Brother DA-927A, DA-928A Instruction Manual

INSTRUCTION

DA-927A

MANUAL

DA-928A

Please read this manual before using the machine.

Please keep this manual within easy reach for quick reference.

TWIN NEEDLE / THREE NEEDLE FEED OFF THE ARM DOUBLE

CHAIN STITCHER

Thank you very much for buying a BROTHER sewing machine. Before using your new machine, please

read the safety instructions and the explanations given in the instruction manual.

With industrial sewing machines, it is normal to carry out work while positioned directly in front of moving parts

such as the needle and thread take-up, and consequently there is always a danger of injury that can be caused by

these parts. Follow the instructions from training personnel and instructors regarding safe and correct operation

before operating the machine so that you will know how to use it correctly.

SAFETY INSTRUCTIONS

[1] Safety indications and their meanings

This instruction manual and the indications and symbols that are used on the machine itself are provided in order to ensure

safe operation of this machine and to prevent accidents and injury to yourself or other people.

The meanings of these indications and symbols are given below.

Indications

CAUTION

Symbols

· · · · ·

· · · · ·

· · · · ·

The instructions which follow this term indicate situations where failure to follow the

instructions may result in minor or moderate injury.

This symbol (△) indicates something that you should be careful of. The picture inside the triangle

indicates the nature of the caution that must be taken.

(For example, the symbol at left means “beware of injury”.)

This symbol ( ) indicates something that you must not do.

This symbol (●) indicates something that you must do. The picture inside the circle indicates the

nature of the thing that must be done.

(For example, the symbol at left means “you must make the ground connection”.)

i

DA-927A, DA-928A

[2] Notes on safety

CAUTION

Environmental requirements

Use the sewing machine in an area which is free

from sources of strong electrical noise such as

electrical line noise or static electric noise.

Sources of strong electrical noise may cause

problems with correct operation.

Any fluctuations in the power supply voltage should

be within 10% of the rated voltage for the machine.

Voltage fluctuations which are greater than this may

cause problems with correct operation.

The power supply capacity should be greater than

the requirements for the sewing machine's power

consumption.

Insufficient power supply capacity may cause

problems with correct operation.

Machine installation should only be carried out by a

qualified technician.

Contact your Brother dealer or a qualified

electrician for any electrical work that may need to

be done.

The sewing machine weighs approximately 49 kg

(108lb). The installation should be carried out by

two or more people.

Do not connect the power cord until installation is

complete. The machine may operate if the treadle

is depressed by mistake, which could result in

injury.

Be sure to connect the ground. If the ground

connection is not secure, you run a high risk of

receiving a serious electric shock, and problems

with correct operation may also occur.

The ambient temperature should be within the

range of 5C to 35C during use.

Temperatures which are lower or higher than this

may cause problems with correct operation.

The relative humidity should be within the range of

45% to 85% during use, and no dew formation

should occur in any devices.

Excessively dry or humid environments and dew

formation may cause problems with correct

operation.

In the event of an electrical storm, turn off the power

and disconnect the power cord from the wall outlet.

Lightning may cause problems with correct

operation.

Installation

All cords should be secured at least 25 mm away

from any moving parts. Furthermore, do not

excessively bend the cords or secure them too

firmly with staples.

If this is not observed, fire or electric shocks may

result.

If using a work table which has casters, the casters

should be secured in such a way so that they cannot

move.

Be sure to wear protective goggles and gloves when

handling the lubricating oil, so that it does not get

into your eyes or onto your skin. If care is not taken,

inflammation can result.

Furthermore, do not drink the lubricating oil.

Diarrhea or vomiting may result.

Keep the oil out of the reach of children.

