Page 1

Service Documentation Market Release 7/84

Braun Kitchen machine KM 32 B 4209

with lamp

4209

Page 2

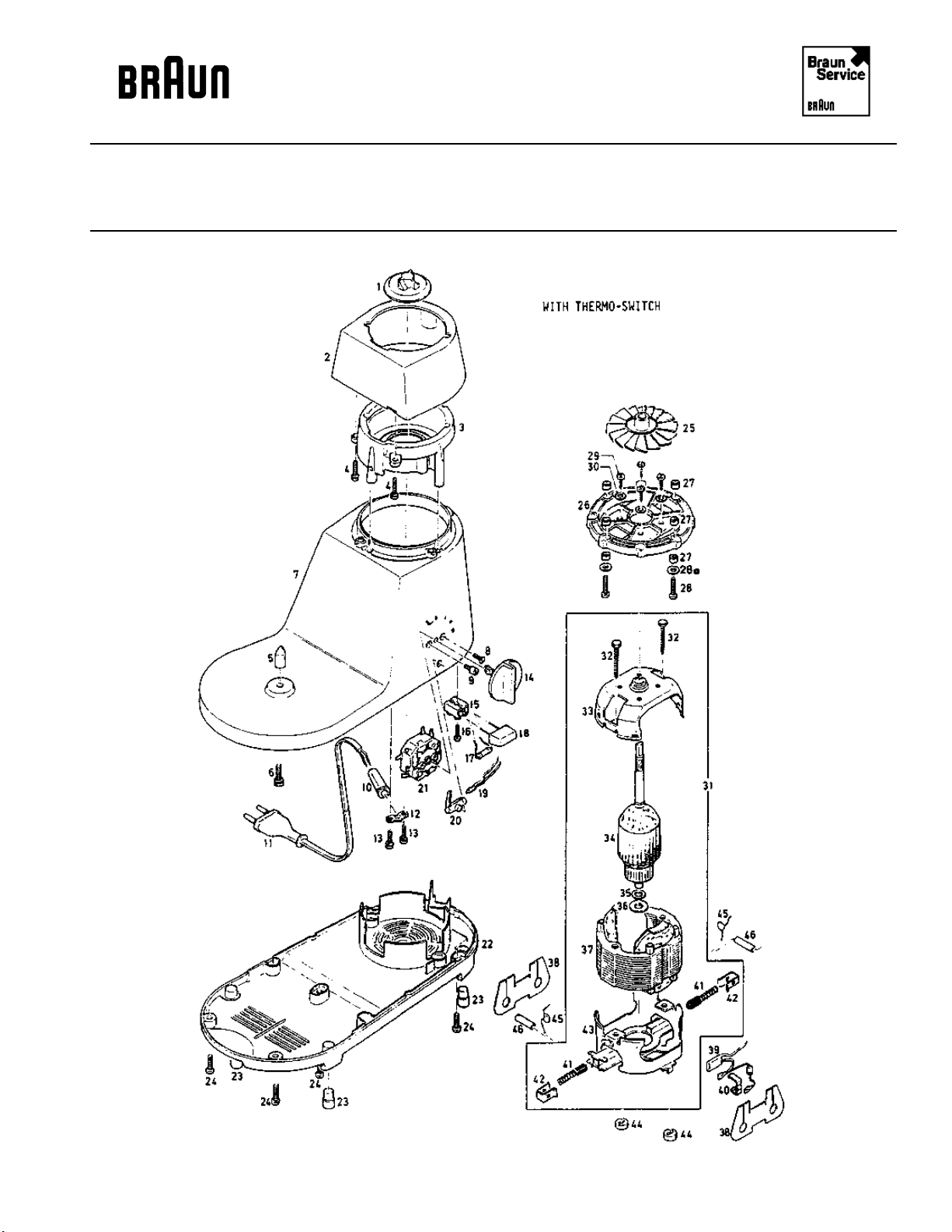

BINC Rev: 7/96 Service Documentation

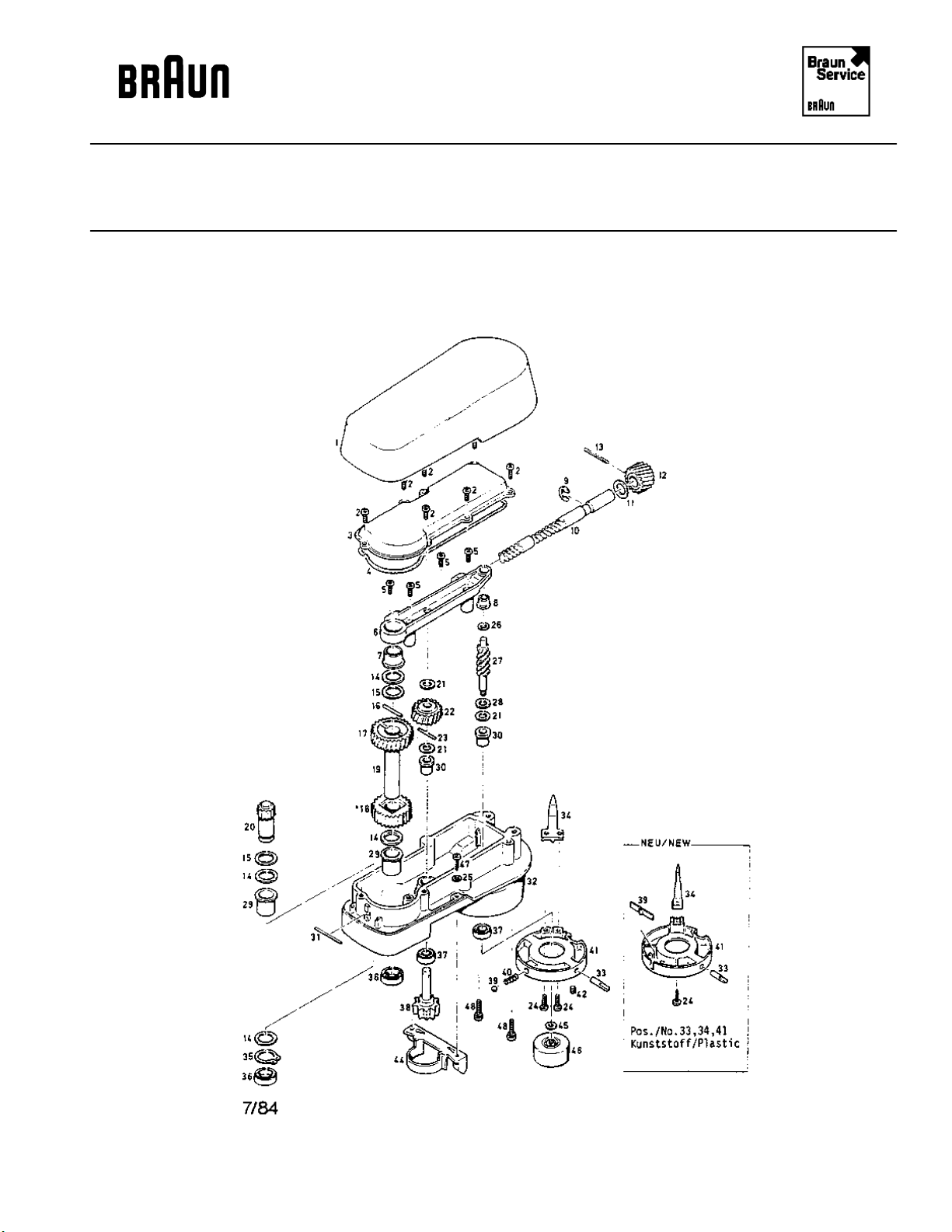

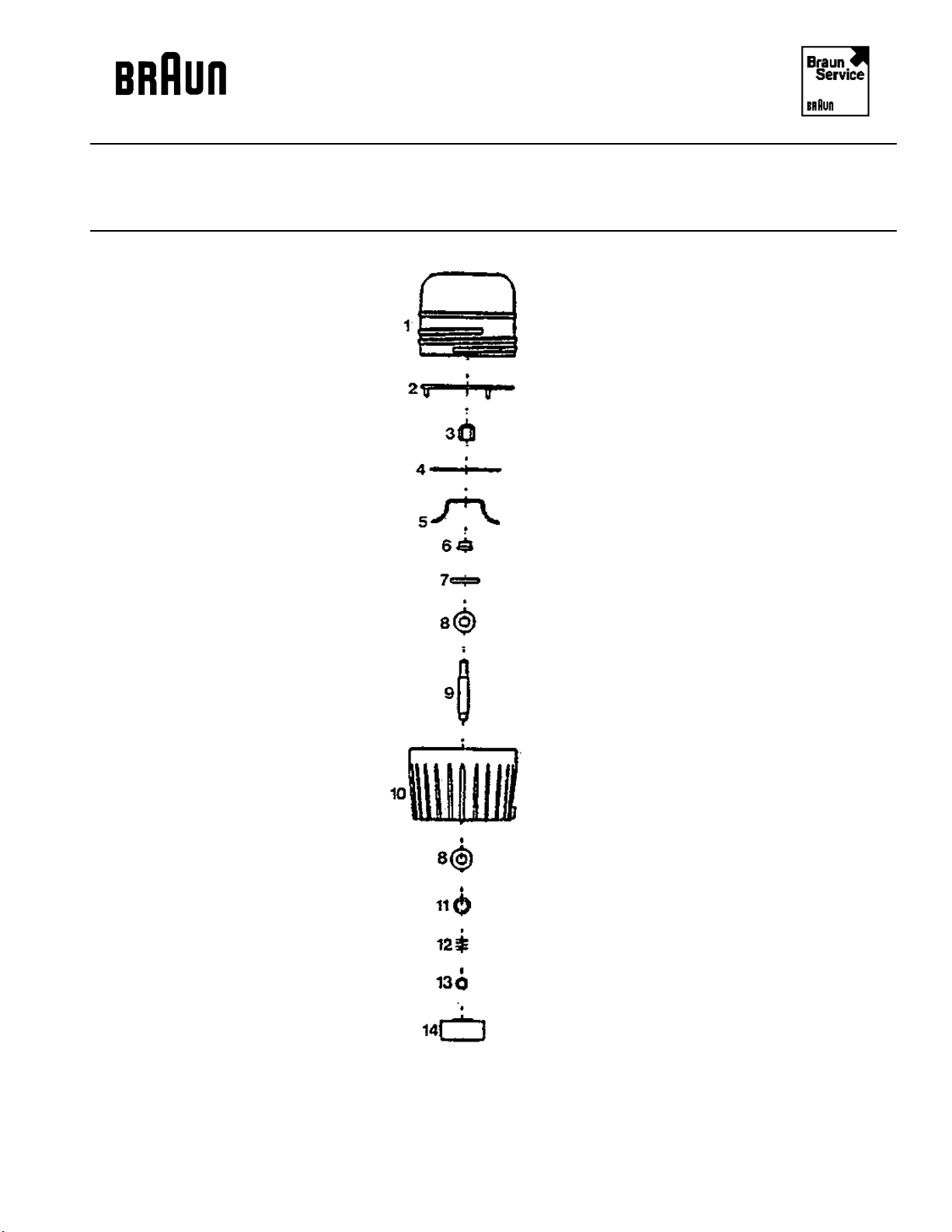

Exploded Drawing

BAG Rev: 7/84 4209

4209 - 2

Page 3

BINC Rev: 7/96 Service Documentation

Service Information

BAG Rev: 12/88 4209

Pos. No. Part Description Part Number

1 Male drive coupling 4207100

2 Upper housing 4207923

3 Attachment cone 4207199

4 Screw 0033120

5 Pivon 4207131

6 Screw 0003302

7 Lower housing 4209875

8 Screw 0001500

9 Stop screw 4207500

10 Protective sleeve 4209003

11 Mains lead 4390264

12 Cable clamp 4206149

12a Cable clamp for pos. 12 4203051

13 Screw 0003170

14 Switch knob 4216193

15 Terminal block 0717253

16 Screw 0002706

17 Resistor 0612717

18 Capacitor 0622099

19 Glow lamp NLA

20 Glow lamp holder 4230051

21 Switch 4230005

22 Bottom plate cpl. NLA

23 Foot 4243054

24 Screw 0034115

25 Fan wheel 4230002

26 Suspension of the motor 4207534

27 Rubber buffer 4230006

28a Washer 0108111

