Broan HRV100H, HRV200H, ERV100HC, ERV200HC, 1001 ERV Installer Manual

...

INSTALLER MANUAL

VENTILATION SYSTEMS

VB0065

vänEE Canadian Model Numbers

1001 ERV

1001 HRV*

2001 ERV

2001 HRV*

READ AND SAVE THESE INSTRUCTIONS

Broan U.S.A. Model Numbers

HRV100H

HRV200H

ERV100HC

ERV200HC

* These products earned the ENERGY STAR® by meeting strict energy efficiency

guidelines set by Natural Resources Canada and the US EPA. They meet

ENERGY STAR requirements only when used in Canada.

03119 rev. 09

TABLE OF CONTENTS

1. SERVICE ........................................................................................................................................................3-4

1.1 3-D DRAWING ............................................................................................................................................................3

1.2 PARTS ORDERING CHART .............................................................................................................................................4

1.3 T

2. UNIT TYPE & DEFROST SETTING VS GEOGRAPHICAL LOCATION .................................................................................. 5

3. T

3.1 AIR DISTRIBUTION (NORMAL OPERATION) ........................................................................................................................6

3.2 AIR DISTRIBUTION (DEFROST MODE) ..............................................................................................................................6

3.3 DEFROST CYCLE TABLE..................................................................................................................................................6

3.4 DIMENSIONS ...............................................................................................................................................................7

3.5 C

3.6 S

4. TYPICAL INSTALLATIONS .......................................................................................................................................8

4.1 FULLY DUCTED SYSTEM ................................................................................................................................................8

4.2 EXHAUST DUCTED SYSTEM (SOURCE POINT VENTILATION) .................................................................................................8

4.3 SIMPLIFIED (VOLUME VENTILATION) .................................................................................................................................8

5. INSTALLATION ................................................................................................................................................ 9-14

5.1 LOCATING AND MOUNTING THE UNIT ...............................................................................................................................9

5.2 PLANNING OF THE DUCTWORK .......................................................................................................................................9

5.3 CALCULATING THE DUCT SIZE ...................................................................................................................................... 10

5.3.1 EXAMPLE OF CALCULATION ...................................................................................................................................................10

5.3.2 E

5.4 INSTALLING THE DUCTWORK AND REGISTERS .................................................................................................................. 11

5.4.1 FULLY DUCTED SYSTEM.......................................................................................................................................................11

5.4.2 E

5.4.3 S

5.5 CONNECTING DUCT TO THE UNIT .................................................................................................................................13

5.6 INSTALLING EXTERIOR HOODS ...................................................................................................................................... 14

5.7 CONNECTING THE DRAIN .............................................................................................................................................14

6. CONTROL DEVICES ...................................................................................................................................... 15-16

6.1 MAIN CONTROLS .......................................................................................................................................................15

6.2 OPTIONAL CONTROLS .................................................................................................................................................16

6.3 OTHER FEATURES ......................................................................................................................................................16

6.4 MAIN AND OPTIONAL CONTROLS AVAILABLE FOR YOUR UNIT .............................................................................................16

7. I NSTALLATION OF THE CONTROLS .....................................................................................................................17-20

7.1 DIMENSIONS AND SPECIFICATIONS (MAIN CONTROLS) ......................................................................................................17

7.2 INSTALLATION OF THE MAIN CONTROL ....................................................................................................................... 17-19

7.2.1 PLATINUM MAIN CONTROL INSTALLATION .................................................................................................................................17

7.2.2 D

7.2.3 D

7.2.4 M

7.3 ELECTRICAL CONNECTION TO OPTIONAL CONTROLS ........................................................................................................19

7.4 E

8. WIRING DIAGRAMS ...................................................................................................................................... 21-22

9. A

9.1 WHAT YO U NEED TO BALANCE THE UNIT .......................................................................................................................23

9.2 PRELIMINARY STAGES TO BALANCE THE UNIT .................................................................................................................23

9.3 INSTALLATION OF FLOW COLLARS OR "FLOW MEASURING STATIONS" ...................................................................................23

9.4 BALANCING PROCEDURE .............................................................................................................................................24

10. OVERALL VERIFICATION ................................................................................................................................ 25-26

10.1 MAIN CONTROLS .......................................................................................................................................................25

10.2 OPTIONAL CONTROL ..................................................................................................................................................26

11. MAINTENANCE/INSTRUCTIONS FOR USER .............................................................................................................. 26

12. T

13. R

ECHNICAL SUPPORT ...................................................................................................................................................4

ECHNICAL DATA ............................................................................................................................................. 6-7

ONTROLS AND FURNACE LINK OPTION ...........................................................................................................................7

PECIFICATIONS ...........................................................................................................................................................7

XAMPLE OF A DESIGN FOR A FULLY DUCTED SYSTEM .............................................................................................................10

XHAUST DUCTED SYSTEM (SOURCE POINT VENTILATION) ........................................................................................................11

