Page 1

INSTRUCTION MANUAL

DA-9270

Please read this manual before using the machine.

Please keep this manual within easy reach for quick reference.

TWIN NEEDLE (THREE NEEDLE) FEED OFF THE ARM

DOUBLE CHAIN STITCHER

Page 2

Thank you very much for buying a BROTHER sewing machine. Before using your new machine, please

read the safety instructions below and the explanations given in the instruction manual.

With industrial sewing machines, it is normal to carry out work while positioned directly in front of moving

parts such as the needle and thread take-up lever, and consequently there is always a danger of injury that

can be caused by these parts. Follow the instructions from training personnel and instructors regarding

safe and correct operation before operating the machine so that you will know how to use it correctly.

SAFETY INSTRUCTIONS

z Safety indications and their meanings

This instruction manual and the indications and symbols that are used on the machine itself are provided

in order to ensure safe operation of this machine and to prevent accidents and injury to yourself or other

people.

The meanings of these indications and symbols are given below.

Indications

The instructions which follow this term indicate situations where failure to

CAUTION

Symbols

follow the instructions could cause injury when using the machine or physical damage to equipment and surroundings.

................ This symbol ( ) indicates something that you should be careful of. The picture in-

side the triangle indicates the nature of the caution that must be taken.

(For example, the symbol at left means “beware of injury”.)

................ This symbol ( ) indicates something that you

................ This symbol ( ) indicates something that you

indicates the nature of the thing that must be done.

(For example, the symbol at left means “you must make the ground connection”.)

x Notes on safety

¡ Machine installation should only be car-

ried out by a qualified technician.

¡ Contact your Brother dealer or a quali-

fied electrician for any electrical work

that may need to be done.

¡ The sewing machine weighs more than

49 kg. The installation should be carried

out by two or more people.

¡ Do not connect the power cord until in-

stallation is complete, otherwise the

machine may operate if the treadle is

pressed by mistake, which could result

in injury.

¡ Be sure to connect the ground. If the

ground connection is not secure, you run

the risk of receiving a serious electric

shock.

must not do.

must do. The picture inside the circle

CAUTION

Installation

¡ All cords should be secured at least 25

mm away from any moving parts. Furthermore, do not excessively bend the

cords or secure them too firmly with

staples, otherwise there is the danger

that fire or electric shocks could occur.

¡ Install the belt covers to the machine

head and motor.

¡ If using a work table which has casters,

the casters should be secured in such a

way so that they cannot move.

¡ Be sure to wear protective goggles and

gloves when handling the lubricating oil,

so that no oil gets into your eyes or onto

your skin, otherwise inflammation can

result.

Furthermore, do not drink the oil under

any circumstances, as it can cause vom-

iting and diarrhoea.

Keep the oil out of the reach of children.

i

DA-9270

Page 3

CAUTION

Sewing

¡ This sewing machine should only be

used by operators who have received

the necessary training in safe use beforehand.

¡ The sewing machine should not be used

for any applications other than sewing.

¡ Attach all safety devices before using the

sewing machine. If the machine is used

without these devices attached, injury

may result.

¡ Do not touch any of the moving parts or

press any objects against the machine

while sewing, as this may result in personal injury or damage to the machine.

Cleaning

¡ Turn off the power switch before carry-

ing out cleaning. The motor will keep

turning even after the power is switched

off as a result of the motor’s inertia. Wait

until the motor stops fully before starting work.

The machine may operate if the treadle

is pressed by mistake, which could result

in injury.

¡ Turn off the power switch at the follow-

ing times, the machine may operate if

the treadle is pressed by mistake, which

could result in injury.

¡ When threading the needle

¡ When replacing the needle

¡ When not using the machine and

when leaving the machine unattended

¡ If using a work table which has casters,

the casters should be secured in such a

way so that they cannot move.

¡ If an error occurs in machine, or if abnor-

mal noises or smells are noticed, immediately turn off the power switch. Then

contact your nearest Brother dealer or a

qualified technician.

¡ If the machine develops a problem, con-

tact your nearest Brother dealer or a

qualified technician.

¡ Be sure to wear protective goggles and

gloves when handling the lubricating oil,

so that no oil gets into your eyes or onto

your skin, otherwise inflammation can

result.

Furthermore, do not drink the oil under

any circumstances, as it can cause vom-

iting and diarrhoea.

Keep the oil out of the reach of children.

Maintenance and inspection

¡ Maintenance and inspection of the sew-

ing machine should only be carried out

by a qualified technician.

¡ Ask your Brother dealer or a qualified

electrician to carry out any maintenance

and inspection of the electrical system.

¡ Turn off the power switch and discon-

nect the power cord from the wall outlet at the following times, otherwise the

machine may operate if the treadle is

pressed by mistake, which could result

in injury.

However, the motor will keep turning

even after the power is switched off as

a result of the motor’s inertia. Wait until

the motor stops fully before starting

work.

¡ When carrying out inspection, adjust-

ment and maintenance

¡ When replacing consumable parts

such as the looper

¡ If the power switch needs to be left on

when carrying out some adjustment, be

extremely careful to observe all safety

precautions.

¡ Use only the proper replacement parts

as specified by Brother.

¡ If any safety devices have been re-

moved, be absolutely sure to re-install

them to their original positions and

check that they operate correctly before

using the machine.

¡ Any problems in machine operation

which result from unauthorized modifications to the machine will not be covered by the warranty.

