Page 1

B R O O K F I

E L D E N G I N E E R I N G L A B O R AT O R I E S , I N C .

Comm erce B oule va rd • M i dd le bo r o , MA 0 46 US A

ISO9001 CERTIFIED

T

E L

5 0 8 - 9 4 6 - 6 0 0 o r 8 0 0 - 6 8 - 8 9 F

A X

5 0 8 - 9 46 - 6 6

w w w . b r o o k f i e l d e n g i n e e r i n g . c o m

Bosto n • Chicag o • London • Stuttg art • Guan gzhou

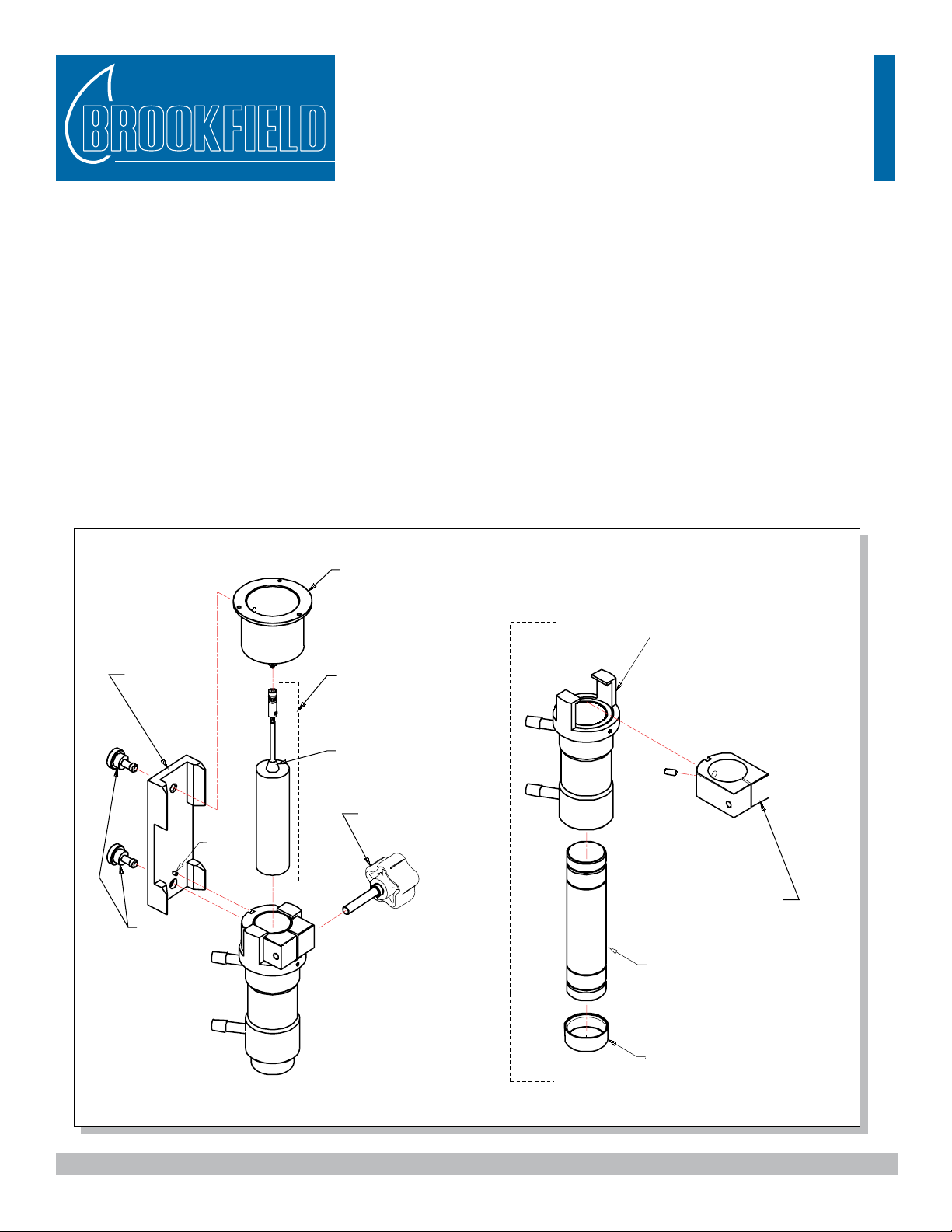

Enhanced UL Adapter

PIVOT CUP,

BR-3

(PART OF

LAB VISCOMETER)