IMPLIFIED INSTALLATION (VOLUME VENTILATION) .....................................................................................................................12

ECO-TOUCH MAIN CONTROL INSTALLATION ...........................................................................................................................18

EHUMIDISTAT, DH100W, VT1W AND VT2W MAIN CONTROL INSTALLATION ..............................................................................18

AIN CONTROL ELECTRICAL CONNECTION ..............................................................................................................................19

LECTRICAL CONNECTION TO THE FURNACE ...................................................................................................................20

IR FLOW BALANCING .................................................................................................................................23-24

ROUBLESHOOTING ...................................................................................................................................... 27-28

EFERENCES .................................................................................................................................................. 28

2

ABOUT THIS MANUAL

This manual uses the following symbols to emphasize particular information:

!

WARNING

Identifies an instruction which, if not followed, might cause serious personal injuries including possibility of

death.

CAUTION

Denotes an instruction which, if not followed, may severely damage the unit and/or its components.

NOTE: Indicates supplementary information needed to fully complete an instruction.

!

WARNING

Installation work and electrical wiring must be done by a qualified person(s) in accordance with all applicable

codes and standards, including fire-rated construction codes and standards.

1. SERVICE

1.1 3-D DRAWING

DAMPER ASSEMBLY (REAR VIEW)

23

6

1

4

5

7

8

2

3

20

9

10

11

15

12

26

25

24

23

22

21

19

18

3

VL0016

13

14

16

17

3

1. SERVICE (CONT'D)

1.2 PARTS ORDERING CHART

NO.DESCRIPTION

1DOUBLE COLLAR PORT NO. 2 00866 00866 00866 00866 00866 00866 00866 00866

ING NUT NO. 10-32 00874 00874 00874 00874 00874 00874 00874 00874

2W

3B

ALANCING DOUBLE COLLAR PORT 02256 02256 02256 02256 02256 02256 02256 02256

4INLET RING 12913 12913 12913 12913 12913 12913 12913 12913

OP WHEEL 14307 03093 14308 03093 14307 03093 14308 03093

5T

6ELECTRONIC BOARD V99 13507 13507 13507 13507 13508 13507 13508 13507

7MOTOR ASSEMBLY 13504 13555 13556 13506 13504 13555 13505 13506

8BOTTOM WHEEL 02015 02015 03093 03093 02015 02015 03093 03093

9SQUARE BALANCING DAMPER 12645 12645 12645 12645 12645 12645 12645 12645

10 DOOR LATCHES (LATCH) 00886 00886 00886 00886 00886 00886 00886 00886

11 D RAIN CONNECTOR 02418 02418 02418 02418 02418 02418 02418 02418

12 DRAIN GASKET 0.625" D 02419 02419 02419 02419 02419 02419 02419 02419

ASHER 5/8" ID X 1" OD 03117 03117 03117 03117 03117 03117 03117 03117

13 W

14 NUT 5/8-18 02420 02420 02420 02420 02420 02420 02420 02420

15 RECOVERY CORE 03132 03136 03133 03137 03134 03136 03135 03137

16 DOOR ASSEMBLY 12644 12644 12644 12644 12648 12648 12648 12648

17 DOOR LATCHES (KEEPER) 00887 00887 00887 00887 00887 00887 00887 00887

18 HINGE ASSEMBLY 00672 00672 00672 00672 00672 00672 00672 00672

19 FILTER 03096 03096 03097 03097 03096 03096 03097 03097

20 SWITCH E69 10A 01825 01825 01825 01825 01825 01825 01825 01825

21 DAMPER ASSEMBLY NO. 2 12643 12643 12649 12649 12643 12643 12649 12649

22 PLASTIC BALANCING DAMPER 02253 02253 02253 02253 02253 02253 02253 02253

AMPER ROD 12620 12620 12620 12620 12620 12620 12620 12620

23 D

24 DOUBLE COLLAR PORT NO. 5 02021 02021 02021 02021 02021 02021 02021 02021

25 DAMPER NO. 1 12459 12459 12459 12459 12459 12459 12459 12459

26 DAMPER ACTUATOR ASSEMBLY 03124 03124 03124 03124 03124 03124 03124 03124

1001

HRV

1001

ERV

2001

HRV

2001

ERV

HRV

100H

ERV

100HC

HRV

200H

ERV

200HC

Please note that parts not listed are not available; those parts require assembly knowledge that only manufacturer can guarantee.

REPLACEMENT PARTS AND REPAIRS

In order to ensure your ventilation unit remains in good working condition, you must use the manufacturer genuine replacement parts

only. The manufacturer replacement parts are specially designed for each unit and are manufactured to comply with all the applicable

certification standards and maintain a high standard of safety. Any third party replacement part used may cause serious damage and

drastically reduce the performance level of your unit, which will result in premature failing. The manufacturer recommends to contact a

certified service depot for all replacement parts and repairs.

TO ORDER PARTS: Contact your local distributor.

