Page 1

DS-TMF-GF135-MFC-eng

November, 2017

Data Sheet

GF135

Digital Mass Flow Controller

Model GF135

Thermal Mass Flow

Pressure Transient Insensitive

Mass Flow Controller with Real-Time

Flow Error Detection and Advanced Diagnostics

OverviewOverview

Overview

OverviewOverview

Designed for the next step in semiconductor etch, thin film and other advanced process

gas control applications, the GF135 combines all of the benefits provided by the most

advanced pressure transient insensitive mass flow controller (MFC) and adds real-time

flow error detection with advanced diagnostics.

Device manufacturers are driving programs to improve wafer level yield. The current

downstream quality control approach can allow hundreds of wafers to be processed

before issues are detected. Process gas stability and repeatability have been identified as

critical to meeting yield enhancement goals and MFC accuracy has been identified as

critical to maintaining process control.

The GF135 provides third generation pressure transient insensitivity, market leading

process gas accuracy and ultra fast flow settling times for reduced process cycle time and

to address advanced 3D device processing requirements. This platform also offers patent

pending real-time flow error trending using Rate of Decay (ROD) techniques that are

immune to typical MFC failure/degradation modes ensuring accurate and reliable

diagnostic capabilities. After a baseline is established at tool start-up, the GF135 can

detect changes in flow rate to within 2% of set point. These advanced diagnostic

capabilities provide a shift from downstream quality control to real-time quality

assurance and predictive maintenance resulting in higher yield and improved uptime.

PrPr

oduct Descriptionoduct Description

Pr

oduct Description

PrPr

oduct Descriptionoduct Description

The GF135, with integral real-time ROD flow error detection, drops into the standard

ultra high purity surface mount or VCR® MFC footprint providing an easy path to upgrade

critical gas lines on existing systems.

With the GF135, the user will be able to take advantage of enhanced process gas

accuracy, market leading pressure transient performance and MFC health indicators such

as automatic trending of sensor stability and valve shutdown (leak-by). Using these

health indicators and user programmable alarm limits, via MFC service port or remote

digital commands, the user can establish limits to improve the yield and/or manage

maintenance schedules to maximize uptime.

1

Page 2

FeaturFeatur

Featur

FeaturFeatur

FeaturFeatur

Featur

FeaturFeatur

Real-time flow error detection Support yield improvement programs by capturing wafer impacting flow deviations

Sensor stability tracking Improves system uptime by supporting predictive maintenance

Valve leak-by tracking Allows user to monitor and set limits to minimze first wafer effects

Enhanced process gas accuracy Meet process gas chemistry control challenges at 10nm

Market leading ultra-fast flow settling time Optimize wafer process cycle time by reducing non-productive flow stabilizaton steps.

Enhanced pressure insensitivity Superior process gas control for enhanced etch and deposition control

Corrosion resistant Hastelloy

Drop-in upgrade for surface-mount and VCR MFCs Easy upgrade for critical gas lines on existing systems

PrPr

Pr

PrPr

Real-time Flow Error DetectionReal-time Flow Error Detection

Real-time Flow Error Detection

Real-time Flow Error DetectionReal-time Flow Error Detection

es and Benefitses and Benefits

es and Benefits

es and Benefitses and Benefits

eses

es

eses

®

sensor Provides unmatched long-term sensor stability ensuring maximum yield and throughput

oduct Descriptionoduct Description

oduct Description

oduct Descriptionoduct Description

BenefitsBenefits

Benefits

BenefitsBenefits

Supports advanced 3D device processing

Process contamination buildup in the flow sensor results in higher

than indicated actual flow. Process contamination buildup in the

flow restrictor results in lower than indicated actual flow. Process

contamination on the valve orifice or seat results in leak past the

valve. All of these situations can cause lost wafers and cost

thousands. When using a standard MFC, these errors cannot be

detected without stopping production to run a flow check. The

GF135 has patent pending real-time flow error detection and

trending using Rate of Decay (ROD) techniques that are immune to

typical MFC failure/degradation modes ensuring accurate and

reliable diagnostic capabilities. After a baseline is established at tool

start-up, the GF135 can detect changes in flow, drift and leak rate.

