Bradley Corporation S19-690 Installation Manual

Installation

P.O. Box 309, Menomonee Falls, WI USA 53052-0309

PHONE 800.BRADLEY (800.272.3539) FAX 262.251.5817

bradleycorp.com

215-321C Rev. V; ECN 14-05-015

© 2014 Bradley

Page 1 of 19 7/29/2014

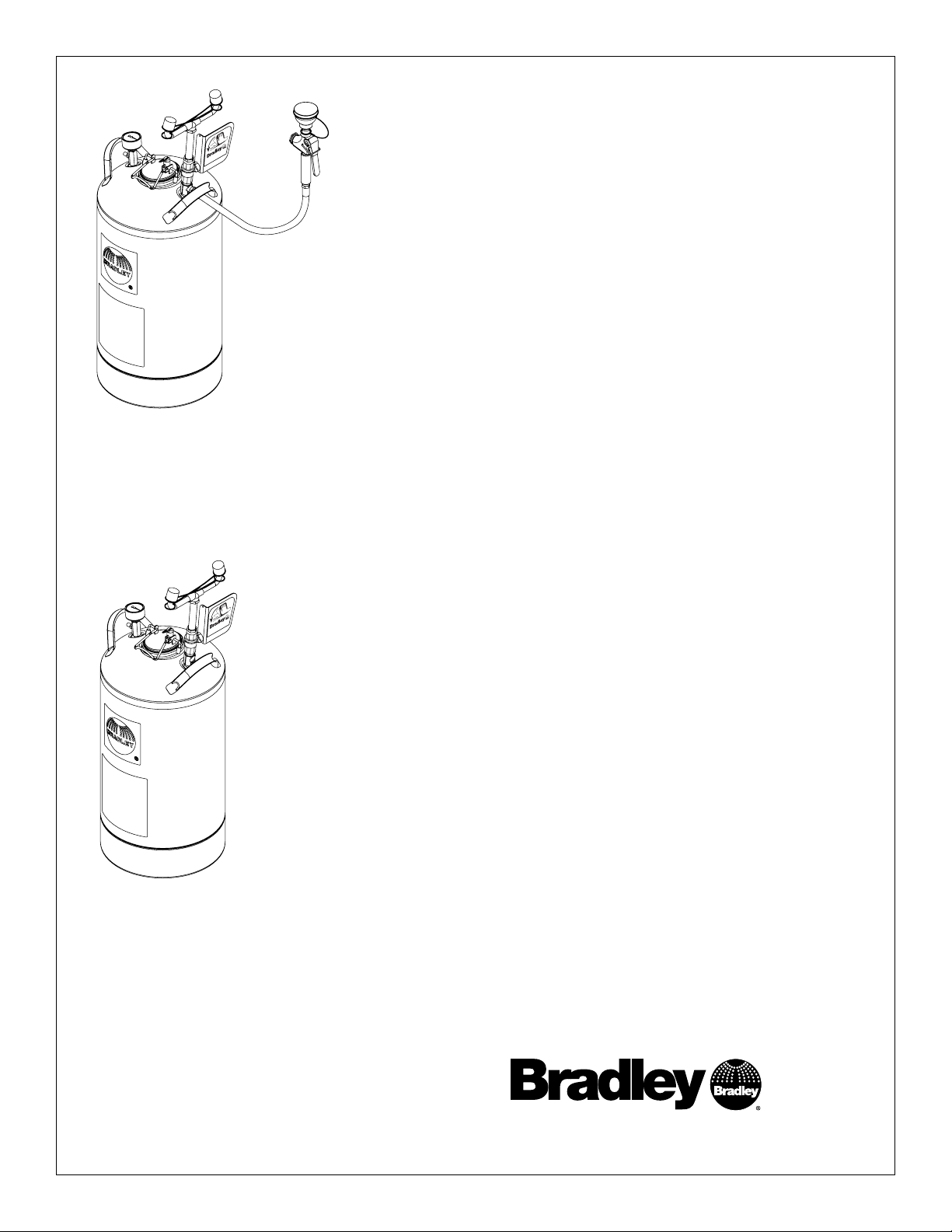

S19-690

10-Gallon Tank with Eyewash and

Hose Spray

Réservoir de 10 gallons avec

douche oculaire et douchette

Depósito de 10 galones con

lavaojos y manguera de aspersión

S19-690LHS

10-Gallon Tank with Eyewash

Réservoir de 10 gallons avec

douche oculaire

Depósito de 10 galones con

lavaojos

Table of Contents

Pre-Installation Information ...................... 2

Dimensions ..................................3

Eyewasy Installation ........................... 3

Filling the Tank................................4

Maintenance & Troubleshooting .................. 5

S19-690 Components & Parts List ................ 6

S19-690LHS Components & Parts List............. 7

Table des matières

Avant l’installation ............................. 8

Dimensions ..................................9

Installation de la douche oculaire ................. 9

Remplissage du réservoir ......................10

Entretien et dépannage ........................ 11

S19-690 Composantes et liste des pièces ......... 12

S19-690LHS Composantes et liste des pièces...... 13

Contenido

Información previa a la instalación ............... 14

Dimensiones ................................15

Instalación del lavaojos ........................ 15

Llenar el tanque..............................16

Mantenimiento y resolución de problemas ......... 17

S19-690 Componentes y lista de piezas........... 18

S19-690LHS Componentes y lista de piezas ....... 19

P.O. BOX 309

MENOMONEE FALLS, WI 53052-0309 USA

TEL: 1-800-BRADLEY FAX: (262-251-5817)

http://www.bradleycorp.com

P.O. BOX 309

MENOMONEE FALLS, WI 53052-0309 USA

TEL: 1-800-BRADLEY FAX: (262-251-5817)

http://www.bradleycorp.com

S19-690

S19-690LHS

2

S19-690, S19-690LHS Installation

