Page 1

B R O O K F I

E L D E N G I N E E R I N G L A B O R AT O R I E S , I N C .

11 Comm e rce B oule va r d • M i dd le b o r o , MA 0 2 3 46 US A

ISO9001 CERTIFIED

T E L 5 0 8 - 9 4 6 - 6 2 0 0 o r 8 0 0 - 6 2 8 - 8 1 3 9 F A X 5 0 8 - 94 6 - 62 6 2

w w w . b r o o k f i e l d e n g i n e e r i n g . c o m

Boston • Chicago • London • Stuttgart • Guang zhou

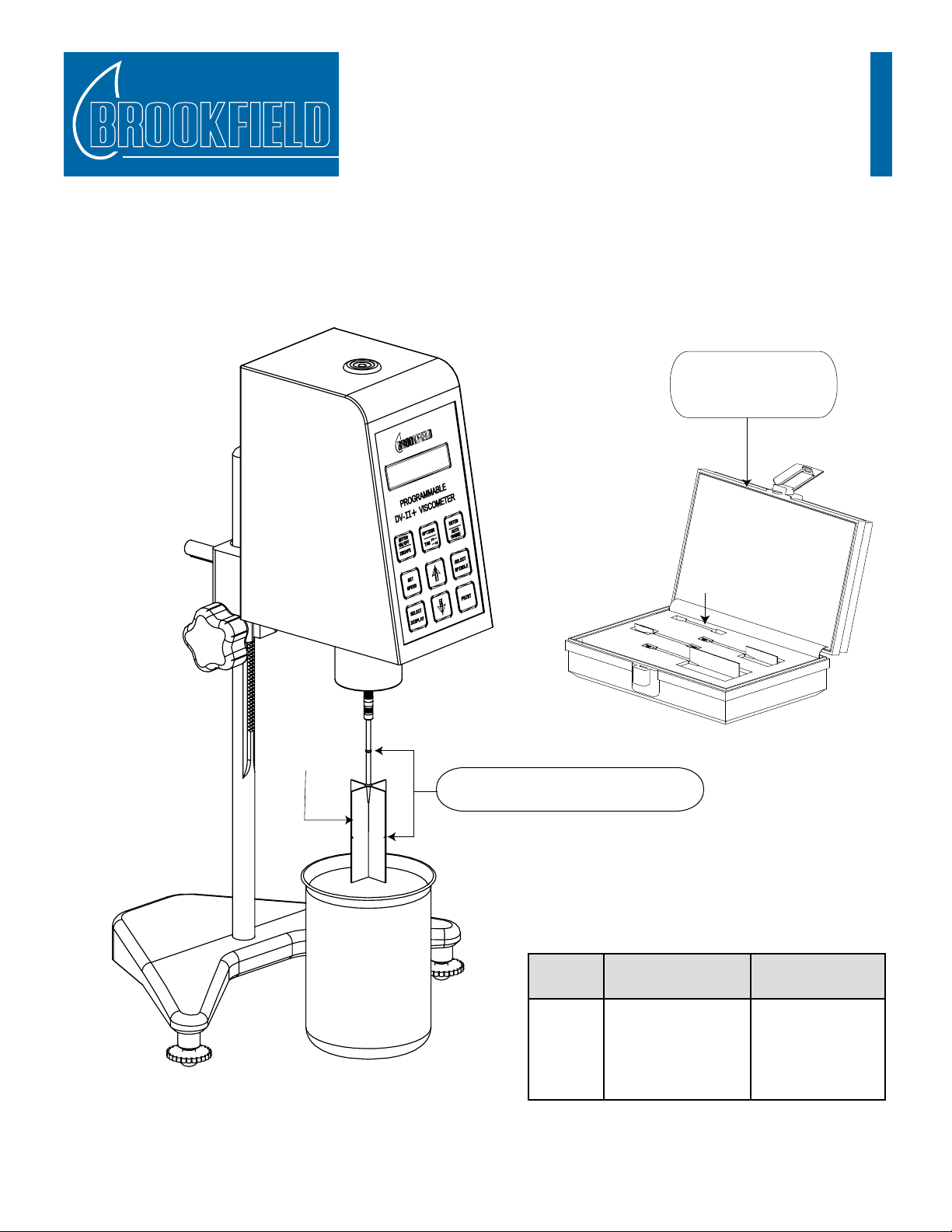

Vane Spindles

Primary Immersion Mark

Secondary Immersion Mark

Vane

Spindle

Choose the immersion mark which best suits

the size of container for your sample material.

