Broan SP200 Installation Manual

MODELS SP100, SP140 & SP200

SINGLE-PORT IN-LINE VENTILATORS

READ AND SAVE THESE INSTRUCTIONS

WARNING

TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK,

OR INJURY TO PERSONS, OBSERVE THE FOLLOWING:

1. Use this unit only in the manner intended by the manufacturer. If you have questions, contact the manufacturer at the address or telephone number listed below the

warranty.

2. Before servicing or cleaning unit, switch power off at

service panel and lock the service disconnecting means

to prevent power from being switched on accidentally.

When the service disconnecting means cannot be locked,

securely fasten a prominent warning device, such as a

tag, to the service panel.

3. Installation work and electrical wiring must be done by

qualified person(s) in accordance with all applicable

codes and standards, including fire-rated construction

codes and standards.

4. Sufficient air is needed for proper combustion and

exhausting of gases through the flue (chimney) of fuelburning equipment to prevent backdrafting. Follow the

heating equipment manufacturer’s guideline and safety

standards such as those published by the National Fire

WARNING

Protection Association (NFPA), and the American Society for Heating, Refrigeration and Air Conditioning Engineers (ASHRAE), and the local code authorities.

5. When cutting or drilling into wall or ceiling, do not

damage electrical wiring and other hidden utilities.

6. Ducted fans must always be vented to the outdoors.

7. This unit must be grounded.

CAUTION

1. For general ventilating use only. Do not use to exhaust

hazardous or explosive materials and vapors.

2. To avoid motor bearing damage and noisy and/or unbalanced impellers, keep drywall spray, construction dust,

etc. off power unit.

3. If ventilator is installed in an unconditioned space

(such as an attic): Surround the ventilator with thermal

insulation - to minimize possible condensation.

4. Please read specification label on product for furth er

information and requirements.

PLAN THE INSTALLATION

Adequate ventilation requires that both intermittent and

continuous contamination be controlled.

Intermittent ventilation must be provided in the bathroom

and kitchen. The bathroom requires 8 air changes per hour.

(Multiply bathroom sq. footage by 1.1 for proper fan sizing.)

The kitchen requires a minimum of 150 CFM capacity (71

l/s) when a ducted range hood is used. If a kitchen fan is

used, determine fan capacity by multiplying the room's sq.

footage by 2. All are run intermittently to control pollution at

the source.

Continuous ventilation, while the house is occupied, provides the flow of fresh air for good indoor air quality.

This ventilator is intended for continuous operation, supplying fresh air to the entire house.

RECOMMENDED VENTILATOR SIZING

DWELLING SIZE RANGE (Sq. Ftg.)

(include finished basement area)

MODEL

SP100

SP140

SP200

*AC/HR = Air Changes per Hour. Based on 8' ceilings.

Square Feet x .093 = Square Meters

.50 AC/HR* .35 AC/HR* .30 AC/HR*

1500 2140 2500

2100 3000 3500

3000 4285 5000

PLAN THE INSTALLATION

LOCATION OF DIFFUSERS & INLETS

FRESH AIR

STALE

AIR

VENTILATOR

DIFFUSER

INLET

FRESH

AIR

AIR FLOW IN TYPICAL INSTALLATION

VENTILATOR

The ventilator exhausts stale air. There are normally sufficient natural intake openings into a dwelling to admit fresh

outside air to be drawn in to replace the stale air. For better

control, fresh air inlets may be used.

SINGLE-STORY HOME

FRESH AIR INLETS

DUCTED

KITCHEN

RANGE HOOD

DIFFUSER

DUCTED

BATH FAN

FRESH AIR INLETS

The ventilator should be centrally located to keep ductwork

as short as possible. Locations for the ventilator include:

joists in an attic space or the basement, or a wall away from

the living areas.

EXHAUST DIFFUSERS (Available separately)

Exhaust diffusers regulate the flow of fresh air drawn

through the house.

Exhaust diffusers should be mounted in the ceilings or high

on the wall.

For best performance, exhaust diffusers should be mounted

in a central location. An exhaust diffuser should not be

installed near a cooking area. (see figure)

FRESH AIR INLETS (Available separately)

For best control of fresh air in a room, install a fresh air inlet.

The number of inlets depend on the floor plan. Consider the

rooms/areas through which fresh air should flow toward the

exhaust diffuser(s).

COOKING AREA

Do not install above

or inside this area

45

Cooking

Equipment

45

Floor

Inlets should be located in outside walls, preferably near

the ceiling. Each inlet should be approximately the same

distance from a diffuser. Inlets should be separated from

diffusers far enough to allow fresh air to mix with room air

before being exhausted.

INSTALL FRESH AIR INLETS

CONNECT DUCTWORK

1. Mount all fresh air inlets in chosen locations during

rough-in construction. Follow directions packed with

inlets.

