Page 1

AP1 & RP SERIES

PROFESSIONAL STYLE

RANGE HOOD

READ AND SAVE THESE INSTRUCTIONS

FOR DOMESTIC COOKING ONLY

Page 1

WARNING

TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK, OR INJURY TO PERSONS, OBSERVE THE FOLLOWING:

1. Use this unit only in the manner intended by the manufacturer. If you have questions, contact the manufacturer at the

address or telephone number listed in the warranty.

2. Before servicing or cleaning unit, switch power off at service

panel. Lock or tag service panel to prevent power from being

switched on accidentally.

3. Installation work and electrical wiring (including switch location) must be done by a qualified person(s) in accordance

with all applicable codes and standards, including fire-rated

construction.

4. Provide sufficient air for proper combustion and exhausting of

gases through the flue (chimney) of fuel burning equipment

to prevent backdrafting. Follow the combustion equipment

standards such as those published by the National Fire Protection Association (NFPA), the American Society for Heating, Refrigeration and Air Conditioning Engineers (ASHRAE),

and local codes.

5. This product may have sharp edges. Be careful to avoid cuts

and abrasions during installation and cleaning.

6. When cutting or drilling into wall or ceiling, do not damage

electrical wiring and other hidden utilities.

7. Ducted fans must always be vented to the outdoors.

8. Use only metal ductwork.

9. As an alternative, this product may be installed with the ULapproved cord kit designated for the product, following instructions packed with the

10. This unit must be grounded.

TO REDUCE THE RISK OF A RANGE TOP GREASE FIRE:

1. Never leave surface units unattended at high settings.

Boilovers cause smoking and greasy spillovers that may ignite. Heat oils slowly on low or medium settings.

2. Always turn hood ON when cooking at high heat or when

flambeing food (i.e. Crepes Suzette, Cherries Jubilee, Peppercorn Beef Flambe).

3. Clean ventilating fans frequently. Grease should not be allowed to accumulate on fan or filter.

4. Use proper pan size. Always use cookware appropriate for

the size of the surface element.

cord kit.

WARNING

TO REDUCE THE RISK OF INJURY TO PERSONS IN THE

EVENT OF A RANGE TOP GREASE FIRE, OBSERVE THE

FOLLOWING:*

1. SMOTHER FLAMES with a close-fitting lid, cookie sheet,

or metal t ray, then turn off the burner. BE CAREFUL TO

PREVENT BURNS. If the flames do not go out immediately,

EVACUATE AND CALL THE FIRE DEPARTMENT.

2. NEVER PICK UP A FLAMING PAN — Yo u may be burned or

spread the fire.

3. DO NOT USE WATER, including wet dishcloths or towels violent steam explosion will result.

4. Use an extinguisher ONLY if:

A. You know you have a Class ABC extinguisher and you

already know how to operate it.

B. The fire is small and contained in the area where it started.

C. The fire department is being called.

D. Yo u can fight the fire with your back to an exit.

* Based on “Kitchen Fire Safety Tips” published by NFPA.

CAUTION

1. F o r indoor use only.

2. For general ventilating use only. Do not use to exhaust hazardous or explosive materials and vapors.

3. For best capture of cooking impurities, range hood should be

mounted so that the bottom of the hood is 18”-24” above the

cooking surface.

4. Read specification label on product for information and requirements.

NOTE These instructions are for ducted installations only.

If hood is to be installed non-ducted:

Purchase a non-ducted filter kit from your local distributor or

retailer. (Available for AP1 & RP2 Series hoods only.) Follow

instructions included with the non-ducted kit.

Register your product online at: www.broan.com/register

Installer: Leave this manual with the homeowner.

Homeowner: Cleaning, Maintenance and Operating instructions on page 2.

Page 2

AP1 & RP SERIES

(For horizontal discharge)

Page 2

CLEANING & MAINTENANCE

For performance, appearance, and health reasons, clean filter,

fan and grease-laden surfaces. Use only a clean cloth and mild

detergent solution on stainless and painted surfaces. Clean allmetal filters in the dishwasher.

The motor is permanently lubricated and never needs oiling. If

the motor bearings make excessive or unusual noise, replace

the motor with the exact service motor. The impeller should also

be replaced.

Use 120 V, 50 W, shielded halogen bulbs - MR16 or PAR16 with

GU10 base. Purchase bulbs separately.

The grease filters, bottom panel, and blower wheel should be

cleaned frequently. Use a warm detergent solution. The grease

filters and blower wheel are dishwasher safe.

Note: Some minerals, when in contact with dishwasher

soap additives, may cause filters to discolor. This discoloration is not covered by the warranty.

OPERATION

Always turn the hood ON before cooking in order to establish an

air flow in the kitchen. After turning off the range, let the hood run

for a few minutes to clear the air.

AP SERIES HOOD

Operate the hood as follows:

FAN

ON OFF

LIGHTFAN

FAN

The 2-position switch (in center) turns blower ON and OFF.

The 5-position switch (at left) controls blower speed.

Blower is OFF (secondary blower OFF).

Blower is ON at highest speed.

As dots get smaller - blower speed decreases.

LIGHT

This 3-position switch (at right) turns lights ON and OFF and

controls their intensity.

Lights are OFF.

Lights are ON to low intensity.

Lights are ON to highest intensity.

HEAT SENTRY™

The hood is equipped with a Heat Sentry™ thermostat. This safety

device will turn on or speed up the blower if it senses excess heat

above the cooking surface.

If the blower is not on, or if it is running at low speed, the Heat

Senttry™ will override the normal blower control and trun the

blower on the high speed. When the temperature level drops to

normal levels, the blower will return to its original setting.

RP SERIES HOOD

Operate the hood as follows:

BLOWER SWITCH

This 3-position switch turns blower ON and OFF and controls

blower speed.

Set switch to (1) position to turn blower ON to low speed.

Set switch to (2) position to turn blower ON to high speed.

Set switch to (0) position to turn blower OFF.

LIGHT SWITCH

This 3-position switch turns lights ON and OFF and controls their

intensity.

Set switch to (1) position to turn lights ON to low intensity.

Set switch to (2) position to turn lights ON to high intensity.

Set switch to (0) position to turn lights OFF.

PREPARE HOOD LOCATION

ROOF CAP

SOFFIT

CABINET

HOODHOOD

18" - 24" ABOVE

COOKING SURFACE

1 Determine whether hood will discharge vertically or hori-

zontally. For vertical or horizontal discharge, run ductwork

between the hood location and a roof cap or wall cap. For

best results, use a minimum number of transitions and

elbows.

3¼" X 10"

(For vertical

discharge)

HOUSE WIRING

(Top or Back of hood)

WALL CAP

3¼" X 10" DUCT

Page 3

AP1 & RP SERIES

WOOD SHIMS

9"

CENTER

LINE

HOOD MOUNTING SCREWS (4)

ELECTRICAL

ACCESS HOLE

(in cabinet bottom)

WOOD SHIMS

(recessed-bottom

cabinets only)

CABINET FRONT

CABINET

BOTTOM

1615/16" (36" hood)

1615/16" (36" hood)

1315/16" (30" hood)

1315/16" (30" hood)

1

1

/

2

"

7

1

/

2

"

VERTICAL DUCT

ACCESS HOLE

6¼"

6¼"

10

5

/

8

"

6

7

/

8

"

9

7

/

8

"