28 Screw 0003135

29 Screw 0028101

30 Washer 0102102

31 Motor 4230550

32 Screw 0030112

33 Upper end shield 4250806

34 Rotor 4230846

35 Washer 4250016

36 Washer 4250017

37 Stator 4230847

38 Air baffle 4250070

39 Thermo-switch NLA

40 Tension spring for pos. 39 NLA

4209 - 3

Page 4

BINC Rev: 7/96 Service Documentation

Spare Parts List

BAG Rev: 12/88 4209

Pos. No. Part Description Part Number

41 Carbon brush 4250048

42 Fixing clamp 4250047

43 Lower end shield 4243817

44 Centering rubber 4250045

45 Capacitor NLA

46 Ferrite-tube 4243078

- Insulating tube NLA

- Plug junction 0710127

- Double plug junction NLA

- Wiring (w/ 1 slip on terminal) NLA

- Wiring (w/ 2 slip on terminals) NLA

- Type plate NLA

Accessories

Large mixing bowl 4203014

Small mixing bowl 4207055

Dough hook 4207814

Whisk 4207048

Whisk for whipped cream 4207620

Circlip for whisk/hook 4207530

Spatula 4203118

Dust cover 4203200

For additional attachment parts see page 16

4209 - 4

Page 5

BINC Rev: 7/96 Service Documentation

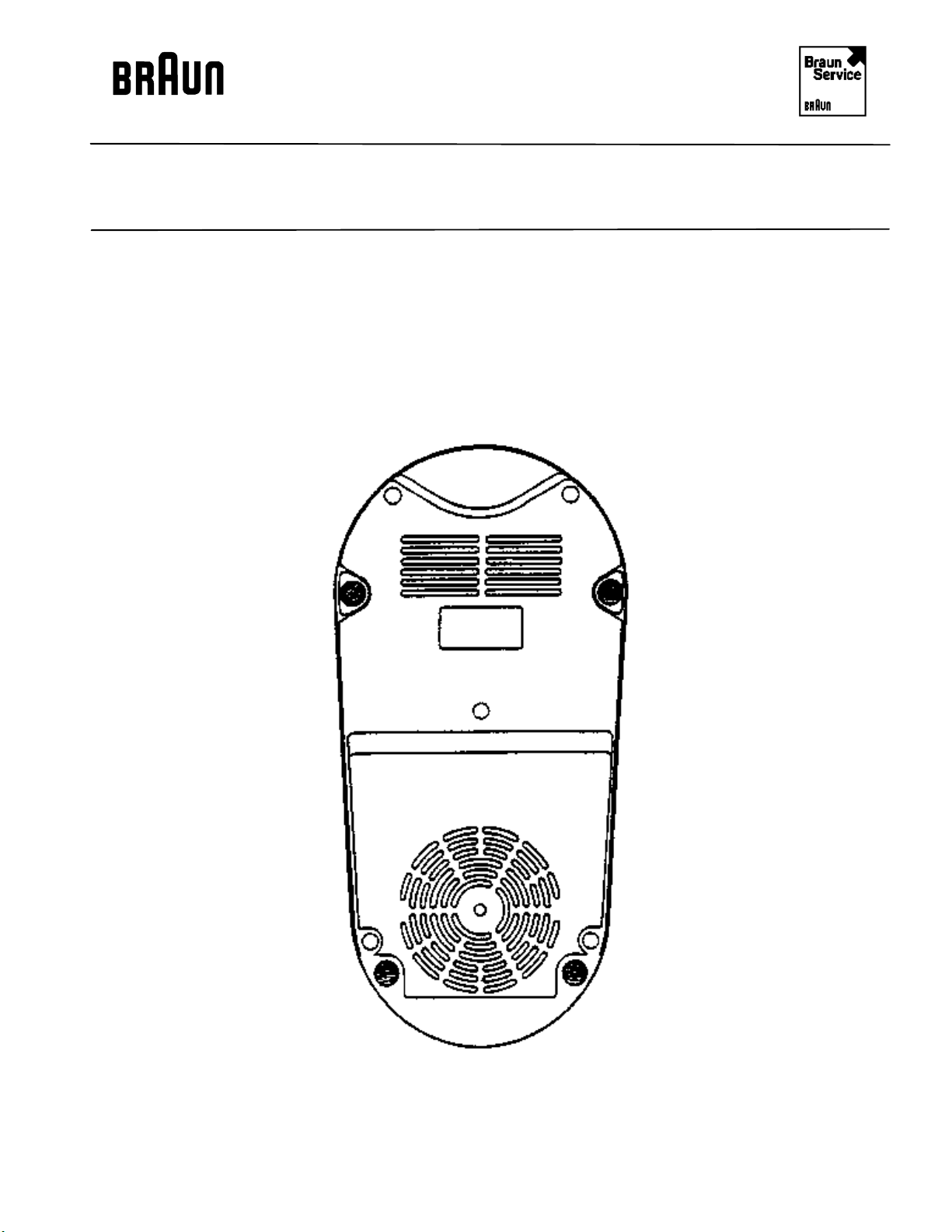

Reference Drawing

BAG Rev: 7/84 4209

Bottom of the product

4209 - 5

Page 6

BINC Rev: 7/96 Service Documentation

Service Information

BAG Rev: 12/88 4209

Technical Data

Voltage/Frequency: 110 V/120 V 40-60 Hz

No-load power Position 1: appr. 125 W + 10 %

Position 2: appr. 130 W + 10 %

Position 3/L: appr. 205 W + 10 %

No load speed Position 1: appr. 10700 min

Position 2: appr. 12500 min

Position 3/L: appr. 16000 min

-1

-1

-1

Overheating protection: Thermo-switch/Fuse

Length of mains lead: appr. 1.30 m

Operating time: continuous operation at 400W

4209 - 6

Page 7

BINC Rev: 7/96 Service Documentation

Service Information

BAG Rev: 7/84 4209

1. Removal of motor (31)

Disconnect appliance mains plug from the socket. Loosen the holding screws from the bottom

cover plate (22) and remove plate. Then withdraw the male-drive coupling (1) with the aid of

an angle-shaped screw-driver.

Draw off switch knob (14) and unscrew switch securing screws (8, 9). Proceed by

disconnecting the motor wiring on the terminal block (15). Subsequently loosen the 4 screws

(28) with a long screw-driver and take the motor together out of the housing.