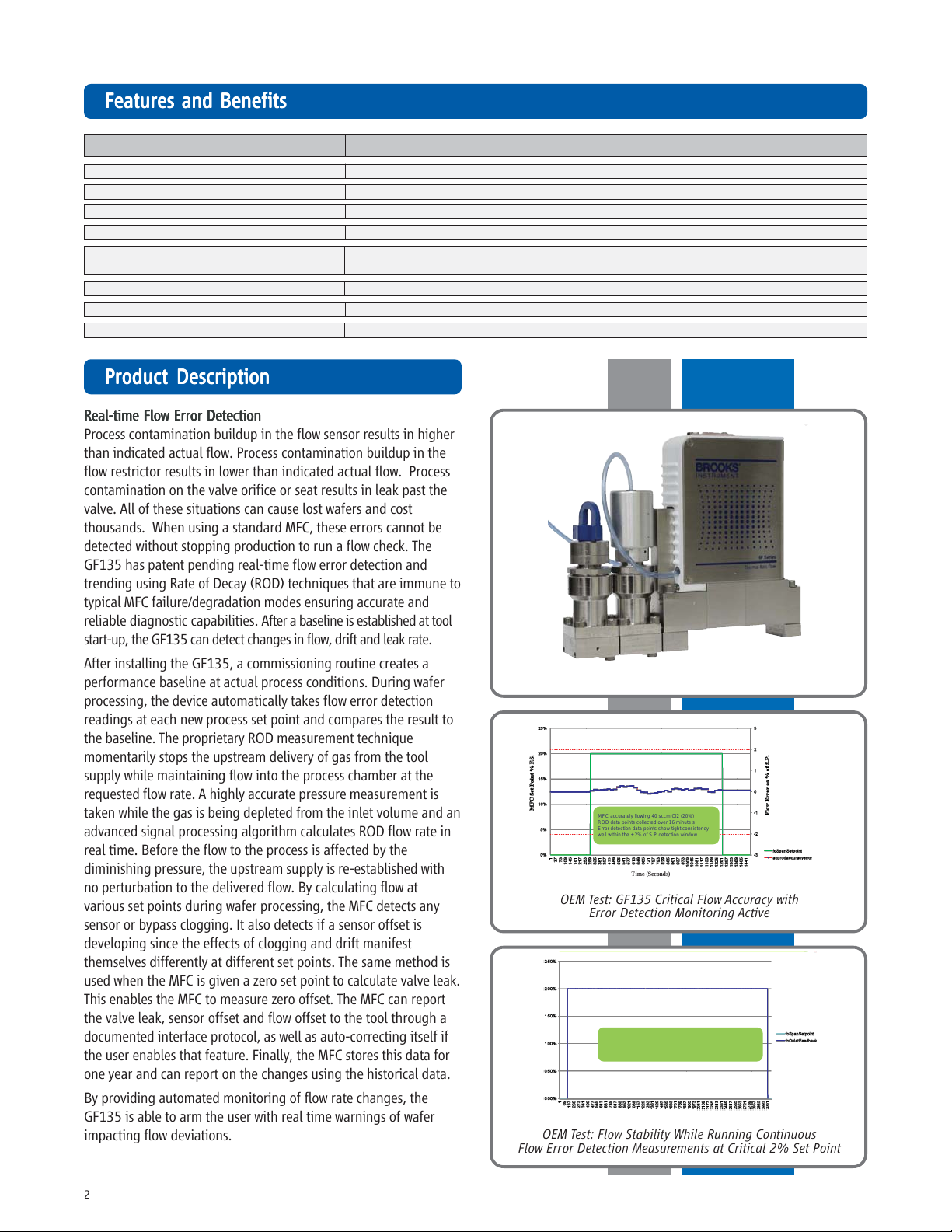

After installing the GF135, a commissioning routine creates a

performance baseline at actual process conditions. During wafer

Model GF135 on Gas Stick

processing, the device automatically takes flow error detection

readings at each new process set point and compares the result to

the baseline. The proprietary ROD measurement technique

momentarily stops the upstream delivery of gas from the tool

supply while maintaining flow into the process chamber at the

requested flow rate. A highly accurate pressure measurement is

taken while the gas is being depleted from the inlet volume and an

advanced signal processing algorithm calculates ROD flow rate in

MFC accurately flowing 40 sccm Cl2 (20%)

ROD data points collected over 16 minute s

Error detection data points show tight consistency

well within the ± 2% of S.P detection window

real time. Before the flow to the process is affected by the

diminishing pressure, the upstream supply is re-established with

no perturbation to the delivered flow. By calculating flow at

various set points during wafer processing, the MFC detects any

sensor or bypass clogging. It also detects if a sensor offset is

OEM Test: GF135 Critical Flow Accuracy with

Time (Seconds)

Error Detection Monitoring Active

developing since the effects of clogging and drift manifest

themselves differently at different set points. The same method is

used when the MFC is given a zero set point to calculate valve leak.

This enables the MFC to measure zero offset. The MFC can report

the valve leak, sensor offset and flow offset to the tool through a

documented interface protocol, as well as auto-correcting itself if

the user enables that feature. Finally, the MFC stores this data for

MFC flowing 4 sccm Cl2 (2% of F.S.) for 50 minutes

ROD measurements taken at 5 second intervals

No spiking or overshoot after each ROD measurement

one year and can report on the changes using the historical data.

