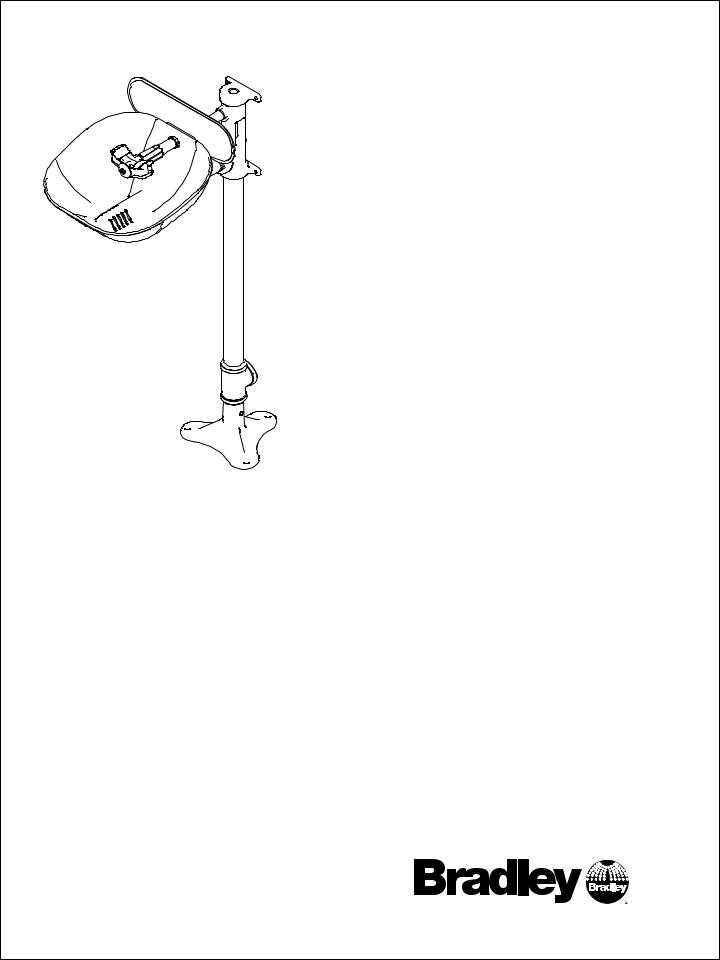

Bradley Corporation S19214FW, S19214PDC User Manual

Installation

S19214 Series

Halo™ Pedestal-Mount Eyewash or Eye/Face Wash

215-1685 Rev. M; ECN 13-05-023 |

P.O. Box 309, Menomonee Falls, WI USA 53052-0309 |

© 2015 Bradley |

PHONE 800.BRADLEY (800.272.3539) FAX 262.251.5817 |

Page 1 of 44 1/22/2015 |

bradleycorp.com |

S19214 Installation

Table of Contents |

|

|

|

|

|

|

Table of Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . . . . . |

. |

. |

. . . |

. 2 |

|

Pre-Installation Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . |

. |

. . . 3.-.4. . . . |

. . . |

||

Halo Pre-Configured Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . . . . . |

. |

. |

. . .5-6 |

|

|

Product Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . |

. |

. |

. . |

. 7. . . . |

. . . . . |

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . |

. |

|

. . . |

.8. . . . |

. . . . . |

Installation Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . |

. . |

. . . 9. . . . |

. . . . . |

||

Service Parts — Bowl and Hub . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . . . . . |

. |

. |

10–11 |

|

|

Service Parts — Eyewash, Eye/Face Wash and Bowl Covers . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . . |

. |

. |

. .12–.14. |

|

|

Service Parts — Base and Drain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . . . . . |

. |

. |

. . . |

15 |

|

Service Parts — Optional Accessories . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . . . . |

. |

. |

. . . |

16. . |

|

Avant l’installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . |

. |

. |

.17. -18. . . . . |

. . . . . |

|

Modèles préconfigurés Halo . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . |

. |

. |

.19. -. |

20. . . . . |

. . . . |

Configuration du produit . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . |

. |

. |

. . |

21. . . . . |

. . . . |

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . |

. |

|

. . . |

22. . . . . |

. . . . . |

Instructions d'installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . . . |

. |

. |

. . . |

23. . . . . |

|

Pièces de remplacement — Récepteur et moyeu . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . . . . . |

. |

. |

24–25 |

|

|

Pièces de remplacement — Douche oculaire, Douche oculaire/faciale et couvercle anti-poussières . . . . .26–28 |

|

|||||

Pièces de remplacement — Bride et drain . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . . |

. |

. |

. . . |

29. . . . . |

|

Pièces de remplacement — Accessoires en option . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . |

. |

. |

. . . |

30. . . . . |

. . . |

Información previa a la instalación.. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. |

.. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. |

.. .. |

31-32 |

|

||

Modelos preconfigurados Halo . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . |

. . |

33. . -34. . . . . . |

. . . . |

||

Configuración del producto . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . . |

. |

. |

. . . |

35. . . . . . |

. |

Dimensiones . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . . . |

36. . . . . |

. . . . . |

|||

. . . . .Instrucciones de instalación.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37 |

|

|||||

Piezas de repuesto — Receptor y buje . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . . . . . |

. |

. |

38–39 |

|

|

Piezas de repuesto — Lavaojos, lavaojos/rostro y cubierta contrapolvo |

. . . . . . . . . . . . . . . . . . . |

. |

. 40. –.42. . . . |

|

||

Piezas de repuesto — Base y drenaje . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . |

. |

. |

. . |

43. . . . . . |

. . . . |

Piezas de repuesto — Accesorios opcionales . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . |

. |

. |

. . |

44. . . . . |

. . . . . |

2 |

1/22/2015 |

Bradley • 215-1685 Rev. M; ECN 13-05-023 |

Installation |

S19214 |

IMPORTANT

The installation and location of all safety drench showers, eye and eye/face washes must comply with the requirements of ANSI Z358.1.

