Page 1

CONTENTS

Contents......................................................................................................................................... 1-2

Warranty.............................................................................................................................................3

Safety Information.............................................................................................................................4

Electrostatic Discharge Sensitive (ESDS) Device Handling.......................................................... 4

Specifications, Entero™ SE 16 Audio Processor..................................................................... 5-16

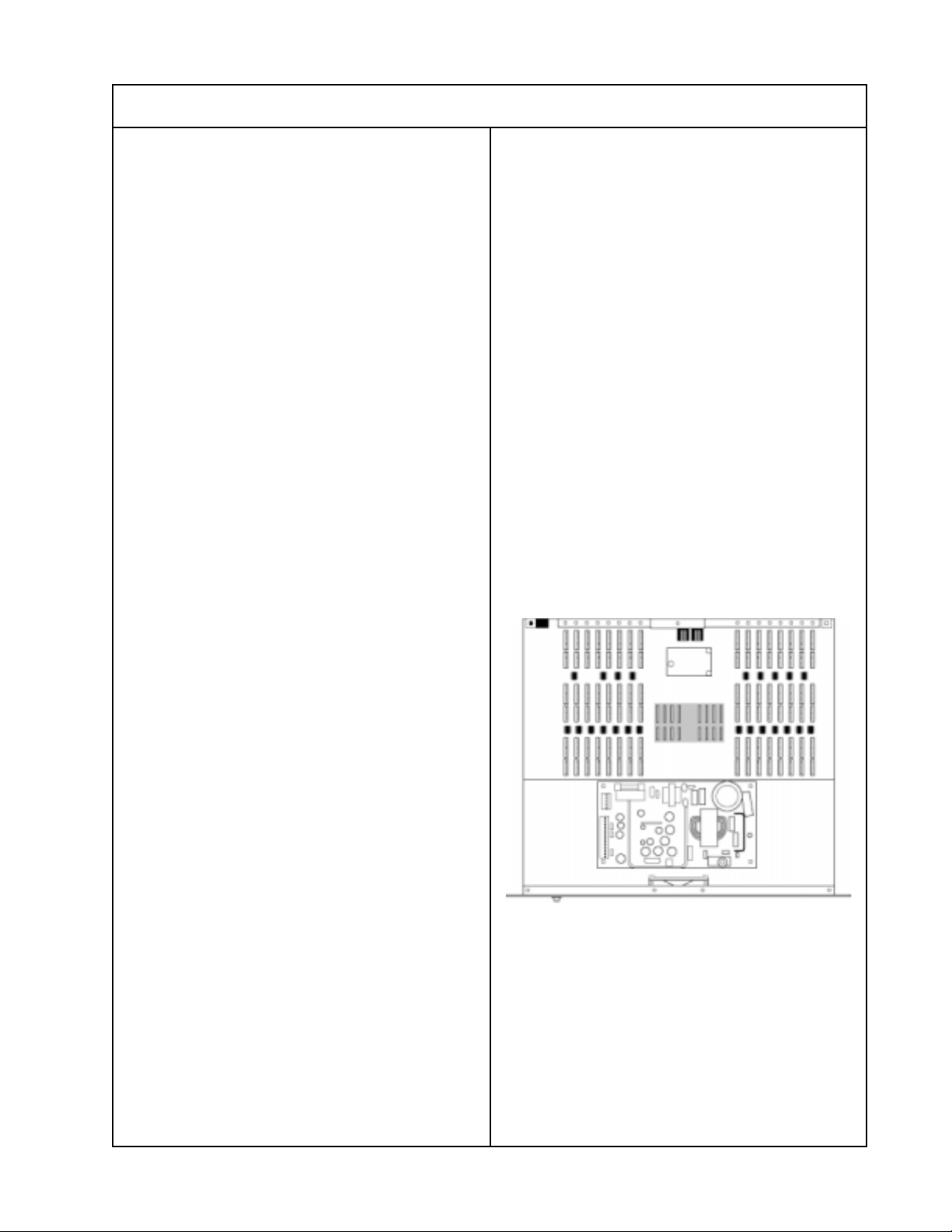

SE 16 audio processor chassis with no modules installed...........................................................5

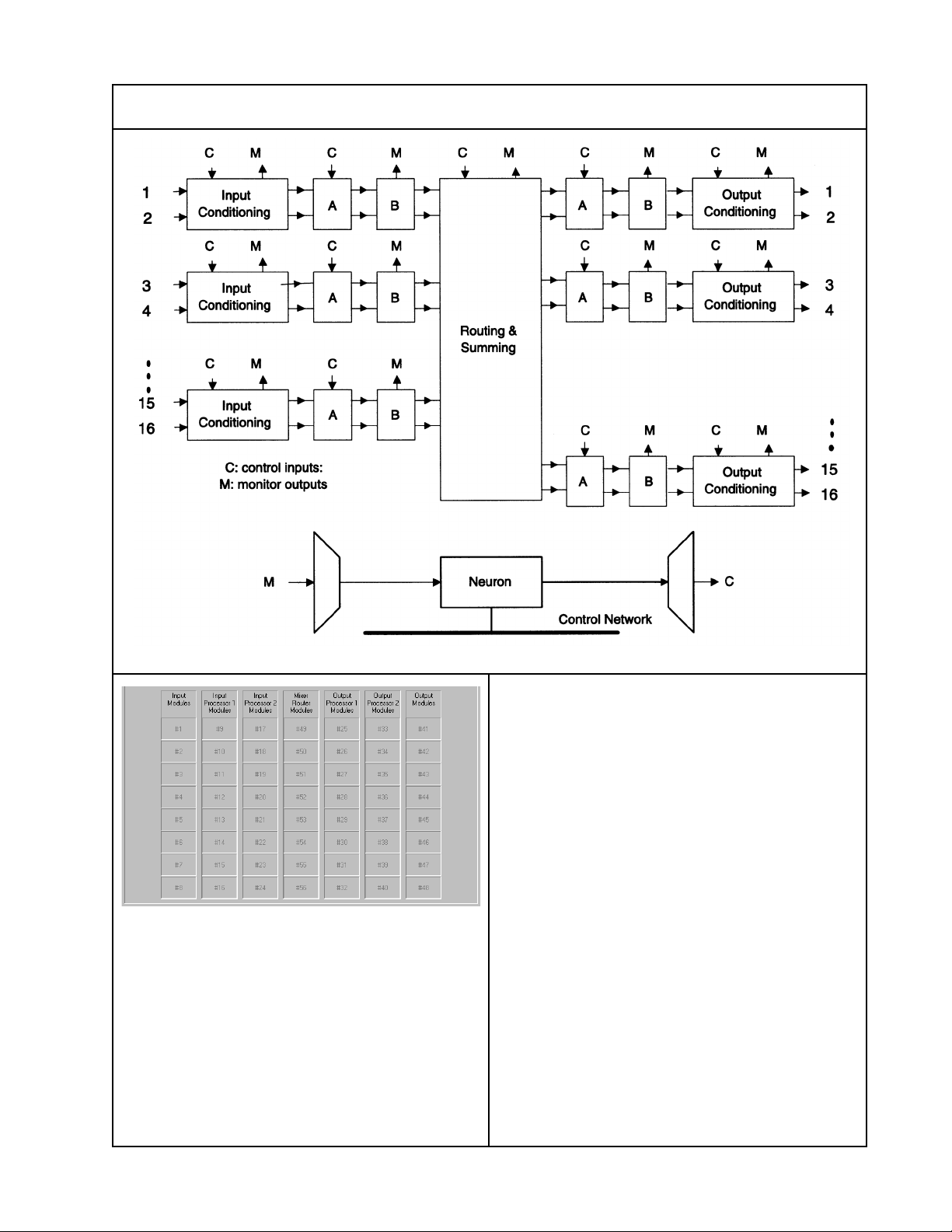

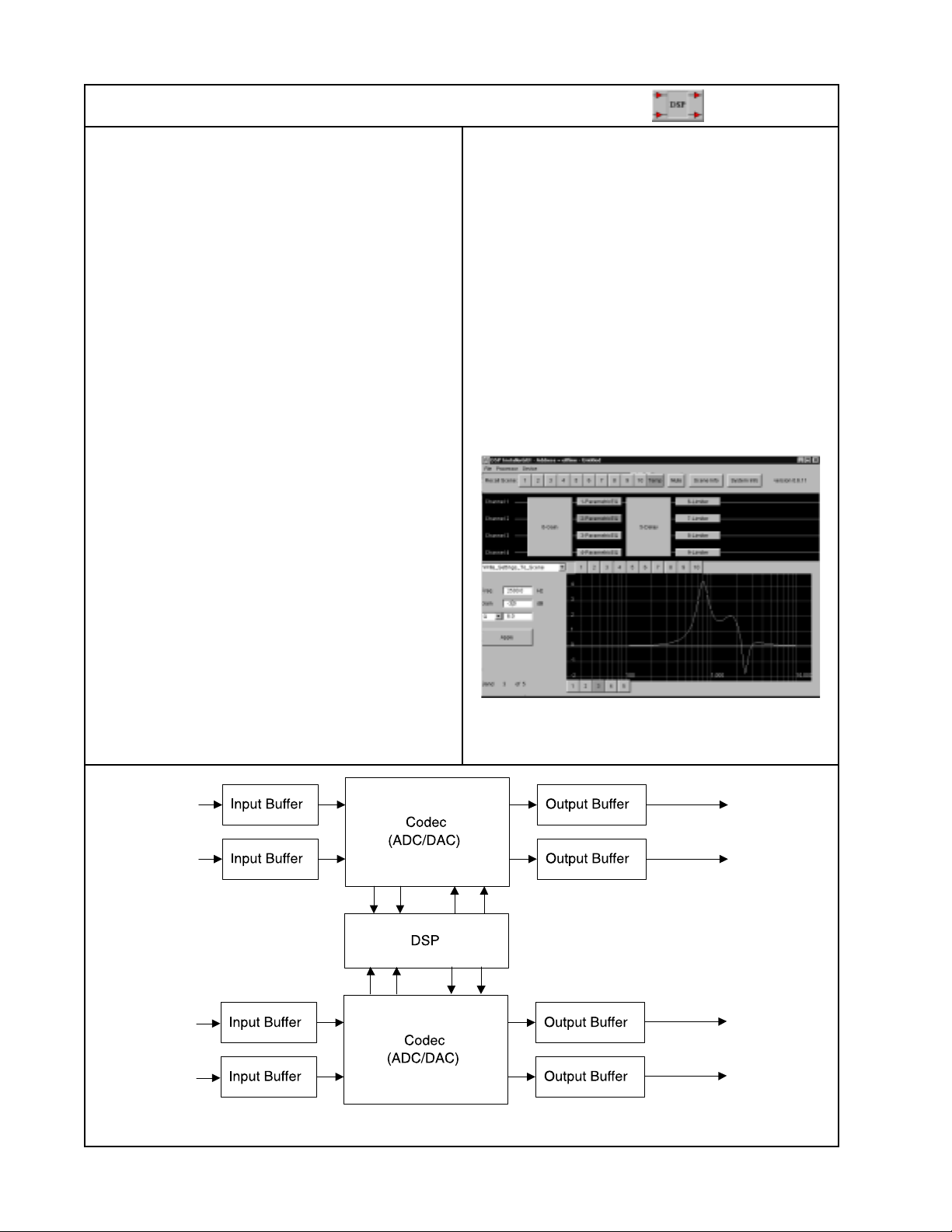

SE 16 Audio Processor block diagram .........................................................................................6

Software view of an unpopulated SE 16 chassis ........................................................................6

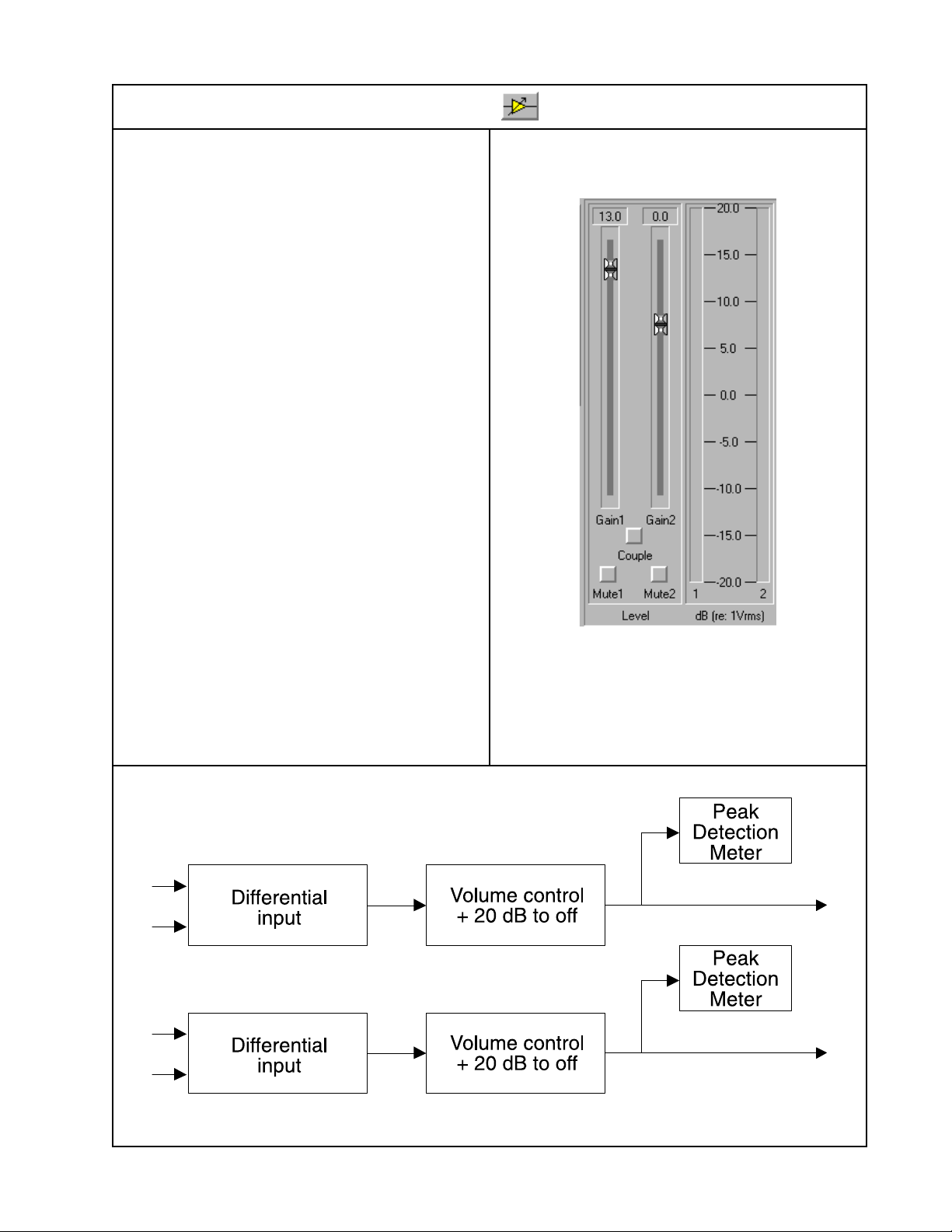

Specifications, Entero Line Level Input module.............................................................................7

Line Level Input module block diagram ........................................................................................7

Software view of Line Level Input module ....................................................................................7

