Page 1

Operation Manual

Cover stitch machine / Top cover stitch machine

Product Code: 884-B30 / B31

Manual de instrucciones

Máquina recubridora / Máquina recubridora superior

Product Code (Código de producto): 884-B30 / B31

EnglishEspañol

Be sure to read this document before using the machine.

We recommend that you keep this document nearby for future reference.

Lea este documento antes de utilizar la máquina.

Recomendamos que tenga este documento a mano por si necesita consultarlo más adelante.

Page 2

IMPORTANT SAFETY INSTRUCTIONS

When using the sewing machine, basic safety precautions should always be followed, including the following.

Read all instructions before using this machine.

19. Do not disassenble the machine.

If the LED light unit (light-emitting diode) is damaged, it

DANGER

To reduce the risk of electric shock.

The sewing machine should never be left unattended

when plugged in. Always unplug this sewing machine

from the electrical outlet immediately after using and

before cleaning.

WARNING

To reduce the risk of burns, fire, electric shock,

or injury to persons.

1. Do not allow to be used as a toy. Close attention is

necessary when the sewing machine is used by or near

children.

2.

Use this se

as described in this manual. Use only accessories

recommended by the manufacturer as contained in this

manual.

3. Never operate this sewing machine if it has a damaged

cord or plug, if it is not working properly, if it has been

dropped or damaged, or dropped into water. Return

the sewing machine to the nearest authorized dealer

or service center for examination, repair, electrical or

mechanical adjustment.

4. Never operate the sewing machine with any air openings

blocked. Keep ventilation openings of the sewing

machine and foot controller free from the accumulation

of lint, dust, and loose cloth.

5. Never drop or insert any object into any openings.

6. Do not use outdoors.

Do not oper

7.

used or where oxygen is being administered.

8.

o disconnect, turn the main switch to the symbol “O”

T

position which represents off, then remove plug from

outlet.

9. Do not unplug by pulling on cord. To unplug, grasp the

plug, not the cord.

10. Keep fingers away from all moving parts. Special care is

required around the sewing machine needle.

11. Always use the proper needle plate. The wrong plate can

cause the needle to break.

12. Do not use bent needles.

13.

Do not pull or push f

the needle causing it to break.

14.

Switch the se

when making any adjustments in the needle area, such

as threading needle, changing needle, or changing

presser foot, etc.

Alw

15.

outlet when removing covers, lubricating, or when

making any other user servicing adjustments mentioned

in the instruction manual.

Electr

16.

- This machine should be connected to an AC power

source within the range indicated on the rating label.

Do not connect it to a DC power source or inverter. If

you are not sure what kind of power source you have,

contact a qualified electrician.

This machine is appro

-

purchase only.

This se

17.

children or infirm persons without supervision.

18. Young children should be supervised to ensure that they

do not play with this sewing machine.

wing machine only for its intended use

ate where aerosol (spray) products are being

abric while stitching. It may deflect

wing machine to the symbol “O” position

ays unplug the sewing machine from the electrical

ical Hazards:

ved for use in the country of

wing machine is not intended for use by young

20.

m

ust be replaced by authorized dealer.

CAUTION

To use the machine safely

1. (For U.S.A. only)

This appliance has a polarized plug (one blade wider

than the other) to reduce the risk of electric shock, this

plug is intended to fit in a polarized outlet only one way.

If the plug does not fit fully in the outlet, reverse the plug.

If it still does not fit, contact a qualified electrician to

install the proper outlet.

Do not modify the plug in any way.

2. Make sure you watch the needles carefully while you are

sewing. Do not touch the handwheel, needles, knives, or

other moving parts.

3.

urn off the main power and unplug the cord in the

T

following circumstances:

- When you have stopped using the machine

- When you are replacing or removing the needle or any

other part

- If there is a power failure while you are using the

machine

- If you are checking or cleaning the machine

- Leaving the machine unattended

4. Do not store anything on the foot controller.

5.

Fully plug the machine directly into the w

extension cords.

6.

ater is dropped on the machine, unplug the machine

If w

immediately, and contact your local authorized dealer.

7.

Do not put fur

8. Do not bend the cord, or pull on the cord to unplug.

9.

Do not touch the cord with w

10. Place the machine near to the wall outlet.

11. Do not place the machine on an unstable surface.

12. Do not put on the soft cover.

13. If you notice any abnormal sound or condition, consult

your local authorized dealer.

To give your machine a longer life

1. Do not store this machine in direct sunlight or in high

humidity conditions. Do not use or store the machine

near a heater, iron, halogen lamp or other hot object.

2.

Use only mild soaps or detergents to clean the case

Benzene, thinner, and scouring powders can damage

the case and machine, and should never be used.

3. Do not drop or hit the machine.

4.

ays consult this manual before you replace or fit the

Alw

presser foot, needle, or any other parts to make sure

you fit them correctly.

To repair or adjust the machine

If the machine breaks down or needs adjustment,

first follow the troubleshooting table to inspect and

adjust the machine yourself. If the problem persists,

consult your local authorized dealer.

niture on the cord.

et hands.

all. Do not use

.

Page 3

SAVE THESE INSTRUCTIONS

This machine is intended for household use.

FOR USERS IN COUNTRIES EXCEPT CENELEC COUNTRIES

This appliance is not intended for use by persons (including children) with

reduced physical, sensory or mental capabilities, or lack of experience and

knowledge, unless they have been given supervision or instruction concerning

use of the appliance by a person responsible for their safety. Children should be

supervised to ensure that they do not play with the appliance.

FOR USERS IN CENELEC COUNTRIES

This appliance can be used by children aged from 8 years and above and persons

with reduced physical, sensory or mental capabilities or lack of experience and

knowledge if they have been given supervision or instruction concerning use of

the appliance in a safe way and understand the hazards involved. Children shall

not play with the appliance. Cleaning and user maintenance shall not be made by

children without supervision.

CAUTION

When leaving this sewing machine unattended, the main power and light switch of the machine must be

switched off or the plug must be removed from the socket-outlet.

English

When servicing the sewing machine, or when removing covers, the machine or the electrical set must be

disconnected from the supply by removing the plug from the socket-outlet.

FOR USERS IN THE UK, EIRE,

MALTA AND CYPRUS ONLY

IMPORTANT

- In the event of replacing the plug fuse, use a fuse approved by ASTA to BS 1362, i.e. carrying the mark,

rating as marked on plug.

- Always replace the fuse cover. Never use plugs with the fuse cover omitted.

- If the available electrical outlet is not suitable for the plug supplied with this equipment, you should contact

your authorized dealer to obtain the correct lead.

1

Page 4

CONGRATULATIONS ON CHOOSING THIS COMPACT

AVERTISSEMENT:

PARTIES EN MOUVEMENT. POUR

ÉVITER TOUTE BLESSURE:

FERMER LE CAPOT AVANT DE

COUDRE.

DÉBRANCHER AVANT ENTRETIEN.

OVERLOCK MACHINE

Your machine is a high quality, easy-to-use product. To fully enjoy all the features, we suggest that you study

this booklet.

If you need more information regarding the use of your machine, your nearest authorized dealer is always

happy to be of service.

Enjoy yourself!

CAUTION

When threading or replacing needle, the main power and light switch of the machine must be switched off or

the plug must be removed from the socket-outlet.

When the machine is not in use, it is recommended that the electric supply plug is disconnected from the

wall socket to avoid any possible hazards.

Notes on the motor

- The maximum operating speed of this sewing machine is 1,000 stitches per minute, which is quite fast

compared to the normal operating speed of 300 to 800 stitches per minute for the ordinary sewing machine.

- The bearings in the motor are made of a special material (oil-impregnated alloy mounted in felt heat-treated

with oil) that enables them to withstand long hours of continuous operation.

- Continuous operation of the sewing machine can cause heat to build in the motor area, but not enough to

adversely affect its performance.

It is important to keep fabric and paper away from the air openings on the back and sides of the machine so

air can get to these openings.

- When the motor is running, sparks can be seen through the air openings in the motor bracket on the side

opposite the handwheel. These sparks are produced by the carbon brushes and the commutator, and are part

of the machines normal operation.

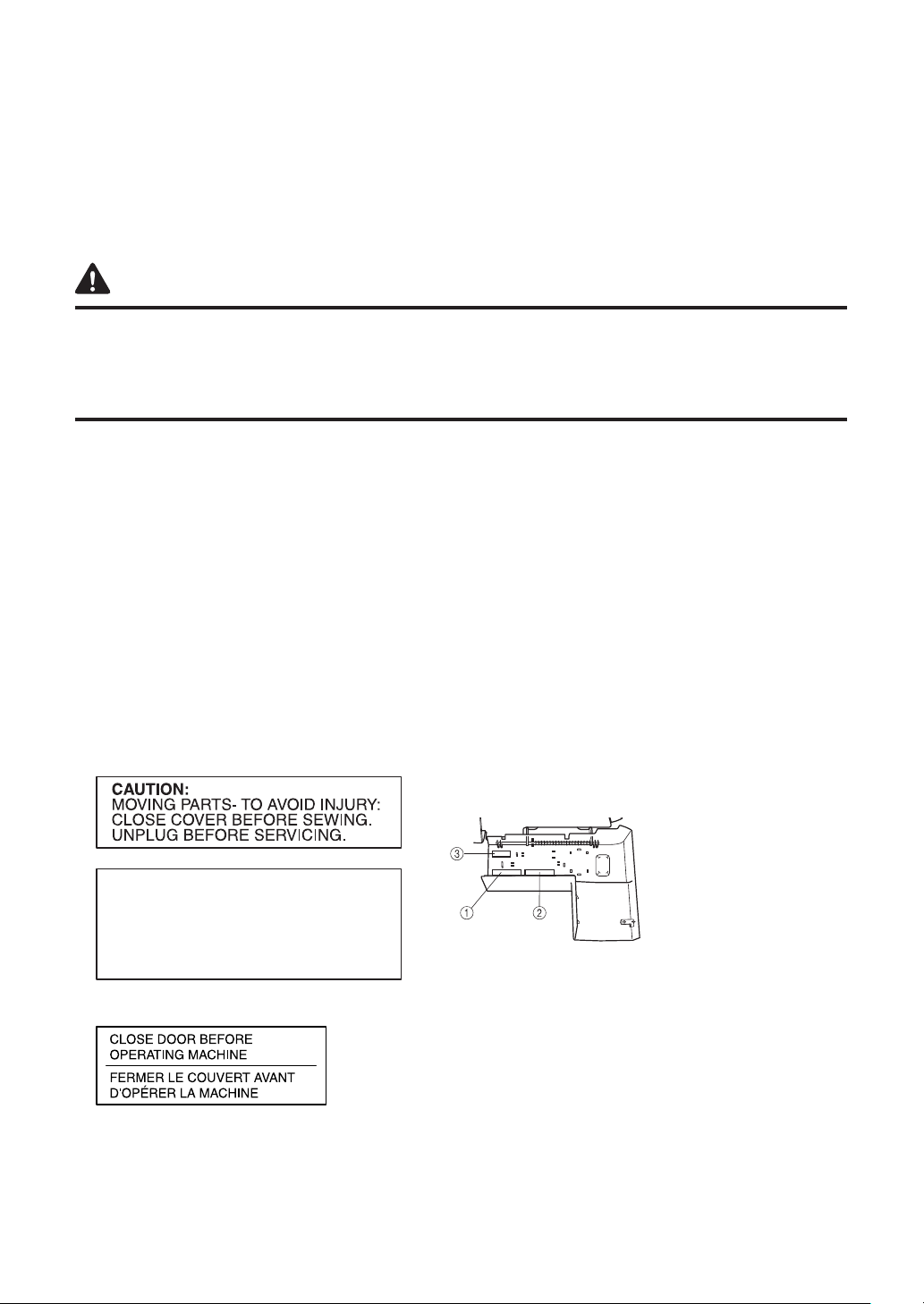

WARNING LABELS

The following warning labels are on the machine.

Be sure to observe the precautions described in the labels.

Caution (U.S.A. and CANADA only)

1

2

Face plate sticker (U.S.A. and CANADA only)

3

(for complying with UL and CSA requirements)

Label locations

2

Page 5

Contents

Chapter 1 : NAMES OF PARTS AND THEIR FUNCTIONS .................................................... 4

Machine (Cover stitch model) (Product code: 884-B30) .....................................................4

Accessories (Cover stitch model) .......................................................................................5

Machine (Top cover stitch model) (Product code: 884-B31) ...............................................6

Accessories (Top cover stitch model) .................................................................................7

Powering the machine.........................................................................................................8

Turning direction of handwheel ...........................................................................................8

Opening/Closing front cover ...............................................................................................8

Attaching/Removing a presser foot .....................................................................................8

Free-arm sewing (removing the bed extension) ..................................................................9

Looper thread tension adjustment lever ..............................................................................9

Stitch length ........................................................................................................................10

Differential feed ...................................................................................................................10

Adjusting the presser foot pressure ....................................................................................11

Adjusting the tension dials ..................................................................................................11

Needle ................................................................................................................................12

Removing/Installing the needle ...........................................................................................12

Chapter 2 : PREPARATION BEFORE THREADING .............................................................. 13

Thread tree .........................................................................................................................13

Using the thread spool cap .................................................................................................13

Spool mat ............................................................................................................................13

Using the spool mat ............................................................................................................13

Using the thread net ...........................................................................................................14

Before threading .................................................................................................................14

Chapter 3 : THREADING (Cover stitch model) ..................................................................... 15

Threading the looper ...........................................................................................................15

Threading the needles ........................................................................................................16

Chapter 4 : THREADING (Top cover stitch model) .............................................................. 17

Threading the looper ...........................................................................................................17

Threading the needles ........................................................................................................18

Attaching/Removing the top cover spreader and top cover thread guide ...........................19

Threading the top cover spreader .......................................................................................20

Chapter 5 : TYPE OF STITCHES COMPARISON CHART ..................................................... 21

Chapter 6 : SEWING ............................................................................................................... 24

Sewing fl at fabric (for example, trial sewing) .......................................................................24

Removing the fabric from the machine (Cover stitch model) ..............................................24

Removing the fabric from the machine (Top cover stitch model) ........................................25

Sewing a cover stitch ..........................................................................................................27

Sewing tubular garments (for example, cuffs) .....................................................................27

Stabilizing the beginning and end of stitching .....................................................................28

Chapter 7 : TROUBLESHOOTING .......................................................................................... 29

Chapter 8 : MAINTENANCE ................................................................................................... 30

Cleaning ..............................................................................................................................30

SPECIFICATIONS .................................................................................................................... 31