ULA-E SPINDLE

WITH COUPLING NUT,

YULA-15E -304 SS

YULA-15EZ-316 SS

MOUNTING

CHANNEL,

ULA-10E

MOUNTING

SCREW,

HT-99

CLAMPING

KNOB,

ULA-05EY

TUBE END CAP,

ULA-34

(NOT REQ’D WITH ULA-31EYZ

SAMPLE CHAMBER)

SAMPLE CHAMBER,

ULA-31EY

(304 s/s, open tube)

ULA-31EYZ

(316s/s, closed tube)

CLAMPING

COLLAR,

ULA-02E

WATER JACKET with

MOUNTING COLLAR,

ULA-49EAY

CONICAL PORTION

OF SHAFT

PIN

Assembly & Operating Instructions

No. M06-084

The Enhanced UL Adapter, shown in Figure 1, is a kit consisting of a spindle with coupling nut attached, sample

chamber, mounting channel, and water jacket with mounting collar. It is available in two versions: (1) with type

304 stainless steel suitable for most general purpose applications; (2) with type 316 stainless steel for use with

corrosive/acidic applications. All versions are shipped with the water jacket (ULA-49EAY) mounted on the

sample chamber.

The type 304 s/s UL Adapter (Part No. ULA-EY) may be used either as an “open tube” or “closed tube” system.

In the “open tube” method, the water jacket (ULA-49EAY) must be removed, allowing measurement in a beaker

or other suitable vessel. In the “closed tube” method, the sample is poured into the sample chamber with tube end

cap installed, which may be temperature controlled by direct immersion into a water bath or with the use of the

water jacket connected to a circulating water bath. The 316 s/s UL Adapter (Part No. ULA-EZY) has a closed

sample chamber with solid bottom and cannot be used as an open tube conguration.

The Enhanced UL Adapter may be ordered without the water jacket (Part No ULA-E). Check your sales order to

verify that you have received the correct conguration for your Enhanced UL Adapter.