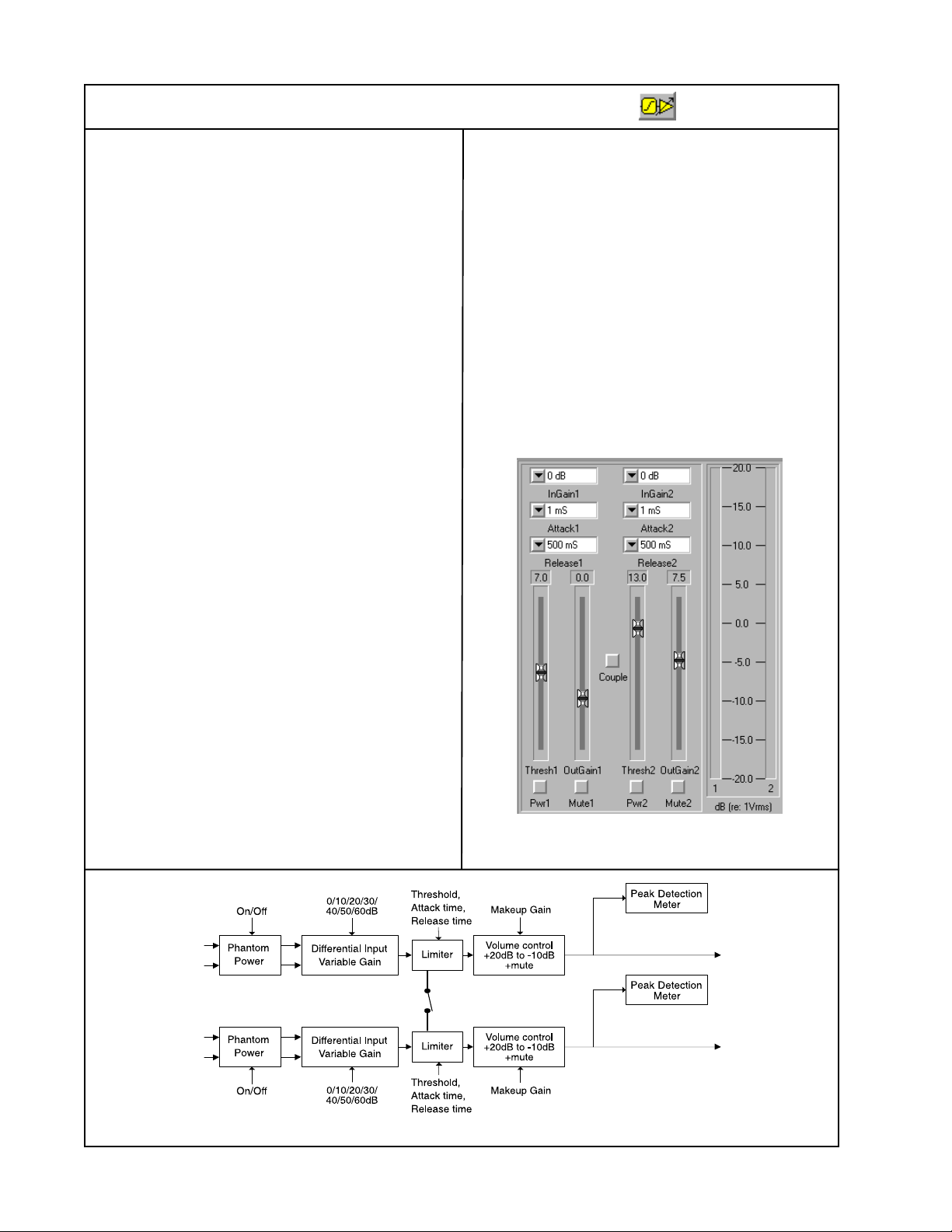

Specifications, Entero Mic/Line Level Input module with Limiter.................................................8

Line Level Input module with Limiter block diagram .....................................................................8

Software view of Line Level Input with Limiter module ................................................................. 8

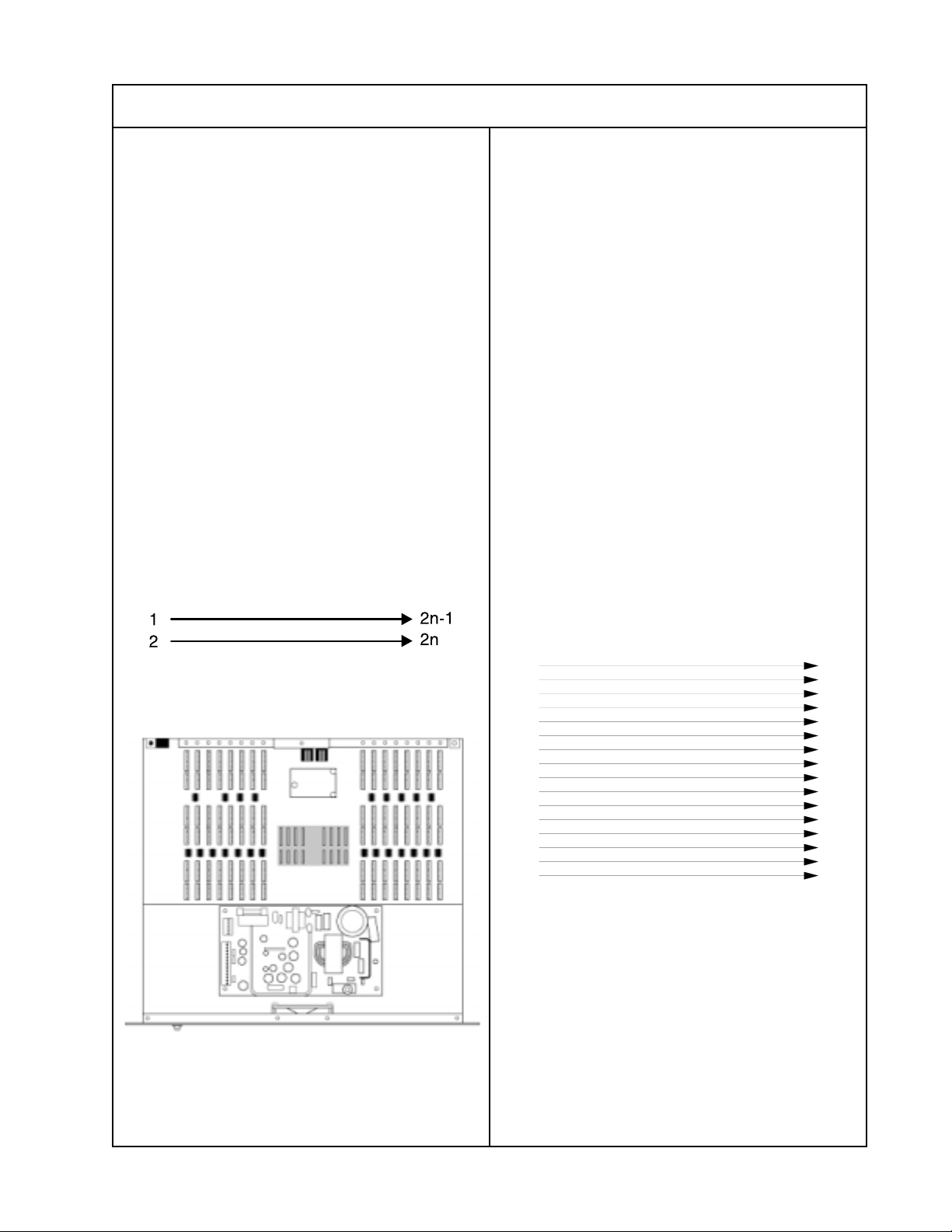

Specifications, Entero Router Modules...........................................................................................9

2 x 2 Router module...................................................................................................................9

2 x 2 Router module block diagram..............................................................................................9

Entero SE 16 audio processor router slots .................................................................................9

16 x 16 Router module...............................................................................................................9

16 x 16 Router module block diagram..........................................................................................9

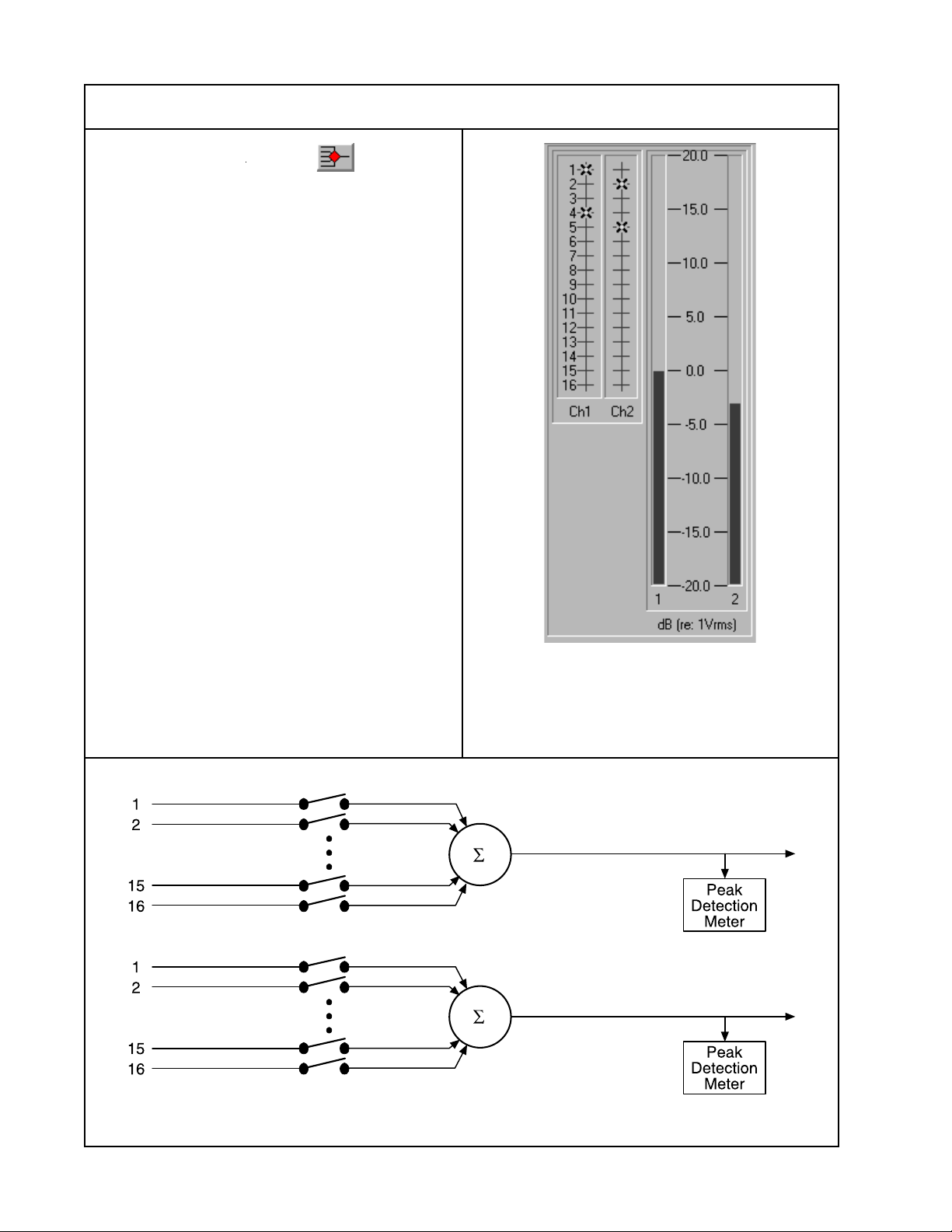

16 x 2 Router module...............................................................................................................10

16 x 2 Router module block diagram..........................................................................................10

Software view of 16 x 2 Router module.....................................................................................10

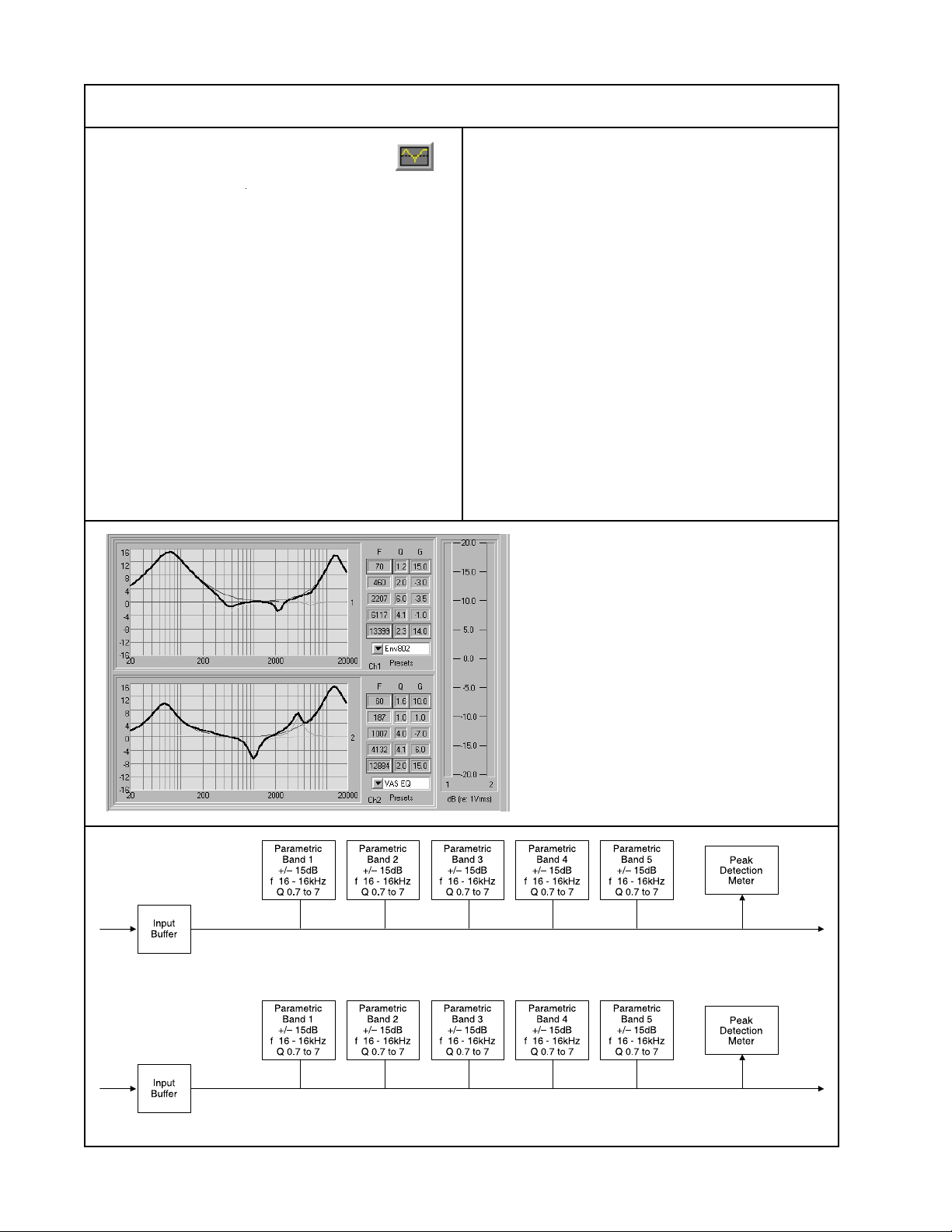

Specifications, Entero SE 16 Equalization....................................................................................11

Fixed EQ Carrier module .........................................................................................................11

Fixed EQ Carrier with 2 submodules block diagram ..................................................................11

Software view of Fixed EQ Carrier module ................................................................................11

5-Band Parametric EQ module................................................................................................12

5-Band Parametric EQ module block diagram ...........................................................................12

