Brooks Instrument 5882/92 User Manual

Installation and Operation Manual

X-TMF-FM-MFC-eng

PN 541-C-007-AAG

April, 2008

Flomega, Liquid MFC’s/MFM’s

Brooks® Flomega, Liquid MFC’s/MFM’s

Model 5881/5891 and 5882/5892

1

1

Installation and Operation Manual

X-TMF-FM-MFC-eng

Flomega, Liquid MFC’s/MFM’s PN 541-C-007-AAG

April, 2008

WARNING !

This publication must be read in its entirety before performing any operation.

Failure to understand and follow these instructions could result in serious personal injury and/or damage to the equipment. Should this equipment require repair or adjustment, contact the nearest Brooks Sales & Repair Office. It is important that servicing is performed by trained and qualified personnel only.

If this equipment is not properly serviced, serious personal injury and/or damage to the equipment could result.

Dear customer,

We appreciate this opportunity to service your flow measurement and control requirements with a Brooks Instrument device. Every day, flow customers all over the world turn to Brooks Instrument for solutions to their gas and liquid low-flow applications. Brooks provides an array of flow measurement and control products for various industries from biopharmaceuticals, oil and gas, fuel cell research and chemicals, to medical devices, analytical instrumentation, semiconductor manufacturing, and more.

The Brooks product you have just received is of the highest quality available, offering superior performance, reliability and value to the user. It is designed with the ever changing process conditions, accuracy requirements and hostile process environments in mind to provide you with a lifetime of dependable service.

We recommend that you read this manual in its entirety. Should you require any additional information concerning Brooks products and services, please contact your local Brooks Sales and Service Office listed on the back cover of this manual or visit www.BrooksInstrument.com

Yours sincerely, Brooks Instrument

CAUTION !

This instrument contains electronic components that are susceptible to damage by static electricity. Proper handling procedures must be observed during the removal, installation or other handling of internal circuit boards or devices.

Handling Procedure:

1. Power must be removed.

2. Personnel must be grounded, via a wrist wrap or other safe, suitable means, before any printed circuit card or other internal device is installed, removed or adjusted.

3. Printed circuit board must be transported on a conductive bag or other conductive container. Boards

must not be removed from protective enclosure until the immediate time of installation. Removed boards must be placed immediately in a protective container for transport, storage or factory.

Comments:

This instrument is not unique in its content of ESD (electrostatic discharge) sensitive components. Most modern electronics designs contain microprocessor technology including SMD-components. Experience has proven that even small amounts of static electricity can damage or destroy these devices. Damaged components, even though they appear to function properly, exhibit early failure.

2

Installation and Operation Manual

X-TMF-FM-MFC-eng

PN 541-C-007-AAG

April, 2008

Flomega, Liquid MFC’s/MFM’s

Essential Instructions

Read this page before proceeding!

Brooks Instrument designs, manufactures and tests its products to meet many national and international standards. Because these instruments are sophisticated technical products, you must properly install, use and maintain them to ensure they continue to operate within their normal specifications. The following instructions must be adhered to and integrated into your safety program when installing, using and maintaining Brooks Products.

•Read all instructions prior to installing, operating and servicing the product. If this instruction manual is not the correct manual, please see back cover for local sales office contact information. Save this instruction manual for future reference.

•If you do not understand any of the instructions, contact your Brooks Instrument representative for clarification.

•Follow all warnings, cautions and instructions marked on and supplied with the product.

•Inform and educate your personnel in the proper installation, operation and maintenance of the product.

•Install your equipment as specified in the installation instructions of the appropriate instruction manual and per applicable local and national codes. Connect all products to the proper electrical and pressure sources.

•To ensure proper performance, use qualified personnel to install, operate, update, program and maintain the product.

•When replacement parts are required, ensure that qualified people use replacement parts specified by Brooks Instrument. Unauthorized parts and procedures can affect the product’s performance and place the safe operation of your process at risk. Look-alike substitutions may result in fire, electrical hazards or improper operation.

•Ensure that all equipment doors are closed and protective covers are in place, except when maintenance is being performed by qualified persons, to prevent electrical shock and personal injury.

Pressure Equipment Directive (PED)

All pressure equipment with an internal pressure greater than 0,5 bar (g) and a size larger than 25 mm or 1" (inch) falls under the Pressure Equipment Directive (PED). The Directive is applicable within the European Economic Area (EU plus Norway, Iceland and Liechtenstein). Pressure equipment can be traded freely within this area once the PED has been complied with.

