Page 1

Data Sheet

DS-PD-BM 01-02-eng

March, 2008

Brooks® Models BM01 and BM02

Brooks® Oval Flowmeters, BM Oval Series

BM01 and BM02

FEATURES

• Low flow measure ment, 0.53 to 132 GPH

(2 to 500 LPH)

• Very low pressure drop

• Viscosity to 1000 Cp (Centipoise)

• High Accuracy, 1% rate or better

• 0.03% repeatability

• Only two moving parts

• Reed or solid state Hall Effect Switch

• ¼ inch female NPT standard

• Available in PPS or 316 Stainless Steel

(Hastelloy® C shaft option)

DESCRIPTION

The Brooks BM01 and BM02 are low flow positive

displacement oval flowmeters designed for

applications requiring the high accuracy measurement

of clean liquids with viscosities less than 1000 Cp.

Units are available with a pulse output from a Reed

switch or solid state Hall effect switch for remote

registration and/or totalization.

PRINCIPLE OF OPERATION

The oval meter is a positive displacement meter. As

the fluid being measured passes through the meter, it

rotates 2 oval gears in a measuring chamber to

displace a precision volume of fluid. A sensor detects

the gear rotation to determine displaced volume and

flow rate.

Fluid pressure rotates the oval gears, Figure 1. In

position 1, the fluid exerts a clockwise driving force on

Gear A.

Typical BM01 and BM02

There is no net driving force on Gear B. It is

perpendicular to the flow so the fluid forces are

balanced around the shaft. As the gears rotate to

position 2, the fluid begins to exert a force on Gear B.

At position 3, all the driving force is on Gear B. This

alternating driving force provides a smooth rotation of

almost constant torque.

The meter design minimizes the slippage between the

gears and the measuring chamber wall. As a result, the

oval meter is less affected than other designs by the

liquid's viscosity and lubricity.

Figure 1 Principle of Operation Chart

1

Page 2

Brooks® Models BM01 and BM02

Data Sheet

DS-PD-BM 01-02-eng

March, 2008

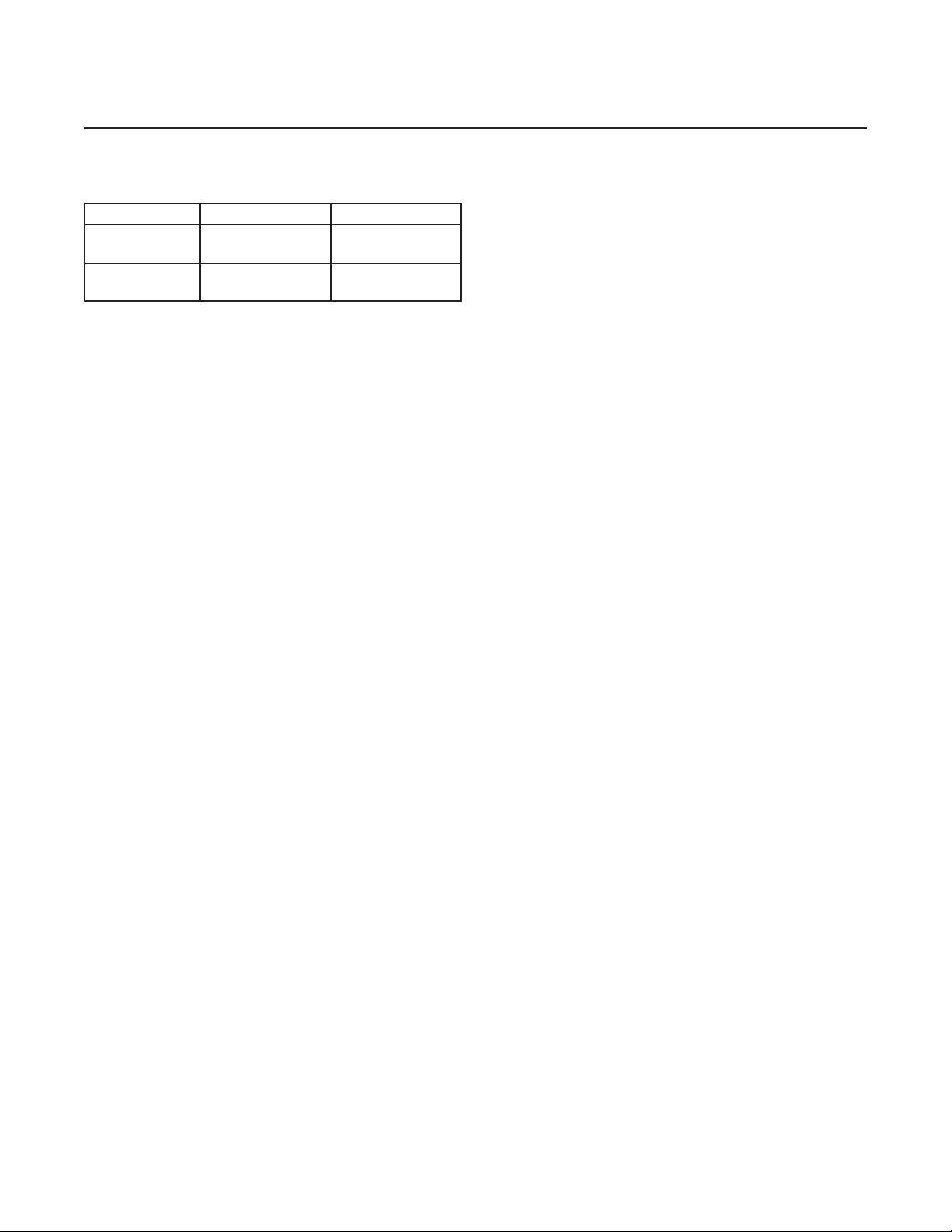

SPECIFICATIONS

Capacities

Viscosity BM01 BM02

< 5cP 1.32 to 26 gph 6 to 132 gph

(5 to 100 lph) (25 to 500 lph)

5 to 1,000cP 0.53 to 26 gph 4 to 132 gph

(2 to 100 lph) (15 to 500 lph)

Performance

Accuracy: +/- 1%

Repeatability: 0.03%

Typical meter performance and pressure drop:

Refer to Figure 2.