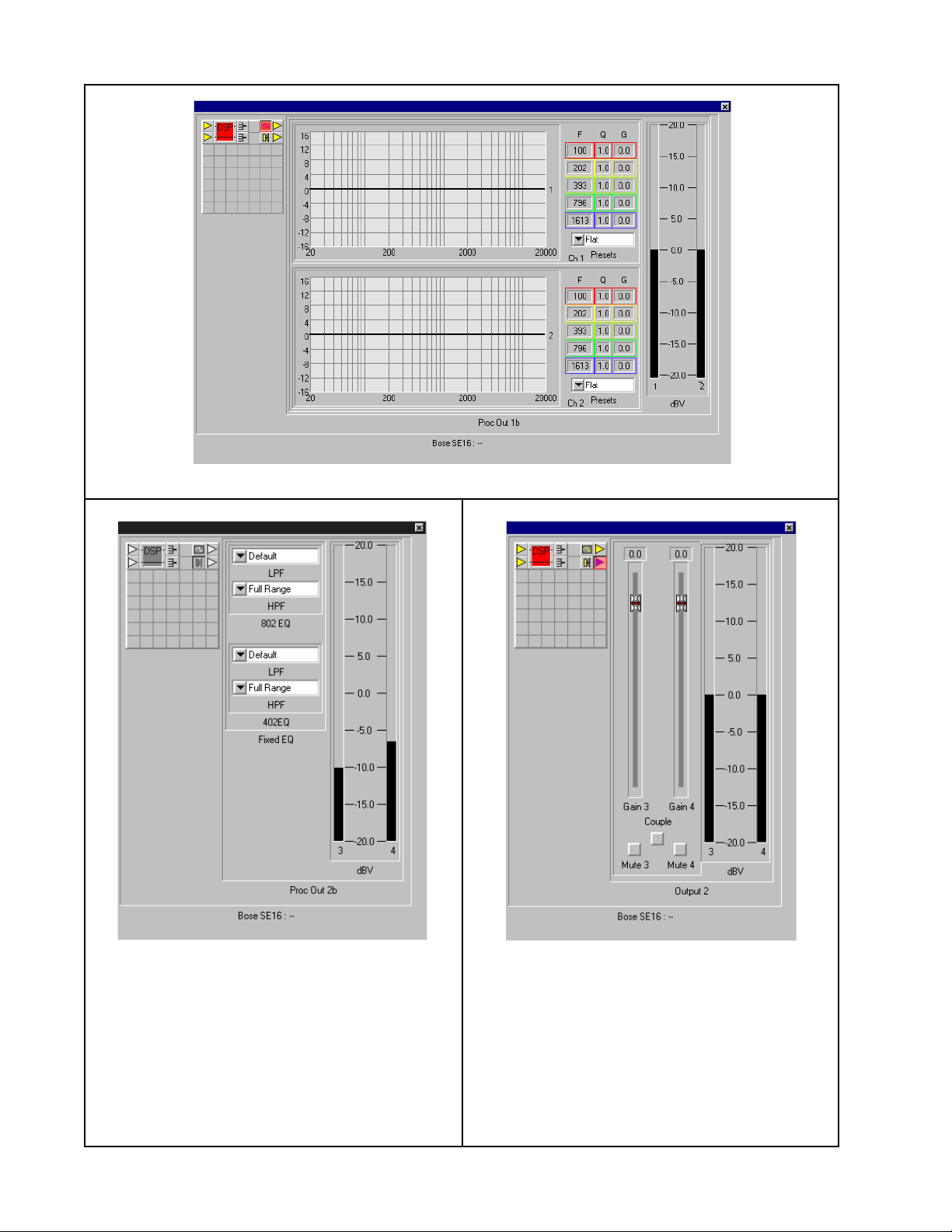

Software view of 5-Band Parametric EQ module .......................................................................12

Dynamic EQ module ................................................................................................................13

Dynamic EQ module block diagram ...........................................................................................13

Software view of Dynamic EQ module .......................................................................................13

Specifications, Entero SE 16 4x4 Digital Signal Processing (DSP) Module...............................14

4x4 Digital Signal Processing (DSP) Module .............................................................................14

Software view of the 4x4 Digital Signal Processing (DSP) Module ............................................14

Specifications, Entero SE 16 Output Modules..............................................................................15

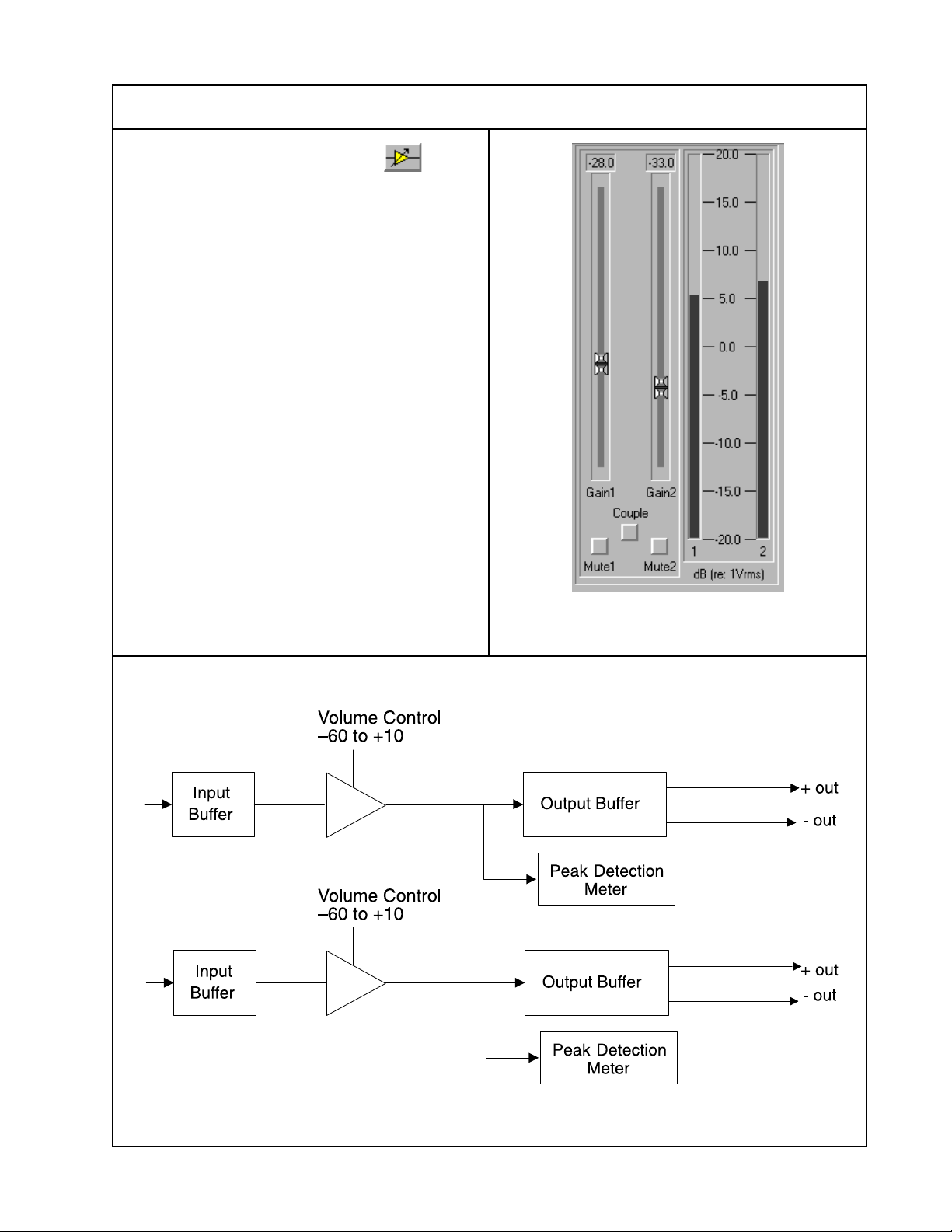

Line Level Output module .......................................................................................................15

Line Level Output module block diagram ...................................................................................15

Software view of the Line Level Output module .........................................................................15

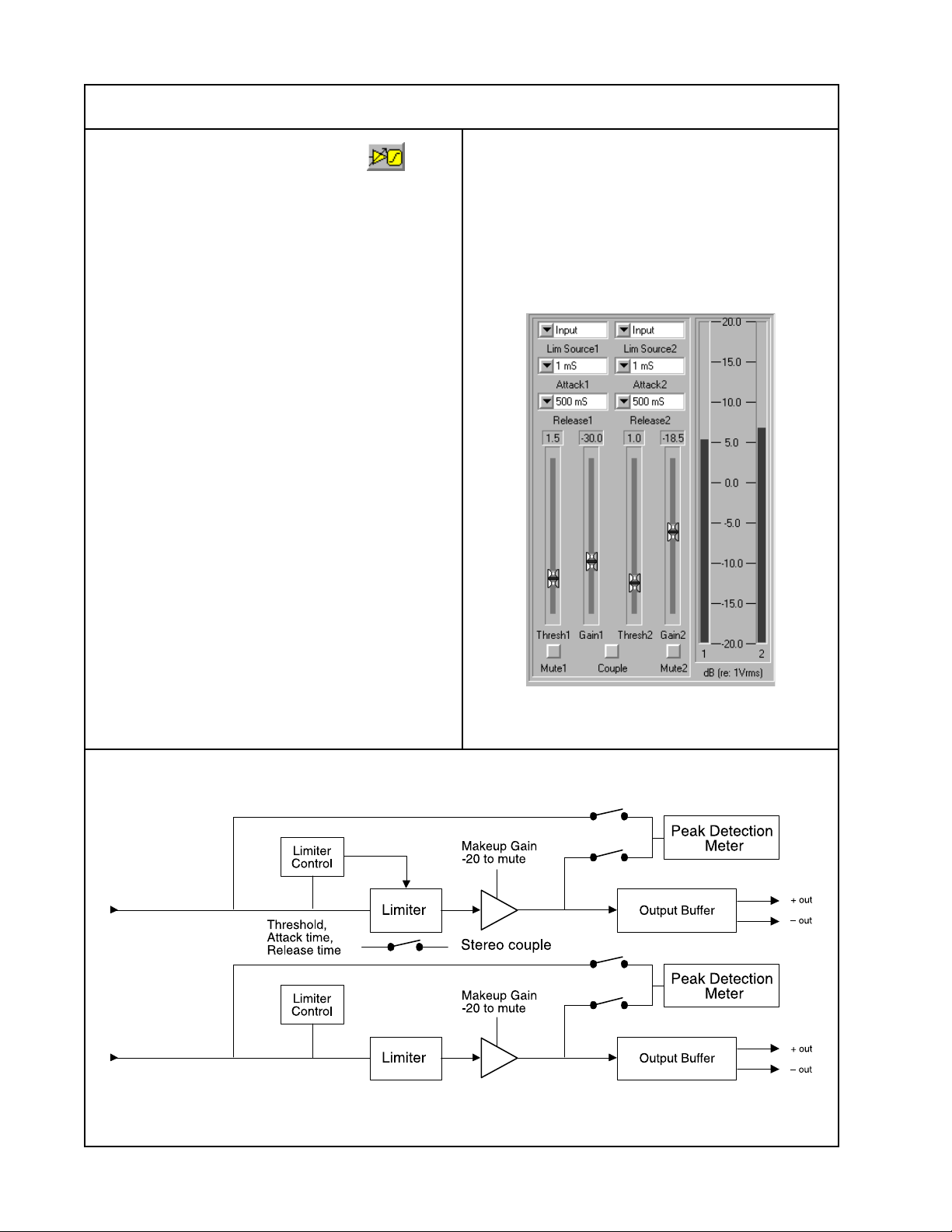

Line Level Output module with limiter ...................................................................................16

Line Level Output with Limiter module block diagram ................................................................16

Software view of Line Level Output with Limiter module ............................................................16

Disassembly/Assembly Procedures........................................................................................ 17-21

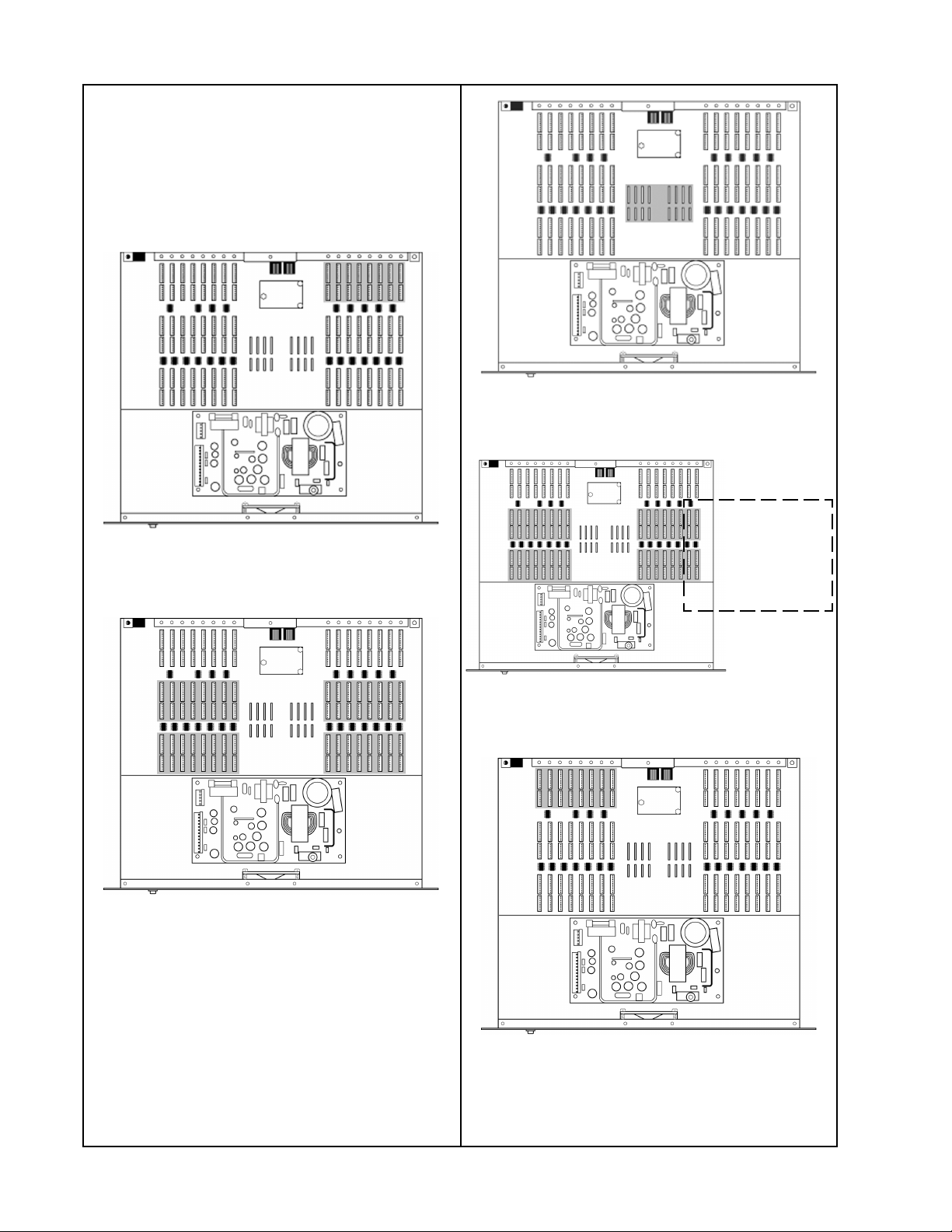

Entero Module Installation Location Diagrams ...........................................................................17

Entero SE 16 Audio Processor input slots .................................................................................17

Entero SE 16 Audio Processor audio processing slots ..............................................................17

Entero SE 16 Audio Processor router slots...............................................................................17

Entero SE 16 Audio Processor 4x4 DSP installation diagram....................................................17

Entero SE 16 Audio Processor output slots ...............................................................................17

1

Page 2

CONTENTS

Test Setup Parameters....................................................................................................................22

Test Procedures ........................................................................................................................ 22-29

GUI showing Entero chassis populated with modules to be tested............................................26

Mic/Line Level Input Module.......................................................................................................26

4x4 DSP - Empty Block Diagram ...............................................................................................27

Line Level Input Module .............................................................................................................27

16x2 Router Module...................................................................................................................27

5-Band Parametric EQ ...............................................................................................................28

Fixed EQs ..................................................................................................................................28

Line Level Output Module ..........................................................................................................28

Line Level Output with Limiter Module ....................................................................................... 29

Part List Notes .................................................................................................................................30

Main Part List, SE16 Audio Processor (see Figure 1) ............................................................ 31-32

Figure 1. SE 16 Chassis Exploded Views ..................................................................................32

Electrical Part Lists ................................................................................................................... 33-99

Power Supply, 80 Watt (P/N: 181269) ....................................................................................... 33-36

Bose® Control Module, BCM-FT (P/N: 198439-000E) ............................................................. 37-38

16x16 Motherboard (P/N: 250590)............................................................................................ 39-48

Accessory Kit (P/N: 195567)...........................................................................................................49

Line Level Input Module (P/N: 250564) .................................................................................... 50-51

Mic Line Input with Limiter Module (P/N: 250585) .................................................................. 52-56

4x4 Digital Signal Processor (DSP) Module (P/N: 250904) .................................................... 57-62

16 x 2 Router Module (P/N: 251030)......................................................................................... 63-64

Line Level Output Module (P/N: 250563-2).............................................................................. 65-67

Line Level Output with Limiter Module (P/N: 250563-1)......................................................... 68-73

Signal Pass-Thru Module (P/N: 250565) ........................................................................................73

16x16 Null Router Module (P/N: 250587) .......................................................................................73

Fixed EQ Carrier Module (P/N: 250570) ................................................................................... 74-76

402® EQ Submodule (P/N: 250569-3) ...................................................................................... 76-77

502®A EQ Submodule (P/N: 250569-2).................................................................................... 78-79

802® EQ Submodule (P/N: 250569-1) ...................................................................................... 80-81

Model 25/32 EQ Submodule (P/N: 250569-6)........................................................................... 82-83

502®B EQ Submodule (P/N: 250569-7).................................................................................... 84-85

AWCS II EQ Submodule (P/N: 250569-9) ................................................................................. 86-87

2x2 Router Module (P/N: 251034)............................................................................................. 88-89

Dynamic EQ Module (P/N: 250568) .......................................................................................... 90-93

5 Band Parametric EQ Module (P/N: 250580).......................................................................... 94-99

2

Page 3

CAUTION: The Bose

®

Entero™ SE 16 Audio Processor

contains no user-serviceable parts.