2. Reassembly

The reassembly is carried out in the reverse order, however attention should be paid to the

rubber buffer (27).

The motor shaft must be supported at the bottom end, when the new male drive coupling (1) is

mounted onto the shaft. Pay attention to the wiring diagram.

3. Replacement of the thermo-switch (39)

Remove motor (31) as described in paragraph 1.

Withdraw the air baffle (38) and loosen spring (40). Continue by disconnecting the plug

connection on switch (21) and also connection on the terminal block (15) and install new

thermo-switch.

4. Dismantling of motor (31)

With the aid of a screwdriver, push off the fan wheel (25).

Before starting to dismantle the motor, mark the latter in the longitudinal direction, so that all

parts are again placed correctly left to right during the assembly. Use a 8 mm box spanner for

removing screws (32). Before the motor is taken apart, first remove the carbon brushes (41).

Prior to removing the brushes, loosen the fixing clips (42) at the sides and withdraw carefully.

5. Carry out a functional test

4209 - 7

Page 8

BINC Rev: 7/96 Service Documentation

Reference Drawing

BAG Rev: 7/84 4209

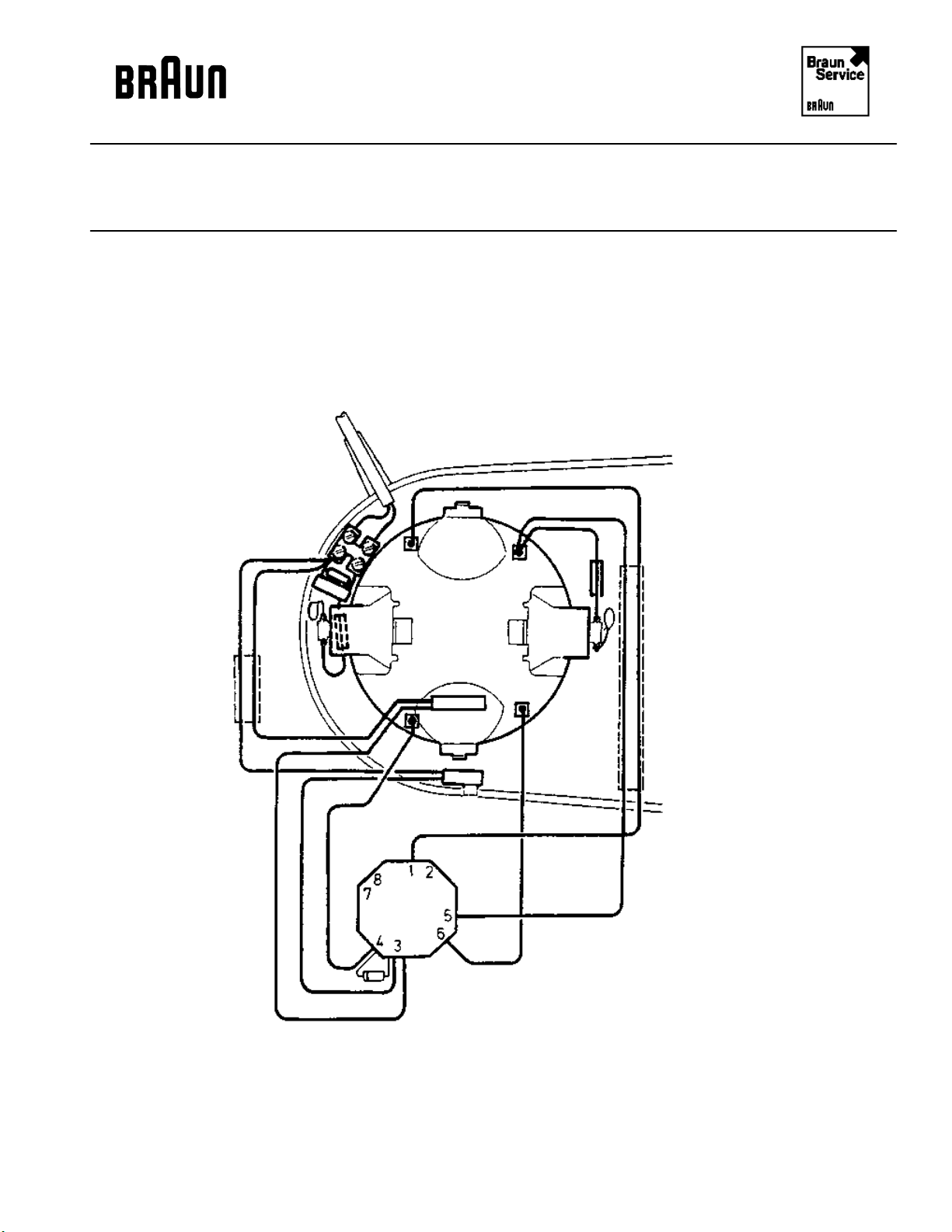

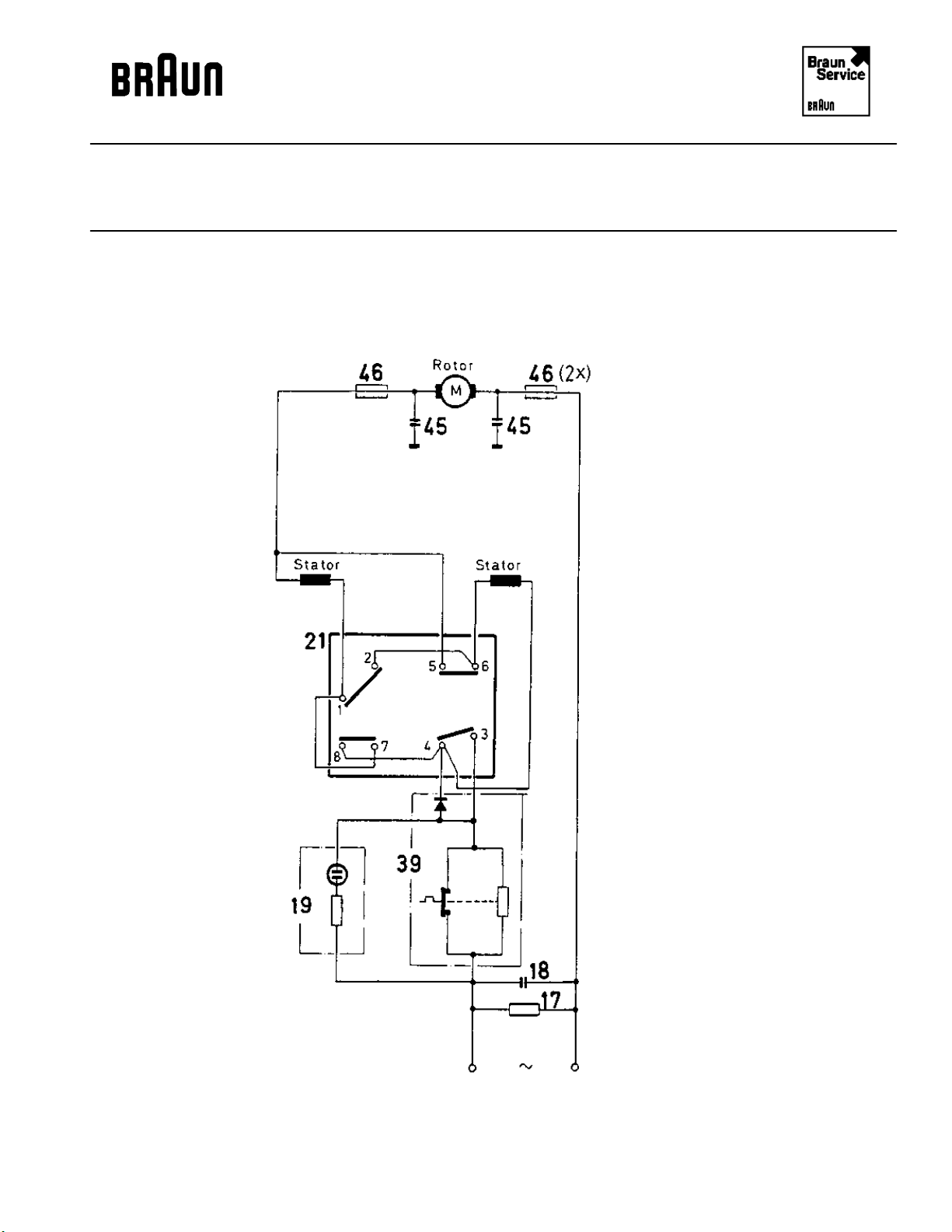

Wiring with thermo-switch

4209 - 8

Page 9

BINC Rev: 7/96 Service Documentation

Reference Drawing

BAG Rev: 7/84 4209

Wiring diagram

4209 - 9

Page 10

BINC Rev: 7/96 Service Documentation

Reference Drawing

BAG Rev: 10/88 4209

Wiring diagram

4209 - 10

Page 11

BINC Rev: 7/96 Service Documentation

Service Information

BAG Rev: 11/85 4209

Products which are considered to be too loud or are returned for this defect.

When judging the operating noise, the mixing arm of KM 32/B or the mixer attachment of the MX

32/B should be engaged. If the operating noise is still considered to be too loud, the following

measures should be taken:

1. The motor should not have any off-center condition that means, the outside diameter of

the male drive coupling (Pos. 1 must coincide with the inside diameter of the raised

attachment cone shoulder (observe an even gap!). If necessary this has to be newly

adjusted.

2. All screws of the motor-suspension (Pos. 26 respectively 37) must be tightly fastened. If

necessary. this has to be corrected.

3. The motor suspension (Pos. 26 respectively 37), must be checked for areas of breakage or

other defects if necessary the parts must be exchanged.

4. Remove the lower centering rubber parts of the motor (Pos. 44 resp. 58 and attach, if

necessary, the new and Changed base plate (see instructions below).

Instructions for Braun kitchen machine KM 32/B (4209) and Braun multimix MX 32/B (4142)