DA-9270

ii

Page 4

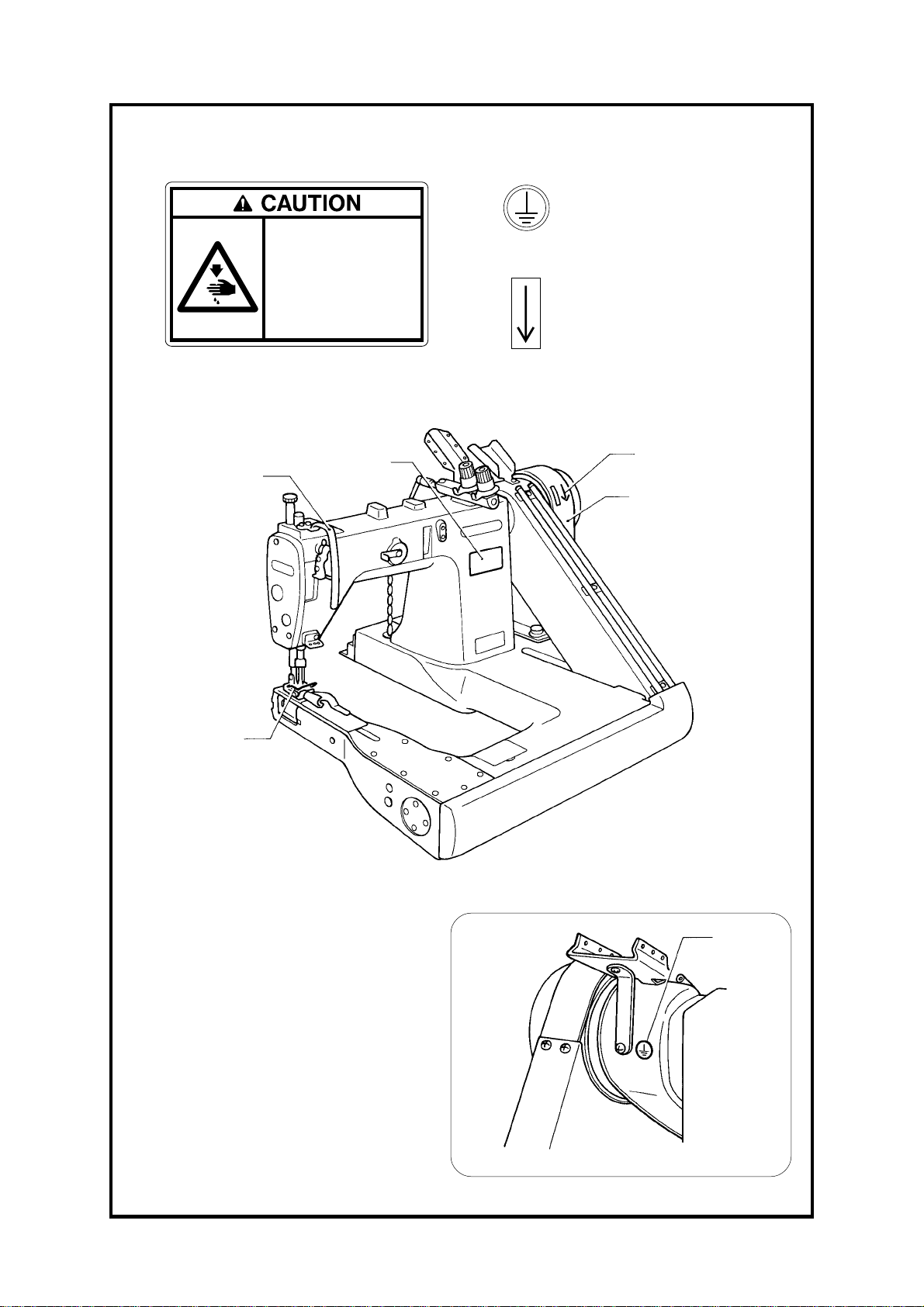

c Warning labels

★ The following warning labels appear on the sewing machine.

Please follow the instructions on the labels at all times when using the machine. If the labels have

been removed or are difficult to read, please contact your nearest Brother dealer.

1

Safety devices

q Finger guard

w Thread take-up cover

e Pulley cover, etc.

w

Moving parts

may cause injury.

Operate with safety de vices .

Turn off main switch before

threading, changing bobbin

and needle, cleaning etc.

1

2

3

Be sure to connect the ground.

If the ground connection is not

secure, you run the risk of receiving a serious electric shock.