To prevent warranty infractions, refer servicing

to warranty service centers or factory service.

PROPRIETARY INFORMATION

THIS DOCUMENT CONTAINS PROPRIETARY INFORMATION OF

BOSE® CORPORATION WHICH IS BEING FURNISHED ONLY FOR

THE PURPOSE OF SERVICING THE IDENTIFIED BOSE PRODUCT

BY AN AUTHORIZED BOSE SERVICE CENTER OR OWNER OF THE

BOSE PRODUCT, AND SHALL NOT BE REPRODUCED OR USED

FOR ANY OTHER PURPOSE.

Warranty

The Bose Entero SE 16 Audio Processor and Modules are

covered by a transferable five-year limited warranty.

3

Page 4

SAFETY INFORMATION

1. Parts that have special safety characteristics are identified by the symbol on schemat-

ics or by special notes on the parts list. Use only replacement parts that have critical characteristics recommended by the manufacturer.

2. Make leakage current or resistance measurements to determine that exposed parts are

acceptably insulated from the supply circuit before returning the unit to the customer. Use the

following checks to perform these measurements:

A. Leakage Current Hot Check-With the unit completely reassembled, plug the AC line cord

directly into a 120V AC outlet. (Do not use an isolation transformer during this test.) Use a

leakage current tester or a metering system that complies with American National Standards

Institute (ANSI) C101.1 "Leakage Current for Appliances" and Underwriters Laboratories (UL)

1492 (71). With the unit AC switch first in the ON position and then in OFF position, measure

from a known earth ground (metal waterpipe, conduit, etc.) to all exposed metal parts of the

unit (antennas, handle bracket, metal cabinet, screwheads, metallic overlays, control shafts,

etc.), especially any exposed metal parts that offer an electrical return path to the chassis. Any

current measured must not exceed 0.5 milliamp. Reverse the unit power cord plug in the outlet

and repeat test. ANY MEASUREMENTS NOT WITHIN THE LIMITS SPECIFIED HEREIN

INDICATE A POTENTIAL SHOCK HAZARD THAT MUST BE ELIMINATED BEFORE RETURNING THE UNIT TO THE CUSTOMER.

B. Insulation Resistance Test Cold Check-(1) Unplug the power supply and connect a

jumper wire between the two prongs of the plug. (2) Turn on the power switch of the unit. (3)

Measure the resistance with an ohmmeter between the jumpered AC plug and each exposed

metallic cabinet part on the unit. When the exposed metallic part has a return path to the

chassis, the reading should be between 1 and 5.2 Megohms. When there is no return path to

the chassis, the reading must be "infinite". If it is not within the limits specified, there is the

possibility of a shock hazard, and the unit must be repaired and rechecked before it is returned

to the customer.

ELECTROSTATIC DISCHARGE SENSITIVE (ESDS)

DEVICE HANDLING

This unit contains ESDS devices. We recommend the following precautions when repairing,

replacing or transporting ESDS devices:

• Perform work at an electrically grounded work station.

• Wear wrist straps that connect to the station or heel straps that connect to conductive

floor mats.

• Avoid touching the leads or contacts of ESDS devices or PC boards even if properly

grounded. Handle boards by the edges only.

• Transport or store ESDS devices in ESD protective bags, bins, or totes. Do not insert

unprotected devices into materials such as plastic, polystyrene foam, clear plastic bags,

bubble wrap or plastic trays.

4

Page 5

SPECIFICATIONS

Entero™ SE 16 Audio Processor

Technical Information

Inputs/Outputs: Up to 16/16

Power Supply:

Operates on universal input power

supply with any mains voltage from

80-265VAC, 50-60Hz

Maximum Power Consumption:

240 Watts

Network Input/Output:

LonWorks

®

8 pin RJ45

Dimensions:

3.5"H x 19"W x 15.5"D, nominal

(8.9 cm x 48.3 cm x 39.37 cm)

2 U in a standard full rack

Weight:

9 lb (4 kg) approx., according to number

of modules installed

Features:

• Signal processing for up to 16 channels

with 16 inputs and outputs

• Capacity for 4 DSP modules

(with 4 in x 4 out for each)

• Supports both analog and digital signal

processing technology

• Input compatibility with microphones and

line level sources, balanced and

unbalanced

• Output compatibility with power

amplifers and other line-level equipment

• Internal routing and summing of any

sources to any output

• Network control through LonWorks and

compatible devices, including amplifiers

and video, lighting, and other networked

devices

• Assignment of any system control

function to any user interface, whether

computer-based or not

Chassis rear

Technical Specifications for a Simple

Configuration

In a very basic system design, the chassis

configuration could include 2 input

modules, 2 output modules, and 2 router

modules, to produce the following

specifications.

Maximum Output: +17dBV

Gain: 0dB nominal

Dynamic Range: 113dB

Harmonic Distortion and Noise:

0.05% nominal, 0.10% limit

Crosstalk at 1kHz: -70dB

Frequency Response:

20Hz to 20kHz referenced at 1kHz, ±1dB

Chassis front

SE 16 audio processor chassis with no

modules installed

5

Page 6

SPECIFICATIONS

Entero™ SE 16 Audio Processor (continued)

SE 16 Audio Processor block diagram

Software view of an unpopulated

SE 16 chassis

Safety and EMC Compliance

The Bose® Entero SE 16 audio processor

complies with the following safety and other

regulatory standards:

Safety Specifications: UL 1950, CSA C22.2

No. 950, EN 60950, CB Scheme per

IEC60950 with all country deviations.

EMI/RFI Specifications: FCC Part 15 Subpart B Class A, ICES-003 Class A, AS/NZS

1053, CISPR 22, EN 55103-1, EN 55103-2.

6

Page 7

SPECIFICATIONS

Entero™ Line Level Input module

Technical Information

Inputs/Outputs: 2/2

Input Impedance Differential:

20k Ohms, balanced

10k Ohms, unbalanced

Equivalent Input Noise:

–103dBV, A weighted

Gain/Input Range: –60dB to +20dB

Input Gain Steps: 1dB

THD+N at 1kHz: 0.02%, 0dB gain

CMRR at 1kHz: 65dB

Crosstalk at 1kHz: –70dB

Frequency Response:

20Hz to 20kHz nominal, ±1dB

Size:

2.82"H x 2.24"W

(57.50 mm x 56.25 mm)

Features:

• Handles two channels

• Provides line level differential input stage

• Provides gain control

• Peak detector

• Appropriate for use with all line level

sources, such as:

– CD player

– video cassette

– DAT

– Mixing board output

Software view of Line Level Input module

Line Level Input module block diagram

7

Page 8

SPECIFICATIONS

Entero™ Mic/Line Level Input module with Limiter

Technical Information

Inputs/Outputs: 2/2

Input Impedance Differential: 20k Ohms

Input Impedance Differential,

Phantom Power On: 4k Ohms

Equivalent Input Noise:

–120dBV (60dB gain)

–95dBV (0dB gain)

CMRR at 1kHz: 70dB, typical

THD: 0.02%, 1kHz, 50dB gain

Limiter Attack Time: 1mS, 5mS, 10mS

Limiter Release Time: .5S, 1S, 2S

Gain Steps:

0dB, 10dB, 20dB, 30dB, 40dB,

50dB, 60dB

Features:

• Handles two channels

• Provides selectable input stage gain to

accommodate a wide range of sources

from mic to line-level

• Supplies 12VDC phantom power for

condenser microphones

• Provides limiter to ensure consistent

output level for a wide range of mic input

• Includes gain control before the limiter

• Provides makeup gain after limiter

• Peak detector

• Appropriate for use with all microphone

inputs and for input jacks that accept both

mic and line sources

Crosstalk at 1kHz: –70dB

Frequency Response:

20Hz-20kHz nominal, ±1dB limit

Phantom Power: 12VDC

Size:

2.82"H x 2.24"W

(70.50 mm x 56.00 mm)

Software view of Line Level Input with

Limiter module

Stereo couple

Line Level Input module with Limiter block diagram

8

Page 9

SPECIFICATIONS

Entero™ Router Modules

2 x 2 Router module

Technical Information

Inputs/Outputs: 2/2

Maximum Signal Handling: +17dBV

Size: .94"H x 2.25"W

(23.5 mm x 56.25 mm)

Features

• Handles 2 channels

• Includes no active components

• Connects chassis inputs 1 and 2 to the

outputs the router serves

• Peak detector

• Appropriate for use when 2

or fewer inputs are used

Note: There is no software view of this

module in the GUI. It is a hardware only

component and is not controlled by the

Entero software.

16 x 16 Router module

Technical Information

Inputs/Outputs: 16/16

Maximum Input/Output: +17dBV

Size: 2.80"H x 1.97"W

(70 mm x 24.25 mm)

Features

• No active components

• For use only when the audio processor

chassis is configured for 16 independent

signal processing channels

• For use alone, in place of other routers*

* CAUTION: Do not use the 16 x 16 router

module with any other router. Damage to

the module or chassis may result.

Note: There is no software view of this

module in the GUI. It is a hardware only

component and is not controlled by the

Entero software.

2 x 2 Router module block diagram

Entero SE 16 audio processor

Router slots

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

16 x 16 Router module block diagram

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

9

Page 10

SPECIFICATIONS

Entero™ Router Modules

16 x 2 Router module

Technical Information

Inputs/Outputs: 16/2

Maximum Output: +17dBV at 1 kHz

Summing Gain: 0dB, –6dB, –12dB, –18dB

THD+N at 1kHz: 0.02%

Output Noise:

–95dBV, A weighted, with all switches

closed (16 channels summed)

–100dBV, A weighted, with 1 switch

closed

Crosstalk at 1kHz: –70dB

Frequency Response:

+0/–0.5dB, 20 Hz to 20kHz

Size: 2.80"H x 1.97"W (70 mm x 24.25 mm)

Features:

• Sums from 1 to 16 source signals in any

combination

• Provides two independent outputs

• Peak detector

• Appropriate for use with each pair of

outputs, unless the 2 x 2 Router module

can be used

Software view of 16 x 2 Router module

Note: Entero 16 x 16 and 2 x 2 router

modules have no programmable controls

16 x 2 Router module block diagram

10

Page 11

SPECIFICATIONS

Entero™ SE 16 Equalization

Fixed EQ Carrier module

Technical Information

Inputs/Outputs: 2/2

Maximum Output at 1kHz: +17dBV

Gain: 0dB nominal (varies with EQ curve)

Output Noise: –90dBV, A weighted

THD+N at 1kHz: 0.05%

Crosstalk at 1kHz: –70dB

Frequency Response:

±.5dB, 20Hz to 20kHz with no speaker

submodule installed

Size:

2.82"H x 2.24"W

(70.5 mm x 56.8 mm)

Features:

• Capacity for two speaker EQ submodules

(the same or different, specific to the

speakers connected to the outputs it

serves)

• Accepts submodules* for:

- 802® II loudspeaker

- 502® A loudspeaker

- 402® loudspeaker

- FreeSpace® 8 flush-mount loudspeaker

- FreeSpace 8 surface-mount

loudspeaker

- FreeSpace 25/32 loudspeaker

- 502B loudspeaker

- 502BEX loudspeaker

- AWCS II CannonTM loudspeaker

• Allows use of an EQ submodule on one

channel with unaffected signal pass-

through on the other

• Selectable low pass and high pass

switches, for use with different speakers

• Peak detector

• Suited to the output signal processing

chain

* Submodules must be specified when

ordering

Software view of Fixed EQ Carrier module

Fixed EQ Carrier with 2 submodules block diagram

11

Page 12

SPECIFICATIONS

Entero™ SE 16 Equalization

5-Band Parametric EQ module

Technical Information

Inputs/Outputs: 2/2

EQ Bands: 5 fully independent per channel

Q adjustment: 0.7 to 7

Frequency response:

Programmable, from 16Hz to 16kHz

Boost or Cut: –15dB to 15dB

Maximum Output at 1kHz:

+17dBV full band, flat EQ

Maximum Input at 1kHz: +17dBV

Gain: 0dB nominal, ±0.5dB limit with all

bands flat

Output Noise: –95dBV limit with all bands

flat –85dBV limit with typical speaker

EQ curve

Crosstalk at 1kHz: –70dBV

Accuracy:

±5% nominal center frequency accuracy

±10% nominal Q accuracy

Size:

2.82"H x 2.24"W

(70.5 mm x 56.8 mm)

Features:

• 5 fully independent parametric EQ bands

for each channel

• Allows each band to be set to any center

frequency

• Q adjustment from 0.7 to 6.7

• Frequency adjustment from 16Hz to

16kHz

• Boost or cut from –15dB to 15dB

• Peak detector

Software view of 5-Band Parametric

EQ module

5-Band Parametric EQ module block diagram

12

Page 13

SPECIFICATIONS

Entero™ SE 16 Equalization

Dynamic EQ module

Technical Information

Inputs/Outputs: 2/2

Bandpass Filter Response:

55Hz: 55Hz, ±10%;

29dB maximum boost

±2.5dB limit

Q=3.5 ±10%

60Hz: 60Hz, ±10%;

27.5dB maximum boost

±2.5dB limit

Q=3.6 ±10%

70Hz: 70Hz, ±10%;

24.5dB maximum boost

±2.5dB limit

Q=4.4 ±10%

80Hz: 80Hz, ±10%;

22dB maximum boost

±2.5dB limit

Q=5.0 ±10%

90Hz: 90Hz, ±10%;

22dB maximum boost

±2.5dB limit

Q=5.5 ±10%

Maximum Output at 1 kHz: +17dBV

Gain:

0dB nominal, ±1dB limit from 100 Hz to

15kHz. Gain below 100Hz dependent

upon input signal, filter selection, and

calibration

Sensitivity:

100mV (–20dBV) to 3.0V (+10dBV)

required for proper calibration

Output Noise: –95dBV, A weighted, RMS

• Bose® proprietary technology to detect

the signal level and use it to control the

bass boost provided by a frequency

bandpass filter

• Ensures a boost for low level (soft)

signals and a flat response for high level

(loud) signals

• Choice of five boost filters suited to

different loudspeakers driven from the

dynamic EQ channel

• Stereo coupling option to force tracking

of the EQ in both channels of stereo

program material

• Adjustable signal sensitivity for setting

the signal level threshold. Only signals

that fall below that threshold receive a

bass boost.

