Broan EPLEC1, NPLEC1 Installation Use And Care Manual

WWW.BROAN.COM WWW.BROAN.CA WWW.NUTONE.CA

DE CUISINIÈRE

RANGE HOOD

Series: EPLEC1 and NPLEC1

INSTALLATION, USE

AND CARE MANUAL

English - See page 2

HOTTE

Séries : EPLEC1 et NPLEC1

MANUEL D’INSTALLATION,

D’UTILISATION ET D’ENTRETIEN

Français - Voir en page 27

CAMPANA

DE COCINA

Series: EPLEC1 y NPLEC1

MANUAL DE INSTALACIÓN,

USO Y CUIDADO

Español - Vease la pagína 60

Serial number:

99045656-003A

For ADA compliance installation guidelines, please visit www.broan-nutone.com

Recommended Tools and Accessories

for Installation

• Measuring tape

• Phillips screwdriver no. 2

• Nut driver or socket 11/32”

• Flat blade screwdriver (to open knockout holes)

• Drill, 1/8” drill bit and 1½” hole saw (to mark holes for ducting and cut electrical access hole)

• 7/64” drill bit (to drill holes for EZ1 brackets mounting screws)

• Wood shims (2) and wood screws (4) (required for standard installation to framed cabinet)

• Saw (to cut holes for ducted application)

• Sheet metal shears (ducted installation only, for duct adjustment)

• Pliers (ducted installation only, for duct adjustment)

• Metal foil duct tape (for ducted applications)

• Scissors (to cut metal foil duct tape)

• Pencil

• Wire stripper

• Strain relief, 1/2” diameter (to secure house wiring cable to the hood)