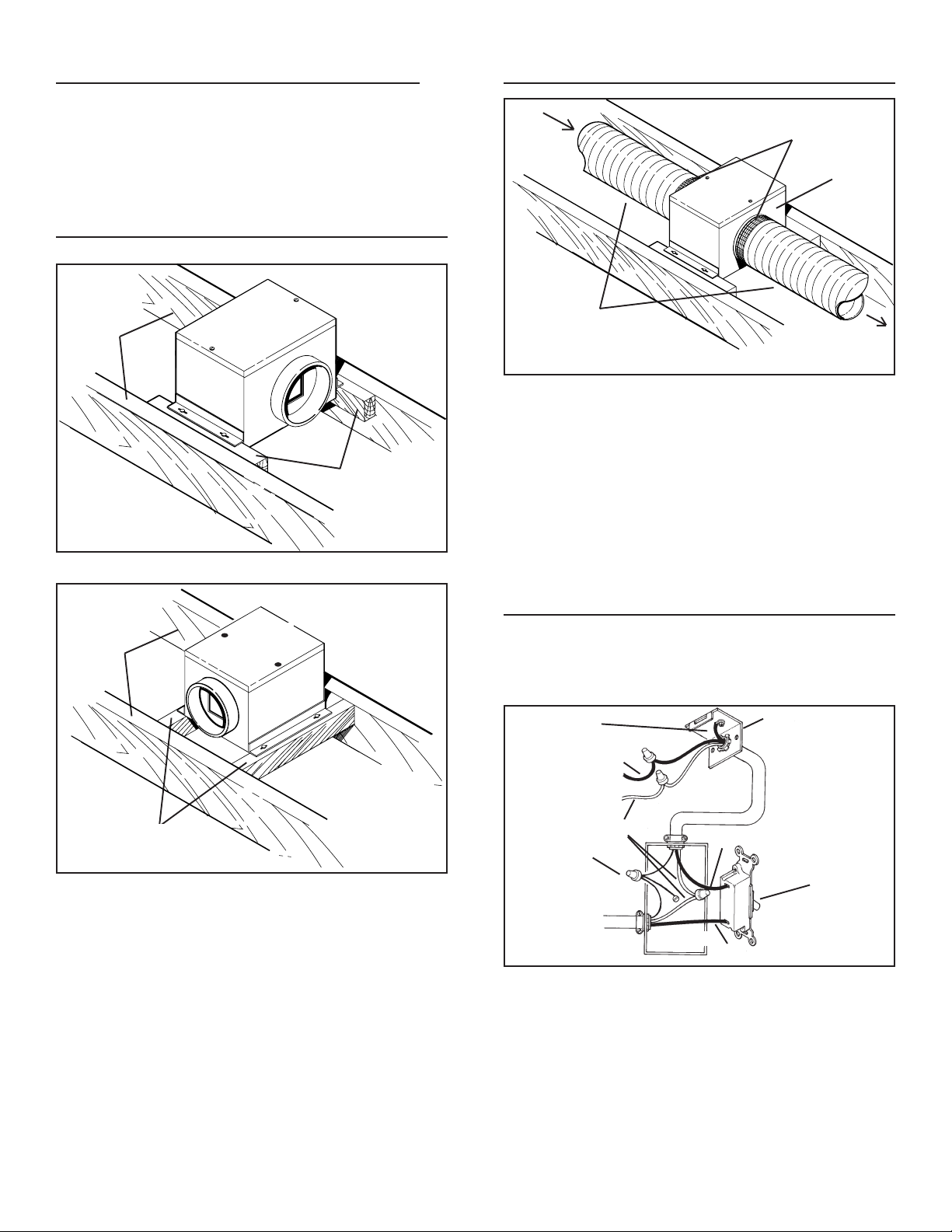

MOUNT THE VENTILATOR

CEILING

JOISTS

2 X 4

FRAMING

OR

DUCT

FROM

DIFFUSER

6" ROUND

INSULATED

FLEXIBLE

DUCT

TAPE OR CLAMP

OUTLET

SIDE

TO ROOF OR

WALL CAP

1. Run 6" insulated, flexible ductwork from ventilator inlet

to diffuser location(s) and from ventilator outlet to roof or

wall cap. Outlet side is marked with a label.

2. To minimize condensation inside of ductwork in the attic, cover ductwork with additional insulation. Also, avoid

forming condensation traps in the ductwork runs.

3. Seal ductwork to ventilator and roof or wall cap with duct

tape or clamp (available separately)

CEILING

JOISTS

2 X 4

FRAMING

1. Add framing to ceiling joists as shown.

2. Set ventilator in place and screw it to framing with screws

provided. Ventilator may also be hung from ceiling joists

or rafters with hanging straps (available separately).

WIRE THE VENTILATOR

WARNING: DISCONNECT POWER AT SERVICE

ENTRANCE AND LOCK OUT SERVICE PANEL

TO PREVENT POWER FROM BEING SWITCHED

ON ACCIDENTALLY.

GROUND

WIRE

BLACK

WHITE

GROUND

(Green or

Bare Wires)

120 VAC

LINE IN

BLACK

BLACK

Use an ON/OFF switch to control the in-line ventilator.

Accessory timers and humidity controls are also available.

1. Remove the wiring adapter plate.

2. Attach power cable to wiring adapter plate using U.L./

CSA approved connector.

3. Connect black to black, white to white, and green or bare

wire to green ground screw.

4. Replace wiring adapter plate. Make sure tab on housing

slides through slot in plate.

WIRING ADAPTER

PLATE

ON/OFF

SWITCH

Loading...

Loading...