Direction of operation

3

e

q

2

<Rear view>

iii

DA-9270

Page 5

CONTENTS

1. NAMES OF MAJOR PARTS...................... 01

2. MACHINE SPECIFICATIONS ..................... 01

3. WORK TABLE AND MOTOR .................... 02

4. INSTALLATION............................................. 03

4-1. Installing the machine head ............... 03

4-2. Ground wire connections ................... 04

4-3. Installing the pulley cover .................. 05

4-4. Belt tension adjustment ...................... 06

4-5. Cotton stand......................................... 06

4-6. Lubrication ............................................ 07

4-7. Checking the machine pulley

rotating direction ................................. 08

5. PREPARATION BEFORE SEWING ........... 08

5-1. Needles and threads ............................ 08

5-2. Installing the needles .......................... 08

5-3. Threading the lower threads.............. 09

5-4. Threading the upper threads ............. 09

6. SEWING......................................................... 10

6-1. Sewing .................................................. 10

7. THREAD TENSION...................................... 11

7-1. Adjusting the thread tension ............. 11

7-2. Presser foot pressure adjustment ..... 11

7-3. Adjusting the stitch length................. 12

7-4. Puller feed adjustment (Machines

with puller) ........................................... 12

9. STANDARD ADJUSTMENTS ................... 15

9-1. Needle bar height adjustment ........... 15

9-2. Needle and looper timing

adjustment............................................ 16

9-3. Timing of loopers running clear of

needles .................................................. 17

9-4. Needle guard adjustment ................... 17

9-5. Feed dog height adjustment .............. 18

9-6. Upper thread take-up thread

guide adjustment................................. 19

9-7. Upper thread arm thread guide

adjustment............................................ 19

9-8. Thread release shaft adjustment ....... 19

9-9. Lower thread take-up timing

adjustment............................................ 19

9-10. Installing the lapper ............................. 20

9-11. Puller height adjustment

(Machines with puller) ........................ 20

9-12. Puller device timing adjustment

(Machines with puller) ........................ 20

10.TROUBLESHOOTING ................................. 21

8. CLEANING..................................................... 14

8-1. Daily cleaning ....................................... 14

8-2. Changing the lubricating oil

(every three months)........................... 14

DA-9270

iv

Page 6

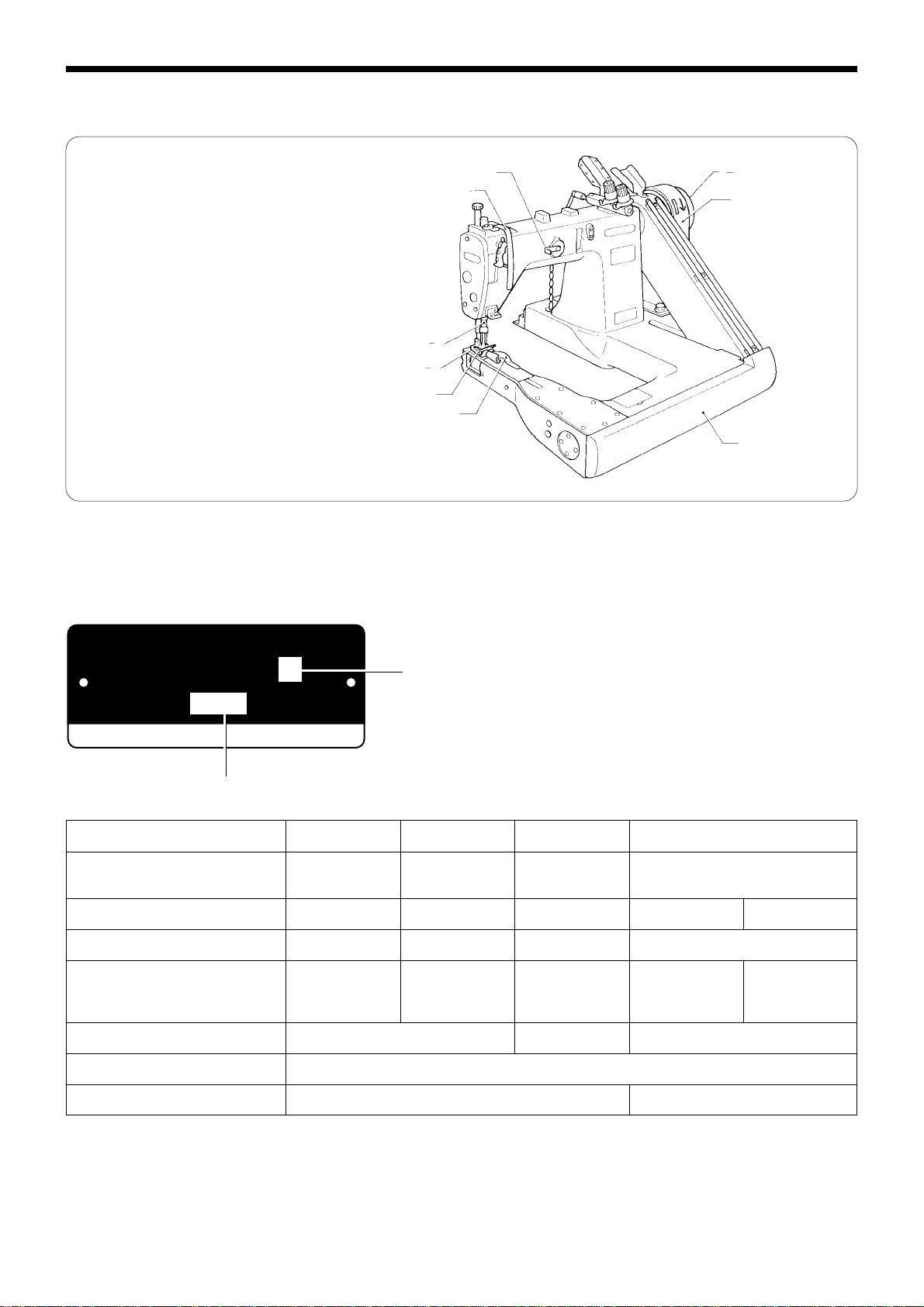

1. NAMES OF MAJOR PARTS

2. MACHINE SPECIFICATIONS

1. NAMES OF MAJOR PARTS

q Machine pulley

w Front cover

e Presser

r Needle bar

t Upper thread arm guide

y Lapper

r

Safety device

u Thread take-up cover

i Finger guard

o Pulley cover

e

i

2. MACHINE SPECIFICATIONS

y

u

t

q

o

w

BROTHER INDUSTRIES, LTD.

DA-9270-1

MADE IN JAPAN

Optional device

Specifications -1 -2 -3 -A

Applications Light materials Light - medium Medium Light materials, with puller

No. of needles 2 2 2 2 3

Needle TV X 64 #12 #14 #16 #11PSU

Needle gauge 4.8 mm (3/16) 3.2 mm (1/8) 6.4 mm (1/4) 4.8 mm (3/16) 6.4 mm (1/4)

6.4 mm (1/4) 4.0 mm (5/32) 6.4 mm (1/4)

Max. stitch length 3.0 mm 3.5 mm 3.0 mm

Min. arm size 171 mm

Specifications

materials materials

4.8 mm (3/16)

Max. sewing speed 4,000 rpm 3,600 rpm

1

DA-9270

Page 7

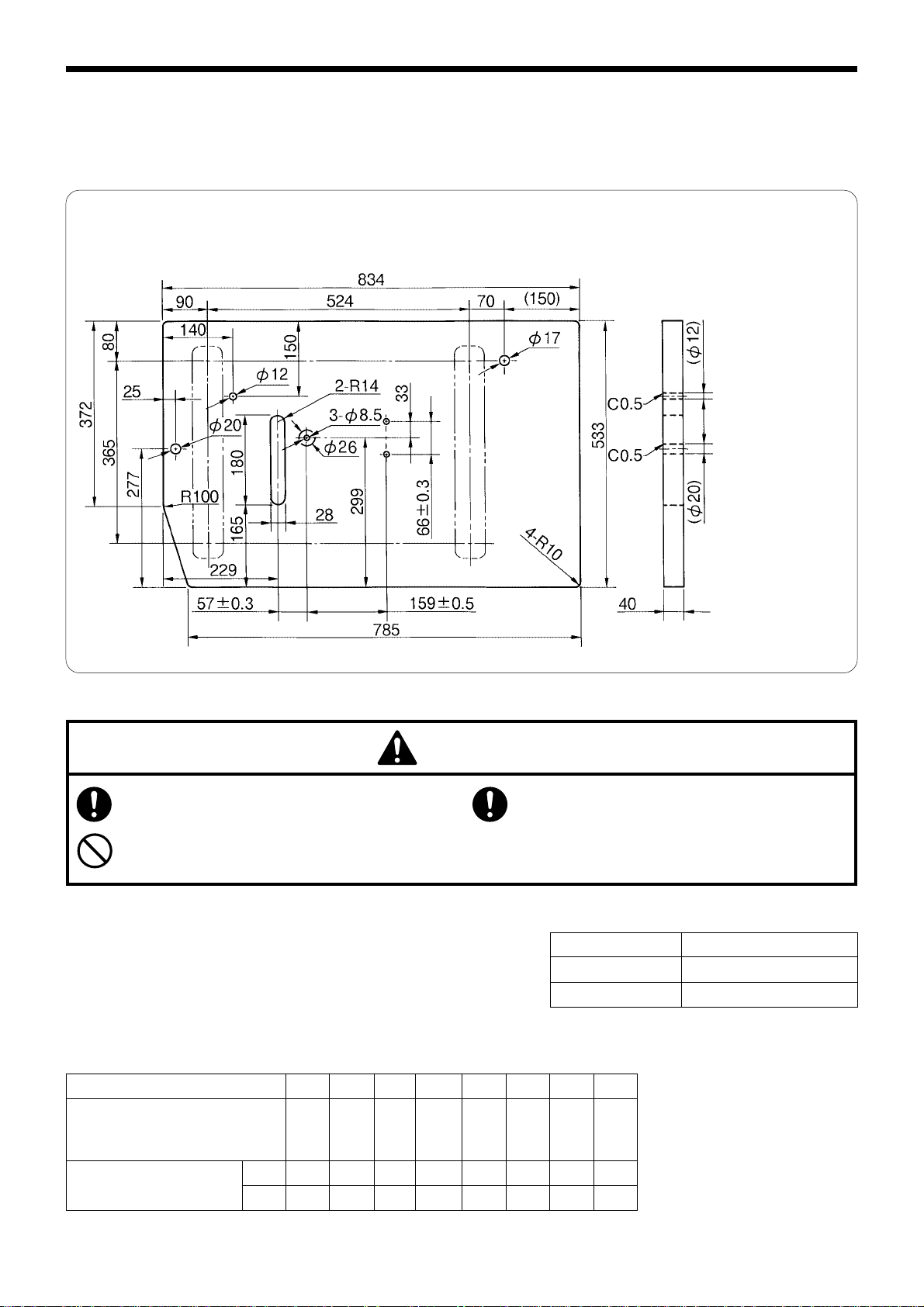

3. WORK TABLE AND MOTOR

3. WORK TABLE AND MOTOR

■ Work Table

If using a commercially-available table

¡ The top of the table should be 40 mm in thickness and should be strong enough to hold the weight and with-

stand the vibration of the sewing machine.

¡ Drill holes as indicated in the illustration below.

A

C

D

A

Depth 1

+0.5

B

0

Chain hole

B

Motor mounting holes

C

Cotton stand hole

D

Ground hole

■ Motor

CAUTION

¡ All cords which are connected to the motor

should be secured at least 25 mm away from

any moving parts. Furthermore, do not excessively bend the cords or secure them too firmly

with staples, otherwise there is the danger that

fire or electric shocks could occur.

<Motor>

¡ Select the correct motor from those listed in the above table.

¡ Refer to the instruction manual for the motor for details on in-

stalling and using the motor.

<Motor pulley and V-belt>

¡ Refer to the table below to select the motor pulley and belt combination.

