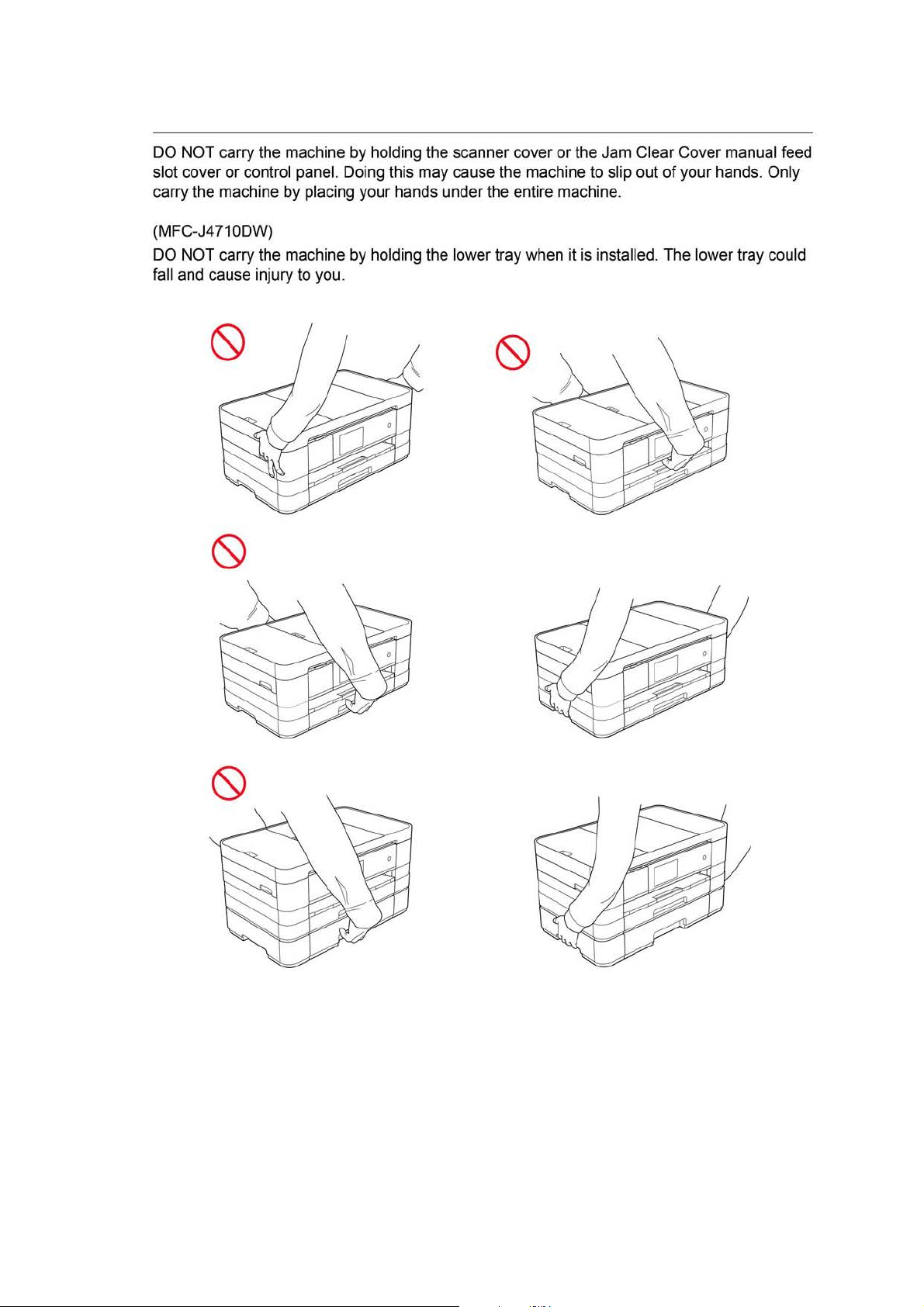

DO

NOT

carry

the

slot cover or control

carry the machine

(MFC-J4710DW)

DO

NOT

carry

the

fall

and

cause

injury to

machine

panel. Doi

by

placi

machine

you

by

holding

ng

ng

your hands under

by

holding

this

the

may

the

.

scanner cover or

cause

the

machine

the

entire machine.

lower tray

when

the

Jam

to

slip out of your

it

is

installed.

Clear Cover

The

lower tray

manual

hands.