Emergency equipment must be supplied with tepid water (60°F to 100°F/15.6°C to 37.8°C). Any prolonged exposure to near freezing water affects the body's ability to maintain body temperature, increasing the risk of hypothermia.

Before installing this product, ensure that there are adequate clearances around the product and activation of the product does not interfere with other products or obstructions.

Read this installation manual completely to ensure proper installation, then file it with the owner or maintenance department. Compliance and conformity to drain requirements and other local codes and ordinances is the responsibilityof the installer.

Separate parts from packaging and make sure all parts are accounted for before discarding any packaging material.

Flush the water supply lines before beginning installation and after installation is complete. Test the unit for leaks and adequate water flow. Main water supply to the eyewash should be “ON” at all times. Provisions shall be made to prevent unauthorized shutoff.

The ANSI Z358.1 standard requires an uninterrupted supply of flushing fluid. Bradley plumbed emergency fixtures require a minimum of 30 PSI (0.21MPa) flowing pressure.

Self -closing spring-loaded valves are not UL classified to ANSI Z358.1.

Weekly activation must be conducted on all plumbed emergency equipment to ensure a suitable flushing fluid supply is present and any sediment build-up in the supply line is cleared. Emergency equipment should be inspected monthly to address any maintenance issues ensuring the equipment is in good operating condition and that there are no signs of wear.

Workers who may come in contact with potentially hazardous materials should be trained regarding the placement and proper operation of emergency equipment per ANSI Z358.1.

For questions regarding the operation or installation of this product, visit www.bradleycorp.com or call 800-BRADLEY (272.3539).

Product warranties and parts information may also be found under ”Products” on our web site at bradleycorp.com.

NOTICE Avoid cleaners containing organic solvents, alcohols and hydrocarbons. Rinse with water after cleaning.

Bradley • 215-1685 Rev. M; ECN 13-05-023 |

1/22/2015 |

3 |

S19214 |

Installation |

Supplies Required:

•(3) 3⁄8" floor anchors and bolts

•Teflon tape and pipe sealant

•30 PSI (2..0 bar) min/90 PSI (6..1 bar) max flow pressure

•125 PSI (8..6 bar) max static pressure

•Piping to ½" NPT (BSPP) water supply inlet (30–90 psi [2..0-6..1 bar])

•Piping to 1¼” NPT drain outlet on unit (if included with unit)

•OPTIONAL: sign-mounting hardware

•DVGW certified teflon tape (for DVGW certified models only)

Local codes may require the installation of a backflow prevention valve to complete proper installation. Compliance with local codes is the responsibility of the installer. Valve must be tested annually to verify that it is functioning properly. Backflow prevention valves are not included with the fixture and may be supplied by the contractor or purchased from Bradley Corporation.

4 |

1/22/2015 |

Bradley • 215-1685 Rev. M; ECN 13-05-023 |

Installation |

S19214 |

Halo Pre-Configured Models

Halo Model |

Description |

UL certified to |

Intertek certified |

|

Number |

ANSI/ISEA |

to EN standards |

||

|

||||

|

|

|

|

|

Eyewashes |

|

|

|

|

|

|

|

|

|

S19214EW |

Halo Eyewash, plastic bowl |

X |

X |

|

|

Halo Eyewash, stainless steel bowl |

|

|

|

S19214B |

X |

X |

||

|

|

|

|

|

Eyewashes with Dust Cover |

|

|

||

|

|

|

|

|

S19214PDC |

Halo Eyewash, plastic bowl w/ dust cover |

X |

X |

|

S19214DC |

Halo Eyewash, stainless steel bowl & hinged dust cover |

|

|

|

X |

X |

|||

|

|

|

|

|

Eye-Face Washes |

|

|

|

|

|

|

|

|

|

S19214FW |

Halo Eye/face wash, plastic bowl |

X |

X |

|

S19214Y |

Halo Eye/face wash, stainless steel bowl |

|

|

|

X |

X |

|||

S19214P |

Halo Eye/face wash, stainless steel bowl w/ hose spray |

|

|

|

X |

X |

|||

S19214YF |

Halo Eye/face wash, stainless steel bowl, hand/foot operated |

|

|

|

X |

X |

|||

|

|

|

|

|

Eye-Face Washes with Dust Cover |

|

|

||

|

|

|

|

|

S19214PDCFW |

Halo Eye/face wash, plastic bowl w/ dust cover |

X |

X |

|

S19214DCFW |

Halo Eye/face wash, stainless steel bowl & hinged dust cover |

|

|

|

X |

X |

|||

|

|

|

|

|

All Stainless Steel Eye/Face Wash |

|

|

||

|

|

|

|

|

S19214BSS |

Halo stainless steel eye/face wash and bowl |

X |

X |

|

S19214SC |

Halo stainless steel eye/face wash, bowl and cover |

|

|

|

X |

X |

|||

S19214SS |

Halo stainless steel eye/face wash and bowl with foot activation |

|

|

|

X |

X |

|||

|

|

|

|

|

Models with BSPP threading available. For BSPP threading, add a Z to end of existing part number. For example, S19214EW will be S19214EWZ.

Bradley • 215-1685 Rev. M; ECN 13-05-023 |

1/22/2015 |

5 |

S19214 |

Installation |

Halo Pre-Configured Models

All models with AS4775 & AS/NZS 4020 Certification include stainless steel pipe material with BSPP threading.

All models with AS4775 & AS/NZS 4020 Certification include stainless steel pipe material with BSPP threading.