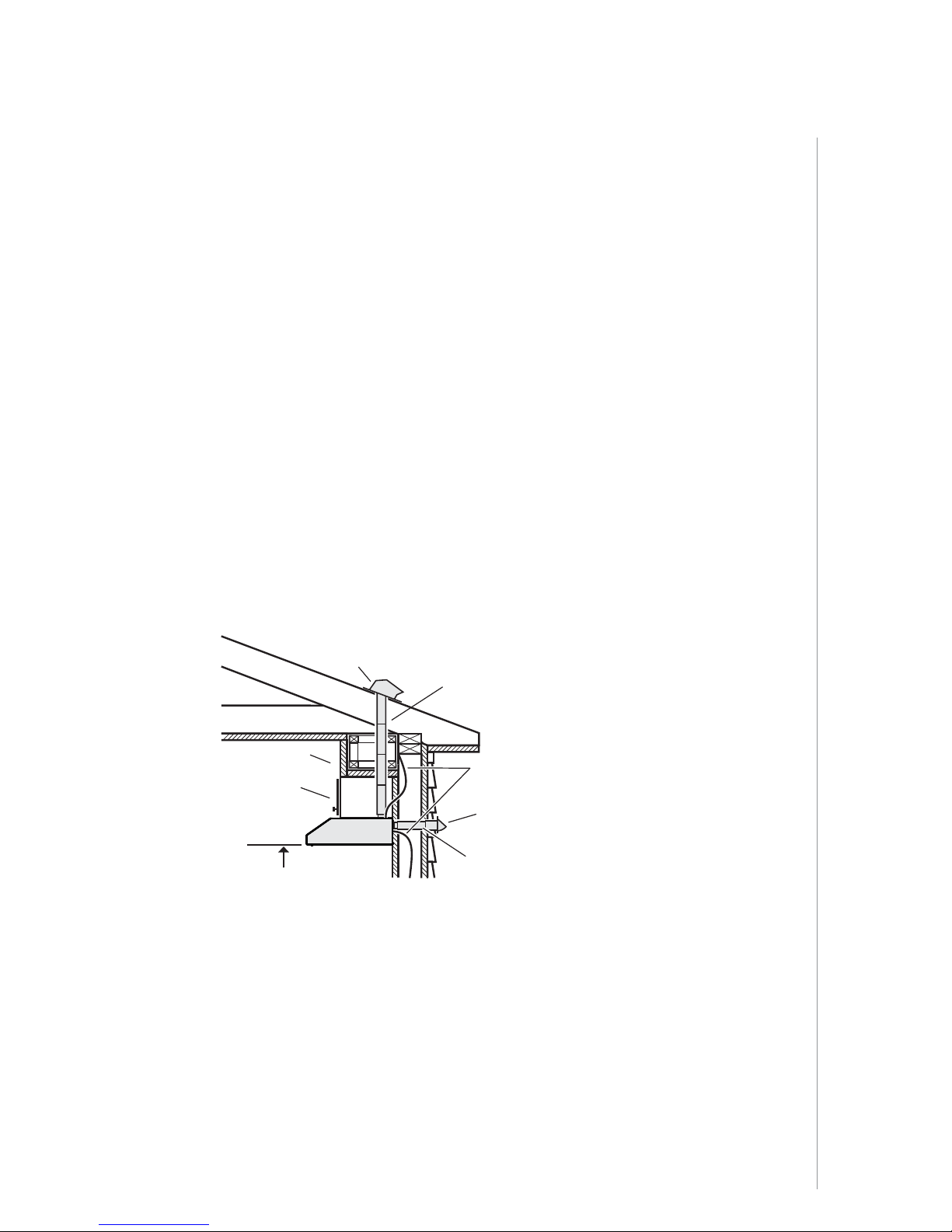

Install Ductwork (Ducted Installations Only)

ROOF CAP

3¼" X 10", 3¼" X 14" OR

7" ROUND DUCT

(FOR VERTICAL

DISCHARGE

SOFFIT

CABINET

HOOD

18" MIN - 24" MAX

COOKING SURFACE

ABOVE

NOTE: Distances over 24” are at the installer and user discretion.

1 ] Determine whether hood will discharge vertically (3¼” x 10”, 3¼” x 14” or 7” round),

or horizontally (3¼” x 10” or 3¼” x 14” only).

2 ] Decide where the ductwork will run between the hood and the outdoors.

3 ] Choose a straight, short duct run to allow the hood to perform most efficiently. Long duct

runs, elbows and transitions will reduce the performance of the hood. Use as few of them as

possible. When possible, use at least 2 foot straight runs before any turns. Larger ductwork

may be required for best performance with longer duct runs.

4 ] Install wall cap or roof cap (sold separately); ensure there is no leak in house insulation.

Connect metal ductwork to cap and work back towards the hood location. Use 2” metal foil

duct tape to seal the joints between ductwork sections.

HOUSE WIRING

(TOP OR BACK OF HOOD)

WALL CAP

3¼" X 10" OR

3¼" X 14" DUCT

(FOR HORIZONTAL DISCHARGE)

)