Center Frequency,

Ch. 1

Input

Ch. 2

Input

Stereo Tracking

On/Off

Sensitivity

Dynamic EQ

Filter and VCA

Dynamic EQ

Filter and VCA

Center Frequency,

Sensitivity

Summing

Amplifier

Peak Detection Meter

Peak Detection Meter

Summing

Amplifier

Dynamic EQ module block diagram

Ch. 1 Out

Peak 1

Peak 2

Ch. 2 Out

Crosstalk at 1kHz: 70dB

Frequency Response:

±0.5dB nominal, +2/–1dB limit for high

level signals, referenced at 1kHz,

0dBV in, over a 20Hz-15kHz range

Size: 2.82"H x 2.36"W (70.5 mm x 59.5

mm)

Features:

• Provides a natural balance of high and

low frequencies at a wide variety of

listening levels

Software view of Dynamic EQ module

13

Page 14

SPECIFICATIONS

Entero™ SE 16 4x4 Digital Signal Processing (DSP) Module

Technical Information

Inputs/Outputs: 4/4

Maximum Output: +17dBV

Gain: 0dB nominal, +/–0.5dB

THD+N:

–80dB (0.01%) max at –1dB fs, 1 kHz

–75dB (0.015%) max, 20Hz to 20kHz

Dynamic Range:

92dB typical, 90dB minimum A-weighted

Sampling Rate: 32.55kHz

Crosstalk at 1kHz: –70dB

Frequency Response:

20Hz to 15kHz, ±.5dB limit

Size: 2.83"H x 5.41"W

(71.31mm x 136.33mm)

Features:

• Processes 4 channels

• Occupies 4 slots in the processor chassis

• Up to 4 DSP modules can populate one

SE-16 processor chassis

• Capable of performing multiple audio

processing functions simultaneously

• Allows the designer to customize the

block diagram and select only those

functions appropriate to the system

design, including:

– Parametric equalization

– Speaker equalization

– Multi-way crossovers with

separate control of gain, phase,

low/high pass filter frequency,

type, and order for each channel

– Single and multi-tap delays

(delay budget is 800ms per

DSP module)

– Routing, level meters, and gain/

attenuation.

– Muting

– Scene construction/recall

– Full featured compressors/limiters/

gates that allow for adjustment of

the slope, threshold, attack and

release times

Software view of the 4x4 Digital Signal

Processing (DSP) Module

4x4 Digital Signal Processing (DSP) Module

14

Page 15

SPECIFICATIONS

Entero™ SE 16 Output Modules

Line Level Output module

Technical Information

Inputs/Outputs: 2/2

Maximum Output: +17dBV

Output Impedance: 200 Ohms per leg

Output Volume Range:

–60dB to +10dB, with mute

THD+N at 1kHZ: 0.1%

Output Noise: –95dBV, A weighted

Crosstalk at 1kHz: –70dB

Frequency Response:

20Hz to 20kHz, ±1dB

Size:

2.30"H x 2.25"W (57.50 mm x 56.25 mm)

Features:

• Handles two channels

• Includes volume control

• Peak detector

Software view of the Line Level Output

module

Line Level Output module block diagram

15

Page 16

SPECIFICATIONS

Entero™ SE 16 Output Modules

Line Level Output module with limiter

Technical Information

Inputs/Outputs: 2/2

Maximum Output: +17dBV

Output Impedance: 200 Ohms

Limiter Threshold Range: –3dB to +17dB

Limiter Slope: 10dB:1dB

Limiter Attack time: 1mS, 5mS, 120mS

Limiter Release Time: .5S, 1S, 2S

Maximum Gain: +10dB

THD+N at 1kHz: 0.1% with no limiting

Output Noise: –95dBV, A weighted

Crosstalk at 1kHz: –70dB

Frequency Response:

20Hz to 20kHz, ±1dB limit

Size:

2.30"H x 2.25"W

(57.50 mm x 56.25 mm)

• Offers user adjustable settings,

including:

– Volume control

– Limit threshold

– Attack time

– Release time

• Appropriate for all outputs that require

a limiter to protect the loudspeakers

Features:

• Handles two channels

• Includes fast-acting limiters

• Provides differential, impedance

balanced outputs

• Includes volume control

• Peak detector

Software view of Line Level Output with

Limiter module

Line Level Output with Limiter module block diagram

16

Page 17

DISASSEMBLY/ASSEMBLY PROCEDURES

Module Installation Locations

The diagrams below show where the

various types of modules available for the

Entero

installed in the chassis.

Entero SE 16 Audio Processor input slots

TM

SE 16 audio processor should be

Entero SE 16 Audio Processor

router slots

DSP modules

require four audio

processing slots.

These can be either

input or output

processing slots.

Entero SE 16 Audio Processor audio

processing slots

Entero SE 16 Audio Processor 4x4 DSP

installation diagram

Entero SE 16 Audio Processor output slots

17

Page 18

DISASSEMBLY/ASSEMBLY PROCEDURES

Note: Refer to Figure 1 on page 32 for the

following procedures.

1. Top Cover Removal

1.1 Remove the seven screws that secure

the top cover (1) to the chassis (13).

1.2 Lift the rear of the top cover and slide

the cover to the rear of the chassis.

1.3 Lift off the top cover.

2. Top Cover Replacement

2.1 Align the top cover (1) with the chassis

(13).

2.2 Slide the front of the top cover under the

lip on the front of the chassis.

2.3 Secure the top cover to the chassis

using the seven screws removed in step

1.1.

3. Power Supply Removal

3.1 Perform procedure 1.

3.2 Unplug the the two cables from the

power supply (2) at J1 and J2.

Note: These cables can be difficult to

remove. Be careful not to damage the

power supply board.

3.3 Remove the four screws that secure the

power supply to the chassis (13).

4.2 Align the power supply with the studs

located in the bottom of the chassis (13).

4.3 Secure the power supply to the chassis

using the four screws and one 5/16”

locknut removed in steps 3.3 and 3.4.

5. Bose® Control Module Removal

5.1 Perform procedure 1.

5.2 Remove the three 5/16” locknuts that

secure the Bose control module (10) to

the motherboard (11).

5.3 Lift the Bose control module straight

up until it is clear of the connectors.

Be careful not to bend the pins on the

connectors.

6. Bose Control Module Replacement

6.1 Align the connectors on the Bose

control module (10) with those on the

motherboard (11).

Note: The connectors are different sizes.

The module will fit only one way.

6.2 Gently press the Bose control module

down until it is fully seated in the

motherboard connectors.

6.3 Secure the Bose control module to the

motherboard using the three 5/16” locknuts

removed in step 5.2. Do not overtighten.

7. Input or Output Module Removal

3.4 Remove the one 5/16” locknut that

secures the power supply bracket (9) to

the chassis.

3.5 Lift the power supply out of the chassis.

4. Power Supply Replacement

4.1 Be sure the power supply bracket (9) is

properly aligned and attached to the heat

sink on the power supply (2) using two

screws.

7.1 Perform procedure 1.

7.2 Remove one screw located at the rear

of the chassis (13) which secures the

module in the chassis.

7.3 Using a gentle rocking motion, lift

the module off of the motherboard (11)

connectors and chassis.

18

Page 19

DISASSEMBLY/ASSEMBLY PROCEDURES

8. Input or Output Module Replacement

8.1 Align the module connectors with

the corresponding connectors on the

motherboard (11).

Note: Input and Output modules are installed in different locations on the

motherboard. Incorrect module placement

may damage the module and/or the

motherboard. Refer to the silkscreen on the

rear of the chassis (13).

8.2 With the connectors properly aligned,

press the module in place until it is fully

seated in the motherboard connectors.

8.3 Secure the module in place using the

screw removed in step 7.2.

9. 4x4 DSP Module Removal

Note: The 4x4 DSP module processes

audio for four motherboard channels at

once. As a result, it’s installed differently

than an audio processing module. It’s used

in conjunction with a Null module and the

DSP Sidecar PCB, which uses an 8 conductor ribbon cable to connect the audio

from the DSP PCB to the other two channels on the motherboard.

10. 4x4 DSP Module Replacement

Note: The 4x4 DSP module processes

audio for four motherboard channels at

once. As a result, it’s installed differently

than an audio processing module. It’s used

in conjunction with a Null module and the

DSP Sidecar PCB, which uses an 8 conductor ribbon cable to connect the audio

from the DSP PCB to the other two channels on the motherboard.

10.1 Align the 4x4 DSP module with the

corresponding motherboard connectors.

10.2 Gently press the 4x4 DSP module

into the motherboard connectors until it

is fully seated.

10.3 Install the DSP Sidecar PCB into the

motherboard connector for the two

adjacent channels. This is the small 8 pin

connector located below and just to the

right of the E1 connector on component

side of the installed 4x4 DSP module.

Make sure it is fully seated into the

motherboard connector. Connect the other

end of the ribbon cable to the E1 connector

on the 4x4 DSP module. This cable should

extend straight to the left to connect to E1.

9.1 Disconnect the DSP Sidecar PCB cable

from the E1 connector on the top-left of the

DSP PCB. Unplug the DSP Sidecar PCB

from the motherboard (11) connector.

9.2 Grasp the DSP PCB at the corners and

using a gentle rocking motion, pull the DSP

PCB out of the motherboard connectors.

9.3 Remove the associated Null module

using a gentle rocking motion. This would

be the Null module installed in the 8 pin

motherboard connector located near the

bottom right corner of the installed 4x4 DSP

module.

10.4 Install a Null module in the other 8 pin

motherboard connector located near the

bottom right corner of the component side

of the installed 4x4 DSP module. This Null

module is needed to jumper the audio

information across this connector. Without

this module installed, you will have no

audio output on these two channels.

10.5 Verify that the 4x4 DSP module, the

DSP Sidecar PCB and the required Null

module are properly installed. For example,

if the 4x4 DSP module were installed in

motherboard connectors J108, J208, J116

and J216, then the DSP Sidecar PCB

would be installed into J209 and the Null

module would be installed into J217.

19

Page 20

DISASSEMBLY/ASSEMBLY PROCEDURES

11. Router Module Removal

11.1 Perform procedure 1.

11.2 Grasp the corners of the Router

module. Using a gentle rocking motion, lift

up on the Router module until it is clear of

the motherboard connectors.

12. Router Module Replacement

12.1 Align the Router module with the

corresponding connectors on the

motherboard (11).

Note: The Router modules must be installed into the correct connectors on the

motherboard. These connectors are located

in the center of the motherboard near J1.

Only the Router modules will fit into these

connectors.

12.2 Gently press the Router module

straight down into the motherboard

connectors until it is fully seated.

13. Motherboard Removal

13.6 Using a 5/16” nutdriver, remove the

three locknuts that secure the Bose

control Module (10) to the motherboard.

Lift the Bose control module straight up to

remove it from the motherboard connectors.

13.7 Using a 1/4” nutdriver, remove the

three standoffs located under the Bose

control module. These standoffs must be

removed to remove the motherboard.

13.8 Lift up on the motherboard, starting at

the edge of the motherboard nearest the

power supply (2).

13.9 Slide the motherboard up and out

toward the front panel of the chassis until

the D52 and D53 LEDs and RJ45 network

connectors have cleared the chassis.

14. Motherboard Replacement

14.1 Align the the motherboard (11) D52

and D53 LEDs and RJ45 network connectors with the corresponding openings in

the chassis (13).

®

13.1 Perform procedure 1.

13.2 Remove all of the Input, Output,

4x4 DSP, Router and audio processing

modules using the disassembly/assembly

procedures located in this section.

13.3 Unplug the power supply to

motherboard cable harness (4) at J1.

Note: Use caution when removing this

connector.

13.4 Using a small flat-head screwdriver,

disconnect the red, green and black wires

that run from the front panel LED harness

assembly (8) to the motherboard (11) at J6.

13.5 Using a phillips-head screwdriver,

remove the fifteen screws that secure the

motherboard (11) into the chassis (13).

14.2 Slide the motherboard into the

chassis, aligning it with the chassis screw

studs. Make sure that the RJ45 network

connectors and LEDs D52 and D53 protrude through their openings in the rear of

the chassis.

14.3 Secure the motherboard to the

chassis using the fifteen screws removed

in step 13.5.

14.4 Using a 1/4” nutdriver, install the three

standoffs removed in step 13.7

14.5 Reinstall the Bose control module (10)

into its connectors on the motherboard.

Be careful not to bend the pins on the

connectors.

14.6 Using a 5/16” nutdriver, secure the

Bose control module to the chassis using

the three locknuts removed in step 13.6

20

Page 21

DISASSEMBLY/ASSEMBLY PROCEDURES

14.7 Re-connect the power supply to

motherboard cable harness (4) from

the power supply (2) to motherboard

connector at J1.

14.8 Using a small flat-blade screwdriver,

re-connect the Front Panel LED harness

(8) wires to motherboard connector J6.

Be sure that the green, red and black wires

are installed in the correct locations, and

that there are no strands of wire shorting

across to the other wires.

14.9 Reinstall the Input, Output, Router, 4x4

DSP, Null Module and audio processing

Modules using the disassembly/assembly

procedures located earlier in this section.

15. Fan Removal

15.1 Perform procedure 3.

16.4 Observing polarity, solder the wires

from the power supply harness and the

new fan together. Insulate the connections

using heat shrink tubing.

16.5 Perform procedure 4.

15.2 With the chassis disconnected from

AC mains, cut the red and black wires that

run from the power supply (2) connector at

J2 to the fan (12).

15.3 Remove the four locknuts that secure

the fan to the chassis (13). Slide the fan off

of the chassis studs.

16. Fan Replacement

16.1 Slide the fan (12) over the four chassis

studs. Be sure to face the fan in the same

direction as the original for correct airflow.

16.2 Secure the fan to the chassis (13)

using the four locknuts removed in step

15.4. Do not overtighten them or you will

crack the fan housing.

16.3 Strip the red and black wires from the

power supply (2) harness at J2 and the

wires from the new fan.

21

Page 22

TEST PROCEDURES

Test Setup Parameters

In order to perform these tests, you will

need the following:

®

• A Microsoft

computer with at least 40Mbytes of hard

disk space, 32Mbytes of RAM and a CD

ROM drive.

• Bose

Owner’s Guide.

• Windows 95 or Windows NT 4.0.

• Network Interface Card, such as the

Echelon® PCNSI for desktops or the

PCC-10 for laptops.

• An Entero SE 16 audio processor

chassis to be used as a test-bed.

• A length of CAT-5 network cable long

enough to reach from the network card

in your PC to your Entero chassis.

1. Verify that the Entero software is

properly installed and operating on the

computer that you will be using for these

tests. If the software is not installed, refer to

the Entero Designer Software User’s Guide.

2. Verify that the Echelon Network Interface

Card is installed and working properly.

3. Connect the CAT-5 cable from your PC to

the Entero SE 16 audio processor chassis

under test.

1. Power Up Test

1.1 Remove the top cover using disassem-

bly/assembly procedure 1.

®

Windows® compatible

Entero™ software (CD ROM) and

1.4 Turn on the power switch on the front

panel of the SE 16 audio processor.

1.5 Turn on the Variac and slowly increase

the AC mains voltage to the proper level

while observing the SE 16 audio processor

for problems.

1.6 The front panel LED may illuminate if

the neuron module has been previously

configured, otherwise it remains off.

1.7 Verify that the fan is operating and

drawing air into the front of the chassis.

1.8 Using a Voltmeter, check the AC and

DC voltages at the power supply in accordance with the following table.

Pin Voltage

J1 (AC Input)

PIN 1 AC GROUND

PIN 2 AC NEUTRAL

PIN 3 AC LINE

J2 (DC Output)

PIN 1 +5V (+/-2%)

PIN 2 +5V (+/-2%)

PIN 3 +5V (NOT USED)

PIN 4 RETURN

PIN 5 RETURN

PIN 6 RETURN

PIN 7 RETURN

PIN 8 +15V (+/-3%)

PIN 9 +15V (NOT USED)

PIN 10 -15V RETURN

PIN 11 -15V (+/-3%)

PIN 12 KEY

PIN 13 +24V (+10%/-5%)

1.2 Using an Ohmmeter, verify that the

fuses are good. Also make sure they are

the correct value in accordance with the

part list in the back of this manual.

1.3 Connect an AC mains cable to the unit

under test. Connect the other end of the AC

mains cable to a Variac.

Caution: Use care when working inside

the chassis with AC mains power applied.

Note: If any of the DC voltages in the table

are low, remove AC mains power and

unplug J1 on the motherboard. Re-apply

AC mains power to the chassis and recheck the DC voltage levels at J2 of the

power supply.

If the DC voltage is now at the correct level,

then the problem is on the motherboard.

22

Page 23

TEST PROCEDURES

1.9 Measure the motherboard DC voltages

at motherboard connectors J100-J147 in

accordance with the following table.

All measurements are referenced to pin 10

of the connector you are testing.

Refer to the motherboard schematic

diagram for more information.

Note: Be careful not to short across pins

during these tests.

Connector Pin # DC Voltage

PIN 5 +5V (+/-.05V%)

PIN 6 +15V (+/-.1V%)

PIN 7 +5V (+/-.05V%)

PIN 8 -5V (+/-.05V%)

PIN 9 -15V (+/-.1V%)

1.10 Measure the motherboard DC voltages

at motherboard connectors J348-J355 in

accordance with the following table. All

measurements are referenced to pin 10 of

the connector you are testing.