Figure 1: Enhanced UL Adapter Assembly

Brookeld Engineering Laboratories Inc. - - Operating Instructions M06-084-A0507

Page 2

Assembly & Operation

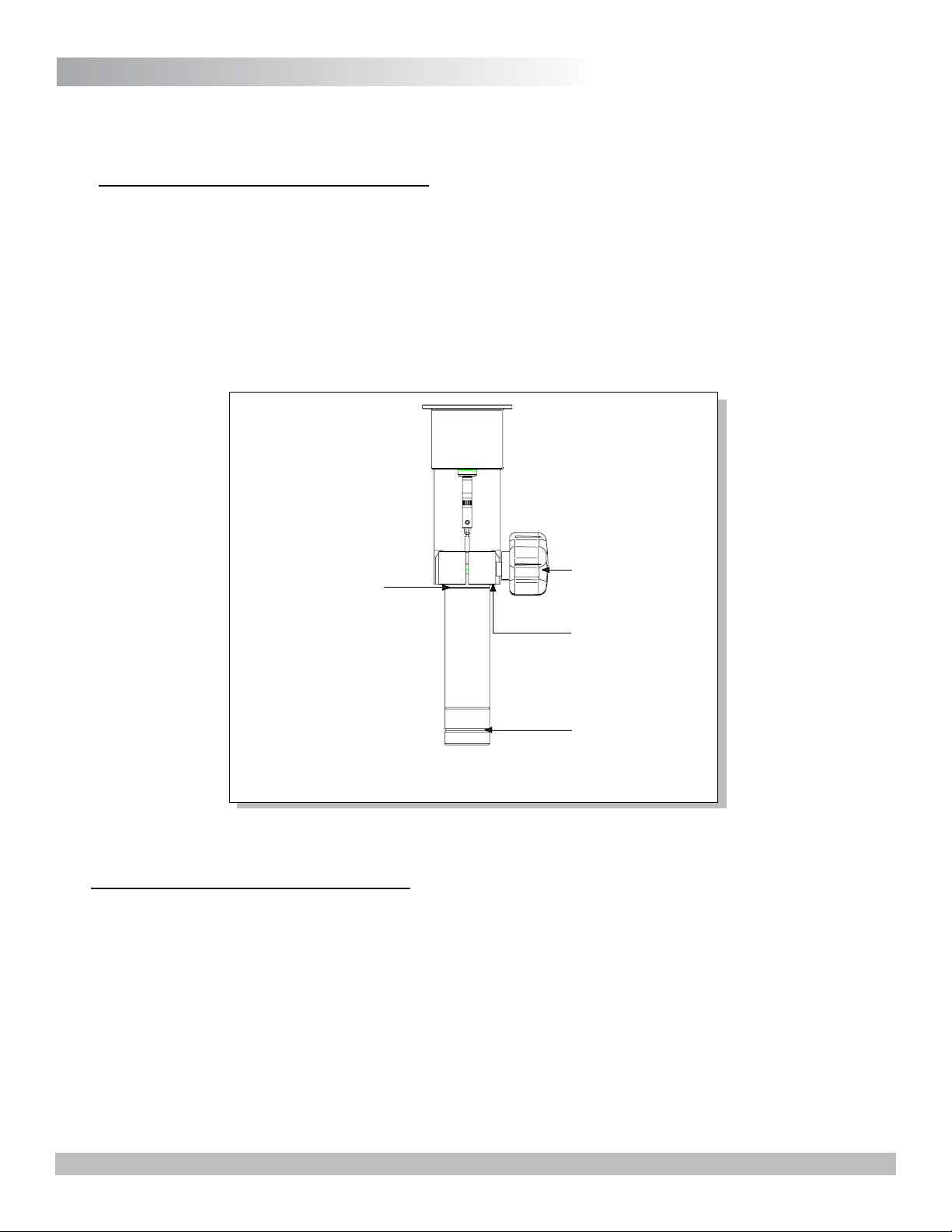

CLAMPING COLLAR

CLAMPING KNOB

IMMERSION GROOVE

END CAP GROOVE

1. Attach the mounting channel to the viscometer by threading the upper mounting screw into the viscometer

pivot cup. Do not overtighten. The end of the mounting channel with the pin must be at the bottom, as

shown in Figure 1.

2. Open Tube Operation (#304 stainless steel)

The water jacket (ULA-49EAY) must be removed when the “open tube” method is used. This allows

measurement in a beaker or other container. The sample chamber must be inserted into the clamping collar

before immersion in sample uid. The top of the sample chamber should be ush with the top edge of the

clamping collar.

The clamping collar connects to the mounting channel as shown in Figure 1. The spindle with coupling nut

can be attached to the viscometer beforehand for easy handling. Observe the immersion groove located on

the outside of the sample chamber as shown in Figure 2.

3. Closed Tube Operation with Water Jacket

The UL Adapter may be used with the ULA-49EAY water jacket and a circulating water bath by connecting

the water jacket to the bath inlet and outlet ports (Figure 3). The tube end cap (ULA-34) is snapped over

the bottom end of the sample chamber before the sample is added. Be sure that it is securely seated in the

groove. Fill with 16 mL of sample uid. Insert the clamping collar into the mounting collar as shown in

Figure 1. Insert the sample chamber upwards into the water jacket and clamping collar. When fully inserted,

secure the sample chamber by tightening the clamping knob. Insert the spindle into the chamber. Attach the

clamping collar to the mounting channel. Connect the spindle coupling to the viscometer; note left hand

thread. Conrm that the uid level in the sample chamber covers the conical portion of the spindle shaft.

CAUTION: The spindle, sample chamber, and cap (if used) should be clean before use. The cap material

Brookeld Engineering Laboratories Inc. - - Operating Instructions M06-084-A0507

Figure 2: Sample Tube Immersion

Chamber Shown is #304 Stainless Steel

is low density polyethylene. Replace when damaged or loose.