Page 3

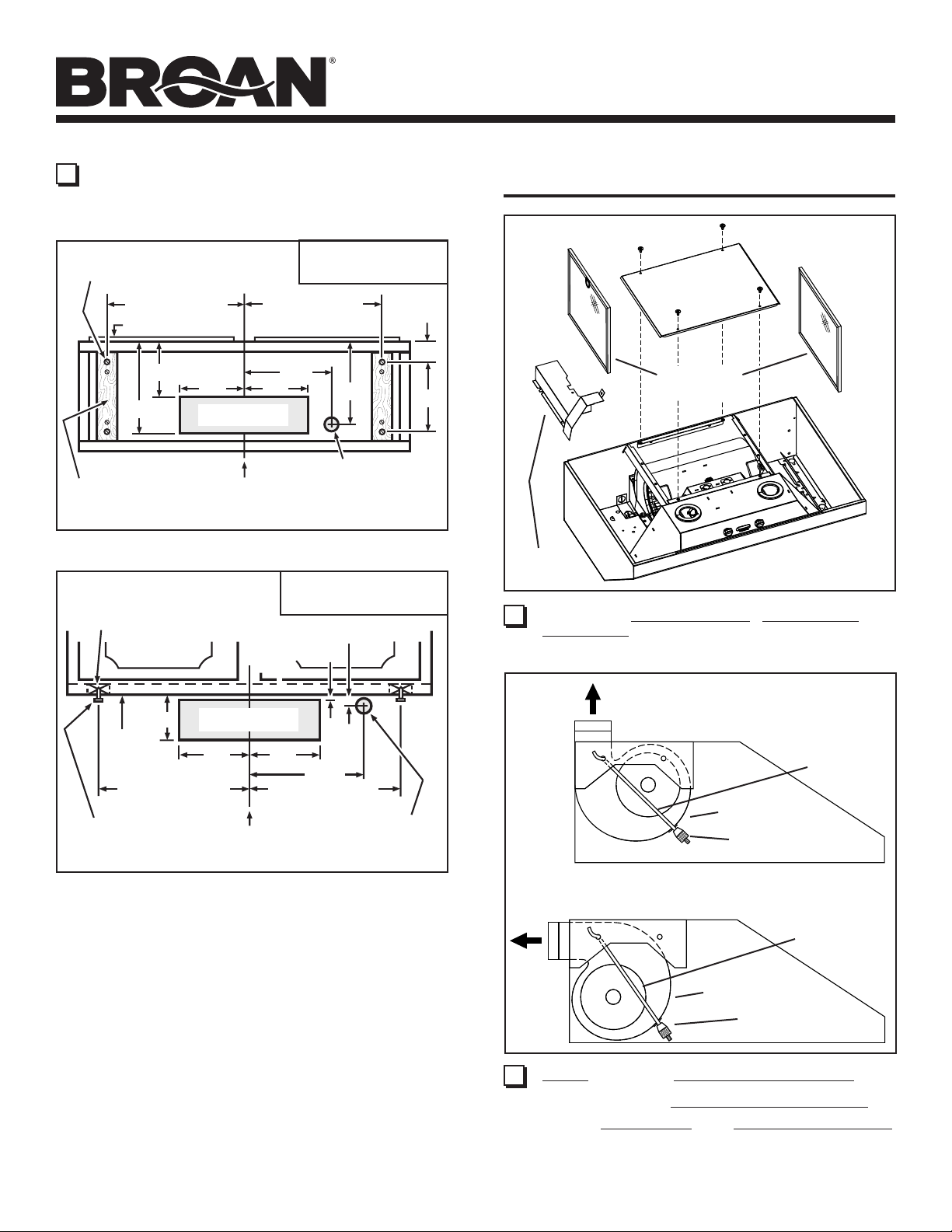

2 Use the proper diagram below, for placement of ductwork

and electrical cutout in cabinet or wall. For a non-ducted

installation, DO NOT cut a duct access hole.

3¼” X 10”

VERTICAL DUCTING

3¼” X 10”

(recessed-bottom

cabinets only)

CABINET FRONT

HORIZONTAL DUCTING

3

/

"

4

1

/

"

8

PREPARE THE HOOD

BOTTOM

COVER

ALUMINUM

FILTERS

WIRING

COVER

3 Remove the Aluminum Filters, Bottom Cover, and

Wiring Cover from the hood.

7

3

HORIZONTAL DUCT

/

"

8

CABINET

BOTTOM

1315/16" (30" hood)

1615/16" (36" hood)

HOOD

MOUNTING

SCREWS (4)

ACCESS HOLE

6¼"

6¼"

1315/16" (30" hood)

1615/16" (36" hood)

CENTER

LINE

1

/

7

"

2

ELECTRICAL

ACCESS HOLE

(in wall)

VERTICAL DISCHARGE POSITION

BLOWER

MOUNTING

ROD (2)

BLOWER

KNURLED NUT (2)

HORIZONTAL DISCHARGE POSITION

BLOWER

MOUNTING

ROD (2)

BLOWER

KNURLED NUT (2)

4 Blower is shipped in Vertical Discharge Position.

To change blower to Horizontal Discharge Position:

Remove Knurled Nuts from Blower Mounting Rods.

Disengage mounting rods from blower and rotate blower

to horizontal discharge position. Re-engage mounting

rods and tighten blower in place with knurled nuts.

Page 4

AP1 & RP SERIES

Page 4

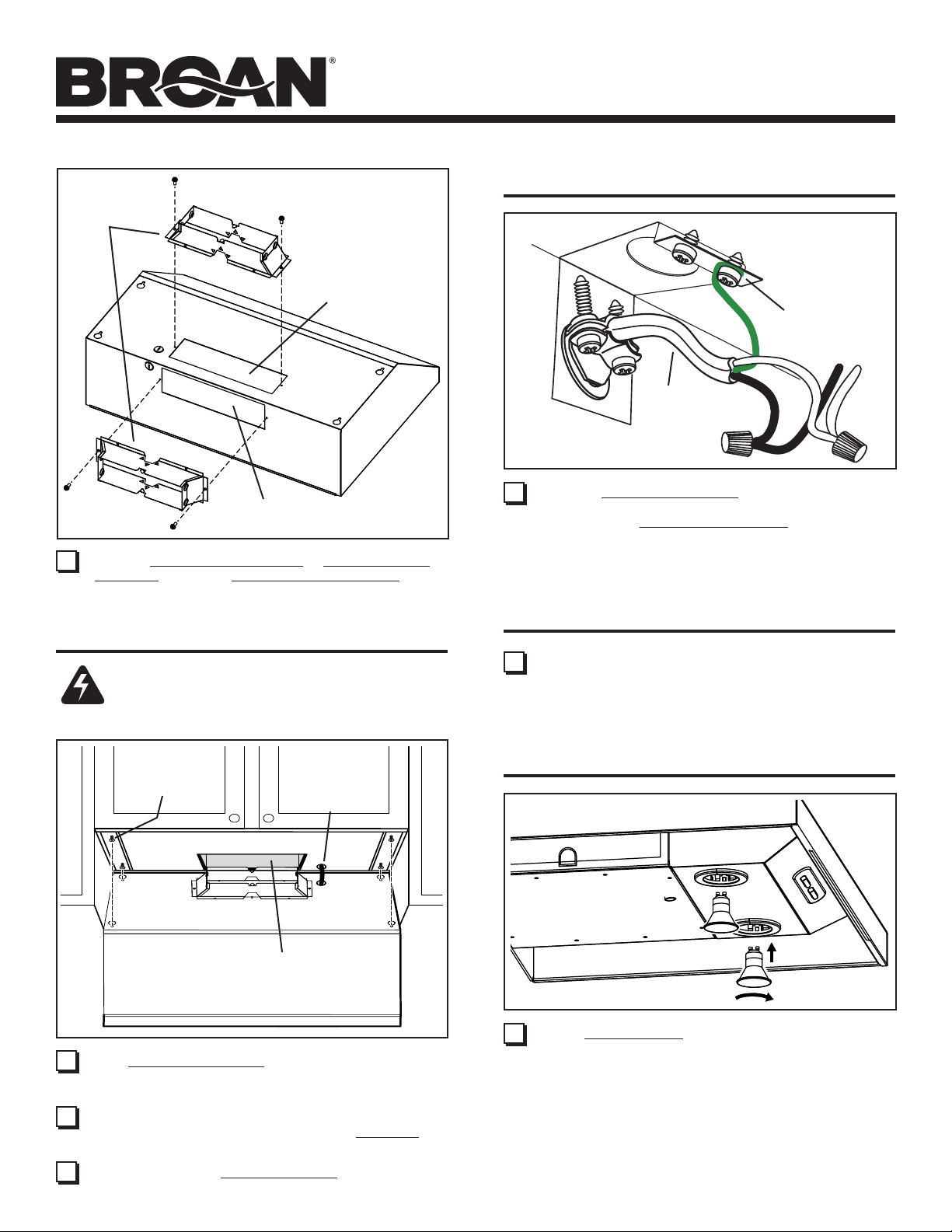

DAMPER /

DUCT

CONNECTOR

VERTICAL DUCT

KNOCKOUT

HORIZONTAL DUCT

KNOCKOUT

5 Remove Vertical Duct Knockout or Horizontal Duct

Knockout and attach Damper / Duct Connector with

two (2) screws (supplied).

INSTALL THE HOOD

WARNING

To reduce the risk of electrical shock, switch power off

at service panel. Lock or tag service panel to prevent

power from being switched on accidentally.

CONNECT THE WIRING

GREEN

GROUND

SCREW

HOUSE

POWER

CABLE

HE0059

9 Connect House Power Cable to range hood wiring -

BLACK to BLACK, WHITE to WHITE, and GREEN or

BARE WIRE to GREEN Ground Screw.

COMPLETE INSTALLATION

10 Re-install the wiring cover, bottom cover, and filters that

were removed in Step 3.

MOUNTING

SCREWS (4)

DUCTWORK

6 Run House Power Cable between service panel and

hood location. Attach power cable to hood using appropriate connector.

7 Hold the hood in position under the cabinet. Make sure

the damper / duct connector enters the Ductwork and

that the damper opens and closes freely.

8 Tighten the four (4) Mounting Screws completely to se-

cure the hood to the cabinet.

HOUSE

POWER

CABLE

INSTALL LIGHT BULBS

(1) PUSH IN

(2) ROTATE

CLOCKWISE

11 Install Halogen Bulbs. Use 120 V, 50 W, shielded halo-

gen bulbs - MR16 or PAR16 with GU10 base. Purchase

bulbs separately.

