WWW.BROAN.COM

WWW.BROAN.CA

RANGE HOOD

Series: ALT1 and ALT2

INSTALLATION, USE

AND CARE MANUAL

Serial number:

99046182A

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Cleaning and Maintenance . . . . . . . . . . . . . . . . . 6

Motor

Grease Filters

Non-Ducted Recirculation Filters

Fan Blade

Stainless Steel Cleaning

Painted Finish Cleaning

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-20

Recommended Tools

and Accessories for Installation . . . . . . . . . . . . 7

Install Ductwork (Ducted Installations Only) . . . 7

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Prepare the Hood . . . . . . . . . . . . . . . . . . . . . . . 9-11

Prepare the Hood Location . . . . . . . . . . . . . . . . 12

EZ1 one-person Installation . . . . . . . . . . . . . . 12-14

Install the Hood (EZ1 Bracket) . . . . . . . . . . . . 15-16

Standard Installation . . . . . . . . . . . . . . . . . . . 17

Install the Hood (Standard Installation) . . . . . 18

Connect the Wiring . . . . . . . . . . . . . . . . . . . . . . 19

Light Bulbs (ALT1 Series only) . . . . . . . . . . . . . 20

Install the Filters . . . . . . . . . . . . . . . . . . . . . . . . 20

Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . 21

Service Parts . . . . . . . . . . . . . . . . . . . . . . . . . 22-23

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

INSTALLATION MANUAL

TABLE OF CONTENTS

2

READ AND SAVE THESE INSTRUCTIONS

!

Intended for domestic cooking only

!

INSTALLER: LEAVE THIS MANUAL WITH HOMEOWNER.

In U.S.A., register your range hood online at www.broan.com

In Canada, register your range hood online at www.broan.ca

!

WARNING

TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK, OR INJURY TO

PERSONS, OBSERVE THE FOLLOWING:

• Use this unit only in the manner intended by the manufacturer. If you have

questions, contact the manufacturer at the address or telephone number

listed in the warranty.

• Before servicing or cleaning unit, switch power off at service panel and

lock the service disconnecting means to prevent power from being

switched on accidentally. When the service disconnecting means cannot

be locked, securely fasten a prominent warning device, such as a tag, to

the service panel.

• Installation work and electrical wiring must be done by a qualified

person(s) in accordance with all applicable codes and standards, including

fire-rated construction.

• Sufficient air is needed for proper combustion and exhausting of

gases through the flue (chimney) of fuel burning equipment to prevent

backdrafting. Follow the heating equipment manufacturer’s guidelines and

safety standards such as those published by the National Fire Protection

Association (NFPA) and the American Society for Heating, Refrigeration

and Air Conditioning Engineers (ASHRAE) and the local code authorities.

• When cutting or drilling into wall or ceiling, do not

damage electrical wiring and other hidden utilities.

• Ducted fans must always be vented to the outdoors.

• Do not use this unit with any additional solid-state speed control device.

• To reduce the risk of fire, use only metal ductwork.

• This unit must be grounded.

• As an alternative, this product may be installed with the UL-approved cord

kit designated for the product, following instructions packed with the cord

kit.

• When applicable local regulations comprise more restrictive installation

and/or certification requirements, the aforementioned requirements prevail

on those of this document and the installer agrees to conform to these at

his own expense.

INSTALLATION MANUAL

SAFETY

3

!

WARNING

TO REDUCE THE RISK OF A RANGE TOP GREASE FIRE:

a) Never leave surface units unattended at high settings. Boilovers cause

smoking and greasy spillovers that may ignite. Heat oils slowly on low or

medium settings.

b) Always turn hood ON when cooking at high heat or when flambeing food

(i.e.: Crêpes Suzette, Cherries Jubilee, Peppercorn Beef Flambé).

c) Clean ventilating fan frequently. Grease should not be allowed to

accumulate on fan, filters or in exhaust ducts.

d) Use proper pan size. Always use cookware appropriate for the size of

the surface element.

TO REDUCE THE RISK OF INJURY TO PERSONS IN THE EVENT OF A

RANGE TOP GREASE FIRE, OBSERVE THE FOLLOWING*:

1. SMOTHER FLAMES with a close-fitting lid, cookie sheet or metal tray,

then turn off the burner. BE CAREFUL TO PREVENT BURNS. IF THE

FLAMES DO NOT GO OUT IMMEDIATELY, EVACUATE AND CALL

THE FIRE DEPARTMENT.

2. NEVER PICK UP A FLAMING PAN — You may be burned.

3. DO NOT USE WATER, including wet dishcloths or towels — This could

cause a violent steam explosion.

4. Use an extinguisher ONLY if:

A. You own a Class ABC extinguisher and you know how to operate it.

B. The fire is small and contained in the area where it started.

C. The fire department has been called.

D. You can fight the fire with your back to an exit.

* Based on “Kitchen Fire Safety Tips” published by NFPA.

INSTALLATION MANUAL

SAFETY

4

!

CAUTION

• For indoor use only.

• For general ventilating use only. Do not use to exhaust hazardous or explosive materials

and vapors.

• To avoid motor bearing damage and noisy and/or unbalanced fan blade, keep drywall

spray, construction dust, etc. off range hood.

• Your hood motor has a thermal overload which will automatically shut off the motor if it

becomes overheated. The motor will restart when it cools down. If the motor continues to

shut off and restart, have the hood serviced.

• For best capture of cooking fumes, the bottom of the hood MUST NOT BE LESS than 18”

and at a maximum of 24” above the cooking surface.

• Always follow the cooking equipment manufacturer’s requirements regarding the ventilation

needs.

• To reduce the risk of fire and to properly exhaust air, be sure to duct air outside — Do not

exhaust air into spaces within walls or ceiling or into attics, crawl space or garage.

• When installing, servicing or cleaning the unit, it is recommended to wear safety glasses

and gloves.

• Please read specification label on product for further information and requirements.

Operation

Always turn your hood on before you begin cooking to establish an air flow in the kitchen.

Let the blower run for a few minutes to clear the air after you turn off the range. This will help

keep the whole kitchen cleaner and fresher. Operate the hood as follows:

ALT2 SERIES

BLOWER BUTTON

When blower is OFF, press this button to turn ON the blower at the last saved speed. If there was

no speed saved, the blower will be set on LOW speed.

NOTE: When LOW speed is activated from OFF, the blower starts on MEDIUM speed for a very

short lapse of time, and then resume to LOW speed.

To change the blower speed, press on this button again until the desired speed is reached (from

LOW to MEDIUM to HIGH speed to OFF). Each time a blower speed is activated, a beep is heard

and LED indicators light up to show the corresponding speed chosen (lower LED for LOW speed,

lower and center LEDs for MEDIUM speed and all LEDs for HIGH speed).

When blower is on (no matter the speed level), press and hold this button until the beep sound

ends; this will turn off the blower and save this blower speed to memory.

LIGHT BUTTON

When lights are OFF, press once on this button to turn ON the lights at the last saved setting. If

there was no light setting saved, the lights will be set on LOW intensity. Press another time to set

the lights on HIGH intensity. Pressing another time after the HIGH setting will turn OFF the lights.

Each time the lights are turned ON, a beep is heard and LED indicators light up to show the

corresponding intensity chosen (lower LED for LOW and both LEDs for HIGH).

When lights are on (no matter the lighting level), press and hold this button until the beep sound

ends; this will turn off the lights and save the chosen light intensity.

The LED modules included with this hood are the latest in LED cooktop illumination technology

specially designed to operate in the elevated temperatures of cooking - offering bright lighting and

lasting up to 25 times as long as a standard bulb and greater reliability than typical replacement

LED bulbs.

FILTER CLEANING REMINDER

When it is time to clean the hood and filters (refer to Cleaning and Maintenance on page 6), the

3 blower button LED indicators will flash slowly for 30 seconds after turning the blower OFF. This will

happen every time the blower is turned OFF until the filter cleaning reminder has been reset. Once

the cleaning is done, reset the filter cleaning reminder indicators by pressing on blower button for

3 seconds during the 30 seconds the 3 blower button LED indicators flash slowly.

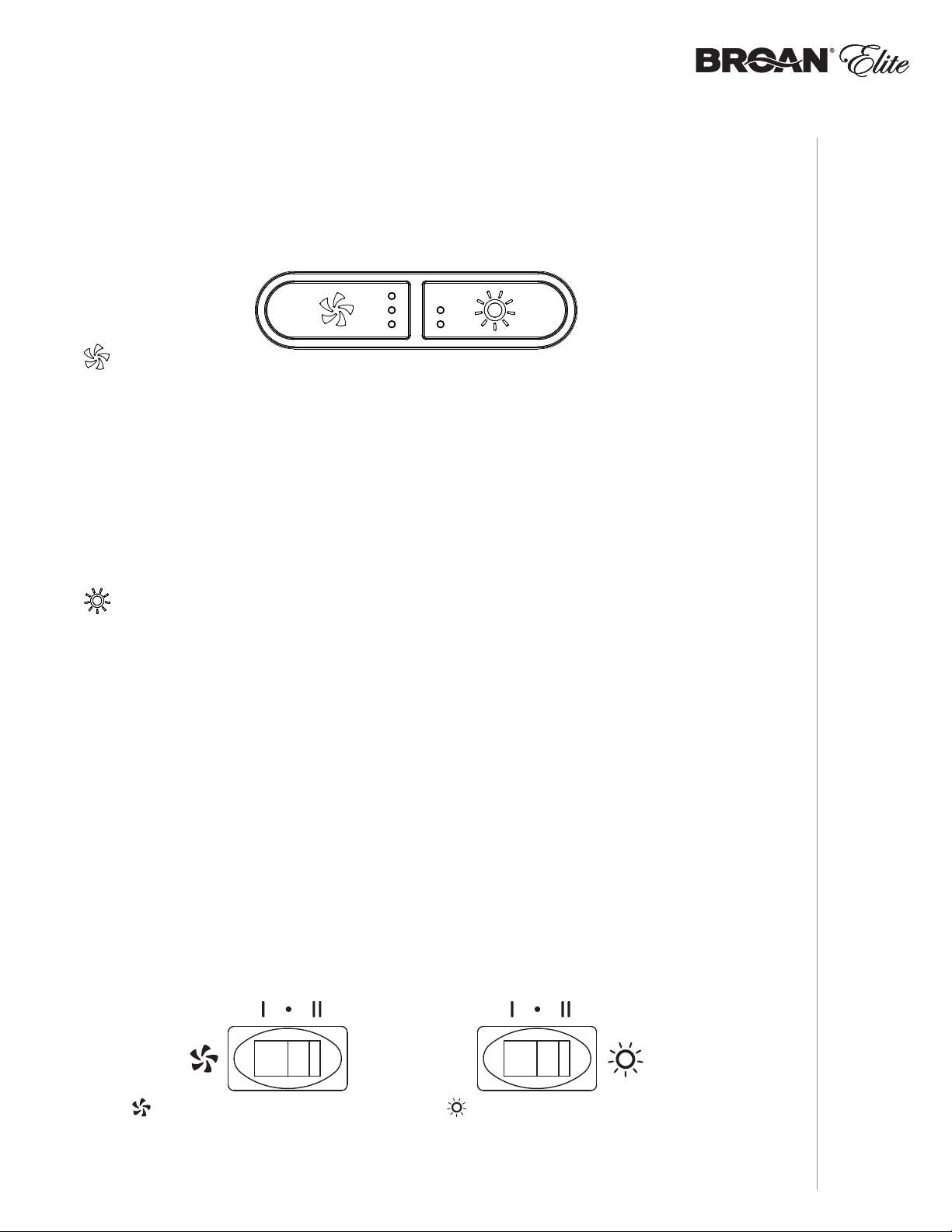

ALT1 SERIES

OPERATION

INSTALLATION MANUAL

BLOWER SWITCH

I Turns blower on to LOW speed.

• Turns blower OFF.

II Turns blower on to HIGH speed.

LIGHT SWITCH

I Turns light on in LOW intensity.

• Turns light OFF.

II Turns light on to HIGH intensity.

5

Cleaning and Maintenance

Proper maintenance of the Range Hood will assure proper performance of the unit.

MOTOR

The motor is permanently lubricated and never need oiling. If the motor bearings make excessive

or unusual noise, replace the motor with the exact service motor. The fan wheel should also be

replaced.

GREASE FILTERS

The grease filters should be cleaned frequently. Use a warm dishwashing detergent solution.

Grease filters are dishwasher safe.

Clean all-metal filters in the dishwasher using a non-phosphate detergent. Discoloration of the

filters may occur if using phosphate detergents, or as a result of local water conditions - but this

will not affect filter performance. This discoloration is not covered by the warranty. To minimize or

prevent discoloration, hand wash filters using a mild detergent.

NON-DUCTED RECIRCULATION FILTERS

The non-ducted recirculation filters should be changed every 3 to 6 months. Replace more often

if your cooking style generates extra grease, such as frying and wok cooking. Refer to installation

instructions included with non-ducted recirculation filters.

FAN BLADE

The fan blade should be cleaned frequently. Use a clean cloth soaked with warm detergent solution.

STAINLESS STEEL CLEANING

Do:

• Regularly wash with clean cloth or rag soaked with warm water and mild soap or liquid dish

detergent.

• Always clean in the direction of original polish lines.

• Always rinse well with clear water (2 or 3 times) after cleaning. Wipe dry completely.

• You may also use a specialized household stainless steel cleaner.

Don’t:

• Use any steel or stainless steel wool or any other scrapers to remove stubborn dirt.

• Use any harsh or abrasive cleansers.

• Allow dirt to accumulate.

• Let plaster dust or any other construction residues reach the hood. During construction/

renovation, cover the range hood to make sure no dust sticks to the stainless steel surface.

Avoid when choosing a detergent:

• Any cleaners that contain bleach will attack stainless steel.

• Any products containing: chloride, fl uoride, iodide, bromide will deteriorate surfaces

rapidly.

• Any combustible products used for cleaning such as acetone, alcohol, ether, benzol, etc.,

are highly explosive and should never be used close to a range.

PAINTED FINISH CLEANING:

INSTALLATION MANUAL

CLEANING AND MAINTENANCE

Clean with warm water and mild detergent only. If discoloration occurs, use a finish polish such

as automotive polish. (DO NOT use rough abrasive cleaner or porcelain cleaner.)

