Brooks Instrument 5800S User Manual

Installation and Operation Manual

X-TMF-5800S-MFC-eng

PN 541-C-051-AAG

November, 2008

Models 5800-S

Brooks® Smart-Series Digital Mass

Flow Meters and Controllers

Brooks Smart Family

1

|

Installation and Operation Manual |

||

|

X-TMF-5800S-MFC-eng |

||

Models 5800-S |

PN 541-C-051-AAG |

||

November, 2008 |

|

||

|

|

|

|

|

Essential Instructions |

|

|

Read this page before proceeding!

BrooksInstrumentdesigns,manufacturesandtestsitsproductstomeetmanynationalandinternationalstandards.Becausethese instruments are sophisticated technical products, you must properly install, use and maintain them to ensure they continue to operate within their normal specifications. The following instructions must be adhered to and integrated into your safety program when installing, using and maintaining Brooks Products.

• Read all instructions prior to installing, operating and servicing the product. If this instruction manual is not the correct manual,

please see back cover for local sales office contact information. Save this instruction manual for future reference.

• If you do not understand any of the instructions, contact your Brooks Instrument representative for clarification.

• Follow all warnings, cautions and instructions marked on and supplied with the product.

• Informandeducateyourpersonnelintheproperinstallation,operationandmaintenanceoftheproduct.

• Install your equipment as specified in the installation instructions of the appropriate instruction manual and per applicable local and national codes. Connect all products to the proper electrical and pressure sources.

• Toensureproperperformance,usequalifiedpersonneltoinstall,operate,update,programandmaintaintheproduct.

• When replacement parts are required, ensure that qualified peopleuse replacement parts specifiedby Brooks Instrument.

Unauthorized parts and procedures can affect the product's performance and place the safe operation of your process at risk.

Look-alike substitutions may result in fire, electrical hazards or improper operation.

• Ensure that all equipment doors are closed and protective covers are in place, except when maintenance is being performed by

qualified persons, to prevent electrical shock and personal injury.

Pressure Equipment Directive (PED)

Allpressureequipmentwithaninternalpressuregreaterthan0.5bar(g)andasizelargerthan25mmor1"(inch)fallsunderthePressure

EquipmentDirective(PED).TheDirectiveisapplicablewithintheEuropeanEconomicArea(EUplusNorway,Icelandand

Liechtenstein).PressureequipmentcanbetradedfreelywithinthisareaoncethePEDhasbeencompliedwith.

• Section 1 of this manual contains important safety and operating instructions related to the PED directive.

• Meters described in this manual are in compliance with EN directive 97/23/EC module H ConformityAssessment.

• All Brooks Instrument Flowmeters fall under fluid group 1.

• Meterslargerthan25mmor1"(inch)areincompliancewithcategoryI,II,IIIofPED.

• Metersof 25mmor1"(inch)orsmallerareSoundEngineeringPractice(SEP).

ESD (Electrostatic Discharge)

HandlingProcedure:

1. Powertounitmustberemoved.

2. Personnel must be grounded, via a wrist strap or other safe, suitable means before any printed circuit card or other internal device is installed, removedor adjusted.

3. Printed circuit cards must be transported in a conductive container. Boards must not be removed from protective enclosure until immediately before installation. Removed boards must immediately be placed in protective container for transport, storage or return tofactory.

Comments

This instrument is not unique in its content of ESD (electrostatic discharge) sensitive components. Most modern electronic designs contain components that utilize metal oxide technology (NMOS, SMOS, etc.). Experience has proven that even small amounts of static electricity can damage or destroy these devices. Damaged components, even though they appear to function properly, exhibit early failure.