¡ The belt should be an M-type V-belt.

Pulley O.D. 65 70 75 80 85 90 95 100

M42

..

..

....

..

Belt size (inches)

Sewing speed (rpm)

.

.

..

..

50Hz 3100 3600 4000

60Hz 3100 3600 4000

..

....

.

..

././

./

././

,,

..........

,

.....

,,

..........

M43

..

../../

.

../

..

../../

¡ Install the correct belt cover which corresponds

to the motor being used.

..

.

..

..

.

..

M44

......

...

......

,,

,

,,

Power Motor

Single-phase 2-pole, 400 W motor

Three-phase 2-pole, 400 W motor

..

../../

.

../

..

../../

DA-9270

2

Page 8

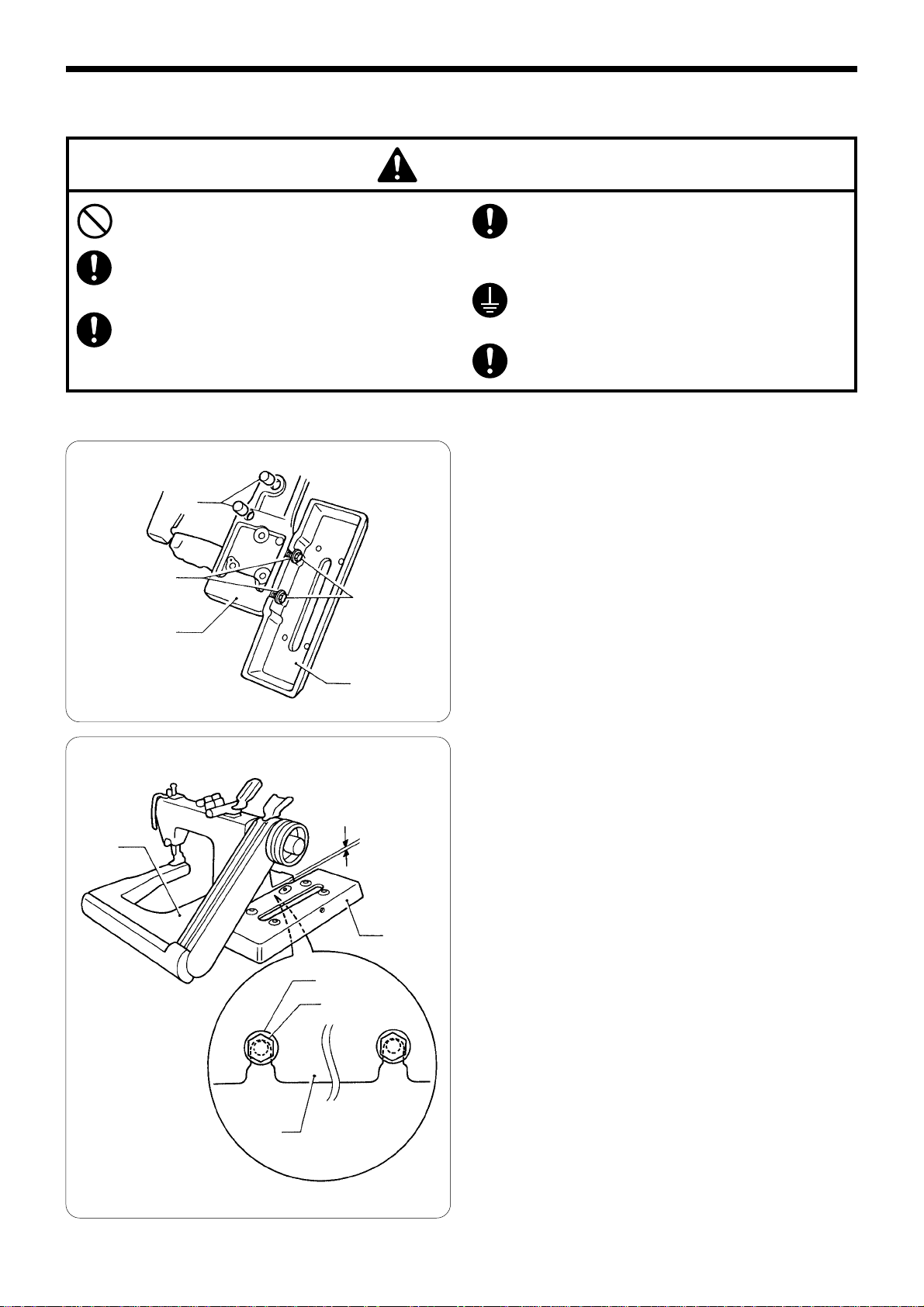

4. INSTALLATION

4. INSTALLATION

CAUTION

CAUTION

¡ The sewing machine should only be installed

by a qualified technician.

¡ Ask your Brother dealer or a qualified electri-

cian for any electrical work that may need to

be done.

¡ The sewing machine weighs more than 49 kg.

The installation should be carried out by two

or more people.

4-1. Installing the machine head

t

r

q

e

¡ Do not connect the power cord until installation

is complete, otherwise the machine will operate if the treadle is pressed by mistake, which

could result in injury.

¡ Be sure to connect the ground. If the ground

connection is not secure, serious electric shocks

will result.

¡ Install the pulley cover to the machine head.

1. Install pulley cover base w on machine bed q with two

hexagonal bolts

2. Insert two bar cushions

of the bed.

e and two washers r.

t into the holes in the bottom

q

(Bottom view)

w

Parallel

r

e

w

w

* At this time, install the two hexagonal bolts e so that

they go as far as possible into the notches in the

pulley cover base

Furthermore, check that the pulley cover base

parallel to the bed. (If it is not parallel, the pulley

cover may touch the machine pulley.)

w.