feed

Only

could

xx

Confidential

Page 24

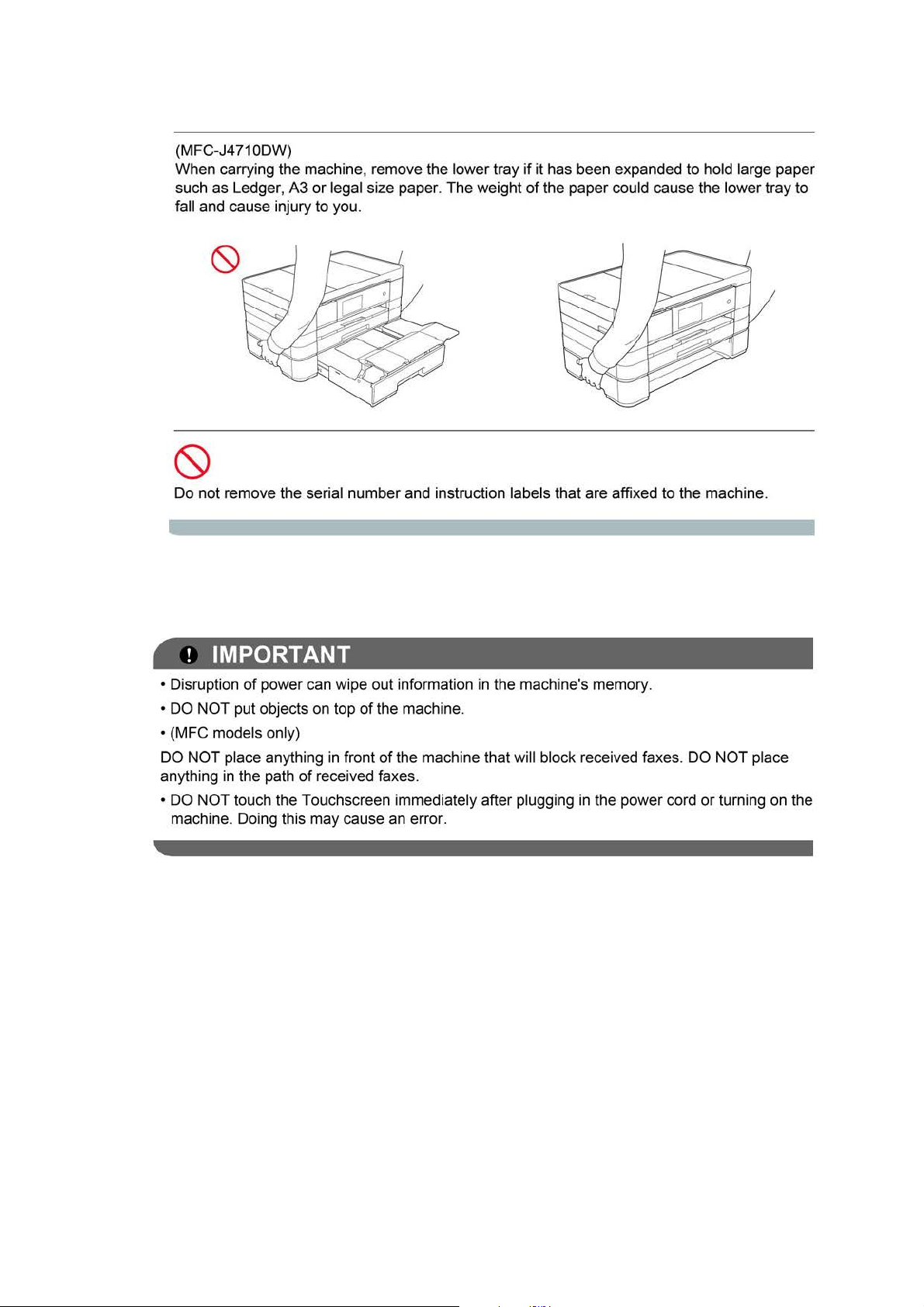

(MFC-J4710DW)

When carrying the machine, remove the lower tray if it has been expanded to hold large paper

such as Ledger, A3

fall and cause injury to you.

Do not remove the serial number and instruction labels that are affixed to the machine.

or

legal size paper. The weight

of

the paper could cause the lower tray to

! IMPORTANT

•D

isruption

• DO NOT put objects on top

• (MFC mode ls only)

DO

NOT place anything in front

anything in the path

•DO

machine. Doing this may cause an error.

of

power can wipe out information in the machine's memory.

of

the machine.

of

the machine that wi

of

received faxes.

NOT touch the Touchscreen immediately after plugging in the power cord

ll

block received faxes. DO

NOT

place

or

turning on the

xxi

Confidential

Page 25

CHAPTER 1 SPECIFICATIONS

This chapter lists the specifications of each model, which enables you to make a comparison of

different models.

1GENERAL

1.1 General

Model ALL models

Print Head BH13 BK/C/M/Y: 420/420/420/420 nozzles

Minimum Droplet Size

Scanning Method CIS

CPU Speed 288 MHz

Backup Clock Yes (Up to 1 hour)

BK: 3 pl

CMY: 1.5 pl

1.2 Media Specification

Model DCP-J4110DW MFC-J2310 MFC-J2510 MFC-J4310DW

Standard Tray

Lower Tray

Media

Sizes

Media

Weights

Media

Types

*1

*2

Manual Feed Slot

Duplex Print <PC Print>A4/LTR/EXE/A5,<Copy>LTR/A4/A5/EXE *

ADF (width/length)

Scanner Glass

(width/length)

Standard Tray 64-220 g/m

Lower Tray N/A

Manual Feed Slot 64-220 g/m

Duplex Print 64-105 g/m

ADF N/A 64-90 g/m

Standard Tray Plain, Inkjet, Glossy (cast/resin), Transparency

Lower Tray

Manual Feed Slot Plain, Inkjet, Glossy (cast/resin), Transparency

Duplex Print Plain

ADF

MFC-J2510 For CHN

MFC-J2510 For CHN, HK, TW and KOR

<Landscape>A4, LTR, EXE, B5

*1

Indexcard (127 x 203 mm/5 x 8"), Photo-L (89 x 127 mm/3.5 x 5"),

Photo-2L (127 x 178 mm/5 x 7"), Com-10, DL Envelope, Monarch

<Landscape>A4, LTR, EXE, B5

<Portrait>A3, LGR, LGL, A5, A6, Photo (102 x 152 mm/4 x 6"),

Indexcard (127 x 203 mm/5 x 8"), Photo-L (89 x 127 mm/3.5 x 5"),

Photo-2L (127 x 178 mm/5 x 7"), C5, Com-10, DL Envelope, Monarch

N/A

Up to 215.9/297 mm (up to 8.5/11.7")

N/A Plain N/A

<Portrait>A5, A6, Photo (102 x 152 mm/4 x 6"),

N/A

*2

*2

, B4

148/148 mm to 215.9/

355.6 mm

(5.8/5.8" to 8.5/14.0")

2

(17-58 lb. )

2

(17-58 lb. )

2

(17-28 lb. )

2

(17-24 lb. ) N/A

N/A

N/A

1-1

Confidential

Page 26

Standard Tray

Lower Tray

Media

Sizes

Manual Feed Slot

Duplex Print <PC Print>A4/LTR/EXE/A5,<Copy>LTR/A4/A5/EXE *

ADF(width/length) 148/148 mm to 215.9/355.6 mm (5.8/5.8" to 8.5/14.0")

Scanner Glass

(width/length)

Standard Tray 64-220 g/m

Lower Tray N/A 64-105 g/m

Media

Weights

Manual Feed Slot 64-220 g/m

Duplex Print 64-105 g/m

ADF 64-90 g/m

Standard Tray Plain, Inkjet, Glossy (cast/resin), Transparency

Lower Tray

Media

Types

Manual Feed Slot Plain, Inkjet, Glossy (cast/resin), Transparency

Duplex Print Plain

ADF Plain

* For US only

Model MFC-J4410DW MFC-J4510DW MFC-J4610DW MFC-J4710DW

<Landscape>A4, LTR, EXE<Portrait>A5, A6, Photo (102 x 152 mm/4 x 6"),

Indexcard (127 x 203 mm/5 x 8"), Photo-L (89 x 127 mm/3.5 x 5"),

Photo-2L (127 x 178 mm/5 x 7"), Com-10, DL Envelope, Monarch

N/A A4, LTR

A3, LGR, A4, LTR,

LGL

<Landscape>A4, LTR, EXE,

<Portrait>A3, LGR, LGL, A5, A6, Photo (102 x 152 mm/4 x 6"),

Indexcard (127 x 203 mm/5 x 8"), Photo-L (89 x 127 mm/3.5 x 5"),

Photo-2L (127 x 178 mm/5 x 7"), C5, Com-10, DL Envelope, Monarch

Up to 215.9/297 mm (up to 8.5/11.7")

2

(17-58 lb. )

2

(17-28 lb. )

2

(17-58 lb. )

2

(17-28 lb. )

2

(17-24 lb. )