Refer to the motherboard schematic

diagram for more information.

Note: Be careful not to short across pins

during these tests.

2.1 Verify that the modules are properly

installed in the desired test configuration.

If you are testing a failed chassis you would

configure the modules as they were when

the chassis failed.

2.2 Apply AC mains voltage to the chassis

under test. Turn the front panel power

switch ON.

2.3 In the Microsoft

®

Windows® operating

system, click START, and select the icon to

TM

open the Entero

Designer software.

Using the Entero Graphical User Interface

(GUI), add the device (SE 16 chassis) to

the GUI. When the GUI window opens,

click on the DEVICE FINDER tab at the

bottom of the window as shown below.

Connector Pin # DC Voltage

PIN 5 +5VD (+/-.05V%)

PIN 9 +15V (+/-.1V%)

PIN 10 +5VA (+/-.05V%)

PIN 11 -5VA (+/-.05V%)

PIN 12 -15V (+/-.1V%)

2. Module Discovery Tests

Note: These tests verify most of the

circuitry on the motherboard. They do not

test every IC 100%. The following circuits

will be exercised during these tests.

• Neuron module with Flash memory

• RJ45 connectors and EMI filtering

• Oscillator and divider circuitry

• PLDs U54 and U55

• Clock, Data, Enable and Channel Select

signals

• Module ID Mux chain

• Peak detect Mux chain

• A/D Converter and Dump circuit

• Service Pin and drive circuitry

• LEDs and drive circuitry

The view will change to the device view.

At the top of the GUI window, click on the

TOOLS pull-down menu. Select ADD

DEVICE as shown below.

23

Page 24

TEST PROCEDURES

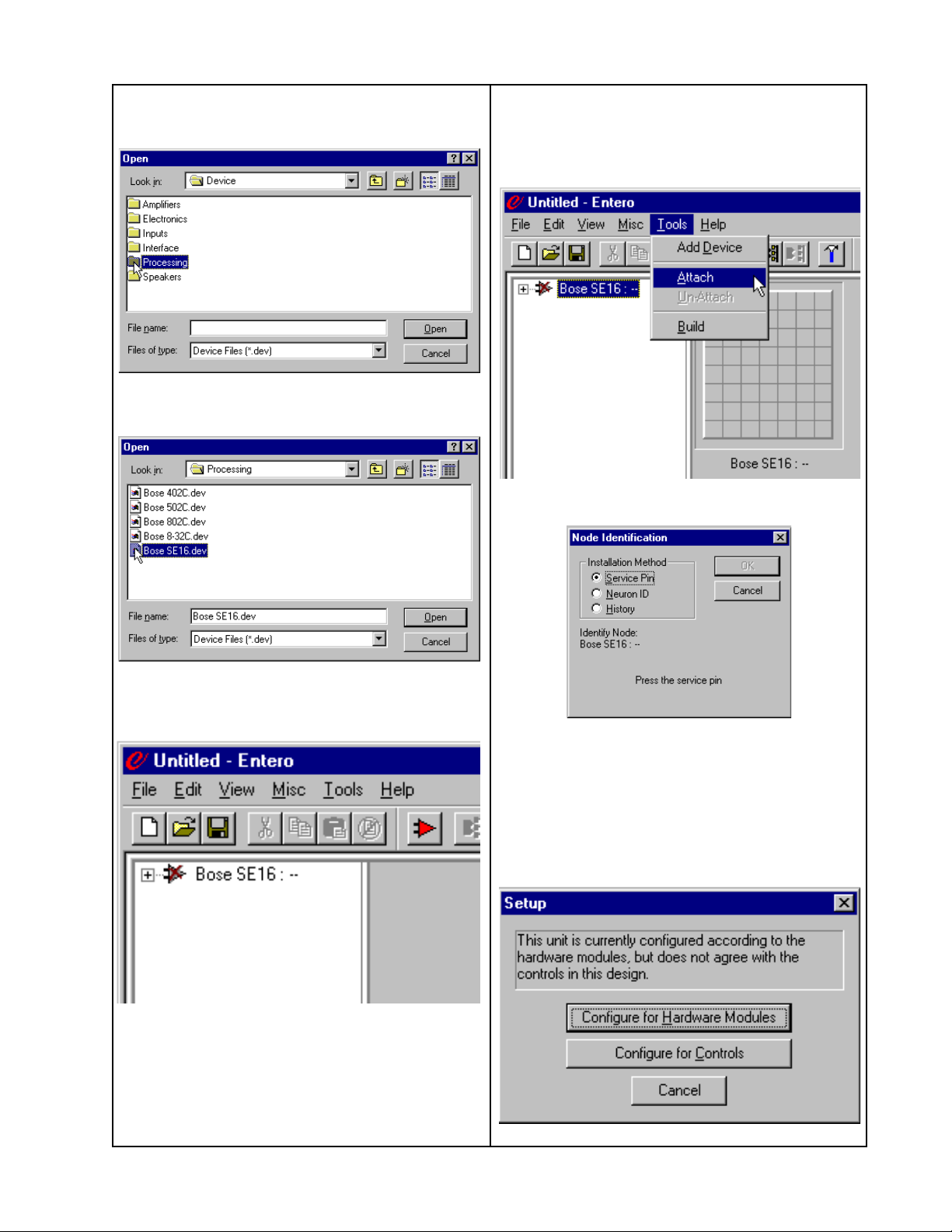

When the box opens, open the

PROCESSING folder,

and click on the file named Bose

SE16.dev. Click OPEN.

Click on the icon once to highlight it, and

click on the TOOLS list at the top of the GUI

window. In the pull-down menu, select

ATTACH.

®

The dialog box shown below will open.

You will see a triangular icon with an “X”

through it appear in the white left-hand

column.

Select the “Service Pin” option in the dialog

box. Press the service pin on the rear of

the SE 16 chassis. Ensure that the yellow

“service” LED on the rear panel of the

chassis illuminates when you press the

service pin. You will get the dialog shown

below.

24

Page 25

TEST PROCEDURES

2.4 When this dialog box opens, click on

the “Configure for Hardware Modules”

option. Verify that the green LED on the

chassis rear panel illuminates during this

procedure. The front panel LED should now

be a solid green.

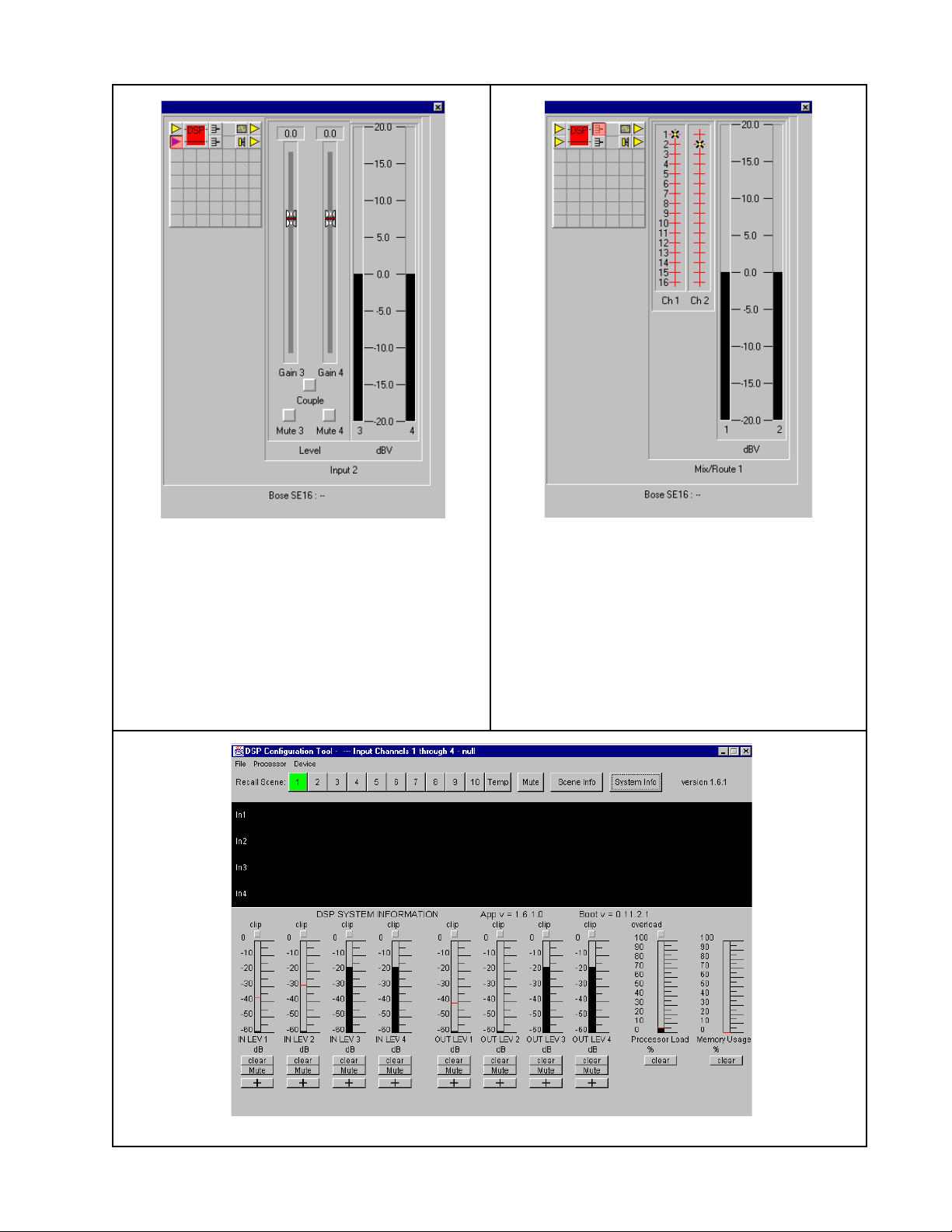

2.5 You should now see a gray block with

56 sections in the gray right-hand column

with icons for the various installed modules

in them. The “X” through the icon for the

SE16 processor should be gone. See the

example below.

Using the Entero GUI, verify that all of the

modules installed in the chassis were

discovered correctly by the GUI. As you

click on each one of the icons in the gray

block. The controls for that module should

appear to the right of the gray block.

Make sure that the correct controls for the

module appear. See the photos on the

following pages for examples.

If the module is not correctly discovered,

replace it with a known good one and

repeat these tests.

3. Automatic Clock Switching Tests

Note: These tests verify the functionality

of the DSP clock routing to J108-J115 and

J132-J139. The following circuits will be

exercised during these tests.

• DSP module ID Detectors

• DSP Clock MUXing

3.1 With no DSP modules installed, apply

AC mains power to the EnteroTM chassis

under test. Place the front panel power

switch to the ON position.

3.2 Configure the chassis in the Entero GUI

for the installed modules using the Module

Discovery tests in this section. Verify that

the modules were correctly discovered.

3.3 Using a frequency counter or oscilloscope, verify that there is no 10 MHz clock

signal present at pin 4 of the input signal

processing connectors at J108, J110, J112,

J114 and the output signal processing

connectors at J132, J134, J136 and J138

of the motherboard.

3.4 Place the chassis front panel switch to

the OFF position. Install a DSP module into

the input or output signal processing connectors that you want to test. For example,

lets install the DSP module into J108, J208,

J116, J216, J209 and J217. In this case the

DSP sidecar module used with the DSP

module would install into J209 and the

other end of the ribbon cable plugs into E1

on the DSP card. A signal pass-thru or null

module would normally be installed in J217

as well to pass the audio for that channel to

the rest of the motherboard. Place the front

panel power switch to the ON position.

3.5 Configure the chassis in the Entero GUI

for the installed modules using the Module

Discovery tests in this section. Verify that

the DSP module was correctly discovered.

3.6 Using a frequency counter or oscilloscope, verify that the 10 MHz clock signal

now appears on the DSP at J1 pin 4 of the

DSP board.

3.7 Repeat these tests for the rest of the

connectors you want to test as listed in

step 3.3. For example, the next connector

for test would be J110. Install the DSP

module and configure the chassis.

Using a frequency counter, verify that there

is now a 10 MHz signal at J110 pin 4.

25

Page 26

TEST PROCEDURES

4. Signal Path Tests

4.1 Populate the chassis with modules in

the same configuration as when the module

or chassis failed (see the example in the

diagram below). In this way you should be

able to determine whether or not you have

a failed module or a failed channel on the

motherboard.

Note: In order to pass an audio signal

through the chassis you will need an Input

module, Output module, Router and Null

modules. The Null modules (also referred

to as Signal Pass-Thru modules) are used

to jumper the audio signal through the

unused audio connectors on the

motherboard. Without these modules in

place, you will not pass audio through the

chassis on that motherboard channel.

4.2 Once the chassis is configured physically, you will need to configure the modules

in the EnteroTM GUI as shown in the following examples. You will set up only the

modules that are actually used in the signal

path of the chassis channel you want to

test.

Mic/Line Level Input Module

Set the GUI controls for this module as

shown in the above figure.

1. Input Gain 1 and 2: 0 dB

2. Attack 1 and 2: 1 mS

3. Release 1 and 2: 500 mS

4. Threshold 1 and 2 slider: +17 dB

5. Output Gain 1 and 2 slider: 0 dB

6. Phantom Power 1 and 2: unchecked

7. Mute 1 and 2: unchecked

GUI showing Entero chassis populated with modules to be tested

26

Page 27

TEST PROCEDURES

Line Level Input Module

Set the GUI controls for this module as

shown in the above figure.

1. Output Gain sliders for both

channels: 0 dB

2. Channel Couple: unchecked

3. Mute for both channels: unchecked

16x2 Router Module

Set the GUI controls for this module as

shown in the above figure.

1. Channel 1 input to channel 1 output

2. Channel 2 input to channel 2 output

3. Channels 1 and 2 NOT summed

Note: Channel 1 and 2 shown above,

setup also applies to channels 3 through 8.

4x4 DSP - Empty Block Diagram (Note: 0 dBV on analog meter = -17 dBFS on DSP meter)

27

Page 28

TEST PROCEDURES

5-Band Parametric EQ (configure for flat frequency response)

Fixed EQs (measured at 700 Hz)

Set the GUI controls for this module as

shown in the above figure.

1. Low Pass Filter (LPF) channel 1 and 2:

Default

2. High Pass Filter (HPF) channel 1 and 2:

Full Range

Line Level Output Module

Set the GUI controls for this module as

shown in the above figure.

1. Channel 1 and 2 Gain Sliders: 0 dB

2. Channel 1 and 2 Couple button:

unchecked

3. Channel 1 and 2 Mute buttons:

unchecked

28

Page 29

TEST PROCEDURES

Line Level Output with Limiter Module

Signal Path Tests (continued)

4.3 Apply a 0 dBV (1 Vrms), 1 kHz signal to

the channel 1 and 2 inputs located on the

Input Module.

4.4 Using the GUI, check the signal levels

on the module meters. Verify that the 0 dBV

sine wave is passing through each module

in the chassis. If the sine wave goes into a

card, but not out, check the settings for that

module and ensure that it is set up correctly.

4.5 If the module settings are correct, and

audio is still not flowing out of a module,

then swap out the module with a known

good module, if available, to verify that the

module under test has failed.

Set the GUI controls for this module as

shown in the previous figure.

1. Attack 1 and 2: 1 mS

2. Release 1 and 2: 500 mS

3. Channel 1 and 2 Gain sliders: 0 dB

4. Channel 1 and 2 Threshold: +17 dB

5. Channel 1 and 2 Couple: unchecked

6. Channel 1 and 2 Mute buttons:

unchecked.

4.6 If you have audio coming out of both

channels, but it is distorted, then:

4.6.1 Verify that the signal applied to the

input modules is not distorted.

4.6.2 Check the meters on the various

modules to be sure that the signal is not

being overloaded by too high gain.

Verify setup of the modules using the

setup diagrams on the previous pages

of this section.

4.7 If the audio output is still distorted,

sequentially replace the modules with

known good modules until the distortion is

eliminated. Return the defective module for

replacement.

29

Page 30

PART LIST NOTES

1. This part is not normally available from Customer Service. Approval from the Field Service

Manager is required before ordering.