6

For ADA compliance installation guidelines, please visit www.broan.com

Recommended Tools and Accessories

for Installation

• Measuring tape

• Phillips screwdriver no. 2

• Flat blade screwdriver (to open knockout holes)

• Drill, 1/8” drill bit and 1½” hole saw (to mark holes for ducting and cut electrical access hole)

• 7/64” drill bit (to drill holes for EZ1 brackets mounting screws)

• Wood shims (2) and wood screws (4) (required for standard installation to framed cabinet)

• Saw (to cut holes for ducted application)

• Sheet metal shears (ducted installation only, for duct adjustment)

• Pliers (ducted installation only, for duct adjustment)

• Metal foil duct tape (for ducted applications)

• Scissors (to cut metal foil duct tape)

• Pencil

• Wire stripper

• Strain relief, 1/2” diameter (to secure house wiring cable to the hood)

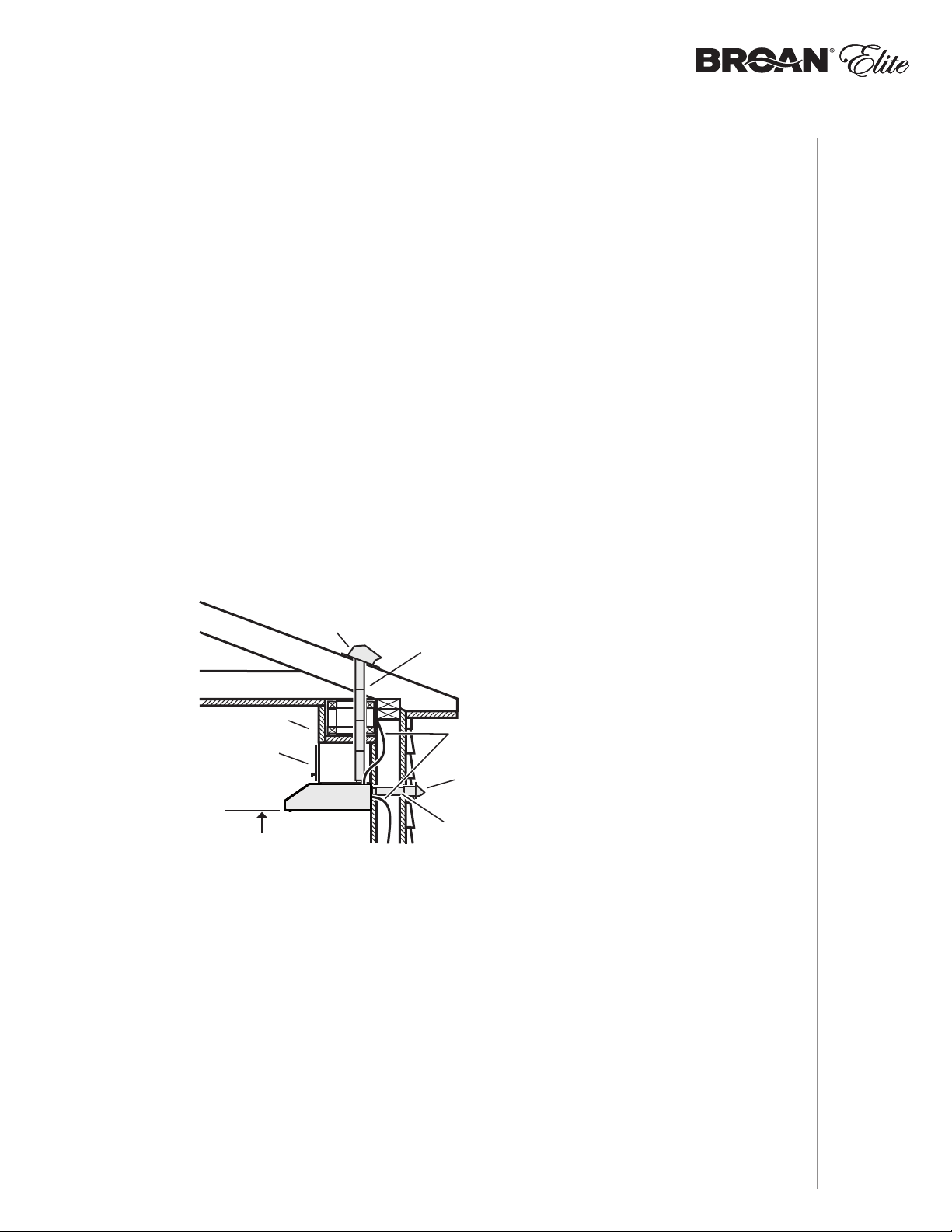

Install Ductwork (Ducted Installations Only)

ROOF CAP

SOFFIT

CABINET

HOOD

18" MIN - 24" MAX

ABOVE

COOKING SURFACE

NOTE: Distances over 24” are at the installer and user discretion.

1 ] Determine whether hood will discharge vertically (3¼” x 10” or 7” round),

or horizontally (3¼” x 10” only).

2 ] Decide where the ductwork will run between the hood and the outdoors.

3 ] Choose a straight, short duct run to allow the hood to perform most efficiently. Long duct

runs, elbows and transitions will reduce the performance of the hood. Use as few of them as

possible. When possible, use at least 2 foot straight runs before any turns. Larger ductwork

may be required for best performance with longer duct runs.

NOTE: To use 6” round ducting, install a 3¼” x 10” to 6” round transition (not included). The

performances may be affected.

4 ] Install wall cap or roof cap (sold separately); ensure there is no leak in house insulation.

Connect metal ductwork to cap and work back towards the hood location. Use 2” metal foil

duct tape to seal the joints between ductwork sections.

3¼" X 10" OR

7" ROUND DUCT

(FOR VERTICAL

DISCHARGE

HOUSE WIRING

(TOP OR BACK OF HOOD)

3¼" X 10" DUCT

(FOR HORIZONTAL DISCHARGE)

)

WALL CAP

INSTALLATION

INSTALLATION MANUAL

7

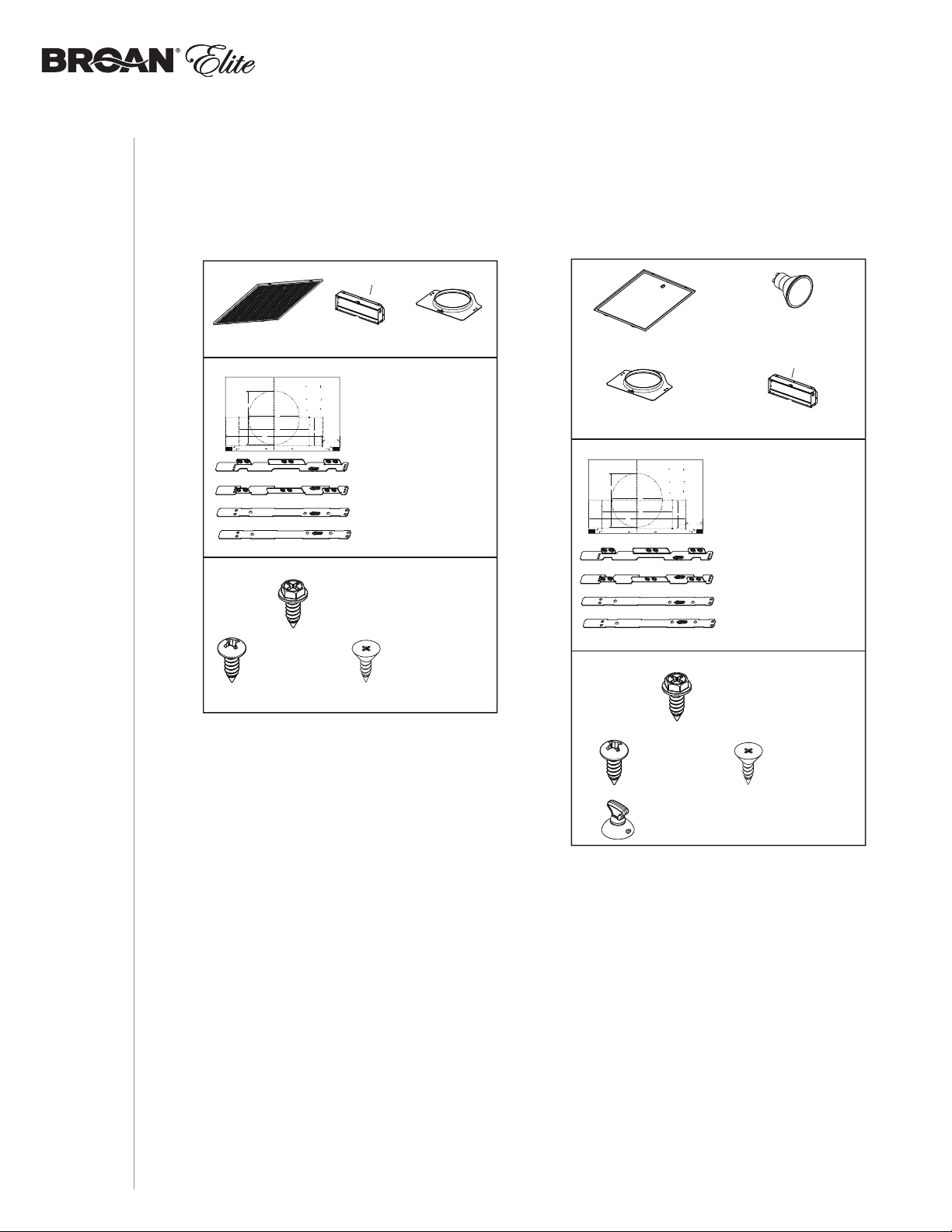

Contents

VERTICAL EXHAUST

VERTICAL EXHAUST

Before proceeding to the installation, check the contents of the box. If items are missing or

damaged, contact the manufacturer.

Make sure that the following items are included:

ALT2 Series ALT1 Series

* FIND INSIDE

HOOD

OF

(2) SHIELDED HALOGEN BULBS

(50W, GU10)

* FIND INSIDE OF HOOD

(1) 3¼” X 10”

D

AMPER ASSEMBLY*

(1) TEMPLATE FOR DUCTING

(PRINTED BOTH SIDES)

(2) INSTALLATION BRACKETS**

FOR FRAMED CABINET

Apoyar este borde contra la pared de atrásPlace this edge against back wall

EZ1 C

MARKWHEREINDICATED

FORTHEAPPROPRIATESIZE DUCTOPENING

OR

MARQUERLESREPÈRES AUX ENDROITS INDIQUÉS SELON

LEFORMATDECONDUIT UTILISÉ

OU

TITLETOBE TRANSLATED IN SPANISH

O

7 PULG.

DE

4¼”

D

RECTANGULAR DUCTING7” ROUND DUCTING

= 3¼” x 10”

= 3¼” x 14”

CONDUITRECTANGULAIRECONDUITRONDDE 7 PO

= 3¼ po x 10 po

= 3¼ po x 14 po

CONDUCTORECTANGULARCONDUCTOREDONDO

= 3¼ pulg. x 10 pulg.

= 3¼ pulg. x 14 pulg.

(1) 3¼”

AMPER ASSEMBLY*

OMPONENTS

Electrical access hole center

A = single blower hood

B = double blower hood

Centre du trou pour fil

d’alimentation électrique

A = hotte ventilateur simple

B = hotte ventilateur double

To be translated in Spanish

Electrical access hole center

A = single blower hood

B = double blower hood

AB

C

(2) GREASE FILTERS

Use this template for marking;do not attempt to cut out the ducting hole through it.

NOTE: These cutouts are clearance holes; they do not need to be the exact size of ducting.

Utiliser ce gabarit pour marquer vos repères;ne pas tenter de découper

le trou pour le conduit à travers le gabarit.

NOTE : Les découpes incluent le jeu nécessaire à l’installation; elles ne doivent pas

être du format exact des conduits.

Use esta plantilla para crear marcados;no trate de cortar el

agujero del conducto a través de la plantilla.

NOTA: To be translated in Spanish.

Bend template along graduated

scale when installing to framed

cabinet.

C

Pour une installation sous une

armoire à fond en retrait, utiliser les

lignes pour mesurer l’épaisseur du

décalage causé par le mur de

l’armoire et plier le gabarit en

8”

conséquence.

To be translated in Spanish.

C

L

7½”

10½”

14½”

C

Appuyer ce bord au mur arrière

** FIND EZ1 BRACKETS ATTACHED INSIDE OF HOOD

(1) PARTS BAG*** CONTAINING:

X 10”

(1) TEMPLATE FOR DUCTING

(PRINTED BOTH SIDES)

(2) INSTALLATION BRACKETS**

FOR FRAMED CABINET

(2) INSTALLATION BRACKETS**

FOR FRAMELESS CABINET

OUND

(1) 7” R

DUCT CONNECTOR

(2) GREASE FILTERS

(1) 7” R

DUCT CONNECTOR

Use this template for marking;do not attempt to cut out the ducting hole through it.

NOTE: These cutouts are clearance holes; they do not need to be the exact size of ducting.

Utiliser ce gabarit pour marquer vos repères;ne pas tenter de découper

le trou pour le conduit à travers le gabarit.

NOTE : Les découpes incluent le jeu nécessaire à l’installation; elles ne doivent pas

être du format exact des conduits.

Use esta plantilla para crear marcados;no trate de cortar el

agujero del conducto a través de la plantilla.

NOTA: To be translated in Spanish.

Bend template along graduated

scale when installing to framed

cabinet.

C

Pour une installation sous une

armoire à fond en retrait, utiliser les

lignes pour mesurer l’épaisseur du

décalage causé par le mur de

l’armoire et plier le gabarit en

8”

conséquence.

To be translated in Spanish.

C

L

7½”

10½”

14½”

C

Appuyer ce bord au mur arrière

OUND

Apoyar este borde contra la pared de atrásPlace this edge against back wall

MARKWHEREINDICATED

FORTHEAPPROPRIATESIZE DUCTOPENING

OR

MARQUERLESREPÈRES AUX ENDROITS INDIQUÉS SELON

LEFORMATDECONDUIT UTILISÉ

OU

TITLETOBE TRANSLATED IN SPANISH

O

DE

7 PULG.

4¼”

EZ1 C

RECTANGULAR DUCTING7” ROUND DUCTING

= 3¼” x 10”

= 3¼” x 14”

CONDUITRECTANGULAIRECONDUITRONDDE 7 PO

= 3¼ po x 10 po

= 3¼ po x 14 po

CONDUCTORECTANGULARCONDUCTOREDONDO

= 3¼ pulg. x 10 pulg.

= 3¼ pulg. x 14 pulg.

Electrical access hole center

A = single blower hood

B = double blower hood

Centre du trou pour fil

d’alimentation électrique

A = hotte ventilateur simple

B = hotte ventilateur double

To be translated in Spanish

Electrical access hole center

A = single blower hood

B = double blower hood

AB

C

OMPONENTS

(4) NO. 8-18 X 1/2”

M

ETAL SCREWS

O. 8 X 5/8”

(6) N

RD. HD.

W

OOD SCREWS

(6) NO. 8 X 1/2”

C

OUNTERSUNK

WOOD SCREWS

*** FIND PARTS BAG BEHIND THE DAMPER ASSEMBLY INSIDE OF HOOD

(2) INSTALLATION BRACKETS**

** FIND EZ1 BRACKETS

ATTACHED

(1) PARTS BAG*** CONTAINING:

(4) NO. 8-18 X 1/2”

M

ETAL SCREWS

(6) NO. 8 X 5/8”

RD. HD.