1.3 TECHNICAL SUPPORT (FOR ASSISTANCE)

For assistance, call on weekdays, from 8:30 a.m. to 5:00 p.m. (Eastern Standard Time).

NOTE: Do not call these numbers for ordering parts.

Technical Support Department

Canada: 1-888-908-2633 (for distributors only)

U.S.A.: 1-800-637-1453

4

2. UNIT TYPE AND DEFROST SETTING VS GEOGRAPHICAL LOCATION

ST JOHN'S

GOOSE BAY

CHARLOTTETOWN

BATHURST

QUEBEC

HALIFAX

ST-JOHN

BOSTON

SEPT-ILES

LABRADOR CITY

GASPÉ

MATANE

SOLUTION

SYMPTOM

(CONDENSATION)

ERV

ERV

HRV

YELLOWKNIFE

FORT SMITH

HAY RIVER

FORT MCMURRAY

ZONE A

PRINCE ALBERT

EDMONTON

GRANDE PRAIRIE

JASPER

SASKATOON

KAMLOOPS

CHIBOUGAMAU

WINNIPEG

REGINA

CALGARY

PENTICTON

CHICOUTIMI

VAL-DOR

TIMMINS

ZONE B

HELENA

LETHBRIDGE

MONTRÉAL

OTTAWA

NORTH BAY

SUDBURY

SAULT STE MARIE

ST. PAUL

BISMARCK

TORONTO

DETROIT

MADISON

DES MOINES

ZONE C

SALT LAKE CITY

BOISE

HARTFORD

HARRISBURG

COLUMBUS

INDIANAPOLIS

SPRINGFIELD

DENVER

RENO

WASHINGTON

TOPEKA

RALEIGH

COLUMBIA

NASHVILLE

OKLAHOMA CITY

SANTA FE

ATLANTA

ZONE D

PHOENIX

BATON ROUGE

AUSTI N

ZONE C SELECTION CHART

INDOOR AIR QUALITY PROBLEM

AND/OR EXCESS MOISTURE PROBLEM

particular problems)

AND/OR IMPORTANT EXCESS MOISTURE PROBLEM

Prince Rupert

JUNEAU

WHITEHORSE

ANCHORAGE

VICTORIA

OLYMPIA

SALEM

ZONE C (HRV or ERV according to your client’s

See ZONE C SELECTION CHART at right.

• HRV MODELS: 1001 HRV, 2001 HRV, HRV100H, HRV200H

• ERV MODELS: 1001 ERV, 2001 ERV, ERV100HC, ERV200HC

ZONE D (ERVs recommended)

SACRAMENTO

VN0002

ZONE A (HRVs only)

• Set Extended Defrost according to section 7.2.3, point 4

• MODELS: 1001 HRV, 2001 HRV, HRV100H, HRV200H

ZONE B (HRVs only)

• ERV MODELS: 1001 ERV, 2001 ERV, ERV100H, ERV200H

strategy pre-set)