2. The individual parts located on the PCBs are listed in the Electrical Part List.

3. This part is critical for safety purposes. Failure to use a substitute replacement with the

same safety characteristics as the recommended replacement part might create shock, fire

and/or other hazards.

®

4. The 80 Watt Power Supply, Bose

manufactured by:

Artesyn Technologies

125 Newbury Street

Framingham, Ma. 01701

(508) 628-5600

888-283-3122

http://www.artesyn.com

part number 181269, is a purchase for resale item that is

The part numbers listed in the part list for the 80 Watt Power Supply are the part numbers

used by Artesyn Technologies, and are provided for informational purposes. If you have a

defective power supply in your Entero

TM

SE 16 chassis, it is recommended that you purchase

a replacement power supply from Bose Corporation. If the power supply is no longer

available, then you may need to repair your defective unit using the information supplied in

this manual.

30

Page 31

MAIN PART LIST

SE16 Audio Processor (see Figure 1)

Item

Number

1 Cover, Chassis, SE 16 Processor 181284 1 3

2 Power Supply, 80 Watt 181269 1 3, 4

3 Cable Assembly, IEC, AC RCPT Switch 181270 1 3

4 Cable Assembly, Power Supply, M-Board 181272 1

5 Cable Assembly, AC Switch Power Supply 181271 1 3

6 Faceplate, Blanking 181285 8 8x8 chassis

6 Faceplate, Blanking 181285 11 2x8 chassis

7 Switch, Rocker, DPST 181273 1 3

8 Harness Assy, Front Panel LED 181280 1

9 Bracket, Power Supply 181282 1

10

11 Motherboard, SE 16, 16x16 250590 1

12 Fan, 24V, 25CFM, SE 16 Processor 181267 1 3

Bose

(BCM-FT)

Control Module System Assembly

Description Part

Number

198439-

000E

Qty. Note

1

13 Chassis Assembly, SE 16 Processor 181281 1 3

- Line Cord, 120V, Detachable, US/CAN 173350 1 3

- Line Cord, 220V, Detachable, EURO 173352 1 3

- Line Cord, 100V, Detachable, Japan 181690 1 3

- Fuse, Fast Blo, 5x20mm, 250V, 5 Amp 1955745000

- Mic/Line Level Input with Limiter PC Board 250585 4 16x16 chassis

- Mic/Line Level Input with Limiter PC Board 250585 2 8x8 chassis

- Line Level Input PC Board 250564 4 16x16 chassis

- Line Level Input PC Board 250564 2 8x8 chassis

- Line Level Input PC Board 250564 1 2x8 chassis

- 4x4 DSP PC Board 250904 4 16x16 chassis

- 4x4 DSP PC Board 250904 3 8x8 chassis

- 16x2 Router PC Board 251030 8 16x16 chassis

- 16x2 Router PC Board 251030 4 2x8, 8x8

- Signal Pass Thru PC Board 250565 20 16x16 chassis

- Signal Pass Thru PC Board 250565 7 8x8 chassis

- Signal Pass Thru PC Board 250565 10 2x8 chassis

- Line Level Output PC Board 250563-2 8 16x16 chassis

- Line Level Output PC Board 250563-2 4 2x8, 8x8

23

chassis

chassis

31

Page 32

MAIN PART LIST

SE 16 Audio Processor (continued)

Item

Number

Qty. Description Part

Number

- - Line Level Output with Limiter PC Board 250563-1 Obsolete

- - Dynamic EQ PC Board 250568 Obsolete

--

--

--

802

502

402

EQ Submodule PC Board

A EQ Submodule PC Board

EQ Submodule PC Board

250569-1 Obsolete

250569-2 Obsolete

250569-3 Obsolete

- - Model 25/32 EQ Submodule PC Board 250569-6 Obsolete

- - 502B EQ Submodule PC Board 250569-7 Obsolete

- - AWCS II EQ Submodule PC Board 250569-9 Obsolete

- - Fixed EQ Carrier PC Board (used with the

250570 Obsolete

Fixed EQ Submodules)

- - 5 Band Parametric EQ PC Board 250580 Obsolete

- - 16 x 16 Null Router PC Board 250587 Obsolete

- - 2 x 2 Router PC Board 251034 Obsolete

10

Note

12

13

1

11

4

5

7

8

2

3

6

9

Figure 1. SE 16 Chassis Exploded Views

32

Page 33

ELECTRICAL PART LIST

Power Supply, 80 Watt (P/N: 181269)

Resistors

Reference

Designator

RT1 THERMISTOR, 10 OHM, 4A, 15% 390013 3

R1 470K, MF, 1/2W, 5% 3210005-474

R2 3.3K, MO, 5W, 5% 330021-332

R3 3.09K, AXIAL, MF, 1/4W, 1% 3210001-3091

R4 4.7 OHM, CF, 1/4W, 5% 300020-4.7

R5 100 OHM, AXIAL, CF, 1/4W, 5% 3010001-101

R6 301 OHM, AXIAL, MF, 1/4W, 1% 3210001-3010

R7 240 OHM, CF, 1/2W, 5% 300040-241

R8 330 OHM, AXIAL, CF, 1/4W, 5% 3010001-331

R9 39 OHM, AXIAL, CF, 1/4W, 5% 3010001-390

R10 22K, AXIAL, CF, 1/4W, 5% 3010001-223

R11A 0.16 OHM, MO, 1W, 5% 330020-.16

R11B 0.16 OHM, MO, 1W, 5% 330020-.16

R12 100 OHM, MO, 1W, 5% 330020-101

R13 1.2K, MO, 1W, 5% 330020-122

R14 4.7K, AXIAL, CF, 1/4W, 5% 3010001-472

R15 3.3K, AXIAL, CF, 1/4W, 5% 3010001-332

R16 16.2K, AXIAL, MF, 1/4W, 1% 3210001-1622

R17 3.24K, AXIAL, MF, 1/4W, 1% 3210001-3241

R18 680 OHM, CF, 1/2W, 5% 300040-681

R19 39 OHM, AXIAL, CF, 1/4W, 5% 3010001-390

R20 47 OHM, MO, 1W, 5% 33020-470

R21 16.2K, AXIAL, MF, 1/4W, 1% 3210001-1622

R22 3.24K, AXIAL, MF, 1/4W, 1% 3210001-3241

R23 680 OHM, CF, 1/2W, 5% 300040-681

R24 2.37K, AXIAL, MF, 1/4W, 1% 3210001-2371

R25 2.05K, AXIAL, MF, 1/4W, 1% 3210001-2051

R26 500 OHM, VAR, TADJ 380002-501

R27 1.2K, AXIAL, CF, 1/4W, 5% 3010001-122

R28 6.8K, AXIAL, CF, 1/4W, 5% 3010001-682

R29 330 OHM, AXIAL, CF, 1/4W, 5% 3010001-331

R30 1.5K, AXIAL, CF, 1/4W, 5% 3010001-152

R31 1K, AXIAL, CF, 1/4W, 5% 3010001-102

R32 2.2K, AXIAL, CF, 1/4W, 5% 3010001-222

R33 2.2K, AXIAL, CF, 1/4W, 5% 3010001-222

R34 39 OHM, AXIAL, CF, 1/4W, 5% 3010001-390

R35 10 OHM, AXIAL, CF, 1/4W, 5% 3010001-100

R36 2K, CF, 1/2W, 5% 300040-202

R37 1.2K, AXIAL, CF, 1/4W, 5% 3010001-122

R38 2K, CF, 1/2W, 5% 300040-202

R40 470K, MF, 1/2W, 5% 3210005-474

R41 1.2K, AXIAL, CF, 1/4W, 5% 3010001-122

R42 1.2K, AXIAL, CF, 1/4W, 5% 3010001-122

Description ArtesynTM Part

Number

Note

33

Page 34

ELECTRICAL PART LIST

Power Supply, 80 Watt (P/N: 181269)

Capacitors

Reference

Designator

C1 .47uF, SEV, MPST, 250V, 20% 220076-474 3

C2 .047uF, SEV, MPST, 250V, 20% 220079-473 3

C3 1000pF, CER DISC, 250V, Y5V, 20% 240005-102 3

C4 1000pF, CER DISC, 250V, Y5V, 20% 240005-102 3

C5 1000pF, CER DISC, 250V, Y5V, 20% 240005-102 3

C6 330uF, EL, AL, 35V, 20%, 35X40 200164-331

C7 .047uF, MPAP, 630V, 10% 224801-473

C8 47uF, EL, AL, 50V, 20%, 6.3X11 200121-476

C9 220pF, PCAR, 100V, 5% 220041-221

C10 470pF, PPRO, 1K/1.5K, 10% 220019-471

C11 1000uF, EL, AL, 35V, 20%, 13X32 210046-108

C12 330uF, EL, AL, 35V, 20%, 10X20 210045-337

C13 1uF, CER, RAD, 50V, Z5U, 20% 240001-105

C14 1uF, CER, RAD, 50V, Z5U, 20% 240001-105

C15 1000uF, EL, AL, 35V, 20%, 13X32 210046-108

C17 47uF, EL, AL, 50V, 20%, 6.3X11 200121-476

C18 100uF, EL, AL, 50V, 20%, 10X16 210059-107

C19 2200uF, EL, AL, 16V, 20%, 13X32 210055-228

C20 2200uF, EL, AL, 16V, 20%, 13X32 210055-228

C21 2200uF, EL, AL, 16V, 20%, 13X32 210055-228

C22 .1uF, MPST, 63V, 5% 220010-104

C23 2200uF, EL, AL, 16V, 20%, 13X32 210055-228

C24 100uF, EL, AL, 50V, 20%, 10X16 210059-107

C25 .0047uF, CER DISC, 1KV, Z5U 240009-472

C26 1000uF, EL, AL, 35V, 20%, 13X32 210046-108

C27 47uF, EL, AL, 50V, 20%, 6.3X11 200121-476

C28 1uF, CER, RAD, 50V, Z5U, 20% 240001-105

C29 .0047uF, CER, AXIAL, 50V, X7R, 10% 240011-472

C30 .1uF, MPST, 63V, 5% 220010-104

C31 .1uF, MPST, 63V, 5% 220010-104

C32 4700pF, PCAR, 100V, 5% 220042-472

C33 .1uF, MPST, 63V, 5% 220010-104

C34 .1uF, MPST, 63V, 5% 220010-104

C36 .1uF, MPST, 63V, 5% 220010-104

C37 .1uF, MPST, 63V, 5% 220010-104

C38 1uF, CER, RAD, 50V, Z5U, 20% 240001-105

C39 470pF, CER DISC, 1KV, Z5F, 20% 240015-471

C40 .01uF, CER DISC, 1KV, Z5U, 20% 240019-103

Description ArtesynTM Part

Number

Note

34

Page 35

ELECTRICAL PART LIST

Power Supply, 80 Watt (P/N: 181269)

Inductors and Transformers

Reference

Designator

L1 SUPER BALUN, LOW WDG, B-130 800412 3

L2 3.4uH, PWDR IRON, 6A 14033

L3 INDUCTOR, 18 ½ TURN, 1” HIGH 71075

L4 INDUCTOR, 18 ½ TURN, 1” HIGH 71075

L5 INDUCTOR, 18 ½ TURN, 1” HIGH 71075

T1 XRMR, B-130 800341 3

T2 XFMR, PULSE 800056 3

Reference

Designator

CR1 DIODE, BR, 4A, GBL06 100006-600 3

CR2 DIODE, FR, 1A, 600V, SOD57, BYV26C 100014-600

CR3 DIODE, SW, .2W, DO-35, 1N4448 100065-075

CR4 DIODE, ZNR, 1W, 12V, 5%, 1N4742A 110005-012

CR5 DIODE, FR, 1A, 600V, DO41, 1N4937 100015-600

CR6 DIODE, FR, 3A, 400V, MR854 100020-400

CR7 DIODE, FR, 8A, 200V, BYW29-200 100029-200

CR8 DIODE, SCH, 30A, 45V, MBR3045PT 100052-045

CR9 DIODE, FR, 8A, 200V, BYW29-200 100029-200

CR10A DIODE, SW, .2W, DO-35, 1N4448 100065-075

CR10B DIODE, ZNR, .4W, 10V, 2%, BZX79-B10 110001-010

CR11A DIODE, SW, .2W, DO-35, 1N4448 100065-075

CR11B DIODE, ZNR, .4W, 10V, 2%, BZX79-B10 110001-010

CR12 DIODE, SCR, 8A, 100V, MCR72-3 150002-100

CR13 DIODE, ZNR, .4W, 5.6V, 2%, BZX79 110001-5.6

CR14 DIODE, SW, .2W, DO-35, 1N4448 100065-075

CR15 DIODE, SW, .2W, DO-35, 1N4448 100065-075

CR16 DIODE, SW, .2W, DO-35, 1N4448 100065-075

CR17 DIODE, FR, 1A, 600V, DO41, 1N4937 100015-600

Description ArtesynTM Part

Number

Diodes

Description Artesyn Part

Number

Note

Note

Transistors

Reference

Designator

Q1 NCH, HEXFET, IRF840 130092

Q2 NPN, TO-92, SIG MPS6601 130058

Q3 PNP, TO-92, MPS4250 120024

Q4 NCH, MOSFET, MTP3055E 130096

Q5 PNP, TO-92, 2N3906 120004

Q6 PNP, TO-92, 2N3906 120004

Q7 NCH, MOSFET, MTP3055E 130096

Description Artesyn Part

Number

35

Note

Page 36

ELECTRICAL PART LIST

Power Supply, 80 Watt (P/N: 181269)

Integrated Circuits

Reference

Designator

VR1 IC, SHUNT REG, ADJ, TL431CLP 140017

VR2 IC, SEL SHUNT REG, TO-92, AS431 180017-04

VR3 IC, SEL SHUNT REG, TO-92, AS431 180017-04

VR4 IC, SHUNT REG, ADJ, TL431CLP 140017

Reference

Designator

F1 FUSE, GLASS, 5A, 250V 440008 3

J1 CONN, FR LOCK, .312 CTR, 3 POS 450167-03 3

J2 CONN, LK, SQ, .156 CTR, 13 POS 450089-13

JP1 BUSS WIRE, 22 AWG 430064-22

JP2 BUSS WIRE, 22 AWG 430064-22

JP3 BUSS WIRE, 22 AWG 430064-22

- CLIP, FUSE, PCB TYPE, USED WITH F1 440050 3

- SPRING CLIP, LRG HTSK 04-.065 500062 USED WITH Q1

- SPRING CLIP, LRG BRKT, .125 THK 500063 USED WITH CR8

- SPRING CLIP, SML BRKT, .125 THK 500085 USED WITH Q4,

- HEATSINK, PCB MOUNT 500088 USED WITH Q1

- HEATSINK, PCB MOUNT 500144 USED WITH CR6

- INSULATOR, MICA, 1.09 X 1.25 520058 USED WITH Q1,

- INSULATOR, MICA, .715 X 1.00 520059 USED WITH Q4,

- SPACER, GLASS, .220 X .08 X .062 610011 USED WITH CR1

Description Artesyn

Miscellaneous

Description Artesyn Part

TM

Number

Number

Part

Note

Note

QTY 2

Q7, CR7, CR9,

CR12

CR8

Q7, CR7, CR9,

CR12

36

Page 37

ELECTRICAL PART LIST

Bose® Control Module, BCM-FT (P/N: 198439-000E)