Halo Model |

|

IAPMO Oceana |

|

Description |

certified to AS4775 |

||

Number |

|||

|

& AS4020 |

||

|

|

||

|

|

|

|

Eyewashes |

|

|

|

|

|

|

|

S19214EWZS |

Halo Eyewash, plastic bowl |

X |

|

|

|

|

|

S19214BZS |

Halo Eyewash, stainless steel bowl |

X |

|

|

|

|

|

Eyewashes with Dust Cover |

|

||

|

|

|

|

S19214PDCZS |

Halo Eyewash, plastic bowl w/ dust cover |

X |

|

|

|

|

|

S19214DCZS |

Halo Eyewash, stainless steel bowl & hinged dust cover |

X |

|

|

|

|

|

Eye-Face Washes |

|

|

|

|

|

|

|

S19214FWZS |

Halo Eye/face wash, plastic bowl |

X |

|

|

|

|

|

S19214YZS |

Halo Eye/face wash, stainless steel bowl |

X |

|

|

|

|

|

S19214YFZS |

Halo Eye/face wash, stainless steel bowl, hand/foot operated |

X |

|

|

|

|

|

Eye-Face Washes with Dust Cover |

|

||

|

|

|

|

S19214PDCFWZS |

Halo Eye/face wash, plastic bowl w/ hinged dust cover |

X |

|

|

|

|

|

S19214DCFWZS |

Halo Eye/face wash, stainless steel bowl & hinged dust cover |

X |

|

|

|

|

|

All Stainless Steel Eye/Face Wash |

|

||

|

|

|

|

S19214BSSZ |

Halo stainless steel eye/face wash and bowl |

X |

|

|

|

|

|

S19214SCZ |

Halo stainless steel eye/face wash, bowl and cover |

X |

|

|

|

|

|

S19214SSZ |

Halo stainless steel eye/face wash and bowl with foot activation |

X |

|

|

|

|

|

6 |

1/22/2015 |

Bradley • 215-1685 Rev. M; ECN 13-05-023 |

Installation |

S19214 |

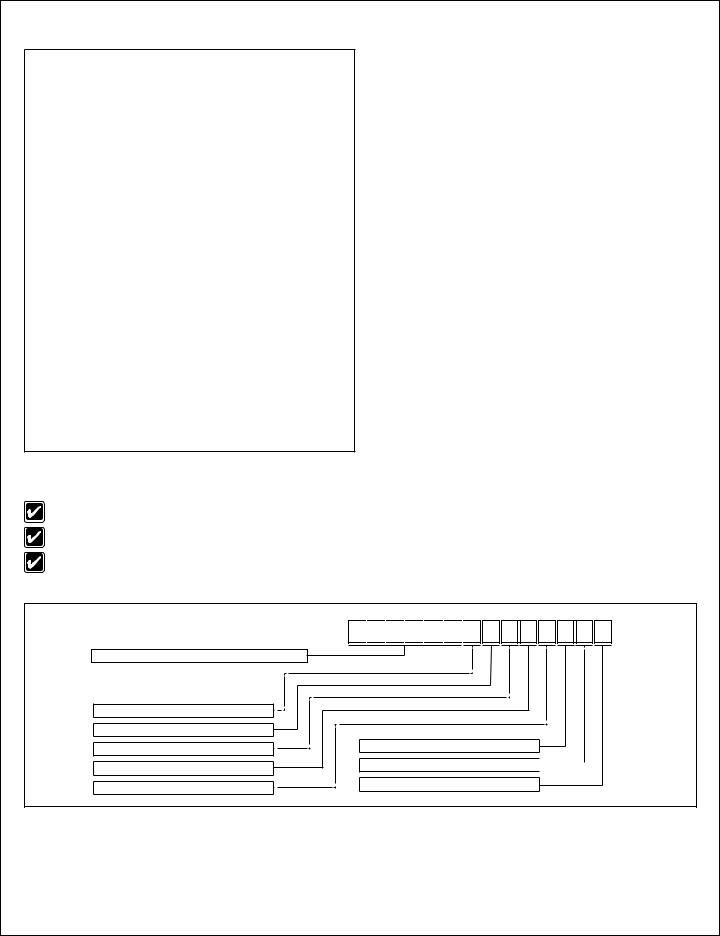

Product Configuration

Standard Selections (Must select one from each category)

Configuration |

|

¨ B |

24" Drain Height |

¨ 0 |

Standard, 6" Drain Height |

|

|

Pipe Material |

|

¨ A |

NPT, Yellow BradTect Galvanized Steel |

¨ B |

NPT, All 304 Stainless Steel |

¨ C |

NPT, All 316 Stainless Steel * |

¨ D |

NPT, Chrome-Plated |

¨ F |

BSPP, Yellow BradTect Galvanized Steel ‡ |

¨ G |

BSPP, All 304 Stainless Steel ‡ |

¨ J |

BSPP, Chrome-Plated ‡ |

|

|

Ball Valve |

|

¨ 1 |

Stay-Open Eyewash, Chrome-Plated Brass |

¨ 2 |

Stay-Open Eyewash, 316 SS |

|

|

Eyewash – Eye/Face Wash |

|

A |

Halo Eyewash |

¨ B |

Halo Eye/Face Wash |

¨ D |

Halo Eyewash, 304 SS Yoke |

¨ E |

Halo Eye/Face Wash, 304 SS Yoke |

¨ F |

304 SS Halo Eye/Face Wash, 304 SS Yoke |

¨ G |

Halo Eyewash, 316 SS Yoke |

H |

Halo Eye/Face Wash, 316 SS Yoke |

J |

316 SS Halo Eye/Face Wash, 316 SS Yoke |

* Not available with barrier-free configurations.