• Extended Defrost setting not required (factory defrost

• MODELS: 1001 HRV, 2001 HRV, HRV100H, HRV200H

5

3. TECHNICAL DATA

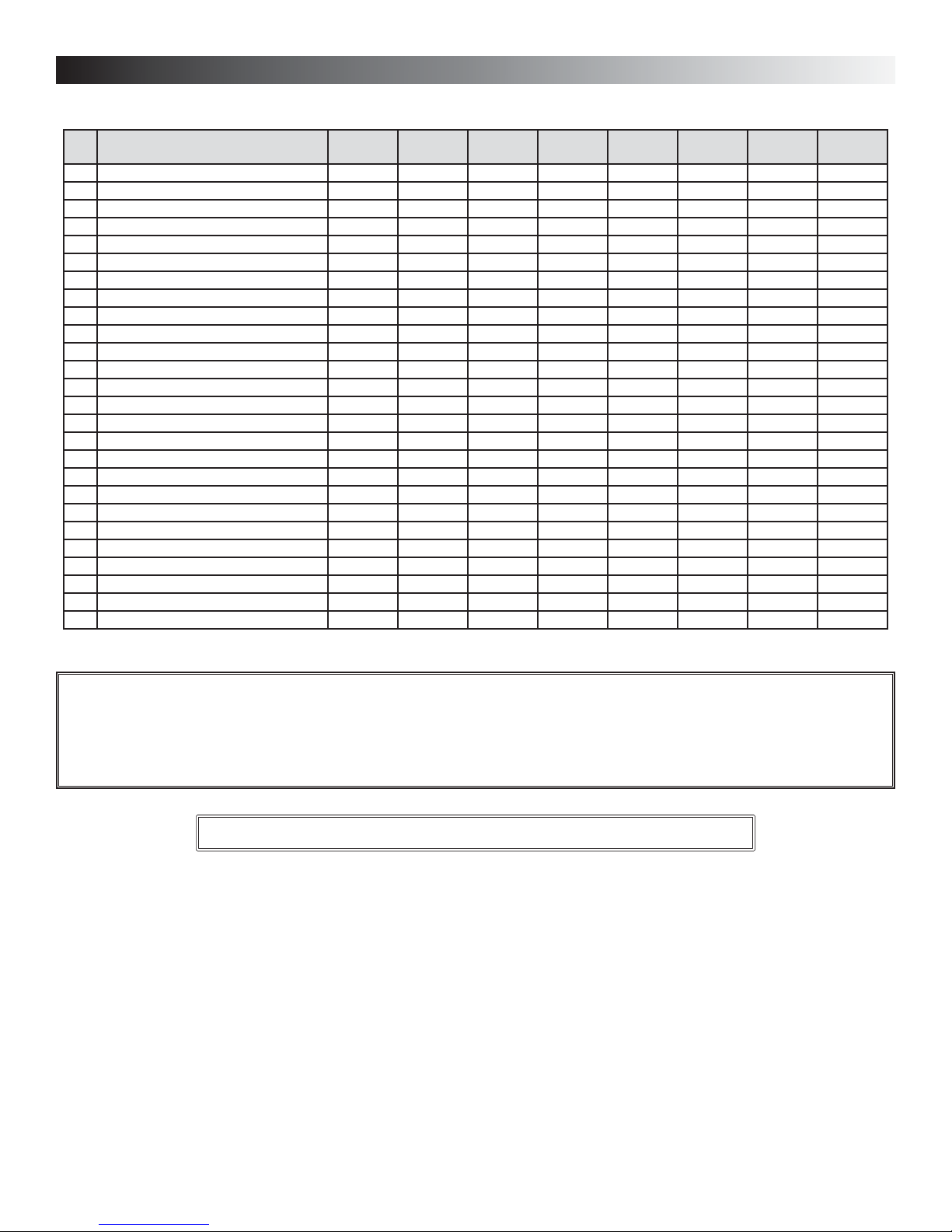

3.1 AIR DISTRIBUTION (NORMAL OPERATION)

STALE AIR

TO OUTSIDE

FRESH AIR

TO BUILDING

VF0013

3.2 AIR DISTRIBUTION (DEFROST MODE)

FRESH AIR

FROM OUTSIDE

STALE AIR

FROM BUILDING

FRESH AIR

TO BUILDING

VF0020

3.3 D

NOTE: The unit performance charts are listed on their own specification sheets. To access those documents,

EFROST CYCLE TABLE

OUTSIDE TEMPERATURE DEFROST CYCLES EXTENDED DEFROST CYCLE

CELCIUS (°C) FAHRENHEIT (°F) DEFROSTING (MIN.)

OPERATION TIME (MIN.)

BETWEEN EACH DEFROST CYCLE

DEFROSTING (MIN.)

-5 23 6 32 10 30

-1556 321020

-27 -17 6 20 10 15

visit: www.vanee-ventilation.com (Canadian units) or www.broan.com (U.S.A. units).

STALE AIR

FROM BUILDING

OPERATION TIME (MIN.)