INSTALLATION

INSTALLATION MANUAL

7

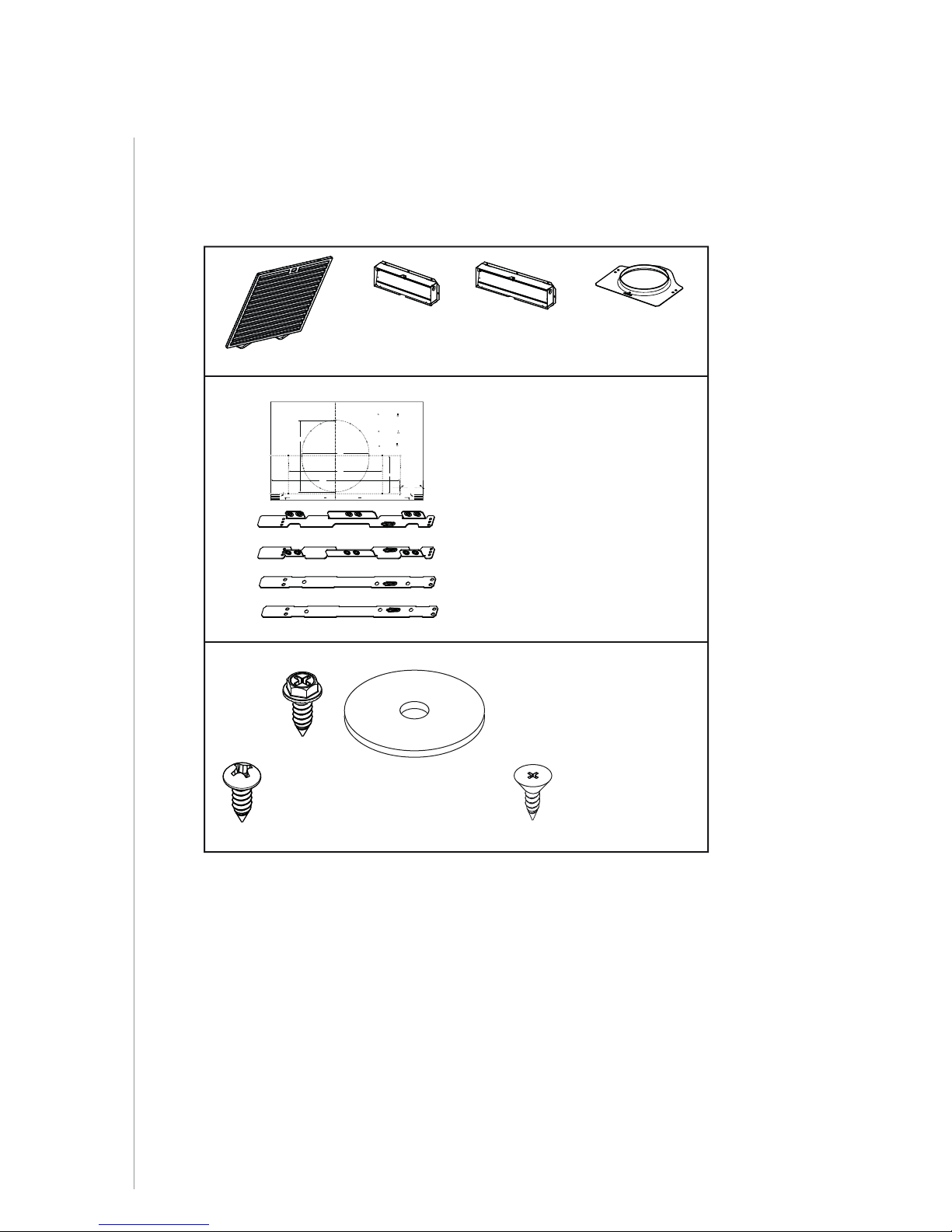

Contents

VERTICAL EXHAUST

Before proceeding to the installation, check the contents of the box. If items are missing or

damaged, contact the manufacturer.

Make sure that the following items are included:

(2) GREASE FILTERS

Use this template for marking; do not attempt to cut out the ducting hole through it.

NOTE: These cutouts are clearance holes; they do not need to be the exact size of ducting.

Utiliser ce gabarit pour marquer vos repères; ne pas tenter de découper

le trou pour le conduit à travers le gabarit.

NOTE : Les découpes incluent le jeu nécessaire à l’installation; elles ne doivent pas

être du format exact des conduits.

Use esta plantilla para crear marcados; no trate de cortar el

agujero del conducto a través de la plantilla.

NOTA: To be translated in Spanish.

Bend template along graduated

scale when installing to framed

cabinet.

C

Pour une installation sous une

armoire à fond en retrait, utiliser les

lignes pour mesurer l’épaisseur du

décalage causé par le mur de

l’armoire et plier le gabarit en

8”

conséquence.

To be translated in Spanish.