English

3

Page 6

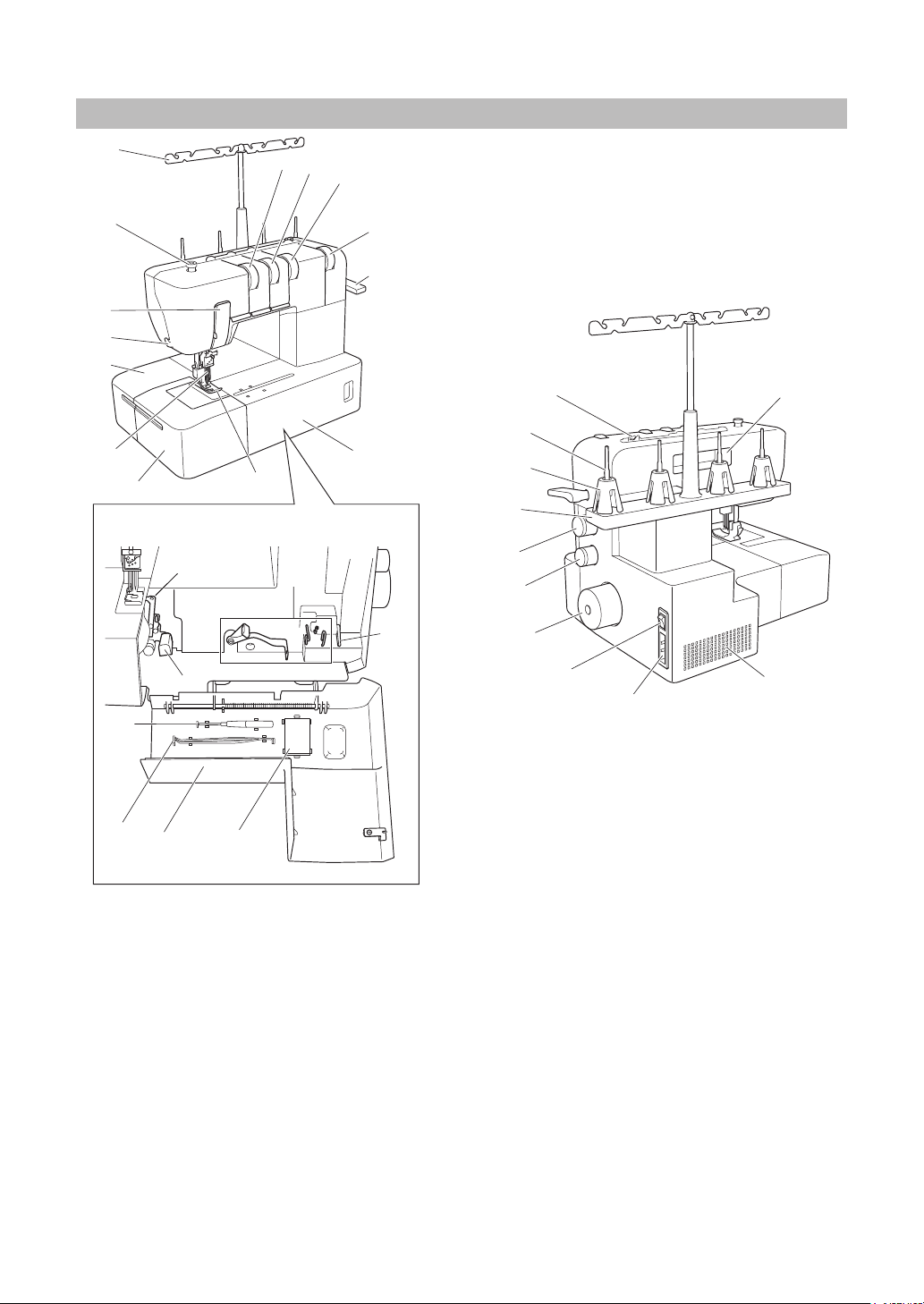

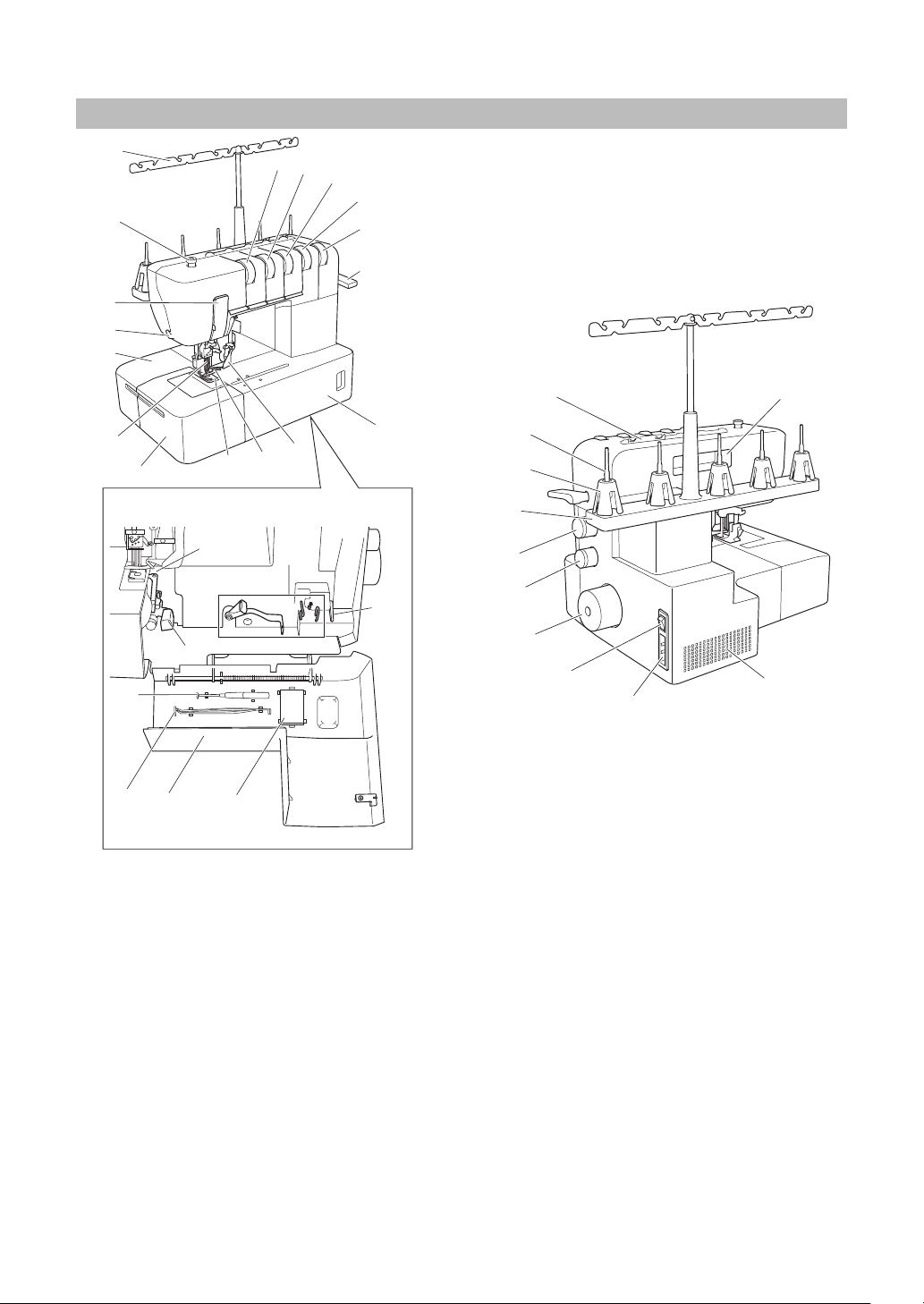

CHAPTER 1

NAMES OF PARTS AND THEIR FUNCTIONS

Machine (Cover stitch model) (Product code: 884-B30)

1

9

0

A

2

3

4

5

6

7

8

B

C

E

F

D

G

H

N

Inside of the front cover

I

J

K

L

M

O

<C>

R

S

Q

P

<B>

T

Thread tree

1

Presser foot pressure adjustment screw

2

Thread take-up cover

3

Thread cutter

4

Material plate cover

5

Needles

6

Bed extension

7

Presser foot

8

Left needle thread tension dial

9

Center needle thread tension dial

0

Right needle thread tension dial

A

Looper thread tension dial

B

Presser foot lever

C

Front cover

D

Thread guide

E

Spool pin

F

Spool cushion

G

<A>

4

Spool support

H

Stitch length adjustment dial

I

Differential feed ratio adjustment dial

J

Handwheel

K

Main power and light switch

L

Foot controller socket

M

Handle

N

Air openings

O

Inside of the front cover

Looper thread tension adjustment lever

P

Looper thread take-up

Q

Looper

R

Looper release lever

S

Front cover compartment

t

You can store the included accessories in this

front cover compartment. <A>: Needle set,

<B>: Tweezers, <C>: Hexagonal driver

Page 7

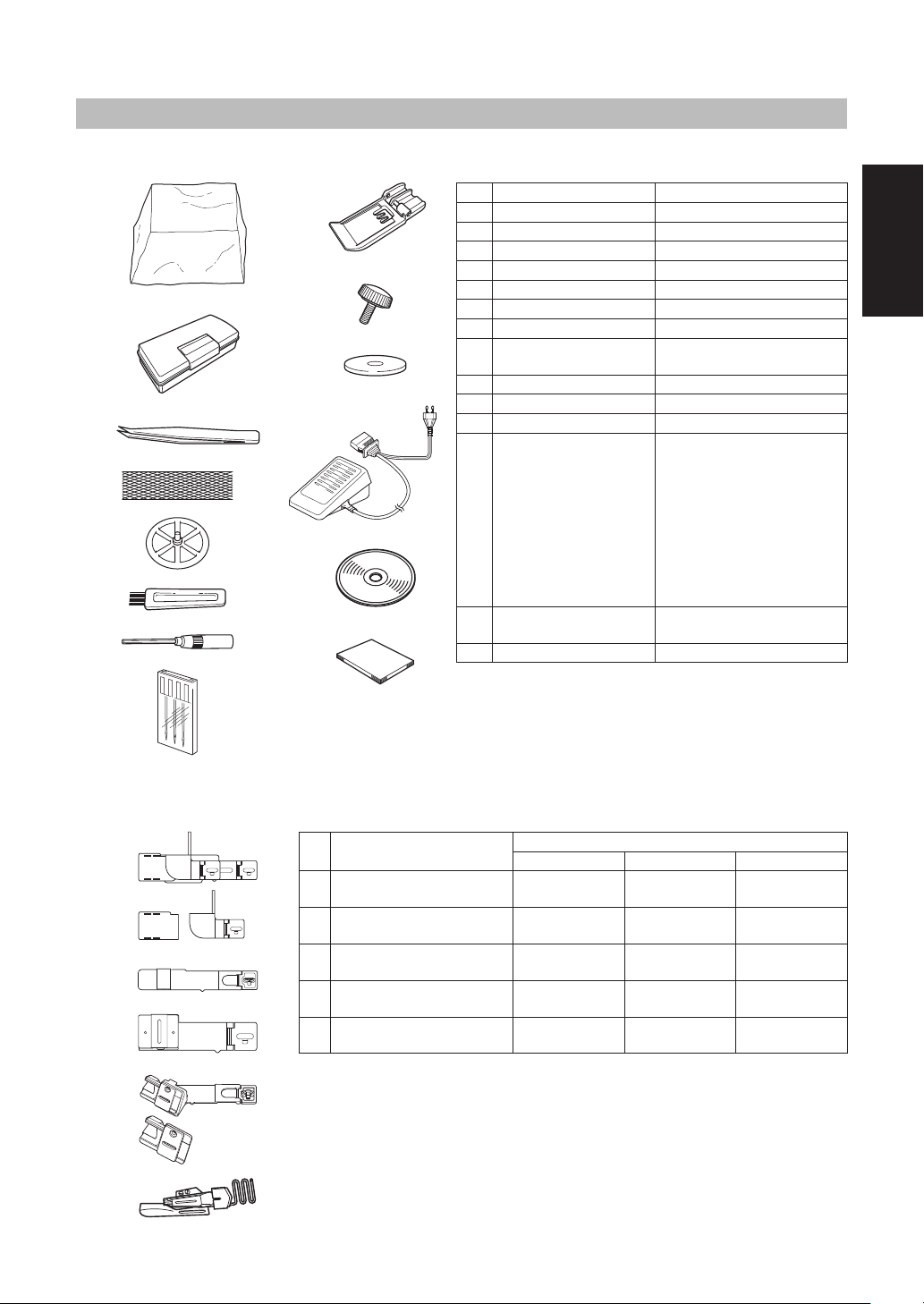

Included accessory

Accessories (Cover stitch model)

1

2

3

4

5

6

7

8

9

0

A

B

C

D

No. Part Name Part Code

1

Soft cover XB3264001

2

Accessory box XB3291001

3

Tweezers XB1618001

4

Thread net (4) X75904000

5

Thread spool cap (4) X77260000

6

Cleaning brush X75906001

7

Hexagonal driver XB0393001

Needle set (130/705H)

8

#90: 3 pcs.

9

Clear foot XB3361001

0

Attachment screw (2) XB3292001

A

Spool mat (4) XB1218001

B

Foot controller

C

Instruction DVD

D

Operation Manual -

XB1216001

XC7359021 (120V Area)

XB3112001 (230V Area)

XB3134001 (U.K.)

XB3200001 (Argentina)

XB3156001 (Korea)

XB3255001 (China)

XB3190001

(Australia, New Zealand)

XF2826001 (Brazil 127V)

XB3178001 (Brazil 220V)

XB3301001 (NTSC)

XB3305001 (PAL)

English

Optional accessory

When using the following accessories, use the presser foot included in the accessories.

E

F

G

H

I

No. Product Name

E

Hemming set SA221CV

F

Bias tape folder SA222CV

G

Belt loop guide SA223CV

H

Bias tape binding set SA230CV

I

Dual function fold binder SA231CV

Americas Europe Others

Part Code

SA221CV/

XB2970-101

SA222CV/

XB2971-101

SA223CV/

XB2972-101

SA230CV/

XB3387-001

SA231CV/

XB3388-001

SA221CV

SA222CV

SA223CV

SA230CVAP

SA231CVAP

5

Page 8

Machine (Top cover stitch model) (Product code: 884-B31)

P

a

b

c

d

e

k

l

m

n

o

p

f

g

h

j

i

Inside of the front cover

U

V

<C>

<B>

W

Thread tree

1

Presser foot pressure adjustment screw

2

Thread take-up cover

3

Thread cutter

4

Material plate cover

5

Needles

6

Bed extension

7

Presser foot

8

Top cover spreader

9

Top cover thread guide

0

Left needle thread tension dial

A

Center needle thread tension dial

B

Right needle thread tension dial

C

Top cover thread tension dial

D

Looper thread tension dial

E

Presser foot lever

F

Front cover

G

Thread guide

H

Spool pin

I

<A>

T

H

q

S

I

J

K

L

M

N

O

Spool cushion

J

Spool support

K

Stitch length adjustment dial

L

Differential feed ratio adjustment dial

M

Handwheel

N

Main power and light switch

O

Foot controller socket

P

Handle

Q

Air openings

R

Q

R

Inside of the front cover

Looper thread tension adjustment lever

S

Looper thread take-up

t

Looper

U

Looper release lever

V

Front cover compartment

W

You can store the included accessories in this

front cover compartment. <A>: Needle set, <B>:

Tweezers, <C>: Hexagonal driver

6

Page 9

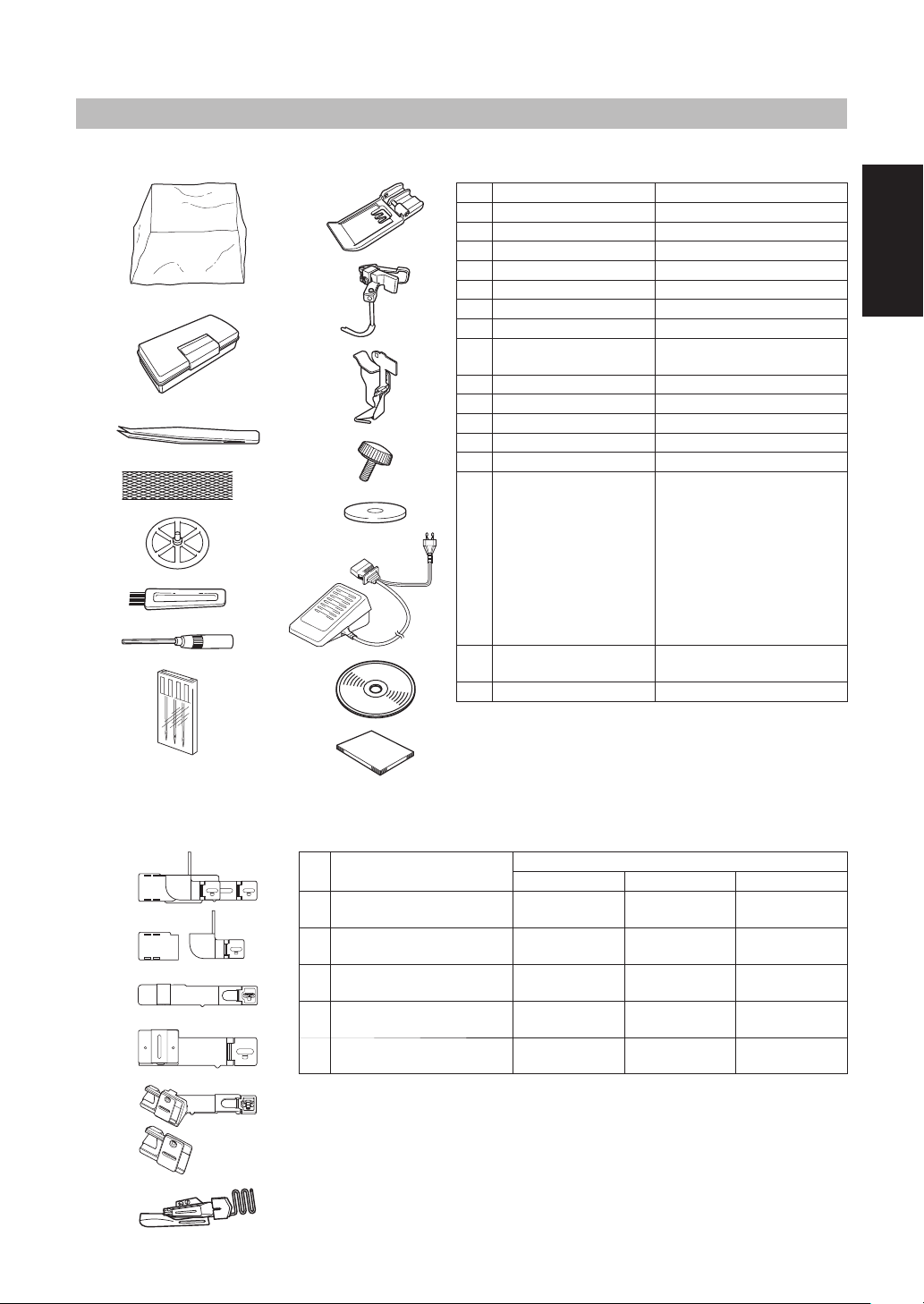

Accessories (Top cover stitch model)

Included accessory

1

2

3

4

5

6

7

8

9

0

A

B

C

D

E

No. Part Name Part Code

1

Soft cover XB3264001

2

Accessory box XB3291001

3

Tweezers XB1618001

4

Thread net (5) X75904000

5

Thread spool cap (5) X77260000

6

Cleaning brush X75906001

7

Hexagonal driver XB0393001

Needle set (130/705H)

8

#90: 3 pcs.

9

Clear foot XB3361001

0

Top cover spreader XB3090001

A

Top cover thread guide XB3105001

B

Attachment screw (2) XB3292001

C

Spool mat (5) XB1218001

D

Foot controller

E

Instruction DVD

F

Operation Manual -

XB1216001

XC7359021 (120V Area)

XB3112001 (230V Area)

XB3134001 (U.K.)

XB3200001 (Argentina)

XB3156001 (Korea)

XB3255001 (China)

XB3190001

(Australia, New Zealand)

XF2826001 (Brazil 127V)

XB3178001 (Brazil 220V)

XB3301001 (NTSC)

XB3305001 (PAL)

English

F

Optional accessory

When using the following accessories, use the presser foot included in the accessories.

G

H

I

J

K

No. Product Name

G

Hemming set * SA221CV

H

Bias tape folder SA222CV

I

Belt loop guide SA223CV

J

Bias tape binding set SA230CV

K

Dual function fold binder SA231CV

Americas Europe Others

* Can be used only with a cover stitch; cannot be used with a top cover stitch.

Part Code

SA221CV/

XB2970-101

SA222CV/

XB2971-101

SA223CV/

XB2972-101

SA230CV/

XB3387-001

SA231CV/

XB3388-001

SA221CV

SA222CV

SA223CV

SA230CVAP

SA231CVAP

7

Page 10

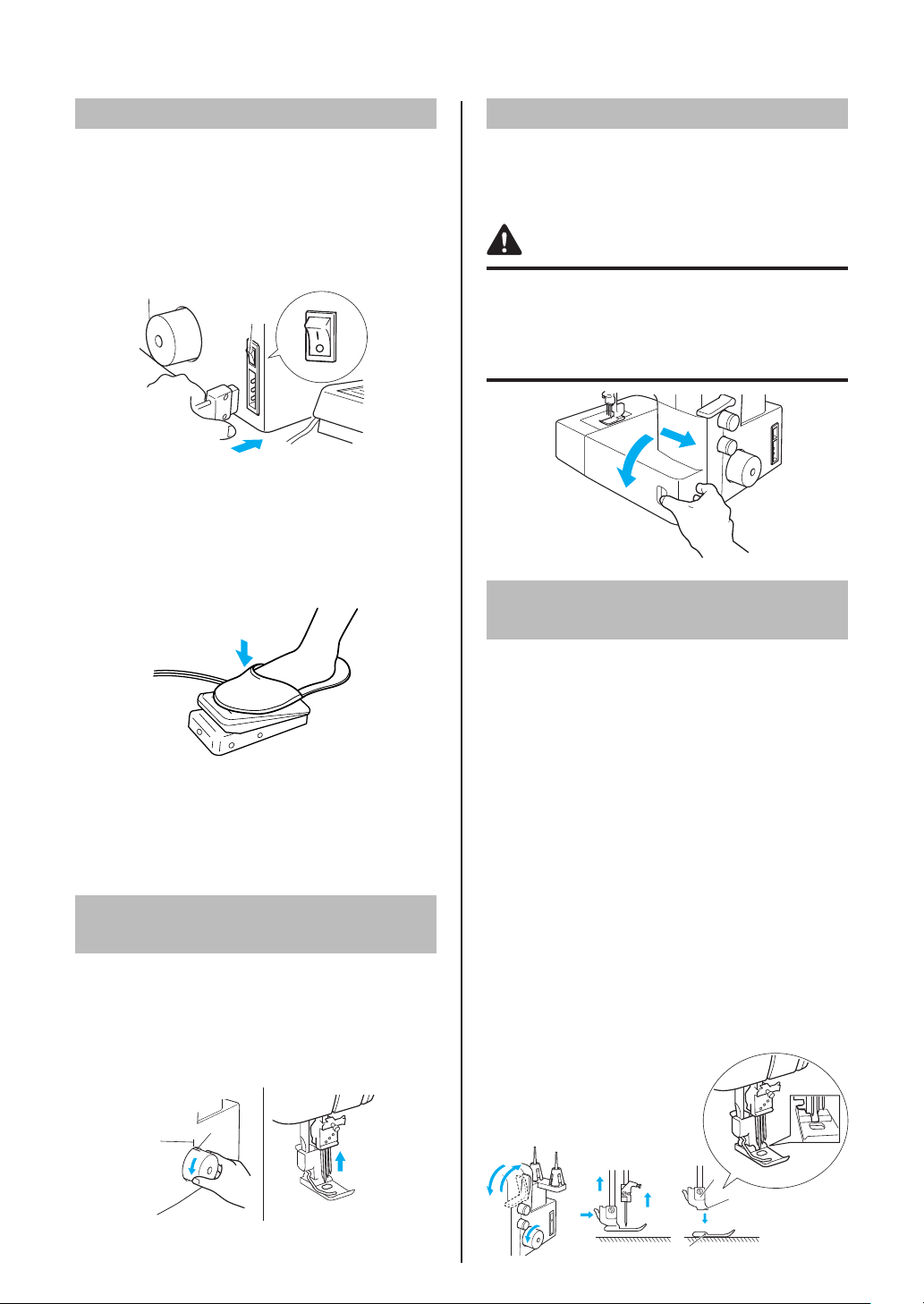

Powering the machine

Turning on the machine

1. Insert the three-pin plug into the socket on the

lower-right side of the machine. Insert the power

supply plug into a power outlet.

2. Turn the main power and light switch <A> to “I”

mark (to “O” mark to turn off).

<A>

Opening/Closing front cover

It is necessary to open the front cover when

threading this machine. Slide it to the right 1, and

then open it 2. After closing it, slide it to the left.

CAUTION

For your safety, make sure that the front cover is

closed when operating the machine.

Always turn off the machine before opening the

front cover.

a

Operation

When the foot controller is pressed lightly, the

machine runs at a low speed. As the foot controller

is pressed further, the machine will increase

speed. When the foot controller is released, the

machine stops.

NOTE (For U.S.A. only):

Foot controller: Model KD-1902

This foot controller can be used on the machine

with product code 884-B30 and 884-B31.

* The product code is shown on the machine rating

plate.

Turning direction of

handwheel

The handwheel <A> turns in a counterclockwise

direction (direction of arrow). This is the same

direction as an ordinary home sewing machine.

Move the needles to their highest positions by

turning the handwheel so that the mark <B> on the

handwheel is aligned with the line on the machine.

b

Attaching/Removing a

presser foot

1. Turn off the main power and light switch or

disconnect the power supply plug.

2. Raise the presser foot lever 1.

3. Turn the handwheel 2 so that the line on

the handwheel is aligned with the line on the

machine. (See “Turning direction of handwheel”

in CHAPTER 1.)

4.

Push the button on the presser foot holder 3 to

release the standard presser foot.

5. Raise the presser foot farther by pushing the

presser foot lever upward. Then, remove the

presser foot and store it in a safe location.

6. Again, raise the presser foot farther by pushing

the presser foot lever upward. Place the presser

foot just under the presser foot holder <A> so

that the groove in the bottom of the presser foot

holder <B> is aligned with the bar on the top of

the foot <C>, and then lower the presser foot

lever to attach the foot 4.

<B>

<A>

d

a

b

a

c

b

<A>

<B>

d

<C>

8

Page 11

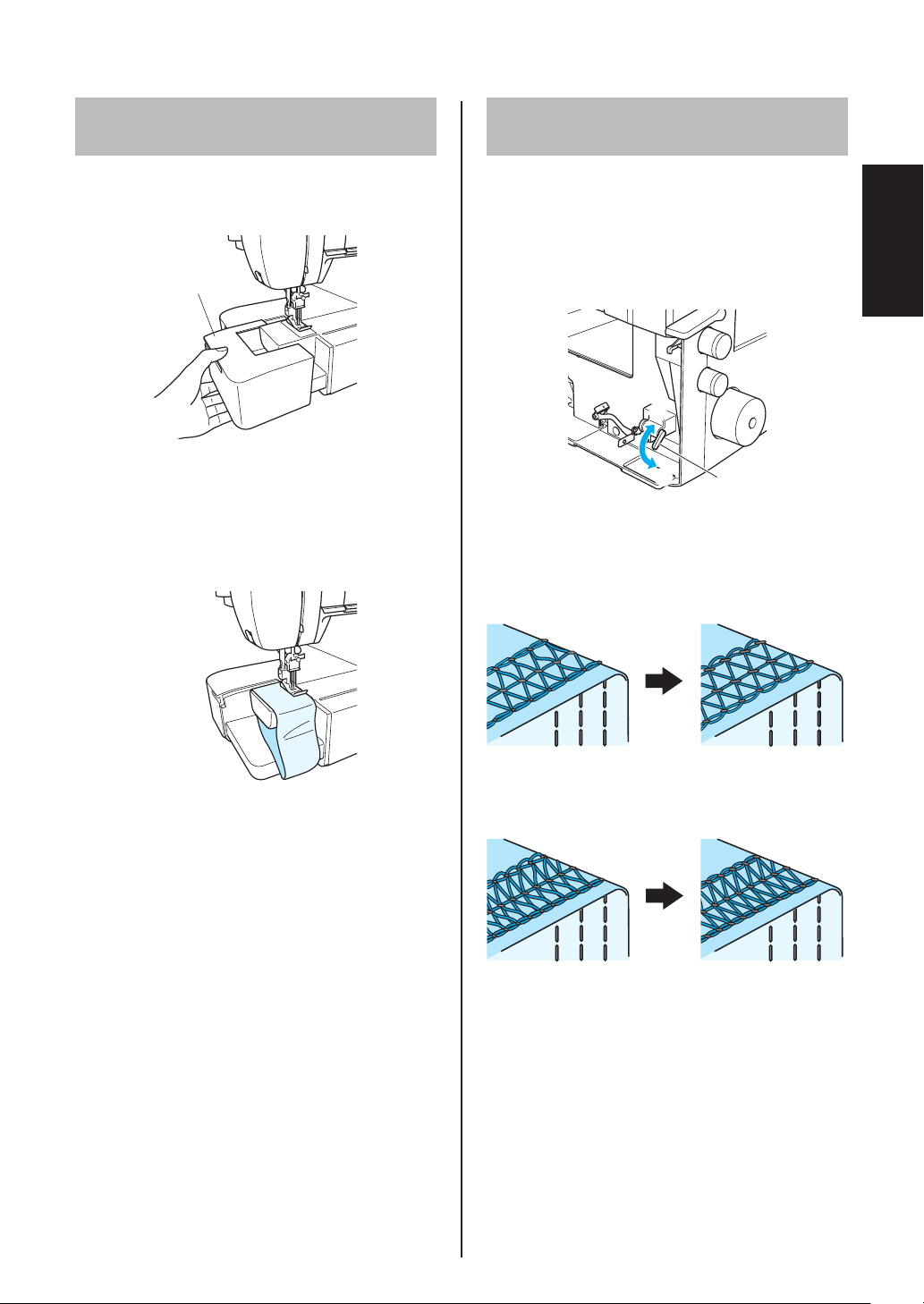

Free-arm sewing

(removing the bed extension)

Free-arm sewing enables tubular pieces to be

sewn more easily.

1. Remove the bed extension.

1

Bed extension

1

NOTE:

Be careful not to lose the removed bed

extension.

2. Position the fabric, and then start sewing.

(See CHAPTER 5.)