**Appendix 1 of this manual contains important safety and operating instructions related to the PED directive

**Meters decribed in this manual are in compliance with EN directive 97/23/EC module H Conformity Assessment.

**All Brooks Instrument flowmeters falls under Fluid-group I

**Meters larger then 25mm or 1" (inch) are in compliance with category I, II or III of the PED.

**Meters of 25mm or 1" (inch) or smaller are Sound Engineering Practice (SEP).

3

Flomega, Liquid MFC’s/MFM’s

Installation and Operation Manual

X-TMF-FM-MFC-eng

PN 541-C-007-AAG

April, 2008

CAUTION

CAUTION

This instrument contains electronic components that are susceptible to damage by static electricity. Proper handling: procedures must be observed during the removal, installation or other handling of internal circuit boards or devices.

Handling procedure:

1. Power to unit must be removed.

2. Personnel must be grounded, via a wrist strap or other safe, suitable means before any printed circuit card or other internal device is installed, removed or adjusted.

3. Printed circuit cards must be transported in a conductive bag or other conductive container. Boards must not be removed from protective enclosure until immediately before installation. Removed boards must immediately be placed in protective container for transport, storage or return to factory.

Comments:

This instrument is not unique in its content of ESD (electrostatic discharge) sensitive components. Most modern electronic designs contain components that utilize metal oxide technology (NMOS, CMOS, etc.). Experience has proven that even small amounts of static electricity can damage or destroy these devices. Damaged components, even though they appear to function properly, exhibit early failure.

4

|

Installation and Operation Manual |

Contents |

|

|

X-TMF-FM-MFC-eng |

|

|

|

PN 541-C-007-AAG |

|

Flomega, Liquid MFC’s/MFM’s |

|

April, 2008 |

|

|

Paragraph |

|

Page |

|

Number |

|

Number |

|

|

Section 1 |

Introduction ............................................................................................................... |

7 |

1-1 |

Purpose ............................................................................................................... |

7 |

|

1-2 |

Description ............................................................................................................... |

7 |

|

1-3 |

Specifications .............................................................................................................. |

7 |

|

|

Section 2 |

Installation ............................................................................................................... |

10 |

2-1 |

General ............................................................................................................... |

10 |

|

2-2 |

Receipt of Equipment .................................................................................................. |

10 |

|

2-3 |

Recommended Storage Practice ................................................................................. |

10 |

|

2-4 |

Return Shipment .......................................................................................................... |

11 |

|

2-5 |

Transit Precautions...................................................................................................... |

11 |

|

2-6 |

Removal from Storage ................................................................................................. |

11 |

|

2-7 |

In-line Filter ............................................................................................................... |

12 |

|

2-8 |

Connections ............................................................................................................... |

12 |

|

2-9 |

Precision 5V Reference ............................................................................................... |

12 |

|

2-10 |

Command Input ........................................................................................................... |

12 |

|

2-11 |

Valve Override .............................................................................................................. |

12 |

|

2-12 |

Installation ............................................................................................................... |

14 |

|

2-13 |

Start-up Guidelines ...................................................................................................... |

15 |

|

|

Section 3 |

Operation ............................................................................................................... |

16 |

3-1 |

Theory of operation ...................................................................................................... |

16 |

|

3-2 |

Calibration procedure ................................................................................................... |

21 |

|

3-3 |

Response Adjustment ................................................................................................. |

21 |

|

3-4 |

Rangeability ............................................................................................................... |

21 |

|

|

Section 4 |

MAINTENANCE AND TROUBLE SHOOTING ............................................................. |

22 |

4-1 |

General ............................................................................................................... |

22 |

|

4-2 |

Disassembly and Assembly ........................................................................................ |

22 |

|

4-3 |

Trouble shooting Guidelines ........................................................................................ |

23 |

|

|

Section 5 |

PARTS LIST ............................................................................................................... |

25 |

5-1 |

General ............................................................................................................... |

25 |

|

5-2 |

Service Tools ............................................................................................................... |

26 |

|

|

Section 6 |

Modellist ............................................................................................................... |

27 |

|

Section 7 |

CE Certification ......................................................................................................... |

28 |

|

Section 8 |

Safety Instructions .................................................................................................... |

33 |

|

Appendix A |

ATEX Certification(EEx nA II T4) .............................................................................. |

38 |

|

|

ATEX Certification (EEx d IIB T6...T4) ..................................................................... |