‡ Not available in the U.S.

NPT = National Pipe Thread

BSPP = British Standard Pipe Parallel Threads

All selections made through the configurator are only UL certified to ANSI Z358.1

Bowl and Dust Cover |

|

A |

Plastic Bowl, No Dust Cover |

¨ B |

Plastic Bowl, Plastic Dust Cover |

¨ D |

304 SS, No Dust Cover |

¨ E |

304 SS, 304 SS Dust Cover |

¨ F |

304 SS, Plastic Dust Cover |

¨ G |

316 SS, No Dust Cover |

H |

316 SS, 316 SS Dust Cover |

J |

316 SS, Plastic Dust Cover |

0 |

No Bowl or Dust Cover |

|

|

Activation |

|

¨ A |

304 SS Handle |

¨ B |

316 SS Handle |

¨ D |

304 SS Handle with Stainless Steel Foot Pedal * |

¨ E |

316 SS Handle with Stainless Steel Foot Pedal * |

Drench Hose and Backflow Prevention |

|

¨ A |

Drench Hose Kit with Vacuum Breaker |

¨ B |

Drench Hose Kit with N9 Backflow Preventer |

¨ C |

Drench Hose Kit with 9D Backflow Preventer |

¨ D |

Drench Hose Kit without Backflow Preventer |

¨ 0 |

No Drench Hose and No Backflow Prevention |

Freeze and Scald Protection |

|

N |

Anti-Freeze Valve |

¨ P |

Anti-Scald Valve |

¨ R |

Anti-Freeze and Anti-Scald Valves |

0 |

No Anti-Freeze Valve and No Anti-Scald Valve |

How to Specify Model and Configurations for Bradley Halo Products:

Model No. S19214

1. Configuration

2. Pipe Material

3. Ball Valve

4. Eyewash – Eye/Face Wash

5. Bowl and Dust Cover

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

S

1

1

9

9

2

2

1

1

4

4

6. Activation

7. Drench Hose and Backflow Prevention

8. Freeze and Scald Protection

Bradley • 215-1685 Rev. M; ECN 13-05-023 |

1/22/2015 |

7 |

S19214 |

Installation |

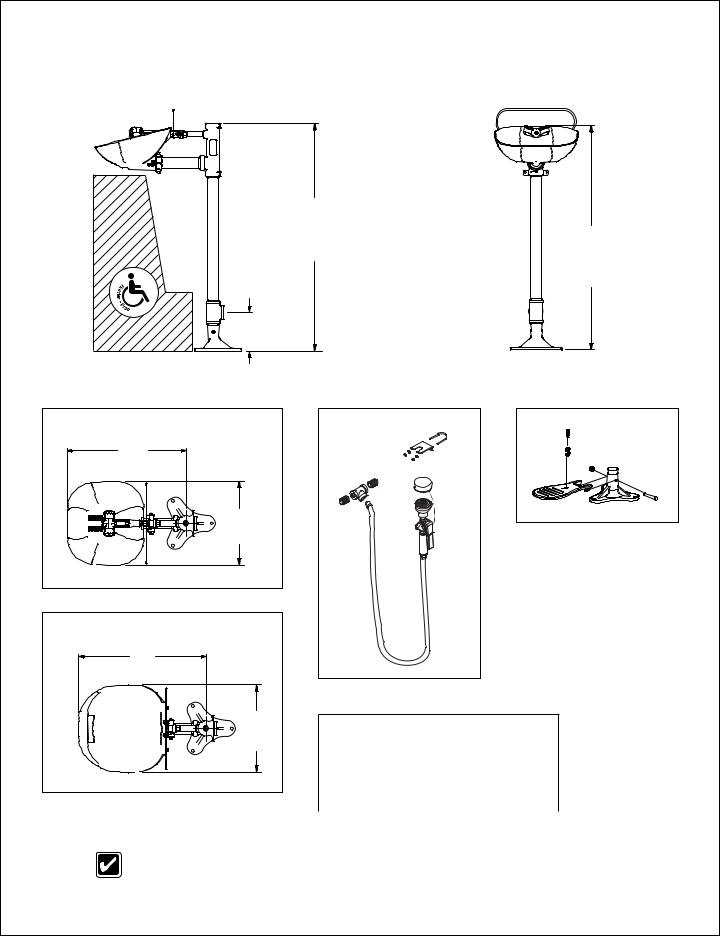

Dimensions

S19214 shown with Eyewash and Plastic Bowl

35½"

(902mm)

to Bottom

of Base 34¾" (883mm)

to Bottom of Base

6"

(152mm)

Eyewash Bowl

18½"

(470mm)

13"

(330mm)

Dust Cover |

19¾" |

(502mm) |

13¼" |

(337mm) |

S19-430EH Drench Hose |

Foot Pedal Activation |

Water Flow Rate

Eyewash |

4–5¼ gpm |

|

|

Eye/Face Wash |

4–5¼ gpm |

|

|

Body Wash |

2–8 gpm |

|

|

All dimensions assume standard thread engagement. Variations in manufacturing allow for +/- 1⁄8" (3mm) per threaded joint. To find the tolerance of a dimension, add the number of thread joints across the length of the dimension and multiply it by 1⁄8" (3mm).