By providing automated monitoring of flow rate changes, the

GF135 is able to arm the user with real time warnings of wafer

impacting flow deviations.

OEM Test: Flow Stability While Running Continuous

Flow Error Detection Measurements at Critical 2% Set Point

2

Page 3

PrPr

oduct Description (conoduct Description (con

Pr

oduct Description (con

PrPr

oduct Description (conoduct Description (con

Ultra-Fast ResponseUltra-Fast Response

Ultra-Fast Response

Ultra-Fast ResponseUltra-Fast Response

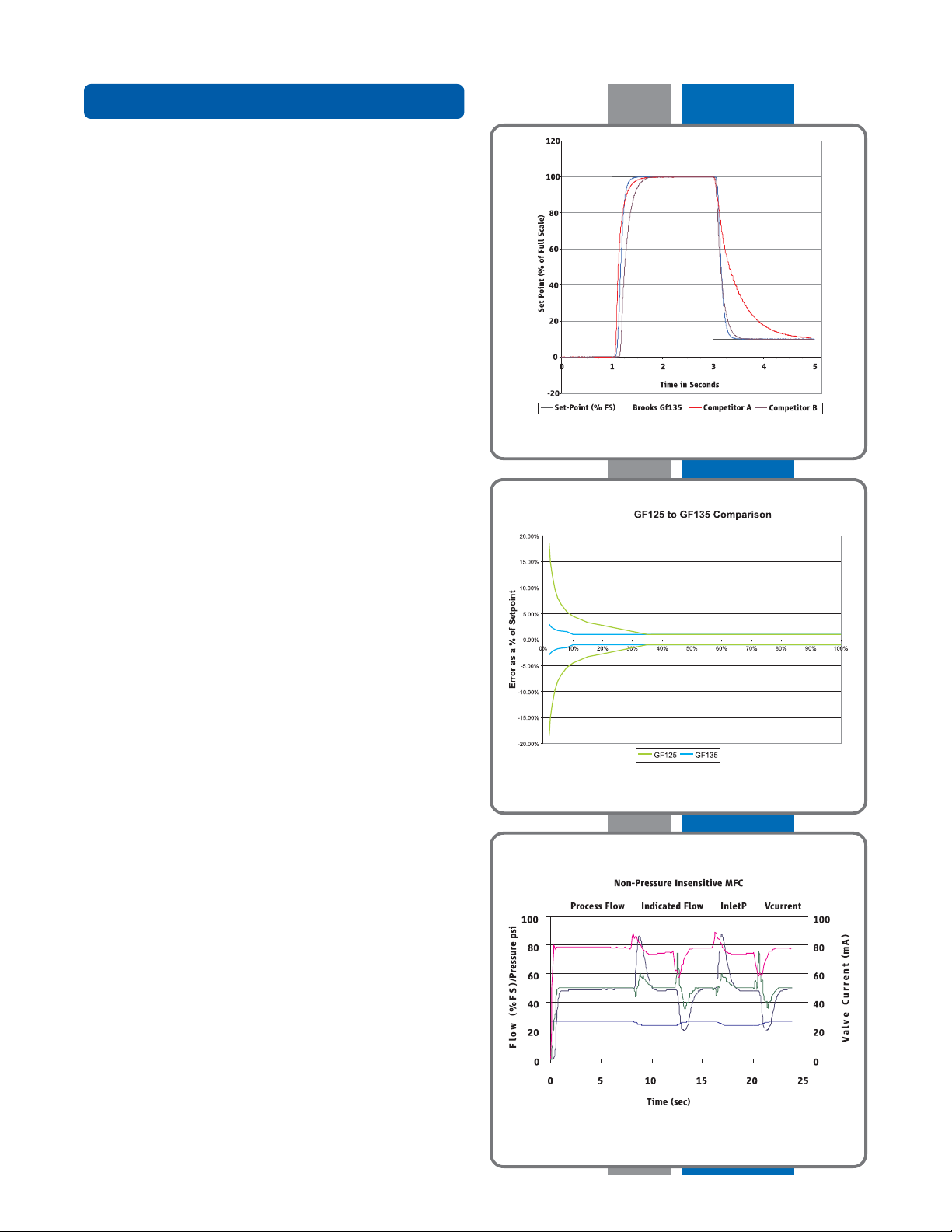

By combining Brooks’ patented flow sensor technology with a

high speed ARM processor and fast acting diaphragm free valve

assembly, the GF Series delivers up to 3 times faster response

and settling time compared to other mass flow controllers,

enabling:

• Improved wafer throughput by reducing nonproductive flow

settling steps

• Critical Etch and 3D device processes requiring ultra-fast sub

500 millisecond etch steps

• Reduced diverted gas consumption and associated

abatement costs

• Time-sensitive gas delivery steps in Atomic Layer Deposition (ALD)

