Brother DB2-797, DB2-798 Service Manual

SERVICE

MANUAL

FOR

082-8797

082-8798

SINGLE NEEDLE ADJUSTABLE

TOP

AND

BOTTOM

FEED

LOCK STITCH MACHNE

. .

~

·

'

CONTENTS

I

SPECIFICATIONS,........................................................

1

I

MECHANICAL

DESCRIPTIONS

I·.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

II)

Upper shaft and needle bar mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . 3

IZ]Lower shaft and rotary

hook

mechanism . . . . . . . . . . . . . . . . . . . . . . . . . 4

~Upper

feed mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . • . 5

II]

Presser

foot

mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . • . . . . . . . . . . . . . . 6

I

STANDARD

ADJUSTMENT

I·.............................................. 7

IIJAdjusting feed

timing

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

IZ]Adjusting

timing

between needle and rotary hook . . . . . . . . . . . . . . . . 7

~Adjusting

presser

foot

height

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

IIJAdjusting feed

dog

height

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

rn:JAdjusting

feeding

foot

and presser

foot

. . . . . . . . . . . . . . . . . . . . . . . . . . 9

<Alternative

up and

down

movement

of

feeding and presser

foot>

9

<Feeding

foot

and presser

foot

height>

. 0

0. 0 ••••••••

0

••

0. 0 0...

9

<Adjusting

feeding

foot

front

and rear

position>

0

••• 0 •••••

0...

9

<Adjusting

feeding

foot

feed>

....

0

••••

0 0

••••••

0

••• 0 •••••

0 • • • • 9

II)Synchronizer

{082-8798)

. . . . . . • . • . . . . . . . . . . . . . . . . . . . • . . . • . . . . . • 10

[l]Replacing

fixed and movable knives

{082-8798)

. . . . . . . . . . . . • . . . . .

11

'OTHER,

....... .-.......................................................

12

[!]Sewing

with

synthetic thread . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12

IZ1Sewing

with

vi nylon thread . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12

~Attaching

presser

foot

lifter

set . . . • . . . . . . . . . . . . . . . . . . . . . . . . . . .

13

IIJAttaching material end sensor . . . . . . . . . . . . . . . . . . . • . . . • . . . . . . . . . . 14

I

SPECIFICATIONS

I

[B

797]

Options are

as

follows.

Operation panel

E- 20

E-

40

E-20

0

E -

40

0

E-

100

-1

-

[B798]

Production counter

@

brother

EJ

P.COUNTER

Material end sensor

SENSORll

Us

e one

of

the

operation

panels and

the sensor t

ogether

.