N/A Plain

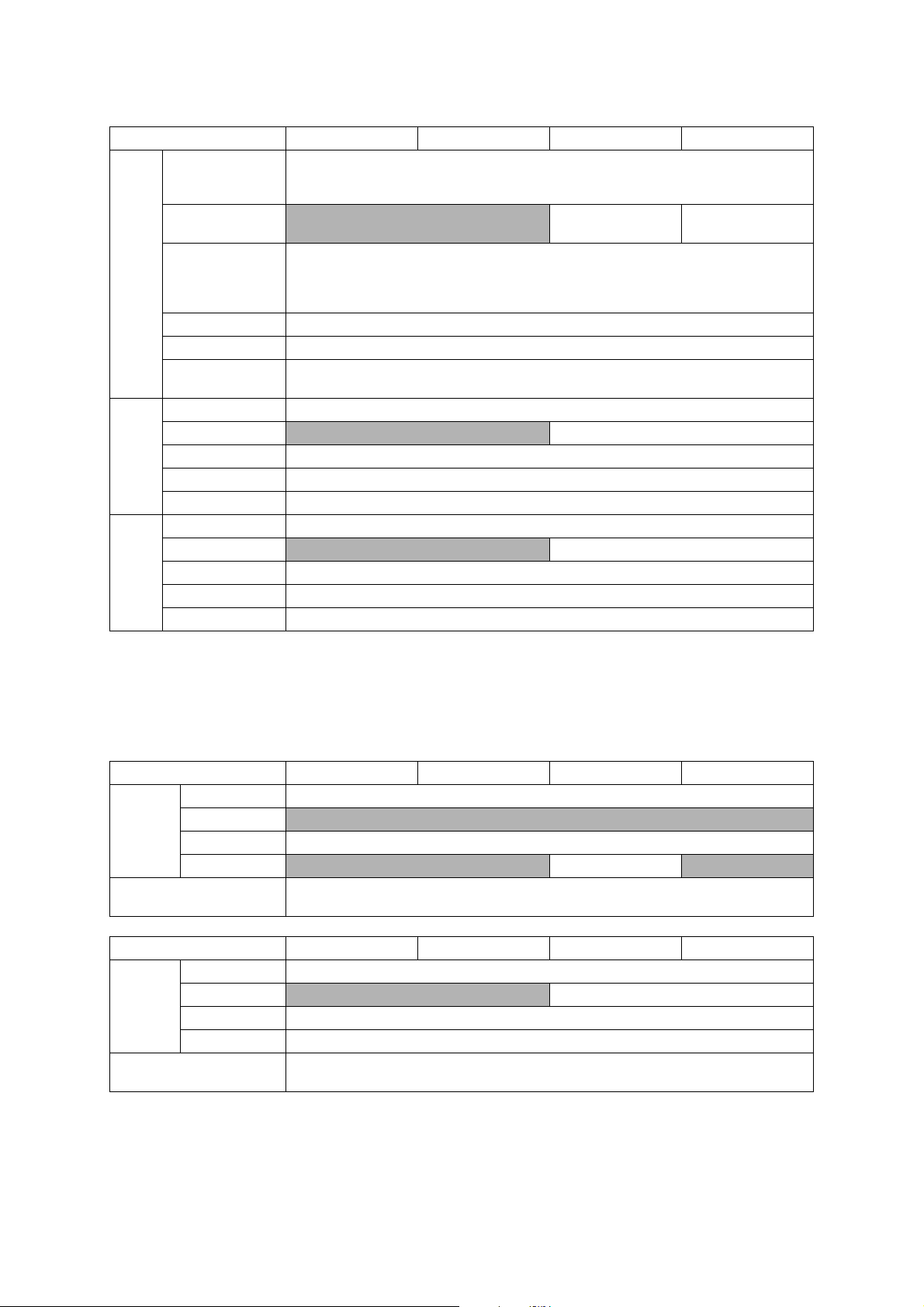

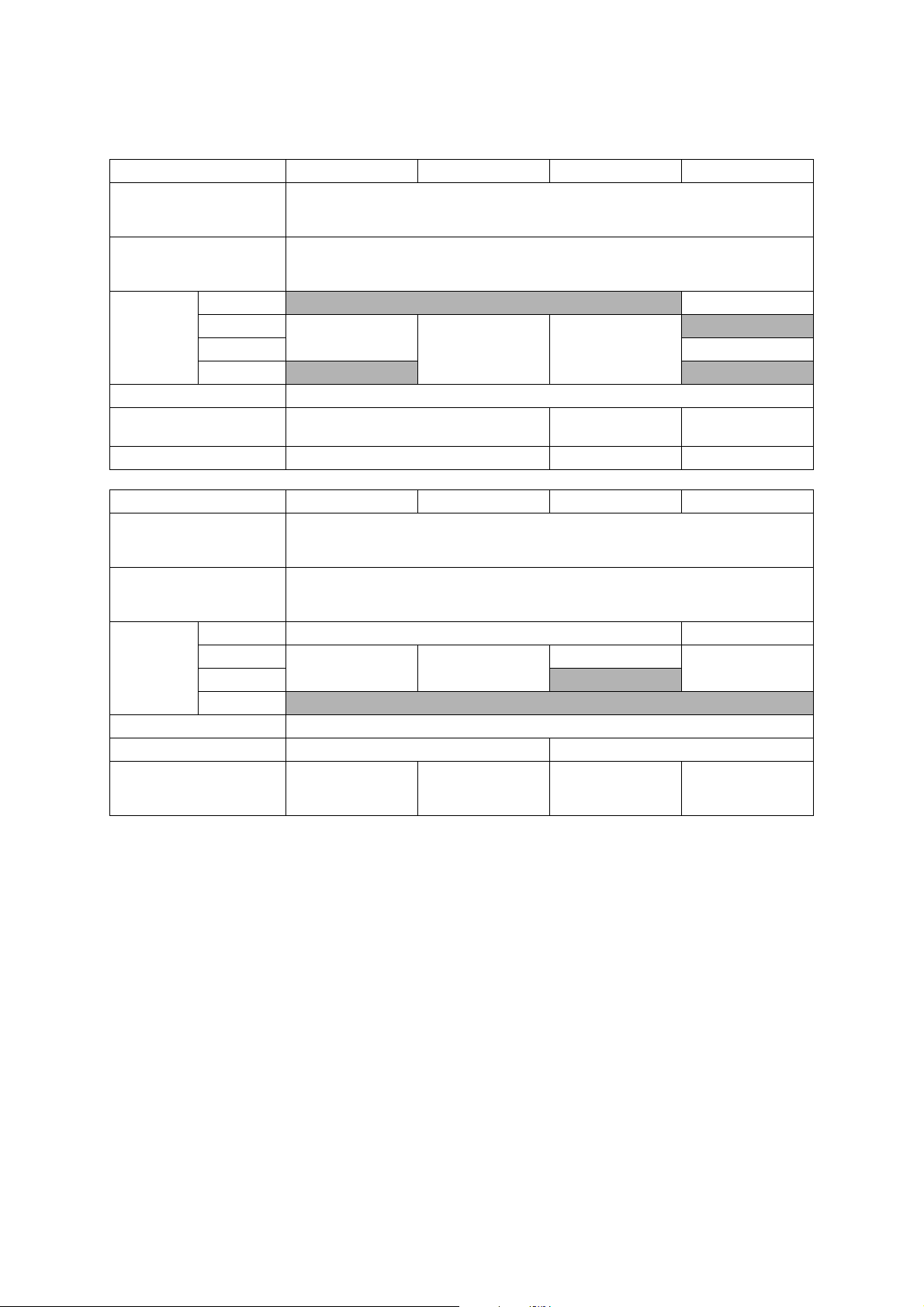

1.3 Paper Handling

Model DCP-J4110DW MFC-J2310 MFC-J2510 MFC-J4310DW

Standard Tray 150 (80 g/m

Paper Input

(sheets)

Output Paper Capacity

(sheets)

Paper Input

(sheets)

Output Paper Capacity

(sheets)