• Processes requiring a slow ramped gas turn-on or time

critical transitions between flow rates with user

programmable ramp function

Enhanced Process Gas AccuracyEnhanced Process Gas Accuracy

Enhanced Process Gas Accuracy

Enhanced Process Gas AccuracyEnhanced Process Gas Accuracy

A major advancement over traditional single point gas

conversion factors, Brooks delivers up to a three-times

improvement in process gas accuracy. This is achieved through

advanced gas modeling optimized through actual gas testing

providing compensation for non-linear gases.

tinued)tinued)

tinued)

tinued)tinued)

Comparison of GF135 vs Competititor’s Response Time

to Ascending & Descending Set Points

The GF135 is a gas and range specific device for critical gas

process applications requiring the widest working range with

tightest flow control accuracy. A typical application is for multistep processes requiring a high flow rate (up to 5 slpm) and a

very accurate low flow rate. Traditionally this has been

addressed by using two mass flow controllers. With wide

turndown (100:1) and superior accuracy offered by the GF135,

it is often possible to replace two mass flow controllers with

one, providing immediate cost savings while freeing up a gas

line for greater gas panel flexibility.

Pressure Transient InsensitivityPressure Transient Insensitivity

Pressure Transient Insensitivity

Pressure Transient InsensitivityPressure Transient Insensitivity

Cost and space constraints have driven gas panel designers to

remove point of use pressure regulators and pressure

monitoring components, placing more burden on the mass flow

controller to control accurately under dynamic pressure

conditions. Conventional mass flow controllers react strongly to

small inlet pressure fluctuations resulting in unstable

performance and unpredictable accuracy (see Non-Pressure

Insensitive MFC). This drove Brooks to develop Pressure

Transient Insensitive mass flow controller technology (PTI-MFC).

The GF135 PTI-MFC is a third generation PTI-MFC utilizing a

patented control algorithm that inverts the pressure signal,

compares it to the pre-fluctuation signal and drives real-time

valve position compensation to maintain stable flow. Enhanced

pressure transient insensitivity is achieved through faster

sensing, faster processing, and a reduction in internal dead

volume between the sensors and valve orifice.

Pressure Fluctuations in Non-Pressure Transient Insensitivity MFC

3

Page 4

PrPr

oduct Description (conoduct Description (con

Pr

oduct Description (con

PrPr

oduct Description (conoduct Description (con

Advanced Thermal Flow Measurement SensorAdvanced Thermal Flow Measurement Sensor

Advanced Thermal Flow Measurement Sensor

Advanced Thermal Flow Measurement SensorAdvanced Thermal Flow Measurement Sensor

Brooks’ sensor technology combines:

• Improved signal to noise performance for improved accuracy

at low setpoints

• Improved reproducibility at elevated temperatures through

new isothermal packaging, onboard conditioning electronics

with ambient temperature sensing and compensation

• Improved long-term stability through enhanced sensor

manufacturing and burn in process

• Highly corrosion resistant Hastelloy C-22 sensor tube

• Optimized temperature profile for gases prone to thermal

decomposition

High Purity Flow PathHigh Purity Flow Path

High Purity Flow Path

High Purity Flow PathHigh Purity Flow Path

All metal, corrosion resistant flow path with reduced surface

area and un-swept volumes for faster dry-down during purge

steps:

• SEMI F-20 compliant wetted flow path

• 4μ inch Ra surface finish standard

• Highly corrosion resistant Hastelloy C-22 valve seat and jet orifice

tinued)tinued)

tinued)

tinued)tinued)

User InterfaceUser Interface

User Interface

User InterfaceUser Interface

The user interface has a high visibility electronically rotatable

LCD display that provides a local indication of Flow (%),

Temperature (°C), Pressure (PSIA/KPa) and Network Address,

selectable through the Display button. A Zero button provides a

simple means to re-zero the mass flow controller as part of

scheduled maintenance.

Communication InterfaceCommunication Interface

Communication Interface

Communication InterfaceCommunication Interface

The GF135 supports analog 0-5 Vdc, RS485, and DeviceNet™

communication protocols. A range of low profile adapter cables

facilitate replacing older mass flow controllers with the GF

Series eliminating the need to carry mass flow controllers of

same gas/range but different electrical connectors.

4

GF135 Diagram

Communication Interface

Page 5

PrPr

oduct oduct

Pr

oduct

PrPr

oduct oduct

Etch ProcessEtch Process

Etch Process

Etch ProcessEtch Process

The transition to 22nm and 10nm nodes and complex 3D

device geometries place greater profile and variability control

challenges on the etch tool and its gas delivery sub system.