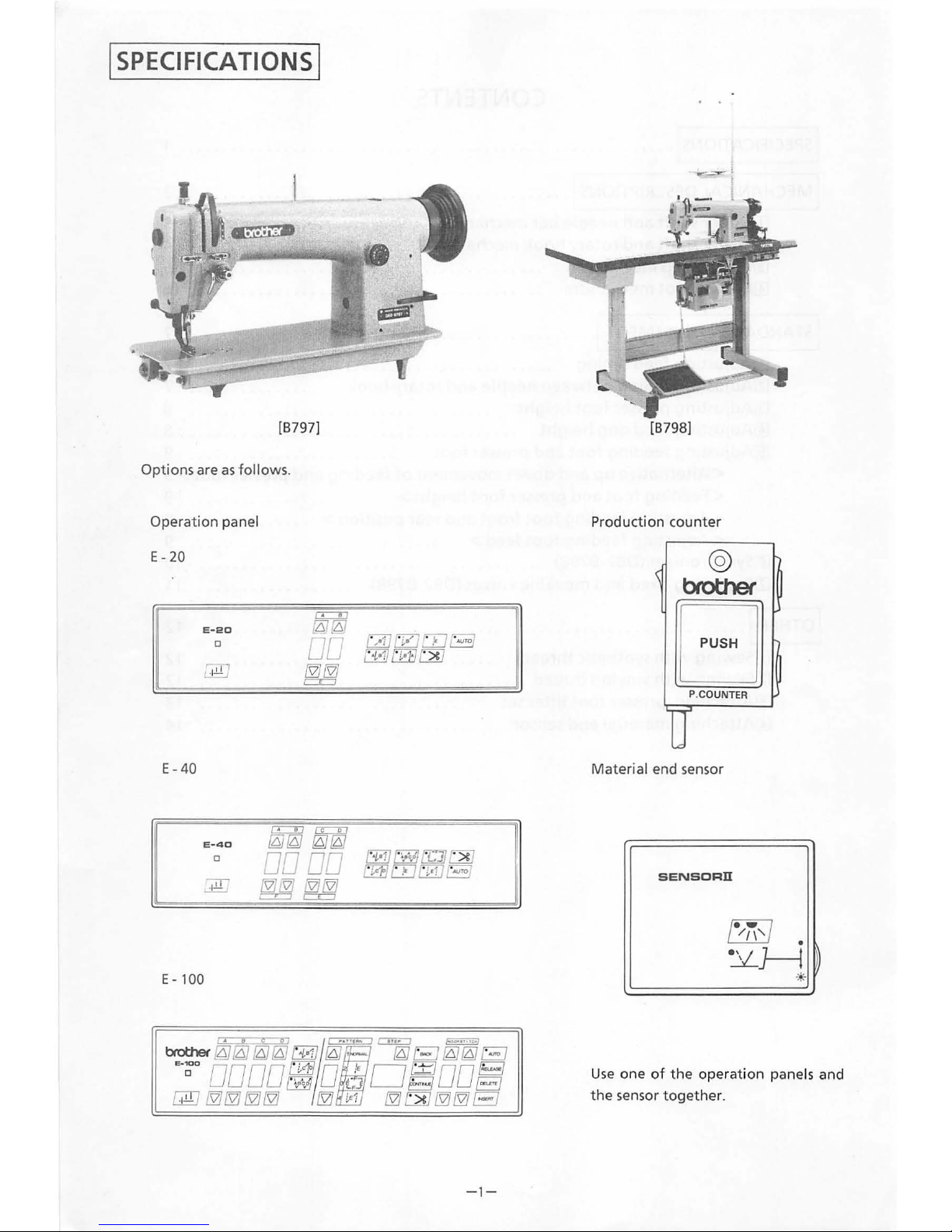

DB2-B797

DB2-B798

Application

Thick material

Thick material

Sewing speed

2000spm

2000spm

Sewing

length

0-Smm

0-9mm

Height

of

presser

foot

14mm

15mm

(knee

lifter)

Height

of

presser

foot

7.5mm

Smm

(presser bar

lifter

lever)

Rotary hook

Double sized

Double sized

Lubrication

Manual lubrication

Manual lubrication

Needle

DPx

17#23

(39mm)

DPx

17#23

Weight

of

machine head 30kg 30kg

Thread take-up stroke 73mm 73mm

Needle bar stroke

34mm

38mm

Presser

foot

stroke 4.5mm 4.5mm

Feeding

foot

stroke

2-4.5mm

2.2-4mm

Height

of

feed dog

1.2mm

1.2mm

Durability

•

Thread take-up and needle

•

Thread take-up and needle

bar crank have bearings. bar crank

do

not

have

bearings.

•

Upper feed rock lever

uses

•

Upper feed rock lever

uses

stud screws.

taper

threads.

-2-

I MECHANICAL

DESCRIPTIONS!