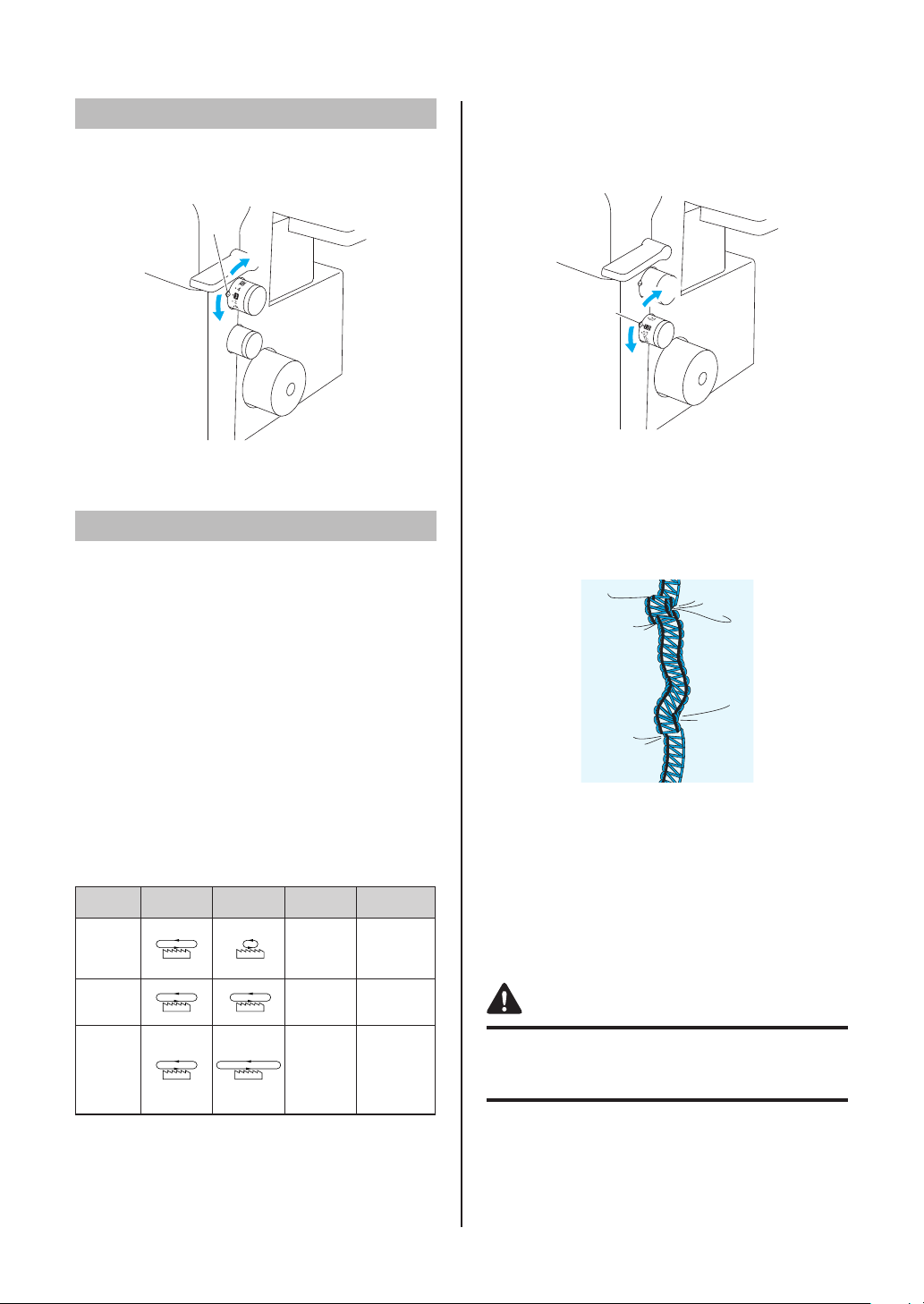

Looper thread tension

adjustment lever

With the looper thread tension adjustment lever,

fi ne adjustments can be made to the looper thread

tension. When sewing stretch fabric or with a small

stitch length, raise the lever to increase the tension

of the looper thread. When sewing non-stretch

fabric or with a large stitch length, lower the lever

to reduce the tension of the looper thread.

1

2

Raise the lever to increase the tension of the looper thread.

1

Lower the lever to reduce the tension of the looper thread.

2

<A> Looper thread tension adjustment lever

Non-stretch fabric such as serge

Reduce the tension of the looper thread.

<A>

English

Lever position: Center Lever position: Down

Stretch fabric such as smooth knit

Increase the tension of the looper thread.

Lever position: Center Lever position: Up

9

Page 12

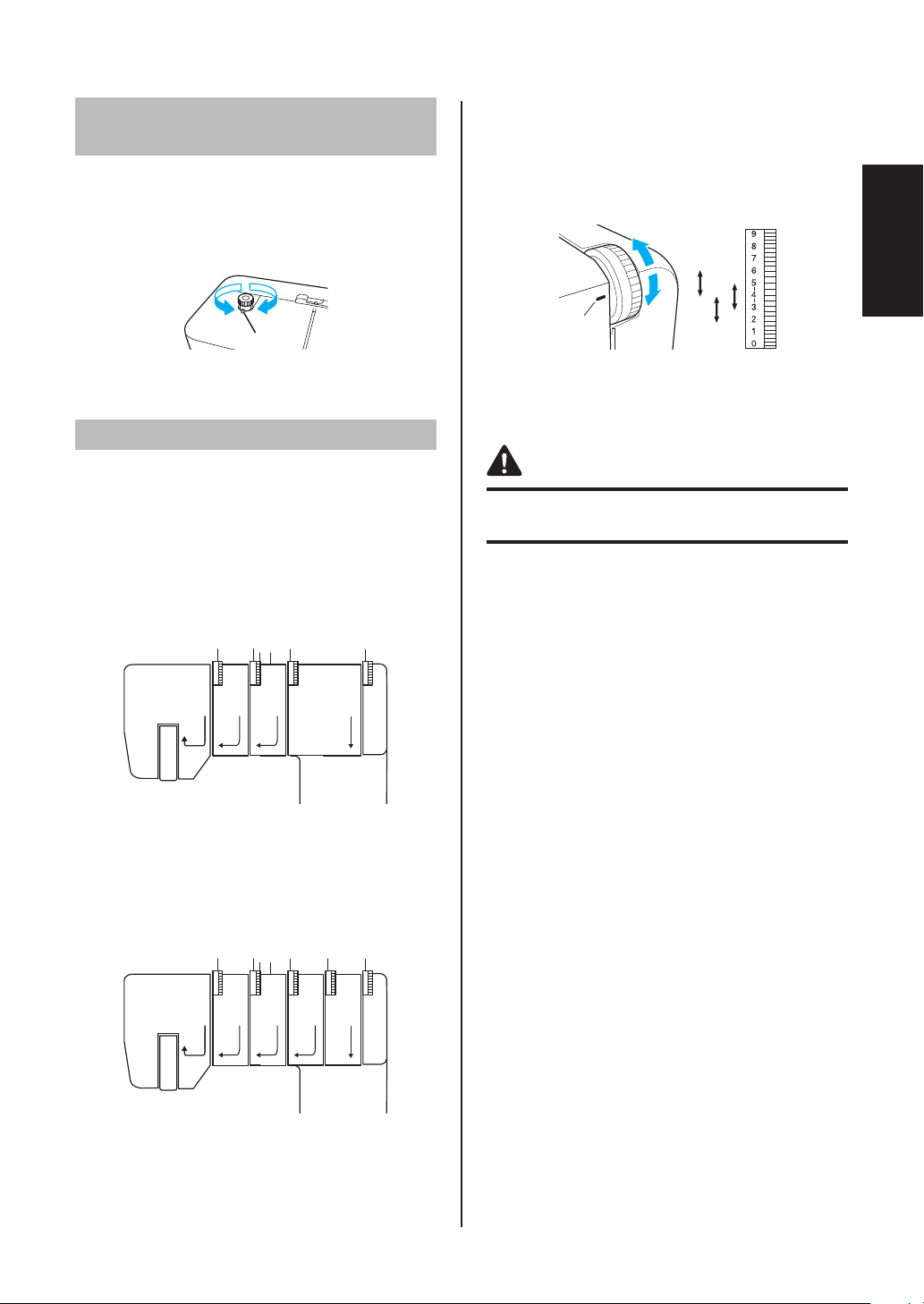

Stitch length

The normal stitch length setting is 3 mm. To

change the stitch length, turn the stitch length

adjustment dial on the right side of the machine.

<A>

a

b

Shorten the stitch length to a minimum of 2 mm (5/64 inch).

1

Lengthen the stitch to a maximum of 4 mm (5/32 inch).

2

<A> Selection mark

The normal setting is 1.0 on the differential feed

adjustment dial.

To adjust the differential feed, turn the dial on the

lower-right side of the machine.

a

<A>

b

Less than 1.0

1

Greater than 1.0

2

<A> Selection mark

Differential feed

There are two sets of feed dogs under the presser

foot to move the fabric through the machine. The

differential feed controls the movement of both the

front and the rear feed dogs. When set at 1, the

feed dogs are moving at the same speed (ratio of 1).

When the differential feed ratio is set at less than

1, the front feed dogs move less than the rear

feed dogs, stretching the fabric as it is sewn. This

is effective on lightweight fabric that may pucker.

When the differential feed ratio is set at greater

than 1, the front feed dogs move more than the

rear feed dogs, gathering the fabric as it is sewn.

This function assists in removing rippling when

sewing stretch fabrics.

Differential feed adjustment

Feed ratio Main feed

(rear)

Less than

1.0

1.0

Greater

than 1.0

Differential

feed (front)

Effect Application

Material is

pulled tight.

Without

differential

feed.

Material is

gathered

or pushed

together.

Prevents thin

materials

from

puckering

Normal

sewing

Prevents

stretch

materials

from

stretching or

puckering

An example

When stretch material is sewn without using the

differential feed, the fabric will be wavy.

To get a smooth fi nish, adjust the feed ratio from 1.0

toward 2.0.

(The feed ratio required depends on the elasticity

of the material.)

The more elastic the material, the further toward

2.0 the differential feed ratio should be set. Test

sew with a scrap of the fabric to fi nd the correct

adjustment.

CAUTION

When sewing thick non-stretchable material such

as denim, do not use the differential feed as it may

damage the fabric.

10

Page 13

Adjusting the presser

foot pressure

Turn the pressure adjustment screw on the left of

the top of the machine. Refer to the value on the

screw to make the adjustment.

The normal setting is “2”.

ab

<A>

Less pressure

1

More pressure

2

<A> Selection mark

Adjusting the tension dials

There is a thread tension dial for each needle

thread, the looper thread and the top cover thread.

The correct thread tension may vary according to

the type and thickness of the fabric and the type of

thread used. Thread tension adjustments may be

necessary for any change in sewing materials.

Cover stitch model

Tension control

Sewing is possible at position “4” for most

circumstances. (Standard: SPAN #60)

If the stitch quality is insuffi cient, select a different

tension setting.

5

4

3

1

3

2

<A>

For heavy tension: 4 to 6

1

For light tension: 4 to 2

2

For medium tension: 5 to 3

3

<A> Tension selection mark

CAUTION

Make sure that the thread is properly seated in the

tension discs.

English

123

The tension dial marked in yellow is for the left needle thread.

1

The tension dial marked in green is for the center needle

2

thread.

The tension dial marked in pink is for the right needle thread.

3

The tension dial marked in blue is for the looper thread.

4

4

4444

Top cover stitch model

1234

The tension dial marked in yellow is for the left needle thread.

1

The tension dial marked in green is for the center needle

2

thread.

The tension dial marked in pink is for the right needle thread.

3

The tension dial marked in purple is for the top cover thread.

4

The tension dial marked in blue is for the looper thread.

5

5

4

4444

11

Page 14

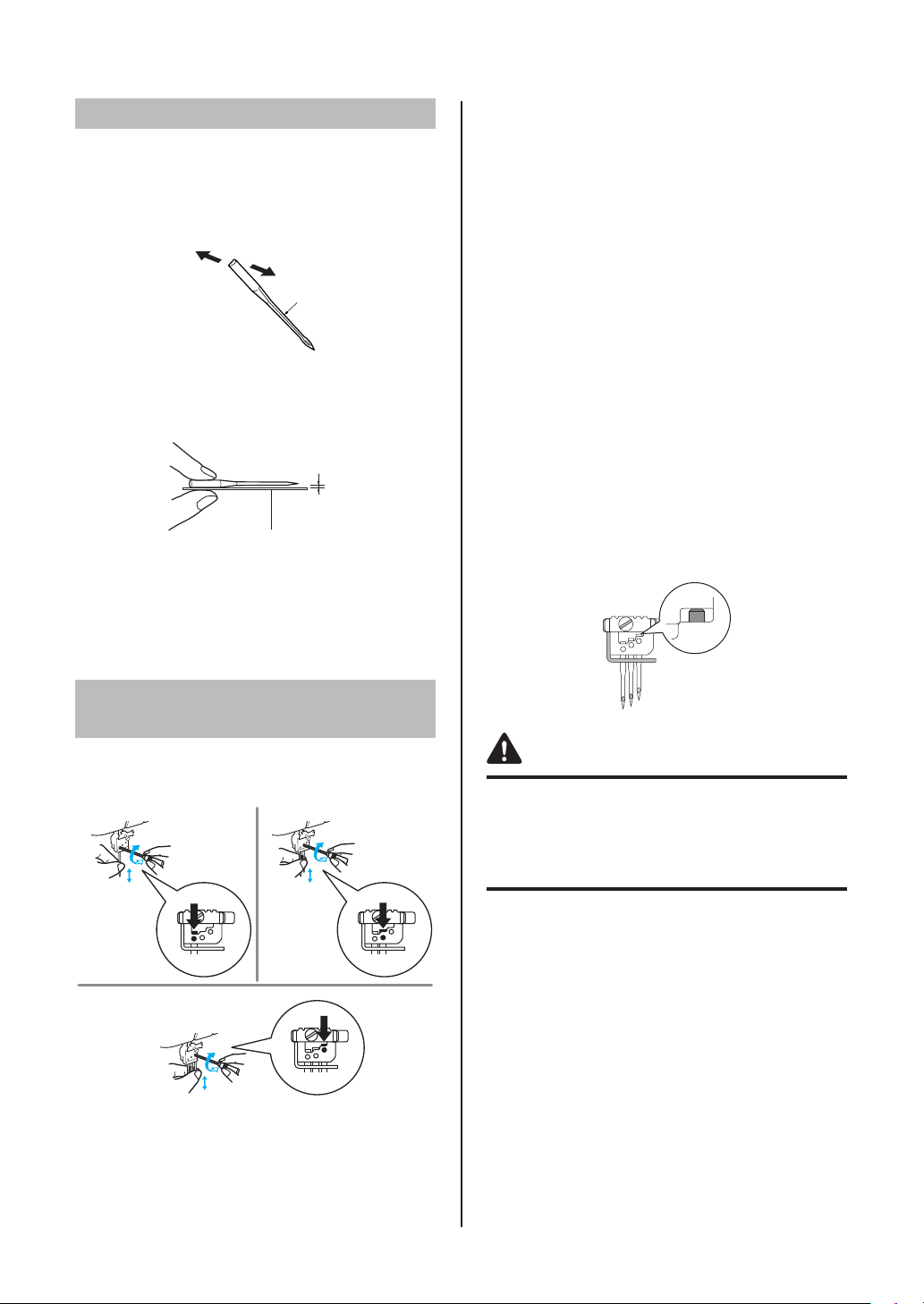

Needle

This machine uses a standard home sewing

machine needle.

The recommended needle is 130/705H (#90).

Needle description

1

Back (fl at side)

1

Front

2

Groove

3

How to check the needle

Flat surface

4

Place the needle on its fl at side and check to see if the space

5

is even.

NOTE:

Fabric damage can be reduced by using 130/705H

SUK (#90) BALL POINT.

2

3

5

4

To remove:

1. Turn off the main power and light switch.

2. Turn the handwheel so that the line on the

handwheel is aligned with the line on the

machine. (See “Turning direction of handwheel”

in CHAPTER 1.)

3. Loosen the corresponding needle set screw

by turning it with the included hexagonal driver

toward 2 in the illustration, and then remove

the needle.

To install:

1. Turn off the main power and light switch.

2. Turn the handwheel so that the line on the

handwheel is aligned with the line on the

machine.

3. Hold the needle with its fl at side away from you

and insert it up as far as it will go.

4. Tighten the needle set screw securely by

turning it with turning the included hexagonal

driver toward 1 in the illustration.

NOTE:

Be sure to insert the needles all the way.

