Broan ERV100SP Series, ERV100S, Sky Series, ERV100SP Installation Manual

INSTALLATION GUIDE FOR

BROAN ERV100S AND ERV100SP

VB0198

VB0197

Model ERV100S

*This product earned the ENERGY STAR® by meeting strict energy efficiency guidelines set by Natural Resources Canada and the

US EPA. They meet ENERGY STAR requirements only when used in Canada.

! !

RESIDENTIAL USE ONLY

Model ERV100SP*

READ AND SAVE THESE INSTRUCTIONS

Broan-NuTone LLC; Hartford, Wisconsin www.broan.com 800-543-3055

REGISTER YOUR PRODUCT ONLINE AT: www.broan.com/register

For additional information - visit www.broan.com

22634 rev. 05

ABOUT THIS MANUAL

Please take note that this manual uses the following symbols to emphasize particular information:

!

WARNING

Identifies an instruction which, if not followed, might cause serious personal injuries including possibility of death.

CAUTION

Identifies an instruction which, if not followed, may severely damage the unit and/or its components.

NOTE: Indicates supplementary information needed to fully complete an instruction.

ABOUT THESE UNITS

LIMITATION

For residential (domestic) installation only. Installation work and electrical wiring must be done by a qualified person(s) in accordance with

all applicable codes and standards, including fire-rated construction codes and standards.

!

WARNING

TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK, OR INJURY TO PERSON(S) OBSERVE THE FOLLOWING:

1. Use this unit only in the manner intended by the manufacturer. If you have questions, contact the manufacturer at the address or

telephone number listed in the warranty.

2. Before servicing or cleaning the unit, disconnect power cord from electrical outlet.

3. This unit is not designed to provide combustion and/or dilution air for fuel-burning appliances.

4. When cutting or drilling into wall or ceiling, do not damage electrical wiring and other hidden utilities.

5. Do not use this unit with any solid-state speed control device other than following controls:

UNIT MAIN CONTROL AUXILIARY CONTROLS

ERV100SP VT8W, VT7W, VT4W OR VT6W VB60W AND 59W

ERV100S VT7W, VT4W

6. This unit must be grounded. The power supply cord has a 3-prong grounding plug for your personal safety. It must be plugged into a

mating 3-prong grounding receptacle, grounded in accordance with the national electrical code and local codes and ordinances. Do

not remove the ground prong. Do not use an extension cord.

7. Do not install in a cooking area or connect directly to any appliances.

8. Do not use to exhaust hazardous or explosive materials and vapors.

9. When performing installation, servicing or cleaning these units, it is recommended to wear safety glasses and gloves.

10. When applicable local regulation comprise more restrictive installation and/or certification requirements, the aforementioned

requirements prevail on those of this document and the installer agrees to conform to these at his own expenses.

OR VT6W VB20W AND 59W

CAUTION

1. To avoid prematurate clogged filters, turn OFF the unit during construction or renovation.

2. Please read specification label on product for further information and requirements.

3. Be sure to duct air outdoor – Do not intake/exhaust air into spaces within walls or ceiling or into attics, crawl spaces, or garage.

4. Intended for residential installation only in accordance with the requirements of NFPA 90B.

5. Do not run any air ducts directly above or closer than 2 ft to any furnace or its supply plenum, boiler, or other heat producing appliance.

If a duct has to be connected to the furnace return plenum, it must be connected not closer than 9’ 10” from this plenum connection to

the furnace.

6. The ductwork is intended to be installed in compliance with all local and national codes that are applicable.

7. When leaving the house for a long period of time (more than two weeks), a responsible person should regularly check if the unit

operates adequately.

8. If the ductwork passes through an unconditioned space (e.g.: attic), the unit must operate continuously except when performing

maintenance and/or repair. Also, the ambient temperature of the house should never drop below 65°F.