8 |

1/22/2015 |

Bradley • 215-1685 Rev. M; ECN 13-05-023 |

Installation |

S19214 |

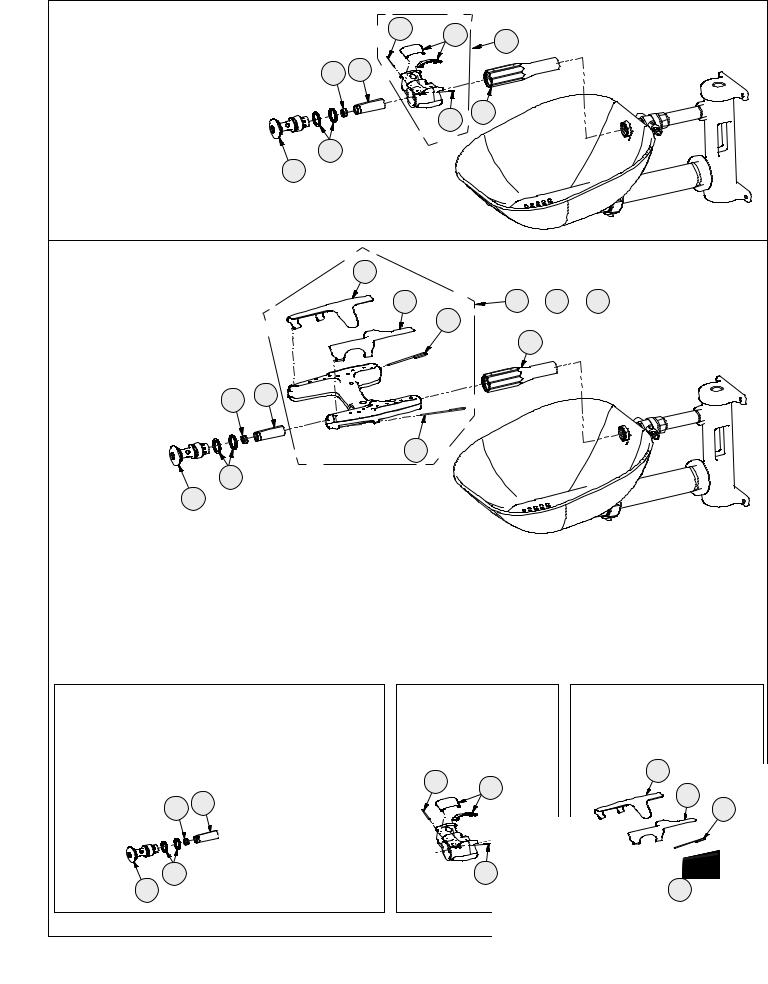

1 Assembly — Connect Base and Eyewash

Standard eyewash unit is shown. Other units are similar.

Connect components before securing the base to the floor. When connecting components, use the rubber grip pad (provided) around pipes to prevent marring.

Apply pipe sealant (supplied by installer) to all male-threaded pipe joints, making sure not to get any excess over the edge of the pipes.

BSPP = British Standard Pipe Parallel Thread (not available in the U.S.)

Halo unit with standard drain option

½" NPT below supply inlet, or ½" BSPP

Adapter when option is specified

(3) Ø 3⁄8" (10mm) holes on Ø 8" (203mm) bolt circle

20½"

(521mm) pipe length

1¼" NPT drain outlet or 1-1/4" BSPP Adapter when option is specified

For optional foot pedal installation, the base must be positioned so that the hole in the base is perpendicular to the user..

³⁄" bolts and anchors supplied by installer..

Halo unit with 24" drain option

½” NPT below supply inlet, or ½" BSPP Adapter when option is specified

1¼" NPT drain outlet or 1-1/4" BSPP

Adapter when option is specified

12¾"

