Broan 345 Instructions Manual

MODEL 345 ROOF-MOUNT

!

POWERED ATTIC VENTILATOR

READ AND SAVE THESE INSTRUCTIONS

MODEL 345

Page 1

WARNING

TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK, OR

INJURY TO PERSONS, OBSERVE THE FOLLOWING:

1. Use this unit only in the manner intended by the manufacturer.

If you have any questions, contact the manufacturer at the

address or telephone number listed in the warranty.

2. Before servicing or cleaning unit, switch power off at

service panel and lock the service disconnecting means to

prevent power from being switched on accidentally. When the

service disconnecting means cannot be locked, securely

fasten a prominent warning device, such as a tag, to the

service panel.

3. Installation work and electrical wiring must be done by a

qualified person(s) in accordance with all applicable codes

and standards, including fire-rated construction codes and

standards.

4. Sufficient air is needed for proper combustion and

exhausting of gases through the flue (chimney) of fuel burning

equipment to prevent backdrafting. Follow the heating

equipment manufacturer’s guideline and safety standards such

as those published by the National Fire Protection Association

(NFPA), and the American Society for Heating, Refrigeration

and Air Conditioning Engineers (ASHRAE), and the local code

authorities.

5. When cutting or drilling into wall or ceiling, do not damage

electrical wiring and other hidden utilities.

6. The wiring must be permanent. DO NOT USE AN EXTENSION

CORD! Use 14 GA. MINIMUM copper wire. Although the

Powered Attic Ventilator may be wired directly to power, we

advise that some type of shut off switch be installed in the

line. Please see the section on electrical wiring for suggested

wiring diagrams and instructions.

7. To reduce the risk of electric shock, do not use this fan with

any solid-state speed control device.

8. This unit must be grounded.

9. When applicable local regulations comprise more restrictive

installation and/or certification requirements, the aforementioned

requirements prevail on those of this document and the installer

agrees to conform to these at his own expenses.

10. When performing installation, servicing or cleaning this unit, it

is recommended to wear safety glasses and gloves.

CAUTION

1. For general ventilating use only. Do not use to exhaust

hazardous or explosive materials and vapors.

2. To avoid motor bearing damage and noisy and/or unbalanced

impeller, keep drywall spray, construction dust, etc. off power

unit.

3. This unit has an unguard impeller. Do not use in locations

readily accessible to people or animals.

4. Fan is equipped with a thermostat which may start fan

automatically. To reduce risk of injury or electric shock while

servicing or cleaning unit, switch power off at service panel

and lock service panel to prevent power from being switched

on accidentally. When the service disconnecting means cannot

be locked, securely fasten a prominent warning device, such

as a tag, to the service panel.

5. Home Ventilating Institute (HVI) recommends one square foot of

open air inlet per 300 cfm of fan capacity. The best location for

these air intake vents are under the eaves with direct access

to the attic. Failure to provide these intakes could cause naturaldraft

gas appliances to backdraft.

6. Your attic fan installation will create a screened opening into

your attic space. During a heavy rain storm there could be a light

spray of rain into this attic space. This is a normal condition with

all attic ventilators and will not cause any damage to the structure.

We recommend that you do not store any valuable articles

directly under the fan opening in the roof. During extreme rain

and wind storms you may want to turn on your attic ventilator

to prevent excess moisture accumulation in your attic.

7. Records show, under ideal conditions, exposed galvanized steel

can remain rust free up to 100 years. For best protection, the

exposed portion of the roof sheet should be painted, especially

in areas of unusually high industrial air pollution. Follow paint

manufacturer’s instructions for good adhesion.

8. This ventilator is intended for roof installation.

9. The dome may be painted with a high-quality paint. Follow the

paint manufacturer’s recommendations for powder-coated steel.

10. Please read specification label on product for further information

and requirements.

Register your product

online at www.broan.ca

TOOLS AND MATERIAL REQUIRED

Slotted Screwdriver Sabre Saw or Keyhole Saw Pencil Roofing Cement

Drill Utility Knife or Shears (to cut shingles) Hammer Galvanized Roofing Nails (1¾” min)

1/4” Drill Bit Pry Bar (to remove roofing nails) Measuring tape Electrical Supplies (to comply with codes)

Installer: Leave this manual with the homeowner.