C

(1) 3¼” X 10”

D

AMPER ASSEMBLY*

(1) 3¼” X 14”

D

AMPER ASSEMBLY*

* FIND INSIDE OF HOOD

OMPONENTS

EZ1 C

MARK WHERE INDICATED

FOR THE APPROPRIATE SIZE DUCT OPENING

RECTANGULAR DUCTING7” ROUND DUCTING

OR

= 3¼” x 10”

= 3¼” x 14”

MARQUER LES REPÈRES AUX ENDROITS INDIQUÉS SELON

LE FORMAT DE CONDUIT UTILISÉ

CONDUIT RECTANGULAIRECONDUIT ROND DE 7 PO

OU

= 3¼ po x 10 po

= 3¼ po x 14 po

TITLE TO BE TRANSLATED IN SPANISH

CONDUCTO RECTANGULARCONDUCTO REDONDO

O

= 3¼ pulg. x 10 pulg.

DE

7 PULG.

C

14½”

Appuyer ce bord au mur arrière

L

7½”

10½”

= 3¼ pulg. x 14 pulg.

Electrical access hole center

A = single blower hood

B = double blower hood

Centre du trou pour fil

d’alimentation électrique

A = hotte ventilateur simple

B = hotte ventilateur double

To be translated in Spanish

Electrical access hole center

4¼”

A = single blower hood

B = double blower hood

AB

Apoyar este borde contra la pared de atrásPlace this edge against back wall

C

(1) TEMPLATE FOR DUCTING

(PRINTED BOTH SIDES)

(2) INSTALLATION BRACKETS**

FOR FRAMED CABINET

(2) INSTALLATION BRACKETS**

FOR FRAMELESS CABINET

** FIND EZ1 BRACKETS ATTACHED INSIDE OF HOOD

ARTS BAG*** CONTAINING:

(1) P

(4) NO. 8-18 X 1/2”

M

ETAL SCREWS WITH

(4) WASHERS

(1) 7” R

OUND

DUCT CONNECTOR*

O. 8 X 5/8”

(6) N

RD. HD.

W

OOD SCREWS

INSTALLATION MANUAL

INSTALLATION

8

*** FIND PA RT S BAG INSIDE OF HOOD

(6) NO. 8 X 1/2”