2

TABLE OF CONTENTS

1. T YPICAL INSTALLATIONS ......................................................................................................................... 4-5

1.1 FOR HOUSE .................................................................................................................................................. 4

1.1.1 FULLY DUCTED SYSTEM ............................................................................................................................................4

1.1.2 CENTRAL DRAW POINT .............................................................................................................................................4

1.1.3 SIMPLIFIED INSTALLATION ...........................................................................................................................................4

1.2 FOR HIGH-RISE DWELLING .............................................................................................................................. 5

1.2.1 FULLY DUCTED SYSTEM ...........................................................................................................................................5

1.2.2 CENTRAL DRAW POINT ............................................................................................................................................5

2. INSTALLATION ..................................................................................................................................... 5-12

2.1 INSPECT THE CONTENT OF THE BOX .................................................................................................................. 5

2.2 U

2.3 L

2.4 HOW TO HANG THE UNIT .............................................................................................................................. 6-8

2.5 P

2.6 I

2.6.1 FULLY DUCTED SYSTEM ...........................................................................................................................................8

2.6.2 CENTRAL DRAW POINT ............................................................................................................................................9

2.6.3 SIMPLIFIED INSTALLATION ........................................................................................................................................ 10

2.7 CONNECTING THE DUCTS TO THE UNIT ..............................................................................................................11

2.8 I

2.9 I

NIT PREPARATION ......................................................................................................................................... 5

OCATING THE UNIT ........................................................................................................................................ 6

LANNING OF THE DUCTWORK .......................................................................................................................... 8

NSTALLING THE DUCTWORK AND REGISTERS ................................................................................................. 8-10

NSTALLING 2 EXTERIOR HOODS ...................................................................................................................... 12

NSTALLING TANDEM

®

TRANSITION KIT .............................................................................................................. 12

3. CONTROLS ...................................................................................................................................... 13-16

3.1 BOOTING SEQUENCE ..................................................................................................................................... 13

3.1.1 ERV100SP UNIT BOOTING SEQUENCE ................................................................................................................... 13

3.1.2 ERV100S UNIT BOOTING SEQUENCE ..................................................................................................................... 13

3.2 ERV100SP UNIT INTEGRATED DEFROST CONTROL ........................................................................................... 14

3.3 ERV100S U

3.4 S

3.5 E

3.5.1 ELECTRICAL CONNECTION TO VT8W MAIN WALL CONTROL ........................................................................................ 16

3.5.2 ELECTRICAL CONNECTION TO VT7W MAIN WALL CONTROL ........................................................................................ 16

3.5.3 ELECTRICAL CONNECTION TO VT4W MAIN WALL CONTROL ........................................................................................ 16

3.5.4 ELECTRICAL CONNECTION TO VT6W MAIN WALL CONTROL ........................................................................................ 16

3.5.5 ELECTRICAL CONNECTION TO OPTIONAL AUXILIARY WALL CONTROLS ............................................................................16

ETTING EXTENDED DEFROST FOR ERV100S UNIT .......................................................................................... 14

LECTRICAL CONNECTION TO WALL CONTROLS ............................................................................................ 15-16

NIT INTEGRATED CONTROL ........................................................................................................... 14

4. ELECTRICAL CONNECTION TO THE FURNACE ...............................................................................................17

5. SPEED SELECTION .................................................................................................................................17

6. WIRING DIAGRAM ..................................................................................................................................18

7. B ALANCING THE UNIT ..............................................................................................................................19

7.1 WHAT YOU NEED TO BALANCE THE UNIT .......................................................................................................... 19

7.2 P

7.3 B

RELIMINARY STAGES TO BALANCE THE UNIT .................................................................................................... 19

ALANCING PROCEDURE ................................................................................................................................ 19

8. SERVICE PARTS ............................................................................................................................... 20-21

9. TROUBLESHOOTING .......................................................................................................................... 22-24

3

1. TYPICAL INSTALLATIONS

Use the following illustrations as guidelines to help you decide on how the unit will be installed.

All the units should be hung from the joists or ceiling using brackets (included with the unit). If desired, an optional chains and spring kit

(part no. V61239, sold separately) can be used instead of brackets.

If required, bathroom fans and a range hood can be used to exhaust stale air. Also, for homes with more than one level, we recommend

one exhaust register at the highest level.

There are 3 installation methods: Fully ducted, Central Draw Point and Simplified Installation.

NOTE: A standard 3-prong electrical outlet has to be available within 3 feet of the unit.