Removing/Installing

the needle

<A> Removing/installing the left needle

<B> Removing/installing the center needle

<C> Removing/installing the right needle

<A>

Tighten

1

Loosen

2

1

2

<C>

1

2

<B>

CAUTION

Always be sure to turn off the power before

removing/inserting the needle.

1

2

Do not drop the needle and needle set screw in

the machine, otherwise it may be damaged.

12

Page 15

CHAPTER 2

PREPARATION BEFORE THREADING

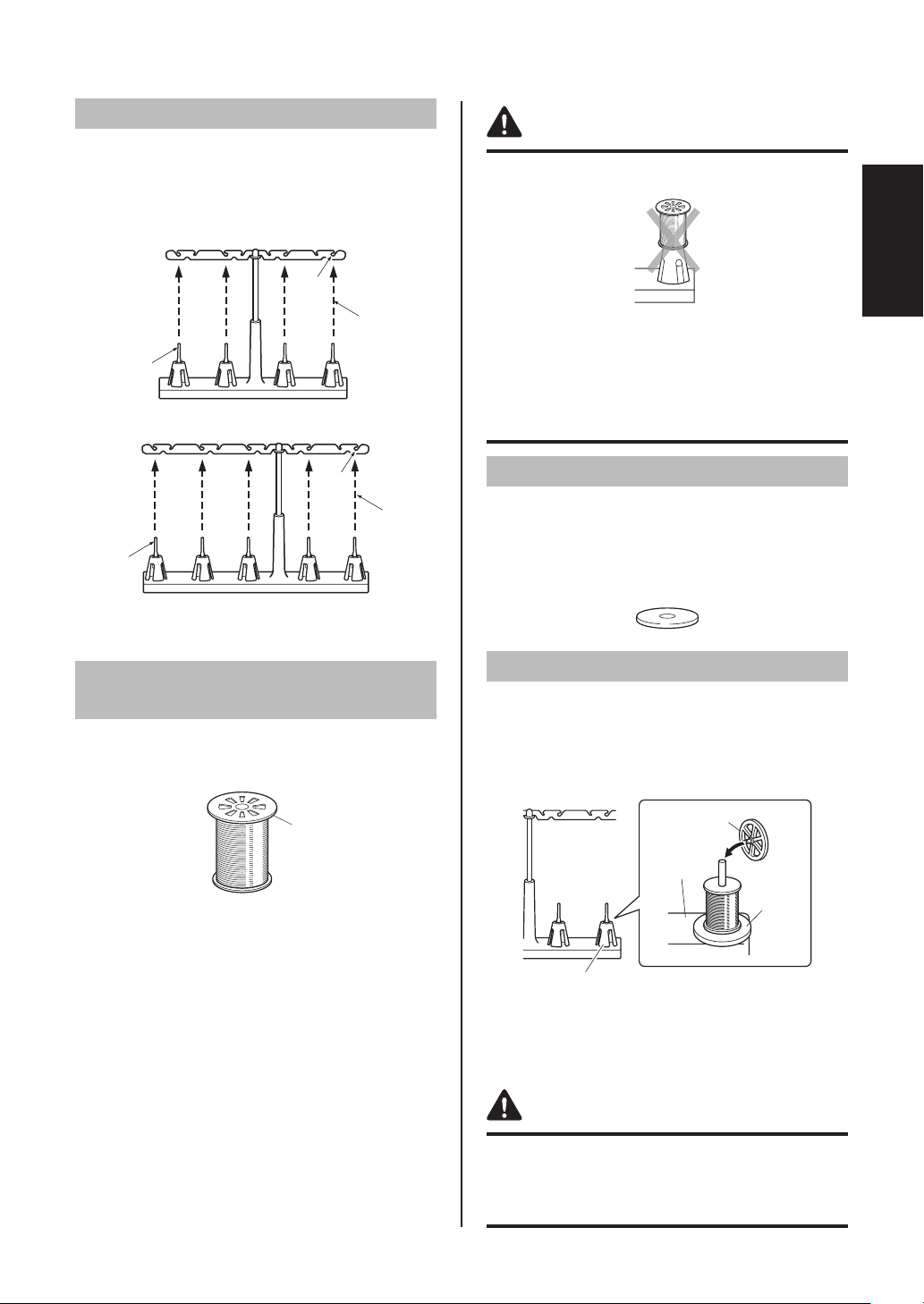

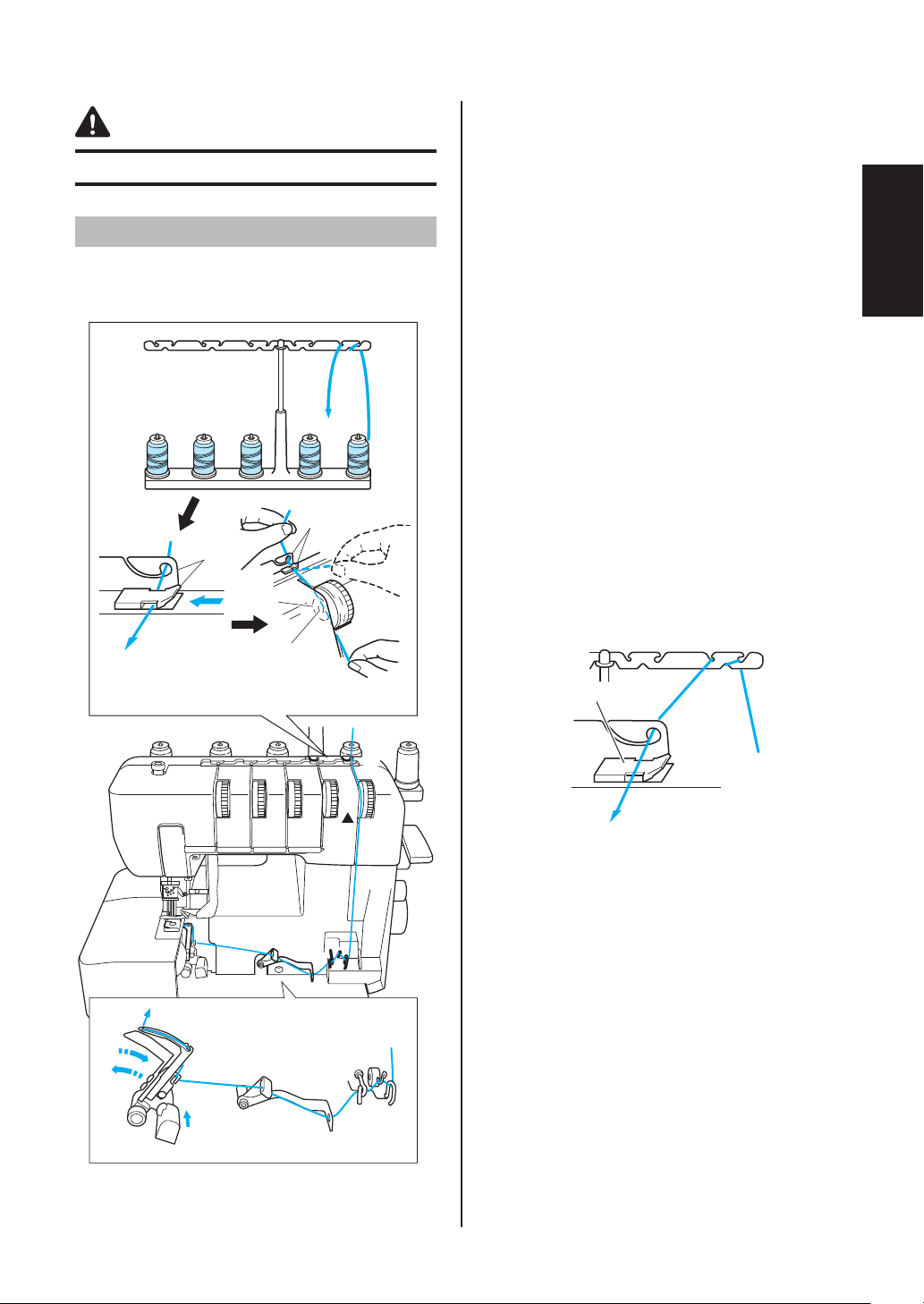

Thread tree

Raise the telescoping thread tree to its highest

position. Make sure that the thread holders are

in alignment above the spool pins as illustrated

below.

Cover stitch model

1

3

2

Top cover stitch model

1

3

2

Thread holder on thread tree

1

Spool pin

2

Correct position

3

CAUTION

Before using a thread spool, be sure to remove the

spool cushion.

English

Before using loosely spun nylon thread, be sure to

install the spool cushion.

If the thread spool cap is not fully pushed down,

the thread may become entangled on the spool pin

or the needle may bend or break.

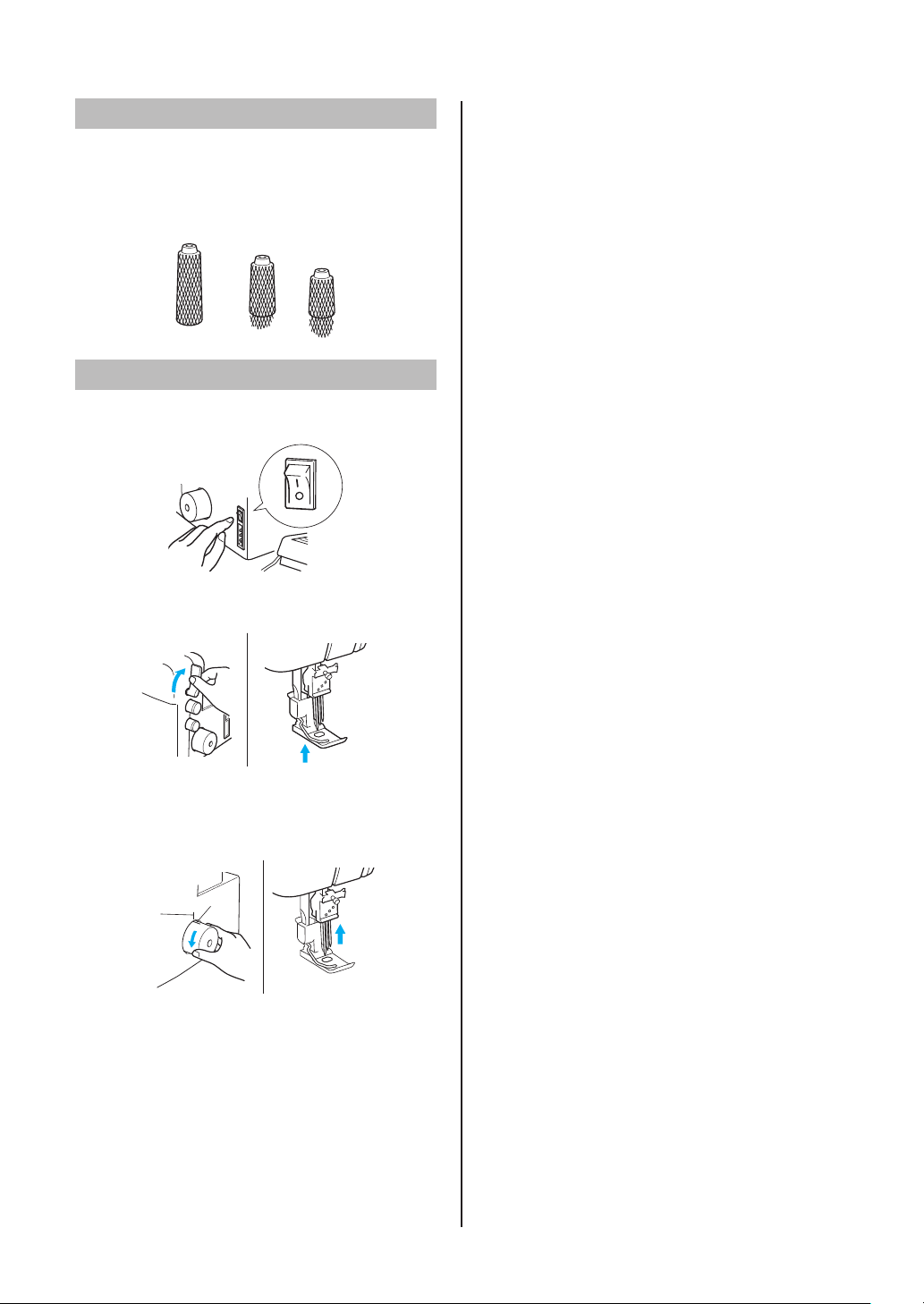

Spool mat

When using thread spools or loosely spun thread

that easily slips off the spool, place this mat under

the spool.

This prevents the thread from becoming entangled

on the spool pin.

Using the thread

spool cap

When using sewing thread spools, the thread

spool cap should be used as illustrated below.

Make sure that the spool notch is on the bottom.

1

Thread spool cap

1

Using the spool mat

1. Remove the spool cushion, and then place the

spool mat on the spool pin.

2. Place the thread spool (with the spool notch at

the bottom) on the spool pin, and then place the

thread spool cap on top and fully push it down.

2

3

4

1

Spool cushion

1

Thread spool cap

2

Spool support

3

Spool mat

4

CAUTION

If the thread spool cap is not fully pushed down

against the thread spool, the thread may become

entangled on the spool pin or the needle may bend

or break.

13

Page 16

Using the thread net

If you are sewing with loosely spun nylon thread,

we recommend that you cover the spool with the

included net in order to prevent the thread from

slipping off the spool.

Adapt the net to the shape of the spool.

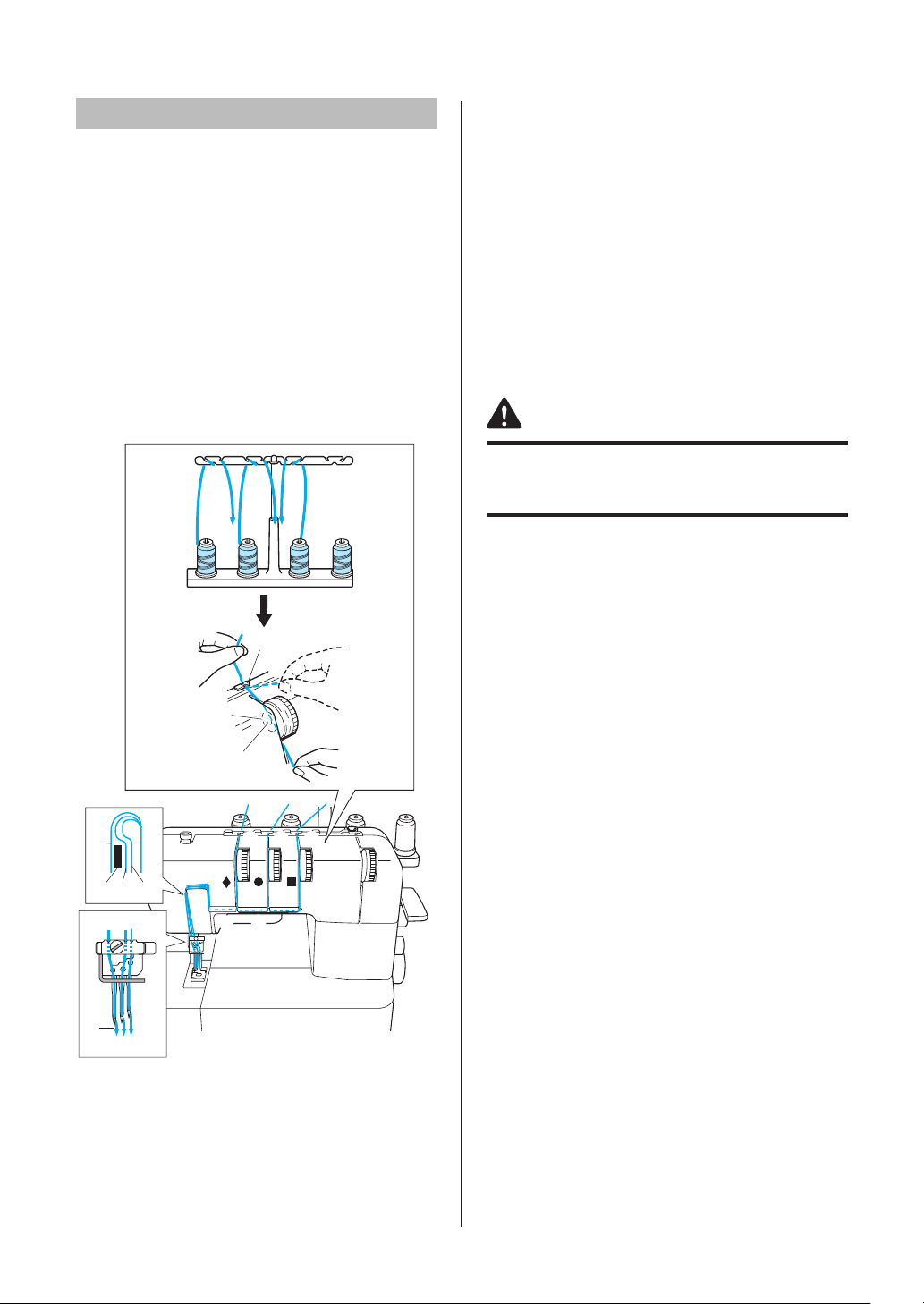

Before threading

1. Turn off the main power and light switch for

safety.