2

Installation and Operation Manual

X-TMF-5800S-MFC-eng

PN 541-C-051-AAG

November, 2008

Models 5800-S

Dear Customer,

We appreciate this opportunity to service your flow measurement and control requirements with a Brooks Instrument device. Every day, flow customers all over the world turn to Brooks Instrument for solutions to their gas and liquid low-flow applications. Brooks provides an array of flow measurement and control products for various industries from biopharmaceuticals, oil and gas, fuel cell research and chemicals, to medical devices, analytical instrumentation, semiconductor manufacturing, and more.

The Brooks product you have just received is of the highest quality available, offering superior performance, reliability and value to the user. It is designed with the ever changing process conditions, accuracy requirements and hostile process environments in mind to provide you with a lifetime of dependable service.

We recommend that you read this manual in its entirety. Should you require any additional information concerning Brooks products and services, please contact your local Brooks Sales and Service Office listed on the back cover of this manual or visit www.BrooksInstrument.com

Yours sincerely, Brooks Instrument

3

|

|

|

Installation and Operation Manual |

|

|

|

X-TMF-5800S-MFC-eng |

|

|

|

PN 541-C-051-AAG |

Models 5800-S |

|

November, 2008 |

|

|

|

Table of Contents |

|

Section |

1:Introduction ......................................................................................................................................... |

|

5 |

|

1.1 Purpose ........................................................................................................................................... |

|

5 |

|

1.2 How to use this Manual .................................................................................................................... |

|

5 |

|

1.3 Description ....................................................................................................................................... |

|

6 |

Section |

2: Installation ......................................................................................................................................... |

|

9 |

|

2.1 General ............................................................................................................................................ |

|

9 |

|

2.2 Receipt of Equipment ....................................................................................................................... |

|

9 |

|

2.3 Recommended Storage Practice ..................................................................................................... |

|

10 |

|

2.4 Return Shipment ............................................................................................................................. |

|

10 |

|

2.5 Gas Connections ............................................................................................................................ |

|

10 |

|

2.6 Mechanical Installation .................................................................................................................... |

|

11 |

|

2.7 IN-LINE Filter .................................................................................................................................. |

|

11 |

|

2.8 Electrical Interfacing ........................................................................................................................ |

|

12 |

|

2.9 Digital Communication .................................................................................................................... |

|

14 |

|

2.10 Interconnection .............................................................................................................................. |

|

16 |

Section |

3: Operation .......................................................................................................................................... |

|

19 |

|

3.1 Operating Procedure ....................................................................................................................... |

|

19 |

|

3.2 Zero Adjustment .............................................................................................................................. |

|

19 |

|

3.3 Calibration Procedure ...................................................................................................................... |

|

19 |

Section |

4: Maintenance ..................................................................................................................................... |

|

20 |

|

4.1 General ........................................................................................................................................... |

|

20 |

|

4.2 Troubleshooting and System checks ............................................................................................... |

|

20 |

|

4.3 Cleaning Procedures ....................................................................................................................... |

|

23 |

|

4.4 Calibration Procedure ...................................................................................................................... |

|

23 |

|

4.5 Valve (Dis)Assembly Procedure ..................................................................................................... |

|

23 |

Section 5: Specification ........................................................................................................................................ |

|

24 |

|

Appendix A: Gas Conversion Tables ..................................................................................................................... |

|

28 |

|

Appendix B: Dimensional drawings ...................................................................................................................... |

|

32 |

|

Appendix C:Translation of CE Marking electrical installation instructions |

34 |

||

Appendix D: Important Safety Instructions ............................................................................................................ |

|

39 |

|

Appendix E: Modellist ......................................................................................................................................... |

|

44 |

|

Figures |

|

|

|

Figure 2-1: Open Collector ................................................................................................................................... |

|

13 |

|

Figure 2-2: p.c. boards with the locations of jumper switches Note: Switch number 1 is the switch at the bottom 14 |

|||

Figure 2-3: RS-232 interconnection of TMF and PC .............................................................................................. |

|

16 |

|

Figure 2-4: RS-485 multidrop interconnection TMFs and PC................................................................................. |