Lower Tray N/A

Manual Feed Slot 1

ADF

Model MFC-J4410DW MFC-J4510DW MFC-J4610DW MFC-J4710DW

Standard Tray 150 (80 g/m

Lower Tray N/A 250 (80 g/m

Manual Feed Slot 1

ADF 20 (80 g/m

2

)

N/A 20 (80 g/m2) N/A

50 (80 g/m

50 (80 g/m

2

)

2

)

2

)

2

)

2

)

1-2

Confidential

Page 27

1.4 LCD Panel

Model DCP-J4110DW MFC-J2310 MFC-J2510 MFC-J4310DW

Type & Size 1.8 inch TFT 3.7 inch TFT 1.8 inch TFT

LCD

Touch-Panel Yes

Model MFC-J4410DW MFC-J4510DW MFC-J4610DW MFC-J4710DW

Type & Size 1.8 inch TFT 3.7 inch TFT 1.8 inch TFT 3.7 inch TFT

LCD

Touch-Panel Yes

1.5 Memory

Model DCP-J4110DW MFC-J2310 MFC-J2510 MFC-J4310DW

Memory Capacity

(physical: Mbytes)

Memory Backup

(with Flash memory)

Model MFC-J4410DW MFC-J4510DW MFC-J4610DW MFC-J4710DW

Memory Capacity

(physical: Mbytes)

Memory Backup

(with Flash memory)

128 MB

N/A Yes

128 MB 256 MB

Ye s

1.6 Interface

Model All models

Host Interface Hi-Speed USB 2.0

LAN Ye s

Wireless LAN Yes

PictBridge Yes

USB Memory up to 32 GB

Memory Stick Duo: 16 MB-128 MB

Memory Stick Pro Duo: 256 MB-32 GB (MagicGate: YES if not use MG function)

Memory Stick Micro: 256 MB-32 GB (MagicGate: YES if not use MG function)

Acceptable Media Cards

(Type & Size)/Media Card

SD Memory Card: 16 MB-2 GB (miniSD, miroSD with Adapter)

SDHC Memory Card: 4 GB-32 GB (miniSDHC, miroSDHC with Adapter)

SDXC Memory Card: 48 GB-128 GB

MultiMedia Card: 32 MB-2 GB

MultiMedia Card plus: 128 MB-4 GB

MultiMedia Card mobile: 64 MB-1 GB (with Adapter)

1-3

Confidential

Page 28

1.7 Others

Model DCP-J4110DW MFC-J2310 MFC-J2510 MFC-J4310DW

Operating Environment

Temperature

(Best Print Quality)

Operating Environment

Humidity

(Best Print Quality)

Power

Consumption

(Operating/

Standby/Sleep

mode/Off)

Machine Noise (Operating)

Machine Dimensions W480 x D290 x H163 mm

Machine Weight 8 kg (17.6 lb) 9.3 kg (20.5 lb) 8 kg (17.6 lb)

Operating Environment

Temperature

(Best Print Quality)

Operating Environment

Humidity

(Best Print Quality)

Power

Consumption

(Operating/

Standby/Sleep

mode/Off)

Machine Noise

Machine Dimensions W480 x D290 x H186 mm W480 x D290 x H254 mm

Machine Weight 9.2 kg (20.3 lb) 9.3 kg (20.5 lb)

U.S.A

Europe

Asia/Oceania 21/6/1.5/0.04W

China

Model MFC-J4410DW MFC-J4510DW MFC-J4610DW MFC-J4710DW

U.S.A 21/5/1.5/0.04W 23/5/1.5/0.04W

Europe

Asia/Oceania

China N/A

21/5.5/1/0.04W

N/A N/A

21/6/1.5/0.04W 21/5.5/1.5/0.04W

10-35 (20-33) degrees centigrade

20-80 (20-80) %

N/A 21/5/1.5/0.04W

21/6/1.5/0.04W 21/5.5/1.5/0.04W

50 dBA (Average)

W480 x D290 x

H186 mm

10-35 (20-33) degrees centigrade

20-80 (20-80) %

21/6/1.5/0.04W

N/A

50 dBA (Average)

For US 11 kg (24.3 lb)

For EU 10.8 kg (23.8 lb)

W480 x D290 x

21/5.5/1.5/0.04W

For US 11.5 kg (25.4 lb)

For EU/AP 11.3 kg

N/A

H163 mm

(24.9 lb)