From production week 45,1985 on, the lower four rubber buffers (Pos. 27 resp. 38) of the motor

suspension (plastic-type), will be eliminated without a replacement. The motor suspension will be

changed accordingly. In previously produced products, the rubber buffers should continue to be

used.

At the same time, also the previously used centering rubber parts (Pos. 44 resp. 58) will be

eliminated without a replacement. Also in this case, the base plate has been changed accordingly.

That means the holes to accept the centering rubber parts in the base plate, have been eliminated.

For replacement of these parts, ribs have been molded in the same spot. It is not possible, to attach

the new base plate, if the motor still has any centering rubber parts.

The new base plate can be used without problem for previously produced products, it the centering rubber parts have been removed.

Only when these points have been considered, the machine will correspond with the noise allowed

by the factory.

4209 - 11

Page 12

BINC Rev: 7/96 Service Documentation

Exploded Drawing

BAG Rev: 7/84 4209

Mixing arm for Kitchen Machine

4209 - 12

Page 13

BINC Rev: 7/96 Service Documentation

Spare Parts List

BAG Rev: 2/94 4209

Pos. No. Part Description Part Number

1 Mixing arm cover 4207033

2 Screw 0030008

3 Gear cover 4207020

4 Rubber seal 4207044

5 Screw 0030008

6 Bearing bracket 4207822

7 Flanged bearing 4207107

8 Flanged bearing 4207005

9 Circlip 0109301

10 Main worm shaft 4207394

11 Fiber washer 4207019

12 Worm gear 4207478

13 Spring pin 0127201

14 Fiber washer 4207015

15 Washer 4207014

16 Grooved pin 0125102

17/18 Gear wheel-set 4207623

19 Shaft 4207821

20 Pinion 4207820

21 Fiber washer 4207007

22 Worm gear 4207010

23 Pin 4207384

24 Screw 0003135

24 Screw, self tapping * 0038022

25 Washer 0103001

26 Fiber washer 4207008

27 Driving worm 4207006

28 Washer 4207034

29 Flanged bearing 4207004

30 Flanged bearing 4207002

31 Retaining rod 4207112

32 Mixing arm housing 4207819

33 Coupling pin (Metal) 4207030

33 Coupling pin (Plastic) * 4207533

34 Locking lever (Metal) 4207028

34 Locking lever (Plastic)* 4207528

35 Circlip 0112001

36 Radial oil seal ring 4207351

37 Radial oil seal ring 0104003

38 Bowl drive with shaft 4207035

39 Ball 0162002

4209 - 13

Page 14

BINC Rev: 7/96 Service Documentation

Spare Parts List

BAG Rev: 2/94 4209

Pos. No. Part Description Part Number

39 Leaf spring * 4207529

40 Spring 4207180

41 Locking ring (metal) 4207027

41 Locking ring (plastic) * 4207527

42 Grub screw 0015101

44 Guide bracket 4207032

45 Distance washer 4213042

46 Coupling 4203055

47 Screw 0031077

48 Screw 0003126

No. 17 and 18 are replaced together.