Page 5

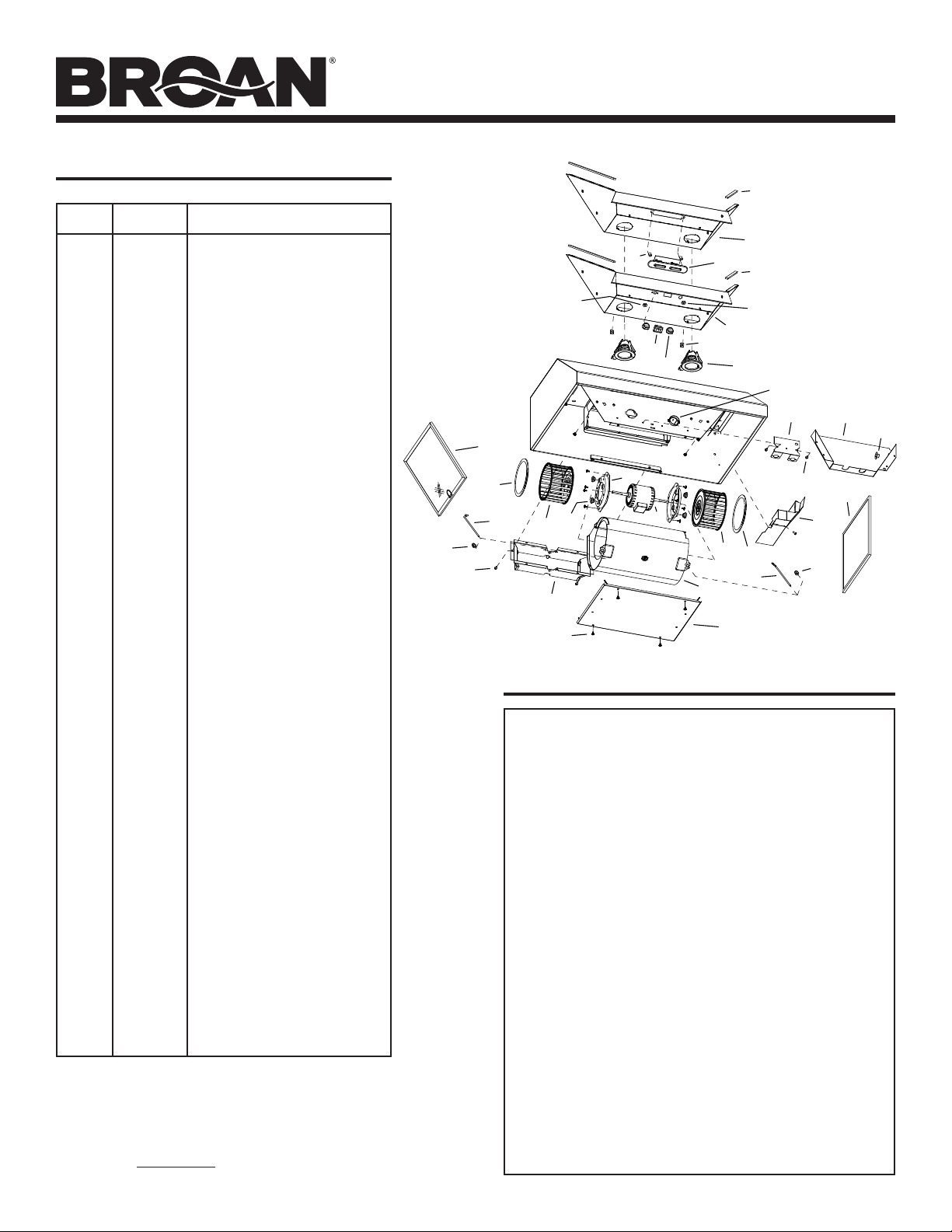

SERVICE PARTS

KEY NO. PART NO. DESCRIPTION

1 97017222 Feature Panel Weldment - RP-Black

97017223 Feature Panel Weldment - RP-White

97017224 Feature Panel Weldment - RP-Silver

2 97017324 Feature Panel Weldment - AP-Black

97017325 Feature Panel Weldment - AP-White

97017326 Feature Panel Weldment - AP-Silver

3 97009517 Bottom Cover - Black

97007895 Bottom Cover - White

97007631 Bottom Cover - Silver

4 97017429 Damper Assembly

5 97007656 Wire Cover Assembly

6 97017428 Thermostat Bracket Assembly

7 98006546 Light Socket Cover

8 99400084 Bushing Split Heyco #2873

9 99271346 Socket/Trim Ring Assembly

10 97017312 Control - RP, Black

97017264 Control - RP, White

11 99111379 Spacer .50 x .375 Nylon

12 97017455 Filter, Aluminum (Qty. 2)

97017456 Filter, Aluminum with antimicrobial

protection (Qty. 2)

13 99420464 Blower Mounting Rod

14 99150617 8-18 x .375 Truss Head

Sheet Metal Screw *

15 99170245 8-18x.375 Hex Head

Phillips Sheet Metal Screw *

16 99260476 Blower Mounting Rod Nut

17 97007313 Blower Scroll Housing

18 99100491 Motor Isolation Bushing

19 98005212 Motor Retaining Ring

20 99080597 Motor

21 99020142 Blower Wheel, Clockwise

22 99020143 Blower Wheel, Counterclockwise

23 99400055 Heyco Snap Bushing

24 99500323 PVC Foam

25 98010342 Ring, Inlet

26 99260491 Hex Nut 3/8-32

27 99260470 Hex Nut 15/32-32

28 600348 Knob - Black

600349 Knob - White

29 97016970 Switch - Black

97016971 Switch - White

30 99260485 Nut Sheet Metal U-Type

** 99400052 Bushing Strain Relief (Not Shown)

** 99770113 Wire Harness - NSP, RP

** 99770115 Wire Harness - AP

** 99030132 Rotary Fan Control

** 97016439 Rotary Light Control

* Standard hardware - may be purchased locally.

** Not illustrated

Order replacement parts by PART NO. - not by KEY NO.

Replacement parts can now be ordered on our website.

Please visit us at www.broan.com.

16

27

12

25

13

15

22

18

4

14

WARRANTY

Broan-NuTone warrants to the original consumer purchaser of its products that

such products will be free from defects in materials or workmanship for a period of

one year from the date of original purchase. THERE ARE NO OTHER WARRANTIES,

EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, IMPLIED WARRANTIES

OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

During this one-year period, Broan-NuTone will, at its option, repair or replace, without

charge, any product or part which is found to be defective under normal use and service.

THIS WARRANTY DOES NOT EXTEND TO FLUORESCENT LAMP STARTERS, TUBES,

HALOGEN AND INCANDESCENT BULBS, FUSES, FILTERS, DUCTS, ROOF CAPS,

WALL CAPS AND OTHER ACCESSORIES FOR DUCTING. This warranty does not cover

(a) normal maintenance and service or (b) any products or parts which have been

subject to misuse, negligence, accident, improper maintenance or repair (other than by

Broan-NuTone), faulty installation or installation contrary to recommended installation

instructions.

The duration of any implied warranty is limited to the one-year period as specified

for the express warranty. Some states do not allow limitation on how long an implied

warranty lasts, so the above limitation may not apply to you.

BROAN-NUTONE’S OBLIGATION TO REPAIR OR

OPTION, SHALL BE THE PURCHASER’S SOLE AND EXCLUSIVE REMEDY UNDER

THIS WARRANTY. BROAN-NUTONE SHALL NOT BE LIABLE FOR INCIDENTAL,

CONSEQUENTIAL OR SPECIAL DAMAGES ARISING OUT OF OR IN CONNECTION

WITH PRODUCT USE OR PERFORMANCE. Some states do not allow the exclusion or

limitation of incidental or consequential damages, so the above limitation or exclusion

may not apply to you.

This warranty gives you specific legal rights, and you may also have other rights, which

vary from state to state. This warranty supersedes all prior warranties.

To qualify for warranty service, you must (a) notify Broan-NuTone at the address or

telephone number below, (b) give the model number and part identification and (c)

describe the nature of any defect in the product or part. At the time of requesting

warranty service, you must present evidence of the original purchase date.

Broan-NuTone LLC, 926 W. State Street, Hartford, Wisconsin 53027

www.broan.com 800-558-1711

Broan-NuTone Canada, Inc., 1140 Tristar Drive, Mississauga, Ontario L5T 1H9

www.broan.ca 877-896-1119

AP1 & RP SERIES

24

1

11

29

28

19

20

BROAN-NUTONE ONE YEAR LIMITED WARRANTY

10

24

26

2

30

9

23

6

15

21

25

13

17

3

REPLACE, AT BROAN-NUTONE’S

Page 5

7

8

12

5

16

Page 6

SÉRIES AP1 ET RP

Page 6

HOTTE DE CUISINIÈRE DE

STYLE PROFESSIONNEL

VEUILLEZ LIRE CES DIRECTIVES ET LES CONSERVER

POUR USAGE DOMESTIQUE SEULEMENT

AVERTISSEMENT

AFIN DE RÉDUIRE LES RISQUES D’INCENDIE, DE CHOC

ÉLECTRIQUE OU DE BLESSURES CORPORELLES,

VEUILLEZ OBSERVER LES DIRECTIVES SUIVANTES :

1. N’utilisez cet appareil que de la manière prévue par le fabricant. Si

vous avez des questions, communiquez avec le fabricant à l’adresse

ou au numéro de téléphone indiqués dans la garantie.

