Bradley Corporation S59-2025 Installation Manual

Installation

S59-2025

Thermostatic Mixing Valve (TMV25) with Optional Cabinet

S59-2025RE (with Recess-Mounted Enamel Cabinet)

S59-2025RS (with Recess-Mounted Stainless Steel Cabinet)

S59-2025SE (with Surface-Mounted Enamel Cabinet)

S59-2025SS (with Surface-Mounted Stainless Steel Cabinet)

Table of Contents

Supplies Required . . . . . . . . . . . . . . 2

Installation Instructions . . . . . . . . . . . . 2

Dimensions . . . . . . . . . . . . . . . . . 3

Optional Equipment Installation . . . . . . . . . 5

Troubleshooting . . . . . . . . . . . . . . . 6

Inlet Connections: 3/4" NPT

Outlet Connection: 1" NPT

Temperature Range: 85 – 135°F

Maximum Pressure: 125 PSIG

ASSE 1017 & UPC Certified

Inlet Temperature Hot: 120 – 200° F Inlet Temperature Cold: 33 – 80° F

Minimum Temperature Differential (from valve set point): 20° F

215-1300 Rev. H; EN 10-09-010 |

P.O. Box 309, Menomonee Falls, WI USA 53052-0309 |

|

© 2012 Bradley |

|

|

|

PHONE 800.BRADLEY (800.272.3539) FAX 262.251.5817 |

|

Page 1 of 8 |

10/3/2012 |

|

|

|

bradleycorp.com |

S59-2025 |

Installation |

Installation |

|

Packing List |

|

• |

|

• |

THIS |

• |

SIDE |

• |

UP |

IMPORTANT!

Read this entire installation manual to ensure proper installation. When finished with the installation, file this manual with the owner or

maintenance department. Compliance and conformity to local codes and ordinances is the responsibility of the installer.

Separate parts from packaging and make sure all parts are accounted for before discarding packaging material. If any parts are missing, do not begin installation until you obtain the missing parts.

Make sure that all water supply lines have been flushed and then completely turned off before beginning installation. Debris in supply lines can cause valves to malfunction.

Product warranties may be found under “Products” on our web site at bradleycorp.com.

Supplies recommended for installation

•Lockable shut-off on the outlet if tempered water is supplied to one or more remote fixtures

•Lockable shut-off on the inlets/supplies

•(6) 3/8" wall anchors and fasteners for surface-mounted cabinet

•(4) 1/4" and (2) 3/8" fasteners (and wall anchors, if necessary) for recess-mounted cabinet

•Unions on all connections to facilitate removal of valve

Tools required for temperature adjustment

•5/32" Allen wrench

•Blade screwdriver

1 Install Optional Cabinet (If not installing cabinet, skip to Step 2)

Recessed Cabinet:

1.Rough-in wall opening 24-1/2" W x 24-1/2" H.

2.Insert the cabinet and secure to wall with four 1/4" fasteners properly anchored (supplied by installer.)

3.Install two 3/8" anchors and screws through the valve bracket in back of the cabinet into a secure brace (supplied by installer) or into wall. This will support the valve.

4.Install the valve nipples and one-half of the union ball valve using pipe sealant or teflon tape. Install the other half of the union ball valve onto inlet and outlet pipe.

5.Insert the valve into the bracket in the cabinet (right side goes in first). Continue with the valve installation procedure.

6.Position the wall flange tight to the wall and caulk in place.

Surface-Mounted Cabinet:

1.Measure and mark the cabinet mounting hole locations at the dimensions shown on next page. Install six 3/8" wall anchors (supplied by installer).

2.Position the cabinet onto the wall and secure into place with six 3/8" wall fasteners (supplied by installer).

3.Install the valve nipples and one-half of the union ball valve using pipe sealant or teflon tape. Then install the other half of the union ball valve onto the inlet and outlet piping.