Vane Spindle Set

includes 3 vane spindles

and storage case

Part No. SSVANE

(empty slot)

Table 1 - Vane Spindle Dimensions

Spindle

Vane Length

inches cm

Vane Diameter

inches cm

V-71 2.708 6.878 1.354 3.439

V-72 1.708 4.338 .853 2.167

V-73 .998 2.535 .499 1.267

V-74 .463 1.176 .232 .589

V-75 .632 1.61 .316 .803

Note: Sample container diameter should be at least twice (2x) the vane

diameter when possible. Sample container depth should provide

clearance, at the bottom, greater than or equal to vane spindle

diameter when possible.

Assembly & Operating Instructions

Manual No. M02-290-C0809

Vane spindles can be used with any standard Brookeld Viscometer/Rheometer. V-71, V-72, and V-73 are

supplied in the Vane Spindle Set (Part No. SSVANE). The V-74 and V-75 spindles are optional extras. The

small size of the V-74 vane spindle is ideal for testing small sample sizes and tting into sample containers

with small openings. However, limited surface area for spindle measurement geometry may make it more

challenging to obtain repeatable shear stress and viscosity values.

Page 2

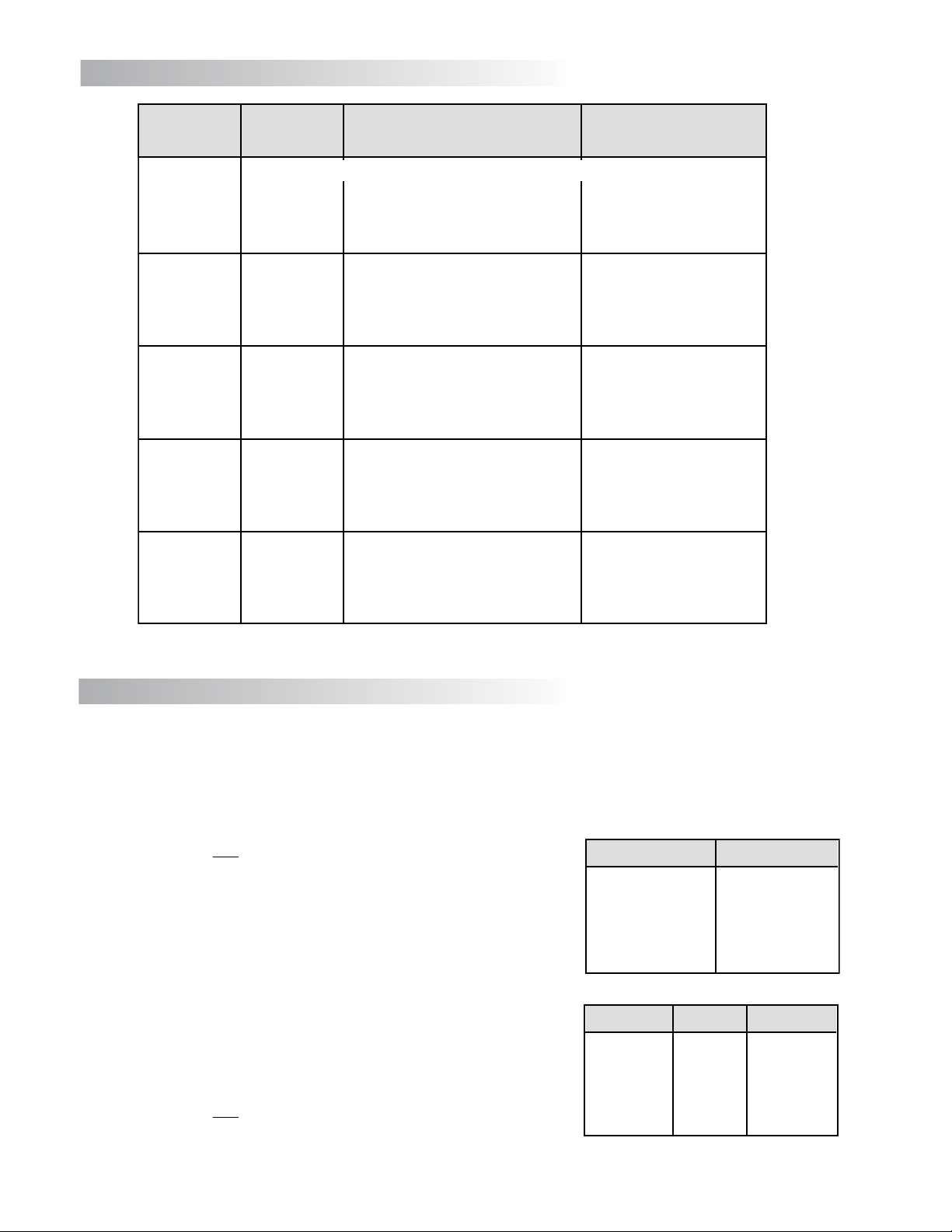

Spindle

Torque Shear Stress Range Viscosity Range cP

Range Pa dyne/cm (mPa•s) @ 10 rpm

2

Table 2 - Spindle Range Data

V-71

V-72 LV .188-1.88 1.88-18.8 104.04 - 1040

V-73 LV .938-9.38 9.38-93.8 502 - 502000

V-74 LV 9.38-93.8 93.8-938 5.09 - 50900

V-75 LV 3.75-37.5 37.5-375 1996 - 19960

V-71 RV .5-5 5-50 262 - 2620

V-72 RV 2-20 20-200 1110 - 11100

V-73 RV 10-100 100-1000 5350 - 53500

V-74 RV 100-1000 1000-10000 54300 - 543000

V-75 RV 40-400 400-4000 21300 - 213000

V-71 HA 1-10 10-100 524 - 5240

V-72 HA 4-40 40-400 2220 - 22200

V-73 HA 20-200 200-2000 10700 - 107000

V-74 HA 200-2000 2000-20000 108600 - 1086000

V-75 HA 80-800 800-8000 42600 - 426000

V-71 HB 4-40 40-400 2096 - 20960

V-72 HB 16-160 160-1600 8880 - 88800

V-73 HB 80-800 800-8000 42800 - 428000