1-4

Confidential

Page 29

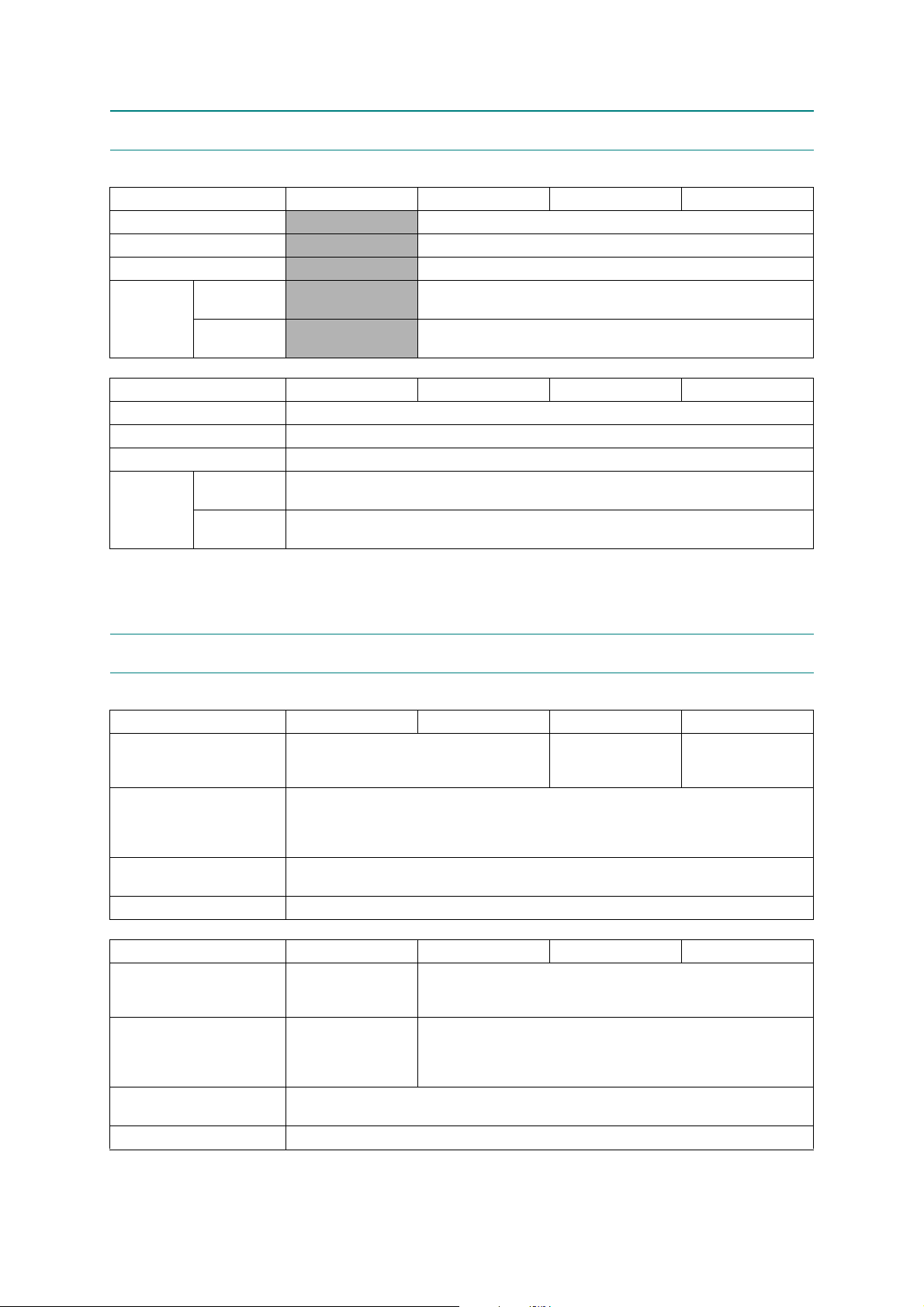

2FAX

Model DCP-J4110DW MFC-J2310 MFC-J2510 MFC-J4310DW

Modem Speed (bps)

Transmission Speed

ITU-T Group

Document

COLOR FAX

Modem Speed (bps)

Transmission Speed

ITU-T Group

COLOR FAX

(Send/Receive)

Memory

(Send/Receive)

Model MFC-J4410DW MFC-J4510DW MFC-J4610DW MFC-J4710DW

Document

(Send/Receive)

Memory

(Send/Receive)

N/A 33,600 (FAX)

N/A Approx.3sec (ITU-T Test Chart #1, MMR)

N/A Super G3

N/A Yes/Yes (ITU-T color FAX)

N/A No/No (ITU-T color FAX)

33,600 (FAX)

Approx.3sec (ITU-T Test Chart #1, MMR)

Super G3

Yes /Ye s (I T U -T c olor FA X )

No/No (ITU-T color FAX)

3 PRINTER

Model DCP-J4110DW MFC-J2310 MFC-J2510 MFC-J4310DW

Print Speed ESAT

(mono/color)

(based on ISO/IEC 24734)

Draft Print Speed

(mono/color)

*time calculated including

paper feeding

Resolution

(horizontal x vertical)

Auto Duplex Print Yes (up to A4/LTR)

Model MFC-J4410DW MFC-J4510DW MFC-J4610DW MFC-J4710DW

Print Speed ESAT

(mono/color)

(based on ISO/IEC 24734)

Draft Print Speed

(mono/color)

*time calculated including

paper feeding

Resolution

(horizontal x vertical)

Auto Duplex Print Yes (up to A4/LTR)

18/16 ipm 20/18 ipm

33/25 ppm 35/27 ppm

18/16 ipm 20/18 ipm 18/16 ipm

33/25 ppm

Up to 1,200 x 6,000 dpi

Up to 1,200 x 6,000 dpi

1-5

Confidential

Page 30

4COPY

Model DCP-J4110DW MFC-J2310 MFC-J2510 MFC-J4310DW

COPY SPEED ESAT

(based on ISO/IEC 24735)

(mono/color)

*This spec is for ADF model only.

COPY SPEED sESAT

(based on ISO/IEC 29183)

*

This spec is for non-ADF model only.

COPY SPEED FCOT

(based on ISO/IEC 24735

Annex D)

Resolution

(horizontal x

vertical)

Auto Duplex Print Yes

COPY SPEED ESAT

(based on ISO/IEC 24735)

(mono/color)

*This spec is for ADF model only.

COPY SPEED sESAT

(based on ISO/IEC 29183)

*

This spec is for non-ADF model only.

COPY SPEED FCOT

(based on ISO/IEC 24735

Annex D)

Resolution

(horizontal x

vertical)