w is

3

DA-9270

Page 9

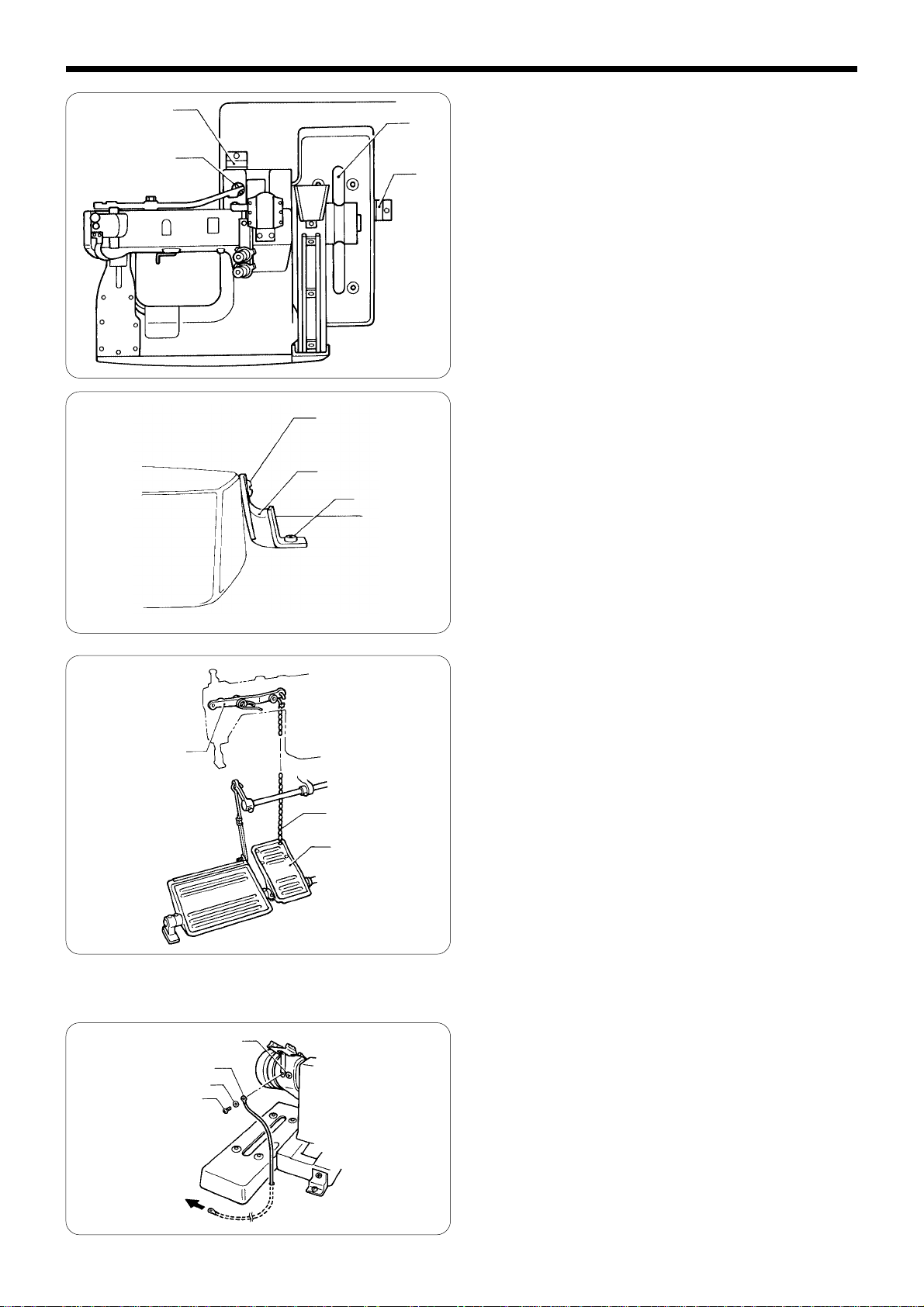

4. INSTALLATION

u

y

i

u

o

!0

u

3. Place the machine head on the table, adjust its position in forward and backward directions by aligning it

with the hole for presser bar lifter chain

wise directions by aligning it with belt hole

4. After fastening cushions u to the machine bed and

pulley cover base with set screws i, fix them to the

table with screws

* Place the work table so that the machine head is

horizontal.

If the machine head is not horizontal, lubrication will

not be carried out correctly.

o.

y, and in side-

!0.

!1

4-2. Ground wire connections

r

q

e

w

To motor

y

!2

5. Connect the presser bar lifter chain y to the knee lifter

lever !1 and the presser lifter pedal !2.

Connect the ground wire to the sewing machine head and

motor.

(Use the correct type of ground wire and washer.)

1. Remove lower thread guide holder screw

2. Secure the ground wire q to the sewing machine head

with screw

(The attachment location is indicated by a ground sym-

r.)

bol

3. Pass the ground wire

4. Connect the ground wire

with the instructions in the instruction manual for the

motor.

w and washer e.

q through the hole in the table.

q to the motor in accordance

w.

DA-9270

4

Page 10

4. INSTALLATION

4-3. Installing the pulley cover

w

q

1. Place the belt w onto the machine pulley q.

* Pull the belt

e.

A

w upward when installing pulley cover

r

y

t

e

t

e

u

2. Place pulley cover A e so that it is in between the eight

pulley cover seats t, and then secure it to the pulley

cover base with the four screws

3. Push the belt

cover B

u.

w downward, and then install pulley

y to pulley cover A e with the three screws

r.

w

4. If the machine is being used with the puller attached,

install the puller belt cover

o

i

5

DA-9270

i with the two screws o.

Page 11

4-4. Belt tension adjustment

20 - 30mm

q

4. INSTALLATION

1. Place the V-belt e onto the motor pulley w.

2. Turn the two nuts

mm of deflection in the V-belt

the midway point with a force of 9.8 N.

r to adjust so that there is 20 - 30

e when it is pressed at

r

4-5. Cotton stand

w

e

1. Assemble the cotton stand while referring to the cotton stand instruction manual.

2. Install the cotton stand to the cotton stand mounting

hole in the work table with the nut

q.

q

DA-9270

6

Page 12

4. INSTALLATION

4-6. Lubrication

¡ Be sure to wear protective goggles and gloves when handling the lubricating oil, so that no oil gets into

your eyes or onto your skin, otherwise inflammation can result.

Furthermore, do not drink the oil under any circumstances, as it can cause vomiting and diarrhoea.

Keep the oil out of the reach of children.

y

r

CAUTION

¡ The sewing machine should always be lubricated and

the oil supply replenished before it is used for the first

time, and also after long periods of non-use.

★ Use only the lubricating oil (Nisseki Mitsubishi Sewing

Lube 15N; VG15) specified by Brother.

Upper

reference

line

e

Lower reference line

u

w

i

o

t

q

1. Open the front cover

q, remove the rubber plug w, and

then fill with oil until the oil level reaches the point in

between the reference lines on the oil gauge

e.

* If the oil level drops to the lower reference line, be

sure to add more oil.

2. Insert the rubber plug

q.

w and then close the front cover

3. Add 1 - 2 drops of oil once a week to needle bar bracket

lubrication hole

r.

4. Periodically loosen the oil drain screw t to drain out

any oil which collects in the front bed oil sump. After

draining the oil, tighten the oil drain screw

t.

5. Periodically wipe away any oil which collects in the rear

bed oil sump

y with a cloth.

6. Turn the machine pulley, so that the oil hole cover u

is facing upward, and then remove the oil hole cover

u and fill the oil tank i with oil.

If the level of lubricating oil drops below the middle reference line

o on the oil tank, no oil will be drawn into

the upper shaft, and the upper shaft will thus not be

lubricated sufficiently. Be sure to maintain the lubricating oil level at a level above the center reference line.

7. Attach the oil hole cover

u.

* If the machine is being used with the puller attached,

!1

remove the cover screws !1 and fill with oil until the

level reaches the upper reference line in the oil sight

glass.

* If the oil level drops to the lower reference line, be

Upper

reference

line

Lower

reference

line

7

DA-9270

sure to add more oil.

After lubrication is completed, tighten the cover

screws

!1.

Page 13

4-7. Checking the machine pulley rotating direction

CAUTION

¡ Do not touch any of the moving parts or place any objects against the machine while sewing, as this may

result in personal injury or damage to the machine.

1. Insert the power cord plug into the wall outlet, and

q

2. Depress the treadle slightly and check that the ma-

4. INSTALLATION

5. PREPARATION BEFORE SEWING

then turn on the power switch.

chine pulley starts to turn in the direction of the ar-

q.

row

* If the direction of rotation is reversed, change the

direction of rotation to the correct direction while

referring to the instruction manual for the motor.

* For the first 3 - 4 days of use, run the machine at

500 rpm lower than the usual speed. This will help

contribute to a longer service life for the machine.