BETWEEN EACH DEFROST CYCLE

6

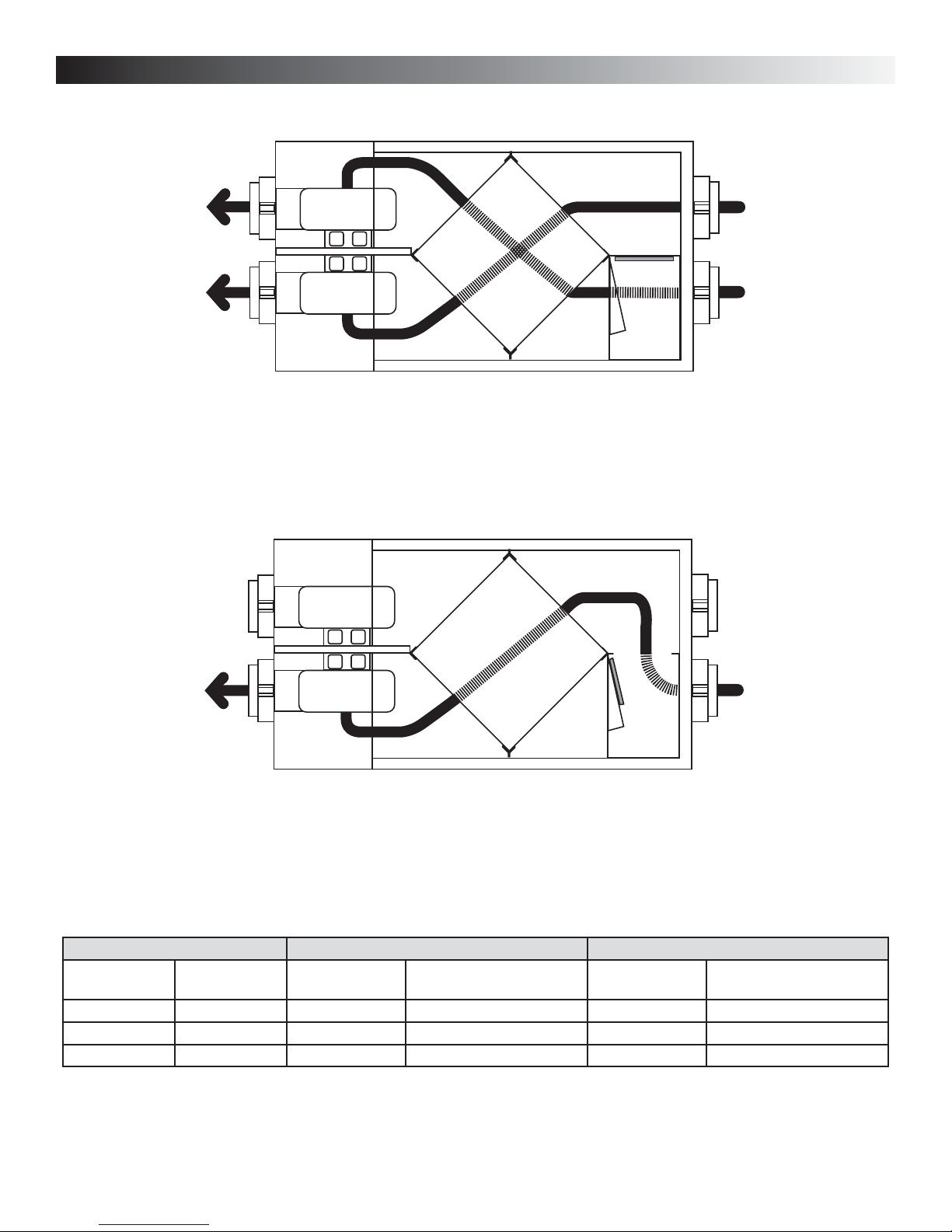

3. TECHNICAL DATA (CONT'D)

3.4 DIMENSIONS

Models:

• 1001 ERV

• 1001 HRV

• HRV100H

• ERV100HC

Models:

• 2001 ERV

• 2001 HRV

• HRV200H

• ERV200HC

VK0040A

6" (152mm)

6" (152mm)

30¼" (768mm)

30¼" (768mm)

13¾" (349mm)

20"

(508mm)

2½" (63mm)

19" (483mm)

20"

(508mm)

VK0039A

3.5 CONTROLS AND FURNACE LINK OPTION

Main controls:

• Platinum (Canada only)

• Deco-Touch (Canada only)

• VT1W (U.S.A. only)

• VT2W (U.S.A. only)

Optional controls:

• 20-minute push-button (for HRV100H and

HRV200H models only)

• 20/40/60-minute push-button

(for all other models)

• 60-minute crank timer

• Dehumidistat

3.6 SPECIFICATIONS

MODELS 1001 ERV, 1001 HRV, HRV100H, ERV100HC 2001 ERV, 2001 HRV, HRV200H, ERV200HC

WEIGHT 65 LB. (30 KG) 73 LB. (33 KG)

PORT DIAMETER 6” (152 MM) 6” (152 MM)

DRAIN DIAMETER 1/2” (12 MM) 1/2” (12 MM)

NSTALLATION CHAINS, SPRING AND HOOKS (PROVIDED WITH U.S.A. UNITS)

I

M

OTOR SPEED HIGH AND LOW SPEEDS FACTORY SET (OPTIONAL INCREASED LOW SPEED - BLUE WIRE)

ELECTRICAL SUPPLY 120 V, 60 HZ 120 V, 60 HZ

POWER CONSUMPTION 150 WATTS 225 WATTS

2½" (63mm)

Link option:

• Furnace interlock

(use with forced air systems)

TRAPS AND WASHERS (PROVIDED WITH CANADIAN UNITS)