DA-927A, DA-928A

ii

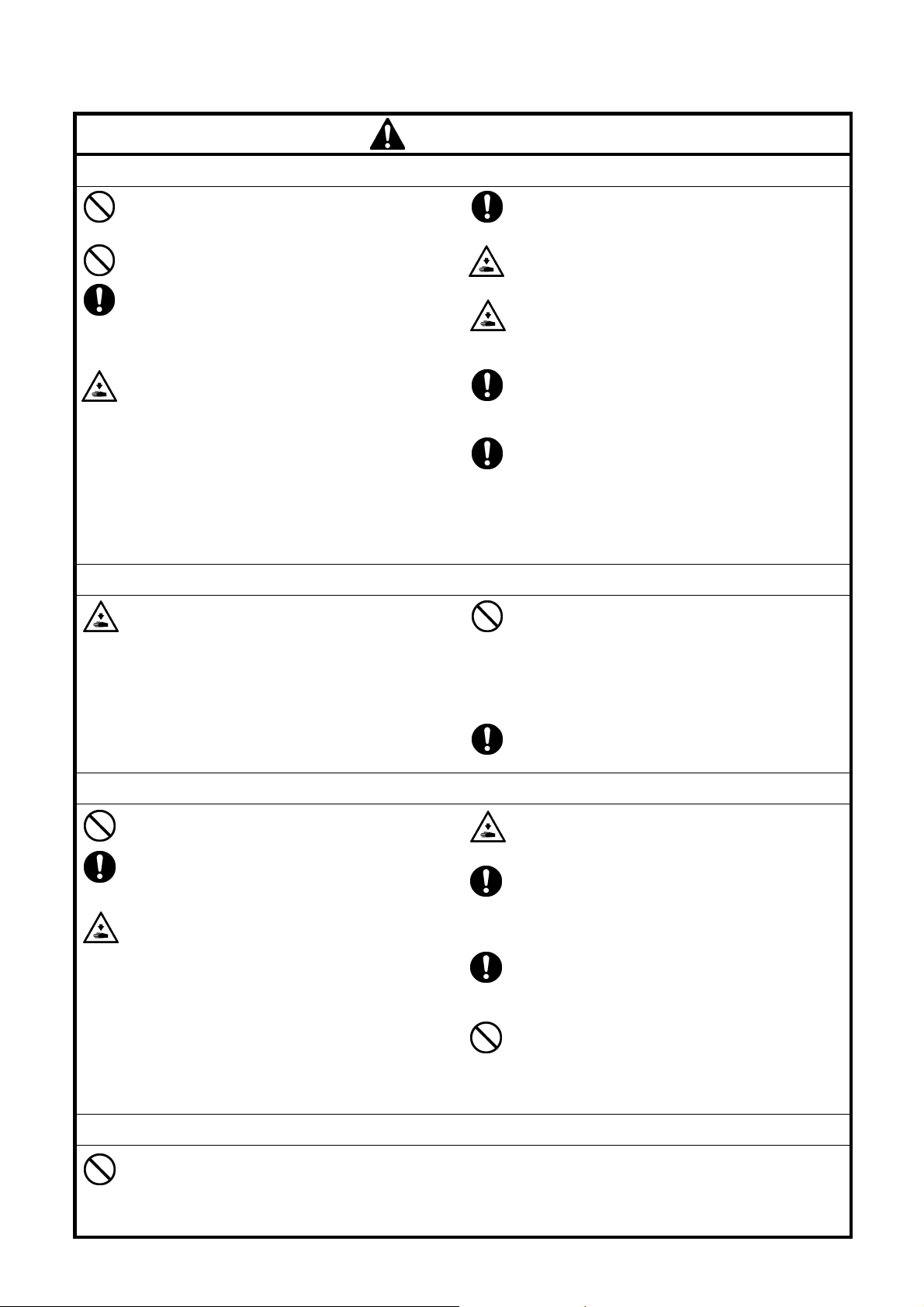

CAUTION

Sewing

This sewing machine should only be used by

operators who have received the necessary training

in safe use beforehand.

The sewing machine should not be used for any

applications other than sewing.

Be sure to wear protective goggles when using the

machine.

If goggles are not worn, there is the danger that if a

needle breaks, parts of the broken needle may enter

your eyes and injury may result.

Turn off the power switch at the following times.

However, the motor will keep turning even after the

power is switched off as a result of the motor’s

inertia. Wait until the motor stops fully before starting

work.

The machine may operate if the treadle is depressed

by mistake, which could result in injury.

When threading the needle

When replacing the needle

When not using the machine and when leaving the

machine unattended

If using a work table which has casters, the casters

should be secured in such a way so that they cannot

move.

Attach all safety devices before using the sewing

machine. If the machine is used without these

devices attached, injury may result.

Do not touch any of the moving parts or press any

objects against the machine while sewing, as this

may result in personal injury or damage to the

machine.

If an error occurs in machine operation, or if

abnormal noises or smells are noticed, immediately

turn off the power switch. Then contact your nearest

Brother dealer or a qualified technician.

If the machine develops a problem, contact your

nearest Brother dealer or a qualified technician.

Cleaning

Turn off the power switch before carrying out

cleaning.