16 |

||

Figure 2-5: TMF/C to Read-out cable ................................................................................................................... |

|

17 |

|

Figure 2-6: TMF/C Read-out and pc ..................................................................................................................... |

|

17 |

|

Tables |

|

|

|

Table 1-1: Flow ranges per model .......................................................................................................................... |

|

6 |

|

Table 2-1: Electrical interfacing. Smart TMF ........................................................................................................ |

|

12 |

|

Table 2-2: Dipswitch settings ............................................................................................................................... |

|

15 |

|

Table 2-3: Electrical interfacing. Smart TMF cable ............................................................................................... |

|

18 |

|

Table 4-1: Troubleshooting ................................................................................................................................... |

|

22 |

|

Table 5-1: Flow ranges and pressure ratings ........................................................................................................ |

|

25 |

|

4

Installation and Operation Manual |

|

|

X-TMF-5800S-MFC-eng |

|

|

PN 541-C-051-AAG |

|

Models 5800-S |

November, 2008 |

|

|

Section 1 |

Introduction |

|

1.1 Purpose

This instruction manual is intended to provide the user with all the information necessary to install, operate and maintain the Brooks Smart series Mass Flow meters 5860S, 5861S, 5863S and controllers 5850S, 5851S, 5853S.

1.2 How to use this Manual

It is recommended to read this manual before installing, operating or repairing these Mass Flow Instruments. This manual is organised into nine sections:

Section 1. |

Introduction |

Section 2. |

Installation |

Section 3. |

Operation |

Section 4. |

Maintenance |

Section 5. |

Specification |

Appendices |

A - E |

This instruction manual is intended to provide the user with all the information necessary to install, operate and maintain the Brooks Smart Mass Flow Meters and Controllers.

This series of microprocessor-based field instruments is designed to meet the rigorous demands of various industries/applications. The use of digital technology ensures that the Brooks Smart series provides maximum accuracy and signal integrity. In addition it allows easy interfacing to any peripheral equipment either through analogue or digital communication.

This manual covers Smart Mass Flow Meter models: 5860S, 5861S, 5863S and 5864S and Smart Mass Flow Controller models: 5850S, 5851S and 5853S.

Digital communication

The presence of a computer icon to the left of the text (as shown here) denotes that the accompanying text refers to digital communication.

Smart Control

Digital communication (either via RS-232 or RS-485) allows to connect our Brooks model 0160 Smart Control. This interface program can be used to operate and (re)configure Smart Mass Flow Products (calibration parameters are not accessible).

Smart DDE

If you require bi-directional links between your Windows-based applications software and Brooks Smart Mass Flow Products,our model 0162 Smart DDE (a powerful, user-friendly Dynamic Data Exchange software program) offers all the features you need.

5

Section 1: Introduction |

Installation and Operation Manual |

|

X-TMF-5800S-MFC-eng |

Models 5800-S |

PN 541-C-051-AAG |

November, 2008 |

Smart Service

If you are equipped with primary standard Volumeter calibration equipment or (secondary standard) Brooks Smart Mass Flow Meters, you can use the model 0163 Brooks Smart Service program for (re)configuration, diagnostics, calibration and/or verification.The HART protocol-based commands are listed in a separate.

Communication manual

Document: Brooks part number: 541-C-053-AAA.

1.3 Description

Models 5860S, 5861S, 5863S and 5864S Brooks Smart Mass Flow Meters are primarily used to provide accurate measurements of gas flows. The heart of these systems is the thermal mass flow sensor, which produces an electrical output signal as a function of flow rate.

In addition, models 5850S, 5851S and 5853S Brooks Smart Mass Flow Controllers control gas flows. The flow ranges per model are listed in Table 1-1.