S

7

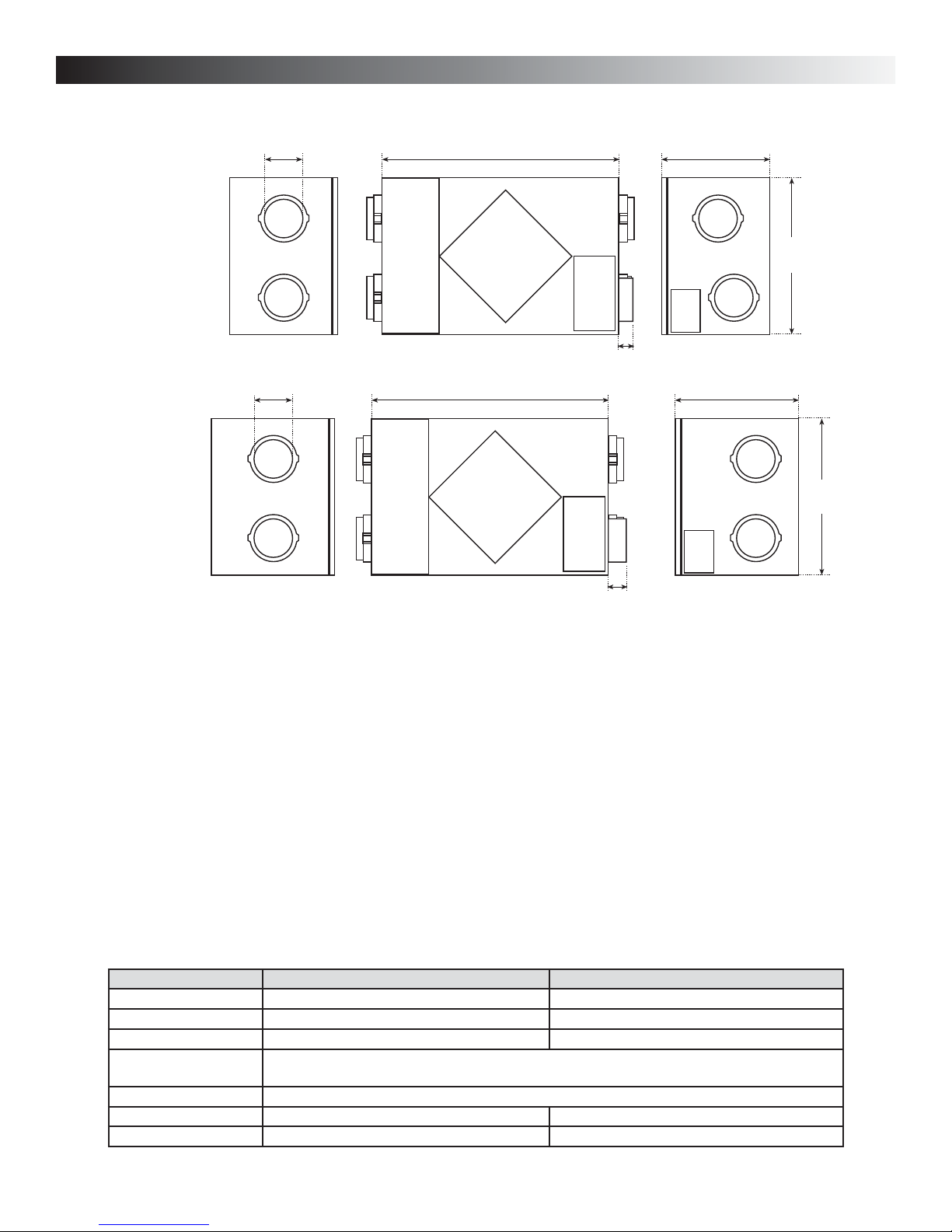

4. TYPICAL INSTALLATION

There are three common installation methods.