However, the motor will keep turning even after the

power is switched off as a result of the motor’s

inertia. Wait until the motor stops fully before starting

work.

The machine may operate if the treadle is depressed

by mistake, which could result in injury.

Be sure to wear protective goggles and gloves when

handling the lubricating oil, so that it does not get

into your eyes or onto your skin. If care is not taken,

inflammation can result.

Furthermore, do not drink the lubricating oil.

Diarrhea or vomiting may result.

Keep the oil out of the reach of children.

Use only the proper replacement parts as specified

by Brother.

Maintenance and inspection

Maintenance and inspection of the sewing machine

should only be carried out by a qualified technician.

Ask your Brother dealer or a qualified electrician to

carry out any maintenance and inspection of the

electrical system.

Turn off the power switch and disconnect the power

cord from the wall outlet at the following times.

However, the motor will keep turning even after the

power is switched off as a result of the motor’s

inertia. Wait until the motor stops fully before starting

work.

The machine may operate if the treadle is depressed

by mistake, which could result in injury.

When carrying out inspection, adjustment and

maintenance

When replacing consumable parts such as the

looper.

If the power switch needs to be left on when carrying

out some adjustment, be extremely careful to

observe all safety precautions.

Use only the proper replacement parts as specified

by Brother.

Brother will not be held responsible for any accidents

or problems resulting from the use of non-genuine

parts.

If any safety devices have been removed, be

absolutely sure to re-install them to their original

positions and check that they operate correctly

before using the machine.

Any problems in machine operation which result

from unauthorized modifications to the machine will

not be covered by the warranty.

iii

To prevent accidents and problems, do not modify

the machine yourself.

Brother will not be held responsible for any accidents

or problems resulting from modifications made to the

machine.