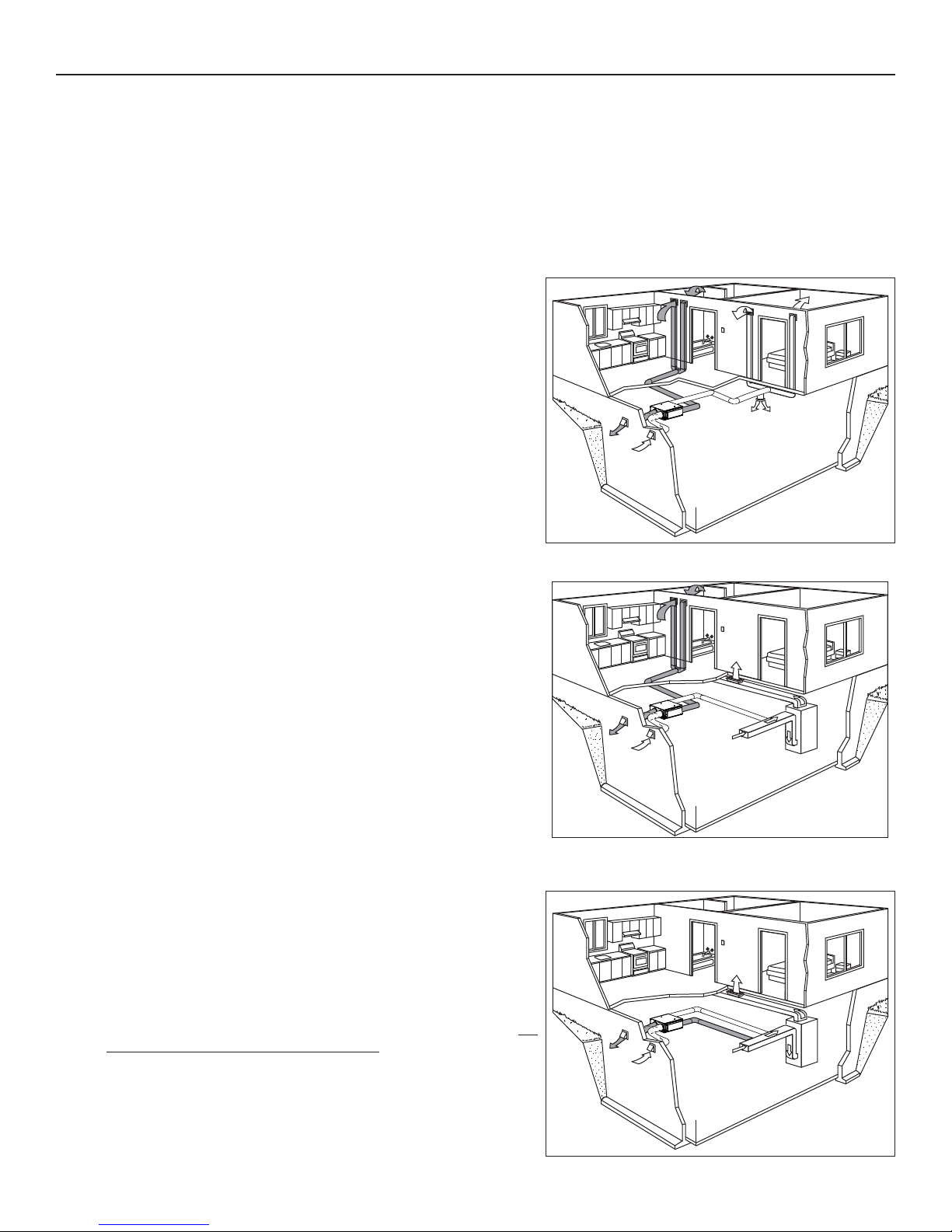

1.1 FOR HOUSE

1.1.1 F

ULLY DUCTED SYSTEM (PRIMARILY FOR HOMES WITH RADIANT HOT WATER OR ELECTRIC BASEBOARD HEATING)

Stale air coming from the registers located at the highest level of the

house is exhausted to the outdoors. Fresh air from outdoors is filtered

and supplied by the register located in the lowest liveable level.

Homes with more than one level require at least one exhaust register

at the highest level.

See figure at right.

1.1.2 C

ENTRAL DRAW POINT (CONNECTION TO A FORCED AIR SYSTEM)

Stale air coming from the registers located at the highest level of the

house is exhausted to the outdoors. Fresh air from outdoors is filtered

and supplied to the return (plenum) or the supply duct of the forced air

unit. See figure at right.