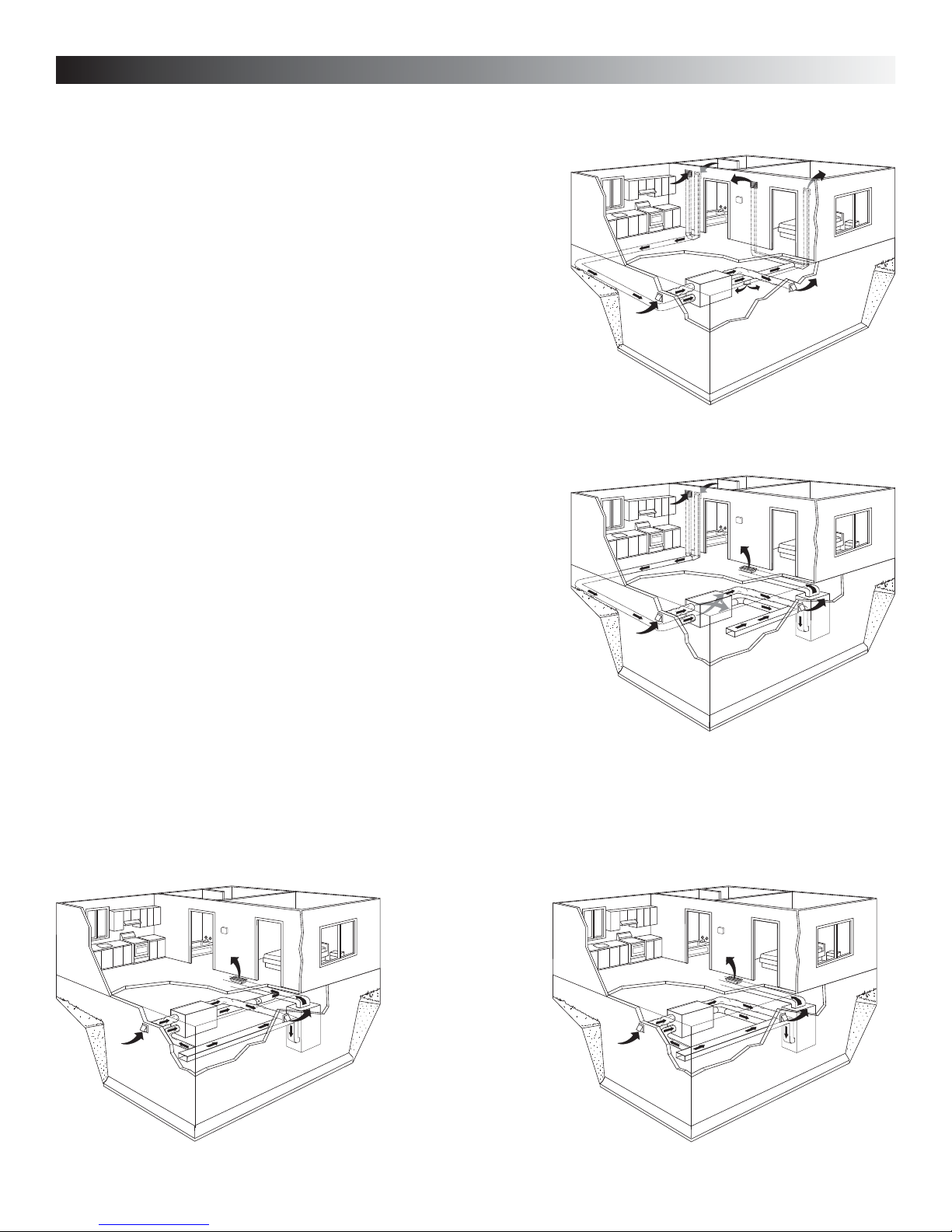

4.1 FULLY DUCTED SYSTEM

(Primarily for homes with radiant hot water or electric baseboard heating. See

Figure at right.)

Moist, stale air is exhausted from the high humidity areas in the home, such as

bathrooms, kitchen and laundry room. Fresh air is supplied to bedrooms and

principal living areas.

If required, bathroom fans and a range hood may be used to better exhaust stale

air.

Homes with more than one level require at least one exhaust register at the

highest level.

VH0024

4.2 EXHAUST DUCTED SYSTEM (SOURCE POINT VENTILATION)

(For homes with forced air heating. See Figure at right.)

Moist, stale air is exhausted from the high humidity areas in the home, such as

bathrooms, kitchen and laundry room. Fresh air is supplied to the cold air return or

the supply duct of the furnace.

If required, bathroom fans and a range hood may be used to better exhaust stale air.

Homes with more than one level require at least one exhaust register at the highest

level.

NOTE: For this type of installation, it is not essential that the furnace blower runs

when the unit is in operation, but we recommend it.

VH0025

4.3 SIMPLIFIED (VOLUME VENTILATION)

(For homes with forced air heating. See Figures A and B below.)

Fresh air and exhaust air flow through the furnace ducts which simplifies the installation.

The use of bathroom fans and range hood is suggested to better exhaust stale air.

NOTE: For the installation type shown in Figure B, furnace blower should be running when the unit is in operation.

See 5.4.1

for details

See 5.4.2

for details

VH0027

See 5.4.3

for details

AB

OR

VH0026

See 5.4.3

for details

8

5. INSTALLATION

!

WARNING

When applicable local regulations comprise more restrictive installation and/or certification requirements, the

aforementioned requirements prevail on those of this document and the installer agrees to conform to these at

his own expenses.

!

WARNING

When performing installation, servicing or cleaning the unit, it is recommended to wear safety glasses and gloves.

INSPECTING THE BOX CONTENT

• Inspect the exterior of the unit for shipping damage. Ensure that there is no damage to the door, door latches, door hinges, dampers,

duct collars, cabinet, etc.

• Inspect the interior of the unit for damage. Ensure that the fan motor assembly, recovery core, insulation, dampers, damper actuator

and drain pan are all intact.

• If the unit was damaged during shipping, contact your local distributor. (Claims must be made within 24 hours after delivery.)

• Use checklist included with the unit to ensure that no parts are missing.