39 |

5

Contents |

|

Installation and Operation Manual |

|

|

|

X-TMF-FM-MFC-eng |

|

Flomega, Liquid MFC’s/MFM’s |

PN 541-C-007-AAG |

||

April, 2008 |

|

||

Figure |

|

Page |

|

Number |

|

Number |

|

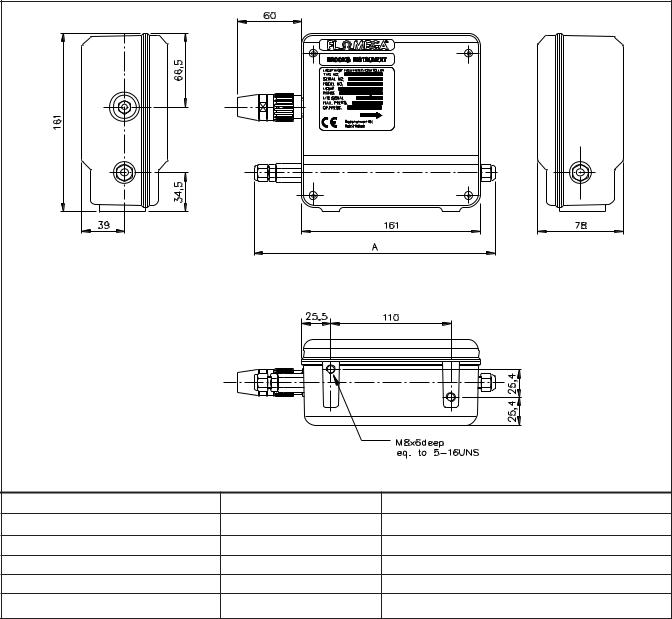

1-1 |

Dimensions .................................................................................................................................... |

9 |

|

2-1 |

Standard and EEx nA execution .................................................................................................... |

13 |

|

2-2 |

Pin Function ................................................................................................................................... |

13 |

|

2-3 |

Eex d. execution ............................................................................................................................ |

13 |

|

2-4 |

Pin Wire Color Function ................................................................................................................. |

13 |

|

3-1 |

Measurement Principle 5891 .......................................................................................................... |

16 |

|

3-2 |

Measurement Principle .................................................................................................................. |

17 |

|

3-3 |

Principle Mass Flow Controller ....................................................................................................... |

18 |

|

3-4 |

Jumper Settings for Flomega ......................................................................................................... |

20 |

|

3-5 |

Jumper Settings for Flomega ......................................................................................................... |

20 |

|

5-1 |

Flomega spare parts ...................................................................................................................... |

26 |

|

Table |

|

|

|

Number |

|

|

|

5-1 |

Spare Parts list .............................................................................................................................. |

25 |

|

6

Installation and Operation Manual |

Section 1 Introduction |

|

X-TMF-FM-MFC-eng |

|

|

PN 541-C-007-AAG |

Flomega, Liquid MFC’s/MFM’s |

|

April, 2008 |

||

1-1 |

Purpose |

|

|

|

|

|

|

|

The Brooks models 5881/5882 Flow Controllers are a mass flow measurement devices designed for accu rately measuring and controlling flows of liquids. This instruction manual is intended to provide the user with all the information necessary to install, operate and maintain the Brooks 5881/5882 Mass Flow Controllers and 5891/5892 Flow Meters. This manual is organized into six chapters:

1.Introduction

2.Installation

3.Operation

4.Maintenance

5.Replacement parts

6.Modellist

It is recommended that this manual be read in its entirety before attempting to operate or repair.

1-2 |

Description |

|

|

|

|

|

The Brooks models 5881/5882 consist of three basic units: a flow sensor, a control valve and an integral |

|

electronic control system. Designed to operate at +15 Vdc or +24 Vdc, the models 5881/5882 monitor |

|

and maintain a stable mass flow relatively independent of pressure and temperature variations. |

|

Standard features include: |

|

a. Thru-flow (patented) design of the sensor |

|

b. In-line type control valve |

|

c. Soft start |

|

d. Valve override |

|

e. Low command valve inhibit |

|

f. Flow output limiting |

|

g. Temperature of heater output |

|

h. Field adjustable orifice |

1-3 |

Performance Specifications |

|

|

|

||

|

|

|

|

|||

|

Accuracy incl. linearity |

± 0.5% full scale measured at calibration conditions |

|

|||

|

Process temperature effects |

± 0.03% F.S./°C |

|

|||

|

Ambient temperature effects |

± 0.1 % F.S./°C |

|

|||

|

Repeatability |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Applicable flowrange |

|

|

|

|

|

|

|

|

|

|

|

Models |

|

from 100% to 50% of max. f.s. |

less than 50% of max. f.s. |

|

|

|

5881/91 |

|

± 0.2% of rate |

|

± 0.2% f.s.* |

|

|

|

|

|

|

|

|

|

5882/92 |

|

± 0.2% of rate |

|

± 0.4% of rate |

|

|

|

|

|

|

|

|

*The measured repeatability is (technically) limited by the current calibration method using an highly accurate balance (weighscale)