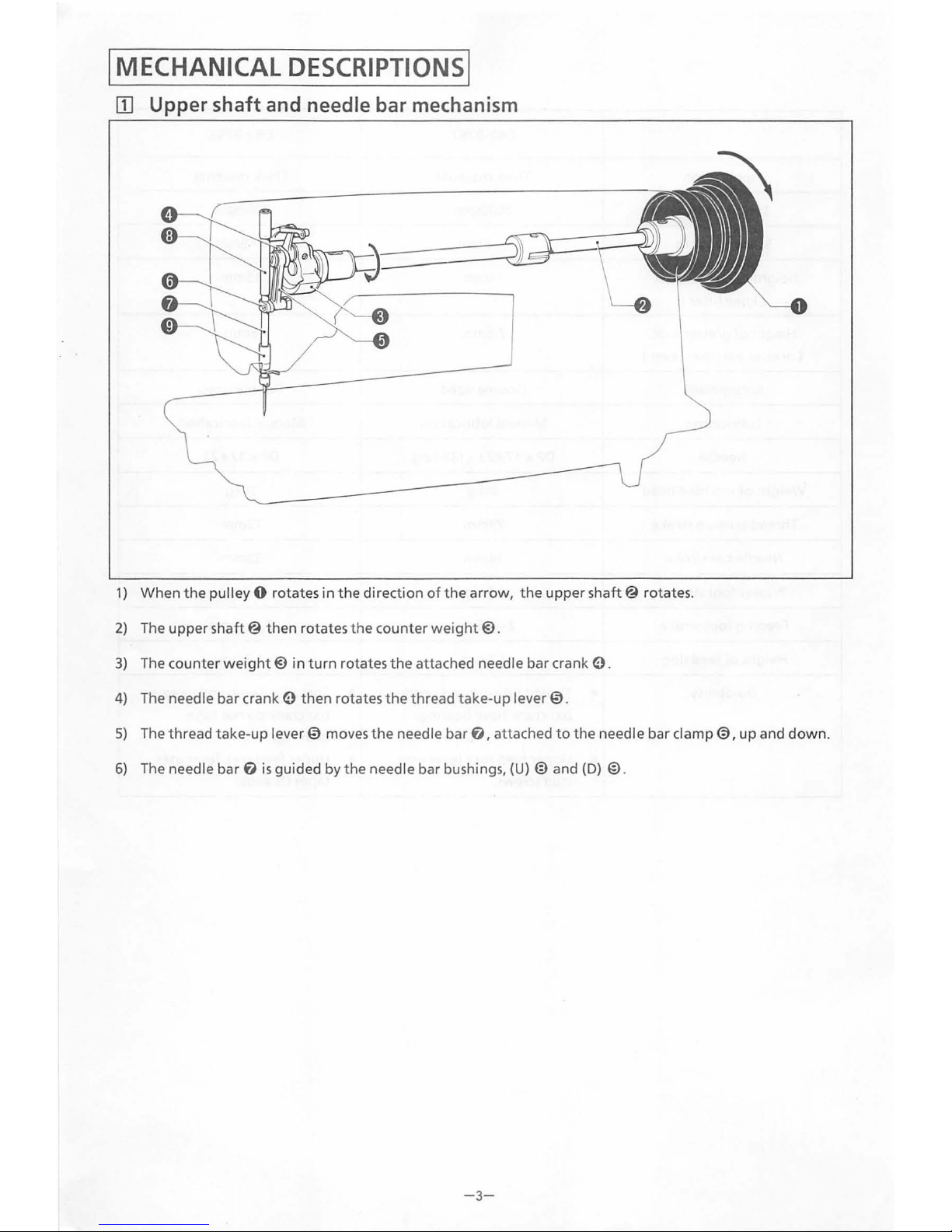

[II

Upper shaft and needle bar mechanism

1)

When

the

pulley 0 rotates

in

the

direction

ofthe

arrow,

the

upper

shaft@

rotates.

2)

The

upper

shaft@

then

rotates

the

counter

weight@.

3)

The counter

weight@

in

turn

rotates

the

attached needle bar crank e.

4)

The needle bar crank e

then

rotates

the

thread take-

up

lever

0.

5)

The thread

take-up

lever 0 moves

the

needle

bar

f),

attached

to

the

needle bar clamp

0,

up

and

down.

6)

The needle bar

f)

is

guided by

the

needle bar bushings, (U) @ and

(D)

@.