For this type of installation, it is not essential that the forced air system

blower runs when the unit is in operation, but we recommend it.

NOTE: Home with multiple forced air systems should have one unit on

each system.

1.1.3 SIMPLIFIED INSTALLATION (CONNECTION TO A FORCED AIR SYSTEM)

Stale air is exhausted to the outdoors. Fresh air from outdoors is filtered

and supplied to the return (plenum) or the supply duct of the forced air

unit.

See figure at right.

To avoid cross-contamination and achieve the highest efficiencies, the

forced air system blower must always be ON.

NOTE: Home with multiple forced air systems should have one unit on

each system.

VH0096

VH0097

VH0098

4

1. TYPICAL INSTALLATIONS (CONT'D)

VR0087

VR0086

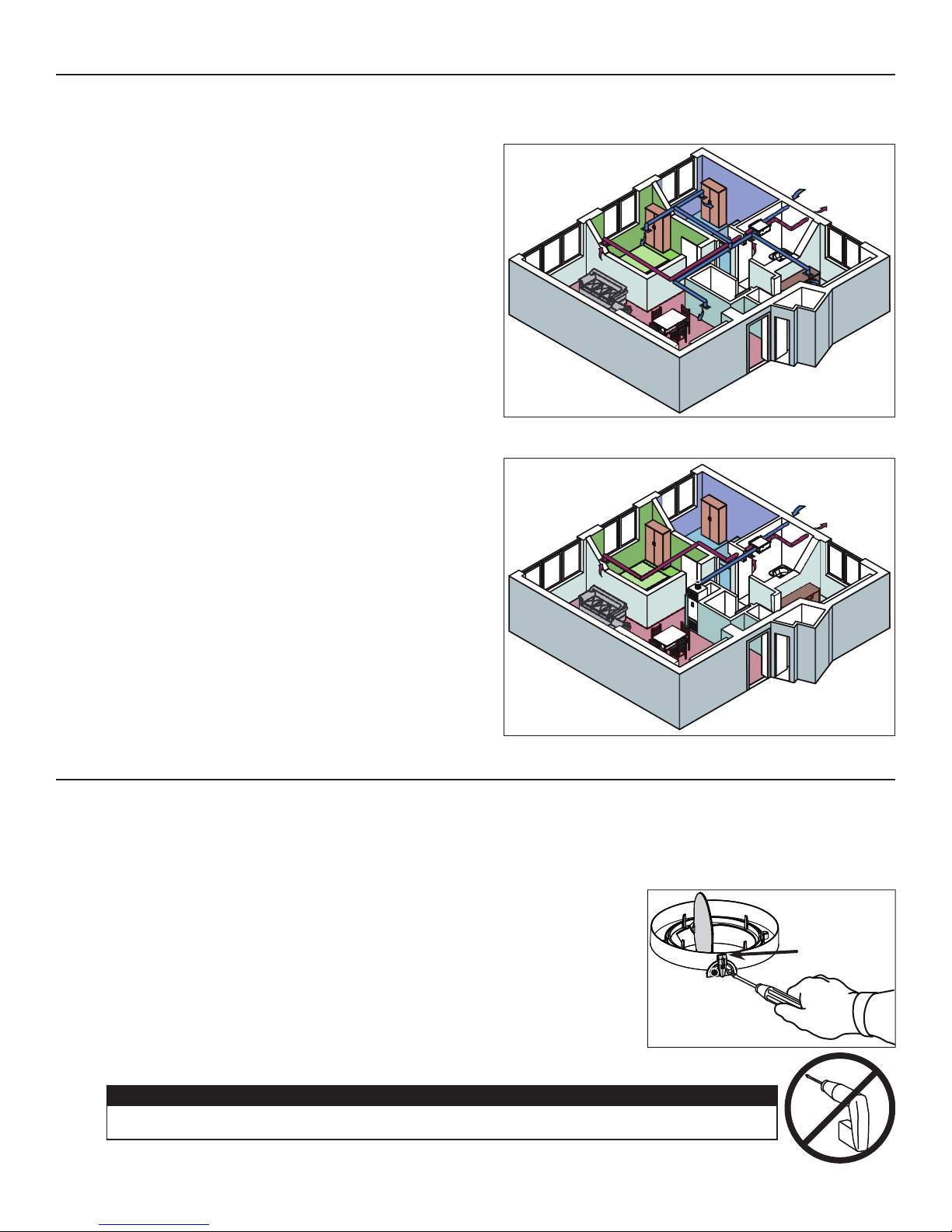

1.2 FOR HIGH-RISE DWELLING

1.2.1 FULLY DUCTED SYSTEM (PRIMARILY FOR HOMES WITH RADIANT HOT WATER OR ELECTRIC BASEBOARD HEATING)

Stale air coming from the registers located in bathrooms and

kitchen is exhausted to the outdoors. Fresh air from outdoors is

filtered and supplied by the registers located in bedrooms and

living room.