* Parts that are to be replaced together. When rebuild from metal to plastic version all

parts with * should be used together.

4209 - 14

Page 15

BINC Rev: 7/96 Service Documentation

Reference Drawing

BAG Rev: 11/85 4209

4209 - 15

Page 16

BINC Rev: 7/96 Service Documentation

Service Information

BAG Rev: 8/85 4209

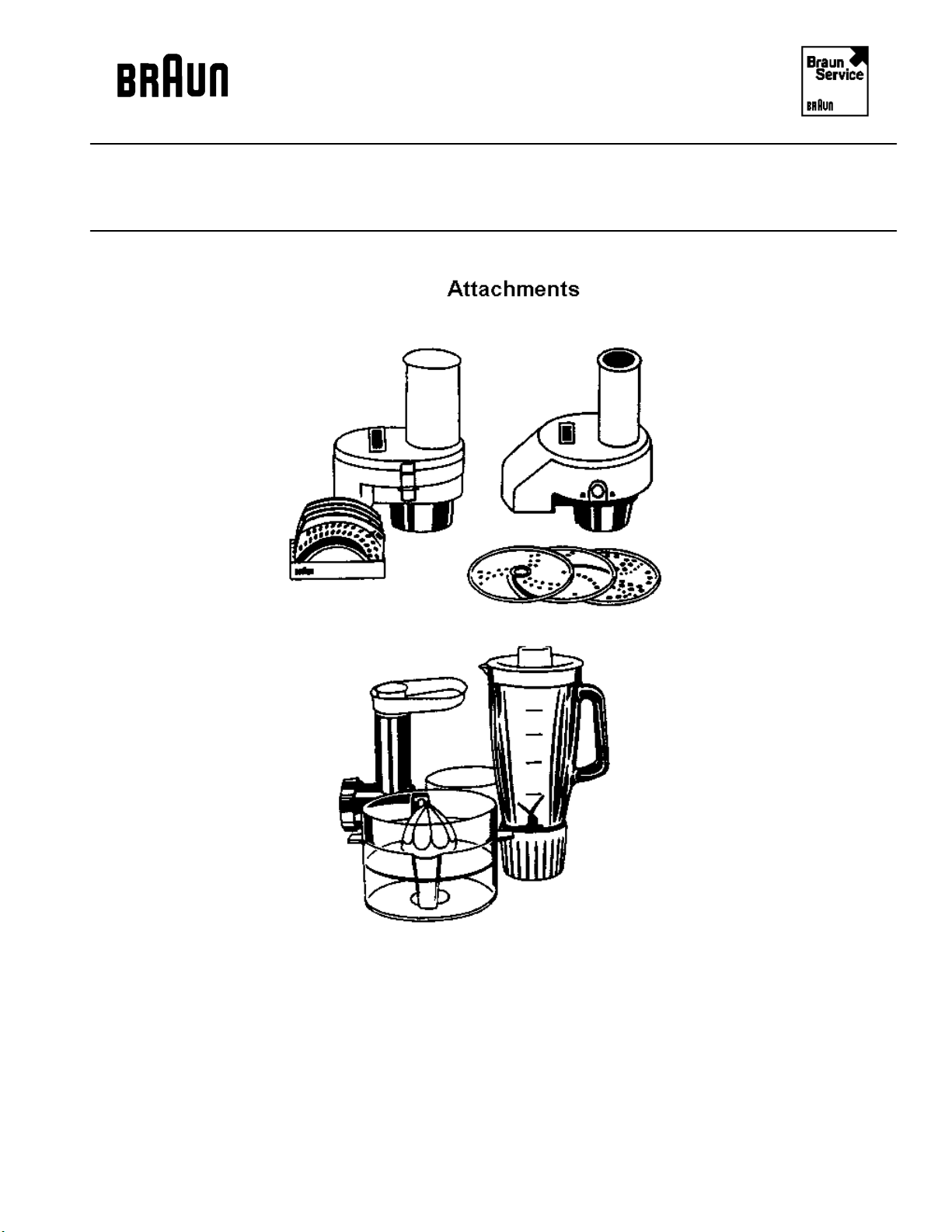

Shredder KS 33 4247

Meat Mincer KGZ 2 4610

Citrus Juicer KMZ 3 4612

Shredder KS 32 4613

Liquidizer KX 32 4614

Coffee Grinder MXK 4615

4209 - 16

Page 17

BINC Rev: 7/96 Service Documentation

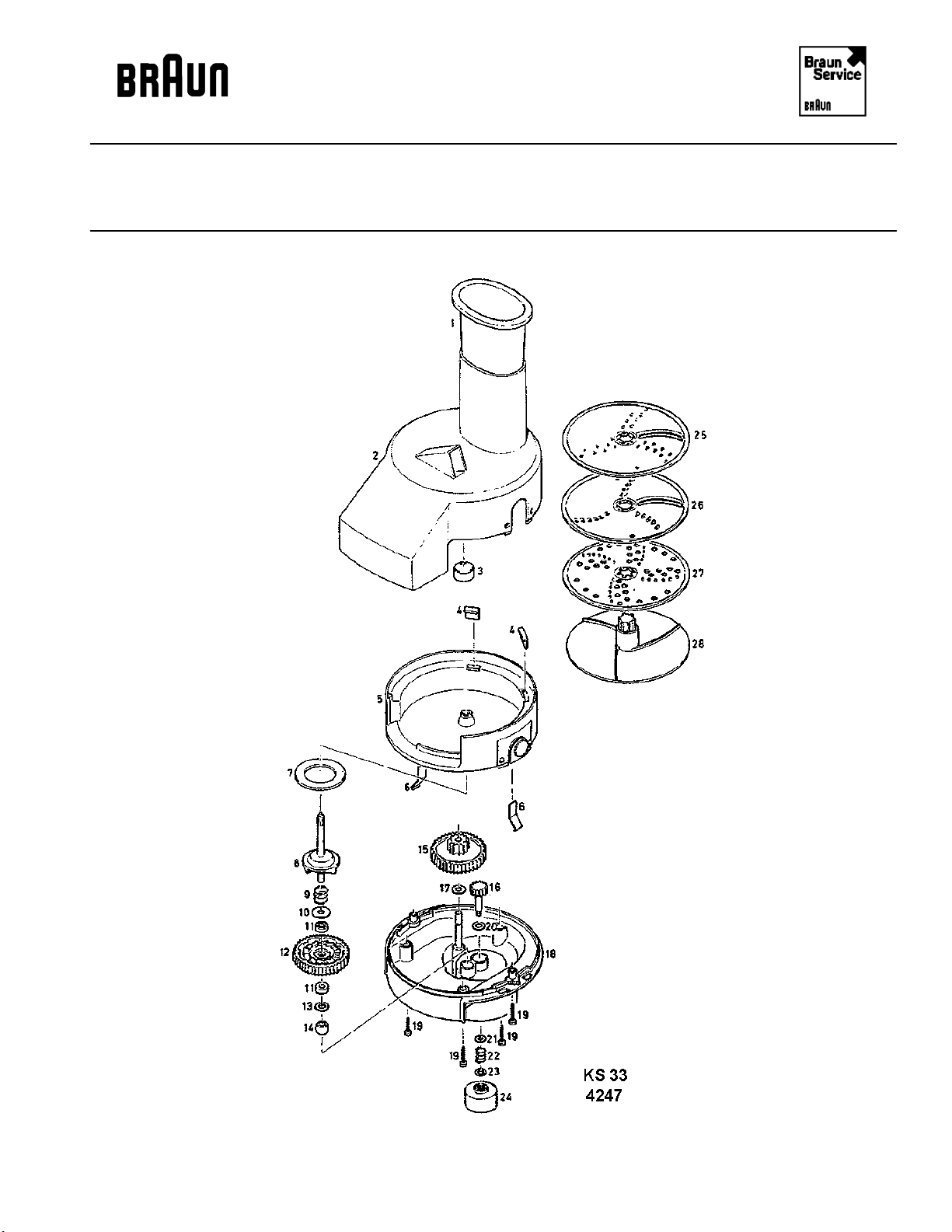

Exploded Drawing

BAG Rev: 8/85 4247

4209 - 17

Page 18

BINC Rev: 7/96 Service Documentation

Spare Parts List

BAG Rev: 6/91 4247

Pos. No. Part Description Part Number

1 Pusher 4207492

2 Lid with no. 3 4247851

3 Cap 4247022

4 Guide block 4247035

5 Upper housing cpl. 4247852

6 Flat spring 4247028

7 Felt washer 4242126

8 Driving shaft coupling 4247853

9 Spring 4247007

10 Washer 4247026

11 Thrust bearing 4247037

12 Gear wheel 4247015

13 Washer 4247025

14 Swivel bearing 4247024

15 Intermediate gear wheel 4247014

16 Pinion 4247016

17 Fibre washer 4247017

18 Lower housing 4247625

19 Screw 0031052

20 Fibre washer 4250082

21 Bronze washer 4213041

22 Spring 4203135

23 Washer 4213042

24 Coupling 4203055

25 Working disc I 4247047

26 Working disc II 4247048

27 Grater disc for potatoes 4247039

28 Carrier disc 4247858

- Adapter for KMZ 3 4247038

4209 - 18

Page 19

BINC Rev: 7/96 Service Documentation

Exploded Drawing

BAG Rev: 1/82 4610

4209 - 19

Page 20

BINC Rev: 7/96 Service Documentation

Spare Parts List

BAG Rev: 12/83 4610

Pos. No. Part Description Part Number

Gear Head for Meat Mincer

1 Cover 4241020

2 Cheese-head screw 0003101

3 Split lock washer 0101001

4 Upper gear housing cover 4240803

5 Plain seal 4240012

6 Steel washer 4240021