7/29/2014 Bradley • 215-321C Rev. V; ECN 14-05-015

IMPORTANT

Read this installation manual completely to ensure proper installation, then file it with the

owner or maintenance department. Compliance and conformity to drain requirements and

other local codes and ordinances is the responsibility of the installer.

Separate parts from packaging and make sure all parts are accounted for before discarding

any packaging material. If any parts are missing, do not begin installation until you obtain

the missing parts.

The inspection and testing results of this equipment should be recorded weekly to verify

proper operation. This equipment should be inspected annually to ensure compliance with

ANSI Z358.1.

Workers who may come in contact with potentially hazardous materials should be trained

regarding the placement and proper operation of emergency equipment per ANSI Z358.1.

For questions regarding the operation or installation of this product, visit www.bradleycorp.

com or call 1-800-BRADLEY.

Product warranties and service parts information may also be found under ”Products” on our

web site at www.bradleycorp.com.

This unit is to be used with tepid, potable water as defined by ANSI Z358.1. (Note: avoid

prolonged exposure to ambient heat sources above 100° F, or below 60° F).

Failure to lift unit by the provided handles may damage unit.

Installation

THIS

SIDE

UP

Packing List

•

•

•

•

P.O. Box 309, Menomonee F

alls,

WI 53051

R

TEST THIS

UNIT EACH

WEEK

Test-operate valv

e(s) each week and sign

below.

Report an

y malfunctions immediatel

y.

Ventil(e) wöc

hentlich im

Testbetrieb prüfen,

bestätigt

durch Untersc

hrift. Jeglic

he Störung sofor

t melden.

Date

Datum

Date

Signed

Unterschrift

Signe

Date

Date

Date Signed

Signed

Signed

DIESES GERÄT 1ST

WÖC

HENTLICH ZU

PRÜFEN.

ESSAI HEBDOMA

DAIRE

Test le fonctionnement des v

alves chaque semaine et

signe en bas. S'il y à quelqu

e chose qui ne v

a pas fait

un rappor

t immédiatement.