See figure at right.

VH0095

1.2.2 CENTRAL DRAW POINT (CONNECTION TO A FAN -COIL SYSTEM)

Stale air coming from the registers located in bathrooms and

kitchen is exhausted to the outdoors. Fresh air from outdoors

is filtered and supplied to the supply duct of the fan-coil system

unit. See figure at right.

For this type of installation, it is not essential that the fan-coil

system blower runs when the unit is in operation, but we

recommend it.

2. INSTALLATION

2.1 INSPECT THE CONTENTS OF THE BOX

• Inspect the exterior of the unit for shipping damage. Ensure that there is no damage to the door, door hinges, power cord, etc.

• Open the unit door and inspect the interior of the unit for damage. Ensure that energy recovery core, core filters, insulation,

dampers, etc. are all intact.

2.2 UNIT PREPARATION

All units are equipped with 2 ports having integrated balancing damper (Fresh air to

building and Exhaust air to outdoors ports). Before installing the unit, check if these

2 ports are in wide open position. If not, proceed as follow:

Loosen the damper lever locking screw.

Use the damper lever to open the damper.

Lock the damper in position by tightening the locking screw.

VH0094

DAMPER LEVER

When loosing or tightening the damper lever locking screw, never use an electric screwdriver or drill,

use a standard screwdriver.

CAUTION

5

2. INSTALLATION (CONT’D)

2.3 LOCATING THE UNIT

Choose an appropriate location for the unit.

• Within an area of the house where the ambient temperature is kept between 65°F and 104°F.

• So as to provide easy access to the interior of the unit, for quarterly and annual maintenance.

• Close to an exterior wall, so as to limit the length of the insulated flexible duct to and from the unit.

• Away from hot chimneys and other fire hazards.

• Allow for a power source within 3 feet (standard 3-prong grounding outlet).