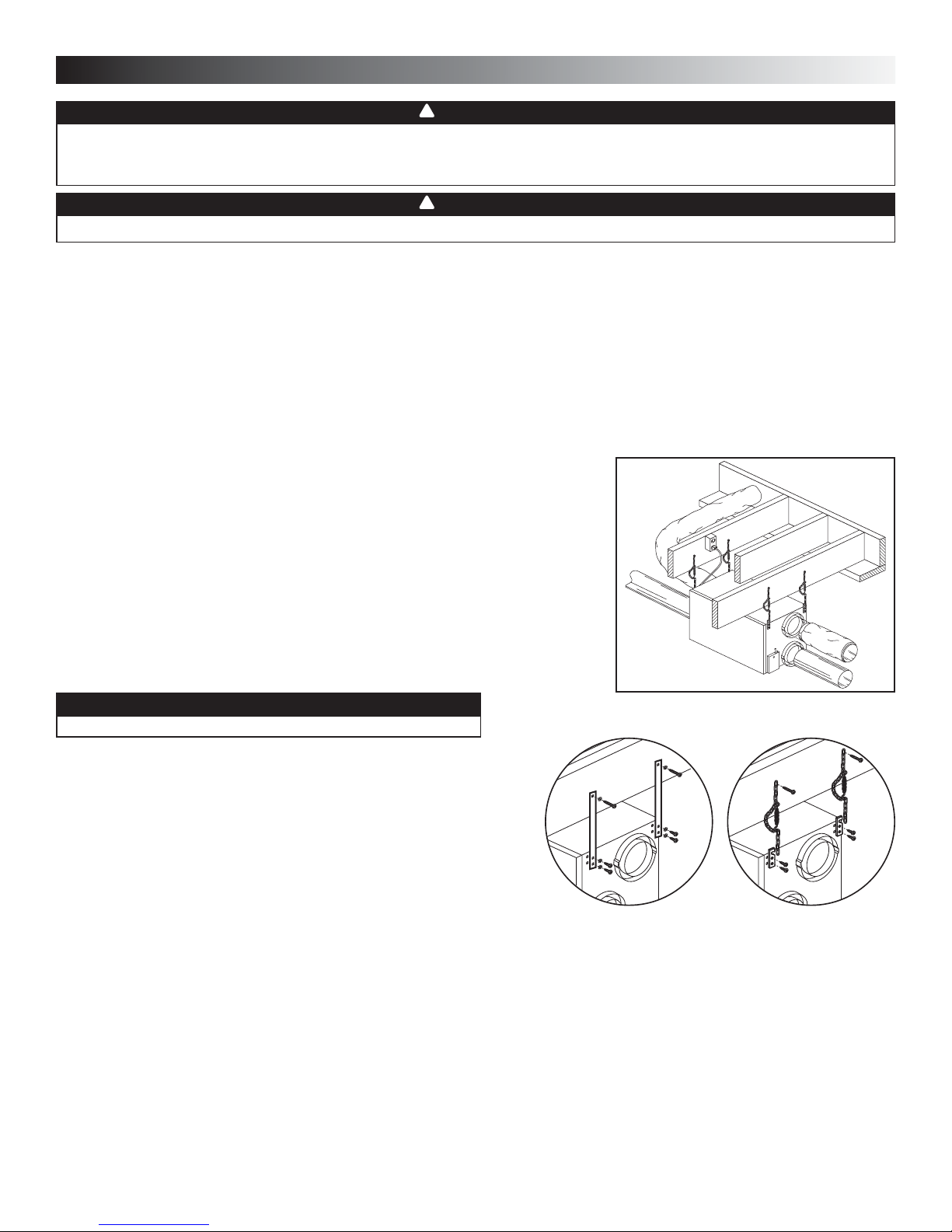

5.1 LOCATING AND MOUNTING THE UNIT

Choose an appropriate location for the unit:

• Within an area of the house where the temperature is kept above 10°C/50°F and below

40°C/104°F

• Away from living areas (dining room, living room, bedroom), if possible.

• So as to provide easy access to the interior cabinet for every three months and annual

maintenance, and to the control panel on the right hand side of the unit.

• Close to an exterior wall, so as to limit the length of the insulated flexible duct to and from

the unit.

• Close to a drain. If no drain is close by, use a pail to collect run-off.

• Away from hot chimneys, electrical panel and other fire hazards.

• Allow for a power source (110 V standard outlet).

VD0064

CAUTION

Make sure the unit is level.

For vänEE Canadian models 1001 VRE, 1001 VRC, 2001 VRE and 2001 VRC,

hang the unit to ceiling joists with washers and 4 straps (included) (see figure

at right).

For Broan U.S.A. models HRV100H, HRV200H, ERV100HC, and ERV200HC,

hang the unit to ceiling joists with the 4 chains, springs and hooks (included)

(see figure at right).

VD0212

VÄN EE CANADIAN MODELS

1001 ERV, 1001 HRV,

2001 ERV AND 2001 HRV

BROAN U.S.A. MODELS

HRV100H, HRV200H,

ERV100HC AND ERV200HC

5.2 PLANNING THE DUCTWORK

a) Follow the instructions in Section 5.3 on next page to determine the appropriate duct diameters for your system.

b) Keep it simple. Plan for a minimum number of bends and joints. Keep the length of insulated duct to a minimum.

c) Do not use wall cavities as ducts. Do not use branch lines smaller than 4” (102 mm) Ø.

d) Do not ventilate crawl spaces or cold rooms. Do not attempt to recover the exhaust air from a dryer or a range hood. This would cause

clogging of the recovery module. Use sheet metal for the kitchen exhaust duct.

e) Be sure to plan for at least one exhaust register on the highest lived-in level of the house if it has 2 floors or more.

9

Loading...

Loading...