W

OOD SCREWS

(1) BULB SUCTION

CUP TOOL

FOR FRAMELESS CABINET

INSIDE OF HOOD

(6) NO. 8 X 1/2”

C

OUNTERSUNK

WOOD SCREWS

*** FIND PARTS BAG BEHIND

THE DAMPER ASSEMBLY

OF HOOD

INSIDE

INSTALLATION MANUAL

8

INSTALLATION

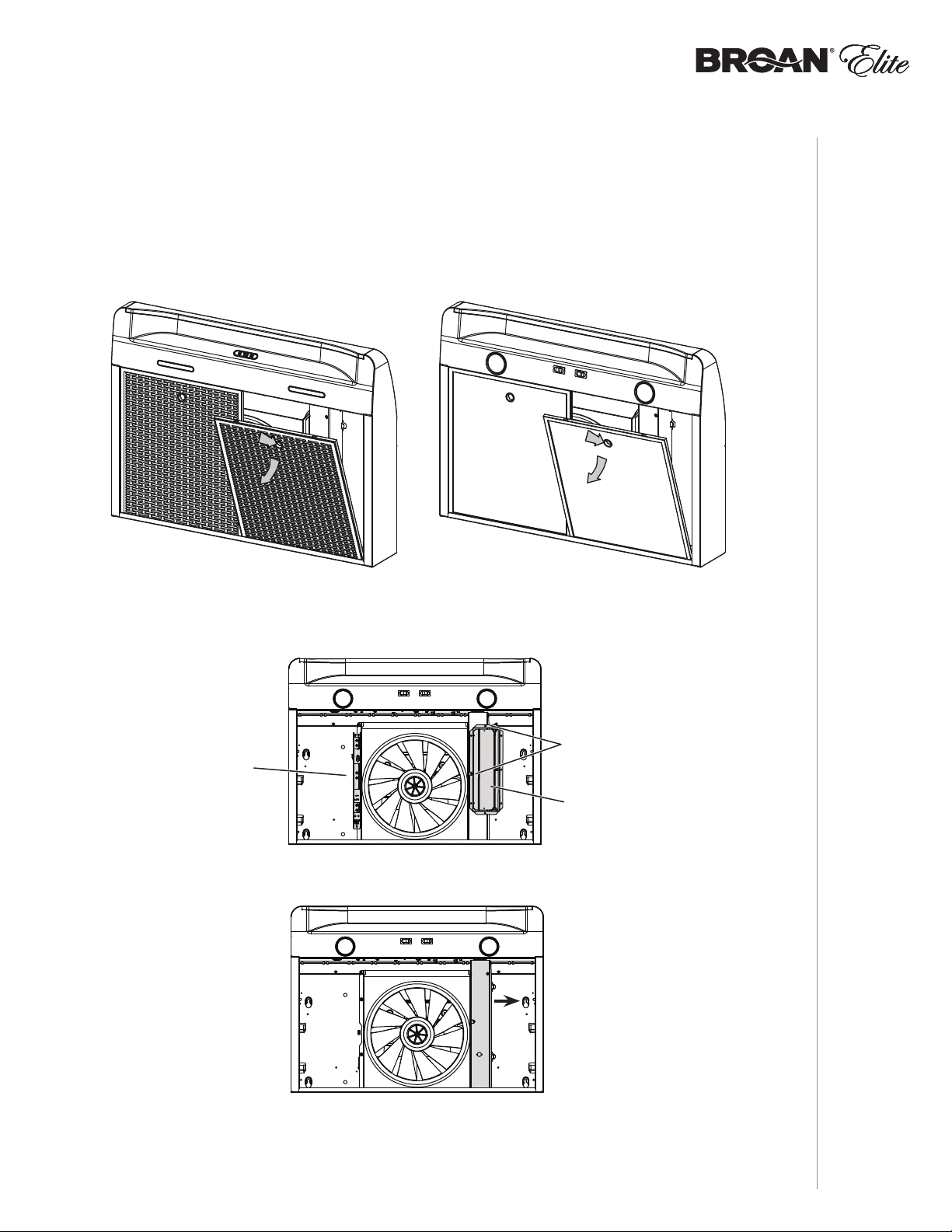

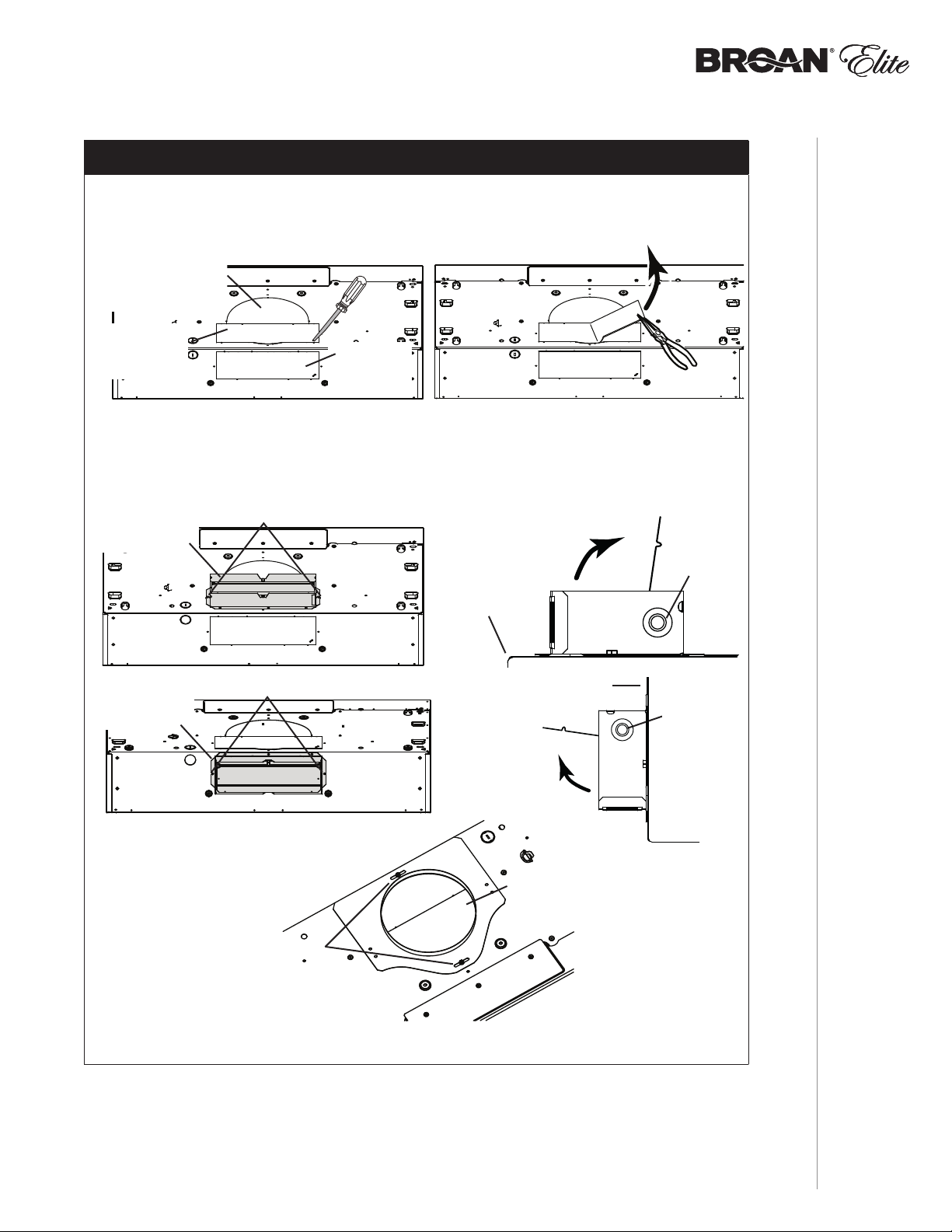

Prepare the Hood

NOTE: Since this manual covers many range hood models, some details in the following

illustrations may sligthly differ from your unit.

1 ] If present, remove all protective polyfilm from the hood and/or parts.

2 ] Using the finger cup, remove the grease filters from the hood by pushing down and tilting

filter out .

B

C

3 ] Remove the EZ1 brackets from inside the hood by cutting off the tie wrap. Remove both

screws holding damper assembly to hood. Remove parts bag (captured behind the damper

assembly). Remove damper assembly from inside the hood and keep the screws for further

use.

EZ1

BRACKETS

4 ] Remove the wiring cover (shaded part on illustration below) by sliding it out from the hood

and set it aside.

B

C

SCREWS

DAMPER

ASSEMBLY

INSTALLATION

9

INSTALLATION MANUAL

5 ] Remove 7” Round Duct Plate from top/back of hood (see illustration below). Keep the screws

for further use.

7” ROUND

DUCT

PLATE

2 SCREWS

6 ] Remove Electrical Power Cable Knockout from top (vertical wiring) or back (horizontal wiring)

of hood. Install an appropriate strain relief, 1/2” diameter (not included).

ELECTRICAL

POWER CABLE

KNOCKOUT

INSTALLATION MANUAL

INSTALLATION

NON-DUCTED INSTALLATION ONLY

7 ] Remove 3 screws retaining the recirculation cover plate (shaded part in illustration below)

to the hood. Discard this plate with its screws.

RECIRCULATION

COVER PLATE

SCREWS

10

DUCTED INSTALLATION ONLY

8 ] Remove 3¼” x 10” vertical, 3¼” x 10” horizontal, or 7-inch round knockout plate as

appropriate for your ducting method (see FIGURES 1 A and 1 B).

FIGURE 1 A

7” ROUND KNOCKOUT

PLATE (ALSO REMOVE

VERTICAL KNOCKOUT PLATE)

3¼” X 10”

VERTICAL

KNOCKOUT

PLATE

3¼” X 10”

HORIZONTAL

KNOCKOUT

PLATE

9 ] Attach 3¼” x 10” Damper Assembly on top OR back of hood (if using 3¼” x 10” duct; shaded

part in FIGURE 2 A below) or 7” Round Duct Plate (if using 7-inch round duct, FIGURE 3) over

the knockout opening. When installed, the 3¼” x 10” damper assembly must open as

shown in FIGURE 2 B.

FIGURE 2 A FIGURE 2 B

3¼” X 10”

DAMPER

ASSEMBLY

SCREWS

FIGURE 1 B

TOP/BACK

EDGE OF

HOOD

DAMPER

FLAP

PIVOT

SCREWS

3¼” X 10”

DAMPER

ASSEMBLY

FIGURE 3

7” ROUND

SCREWS

BACK OF

HOOD

DAMPER

FLAP

PIVOT

DUCT

PLATE

NOTE: To accommodate off-center ductwork, the 7” round duct plate can be installed up

to 1/2” on either side of the hood center.

TIP: Insert a small length of duct over the 3¼” x 10” damper assembly (for rectangular ducting)

or 7” round (for round ducting) and seal the joint using aluminum foil duct tape to ease

connection with the house ductwork.

INSTALLATION

INSTALLATION MANUAL

11

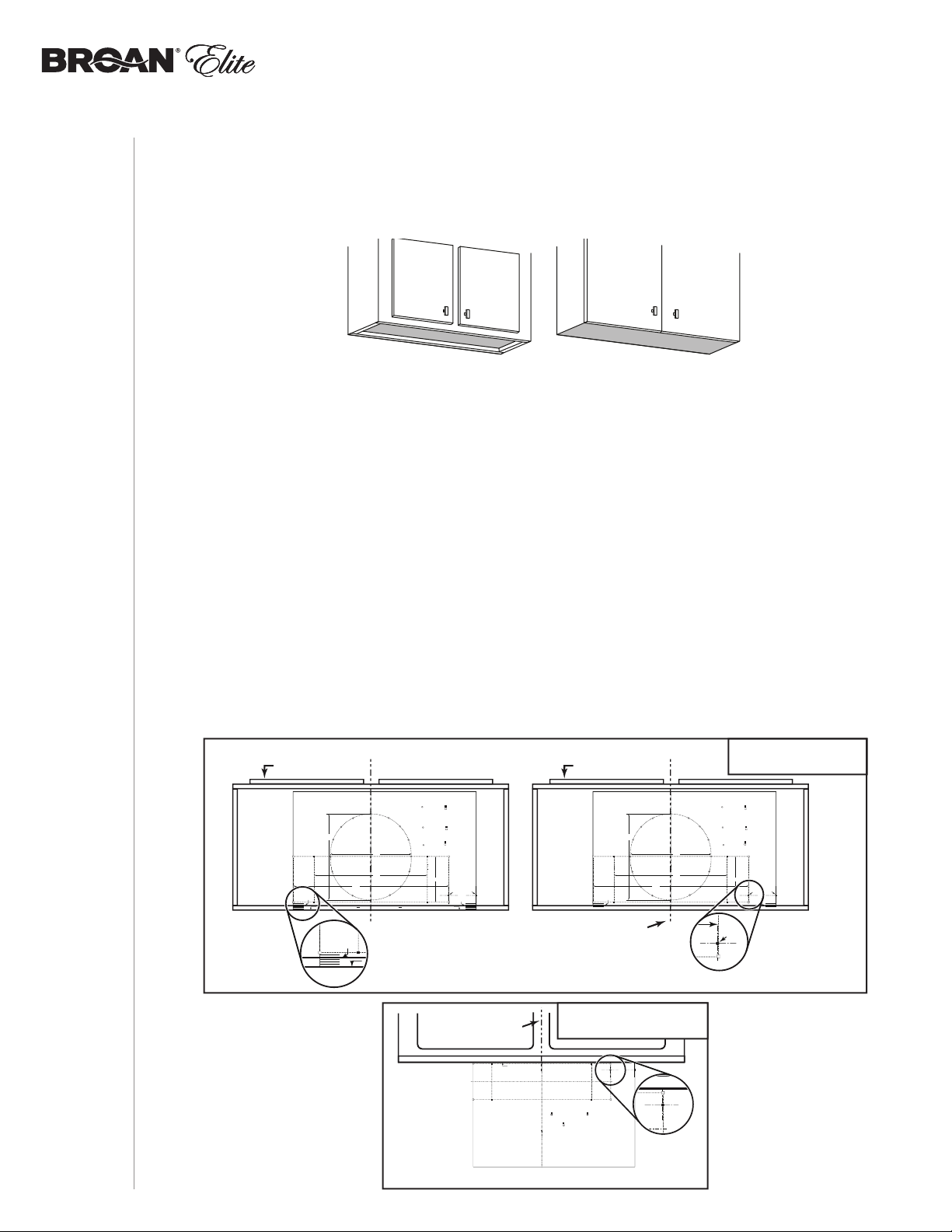

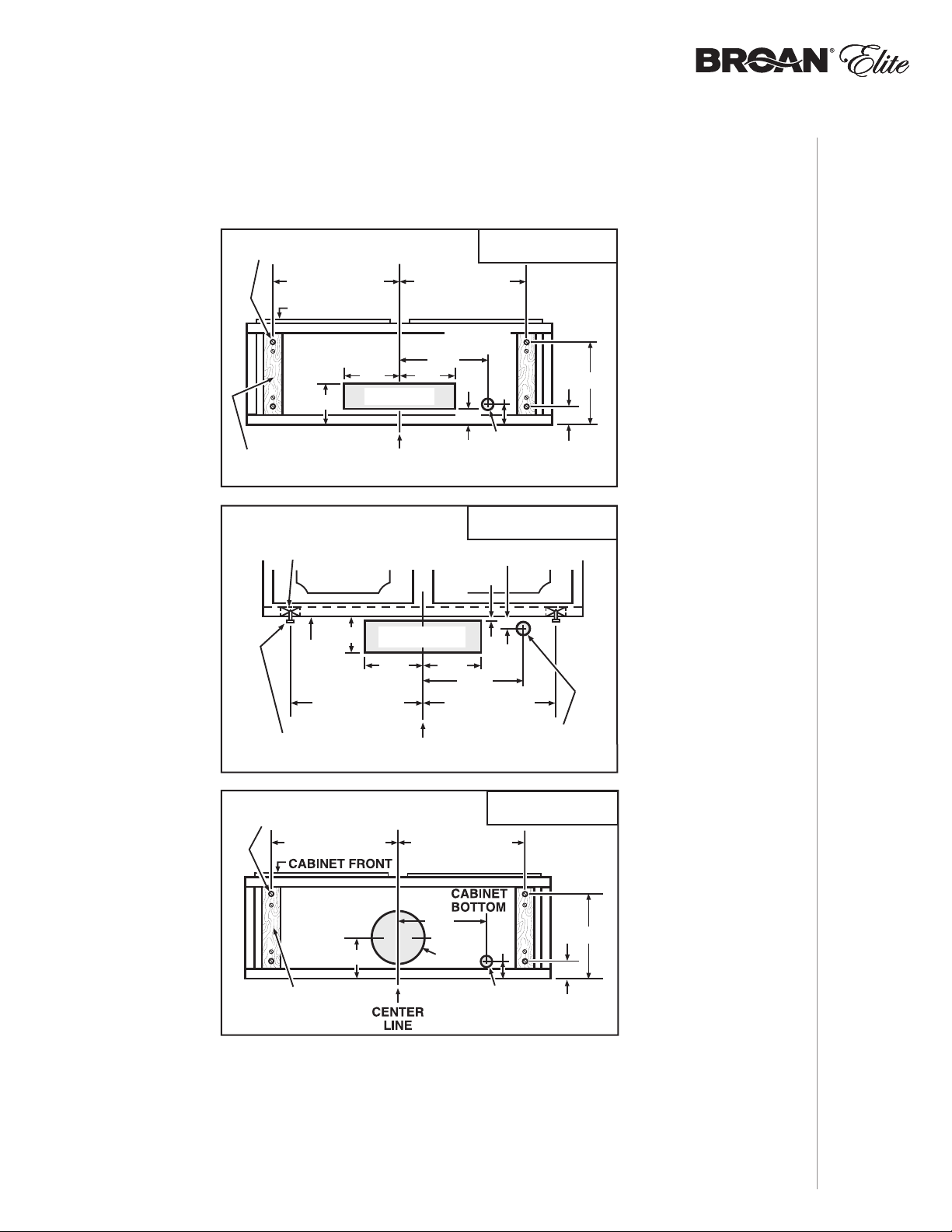

Prepare the Hood Location

VERTICAL EXHAUST

VERTICAL EXHAUST

NOTE: Before starting installation, read all the steps of these instructions.