P.O. BOX 309, MENOMONEE FALLS, WI 53052-0309 USA

TEL: 1-800-BRADLEY FAX: (262-251-5817)

http://www.bradleycorp.com

114-051

NOTICE! Avoid cleaners containing organic solvents, alcohols, and hydrocarbons.

Rinse with water after cleaning.

Supplies Required:

• Pipe sealant

• Air pressure equipment or supply (clean and free of oil contaminants) capable of up to 100 psi

• Sign-mounting hardware

• Adjustable wrench

60˚ F

100˚

F

3

Installation S19-690, S19-690LHS

Bradley • 215-321C Rev. V; ECN 14-05-015 7/29/2014

26"

(660mm)

12¼"

(311mm)

34"

(864mm)

24³⁄₈"

(619mm)

6"

(152mm)

Dimensions

1

Eyewash installation

Remove the plastic dust plug from the bottom of

the yoke assembly and discard.

Hose spray for S19-690 model only. Do not

attach body wash spray head at this time.

Attach the eyewash yoke assembly

to the tank. Max. torque 150 In-Lbs.

A

Attach the pressure gauge to

the adapter on the pressure

side of the tank with pipe

sealant (by installer).

C

NOTICE: When attaching the pressure

gauge and hose spray to the tank

outlet, hold the adapter (item 3) with a

wrench to prevent stripping. Failure to

do so may damage the seal and cause

leakage. Max. torque 150 in-lbs.

Connect the hose with appropriate

pipe sealant (by installer). Do not

use sealant tape.

B

Body Wash Spray Head

4

S19-690, S19-690LHS Installation

7/29/2014 Bradley • 215-321C Rev. V; ECN 14-05-015

Fill tank and pressurize

CAUTION! DO NOT open the cover until the pressure gauge reads “0.”

1. Open the tank by pulling up on the wire handle located on top of the Quick-lock cover. Push down, rotate and remove. Make

sure that the interior of the container is clean. Fill the container with 8 gallons of tepid potable water.

2. Replace the cover and secure by pulling up on the cover and down on the wire handle.

3. After filling the tank with tepid water and before pressurizing the unit, open the activation valve to the full open position and

remove the dust covers from the eyewash heads.

4. Located beneath the pressure gauge is an air valve. Remove protective cover and begin to pressurize the unit by applying

pressured air through the valve. As soon as water begins discharging from the eyewash heads, close the activation lever

completely. Finish pressurizing the tank to 90 psi and replace the air valves protective cover.

If this is the initial startup of this unit or if the unit has been unfilled and/or un-pressurized for a prolonged period of time the

unit should be flushed out per the procedure below.

Prior to placing unit in service let unit stand for one hour. If there is a noticeable pressure drop, re-pressurize and let

stand for an additional hour. If unit continues to exhibit pressure loss DO NOT place unit in service and consult the

Troubleshooting guide found on page 5 of this manual.

CAUTION! Relief valve is designed to vent automatically at 100-130 psi to prevent the tank from over pressurizing.

If the gauge ever reads more then 130 psi immediately open the pressure relief valve manually by pulling

up on the relief valve tab until the pressure reads zero. Remove the unit from service and consult the

troubleshooting guide found on page 5 in this manual for steps to correct the problem. Return the unit to

service only when over-pressurization issue is corrected.

Flush tank

1. Be sure the unit is assembled, filled and pressurized according to Steps 1 & 2 above, (If this is the initial start up of the unit

the body wash spray head will not be attached to the drench hose activation valve at this time.)

2. Discharge the water through the eyewash and hose spray (if provided with unit) for at least five minutes to flush the system.

3. Flush all remaining fluid in the tank.

4. Attach the body wash sprayhead (S19-690).

5. Refill the tank and pressurize as described in Step 2 above.

2

Filling the Tank

5

Installation S19-690, S19-690LHS

Bradley • 215-321C Rev. V; ECN 14-05-015 7/29/2014

Maintenance

WARNING! Follow instructions of the preservative manufacturer for the proper use of water preservative.