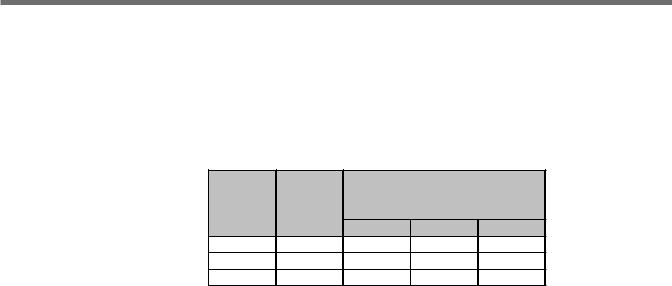

Table 1-1: Flow ranges per model

Mass Flow Mass Flow |

|

Flow Ranges |

||

Controller |

Meter |

|

||

Model |

Model |

min. f.s. |

max. f.s. |

Unit * |

|

|

|||

5850 S |

5860 S |

0.003 |

30 |

ln/min. |

5851 S |

5861 S |

20 |

100 |

ln/min. |

5853 S |

5863 S |

100 |

2500 |

ln/min. |

*refers to ‘normal’ conditions, i.e. 0°C, 1013.25mbar. |

||||

The Brooks Smart Mass Flow Meter is a stand-alone instrument with microprocessor-based electronics on board. The MF-series Smart Mass Flow Controller has an integrally-mounted control-valve module with which stable gas flows can be achieved.

The standard features listed below apply to all models.

The supplied inlet adapter has a built-in, upstream inlet filter for flow straightening. Besides reducing the effects of changes in upstream piping, this also protects the measuring element from occasional debris in the flow stream. In addition, it eliminates the need for extra (expensive) nlet filtering.

•Flow signal adjustable via software: 0-5 Vdc or 1-5 Vdc or

0-20 mA or 4-20 mA.

Note: Digital output (communication) is simultaneously available with analogue output.

6

Installation and Operation Manual

X-TMF-5800S-MFC-eng

PN 541-C-051-AAG

November, 2008

Section 1: Introduction

Models 5800-S

•Output damping provides a constant scale reading under fluctuating flow rate conditions. Standard factory setting: 0.5 sec.

•Output limiting prevents possible damage to delicate acquisition devices by limiting the output to 0-5.25 Vdc on the voltage signal output and 0-21 mA on the current output.

An alarm (TTL open collector) signal output is available to the user. If the instrument’s specifications are exceeded, either by process conditions or by the device itself, an alarm signal can be generated.

MASS FLOW CONTROLLER

Standard features include:

• Each Smart Mass Flow Controller is provided with an adaptive valve-control algorithm for the maintenance of stable flow control, even under varying process conditions (pressure/temperature).

• Setpoint source selectable: Setpoint signal source for the Mass Flow Controller can be selected from:

- communication (RS232 / RS485) or - 0-5 Vdc or

- 1-5 Vdc or - 0-20 mA or - 4-20 mA.

• Fast Response Control provides rapid gas settling times with minimal over/ undershoot. Standard factory setting: 1 sec. for 5850/51 and meter models, 3 sec. for 5853.

• Valve Override (VOR, availabe at pin 12) allows the user to fully open or close the control valve independently of the set-point.

• Low flow cut-off prevents the valve from opening whenever the Set point is less than 1% of full scale.

Digital communication features

Digital communication, via RS485 or RS232, provides access to all of the Smart TMF’s functions, including:

Accurate mass flow measurement and Set point regulation (controller only), as a percentage of full scale and in selectable engineering units

• Flow totalizer

• Ambient temperature

• Operational settings

Calibration (storage of up to 10 calibration curves)Controller settings (controller only)

• PID settings

7

Section 1: Introduction |

Installation and Operation Manual |

|

X-TMF-5800S-MFC-eng |

Models 5800-S |

PN 541-C-051-AAG |

November, 2008 |

•selectable soft start

•adaptive valve control

Adaptive filtering for signal flow component

•Alarms

Self-diagnostic

•EEPROM error

•database error

•analogue output errorOut-of-range indications

•for analogue set points higher than 100% (controller only)

•flow

•valve (controller only)

•analogue output

Environmental errors

•no gas flow detected

•power supply outside specification range

•ambient temperature outside specified range

•high and low flow alarms

8

Installation and Operation Manual

X-TMF-5800S-MFC-eng

PN 541-C-051-AAG Models 5800-S

November, 2008

Section 2: Installation

2.1 General

This section contains the procedures for the receipt and installation of the instrument. Do not attempt to start the system until the instrument has been permanently installed. It is extremely important that the start-up procedures be followed in the exact sequence presented.