Use the illustration below to identify your kitchen cabinet type.

FRAMED CABINET FRAMELESS CABINET

This manual covers 2 kinds of installation: the standard (without EZ1 brackets) and the

EZ1 one-person installation system (using included template and brackets).

For the standard installation, go to page 17.

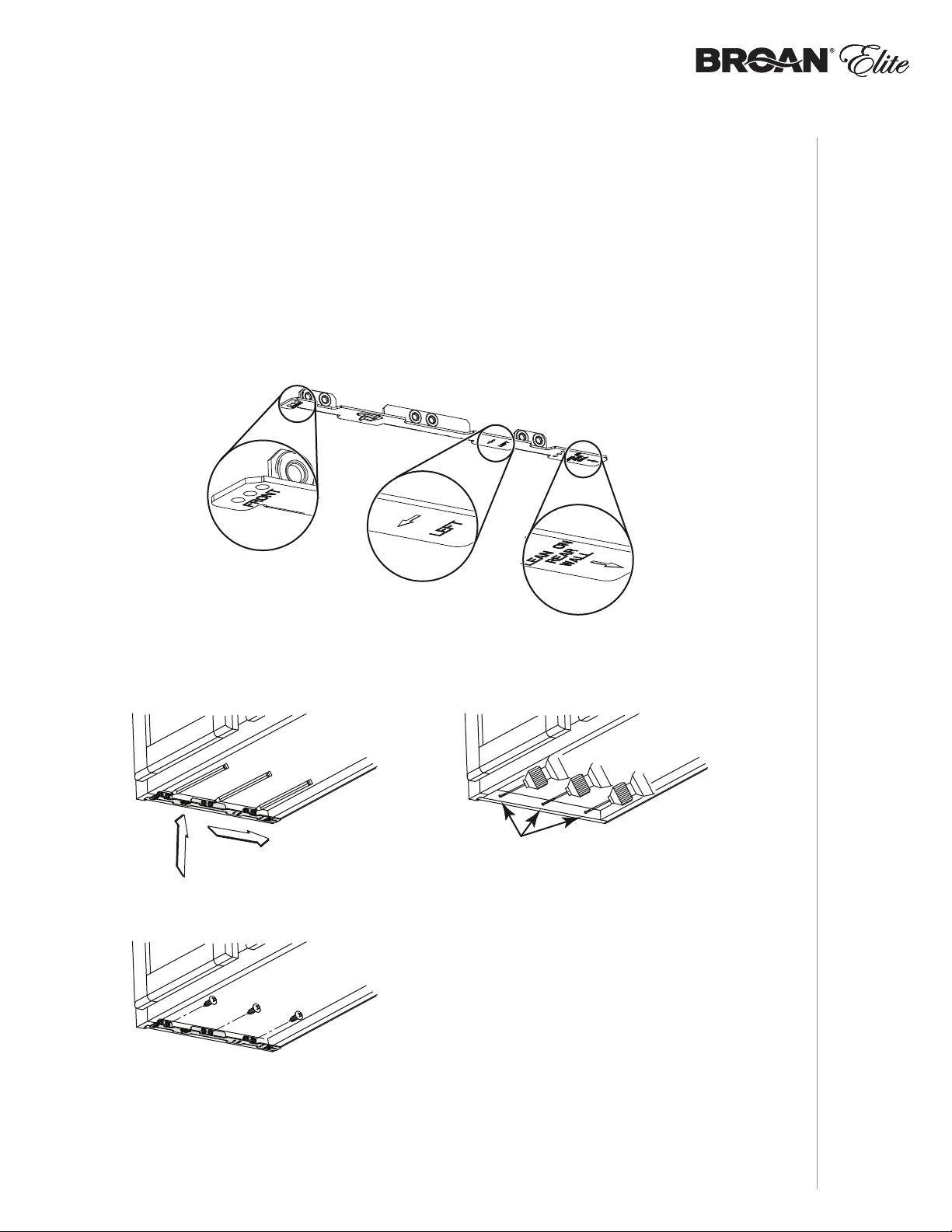

EZ1 one-person installation system

EZ1 installation is designed for use with kitchen cabinets that have the same width designation

as the range hood width. If the cabinet is greater than 1/2” wider than the range hood width,

please use the standard installation method.

1 ] Use the proper template for vertical OR horizontal discharge (included) for placement of

ductwork and electrical cutout in cabinet or wall. For a non-ducted installation, DO NOT cut a

duct access hole, only cut the hole for electrical wiring. If replacing a hood and plan to use

the existing duct and electrical, steps 2 to 5 may not be necessary. If so, skip to step 6.

2 ] Measure and mark the hood center line on cabinet bottom.

3 ] Align the center line on template with the hood center line marked on the bottom of the

cabinet, placing the edge (where indicated) of the template against back wall. When using

with framed cabinet for vertical exhaust installation, fold over rear edge of template equal

to the depth of the cabinet frame at the wall (use graduations on template, C locations on

template). Tape the template in place.

NOTE: When facing the installation, A and B (on template) must be at right.

VERTICAL EXHAUST

CABINET FRONT

CABINET FRONT

DUCTING

INSTALLATION MANUAL

INSTALLATION

12

Use this template for marking;do not attempt to cut out the ducting hole through it.

NOTE: These cutouts are clearance holes; they do not need to be the exact size of ducting.

Utiliser ce gabarit pour marquer vos repères;ne pas tenter de découper

le trou pour le conduit à travers le gabarit.

NOTE : Les découpes incluent le jeu nécessaire à l’installation; elles ne doivent pas

être du format exact des conduits.

Use esta plantilla para crear marcados;no trate de cortar el

agujero del conducto a través de la plantilla.

NOTA: To be translated in Spanish.

Bend template along graduated

scale when installing to framed

cabinet.

C

Pour une installation sous une

armoire à fond en retrait, utiliser les

lignes pour mesurer l’épaisseur du

décalage causé par le mur de

l’armoire et plier le gabarit en

8”

conséquence.

To be translated in Spanish.

C

C

MARKWHERE INDICATED

FORTHE APPROPRIATE SIZE DUCT OPENING

RECTANGULAR DUCTING7” ROUND DUCTING

OR

= 3¼” x 10”

= 3¼” x 14”

MARQUERLES REPÈRES AUX ENDROITS INDIQUÉSSELON

LEFORMATDE CONDUITUTILISÉ

CONDUITRECTANGULAIRECONDUITROND DE 7 PO

OU

= 3¼ po x 10 po

= 3¼ po x 14 po

TITLETO BE TRANSLATED IN SPANISH

CONDUCTORECTANGULARCONDUCTOREDONDO

O

= 3¼ pulg. x 10 pulg.

7 PULG.

C

14½”

Appuyer ce bord au mur arrière

L

DE

= 3¼ pulg. x 14 pulg.

4¼”

Electrical access hole center

A = single blower hood

B = double blower hood

Centre du trou pour fil

d’alimentation électrique

A = hotte ventilateur simple

B = hotte ventilateur double

To be translated in Spanish

Electrical access hole center

A = single blower hood

B = double blower hood

AB

C

7½”

10½”

Apoyar este borde contra la pared de atrásPlace this edge against back wall

FOLD TEMPLATE ALONG GRADUATED

SCALE

WHEN INSTALLING TO FRAMED

P

CABINET

.

CENTER LINE

Place this edge against

cabinet bottom.

Appuyer ce bord contre le bas

de l’armoire.

Apoyar este borde contra

la base del armario.

Use this template for marking;do not attempt to cut out the ducting hole through it.

NOTE: These cutouts are clearance holes; they do not need to be the exact size of ducting.

Utiliser ce gabarit pour marquer vos repères;ne pas tenter de découper

le trou pour le conduit à travers le gabarit.

NOTE : Les découpes incluent le jeu nécessaire à l’installation; elles ne doivent pas

être du format exact des conduits.

Use esta plantilla para crear marcados;no trate de cortar el

agujero del conducto a través de la plantilla.

NOTA: To be translated in Spanish.

Use this template for marking;do not attempt to cut out the ducting hole through it.

NOTE: These cutouts are clearance holes; they do not need to be the exact size of ducting.

Utiliser ce gabarit pour marquer vos repères;ne pas tenter de découper

le trou pour le conduit à travers le gabarit.

NOTE : Les découpes incluent le jeu nécessaire à l’installation; elles ne doivent pas

être du format exact des conduits.

Use esta plantilla para crear marcados;no trate de cortar el

agujero del conducto a través de la plantilla.

NOTA: To be translated in Spanish.

Bend template along graduated

scale when installing to framed

cabinet.

C

Pour une installation sous une

armoire à fond en retrait, utiliser les

lignes pour mesurer l’épaisseur du

décalage causé par le mur de

l’armoire et plier le gabarit en

8”

conséquence.

To be translated in Spanish.

C

CENTER LINE

HORIZONTAL EXHAUST

DUCTING

AB

Electrical access hole center

A = single blower hood

B = double blower hood

Centre du trou pour fil

d’alimentation électrique

ple

A = hotte ventilateur sim

B = hotte ventilateur double

MARQUERLESREPÈRES AUXENDROITS INDIQUÉS SELON

LEFORMATDE CONDUIT UTILISÉ

CONDUITRECTANGULAIRE

= 3¼ po x 10 po

= 3¼ po x 14 po

To be translated in Spanish

Electrical access hole center

A = single blower hood

B = double blower hood

ELECTRICAL

ACCESS HOLE

LOCATION (A)

(

C

L

MARKWHEREINDICATED

FORTHEAPPROPRIATE SIZE DUCTOPENING

RECTANGULAR DUCTING

= 3¼” x 10”

= 3¼” x 14”

TITLETOBE TRANSLATEDIN SPANISH

CONDUCTORECTANGULAR

= 3¼ pulg. x 10 pulg.

= 3¼ pulg. x 14 pulg.

C

L

14½”

A

Electrical access hol

A = single blower ho

B = double blower

Centre du tr

d’alim

IN WALL)

MARKWHERE INDICATED

FORTHE APPROPRIATE SIZE DUCT OPENING

RECTANGULAR DUCTING7” ROUND DUCTING

OR

= 3¼” x 10”

= 3¼” x 14”

MARQUERLES REPÈRES AUX ENDROITS INDIQUÉSSELON

LEFORMATDE CONDUITUTILISÉ

CONDUITRECTANGULAIRECONDUITROND DE 7 PO

OU

= 3¼ po x 10 po

= 3¼ po x 14 po

TITLETO BE TRANSLATED IN SPANISH

CONDUCTORECTANGULARCONDUCTOREDONDO

O

= 3¼ pulg. x 10 pulg.

7 PULG.

DE

= 3¼ pulg. x 14 pulg.

7½”

10½”

Electrical access hole center

A = single blower hood

B = double blower hood

Centre du trou pour fil

d’alimentation électrique

A = hotte ventilateur simple

B = hotte ventilateur double

To be translated in Spanish

Electrical access hole center

4¼”

A = single blower hood

B = double blower hood

AB

A

C

C

ELECTRICAL

ACCESS HOLE

LOCATION (A)

IN CABINET BOTTOM)

(

4 ] Drill a 1/8” dia. pilot hole for house wiring, at A location on template.

5 ] Use a sharp pencil or 1/8” drill bit to mark the locations for the appropriate duct access

holes (16 locations for 7” round duct, or 4 corner locations for rectangular duct). Remove the

template.

6 ] Draw the border for the exhaust ducting by linking its marks (16 for round duct and 4 for

rectangular duct), then cut the opening in the cabinet bottom (vertical exhaust) or in the wall

(horizontal exhaust). Drill the house wiring hole by using a 1½” hole saw centered with the

pilot hole previously made in 4.

7 ] Install the proper installation brackets according to the type of cabinet (framed or frameless).

See below.

FRAMED CABINET

Refer to the marking on brackets to determine the correct installation side and orientation.

XY

7/64”

Z

Mate the corresponding bracket to the cabinet side frame, while placing rear end

of bracket against the wall. Use a pencil to mark 3 holes (there are 6 holes but only

3 are necessary).

INSTALLATION

INSTALLATION MANUAL

Remove the bracket. Using a 7/64” drill bit, drill 3 holes where marked.

Assemble the bracket to the side frame using a Phillips screwdriver and 3 provided

no. 8 x 5/8” wood screws. Repeat for the other side frame.

13

FRAMELESS CABINET

Refer to the marking on brackets to determine the correct installation side and orientation.

X

Y

3 X

Z

[ \

7/64”

Align the corresponding bracket to the cabinet side, while placing rear end of bracket

against the wall. Draw a line on the outer edge of the bracket (as shown).

Slide the bracket towards the center of cabinet and align side edge to marked line,

keeping the rear end edge leaning on the wall.

Use a pencil to mark 3 holes.

INSTALLATION MANUAL

14

Remove the bracket. Using a 7/64” drill bit, drill 3 holes where marked.

Assemble the bracket to the cabinet bottom using a Phillips screwdriver and 3 provided

countersunk wood screws. Repeat for the other cabinet side.

INSTALLATION

Install the Hood (EZ1 Bracket)

OTE: N The following procedure applies to both frame or frameless cabinet installations.

1 ] Run house power cable between service panel and hood location.

2 ] There are 2 pairs of recessed holes on each side of the top of the hood (on rear: A and B,

on front C and D on illustration below); these holes allow the range hood to hang on the

brackets (previously installed).

A

C

HORIZONTAL EXHAUST INSTALLATION ONLY

3 ] Temporarily hang the hood on the brackets using its (2) recessed REAR HOLES (A and B).

While holding the hood, run the house power cable into the hood through the strain relief

previously installed in step 6 on page 10.

D

B

A

B

4 ] Unhook the rear holes from the brackets and hang the hood using its (2) recessed FRONT

HOLES (C and D). Attach power cable to the hood using the strain relief.

VERTICAL EXHAUST INSTALLATION AND NON-DUCTED INSTALLATION ONLY

5 ] Hang the hood on the brackets using the (2) recessed FRONT HOLES (C and D). While

holding the hood, run the house power cable into the hood through the strain relief previously

installed in step 6 on page 10. Secure power cable to the hood using the strain relief.

DUCTED INSTALLATION ONLY

6 ] Connect ductwork to hood and use metal foil duct tape to make joints secure and air-tight.

Make sure the damper assembly (or round duct plate) enters the ductwork and that the

damper opens and closes freely.

NOTE: See final installation steps on next page.