2. Avant d’effectuer l’entretien ou le nettoyage de cet appareil,

coupez le courant au panneau électrique. Verrouillez ou installez

un sceau sur le panneau afin d’éviter que le courant ne soit rétabli

accidentellement.

3. La pose de l’appareil et les travaux d’électricité (y compris la

pose de l’interrupteur) doivent être effectués par des personnes

qualifiées conformément à la réglementation en vigueur, notamment

les normes de construction ayant trait à la protection contre les

incendies.

4. Pour éviter les refoulements, l’apport d’air doit être suffisant pour

brûler les gaz produits par les appareils à combustion et les

évacuer dans le conduit de fumée (cheminée). Respectez les

directives du fabricant de l’appareil de chauffage et les normes de

sécurité, notamment celles publiées par la National Fire Protection

Association (NFPA), l’American Society for Heating, Refrigeration

and Air Conditioning Engineers (ASHRAE) et les codes des autorités

locales.

5. Ce produit peut comporter des arêtes tranchantes. Prenez garde aux

coupures et aux éraflures lors de l’installation et du nettoyage.

6. Veillez à ne pas endommager le câblage électrique ou d’autres

équipements non apparents lors de la découpe ou du perçage du

mur ou du plafond.

7. Les ventilateurs canalisés doivent toujours rejeter l’air à l’extérieur.

8. N’utilisez que des conduits métalliques.

9. Ce produit peut également être installé avec un ensemble de cordon

électrique homologué UL de conception spéciale, en suivant les

instructions accompagnant l’ensemble de cordon électrique.

10. Cet appareil doit être relié à une mise à la terre.

POUR RÉDUIRE LES RISQUES D’INCENDIE CAUSÉS PAR

DE LA GRAISSE SUR LE PLAN DE CUISSON :

1. Ne laissez jamais les éléments de surface allumés à haute

température. Les débordements peuvent causer de la fumée et

occasionner des écoulements de graisse inflammables. L’huile doit

être chauffée graduellement à basse ou à moyenne température.

2. Mettez toujours la hotte en MARCHE lors de la cuisson à feu vif

ou lors de la cuisson d’aliments à flamber (par ex., crêpes Suzette,

cerises jubilé, boeuf au poivre flambé).

3. Nettoyez souvent la hotte. Ne laissez pas la graisse s’accumuler sur

le ventilateur ou le filtre.

4. Utilisez des casseroles de dimension appropriée. Utilisez toujours

une batterie de cuisine adaptée à la dimension de la surface

chauffante.

AVERTISSEMENT

OBSERVEZ LES CONSIGNES SUIVANTES DE MANIÈRE À

RÉDUIRE LES RISQUES DE BLESSURES CORPORELLES

EN CAS D’INCENDIE CAUSÉ PAR DE LA GRAISSE SUR LE

PLAN DE CUISSON :*

1. ÉTOUFFEZ LES FLAMMES à l’aide d’un couvercle étanche,

d’une tôle à biscuits ou d’un plateau en métal puis éteignez le

brûleur. FAITES ATTENTION DE NE PA S VOUS BRÛLER. SI LES

FLAMMES NE S’ÉTEIGNENT PAS IMMÉDIATEMENT, QUITTEZ

LES LIEUX ET APPELEZ LES POMPIERS.

2. NE SOULEVEZ JAMAIS UNE CASSEROLE EN FLAMMES – vous

pourriez vous brûler ou propager l’incendie.

3. N’UTILISEZ PAS D’EAU, ni de serviettes ou de linges mouillés – une

violente explosion de vapeur pourrait survenir.

4. Utilisez un extincteur SEULEMENT si :

A. Vous savez qu’il est de classe ABC et vous connaissez déjà son

mode de fonctionnement.

B. L’incendie n’est pas très important et ne se propage pas.

C. Les pompiers ont été avisés.

D. Vous pouvez combattre l’incendie en faisant dos à une sortie.

*

Conseils tirés de la publication de la NFPA « Kitchen Fire Safety Tips ».

ATTENTION

1. Pour l’usage d’intérieur seulement.

2. Cet appareil ne doit servir qu’à la ventilation générale. Ne pas

l’utiliser pour l’évacuation de matières ou de vapeurs dangereuses

ou explosives.

3. Pour un captage optimal des impuretés, installez la hotte de sorte

que sa partie inférieure soit entre 46 et 61 cm (18 et 24 pouces) audessus de la surface de cuisson.

4. Veuillez lire l’étiquette de spécifications du produit pour obtenir plus

de renseignements, notamment sur les exigences.

REMARQUE Ces instructions correspondent uniquement aux

Si la hotte est installée sans conduit :

Veuillez vous procurer un ensemble de filtres pour hotte sans

conduit chez votre distributeur local ou votre détaillant. (Disponible

pour hottes de série AP1 et RP2 seulement.) Suivez les instructions

accompagnant l’ensemble pour hotte sans conduit.

Enregistrez votre produit en ligne à : www.fr.broan.ca/register

installations avec conduits.

Installateur : Veuillez remettre ce manuel au propriétaire.

Propriétaire : Nettoyage, entretien et mode d’emploi à la page 7.

Page 7

SÉRIES AP1 ET RP

CAPUCHON DE TOIT

8,3 x 25,4 cm

Page 7

NETTOYAGE ET ENTRETIEN

Pour des raisons de santé, de performance et d’apparence, nettoyez le

filtre, le ventilateur et les surfaces graisseuses. Utilisez seulement un

chiffon propre et une solution de détergent doux sur l’acier inoxydable

et les surfaces peintes. Lavez les filtres d’aluminium au lave-vaisselle.

Le moteur est lubrifié en permanence et n’a pas besoin d’être huilé. Si

les roulements du moteur sont anormalement bruyants, remplacez le

moteur exactement par le même modèle. La roue à ailettes doit aussi

être remplacée.

Utilisez des ampoules halogènes avec écran de 120 V, 50 W - MR16 ou

PAR16 à culot GU10. Les ampoules sont vendues séparément.

Les filtres à graisses, le panneau inférieur et la roue à ailettes doivent

être nettoyés fréquemment. Utilisez une solution tiède de détergent. Les

filtres à graisses et la roue à ailettes sont lavables au lave-vaisselle.

Remarque : Certains minéraux, lorsqu’ils entrent en contact avec

les additifs des savons pour lave-vaisselle, peuvent décolorer

les filtres. Cette décoloration n’est pas couverte par la garantie.

FONCTIONNEMENT

Mettez toujours la hotte en MARCHE avant de cuisiner afin d’établir une

circulation d’air dans la cuisine. Laissez la hotte fonctionner quelques

minutes après l’arrêt de la cuisinière afin de nettoyer l’air.

DÉTECTEUR HEAT SENTRY

Votre hotte est équipée d’un thermostat HEAT SENTRYMC. Il s’agit d’un

détecteur de chaleur qui actionne le ventilateur ou en augmente le régime

en cas de chaleur excessive dégagée par les éléments de cuisson.

Si le ventilateur est arrêté ou tourne à bas régime, le détecteur Heat

MC

Sentry

haut régime. Une fois la température revenue à la normale, le ventilateur

revient à son réglage d’origine.

supplante la commande normale du ventilateur et l’actionne à

HOTTE DE SÉRIE RP

Pour utiliser la hotte, faites comme suit :

MC

HOTTE DE SÉRIE AP

Pour utiliser la hotte, faites comme suit :

FAN

ON OFF

LIGHTFAN

VENTILATEUR

L’interrupteur à deux positions (au centre) actionne ou arrête le

ventilateur.

L’interrupteur à cinq positions (à gauche) commande la vitesse

du ventilateur.

Le ventilateur est ARRÊTÉ (ventilateur secondaire ARRÊTÉ).

Le ventilateur est en MARCHE au régime élevé.

Plus les points sont petits - plus le régime diminue.

LAMPE

Cet interrupteur à trois positions permet d’ALLUMER et

d’ÉTEINDRE les lumières et de commander leur intensité.

Les lumières sont ÉTEINTES.

Les lumières sont ALLUMÉES à faible intensité.

Les lumières sont ALLUMÉES à haute intensité.

PRÉPARATION DE

L’EMPLACEMENT DE LA HOTTE

CONDUIT 8,3 x 25,4 cm

(3-1/4 X 10 po.)

(Pour évacuation verticale)

INTERRUPTEUR DU VENTILATEUR

Cet interrupteur à trois positions met la hotte en MARCHE, sur ARRÊT

et commande la vitesse du ventilateur.

Placez l’interrupteur sur (1) pour mettre le ventilateur en MARCHE au

régime lent.

Placez l’interrupteur sur (2) pour mettre le ventilateur en MARCHE au

régime élevé.

Placez l’interrupteur sur (0) pour mettre le ventilateur sur ARRÊT.