7 Worm drive shaft 4240003

8 Fiber washer 4213040

9 Gear wheel 4240008

10 Fiber washer 4240004

11 Intermediate gear 4240022

12 Plain seat 4240025

13 Gear shaft 4240807

14 Split lock washer NLA

15 Cheese head screw NLA

16 Winged screw 4241003

17 Retainer ring 0109003

18 Bronze washer 4241014

19 Fiber washer 4241015

20 Straight pin 0120101

21 Shaft 4240009

22 Seal-ring 0104001

23 Lower housing 4240801

24 Seal-ring 0712001

25 Washer 4213042

26 Coupling 4203055

4209 - 20

Page 21

BINC Rev: 7/96 Service Documentation

Spare Parts List

BAG Rev: 2/95 4610

Pos. No. Part Description Part Number

Meat Mincer attachment

1 Tamper 4242 040

2 Meat tray 4241004

3 Housing 4240811

4 Worm screw 4240045

5 Spring 4242148

5 Spring 4242148

6 Cross shaped blade ** 4242133

6 Cross shaped blade 4240048

7 Perforated disc, 4.5 dia. 4 195090

7 Perforated disc, 3.0 dia. 4 195091

7 Perforated disc, 8.0 dia. 4195092

8 Locking ring 4240050

** Two sided applicable

4209 - 21

Page 22

BINC Rev: 7/96 Service Documentation

Exploded Drawing

BAG Rev: 1/82 4612

4209 - 22

Page 23

BINC Rev: 7/96 Service Documentation

Spare Parts List

BAG Rev: 10/86 4612

Pos. No. Part Description Part Number

1 Reamer cone 4207391

2 Strainer 4253285

3 Juice container 4253284

- Adapter for KS 33 4247038

4209 - 23

Page 24

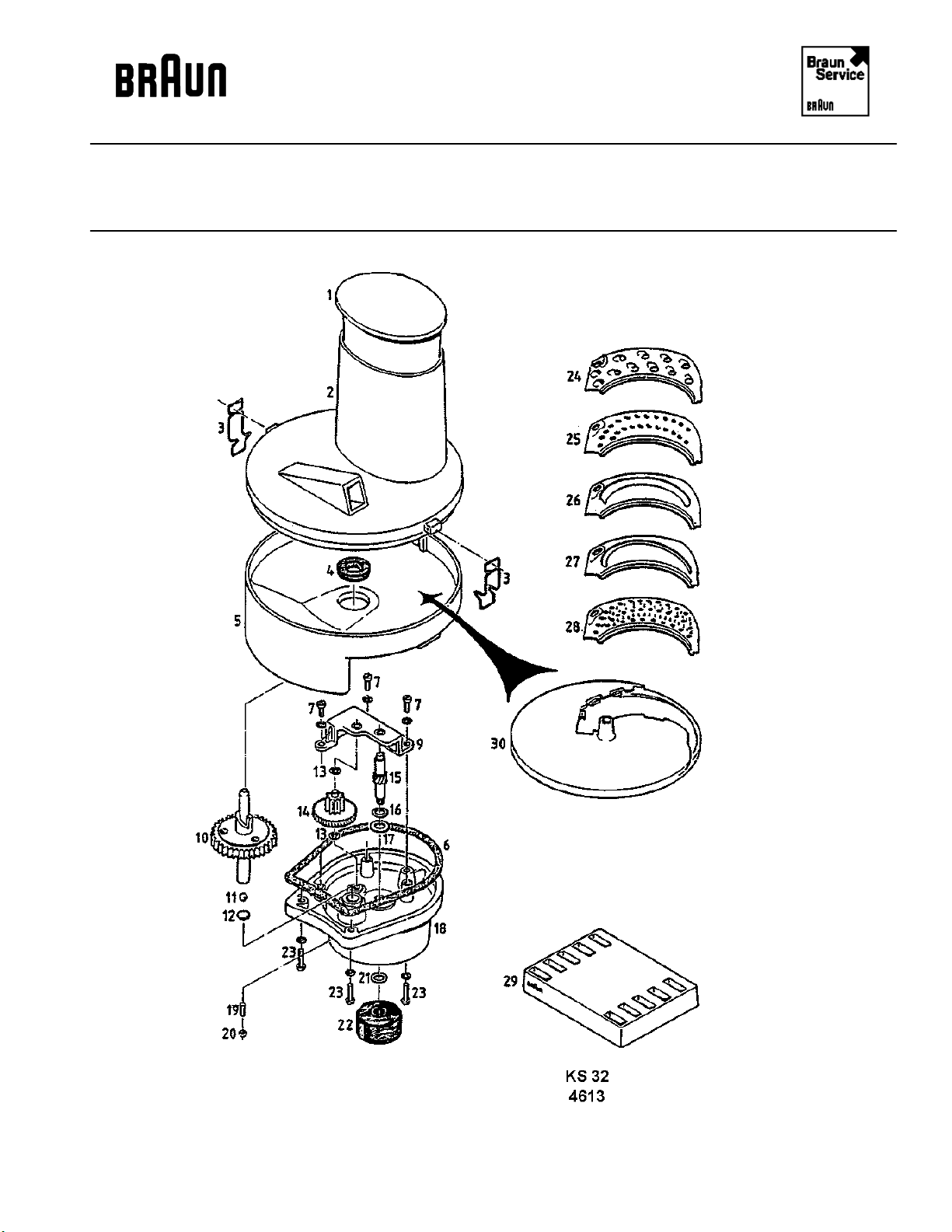

BINC Rev: 7/96 Service Documentation

Exploded Drawing

BAG Rev: 1/82 4613

4209 - 24

Page 25

BINC Rev: 7/96 Service Documentation

Spare Parts List

BAG Rev: 11/93 4613

Pos. No. Part Description Part Number

1 Tamper (old with lid) 4207809

1 Tamper (new without lid) 4207492

2 Upper housing NLA

3 Retaining clamp 4203270

4 Oil sealing ring 4207093

5 Lower housing NLA

6 Plain seal 4203266

7 Screw 0003101

9 Bearing bracket 4203883

10 Output gear 4203884

11 Ball 0162003

12 Ball thrust plate 4203264

13 Washer 4203257