INSTALLATION

INSTALLATION MANUAL

15

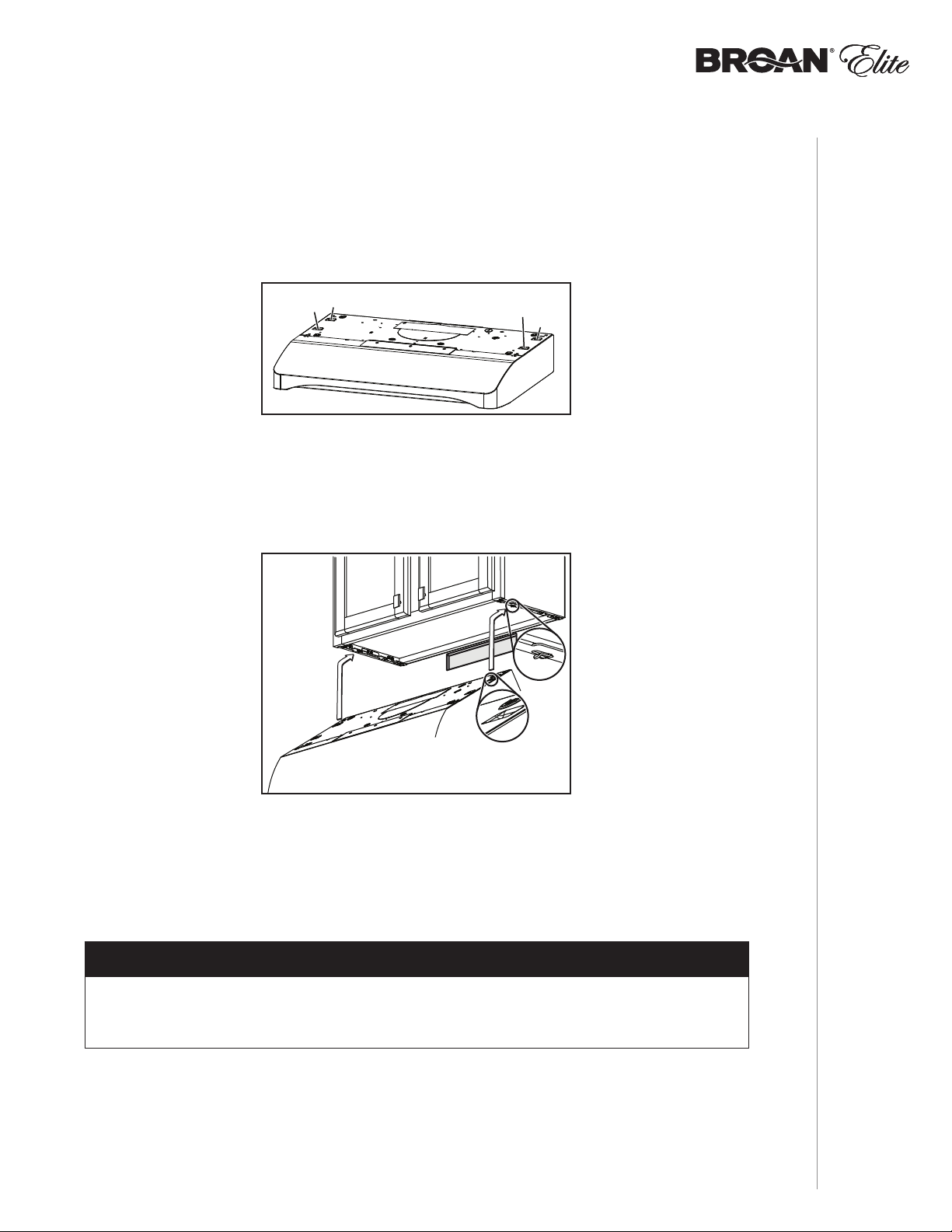

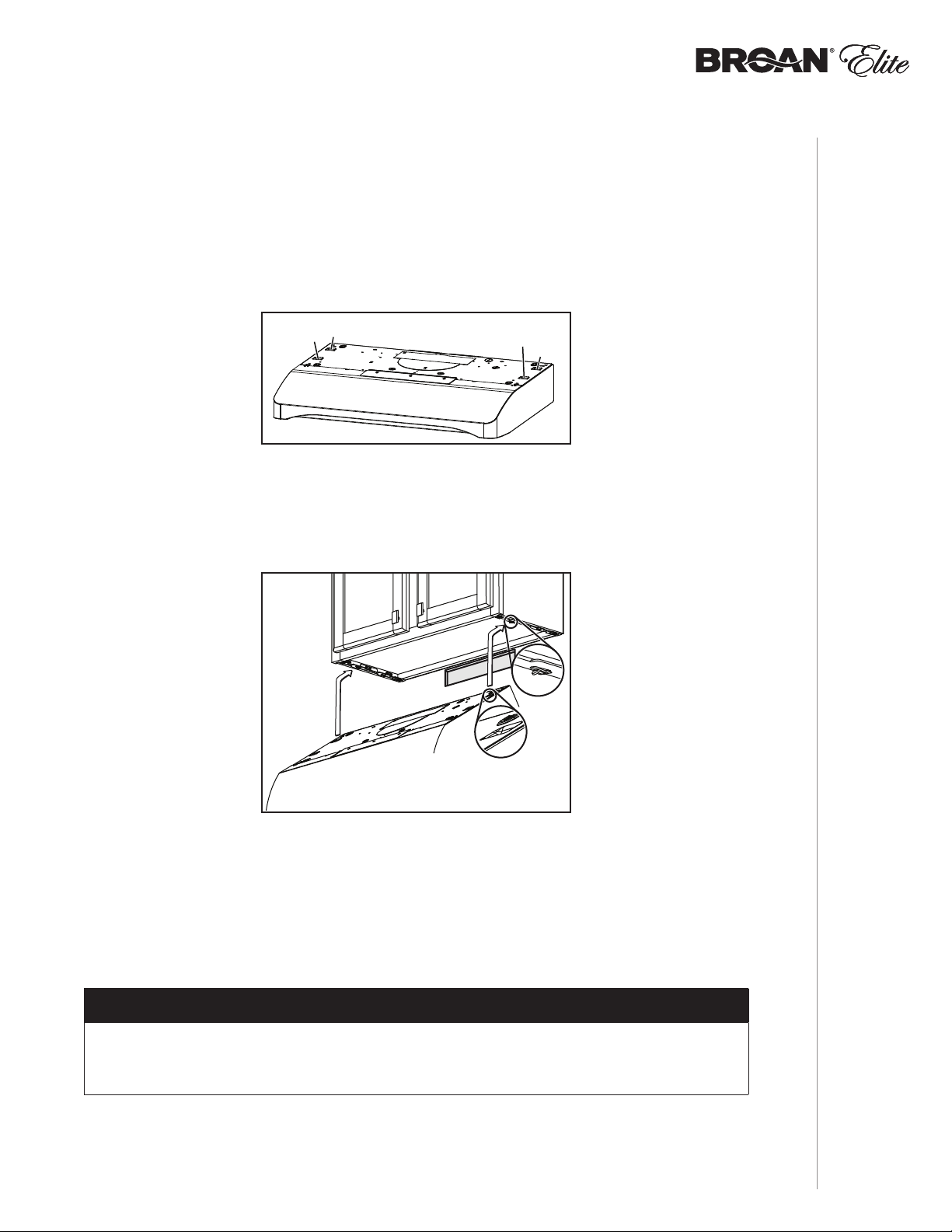

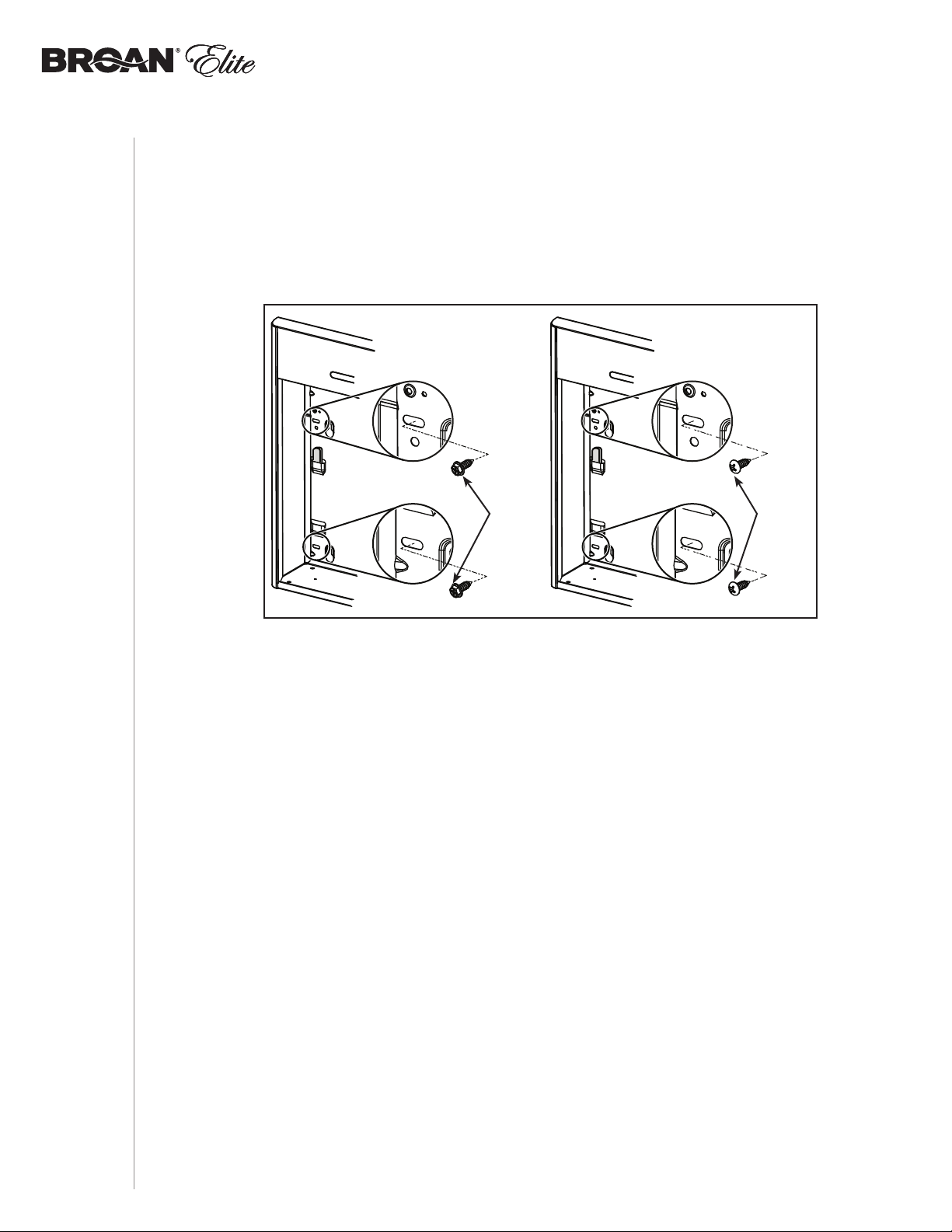

7 ] For framed cabinet, secure the hood to the EZ1 brackets using 4 no. 8-18 x 1/2” metal screws

(included in parts bag). Insert 2 screws per side, in the slots (as shown in insets on illustration

below).

8 ] For frameless cabinet, secure the hood to the cabinet using 4 no. 8 x 5/8” round head wood

screws (included in parts bag). Insert 2 screws per side, in the slots (as shown in insets on

illustration below).

FRAMED CABINET FRAMELESS CABINET

METAL

SCREWS

WOOD

SCREWS

INSTALLATION MANUAL

16

INSTALLATION

Standard Installation (without EZ1 brackets)

VERTICAL DUCT

ACCESS HOLE

1015/16"

5¼"

5¼"

CENTER

LINE

HOOD MOUNTING SCREWS (4)

ELECTRICAL

ACCESS HOLE

(

IN CABINET BOTTOM)

WOOD SHIMS

(

RECESSED-BOTTOM

CABINETS

ONLY)

CABINET FRONT

3/4"

1⅜"

1½"

7³/16"

12⅞" (30" HOOD)

15⅞" (36"

HOOD)

47/16"

CABINET

BOTTOM

12⅞" (30"

HOOD)

15⅞" (36"

HOOD)

CABINET

BOTTOM

CABINET FRONT

HORIZONTAL DUCT

ACCESS HOLE

HOOD

MOUNTING

SCREWS (4)

ELECTRICAL

ACCESS HOLE

(

IN WALL)

3⅞"

CENTER

LINE

WOOD SHIMS

(

RECESSED-BOTTOM

CABINETS

ONLY)

13/16"

3/16"

5¼"

5¼"

12⅞" (30" HOOD)

15⅞" (36"

HOOD)

12⅞" (30"

HOOD)

15⅞" (36"

HOOD)

7³/

16"

7-IN. ROUND

DUCT

ACCESS

HOLE

1 ] Use the proper diagram below for placement of ductwork and electrical cutout in cabinet

or wall. For a non-ducted installation, DO NOT cut a duct access hole, only cut the hole for

electrical wiring.

3¼" X 10"

VERTICAL DUCTING

3¼" X 10"

HORIZONTAL DUCTING

2 ] Install part-way four (4) ROUND HEAD no. 8 x 5/8” mounting screws into shims/cabinet,

according to the proper diagram above. (Mounting screws are included in parts bag, but wood

shims and shim mounting screws are not included).

HOOD MOUNTING SCREWS (4)

12⅞" (30"

15⅞" (36"

HOOD)

HOOD)

7-IN. ROUND

7-IN. ROUND

4¹¹/16"

WOOD SHIMS

RECESSED-BOTTOM

(

CABINETS

ONLY)

DUCT

DUCT

ACCESS

ACCESS

HOLE

HOLE

12⅞" (30"

15⅞" (36"

7³/

16"

8" DIA.

HOLE

ACCESS HOLE

IN CABINET BOTTOM)

(

7-IN. ROUND

VERTICAL DUCTING

HOOD)

HOOD)

1⅜"

ELECTRICAL

1½"

10

INSTALLATION

15

/16"

INSTALLATION MANUAL

17

Install the Hood (Standard Installation)

OTE: N Two installers are recommended because of the weight of this hood.

1 ] Run house power cable between service panel and hood location. Run the house power cable

into the hood through the strain relief previously installed in step 6 on page 10.

2 ] Hang hood from (4) mounting screws previously installed. Slide hood back towards wall until

mounting screw heads are engaged in narrow end of keyhole slots in top of hood. While

holding the hood, tighten screws securely. Attach power cable to the hood using the strain

relief.

DUCTED INSTALLATION ONLY

3 ] Connect ductwork to hood and use metal foil duct tape to make joints secure and air-tight.

Make sure the damper assembly (or round duct plate) enters the ductwork and that the

damper opens and closes freely.