4.Insert the valve into the bracket in the cabinet (right side of the valve goes in first). Continue with the valve installation procedure.

2 |

10/3/2012 |

Bradley • 215-1300 Rev. H; EN 10-09-010 |

Installation |

S59-2025 |

|

|

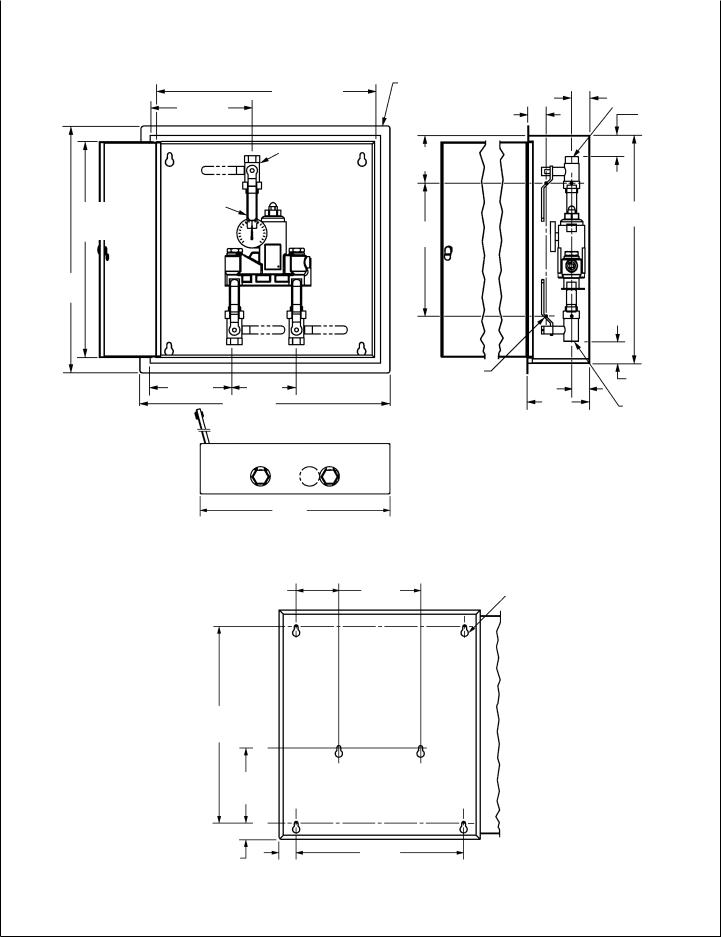

Optional Recessed / Surface Mounted Cabinet Dimensions |

(mm) |

22-3/4" (578) Front View 10-5/16" Door

(262)

Union

Ball Valve

22-3/4" Nipple

(578)

Door

26"

(660)

7-5/8" 8-3/4"

(194) (222) 26"

(660)

Bottom View

24"

(610)

5-1/8"

Mounting Hole Locations (130) for Surface Mount

24"

(610)

9-3/16"

(233)

2" 2"

(51) (51)

Wall |

|

3/4" NPT |

Side View |

|

Flange |

|

Outlet |

||

2" (51) |

||||

|

|

|

|

|

|

2" (51) |

||

5" |

|

|

|

(127) |

|

|

|

|

|

|

|

|

24" |

|

|

14" |

(610) |

|

|

|

|

|

|

|

|

|

|

(356) |

|

|

|

0.28" Dia. Holes |

2" |

|

2" |

|

(4) each side, |

(51) |

|

(51) |

|

(8) Total for |

|

|

|

|

6-1/2" |

|

|

||

|

|

3/4" NPT |

||

Recessed Mount |

|

(165) |

|

Inlets |

|

Wall Opening: |

|||

|

|

|||

24-1/2" W x 24-1/2" H

0.47 Dia. Holes

9-3/4" (6) Places

(248)

20"

(508)

Bradley • 215-1300 Rev. H; EN 10-09-010 |

10/3/2012 |

3 |

Loading...

Loading...