NOTE: Operating procedure: do not operate this instrument outside the specification range listed in section 5.

Before bringing the unit into operation, make sure that all gas connections have been correctly tightened and that all the necessary electrical connections have been made.

2.2 Receipt of Equipment

When the equipment is received, the outside packing case should be checked for damage incurred during shipment. If the packing case is damaged, the local carrier should be notified at once regarding his liability. A report should be submitted to your nearest Product Service Department.

Brooks Instrument

407 W. Vine Street

P.O. Box 903

Hatfield, PA 19440 USA

Toll Free (888) 554-FLOW (3569)

Tel (215) 362-3700

Fax (215) 362-3745

Email: BrooksAm@BrooksInstrument.com

http://www.brooksinstrument.com

Brooks Instrument |

Brooks Instrument |

Neonstraat 3 |

1-4-4 Kitasuna Koto-Ku |

6718 WX Ede, Netherlands |

Tokyo, 136-0073 Japan |

P.O. Box 428 |

Tel 011-81-3-5633-7100 |

6710 BK Ede, Netherlands |

Fax 011-81-3-5633-7101 |

Tel 31-318-549-300 |

Email: BrooksAs@BrooksInstrument.com |

Fax 31-318-549-309 |

|

Email:BrooksEu@BrooksInstrument.com |

|

Remove the envelope containing the packing list. Carefully remove the instrument from the packing case. Make sure spare parts are not discarded with the packing materials. Inspect for damaged or missing parts.

9

Section 2: Installation |

Installation and Operation Manual |

|

X-TMF-5800S-MFC-eng |

Models 5800-S |

PN 541-C-051-AAG |

November, 2008 |

2.3 Recommended Storage Practice

If equipment supplied by Brooks Instrument is to be placed in intermediate or long-term storage, it is recommended that it be:

a.Stored within the original shipping container.

b.Stored in a sheltered area, under the following conditions:

1)Optimum ambient temperature 21°C (70 °F), maximum 32 °C (90 °F), minimum 7 °C (45 °F),.

2)Optimum relative humidity 45% (maximum 60%/minimum 25%).

c.Subjected to a visual inspection upon removal from storage, to verify that the condition of the equipment is ‘as received’. If the equipment has been in storage for more than ten months or if it has not been stored under the recommended conditions, all pressure containing seals should be replaced. In addition, the device should be subjected to a pneumatic pressure test in accordance with the applicable vessel codes.

2.4 Return Shipment

Prior to returning any instrument to the factory, contact your nearest Brooks location for a Return Materials Authorization Number (RMA#). This can be obtained from one of the following locations:

Brooks Instrument |

|

407 W. Vine Street |

|

P.O. Box 903 |

|

Hatfield, PA 19440 USA |

|

Toll Free (888) 554-FLOW (3569) |

|

Tel (215) 362-3700 |

|

Fax (215) 362-3745 |

|

Email: BrooksAm@BrooksInstrument.com |

|

http://www.brooksinstrument.com |

|

Brooks Instrument |

Brooks Instrument |

Neonstraat 3 |

1-4-4 Kitasuna Koto-Ku |

6718 WX Ede, Netherlands |

Tokyo, 136-0073 Japan |

P.O. Box 428 |

Tel 011-81-3-5633-7100 |

6710 BK Ede, Netherlands |

Fax 011-81-3-5633-7101 |

Tel 31-318-549-300 |

Email: BrooksAs@BrooksInstrument.com |

Fax 31-318-549-309 |

|

E-mail: BrooksEu@BrooksInstrument.com |

|

Any instrument returned to Brooks requires completion of Form RPR003-1, Brooks Instrument Decontamination Statement, as well as, a Material Safety Data Sheet (MSDS) for the fluid(s) used in the instrument. This is required before any Brooks Personnel can begin processing. Copies of the form can be obtained from any Brooks Instrument location listed above.