2. Raise the presser foot using the presser foot

lever.

3. Turn the handwheel so that the line on the

handwheel <A> is aligned with the line <B>

on the machine. (See “Turning direction of

handwheel” in CHAPTER 1.)

<B>

<A>

14

Page 17

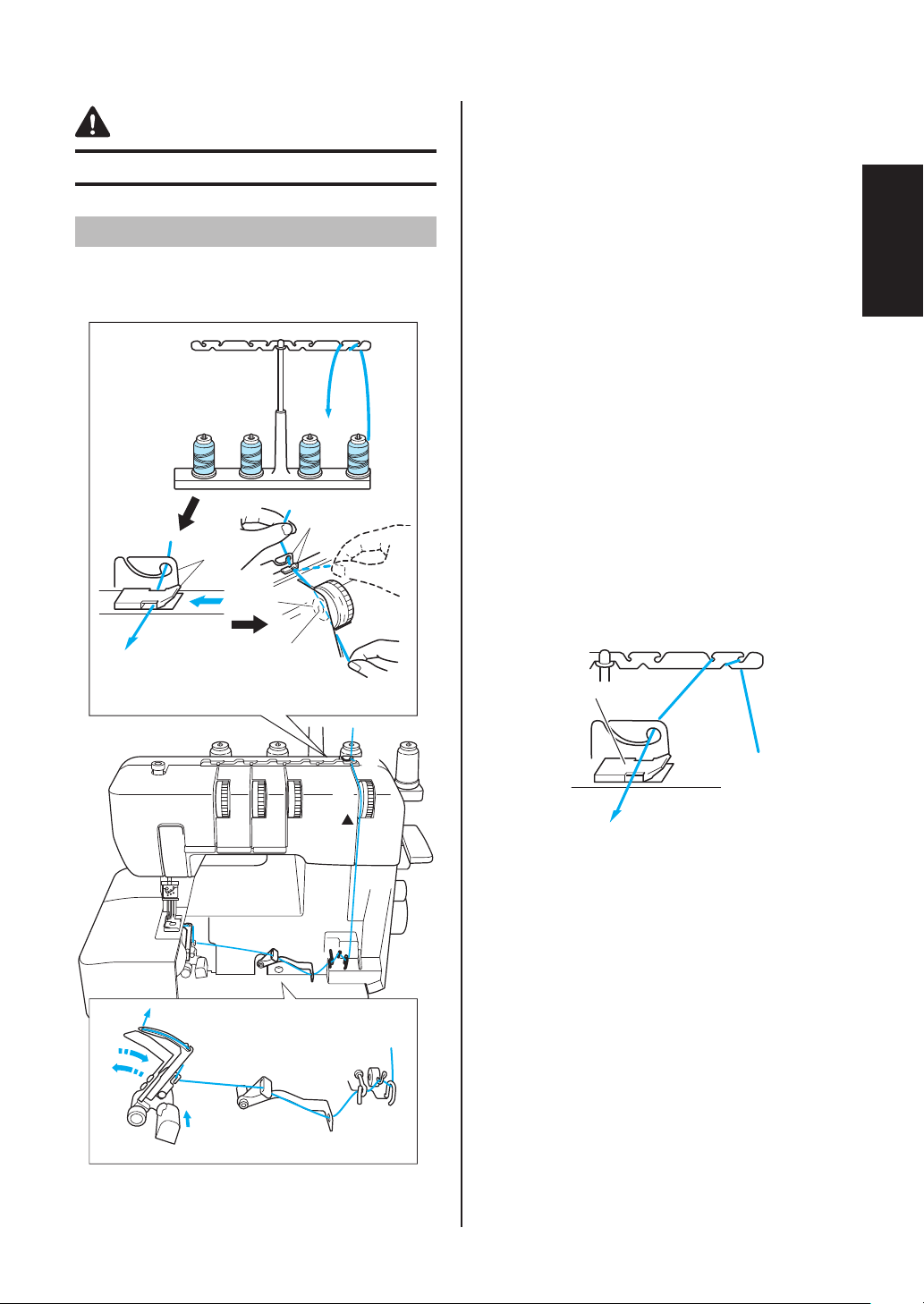

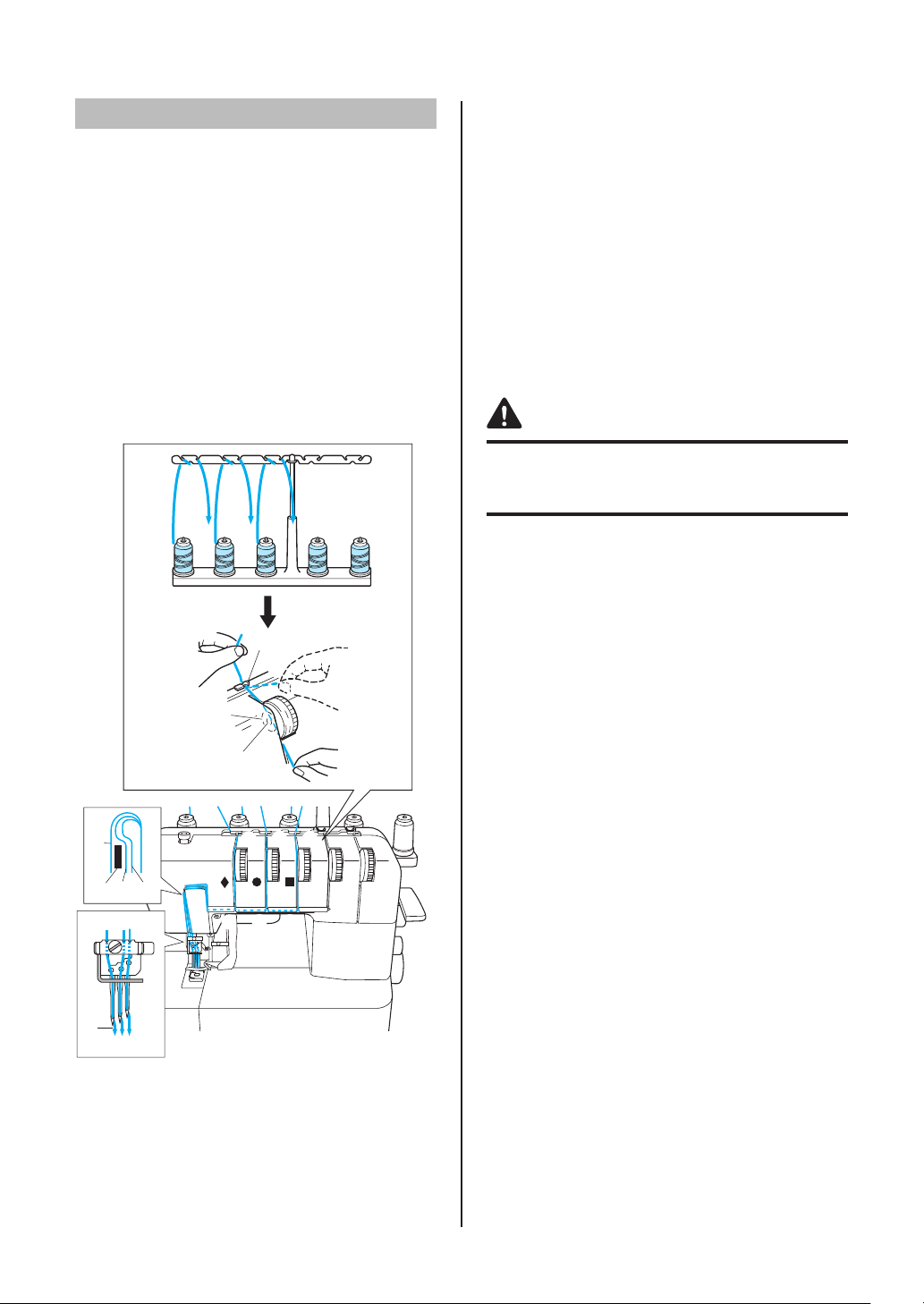

CHAPTER 3

THREADING (Cover stitch model)

1. Open the front cover by sliding it to the right and

CAUTION

Before threading, turn off the machine for safety.

Threading the looper

Run the thread in the sequence illustrated,

following the blue line and the numbers next to

each threading point.

2

1

3

3

6

A

4

5

4

guiding the top toward you.

2. Pull the thread off the spool and directly up

through thread holder 1 and thread holder 2

on the thread tree, from back to front.

3. Pass the looper thread 3 as shown in the

illustration.

4. Pass the thread through the tension disc 4 in

the channel next to the tension dial marked with

a blue c.

5. Guide the thread down the channel and through

threading points 5-9, following the numerical

order in the illustration.

6. After running the thread to 9, push the looper

release lever 0 to move the looper to the right A,

and then run the thread through B-C.

7. Pull about 10 cm (4 inch) of thread through the

eye of the looper.

8. While pushing the looper D, return the looper

to its original position.

9. Close the front cover.

NOTE:

When using thick thread, such as decorative

thread, as the looper thread, run the thread as

shown in the illustration.

English

A

D

C

:

B

9

8

A

3

4

Do not run the thread through A.

6

5

7

15

Page 18

Threading the needles

Needle threads used by the various

stitches

The triple cover stitch (three-needle, four-thread

cover stitch) uses the left needle thread, center

needle thread and right needle thread.

The two-needle, three-thread cover stitch (Wide) (6

mm (15/64 inch)) uses the left needle thread and

right needle thread.

The two-needle, three-thread cover stitch (Narrow)

(3 mm (1/8 inch)) uses the center needle thread

and right needle thread.

The chain stitch uses the center needle thread

and looper thread.

212

2

1

F

444

333

6

5

1

4

Threading the left needle

Run the thread in the sequence illustrated,

following the yellow numbers and ¡ marks next to

the threading points. (1-9)

Threading the center needle

Run the thread in the sequence illustrated,

following the green numbers and z marks next to

the threading points. (1-9)

Threading the right needle

Run the thread in the sequence illustrated,

following the pink numbers and marks next to

the threading points. (1-9)

CAUTION

When threading the needles, always thread in the

following order: left needle, center needle and right

needle.

1. Pull the thread off the spool and directly up

through thread holder

on the thread tree, from back to front.

222

2. Pass each thread through

illustration.

3. Pass the thread through the tension disc

in the channel next to the tension dial.

4. Guide the thread down the channel and across

through threading points

the color marks, following the numerical order in

the illustration.

5. Pass the thread through the eye of the needle,

front to back.

and thread holder

111

333

555-888

, shown in the

444

next to

A

DB

7

8

666

C

77

88

4

5

3

4

5

4

5

3

3

E

9

99

To left needle

A

To center needle

B

To right needle

C

Branching plate

D

Pull about 6 cm (about 2-1/2 inches) of thread through the

E

eye of the needle.

999

Front to back

16

Page 19

CHAPTER 4

THREADING (Top cover stitch model)

1. Open the front cover by sliding it to the right and

CAUTION

Before threading, turn off the machine for safety.

Threading the looper

Run the thread in the sequence illustrated,

following the blue line and the numbers next to

each threading point.

2

1

3

3

6

A

4

5

4

guiding the top toward you.

2. Pull the thread off the spool and directly up

through thread holder 1 and thread holder 2

on the thread tree, from back to front.

3. Pass the looper thread 3 as shown in the

illustration.

4. Pass the thread through the tension disc 4 in

the channel next to the tension dial marked with

a blue c.

5. Guide the thread down the channel and through

threading points 5-9, following the numerical

order in the illustration.

6. After running the thread to 9, push the looper

release lever 0 to move the looper to the right A,

and then run the thread through B-C.

7. Pull about 10 cm (4 inch) of thread through the

eye of the looper.

8. While pushing the looper D, return the looper

to its original position.

9. Close the front cover.

NOTE:

When using thick thread, such as decorative

thread, as the looper thread, run the thread as

shown in the illustration.

English

A

D

C

:

B

9

8

A

3

4

Do not run the thread through A.

6

5

7

17

Page 20

Threading the needles

Needle threads used by the various

stitches

The triple cover stitch (three-needle, four-thread

cover stitch) uses the left needle thread, center

needle thread and right needle thread.

The two-needle, three-thread cover stitch (Wide) (6

mm (15/64 inch)) uses the left needle thread and

right needle thread.

The two-needle, three-thread cover stitch (Narrow)

(3 mm (1/8 inch)) uses the center needle thread

and right needle thread.

The chain stitch uses the center needle thread and

looper thread.

212

2

1

444

F

1

333

6

5

4

Threading the left needle

Run the thread in the sequence illustrated,

following the yellow numbers and ¡ marks next to

the threading points. (1-9)

Threading the center needle

Run the thread in the sequence illustrated,

following the green numbers and z marks next to

the threading points. (1-9)

Threading the right needle

Run the thread in the sequence illustrated,

following the pink numbers and marks next to

the threading points. (1-9)

CAUTION

When threading the needles, always thread in the

following order: left needle, center needle and right

needle.

1. Pull the thread off the spool and directly up

through thread holder

on the thread tree, from back to front.

222

2. Pass each thread through

illustration.

3. Pass the thread through the tension disc

in the channel next to the tension dial.

4. Guide the thread down the channel and across

through threading points

the color marks, following the numerical order in

the illustration.

5. Pass the thread through the eye of the needle,

front to back.

and thread holder

111

333

555-888

, shown in the

444

next to

A

DB

7

8

666

C

77

88

4

5

3

4

5

4

5

3

3

E

9

99

To left needle

A

To center needle

B

To right needle

C

Branching plate

D

Pull about 6 cm (about 2-1/2 inches) of thread through the

E

eye of the needle.