(324mm) pipe length

Bradley • 215-1685 Rev. M; ECN 13-05-023 |

1/22/2015 |

9 |

S19214 |

Installation |

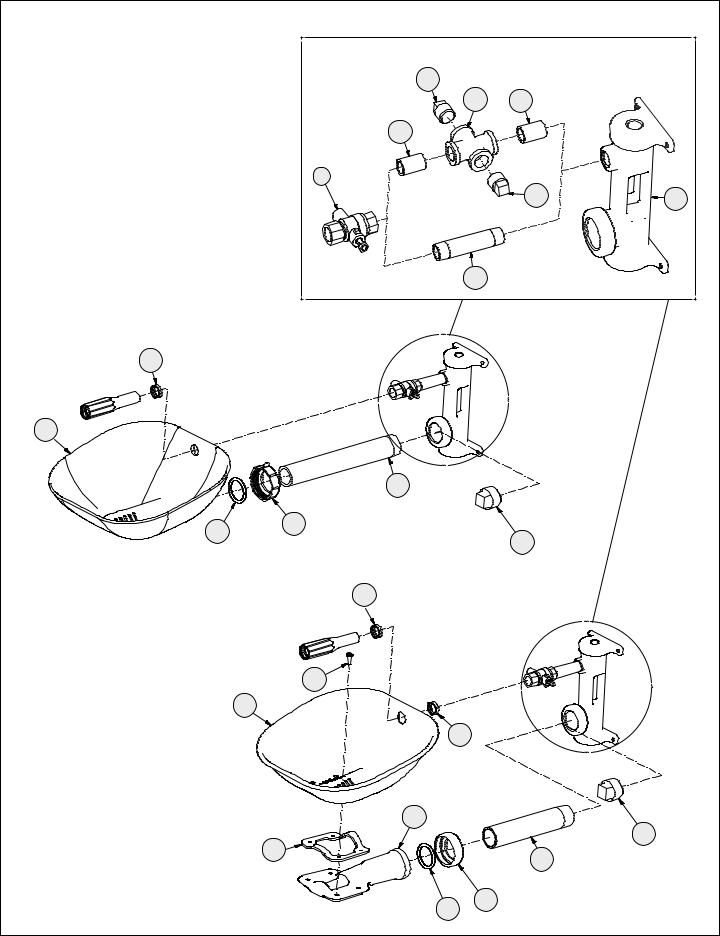

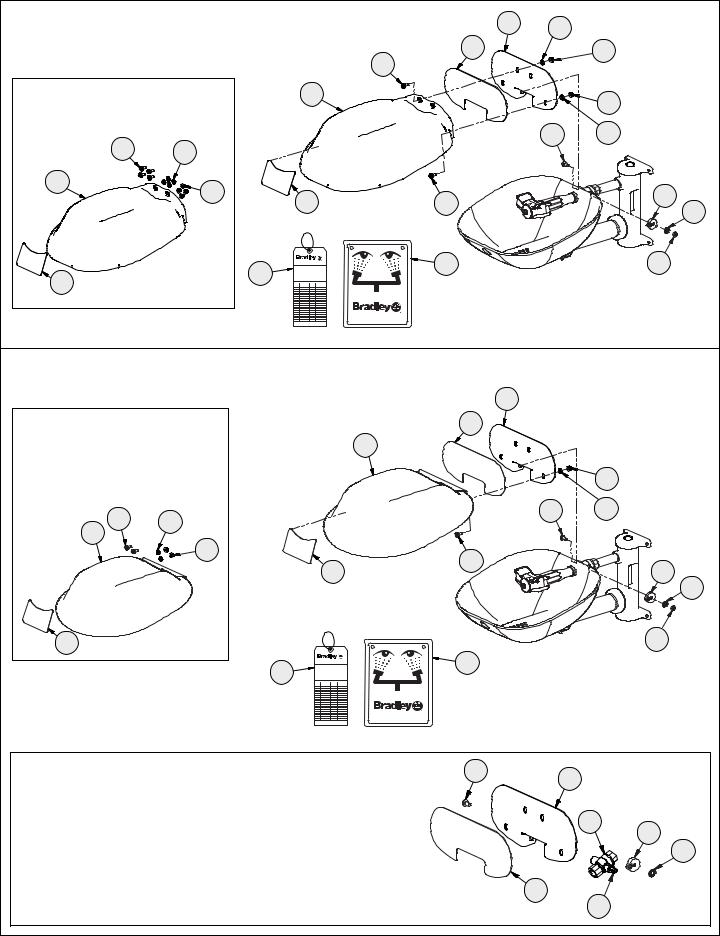

Service Parts — Hub with Bowl

Cross (Item #3) is for use with freeze/scald valves and drench hose accessories only.

4

3 2b

2b

5

4 |

1 |

|

2a

Hub with Plastic Bowl

17

15a

10a

11a

12

10c

17

Hub with Stainless Steel Bowl

16

15b

17

13

10c

14

10b

11b

12

10 |

1/22/2015 |

Bradley • 215-1685 Rev. M; ECN 13-05-023 |

Installation |

S19214 |

Service Parts List –— Bowl and Hub

BSP = British Standard Pipe Thread (not available in the U.S.)