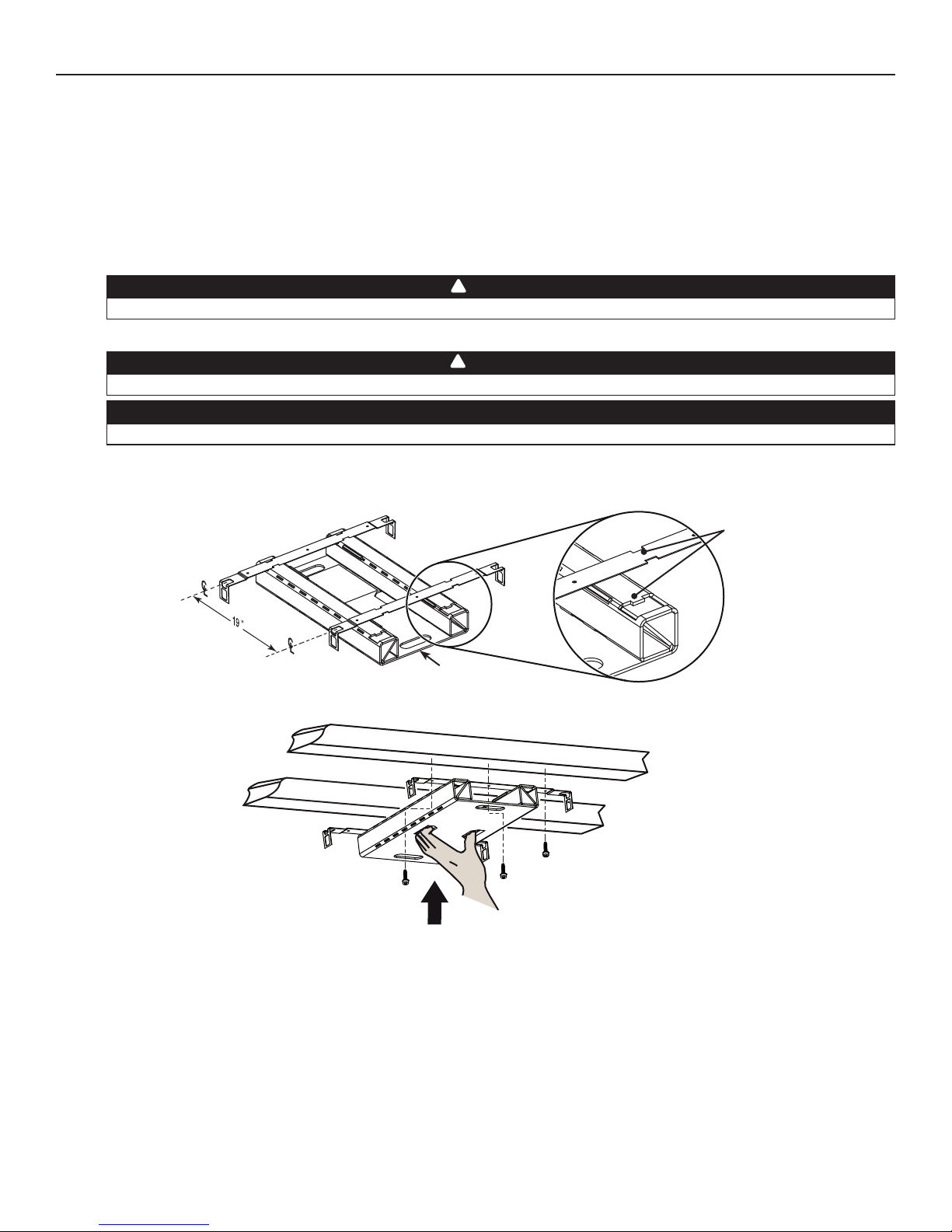

2.4 HOW TO HANG THE UNIT

Never handle the unit using its ports; hold the unit by its sides.

Hang the unit using 2 included brackets. See below.

To ensure occupants safety, ensure the brackets are mounted to solid surface (e.g.: concrete ceiling, joists).

The included screws are for wood joist only; do not use them to secure brackets to concrete ceiling or metal joists.

Mount brackets to ceiling or joists. To ease the brackets location, use the template printed on the cardboard filler located in

the unit box. See below.

!

WARNING

!

WARNING

CAUTION

VO0259A

Cardboard filler

A

A

Align bracket notches with

carboard filler tabs.

Use at least 2 end screws (A) (or nails)

per bracket to secure them to the joists or

ceiling; the center one is optional.