999

Front to back

18

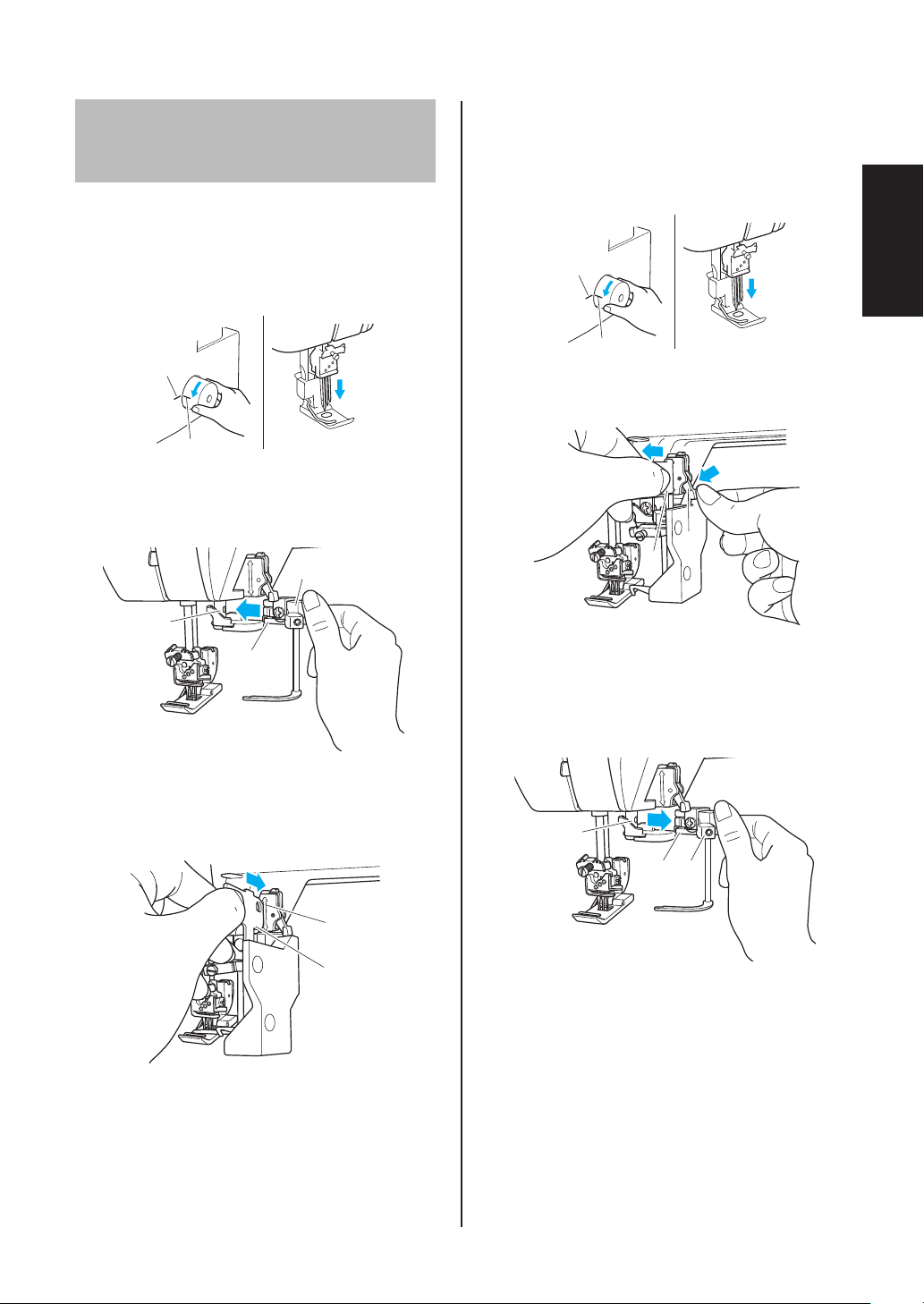

Page 21

Attaching/Removing

the top cover spreader and

top cover thread guide

Attaching the top cover spreader and

top cover thread guide

1. Turn the handwheel so that the line on the

handwheel <A> is aligned with the line <B> on

the machine.

<B>

<A>

2. Squeeze the grip of the top cover spreader to

spread the tips, and then, from the right side,

clamp the mount of the top cover spreader onto

the top cover drive shaft.

1

Removing the top cover spreader and

top cover thread guide

1. Turn the handwheel so that the line on the

handwheel is aligned with the line on the

machine.

<B>

<A>

2. Press the lever on the top cover thread guide

mount, and then remove the top cover thread

guide.

1

2

English

3

2

Grip of top cover spreader

1

Mount of top cover spreader

2

Top cover drive shaft

3

3. Insert the top cover thread guide into the slot in

the top cover thread guide mount.

5

4

Top cover thread guide

4

Slot

5

Lever

1

Top cover thread guide

2

3. Squeeze the grip of the top cover spreader to

spread the tips, and then remove the mount of

the top cover spreader from the top cover drive

shaft.

5

4

3

Grip of top cover spreader

3

Mount of top cover spreader

4

Top cover drive shaft

5

19

Page 22

Threading the top cover

spreader

NOTE:

Thread the top cover thread after fi rst sewing a

cover stitch seam.

Needle threads used by the various

stitches

The triple top cover stitch (three-needle, fi vethread) uses the left needle thread, center needle

thread and right needle thread.

The top cover two-needle, three-thread cover

stitch (Wide) (6 mm (15/64 inch)) uses the left

needle thread and right needle thread.

The top cover two-needle, three-thread cover

stitch (Narrow) (3 mm (1/8 inch)) uses the center

needle thread and right needle thread.

Run the thread in the sequence illustrated,

following the purple color and the numbers next to

each threading point.

2

1. Pull the thread off the spool and directly up

through thread holder 1 and thread holder 2

on the thread tree, from back to front.

2. Pass each thread through 3, shown in the

illustration.

3. Pass the thread through the tension disc 4 in

the channel next to the tension dial marked with

a purple .

4. Guide the thread down the channel and across

through threading points 5-9 next to the color

marks, following the numerical order in the

illustration.

5. Turn the handwheel counterclockwise to move

the point of the top cover spreader completely

to the left.

6. Thread the point of the top cover spreader as

shown in the illustration 0.

1

7. Pass the top cover thread under the presser

foot, from left to right, as shown in the

illustration A, and then lower the presser foot.

3

3

6

F

5

4

4

8. Turn the handwheel counterclockwise 2 to 3

times to check that the top cover thread forms

stitches.

3

4

6

5

NOTE:

When using thick thread, such as decorative

thread, as the top cover thread, run the thread as

shown in the illustration.

A

7

8

9

0

A

Do not run the thread through A.

20

Page 23

CHAPTER 5

TYPE OF STITCHES COMPARISON CHART

Type of

stitch

Triple

cover

stitch

Cover

stitch

(Wide)

Cover

stitch

(Narrow)

Chain

stitch

Triple top

cover

stitch

Top cover

stitch

(Wide)

Top cover

stitch

(Narrow)

Number

of needles

Number

of threads

3 4 2-5 2-5 2-5 2-5

2 3 3-5 - 3-5 2-5

2 3 - 3-5 3-5 2-5

1 2 - 2-5 - 2-5

3 5 3-5 3-5 3-5 3-5 3-5

2 4 3-5 - 3-5 3-5 3-5

2 4 - 3-5 3-5 3-5 3-5

Left

needle

Thread tension dial

Center

needle

Right

needle

Top cover

thread*

Looper

thread

Stitch

Model

Cover

stitch

Top cover

stitch

33

33

33

33

3

3

3

* Top cover stitch model only.

NOTE:

The thread tension dial settings listed above are based on a stitch length of 3 and a differential feed ratio of 1.0.

Since the settings may differ depending on the types of fabric and thread used, be sure to check the thread

tension.

English

Triple cover stitch

Balanced tension

The needle thread sews a straight seam on the

surface of the fabric, and the looper thread forms

loops on the back.

Stitching direction

Needle thread is too loose.

Turn the needle thread tension dial to a higher

number to increase the tension, or turn the looper

thread tension dial to a lower number to decrease the

tension.

Needle thread is too tight.

Turn the needle thread tension dial to a lower number

to decrease the tension, or turn the looper thread

tension dial to a higher number to increase the

tension.

21

Page 24

Cover stitch (Wide/Narrow)

Stitching direction

Chain stitch

Stitching direction

Balanced tension

The needle thread sews a straight seam on the

surface of the fabric, and the looper thread forms

loops on the back.

Needle thread is too loose.

Turn the needle thread tension dial to a higher

number to increase the tension, or turn the looper

thread tension dial to a lower number to decrease the

tension.

Needle thread is too tight.

Turn the needle thread tension dial to a lower number

to decrease the tension, or turn the looper thread

tension dial to a higher number to increase the

tension.

Balanced tension

The needle thread sews a straight seam on the

surface of the fabric, and the looper thread forms

loops on the back.

Needle thread is too loose.

Turn the needle thread tension dial to a higher

number to increase the tension, or turn the looper

thread tension dial to a lower number to decrease the

tension.

Needle thread is too tight.

Turn the needle thread tension dial to a lower number

to decrease the tension, or turn the looper thread

tension dial to a higher number to increase the

tension.

22

Page 25

Triple top cover stitch

Balanced tension

The top cover thread sews a straight seam on the

surface of the fabric, and the looper thread forms

loops on the back.

Stitching direction

Top cover stitch (Wide/Narrow)

Stitching direction

Top cover thread is too loose.

Turn the top cover thread tension dial to a higher

number to increase the tension, or turn the needle

thread tension dial to a lower number to reduce the

tension.

Top cover thread is too tight.

Turn the top cover thread tension dial to a lower

number to decrease the tension, or turn the needle

thread tension dial to a higher number to increase the

tension.

Balanced tension

The top cover thread sews a straight seam on the

surface of the fabric, and the looper thread forms

loops on the back.

Top cover thread is too loose.

Turn the top cover thread tension dial to a higher

number to increase the tension, or turn the needle

thread tension dial to a lower number to reduce the

tension.

English

Top cover thread is too tight.

Turn the top cover thread tension dial to a lower

number to decrease the tension, or turn the needle

thread tension dial to a higher number to increase the

tension.

23

Page 26

CHAPTER 6

SEWING

CAUTION

While the machine is in operation, pay special

attention to the needle location. In addition, keep

your hands away from all moving parts such as

the needle and handwheel, otherwise injuries may

occur.

Sewing fl at fabric

(for example, trial sewing)

1. Raise the presser foot, and then place the

fabric at the needle drop position.

NOTE:

When sewing stretch fabrics, adjust the

differential feed and check that the desired

fi nish is achieved.

Removing the fabric

from the machine

(Cover stitch model)

1. By hand, turn the handwheel toward you until

the needle is at its highest position.

2. Raise the presser foot.

2. Lower the presser foot, turn the handwheel

toward you a few times by hand, and then

lightly step on the foot controller to start sewing.

NOTE:

When starting to sew or after changing the

thread, in order for the needle thread to be on

top of the presser foot, sew with it positioned

under the presser foot when you begin sewing.

If necessary, turn the handwheel toward you a

few times by hand, and then cut the thread as

shown in the illustration.

3. Slowly pull the fabric in the direction of the

arrow.

NOTE:

Be sure to pull the fabric to the back.

4. Cut the needle threads, which come out from

the surface of the fabric.

24

Page 27

5. Slowly pull the fabric in the direction of the

arrow so that the ends of the needle threads

are pulled to the back of fabric.

6. Cut the looper thread.

Removing the fabric

from the machine

(Top cover stitch model)

1. By hand, turn the handwheel toward you until

the needle is at its highest position.

English

2. Raise the presser foot.

3. Slowly pull the fabric in the direction of the

arrow.

NOTE:

Be sure to pull the fabric to the back.

NOTE:

We recommend using scissors to cut the looper

thread. Scissors can also be used to cut the

machine threads.

7. Pull all threads at the back of the fabric.

Tie all threads together and cut.

4. Cut the needle threads, which come out from

the surface of the fabric.

25

Page 28

5. Slowly pull the fabric in the direction of the

arrow so that the ends of the needle threads

are pulled to the back of fabric.

6. Cut the looper thread.

7. Use a pointed object, such as a needle, to push

in the top cover thread from the surface of the

fabric, and then pull the thread at the back of

the fabric.

8. Pull all threads at the back of the fabric.

Tie all threads together and cut.

NOTE:

We recommend using scissors to cut the looper

thread. Scissors can also be used to cut the

machine threads.

26

Page 29

Sewing a cover stitch

1. Determine how much of the fabric will be folded

up.

2. Fold up the fabric the desired amount, and then

iron it in place.

3. Use a ruler to measure, and then use a

fabric marker to mark the top of the fabric to

sew where the edge of the folded fabric is

positioned.

4. Place the bottom of the presser foot onto the

top of fabric, and then check that the drawn

mark is just barely to the right of the left needle.

5. Sew exactly on the mark.

6. After sewing is fi nished, refer to “Removing the

fabric from the machine (Cover stitch model)”

on page 24 for details on taking care of the

threads.

2

3

1

4

Sewing tubular garments

(for example, cuffs)

Without free-arm sewing

1. Raise the presser foot, insert the fabric as

shown in the illustration, lower the presser foot,

and then begin sewing.

English

2. Finish sewing by overlapping about 4 cm (1-1/2

inch) of the beginning and end of the stitching.

6

5

Fabric (surface)

1

Mark drawn with fabric marker

2

Left needle (just barely on the left side of the mark)

3

Right needle

4

Fabric

5

Needle

6

NOTE:

When sewing tubular garments, overlapping

the beginning and end of the stitching by about

4 cm (1-1/2 inch) will prevent the seam from

tearing.

3. Remove the fabric as explained in “Removing

the fabric from the machine (Cover stitch model)”

and “Removing the fabric from the machine (Top

cover stitch model)” on pages 24 and 25.

27

Page 30

With free-arm sewing

1. Remove the bed extension.

1

Bed extension

1

2. Position the fabric, and start sewing.

(See CHAPTER 5.)

Stabilizing the beginning and

end of stitching

To sew with the beginning and end of stitching

stabilized, fi nish the beginning and end of stitching

with a 4-cm-square piece of scrap fabric as

described below.

Beginning of stitching

1. Raise the presser foot, and then insert the

scrap fabric. Lower the presser foot, turn the

handwheel toward you a few times by hand,

and then lightly step on the foot controller to

start sewing.

2. When nearing the end of stitching for the scrap

fabric, stop the machine. Insert the fabric as

shown in the illustration below, and then lightly

step on the foot controller to start sewing.

a

b

(1) Raise the presser foot, insert the fabric as

shown in the illustration, lower the presser foot,

and then begin sewing.

(2) Finish sewing by overlapping about 4 cm

(1-1/2 inch) of the beginning and end of the

stitching.

Scrap fabric

1

Fabric

2

End of stitching

1. When nearing the end of stitching for the fabric,

stop sewing. Insert the scrap fabric as shown in

the illustration below, and then fi nish sewing.

2. Sew into the scrap fabric, stop the machine, and

then use scissors to cut the threads between

the fabrics and scrap fabrics.

28

Page 31

CHAPTER 7

TROUBLESHOOTING

This sewing machine is designed for trouble-free operation. However, the following chart indicates trouble

which may occur if basic adjustments are not made properly.

Trouble Cause Remedy

1. Does not feed Presser foot pressure too loose Turn the pressure adjustment

screw clockwise to increase the

presser foot pressure.

(See page 11.)

2. Needles break 1. Needles bent, or needle tip blunt Replace with new needle.

(See page 12.)

2. Needles incorrectly installed Install needles correctly.

(See page 12.)

3. Material pulled forcibly Do not press or pull material too

hard when sewing.

3. Threads break 1. Improper threading Thread correctly.

(See pages 15-18, 20.)

2. Thread tangled Check spool pin, thread holders,

etc., and remove tangled thread.