ApplicationApplication

Application

ApplicationApplication

GF Series

Controllers

Creating and maintaining highly reproducible gas chemistry

requires leading edge mass flow control.

The GF135 is the preferred mass flow controller for

demanding etch applications. With ultra fast 300msec flow

settling time, market leading pressure transient insensitivity,

wide rangeability, process gas accuracy and real-time flow

error detection with advanced diagnostics, the GF135 is the

right choice for these demanding applications.

PrPr

oduct Specificationsoduct Specifications

Electrical InElectrical In

Pr

oduct Specifications

Electrical In

PrPr

oduct Specificationsoduct Specifications

Electrical InElectrical In

PDC OrPDC Or

dering Code G2dering Code G2

PDC Or

dering Code G2

PDC OrPDC Or

dering Code G2dering Code G2

Description: Industry standard

Analog / RS485 interface

terface Optionsterface Options

terface Options

terface Optionsterface Options

123

N2

Ar

Hbr

Sf6

O2

O2

CHF3

SiCl4

C4F6

CHAMBER

PDC OrPDC Or

dering Code D0-D9dering Code D0-D9

PDC Or

dering Code D0-D9

PDC OrPDC Or

dering Code D0-D9dering Code D0-D9

and Dand D

AA

-D-D

and D

and Dand D

Description: Industry standard

ODVA compliant DeviceNet

interface

XX

A

-D

X

AA

-D-D

XX

ETCH

EXHAUST

5

Page 6

PrPr

oduct Specificationsoduct Specifications

Pr

oduct Specifications

PrPr

oduct Specificationsoduct Specifications

PP

erformanceerformance

P

erformance

PP

erformanceerformance

Full Scale Flow Range:Full Scale Flow Range:

Full Scale Flow Range: 3 sccm to 5 slm (N2 Eq.)

Full Scale Flow Range:Full Scale Flow Range:

Gasses Supported:Gasses Supported:

Gasses Supported: N2, O2, Ar, H2, SF6, NH3, CO2, Cl2, HBr, NF3, CF4, CH4, CH3F, CH2F2, SiCl4 (@ 100 Torr),

Gasses Supported:Gasses Supported:

Flow Flow

AccurAccur

Flow

Flow Flow

Repeatability & ReprRepeatability & Repr

Repeatability & Repr

Repeatability & ReprRepeatability & Repr

Linearity:Linearity:

Linearity: Included in accuracy

Linearity:Linearity:

Settling Settling

Settling

Settling Settling

PrPr

Pr

PrPr

ConCon

Con

ConCon

VV

V

VV

ZZ

Z

ZZ

TT

emperemper

T

emper

TT

emperemper

Rate-of-Decay PRate-of-Decay P

Rate-of-Decay P

Rate-of-Decay PRate-of-Decay P

RatingsRatings

Ratings

RatingsRatings

OperOper

Oper

OperOper

DifferDiffer

Differ

DifferDiffer

Maximum OperMaximum Oper

Maximum Oper

Maximum OperMaximum Oper

Pneumatic Pneumatic

Pneumatic

Pneumatic Pneumatic

Leak InLeak In

Leak In

Leak InLeak In

MecMec

hanicalhanical

Mec

hanical

MecMec

hanicalhanical

VV

V

VV

WW

W

WW

Surface Finish:Surface Finish:

Surface Finish: 4μ inch Ra (0.1 μm Ra)

Surface Finish:Surface Finish:

Diagnostics & DisplayDiagnostics & Display

Diagnostics & Display

Diagnostics & DisplayDiagnostics & Display

Status Lights:Status Lights:

Status Lights: MFC Health, Network Status

Status Lights:Status Lights:

Alarms:Alarms:

Alarms: Sensor Output, Control Valve Output, Over Temperature, Power Surge/Sag, Network Interruption,

Alarms:Alarms:

Display Display

Display

Display Display

Viewing Distance:Viewing Distance:

Viewing Distance: Fixed / 10 feet

Viewing Distance:Viewing Distance:

Units Displayed / Resolution:Units Displayed / Resolution:

Units Displayed / Resolution: Flow (%), Temp. (°C), Pressure (psia, kPa) / 0.1 (unit)

Units Displayed / Resolution:Units Displayed / Resolution:

ElectricalElectrical

Electrical

ElectricalElectrical

Electrical Connection:Electrical Connection:

Electrical Connection: Analog/RS-485 via 9-Pin “D” connector, DeviceNet via 5-Pin “M12” connector

Electrical Connection:Electrical Connection:

Digital Communication:Digital Communication:

Digital Communication: RS485+ (model specific), DeviceNet (model specific), RS485 Diagnostic Port (all models)

Digital Communication:Digital Communication:

Diagnostic / Service PDiagnostic / Service P

Diagnostic / Service P

Diagnostic / Service PDiagnostic / Service P

PP

P

PP

ComplianceCompliance

Compliance

ComplianceCompliance

EMCEMC

EMC EC Directive 2004/108/EC CE: EN61326: 2006 (FCC Part 15 & Canada IC-subset of CE testing)

EMCEMC

Environmental ComplianceEnvironmental Compliance

Environmental Compliance RoHS Directive 2011/65/2006

Environmental ComplianceEnvironmental Compliance

*Exceptions for max ROD flow include SiCl4 (60 sccm), C4F8 (500 sccm) and C4F6-q) (500 sccm). Consult factory for more information.