INTERRUPTEUR D’ÉCLAIRAGE

Cet interrupteur à trois positions permet d’ALLUMER et d’ÉTEINDRE les

lumières et de commander leur intensité.

Placez l’interrupteur sur (1) pour ALLUMER les lumières à faible intensité.

Placez l’interrupteur sur (2) pour ALLUMER les lumières à haute intensité.

Placez l’interrupteur sur (0) pour ÉTEINDRE les lumières.

SOFFITE

ARMOIRE

HOTTE

46 À 61 CM (18 À 24 PO.)

AU-DESSUS DE

LA SURFACE DE CUISSON

CÂBLAGE ÉLECTRIQUE

(Haut ou arrière de la hotte)

CAPUCHON MURAL

CONDUIT

(3-1/4 X 10 po.) (Pour

évacuation horizontale)

1 Déterminez si l’évacuation de la hotte sera verticale ou

horizontale. Que l’évacuation soit verticale ou horizontale,

installez les conduits entre la hotte et le capuchon mural ou de

toit. Pour obtenir les meilleurs résultats, utilisez un minimum de

coudes et de transitions.

Page 8

SÉRIES AP1 ET RP

CALES DE BOIS

LIGNE DE

CENTRE

(4) VIS DE MONTAGE DE LA HOTTE

TROU POUR FIL

D'ALIMENTATION

ÉLECTRIQUE

(dans le dessous

de l’armoire)

AVANT DE L’ARMOIRE

DESSOUS DE

L’ARMOIRE

35,4 cm (1315/16 po.)

(hotte de 30 po.)

TROU POUR

CONDUIT VERTICAL

15,8 cm

(6-1/4 po.)

15,8 cm

(6-1/4 po.)

43,0 cm (1615/16 po.)

(hotte de 36 po.)

35,4 cm (1315/16 po.)

(hotte de 30 po.)

43,0 cm (1615/16 po.)

(hotte de 36 po.)

27 cm

(10-5/8 po.)

19 cm

(7-1/2 po.)

25,1 cm

(9-7/8 po.)

3,8 cm

(1-1/2 po.)

22,8 cm

(9 po.)

17,5 cm

(6-7/8 po.)

CALES DE BOIS

(seulement pour

armoires à base en

retrait)

Page 8

2 À l’aide des diagrammes ci-dessous, déterminez l’emplacement

exact des coupes à effectuer pour le conduit et le fil d’alimentation

électrique dans l’armoire ou le mur. Pour une installation sans

conduit, NE PAS découper de trou pour le conduit.

CONDUIT VERTICAL

8,3 X 25,4 CM (3-1/4 X 10 PO.)

CONDUIT HORIZONTAL

(armoires à dessous

8,3 X 25,4 CM (3-1/4 X 10 PO.)

encastré seulement)

AVANT DE L’ARMOIRE

0,3 cm (1/8 po.)

1,9 cm (3/4 po.)

PRÉPARATION DE LA HOTTE

COUVERCLE

DU FOND

FILTRES EN

ALUMINIUM

COUVERCLE

DU BOÎTIER DE

CÂBLAGE

3 Enlevez les filtres en aluminium, le couvercle du fond et le

couvercle du boîtier de câblage de la hotte.

POSITION D’ÉVACUATION VERTICALE

9,8 cm

(3-7/8 po.)

DESSOUS

DE L’ARMOIRE

35,4 cm

(1315/16 po.) (hotte de 30 po.)

43,0 cm

(1615/16 po.) (hotte de 36 po.)

CONDUIT HORIZONTAL

15,8 cm

(6-1/4 po.)

(4) VIS DE

MONTAGE

DE LA HOTTE

TROU POUR

15,8 cm

(6-1/4 po.)

35,4 cm

43,0 cm

19 cm

(7-1/2 po.)

(

1315/16 po.) (hotte de 30 po.)

(

1615/16 po.) (hotte de 36 po.)

TROU POUR FIL

LIGNE DE

D’ALIMENTATION

CENTRE

ÉLECTRIQUE

(dans le mur)

TIGE DE

MONTAGE DU

VENTILATEUR

(2)

VENTILATEUR

ÉCROU MOLETÉ (2)

POSITION D’ÉVACUATION HORIZONTALE

TIGE DE

MONTAGE DU

VENTILATEUR (2)

VENTILATEUR

ÉCROU MOLETÉ (2)

4 Le ventilateur est livré en position d’évacuation verticale.

Pour placer le ventilateur en position d’évacuation horizontale :

Enlevez les écrous moletés des tiges de montage du ventilateur.

Dégagez les tiges de montage du ventilateur et tournez celuici en position d’évacuation horizontale. Réengagez les tiges de

montage et fixez le ventilateur en place avec les écrous moletés

.

Page 9

SÉRIES AP1 ET RP

Page 9

CLAPET /

RACCORD DE

CONDUIT

OUVERTURE

PRÉAMORCÉE

VERTICALE

OUVERTURE PRÉAMORCÉE

HORIZONTALE

5 Enlevez l’ouverture préamorcée verticale ou l’ouverture

préamorcée horizontale et fixez le clapet / raccord de

conduit avec deux (2) vis (fournies).

INSTALLATION DE LA HOTTE

AVERTISSEMENT

Pour réduire les risques de choc électrique, coupez le courant

du panneau électrique. Verrouillez ou posez un sceau sur le

panneau afin d’éviter que le courant ne soit rétabli accidentellement.

RACCORD DU CÂBLAGE

VIS VERTE

DE MISE À

LA TERRE

FIL

D’ALIMENTATION

ÉLECTRIQUE

HE0059

9 Connectez le fil d’alimentation électrique à la hotte en raccor-

dant le fil NOIR au fil NOIR, le fil BLANC au fil BLANC, et le fil

VERT ou le FIL DÉNUDÉ à la vis VERTE de mise à la terre.

TERMINER L’INSTALLATION

10 Réinstallez le couvercle du boîtier de câblage, le couvercle du

fond et les filtres enlevés à l’étape 3.

VIS DE

MONTAGE (4)

CONDUITS

6 Acheminez le fil d’alimentation électrique du panneau élec-

trique jusqu’à l’emplacement de la hotte. Fixez le fil d’alimentation

à la hotte avec le connecteur approprié.

7 Maintenez la hotte en place sous l’armoire. Assurez-vous que le

clapet / raccord de conduit s’insère à l’intérieur du conduit et que

le clapet s’ouvre et se ferme librement.

8 Serrez complètement les quatre (4) vis de montage pour fixer la

hotte sous l’armoire.

FIL

D’ALIMENTATION

ÉLECTRIQUE

INSTALLATION DES AMPOULES

(1) POUSSER

(2) TOURNER

VERS LA DROITE

11 Installez les ampoules halogènes. Utilisez des ampoules

halogènes avec écran de 120 V, 50 W - MR16 ou PAR16 à culot

GU10. Les ampoules sont vendues séparément.

Page 10

SÉRIES AP1 ET RP

PIÈCES DE RECHANGE

REPÈRE N° DE PIÈCE. DESCRIPTION

1 97017222 Boîtier soudé - RP-Noir

97017223 Boîtier soudé - RP-Blanc

97017224 Boîtier soudé - RP-Argent

2 97017324 Boîtier soudé - AP-Noir

97017325 Boîtier soudé - AP-Blanc

97017326 Boîtier soudé - AP-Argent

3 97009517 Couvercle de fond - Noir

97007895 Couvercle de fond - Blanc

97007631 Couvercle de fond - Argent

4 97017429 Ensemble de clapet

5 97007656 Ensemble de couvercle de câblage

6 97017428 Ensemble de support de thermostat

7 98006546 Couvercle de douille de lumière

8 99400084 Manchon, butée fendue, n° 2873

9 99271346 Ensemble de douille/contour

10 97017312 Commande - RP, Noire

97017264 Commande - RP, Blanche

11 99111379 Cale .50 x .375 po. en nylon

12 97017455 Filtre, aluminium (qté 2)

97017456 Filtre, aluminium avec protection

antimicrobien (qté 2)

13 99420464 Tige de montage

14 99150617 Vis à tôle à tête bombée

n° 8-18 x 0,375 po.*

15 99170245 Vis à tôle cruciforme à tête

hexagonale n° 8-18 x 0,375 po.*

16 99260476 Écrou de montag

17 97007313 Boîtier du ventilateur

18 99100491 Manchon isolant du moteur

19 98005212 Anneau de retenue du moteur

20 99080597 Moteur

21 99020142 Roue à ailettes, sens horaire

22 99020143 Roue à ailettes, sens antihoraire

23 99400055 Manchon, butée fendue

24 99500323 Mousse en PVC

25 98010342 Anneau, entrée

26 99260491 Écrou hexagonal 3/8 po. - 32

27 99260470 Écrou hexagonal 15/32 po. - 32

28 600348 Bouton - Noir

600349 Bouton - Blanc

29 97016970 Interrupteur - Noir

97016971 Interrupteur - Blanc

30 99260485 Écrou à tôle, Type U

** 99400052 Bride de cordon (non illustré)

NSP,

** 99770113 Socle de câblage ** 99770115 Socle de câblage - AP

** 99030132 Commande rotatoire de ventilateur

** 97016439 Commande rotatoire de lumière

* Quincaillerie ordinaire vendue séparément.