Modification

DA-927A, DA-928A

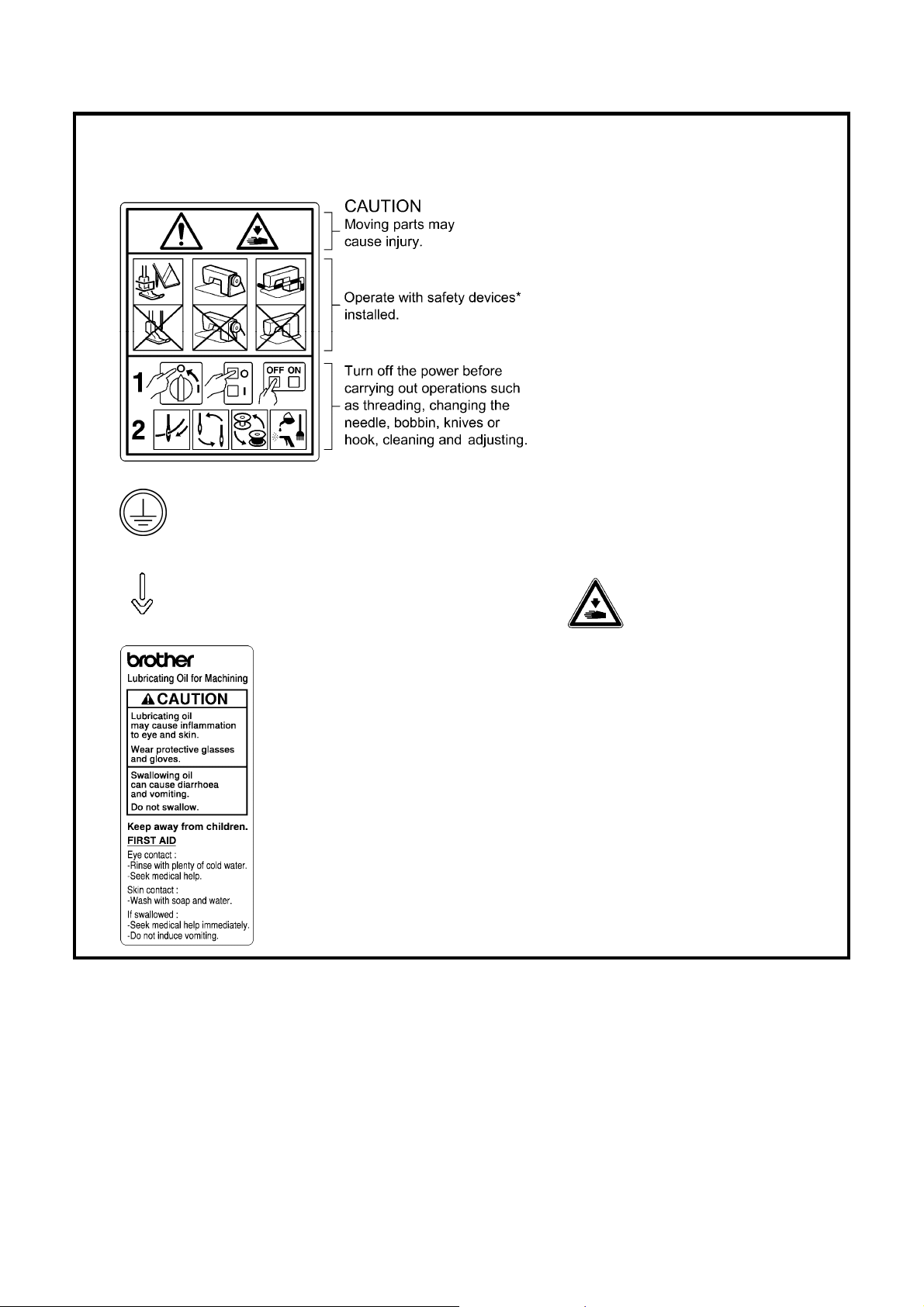

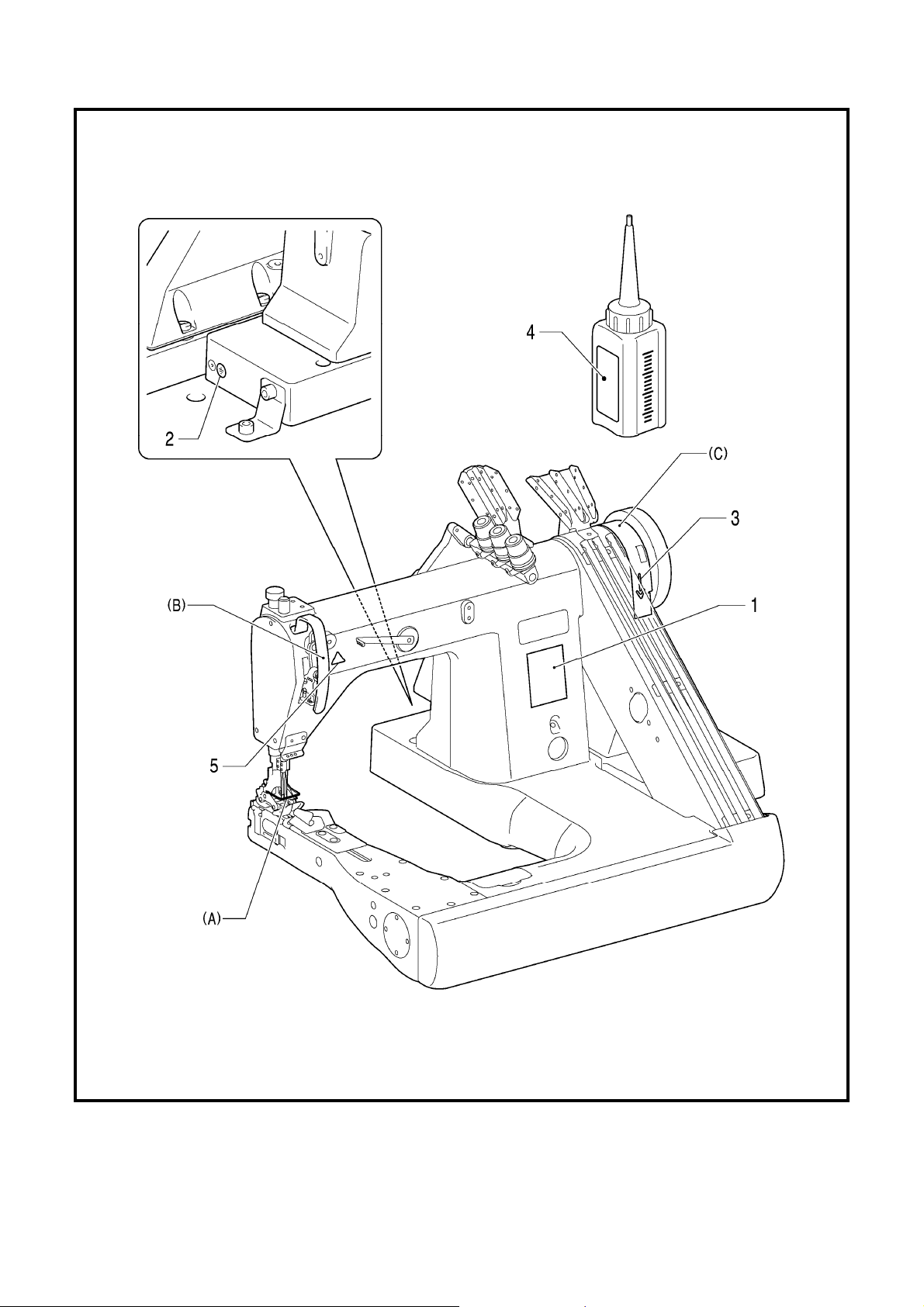

[3] Warning labels

The following warning labels appear on the sewing machine.

Please follow the instructions on the labels at all times when using the machine. If the labels have been removed or are

difficult to read, please contact your nearest Brother dealer.

1

2

3

4

Be sure to connect the ground. If the ground connection is not secure, you run a high risk of receiving a

serious electric shock, and problems with correct operation may also occur.

Direction of operation

5

* Safety devices:

(A) Finger guard

(B) Thread take-up cover

(C) Pulley cover, etc.

Be careful to avoid injury from

the moving thread take-up.

DA-927A, DA-928A

iv

Oil tank

4378B

v

DA-927A, DA-928A

CONTENTS

1. NAMES OF MAJOR PARTS ...... 1

2. MACHINE SPECIFICATIONS .....

3. TABLE AND MOTOR .................

3-1. Table processing diagram ............................... 3

3-2. Motor ............................................................... 4

4. INSTALLATION .......................... 5

4-1. Installing the machine head ............................ 5

4-2. Ground wire connections ................................ 7

4-3. Installing the pulley cover ................................ 7

4-4. BeIt tension adjustment .................................. 8

4-5. Assembling the cotton stand ........................... 8

4-6. Lubrication....................................................... 9

4-7. Checking the machine pulley

rotating direction ........................................... 10

5. PREPARATION BEFORE

SEWING ...................................