6

acy:acy:

Accur

acy: +/-1.0% S.P. (10-100% F.S.), +/-1% S.P. plus +/-0.04% F.S. (2-10% F.S.)

AccurAccur

acy:acy:

oducibility:oducibility:

oducibility: < +/- 0.15% S.P.

oducibility:oducibility:

Time (to within +/- 2% FS):Time (to within +/- 2% FS):

Time (to within +/- 2% FS): <300ms (<860 sccm N2 Equivalent), <400ms (861-5000 sccm N2 Equivalent)

Time (to within +/- 2% FS):Time (to within +/- 2% FS):

essuressur

e Insensitivity:e Insensitivity:

essur

e Insensitivity: < 1% S.P. up to 5 psi/sec upstream press. spike

essuressur

e Insensitivity:e Insensitivity:

trtr

ol Range:ol Range:

tr

ol Range: 1-100%

trtr

ol Range:ol Range:

alve Shut Down:alve Shut Down:

alve Shut Down: < 0.5% of F.S. N2

alve Shut Down:alve Shut Down:

erer

o Stability:o Stability:

er

o Stability: < +/- 0.5% F.S. per year

erer

o Stability:o Stability:

aturatur

e Coefficiene Coefficien

atur

e Coefficien

aturatur

e Coefficiene Coefficien

Flow Rate:Flow Rate:

Flow Rate: Maximum flow rate for which an ROD measurement can be obtained is 800 sccm*

Flow Rate:Flow Rate:

T

T

emperemper

aturatur

T

emper

atur

TT

emperemper

aturatur

PrPr

essuressur

e Sensitivity:e Sensitivity:

Pr

essur

e Sensitivity: +/- 0.04% F.S./psi

PrPr

essuressur

e Sensitivity:e Sensitivity:

Minimum Detectable ChangeMinimum Detectable Change

Minimum Detectable Change Zero Drift: +/- 0.02% F.S.

Minimum Detectable ChangeMinimum Detectable Change

frfr

om Commissioning Baseline:om Commissioning Baseline:

fr

om Commissioning Baseline: Valve Leak: +0.1% F.S.

frfr

om Commissioning Baseline:om Commissioning Baseline:

ating ating

TT

emperemper

ating

T

emper

ating ating

TT

emperemper

enen

tial Prtial Pr

en

tial Pr

enen

tial Prtial Pr

VV

alve Operalve Oper

V

alve Oper

VV

alve Operalve Oper

tegrity (external):tegrity (external):

tegrity (external): 1x10-10 atm. cc/sec He

tegrity (external):tegrity (external):

alve alve

TT

ype:ype:

alve

T

ype: Normally Closed

alve alve

TT

ype:ype:

etted Materials:etted Materials:

etted Materials: SEMI F20 UHP Compliant 316L VIM/VAR, Hastelloy C-22,316L Stainless Steel, 304 Stainless Steel, KM-45

etted Materials:etted Materials:

TT

ype:ype:

T

ype: Top Mount Electronically Rotatable Integrated LCD

TT

ype:ype:

ower Supply/Consumption:ower Supply/Consumption:

ower Supply/Consumption: DeviceNet: +11-25 Vdc., 545 mA max. @ 11 Vdc., 250 mA (max.) @ 24 Vdc.,

ower Supply/Consumption:ower Supply/Consumption:

t:t:

t: Span: 0.05% setpoint per °C, Zero: 0.005% F.S. per °C

t:t:

erformance:erformance:

erformance: (ROD by default is disabled/off. It should not be enabled until after MFC is installed and properly commissioned)

erformance:erformance:

e Sensitivity:e Sensitivity:

e Sensitivity: +/- 0.04% S.P./Deg C

e Sensitivity:e Sensitivity:

aturatur

e Range:e Range:

atur

e Range: 10-50°C

aturatur

e Range:e Range:

essuressur

e Range**:e Range**:

essur

e Range**: 3-860 sccm = 7-45 psid, 861- 5000 sccm = 10-45 psid

essuressur

e Range**:e Range**:

ating Prating Pr

essuressur

ating Pr

ating Prating Pr

e:e:

essur

e: 100 psia max

essuressur

e:e:

ating Prating Pr

essuressur

ating Pr

essur

ating Prating Pr

essuressur

ort:ort:

ort: RS485 via 2.5 mm jack

ort:ort:

C4F6-q (@ 800 Torr), C4F8 (@ 1200 Torr), N2O, CHF3, SiH2Cl2, He, SiH4, BCl3, SiHCl3

Repeatability: +/- 0.3% S.P. (SiCl4 +/- 0.5% from 5-100% S.P. up to 100 sccm flow)

**Typical pressure drop. Actual pressure drop will be gas and flow dependent.

Argon gas applications require higher differential pressure.