MODEL 345

6

1

2

3

4

5

7

8

9

17½

14

3

/

8

Page 2

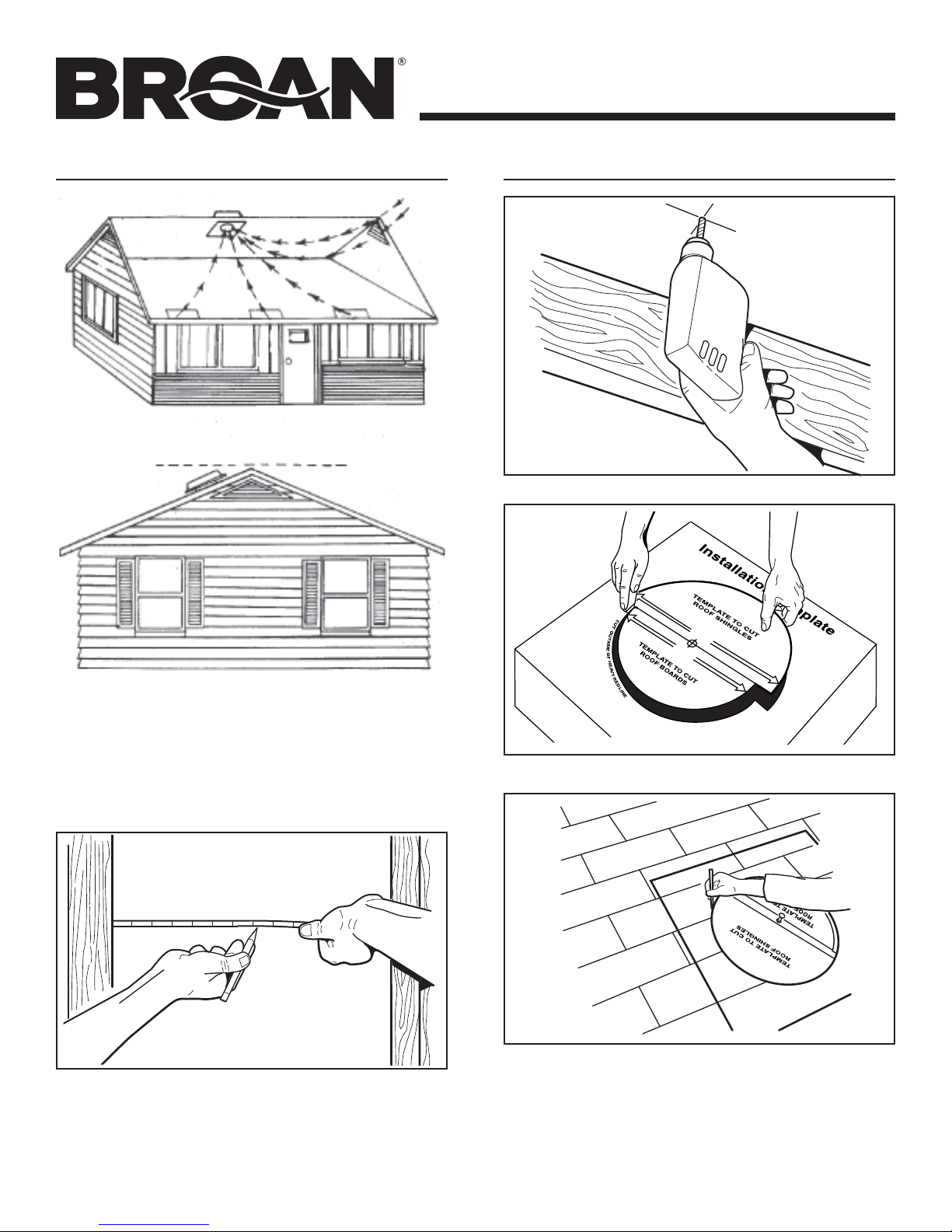

INSTALLATION

A

B

INSTALLATION (CONTINUED)

3. Drill a guide hole through the roof at this mark.

1. Locate the ventilator at the center of the rear slope of the roof.

Place it as high on the roof as possible. The location should

be free of obstacles (T.V. leads, electrical lines, etc., see A in

illustration). If the ventilator top is level with the roof peak, it

can’t be seen from the street (see B in illustration). Keep this

approximate location in mind as you work from within the attic.

With the location set, measure down from the roof peak to the

center or the powered attic ventilator. Note this measurement.

2. From inside the attic, measure and place a mark at the point

which is one half the distance between 2 rafters, closest to

the position of the powered attic ventilator. Draw a line parralel

to the rafters. Measure down from the roof peak the distance

found in Step 1 and mark that measurement on the center

line between the 2 rafters.

4. Cut out the red and blue template found on the carton.

5. On the roof outside, mark 4 lines at 11½” from the guide hole

to form a 23" square. These lines will be used to center the

unit over the hole to be cut off.

Push a large nail through the center of the cardboard template

and into the guide hole.

Using the large half of the template, draw a 17½” diameter

circle on the shingles.