5-1. Needles and threads ..................................... 11

5-2. Installing the needles .................................... 11

5-3. Threading the lower threads ......................... 12

5-4. Threading the upper threads ......................... 12

11

9. STANDARD ADJUSTMENTS .... 17

2

3

9-1. Needle bar height adjustment ....................... 17

9-2. Adjusting the looper rocking movement and

forward-back movement ................................ 18

9-3. Needle and looper timing adjustment ............ 19

9-4. The clearance between the needles and

loopers ........................................................... 20

9-5. Needle guard adjustment .............................. 21

9-6. Feed dog height adjustment .......................... 22

9-7. Upper thread take-up guide adjustment ........ 22

9-8. Adjusting the upper thread guide .................. 23

9-9. Tension release shaft adjustment ................. 23

9-10. Lower thread take-up timing adjustment ..... 23

9-11. Lower thread take-up thread guide

adjustment .................................................. 24

9-12. Installing the lapper ..................................... 24

10. TROUBLESHOOTING .............. 25

6. SEWING ................................... 13

6-1. Sewing .......................................................... 13

7. THREAD TENSION .................... 14

7-1. Adjusting the thread tension ......................... 14

7-2. Presser foot pressure adjustment ................. 14

7-3. Adjusting the stitch length ............................. 15

8. CLEANING ................................. 16

8-1. Daily cleaning ................................................ 16

8-2. Changing the lubricating oil

(every three months) ..................................... 16

DA-927A, DA-928A

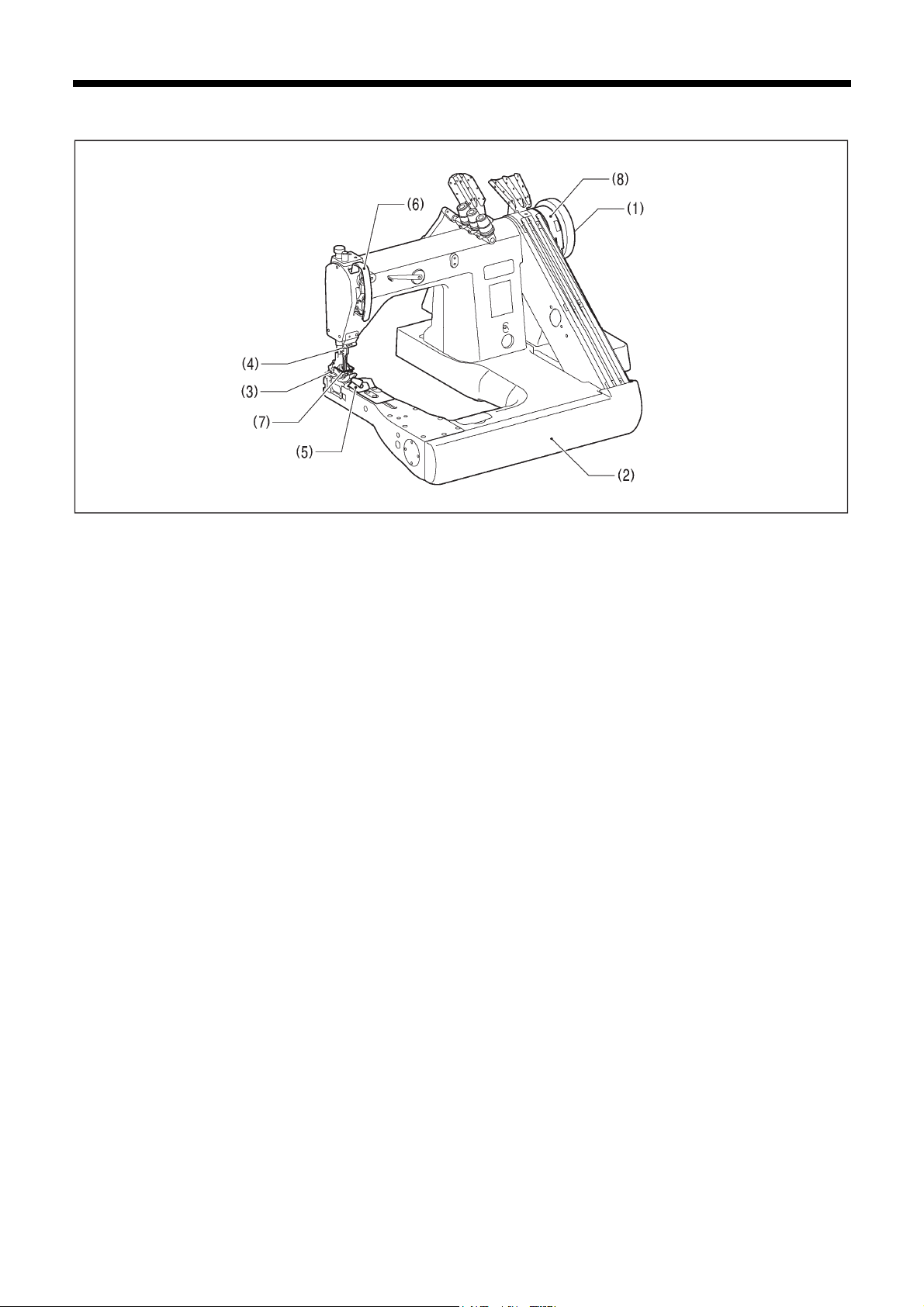

1. NAMES OF MAJOR PARTS

1. NAMES OF MAJOR PARTS

(1) Machine pulley (4) Needle bar

(2) Front cover (5) Lapper

(3) Presser foot

Safety devices

(6) Thread take-up cover

(7) Finger guard

(8) Pulley cover

4243B

1

DA-927A, DA-928A

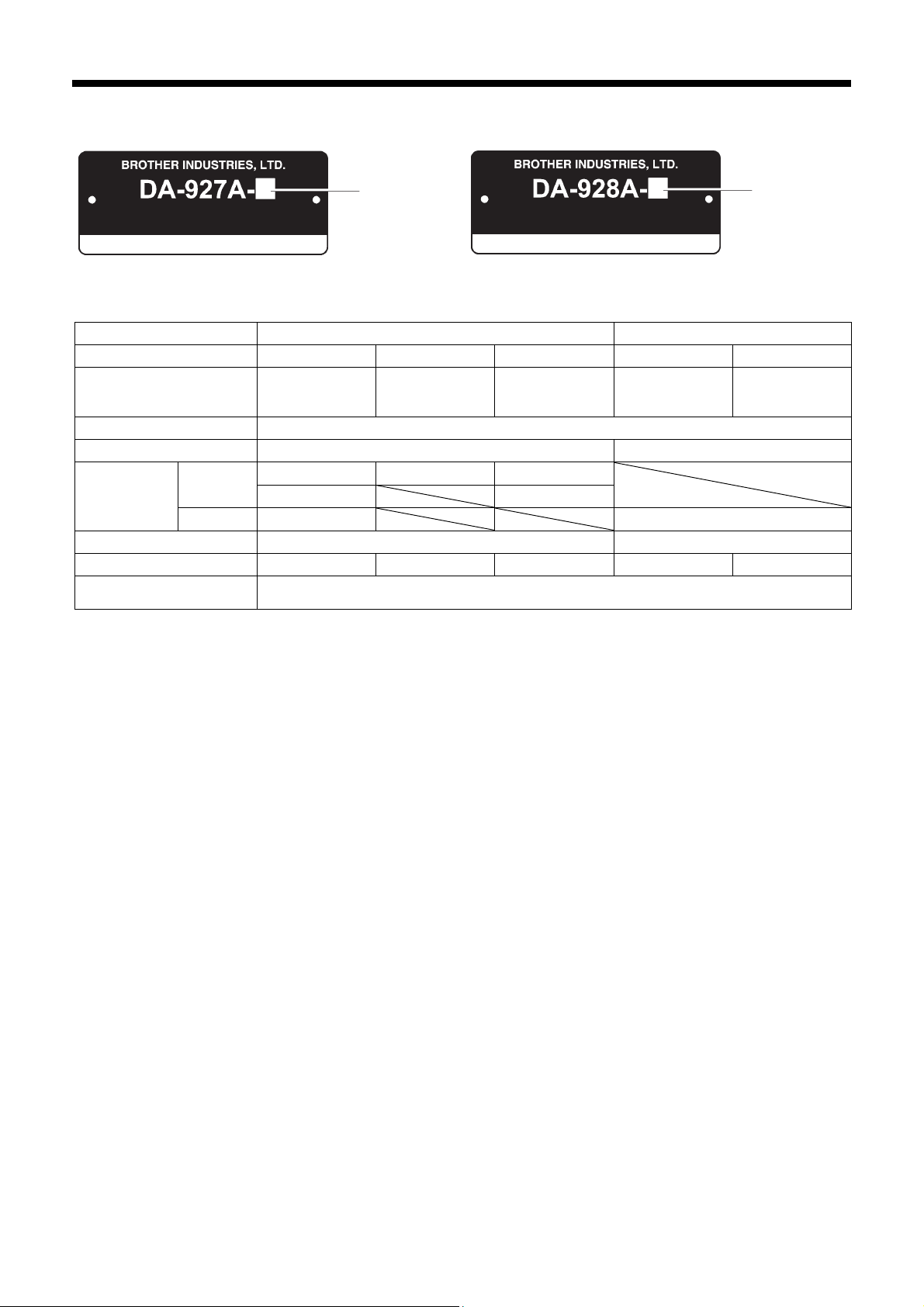

2. MACHINE SPECIFICATIONS

4244B

4245B

2. MACHINE SPECIFICATIONS

Specifications Specifications

Model

Specifications -1 -2 -3 -5 -7

Use

Max. sewing speed (sti/min) 4,000

Max. stitch length (mm) 3.8 4.7

Needle gauge

Needle (type) Organ TV x 64NY SCHMETZ TV x 5

Needle (count) #12 #14 #16 #130 #140

Outer perimeter of needle

drop cylinder (mm)

2 needles

3 needles 1/8 x 2 1/8 x 2

Light-weight

materials

3/16 3/16 3/16

1/4 1/4

DA-927A DA-928A

Light-weight to

medium-weight

materials

Medium-weight

materials

165

Heavy materials

Extra heavy

materials

* When the thread breaks due to heat at a speed of 4,000 sti/min sewing, reduce the sewing speed.