Inspect eyewash unit

1. Visually inspect the pressure gauge weekly to ensure the unit is maintaining the proper pressure. If the unit is not working

properly, remove it from the hazard area immediately and refer to the troubleshooting instructions. For further assistance,

contact the Bradley Corporation.

Clean eyewash unit

When using potable water only:

1. Empty the tank any time from once per week to once per month, depending on the quality of your water supply. The

manufacturer is not responsible for variations in the water supply.

2. Clean the inside of the tank using warm water and mild soap. Rinse the tank thoroughly with warm water.

3. Refill the eyewash tank with tepid potable water.

When using potable water and water preservative (recommended):

1. Clean the inside of the tank using warm water and mild soap. Rinse the tank thoroughly with warm water.

2. Refill the eyewash tank with tepid potable water. Follow instructions of the preservative manufacturer for the proper use of

water preservative.

Troubleshooting

1. If pressure relief valve relieves prior to the required pressure, do the following (when in the unpressurized condition):

• Tighten the valve completely into the cap by turning the gray hex head portion of the pressure relief valve clockwise.

Do not use a wrench.

• ull up on the relief valve ring and ensure that the ring is not preventing the valve from closing completely. Push on the

center pin of the relief valve to ensure that it is completely closed. Repressurize tank to required pressure. This may

have to be done several times to get the valve to seat completely.

2. If the pressurized tank loses pressure over time, check the connections with diluted liquid dish soap or children’s bubbles to

identify the leak location. Tighten the connection slightly and test again.