Item |

Part No. |

Qty |

Description |

|

|

|

|

1 |

111-096 |

1 |

Hub |

1 |

111-097 |

1 |

Hub stainless steel |

1 |

111-103 |

1 |

Hub stainless steel 316 |

1 |

111-098 |

1 |

Hub stainless steel polish |

|

|

|

|

2a |

113-006LQ |

1 |

Pipe ½" x 3½" |

2a |

113-965 |

1 |

Pipe ½" x 3½" stainless steel |

2a |

113-1211 |

1 |

Pipe ½" x 3½" stainless steel 316 |

2a |

113-596 |

1 |

Pipe ½" x 3½" chrome |

2b |

113-006LG |

2 |

Pipe ½" x close |

2b |

113-867 |

2 |

Pipe ½" x close stainless steel |

2b |

113-1210 |

2 |

Pipe ½" x close stainless steel 316 |

2b |

113-006aw |

2 |

Pipe ½" x close chrome |

|

|

|

|

3 |

169-1090 |

1 |

Cross ½" |

3 |

169-1091 |

1 |

Cross ½" stainless steel |

3 |

169-1098 |

1 |

Cross ½" stainless steel 316 |

3 |

169-1097 |

1 |

Cross ½" chrome |

|

|

|

|

4 |

300-0393 |

2 |

Plug ½" chrome |

4 |

153-230 |

2 |

Plug ½" stainless steel |

4 |

153-460 |

2 |

Plug ½” stainless steel 316 |

|

|

|

|

5 |

S27-327 |

1 |

Ball valve ½" with nut |

5 |

S27-328 |

1 |

Ball valve ½" ss 316 with nut |

5 |

S27-329 |

1 |

Ball valve ½" frost proof with nut |

5 |

S27-330 |

1 |

Ball valve ½" ss 316 frost proof with nut |

5. .1 |

110-215 |

1 |

Nut |

5..1 |

110-248 |

1 |

Nut stainless steel 316 |

|

|

|

|

Item |

Part No. |

Qty |

Description |

|

|

|

|

10a |

113-1202 |

1 |

Pipe 1¼" x 11" thd.. one end |

10a |

113-1203 |

1 |

Pipe 1¼" x 11" thd.. one end stn.. steel |

|

|

|

|

10b |

113-1204 |

1 |

Pipe 1¼" x 7" thd.. one end |

10b |

113-1205 |

1 |

Pipe 1¼" x 7" thd.. one end stainless steel |

10b |

113-1206 |

1 |

Pipe 1¼" x 7" thd.. one end chrome |

10b |

113-1212 |

1 |

Pipe 1¼" x 7" thd.. one end stn.. steel 316 |

|

|

|

|

10c |

169-724 |

1 |

Plug 1¼" painted galvanized |

10c |

269-251 |

1 |

Plug 1¼" chrome |

10c |

269-238 |

1 |

Plug 1¼" stainless steel |

10c |

269-1402 |

1 |

Plug 1¼" stainless steel 316 |

|

|

|

|

11a |

110-239 |

1 |

Nut plastic, slip joint |

11b |

110-240 |

1 |

Nut, stainless steel slip joint |

11b |

110-242 |

1 |

Nut, stainless steel 316 slip joint |

|

|

|

|

12 |

125-176 |

1 |

O-ring |

|

|

|

|

13 |

111-099 |

1 |

Bowl mount aluminum |

13 |

111-100 |

1 |

Bowl mount aluminum painted |

13 |

111-101 |

1 |

Bowl mount stainless steel |

13 |

111-102 |

1 |

Bowl mount stainless steel 316 |

|

|

|

|

14 |

124-082 |

1 |

Bowl gasket |

|

|

|

|

15a |

187-320 |

1 |

Bowl plastic |

15b |

S90-393 |

1 |

Bowl stainless steel (includes Item 14) |

15b |

S90-394 |

1 |

Bowl stn.. steel 316 (includes Item 14) |

|

|

|

|

16 |

160-467 |

4 |

Screw |

|

|

|

|

17 |

110-115a |

as req’d.. |

Nut ½" NPSM chrome brass |

17 |

110-238 |

as req’d.. |

Nut ½" NPSM stainless steel |

17 |

110-241 |

as req’d.. |

Nut ½" NPSM stainless steel 316 |

|

|

|

|

S90-395 Plastic Prepack includes items 10a, |

300 Series SS Prepack S90-391 includes items 10b, 11b, |

||

11a, 12, 15a |

|

12, 13, 14, 15b |

|

|

|

316 Series SS Prepack S90-392 includes items 10b, 11b, |

|

|

|

12, 13, 14, 15b |

|

15a |

|

15b |

|

|

10a |

|

|

12 |

11a |

|

13 |

|

|

||

|

|

14 |

10b |

|

|

|

|

|

|

|

11b |

|

|

|

12 |

Bradley • 215-1685 Rev. M; ECN 13-05-023 |

1/22/2015 |

11 |

S19214 Installation

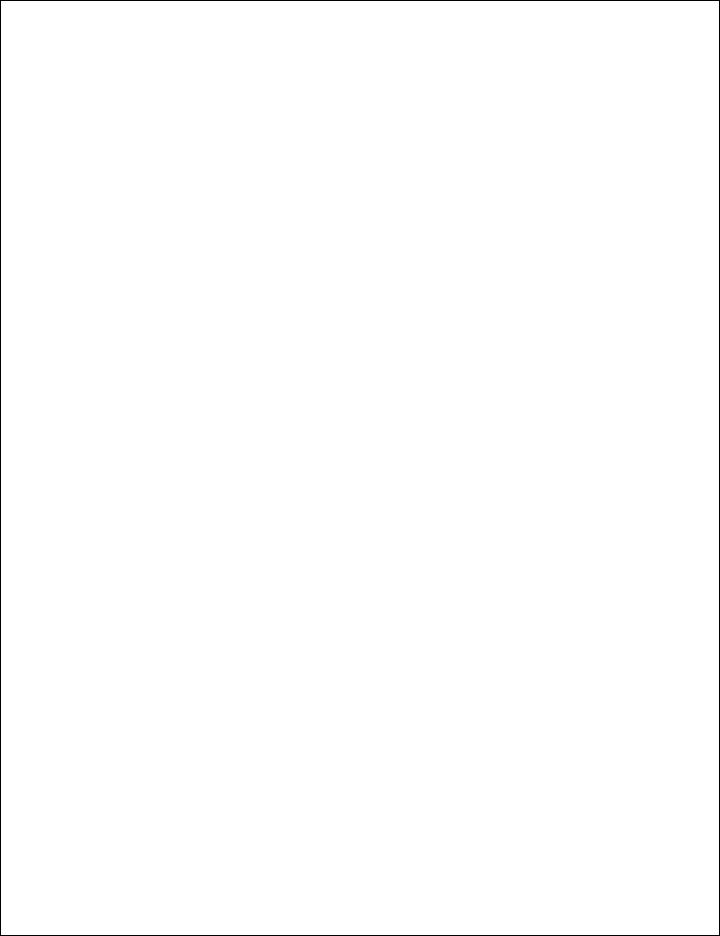

Service Parts — Eyewash |

|

22 |

23 |

|

|

|

|

||

|

|

|

21a |

|

|

|

|

|

|

|

27 |

28 |

|

|

|

|

|

|

20

22

26

25

Service Parts — Eye/Face Wash

24b

24a |

21b or 21f or 21j |

22

20

27 28

22

26

25

|

Prepack S65-339 includes items 26, 27, 28 |

Eyewash Cover Prepack |

Eye/Face Wash Cover Prepack |

||

|

Prepack S88-068 includes items 25, 26, 27, 28 |

S45-2675 includes items |

S45-2676 includes items 22, |

||

|

22 and 23 |

|

24a and 24b |

||

|

Prepack S88-069 includes items 25, 26, 27, 28 |

|

|||

|

|

|

|

||

|

(300 series ss) |

|

|

|

|

|

Prepack S88-070 includes items 25, 26, 27, 28 |

22 |

|

24b |

|

|

(316 ss) |

|

23 |

|

|

|

|

|

24a |

||

|

|

28 |

|

|

|

|

27 |

|

|

22 |

|

|

|

|

|

||

|

26 |

|

|

22 |

|

|

25 |

|

|

|

22 |

12 |

|

1/22/2015 |

|