Resistors

Reference

Designator

R1 JUMPER, CHIP 124896

R2 274 OHM, 0805, 1/10W, 1%, 133625-2740

R3 274 OHM, 0805, 1/10W, 1%, 133625-2740

R4 274 OHM, 0805, 1/10W, 1%, 133625-2740

R41 100K, CHIP, 0805, 1%, 133625-1003

Reference

Designator

C1 .10uF, 0805, Y5V, 25V, 80%, 133624

C2 33pF, 0805, COG, 50V, 5%, 133622-330

C3 .10uF, 0805, Y5V, 25V, 80%, 133624

C4 .10uF, 0805, Y5V, 25V, 80%, 133624

C5 22UF, TANT SMD, 10V, 10%, 196981-A226C1

C6 .10uF, 0805, Y5V, 25V, 80%, 133624

C7 .10uF, 0805, Y5V, 25V, 80%, 133624

C8 .10uF, 0805, Y5V, 25V, 80%, 133624

C9 .10uF, 0805, Y5V, 25V, 80%, 133624

C10 .10uF, 0805, Y5V, 25V, 80%, 133624

C11 .10uF, 0805, Y5V, 25V, 80%, 133624

C12 22uF, EL, 5.5MM, 85C, 25V, 177902-220E

C13 68pF, 0805, COG, 50V, 5%, 133622-680

C14 68pF, 0805, COG, 50V, 5%, 133622-680

C15 .10uF, 0805, Y5V, 25V, 80%, 133624

C18 .001UF, CER, 125, 2K 193532

C19 22uF, EL, 5.5MM, 85C, 25V, 177902-220E

C20 33pF, 0805, COG, 50V, 5%, 133622-330

Description Part Number Note

Capacitors

Description Part Number Note

Diodes

Reference

Designator

CR1 BAV99, SOT23 147239

CR2 BAV99, SOT23 147239

CR3 BAV99, SOT23 147239

CR4 BAV99, SOT23 147239

Description Part Number Note

37

Page 38

ELECTRICAL PART LIST

Bose® Control Module, BCM-FT (P/N: 198439-000E)

Integrated Circuits

Reference

Designator

U1 QUAD, OR GATE, SOIC-14, 74AC32 191934

U2 CMOS, SRAM, SOIC-28, 32KX8 191949

U3 NAND, QUAD, SOIC-14, 74AC00 193889

U4 NEURON, PQFP-64, MC143150B1FU 191961

U5 FL PEROM, PGRM, 512K, 70NS 252421-001

U6 PWR ET, SOT223, DS1233Z-5 193530

TRS1 XCVR, FREE TOPOLOGY, FTT-10A 191932

Reference

Designator

Y1 CRYSTAL, SMD, 10MHZ, 30PF 194021-10R0C30

US5 SOCKET, IC, PLCC-32 191933

P1 CONN, 2X9, .1 CTC 193533

P2 CONN, 6X1, .1 CTC 193534

Description Part Number Note

Miscellaneous

Description Part Number Note

38

Page 39

ELECTRICAL PART LIST

16x16 Motherboard (P/N: 250590)

Resistors

Reference

Designator

N11 4X33, .125W 195577-3304 Koa Speer, CN2B4(TE)330J

N12 4X33, .125W 195577-3304 Koa Speer, CN2B4(TE)330J

N13 4X33, .125W 195577-3304 Koa Speer, CN2B4(TE)330J

N14 4X33, .125W 195577-3304 Koa Speer, CN2B4(TE)330J

N15 4X33, .125W 195577-3304 Koa Speer, CN2B4(TE)330J

N16 4X33, .125W 195577-3304 Koa Speer, CN2B4(TE)330J

N19 4X10K, .125W 195577-1034 Koa Speer, CN2B4(TE)103J

N51 4X33.2K, .125W, 1% 195576-33224 Koa Speer, CN2B4(TE)3322F

N71 4X100K, .125W, 5% 195577-1044 Koa Speer, CN2B4(TE)104J

N72 4X100K, .125W, 5% 195577-1044 Koa Speer, CN2B4(TE)104J

N73 4X100K, .125W, 5% 195577-1044 Koa Speer, CN2B4(TE)104J

N74 4X100K, .125W, 5% 195577-1044 Koa Speer, CN2B4(TE)104J

N75 4X100K, .125W, 5% 195577-1044 Koa Speer, CN2B4(TE)104J

N76 4X100K, .125W, 5% 195577-1044 Koa Speer, CN2B4(TE)104J

R11 332 OHMS, 0805, .1W, 1% 173767-332R Panasonic, ERJ6ENF3320V

R12 332 OHMS, 0805, .1W, 1% 173767-332R Panasonic, ERJ6ENF3320V

R13 332 OHMS, 0805, .1W, 1% 173767-332R Panasonic, ERJ6ENF3320V

R14 332 OHMS, 0805, .1W, 1% 173767-332R Panasonic, ERJ6ENF3320V

R21 499 OHMS, 0805, .1W, 1% 133625-4990 Panasonic, ERJ6ENF4990V

R22 499 OHMS, 0805, .1W, 1% 133625-4990 Panasonic, ERJ6ENF4990V

R23 499 OHMS, 0805, .1W, 1% 133625-4990 Panasonic, ERJ6ENF4990V

R24 499 OHMS, 0805, .1W, 1% 133625-4990 Panasonic, ERJ6ENF4990V

R31 10K, 0805, .1W, 1% 133625-1002 Koa Speer, RK73H2A(TE)1002F

R32 10K, 0805, .1W, 1% 133625-1002 Koa Speer, RK73H2A(TE)1002F

R33 10K, 0805, .1W, 1% 133625-1002 Koa Speer, RK73H2A(TE)1002F

R34 10K, 0805, .1W, 1% 133625-1002 Koa Speer, RK73H2A(TE)1002F

R35 10K, 0805, .1W, 1% 133625-1002 Koa Speer, RK73H2A(TE)1002F

R36 10K, 0805, .1W, 1% 133625-1002 Koa Speer, RK73H2A(TE)1002F

R37 10K, 0805, .1W, 1% 133625-1002 Koa Speer, RK73H2A(TE)1002F

R38 10K, 0805, .1W, 1% 133625-1002 Koa Speer, RK73H2A(TE)1002F

R39 10K, 0805, .1W, 1% 133625-1002 Koa Speer, RK73H2A(TE)1002F

R40 10K, 0805, .1W, 1% 133625-1002 Koa Speer, RK73H2A(TE)1002F

R41 10K, 0805, .1W, 1% 133625-1002 Koa Speer, RK73H2A(TE)1002F

R42 10K, 0805, .1W, 1% 133625-1002 Koa Speer, RK73H2A(TE)1002F

R43 10K, 0805, .1W, 1% 133625-1002 Koa Speer, RK73H2A(TE)1002F

R44 10K, 0805, .1W, 1% 133625-1002 Koa Speer, RK73H2A(TE)1002F

R45 10K, 0805, .1W, 1% 133625-1002 Koa Speer, RK73H2A(TE)1002F

R46 10K, 0805, .1W, 1% 133625-1002 Koa Speer, RK73H2A(TE)1002F

R47 10K, 0805, .1W, 1% 133625-1002 Koa Speer, RK73H2A(TE)1002F

R48 10K, 0805, .1W, 1% 133625-1002 Koa Speer, RK73H2A(TE)1002F

R51 20K, 0805, .1W, 1% 133625-2002 Koa Speer, RK73H2A(TE)2002F

R52 20K, 0805, .1W, 1% 133625-2002 Koa Speer, RK73H2A(TE)2002F

R61 75 OHMS, 0805, .1W, 1% 133625-75R0 Koa Speer, RK73H2A(TE)75R0F

R62 75 OHMS, 0805, .1W, 1% 133625-75R0 Koa Speer, RK73H2A(TE)75R0F

Description

Bose

Number

Part

Manufacturer Part Number

39

Page 40

ELECTRICAL PART LIST

16x16 Motherboard (P/N: 250590)

Resistors

Reference

Designator

R63 75 OHMS, 0805, .1W, 1% 133625-75R0 Koa Speer, RK73H2A(TE)75R0F

R64 75 OHMS, 0805, .1W, 1% 133625-75R0 Koa Speer, RK73H2A(TE)75R0F

R65 75 OHMS, 0805, .1W, 1% 133625-75R0 Koa Speer, RK73H2A(TE)75R0F

R66 75 OHMS, 0805, .1W, 1% 133625-75R0 Koa Speer, RK73H2A(TE)75R0F

R67 75 OHMS, 0805, .1W, 1% 133625-75R0 Koa Speer, RK73H2A(TE)75R0F

R68 75 OHMS, 0805, .1W, 1% 133625-75R0 Koa Speer, RK73H2A(TE)75R0F

R69 75 OHMS, 0805, .1W, 1% 133625-75R0 Koa Speer, RK73H2A(TE)75R0F

R70 75 OHMS, 0805, .1W, 1% 133625-75R0 Koa Speer, RK73H2A(TE)75R0F

R71 75 OHMS, 0805, .1W, 1% 133625-75R0 Koa Speer, RK73H2A(TE)75R0F

R72 75 OHMS, 0805, .1W, 1% 133625-75R0 Koa Speer, RK73H2A(TE)75R0F

R73 75 OHMS, 0805, .1W, 1% 133625-75R0 Koa Speer, RK73H2A(TE)75R0F

R74 75 OHMS, 0805, .1W, 1% 133625-75R0 Koa Speer, RK73H2A(TE)75R0F

R75 75 OHMS, 0805, .1W, 1% 133625-75R0 Koa Speer, RK73H2A(TE)75R0F

R76 75 OHMS, 0805, .1W, 1% 133625-75R0 Koa Speer, RK73H2A(TE)75R0F

R77 75 OHMS, 0805, .1W, 1% 133625-75R0 Koa Speer, RK73H2A(TE)75R0F

R78 75 OHMS, 0805, .1W, 1% 133625-75R0 Koa Speer, RK73H2A(TE)75R0F

R79 75 OHMS, 0805, .1W, 1% 133625-75R0 Koa Speer, RK73H2A(TE)75R0F

R81 10M, 0805, .1W, 1% 133625-1005 Koa Speer, RK73H2A(TE)1005F

R82 10M, 0805, .1W, 1% 133625-1005 Koa Speer, RK73H2A(TE)1005F

R83 10M, 0805, .1W, 1% 133625-1005 Koa Speer, RK73H2A(TE)1005F

R84 10M, 0805, .1W, 1% 133625-1005 Koa Speer, RK73H2A(TE)1005F

R85 10M, 0805, .1W, 1% 133625-1005 Koa Speer, RK73H2A(TE)1005F

R86 10M, 0805, .1W, 1% 133625-1005 Koa Speer, RK73H2A(TE)1005F

R87 10M, 0805, .1W, 1% 133625-1005 Koa Speer, RK73H2A(TE)1005F

R88 10M, 0805, .1W, 1% 133625-1005 Koa Speer, RK73H2A(TE)1005F

R89 10M, 0805, .1W, 1% 133625-1005 Koa Speer, RK73H2A(TE)1005F

R90 10M, 0805, .1W, 1% 133625-1005 Koa Speer, RK73H2A(TE)1005F

R91 10M, 0805, .1W, 1% 133625-1005 Koa Speer, RK73H2A(TE)1005F

R92 10M, 0805, .1W, 1% 133625-1005 Koa Speer, RK73H2A(TE)1005F

R93 10M, 0805, .1W, 1% 133625-1005 Koa Speer, RK73H2A(TE)1005F

R94 10M, 0805, .1W, 1% 133625-1005 Koa Speer, RK73H2A(TE)1005F

R95 10M, 0805, .1W, 1% 133625-1005 Koa Speer, RK73H2A(TE)1005F

R96 10M, 0805, .1W, 1% 133625-1005 Koa Speer, RK73H2A(TE)1005F

R98 110K, 0805, .1W, .25% - Koa Speer, RN73C2A(TE)1103C

R99 54.90K, 0805, .1W, 0.1% 181896-5492 Koa Speer, RN73E2A(TE)5492B

R100 221.0K, 1210, .25W, 0.1% - Koa Speer, RN73E2E(TE)2213B

Description

Bose

Number

Part

Manufacturer Part Number

40

Page 41

ELECTRICAL PART LIST

16x16 Motherboard (P/N: 250590)

Capacitors

Reference

Designator

C1 .1uF, 0805, X7R, 25V, 10% 181264-104 Murata, GRM40X7R104K025(B)(L)

C2 .1uF, 0805, X7R, 25V, 10% 181264-104 Murata, GRM40X7R104K025(B)(L)

C3 .1uF, 0805, X7R, 25V, 10% 181264-104 Murata, GRM40X7R104K025(B)(L)

C4 .1uF, 0805, X7R, 25V, 10% 181264-104 Murata, GRM40X7R104K025(B)(L)

C5 .1uF, 0805, X7R, 25V, 10% 181264-104 Murata, GRM40X7R104K025(B)(L)

C6 .1uF, 0805, X7R, 25V, 10% 181264-104 Murata, GRM40X7R104K025(B)(L)

C7 .1uF, 0805, X7R, 25V, 10% 181264-104 Murata, GRM40X7R104K025(B)(L)

C8 .1uF, 0805, X7R, 25V, 10% 181264-104 Murata, GRM40X7R104K025(B)(L)

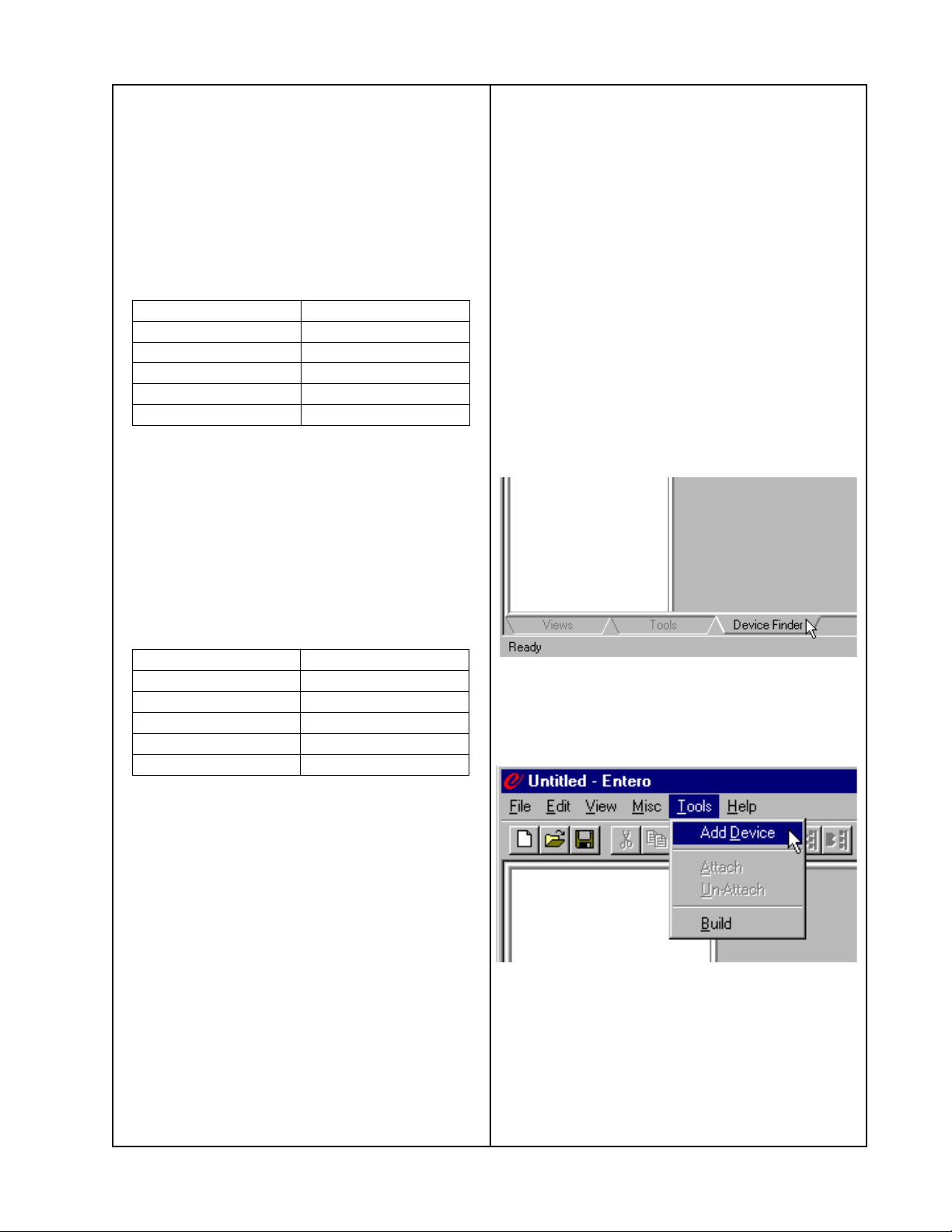

C9 .1uF, 0805, X7R, 25V, 10% 181264-104 Murata, GRM40X7R104K025(B)(L)