C

OUNTERSUNK

WOOD SCREWS

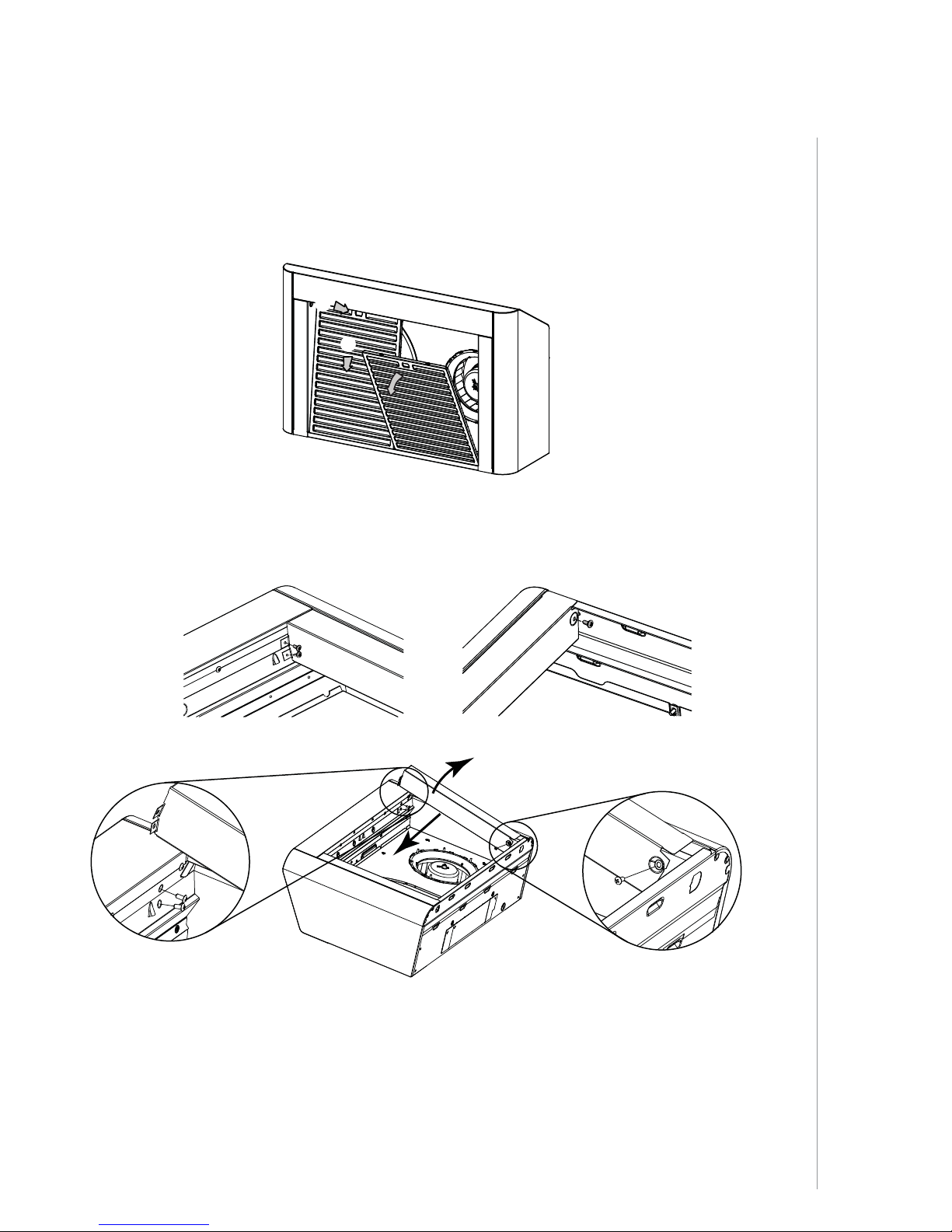

Prepare the Hood

1 ] If present, remove all protective polyfilm from the hood and/or parts.

2 ] Using the finger cup, remove the grease filters from the hood by pushing down and tilting

filters out .

B

C

3 ] Remove both fillers by removing the 3 screws holding each one of them. Slide each one

towards the center of the hood and tilt it up to remove it completely. Set the fillers and screws

aside.