Auto Duplex Print Yes

Mono

Color

Model MFC-J4410DW MFC-J4510DW MFC-J4610DW MFC-J4710DW

Mono

Color

N/A 12/9 ipm N/A

15/10 ipm N/A

18 sec

Print: Max. 1,200 x 1,200 dpi

Scan: Max. 1,200 x 1,200 dpi

Print: Max. 1,200 x 1,200 dpi

Scan: Max. 1,200 x 1,200 dpi

12/9 ipm

N/A

18 sec

Print: Max. 1,200 x 1,200 dpi

Scan: Max. 1,200 x 1,200 dpi

Print: Max. 1,200 x 1,200 dpi

Scan: Max. 1,200 x 1,200 dpi

1-6

Confidential

Page 31

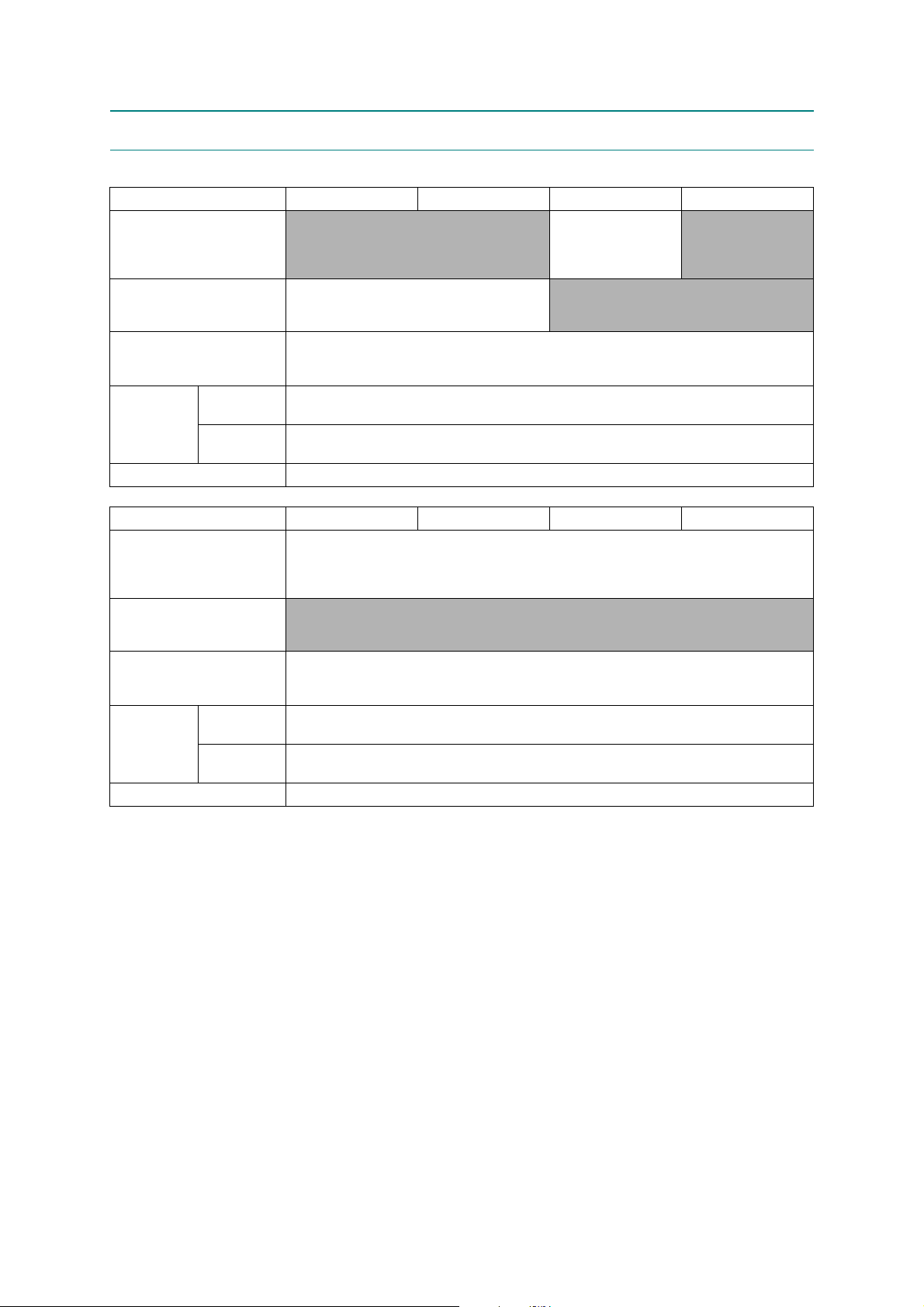

5 SCANNER

Model DCP-J4110DW MFC-J2310 MFC-J2510 MFC-J4310DW

Scan speed

(Mono/Color) *@100 dpi

Scan speed (Duplex)

(Mono/Color) *@100 dpi

Resolution

(horizontal x

vertical)

Scan speed

(Mono/Color) *@100 dpi

Scan speed (Duplex)

(Mono/Color) *@100 dpi

Resolution

(horizontal x

vertical)

Optical FB: 2,400 x 2,400 dpi

Interpolated For XP/Vista/Windows 7, up to 19,200 x 19,200 dpi with Scanner Utility

Model MFC-J4410DW MFC-J4510DW MFC-J4610DW MFC-J4710DW

Optical

Interpolated For XP/Vista/Windows 7, up to 19,200 x 19,200 dpi with Scanner Utility

A4: 3.37 sec/3.37 sec

LTR: 3.17 sec/3.17 sec

N/A

FB: 2,400 x 2,400 dpi

ADF: 2,400 x 1,200 dpi

A4: 3.37 sec/3.37 sec

LTR: 3.17 sec/3.17 sec

N/A

FB: 2,400 x 2,400 dpi

ADF: 2,400 x 1,200 dpi

FB: 2,400 x 2,400 dpi

A4: 3.37 sec/13.37 sec

LTR: 3.17 sec/13.17 sec

6 SOFTWARE

Model All models

Driver Support

OS Version

Windows

Macintosh Mac OS X v10.5.8/10.6.x/10.7.x

Windows XP/XP x64/Vista/7

Windows Server 2003/2008

1-7

Confidential

Page 32

7NETWORK

7.1 Network

Model DCP-J4110DW MFC-J2310 MFC-J2510 MFC-J4310DW

Internet FAX (Firmware)

(versionT37)

Model MFC-J4410DW MFC-J4510DW MFC-J4610DW MFC-J4710DW

Internet FAX (Firmware)

(versionT37)

7.2 Wired

Model All models

Model Name (Ethernet) Embedded (NC-280h)

Network Connection (Ethernet) Ethernet 10/100BASE-TX Auto Negotiation

N/A Yes (Download)

Yes (Download)

7.3 Wireless

Model All models

Model Name (Wireless) Embedded (NC-290w)

Network Connection

(Wireless)

Wireless Security

AOSS Yes

Setup Support

Utility

WPS (Wifi

Protected

Setup)

SSID (32 chr), WEP 64/128 bit, WPA-PSK (TKIP/AES),

IEEE802.11 b/g/n

WPA2-PSK (AES) **NO LEAP**

Ye s

1-8

Confidential

Page 33

8 SUPPLIES/OPTIONS

Model All models

Ink

Cartridge

Yield @

ISO/IEC

pattern

Storage Condition of Ink

Cartridge

Bundled Cartridges

Supply High Yield

Cartridges

Supply Super High

Yield Cartridges

*Storage condition at the temperature of 40 to 50°C and the humidity of 80 to 95% :

*Storage condition at the temperature of 40 to 60°C and the humidity of Non controll condition :

9 SERVICE INFORMATION

BK: 390

CL: 390

BK: 600

CL: 600

BK: 1,200

CL: 1,200

(Temperature) Normal condition : -20 to 40°C

(Humidity) Normal condition : 20 to 80%

Up to 5 days

Up to 5 days

Model All models

Monthly Volume 13,000 pages

Machine Life 50,000 pages or 5 years

MTBF (Mean Time Between

Failures)

MTTR (Mean Time To Be

Repaired)

4,000 hours

30 minutes

1-9

Confidential

Page 34

10 PAPER

10.1 Paper

Paper type and size for each operation

Paper Type Paper Size Usage

Fax Copy Photo

Capture

Cut-Sheet Ledger 11 x 17 in. (279.4 x 431.8 mm) Yes

*2

Letter 8 1/2 x 11 in. (215.9 x 279.4 mm) Yes Yes Yes Yes

A3 11.7 x 16.5 in. (297 x 420 mm) Yes

*2

A4 8.3 x 11.7 in. (210 x 297 mm) Yes Yes Yes Yes

Legal 8 1/2 x 14 in. (215.9 x 355.6 mm) Yes*2Yes

Executive 7 1/4 x 10 1/2 in. (184 x 267 mm) -- Yes -- Yes

JIS B4 10.1 x 14.3 in. (257 x 364 mm) -- -- -- User

JIS B5 7.2 x 10.1 in. (182 x 257 mm) -- -- -- User

A5 5.8 x 8.3 in. (148 x 210 mm) -- Yes -- Yes

A6 4.1x 5.8 in. (105 x 148 mm) -- -- -- Yes

Cards Photo 4 x 6 in. (10 x 15 cm) -- Yes Yes Yes

Photo L 3 1/2 x 5 in. (89 x 127 mm) -- -- -- Yes

Photo 2L 5 x 7 in. (13 x 18 cm) -- -- Yes Yes

Index Card 5 x 8 in. (127 x 203 mm) -- -- -- Yes

Postcard 1 3.9 x 5.8 in. (100 x 148 mm) -- -- -- User

Postcard 2

5.8 x 7.9 in. (148 x 200 mm) -- -- -- User

(Double)

Envelopes C5 Envelope 6.4 x 9 in. (162 x 229 mm) -- -- -- Yes

DL Envelope 4.3 x 8.7 in. (110 x 220 mm) -- -- -- Yes

COM-10 4 1/8 x 9 1/2 in. (105 x 241 mm) -- -- -- Yes

Monarch 3 7/8 x 7 1/2 in. (98 x 191 mm) -- -- -- Yes

Y4 Envelope 4.1 x 9.3 in. (105 x 235 mm) -- -- -- User

Transparencies Letter 8 1/2 x 11 in. (215.9 x 279.4 mm) -- Yes -- Yes

A4 8.3 x 11.7 in. (210 x 297 mm) -- Yes -- Yes

Legal 8 1/2 x 14 in. (215.9 x 355.6 mm) -- Yes -- Yes

A5 5.8 x 8.3 in. (148 x 210 mm) -- Yes -- Yes

*1

Manual Feed Slot only (MFC-J4510DW)