INSTALLATION MANUAL

18

INSTALLATION

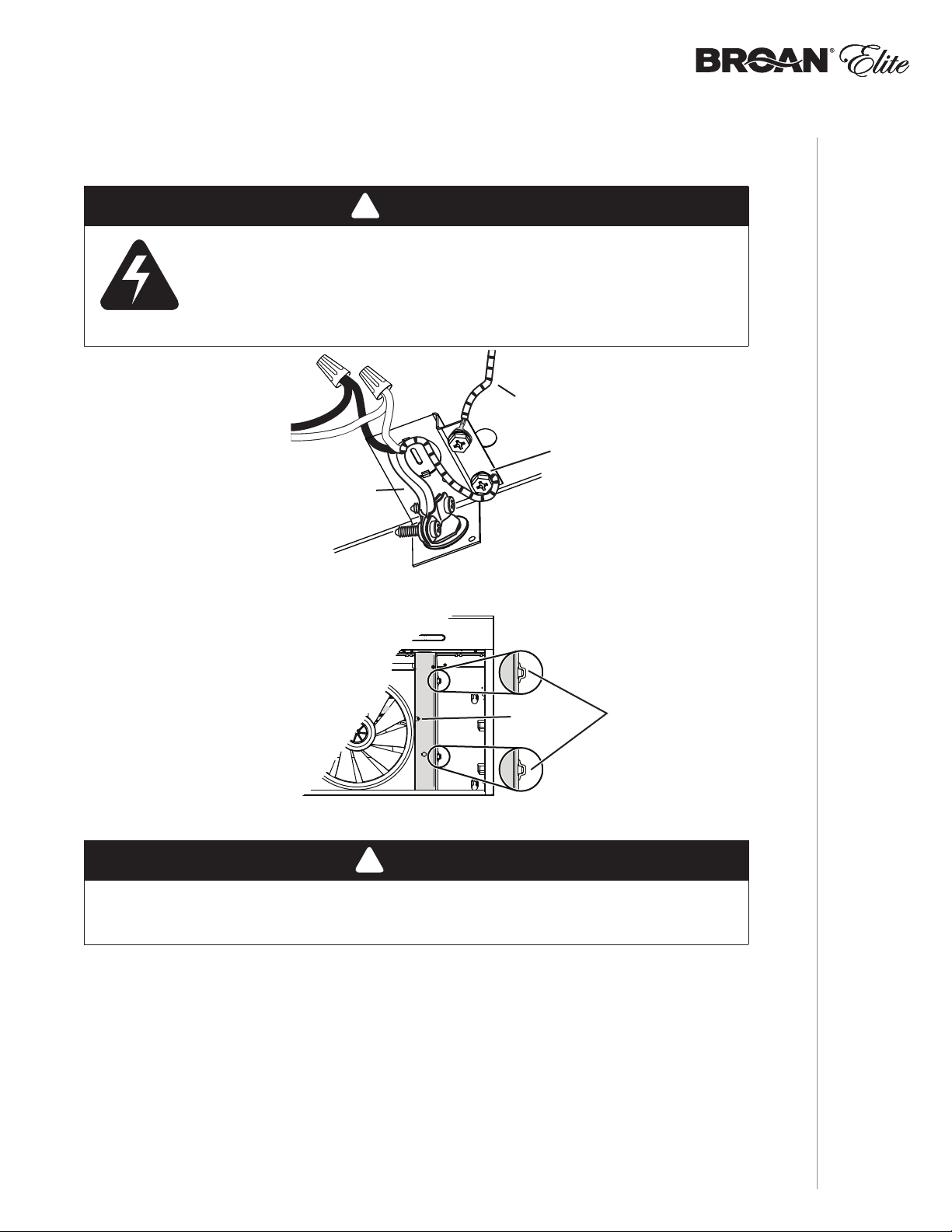

Connect the Wiring

!

WARNING

Risk of electric shock. Electrical wiring must be done by qualifi ed

personnel in accordance with all applicable codes and standards.

Before connecting wires, switch power off at service panel and lock

service disconnecting means to prevent power from being switched

on accidentally.

MOTOR

GROUND

WIRE

GROUND

SCREW

HOUSE

POWER CABLE

1 ] Connect House Power Cable to range hood wiring: BLACK to BLACK, WHITE to WHITE and

GREEN or bare wire under GREEN ground screw.

TABS ON INNER

TOP OF HOOD

SCREW

2 ] Reinstall wiring cover and attach it to the hood using its retaining screw.

!

CAUTION

Ensure both tabs on inner top of hood are engaged in their corresponding slots in

wiring cover. Also, take care not to pinch wires while reinstalling wiring cover.

ENGAGED IN

WIRING COVER

SLOTS.

INSTALLATION

INSTALLATION MANUAL

19

Light Bulbs (ALT1 Series only)

The ALT1 Series range hoods require two shielded Halogen Bulbs (120 V, 50 W max., MR16 or

PAR16 with GU10 base), included.

NOTE: Before using lamps, remove shipping tape on them (if present).

!

WARNING

Do not touch lamps during or soon after operation. Burns may occur. In order to prevent

the risk of personal injury, only install shielded halogen lamps. Also, never install a cool

beam, a dichroic lamp, a lamp not suitable for use in recessed luminaires or identified for

use in enclosed fixtures.

BULB LEADS

1 ] Align the bulb leads with the small indentations located on the border of the lamp location on

hood (see inset above), then install the bulbs by placing the bulb leads into their grooves in

the socket.

2 ] Gently push upwards and turn clockwise until secure.

NOTE: The Suction Cup Tool (included with hood) can be used to install and remove light bulbs.

Press suction cup tool on bulb and rotate counterclockwise to remove bulb or clockwise to

install bulb.

Most GU10 LED replacement bulbs commonly found in the market are not designed

for use in a cooking environment and might not perform as advertised. Their usage

with this product is not recommended.

BULB LEAD

GROOVES

(IN SOCKET)

!

CAUTION

SUCTION

CUP TOOL

INSTALLATION MANUAL

20

Install the Filters

Ducted Installation Only:

Re-install grease filters removed in step 2 , page 9, under “Prepare the Hood”.

Non-ducted Installation Only:

Purchase two non-ducted filters from your local distributor or retailer (see product specification

label for filter type). Attach the non-ducted filters following instructions packed with the

non-ducted filter.

INSTALLATION

ALT1 SERIES

12 34 56

1

2

3

4

J6

Override

J4

LED

J10

Interface

1

2

3

4

5

6

7

8

User interface mounted

to J10 on back of

control board.

J1

Transformer

J2

Power, Motor

5

4

3

2

1

5

4

3

2

1

6

7

Control Board

R

R

BL

BL

BK

W

BK

BK

W

G/Y

R (Low)

O (Medium)

BK (High)

W

120 V AC

Line

Neutral

Ground

G/Y

W

BK

O

R

FAN MOTOR

BN

BN/W

R

BK

LED

LED

W

COLOR CODE

BK

BL

BN

BN/W

BLACK

BLUE

BROWN

BROWN/WHITE

G/Y

O

R

W

GREEN/YELLOW

ORANGE

RED

WHITE

1

2

3

4

5

6

Light Switch

COLOR CODE

BROWN/WHITE

BLACK

BK

BLUE

BL

BROWN

BN

1

2

BN/W

G/Y

O

BL (High)

Y (Low)

GREEN/YELLOW

ORANGE

RED

R

WHITE

W

YELLOW

Y

BK

BK

Line

Neutral

Ground

120 V AC

ALT2 SERIES

BK

Motor Switch

W

W

1

2

R (Low)

BK (High)

G/Y

W

W

BK

6

5

4

3

2

1

FAN MOTOR

R

O

BK

G/Y

W

BN

BN/W

WIRING DIAGRAMS

INSTALLATION MANUAL

21

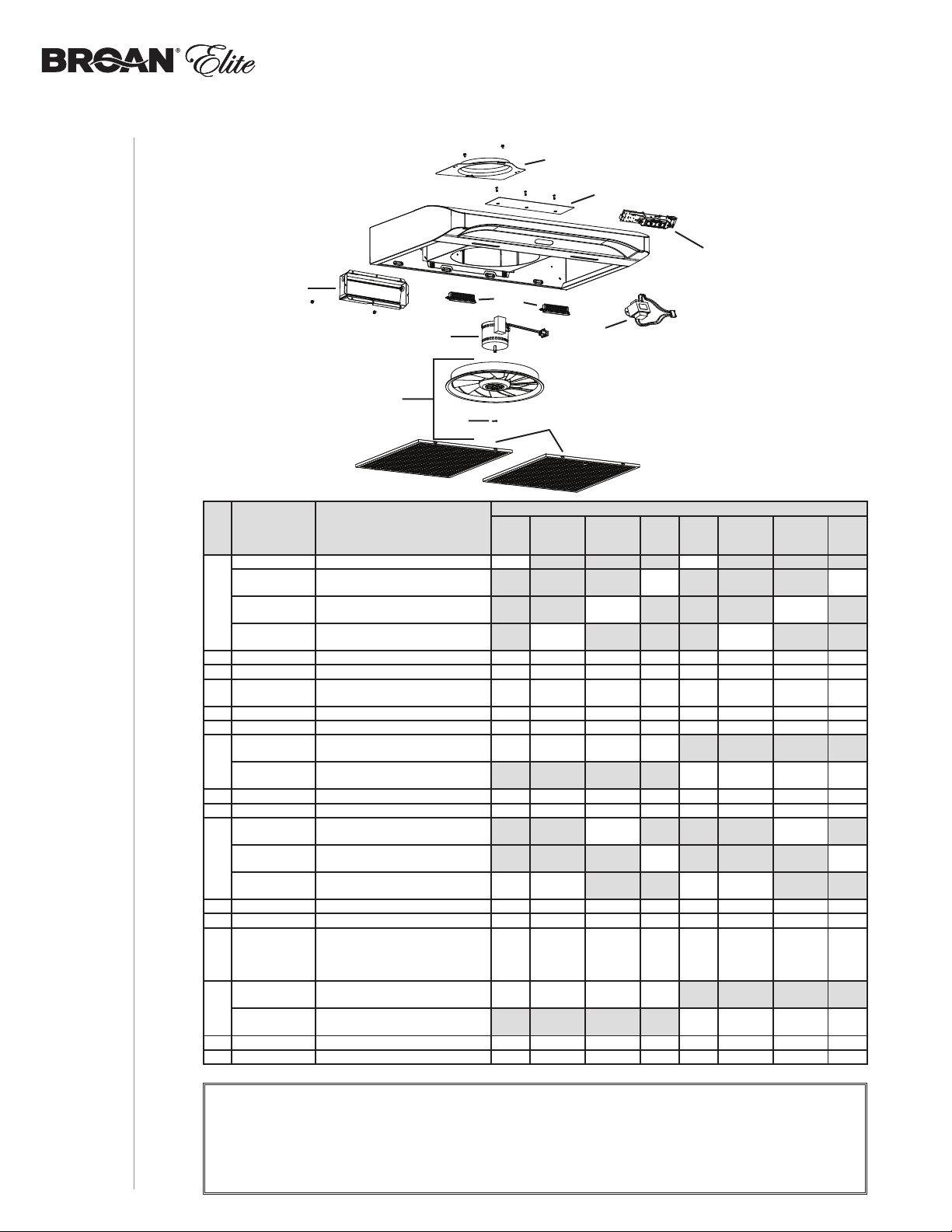

ALT2 SERIES

C

B

K

INSTALLATION MANUAL

22

SERVICE PARTS

D

E

I

J

F

G

KEY

NO.

10

* ITEM NOT SHOWN.

REPLACEMENT PARTS AND REPAIRS

In order to ensure your unit remains in good working condition, you must use Broan-NuTone LLC or Venmar Ventilation ULC genuine

replacement parts only. Broan-NuTone LLC or Venmar Ventilation ULC genuine replacement parts are specially designed for each

unit and are manufactured to comply with all the applicable certification standards and maintain a high standard of safety. Any third

party replacement part used may cause serious damage and drastically reduce the performance level of your unit, which will result in

premature failing. Broan-NuTone LLC and Venmar Ventilation ULC recommend to contact a certified service depot for all replacement

parts and repairs.

ART NO.DESCRIPTION

P

S97020029 R

S97020030

1

S97020031

S98011873

2 SR680508 7'' R

3 S97020534 3¼” X 10” DAMPER ASS’Y (INCL. SCREWS)11111111

4 S97020409

5 S97020407 F

6 SR99420635 C

S99010431-002

7

S99010431-003

8 S97020444 LED

9 S97020445 T

S97020431

S97020432

S97020433

* S97020452 W

* S98011637 W

* S97020360

S97020466

*

S97020467

* S99527587 NON-DUCTED FILTER CLIP KIT (INCL. 4 CLIPS)11111111

* S97020470 E

ECIRC. COVER PLATE, BLACK (INCL. SCREWS)1 1

ECIRCULATION COVER PLATE, WHITE

R

(INCLUDING SCREWS)

ECIRC. COVER PLATE, STAINLESS STEEL

R

(INCLUDING SCREWS)

ECIRCULATION COVER PLATE, BLACK

R

STAINLESS (INCLUDING SCREWS)

OUND DUCT PLATE (INCL. SCREWS)11111111

LOWER MOTOR (INCLUDING CAPACITOR

B

AND 4 SCREWS)

ANPELLER (INCLUDING ITEM 6) 11 1111 11

LIP FOR FANPELLER 11 1111 11

REASE FILTER - MICRO MESH OBLONG

G

-TYPE C3 (SET OF 2)

GREASE FILTER - MICRO MESH OBLONG

-TYPE D3 (SET OF 2)

MODULE (PAIR) 11 1111 11

RANSFORMER 24 V 18 VA (WITH SCREWS)11111111

C

APTOUCH CONTROL LED,

STAINLESS (WITH SCREWS)

APTOUCH CONTROL LED, WHITE

C

(WITH SCREWS)

APTOUCH CONTROL LED, BLACK

C

(

WITH SCREWS)

IRE HARNESS 11 1111 11

IRING COVER 11 1111 11

ARTS BAG INCLUDING: 4 METAL SCREWS

P

. 8-18 X 1/2”, 6 ROUND HEAD

NO

NO. 8 X 5/8” WOOD SCREWS, 6 NO. 8 X 1/2”

COUNTERSUNK WOOD SCREWS

ON-DUCTED F ILTER - TYPE X C ( SET OF 2)

N

NON-DUCTED INSTALLATION ONLY)

(

ON-DUCTED F ILTER - TYPE X D ( SET OF 2)

N

NON-DUCTED INSTALLATION ONLY)

(

ASY INSTALL KIT (INCL. HARDWARE)11 11 1 11

B

H

30"

30"

B

LACK

LACK

STAINLESS

11

11 1111 11

11 11

11 11

11 1111 11

11 11

30"

TAINLESS

S

QUANTITY

30"

36"

HITE

W

B

11

11

11

11

36"

B

LACK

LACK

TAINLESS

S

11 11

11 11

36"

TAINLESS

S

W

36"

HITE

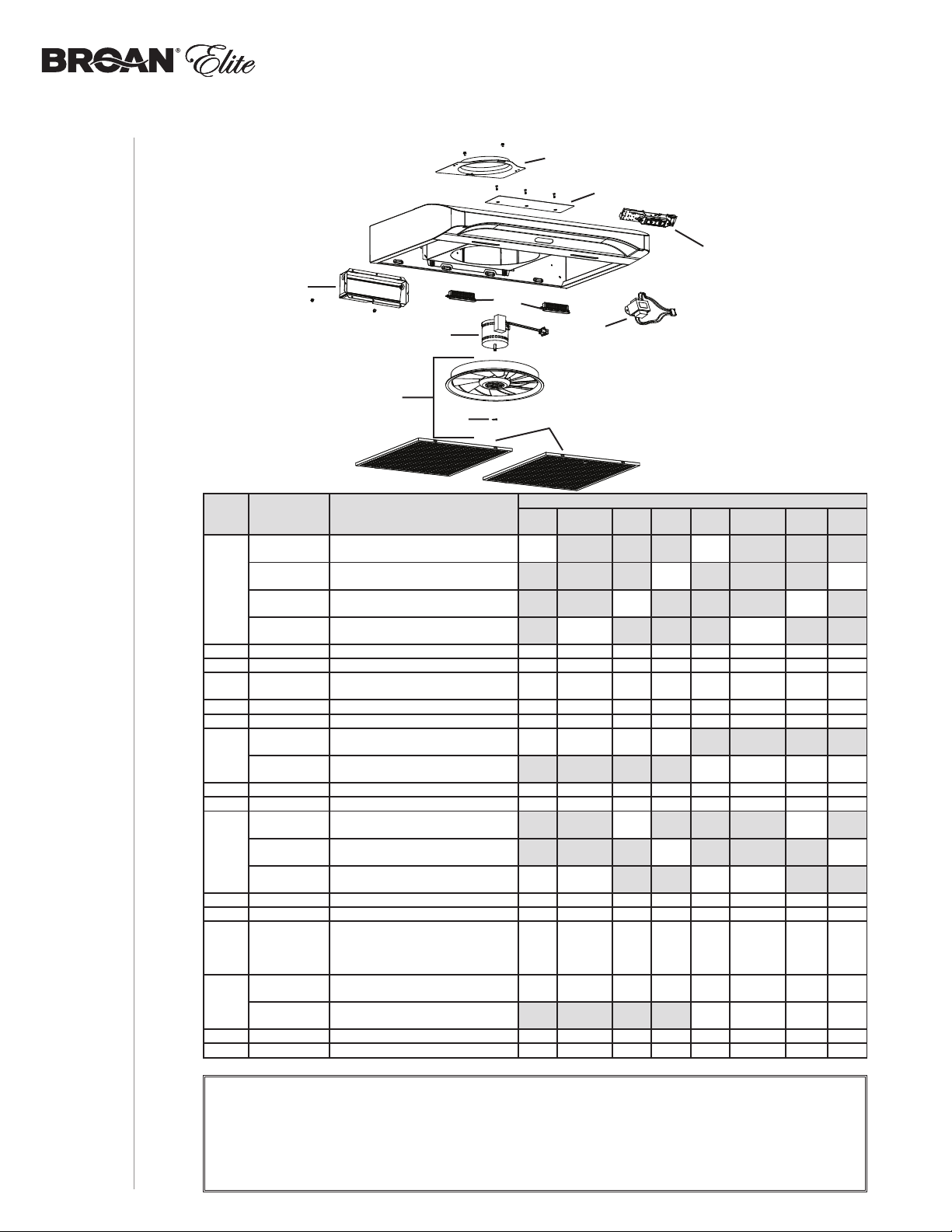

ALT1 SERIES

D

C

B

J

E

I

F

G

KEY

NO.