Low vapor pressure gases require an inlet pressure of > 100 Torr, with vacuum on outlet

(example SiCl4). Contact Brooks Technical Support for more information.

e:e:

e: 43.5 psia - 72.5 psia

e:e:

Sensor Drift, Flow Error, Valve Leak

Analog /RS485: +/-15 Vdc. (+10%), 6 Watts (max) or +24 Vdc +/-10%

Reach Directive EC 1907/2006

Page 7

PrPr

oduct Dimensions GF135, DeviceNetoduct Dimensions GF135, DeviceNet

Pr

oduct Dimensions GF135, DeviceNet

PrPr

oduct Dimensions GF135, DeviceNetoduct Dimensions GF135, DeviceNet

Model GF135, DeviceNet, C-Seal Connections

Model GF135, DeviceNet, VCR Connections

7

Page 8

PrPr

oduct Dimensions GF135, RS485oduct Dimensions GF135, RS485

Pr

oduct Dimensions GF135, RS485

PrPr

oduct Dimensions GF135, RS485oduct Dimensions GF135, RS485

Model GF135, RS485, C-Seal Connections

Model GF135, RS485, VCR Connections

8

Page 9

Model CodeModel Code

Model Code

Model CodeModel Code

Code DescriptionCode Description

Code Description

Code DescriptionCode Description

I.I.

I. Base Model Code

I.I.

II.II.

II. Package/Finish Specifications

II.II.

III.III.

III. Configurability

III.III.

IVIV

..

IV

. Special Application

IVIV

..

VV

..

V

.Valve Configuration

VV

..

VI.VI.

VI.Specific Gas Code & Range,

VI.VI.

VII.VII.

VII. Fitting

VII.VII.

VIII. VIII.

VIII. Downstream Condition

VIII. VIII.

IX.IX.

IX. Sensor

IX.IX.

X.X.

X. Connector DeviceNet Standard Configuration Parameters

X.X.

Code OptionCode Option

Code Option

Code OptionCode Option

GFGF

GF

GFGF

135135

135 Pressure Transient Insensitive (PTI) Ultra High Purity Advanced Diagnostic MFC

135135

XX

X Gas specific

XX

XXXX

XX Standard Application

XXXX

CC

C Normally Closed Valve

CC

XXXX XXXXXXXX XXXX

XXXX XXXX Specify Gas Code & Range, i.e. “0004” = Argon and “010L” = 10 slpm

XXXX XXXXXXXX XXXX

VXVX

VX 1 1/2" VCR 1/4"