7

Section 1 Introduction |

|

|

Installation and Operation Manual |

||||||

|

|

|

|

|

|

|

|

X-TMF-FM-MFC-eng |

|

Flomega, Liquid MFC’s/MFM’s |

|

|

PN 541-C-007-AAG |

||||||

|

|

April, 2008 |

|||||||

Specification |

|

|

|

|

|

|

|

|

|

Flowranges |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Brooks FLOMEGA TM |

|

|

|

|

|

|

|

|

|

Models |

Min. full scale Flowrate* |

|

|

Max. full scale Flowrate* |

|

Units |

|

PED Module Category |

|

|

|

|

|

|

|

|

|

|

|

5881/91 |

15** |

|

|

100 |

|

gr/hour |

|

S.E.P. |

|

5882/92 |

200 |

|

|

1000 |

|

gr/hour |

|

S.E.P. |

|

* To be specified at ordering (factory selectable) (water equivalent flowranges) |

|

|

|

|

|||||

** Down to 15 gr/hour minimum full scale is possible |

|

|

|

|

|||||

@ ± 1% f.s. accuracy and ± 0,4% f.s. repeatability |

|

|

|

|

|||||

Flowranges from > 30 gr/h are within specified accuracy |

|

|

|

|

|||||

Rangeability |

|

50:1 |

|

|

|

|

|

|

|

Viscosity limits |

Up to 200 cP (limited by max. diff. pressure) |

|

|

||||||

Ambient temperature range |

0 - 65°C |

|

|

|

|

||||

Process temperature range |

0 to 100°C (Model 5882/92: max. 90°C) |

|

|

|

|

||||

Pressure limits |

100/400 bar versions |

• Model 5882: 40 bar |

|||||||

Max pressure difference |

• |

Model 5881: 20 bar |

|||||||

Pressure drop sensor |

• Model 5891: 10 mbar @ 100 gram/hour water |

|

|

||||||

|

|

• Model 5892: 150 mbar @ 1000 gram/hour water |

|

|

|||||

Setpoint input/Flow signal output |

0 (4) -20 mA*, or 0-5Vdc* |

|

|

|

|

||||

Power supply |

+ 15Vdc or 24Vdc* ± 10% max. current 660 mA |

|

|

||||||

Warm-up time |

Performance within specifications: 60 minutes |

|

|

||||||

|

|

(Within ± 1.5% F.S. accuracy: 15 minutes) |

|

|

|||||

Response time |

(to within 2% of final value for a 2-100% command change, at a constant |

||||||||

|

|

operating pressure) |

• Models: 5882/92: 7 seconds |

||||||

|

|

• |

Models: 5881/91: 5 seconds |

||||||

Mounting insensitivity |

Not affected by mounting position* |

|

|

|

|

||||

Certification |

|

• ATEX Zone I, II 2 GD KEMA 03 ATEX2036 |

|

|

|||||

|

|

CE 0344 EEx d IIB T6...T4 T100°C (IP 66) |

|

|

|||||

|

|

Temperature Class |

Process Temperature |

||||||

|

|

T6 |

< 75°C |

|

|

||||

|

|

T5 |

75 - 85°C |

|

|

||||

|

|

T4 |

85 - 100°C |

|

|

||||

|

|

|

Per: EN 50014:1997 +A1 + A2 |

|

|

|

|

||

|

|

|

EN 50018:2000 + A2 |

|

|

|

|

||

|

|

|

EN 50281-1-1:1998 + A1 |

|

|

|

|

||

|

|

• ATEX Zone 2, II 3 GD KEMA 99 ATEX3626 |

|

|

|||||

|

|

EEx nA II T4 T75°C (IP65) Per: EN 60079-15:2003 |

|

|

|||||

* To be specified at ordering |

|

|

EN 50281-1-7:1998+A1 |

||||||

|

|

|

|

|

|

|

|

||

Physical specifications |

• Standard: 1/16” or 1/8” tube connections |

|

|

||||||

Mechanical connections |

|

|

|||||||

|

|

• |

Optional: ¼” tube compression, ¼” NPT (F), or ¼”B.VCO fittings |

||||||

Inlet filter |

|

• |

Material: stainless steel |

Mess size: 40 micron |

|||||

Materials of construction |

All wetted materials: stainless steel. For seals: Viton, PTFE, EPDM, |

||||||||

|

|

Buna or Kalrez |

|

|

|

|

|||

|

|

• All stainless steel construction (including welded adapters) for |