14 Intermediate gear 4203882

15 Drive shaft 4203254

16 Bronze washer 4213041

17 Fiber washer 4213040

Bearing 4206047

18 Metal housing 4203881

19 Set screw 0016102

20 Nut 0061108

21 Washer 4213042

22 Coupling 4203055

23 Screw 0003170

24 Shredding insert, coarse 4207068

25 Shredding insert, fine NLA

26 Slicing insert, coarse 4207070

27 Slicing insert, fine 4207071

28 Grating insert 4207072

29 Insert stand 4207094

30 Carrier disc 4207807

4209 - 25

Page 26

BINC Rev: 7/96 Service Documentation

Exploded Drawing

BAG Rev: 5/84 4614

4209 - 26

Page 27

BINC Rev: 7/96 Service Documentation

Spare Parts List

BAG Rev: 12/85 4614

Pos. No. Part Description Part Number

1 Funnel plug 4207091

2 Lid 4207090

3 Glass goblet 4216865

4 Rubber gasket 4216209

5 Complete knife (6 - 20) 4216899

6 Cap nut 0064006

7 Washer (Steel) 4291014

8 Upper knife 4207088

9 Lower knife 4207087

10 Cover 4291006

11 Washer (Steel) 4291010

12 Washer (Fibre) 4250082

13 Cutter base plate (Metal) 4291650

14 Washer (Fibre) 4250082

15 Washer (Bronze) 4213041

16 Socket 4216213

17 Spring 4216212

18 Shaft 4216214

19 Washer (Steel) 4213042

20 Coupling 4203055

21 Knife retainer housing 4207835

4209 - 27

Page 28

BINC Rev: 7/96 Service Documentation

Exploded Drawing

BAG Rev: 1/82 4615

MXK 3

4615

4209 - 28

Page 29

BINC Rev: 7/96 Service Documentation

Spare Parts List

BAG Rev: 12/88 4615

Pos. No. Part Description Part Number

1 Glass 4203136

2 Gasket (black) 4203219

3 Cap nut 4203139

4 Middle knife 4203133

4 Middle knife * 4209606

5 Lower knife 4203132

5 Lower knife * 4209605

6 Knife holder 4213039

7 Steel washer 4213038

8 Washer 4213040

9 Knife shaft 4207054

10 Threaded retainer housing NLA

with bottom

11 Bronze washer 4213041

12 Spring 4203135

13 Coupling washer 4213042

14 Coupling 4203055

* Knife Sharpened

4209 - 29

Loading...

Loading...