VXVX

CXCX

CX 1 1/8" C Seal 92mm

CXCX

WXWX

WX 1 1/8" W Seal 92mm

WXWX

AA

A Atmosphere

AA

VV

V Vacuum

VV

OO

O Default Orientation

OO

D0D0

D0 DeviceNet 5 Pin Micro Idle Count Integer 6000h 2 7 Executing 500KB

D0D0

D1D1

D1 DeviceNet 5 Pin Micro Idle Count Integer 6000h 21 7 Executing 500KB

D1D1

D2D2

D2 DeviceNet 5 Pin Micro Idle SCCM Float 7FFFh 13 19 Executing 500KB

D2D2

D3D3

D3 DeviceNet 5 Pin Micro Idle Count Integer 6000h 22 7 Executing 500KB

D3D3

D4D4

D4 DeviceNet 5 Pin Micro Executing Count Integer 6000h 22 8 Executing 500KB

D4D4

D5D5

D5 DeviceNet 5 Pin Micro Idle Count Integer 6000h 6 8 Executing 500KB

D5D5

D6D6

D6 DeviceNet 5 Pin Micro Idle Count Integer 7FFFh 3 7 Executing 500KB

D6D6

D7D7

D7 DeviceNet 5 Pin Micro Idle Count Integer 7FFFh 6 8 Executing 500KB

D7D7

D8D8

D8 DeviceNet 5 Pin Micro Idle Count Integer 6000h 3 7 Executing 500KB

D8D8

D9D9

D9 DeviceNet 5 Pin Micro Executing Count Integer 6000h 2 7 Executing 500KB

D9D9

DD

AA

D

A DeviceNet 5 Pin Micro Idle Count Integer 7FFFh 22 7 Executing 500KB

DD

AA

DBDB

DB DeviceNet 5 Pin Micro Idle Count Integer 6000h 22 8 Executing 500KB

DBDB

DCDC

DC DeviceNet 5 Pin Micro Idle Count Integer 7FFFh 3 7 Idle 500KB

DCDC

DDDD

DD DeviceNet 5 Pin Micro Executing Count Integer 7FFFh 22 8 Executing 500KB

DDDD

DEDE

DE DeviceNet 5 Pin Micro Executing SCCM Float 6000h 15 19 Executing 500KB

DEDE

DD

XX

D

X DeviceNet 5 Pin Micro To be defined by CSR

DD

XX

G2G2

G2 Analog/RS485 9 Pin D NA NA NA NA NA NA NA NA

G2G2

Option DescriptionOption Description

Option Description

Option DescriptionOption Description

I/O Connector State Setting Setting Setting Producer Consumer Transition Rate

Power On Full Scale Full Scale Full Scale Instance Instance State Baud

Poll IO Poll IO Poll IO External

XI.XI.

XI. Customer Special Request

XI.XI.

XII.XII.

XII. Auto Shut-Off

XII.XII.

XIII.XIII.

XIII. Auto Zero

XIII.XIII.

XIVXIV

..

XIV

. Reference Temperature

XIVXIV

..

Example Model CodeExample Model Code

Example Model Code

Example Model CodeExample Model Code

II

IIII

II

IIII

135135

135

135135

IIIIII

III

IIIIII

XX

X

XX

GFGF

GF

GFGF

I

II

XXXXXXXX

XXXX Customer Special Request Number

XXXXXXXX

AA

A Auto Shut Off (Included)

AA

XX

X Auto Shut Off (Not Included)

XX

AA

A Auto Zero (Included)

AA

XX

X Auto Zero (Not Included)

XX

000000

000 0°C Reference Calibration (Standard) - Default Setting

000000

IVIV

IV

IVIV

XXXX

XX

XXXX

VV

V

VV

CC

C

CC

VIVI

VI

VIVI

XXXX XXXXXXXX XXXX

XXXX XXXX

XXXX XXXXXXXX XXXX

VIIVII

VII

VIIVII

VXVX

VX

VXVX

VIIIVIII

VIII

VIIIVIII

IXIX

IX

IXIX

AA

OO

A

AA

D1D1

O

D1

OO

D1D1

XX

XIXI

XIIXII

XIIIXIII

X

XI

XIXI

XXXXXXXX

XXXX

XXXXXXXX

XII

XIIXII

AA

A

AA

XX

XIII

XIIIXIII

AA

A

AA

XIVXIV

XIV

XIVXIV

000000

000

000000

9

Page 10

BrBr

ooks Service and Supportooks Service and Support

Br

ooks Service and Support

BrBr

ooks Service and Supportooks Service and Support

Brooks is committed to assuring all of our customers receive the ideal flow solution for their application, along with outstanding

service and support to back it up. We operate first class repair facilities located around the world to provide rapid response and

support. Each location utilizes primary standard calibration equipment to ensure accuracy and reliability for repairs and recalibration and is certified by our local Weights and Measures Authorities and traceable to the relevant International Standards.

Visit www.BrooksInstrument.com to locate the service location nearest to you.

STST

ARAR

TT

-UP SERVICE -UP SERVICE

ST

AR

T

-UP SERVICE

STST

ARAR

TT

-UP SERVICE -UP SERVICE

Brooks Instrument can provide start-up service prior to operation when required. For some process applications, where ISO-9001

Quality Certification is important, it is mandatory to verify and/or (re)calibrate the products periodically. In many cases this service

can be provided under in-situ conditions, and the results will be traceable to the relevant international quality standards.

AND IN-SITU CALIBRAAND IN-SITU CALIBRA

AND IN-SITU CALIBRA

AND IN-SITU CALIBRAAND IN-SITU CALIBRA

TIONTION

TION

TIONTION

SEMINARS SEMINARS

SEMINARS

SEMINARS SEMINARS

Brooks Instrument can provide seminars and dedicated training to engineers, end users, and maintenance persons.

Please contact your nearest sales representative for more details.

Due to Brooks Instrument's commitment to continuous improvement of our products, all specifications are subject to change without notice.

TRADEMARKS

Brooks, MultiFlo ............................................................. Brooks Instrument, LLC

All other trademarks are the property of their respective owners.

AND AND

AND

AND AND

TRAININGTRAINING

TRAINING

TRAININGTRAINING

10

Loading...

Loading...