Manual Feed Slot or Tray #2 (MFC-J4710DW)

*2

Lower Tray only (MFC-J4710DW)

*3

Manual Feed Slot only

Yes

Yes

*1

Yes

*1

Yes

*1

-- Yes

*3

*3

Printer

*1

Yes

*1

Yes

*1

Defined

Defined

Defined

Defined

*1

*1

*1

*1

Defined

1-10

Confidential

Page 35

Paper weight and thickness

Paper Type Weight Thickness

2

Cut-Sheet Plain Paper 17 to 32 lb (64 to 120 g/m

(Lower Tray)

17 to 28 lb (64 to 105 g/m

) 3 to 6 mil (0.08 to 0.15 mm)

2

) 3 to 6 mil (0.08 to 0.15 mm)

Plain Paper

Inkjet Paper 17 to 53 lb (64 to 200 g/m2) 3 to 10 mil (0.08 to 0.25 mm)

Glossy Paper

Cards Photo 4"x 6" Card

*1

Up to 58 lb (Up to 220 g/m2) Up to 10 mil (Up to 0.25 mm)

*1

Up to 58 lb (Up to 220 g/m2) Up to 10 mil (Up to 0.25 mm)

Index Card Up to 32 lb (Up to 120 g/m2) Up to 6 mil (Up to 0.15 mm)

Postcard 1

Up to 53 lb (Up to 200 g/m

2

) Up to 10 mil (Up to 0.25 mm)

Postcard 2

Envelopes 20 to 25 lb (80 to 95 g/m2) Up to 20 mil (Up to 0.52 mm)

Transparencies -- --

*1

BP71 69 lb (260 g/m2) paper is especially designed for Brother inkjet machines.

Paper capacity of the paper trays

Paper size Paper types

Standard Tray <Landscape>Letter,

Executive, A4

<Portrait>

A5, A6, Photo, Photo L,

Photo 2L, Index card,

Envelopes (Com-10, DL,

Monarch)

Lower Tray

(MFC-J4610DW/J4710DW)

<Landscape>Letter, A4

<Portrait>Ledger, A3, Legal

Manual Feed Slot <Landscape>Letter,

Executive, A4

<Portrait>

Ledger, A3, Legal, A5, A6,

Photo, Photo L, Photo 2L,

Index card, Envelopes (C5,

Com-10, DL, Monarch)

*1

Up to 250 sheets of plain paper 20 lb (80 g/m2).

Plain Paper 150

Inkjet Paper 20

Glossy Paper, Photo 20

Index Card, Postcard 30

Envelopes, Transparencies 10

Plain Paper 250

Plain Paper, Inkjet Paper,

Glossy Paper, Envelopes and

Transparencies

*1

*1

1

Recommended print media

To get the best print quality, we suggest using Brother paper. (See the table below.)

If Brother paper is not available in your country, we recommend testing various papers before

purchasing large quantities.

We recommend using "3M Transparency Film" when you print on transparencies

Brother paper

Paper Type Item

Premium Plus Glossy Photo

- Ledger BP71GLGR

- Letter BP71GLTR

- 4" x 6" BP71GP

Plain Inkjet

- Ledger BP60PLGR (USA only)

1-11

.

Confidential

Page 36

Handling and using print media

Store paper in its original packaging and keep it sealed. Keep the paper flat and away from

moisture, direct sunlight and heat.

Avoid touching the shiny (coated) side of photo paper. Load photo paper with the shiny side

facing down.

Avoid touching either side of transparencies because they absorb water and perspiration

easily, and this may cause decreased output quality. Transparencies designed for laser

printers/copier may stain your next document. Use only transparencies recommended for

inkjet printing.

1-12

Confidential

Page 37

10.2 Printable Area

1

3

42

1

3

42

Cut-Sheet Paper Envelopes

The printable area depends on the settings in the application you are using. The figures below

show the unprintable areas on cut-sheet paper and envelopes. The machine can print in the

shaded areas of cut-sheet paper only when the Borderless print feature is available and turned

on.

Top (1) Left (2) Bottom (3) Right (4)

Cut-Sheet 0.12 in. (3 mm) 0.12 in. (3 mm) 0.12 in. (3 mm) 0.12 in. (3 mm)

Envelopes 0.87 in. (22 mm) 0.12 in. (3 mm) 0.87 in. (22 mm) 0.12 in. (3 mm)

1-13

Confidential

Page 38

CHAPTER 2 TROUBLESHOOTING

WARNING

1 INTRODUCTION

This section gives the service personnel some of the troubleshooting procedures to be followed

if an error or malfunction occurs with the machine. It is impossible to anticipate all of the

possible problems which may occur in future and determine the troubleshooting procedures, so

this section covers some sample problems. However, those samples will help service personnel

pinpoint and repair other defective elements if he/she analyzes and examines them well.

1.1 Precautions

Be sure to observe the following to prevent any secondary troubles from happening during

troubleshooting.

(1) AC power codes must be removed from their outlets before starting any removal of covers

and PCBs, adjustments and conductivity test using a tester.

(2) When disconnecting the connectors, hold the connector housings. Do not pull the lead

wires.

(3) Static electricity charged in your body may damage electronic parts.

Before handling the PCBs, touch a metal portion of the machine to discharge static

electricity charged in your body. When transporting PCBs, be sure to wrap them in

conductive sheets.

When replacing the PCBs, put on a grounding wrist band and perform the job on a

conductive mat.

Also take care not to touch the conductor sections on the flat cables.

(4) Be sure to observe the warnings.

WARNING

DO NOT use flammable substances such as alcohol, benzine, thinner or any type of spray to

clean the inside or outside of the machine. Doing this may cause a fire or electrical shock.

(5) After repairing the defective section, be sure to check again if the repaired section works

correctly.

2-1

Confidential

Page 39

1.2 Initial Check

Prior to proceeding to the troubleshooting procedures, make the following initial checks:

Environmental conditions

(1) The machine is placed on a flat, firm surface.

(2) The machine is used in clean environment with temperature (10 to 35 degree-C) and

humidity (20 to 80 %.)

(3) The machine is not exposed to direct sunlight, excessive heat, moisture, or dust.

(4) The machine is transported in level.

Power requirements

(1) The power requirements described in label of the machine is supplied. Its variation is

within +/-10% of the rated voltage.

(2) All cables and harnesses are firmly connected.

(3) The fuses are not blown.

Recording paper

(1) A recommended type of paper is being used (refer to Chapter 1, Section 10 "PAPER."

(2) The recording paper is not dampened.

Consumable Parts

(1) Ink cartridge (4 colors) is correctly set.

Head/carriage unit

(1) Repeat purge action (maintenance code 76) for a couple of times. (Refer to Chapter 5,

Section 1.3.29.)

Others

(1) Low temperature

Motor may not run correctly due to excessive load for each drive in low temperature

environment. Warm the room temperature in such case.

2-2

Confidential

Page 40

Cleaning

WARNING

Use a soft dry lint-free cloth.