5. PREPARATION BEFORE SEWING

5-1. Needles and threads

The needle and threads to be used vary depending on sewing conditions. Select the correct ones by referring to the

table below.

Needle

Upper thread Lower thread

ORGAN TV×64

#11 spun yarn #80 spun yarn #80

#12

#14 spun yarn #60 spun yarn #60

#16 spun yarn #50 spun yarn #50

Thread

5-2. Installing the needles

CAUTION

¡ Turn off the power switch before installing the needle, otherwise the machine may operate if the treadle is

pressed by mistake, which could result in injury.

1. Turn the pulley until needle holder q is raised to the

highest position.

2. Loosen needle set screws

long grooved side facing front, insert them into needle

q all the way, and fasten the needle with needle

holder

q

set screws

w

e

DA-9270

w, hold needles e with their

w.

8

Page 14

5. PREPARATION BEFORE SEWING

5-3. Threading the lower threads

¡ Turn off the power switch before threading the upper thread, otherwise the machine may operate if the

treadle is pressed by mistake, which could result in injury.

Pass the lower threads as shown in the figure below.

Needle hole

position

Needle hole

position

2

3

(1)

1

(3)

50 - 60mm

CAUTION

3

1

1

2

3

2

1

2

3

3

5-4. Threading the upper threads

¡ Turn off the power switch before threading the upper thread, otherwise the machine may operate if the

treadle is pressed by mistake, which could result in injury.

Pass the upper threads as shown in the figure below.

4

5

6

1

2

CAUTION

1

2

3

4

5

6

1

6

5

4

2

3

50 - 60mm

6

5

4

9

DA-9270

1

2

6

5

4

6

5

4

3

1

2

3

Page 15

6. SEWING

¡ Attach all safety devices before using the sewing machine. If the machine is used without these devices

attached, injury may result.

¡ Turn off the power switch at the following times, otherwise the machine may operate if the treadle is pressed

by mistake, which could result in injury.

¡ When threading the needle

¡ When replacing the needle

¡ When not using the machine and when leaving the machine unattended

¡ Do not touch any of the moving parts or place any objects against the machine while sewing, as this may

result in personal injury or damage to the machine.

6-1. Sewing

CAUTION

1. Switch the power on.

2. Depress presser lifter pedal

der the presser foot.

3. Release the presser lifter pedal.

4. The machine starts running when treadle

down.

6. SEWING

q and place the work un-

w is stepped

w

e

q

5. After sewing the work, move the work to thread cutter

e to make blank stitches, and cut the thread with it.

DA-9270

10

Page 16

7. THREAD TENSION

7. THREAD TENSION

7-1. Adjusting the thread tension

Upper thread

Lower thread

Lower thread

Upper thread

Good stitches

Loose, bad stitches

Appearance of seam when upper thread

tension is too weak

Becomes

weaker

q

Becomes

stronger

w

Becomes stronger Becomes weaker

1. Adjust the upper thread tension properly by turning upper thread adjusting screw

q.

2. Adjust the lower thread tension properly by turning

lower thread adjusting screw

w.

7-2. Presser foot pressure adjustment

Adjust the presser foot pressure by turning presser adjusting screw q so that the pressure is just enough to feed the

work positively and keep the work from slipping.

* In case of Machines with puller the puller pressure can

be adjusted as appropriate to the work by turning

presser adjusting screw

DA-9270

11

Becomes

stronger

Becomes

weaker

w

Becomes

weaker

Becomes

stronger

q

w.

Page 17

7-3. Adjusting the stitch length

¡ Turn off the power supply before adjusting the stitch length, otherwise the machine will operate if the treadle

is pressed by mistake, which could result in injury.

However, the motor will keep turning even after the power is switched off as a result of the motor’s inertia.

Wait until the motor stops fully before starting work.

w

e

q

CAUTION

¡ The numerals on the machine pulley scale represent the

stitch length (mm), however the actual stitch length will

vary depending on the type and thickness of material being used.

1. Open the front cover

2. While pressing the feed adjustment button

machine pulley toward you slowly. (The feed adjustment button

3. While still pressing the feed adjustment button

turning the machine pulley until the desired numeral

appears in the center of the pulley cover windows

* The higher the value of the numeral, the larger the

stitch length becomes.

Release the feed adjustment button

(Check that the feed adjustment button

out again.)

4. Close the front cover

NOTE:

Do not press the feed adjustment button

machine is operating, as doing so may damage the

machine parts.

When sewing with the stitch length set close to the

maximum length, you will need to adjust the needle

guard in accordance with the type of material and

the type of thread being used.

7. THREAD TENSION

e.

q, turn the

q will move further inward.)

q, keep

w.

q.

q pops back

e.

q while the

7-4. Puller feed adjustment (Machines with puller)

1. With feed adjusting button q lightly pressed with your

finger, turn the pulley toward yourself until feed adjusting button

2. Keep pressing feed adjusting button q, and turn the

pulley to set your desired feed position on the scale to

the reference line.

The more your turn the pulley toward yourself, the

smaller will be the feed.

* Adjust the puller feed after seeing the finished

stitches of the work (Refer to page 13).

Smaller

Larger

Reference

line

q

DA-9270

q goes in one step deeper.

12

Page 18

7. THREAD TENSION

★ The table below shows samples of stitches made with a highly elastic fabric and a fabric which is not so elastic.

Adjust the puller feed by referring to this table.

Puller feed Fabric with high elasticity Fabric with low elasticity

Correct

Feed direction Feed direction

Insufficient

Neither non-alignment nor sewing wrinkles. Neither non-alignment nor sewing wrinkles.

Non-aligned, and wrinkled. Non-aligned, and wrinkled.

Excessive

Non-aligned, and very wavy. Non-aligned, and very wavy.

13

DA-9270

Page 19

8. CLEANING

8. CLEANING

The following cleaning operations should be carried out each day in order to maintain the performance of this machine

and to ensure a long service life.

CAUTION

¡ Turn off the power switch before carrying out cleaning. The motor will keep turning even after the power

is switched off as a result of the motor’s inertia. Wait until the motor stops fully before starting work.

The machine may operate if the treadle is pressed by mistake, which could result in injury.

¡ Be sure to wear protective goggles and gloves when handling the lubricating oil, so that no oil gets into

your eyes or onto your skin, otherwise inflammation can result.

Furthermore, do not drink the oil under any circumstances, as it can cause vomiting and diarrhoea.

Keep the oil out of the reach of children.

8-1. Daily cleaning

■ Cleaning the machine

1. Open the looper side plate q and clean away any

thread scraps and other rubbish.

2. After cleaning, close the looper side plate

q.

■ Lubrication

Refer to “4-6. Lubrication” on page 7.

q

■ Checking

1. Check that the threads are threaded correctly. (Refer to

page 9.)

2. If the tips of the needles are broken, replace the broken needles.

3. Carry out a trial sewing.

8-2. Changing the lubricating oil (every three months)

The lubricating oil should be changed at least once every

three months.

1. Remove the 11 screws

feed arm cover

2. Draw up all of the lubricating oil inside the machine

into the oil bottle

3. Fill the machine with oil until the oil level reaches the

point in between the reference lines on the oil gauge.

(Refer to page 7.)

4. Close the forward feed arm cover

the 11 screws

[Machines with puller]

1. Remove the eight screws

top cover t.