Bradley • 215-1685 Rev. M; ECN 13-05-023 |

|

Installation |

S19214 |

Service Parts — Plastic Bowl Cover

40 42

41 |

43 |

|

39

Plastic Bowl Cover Prepack S90-390 |

35a |

|

43 |

|

includes items 35a, 36, 39, 42, 43 |

|

|

||

|

|

|

||

|

|

|

39 |

42 |

39 |

42 |

|

|

|

|

|

|

|

|

35a |

|

43 |

|

|

|

|

|

44 |

|

|

|

36 |

39 |

|

|

|

45 |

||

|

|

|

|

|

|

|

341 |

342 |

5.1 |

36 |

|

|

|

|

|

|

|

|

|

Service Parts — Stainless Steel Bowl Cover |

|

|

||

|

|

|

40 |

|

Stainless Steel Bowl Cover Prepack |

|

41 |

|

|

S90-388 includes items 35b, 36, 39, |

|

35b |

|

|

42, 43 |

|

|

|

|

|

|

|

|

|

Stainless Steel (316) Bowl Cover |

|

|

43 |

|

Prepack S90-389 includes items 35b, |

|

|

||

|

|

|

||

36, 39, 42, 43 |

|

|

39 |

42 |

39 |

|

|

||

42 |

|

|

|

|

35b |

|

|

|

|

|

|

|

|

|

|

|

43 |

39 |

|

|

|

36 |

44 |

|

|

|

|

||

|

|

|

|

45 |

36 |

|

|

|

5.1 |

|

|

|

|

|

|

|

341 |

342 |

|

|

|

|

|

|

Handle Prepacks include items 39, 40, 41, 44, 45, 5, 5..1 |

39 |

40 |

Prepack S08-390 (for units with brass ball valve) |

|

|

|

|

Prepack S08-391 (for units with stainless steel ball valve)

Prepack S08-392 (for units with brass frost-proof ball valve) |

5 |

||

Prepack S08-393 |

(for units with stainless steel frost-proof ball valve) |

44 |

|

45 |

|||

Prepack S08-394 |

(for units with 316 stainless steel ball valve and handle) |

||

|

|||

Prepack S08-395 |

(for units with 316 stainless steel frost-proof ball valve |

|

|

and handle) |

|

41 |

|

|

|

5.1 |

|

Bradley • 215-1685 Rev. M; ECN 13-05-023 |

1/22/2015 |

13 |

S19214 |

Installation |

Service Parts List –— Eyewashes and Bowl Covers

Item |

Part No. |

Qty |

Description |

|

|

|

|

20 |

171-001 |

1 |

Body |

20 |

171-002 |

1 |

Body stainless steel |

20 |

171-003 |

1 |

Body stainless steel 316 |

20 |

171-004 |

1 |

Body polished |

21a |

S05-190 |

1 |

Sprayhead ass’y. eyewash |

|

|

|

(includes) |

22 |

in service kit |

2 |

Pivot pin |

23 |

in service kit |

2 |

Flip cover eyewash |

21b |

S05-192 |

1 |

Sprayhead ass’y. eye/face wash |

|

|

|

(includes) |

22 |

in service kit |

2 |

Pivot pin |

24a |

in service kit |

1 |

Flip cover right |

24b |

in service kit |

1 |

Flip cover left |

21f |

S05-204 |

1 |

Sprayhead stainless steel 304 |

|

|

|

ass'y. eye/face (includes) |

22 |

in service kit |

2 |

Pivot pin |

24a |

in service kit |

1 |

Flip cover right |

24b |

in service kit |

1 |

Flip cover left |

21j |

S05-205 |

1 |

Sprayhead stainless steel 316 |

|

|

|

ass'y. eye/face (includes) |

22 |

in service kit |

2 |

Pivot pin |

24a |

in service kit |

1 |

Flip cover right |

24b |

in service kit |

1 |

Flip cover left |

25 |

115-158 |

1 |

Cap |

25 |

115-159 |

1 |

Cap stainless steel |

25 |

115-164 |

1 |

Cap stainless steel 316 |

25 |

115-165 |

1 |

Cap polished |

Item |

Part No. |

Qty |

Description |

|

|

|

|

26 |

125-157 |

2 |

O-ring |

27 |

125-175 |

1 |

Flow control |

28 |

S65-340 |

1 |

Screen (incl. 3 per pack) |

35a |

in service kit |

1 |

Bowl cover plastic |

35b |

in service kit |

1 |

Bowl cover stainless steel |

35b |

in service kit |

1 |

Bowl cover stainless steel 316 |

36 |

114-097 |

1 |

Bowl cover decal |

39 |

160-389 |

as req'd. |

Screw ¼-20 x ½" stn. steel |

39 |

160-469 |

as req'd. |

Screw ¼-20 x ½" stn. steel 316 |

40 |

S08-385 |

1 |

Handle ss (incl. items 41, 44, |

|

|

|

45, 5.1) |

40 |

S08-388 |

1 |

Handle ss 316 (incl. items 41, |

|

|

|

44, 45, 5.1) |

41 |

114-096 |

1 |

Decal |

42 |

142-002AV |

as req'd. |

Bowl cover washer |

43 |

161-060 |

as req'd. |

Nut stainless steel |

43 |

161-062 |

as req'd. |

Nut stainless steel 316 |

44 |

153-372R |

1 |

Adapter ball valve |

44 |

153- |

1 |

Adapter ball valve stainless |

|

372R316 |

|

steel 316 |

45 |

142-002DA |

1 |

Lockwasher |

341 |

204-421 |

1 |

Emergency Inspection Tag |

342 |

114-051 |

1 |

Eyewash Safety Sign |

342 |

114-051E |

1 |

Eyewash Safety Sign (not |

|

|

|

available in the U.S.) |

14 |

1/22/2015 |

Bradley • 215-1685 Rev. M; ECN 13-05-023 |

Loading...

Loading...