WARNING

DO NOT use flammable solvent such as alcohol, benzine, thinner to clean the body of the

machine. DO NOT use near by.

2-3

Confidential

Page 41

2OVERVIEW

Document feed roller 2

Second side CIS

unit

Document scanning position actuator

Document separation roller

First side CIS unit

Document feed roller 1

ADF separation pad

Document detection actuator

Document pick-up roller

Document nip piece

Document pressure bar

2.1 Cross-section Drawings

2.1.1 Document scanning

2-4

Confidential

Page 42

2.1.2 Printer part

Switchback actuator

Paper ejection roller

Switchback roller

Control panel ASSY

Registration actuator

Manual feed slot

cover ASSY

Paper feed roller

Head/carriage unit

Duplex paper feed roller

Platen

T1 paper pull-in roller

paper tray 2

Bank ASSY

T2 paper pull-in roller

2-5

Confidential

Page 43

2.2 Document Feeding Path/Recording Paper Feeding Path

Document feeding path during ADF scanning

Feeding path during duplex-printing

Feeding path from the manual feed slot

Feeding path from paper tray 1

Feeding path from paper tray 2

2.2.1 Document Feeding Path

2.2.2 Recording Paper Feeding Path

2-6

Confidential

Page 44

2.3 Parts Names and Functions

Document scanning and feeding

Names Functions

Document detection actuator This detects whether documents are set on the document tray.

Document pick-up roller This pulls documents loaded in the document tray into the ADF.

Document separation roller,

ADF separation pad

Document feed roller 1 This feeds a document to the CIS unit.

Document scanning position

actuator

Document feed roller 2 This ejects the scanned document to ADF document support.

Printing and paper feeding

Names Functions

T1 paper pull-in roller This feeds recording paper from the paper tray 1.

T2 paper pull-in roller This feeds recording paper from the paper tray 2.

Registration actuator This detect the leading edge of recording paper, controlling the

Paper feed roller The leading edge of recording page hits the stopped paper feed

This separates documents sent by the document pick-up roller in

single sheet.

This detects the leading edge of document pages, indicating the

scanning start position.

This detects paper jamming in the ADF.

printing start position.

This detect the leading edge/ending edge of recording paper,

identifying the recording paper size.

This detects paper jamming in the rear.

roller, correcting inclination of the paper. After the correction, the

paper feed roller rotates, feeding the paper to printing start position.

Paper ejection roller This feeds printed recording paper to the switchback roller.

Switchback actuator This detects whether the printed recording papers are ejected.

This detects the ending edge of recording paper after printing the

first side when duplex-printing, adjusting timing to reverse the

switchback roller rotation.

This detect the leading edge/ending edge of recording paper when

duplex-printing, identifying the recording paper size.

This detects whether the recording papers are fed from the

switchback roller to the duplex-printing path.

This detects paper jamming in the ejector.

Detect if paper tray 1 is set.

Switchback roller This ejects the recording paper to the ejected paper tray.

During duplex-printing, after feeding some of the recording papers

printed in the first side to the switchback roller, its rotation is

reversed to feed the recording paper to the duplex-printing path.

Duplex paper feed roller During duplex-printing, this feeds the recording paper that are fed in

the duplex paper path to the paper feed roller.

2-7

Confidential

Page 45

2.4 Block Diagram

Modem PCB

EEPROM

DDR3

ROM

Front Ink Cover Switch

Carriage Unit

Print Engine

INK Refill Unit

ADF Unit

Scanner Unit

Main PCB

Speaker

CR Motor

AC line

Tel line

Ext Tel line

Backup

ROM

MS MSduoSD

USB

SDIO

SPI

LVDS

Power Supply

USB

ASIC

(Saffron)

USB

Host

LAN

(PHY)

LAN

(MAC)

PC

W-LAN

DX:A4 1200,3ch

PF Motor

Ink Cartridge PCB

Ink Empty Sensor PCB

Certification Chip PCB

RMII

AMP

Ethernet

Panel PCB

Panel Unit

Color

LCD

3.7/1.8”

Touch

Panel

LCD PCB

Document Cover Sensor*1

Scanner

Motor

Cartridge Sensor

Thermistor

AFE/ AFE/

LED Driver LED Driver

ADF

Motor

Ink Absorber Full Sensor

Power

Switch

*1 Duplex Model

Sensor Relay PCB

SDAAModem

Print Head Unit

Carriage PCB

CR Encoder Sensor

Head Thermistor

PF EncoderPCB

Registration Sensor PCB

Registration Sensor

Purge Cam Sensor

Switch Back Sensor

Document Detection Sensor PCB

Document Scanning Position Sensor PCB

A4 CIS A4 CIS

Document Scanner Sensor

Paper width Sensor

2-8

Confidential

Page 46

2.5 Components

ADF unit

Scanner cover damper

Scanner cover support

Harness cover

Upper side cover L

Engine unit

Registration sensor

PCB ASSY

Sensor relay PCB ASSY

Ink absorber box

Switchback

frame ASSY

Document scanner unit

Upper cover

Upper side cover R

Main PCB ASSY

Wireless LAN PCB ASSY

MJ PCB ASSY

Main PCB frame

Speaker spring

Speaker

Head/carriage unit

Maintenance unit

Ink refill ASSY

Jam clear cover

Flushing box

PF encoder

PCB ASSY

PF encoder

harness

Lower side cover L

Lower power

supply frame

Power supply PCB ASSY

Frame base

Lower cover

Front cover

2-9

Paper tray ASSY

Lower side cover R

Ink cartridge cover

sensor ASSY

Control panel ASSY

Inner media module cover

Media module cover

(BHS13_COMPONENTS_1_E)

Ink cartridge

cover

Confidential

Page 47

3 ERROR INDICATION

To help the user or the service personnel promptly locate the cause of a problem (if any), the

machine incorporates the self-diagnostic functions which display error messages for equipment

errors.

3.1 Error Code

Error

Code

0D

0E

13

15

17

18

Contents

Paper jam during duplex-printing

The recording papers are fed in reverse on the platen when switchback drive is

started, triggering switchback sensor as paper feeding condition.

Defective during duplex-printing

Switchback sensor detects paper feed condition at out of specified timing

during switchback.

Defective during duplex-printing

Registration sensor detects paper feed condition at out of specified timing

during switchback.

Paper jam during duplex ejecting

Recording paper is not able to be ejected since it is longer than 840 mm when

ejecting the paper.

Recording paper size error (duplex-printing/duplex-copying)

-Paper width is wider than 301.5 mm (detection by media sensor)

-Paper width is narrower than 95.5 mm (detection by media sensor)

-Paper length is longer than 245.9 mm (detection by registration, SB sensor)

-Paper length is shorter than 143.5 mm (detection by registration, SB sensor)

Paper jam during duplex-printing

Registration sensor does not detect paper feed within specified pulse numbers

in the second side paper re-feed.

Refer to

page:

2-21

2-21

2-22

2-22

2-23

2-24

20

21

22

23

24

25 Cannot communicate with ink cartridge IC chip (ink cartridge side.) 2-26

Cannot identify a black ink cartridge.

The ink cartridge detection sensor and the ink remaining sensor are detecting.