c

d

INSTALLATION

INSTALLATION MANUAL

9

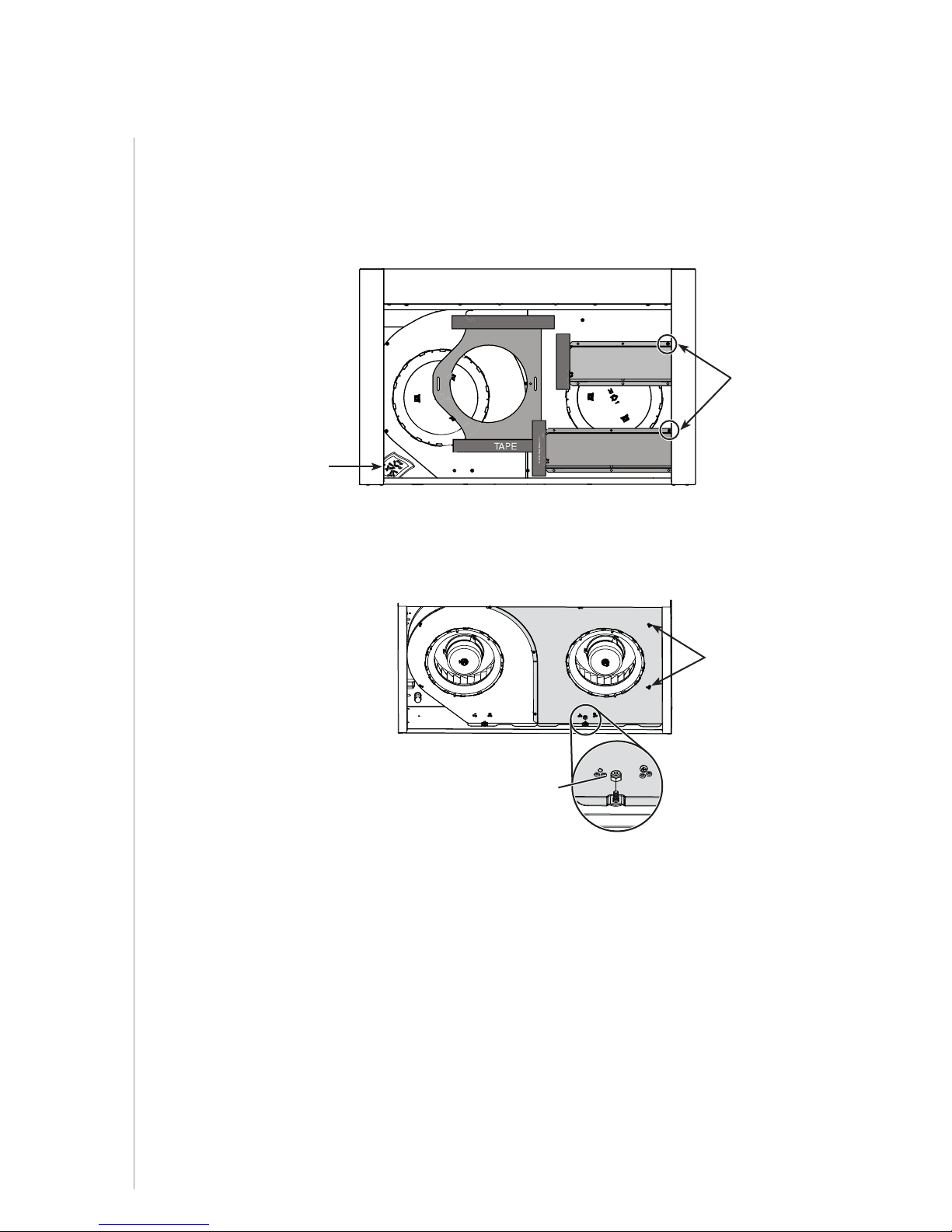

4 ] Remove the screw holding the 3¼” x 10” adapter/damper as well as the one for the 3¼” x 14”

adapter/damper, remove their tape strips and and put the adapter/dampers aside. Save these

screws, they will be used later to hold the blower cover plate.

5 ] Remove both tape strips holding the 7” round adapter, and put the adapter aside.

6 ] Remove the parts bag taped in the lower left corner of the hood.