2. Draw up all of the lubricating oil inside the machine

into the oil bottle

3. Fill the machine with oil until the oil level reaches the

top reference line on the oil gauge. (Refer to page 7.)

4. Close the puller top cover

screws r.

e

r

w

q

t

Upper

reference

line

w.

q, and then open the forward

e.

w and secure it with

q.

r, and then open the puller

e.

t and secure it with the eight

DA-9270

14

Page 20

9. STANDARD ADJUSTMENTS

9. STANDARD ADJUSTMENTS

CAUTION

¡ Maintenance and inspection of the sewing ma-

chine should only be carried out by qualified

personnel.

¡ Ask your Brother dealer or a qualified electri-

cian to carry out any maintenance and inspection of the electrical system.

¡ Turn off the power switch and disconnect the

power cord from the wall outlet at the following times, otherwise the machine may operate

if the treadle is pressed by mistake, which could

result in injury.

However, the motor will keep turning even after the power is switched off as a result of the

motor’s inertia. Wait until the motor stops fully

before starting work.

¡ When carrying out inspection, adjustment

and maintenance

¡ When replacing consumable parts such as

the looper

9-1. Needle bar height adjustment

q

i

r

i

q

w

e

y

q

o

!0

y

11.3mm

(For thin

materials)

10.1mm

(For mediumthick materials)

0

0

w

u

t

¡ If the power switch needs to be left on when

carrying out some adjustment, be extremely

careful to observe all safety precautions.

¡ If any safety devices have been removed, be

absolutely sure to re-install them to their original positions and check that they operate correctly before using the machine.

Adjust the heights of the needles q.

At this time, adjust so that each needle

of the needle hole i in the needle plate w.

1. Remove the screw

!0.

2. Turn the machine pulley to drop the needle bar to its

lowest position.

3. Remove the rubber plug

clamp screw

the bottom of the needle clamp

needle plate w is 11.3 mm (for thin materials) or 10.1

mm (for medium-thick materials).

* If the needle clamp is set in the way described

above, the distance between the points of the

needles

8.5 mm (for thin materials) or 10.3 mm (for mediumthick materials) when the needle clamp

to its highest position.

4. Remove the three screws

needle plate w.

5. Turn the machine pulley so that the needles

needle guard

the needle clamp e so that there is no space between

the left and right needles

this time.

Install the needle plate

after checking that the needles

the needle holes

t.

6. Insert the rubber plug

7. Install the presser foot

q and the top of the needle plate w will be

o, and then remove the presser foot

r, loosen the needle bar

t and adjust so that the distance between

u, and then remove the

y are aligned, and then adjust the tilt of

q and the needle guard y at

w with the three screws u, and

i, tighten the needle bar clamp screw

r.

!0 with the screw o.

q is in the center

e and the top of the

e is raised

q and the

q are in the centers of

15

DA-9270

Page 21

9-2. Needle and looper timing adjustment

r

u

y

t

w

9. STANDARD ADJUSTMENTS

Make an adjustment so that, when needles q are down

lowest loopers

the distance from the needle center to the looper tip is 2.1

to 2.3 mm.

1. Remove the presser foot, needle plate and feed dogs

(Refer to page 15)

e

2. Remove the two screws

cover plate r.

3. Turn the pulley toward yourself until loopers

the end of their backward travel.

4. Loosen cap screw

u on lower belt wheel y.

5. Turn the pulley toward yourself until needles

down to the lowest position.

6. T ighten two set screws

screw

7. Loosen set screw i, move looper holder o in the arrow direction until the distance between the needle

center and the looper tip is 2.1 to 2.3 mm, and retighten

set screw

8. Make sure that the looper thread eyes match the needle

eyes in the forward and backward travels of the loopers.

9. Close the belt cover plate

screws

10. Install the presser foot, needle plate and feed dogs.

w reach the end of their backward travel and

e, and then open the belt

t, and then loosen two set screws

u securely , and then tighten cap

t.

i securely.

r, and then tighten the two

e.

w reach

q come

q

2.1 - 2.3mm

i

Looper forward travel Looper backward travel

o

DA-9270

16

Page 22

9. STANDARD ADJUSTMENTS

9-3. Timing of loopers running clear of needles

q

The loopers run in back of the needles in their forward

travel and in front of the needles in their backward travel.

Adjust the clearance between the needles and the loopers

to anywhere from 0.05 to 0.1 mm in the forward travel.

w

Turning direction

Front

t

r

9-4. Needle guard adjustment

r

e

w

q

1 - 2mm

0.2mm

Rear

Needle

Looper

0.05~0.1mm

q

e

1. Remove forward feed arm cover

q.

2. The forward/back looper timing should be adjusted so

that the set screw which is at the front relative to the

forward/back cam turning direction is aligned with the

screw adjustment hole

e when the set screw which is

at the front relative to the up/down cam turning direction is aligned with the looper connecting rod adjustment hole

w.

To adjust, loosen the set screw which is at the rear relative to the forward/back cam turning direction, and then

loosen the set screw at the front just enough so that

the forward/back cam can be adjusted.

After adjusting, tighten the two set screws.

3. Loosen the looper holder screw

looper holder

t in the direction of the arrow to adjust

r, and then move the

so that the clearance between the tip of the looper and

the center of the needle is 0.05 - 0.1 mm when the two

are aligned.

At this time, do not move the looper holder

t in any

direction except the direction indicated by the arrow.

If it is moved in another direction, carry out the adjustments given in “9 - 2. Adjusting the needle and looper

timing” on page 16.

4. Install the forward feed arm cover

q.

[For movable needle guard]

The clearance between the needle guard q and the needles

w should be 0.2 mm when the stitch length is at the mini-

mum setting and the loopers are moving toward the

needles.

The heights should be adjusted to as low a setting as possible without the loopers breaking.

1. Adjust the stitch length to the minimum setting. (Refer to page 12.)

2. Turn the machine pulley toward yourself to align the

loopers with the centers of the needles.

3. Loosen the set screw

e, and then raise or lower the

needle guard q so that the distance from the bottom

of the needle guard

q to the points of the needles is 1

- 2 mm.

4. Tighten the set screw

5. Loosen the set screw

q to the left or right to adjust so that the clear-

guard

e.

r, and then move the needle

ance between the needle guard q and the needles is

0.2 mm.

6. Tighten the set screw

r.

NOTE:

For some materials and threads, the best results can

be obtained if the needle guard and the needle are

touching slightly when the stitch length is adjusted

to the actual stitch length.

17

DA-9270

Page 23

q

e

w

9. STANDARD ADJUSTMENTS

[For fixed needle guard]

The needle guard prevents the needles from contacting the

loopers in their forward travel. Position the needle guard

as close to the needles as possible but make sure that it is

clear of the needles.

1. Turn the pulley toward yourself until the needles come

down to the lowest position.

2. Loosen lower set screw

feed arm.

3. Adjust the clearance between needles

guard e to anywhere from 0.2 to 0.3 mm by moving

needle guard

e.

4. After the adjustment, retighten set screw

q at the end of the forward

w and needle

q securely.

0.2 - 0.3mm

9-5. Feed dog height adjustment

0.8mm

w

0.8mm

q

Feed dog

Adjust the height of feed dog q so it is 0.8 mm above the

top of the needle plate when feed dog q is at the highest

position.