MODEL 345

INSTALLATION (CONTINUED) INSTALLATION (CONTINUED)

Page 3

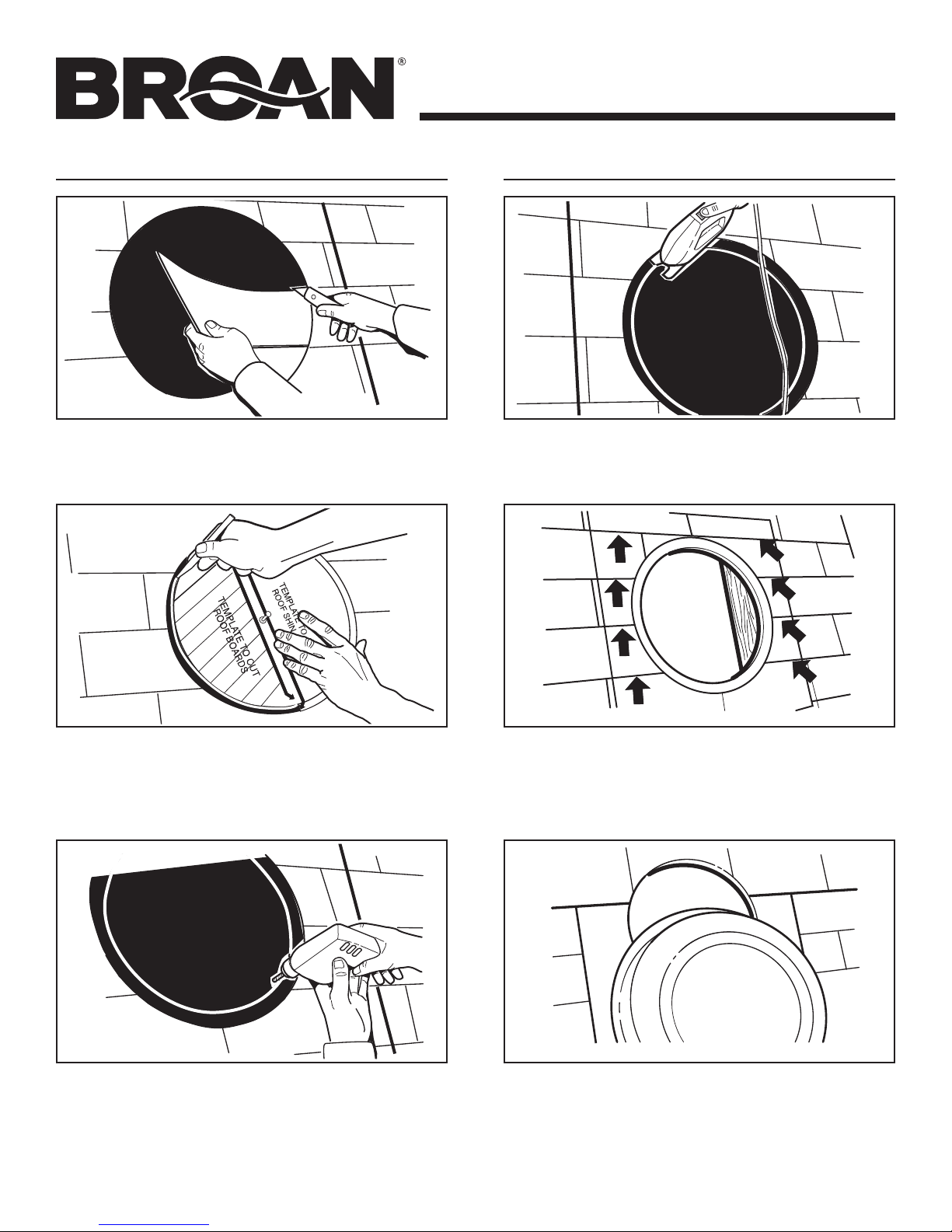

6. Remove the template and cut out the shingles inside of the

circle.

7. Replace template over guide hole and draw a 14 ³/8” diameter

circle on the black paper or roof boards using the smaller half

of the template.

9. Cut out the roof board(s) inside of the line. Do not cut

rafters.

10. Using a pry bar, remove nails holding shingles down from top

two-thirds of the 23” square drawn on the roof.

8. Drill a large starting hole for the sabre saw just inside of the

line drawn in Step 7.

11. Slide the flashing under the shingles. Start two-thirds of the way

down from the top of the 23” square. Do not bend the shingles

any more than necessary. Center the ventilator over the hole

using the 23” square drawn on the roof as guide. Make sure the

logo is parallel to the roof shingles and is not upside down.