- 3-

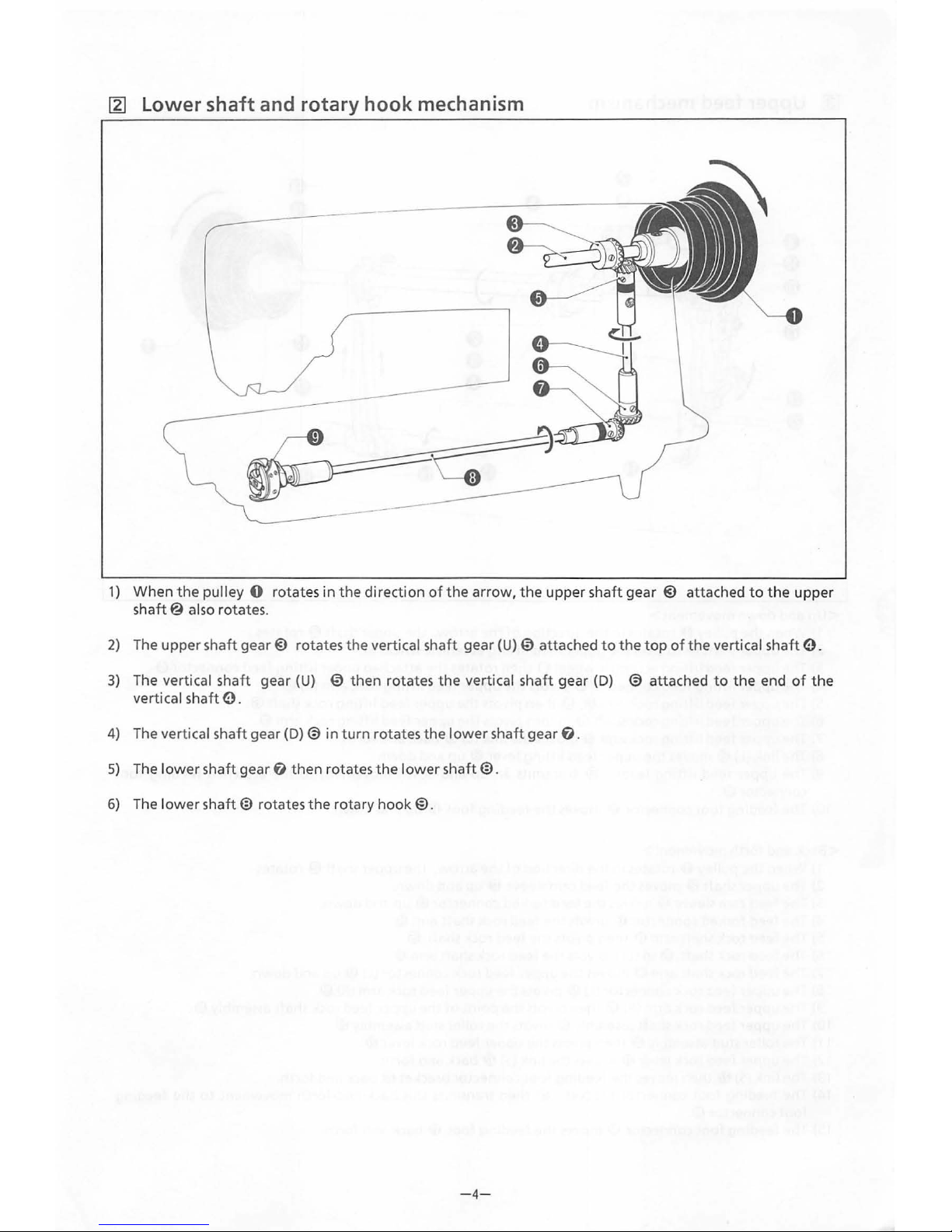

~

lower

shaft and rotary hook mechanism

1)

When

the

pulley 0

rotates

in

the

direction

of

the

arrow,

the

upper

shaft

gear @ attached

to

the

upper

shaft@

also

rotates

.

2)

The

upper

shaft

gear@

rotates

the

vertical sha

ft

gear

(U) 0 attached

to

the

top

of

the

vertical

shaft

e.

3)

The vertical sha

ft

gear

(U)

0

then

rotates

the

vertical

shaft

gear

(D)

@

attached

to

the

end

of

the

vertical

shaft

e.

4)

The vertical

shaft

gear

(D)@ in

turn

rotates

the

lower

shaft

gear

f).

5)

The

lower

shaft

gear

f)

then rotates

the

lower

shaft@.

6)

The l

ower

shaft@

rotates

the

rotary

hook@.

-4-

Loading...

Loading...