6

2. INSTALLATION (CONT’D)

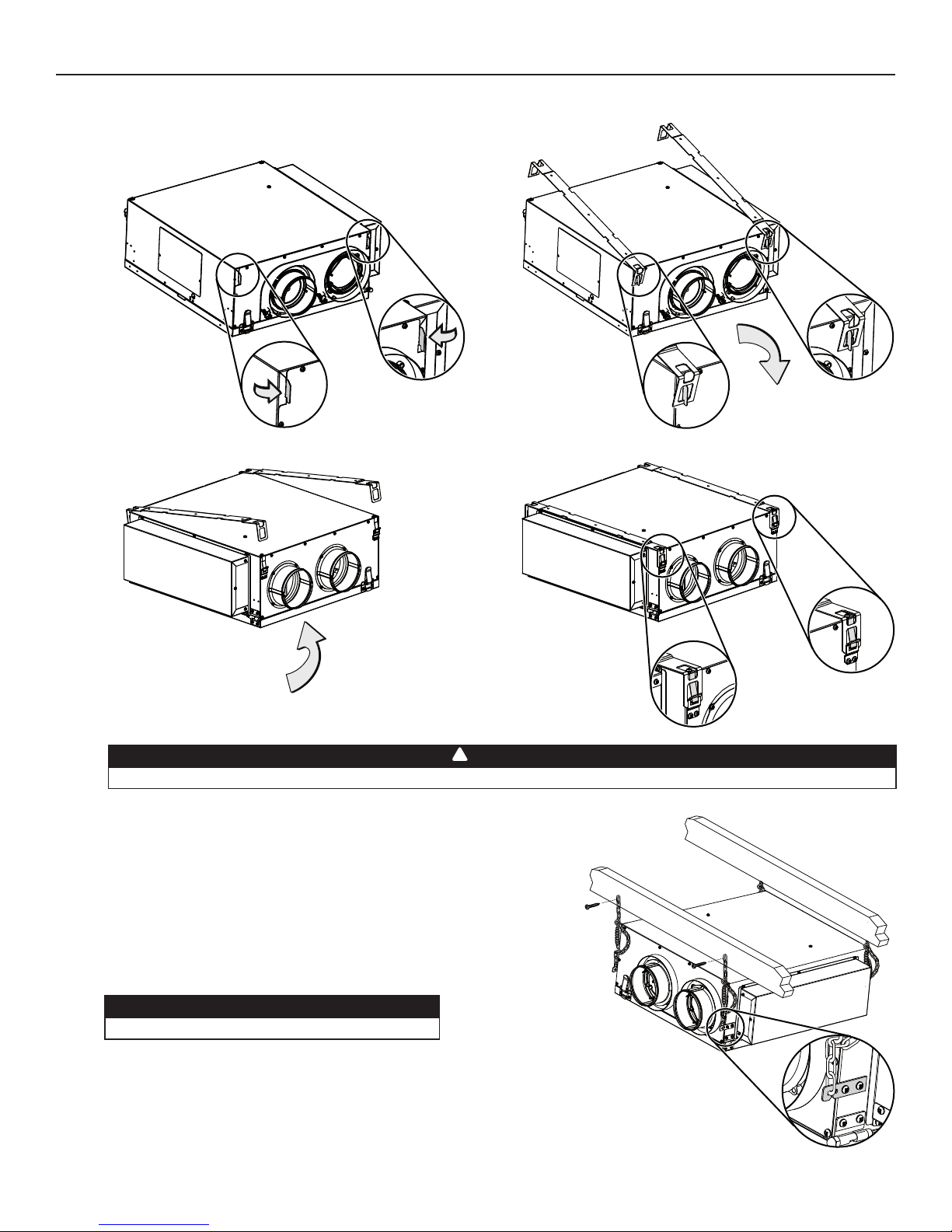

2.4 HOW TO HANG THE UNIT (CONT'D)

Bend 90° integrated hooks (2 places).

Hang the hooks onto

the brackets.

Clip the other side of unit onto the brackets (2 places).

VD0338

!

WARNING

Ensure the unit is completely held by the brackets before continuing the installation.

NOTE: The unit can also be hung using 4 hooks (shaded part in illustration

at right), chains, springs and screws

(kit sold separately, part no. V61239).

CAUTION

Make sure the unit is level.

VD0330

7

2. INSTALLATION (CONT’D)

2.5 PLANNING OF THE DUCTWORK

• Keep it simple. Plan for a minimum of bends and joints.

• Keep the length of insulated ducts to a minimum.

• Do not ventilate crawl spaces or cold rooms. Do not attempt to recover the exhaust air from a dryer or a range hood. This would

cause clogging of the filters and recovery module.

• If the house has two floors or more, be sure to plan for at least one exhaust register on the highest lived-in level.

2.6 INSTALLING THE DUCTWORK AND REGISTERS

Never install a stale air exhaust register in a closed room where a combustion device operates, such as a gas furnace,

a gas water heater or a fireplace.

2.6.1 FULLY DUCTED SYSTEM (AS ILLUSTRATED IN SECTIONS 1.1.1 AND 1.2.1)

Stale air exhaust ductwork:

• Install the stale air exhaust registers where the contaminants are produced: kitchen, living room, etc. Position the registers as far

from the stairway as possible and in such a way that the air circulates in all the lived-in spaces in the house.

• If a register is installed in the kitchen, it must be located at least 4 feet from the range.

• Install the registers 6 to 12 inches from the ceiling on an interior wall OR install them in the ceiling.

Fresh air distribution ductwork:

• Install the fresh air distribution registers in bedrooms, dining rooms, living room and basement.

• Keep in mind that the fresh air registers must be located as far as possible from the stale air registers.

• Install the registers in the ceiling OR 6 to 12 inches from the ceiling on an interior wall.

• If a register must be floor installed, direct the airflow up the wall.

!

WARNING

8

Loading...

Loading...