2.5 Gas Connections

All models are fitted with the following inlet and outlet connectors as standard: NPT(F), tube compression fittings, VCR, VCO, DIN or ANSI flanges. Prior to installation, make certain that all piping is clean and free of obstruction. Install the piping in a manner that permits easy access to the instrument, should it need to be removed for cleaning or test-bench troubleshooting.

10

Installation and Operation Manual |

Section 2: Installation |

|

X-TMF-5800S-MFC-eng |

|

|

PN 541-C-051-AAG |

Models 5800-S |

|

November, 2008 |

||

2.6 Mechanical Installation |

|

|

|

|

|

(For dimensional drawings see Appendix B: Dimensional drawings)

NOTE: When installing the Mass Flow device, care should be taken to prevent foreign materials from entering the instrument’s inlet or outlet. Do not remove the protective end-caps until the actual moment of installation.

When used with reactive gases (some of which may be toxic), contamination or corrosion may occur as a result of plumbing leaks or improper purging. Plumbing should be checked carefully for leaks and the Mass Flow device should be purged (for a significant time) with Nitrogen before and after use on reactive gasses.

Recommended installation procedures:

a. All models should be mounted in places that are relatively free from mechanical shocks and vibration.

b. Leave sufficient room for access to the electrical components.

c. Install in a manner that allows the instrument to be easily removed for cleaning.

d. The mounting position of the Smart Mass Flow Meter or Controller can be either horizontal or vertical, in case process pressures are smaller than 10 bar.

e. For higher process pressures, a horizontal installation is preferred, since these pressures may cause a thermal siphon effect of the output signal at zero flow conditions and degrading specifications.

NOTE: The control valve of the Smart Mass Flow Controller provides precision control and is not designed for positive shut off. If positive shut off is required, it is recommended that a separate shut-off valve be installed in-line, downstream from the Smart Mass Flow Controller.

NOTE: If the power supply to the Smart Mass Flow Controller is interrupted, a NORMALLY CLOSED valve will be fully closed, while a NORMALLY OPEN valve will be fully open. The NORMALLY OPEN control valve meets application specific requirements, since it allows nitrogen gas purging if the power supply is interrupted.

2.7 In-Line Filter

An in-line filter is installed, as standard, in the instrument’s inlet to prevent any foreign material entering the flow sensor or control valve. The filtering element should be periodically replaced or ultrasonically cleaned.

Apply only clean gasses on Mass Flow Meter/Controllers.

11

Section 2: Installation |

Installation and Operation Manual |

||||

|

|

|

X-TMF-5800S-MFC-eng |

||

Models 5800-S |

|

PN 541-C-051-AAG |

|||

|

November, 2008 |

||||

2.8 Electrical Interfacing |

|

|

|

|

|

|

|

|

|

|

|

|

The installation of Smart TMF includes a 15-pin Sub-D connector. For details of |