DA-927A, DA-928A

2

3. TABLE AND MOTOR

3. TABLE AND MOTOR

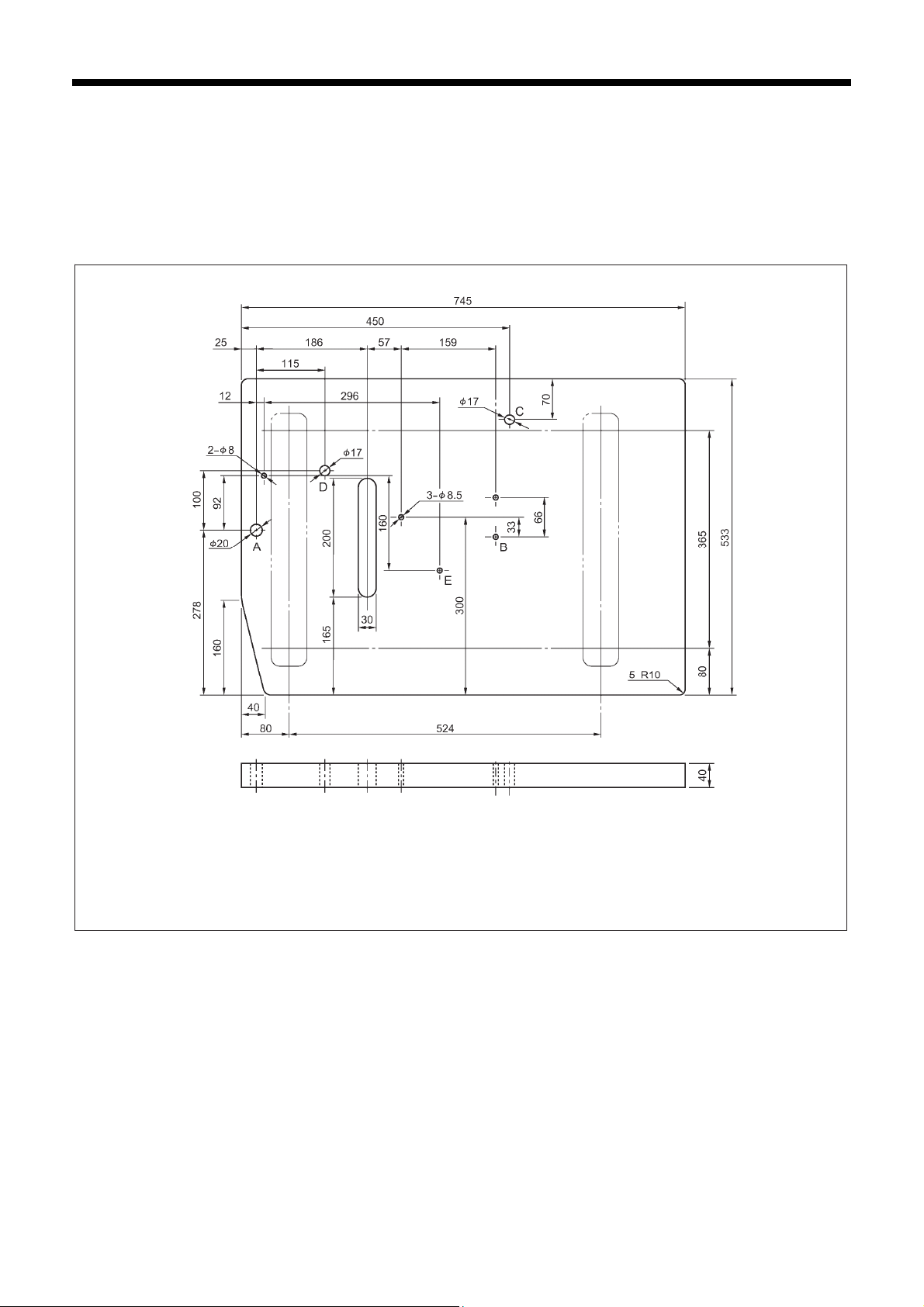

3-1. Table processing diagram

・The top of the table should be 40 mm in thickness and should be strong enough to hold the weight and withstand the vibration of

the sewing machine.

・

Drill holes as indicated in the illustration below.

A: Chain hole

B: Motor mounting holes (3 places)

C: Cotton stand hole

D: Ground hole

E: Sewing machine mounting holes (2 places)

4389B

3

DA-927A, DA-928A

3-2. Motor

CAUTION

All cords should be secured at least 25 mm away from any moving parts. Furthermore, do not excessively bend the cords

or secure them too firmly with staples.

If this is not observed, fire or electric shocks may result.

Install the correct belt cover which corresponds to the motor being used.

<Motor>

・ Use a 400-watt 2-pole clutch motor.

Refer to the instruction manual for the motor for details on installing and using the motor.

・

<Motor pulley and V-belt>

For details on the relationship between the motor pulleys and belts, refer to the table below.

* The belt should be an M-type V-belt.

Pulley O.D. 65 70 75 80 85 90 95 100

M41

Belt size

M42

3. TABLE AND MOTOR

M43

Sewing speed

(sti/min)

50Hz 3100 3500 4000

60Hz 3100 3500 4000

DA-927A, DA-928A

4

Loading...

Loading...