** Non illustré.

Veuillez commander les pièces par N° DE PIÈCE et non par N° DE REPÈRE.

Les pièces de rechange peuvent être commandées sur notre site Web.

Visitez www.broan.com.

RP

16

12

25

13

22

15

4

14

GARANTIE

Broan-NuTone garantit à l’acheteur consommateur original de ses produits qu’ils sont exempts de

vice de matériaux ou de fabrication pour une période d’un an à compter de la date d’achat original. IL

N’Y A PAS D’AUTRES GARANTIES, EXPRIMÉES OU IMPLICITES, INCLUANT MAIS NON LIMITÉES

AUX GARANTIES IMPLICITES DE QUALITÉ MARCHANDE ET DE CONVENANCE DANS UN BUT

PARTICULIER.

Durant cette période d’un an, Broan-NuTone, à sa discrétion, réparera ou remplacera gratuitement

tout produit ou pièce qui s’avèrera défectueux et ayant été utilisé normalement et d’une manière non

abusive.

CETTE GARANTIE NE S’APPLIQUE PAS AUX TUBES FLUORESCENTS ET AUX DÉMARREURS, NI AUX

AMPOULES HALOGÈNES OU INCANDESCENTES, FUSIBLES, FILTRES, CONDUITS, CAPUCHONS DE

TOIT, CAPUCHONS MURAUX ET AUTRES ACCESSOIRES POUR CONDUITS. Cette garantie ne couvre

pas (a) l’entretien et le service normal ou (b) tout produit ou pièce endommagé à la suite d’un mauvais

usage, d’une négligence, d’un accident, d’un entretien inadéquat ou d’une réparation (autre que par

Broan-NuTone), d’une mauvaise installation ou d’une installation non conforme au mode d’installation

recommandé.

La durée de toute garantie implicite est limitée à une période de un an

exprimée. Certains États ou provinces ne permettent pas de limitation de la durée d’une garantie

implicite. Cette condition ne s’applique donc peut-être pas dans votre cas.

L’ENGAGEMENT DE BROAN-NUTONE À RÉPARER OU À REMPLACER, AU CHOIX DE BROANNUTONE, SERA LA SEULE OBLIGATION EXCLUSIVE SOUS CETTE GARANTIE. BROAN-NUTONE NE

SE TIENDRA PAS RESPONSABLE DES DOMMAGES DIRECTS, INDIRECTS OU SPÉCIAUX AYA NT

UN LIEN DIRECT OU INDIRECT AVEC L’UTILISATION OU LA PERFORMANCE DE SES PRODUITS.

Certains États ou provinces ne permettent pas l’exclusion ou la limitation de dommages directs ou

indirects. Cette condition ne s’applique donc peut-être pas dans votre cas.

Cette garantie vous donne des droits spécifiques et il se peut que vous ayez d’autres droits qui varient

d’une province à l’autre ou d’un État à l’autre. Cette garantie annule toutes les garanties précédentes.

Pour le service sous garantie, vous devez (a) aviser Broan-NuTone à l’adresse ou numéro de téléphone

mentionnée ci-dessous, (b) donner le numéro de modèle et l’identification de la pièce et (c) décrire la

nature de tout défaut dans le produit ou la pièce. Au moment de la demande de service sous garantie,

vous devez présenter une preuve de la date d’achat original du

Broan-NuTone LLC, 926 W. State Street, Hartford, Wisconsin 53027

www.broan.com 800-558-1711

Broan-NuTone Canada, Inc., 1140 Tristar Drive, Mississauga, Ontario L5T 1H9

www.broan.ca 877-896-1119

11

27

29

19

18

GARANTIE LIMITÉE DE UN AN DE BROAN-NUTONE

20

30

28

17

10

21

2

3

24

1

24

26

9

25

13

produit en

Page 10

23

6

15

5

16

spécifié pour la garantie

tel que

question.

7

8

12

Page 11

SERIE AP1 Y RP

CAMPANA DE COCINA

ESTILO PROFESIONAL

LEA Y CONSERVE ESTAS INSTRUCCIONES

SOLAMENTE PARA COCINAR EN CASA

Página 11

ADVERTENCIA

PARA REDUCIR EL RIESGO DE INCENDIOS, DESCARGAS

ELÉCTRICAS O LESIONES PERSONALES, OBSERVE LAS

SIGUIENTES PRECAUCIONES:

1. Use la unidad sólo de la manera indicada por el fabricante. Si tiene

preguntas, comuníquese con el fabricante a la dirección o al número

telefónico que se incluye en la garantía.

2. Antes de dar servicio a la unidad o de limpiarla, interrumpa el

suministro eléctrico al panel de servicio. Bloquee el panel de servicio

o póngale una etiqueta de seguridad para evitar que alguien conecte

accidentalmente la energía eléctrica.

3. El trabajo de instalación y cableado eléctrico (incluida la ubicación

del interruptor) debe ser realizado por personal calificado y de

conformidad con todos los códigos y normas correspondientes,

incluidos los de construcción específicos contra incendios.

4. Proporcione suficiente aire para que se lleve a cabo la combustión

y escape adecuados de los gases a través del tubo de humos

(chimenea) del equipo quemador de combustible, a fin de evitar

el contratiro. Siga las normas de los equipos de combustión tales

como las establecidas en los códigos locales y las publicadas por

la Asociación Nacional de Protección contra Incendios (National

Fire Protection Association, NFPA) y la Sociedad Americana de

Ingenieros de Calefacción, Refrigeración y Aire Acondicionado

(American Society for Heating, Refrigeration and Air Conditioning

Engineers, ASHRAE).

5. Este producto podría tener bordes afilados. Trabaje con cuidado

evitar cortadas y abrasiones durante la instalación y la limpieza.

6. Al cortar o perforar a través de la pared o del cielo raso, tenga

cuidado de no dañar el cableado eléctrico ni otros servicios ocultos.

7. Los ventiladores con conductos siempre deben conectarse hacia el

exterior.

8. Utilice únicamente conductos metálicos.

9. Como alternativa, se puede instalar este producto con el juego de

cable de alimentación aprobado por UL y diseñado para el producto,

siguiendo las instrucciones incluidas con el cable.

10. Esta unidad debe conectarse a tierra.

PARA REDUCIR EL RIESGO DE INCENDIO PROVOCADO

POR GRASA PRESENTE EN LA ESTUFA:

1. Nunca deje desatendidas las unidades de la superficie cuando

estén en ajustes altos de calor. Los alimentos en ebullición provocan

derrames grasosos y con humo que se pueden inflamar. Caliente el

aceite lentamente en ajustes de calor bajo o medio.

2. Siempre ENCIENDA la campana cuando esté cocinando a altas

temperaturas o flamee alimentos (por ejemplo crepas Suzette,

cerezas Jubilee, bistec con pimienta flameado).

3. Limpie frecuentemente los ventiladores. No se debe permitir la

acumulación de grasa en el ventilador ni en el filtro.

4. Use una cacerola del tamaño adecuado. Siempre use utensilios

de cocina que sean apropiados para el tamaño del elemento de la

superficie.

par

a

ADVERTENCIA

PARA REDUCIR EL RIESGO DE LESIONES A LAS

PERSONAS EN CASO DE UN INCENDIO PRODUCIDO POR

GRASA EN UNA ESTUFA, OBSERVE LO SIGUIENTE*:

1. APAGUE LAS LLAMAS con una tapa de ajuste exacto, una charola

para galletas o una bandeja de metal, y después apague el quemador.

PROCEDA CON CUIDADO PARA EVITAR QUEMADURAS. Si las

llamas no se apagan inmediatamente, EVACUE EL ÁREA Y LLAME

A LOS BOMBEROS.

2. NUNCA LEVANTE UNA CACEROLA INCENDIADA porque podría

sufrir quemaduras o propagar el incendio.

3. NO TRATE DE APAGAR EL FUEGO CON AGUA ni con trapos o

toallas de cocina mojados, pues ocasionará una explosión violenta

de vapor.

4. Use un extintor SÓLO si:

A. El extintor es de Clase ABC y usted sabe cómo hacerlo funcionar.

B. El incendio es pequeño y está confinado al área en la que se

inició.

C. Va a llamar al Departamento de Bomberos.

D. Puede combatir el incendio teniendo la espalda orientada hacia

una salida.

* Basado en “Kitchen Fire Safety Tips” (Sugerencias para la seguridad

contra incendios en la cocina) publicado por NFPA.

PRECAUCIÓN

1. Pa ra el uso de interior solamente.

2. Sólo para usarse como medio de ventilación general. No debe

usarse para la extracción de materiales ni vapores peligrosos o

explosivos.

3. Para capturar mejor las impurezas resultantes al cocinar, debe

montar la parte inferior de la campana a una altura de 18 a 24 pulg.