TAPE

TAPE

TAPE

PARTS BAG

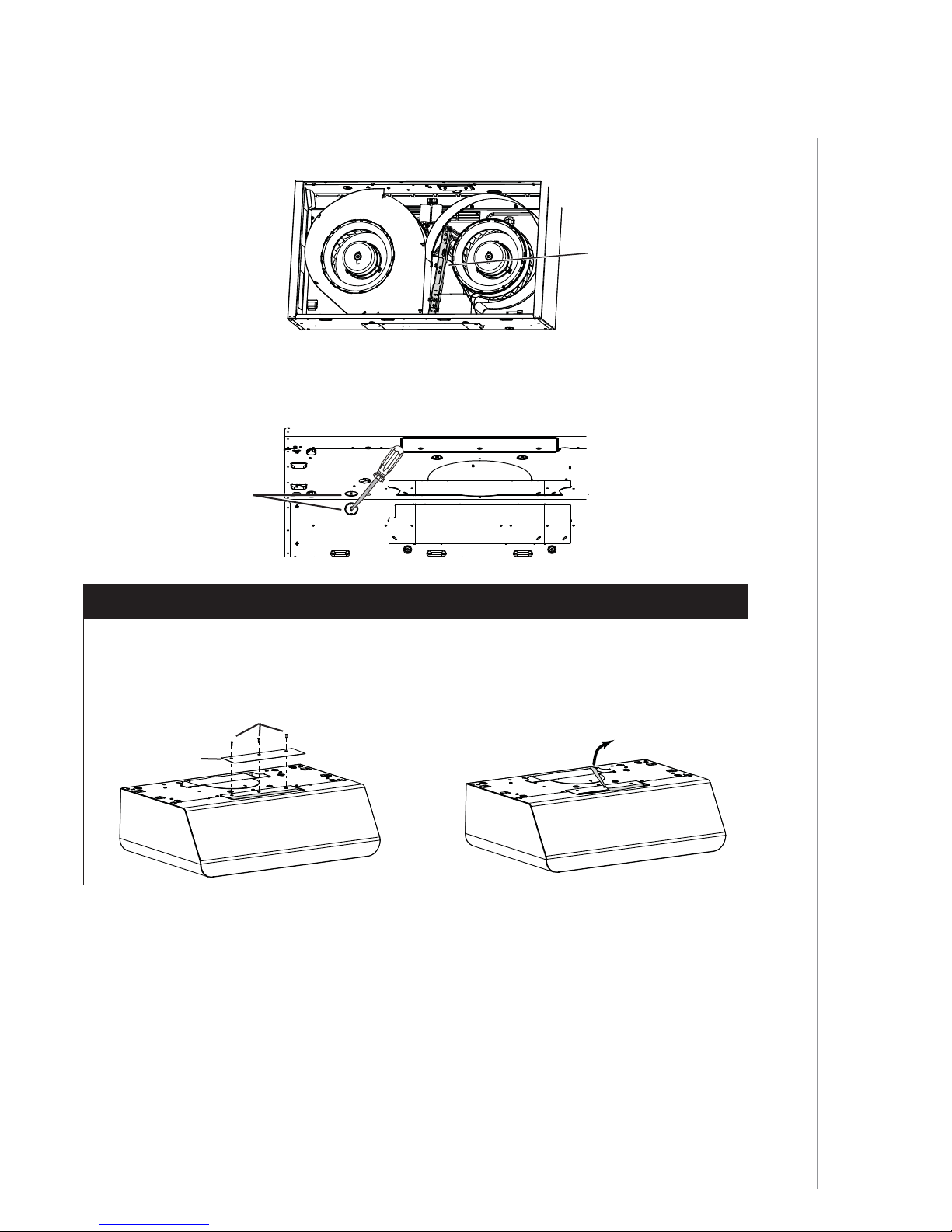

7 ] Using a 11/32” nut driver or socket, remove the lock nut retaining the flange of the right

blower cover plate (shaded part on illustration below) to the inner back of hood (see inset).

Remove the right cover plate remaining retaining screws (5 screws), then set the blower

cover along with its screws and nut aside.

BACK OF HOOD

4

5

LOCK NUT

TAPE

23

1

REMOVE

AND SAVE

THESE

SCREWS

SCREWS REMOVED

IN STEP 4

NOTE: For 30 in.-wide hoods, slightly lift up the cover plate before sliding it towards the left to

remove it.

INSTALLATION MANUAL

INSTALLATION

10

8 ] Remove the EZ1 brackets from inside the hood by cutting off the tie wrap. Discard the tie

wrap.

EZ1

BRACKETS

9 ] Remove Electrical Power Cable Knockout from top (vertical exhaust) or back (horizontal

exhaust) of hood. For knockout removed from back of hood, install an appropriate strain

relief, 1/2” diameter (not included). For knockout removed from top of hood, the strain relief

will be installed later.

ELECTRICAL

POWER CABLE

KNOCKOUT

NON-DUCTED INSTALLATION ONLY

10 ] Remove the 3 screws retaining the recirculation cover plate to the hood. Discard this plate

with its screws.

11 ] Peel off and discard the membrane covering the recirculation grille, ensuring the openings

are totally cleared.

SCREWS

RECIRCULATION

COVER PLATE

INSTALLATION

INSTALLATION MANUAL

11

Loading...

Loading...