Page 3

Fluid Recommended Recommended Note

Temperature Fluid Tubing

-10°C to 15°C TC-FLUID 2

1

ULA-45

R, 2

Do Not Use Gum

Rubber Tubing With

This Fluid

15°C to 65°C Water Gum Rubber

or Fluran

R

65°C to 100°C TC-FLUID 3

3

ULA-45 R Do Not Use Gum

Rubber Tubing With

This Fluid

Table 1

R

Fluran is a Registered Trademark of Norton Co.

1. Use only laboratory grade ethylene glycol. Do not use automobile anti-

freeze which contains materials that can damage the equipment.

2. Fluran tubing (5/16" ID) and clamps are offered in a kit, part # ULA-45A.

3. Do not use high viscosity oil. Recommended is 50 centipoise.

TEMPERATURE

BATH

BATH OUTLET

BATH INLET

VISCOMETER

PIVOT CUP

(on Viscometer)

WATER

JACKET

OUTLET

WATER

JACKET

INLET

T

UBE END CAP, ULA-34

SAMPLE CHAMBER

MOUNTING COLLAR

KNOB

Figure 3: ULA-49EAY Water Jacket Connections

4. Level the viscometer. General operating procedures for making viscosity measurements are described in the

viscometer operating instruction manual.

5. UL Adapter spindle factors are shown on page 4. The factor is used to calculate viscosity when using Dial

Reading Viscometers. All Brookeld digital model Viscometers and Rheometers calculate the viscosity value

automatically. The spindle entry code for the UL Adapter is 00.

Notes

• Maximum recommended viscosity for measurement with the UL Adapter is 2000 cP (mPa•s). If viscosity

exceeds 2000 cP, the material being measured may be too viscous to immerse the spindle into the sample

chamber; damage to internal parts of the viscometer may result.

• For tubing and uid recommendations when using a Constant Temperature Bath, refer to the table below:

Brookeld Engineering Laboratories Inc. - - Operating Instructions M06-084-A0507

Page 4

UL Adapter Factors

SP E CI ALI STS I N T HE

ME AS UR EM EN T AN D

CONTROL OF VISCOSITY

T

EL

508-946-600 or 800-68-89 FAX 50 8-9 4 6 -6 6

www. b r o o k f i e l d e ngine e r i n g . c o m

BROOKFIELD ENGINEERING LABORATORIES, INC.

Commerce Boulevard, Mi ddleboro, MA 0 46-0 USA

TYPE I

TYPE II

TYPE III

Threaded

Hole

The factor is used to calculate viscosity in units of centipoise (cP) or milli Pascal seconds (mPa•s) when using

Dial Reading or Model DV-I Viscometers. The Viscometer Dial Reading/DisplayValue x Factor = cP (mPa•s).

Factors are built-in for Digital Models DV-E, DV-I+, DV-I Prime, DV-II+ (all versions), and DV-III (all versions)

— no calculations required.

LV Models

RV-HA-HB Models

Shear Shear Factor

Speed Rate Speed Rate

(RPM) (sec-1) Factor (RPM) (sec-1) RV HA HB

60.0 73.38 0.1 100.0 122.30 0.64 1.28 5.12

30.0 36.69 0.2 50.0 61.15 1.28 2.56 10.24

12.0 14.68 0.5 20.0 24.46 3.20 6.40 25.60

6.0 7.34 1.0 10.0 12.23 6.40 12.80

3.0 3.67 2.0 5.0 6.12 12.80 25.60

1.5 1.83 4.0 4.0 4.89 16.00

0.6 0.73 10.0 2.5 3.06 25.60

0.3 0.37 20.0 2.0 2.45

1.0 1.22

0.5 0.61

Shear Rate Constant = RPM x .

When an older dial reading viscometer is used, the viscometer pivot

cup may need to be replaced with the

current design. If your viscometer

has a Type I or Type II pivot cup, the

cup should be replaced with a Type

III cup. Contact Brookeld or your

Brookeld agent for information.

Brookeld Engineering Laboratories Inc. - 4 - Operating Instructions M06-084-A0507

Figure 4: Pivot Cup Compatibility

Loading...

Loading...