(46 a 61 cm) sobre la

4.

Lea la información y los requisitos que aparecen en la etiqueta de

especificaciones.

NOTA Estas instrucciones son solamente para

Si la campana se va a instalar en un sistema sin conductos:

Compre un juego de filtros sin conductos con su distribuidor

o tienda minorista local. (Disponible para campanas de

la serie AP1 y RP2 solamente.) Siga las instrucciones

incluidas con este juego de filtros.

Registre su producto en línea en: www.broan.com/register

instalaciones con conductos.

superficie para cocinar.

Aviso al instalador: Deje este manual con el dueño de la casa.

Aviso al dueño de la casa: En la página 12 encontrará las instrucciones de limpieza,

mantenimiento y funcionamiento.

Page 12

SERIE AP1 Y RP

Página 12

LIMPIEZA Y MANTENIMIENTO

Por motivos de desempeño, apariencia y salud, limpie el filtro, el ventilador

y las superficies que tengan grasa. Utilice únicamente un trapo limpio

y una solución de detergente suave en superficies de acero inoxidable

y pintadas. Limpie los filtros completamente metálicos en el lavaplatos.

El motor está permanentemente lubricado y nunca necesitará aceite.

Si los cojinetes del motor están haciendo ruido excesivo o inusual,

reemplace el motor con el motor de servicio exacto. También debe

reemplazar el impulsor.

Utilice bombillasde halógeno con escudo protector de 120 V, 50 W (MR16

o PAR16 con base GU10). Las bombillas se compran por separado.

Los filtros de grasa, el panel inferior y el disco del ventilador deben

limpiarse con frecuencia con una solución tibia de detergente y agua. Los

filtros de grasa y el disco del ventilador pueden lavarse en un lavaplatos.

Nota: Ciertos minerales causan la decoloración de los filtros

al ponerse en contacto con los aditivos de los detergentes

lavaplatos. Esta decoloración no está cubierta por la garantía.

FUNCIONAMIENTO

ENCIENDA siempre la campana antes de comenzar a cocinar, a fin de

establecer un flujo de aire en la cocina. Después de apagar la estufa,

deje que la campana funcione durante unos cuantos minutos para

despejar el aire.

Termostato HEAT SENTRY™

La campana está equipada con un termostato Heat Sentry™. Este

dispositivo de seguridad encenderá el ventilador o aumentará su velocidad

si detecta un calor excesivo sobre la superficie de cocinado.

Si el ventilador no está encendido o si funciona a baja velocidad, el

termostato Heat Sentry™ anulará el control que tenga el ventilador y

lo hará funcionar a alta velocidad. Cuando la temperatura disminuye a

niveles normales, el ventilador regresa a su ajuste original.

CAMPANA SERIE RP

Para hacer funcionar la campana, haga lo siguiente:

CAMPANA SERIE AP

Para hacer funcionar la campana, haga lo siguiente:

FAN

ON OFF

LIGHTFAN

VENTILADOR

El interruptor de 2 posiciones (en el centro) ENCIENDE y APAGA el

ventilador.

El interruptor de 5 posiciones (a la izquierda) controla la velocidad del

ventilador.

El ventilador está APAGADO (el ventilador secundario está APAGADO).

El ventilador está ENCENDIDO a su máxima velocidad.

Mientras más pequeños sean los puntos, menor será la velocidad

del ventilador.

LUCES

Este interruptor de 3 posiciones (a la derecha) ENCIENDE y A PAGA las

luces y controla su intensidad.

Las luces están APAGADAS.

Las luces están ENCENDIDAS con baja intensidad.

Las luces están ENCENDIDAS con alta intensidad.

PREPARE EL LUGAR DONDE

SE VA A INSTALAR LA CAMPANA

TAPÓN DE TECHO

CONDUCTO DE

3 ¼ pulg. x 10 pulg.

(8,3 x 25,4 cm)

(para descarga vertical)

INTERRUPTOR DEL VENTILADOR

Este interruptor de 3 posiciones ENCIENDE y A PAGA el ventilador y

controla su velocidad.

Ponga el interruptor en la posición (1) para ENCENDER el ventilador a

baja velocidad.

Ponga el interruptor en la posición (2) para ENCENDER el ventilador a

alta velocidad.

Ponga el interruptor en la posición (0) para APAGAR el ventilador.

INTERRUPTOR DE LUZ

Este interruptor de 3 posiciones ENCIENDE y APAGA las luces y controla

su intensidad.

Ponga el interruptor en la posición (1) para ENCENDER las luces a baja

intensidad.

Ponga el interruptor en la posición (2) para ENCENDER las luces a alta

intensidad.

Ponga el interruptor en la posición (0) para APAGAR las luces.

PLAFÓN

GABINETE

CAMPANACAMPANA

DE 46 cm a 61 cm (18 a 24 pulg.)

SOBRE LA SUPERFICIE PARA

COCINAR

CABLEADO

ELÉCTRICO

DOMÉSTICO

(parte superior o

posterior de la

campana)

TAPÓN DE

PARED

CONDUCTO DE

3 ¼ pulg. x 10 pulg.

(8,3 x 25,4 cm )

(para descarga

horizontal)

1 Determine si la descarga de la campana va a ser vertical o

horizontal. Para descarga vertical u horizontal, coloque la red

de conductos entre el lugar donde va a instalar la campana y

el tapón de techo o tapón de pared. Para obtener los mejores

resultados, utilice una cantidad mínima de transiciones y codos.

Page 13

SERIE AP1 Y RP

TORNILLOS DE MONTAJE DE LA CAMPANA (4)

FONDO DEL

GABINETE

ORIFICIO DE ACCESO

PARA CONDUCTO VERTICAL

1315/16 pulg.

(35,4 cm )

(campana de 30 pulg.)

1615/16 pulg.

(43,0 cm)

(campana de 36 pulg.)

FRENTE DEL GABINETE

6 ⅞ pulg.

(17,5 cm)

10 ⅝ pulg.

(27 cm)

6 ¼ pulg.

(15,8 cm )

6 ¼ pulg.

(15,8 cm )

7 ½ pulg

(19 cm)

9 ⅞ pulg.

(25,1 cm)

1 ½ pulg.

(3,8 cm)

CUÑAS DE MADERA

(sólo gabinetes de

fondo empotrado)

ORIFICIO DE ACCESO

PARA CABLES

ELÉCTRICOS

(en el fondo del gabinete)

LÍNEA

CENTRAL

9 pulg.

(22,8 cm)

1315/16 pulg.

(35,4 cm )

(campana de 30 pulg.)

1615/16 pulg.

(43,0 cm)

(campana de 36 pulg.)

Página 13

2 Guíese por el diagrama correspondiente (a continuación) para

colocar los conductos y hacer el corte exacto para la conexión

eléctrica en el gabinete o en la pared. Para instalaciones en

sistemas sin conductos, NO haga ningún orificio de acceso para

conducto.

CONDUCTO VERTICAL DE

3 ¼ PULG. X 10 PULG. (8,3 X 25,4 CM)

CONDUCTO HORIZONTAL DE

3 ¼ PULG. X 10 PULG. (98,3 X 25,4 CM)

CUÑAS DE MADERA

(sólo gabinetes de

fondo empotrado)

3 ⅞ pulg.

(9,8 cm)

FONDO

DEL GABINETE

1315/16 pulg. (35,4 cm )

(campana de 30 pulg.)

1615/16 pulg. (43,0 cm)

(campana de 36 pulg.)

TORNILLOS DE

MONTAJE DE LA

CAMPANA (4)

FRENTE DEL

GABINETE

ORIFICIO DE ACCESO

PARA CONDUCTO HORIZONTAL

6 ¼ pulg.

(15,8 cm)

LÍNEA

CENTRAL

6 ¼ pulg.

(15,8 cm)

1315/16 pulg. (35,4 cm )

(campana de 30 pulg.)

1615/16 pulg.

(campana de 36 pulg.)

3/4 pulg.

(1,9 cm)

⅛ pulg.

(0,3 cm)

7½ pulg.

(19 cm)

(43,0 cm)

ORIFICIO DE

ACCESO PARA

CABLES ELÉCTRICOS

(en la pared)

PREPARE LA CAMPANA

CUBIERTA

INFERIOR

FILTROS DE

ALUMINIO

CUBIERTA

DEL

CABLEADO

3 Quite de la campana los filtros de aluminio, la cubierta inferior

y la cubierta del cableado.

POSICIÓN DE DESCARGA VERTICAL

VARILLA DE

MONTAJE DEL

VENTILADOR

(2)

VENTILADOR

TUERCA

MOLETEADA (2)

POSICIÓN DE DESCARGA HORIZONTAL

VENTILADOR

MOLETEADA (2)

4 El ventilador se envía en la posición de descarga vertical.

Para cambiar el ventilador a la posición de descarga horizontal:

Retire las tuercas moleteadas de las varillas de montaje del

ventilador. Desenganche las varillas de montaje del ventilador

y gire éste a la posición de descarga horizontal. Enganche de

nuevo las varillas de montaje y apriete el ventilador en su lugar

con las tuercas moleteadas.