|||||||

|

|

SANITARY sensor |

|

|

|

|

|||

Housing materials |

Cast aluminium |

|

|

|

|

||||

Electrical connections |

12-pole circular connector |

|

|

|

|

||||

Weight |

|

less than 3.5 kg |

|

|

|

|

|||

8

Installation and Operation Manual |

Section 1 Introduction |

X-TMF-FM-MFC-eng |

|

PN 541-C-007-AAG |

Flomega, Liquid MFC’s/MFM’s |

April, 2008 |

When EEx d IIB T4...T6 required, please contact factory for detailed dimensional drawing.

Connections |

A |

A with filter |

5/16” - 24 UNF |

143,5 mm |

175 mm |

1/16” Tube Compression |

176,5 mm |

208 mm |

1/8” Tube Compression |

188 mm |

220 mm |

1/4” Tube Compression |

188 mm |

220 mm |

1/4” NPT(F) |

208 mm |

240 mm |

Figure 1-1 Dimensions

9

Section 2 Installation |

Installation and Operation Manual |

|

X-TMF-FM-MFC-eng |

Flomega, Liquid MFC’s/MFM’s |

PN 541-C-007-AAG |

April, 2008 |

2-1 General

This section contains the procedures for the receipt and installation of the instrument. See Section 1 for dimensional and connection requirements. Do not attempt to start the system until the instrument has been permanently installed. It is important that the start-up procedures be followed in the exact sequence presented.

2-2 Receipt of Equipment

When the instrument is received, the outside packing case should be checked for damage incurred during shipment. If the packing case is damaged, the local carrier should be notified at once regarding his liability. A report should be submitted to your nearest Product Service Department.

Brooks Instrument

407 W. Vine Street

P.O. Box 903

Hatfield, PA 19440 USA

Toll Free (888) 554-FLOW (3569)

Tel (215) 362-3700

Fax (215) 362-3745

E-mail: BrooksAm@EmersonProcess.com

www.BrooksInstrument.com

Brooks Instrument |

Brooks Instrument |

Neonstraat 3 |

1-4-4 Kitasuna Koto-Ku |

6718 WX Ede, Netherlands |

Tokyo, 136-0073 Japan |

P.O. Box 428 |

Tel 011-81-3-5633-7100 |

6710 BK Ede, Netherlands |

Fax 011-81-3-5633-7101 |

Tel 31-318-549-300 |

Email: BrooksAs@EmersonProcess.com |

Fax 31-318-549-309

E-mail: BrooksEu@EmersonProcess.com

Remove the envelope containing the packing list. Carefully remove the instrument from the packing case. Make sure spare parts are not discarded with the packing materials. Inspect for damaged or missing parts.

2-3 Recommended Storage Practice

If intermediate or long-term storage of equipment is required, it is recommended that the equipment be stored in accordance with the following:

a. Within the original shipping container.

b. Stored in a sheltered area, preferably a warm, dry, heated warehouse. c. Ambient temperature of 70° F (21° C) nominal, 109° F (43° C) maximum,

45° F (7° C) minimum.

d. Relative humidity 45% nominal, 60% maximum, 25% minimum.

Upon removal from storage a visual inspection should be conducted to verify the condition of equipment is “as received”.

10

Installation and Operation Manual |

Section 2 Installation |

|

X-TMF-FM-MFC-eng |

|

|

PN 541-C-007-AAG |

Flomega, Liquid MFC’s/MFM’s |

|

April, 2008 |

|

|

2-4 |

Return Shipment |

|

|

|

|

|

Prior to returning any instrument to the factory visit the Brooks website |

|

|

www.BrooksInstrument.com for a Return Materials Authorization Number (RMA#), or contact one of the |