||||

|

correct installation, see Table 2-1 |

|

|

|

|

|

Table 2-1: Electrical interfacing. Smart TMF |

|

|

|

|

|

|

|

|

|

|

|

Pin (TMF side) |

Function |

Controller |

Meter |

|

|

1. |

Setpoint return (-) |

* |

n.a. |

|

|

2. |

0 (1)-5 Vdc Flow signal output |

* |

* |

|

|

3. |

(TTL) Open collector alarm output |

* |

* |

|

|

4. |

0 (4)-20 mA Flow signal output |

* |

* |

|

|

5. |

+15 Vdc to +28 Vdc Power supply |

* |

* |

|

|

6. |

-15 Vdc Power supply (if required) |

* |

* |

|

|

7. |

0 (4)-20 mA Setpoint input (+) |

* |

n.a. |

|

|

8. |

0 (1)-5 Vdc Setpoint input (+) |

* |

n.a. |

|

|

9. |

Power supply common |

* |

* |

|

|

10. |

Flow signal output common |

* |

* |

|

|

11. |

+5 Vdc ref. output |

* |

n.a. |

|

|

12. |

Valve override input |

* |

n.a. |

|

|

13. |

Not connected |

* |

* |

|

|

14. |

Optional RS232C-RxD or RS485-A- |

* |

* |

|

Signal Output (pins 2, 4 and 10)

Pin 2 indicates the flow rate, represented by a 0-5 Vdc or 1-5 Vdc signal proportional to the mass flow. Pin 4 indicates the flow rate, represented by either a 0-20 mA or 4-20 mA signal current proportional to the mass flow. Both the current and voltage signals are returned via pin 10 on the D-connector.

Analogue Setpoint Input (pins 7/8 and 1; Controller models only) . The Smart Mass Flow Controller can be used either with a current or voltage Set point. To use the current Set point, connect the Set point signal to pin 7 and the Set point return signal to pin 1 on the terminal (jumper J1 must be in place refer to Figure 2-2). To use the voltage Set point, connect the Set point signal to pin 8 and the Set point return to pin 1 on the D-connector.

5 Vdc reference (pin 11; Controller models only)

A +5 Vdc ref. voltage is available on pin 11. This can be used to set the Setpoint with the aid of an externally located potentiometer (10 turn 2 KOhm suggested)..

NOTE: I/O configuration to be defined at time of ordering. Reconfiguration at customer side can be accomplished using digital communication.

Power Supply

Mass Flow Meter models (pin 5 and 9): The Mass Flow Meter's power

supply is connected via pins 5 (+15 to +28 Vdc) and 9 (power supply common) on the D-connector.

Mass Flow Controller models (pin 5, 6 and 9): The Mass Flow Controller's power supply is connected via pin 5 (+15 to +28 Vdc) and 9 (power supply

12

Installation and Operation Manual

X-TMF-5800S-MFC-eng

PN 541-C-051-AAG

November, 2008

Section 2: Installation

Models 5800-S

common) on the D-connector. If a -15 Vdc power supply is required, pin 6 must |

|

be connected and jumper [K2] on the p.c. board must be set the lower |

|

position |

(see Figure 2-2). |

This is applicable for model 5851S and/or when a Normally Opened (N.O.) control valve is used.

NOTE: With regard to the power supply connections, the attached cable must be as short as possible to ensure that the minimum required voltage and current is available at the mass flow device.

Cable Shielding Earth

Cable requirements

Compliance with EMC directive 89/336/EEC, requires that the equipment be fitted with fully screened signal cables with at least 80% shielding.The cable shielding should be connected to the PG connector’s metal shell, and have 360° shielding at both ends. The shielding should be connected to an earth terminal.

For translations of this instruction, see Appendix D: Translations of installation instructions

Alarm (pin 3 of 9)

A (TTL) Open Collector alarm output is available.

Type of used transistor is NPN.

Figure 2-1: Open Collector

Valve override (pin 12; Controller models only)

To open or close the control valve independently of the Set point signal (e.g. for safety reasons), pin 12 is available to carry a valve override signal. Leave floating (i.e. not connected) to allow for normal control operation.

≥ 5 Vdc |

Valve Open (for both NO and NC valves) |

≤ 0 Vdc |

Valve Closed (for both NO and NC valves) |

NOTE: The valve override command on pin 12 takes precedence over the communication-mediated valve override command.