VARILLA DE

MONTAJE DEL

VENTILADOR

(2)

TUERCA

Page 14

SERIE AP1 Y RP

Página 14

CONECTOR DEL

REGULADOR DE

TIRO/CONDUCTO

AGUJERO CIEGO DEL

CONDUCTO VERTICAL

AGUJERO CIEGO DEL

CONDUCTO HORIZONTAL

5 Abra el agujero ciego del conducto vertical o el agujero

ciego del conducto horizontal y fije el conector del

regulador de tiro/conducto con dos (2) tornillos (incluidos).

INSTALE LA CAMPANA

CONECTE EL CABLEADO

TORNILLO

VERDE DE

CONEXIÓN

A TIERRA

CABLE

ELÉCTRICO

DE LA

CASA

HE0059

9 Conecte el cable eléctrico de la casa al cableado de la campa-

na de cocina: cable NEGRO con NEGRO, BLANCO con BLANCO y VERDE o SIN FORRO al tornillo de tierra VERDE.

FINALICE LA INSTALACIÓN

ADVERTENCIA

Para reducir el riesgo de una descarga eléctrica, desconecte

6 Tienda el cable eléctrico de la casa entre el panel de servicio

7 Sostenga la campana en su posición debajo del gabinete.

8 Apriete completamente los cuatro (4) tornillos de montaje para

el suministro eléctrico al panel de servicio. Bloquee el panel

de servicio o póngale una etiqueta de seguridad para evitar

que alguien conecte accidentalmente la energía eléctrica.

TORNILLOS DE

MONTAJE (4)

CONDUCTO

y la campana. Conecte el cable eléctrico a la campana con un

conector apropiado.

Asegúrese de que el conector del regulador de tiro/conducto entre a los conductos y que el regulador de tiro pueda abrirse y

cerrarse libremente.

afianzar la campana al gabinete.

CABLE

ELÉCTRICO

DE LA CASA

10 Instale nuevamente la cubierta para cableado, la cubierta inferior

y los filtros que quitó en el paso 3.

INSTALE LAS BOMBILLAS

(1) EMPUJAR HACIA ADENTRO

(2) GIRAR EN

SENTIDO DE

LAS AGUJAS

DEL RELOJ

11 Instale las bombillas de halógeno. Utilice bombillas de

halógeno con escudo protector de 120 V, 50 W (MR16 o PAR16

con base GU10). Las bombillas se compran por separado.

Page 15

PIEZAS DE REPUESTO

SERIE AP1 Y RP

Página 15

CLAVE N.O

PIEZA N.° DESCRIPCIÓN

1 97017222 Conjunto soldado del panel de funciones -

RP - Negro

97017223 Conjunto soldado del panel de funciones -

RP - Blanco

97017224 Conjunto soldado del panel de funciones -

RP - Plata

2 97017324 Conjunto soldado del panel de funciones -

AP - Negro

97017325 Conjunto soldado del panel de funciones -

AP - Blanco

97017326 Conjunto soldado del panel de funciones -

AP - Plata

3 97009517 Cubierta inferior - Negra

97007895 Cubierta inferior - Blanca

97007631 Cubierta inferior - Plata

4 97017429 Conjunto del regulador de tiro

5 97007656 Conjunto de la cubierta para los cables

6 97017428 Conjunto del soporte para el termostato

7 98006546 Cubierta del portalámpara

8 99400084 Separador de casquillo Heyco N.° 2873

9 99271346 Conjunto de aro portalámpara/moldura

10 97017312 Control - RP - Negro

97017264 Control - RP - Blanco

11 99111379 Separador de 0,50 x 0,375 pulg. de nailon

12 97017455 Filtro de aluminio (cant. 2)

97017456 Filtro de aluminio con protección

antimicrobiana (cant. 2)

13 99420464 Varilla de montaje del ventilador

14 99150617 Tornillo metálico cabeza redonda

8-18 x 0,375 pulg. *

15 99170245 Tornillo metálico Phillips cabeza hexagonal

8-18 x 0,375 pulg.*

16 99260476 Tuerca para varilla de montaje del ventilador

17 97007313 Caja de la espiral del ventilador

18 99100491 Buje para aislamiento del motor

19 98005212 Anillo retenedor del motor

20 99080597 Motor

21 99020142 Disco del ventilador, giro a la derecha

22 99020143 Disco del ventilador, giro a la izquierda

23 99400055 Buje de cierre Heyco

24 99500323 Espuma de PVC

25 98010342 Aro, entrada

26 99260491 Tuerca hexagonal, 3/8 pulg. - 32

27 99260470 Tuerca hexagonal, 15/32 pulg. - 32

28 600348 Perilla - Negra

600349 Perilla - Blanca

29 97016970 Perilla - Negra

97016971 Interruptor - Blanco

30 99260485 Tuerca metálica tipo U

** 99400052 Buje de alivio de esfuerzo (no se ilustra)

** 99770113 Mazo de cables - NSP, RP

** 99770115 Mazo de cables - AP

** 99030132 Control rotatorio del ventilador

** 97016439 Control rotatorio de la luz

* Tornillería estándar: se puede comprar en una ferretería de la localidad.

** No se ilustra.

Al pedir piezas de repuesto, indique el N.° DE PIEZA, no el N.° DE CLAVE

Ahora se puede hacer los pedidos de las piezas de repuesto en nuestro sitio

Visítenos en www.broan.com.

web.

16

12

25

13

22

15

4

GARANTÍA

Broan-NuTone garantiza al consumidor comprador original de sus productos que dichos productos

carecerán de defectos en materiales o en mano de obra por un período de un año a partir de la fecha

original de compra. NO EXISTEN OTRAS GARANTIAS, EXPLICITAS O IMPLICITAS, INCLUYENDO,

PERO NO LIMITADAS A, GARANTIAS IMPLICITAS DE COMERCIALIZACION O APTITUD PARA UN

PROPOSITO PARTICULAR.

Durante el período de un año, y a su propio criterio, Broan-NuTone reparará o reemplazará, sin

costo alguno cualquier producto o pieza que se encuentre defectuosa bajo condiciones normales

de servicio y uso.

LA PRESENTE GARANTÍA NO CUBRE LOS TUBOS FLUORESCENTES NI SUS ARRANCADORES,

BOMBILLAS DE HALÓGENO E INCANDESCENTES, FUSIBLES, FILTROS, CONDUCTOS, TAPONES

DE TECHO O PAREDES Y DEMÁS ACCESORIOS PARA CONDUCTOS. Esta garantía no cubre (a)

mantenimiento y servicio normales o (b) cualquier producto o piezas que hayan sido utilizadas de

forma errónea, negligente, que hayan causado un accidente,

das inapropiadamente (por otras compañías que no sean Broan-NuTone), instalación defectuosa, o

instalación contraria a las instrucciones de instalación recomendadas.

La duración de cualquier garantía implícita se limita a un período de un año como se especifica en

la garantía expresa. Algunos estados no permiten limitaciones en cuanto al tiempo de expiración

de una garantía implícita, por lo que la limitación antes mencionada puede no aplicarse a usted.

LA OBLIGACION DE BROAN-NUTONE DE REPARAR O REEMPLAZAR, SIGUIENDO EL CRITERIO

DE BROAN-NUTONE, DEBERA SER EL UNICO Y EXCLUSIVO RECURSO LEGAL DEL COMPRADOR

BAJO ESTA GARANTIA. BROAN-NUTONE NO SERA RESPONSABLE POR DAÑOS INCIDENTALES,

CONSIGUIENTES, O POR DAÑOS ESPECIALES QUE SURJAN A RAIZ DEL USO O DESEMPEÑO

DEL PRODUCTO. Algunos estados no permiten la exclusión o limitación de daños incidentales o

consiguientes, por lo que la limitación antes mencionada puede no aplicarse a usted.

Esta garantía le proporciona derechos legales específicos, y usted puede también tener otros derechos, los cuales varían de estado a estado. Esta garantía reemplaza todas las garantías anteriores.

Para calificar en la garantía de servicio, usted debe (a) notificar a Broan-NuTone al domicilio o al

número de teléfono que se menciona abajo, (b)

y (c) describir la naturaleza de cualquier defecto en el producto o pieza. En el momento de solicitar

servicio cubierto por la garantía, usted debe de presentar evidencia de la fecha original de compra.

Broan-NuTone LLC, 926 W. State Street, Hartford, Wisconsin 53027

www.broan.com 800-558-1711

Broan-NuTone Canada, Inc., 1140 Tristar Drive, Mississauga, Ontario L5T 1H9

www.broan.ca 877-896-1119

11

27

28

30

17

dar el

número del modelo y la identificación de la pieza,

29

19

18

14

GARANTIA BROAN-NUTONE LIMITADA POR UN AÑO

20

24

1

10

24

26

2

9

23

21

25

13

3

hayan sido reparadas o manteni-

o que

6

15

7

8

12

5

16

Page 16

SERIE AP1 Y RP

Página 16

99044040J

Loading...

Loading...