Ratings

Maximum working pressure:

PPS body: 75 PSIG (500 KPAG)

316 SS body: 150 PSIG (1000 KPAG)

Consult factory for higher pressure options.

Maximum working temperature:

PPS body and/or Rotors (Gears): 176° F (80° C).

316 SS body and Rotors (Gears): 248° F (120° C).

Ambient Temperature: -4° F to 104° F (-20° C to

+40° C).

Outputs

Note: each meter contains both switch types

Reed Switch

Detection Method: Reed Switch, Two wire SPST N/O contact.

Max. Voltage: 150 VDC maximum.

Contact Capacity: 0.25 AMPS

Rating 3 Watts.

Termination: 39 inch (1 meter) flying lead.

Nominal K-Factor:

Model BM01: 1000 p/l (3785.4p/gal)

Model BM02: 400 p/l (1514.2 p/gal)

Hall Effect Switch

Detection Method: Hall effect switch

Response Frequency: 1,000 Hz maximum

Output Pulse: Unfactored voltage pulse

Input/Output = 4.5 to 24 VDC (4.6 ~ 9 mA)

Open Collector 25 mA output NPN compatible with

digital logic. Reverse power protection.

Termination: 39 inch (1 meter) flying lead

Nominal K-Factor:

Model BM01: 1000 p/l (3785.4p/gal)

Model BM02: 400 p/l (1514.2 p/gal)

Meter Materials of Construction

Meter Body: PPS (Polyphenylene Sulfide) or 316

Stainless Steel.

Rotors(Gears):

BM01 / BM02 - PPS or 316 Stainless Steel.

316 Stainless Steel only for High Viscosity.

Rotors (Gears) Bearings:

BM01 / BM02 - Zirconia

Note: (PPS Rotors No Bearings Required)

Rotors (Gears) Shafts: 316 Stainless Steel or Optional

Hastalloy® C (PPS body only).

O-Rings: Standard Viton® fluoroelastomers or Optional

Teflon®.

Connections

¼ inch NPT (female)

Dimensions

Refer to Figure 3. For certified dimensional prints, contact

the factory.

Pressure Equipment Directive (97/23/EC)

Equipment falls under Sound Engineering Practice

(SEP) according to the directive.

2

ORDERING INFORMATION

To order please specify:

1. Model Number

2. Product (Process Fluid)

3. Viscosity

4. Maximum Operating Temperature

5. Maximum Operating Pressure

6. Operating Flow Ranges (Min., Max., & Normal)

7. Accessories Required

Page 3

Data Sheet

DS-PD-BM 01-02-eng

March, 2008

Figure 2 Typical Meter Error and Pressure Drop

Brooks® Models BM01 and BM02

Table 1 Brooks Model Code BM01 and BM02 Meters

MODEL BASIC MODEL SIZ E/RANGE

BM01B

BM02B

0.53 - 26 GPH / 2 - 100 LPH

4 -132 GPH / 15 - 500 LPH

CODE

R R

R S

SS

R H

SH

BODY/ROTOR MATERIAL

PPS (PO LYPHENYLENE SULFIDE) BODY & ROTOR (GEAR)

PPS BODY & 316 STAINLESS STEEL ROTOR (GEAR)

316 ST AINLESS ST EEL BODY & ROTOR (G EAR)

PPS BODY & 316 SS HIGH VISC. ROTOR (>10 00cP) BMO 2 ONLY

316 SS BO DY & HIGH VIS C. ROTOR (>1000cP) BM02 ONLY

CODE PULSER/DISPLAY

P

PULSE (BM01 = 3785 PPG BM02 = 1514 PPG)

CODE CONSTRUCTION

A

STAND ARD CONSTRUCTION

CODE PROCESS CONNECTION

2

1/4" NPT FEMALE

CODE OUTPUT

B

REED / HALL SWITCH (STANDARD)

CODE O-RINGS/SEALS

V

VITON (STANDARD)

K

TEFLON

CODE OPTIONS

A

NONE

C

HAST C SH AFTS

(REQUI RED WITH

PPS BODY/ROTOR)

BM01B

R S 1 A 2 B V A

3

Page 4

Brooks® Models BM01 and BM02

Data Sheet

DS-PD-BM 01-02-eng

March, 2008

Shipping Weight (Approximate)

Body BM01 BM02

PPS .53lbs. .53lbs.

.24Kg. .24Kg.

Stainless 1.32lbs. 1.32lbs.

For certified dimension prints, consult factory.

Figure 3 Dimensions

Steel .60Kg. .60Kg.

HELP DESK

In case you need technical assistance:

Americas

Europe +(31) 318 549 290 Within Netherlands 0318 549 290

Asia

Due to Brooks Instrument's commitment to continuous improvement of our products, all specifications are subject to

change without notice.

TRADEMARKS

Brooks .......................................................... Brooks Instrument, LLC

Hastelloy ............................................................Haynes International

Teflon.................................................. E.I. DuPont de Nemours & Co.

Tri-Clover ......................................................................Tri-Clover Inc.

Viton................................................DuPont Performance Elastomers

1-888-554-FLOW

+011-81-3-5633-7100

4

Loading...

Loading...