3. Thread tension too tight Adjust the thread tension.

(See pages 11.)

4. Needles incorrectly installed Install needles correctly.

(See page 12.)

5. Wrong needle used Use correct needle.

130/705H recommended

(See page 12.)

4. Skipped stitches 1. Needle bent, or needle tip blunt Replace with new needle.

(See page 12.)

2. Needle incorrectly installed Install needle correctly.

(See page 12.)

3. Wrong needle used Use correct needle.

130/705H recommended

(See page 12.)

4. Improper threading Thread correctly.

(See pages 15-18, 20.)

5. Presser foot pressure too loose Turn the pressure adjustment

screw clockwise to increase the

presser foot pressure.

(See page 11.)

5. Stitches not uniform Thread tensions not adjusted

properly

6. Fabric puckers 1. Thread tension too tight Decrease thread tension when

2. Improper threading or thread

tangled

Adjust the thread tension.

(See pages 11.)

sewing lightweight or fi ne material.

(See pages 11.)

Thread correctly.

(See pages 15-18, 20.)

English

29

Page 32

CHAPTER 8

MAINTENANCE

Cleaning

CAUTION

Turn off the machine before cleaning.

Turn the handwheel and move the needles down.

Periodically clean out dust, trimmed fabric and

thread with the included cleaning brush.

30

Page 33

SPECIFICATIONS

Cover stitch model

Use Fine to heavy materials

Sewing speed Maximum 1,000 stitches per minute

Stitch width 6 mm / 3 mm

Stitch length (pitch) 2 mm to 4 mm (5/64 to 5/32 inch)

Needle bar stroke 29 mm (1 1/8 inches)

Presser foot Free presser type

Presser foot lift 5 mm to 6 mm (3/16 to 15/64 inch)

Needle SCHMETZ 130/705H (90/#14)

Number of needles and threads Convertible to two/three/four threads

Convertible to one/two/three needles

Stitches One-needle, two-thread double chain stitch

Two-needle, three-thread cover stitch (Wide) (6 mm (15/64inch))

Two-needle, three-thread cover stitch (Narrow) (3 mm (1/8inch))

Three-needle, four-thread triple cover stitch (6 mm (15/64inch))

Machine net weight 7.6 kg

Machine dimensions 396 mm (W) × 297 mm (D) × 358 mm (H)

(Approx. 16 (W) × 12 (D) × 14 (H) inches)

Needle set 130/705H

English

Top cover stitch model

Use Fine to heavy materials

Sewing speed Maximum 1,000 stitches per minute

Stitch width 6 mm / 3 mm

Stitch length (pitch) 2 mm to 4 mm (5/64 to 5/32 inch)

Needle bar stroke 29 mm (1 1/8 inches)

Presser foot Free presser type

Presser foot lift 5 mm to 6 mm (3/16 to 15/64 inch)

Needle SCHMETZ 130/705H (90/#14)

Number of needles and threads Convertible to two/three/four/five threads

Convertible to one/two/three needles

Stitches One-needle, two-thread double chain stitch

Two-needle, three-thread cover stitch (Wide) (6 mm (15/64inch))

Two-needle, three-thread cover stitch (Narrow) (3 mm (1/8inch))

Three-needle, four-thread triple cover stitch (6 mm (15/64inch))

Two-needle, four-thread top cover stitch (Wide) (6 mm (15/64inch))

Two-needle, four-thread top cover stitch (Narrow) (3 mm (1/8inch))

Three-needle, five-thread triple top cover stitch (6 mm (15/64inch))

Machine net weight 7.6 kg

Machine dimensions 396 mm (W) × 297 mm (D) × 358 mm (H)

(Approx. 16 (W) × 12 (D) × 14 (H) inches)

Needle set 130/705H

31

Page 34

INSTRUCCIONES DE SEGURIDAD IMPORTANTES

Cuando utilice la máquina de coser, deben seguirse algunas precauciones básicas de seguridad, como las siguientes.

Lea todas las instrucciones antes de utilizar la máquina.

17. Esta máquina de coser no ha sido diseñada para ser

PELIGRO

Para reducir el riesgo de descarga eléctrica.

La máquina de coser nunca debe dejarse desatendida

mientras esté enchufada. Desconéctela de la toma de

corriente inmediatamente después de su uso y antes

de proceder a su limpieza.

utilizada por niños ni por personas enfermas sin la

supervisión de un adulto.

Los niños pequeños deberán ser vigilados para

18.

asegurarse de que no juegan con esta máquina de coser.

19. No desmonte la máquina.

20. Si la unidad de la luz LED (diodo emisor de luz) está

dañada, deberá cambiarla un distribuidor autorizado.

AVISO

Para reducir el riesgo de quemaduras, incendio,

descarga eléctrica o lesiones.

1. No debe utilizarse como si fuera un juguete. Deberá

prestar especial atención cuando la máquina de coser

se utilice cerca de niños o sea utilizada por ellos.

Utilice esta máquina de coser solo para los fi nes descritos

2.

en este manual. Utilice solo los accesorios recomendados

por el fabricante indicados en este manual.

3. Nunca utilice esta máquina de coser si el cable o el

enchufe están dañados, si no funciona correctamente,

si se ha caído o ha sufrido averías, o si se ha caído

al agua. Lleve la máquina de coser al distribuidor o

centro de reparaciones autorizado más cercano para

su examen, reparación y realización de los ajustes

eléctricos o mecánicos necesarios.

4. Nunca utilice la máquina de coser si las aberturas de

ventilación están bloqueadas. Mantenga las aberturas

de ventilación de la máquina de coser y el pedal libres

de pelusa, polvo y trocitos de tela.

5. Nunca deje que caigan objetos en ninguna de las

aberturas, ni inserte nada en las mismas.

6. No la utilice al aire libre.

7. No la use en lugares donde se utilicen productos con

aerosoles (atomizadores), ni en sitios donde se esté

administrando oxígeno.

Para desconectar, coloque el interruptor principal en

8.

la posición con el símbolo “O” que indica apagado y, a

continuación, desconecte el enchufe de la toma de corriente.

9. No la desenchufe tirando del cable. Para desenchufar,

sujete el enchufe, no el cable.

10. Mantenga los dedos alejados de todas las piezas en

movimiento. Debe tenerse un cuidado especial con el

espacio que rodea a la aguja de la máquina de coser.

Utilice siempre la placa de la aguja correcta. Si utiliza una

11.

placa que no sea la adecuada, la aguja podría romperse.

12. No utilice agujas dobladas.

13. No tire de la tela ni la empuje cuando esté cosiendo.

Podría doblar la aguja y romperla.

Cuando vaya a hacer algún ajuste en la zona de la aguja,

14.

como enhebrarla, cambiarla, cambiar el prensatelas, etc.,

coloque la máquina de coser en la posición con el símbolo “O”.

15. Desenchufe siempre la máquina de coser de la toma

de corriente cuando vaya a quitar alguna tapa, lubricar,

o cuando vaya a realizar cualquier otro ajuste de

mantenimiento indicado en el manual de instrucciones.

16. Peligro de descarga eléctrica:

Esta máquina debe conectarse a una fuente de

-

alimentación de CA dentro del rango indicado en la

etiqueta de tensión nominal. No la conecte a una fuente

de alimentación de CC ni a un inversor. Si no está seguro

del tipo de fuente de alimentación del que dispone,

póngase en contacto con un electricista cualifi cado.

- Este equipo puede utilizarse solamente en el país

donde se haya adquirido.

PRECAUCIÓN

Para utilizar la máquina de forma segura

1. (Solo para EE.UU.)

Este aparato tiene un enchufe de dos clavijas (una más

ancha que la otra). Para reducir el riesgo de descarga

eléctrica, este enchufe está diseñado para que solo se

pueda insertar de una manera en una toma polarizada.

Si el enchufe no se ajusta perfectamente a la toma, pruebe

a darle la vuelta. Si sigue sin encajar, póngase en contacto

con un electricista cualifi cado para que le instale una toma

adecuada. No modifi que el enchufe de ninguna manera.

2.

Observe siempre las agujas atentamente mientras está cosiendo. No

toque la ruedecilla, las agujas, las cuchillas ni otras piezas móviles.

3. Desactive la máquina y desenchufe el cable en estas

circunstancias:

- Cuando no utilice la máquina

- Cuando deba sustituir o retirar la aguja u otras piezas

- Si se produce un corte de corriente mientras está

utilizando la máquina

- Si está reparando o limpiando la máquina

- Si deja la máquina desatendida

4. No deje ningún objeto encima del pedal.

5. Enchufe la máquina directamente a la toma de corriente

de la pared. No utilice alargadores.

6. Si ha caído agua encima de la máquina, desconéctela

inmediatamente y póngase en contacto con su

distribuidor local autorizado.

7. No coloque muebles encima del cable.

8. No doble el cable, ni tire de él para desenchufarlo.

9. No toque el cable con las manos húmedas.

10. Coloque la máquina cerca de la toma de corriente.

11. No coloque la máquina sobre una superfi cie inestable.

12. No se ponga la funda.

13. Si observa cualquier sonido o circunstancia anómalos,

consulte a su distribuidor local autorizado.

Para aumentar la vida útil de la máquina

1. No guarde la máquina bajo la luz solar directa ni en

lugares excesivamente húmedos. No utilice ni guarde

la máquina cerca de un calefactor, plancha, lámpara

halógena u otros objetos calientes.

2. Utilice solamente detergentes o jabones neutros para

limpiar la carcasa. Nunca utilice gasolina, disolvente ni

polvos desengrasantes, ya que pueden dañar la carcasa

y la máquina.

3. No deje caer ni golpee la máquina.

4. Consulte siempre este manual antes de sustituir o

ajustar el prensatelas, la aguja o cualquier otra parte,

para asegurarse de que las coloca correctamente.

Para reparar o ajustar la máquina

Si la máquina se avería o necesita un ajuste,

consulte en primer lugar la tabla de solución de

problemas para inspeccionarla y ajustarla por

su cuenta. Si el problema continúa, póngase en

contacto con su distribuidor local autorizado.

Page 35

CONSERVE ESTAS INSTRUCCIONES

Esta máquina ha sido diseñada para uso doméstico.

PARA USUARIOS DE PAÍSES NO MIEMBROS DEL CENELEC

Este aparato no ha sido diseñado para ser utilizado por personas (niños

incluidos) con alguna discapacidad física, sensorial o mental, ni por personas sin

experiencia o conocimientos técnicos, a menos que hayan recibido supervisión o

instrucciones relativas al uso del aparato por parte de una persona responsable

de su seguridad. Los niños deberán ser vigilados para asegurarse de que no

juegan con el aparato.

PARA USUARIOS DE PAÍSES MIEMBROS DEL CENELEC

Este aparato puede ser utilizado por niños de a partir de 8 años de edad y

por personas con capacidades físicas, sensoriales o mentales reducidas o

que carezcan de la experiencia y los conocimientos siempre y cuando hayan

recibido supervisión o instrucciones relativas al uso del aparato de modo seguro

y comprendan los riesgos existentes. No permita que los niños jueguen con el

aparato. La limpieza y el mantenimiento del usuario no deben ser realizados por

niños sin supervisión.

PRECAUCIÓN

Cuando deje esta máquina de coser desatendida, coloque el interruptor de alimentación principal y de luz

en la posición de apagado o desconecte el enchufe de la toma de corriente.

Español

Cuando deba reparar la máquina de coser, o cuando retire las tapas, la máquina o el conjunto eléctrico

deben desconectarse de la alimentación retirando el enchufe de la toma de corriente.

SÓLO PARA LOS USUARIOS DEL REINO

UNIDO, IRLANDA, MALTA Y CHIPRE

IMPORTANTE

- Si debe cambiar el fusible del enchufe, utilice un fusible homologado por ASTA para BS 1362, es decir, que

lleve la marca

- Vuelva a colocar siempre la tapa del fusible. No utilice nunca enchufes sin la tapa del fusible.

- Si la toma de corriente disponible no es adecuada para el enchufe suministrado con este equipo, deberá

ponerse en contacto con un distribuidor Brother autorizado para obtener el cable correcto.

correspondiente a la marca en el enchufe.

1

Page 36

FELICIDADES POR ELEGIR ESTA MÁQUINA OVERLOCK

COMPACTA

Esta máquina es un producto fácil de usar y de alta calidad. Para disfrutar completamente de sus funciones,

le sugerimos que lea bien este manual.

Si necesita más información acerca de cómo utilizar la máquina, su distribuidor autorizado más cercano

estará encantado de atenderle.

¡Diviértase!

PRECAUCIÓN

Cuando enhebre o sustituya la aguja, coloque el interruptor de alimentación principal y de luz en la posición

de apagado o desconecte el enchufe de la toma de corriente.

Cuando no utilice la máquina, es recomendable desconectar el enchufe de alimentación eléctrica de la toma

de corriente para evitar posibles peligros.

Notas acerca del motor

- La velocidad máxima de funcionamiento de esta máquina de coser es de 1.000 puntadas por minuto, bastante

rápida si la comparamos con la velocidad habitual de estas máquinas, que oscilaría entre las 300 y las 800

puntadas por minuto.

- Los rodamientos del motor están fabricados con un material especial (una aleación impregnada de aceite

montada en un fi eltro con un tratamiento térmico de aceite) que les permite aguantar muchas horas de

funcionamiento continuo.

- El funcionamiento continuo de la máquina de coser puede provocar una acumulación de calor en la zona del

motor, pero no lo sufi ciente como para alterar su rendimiento.

Es importante que los tejidos y los papeles no bloqueen las aberturas de ventilación de la parte posterior y

laterales de la máquina, para que el aire pueda circular por dichas aberturas.

- Cuando el motor está en marcha, pueden verse chispas a través de las aberturas de ventilación en el soporte

del motor, en el lado opuesto a la ruedecilla. Estas chispas las generan las escobillas de carbono y el colector,

y son parte del funcionamiento normal de las máquinas.

2

Page 37

Contenido

Capítulo 1 : NOMBRES DE LAS PARTES Y SUS FUNCIONES ............................................ 4

Máquina (Recubridora) (Product Code (Código de producto): 884-B30) ...........................4

Accesorios (Máquina recubridora) ......................................................................................5

Máquina (Recubridora superior) (Product Code (Código de producto): 884-B31) .............6

Accesorios (Máquina recubridora superior) ........................................................................7

Activar la máquina ..............................................................................................................8

Dirección de giro de la ruedecilla ........................................................................................8

Abrir/cerrar la tapa delantera ..............................................................................................8

Colocar/Retirar un prensatelas ...........................................................................................8

Costura de brazo libre (retirando el suplemento para la mesa) ..........................................9

Palanca de ajuste de la tensión del hilo del Looper ............................................................9

Longitud de la puntada .......................................................................................................10

Alimentación con diferencial ...............................................................................................10

Ajustar la presión del prensatelas .......................................................................................11

Ajustar los discos de tensión ..............................................................................................11

Aguja ...................................................................................................................................12

Retirar/Colocar la aguja ......................................................................................................12

Capítulo 2 : PREPARACIÓN ANTES DE ENHEBRAR ......................................................... 13

Árbol del hilo .......................................................................................................................13

Utilizar el tope del carrete ...................................................................................................13

Amortiguador de carrete .....................................................................................................13

Utilizar el amortiguador de carrete ......................................................................................13

Utilizar la malla para hilo .....................................................................................................14

Antes de enhebrar ..............................................................................................................14

Capítulo 3 : ENHEBRAR (Máquina recubridora) .................................................................. 15

Enhebrar el Looper .............................................................................................................15

Enhebrar las agujas ............................................................................................................16