6

S19-690, S19-690LHS Installation

7/29/2014 Bradley • 215-321C Rev. V; ECN 14-05-015

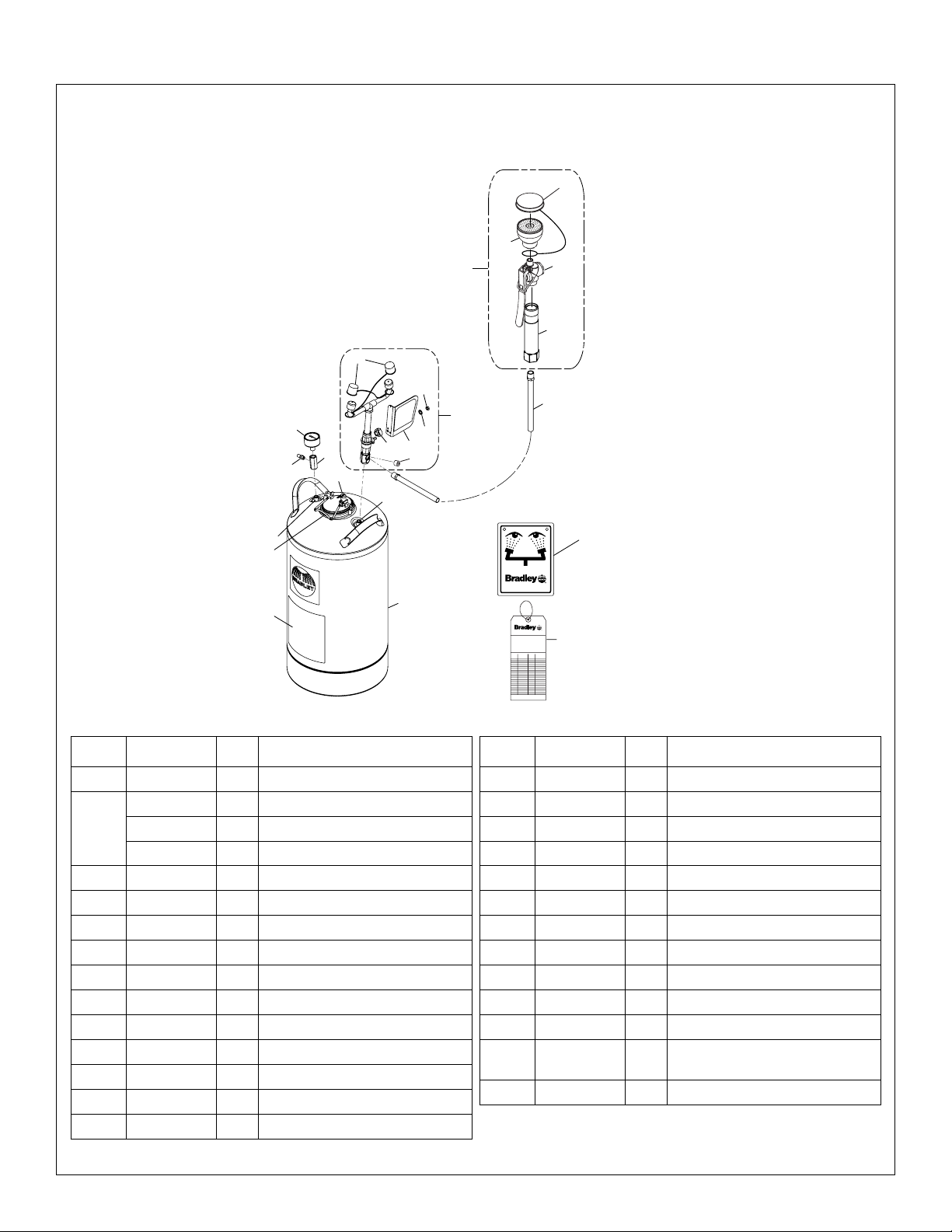

Assembly of Components and Parts List - S19-690

9

9.4

9.3

9.2

9.1

8

1

2

3

5

4

7

6

P.O. Box 309, Menomonee Falls, WI 53051

R

TEST THIS UNIT EACH WEEK

Test-operate valve(s) each week and sign below.

Report any malfunctions immediately.

Ventil(e) wöchentlich im Testbetrieb prüfen, bestätigt

durch Unterschrift. Jegliche Störung sofort melden.

Date

Datum

Date

Signed

Unterschrift

Signe

Date

Date

Date Signed

Signed

Signed

DIESES GERÄT 1ST WÖCHENTLICH ZU PRÜFEN.

ESSAI HEBDOMADAIRE

Test le fonctionnement des valves chaque semaine et

signe en bas. S'il y à quelque chose qui ne va pas fait

un rapport immédiatement.

P.O. BOX 309, MENOMONEE FALLS, WI 53052-0309 USA

TEL: 1-800-BRADLEY FAX: (262-251-5817)

http://www.bradleycorp.com

114-051

1.1

2.1

1.3, 1.5

1.3, 1.4

1.22

1.2, 1.21

2.2

2.3

2.4

2.5

2.6

S45-2410 includes Items 1.21, 1.3

Item Part No. Qty. Description

1 S39-785 1 Tank, 10-Gallon

1.1 204-641 1 Operating Instr. Label, English

204-641FC 1 Operating Instr. Label, French

204-641M 1 Operating Instr. Label, Spanish

1.2 S44-024 1 Lid Assembly

1.21 269-1410 1 Gasket

1.22 269-1642 1 Relief Valve

1.3 269-1411 2 O-Ring

1.4 269-1516 1 Draw Tube

1.5 269-1515 1 Level Indicator Tube

2 S05-182 1 Eyewash Valve Assembly

2.1 107-371 2 Tethered Dust Cover

2.2 S08-336 1 Handle/Label Assembly

2.3 110-215 1 Nut

2.4 153-372R 1 Adapter

Item Part No. Qty. Description

2.5 142-002DA 1 Lockwasher

2.6 169-043 1 Plug (do not save)

3 153-451 1 Adapter

4 169-786 1 Pressure Gauge

5 S27-320 1 Tank Valve Assembly

6 204-421 1 Emergency Inspection Tag

7 114-051 1 Safety Sign

8 S89-002 1 3/8" Yellow Tube

9 S39-817 1 Hose Spray

9.1 S27-332 1 Valve, Hose Spray

9.2 128-182 1 Handle

9.3 S45-2453 1 Service Kit EFW - Black

Sprayheads

9.4 S53-063 1 Tethered Dust Cover

Loading...

Loading...