V-74 HB 800-8000 8000-80000 434400 - 4344000

V-75 HB 320-3200 3200-32000 170400 - 1704000

V-71 5XHB 20-200 200-2000 10480 - 104800

V-72 5XHB 80-800 800-8000 44400 - 444000

V-73 5XHB 400-4000 4000-40000 214000 - 2140000

V-74 5XHB 4000-40000 40000-400000 2172000 - 21720000

V-75 5XHB 1600-16000 16000-160000 852000 - 8520000

NOT RECOMMENDED FOR USE ON LV TORQUE

Notes: 1) 1 Pa = 10 dyne/cm2 2) 1cP = 1 mPa•s 3) Possibility of turbulence at speeds above 10 rpm may give artificially

higher viscosity readings 4) 5xHB torque available with DV-III Ultra Rheometer only.

Viscosity (cP) =

100

* TK * SMC * Torque

RPM

Table 3 - Viscometer Torque Constants

Model TK

LV 0.09373

RV 1

HA 2

HB 8

5xHB 40

Viscosity (cP) =

100

* TK * SMC * 2xTorque

RPM

Spindle Range Data

Table 4 - Spindle Multiplier Constants and Accuracy

Spindle SMC Accuracy*

V-71 2.62 ±2%

V-72 11.1 ±2%

V-73 53.5 ±2%

V-74 543 ±5%

V-75 213 ±3%

* Allowable error percentage is calculated on the

f

ull scale range viscosity for each spindle at a

defined speed.

Viscometer Operation

Attach the Vane Spindle to your Viscometer as shown in the illustration on page one (Note: spindles

have a left-hand thread for installation). Immerse the Vane Spindle into the uid past the top of the

Vane to the primary immersion mark on the shaft. Operate your Viscometer per the instructions in the

Operator’s Manual that came with your instrument. Record the instrument Speed (in RPM) and the

Torque Reading (as a percent). The Viscosity is calculated manually using the following equation:

where

RPM = Viscometer spindle speed in RPM

TK = Viscometer torque constant from Table 3

SMC = Spindle multiplier constant from Table 4

Torque = Viscometer torque (%) expressed as a

number between 0 and 100

If the secondary immersion mark (midpoint of the vane) is

chosen due to small container size, multiply the torque reading

by a factor of two (2).

Loading...

Loading...