1

2 SR680508 7'' R

3 S97020534 3¼”

4 S97020408 B

5 S97020407 F

6 SR99420635 C

7

8

9 SV05921 S

* S97020448 W

* S98011637 W

* S97020292

*

* S99527587 N

* S97020470 E

TEM NOT SHOWN.

* I

ART NO.DESCRIPTION

P

S97020029 R

S97020030 R

S97020031 R

S99010434-002 G

S99010434-003 G

S99030367 R

S99030355 R

S99030356 R

S97020466

S97020467

H

30"

ECIRCULATION COVER PLATE, BLACK (INCLUDING SCREWS)1 1

ECIRCULATION COVER PLATE, WHITE (INCLUDING SCREWS)1 1

ECIRC. COVER PLATE, STAINLESS STEEL (INCL. SCREWS)1 1

OUND DUCT PLATE (INCLUDING SCREWS) 111111

X 10” DAMPER ASSEMBLY (INCLUDING SCREWS) 111111

LOWER MOTOR (INCLUDING CAPACITO R AND 4 SCREWS)111111

ANPELLER (INCLUDING ITEM 6) 111111

LIP FOR FANPELLER 111111

REASE FILTER - MICRO MESH -TYPE C2 (SET OF 2) 1 1 1

REASE FILTER - MICRO MESH -TYPE D2 (SET OF 2) 1 1 1

OCKER SWITCH, GREY (SET OF 2) 1 1

OCKER SWITCH, WHITE (SET OF 2) 1 1

OCKER SWITCH, BLACK (SET OF 2) 1 1

HIELDED HALOGEN BULBS 50 W GU10 2 2 2 2 2 2

IRE HARNESS 111111

IRING COVER 111111

P

ARTS BAG INCLUDING: 4 METAL SCREWS NO. 8-18 X 1/2”,

OUND HEAD NO. 8 X 5/8” WOOD SCREWS, 6 NO. 8 X 1/2”

6 R

C

OUNTERSUNK WOOD SCREWS, 1 SUCTION CUP TOOL

ON-DUCTED FILTER - TYPE XC (SET OF 2)

N

(

NON-DUCTED INSTALLATION ONLY)

ON-DUCTED FILTER - TYPE XD (SET OF 2)

N

NON-DUCTED INSTALLATION ONLY)

(

ON-DUCTED FILTER CLIP KIT (INCL. 4 CLIPS) 111111

ASY INSTALL KIT (INCLUDING HARDWARE) 111111

B

30"

S

LACK

TAINLESS

111111

111

QUANTITY

30"

W

HITE

B

36"

36"

S

LACK

TAINLESS

111

36"

W

HITE

SERVICE PARTS

INSTALLATION MANUAL

REPLACEMENT PARTS AND REPAIRS

In order to ensure your unit remains in good working condition, you must use Broan-NuTone LLC genuine replacement parts only. BroanNuTone LLC genuine replacement parts are specially designed for each unit and are manufactured to comply with all the applicable

certification standards and maintain a high standard of safety. Any third party replacement part used may cause serious damage and

drastically reduce the performance level of your unit, which will result in premature failing. Broan-NuTone LLC recommends to contact a

certified service depot for all replacement parts and repairs.

23

INSTALLATION MANUAL

24

Warranty Period and Exclusions: Broan-NuTone LLC and Venmar Ventilation ULC (either being the “Company”) warrants to the

original consumer purchaser of its product (“you”) that the product (the “Product”) will be free from material defects in the Product or

its workmanship for a period of one (1) year from the date of original purchase (or such longer period as may be required

by applicable law). For Range Hood Product that includes built-in LED modules, the Company warrants the LED modules and

driver to be free from material defects for a period of three (3) years from the date of purchase. The limited warranty period for

any replacement parts provided by the Company and for any Products repaired or replaced under this limited warranty shall

be the remainder of the original warranty period (or such longer period as may be required by applicable law).

This warranty does not cover fluorescent lamp starters, tubes, halogen and incandescent bulbs, fuses, filters, ducts, roof

caps, wall caps and other accessories for ducting that may be purchased separately and installed with the Product. This

warranty also does not cover (a) normal maintenance and service, (b) normal wear and tear, (c) any Products or parts

which have been subject to misuse, abuse, abnormal usage, negligence, accident, improper or insufficient maintenance,

storage or repair (other than repair by the Company), (d) damage caused by faulty installation, or installation or use

contrary to recommendations or instructions, (e) any Product that has been moved from its original point of installation,

(f) damage caused by environmental or natural elements, (g) damage in transit, (h) natural wear of finish, (i) Products

in commercial or nonresidential use, or (j) damage caused by fire, flood or other act of God or (k) Products with altered,

defaced or removed serial numbers. This warranty covers only Products sold to original consumers in the United States and

Canada by the Company or its U.S. and Canadian distributors authorized by the Company.

This warranty supersedes all prior warranties and, subject to applicable law, is not transferable from the original consumer purchaser.

No Other Warranties: This Limited Warranty contains the Company’s sole obligation and your sole remedy for defective

products. The foregoing warranties are exclusive and in lieu of any other warranties and conditions, express or implied. THE

COMPANY DISCLAIMS AND EXCLUDES ALL OTHER EXPRESS WARRANTIES AND CONDITIONS, AND DISCLAIMS

AND EXCLUDES ALL WARRANTIES AND CONDITIONS IMPLIED BY LAW, INCLUDING WITHOUT LIMITATION

THOSE OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. To the extent that applicable law

prohibits the exclusion of implied warranties or conditions, the duration of any applicable implied warranty or condition is

limited to the period specified for the express warranty above. Some jurisdictions do not allow limitations on how long an

implied warranty lasts, so the above limitation may not apply to you. Any oral or written description of the Product is for the

sole purpose of identifying it and shall not be construed as an express warranty.

Whenever possible, each provision of this Limited Warranty shall be interpreted in such manner as to be effective and valid

under applicable law, but if any provision is held to be prohibited or invalid, such provision shall be ineffective only to the

extent of such prohibition or invalidity, without invalidating the remainder of such provision or the other remaining provisions

of the Limited Warranty.

Remedy: During the applicable limited warranty period, the Company will, at its option, provide replacement parts for, or

repair or replace, without charge, any Product or part thereof, to the extent the Company finds it to be covered by and in

breach of this limited warranty under normal use and service. The Company will ship the repaired or replaced Product or

replacement parts to you at no charge. You are responsible for all costs for removal, reinstallation and shipping, insurance or

other freight charges incurred in the shipment of the Product or part to the Company. If you must send the Product or part to

the Company, as instructed by the Company, you must properly pack the Product or part—the Company is not responsible

for damage in transit. The Company reserves the right to utilize reconditioned, refurbished, repaired or remanufactured

Products or parts in the warranty repair or replacement process. Such Products and parts will be comparable in function

and performance to an original Product or part and warranted for the remainder of the original warranty period (or such

longer period as may be required by applicable law).

Company reserves the right, in its sole discretion, to refund the money actually paid by you for the Product in lieu of repair or

replacement. If the Product or component is no longer available, replacement may be made with a similar product of equal

or greater value, at Company’s sole discretion. This is your sole and exclusive remedy for breach of this limited warranty.

Exclusion of Damages: THE COMPANY’S OBLIGATION TO PROVIDE REPLACEMENT PARTS, OR REPAIR,

REPLACE OR REFUND, AT THE COMPANY’S OPTION, SHALL BE YOUR SOLE AND EXCLUSIVE REMEDY UNDER

THIS LIMITED WARRANTY AND THE COMPANY’S SOLE AND EXCLUSIVE OBLIGATION. THE COMPANY SHALL

NOT BE LIABLE FOR INCIDENTAL, INDIRECT, CONSEQUENTIAL OR SPECIAL DAMAGES ARISING OUT OF OR IN

CONNECTION WITH THE PRODUCT, ITS USE OR PERFORMANCE. Incidental damages include but are not limited to

such damages as loss of time and loss of use. Consequential damages include but are not limited to the cost of repairing

or replacing other property which was damaged if the Product does not work properly.

THE COMPANY SHALL NOT BE LIABLE TO YOU, OR TO ANYONE CLAIMING UNDER YOU, FOR ANY OTHER

OBLIGATIONS OR LIABILITIES, INCLUDING, BUT NOT LIMITED TO, OBLIGATIONS OR LIABILITIES ARISING

OUT OF BREACH OF CONTRACT OR WARRANTY, NEGLIGENCE OR OTHER TORT OR ANY THEORY OF STRICT

LIABILITY, WITH RESPECT TO THE PRODUCT OR THE COMPANY’S ACTS OR OMISSIONS OR OTHERWISE.

Some jurisdictions do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation

or exclusion may not apply to you. This warranty gives you specific legal rights, and you may also have other rights, which

vary from jurisdiction to jurisdiction. The disclaimers, exclusions, and limitations of liability under this warranty will not apply

to the extent prohibited by applicable law.

This warranty covers only replacement or repair of defective Products or parts thereof at the Company’s main facility and

does not include the cost of field service travel and living expenses.

Any assistance the Company provides to or procures for you outside the terms, limitations or exclusions of this limited warranty

will not constitute a waiver of such terms, limitations or exclusions, nor will such assistance extend or revive the warranty.

The Company will not reimburse you for any expenses incurred by you in repairing or replacing any defective Product,

except for those incurred with the Company’s prior written permission.

How to Obtain Warranty Service: To qualify for warranty service, you must (a) notify the Company at the address or

WARRANTY

telephone number stated below within seven (7) days of discovering the covered defect, (b) give the model number and part

identification and (c) describe the nature of any defect in the Product or part. At the time of requesting warranty service, you

must present evidence of the original purchase date. If you cannot provide a copy of the original written limited warranty,

then the terms of the Company’s most current written limited warranty for your particular product will control. The most

current limited written warranties for the Company’s products can be found at www.broan.com and www.broan.ca.

Broan-NuTone LLC 926 West State Street, Hartford, WI 53027 www.broan.com 800-637-1453

Venmar Ventilation ULC, 1550 Lemire Blvd., Drummondville, Québec, Canada J2C 7W9 www.broan.ca 1-877-896-1119

Limited Warranty

WWW.BROAN.COM

WWW.BROAN.CA

HOTTE

DE CUISINIÈRE

Séries : ALT1 et ALT2

MANUEL D’INSTALLATION,

D’UTILISATION ET D’ENTRETIEN

Numéro de série :

99046182A

Sécurité . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Fonctionnement . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Nettoyage et entretien . . . . . . . . . . . . . . . . . . . . . 6

Moteur

Filtres à graisses

Filtres de recirculation

Hélice

Nettoyage de l’acier inoxydable

Nettoyage des surfaces peintes

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-20

Outils et accessoires recommandés

pour l’installation . . . . . . . . . . . . . . . . . . . . . . . . 7

Installation des conduits

(installations avec conduits seulement) . . . . . . 7

Contenu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Préparation de la hotte . . . . . . . . . . . . . . . . . . . 9-11

Préparation de l’emplacement de la hotte . . . . . 12

Système d’installation par une personne EZ1 12-14

Installation de la hotte (avec supports EZ1) . . 15-16

Installation standard . . . . . . . . . . . . . . . . . . . . 17

Installation de la hotte (installation standard) . 18

Branchement électrique . . . . . . . . . . . . . . . . . . 19

Ampoules (série ALT1 seulement) . . . . . . . . . . 20

Installation des filtres . . . . . . . . . . . . . . . . . . . . 20

MANUEL D’INSTALLATION

TABLE DES MATIÈRES

22

Schémas électriques . . . . . . . . . . . . . . . . . . . . . 21

Pièces de rechange . . . . . . . . . . . . . . . . . . . . 22-23

Garantie . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

VEUILLEZ LIRE ET CONSERVER CES DIRECTIVES

!

Conçues pour usage domestique seulement

INSTALLATEUR : LAISSER CE MANUEL AU PROPRIÉTAIRE.

Aux États-Unis, enregistrez votre hotte en ligne à www.broan.com

Au Canada, enregistrez votre hotte en ligne à www.broan.ca

!

AVERTISSEMENT

AFIN DE RÉDUIRE LES RISQUES D’INCENDIE, D’ÉLECTROCUTION OU

DE BLESSURES CORPORELLES, SUIVEZ LES DIRECTIVES SUIVANTES :

• N’utilisez cet appareil que de la façon prévue par le manufacturier. Si vous

avez des questions, contactez le manufacturier à l’adresse ou au numéro

de téléphone indiqués dans la garantie.

• Avant de réparer ou de nettoyer l’appareil, couper l’alimentation électrique

en verrouillant le panneau de distribution afin d’éviter sa remise en marche

accidentelle. Si le panneau de distribution ne peut être verrouillé, y fixer un

avertissement en évidence, telle qu’une étiquette de couleur vive.

• Les travaux d’installation et de raccordement électrique doivent être

effectués par une personne qualifiée, conformément aux codes et aux

standards de construction, incluant ceux concernant la protection contre

les incendies.

• Une quantité d’air adéquate est requise afin d’assurer une bonne

combustion et l’évacuation des gaz par la cheminée dans le cas des

équipements alimentés au gaz afin de prévenir les retours de cheminée.

Conformez-vous aux instructions et aux standards de sécurité des

manufacturiers d’équipement de chauffage, tel qu’ils sont publiés par

la National Fire Protection Association (NFPA) et l’American Society for

Heating, Refrigeration and Air Conditioning Engineers (ASHRAE) ainsi

que les responsables des codes locaux.

• Veillez à ne pas endommager le câblage électrique ou d’autres équipements

non apparents lors de la découpe ou du perçage du mur ou du plafond.

• Les ventilateurs avec conduits doivent toujours évacuer l’air à l’extérieur.

• Ne pas utiliser cet appareil avec une commande de vitesse à

semi-conducteur additionnelle.

• Afin de réduire les risques d’incendie, n’utilisez que des conduits de métal.

• Cet appareil doit être mis à la terre.

• Si désiré, ce produit peut être installé avec l’ensemble de cordon

d’alimentation homologué par UL spécialement conçu pour ce produit, en

suivant les directives incluses avec le cordon.

• Lorsqu’une réglementation est en vigueur et qu’elle comporte des

exigences d’installation et/ou de certification plus restrictives, lesdites

exigences prévalent sur celles de ce document et l’installateur entend s’y

conformer à ses frais.

!

MANUEL D’INSTALLATION

SÉCURITÉ

33

!