Adjust the height of feed dog

tric shaft

w.

q by turning feed bar eccen-

Needle plate

DA-9270

18

Page 24

9. STANDARD ADJUSTMENTS

9-6. Upper thread take-up thread guide adjustment

Adjust the distance between the center of the upper thread

take-up and the top of the thread guide will be 2 ~ 3 mm.

q

w

2 - 3mm

1. Turn the pulley toward yourself until the needle bar is

2. Loosen the screw

3. Tighten the screw

9-7. Upper thread arm thread guide adjustment

Adjust the upper thread arm thread guide so that the upper thread has a slight tension when the loopers run out

of upper thread loops.

1. Loosen the screw

2. After the adjustment, retighten the screw

down at the lowest position.

take-up thread guide w up or down to adjust so that

the distance from the top of the upper thread take-up

thread guide

up hole is 2 - 3 mm.

* The higher the upper thread take-up thread guide

the greater will be the upper thread loops.

thread arm thread guide

q, and then move the upper thread

w to the center of the upper thread take-

w,

q.

q, and then adjust so that the upper

w is nearly horizontal.

q.

w

q

9-8. Thread release shaft adjustment

q

w

9-9. Lower thread take-up timing adjustment

Adjusting hole

w

e

7mm

q

Adjust the thread release shaft so that the thread tension

discs loosen when the presser foot is raised and tighten

when the presser foot is lowered.

1. Loosen set screw

2. Make an adjustment by turning thread release shaft w

so that the thread tension discs begin to loosen when

the presser foot rises 4 mm above the top of the needle

plate.

3. After the adjustment, retighten set screw

Make an adjustment so that, when the loopers begin moving backward, lower thread take-up

and is 7 mm up from lower thread take-up base e.

1. Insert screwdriver through the adjusting hole in the

lower thread take-up base, and loosen two set screws

r.

2. Raise lower thread take-up

thread take-up base e.

3. After the adjustment, retighten two set screws

curely.

q.

q securely.

q contacts thread w,

q until it is 7 mm up from

r se-

r

19

DA-9270

Page 25

9-10. Installing the lapper

9. STANDARD ADJUSTMENTS

Insert the lapper guide plate from the front into the oval

slot in the forward feed arm cover, making sure that the

end of lapper is clear of the presser foot.

w

AB

■ Lapper adjustment

Adjust felling distance of point A by loosing set screw q.

After the adjustment, retighten set screw

Adjust felling distance of point

After the adjustment, retighten set screws w.

q

9-11. Puller height adjustment (Machines with puller)

Adjust the height of puller q so that it is 0.4 to 0.5 mm high

from the top of the needle plate.

Loosen set screw

down until puller

needle plate.

w

e

q

After the adjustment, retighten set screw

B by loosing set screws w.

q.

w, and move puller support e up or

q is 0.4 to 0.5 mm above the top of the

w.

0.4 - 0.5mm

9-12. Puller timing adjustment (Machines with puller)

Make an adjust so that, when the needle bar is down at

the lowest position, the mark on timing collar q is in line

with the reference line.

Reference line

w

q

1. Turn the pulley toward yourself until the mark on tim-

2. Loosen two set screws

3. Retighten set screws

ing collar

yourself until the needle bar is lowered all the way

down.

q meets the reference line.

w, and turn the pulley toward

w.

DA-9270

20

Page 26

10. TROUBLESHOOTING

10. TROUBLESHOOTING

¡ Please check the following points before calling for repairs or service.

¡ If the following suggestions do not solve the problem, turn off the machine power supply and contact your nearest

Brother service center.

CAUTION

¡ Turn off the power supply before adjusting the stitch length, otherwise the machine will operate if the treadle

is pressed by mistake, which could result in injury.

However, the motor will keep turning even after the power is switched off as a result of the motor’s inertia.

Wait until the motor stops fully before starting work.

Problem Possible cause Page

1. Upper thread is not tight. ¡ Is the upper thread tension too weak, or is the lower thread tension

too strong?

Adjust the upper thread tension or lower thread tension.

¡ Is the position of the upper thread take-up thread guide incorrect?

Adjust the upper thread take-up thread guide position correctly.

2. Skipped stitches occur while

sewing

¡ Is the needle properly installed?

If it is incorrect, install the needle correctly.

¡ Are the looper points dull?

Replace loopers with good ones.

¡ Is the needle and looper timing incorrect?

Adjust the needle and looper timing correctly.

¡ Is the clearance between needles and loopers incorrect?

Adjust the clearance between needles and loopers correctly.

¡ Is the lower thread take-up timing incorrect?

Adjust the lower thread take-up timing correctly.

3. Seam position is incorrect.

(Machines with puller)

¡ Is the puller timing incorrect?

Adjust the puller timing.

¡ Is the puller feed incorrect?

Adjust the puller feed.

¡ Is the presser foot pressure incorrect?

Adjust the presser foot pressure.

¡ Is the feed dog height incorrect?

Adjust the feed dog height.

4. Machine does not feed

work.

¡ Is the feed dog too low?

Adjust the feed dog height.

¡ Is the presser foot pressure too small?

Adjust the presser foot pressure.

¡ Is the feed dog worn out?

Have serviceman check it. -

¡ Presser foot floats and does not fully press work.

Have serviceman check it. -

¡ Feed dog and presser foot work on one side only.

11

19

8

16

16

17

19

20

12

11

18

18

11

–

–

–

5. Upper and lower threads

are breaking.

¡ Is the needle bent or is the needle tip broken?

Replace the needle if it is bent or broken.

¡ Is the needle properly installed?

If it is incorrect, install the needle correctly.

¡ Is the needle properly threaded?

If it is incorrect thread the needle correctly.

¡ Is the upper or lower thread tension too weak or too strong?

Adjust the upper thread or lower thread tension.

¡ Is the thread release shaft position incorrect?

Adjust the thread release shaft position correctly.

¡ Are the needle eyes too small for threads?

Refer to the section on “Needles and threads”.

¡ Are the loopers damaged?

Replace loopers with good ones.

21

DA-9270

8

8

9

11

19

8

16

Page 27

10. TROUBLESHOOTING

Problem Possible cause Page

6. Broken needles ¡ Is the material being pushed or pulled with excessive force during

sewing?

¡ Is the needle properly installed?

If it is incorrect, install the needle correctly.

¡ Is the needle bent, is the needle tip broken, or is the needle hole

blocked?

If the loopers are damaged, smooth it with an oiled grindstone or

replace it.

¡ Does the needles hit the loopers?

Adjust timing of loopers running clear of needles.

¡ Does the needles hit the needle guard? (For fixed needle guard)

Adjust the needle guard.

¡ Are the needle eyes too small for threads?

Refer to the section on ”Needles and threads”.

Caution

¡ It is extremely dangerous to leave any pieces of broken needle

sticking in the material. If the needle breaks, search for all pieces

until the whole of the needle is found again.

¡ Furthermore, we recommend that through steps be taken to ac-

count for such needles to comply with product liability regulations.

–

8

8

17

18

8

DA-9270

22

Page 28

INSTRUCTION MANUAL

BROTHER INDUSTRIES, LTD.

15-1, Naeshiro-cho, Mizuho-ku, Nagoya 467-8561, Japan. Phone: 81-52-824-2177

Printed in Japan

118-927

S92927-102

2002.03. B (1)

Loading...

Loading...