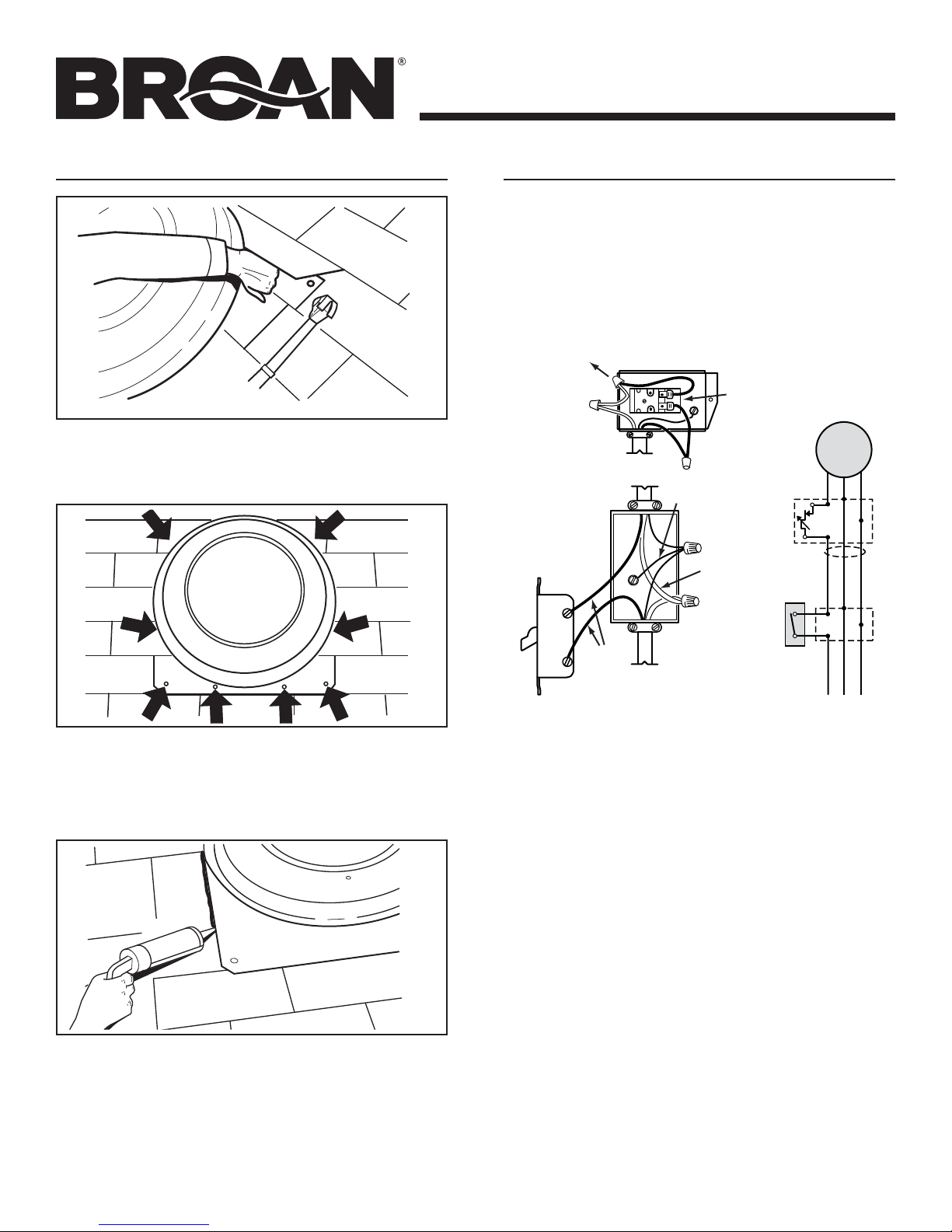

INSTALLATION (CONTINUED) WIRING

MOTOR

VENTILATOR

WIRING BOX

MASTER

ON-OFF

SWITCH

BLK

GRD

WHT

BLK

WHT

GRD

TO

MOTOR

THERMOSTAT

120 VOLTS

LINE IN

WHITE

GROUND TO

SWITCH BOX

BLACK

MASTER

ON-OFF

SWITCH

WARNING: TURN OFF ELECTRICAL HOUSE CURRENT AT

SERVICE ENTRANCE BEFORE WIRING. INSTALLATION WORK

AND ELECTRICAL WIRING MUST BE DONE BY A QUALIFIED

PERSON(S) IN ACCORDANCE WITH ALL APPLICABLE

CODES AND STANDARDS, INCLUDING THE NATIONAL

ELECTRICAL CODE.

1. Remove the thermostat wiring box cover plate. Bring the power

cable at least 6” into the ventilator wiring box. Fasten to box

with appropriate connector.

12. Carefully lift shingles and nail flashing securely to the roof

using broad headed galvanized roofing nails..

MODEL 345

Page 4

13. Nail under shingles at the top two corners and both sides. Nail

flashing directly to the roof in four places on the botttom.

14. Using a good grade of roofing cement material, seal all of the

shingles and heads of nails.

DO NOT SEAL the bottom edge of flashing.

2. For standard installation, connect the two leads in the thermostat

wiring box to the two power leads. Attach ground wire from

the power cable to the GREEN ground screw in the box.

Loading...

Loading...