|

|

following locations: |

|

|

Brooks Instrument |

|

|

407 W. Vine Street |

|

|

P.O. Box 903 |

|

|

Hatfield, PA 19440 USA |

|

|

Toll Free (888) 554-FLOW (3569) |

|

|

Tel (215) 362-3700 |

|

|

Fax (215) 362-3745 |

|

|

E-mail: BrooksAm@EmersonProcess.com |

|

|

www.BrooksInstrument.com |

|

|

Brooks Instrument |

Brooks Instrument |

|

Neonstraat 3 |

1-4-4 Kitasuna Koto-Ku |

|

6718 WX Ede, Netherlands |

Tokyo, 136-0073 Japan |

|

P.O. Box 428 |

Tel 011-81-3-5633-7100 |

|

6710 BK Ede, Netherlands |

Fax 011-81-3-5633-7101 |

|

Tel 31-318-549-300 |

Email: BrooksAs@EmersonProcess.com |

|

Fax 31-318-549-309 |

|

|

E-mail: BrooksEu@EmersonProcess.com |

|

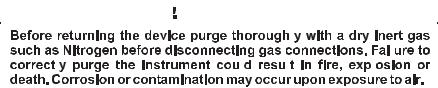

Instrument must have been purged in accordance with the following:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

All flow instruments returned to Brooks requires completion of Form RPR003-1, |

||||||||

|

Brooks Instrument Decontamination Statement, along with a Material Safety Data Sheet (MSDS) for |

||||||||

|

the fluid(s) used in the instrument. Failure to provide this information will delay processing by Brooks |

||||||||

|

personnel. Copies of these forms can be downloaded from the Brooks website |

||||||||

|

www.BrooksInstrument.com or are available from any Brooks Instrument location listed above. |

||||||||

2-5 |

Transit Precautions |

||||||||

|

|

|

|

|

|

|

|

|

|

|

To safeguard the instrument against transportation damage, it is recommended to keep the instrument |

||||||||

|

in its factory container until ready for installation. |

||||||||

2-6 |

Removal from Storage |

||||||||

|

|

|

|

|

|

|

|

|

|

|

Upon removal of the instrument from storage, a visual inspection should be conducted to verify its "as- |

||||||||

|

received" condition. If the instrument has been subject to storage conditions in excess of those |

||||||||

|

recommended (See Section 2-3), it should be subjected to a pneumatic pressure test in |

||||||||

|

accordance with applicable vessel codes. |

||||||||

11

Section 2 Installation |

Installation and Operation Manual |

|||

|

|

|

X-TMF-FM-MFC-eng |

|

Flomega, Liquid MFC’s/MFM’s |

PN 541-C-007-AAG |

|||

April, 2008 |

||||

2-7 |

In-line Filter |

|

|

|

|

|

|

|

|

|

|

An in-line type 40 micron filter has been installed upstream from the flow sensor to prevent the possibility |

||

|

|

of any foreign material entering the flow sensor or control valve. |

|

|

2-8 |

Connections |

|

|

|

|

|

|

|

|

|

|

Standard, the Flomega models are supplied with adapters. Inlet and outlet thread size is 5/16”-24 UNF. |

||

|

|

Optional adapters can be supplied. |

|

|

|

|

5/16”-24 to 1/16” tube compression fittings |

|

|

|

|

5/16”-24 to 1/8” tube compression fittings |

|

|

|

|

5/16”-24 to ¼” tube compression fittings |

|

|

|

|

5/16”-24 to ¼” NPT (F) |

|

|

|

|

Prior to installation, make certain all piping is clean and free of obstructions. Install the piping in such a |

||

|

|

manner that permits easy removal if the instrument is to be removed for cleaning or test bench |

||

|

|

troubleshooting. |

|

|

2-9 |

Precision 5V Reference |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

The 5881/5882 is equipped with a precision 5V reference. The reference voltage is available at terminal 11 |

||

|

|

(ref. to fig. 2-1) for use in conjunction with potentiometer to provide a 0-5 Vdc command. |

||

2.10Command Input

The command input hook-up is as follows: a. Connect the external command voltage to terminal 8, (command input) and to terminal 1 (command input return). Refer to figure 2-1.

2-11 Valve Override

The valve override function allows full opening and closing of the valve independent of the command setting. The valve override function can be accessed from terminal 12. Refer to figure 2-1.

The valve override for the mass flow controller is as follows:

a. To open the valve apply a voltage between +5 Vdc and +15 Vdc to the valve override terminal. (V.O.R.+) b. To close the valve apply 0 Vdc, or “common” to the valve override terminal. (V.O.R.-)

Note: For normal operation terminal 12 must be left open (floating).

12

Loading...

Loading...