Digital communication (pins 14 and 15)

13

Section 2: Installation |

Installation and Operation Manual |

|

X-TMF-5800S-MFC-eng |

Models 5800-S |

PN 541-C-051-AAG |

November, 2008 |

|

|

pins 14 and 15 are available for connecting the device to the RxD/A- or TxD/A+ |

|

lines for RS-232/RS-485 communications. |

|

NOTE: Either RS-232 or RS-485 should be specified at the time of ordering. See |

|

section 2.7 for details of how to configure the p.c. board. |

2.9 Digital Communication |

|

|

|

NOTE: The printed circuit boards only need to be reconfigured if the hardware settings differ from those specified at the time of ordering.

Brooks Smart Mass Flow Meters and Controllers incorporate two printed

circuit boards: one main board containing the processor and a piggyback board. The piggyback board enables the device to communicate with a PC via an RS-232 or RS-485 connection.The piggyback board is installed via the K5, K6 and K7 connectors on the main board (see Figure 2-2).

The p.c. board enclosure must be removed to gain access to the electronics. Disconnect the power to the device and any cables running to the D-connector. Remove the three screws at the base of the electronics enclosure, then lift off the enclosure. The electronics enclosure must be replaced before returning the unit to service.

Figure 2-2: p.c. boards with the locations of jumper switches Note: Switch number 1 is the switch at the bottom

The digital communication piggyback board is used for all communication-related hardware settings. For this purpose, the board is equipped with a dipswitch block (SW1) holding 4 switches. RS-232 Board (097-B-364-ZZZ) or RS-485 Board (097-B-363-ZZZ), and to select the baud rate. Table 2-2 summarises the possible settings.

14

Installation and Operation Manual |

|

|

|

Section 2: Installation |

||||

X-TMF-5800S-MFC-eng |

|

|

|

|

|

|

|

|

PN 541-C-051-AAG |

|

|

|

|

Models 5800-S |

|||

November, 2008 |

|

|

|

|

||||

|

Table 2-2: Dipswitch settings |

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

Physical |

Baud rate |

|

Dipswitch block SW1 |

|

|

|

|

|

layer |

selection |

Switch |

Switch |

Switch |

Switch #4 |

|

|

|

selection |

|

#1 |

#2 |

#3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

RS-232 |

|

Off |

|

|

|

|

|

|

RS-485 |

|

On |

|

|

|

|

|

|

|

1200 |

|

Off |

Off |

Off |

|

|

|

|

2400 |

|

On |

Off |

Off |

|

|

|

|

3600 |

|

Off |

On |

Off |

|

|

|

|

4800 |

|

On |

On |

Off |

|

|

|

|

7200 |

|

Off |

Off |

On |

|

|

|

|

9600 |

|

On |

Off |

On |

|

|

|

|

19200 |

|

Off |

On |

On |

|

|

|

|

38400 |

|

On |

On |

On |

|

|

Since Brooks Smart Mass Flow devices are capable of communication immediately after start-up, you should set the correct baud rates prior to power up. Any changes to the baud rate settings or the physical layer selection made during operation will take effect immediately. The communication I/O drivers are directly connected to the D-connector on top of the device.

The RS-232 is essentially a point-to-point connection, i.e. one host-computer and one Smart Mass Flow device. Most IBM-compatible PCs are equipped with one or more RS-232 ports (COM ports) as standard. The RS 232 usage and definitians are very diverse. On the MF Smart Mass Flow devia the TxD signal is the output signal of the devia and the RxD the input signal.The communication terminals can be directly connected to a serial COM-port of any PC. The other part of the terminals can be connected to Brooks model 0152/0154 Microprocessor-based Read-out and Control Electronics. This model provides the power supply for Smart Mass Flow devices, as well as providing local read-out and displaying the analogue output signals. Figure 2-3 shows the interconnection diagram of the RS-232 configuration. The pin assignment on an IBM Compatible PC. This is standard for RS-232.

15

Loading...

Loading...