AVERTISSEMENT

AFIN DE RÉDUIRE LES RISQUES DE FEU DE CUISINIÈRE :

a) Ne jamais laisser les appareils de cuisson sans surveillance lorsqu’ils sont

réglés à feu vif. Les débordements engendrent de la fumée et des déversements

graisseux pouvant s’enflammer. Chauffez l’huile lentement, à feu doux ou moyen.

b) Mettez toujours la hotte en marche lorsque vous cuisinez à feu vif ou que vous

cuisinez des mets flambés (par ex. : crêpes Suzette, cerises jubilé, steaks au

poivre flambés).

c) Nettoyez régulièrement l’hélice du ventilateur. Ne laissez pas la graisse

s’accumuler sur le ventilateur, le filtre ou les conduits d’évacuation.

d) Utilisez le bon format de casserole. Servez-vous toujours de casseroles et

d’ustensiles appropriés à la dimension de la surface chauffante.

AFIN DE RÉDUIRE TOUT RISQUE DE BLESSURES LORS D’UN FEU DE

CUISINIÈRE, SUIVEZ CES DIRECTIVES* :

1. ÉTOUFFEZ LES FLAMMES avec un couvercle hermétique, une tôle à

biscuits ou un plateau métallique et ensuite, éteignez le brûleur. PRENEZ

SOIN D’ÉVITER LES BRÛLURES. SI LES FLAMMES NE S’ÉTEIGNENT PAS

IMMÉDIATEMENT, ÉVACUEZ LES LIEUX ET APPELEZ LES POMPIERS.

2. NE PRENEZ JAMAIS UNE CASSEROLE EN FLAMMES DANS VOS MAINS.

Vous pourriez vous brûler.

3. N’UTILISEZ PAS D’EAU, incluant un linge à vaisselle ou une serviette mouillée,

cela pourrait occasionner une violente explosion de vapeur.

4. N’utilisez un extincteur QUE DANS LE CAS OÙ :

A. Vous possédez un extincteur de classe ABC et vous en connaissez le

fonctionnement.

B. Le feu est petit et limité à l’endroit où il a débuté.

C. Les pompiers ont été avisés.

D. Vous pouvez combattre le feu en ayant accès à une sortie de secours.

* Tirées du Kitchen Fire Safety Tips publié par la NFPA.

MANUEL D’INSTALLATION

SÉCURITÉ

44

!

ATTENTION

• Pour une utilisation à l’intérieur seulement.

• Pour usage domestique seulement. Ne pas utiliser pour évacuer des vapeurs ou des matières

dangereuses ou explosives.

• Afin d’éviter tout dommage aux moteurs et de déséquilibrer ou de rendre bruyantes les roues du

ventilateur, garder votre appareil à l’abri des poussières de gypse et de construction/rénovation, etc.

• Le moteur de votre hotte possède une protection thermique qui éteindra automatiquement le

moteur s’il devient surchauffé. Le moteur redémarrera automatiquement une fois refroidi. Si le

moteur continue à arrêter et à redémarrer, faites-le vérifier.

• Pour une meilleure évacuation des odeurs de cuisson, le bas de votre hotte devrait être situé À UN

MINIMUM de 18 po et à un maximum de 24 po au-dessus de la surface de cuisson.

• Toujours suivre les recommandations du manufacturier de l’appareil de cuisson concernant les

exigences de cet appareil en matière de ventilation.

• Afin de réduire les risques d’incendie et évacuer l’air adéquatement, assurez-vous que les conduits

évacuent l’air à l’extérieur. Ne pas évacuer l’air dans des espaces restreints comme l’intérieur des

murs ou plafond ou dans le grenier, faux plafond ou garage.

• Il est recommandé de porter des lunettes et des gants de sécurité lors de l’installation, de

l’entretien ou de la réparation de cet appareil.

• Veuillez consulter l’autocollant apposé à l’intérieur de la hotte pour plus d’information ou autres

exigences.

Fonctionnement

Toujours mettre en marche la hotte avant de commencer la cuisson afin d’établir une circulation

d’air dans la cuisine. Laisser également la hotte fonctionner quelques minutes après l’arrêt de la

cuisinière afin de nettoyer l’air. Cela aidera à maintenir la cuisine plus propre et plus fraîche.

Faire fonctionner la hotte comme suit :

SÉRIE ALT2

BOUTON DU VENTILATEUR

Lorsque le ventilateur est en ARRÊT, appuyer sur ce bouton pour ACTIVER le ventilateur à la dernière

vitesse mémorisée. Si aucune vitesse n’est mémorisée, le ventilateur s’activera en BASSE vitesse.

NOTE : Si la basse vitesse est activée lorsque le ventilateur est en ARRÊT, le ventilateur démarre en

vitesse MOYENNE pour un très court laps de temps, puis se règle en BASSE vitesse.

Pour changer la vitesse du ventilateur, appuyer encore sur ce bouton jusqu’à l’atteinte de la vitesse

désirée (de BASSE à MOYENNE à HAUTE). À partir de la HAUTE vitesse, appuyer une autre fois

sur le bouton pour ARRÊTER le ventilateur. À chaque fois qu’une vitesse de ventilateur est activée,

un bip se fait entendre et un ou des témoins DEL s’allument pour indiquer la vitesse choisie (DEL

du bas pour la BASSE vitesse, DEL du bas et centrale pour la vitesse MOYENNE et toutes les

DEL pour la HAUTE vitesse).

Lorsque le ventilateur fonctionne (peu importe la vitesse), appuyer et maintenir la pression sur ce

bouton jusqu’à ce que le bip s’arrête; ceci arrêtera le ventilateur et mémorisera sa vitesse.

BOUTON DE L’ÉCLAIRAGE

Lorsque l’éclairage est ÉTEINT, appuyer une fois sur ce bouton pour ALLUMER les lumières à leur

dernier niveau d’intensité mémorisé. Si aucun niveau d’intensité d’éclairage n’est mémorisé, les

lumières allumeront en BASSE intensité. Appuyer une autre fois pour régler l’éclairage à HAUTE

intensité. À partir de la HAUTE intensité, appuyer une autre fois sur le bouton pour ÉTEINDRE

les lumières. À chaque fois que les lumières sont allumées, un bip se fait entendre et un ou deux

témoins DEL s’allument pour indiquer l’intensité d’éclairage choisie (DEL du bas pour la BASSE

intensité et les deux DEL pour la HAUTE intensité).

Lorsque l’éclairage est allumé (peu importe le niveau), appuyer et maintenir la pression sur ce

bouton jusqu’à ce que le bip s’arrête; ceci éteindra l’éclairage et mémorisera l’intensité choisie.

Cette hotte est munie de modules DEL offrant un éclairage brillant, issus de la plus récente

technologie en matière d’éclairage de surface de cuisson et spécialement conçus pour fonctionner

dans un environnement à chaleur élevée. Leur durabilité est jusqu’à 25 fois supérieure à celle

d’ampoules standards et ils sont plus robustes que les ampoules à DEL typiques.

RAPPEL D’ENTRETIEN DES FILTRES

Lorsqu’il est temps de nettoyer la hotte et les filtres (voir Nettoyage et entretien en page 6), les 3 témoins

DEL du bouton du ventilateur clignoteront lentement durant 30 secondes après avoir arrêté le

ventilateur. Ce clignotement se produira à toutes les fois où on arrêtera le ventilateur, jusqu’à ce que le

rappel d’entretien des filtres soit remis à zéro. Une fois le nettoyage terminé, remettre les témoins à zéro

en appuyant 3 secondes sur le bouton du ventilateur pendant les 30 secondes de clignotement des DEL.

SÉRIE ALT1

FONCTIONNEMENT

MANUEL D’INSTALLATION

COMMUTATEUR DU VENTILATEUR

I Active le ventilateur à BASSE vitesse.

• ARRÊTE le ventilateur.

II Active le ventilateur à vitesse ÉLEVÉE.

COMMUTATEUR DE L’ÉCLAIRAGE

I Allume les lumières à BASSE intensité.

• ÉTEINT les lumières.

II Allume les lumières à HAUTE intensité.

55

Nettoyage et entretien

L’entretien adéquat de la hotte préservera ses performances.

MOTEUR

Le moteur est lubrifié en permanence et n’a pas besoin d’être huilé. Si les roulements du moteur

sont anormalement bruyants, remplacer le moteur uniquement par le même modèle. L’hélice doit

aussi être remplacée.

FILTRES À GRAISSES

Les filtres à graisses doivent être nettoyés fréquemment. Utiliser une solution d’eau chaude et de

détergent. Les filtres sont lavables au lave-vaisselle.

Nettoyer les filtres fabriqués entièrement de métal au lave-vaisselle à l’aide d’un détergent sans

phosphate. L’utilisation d’un détergent avec phosphates ainsi que les conditions locales de l’eau

peuvent entraîner une décoloration des filtres, sans toutefois affecter leur performance. Cette

décoloration n’est pas couverte par la garantie. Afin de prévenir ou de limiter la décoloration,

laver les filtres à la main avec un détergent doux.

FILTRES DE RECIRCULATION

Les filtres de recirculation devraient être remplacés tous les 3 à 6 mois. Remplacer plus souvent

si vos habitudes de cuisson génèrent plus de graisses, comme par exemple la friture ou les

aliments sautés au wok. Voir les directives d’installation incluses avec les filtres de recirculation.

HÉLICE

L’hélice doit être nettoyée fréquemment. Utiliser un chiffon propre imbibé d’une solution d’eau

chaude et de détergent.

NETTOYAGE DE L’ACIER INOXYDABLE

À faire :

• Laver régulièrement les surfaces à l’aide d’un chiffon propre imbibé d’eau chaude et de

savon doux ou de détergent liquide à vaisselle.

• Toujours nettoyer dans le sens du polissage.

• Toujours bien rincer avec de l’eau claire (2 à 3 fois) et essuyer complètement.

• Un nettoyant domestique conçu spécialement pour l’acier inoxydable peut aussi être utilisé.

À ne pas faire :

• Ne pas utiliser de laine d’acier ou d’acier inoxydable ou tout autre grattoir pour enlever la

saleté tenace.

• Ne pas utiliser une poudre nettoyante abrasive ou rugueuse.

• Ne pas laisser la saleté s’accumuler.

• Ne pas laisser la poussière de plâtre ou tout autre résidu de construction atteindre la hotte.

Couvrir la hotte pour la durée des travaux afin de s’assurer qu’aucune poussière n’atteigne la hotte.

À éviter lors du choix du détergent :

• Tous produits nettoyants contenant des agents de blanchiment; ils attaqueront l’acier inoxydable.

• Tous produits contenant du chlorure, du fluorure, de l’iode ou du bromure; ils détérioreront

rapidement les surfaces.

• Tous produits combustibles utilisés pour le nettoyage : acétone, alcool, éther, benzène, etc.;

ils sont grandement explosifs et ne devraient jamais être utilisés près d’une cuisinière.

MANUEL D’INSTALLATION

NETTOYAGE ET ENTRETIEN

NETTOYAGE DES SURFACES PEINTES :

Nettoyer avec de l’eau chaude additionnée de détergent doux seulement. S’il y a décoloration,

utiliser une bonne cire telle qu’une cire automobile. (NE PAS utiliser de nettoyant abrasif ou de

66

nettoyant à porcelaine.)

Pour connaître les lignes directrices de l’ADA (Americans with Disabilities Act) concernant

l’installation, veuillez visiter www.broan.com

Outils et accessoires recommandés pour l’installation

• Ruban à mesurer

• Tournevis Phillips n° 2

• Tournevis à lame plate (pour dégager les ouvertures préamorcées)

• Perceuse, foret de 1/8 po et scie cloche de 1½ po (pour marquer les repères des trous pour

les conduits et découper le trou pour le passage du fil d’alimentation électrique)

• Foret de 7/64 po (pour percer les trous des vis de montage des supports EZ1)

• Cales de bois (2) et vis à bois (4) (requises pour une installation sous une armoire à fond en retrait)

• Scie (pour la découpe des trous d’une installation avec conduits)

• Cisailles à tôle (installation avec conduits, pour l’ajustement de ceux-ci)

• Pinces (installation avec conduits, pour l’ajustement de ceux-ci)

• Ruban adhésif de métal (installation avec conduits)

• Ciseaux (pour couper le ruban adhésif de métal)

• Crayon

• Pince à dénuder

• Serre-fils de 1/2 po de diamètre (pour fixer le câble d’alimentation électrique de la maison à la hotte)

Installation des conduits

(installations avec conduits seulement)

CAPUCHON DE TOIT

SOFFITE

ARMOIRE

HOTTE

DE 18 PO MIN. À 24 PO MAX.

AU-DESSUS DE LA SURFACE DE CUISSON

NOTE : Une distance supérieure à 24 po demeure à la discrétion de l’installateur et de l’utilisateur.

1 ] Déterminer si l’évacuation se fera verticalement (3¼ po x 10 po ou 7 po rond),

ou horizontalement (3¼ po x 10 po seulement).

2 ] Établir où le conduit passera entre la hotte et l’extérieur.

3 ] Un conduit droit et court permettra à votre hotte de fonctionner plus efficacement. Un conduit

long avec des coudes et des transitions réduira la performance de votre hotte. En utiliser le

moins possible. Si possible, utiliser un conduit droit d’au moins 2 pieds avant d’installer un

coude. Pour une grande distance, un conduit d’évacuation de l’air au diamètre plus grand peut

être requis pour obtenir une meilleure performance.

NOTE : Pour utiliser des conduits ronds de 6 po, installer une transition de 3¼ po x 10 po à 6 po

rond (non incluse). Les performances pourraient être affectées.

4 ] Installer un capuchon de toit ou de mur (vendus séparément). Relier le conduit en métal au

capuchon, puis acheminer le conduit jusqu’à l’emplacement de la hotte. Sceller hermétiquement

les raccords à l’aide de ruban adhésif de métal de 2 po de largeur.

CONDUIT DE 3¼ PO X 10 PO

7 PO ROND

OU

(POUR ÉVACUATION VERTICALE)

CÂBLAGE DOMESTIQUE

(DESSUS OU ARRIÈRE

LA HOTTE)

DE

CAPUCHON DE MUR

CONDUIT DE 3¼ PO X 10 PO

(POUR ÉVACUATION HORIZONTALE)

INSTALLATION

MANUEL D’INSTALLATION

77

Contenu

VERTICAL EXHAUST

VERTICAL EXHAUST

Avant de procéder à l’installation, vérifier le contenu de la boîte. Si des articles sont manquants

ou endommagés, contacter le manufacturier.

S’assurer que les articles suivants sont inclus :

Série ALT2 Série ALT1

* À L’INTÉRIEUR DE LA HOTTE

(2) F

ILTRES À GRAISSES

Use this template for marking;do not attempt to cut out the ducting hole through it.

NOTE: These cutouts are clearance holes; they do not need to be the exact size of ducting.

Utiliser ce gabarit pour marquer vos repères;ne pas tenter de découper

le trou pour le conduit à travers le gabarit.

NOTE : Les découpes incluent le jeu nécessaire à l’installation; elles ne doivent pas

être du format exact des conduits.

Use esta plantilla para crear marcados;no trate de cortar el

agujero del conducto a través de la plantilla.

NOTA: To be translated in Spanish.

Bend template along graduated

scale when installing to framed

cabinet.

C

Pour une installation sous une

armoire à fond en retrait, utiliser les

lignes pour mesurer l’épaisseur du

décalage causé par le mur de

l’armoire et plier le gabarit en

8”

conséquence.

To be translated in Spanish.

C

14½”

Appuyer ce bord au mur arrière

(1) ADAPTATEUR/VOLET*

3¼

PO X 10 PO

OMPOSANTS EZ1

C

MARKWHEREINDICATED

FORTHEAPPROPRIATESIZE DUCTOPENING

RECTANGULAR DUCTING7” ROUND DUCTING

OR

= 3¼” x 10”

= 3¼” x 14”

MARQUERLESREPÈRES AUX ENDROITS INDIQUÉS SELON

LEFORMATDECONDUIT UTILISÉ

CONDUITRECTANGULAIRECONDUITRONDDE 7 PO

OU

= 3¼ po x 10 po